Page 1

Original Instructions

Instucciones originales

Consignes originales

Model: J-52405

R-1234yf A/C Recover, Recycle, Recharge Machine

ROBINAIR.COM 800.533.6127

Page 2

Description: Recover, recycle, and recharge machine for use

with R-1234yf equipped air conditioning systems.

PRODUCT INFORMATION

Record the serial number and year of manufacture of this unit for future reference. Refer to the product

identication label on the unit for information.

Serial Number: _______________________________Year of Manufacture: ____________

DISCLAIMER: Information, illustrations, and specications contained in this manual are based on the latest information available at the time

of publication. The right is reserved to make changes at any time without obligation to notify any person or organization of such revisions

or changes. Further, ROBINAIR shall not be liable for errors contained herein or for incidental or consequential damages (including lost

prots) in connection with the furnishing, performance, or use of this material. If necessary, obtain additional health and safety information

from the appropriate government agencies, and the vehicle, refrigerant, and lubricant manufacturers.

Page 3

Table of Contents

Safety Precautions .......................2

Explanation of Safety Signal Words ............... 2

Explanation of Safety Decals. . . . . . . . . . . . . . . . . . . . . 2

Protective Devices ............................. 4

J2843 Requirement Regarding Lubricant ........... 4

Introduction .............................5

Technical Specications ........................ 5

Features ....................................6

Control Panel Functions ........................ 8

Initial Setup Procedure ...................10

Unpack the Accessory Kit ...................... 10

Accessory Kit .............................. 10

Install the Oil Drain Bottle ...................... 10

Power Up the Machine .........................11

Language Selection ............................11

End User License Agreement ....................11

Unit of Measure ...............................11

Dealer Info .................................. 12

Date and Time Setup .......................... 13

Service Vacuum .............................. 13

Tank Fill Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Tank Filling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Register the Machine. . . . . . . . . . . . . . . . . . . . . . . . . . 15

Setup Menu ............................16

Setup Menu Optional Items ..................... 16

Beeper Setting ............................. 16

BlueTooth Conguration ...................... 16

Pairing a U-Scan to a Robinair AC Recover, Recycle,

and Recharge Machine ...................... 16

Viewing Serial Number of Paired VCI ........... 17

Un-pairing a VCI ............................ 17

Ethernet Settings ........................... 17

Default Charge Target ....................... 17

Legal .................................... 17

System Information ......................... 17

Test Network Connection ..................... 17

Date Format Selection ....................... 17

WiFi Conguration .......................... 18

WiFi Conguration for Hidden Networks ......... 19

Database ................................... 20

VIN Entry ................................... 21

A/C Pressure Snapshot ........................ 21

A/C Service Function ....................22

Printouts ...................................22

At the End of Every Function .................. 22

After the Service is Completed and Exited ........ 22

Hose Equalize ...............................23

System Flush ................................ 24

Setup .................................... 24

Operating Instructions ....................... 25

Service Job Data ............................. 26

Procedure to Move Job Records ............... 27

Procedure to Copy Job Record ................ 27

Automatic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Recovery ...................................30

Vacuum .................................... 31

Charge ..................................... 32

Hose Flush .................................34

Unit Maintenance ........................35

Tank Filling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Maintain Vacuum Pump Oil ..................... 36

Maintain Filter ............................... 37

Check Remaining Filter Capacity ............... 37

Replace the Filter and Sample Hose Assembly .... 37

Refrigerant Identier ......................... 39

Calibration Check ............................ 39

Refrigerant Management ....................... 40

Air Purge Info. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Backlight ................................... 40

Replace Service Hoses and/or

Service Couplers ............................. 40

General Maintenance ......................... 41

Maintenance Procedures ................. 42

Replace O2 Sensor in the Refrigerant Identier ..... 42

Tank Fill Hose Filter Service .................... 44

Cleaning the Tank Fill Hose Filter ............... 44

Edit Print Header ............................. 45

Replace Printer Paper ......................... 45

Replacement Parts and Glossary ..........46

Replacement Parts ........................... 46

Glossary ...................................46

Troubleshooting Messages ............... 47

Troubleshooting Procedures ..............49

Setup, Tank Fill, and Background Tank Fill Functions . 49

Display Message: Purity Test Failed ............ 49

Recovery Function or Automatic Function .......... 50

Display Message: Purity Test Failed ............ 50

Recovery Function .......................... 51

Display Message: System Pressure ............ 51

Display Message: Filter Weight XXX LB ......... 51

Display Message: Identier Filter and Sample Tube

May Need Replacement ...................... 51

Vacuum Function ............................. 52

Display Message: Pressure Too High ........... 52

Automatic, System Flush, or Charge Functions ..... 53

Display Message: Insufcient Refrigerant ........ 53

Display Message: Pressure Too High ........... 53

Display Message: Vacuum Time X:XX min ....... 53

Storage and Transportation of Equipment ...54

Storage .................................... 54

Transportation of Equipment .................... 54

Disposal of Equipment ...................55

Disposal of Recycled Materials ..................55

Disposal of the Machine ....................... 55

Disposal of Batteries .......................... 55

581371 REV A

1

Page 4

Safety Precautions

Explanation of Safety Signal Words Used in this Manual

The safety signal word designates the degree, or level, of hazard seriousness.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, could result in minor or

moderate injury.

CAUTION: Used without the safety alert symbol indicates a potentially hazardous situation which, if not

avoided, could result in property damage.

These safety messages cover situations Robinair is aware of. Robinair cannot know, evaluate, or advise as to

all possible hazards. The user must verify that conditions and procedures do not jeopardize personal safety.

Explanation of Safety Decals Used on the Machine

Carefully read the instructions.

Do not use in open air in case of rain or high humidity.

Wear gloves.

Wear protection goggles.

Alternating voltage.

Grounding protection.

Electrical shock hazard.

2

Page 5

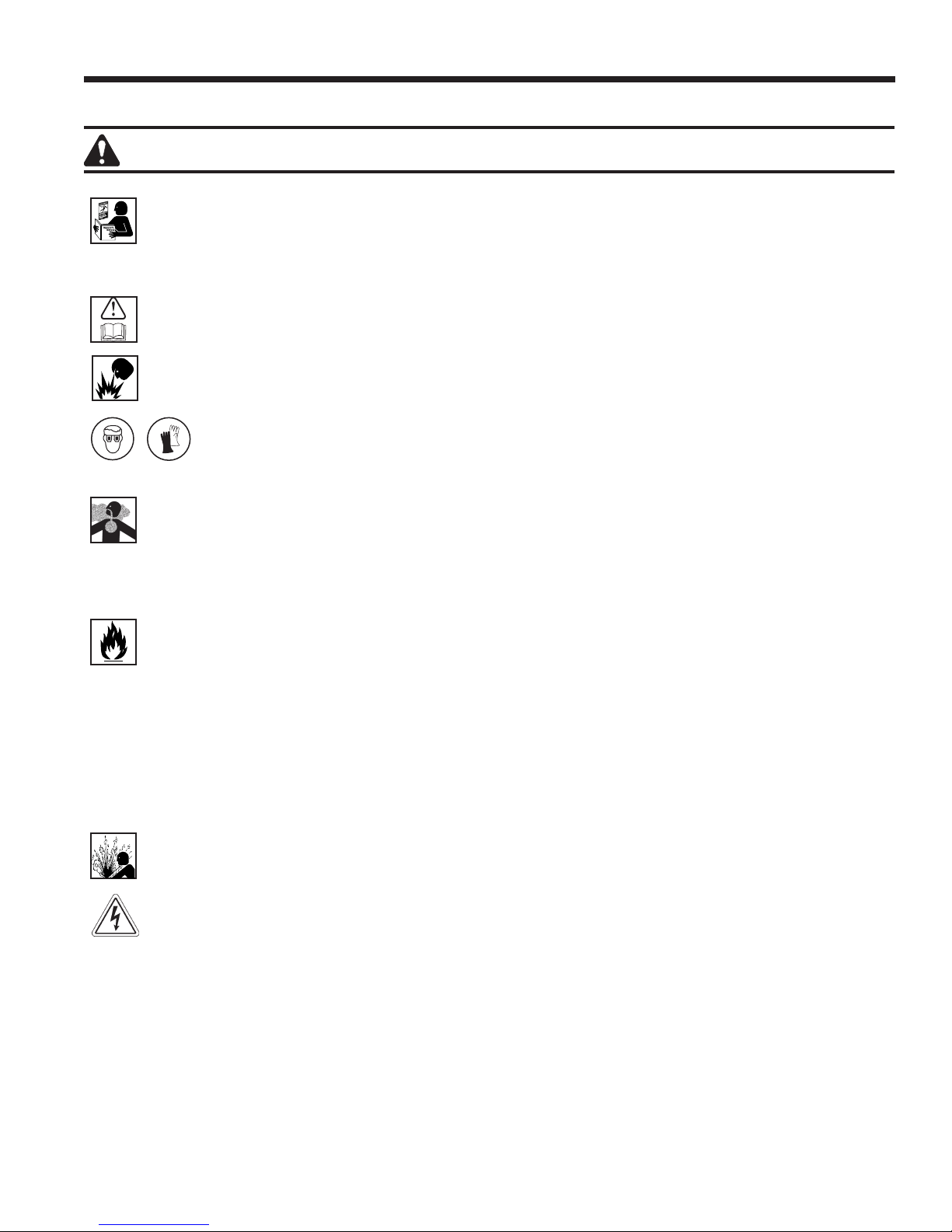

WARNING: To prevent personal injury,

ALLOW ONLY QUALIFIED PERSONNEL TO OPERATE THE MACHINE. Before operating the machine, read

and follow the instructions and warnings in this manual. The operator must be familiar with air conditioning

and refrigeration systems, refrigerants, and the dangers of pressurized components. If the operator cannot

read this manual, operating instructions and safety precautions must be read and discussed in the operator’s

native language.

USE THE MACHINE AS OUTLINED IN THIS MANUAL. Using the machine in a manner for which it was not

designed will compromise the machine and nullify the protections provided.

PRESSURIZED TANK CONTAINS LIQUID REFRIGERANT. Do not overll the internal storage vessel (ISV).

Overlling can cause explosion resulting in personal injury or death. Do not recover refrigerants into nonrellable

containers; use only type-approved rellable containers that have pressure relief valves.

HOSES CAN CONTAIN LIQUID REFRIGERANT UNDER PRESSURE. Contact with refrigerant can

cause personal injury, including blindness and frozen skin. Wear protective equipment, including

goggles and gloves. Disconnect hoses using extreme caution. Ensure the phase is complete before

disconnecting the machine to prevent the release of refrigeration to the atmosphere.

AVOID BREATHING A/C REFRIGERANT AND LUBRICANT VAPOR OR MIST. Exposure can irritate eyes, nose,

and throat. To remove refrigerant from the A/C system, use only equipment certied for the type of refrigerant

being removed. Use the unit in locations with mechanical ventilation that provides at least four air changes per

hour. If accidental system discharge occurs, ventilate the work area before resuming service.

DO NOT DISPERSE REFRIGERANT INTO THE ENVIRONMENT. Prevent the possible presence of refrigerant

in the working environment.

TO REDUCE THE RISK OF FIRE, do not use the machine in the vicinity of spilled or open containers of

gasoline or other ammable substances.

TO REDUCE THE RISK OF FIRE, do not use an extension cord. An extension cord can overheat and cause

re. If an extension cord must be used, use the shortest possible cord with a minimum size of 14 AWG.

TO REDUCE THE RISK OF FIRE, do not use the machine in the vicinity of ames and hot surfaces. Refrigerant

can decompose at high temperatures and free toxic substances to the environment that can be noxious to

the user.

TO REDUCE THE RISK OF FIRE, do not use the machine in environments containing explosive gases or vapors.

TO REDUCE THE RISK OF FIRE, protect the machine from conditions that can cause electrical failure or

other hazards relating to ambient interaction.

CAUTION—DO NOT PRESSURE TEST OR LEAK TEST EQUIPMENT AND/OR VEHICLE AIR CONDITIONING

SYSTEMS WITH COMPRESSED AIR. Some mixtures of air and refrigerant have been shown to be combustible

at elevated pressures. These mixtures, if ignited, can cause injury or property damage.

HIGH VOLTAGE ELECTRICITY INSIDE THE MACHINE HAS A RISK OF ELECTRICAL SHOCK. Exposure

can cause personal injury. Disconnect power before servicing the machine.

Safety Precautions

NEVER LEAVE THE MACHINE LIVE IF AN IMMEDIATE USE IS NOT SCHEDULED. Disconnect the electrical

supply before a long period of inactivity or before internal maintenance is performed.

DO NOT MODIFY THE PRESSURE RELIEF VALVE OR CHANGE THE CONTROL SYSTEM SETTINGS.

Using the machine in a manner for which it was not designed will compromise the machine and nullify the

protections provided.

Additional health and safety information can be obtained

from refrigerant and lubricant manufacturers.

581371 REV A

3

Page 6

Safety Precautions

CAUTION : To prevent equipment damage,

TO PREVENT CROSS-CONTAMINATION, USE THIS MACHINE WITH R-1234YF REFRIGERANT ONLY.

The machine is equipped with special connectors to recover, recycle, and recharge only R-1234yf refrigerant.

Do not attempt to adapt the machine for another refrigerant. Do not mix refrigerant types through a system

or in the same container; mixing of refrigerants will cause severe damage to the machine and the vehicle air

conditioning system.

DO NOT USE THIS MACHINE IN DIRECT SUNLIGHT. Position the machine far from heat sources, such as

direct sunlight, which can cause excessive temperatures. The use of this machine under normal environmental

conditions (10°C to 50°C) keeps pressures under reasonable limits.

DO NOT USE THIS MACHINE OUTDOORS DURING RAIN OR HIGH HUMIDITY. Protect the machine from

conditions that can cause electrical failure or other hazards relating to ambient interaction.

DO NOT USE THIS MACHINE IN AREAS WHERE THERE IS A RISK OF EXPLOSION.

SET UP THE MACHINE ON AN EVEN SURFACE AND UNDER SUFFICIENT LIGHTING. LOCK THE FRONT

WHEELS, AND DO NOT SUBJECT THE MACHINE TO VIBRATION.

Additional health and safety information can be obtained

from refrigerant and lubricant manufacturers.

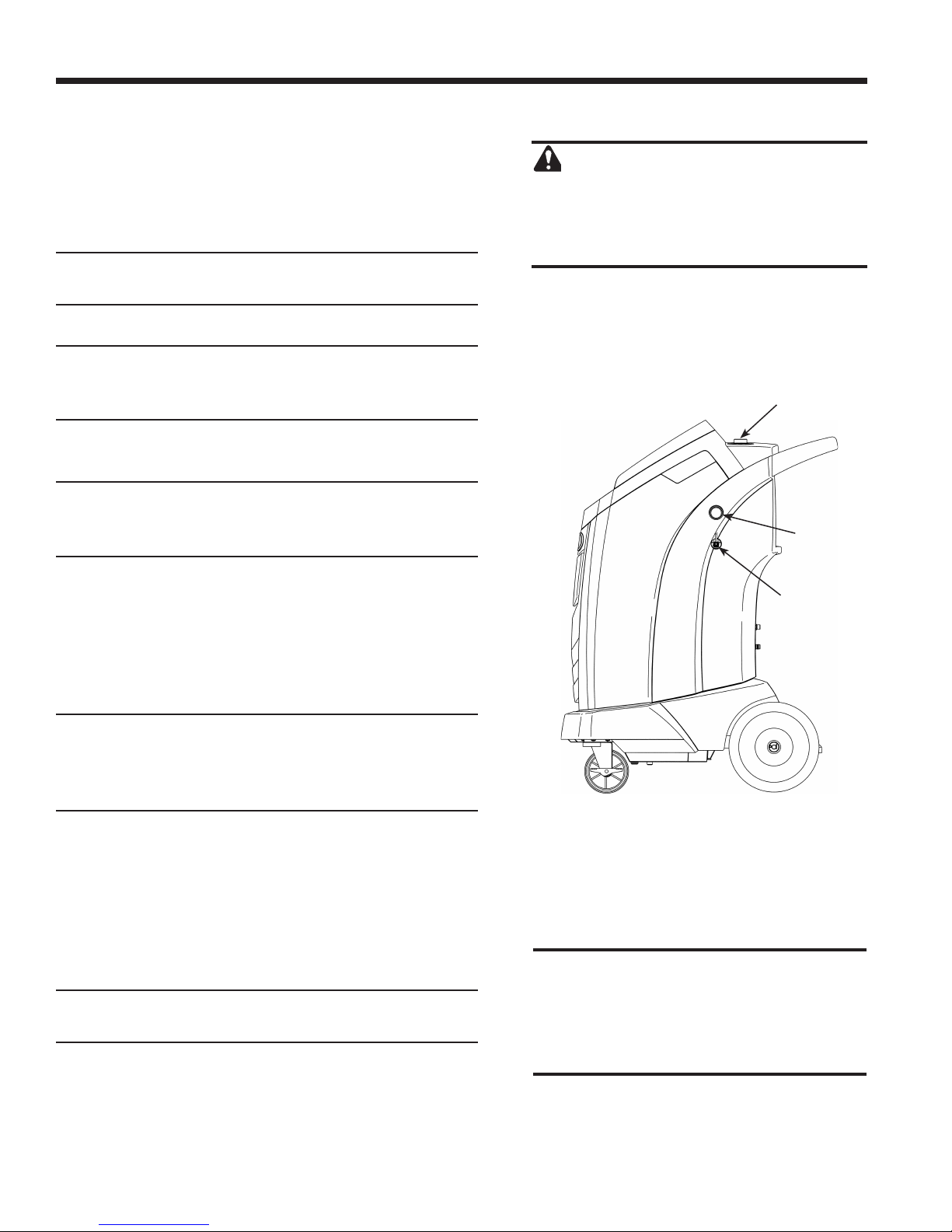

Protective Devices

The machine is equipped with the following protective devices:

• Over pressure valves.

• A maximum pressure switch stops the compressor when excessive pressure is sensed.

WARNING: Tampering with these protective devices could result in serious injury.

J2843 Requirement Regarding Lubricant

Only new lubricant, as specied by the system manufacturer, shall be installed in the MAC (Mobile Air

Conditioning) system. Lubricant removed from the system and / or the equipment shall be disposed of in

accordance with applicable federal, state, and local procedures and regulations.

4

Page 7

This machine is designed and certied to SAE J2843 HFO1234yf Recovery / Recycling / Recharging Equipment for

Flammable Refrigerants for Mobile Air-Conditioning Systems.

The machine is designed to recover and recycle R-1234yf

refrigerant, evacuate air after the system has been open, and

recharge refrigerant.

Other functions include system ush, diagnostic pressures, and

retention of service data by vehicle VIN for recall and printout.

The machine is a single-pass system (i.e. refrigerant ows

through a lter once) that meets SAE J2099 specications

for recycled refrigerant. The machine also meets oil crosscontamination requirements for high-voltage system charge.

Follow recommended service procedures for the containment

of R-1234yf.

Note: R-1234yf systems require special oils. Refer to the A/C

system manufacturer’s service manual for oil specications.

Introduction

Technical Specications

Compressor ..............................1/3 HP

Dimensions .................107 cm x 56 cm x 80 cm

Filter Capacity .............................150 kg

Humidity .......90°F (32.2°C), 86% RH non-condensing

Pressure Gauges .......................Ø 100 mm

Maximum Pressure . . . . . . . . . . . . . . . . . . . . . . . . . 30 bar

Noise .................................<70 dB(A)

Nominal Voltage ................103V to 127V, 60 Hz

Oil Drain Bottle ............................355 ml

Operating Temperature ...50°F to 122°F (10°C to 50°C)

Power Consumption ...................... 1150 VA

Pump Free-Air Displacement ........1.5 CFM (42 l/m)

Service Hoses ..............275 cm (9 ft) / SAE J2888

Tank Capacity ....................9.50 kg (20.94 lb.)

Weight ............................107 kg (235 lb.)

581371 REV A

5

Page 8

Introduction

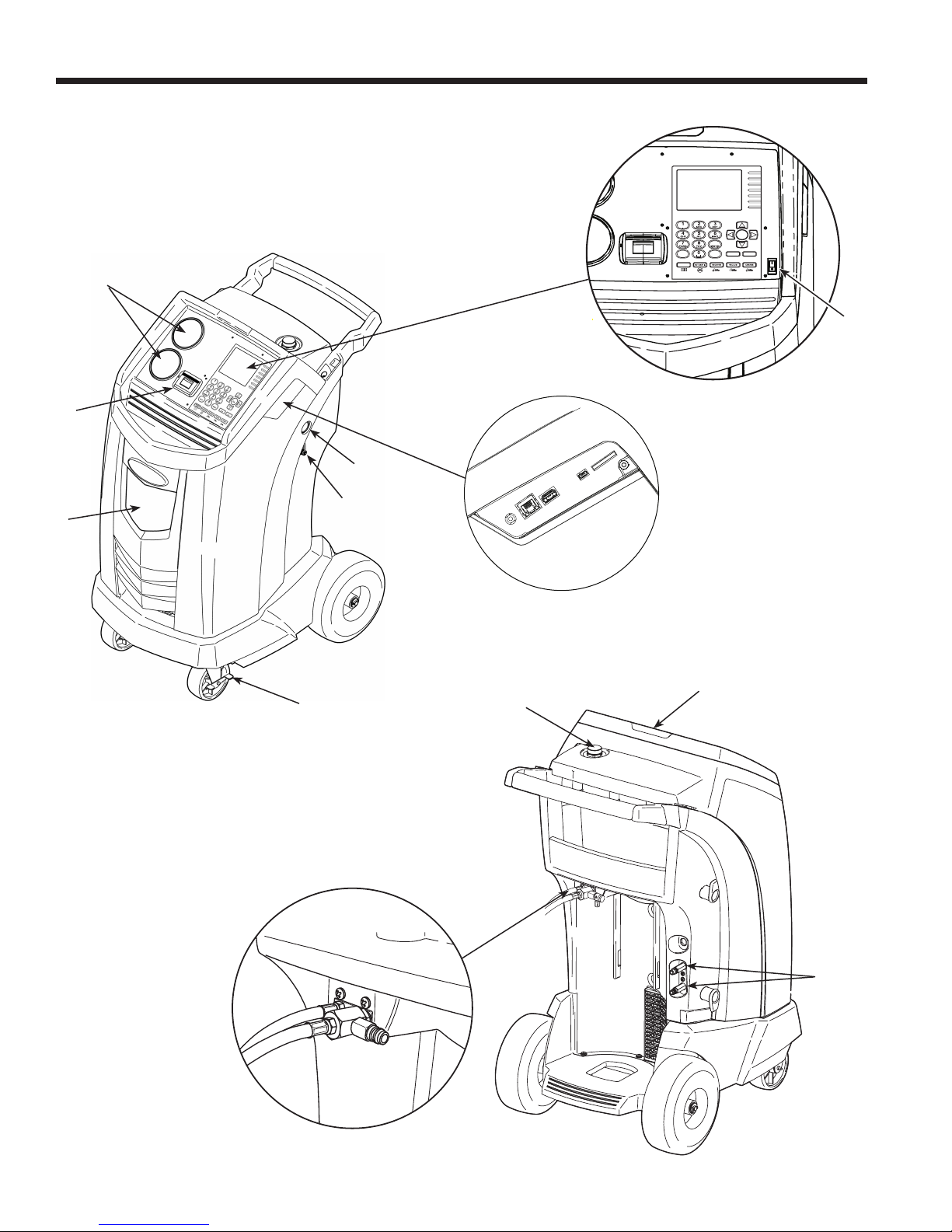

Features

3

2

4

OK

9

HELP MENU

DATABASE

STOP ESC

5

7

1

8

6

10

9

11

6

13

12

Page 9

Introduction

Item

No.

1 Oil Drain Bottle

2 Printer

3 Low-side (blue) and High-side (red) Manifold Gauges

4 Graphic Display and Keypad

5 Power ON / OFF Switch

6 Audio, Ethernet, USB, Mini-USB, and SD Card Connections

7 Vacuum Pump Oil Sight Glass

8 Vacuum Pump Oil Drain Fitting

9 Wheel Lock

10 Visual Alert

Description

11 Vacuum Pump Oil Fill Cap and Port

12 Contaminant Recovery Port

13 Service Hose Storage Ports

581371 REV A

7

Page 10

Introduction

Control Panel Functions

ARROW UP moves selection of a menu item to the previous

item; turns up audio volume.

ARROW DOWN moves selection of a menu item to the

following item; turns down audio volume.

ARROW RIGHT scrolls to next screen; fast forwards

the video.

ARROW LEFT scrolls to previous screen; rewinds the video.

AUTOMATIC activates a menu to set up an

automatic recovery / vacuum / leak test /

charge sequence.

CHARGE activates a sequence to charge

the vehicle A/C system with a programmed

amount of refrigerant.

DATABASE

charge capacity by vehicle model.

supplies information regarding

OK

9

ESC returns the test sequence to the previous screen; or

answers a query.

HELP displays information related to the current display.

MENU accesses additional functions and setup parameters.

OK highlights the menu item, answers a query, or starts

the video.

RECOVER activates a sequence to recover

refrigerant from the vehicle A/C system.

STOP interrupts the active function. Press once to pause,

twice to terminate.

VACUUM activates a sequence to pull a deep

vacuum on the vehicle A/C system to remove

air and moisture.

HELP MENU

DATABASE

Control Panel Keypad

STOP ESC

8

Page 11

Introduction

Press the number

on the keypad

that matches the

number of the

function to access.

1

2

3

4

5

6

Unit Setup

Unit Maintenance

A/C Service Function

Database

Update

Service Menu

9

HELP MENU

DATABASE

ESC

STOP ESC

OK

1

2

3

4

5

6

Hose Equalize

System Flush

Service Job Data

Automatic

Recovery

Vacuum

In this example,

another way to

select Recovery

is by pressing the

RECOVER button on

the control panel.

ESC

Notes regarding main menu items not outlined in this manual:

• Update - use this menu item to update application, database, or URL via WiFi.

To use the WiFi features, the network rewall must allow access to:

http://connectedservicesvc-equip3.bosch-automotive.com/api/RepairResults/upload and

http://9e864a0ddceb616e594a-77285b2f7a214aa453b5113bdf793358.r48.cf1.rackcdn.com

• Service Menu - for service centers’ use only

• Production Menu - for manufacturer’s use only

• Administrator - for manufacturer’s use only

581371 REV A

9

Page 12

Initial Setup Procedure

Unpack the Accessory Kit

Unpack the accessory kit from the box, and remove the plastic packaging.

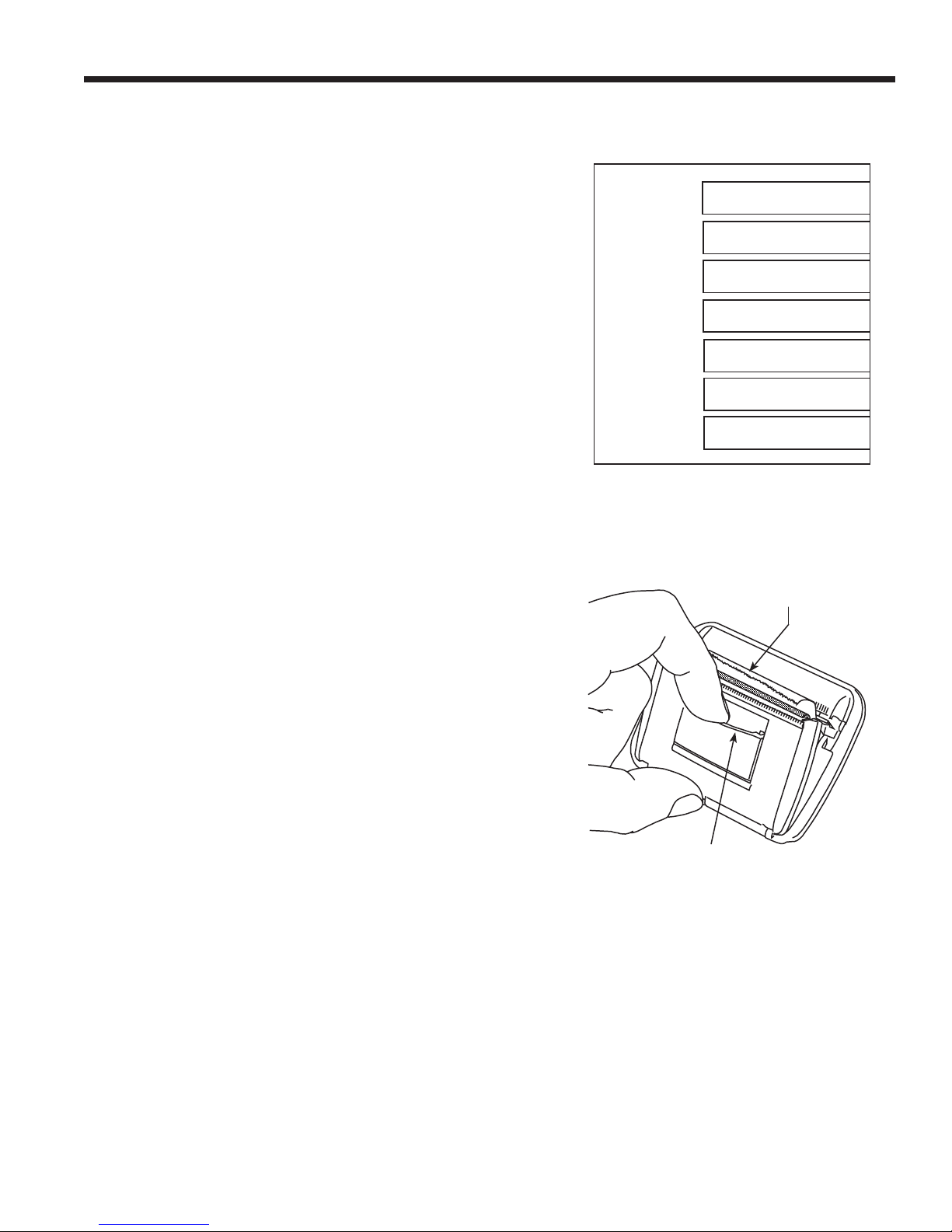

Accessory Kit

Calibration Check

Weight

Cap and Filler Tube

Oil Drain Bottle SD Card

External DLC Cable

Tank Fill Hose

Adapter

Vacuum Pump Oil

16 oz.

Pouch containing SDSs, EPA information, MACS

information, and a service center list.

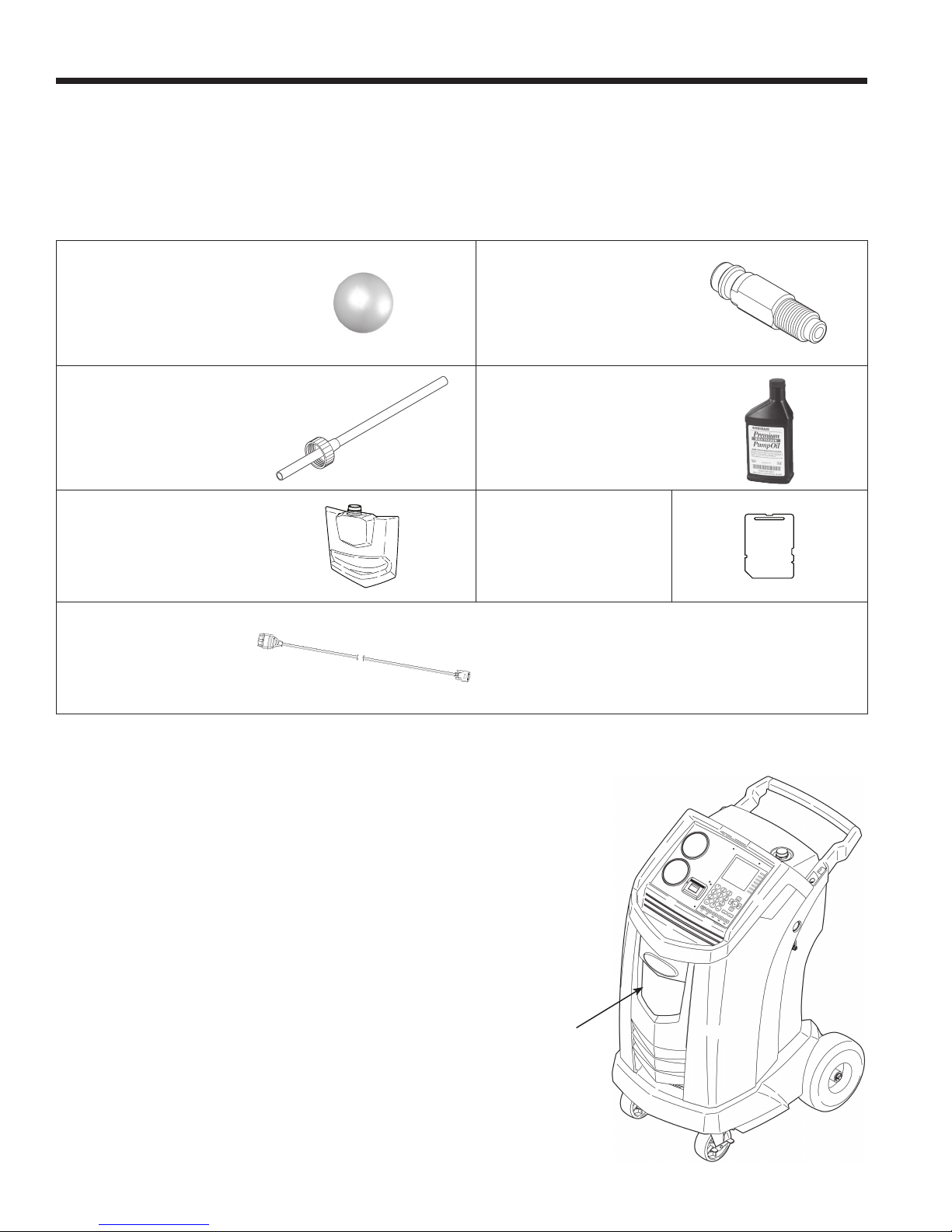

Install the Oil Drain Bottle

Hold the oil drain bottle straight and insert the connector into

the hole behind the shroud until it snaps into place.

10

Oil

Drain

Bottle

Page 13

Initial Setup Procedure

Important:

• This procedure can take several hours. Perform

this initial setup procedure BEFORE the machine

is needed for its rst vehicle A/C service.

• During initial setup, the machine prompts through

the following steps. Any changes to these settings

after the initial setup can be completed through the

Unit Setup menu.

Power Up the Machine

1. Unwind the power cord from the handle, and plug it into

a correct voltage, grounded outlet.

2. Position the machine so the plug and the main power

switch are within easy access of the operator. Verify the

fan vents on the rear of the machine are not obstructed.

3. Lock the front wheels.

4. Turn on the main power switch.

Language Selection

CAUTION: The machine is programmed

to run the setup procedure as outlined

here. To prevent personal injury, do NOT

operate the machine without the oil ll port

plug installed, because the vacuum pump

is pressurized during normal operation.

The operator selects the language for screen prompt

displays.

1. Use the UP or DOWN arrow key to toggle through the

available languages.

2. Press OK to set the selected language.

End User License Agreement

Approve the End User License Agreement to proceed with

the initial setup.

Unit of Measure

Program the machine to display units of measure in

kilograms or pounds. The default display is English.

Note: If English is selected, weights will be displayed in

metric units (per SAE standard J2843); pressures and

temperatures will be displayed in English units.

1. Use the UP or DOWN arrow key to toggle Metric or

English units.

2.

Press OK to choose the displayed unit of measure.

581371 REV A

11

Page 14

Initial Setup Procedure

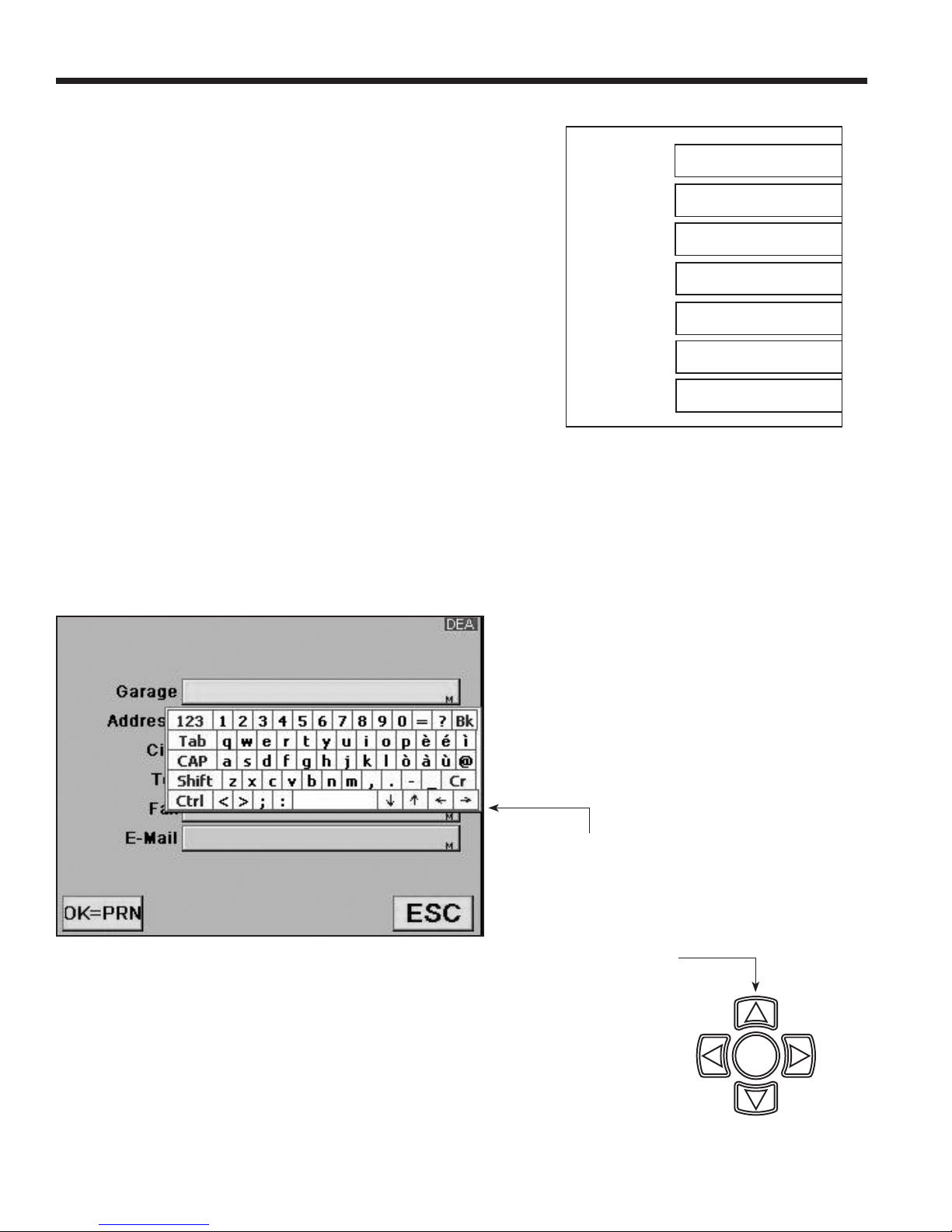

Dealer Info

This machine has the capability to print out recovery, vacuum,

charge, and ush information for each vehicle tested. A printout

may be obtained any time the display screen shows OK=PRN.

The information entered in the ll elds on the Dealer Info

screen will appear on each printout.

1. The cursor is blinking in the Dealer Code eld. Refer to

Figure 1.

2. Press the MENU key and a virtual keyboard appears as

shown in Figure 2. Note: A standard USB keyboard may be

connected to the machine and used to enter information.

3. Use the arrow keys on the machine’s keypad to move

around the keyboard. Press OK to enter a character. The

cursor will move to the next character.

4. Press the MENU key to exit the virtual keyboard. Use the

arrow keys to move to the next eld. Press OK to save

the data once all applicable elds are lled in. Press ESC

when done.

Dealer Code

Garage

Address

City

Tel

Fax

E-mail

Figure 1

Figure 2

12

Use the arrow

keys in the virtual

keyboard to move

the cursor within

the ll eld.

Use the arrow keys

on the machine’s

keypad to move

around the virtual

keyboard.

OK

Page 15

Initial Setup Procedure

Date and Time Setup

The machine is programmed at the factory for the local time

zone using a 24-hr. clock and date.

Note: The date changes only by scrolling through an entire day.

1. Use the LEFT and RIGHT arrow keys to modify the

minutes displayed.

2. Use the UP and DOWN arrow keys to modify the

hour displayed.

3. Press OK to accept the date and time.

Service Vacuum

Follow the prompts to connect the machine’s service hoses to

the storage ports and open the service couplers. The machine

performs a 5-minute vacuum to remove air from its internal

plumbing and the ISV (internal storage vessel).

When prompted, press OK to continue Initial Setup.

Tank Fill Adjustment

The operator can either accept the machine’s preset default

weight of 3.5 kg of refrigerant stored in the internal storage

vessel (ISV), or change the amount to accommodate the

application.

The maximum amount allowed for new refrigerant is 6.8 kg,

which leaves room for additional recovery. The minimum

amount is 1.8 kg.

1. Select TANK FILL ADJUSTMENT from the Unit Setup menu.

2. The machine displays the default amount of refrigerant:

TANK LEVEL

03.500 KG

3. Press OK to accept the default amount, or use the keypad

to enter an amount and press OK.

581371 REV A

13

Page 16

Initial Setup Procedure

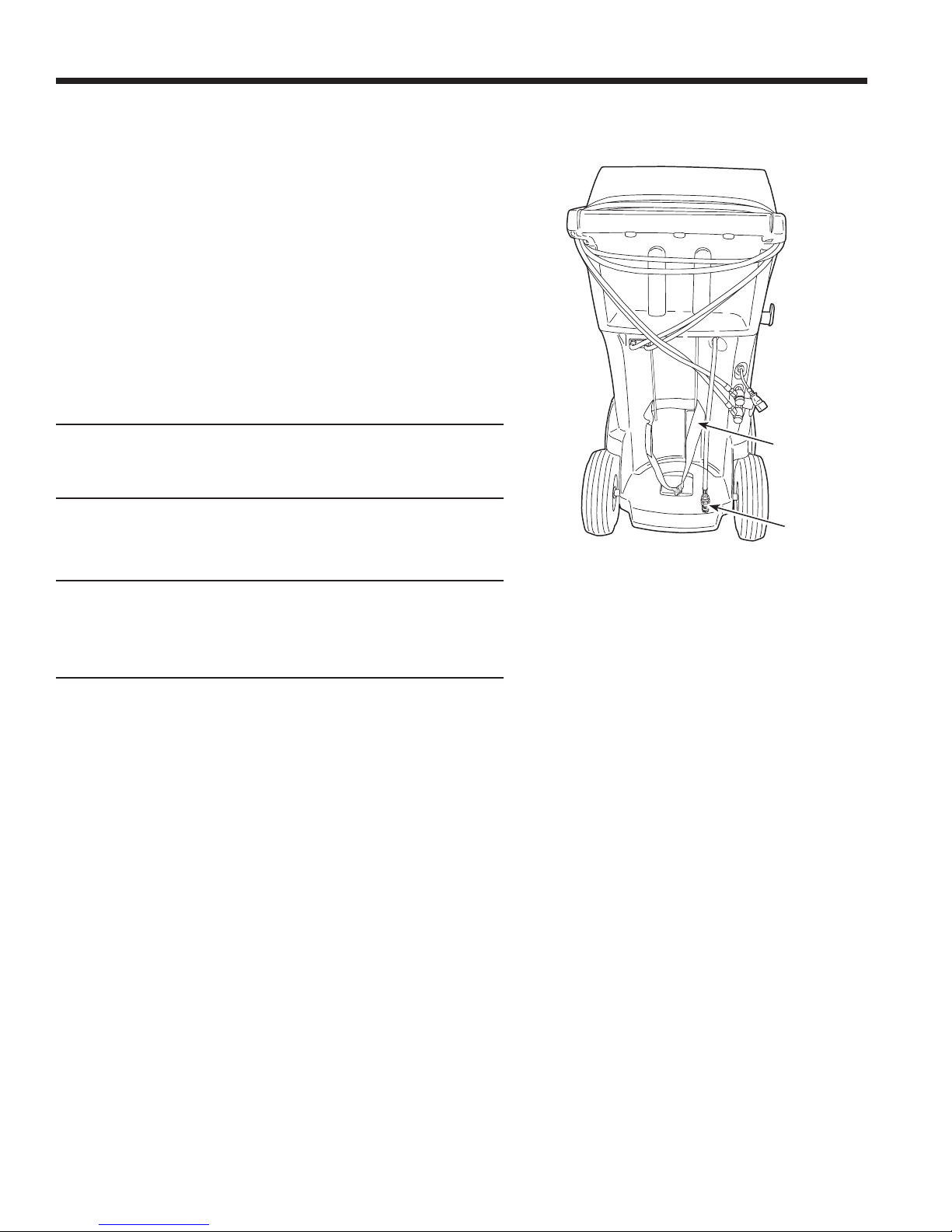

Tank Filling

1. Connect an R-1234yf source tank to the tank ll hose at

the rear of the machine. Hand tighten the tank ll hose.

See Figure 3.

Note: The tank ll hose and the tank access port have

left-hand threads.

2. Open the tank valve.

3. Mount the source tank on the shelf at the rear of the

machine, oriented to supply liquid refrigerant to the

connection. Tighten the holding strap around the source

tank. Verify the tank does not restrict air ow from the vent.

4. The machine displays

FILL AMOUNT

XX.XXX

CONNECT SOURCE TANK TO FILL HOSE

5. Press OK. The machine checks the refrigerant in the

source tank to verify it is R-1234yf and not contaminated,

and displays the following screens:

WARM UP

CALIBRATION IN PROGRESS

GAS IDENTIFY

REFRIGERANT PURITY ACCEPTABLE

After completing the above steps, the machine begins

lling the internal storage vessel (ISV).

6. The machine automatically stops when the preset tank

ll level is reached or the source tank is empty. To stop

tank ll before the preset level is reached, select ESC;

press OK to continue.

7. If using a non-rellable tank, the machine must display

SOURCE TANK EMPTY before the tank may be discarded.

Strap

Tank Fill

Hose

Figure 3

14

Page 17

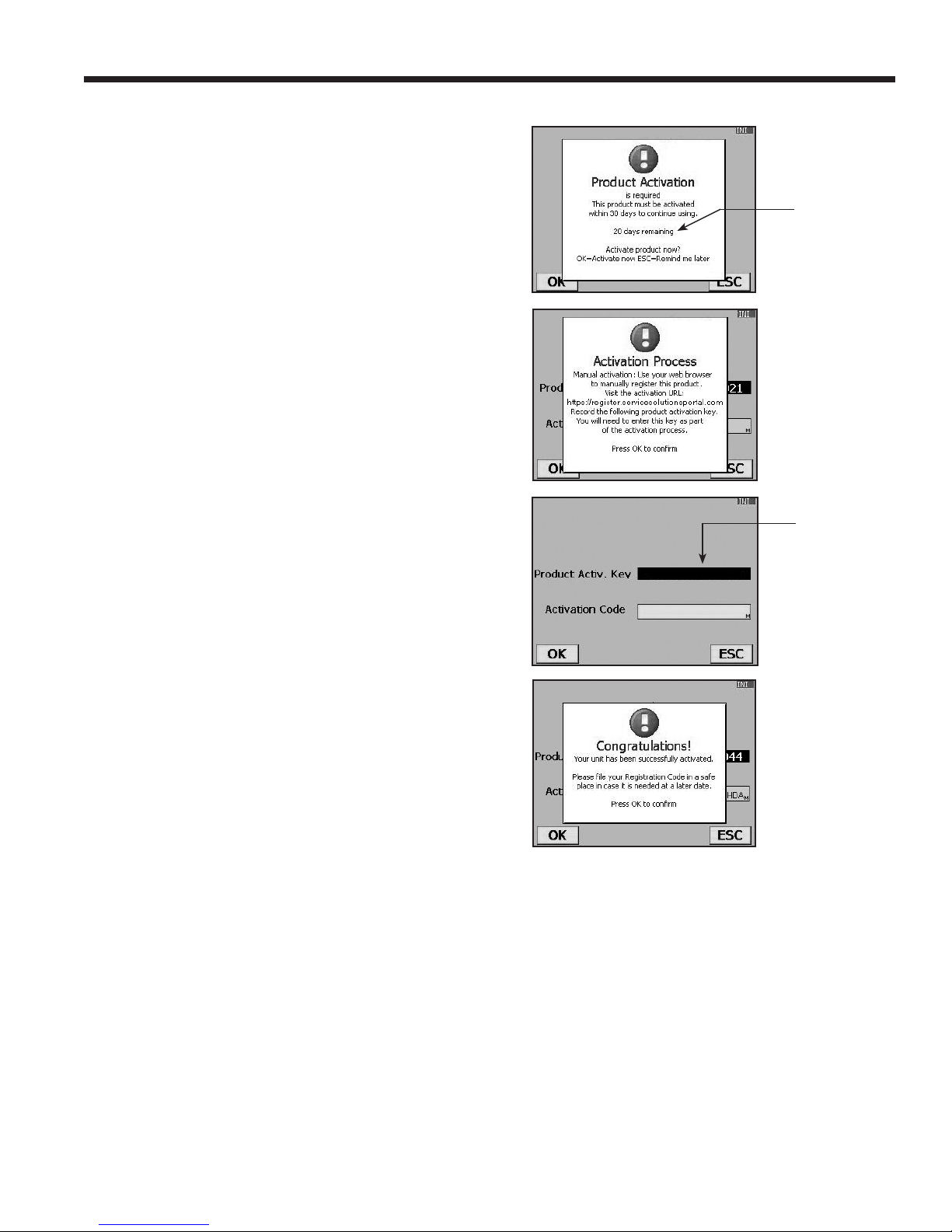

Register the Machine

When the Product Activation screen appears on the

display, follow on-screen prompts to register the machine.

1. Open a web browser on a personal computer. Enter

the web address shown in the Activation Process

screen on the machine.

Enter your user name and password, and log in to

the website.

First-time users, click the REGISTER button to create

a user name and password.

2. On the machine, press OK. The machine displays elds

for the product activation key and an activation code.

3. Enter the product activation key into the correct eld

on the web page. This generates an activation code.

4. Enter the activation code into the machine display

and press OK.

Note: Capitalization is required. A standard USB

keyboard can be connected to the machine to enter

information.

5. Record the product activation key and code and le

it in a secure place.

Initial Setup Procedure

Failure to

register and

activate the

machine

within 30

days of initial

startup will

cause the

machine to

lock out and

no longer

function.

The Product

Activation

Key will be

displayed in

this eld.

6. Press OK.

581371 REV A

15

Page 18

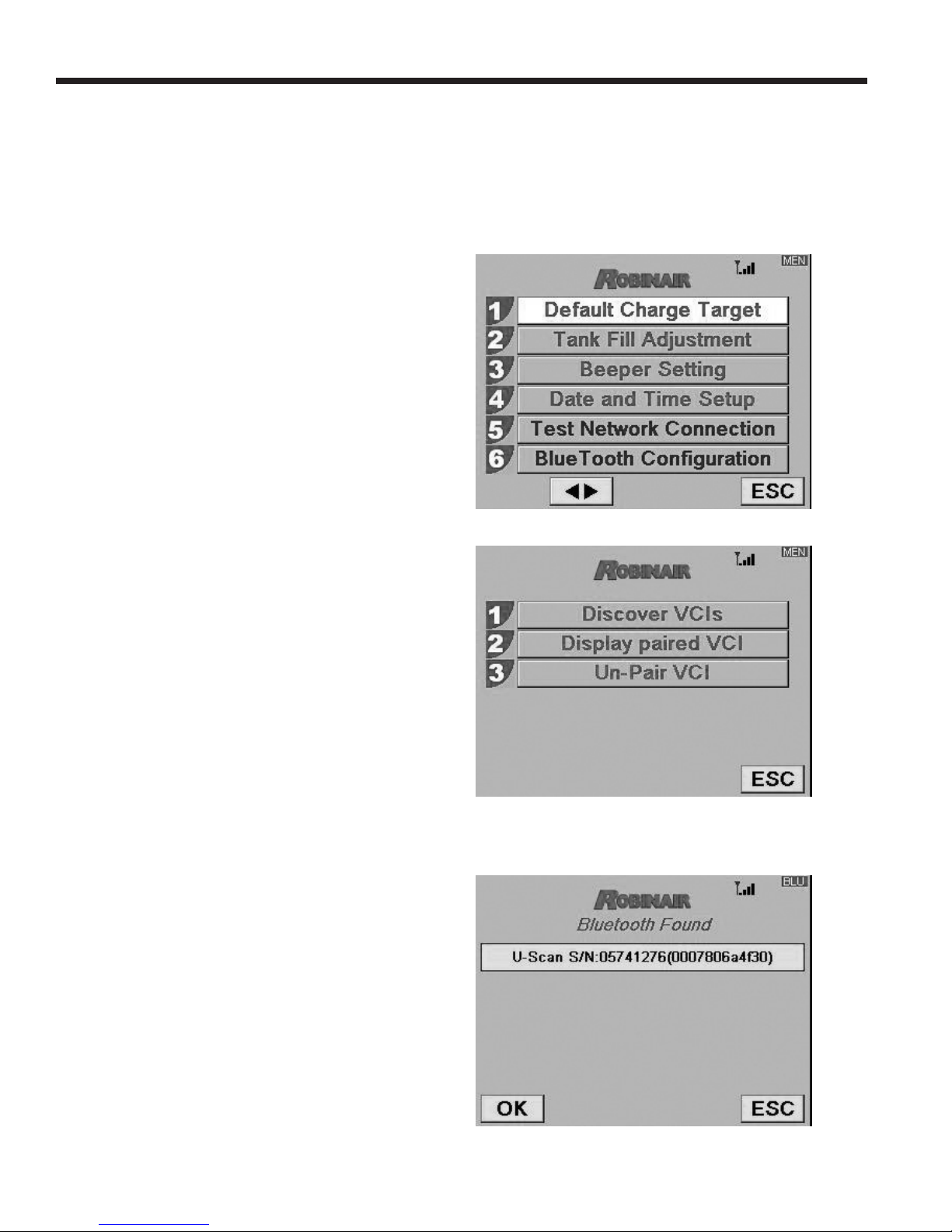

Setup Menu

Setup Menu Optional Items

Many of the functions included in the Initial Setup

Procedure can also be accessed through the

Setup Menu. Additional Setup Menu functions are

explained here.

1. Press the MENU key.

2. Select UNIT SETUP from the menu listings.

Beeper Setting

1. Select BEEPER SETTING from the Unit Setup

menu.

2. Press the OK button to toggle the audio “beep”

OFF and ON.

BlueTooth Conguration

This menu selection programs the machine to discover

and pair with a U-Scan™ VCI (Vehicle Communication

Interface).

• Discover and list BlueTooth devices.

Pairing a U-Scan to a Robinair AC Recover,

Recycle, and Recharge Machine

1. Plug the U-Scan into the vehicle OBDII connector.

2. Select the BLUETOOTH CONFIGURATION

option from the setup menu.

3. Select DISCOVER VCIS and press OK

• Screening eliminates all but U-Scan. There is a limit

of one pairing.

• Pairs U-Scan with the machine. Information will be

saved so future pairings are automatic.

• Option to see serial number and other information

from the paired VCI.

• Un-pair an existing paired VCI. Information will be

deleted for future pairings.

4. Follow the on-screen instructions. At the end of

the discovery process, the screen will display a

list of the VCIs that were discovered.

16

Page 19

Setup Menu

5. Select the appropriate VCI from the list and press

OK. The pairing process will take several seconds.

Note: The serial number of the U-Scan VCI is located

on the U-Scan packaging.

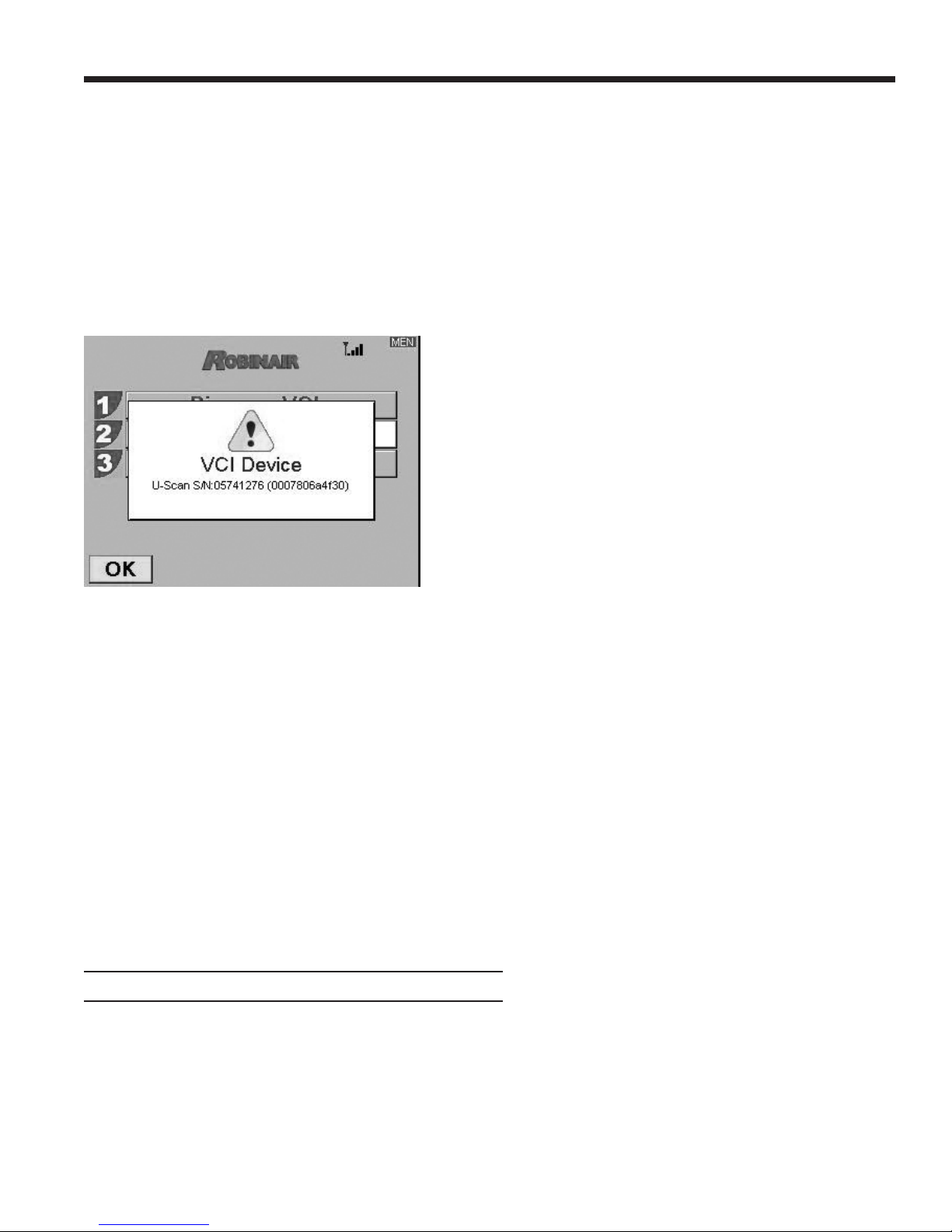

Viewing Serial Number of Paired VCI

Select Display Paired VCI and press OK. The screen

will display the serial number of the VCI with which it is

currently paired.

Legal

This menu selection displays the end user

license agreement.

System Information

Selecting this menu item displays the revision

level, serial number, and other information about

the software and machine.

Test Network Connection

The information from this menu selection can be

used to troubleshoot network connections.

The MAC address of the WiFi card can be viewed

from this menu.

Date Format Selection

Select the display order for the basic components of

the calendar year - day, month, and year. Press OK.

Un-pairing a VCI

Select Un-Pair VCI and press OK. Follow the on-screen

instructions.

Ethernet Settings

Enable or disable DHCP for Ethernet port.

Default Charge Target

Use this menu item to change the default charge amount

that appears on the charge programming screen.

1. Select DEFAULT CHARGE TARGET from the Unit

Setup menu.

2. The machine displays the current default charge

amount:

0.000 KG

3. Press OK to accept the default amount, or use the

keypad and arrow keys to change the amount. Press

OK to continue or ESC to quit.

581371 REV A

17

Page 20

WiFi Conguration

Use this Setup Menu option to program the machine to discover

and connect to a wireless network. Software updates can be

received in this manner.

Note: The WiFi signal strength indicator is displayed at the standby screen when the machine is connected to a WiFi network.

1. Press the MENU key and select WiFi Conguration from

the Unit Setup menu.

2. Select Search Networks.

3. Use the UP or DOWN arrow to select a WiFi network.

Press OK.

4. A passcode prompt appears:

• for WPA / WPA2 – enter the passcode

• for WEP – the following extra characters are required:

-10 unit WEP key – 1+0x[10-digit key]

[index=1,40-bit(10-digit hexadecimal)]

-5 character WEP key – 4+[5-character key]

[index=4, 40-bit(5-char)

-26 digit WEP key – 3+0x[26-digit key]

[index=3, 104-bit(26-digit hexadecimal)

-13 character WEP key – 2+[13-character key]

[index=2, 104-bit(13-char)

For example, for a 104-bit WEP key, the format is

the following:

1+0x[26 hexadecimal character key]

Denition:

1 = key index

+ = key index delimiter

0x = hexadecimal entry indicator

Note: On the R-1234yf A/C Recover / Recycle / Recharge

Machine, the ‘+’ character is one of the multi-tap keys

under ‘1’.

18

Page 21

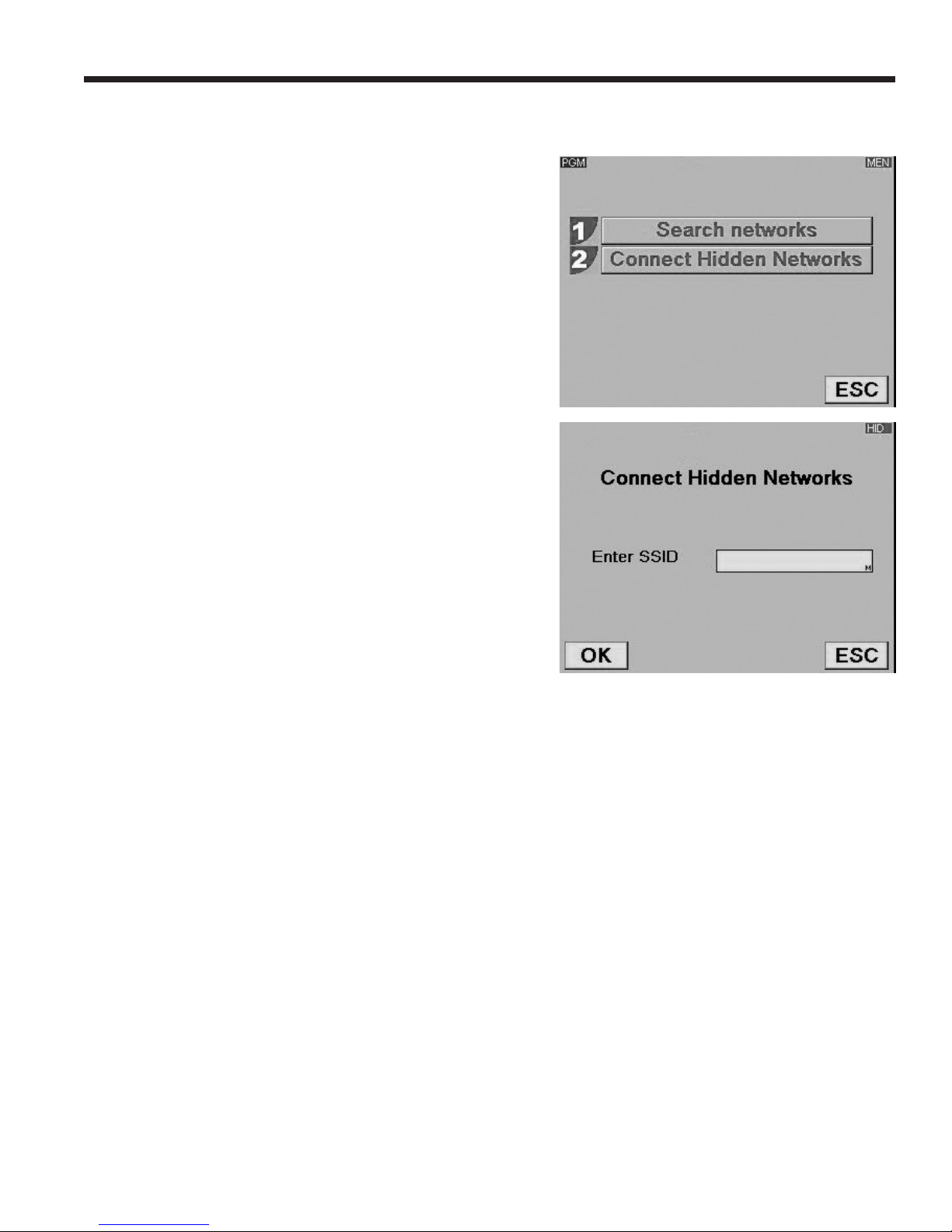

WiFi Conguration for Hidden Networks

1. Press the MENU key and select WiFi Conguration from

the Unit Setup menu.

2. Select Connect Hidden Networks.

3. Enter the SSID of the network and press OK.

581371 REV A

19

Page 22

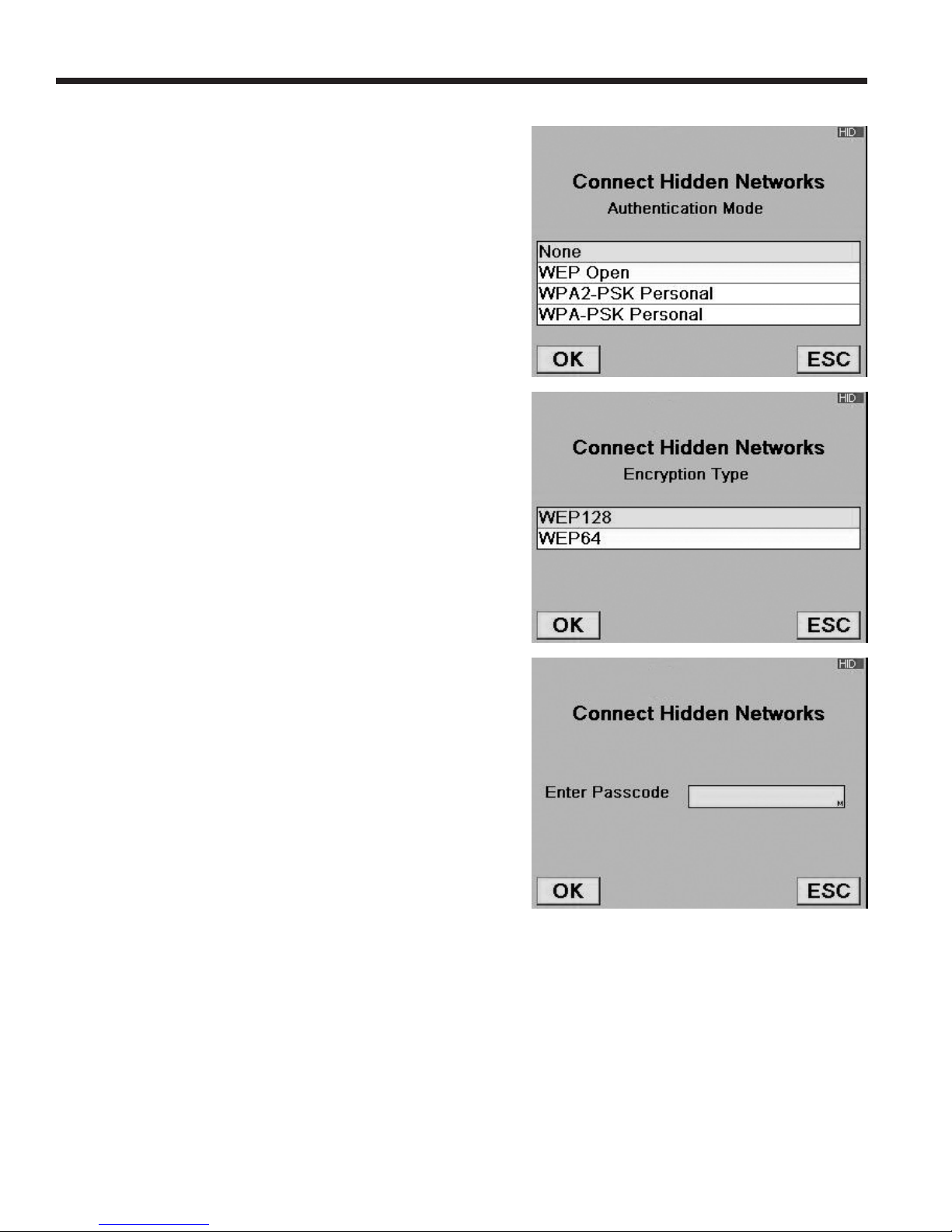

Setup Menu

4. Select the authentication mode of the network and press OK.

5. Select the encryption type for the network and press OK.

6. A passcode prompt appears:

• for WPA / WPA2 – enter the passcode

• for WEP – the following extra characters are required:

-10 unit WEP key – 1+0x[10-digit key]

[index=1,40-bit(10-digit hexadecimal)]

-5 character WEP key – 4+[5-character key]

[index=4, 40-bit(5-char)

-26 digit WEP key – 3+0x[26-digit key]

[index=3, 104-bit(26-digit hexadecimal)

-13 character WEP key – 2+[13-character key]

[index=2, 104-bit(13-char)

For example, for a 104-bit WEP key, the format is

the following:

1+0x[26 hexadecimal character key]

Denition:

1 = key index

+ = key index delimiter

0x = hexadecimal entry indicator

Note: On the R-1234yf A/C Recover / Recycle / Recharge

Machine, the ‘+’ character is one of the multi-tap keys

under ‘1’.

Database

Use this menu option to view refrigerant information by

vehicle.

1. From the Main Menu, select DATABASE.

2. Follow on-screen prompts to select vehicle information.

The screen will display the manufacturer-recommended

refrigerant specications for the vehicle selected.

20

Page 23

VIN Entry

After selecting any A/C Service function, information about

the vehicle and the vehicle identication number (VIN) must

be entered into the machine.

The machine offers various VIN entry methods:

• Wired VCI - connect to the vehicle OBDII port.

• BlueTooth VCI - connect a U-Scan to the vehicle

OBDII port.

Note: The BlueTooth VIN option will only appear if a

U-Scan has been paired to the A/C machine.

• Manual Entry - Use the arrow keys to select a eld, and

use the virtual keypad to enter information.

VIN entry will be used to determine vehicle and service

information using the database.

The information that is entered in this menu item is saved in

Service Job Data.

Setup Menu

A/C Pressure Snapshot

The A/C Pressure Snapshot function is used to capture

vehicle system operating pressures. The captured data

may be viewed, printed, or exported to SD card as part of a

service record.

The following values are captured:

• System high-side pressure

• System low-side pressure

• Ambient temperature

• Ambient humidity

At the start of the RECOVER and AUTOMATIC processes,

the option to perform an A/C Pressure Snapshot to capture

the pre-service operating conditions is given. Again, at the end

of the CHARGE and AUTOMATIC processes, the option is

given to perform the function to allow post-service operating

conditions to be captured.

While the data may be printed at the time of capture, it will also

be stored, printed, or exported with the service record created

for the AUTOMATIC, RECOVER, or CHARGE process.

After the A/C Pressure Snapshot function is completed, the

machine will perform a hose equalization and hose clear as part

of the CHARGE or AUTOMATIC function. This is necessary

to reduce charge loss due to the A/C Pressure Snapshot.

581371 REV A

21

Page 24

A/C Service Function

Printouts

At the End of Every Function

Data for the most recently completed function can be printed

from the results screen by pressing OK on the machine’s

control panel. See Figure 4.

After the Service is Completed and Exited

A summary of the complete service can be printed from

Service Job Data:

1. Press MENU on the machine’s control panel.

2. Select AC SERVICE FUNCTION and then SERVICE

JOB DATA.

3. The choices are:

• VIEW JOB RECORD — a list of VINs is displayed.

Use the UP or DOWN arrow to highlight the VIN for

which to print service data.

Press OK to print data for

the function just completed.

Figure 4

• MOVE JOB RECORD — follow the prompts for this

option to transfer all records to an SD card. The most

recent 100 records will also be retained in Service

Job Data.

• SEND JOB RECORD — follow the prompts for this

option to transfer all records to a server. The most

recent 100 records will also be retained in Service

Job Data.

• COPY JOB RECORD — see “Service Job Data” on

page 26.

Note: Job records must be transferred to a PC for permanent

storage. The SD card will be erased if left in the A/C machine

during a web update.

Note: Refer to “Service Job Data” on page 26.

22

Page 25

Hose Equalize

A/C Service Function

This A/C Service Function menu item directs the user through

clearing the service hoses after running the A/C system to

perform diagnostics. Use this function when the service

hoses were connected, but no refrigerant was charged into

the system.

Following hose equalization prompts prevents leaving part

of the vehicle’s refrigerant charge in the service hoses, a

situation which can cause a loss of A/C performance on

lower-capacity systems.

1. Place the vehicle gear selector in park or neutral, with the

emergency brake ON. Connect the low-side hose to the

A/C system; disconnect the high-side hose.

2. Start the vehicle. Set the A/C system at maximum delivery.

During this operation, the high side and low side are

connected internally, allowing the majority of refrigerant

to be pulled back into the A/C system’s low side.

3. When prompted, disconnect the low-side hose and turn

off the vehicle. Press OK.

4. The machine performs an internal clearing of its plumbing,

and sounds an alarm when complete. Press OK to exit.

1

2

3

4

5

6

Hose Equalize

System Flush

Service Job Data

Automatic

Recovery

Vacuum

È

ESC

Figure 5

Screen 1 of the A/C Service Function Menu

581371 REV A

23

Page 26

A/C Service Function

System Flush

This machine provides a method of removing oil by forcing

liquid refrigerant through an A/C system, or components of an

A/C system. A special ushing adapter (purchased separately)

accesses the A/C system at the compressor block. After

ushing, the refrigerant is recovered by the machine and

ltered by the recycling circuit, returning it to SAE purity levels.

A/C systems vary and may require the adapting and ushing

of individual components. Refer to service bulletins as needed

during this procedure.

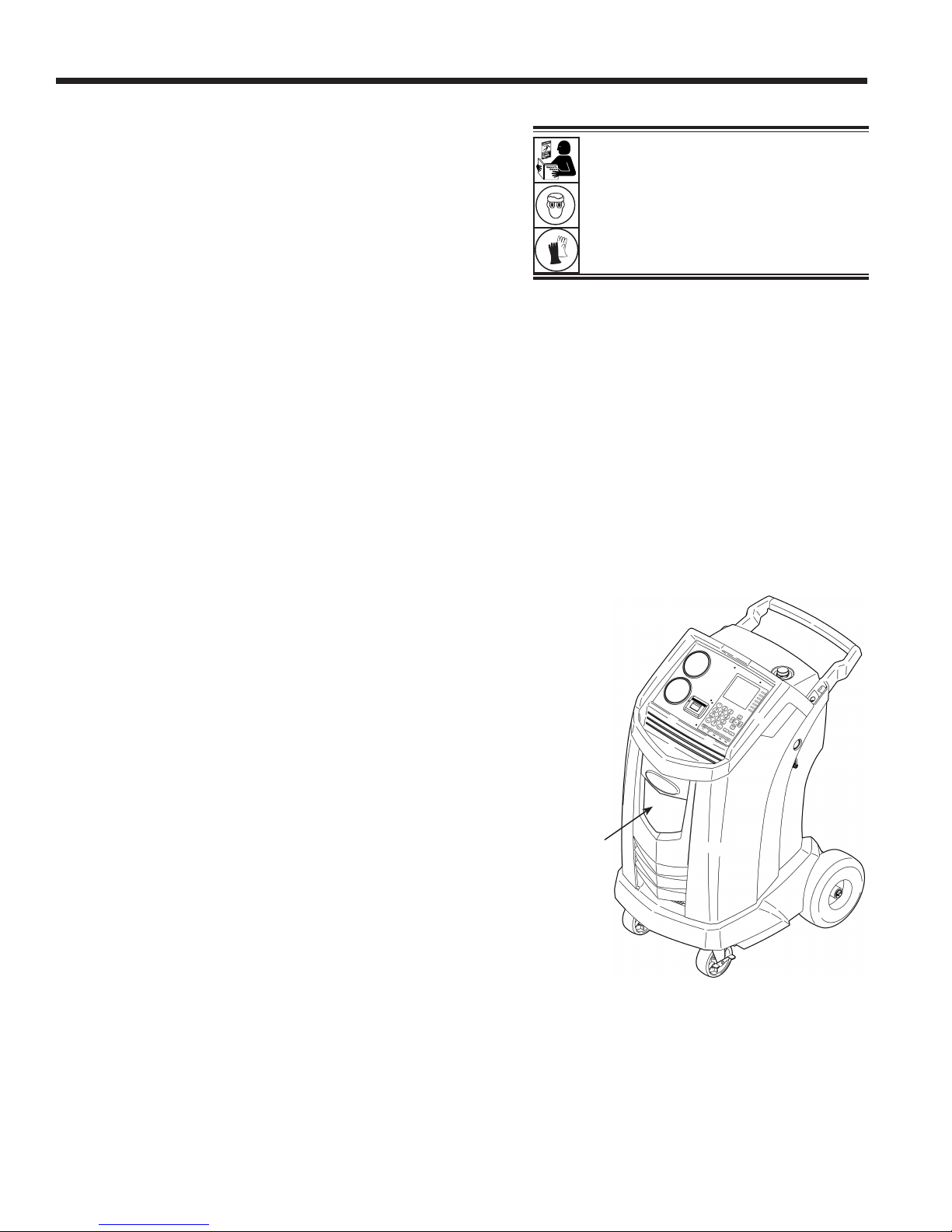

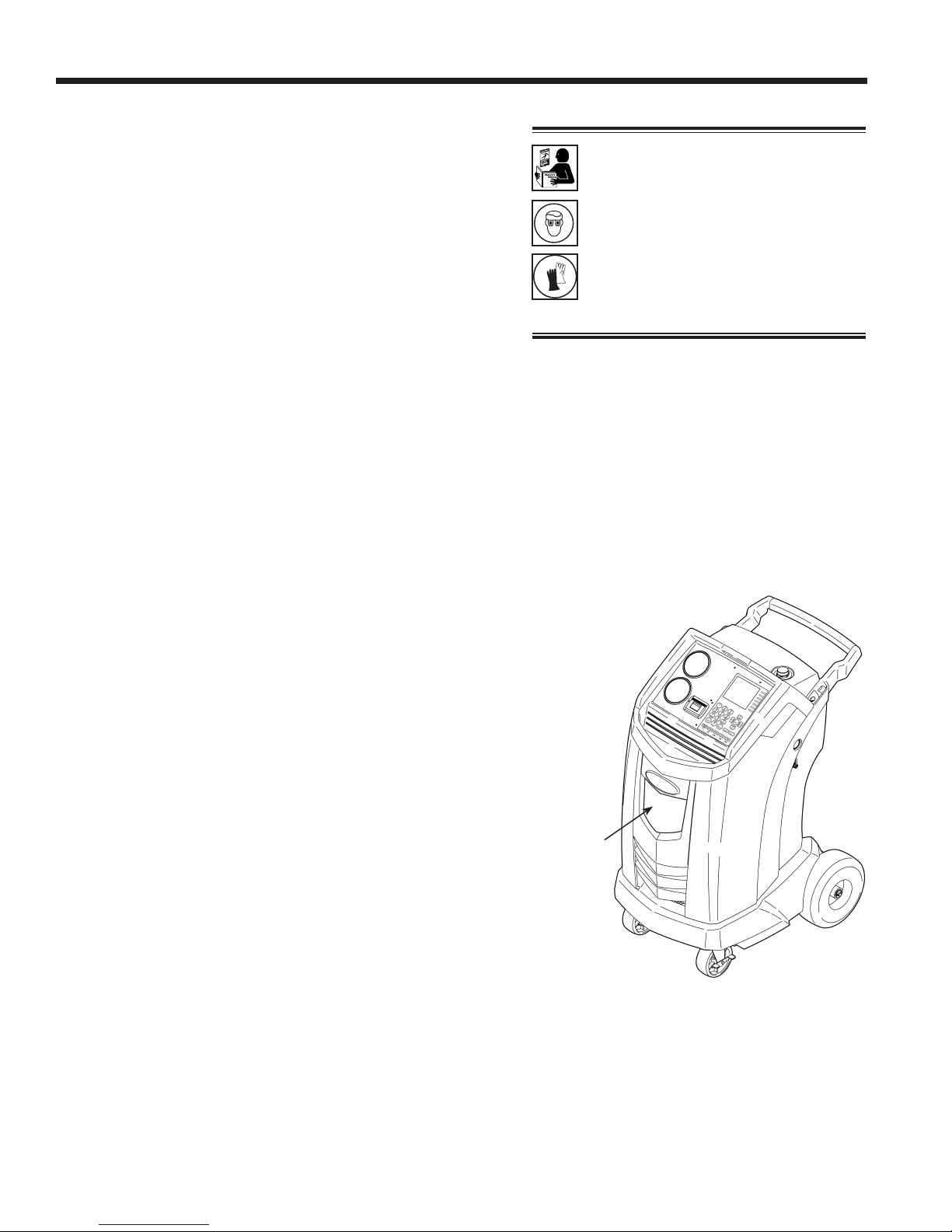

WARNING: To prevent personal

injury while working with refrigerant,

read and follow the instructions

and warnings in this manual, and

wear protective equipment such as

goggles and gloves.

Setup

1. Verify the oil drain bottle on the front of the machine is

empty. See Figure 6. Recover refrigerant as outlined in

this manual.

2. Close service coupler valves and disconnect hoses from

vehicle access ports.

3. Close the valve on the external source tank.

Note: During this procedure, up to

refrigerant is charged into the vehicle A/C system. If the

ushing cycle is stopped before it is complete and the

external source valve is open, the machine automatically

adds refrigerant to the ISV, and there will be no room to

recover the refrigerant used for ushing.

4. Remove the A/C system expansion device, and reconnect

the ttings to create a bypass.

5. Disconnect the refrigerant lines from the vehicle

compressor.

6. Attach the compressor block adapter (from the ushing

kit) to the system side of the compressor block.

3.5 kg (7.7 lbs.)

of

Notes:

The machine must have at least 4.6 kg (10.1

•

lb.) of refrigerant available in the ISV (as

indicated on the display) for charging.

If the ush process is interrupted by an

•

accidental power-down or other fault, use

the recovery mode to remove the refrigerant

from the vehicle.

7. Congure the block connectors to provide forward- or

back-ushing of the refrigerant, which ows from the

machine through the red high-side connection hose. Open

the red service coupler.

8. Connect the lter housing to the desired return side of

the adapter block and to the blue low-side hose. Open

the blue service coupler.

9. Verify that a ushing lter is correctly installed in the ushing

lter housing. Open the isolation valve on the hose.

24

Oil Drain

Bottle

Figure 6

Page 27

Operating Instructions

A/C Service Function

1. Select SYSTEM FLUSH from the A/C Service Function

menu.

2. Perform the VIN entry function

3. Select START to accept the default ush time of 10

minutes, or enter the desired ush time using the keypad

and select START.

4. The following tests are automatic and performed as

required by SAE J2843:

• vacuum that runs 5 – 20 minutes to achieve the

correct level

• 5-minute vacuum rise test

• 15% charge

• manual leak test using a leak detector certied to

SAE J2913

Notes:

• J2843 leak testing is intended to nd a gross leak

before charge, for safety reasons. It is not intended to

take the place of other established leak test practices.

• The 15% charge is automatically recovered before

recharging the programmed amount.

• To avoid false failures, the temperatures of the vehicle

system and the recovery machine should be within ± 5°C.

.

WARNING: Do NOT disconnect service

couplers during the ushing process.

Refrigerant could spray out of the ttings,

and exposure may cause personal injury.

CAUTION: To prevent vehicle damage, use

an oil inject tool to replace the system oil.

Flushing removes all oil from the system

except what remains in the compressor.

Refer to the vehicle service manual for specic vehicle

instructions.

5. The machine ushes the system for the designated length

of time, and then enters a recovery mode.

6. Oil that has been collected drains into the graduated oil

drain bottle. Remove the bottle and measure oil.

Dispose of oil according to the laws in your jurisdiction. It

is the responsibility of the user to determine if a material

is a hazardous waste at the time of disposal.

7. When the machine displays

FLUSH COMPLETE

Close service couplers, remove hoses, and reassemble the

vehicle’s A/C system to its original state.

8. Open the valve on the source tank.

9. Evacuate and recharge the vehicle according to the

instructions in this manual.

Operating Tips

If the external flushing filter is plugged, the

unit displays

POSSIBLE CLOGGED FLUSHING

OR CLOSED CHARGE COUPLER

ESC TO RECOVER REFRIGERANT

After the filter is cleared or replaced,

restart System Flush from the A/C Service

Function menu.

SYSTEM FLUSH

FILTER

VALVE

PRESS OK TO RETRY

581371 REV A

25

Page 28

A/C Service Function

Service Job Data

The machine stores service data for VINs logged into the VIN

Entry screen. Complete service results can be printed at the

end of the vehicle’s entire service by selecting the VIN from

the SERVICE JOB DATA menu.

Service results include

• VIN

• vehicle information, if entered

• type of service

• ambient temperature and humidity

• refrigerant purity

• recovered amount

• vacuum type

• vacuum time

• vacuum successful

• charge mode

• charged amount

• ush time

• encrypt code

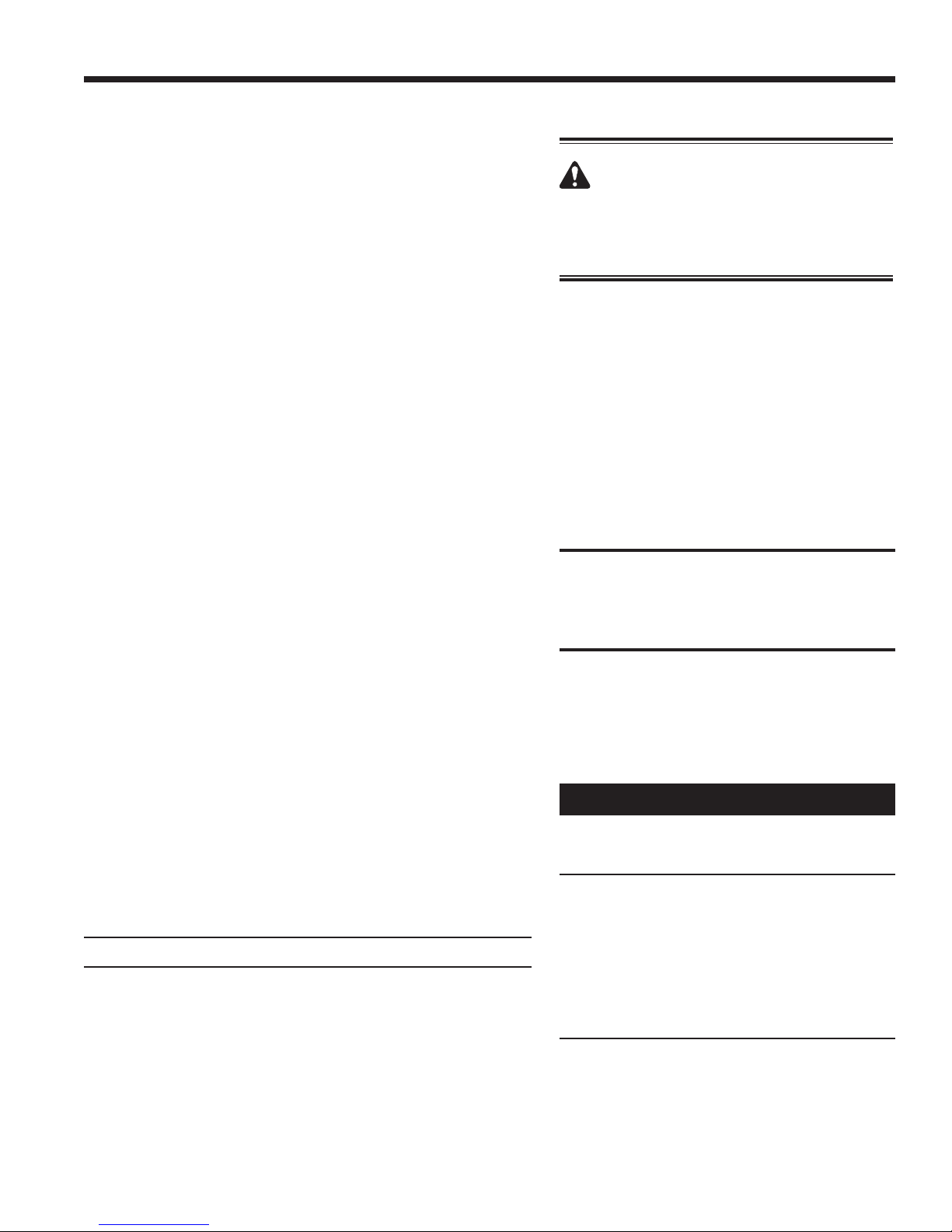

Figure 7

Screen shows the Service Job Data options.

1. Press MENU on the machine’s control panel.

2. Select A/C SERVICE FUNCTION.

3. Select SERVICE JOB DATA.

4. Refer to Figure 7. The choices are:

• VIEW JOB RECORD — a list of VINs is displayed.

Use the UP or DOWN arrow to highlight the VIN for

which to print service data.

• MOVE JOB RECORD — follow the prompts for this

option to transfer all records to an SD card. The most

recent 100 records will also be retained in Service

Job Data.

• SEND JOB RECORD — follow the prompts for this

option to transfer all records to a server. The most

recent 100 records will also be retained in Service

Job Data.

• COPY JOB RECORD — follow the prompts for this

option to select the service job to copy to the SD

memory card.

Note: Job records must be transferred to a PC for permanent

storage. The SD card will be erased if left in the A/C machine

during a web update.

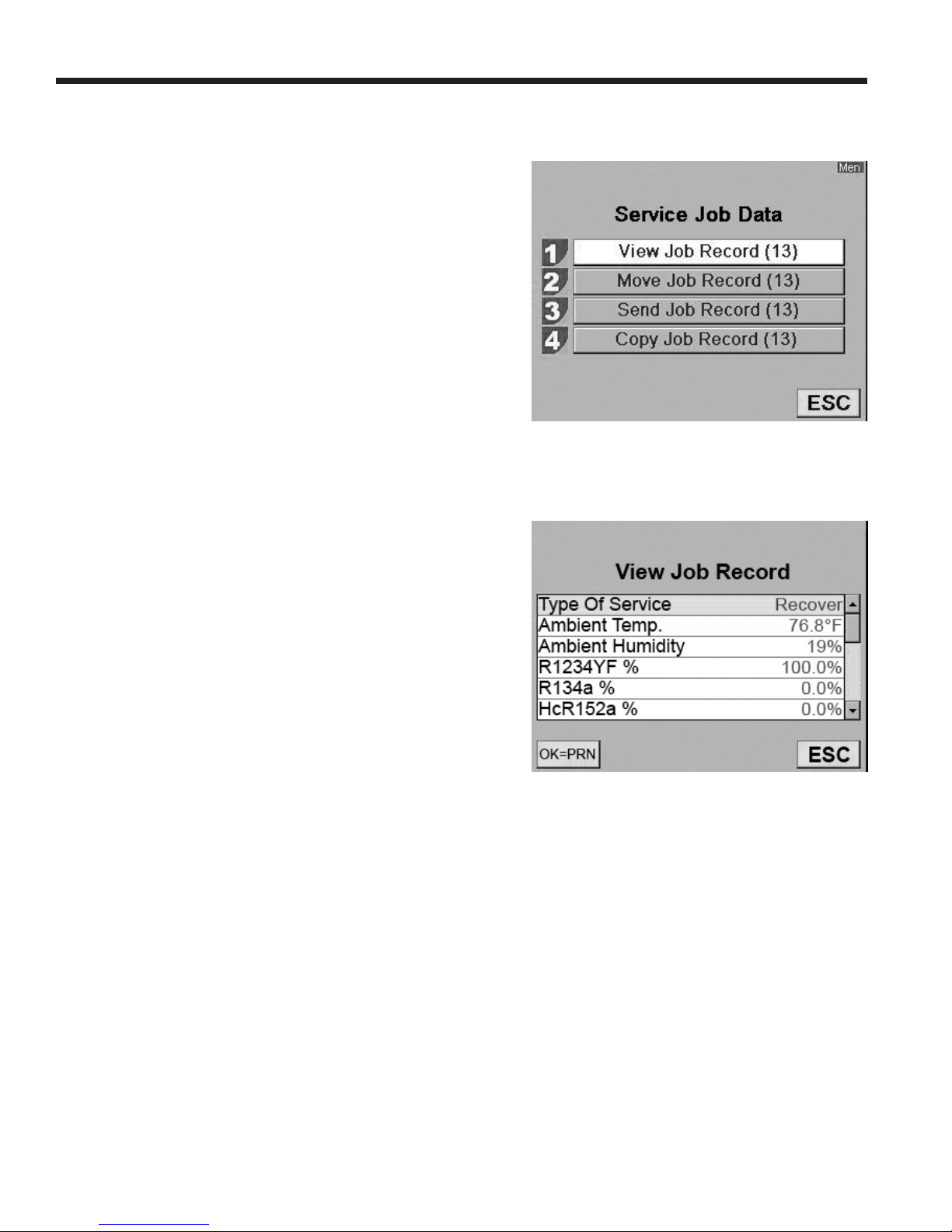

Figure 8

Screen shows some of the information

available under View Job Record.

26

Page 29

Procedure to Move Job Records

1. Lift the rubber ap on the upper right hand side of the

machine, and install an unlocked SD card into the SD

card slot.

2. Select MOVE JOB RECORD from the A/C Service

Function Menu.

3. After the les have been successfully moved to the

SD card, the machine displays

FILE TRANSFERRED

PRESS OK TO CONTINUE

A/C Service Function

4. Press OK and remove the SD card.

5. Upload the les from the SD card to a personal

computer for storage.

Note: Job records should be transferred to a PC for

permanent storage. An SD card will be erased if left

in the A/C machine and a web update is performed.

6. The MOVE JOB RECORD and SEND JOB RECORD

screens will now show there are no les available

to move.

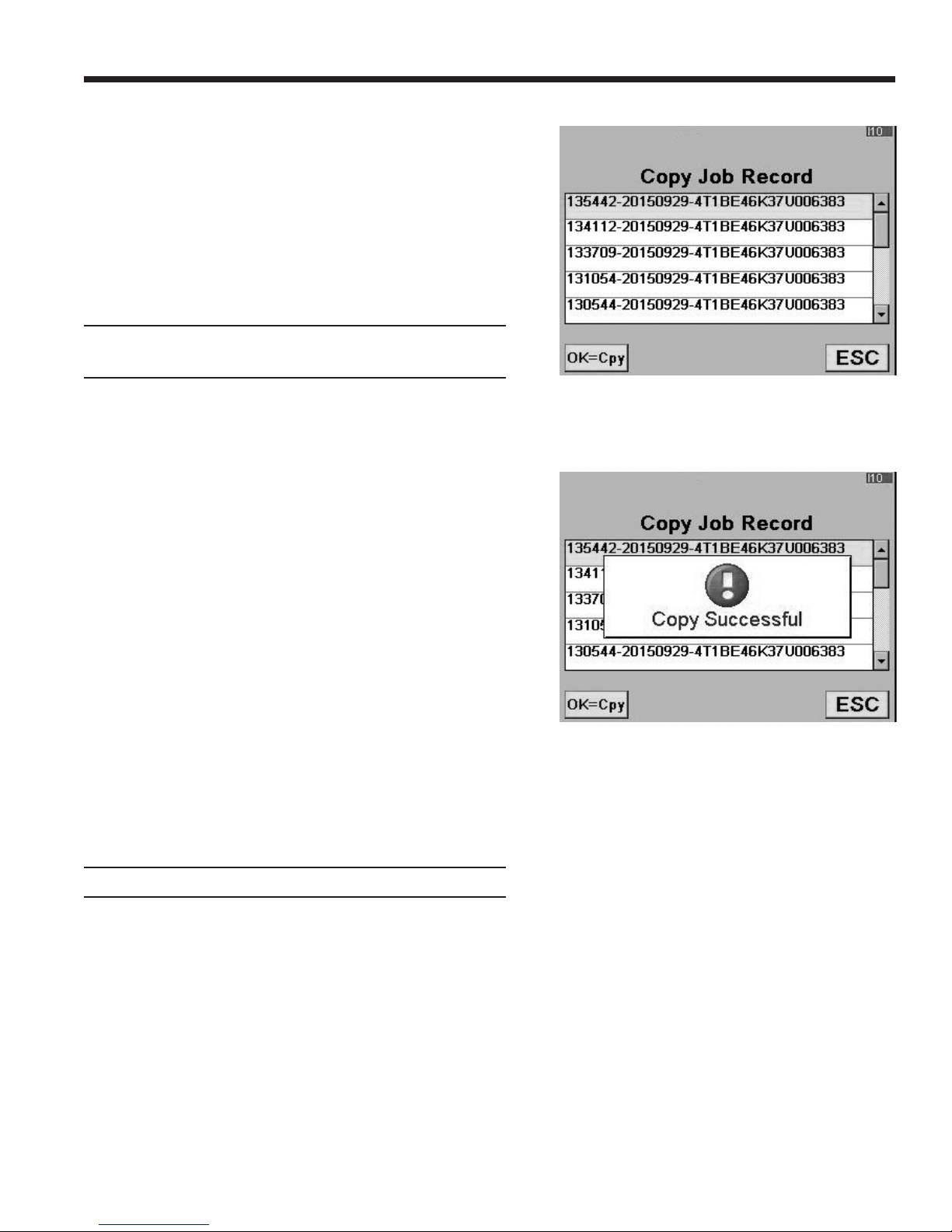

Procedure to Copy Job Record

1. Lift the rubber ap on the upper right hand side of the

machine, and install an unlocked SD card into the SD

card slot.

2. Select COPY JOB RECORD from the A/C Service

Function Menu.

3. Select the job record to copy and press OK. See

Figure 9.

4. After the le has been successfully copied to the SD

card, the machine displays

Figure 9

Screen shows job records available to copy.

Figure 10

Screen shows job record was copied to SD card.

COPY SUCCESSFUL

See Figure 10. Press OK and remove the SD card.

5. Upload the les from the SD card to a personal

computer for storage.

Note: Job records should be transferred to a PC for

permanent storage. An SD card will be erased if left

in the A/C machine and a web update is performed.

581371 REV A

27

Page 30

A/C Service Function

Automatic

The automatic function allows a user to program an automatic

recovery, vacuum, leak test, and/or charge sequence. A total

automatic sequence can take up to an hour.

1. Connect service hoses to the vehicle’s service ports and

open the couplers.

2. Select AUTOMATIC.

3. Perform the VIN entry function. If a matching database

entry is found, the recommended charge amount will be

populated automatically.

4. The machine displays

1

2

3

HP

LP

HP + LP

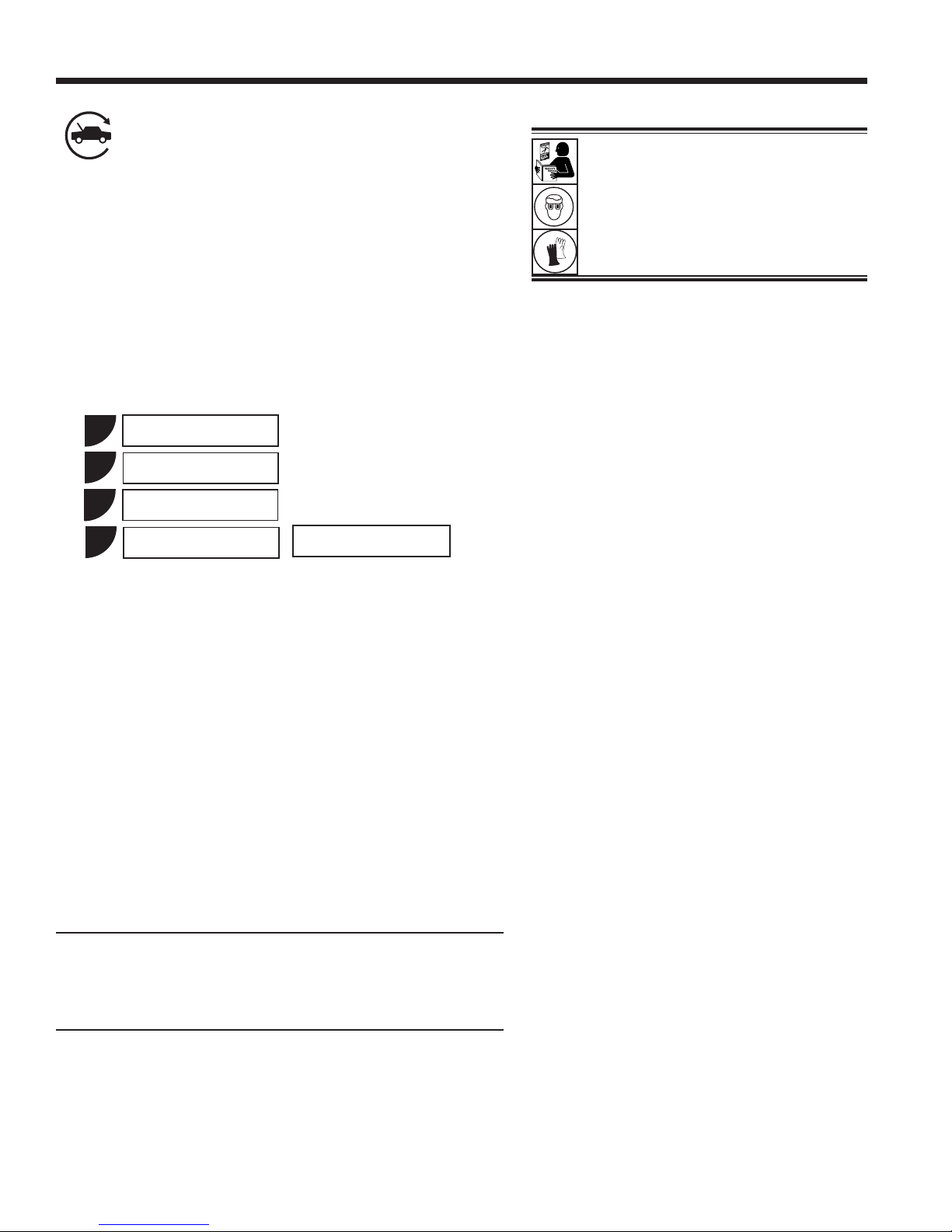

WARNING: To prevent personal

injury while working with refrigerant,

read and follow the instructions

and warnings in this manual, and

wear protective equipment such as

goggles and gloves.

Note: If problems are encountered during the

automatic sequence, the machine will “beep”

three times, the red lights on the front of the

machine will blink, and the control panel

readout will pinpoint the problem encountered.

The sequence remains paused until the user

enters a decision regarding how to proceed.

5

Use the number keys on the keypad to make selections 1–3

for the vehicle A/C system.

For selection 5, accept the default value or enter a value

and press OK.

Note: If the default value is 0.000 kg, a value must be

entered to continue.

5. Select a vacuum time:

• Press OK to accept the default evacuation time, or

• The machine pulls a vacuum on the A/C system for

6. The machine displays

Refrigerant

enter the desired vacuum time using the number keys,

and press OK.

the programmed amount of time. During the vacuum

process, the machine will perform an air purge if

needed.

0.000 kg

HAS THIS MACHINE BEEN USED TO SERVICE A

SYSTEM UTILIZING PAG OIL?

IF YES, SELECT OK TO PERFORM A HOSE FLUSH

OR IF NO, ESC TO CONTINUE CHARGE.

• If OK is selected, the machine prompts for a Hose

Flush procedure. Connect high-side (red) and low-side

(blue) service hoses to the storage ports, and open

the coupler valves. Press OK. Move the service hoses

to the vehicle’s service ports and open the couplers.

Press OK.

28

Page 31

• If ESC is selected, the machine continues on to

RECOVERY (or VACUUM if there is no pressure for

a recovery).

7. If pressure is detected

• The machine checks the refrigerant in the vehicle

to verify it is R-1234yf and not contaminated, which

is required by SAE J2843. If the purity reading is

acceptable, the machine will give the option to run

diagnostic pressures before recovery.

• Press OK to run diagnostic pressures; press ESC to

continue with RECOVERY.

• If OK was selected, follow prompts to start the vehicle

and set the A/C system according to service manual

A/C performance test requirements. Press OK after

pressure stabilizes. Press OK again to print data;

press ESC to continue with RECOVERY.

8. The machine performs the VACUUM process as previously

selected in Step 5.

A/C Service Function

Service

Hoses

Connected

to Storage

Ports

Figure 11

9. The machine performs the CHARGE process:

• 10–20 minute vacuum leak test (applies vacuum,

checks for vacuum decay.

• Pre-charge leak test (charges 15% of overall charge,

prompts user to perform manual leak test using a leak

detector certied to SAE J2913.)

• Charges the A/C system.

10. After the machine charges the system, the machine again

gives the option to run a Diagnostic Pressures test.

• Press OK to run diagnostic pressures; press ESC to

continue.

11. Follow prompts to equalize liquid refrigerant into the vehicle

A/C system for maximum charge accuracy.

12. When the sequence is complete, close the high-side (red)

and low-side (blue) coupler valves.

13. When prompted, remove service hoses from the A/C

system and install them on the machine’s storage ports.

Select OK to begin clearing hoses. This prepares the

machine for the next service.

CAUTION: If the low-side (blue) or high-side

(red) coupler valve is left open during the

hose clearing process, the system will pull

refrigerant back out of the vehicle.

14. The machine displays a summary of actions performed

during the automatic sequence.

581371 REV A

29

Page 32

A/C Service Function

Recovery

1. Empty the oil drain bottle before starting a recovery.

Remove the oil drain bottle from the machine by pulling

the bottle straight down — do not use a twisting or rocking

motion. Refer to Figure 12.

2. Connect the high-side (red) and low-side (blue) hoses to

the vehicle A/C system.

3. Open the coupler valves on the hoses by turning the

collars clockwise.

4. Select the recovery function by pressing the RECOVER button

on the control panel, or by selecting Recovery from the A/C

Service Function menu.

5. Perform the VIN entry function.

6. The machine checks the refrigerant in the vehicle to verify

it is R-1234yf and not contaminated. If the refrigerant

purity is acceptable, the machine begins the recovery

process. A clicking noise indicates a solenoid is opening

and closing — this is normal.

WARNING: To prevent personal

injury while working with refrigerant,

read and follow the instructions

and warnings in this manual, and

wear protective equipment such as

goggles and gloves.

7. The machine displays

RUN DIAGNOSTIC PRESSURES?

To store and/or print diagnostic pressures at this point,

follow the prompts to start the vehicle and set the A/C

system according to service manual A/C performance

test requirements. Press OK.

The machine displays when to capture the values and

when they may be printed.

8. The machine runs a self-clearing cycle to clear refrigerant

from its internal plumbing.

9. When the system has recovered to 0 psi, the vacuum pump

starts and runs until recovery is complete.

10. After oil drain is complete, the machine displays a summary

of gas recovered. At this point you may print out recovery

information and pre-recovery diagnostics by selecting OK.

The displayed recovered weight can vary depending on

ambient conditions and should not be used as an indicator

of scale accuracy.

11. The amount of oil that was removed from the A/C system is the

amount of new oil that should be charged into the A/C system

after evacuation is complete.

Oil Drain

Bottle

Figure 12

• Use only new oil to replace the oil removed during

the recycling process.

• Dispose of used oil according to government regulations.

Recovery is complete.

30

Page 33

A/C Service Function

Vacuum

1. Connect service hoses to the vehicle’s service ports.

2. Open the coupler valves by turning the collars clockwise.

3. Press VACUUM.

4. Perform the VIN entry function.

5. Press OK to accept the default evacuation time, or enter

the desired vacuum time using the number keys, and

press OK.

• The machine pulls a vacuum on the A/C system for

the programmed amount of time. During the vacuum

process, the machine will perform an air purge if

needed.

• The machine stops when the specied amount of

time has elapsed. At this point vacuum information

can be printed by selecting OK. Press ESC to return

to the main menu.

IMPORTANT: The unit pulls a deep vacuum

on the vehicle A/C system to remove air

and boil off moisture that might be present

in the system.

Achievement of a sufcient deep vacuum

depends greatly on vacuum pump oil

condition. Change vacuum pump oil after 10

hours of pump operation; change vacuum

pump oil more frequently if the equipment is

used on A/C systems that have been open

for extended periods of time.

Note: When the vacuum pump has operated for

10 hours, the machine prompts for an oil change.

Select OK to proceed with an oil change; select

ESC

to continue with the vacuum process. Refer

to “Maintain Vacuum Pump Oil” on page 36.

581371 REV A

31

Page 34

A/C Service Function

Charge

The following tests are automatic and performed as required

by SAE J2843:

• vacuum that runs 5–20 minutes to achieve the correct

level

• 5-minute vacuum rise test

• 15% charge

• manual leak test using a leak detector certied to SAE

J2913

Notes:

• J2843 leak testing is intended to nd a gross leak before

charge, for safety reasons. It is not intended to take the

place of other established leak test practices.

• To avoid false failures, the temperatures of the vehicle

system and the recovery machine should be within ±5°C.

WARNING: To prevent personal

injury while working with refrigerant,

read and follow the instructions

and warnings in this manual, and

wear protective equipment such as

goggles and gloves.

Refer to the vehicle service manual for specic vehicle

instructions.

1. Connect service hoses to the vehicle’s service ports and

open the couplers.

2. Press CHARGE.

3. Perform the VIN entry function. If a matching database

entry is found, the recommended charge amount will be

populated automatically.

4. The machine displays

1

2

3

7

Use the number keys on the keypad to select a HP, LP,

or HP / LP charge mode for the vehicle A/C system.

For selection 7, accept the default or enter a value and

press OK twice.

HP

LP

HP + LP

Refrigerant

0.000 kg

Note: If the default value is 0.000 kg, a value must be

entered to continue.

32

Page 35

5. The machine displays

HAS THIS MACHINE BEEN USED

TO SERVICE A SYSTEM UTILIZING

PAG OIL?

IF YES, SELECT OK TO PERFORM A HOSE FLUSH

OR IF NO, ESC TO CONTINUE CHARGE.

If OK is selected, the machine prompts for a Hose Flush

procedure. Connect high-side (red) and low-side (blue)

service hoses to the storage ports, and open the coupler

valves. Press OK. If ESC is selected, the machine

continues with CHARGE.

6. Move the service hoses to the vehicle’s service ports and

open the couplers. Press OK. The machine performs

automatic tests on the system as required by SAE J2843.

7. When prompted, perform a manual leak test using a leak

detector certied to SAE J2913. Once the leak test has

been completed, CHARGE continues.

A/C Service Function

Note: The charge process includes an

automatic vacuum leak test, after which the

system is pressurized with a small amount of

refrigerant for a manual leak test.

Moving or bumping the machine at this point can result in

an inaccurate charge. When the charge cycle gets close

to the desired weight value, the machine slows down. It

will charge, settle, charge again, settle, etc.

8. At the end of CHARGE, the machine prompts through a

Diagnostic Pressures test. This process is required to

provide vehicle system pressures for the stored and

printed warranty service data.

9. Follow prompts to equalize liquid refrigerant into the vehicle

A/C system for maximum charge accuracy.

10. When prompted, close the coupler valves and remove

the service hoses from the A/C system. Install the hoses

on machine’s storage ports.

11. Press OK to begin clearing hoses to prepare the machine

for the next service.

12. When the hoses are clear, the display shows a summary

of charge results, which can be printed by pressing OK.

Note: Complete service results can be printed at the end of

the vehicle’s entire service by selecting the vehicle VIN from

the SERVICE JOB DATA menu.

CAUTION: If the low-side (blue) or high-side

(red) coupler valve is left open during the

hose clearing process, the system will pull

refrigerant back out of the vehicle.

The SERVICE JOB DATA menu is found by pressing MENU

and choosing A/C SERVICE FUNCTIONS.

The vehicle A/C system is now ready for use.

581371 REV A

33

Page 36

A/C Service Function

Hose Flush

Selecting this menu item will cause the machine to ush its

internal plumbing.

1. When prompted, connect the service hoses from the

machine to their storage ports and open coupler valves

as shown in Figure 13.

2. Check the vacuum pump oil level sight glass and verify

the oil level is correct.

3. Open the service couplers by turning the couplers clockwise.

4. The machine performs an internal clearing of its plumbing,

and sounds an alarm when complete. Press OK to exit.

WARNING: To prevent personal

injury,

Only qualied personnel may

•

perform inspections and

repairs to this machine.

Read and follow the

•

instructions and warnings

in this manual, and wear

protective equipment such as

goggles and gloves.

Do not operate the machine

•

when the shroud has been

removed.

Figure 13

Service

Hoses

Connected

to Storage

Ports

34

Page 37

Tank Filling

This menu item is used to transfer refrigerant from a source

tank to the ISV. This procedure works only if the ISV contains

less than the maximum amount of refrigerant programmed

under Tank Fill Adjustment.

Note: If a source tank is connected to the tank ll hose while

the machine is sitting idle, the machine automatically adds

refrigerant up to the level set during Tank Fill Adjustment.

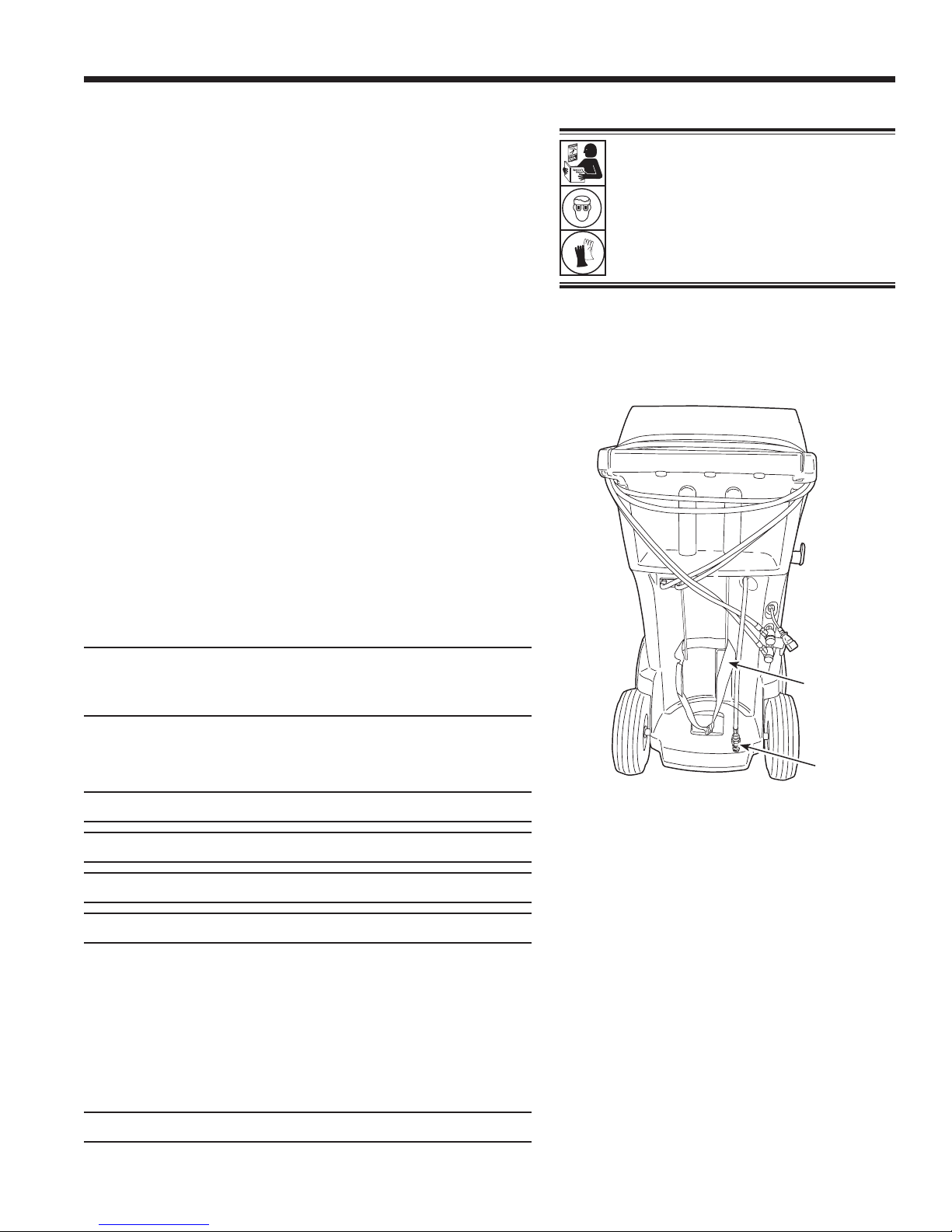

1. Connect an R-1234yf source tank to the tank ll hose at

the rear of the machine. See Figure 14.

Note: The tank ll hose and the tank access port have

left-hand threads.

2. Hand tighten the tank ll hose.

3. Open the tank valve.

4. Mount the source tank on the shelf at the rear of the

machine, oriented to supply liquid refrigerant to the

connection. Tighten the holding strap around the source

tank. Verify the tank does not restrict air ow from the vent.

Unit Maintenance

WARNING: To prevent personal

injury while working with refrigerant,

read and follow the instructions

and warnings in this manual, and

wear protective equipment such as

goggles and gloves.

5. Select TANK FILLING from the Unit Maintenance menu.

The machine displays

FILL AMOUNT

XX.XXX

CONNECT SOURCE TANK TO FILL HOSE

6. Press OK. The machine checks the refrigerant in the

source tank to verify it is R-1234yf and not contaminated.

The machine displays the following screens:

WARM UP

CALIBRATION IN PROGRESS

GAS IDENTIFY

REFRIGERANT PURITY ACCEPTABLE

and after ve seconds begins lling the internal storage

vessel (ISV).

7. The machine automatically stops when the preset tank

ll level is reached. To stop the tank ll before the preset

level is reached, select ESC.

8. If using a non-rellable tank, the machine must display

SOURCE TANK EMPTY

Strap

Tank Fill

Hose

Figure 14

Note: After the tank ll process is complete,

the display will not show the same amount as

the programmed ll level.

The display shows the amount of refrigerant

that is available for charging, which is

approximately 0.91 kg less than the total

amount of refrigerant in the tank.

before the tank can be discarded.

581371 REV A

35

Page 38

Unit Maintenance

Maintain Vacuum Pump Oil

1. Select MAINTAIN VACUUM PUMP OIL from the Unit

Maintenance menu or when prompted. The display

shows how long the vacuum pump has operated since

the last oil change.

X HOURS X MINUTES

CHANGE OIL?

2. Press OK. The machine will display

WARMING OIL FOR BETTER DRAINING

PLEASE WAIT

X:XX

The vacuum pump will run 30 seconds to warm the

oil. The display shows

OIL CHANGE

UNIT CLEARING

WAIT

while the compressor runs to eliminate any pressure

in the vacuum pump.

3. After the compressor stops, slowly open the oil ll

cap to verify there is no pressure in the machine. Then

carefully remove the cap. See Figure 15.

CAUTION: To prevent personal injury,

do NOT operate the machine at any other

time without the oil ll port cap installed,

because the vacuum pump is pressurized

during normal operation.

Oil Fill Cap

and Port

Sight

Glass

Oil Drain

Fitting

4. The display shows

DRAIN THE OLD OIL

ADD 150 ML OF NEW OIL

PRESS OK TO CONFIRM

PRESS ESC TO EXIT

Remove the oil drain tting cap, and drain the oil into

a suitable container for disposal. Replace the cap and

close tightly.

5. S

lowly add approximately

to the pump through the oil ll port. Press OK to start

the vacuum pump.

6. The display shows

150 ml of vacuum pump

FILL PUMP TO CENTER OF SIGHT GLASS

PRESS OK WHEN COMPLETE

S

lowly add

port until the oil level rises to the center of the sight glass.

7. Install the cap on the oil ll port and close tightly

OK to return to the Unit Maintenance menu.

vacuum pump

oil to the pump through the oil ll

Figure 15

oil

Caution: It is the responsibility of the user to

monitor vacuum pump oil level and clarity.

If contaminated oil is not removed from the

vacuum pump and replaced, the vacuum

pump will be permanently damaged.

. Press

36

Page 39

Unit Maintenance

Maintain Filter

The lter is designed to trap acid and particulates and to

remove moisture from refrigerant. To meet the mandate for

adequate moisture and contaminant removal, the lter must be

replaced after 150 kg (331 lb.) of refrigerant has been ltered.

The machine gives a warning when 100 kg (220 lb.) of the

lter capacity has been used; the machine locks down when

the 150 kg (331 lb.) lter capacity has been reached and will

no longer function.

WARNING: Components in the machine are under

high pressure. To prevent personal injury, change

lter only when the machine prompts.

Check Remaining Filter Capacity

1. Select MAINTAIN FILTER from the Unit Maintenance

menu or when the machine prompts. The machine displays

the amount of lter capacity remaining until the machine

locks down.

2. When prompted, select OK to change the lter; select

ESC to resume using the machine.

the

WARNING: To prevent personal

injury while working with refrigerant,

read and follow the instructions

and warnings in this manual, and

wear protective equipment such as

goggles and gloves.

Caution: To prevent equipment damage,

use only authentic Robinair No. 34724

lters in this machine. All performance

tests and claims are based on using this

specic lter.

Replace the Filter and Sample Hose Assembly

1. If OK was selected to change the lter, the machine clears

the lter, then prompts for the new lter code to be entered.

Use the keypad to enter the serial number that appears

on the new lter and select OK. If

SERIAL NUMBER IS NOT VALID

is displayed, the serial number has been incorrectly

entered, or the lter has already been used in this machine.

2. The machine displays

TURN UNIT OFF

REMOVE SHROUD AND REPLACE FILTER,

IDENTIFIER FILTER, AND

IDENTIFIER SAMPLE HOSE ASSEMBLY

Shut off the machine. Remove the oil bottle. Remove the

four screws holding the shroud. See Figure 16.

Remove the four screws

holding the shroud.

581371 REV A

Figure 16

37

Page 40

Unit Maintenance

3. Hang the shroud on the back of the machine as shown

in Figure 17.

4. Remove the lter by turning it counterclockwise (as viewed

from the bottom of the lter).

5. Look at the new lter—verify both o-rings are lubricated

and correctly located in the grooves as shown in Figure 18.

6. Install the new lter by threading it clockwise into place.

Verify the lter is positioned correctly as shown in Figure

19. Tighten the lter to 20 N•m.

Figure 17

Filter

O-rings

H

E

L

9

P ME

O

K

N

U

S

T

OP

E

S

C

Hang

Shroud

Here

Assembled

Correctly

Figure 19

Figure 18

Assembled

Incorrectly

38

Page 41

Refrigerant Identier

Unit Maintenance

The refrigerant identier samples refrigerant going into the

ISV to verify it is R-1234yf and not contaminated. Replace the

sample hose assembly during every lter change and also if

prompted by an error message saying the hose is clogged.

See Figure 20.

1. Disconnect the existing sample hose assembly between

the solenoid and the refrigerant identier, and install a

new sample hose assembly.

Note: If the lter is any color but white, the lter needs to

be replaced also.

2. Pull the lter out of the brackets while removing the barbs

from the rubber connectors.

3. Install a new lter with the arrow pointing upward as

shown. Push the lter barbs into the rubber connectors.

4. Install the shroud on the machine and switch the power ON.

Calibration Check

This function is used to ensure the machine’s internal scale

is always calibrated. During this test, use only the calibration

weight that is provided with the machine.

Barb

Refrigerant Identier

Sample Hose

Assembly

Install new lter with

arrow ↑ positioned as

shown.

Figure 20

Replace the sample hose assembly during

every lter change.

1. Select CALIBRATION CHECK in the Unit Maintenance

menu. The machine displays

ATTACH WEIGHT TO BOTTOM OF MACHINE

PRESS OK TO CONFIRM PRESS ESC TO QUIT

2. Refer to Figure 21, and verify the magnet on the bottom

of the machine is clean.

3. Attach the calibration weight to the magnet on the bottom

of the machine. Select OK.

• If the display shows

PROCEDURE COMPLETED

the scale is in calibration. Select OK.

• If the display shows

CALIBRATION REJECTED

the scale is out of calibration. Contact an authorized

Robinair service center for assistance.

4. Remove the calibration weight from the scale.

Magnet

Figure 21

581371 REV A

39

Page 42

Unit Maintenance

Refrigerant Management

This Unit Maintenance menu item displays the amount of

refrigerant recovered, charged, and replenished (for the life

of the machine), and ltered since the last lter change.

Air Purge Info

This Unit Maintenance menu item displays the internal storage

vessel (ISV) pressure and temperature. Use this information

to check the ISV for excessive pressure.

Backlight

Select this Unit Maintenance menu item and use the left and

right arrow keys to adjust the contrast on the display screen.

Replace Service Hoses and/or

Service Couplers

Ensure pressure has been removed from service hoses before

disconnecting a hose or coupler from the machine. Pressure

gauges must read at or below 0 psig.

If pressure exists, recover the refrigerant from the hoses

before disconnecting a hose or coupler.

1. The machine performs a 30 second vacuum to ensure

hoses are empty.

2. The machine displays

DISCONNECT OLD HOSES AND

REPLACE WITH NEW HOSES

PRESS OK TO CONTINUE

PRESS ESC TO EXIT

Remove and replace old service hoses. Press OK.

3. The unit directs the user to connect hoses to the storage

ports and press OK to begin unit conditioning.

4. A vacuum is performed on the unit until the vacuum level

reaches 525 micron.

5. The machine is now ready to use.

40

Page 43

General Maintenance

Wipe off the machine often using a clean cloth to remove

grease and dirt.

Periodically check hoses and connections for leakage. Use

a J2913 electronic leak detector to check ttings when the

unit has been disconnected from its power source and the

shroud has been removed. If a leak is detected and cannot

be repaired, contact a Robinair authorized service center.

Unit Maintenance

581371 REV A

41

Page 44

Maintenance Procedures

Replace the Oxygen Sensor in the

Refrigerant Identier

The refrigerant identier in the machine contains a replaceable

oxygen sensor that can affect the way the machine works if

the sensor is not functioning correctly.

• If the machine displays the following message, immediately

replace the oxygen sensor:

OPERATING TIME OF THE IDENTIFIER AND UNIT

ARE LIMITED

REPLACE ID O2 SENSOR SOON

UNIT WILL BECOME NONFUNCTIONAL

• If the machine displays the following message, the oxygen

sensor has expired. Neither the identier nor the machine

is able to recover or add refrigerant to the internal tank.

ANALYZER ERROR 6

O2 SENSOR FAILURE

SENSOR MUST BE REPLACED

UNIT WILL NOT RECOVER OR ALLOW TANK FILL

SEE MANUAL

1. Disconnect the machine from its power source.

Remove four screws

holding shroud.

2. Remove the oil bottle, and remove the four screws holding

the shroud. See Figure 22. Hang the shroud on the back

of the machine.

3. Disconnect the wire harness, USB connector, and sample

hose from the identier. See Figure 23.

4. Remove the two screws holding the identier to the

machine, and remove the identier.

5. Carefully pry the oxygen sensor cap from the housing.

Gently pull on the cap and wires until the connector exits

the housing.

CAUTION: The wire connected to the cap is connected

internally to the identier. To prevent equipment damage,

do NOT pull on this wire.

Figure 22

Disconnect wire harness,

USB connector,

and sample hose.

Oxygen

Sensor

Cap

Figure 23

42

Page 45

Maintenance Procedures

6. Disconnect the wire harness at the connector by pressing

on the center tab. Pull the connectors apart. See Figure 24.

7. Move the cap and harness aside. Hold the lead from the

sensor, and use a at-blade screwdriver to unthread and

remove the oxygen sensor. See Figure 25.

8. Remove the pink protective lm from the threaded end

of the new oxygen sensor.

9. Install the new oxygen sensor, using the screwdriver to

thread it into place. Tighten the sensor to 4 in. lb.

10. Reconnect the lead at the connector, and tuck the wires

into the opening.

11. Replace the cap and push until it “clicks” into place. Install

the identier onto the machine, and reconnect the wire

harness, USB connector, and sample hose.

12. Verify the wiring is not binding, and replace the shroud.

Press to

disconnect

wire harness.

Figure 24

Use at-blade

screwdriver to

remove sensor.

581371 REV A

Figure 25

43

Page 46

Maintenance Procedures

Tank Fill Hose Filter Service

The tank ll hose at the rear of the machine (see Figure 26)

contains a lter that can be cleaned when it appears that

refrigerant ow is restricted.

When the machine senses low ow, it can display one of the

following messages:

• SOURCE TANK EMPTY, but the source tank is known

to contain refrigerant, connections are secure, and the

source tank valve is open.

• REPLACE IDENTIFIER FILTER, but the refrigerant

identier lter is known to be unrestricted, the source

tank contains refrigerant, connections are secure, and

the source tank valve is open.

The tank ll hose lter might be plugged.

Cleaning the Tank Fill Hose Filter

1. First ensure that pressure does not exist in the

line. Disconnect the external source tank, and perform

a manual tank ll to capture any refrigerant in the line.

2. Disassemble the tank ll hose at the lter housing as

shown in Figure 27.

3. Remove the lter. The recommended method to remove

debris from the lter is by using air pressure.

Note: If a solvent is used, allow adequate drying time

before reassembly.

4. After the lter has been installed back into the lter housing,

torque the housing assembly to 8.5 N•m (6 ft. lb.).

Tank Fill

Hose

Figure 26

Disassemble the

Filter Housing

Figure 27

44

Page 47

Maintenance Procedures

Edit Print Header

To make changes to the text that appears in the header on

each printout:

1. Select DEALER INFO from the Unit Setup menu.

2. Use the arrow key to move to the eld that needs to

be changed.

3. Press the Menu key to display a virtual keyboard.

4. Use the arrow keys to move around the keyboard. Press

OK to enter a character.

5. Press the Menu key to exit the keyboard and move to

the next ll eld.

6. Press OK to save the data and press ESC to exit

the keyboard.

Dealer Code

Garage

Address

City

Tel

Fax

E-mail

7. This procedure is explained in more detail in “Dealer Info”

on page 12.

Replace Printer Paper

To install a new paper roll in the printer: