OPERATION MANUAL

FOR

MODELS

R2N and R2N Ultra

(3 Quart)

Also includes the submodels

R2 B, R2 C, and R2 Ultra B within the

following serial number groups:

246xxxxx03

247xxxxx03

robot coupe U.S.A., Inc.

P.O. Box 16625, Jackson, MS 39236-6625

280 South Perkins St., Ridgeland, MS 39157

email: info@robotcoupeusa.com

website: www.robotcoupeusa.com

1-800-824-1646

R2N and R2N Ultra

Operation Manual

2

R2N and R2N Ultra

Operation Manual

INTRODUCTION

The Robot Coupe commercial food processor performs

a host of culinary feats. It is designed for high speed

and quality vegetable processing. The Robot Coupe

slices, juliennes, and shreds with the continuous feed

attachment, plus it will chop, grind, puree, mix, or knead

using the cutter bowl attachment.

This operators manual is broken down into sections

giving you detailed instructions for assembly and operation of the continuous feed attachment and the cutter bowl attachment. Close attention should be paid to

all instructions in this manual to ensure a long life utilization of your food processor.

This manual should be kept within easy

access to all users for reference, and

should be read completely by all first time

users of the machine.

I. INTRODUCTION

II. ASSEMBLY/DISASSEMBLY

INSTRUCTIONS

III. OPERATING INSTRUCTIONS

IV. PREVENTIVE MAINTENANCE

GUIDE

V. TROUBLE SHOOTING AIDS

VI. SERVICE AGENCY LISTING

Maintaining the food processor in good working condition is one of the most important measures to be taken.

Inspect the machine and all parts regularly to make

sure they are in good working condition.

DO NOT operate a machine that has malfunctioned in any way.

Discard any food processed at the time of

a malfunction and have the machine inspected and

repaired at one of the Robot Coupe Authorized Service Agencies, a list is provided in the back of this

manual. Contact one of these service agencies for all

of your service, parts and accessory requirements.

CAUTION: Your Robot Coupe comes with

a sharp cutting S blade and cutting

plates. Always handle with safety in mind.

We suggest that a pair of cut-resistant

gloves be worn when handling the S

blade and plates.

Machine Specifications:

The Models R2N and R2N Ultra are equipped with a

high speed motor generating 1/2 Hp which plugs into a

standard 120 volt/ 60 Hz, 15 amp power outlet. The

full load amperage rating is 7 amps. The machines

are supplied with a 3 Quart bowl. The R2N has a plastic bowl, and the R2N Ultra has a metal bowl. The

machines are supplied with an S-blade and a clear plastic cover, a continuous feed assembly, and two cutting

plates. The machines are equipped with push type on/

off/pulse buttons.

3

R2N and R2N Ultra

Operation Manual

II. ASSEMBLY/DISASSEMBLY INSTRUCTIONS

Your Robot Coupe should be placed on a sturdy work surface at a comfortable working height and have a

standard 115 volt power outlet available. Always keep the machine unplugged during assembly and disas-

sembly.

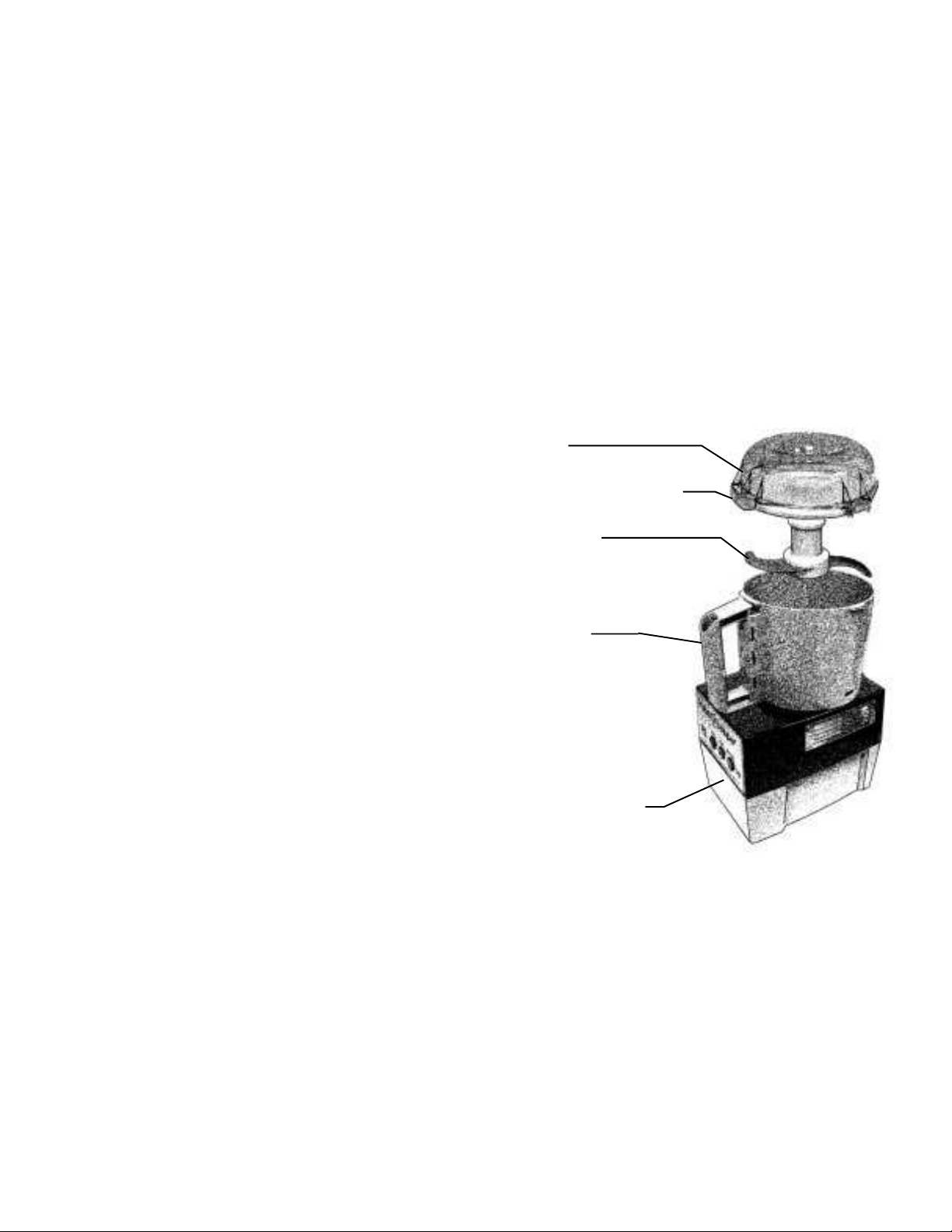

A. CUTTER BOWL ATTACHMENT ASSEMBLY INSTRUCTIONS

Always use caution, and wear cutresistant gloves when handling the

blade or the cutting plates.

Always unplug the machine during

assembly and disassembly.

LidLid

Lid

LidLid

1. Unplug the machine.

RampRamp

Ramp

RampRamp

2. Place the bowl on the motor base assembly

with the handle located just off center and to the

left as you are facing the front of the unit. Then,

turn the bowl back counterclockwise locking it

in place.

BladeBlade

Blade

BladeBlade

3. Place the blade on the motor shaft. Rotate

the blade until it falls into place on the motor

shaft. The bottom blade should be just off, and

parallel with, the bottom of the bowl.

4. Press the off button in case the machine

was left turned on.

5. Facing the front of the motor base assembly,

place the lid on the bowl with the ramp turned

off center and to the left.

6. Turn the ramp back to the right until it locks

in place over the safety switch rod.

7. DO NOT OPERATE THE MACHINE

UNLESS IT IS PROPER L Y A SSEMBLED WITH THE LID CENTERED

OVER THE BOWL AND THE RAMP

LOCKED I N PLACE OVER THE

SAFETY SWITCH ROD!

8. ALWAYS REMOVE THE BOWL LID

BEFORE ATTEMPTING TO REMOVE

THE BOWL . OTHERWISE, THE

SAFETY PIN CAN BE BROKEN, PREVENTING MACHINE OPERATION.

BowlBowl

Bowl

BowlBowl

MotorMotor

Motor

MotorMotor

BaseBase

Base

BaseBase

AssemblyAssembly

Assembly

AssemblyAssembly

4

R2N and R2N Ultra

Operation Manual

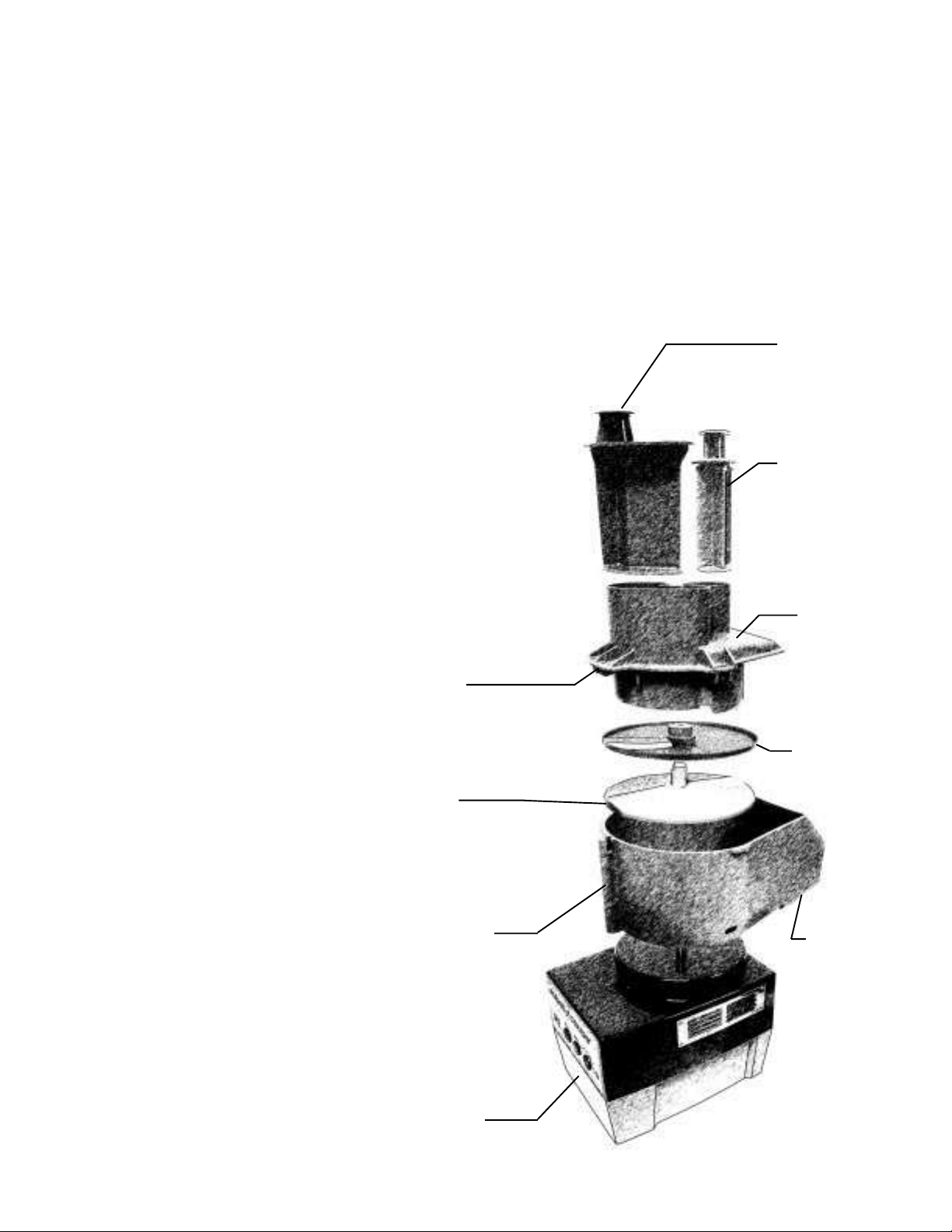

B. CONTINUOUS FEED ATTACHMENT ASSEMBLY INSTRUCTIONS

1. THE CORD SH OULD ALW AYS BE UNPLUGGED DURING ASSEMBLY AND DISASSEMBLY!

2. Place the continuous feed attachment on the motor base with the discharge chute to the back (as you

are facing the front of the motor base).

3. Looking from the top, turn the attachment slightly

clockwise, and with a gentle downward pressure, turn

it back counterclockwise; until it locks into place. The

attachment should be level with the top surface of the

motor base.

4. Place the plastic discharge plate on the motor shaft,

and rotate the plate until it drops fully into place on

the motor shaft. When properly installed, it should be

level with and just off the bottom of the continuous

feed attachment.

5. Place the cutting plate of your choice on the discharge plate. Rotate the plate until it drops into place

and is fully seated on the discharge plate.

6. Press the off button in case the machine was left turned on.

9. DO NOT OPERATE THE MACHINE UNLESS IT IS PROPERLY ASSEMBLED AND

THE CONTINUOUS FEED LEAD IS FULLY

SEATED AND CENTERED OVER THE ATTACHMENT!

LargeLarge

Large

LargeLarge

PusherPusher

Pusher

PusherPusher

SmallSmall

Small

SmallSmall

PusherPusher

Pusher

PusherPusher

ContinuousContinuous

Continuous

ContinuousContinuous

FeedFeed

Feed

FeedFeed

LeadLead

Lead

LeadLead

7. Facing the front of the motor base assembly, place the

continuous feed lead on the

continuous feed attachment

with the ramp on the lead

aligned over the safety switch

rod on the continuous feed atta chment. Whil e looking

down at the top, turn the lead

slightly clockwise then back

counterclockwise, locking it in

place. The lead should be

aligned with the top surface of

the continuous feed attachment.

8. Place the pushers in their

corresponding openings in the

continuous feed lead.

RampRamp

Ramp

RampRamp

DischargeDischarge

Discharge

DischargeDischarge

PlatePlate

Plate

PlatePlate

ContinuousContinuous

Continuous

ContinuousContinuous

FeedFeed

Feed

FeedFeed

AttachmentAttachment

Attachment

AttachmentAttachment

MotorMotor

Motor

MotorMotor

BaseBase

Base

BaseBase

AssemblyAssembly

Assembly

AssemblyAssembly

CuttingCutting

Cutting

CuttingCutting

PlatePlate

Plate

PlatePlate

ExitExit

Exit

ExitExit

ChuteChute

Chute

ChuteChute

5

R2N and R2N Ultra

Operation Manual

The continuous feed lead, with the pushers in place,

provides protection from the cutting plate. When the

lead is turned to its closed position with the ramp in

place over the pin, a safety switch is activated, and

the machine can be turned on and off by use of the

push buttons. If the lead is not in the closed position,

the buttons will not function.

NEVER ATTEMPT TO DEFEAT THE PURPOSE OF THE SAFETY SWITCH MECHANISM.

ALWAYS USE THE OFF AND ON BUTTONS TO OPERATE THE MACHINE.

The Food Processor is now assembled and ready

to perform its desired function.

BEFORE CONTINUING YOU SHOULD

COMPLETELY READ THE INSTRUCTIONS CONTAINED IN THIS MANUAL.

The continuous feed lead has two feed openings, one

large and one small, with matching pushers. The food

is inserted in the chosen opening by removing the

pusher with one hand and then depositing the food

into the chute with the other hand. The pusher should

then be used to push the food through the opening.

DISASSEMBLY INSTRUCTIONS: Simply reverse

the steps outlined in the assembly instructions with

the power cord unplugged from its wall socket.

ALWAYS REMOVE THE CONTINUOUS

FEED LEAD BEFORE REMOVING THE

CONTINUOUS FEED ATTACHMENT.

OTHERWISE, THE SAFETY PIN CAN BE

BROKEN, PREVENTING MACHINE OPERATION.

III. OPERATING INSTRUCTIONS

THE UNIT SHOULD BE OFF EXCEPT WHEN PROCESSING IS UNDERWAY.

It is recommended that the machine be operated on

a 50% duty cycle. This is easily accomplished since

the preparation time (cleaning, coring, peeling, and

loading) takes longer than the processing time. This

will yield the longest life for your machine.

NOTE: This machine is equipped with manual reset

thermal overload protection. If the machine is overloaded or run too long under heavy load conditions,

the overload will trip. If this occurs, first remove the

bowl and reduce the amount of food being processed.

The reset button is located on the bottom of the motor base. Press the button in to reset the overload

protector.

DO NOT ALLOW THE MACHINE TO RUN

UNATTENDED.

A. INSTRUCTIONS FOR USE OF THE

CUTTER BOWL

The cutter bowl attachment is used for grinding, pureeing, blending, mixing, of ingredients. With the

power switch off and the bowl and blade secured in

place (per previous instructions), you are now ready

to add product to the bowl. There are two ways to

run your machine. Chopping, using a quick start/stop

action with the pulse button, or running continuously

for a fine chop or puree.

1. TO CHOP

To achieve a chopped consistency for vegetables,

meats, cheese, etc., fill the bowl 2/3 to 3/4 full with

portions no larger than 1 to 2 inch square. Press the

pulse button until the desired consistency is reached.

If the motor stalls, reduce the amount of product in

the bowl.

2. TO PUREE OR FINE CHOP: For a fine puree,

emulsification, or fine chop, fill the bowl 2/3 to 3/4 full

with portions no larger than 1 to 1 1/2 inches square.

Begin by pulsing the machine to reduce the size then,

press the on button, and allow the machine to run

until the product is finely chopped or pureed. Some

purees may require the addition of a liquid to obtain

the correct consistency.

3. TO CHOP HARD CHEESE: Place uniform 1 to 1

1/2 cubes of chilled cheese up to 1 1/2 pounds into

the bowl and pulse the machine. For powdered

cheese pulse the motor until the cheese is about pea

size then allow the motor to run continuously until you

6

R2N and R2N Ultra

Operation Manual

3. TO CHOP HARD CHEESE: Place uniform 1 to 1

1/2 cubes of chilled cheese up to 1 1/2 pounds into

the bowl and pulse the machine. For powdered

cheese pulse the motor until the cheese is about pea

size then allow the motor to run continuously until you

have a fine powder.

4. TO CHOP ONIONS, CELERY, CABBAGE, ETC.

Quarter onions, and cut other vegetables into 2 to 3

inch portions. Place the product into the bowl up to 3/

4 full and pulse the unit until you reach the desired

consistency. CAUTION: If you overfill or allow the

machine to run continually, the product on the top

may not be cut while that on the bottom will be pureed.

5. TO PUREE OR MIX: To puree, make sauces, or

to mix and blend, place the ingredients into the bowl

(do not overfill), turn the unit on, and allow to run continuously.

Sharpening the S blade

The S blade will require sharpening on a

periodic basis depending on use. The use

of a dull blade will sometimes give unsatisfactory results. Follow the directions shown

to sharpen the blade, or have the blades

sharpened professionally if you prefer.

7. Repeat the procedure for the other blade.

8. Wash the blade before use.

1. Put on your cut-resistant gloves

2. Use a Robot Coupe stone or any good

sharpening stone.

3. Hold or clamp the blade flat on the edge or

corner of a sturdy table.

4. With the other hand, hold the stone at a 30

degree angle against the top bevel of one

blade.

5. Pull the stone into the blade edge moving

from hub to tip, several strokes, until the

blade is sharp.

6. Turn the blade over, and rub the stone flat

against the underside of the blade to remove

the feather edge formed at step 5.

7

R2N and R2N Ultra

Operation Manual

B: INSTRUCTIONS FOR USE OF THE

CONTINUOUS FEED ATTACHMENT:

The Robot Coupe Food Processor will slice, grate,

shred, and juliene. These processes will be performed

in a matter of seconds. Because of the speed of the

process, it is necessary that the operator perform preliminary steps before turning the machine on. Food

preparation, feed chute loading, and availability of a

receptacle for receiving the finished product are some

of the steps to assure positive control of the processing operation.

Food preparation will be required to assure that the

produce will fit a feed chute with the pusher covering

the product. Additionally, according to personal preference, some products may or may not be cored or

peeled. Feed chute selection should be made depending upon the product to be processed. As an

example, good consistency of small round produce

(carrots, cucumbers, etc.) necessitates use of the

small feed chute to allow better operator control. Use

of the larger port for this type of produce may result in

an undesired finished product, e.g., slicing with the

grain. In general, more control of the processing operation can also be obtained by filling the selected

feed chute and placing the pusher in position before

turning the machine on.

Adherence to certain operational techniques will also

enhance the processing operation. For instance, a

consistent pressure with the pusher upon the produce

will yield a consistent output. Application of more pressure will increase the thickness of the product, e.g.,

thicker slice, while reduction in pressure will result in

a finer product. However, do not apply enough pressure to stall or slow the motor. This will cause damage to both the plate and the motor. If no pressure is

applied at all and the produce is permitted to bounce

around, an inconsistent product may result. When

the pusher has settled fully in the feed chute, press

the off switch and re-load the entry port for a repeat

process.

DO NOT remove the continuous feed lead

when the motor is running. Wait until the

motor has come to a full stop.

DO NOT attempt to run frozen products

through the cutting plates.

DO NOT put anything other than food

products in the feed chute.

Wear cut-resistant gloves when handling

the cutting plates.

Keep hands out of the feed openings.

Always use the food pushers.

(1) Slicing Operation: When preparing food to be

sliced, make sure the food will fit into the proper feed

chute. Produce such as carrots, cucumbers, etc.,

should be squared at both ends. This will provide a

consistent slice throughout the whole product. With

cabbage, lettuce or any product that has an undesirable core, the core should be removed. Medium

size heads of lettuce or cabbage may be cut into

thirds to fit the feed chute. It is also suggested that

the rounded half be squared to permit a consistent

cut. The rounded portion can be dropped into the

chute at the end and with no pressure applied, it will

normally be processed uniformly. Larger heads of

cabbage or lettuce may be more effectively processed

if they are cut into fourths. When the preparation has

been accomplished, fill the selected feed chute, place

the pusher in position, turn the machine on and observe the results.

THE UNIT SHOULD BE OFF EXCEPT WHEN PROCESSING IS UNDERWAY. It is recommended that

the machine be operated on a 50% duty cycle. This

is easily accomplished since the preparation time

(cleaning, coring, peeling, and loading) takes longer

than the processing time. This will yield the longest

life for your machine.

8

R2N and R2N Ultra

Operation Manual

(2) Grating Operation: Again, prepare the product

as to allow insertion into the feed chute. Consider

which chute will be used. As an example, placement

of carrots horizontally in the large chute will result in

a long grated product, while vertical insertion in the

smaller chute will result in a short grated product. It

is recommended that chilled cheese be used when

grated cheese is desired, otherwise a gumminess may

result. A fine coating of cornstarch applied to the

cheese before grating will aid in keeping the finished

product separated. A fine coating of cornstarch will

not be visible and is tasteless. Grating cheese is one

of the most trying processes and may cause overheating of the motor if not done in the recommended

manner. It is recommended that a slight pulsating

pressure be applied with the pusher while grating,

alternating slight pressure on the pusherno pressurecontinuing in this manner until the block of

cheese is completely grated. It is recommended that

the cheese be prepared to fit the opening in volumes

which will permit motor cool-down time during long

production runs.

(3) Julienne Operation: Insertion of the product to

be cut must be horizontal if a long stick is to be

achieved, e.g., squash sticks. Vertical insertion will

result in finely chopped products, e.g., chopped celery. A finely chopped onion product may also be

obtained with this operation.

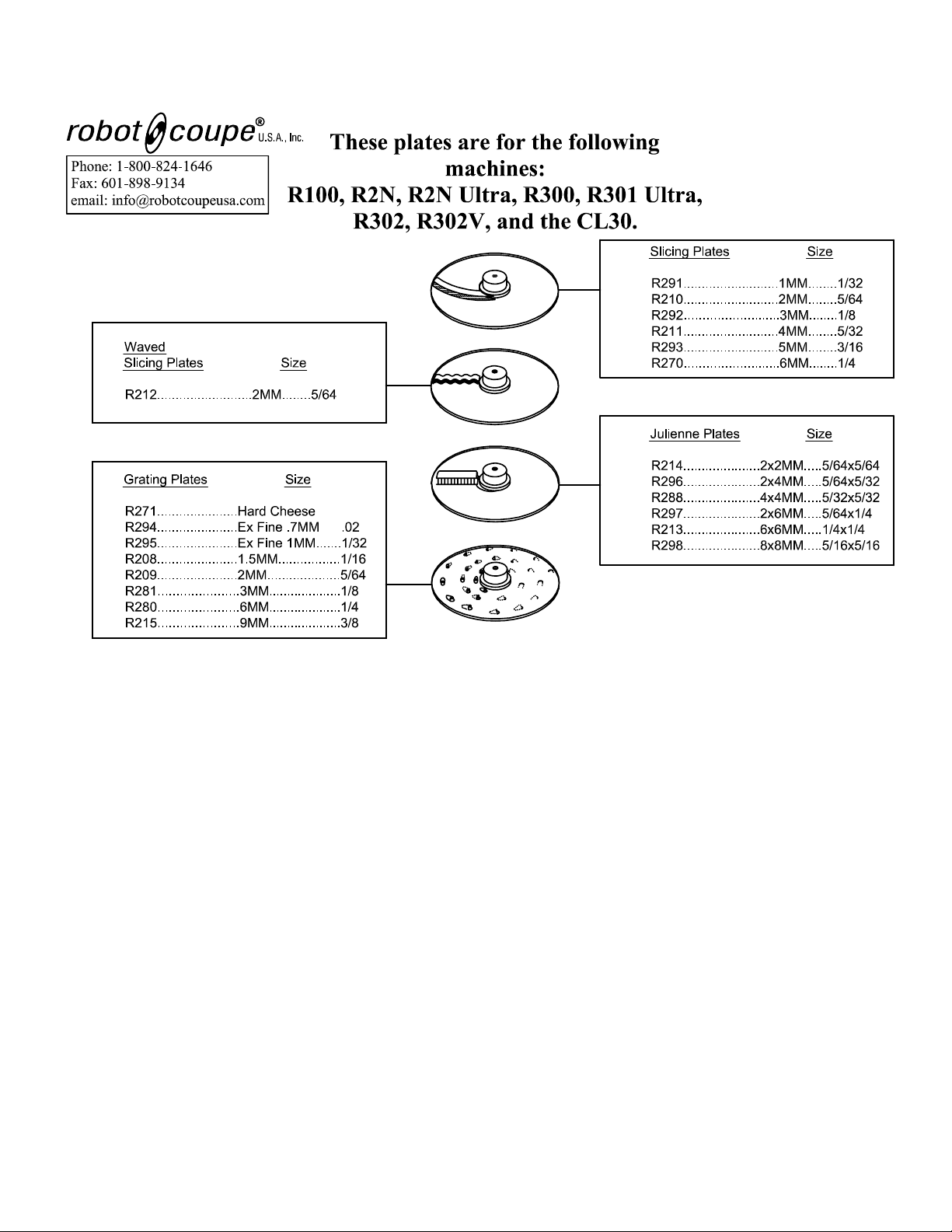

Plate Utilization

The Robot Coupe food processor will perform a variety of functions: slicing, grating, French fry, and

julienne. There are a total of 25 different plates available to perform these functions to meet individual

tastes. The 21 plates consists of:

7 slicing plates

8 grating plates

6 julienne plates

The standard Robot Coupe comes with two (2) plates.

Check your most current price list for the plates which

are included as standard. The number and type of

plates will vary depending upon the use of the machine.

SLICING PLATES

The seven (7) slicing plates range from 1mm (approximately 3/64") to 6.5mm (approximately 1/4"):

Part Number MM Slicing Inches (Approx.)

R291 1mm 1/32 in.

R212 2mm(waved) 5/64 in.

R210 2mm 5/64 in.

R292 3mm 1/8 in.

R211 4mm 5/32 in.

R293 5mm 3/16 in.

R270 6mm 1/4 in.

9

R2N and R2N Ultra

Operation Manual

Plate Usage

SLICING PLATES

R291 1/32" - 1mm Slicing Plate

The thinnest slicing plate is the R291. It is used for

paper thin slicing of potatoes for potato chips. This

plate will also slice carrots lengthwise which can be

soaked in cold water to make flower petals for garnish.

R210 5/64" - 2mm Slicing Plate

The next to the thinnest of the straight slicing plates

is the R210. It provides a wafer thin slice that makes

harder vegetables look best. Carrots, radishes, celery and potatoes look terrific through this plate. This

is the best plate for shredded lettuce for tacos and

sandwiches. This is also the plate for cabbage for a

German style slaw.

R292 1/8" - 3mm Slicing Plate

This is one of the new thickness of slice available.

By cutting 1/8" thick it gives good shelf life and maximum yield. Almost any vegetable can be cut with

this plate and gives greater yield than the standard

slicer which comes with the unit.

R211 5/32" - 4mm Slicing Plate

The R211 is the best all purpose slicing plate. For

most vegetables this thickness is best. Cucumbers,

mushrooms, zucchini, and celery all cut beautifully

with the R211 while providing a good shelf life. This

is the second most popular plate requested and

comes standard with the unit. Even soft foods like

strawberries, bananas, and green onion tops slice

marvelously.

R293 3/16" - 5mm Slicing Plate

Some foods are more attractive when sliced a bit

thicker and that is the function of the R293. Half slices

of tomato or bell pepper work good as well as yellow

squash and zucchini. Try deep fried thick slices of

potato using the R293 for home fries.

R270 1/4" - 6mm Slicing Plate

For soups and stews an extra thick slice is desirable.

Carrots and celery work great this way. Any food

that you want a more generous slice on will look terrific through the R270. For this reason it is the third

most popular plate .

R212 5/64" - 2mm Waved Slicing Plate

This is a decorative, thin, waved slice. Harder vegetables will work best with this plate like carrots, radishes, zucchini and potatoes.

GRATING PLATES

There are eight grating plates available for use with

the Robot Coupe:

Part Number Metric Inches (Approx.)

R271 Hard Cheese Grating

R294 Extra Fine .7mm .02 in

R295 Extra Fine 1mm 1/32 in.

R208 Fine 1.5mm 1/16 in.

R209 Medium 2mm 5/64 in.

R281 Medium Coarse 3mm 1/8 in

R280 Medium Coarse 6mm 1/4 in.

R215 Extra Coarse 9mm 3/8 in.

Plate Usage

GRATING PLATES

R271 Hard Cheese Grating Plate

The R271 is the plate which will make a powder from

hard cheeses. Parmesan and Romano are used most

extensively with this. When potatoes are run through

this plate a batter is produced which is excellent for

potato pancakes.

R294 .02- .7mm Pulping Plate

The R294 pulping plate was created to grind Chinese

radish into a pulp that is served with sushi. Moreover, it will render any vegetable into a wet pulp or

batter, much the way a vegetable juicer does. This is

ideal for vegetable sauces that are low fat.

R295 1/32- 1mm Pulping Plate

The R295 reacts identically to the R294 but is just

slightly coarser so that not as much juice is extracted.

Use on ginger root (shoga), white radish (dikon), baby

turnips (kabo), or lotus root (renkon).

R208 1/16" - 1.5mm Fine Grating Plate

The R208 is a delicate grate used mostly for cheeses

and carrots. The width of the grate is 1/16" or 1.5mm

It also does an excellent job on bread crumbs and

cold chocolate.

R209 5/64" - 2mm Medium Grating Plate

This is the most ordered plate of this series. While

being used mainly for cheeses and carrots its size, 5/

64" or 2mm, gives maximum yield with excellent shelf

life. Also used on coconuts and potatoes for hash

browns. This is the grating plate that comes standard with the unit.

10

R2N and R2N Ultra

Operation Manual

R281 1/8" - 3mm Medium Coarse Grating

This new size grating plate is good for an extra fine

coleslaw or anything you prefer grated a bit coarser

than the standard R209 medium grating plate. This

plate works wonderfully with cheese, potatoes, beets,

eggs, cabbage or sweet potatoes.

R280 1/4" - 6mm Coarse Grating Plate

This in-between size of grate has become popular

with salad bars. Cheeses and carrots appear a bit

more generous when grated this way. Also purple

cabbage run through this plate can add a splash of

color to a salad bowl filled with lettuce.

R215 3/8 - 9mm Extra Coarse Grating Plate

The R215 is the widest grating plate. It provides an

extra thick grate of cabbage for slaw and cheeses for

melting. Mozzarella cheese looks terrific through the

R215

JULIENNE PLATES

There are six julienne plates available:

Part Number Metric Inches (Approx.)

R214 2x2mm 5/64 x 5/64 in.

R296 2x4mm 5/64 x 5/32 in.

R288 4x4mm 5/32 x 5/32 in.

R297 2x6mm 5/64 x 1/4 in.

R213 6x6mm 1/4 x 1/4 in.

R298 8x8mm 5/16 x 5/16 in.

Plate Usage

R288 5/32"x 5/32" - 4mm x 4mm Julienne Plate

This is the most popular of the julienne plates. Carrots, yellow squash, and zucchini work best. These

can be sautéed and makes a beautiful garnish for an

entree. Try steaming these too for a healthy and colorful side dish.

R297 5/64" x 1/4" - 2mm x 6mm Julienne Plate

This new julienne cut is becoming a very popular presentation on salads. Carrots, zucchini and yellow

squash look especially good this way.

R213 1/4 x 1/4" or 6 x 6mm French Fry Plate

This might as well be called the taco plate. Tomatoes and onions can be quartered and allowed to gravity feed through the lead and are chopped without

damage. Lettuce can be cut for a chopped taco lettuce. Chopped onions through the R213 are great

for hot-dogs also. Every school system should have

this plate. Bell peppers can be chopped like the onions for meatloaf or chili. As a sideline the French fry

plate makes great French fries and is the fifth most

popular plate.

R298 5/16" x 5/16" or 8mm x 8mm Julienne Plate

The 8 x 8mm julienne plate is great for zucchini, onions, and eggplants.

While the standard Robot Coupe comes with two specific plates (R209 and R211 at time of printing), many

user applications may require some of the optional

plates available with the unit. As an example, a typical salad bar might use:

JULIENNE PLATES

Products such as squash sticks, chopped celery, and

finely chopped onions are obtainable as well as

julienne celery

DO NOT ATTEMPT TO JULIENNE MEATS

OR CHEESES.

R214 5/64 x 5/64 - 2 x 2mm Julienne Plate

The R214 is an extremely fine julienne which can

dress up a salad. Radishes, potatoes, and carrots

work best. Try julienne radishes with the R214 for an

ultra-fine cut that looks like a top chef worked for hours

preparing.

R296 5/64"x 5/32" - 2mm x 4mm Julienne Plate

This is an interesting flat julienne that gives substance

to a delicate cut. One unique function of this plate is

to duplicate the slaw cut that comes from a buffalo

chopper. Try the R296 with radish, potato, summer

squash, or sweet potato.

R210 2mm (3/32 in.) Slicing plate

R211 4mm (5/32 in.) Slicing plate

R209 Medium Grating plate

The R210 plate could be used to slice cucumbers,

carrots, celery, etc. Good yield with long shelf life.

The R211 plate could be used to provide half slices

of tomatoes, bell peppers, or onions.

The R209 Medium Grating plate would process carrots, cheese, etc.

PLATE HOLDER

R255 Plate Rack

Holds nine plates and is ideal to store your Robot

Coupe accessories.

11

R2N and R2N Ultra

Operation Manual

IV. CLEANING/PREVENTIVE

MAINTENANCE

(1) CLEANING: Proper cleaning of the machine is

one of the most important preventive maintenance

measures the user can employ. The high acid content of food can cause harm to the electrical parts

contained within the housing. Although a seal isolates these elements from the outside, food juices

will tend to seep. If food juices are allowed to collect

on the machine over periods of use, erosion of the

seal can occur. It is recommended that the machine

be cleaned after each operational use.

Correct cleaning procedures are required to assure

that damage is not inflicted in the cleaning process.

The motor base assembly contains the motor and

electrical components.

DO NOT IMMERSE THE MOTOR BASE

ASSEMBLY IN WATER!

CLEANING INSTRUCTIONS

ATTACHMENTS: Remove and disassemble all attachments before cleaning. The bowl and continuous feed attachments should be cleaned per the following instructions or as required by local health department regulations.

Cleaning the Blade Assembly

There is a removable cap attached to the top of the

S-blade assembly. This cap should be removed when

cleaning the blade assembly.

CAUTION: THE BLADES ARE SHARP.

WEAR CUT-RESISTANT GLOVES WHEN

HANDLING THE BLADE.

The blade cap may be removed by carefully pulling

the cap up away from the blade. It may be helpful to

pull slightly to the side. The cap is held in place by

small plastic clips molded into the cap which snap

into the body of the blade assembly. If the cap is

difficult to remove, you can use a small diameter rod

or screwdriver inserted through the bottom side of

the blade assembly to knock out the cap using a quick

sharp impact. Again, use caution when handling the

blade.

The bowl, blade, lid, continuous feed attachment,

continuous feed lead, pushers, and plates are dishwasher safe. All of the attachments listed above can

be washed in a dish machine or three tank system

pot sink. Pre-rinse the attachments before washing

to remove any bulk food on the parts. A stiff bristle

brush or power sprayer faucet attachment is effective in knocking the food out of the crevices as a prerinse procedure. The washer should have an industry standard wash, rinse, and sanitization cycle. Allow the parts to air dry after sanitizing and before reassembly.

NOTE: The high temperatures of dish

machines will tend to shorten the life of

the plastic and rubber parts. Hand washing using a three pot sink will provide for

the longest life of these parts.

Inspect the area around the handle and bowl-switchrod to ensure they are clean. Use a brush on these

areas if necessary.

Cleaning: Clean the blade according to local Health

Department regulations. It may be necessary to pre

wash the blade with a power head sprayer followed

by the use of a small round brush to remove any remaining residue. Typical cleaning instructions may

include the following:

Dishwasher: Clean the blade assembly in a commercial dish machine by removing the blade cap and

placing it flat on a wash tray or in a small parts holder,

it could otherwise be washed out of the rack. The

dish machine should have a standard wash, rinse,

and sanitizing cycle.

Pot Sink: The blade may also be cleaned using the 3

sink method of wash, rinse, and sanitize. Remove

the blade cap, and wash each item separately. The

sanitization sink should include a minimum of 200

PPM chlorine solution or other approved sanitizing

agent. The use of a small brush will assist in removing food particles from around the blade and inside

the hub. Allow the parts to air dry laying flat on a

drying tray.

Autoclave: The blade assembly will withstand cleaning in an autoclave system with temperatures less

than 210 degrees C. However, it will reduce the life

of the blade as compared to other sanitizing methods.

12

R2N and R2N Ultra

Operation Manual

MOTOR BASE: Cleaning of the motor base assembly must be done with care: First unplug the unit.

A sponging with a cloth lightly soaked (not dripping)

in a mild detergent is acceptable, making sure the

water is not permitted to penetrate the shaft seal or

around the switches. Clean around the shaft seal

with a small brush, taking care to remove all food.

Do not forget to clean the motor shaft. Rinse the motor

base first using a cloth lightly dampened (not dripping) with water, then with a sanitizing solution, and

dry the machine with a soft cloth removing all liquids

from seal areas.

(2) PREVENTIVE MAINTENANCE CHECKS

While your Robot Coupe is a ruggedly constructed

machine, overall handling should be accomplished

with a sense of use rather than abuse. Reasonable

care should be exercised. While the machine is reasonably portable, care should be taken not to drop it.

Equally, caution should be exercised in handling all

the parts to assure they are not damaged.

An examination should be made periodically to assure that a seal against liquids is being maintained

around the motor shaft. With proper care, and depending on use, the seal should last for a year or

more. However, it can and should be replaced whenever wear or erosion is noted, or minimally once per

year. It is recommended that the seal be replaced by

an authorized repair agency.

V. TROUBLE SHOOTING AIDS

A. Unit does not start when assembled correctly:

1. Pull plug and try another outlet

2. Make sure bowl lid or continuous feed lead is

in the proper position with the ramp fully

pushed to the right, engaging the safety

mechanism.

3. Check the safety switch pin. It will break if the

attachment cover is not removed before the

attachment.

B. Continuous feed lead will not fit flush with

continuous feed attachment:

1. Processing plate is not in its proper position.

2. Rim of plate should be level with upper edge

of motor base.

C. Unit stops during processing:

1. Turn unit off, and unplug machine

2. Remove continuous feed lead

3. Remove cutting plate

4. Remove product being processed from inside

of machine and continuous feed lead

5. Reassemble unit

D. If unit does not operate after following above:

1. Check outlet for current (Breaker or Fuse)

2. Try unit again

3. Call local authorized service agency.

Blades should be kept sharp. It is not necessary to

have a razor edge however they will need sharpening periodically. Replacement of the dull blades or

plates is recommended.

(3) CARE: Your Robot Coupe is a piece of kitchen

equipment and like all other kitchen equipment, care

and caution should be used when operating. Although

training requirements are minimal, only responsible

individuals familiar with this operation manual should

be allowed to operate your Robot Coupe.

In general, the best preventive measures that can be

applied are close adherence to the assembly, operation, cleaning, and handling instructions, common

sense and regular maintenance.

TROUBLE SHOOTING AIDS: The following

sections indicate potential problems and the correct

solution which should be implemented by the user.

Problems which extend beyond these will require an

experienced serviceman. A list of the authorized

agencies is supplied.

E. Unit starts to spark or smoke:

1. Turn unit off, unplug it, call local authorized

service agency.

F. Unit makes grinding noise:

1. Turn unit off, disassemble, check continuous

feed lead and processing plate to see if they

have been rubbing together (small pieces of

plastic would be present).

2. If this was the case, the processing plate was

not fully seated. Check for food particles

inside stem of processing plate.

3. Replace the plate-insuring that it is fully

seated. Make sure there are not food particles on the motor shaft.

4. If noise continues, turn unit off and remove

processing plate. Assemble unit without plate

and turn unit on. If no noiseprocessing

plate may be bent or warped. Try another

plate. If noise persists, call your local factory

authorized service agency.

G. Cucumbers coming out with torn skins and/

or with seeds knocked out:

1. Cutting plate is dull and must be changed.

13

R2N and R2N Ultra

Operation Manual

NOTE: Cucumber condition before process-

ing should be considered.

H. Carrots are watery after grating:

1. Grating plate is dull and should be replaced.

I. Cheese forms balls instead of shreds:

1. Warm cheese

2. Grating plate is dull and should be replaced.

J. Machine becomes jammed while processing:

1. Turn unit OFF, and unplug machine. Remove

continuous feed lead and remove remnants of

product being processed. Put on a pair of cut-

resistant gloves and try to turn the plate manually in a counterclockwise direction. CAUTION:

This may be very hard to do. As soon as you feel

the plate slip, you will be able to reassemble the

unit and continue processing. If unit jams again,

repeat above until you get the plate to slip. Now,

remove and clean the plate. Before reassembling,

make sure:

a. Motor shaft is clean.

b. Plate is fully seated on motor

shaft.

2. If jamming is too tight to loosen by hand, contact service agency.

VI. SERVICE INFORMATION/

SERVICE AGENCY LIST

Your Robot Coupe has a one year limited warranty

against defects in parts and workmanship (Check

the warranty page within this manual for additional

information and/or coverage). Should the unit require service, check with your distributor to see where

local service is available. If not or if you wish your

unit to be serviced at the factory, call for a return

merchandise authorization (RMA) number, and upon

receipt of same; ship it PREPAID and insured to our

factory address.

Robot Coupe USA, Inc. Service Dept.

Phone: 1-800-824-1646

601-898-8411

CAUTION: IT IS ADVISABLE TO KEEP

THE MACHINE UNPLUGGED WHILE

CLEANING OR SERVICING.

14

PRICES AND OTHER INFORMATION SUBJECT TO CHANGE WITHOUT NOTICE

MODEL

R2N

Serial Numbers 246xxxxx03

(3 Quart)

Part # Description

Indexes

1

103281

2 27242 *(B) R2N Cont. Feed Kit, Gray

3

103280

4 118592 (B) R2 Cont Feed Lead, Gray (replaces white)

5 103288 (B)Discharge Plate

6 102699 (B) R2N/U Cont. Feed Attach, Gray (replaces white)

7

R242

8

R1776

9

Number NA

10

R204

11 27239 *(B) R2N Bowl Kit 3qt, Gray

12

R3030

13

R203

14 27240 * (B) R2N Clear Bowl Kit, 3qt.

15 112204 (B) R2N Gray Bowl Only, 3qt

16 112203 (B) R2N Clear Bowl Only, 3qt

17 39103 (B) Pin Assy, R2N 3qt Gray

18

R1776

19 39077 (B) Pin Assy R2N 3qt. Clear Bowl

20

Number NA

21

R3030

22

R203D

23

R3030

24

R203E

25

R255

26

R248

27 39108 (B) R2N Motor Support, 3qt

28

R262

29

R232A

30

R118

31

R274

32 39106 (B) R2N Switch Assy, 3qt

33 407669 (B) Frant Data Plate R2N, 3qt

34

R239

35

R239D.3

36

R239D

37

R265

38

R278A

39

R277A

40

R286

41 104124 (B) R2 Base, Gray

42

R101

43

R119

44

R276A

45

R240

46 R104 Strain Relief

47

R225

48

R115K

49

R222

50

R237

51

R239D.2

52

R237

53

R239D.1

(B) Small Pusher

(B) Large Pusher

Pin Assy for Plastic Bowl

Spring

Description NA

Cutter Bowl Lid

Cap Only, R301 S. Blade

* Blade

Spring

Description NA

Cap Only, R301 S. Blade

* S Blade, Fine Serration

Cap Only, R301 S. Blade

* S. Blade Coarse Serrations

* Plate Rack

Honing Stone

Screw Cover

Screw (Motor - MS)

Motor Support Seal

Pulse Switch

Mtr F/C 1/3HP 115V/60HZ

Adapter Plate, EM

Motor, EM

Bottom Cushion Bushing

Baffle

Screen Kit

8amp Breaker (R2ANN)

Foot

Screw (Base-MS 3.9x19)

Louvre (mtl) W/Rivits

Cord with Plug

Rubber O Ring (Black)

Safety Switch Assembly

Capacitor F/C Mtr (R2N)

6203 Bearing R2 Top/Btm

Capacitor

6203 Bearing R2 Top/Btm

Relay

PRICES AND OTHER INFORMATION SUBJECT TO CHANGE WITHOUT NOTICE

MODEL

R2N Ultra

Serial Numbers 247xxxxx03

(3 Quart)

Part # Description

Indexes

1

103281

2 27242 * (B) R2N Cont Feed Kit, Gray

3

103280

4 118592 (B) R2 Cont Feed Lead, Gray (replaces white)

5

103288

6 102699 (B) R2N/U Cont. Feed Attach, Gray (replaces white)

7

R242

8

R1776

9

Number NA

10

R204

11 27243 * (B) R2U S.S. Bowl Kit, 3qt

12

R3030

13

R203

14 104099 (B) R2U S.S. Bowl Only,3qt

15 104098 (B) Pin, 3qt S.S. Bowl

16

Number NA

17

R1776

18 104050 (B) Retaining Nut

19

R289

20

R3030

21

R203D

22

R3030

23

R203E

24

R255

25

R248

26

39109

27

R262

28

R232A

29

R118

30

R274

31 39107 (B) R2U Switch Assy, 3qt

32 407670 (B) Front Data Plate R2U,3qt

33

R239

34

R239D.3

35

R239D

36

R265

37

R278A

38

R277A

39

R286

40 104124 (B) R2 Base, Gray

41

R101

42

R119

43

R276A

44

R240

45 R104 Strain Relief

46

R225

47

R115K

48

R222

49

R237

50

R239D.2

51

R237

52

R239D.1

(B) Small Pusher

(B) Large Pusher

(B)Discharge Plate

Pin Assy for Plastic Bowl

Spring

Description NA

Cutter Bowl Lid

Cap Only, R301 S. Blade

* Blade

Description NA

Spring

Lckg Bush Set w/Screws

Cap Only, R301 S. Blade

* S Blade, Fine Serration

Cap Only, R301 S. Blade

* S. Blade Coarse Serrations

* Plate Rack

Honing Stone

(B) R2U Motor Support, 3qt

Screw Cover

Screw (Motor - MS)

Motor Support Seal

Pulse Switch

Mtr F/C 1/3HP 115V/60HZ

Adapter Plate, EM

Motor, EM

Bottom Cushion Bushing

Baffle

Screen Kit

8amp Breaker (R2ANN)

Foot

Screw (Base-MS 3.9x19)

Louvre (mtl) W/Rivits

Cord with Plug

Rubber O Ring (Black)

Safety Switch Assembly

Capacitor F/C Mtr (R2N)

6203 Bearing R2 Top/Btm

Capacitor

6203 Bearing R2 Top/Btm

Relay

ROBOT COUPE U.S.A. INC. LIMITED WARRANTY

R2 SERIES ONE YEAR LIMITED WARRANTY AND

EXTENDED THREE-YEAR MOTOR LIMITED WARRANTY

This LIMITED WARRANTY is to the original purchaser only against defects in material and/or workmanship, and includes

labor for replacement of defective parts, provided repairs are performed by a Robot Coupe Authorized Service Agency (see

attached list). The CUSTOMER must inform the Service Agency of the possibility of warranty coverage and provide a copy of

the dated sales or delivery receipt BEFORE WARRANTY REPAIRS ARE BEGUN. Replacement parts and accessories are

warranted for ninety (90) days from the date of purchase when purchased separately and will be verified by a dated sales

receipt OR packing list, which list that item. All parts or accessories replaced under warranty are the property of Robot Coupe

and must be returned to the Service Agency.

The motor of your new R2 series machine, which serial number begins with 244xxxxxx or 245xxxxxx is warranted an

additional two (2) years against defects for a total of three (3) year motor warranty. Robot Coupe will replace any motor and

shaft seal only which fails due to mechanical malfunction not including

motor warranty does NOT include labor to install, shipping charges, travel or mileage charges, or other incidental charges

incurred during motor replacement. The machine purchase date must be verified with a dated copy of the purchase invoice

from your selling dealer.

Robot Coupe USA designs many attachments and accessories for use on specific models and series of machines.

THE USE OF PARTS, ATTACHMENTS, OR ACCESSORIES OTHER THAN THOSE OFFERED FOR SALE

BY ROBOT COUPE U.S.A. Inc. AND DESIGNED FOR USE ON YOUR SPECIFIC MODEL AND SERIES

WILL VOID YOUR WARRANTY.

THE FOLLLOWING ARE NOT COVERED BY THE ROBOT COUPE LIMITED WARRANTY

1. Damage caused by abuse, misuse, dropping, or other similar incidental damage caused by or as a result of failure to

follow assembly, operating, cleaning, and user maintenance or storage instructions.

2. Labor to sharpen and/or parts to replace knife assemblies or blades which have become dull, chipped, or worn due to

normal use.

3. Material or labor to renew or repair scratched, stained, chipped, dented or discolored surfaces, blades, knives,

attachments, or accessories.

4. Transportation charges to or from an authorized service agency for repairs of a machine designated as CARRY IN

SERVICE . The R2 series are warranted only for carry in service.

5. Labor charges to install or test attachments or accessories (i.e. bowls, cutting plates, blades, attachments) which are

replaced for any reason.

6. SHIPPING DAMAGE IS NOT COVERED BY WARRANTY. Visible and hidden damages are the responsibility

of the freight carrier. The consignee or receiver must file a damage claim promptly against the carrier, or upon

discovery in the case of hidden damage. KEEP ALL ORIGINAL CONTAINERS AND PACKING MATERIAL

FOR CARRIER INSPECTION.

Robot Coupe U.S.A., Inc., Robot Coupe S.A., or any of their affiliates, distributors, officers, directors,

agents, employees, or insurers will not be obligated for consequential or other damages, losses, or

expenses in connection with or by reason of the use of or inability to use the machine for any purpose.

THIS WARRANTY IS GIVEN EXPRESSLY AND IN LIEU OF ALL OTHER WARRANTIES

EXPRESSED OR IMPLIED, FOR MERCHANTABILITY AND FOR FITNESS TOWARD A

PARTICULAR PURPOSE AND CONSTITUTES THE ONLY WARRANTY MADE BY ROBOT

COUPE U.S.A., Inc.

11jan02

seal and bearing failure. The additional two (2) year

Loading...

Loading...