Page 1

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

Operating Instructions

Model: LD3

Dual Mode Refrigerant

Gas Leak Detector

Page 2

PAG E 2

LD3 OPERATORS MANUAL

Contents

Introduction ...................................... 3

Features ......................................... 3

LD3 Control Panel ................................ 4

Operating Instructions ............................ 4

Adjusting Sensitivity Levels ....................... 5

Leak Test Vial .................................... 5

Maintenance ..................................... 6

Product Specications ............................ 7

EN14624/2005 Test Specications ................ 7

Cross Sensitivity to Automotive Chemicals ......... 8

Replacement Parts ............................... 8

Return for Repair Policy & Warranty Policy .......... 9

© Bosch Automotive Service Solutions Inc. / Robinair / November 2017

Page 3

LD3 OPERATORS MANUAL

PAG E 3

Introduction

The LD3 features a long life solid electrolyte semiconductor sensor

technology that is designed to detect all CFC, HCFC, HFC, and HFO

refrigerants including R-1234YF (HFO), R-134A (HFC), R-410A (HFC),

R-22 (HCFC), R-407C (HFC), R-507 (HFC), R-12 (CFC), R-404C (HFC).

The LD3 is designed to detect all SNAP approved refrigerant blends.

The LD3 does not require rechargeable batteries

Features

Long life, stable sensor

R1234yf sensitivity .015 oz/yr

R134a sensitivity .05 oz/yr

Certied to SAE J2791, J2913, ASHRAE 173-2012, EN14624-2012

Automatic calibration and reset to ambient

3 adjustable sensitivity levels

Low battery indicator

True mechanical pump

Uses 4 AA alkaline batteries

CE Certied

Comfortable Santoprene handle grip

2-year warranty includes sensor

Made in USA

© Bosch Automotive Service Solutions Inc. / Robinair / November 2017

Page 4

PAG E 4

LD3 OPERATORS MANUAL

LD3 Control Panel

Sensitivity Level Indicator

Green = MED (default)

RED = HI, Amber = LO Low

Battery indicator when

ashing RED

ON/OFF Switch

Hold down to change

Sensitivity when detector

is on.

Operating Instructions

1. Turn On: Press the ON/OFF button once to turn on and again to turn off.

NOTE: For SAE J2913 sensitivity setting for R1234yf Mode hold down

ON/OFF button until is the LED turns displays red.

2. Warm Up: The detector automatically starts heating the sensor. During

the heating cycle the detector will sound a slow “beep” and the LED will

alternate colors; green, red, yellow. The warm up cycle is complete when

the audio beep increases in frequency and the LED turns to constant green

(the default sensitivity level). Warm up is usually less than 20 seconds.

3. Search: Move the probe tip towards a suspected refrigerant leak at the

rate of less than 2 inches (~50 mm) per second, no more than 1/4 inch

(~5 mm) away from the suspected source.

4. Detection: If a leak exists, the sound will increase in rate and pitch.

NOTE: The leak detector responds to changes in refrigerant concentration.

When detection occurs, move the probe away from the source and back

again to conrm the leak source. The detector alarm will reset if the probe

is held xed at the source (see Automatic Calibration Feature).

© Bosch Automotive Service Solutions Inc. / Robinair / November 2017

Page 5

LD3 OPERATORS MANUAL

PAG E 5

Adjusting Sensitivity Levels

In addition to the automatic calibration, the audio alarm trigger level can be

set by the user to 3 different sensitivity levels- LO (Yellow), MED (Green), HI

(Red). If the detector is continuously alerting while pulled away from the

suspected area of the leak, the sensitivity level can be adjusted so the detector will only alert when the sensor is close to the source of the leak.

The Leak Detector will default to the MED (Green) sensitivity level automatically once the unit comes out of the warm up cycle. To change sensitivity

levels when the detector is on, press and hold the ON/OFF button down

for several seconds. The indicator LED at the top of the keypad will scroll

changing colors; Green for MED, Red for HI and Yellow for LO. Release the

button when the desired sensitivity level is displayed.

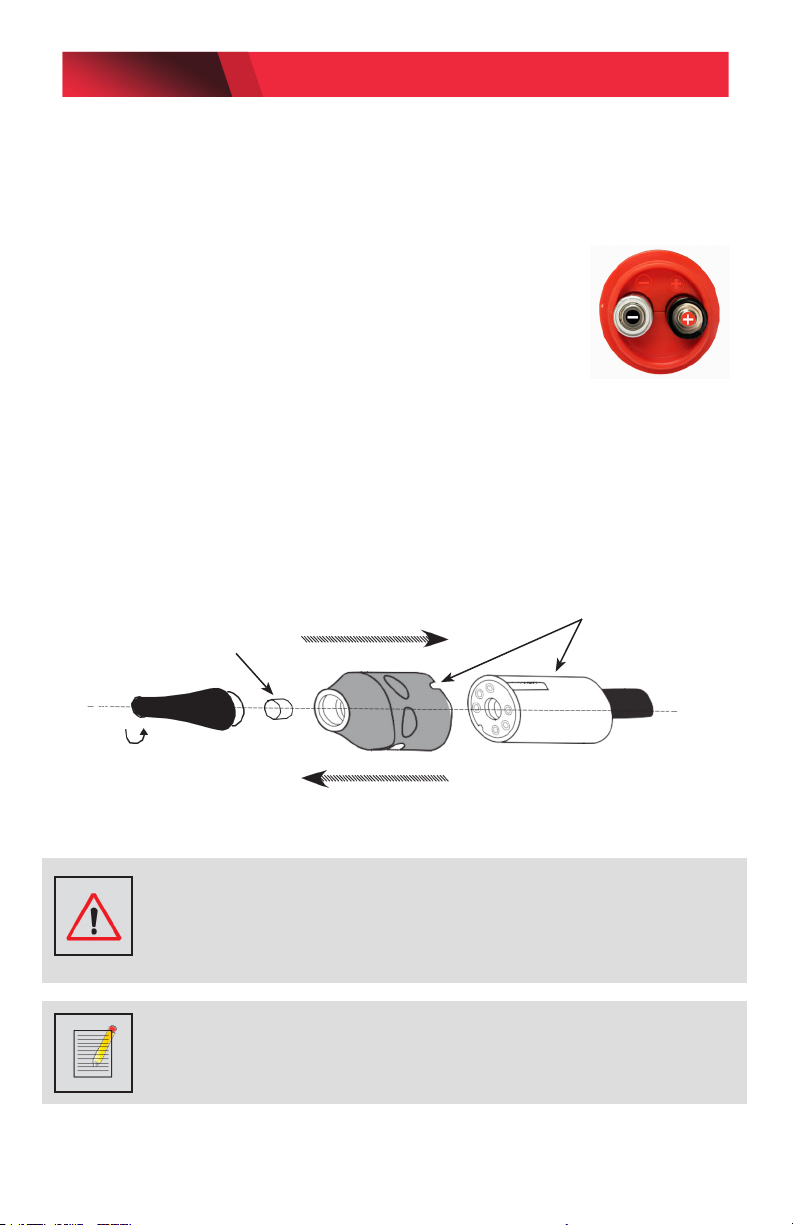

Leak Test Vial

The leak detector comes with a Leak Test Vial that allows the user to

verify the detector is performing properly. Check the expiration date on

the vial before testing the leak detector.

To test:

1. Remove the colored label dot on the center of the screw cap to expose

the vent hole. (see g. below)

2. Turn on the detector and allow the unit to complete the warm up cycle.

Set sensitivity level to HIGH.

3. Place the sensor close to the hole in the Leak Test Vial. The beep rate

should increase indicating that the sensor and electronics are working

properly.

NOTE: The leak detector responds to changes in refrigerant concentration. When detection occurs, move the probe away from the source and

back again to conrm the leak source. The detector alarm will reset if the

probe is held xed at the source (see Automatic Calibration Feature).

Remove label dot over

vent hole before testing.

Vial Cap with Vent Hole

Leak Test VialExpiration Date on Label

© Bosch Automotive Service Solutions Inc. / Robinair / November 2017

Page 6

PAG E 6

LD3 OPERATORS MANUAL

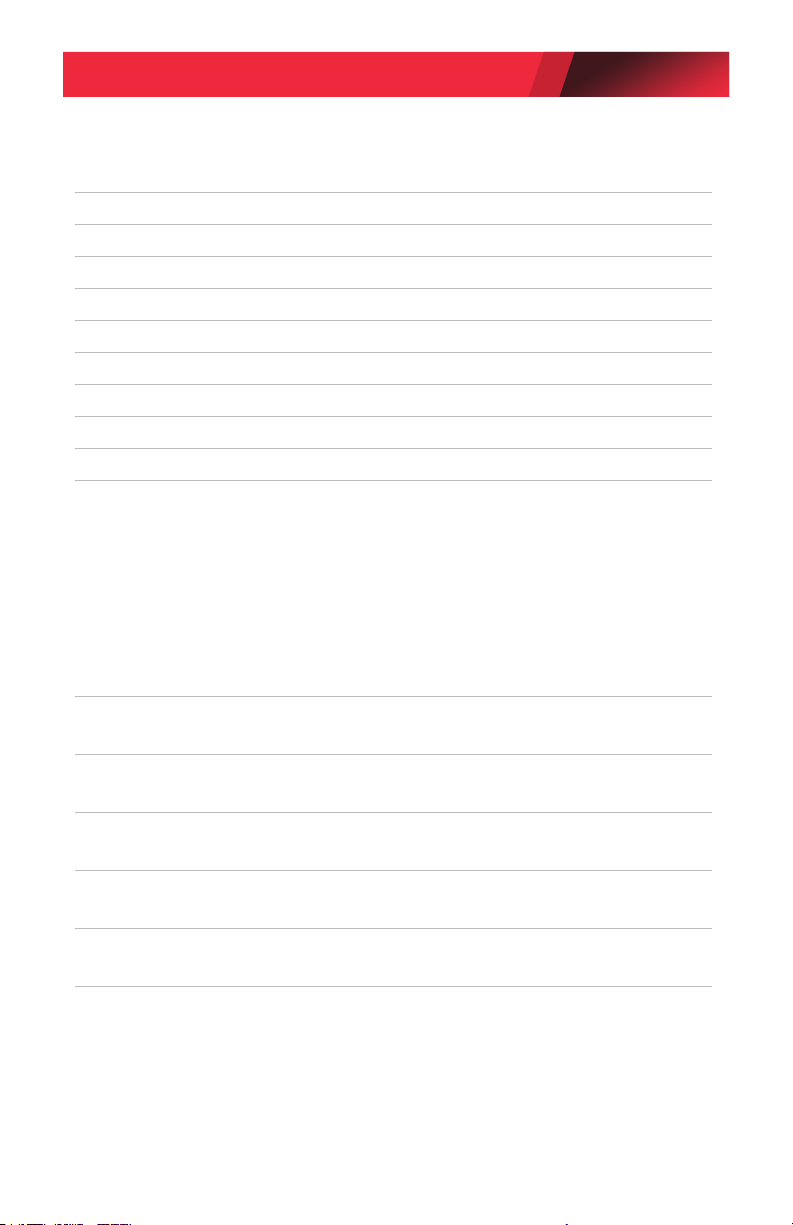

MAINTENANCE

Batteries

Install Batteries: Unscrew the battery cover located at the base of the

unit as shown. Insert all four batteries into the battery compartment

in the same direction. Note the polarity mark on the inside of

the battery compartment for proper battery orientation. Re-

place batteries when the LED Indicator display ashes RED.

Sensor & Sensor Filter

Replace Filter: Unscrew sensor tip as shown to replace lter.

Replace lter when it becomes visible dirty or after 30 hours of usage.

Replace Sensor: Remove sensor by pulling it out of the socket. Install

the new sensor by aligning the Keyway notch in the sensor cover with

the raised keyway on the sensor socket holder (see gure below).

Note: Do not force sensor into socket. Misalignment can damage the

sensor pins.

Push straight on (do not twist) TO INSTALL sensor.

Unscrew tip to

replace lter.

Important: The instrument’s software is designed to alert the user if the sensor is dislodged

or defective. If the sensor is not fully inserted into the six-pin socket, or if it is defective, the

instrument will not come out of the “Warm Up” mode for proper operation when the power

button is turned on. Additionally, if the instrument becomes unstable during its operation,

it is an indication that the sensor may be defective.

Note: If the leak detector has been out of use for an extended period, weeks or months, the

following action is recommended. Power on the instrument and allow it to come out of warm

up, and then run it with the sensitivity level in the (Hi) high position for several minutes before

testing it with the Leak Test Vial. This action will guarantee that the sensor is fully conditioned

for maximum response to refrigerant gas.

© Bosch Automotive Service Solutions Inc. / Robinair / November 2017

Keyway

Alignment

Filter

Pull straight out (do not twist) TO REMOVE sensor.

Page 7

LD3 OPERATORS MANUAL

PAG E 7

Product Specications

Model No. LD3

Name Leak Detector, Refrigerant Gas

Sensitivity .05 oz/yr R134a, .0123 oz/yr R1234yf

Sensor Life > 10 years

Response Time Instantaneous

Power Supply 4 AA Alkaline batteries

Battery Life 4 hours continuous

Warm up time < 20 seconds

Probe Length 17 inches

Weight, lbs 1.5 lbs

Warranty 2 years (includes sensor)

EN14624/2005 Test Specications

Minimum/Maximum 1 gm/yr minimum, >50 gm/yr

Senitivity Threshold (fixed) maximum

Minimum/Maximum 3 gm/yr minimum, >50 gm/yr

Senitivity Threshold (moving) maximum

Minimum Detection Time Approx. 1 second

(1gm/yr)

Clearing Time Approx. 9 seconds after exposure

to >50 gm/yr

Minimum Threshold after 1 gm/yr

Maximum Exposure

Sensitivity Threshold in 1 gm/yr

Polluted Atmosphere

Calibration Frequency 1/yr check with calibrated leak

standard

© Bosch Automotive Service Solutions Inc. / Robinair / November 2017

Page 8

PAG E 8

LD3 OPERATORS MANUAL

Cross Sensitivity to Automotive Chemicals

Some automotive solvents and chemicals have similar hydrocarbon properties as R134a and may elicit a positive response. Before leak checking, clean

up any chemicals in the list below that elicit a positive response.

Chemical Name/Brand Response

Rain-X Windshield Wash Fluid Y

Ford Spot Remover (wet) Y

Ford Rust Inhibitor Y

Ford Gasket Adhesive (wet) Y

Loctite Natural Blue Degreaser (diluted) Y

Ford Brake Parts Cleaner Y

Ford Silicone Rubber (uncured) N

Motorcraft Antifreeze heated to 160 degrees F N (partial)

Gunk Liquid Wrench Y

Ford Silicone Lubricant N

Ford Pumice Lotion (with solvent) Y

Ford Motorcraft Brake Fluid Y

Ford Carburetor Cleaner Y

Dextron Transmission Fluid heated to 160 degrees F N

Quaker State Motor Oil heated to 160 degrees F N

Replacement Parts

Item Part Number

Sensor with Filter F00E901451

Sensor Filters (5 pack) F00E901446

Leak Test Vial F00E901447

Sensor Tip F00E901452

Parts Kit (includes sensor, test

vial & lter kit)

Carrying Case F00E901450

© Bosch Automotive Service Solutions Inc. / Robinair / November 2017

F00E901453

Page 9

LD3 OPERATORS MANUAL

PAG E 9

Return for Repair Policy & Warranty Policy

Every effort has been made to provide reliable, superior quality products.

However, in the event your instrument requires repair, call the Robinair

Technical Hotline below for instructions.

Robinair warrants the LD3 Refrigerant Gas Leak Detector to be free of

defects in materials and workmanship for a period of two years from

the date of purchase. Robinair shall, at its option, repair or replace, at no

charge, such products which, under normal conditions of use and service,

prove to be defective in material and/or workmanship. This warranty

applies to all repairable instruments that have not been tampered with or

damaged through improper use including unauthorized opening of the

unit. Please ship warranty units that require repair freight prepaid to Service Center along with proof of purchase, return address, phone number

and/or email address.

Robinair shall not be liable for any incidental, consequential, special or

punitive damages arising from the sale or use of any products, whether

such claim is in contract or not. No attempt to alter, modify or amend this

warranty shall be effective unless authorized in writing by an ofcer of

Robinair.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES OR REPRESENTATIONS, EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY

IMPLIED BY LAW, WHETHER FOR MERCHANTABILITY OR FITNESS FOR

A PARTICULAR PURPOSE OR OTHERWISE AND SHALL BE EFFECTIVE

ONLY FOR THE PERIOD THAT THIS EXPRESS WARRANTY IS EFFECTIVE.

SOME STATES AND JURISDICTIONS DO NOT ALLOW LIMITATIONS ON

IMPLIED WARRANTIES, SO THE ABOVE LIMITATIONS MAY NOT APPLY

TO YOU.

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

© Bosch Automotive Service Solutions Inc. / Robinair / November 2017

Page 10

PAG E 10

NOTES

LD3 OPERATORS MANUAL

© Bosch Automotive Service Solutions Inc. / Robinair / November 2017

Page 11

LD3 OPERATORS MANUAL

NOTES

PAG E 11

© Bosch Automotive Service Solutions Inc. / Robinair / November 2017

Page 12

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

581644 REV B © Bosch Automotive Service Solutions Inc.

Loading...

Loading...