Robin EH11/W01-115, EH15/W01-150, EH21/W01-210 Repair Manual

GENERAL

INFORMATION

Wisconsin Robin

WO1-115,

150

and

210

engines

are of the four cycle type, in which each ofathe four

operations of suction, compression, expansion and

exhaust constitutes a complete stroke. This produces one power stroke for each

two

revolutions of

the crankshaft.

These engines provide dependable service with

quality and strength where they are needed.

A

heavy

cast iron cylinder liner, forged steel crankshaft and

camshaft, forged alloy bearings and an aluminum

alloy connecting rod, all add up to improved

durability.

MECHANICAL DECOMPRESSOR

For easy engine starting, a mechanical decompressor is mounted on the camshaft to decrease the

recoil pulley force. The decompressor opens the

exhaust valve before compression reaches the max-

imum to reduce the compression pressure, which in

turn decreases the recoil pulley force.

IGNITION SYSTEM

A

pointless magneto ignition system is standard on

these engines. This system, referred to as T.I.C.

(Transistor Ignition Circuit), is completely free of

problems associated with breaker point type ignition

systems such as start-up failure due to dirty, burnt or

oxidized point surfaces, low ignition efficiency

because

of

moisture, rough breaker point surface

and incorrect timing resulting from worn mechanical parts.

A

Solid State Ignition System is an available op-

tion.

LUBRICATION

An oil scraper

on

the connecting rod cap splashes oil

in the crankcase on the rotating and sliding parts.

COOLING

Cooling is accomplished by a flow of air circulated

past the cylinder walls and head fins from a combination fan-flywheel encased in a sheet metal shroud.

Air is divided and directed by ducts and baffle plates

to insure uniform cooling of all parts.

CARBURETOR

The engines are equipped with a horizontal draft car-

buretor that has a float controlled fuel system. The

carburetor has been carefully set to assure satisfac-

tory start-up, acceleration, fuel consumption and out-

put performance.

A

fuel pump is standard on

WO1-115

and

WOl-150

carburetors only. The fuel pump improves engine

operation at a tilted angle.

GOVERNOR

A

centrifugal flyweight governor controls the engine

speed by varying the throttle opening

to

suit the load

imposed upon the engine.

REDUCTION GEAR

A

l/2

reduction gear is an ava,ilable option on the

engines.

ROTATION

Rotation of the crankshaft is clockwise when viewing

from the flywheel side of the engine. This gives counterclockwise rotation at the power take-off end of the

crankshaft.

AIR

CLEANER

The engines are equipped with an oval air cleaner

with a sponge element.

A

cyclone type air cleaner

with semi-wet double elements are an available

option for the engines.

OIL

GRADE

CHART

Crankcase Capacity

E:;::

1.27

pts.

(0.60L)

WOl-2

10

I

1.37

OtS.

(0.65U

f

"Use

oilsclassified as Service

I

SE

or

SF

I

I

Seasons

or

Temperature

I

Gradeof

Oil

I

I

(+49'C

to

+4"a

I

Spring,

Summer

or

Autumn

+120"F

to

+40°F

1

SAE30

I

Winter

+40"F

to

+15"F

1

SAE2O

I

(+ST

to

-9X)

Below

+15"F

(-9°C)

SAEl

OW-30

1-1

IGNlTlC

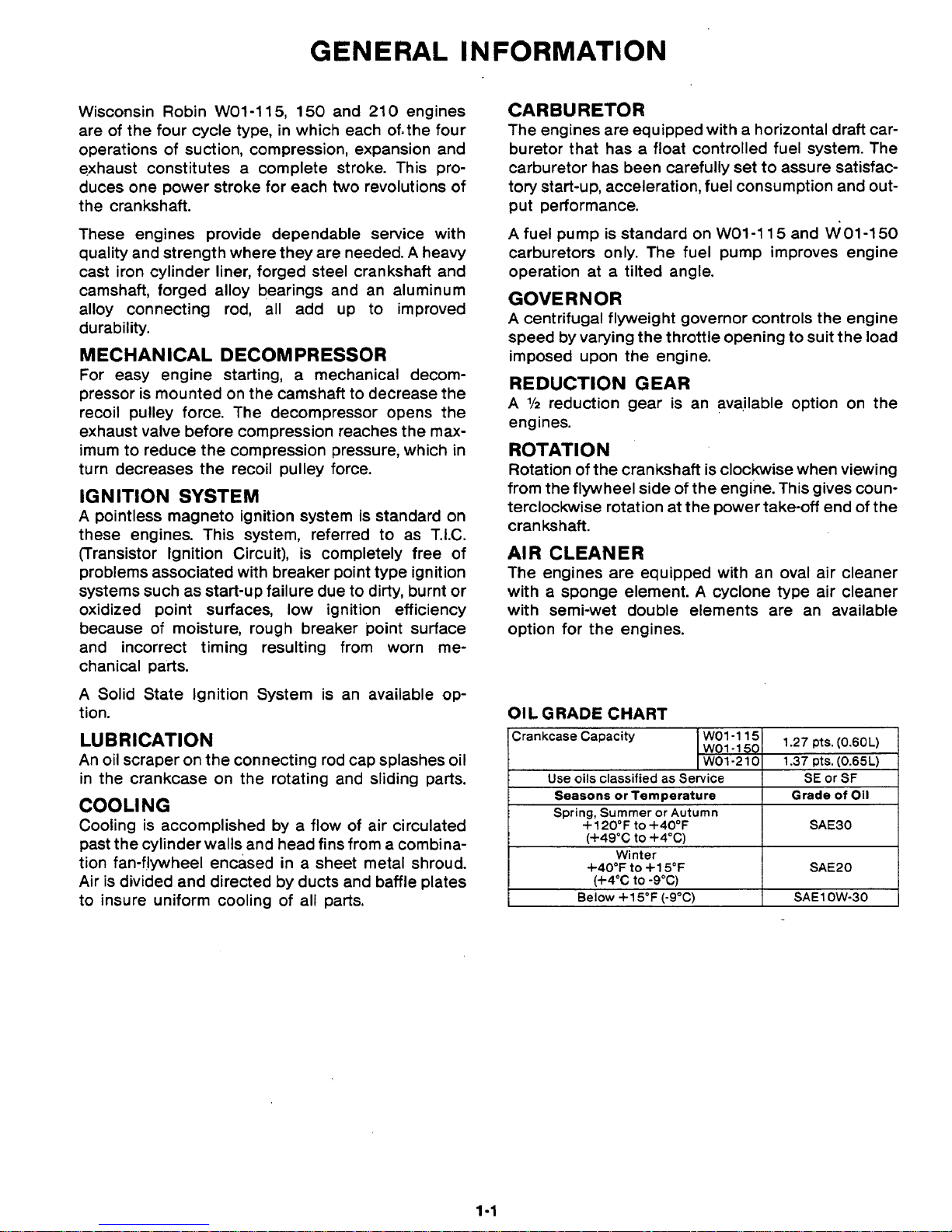

Figure

1-1.

Sectional Views

of

Engine Models

WO1-115

and

WO1-150

,-

1-2

VALVE

ROCKER

ARM

I

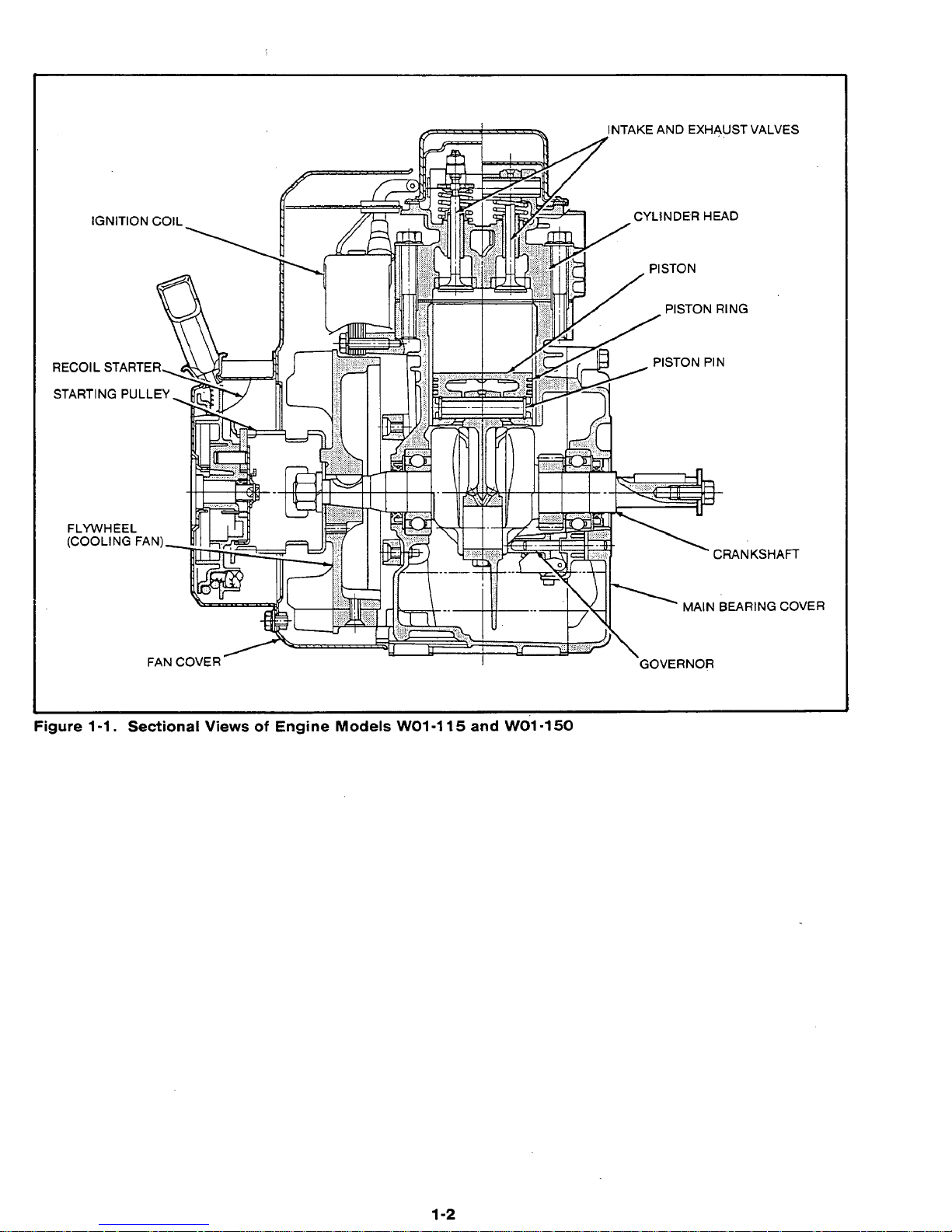

Figure 1-2. Sectional

View

of

Engine

Models

WO1-115 and WO1-150

1-3

Figure

1-3.

Sectional View

of

Engine Model

21

0

I

14

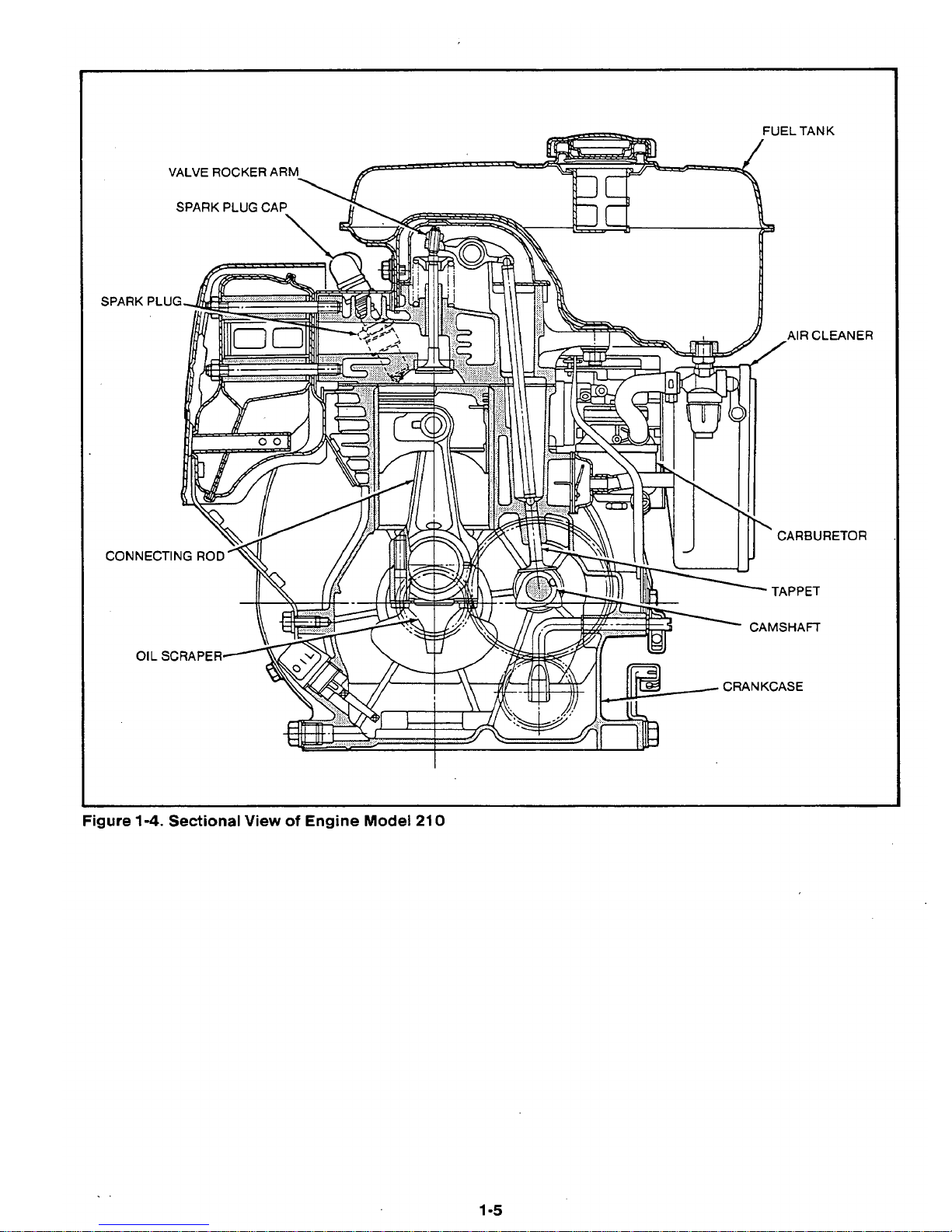

Figure

1-4.

Sectional

View

of

Engine Model

21

0

r

CAR3URETOR

1-5

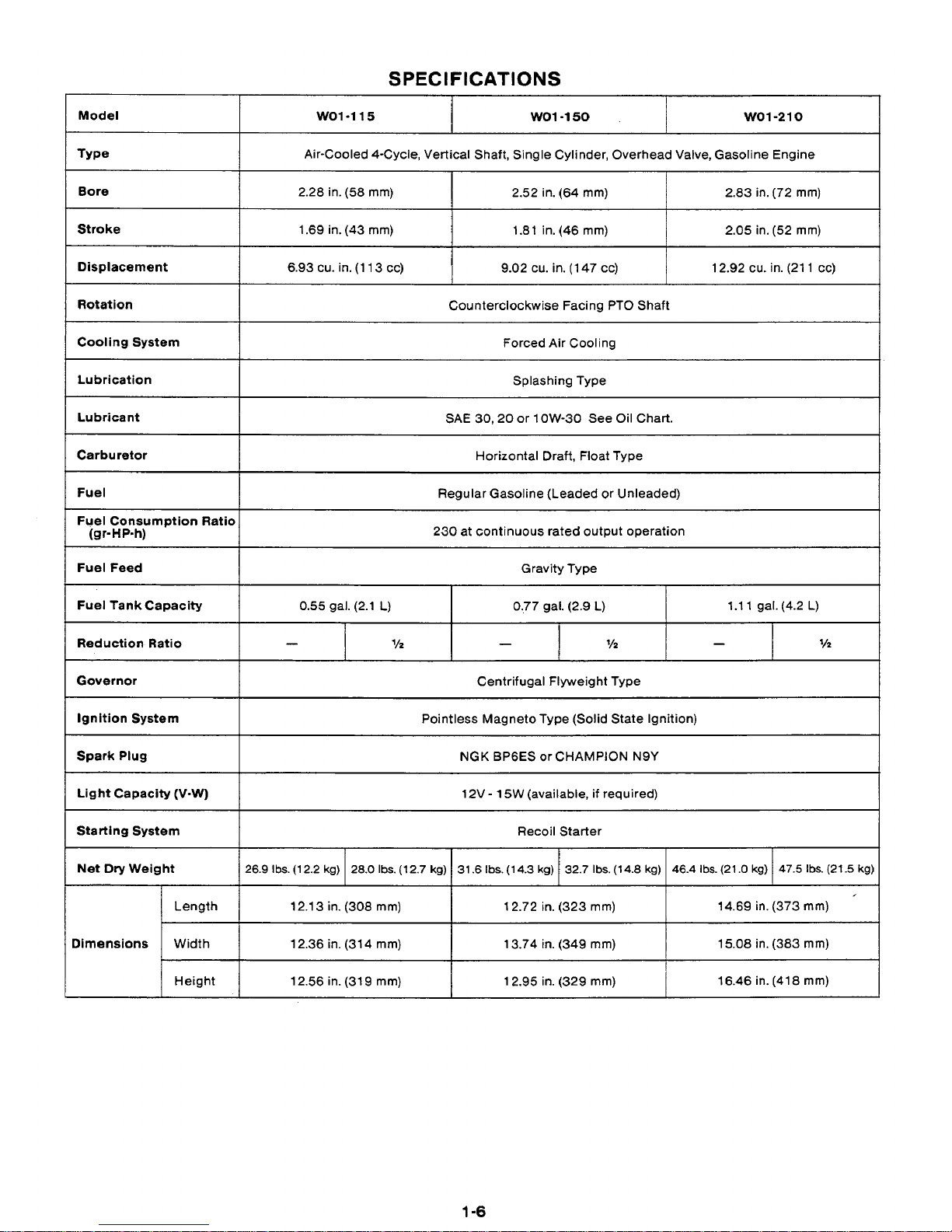

SPECIFICATIONS

Model

wo1-210 WO1-150

WO1-115

Type

2.28 in.

(58

rnm)

Bore

Air-Cooled 4-Cycle, Vertical Shaft, Single Cylinder, Overhead Valve, Gasoline Engine

2.05 in. (52

mm)

1.81 in. (46

mm)

1.69 in. (43

rnrn)

Stroke

2.83 in. (72

mrn)

2.52 in. (64

mrn)

Displacement

Forced

Air

Cooling

Cooling System

Counterclockwise Facing PTO Shaft

Rotation

12.92 cu. in. (21

1

cc) 9.02 cu. in. (1 47 cc)

6.93 cu. in. (1 13 cc)

Lubrication

SAE

30,20

or

1

OW-30

See Oil Chart.

Lubricant

Splashing Type

Carburetor

Regular Gasoline (Leaded or Unleaded)

Fuel

Horizontal Draft, Float Type

Fuel Consumption Ratio

(gr-HP-h)

230 at continuous rated output operation

Fuel Feed

Gravity Type

Fuel Tankcapacity

1.1

1 gal.

(4.2

L)

0..77 gal. (2.9

L)

0.55

gal. (2.1

L)

Reduction Ratio

'/2

-

'/2

-

'/2

-

Governor

Centrifugal Flyweight Type

Ignition System

NGK

BPGES

or

CHAMPION

N9Y

Spark Plug

Pointless Magneto Type (Solid State Ignition)

Light Capacity (V-W)

I

12V

-

15W (available,

if

required)

Starting System Recoil Starter

Net

Dry

Weight

47.5

Ibs.

(21.5 kg)

46.4 lbs(21.0 kg)

32.7 Ibs(l4.8 kg) 31.6 Ibs.(14.3

kg)

28.0 lbs.(12.7

kg)

26.9 Ibs(12.2 kg)

Starting System Recoil Starter

Net

Dry

Weight

47.5

Ibs.

(21.5 kg)

46.4 lbs(21.0 kg)

32.7 Ibs(l4.8 kg) 31.6 Ibs.(14.3

kg)

28.0 lbs.(12.7

kg)

26.9 Ibs(12.2 kg)

Length

15.08 in. (383

rnm)

13.74 in. (349 mm) 12.36 in. (31 4

mrn)

Width Dimensions

14.69 in. (373

rnm)

12.72

in.

(323

mm)

12.1 3 in. (308

rnrn)

Length

15.08 in. (383

rnm)

13.74 in. (349 mm) 12.36 in. (31 4

mrn)

Width Dimensions

14.69 in. (373

rnm)

12.72

in.

(323

mm)

12.1 3 in. (308

rnrn)

Height

16.46 in. (41

8

mm)

12.95 in. (329

rnrn)

12.56 in. (31

9

mm)

1

-6

MAINTENANCE AND STORAGE

ENGINE MAINTENANCE SCHEDULE

ACAUTION: Failure to follow this schedule will seriously damage the engine.

Daily

1

'

MAINTENANCE

Every

I

or 8 hrs.

I

20

hrs.

Add fuel

to

tank.

Check oil level. Add to

full mark.

Do

not overfill.

Clean air intake screen.

Clean cooling fins

if

needed.

0

Inspect unit for

loose hardware, lines,

or hoses.

Change crankcase oil.

Inspect cooling system.

Remove blower housing

and scrape between

fins, around cylinder

head and from housing.

0

a

I

Clean air cleaner.

I

I

Check and clean

Clean fuel filter and fuel

tank.

Clean contact and

breaker points.

Disassemble and clean

carburetor.

Remove carbon

from cylinder head.

Weekly

I

Monthly or I Semi-annual See Note

or

50

hrs.

100-200

hrs.

500-600

hrs. Below

*.

*

*

a

*

0

-*

I*

/.I

I*

1.

*Under severe environmental conditions these items may need to be maintained more frequently.

Cleaning

Air

Cleaner

Remove air cleaner cover. Remove element from base.

Wash element in detergent and hot water, then dry

thorou-ghly. Wipe all other components clean. Saturate

element with light oil. Squeeze firmly to evenly distribute oil and remove any excess.

Service daily

if

engine is operated in very dusty and dry

grass conditions.

A

clogged air cleaner will result in

high fuel consumption,

loss

of

power and excessive

carbon build-up in the combustion chamber.

ENGINE STORAGE

If not properly protected, temperature and humidity

changes can cause corrosion of piston rings, cylinder

walls and bearing surfaces in a stored engine. For maximum protection, prepare the engine for storage as

follows:

1.

Run the engine until it reaches operating temperature. Stop the engine and drain the oil from

crankcase while engine is still warm.

2-1

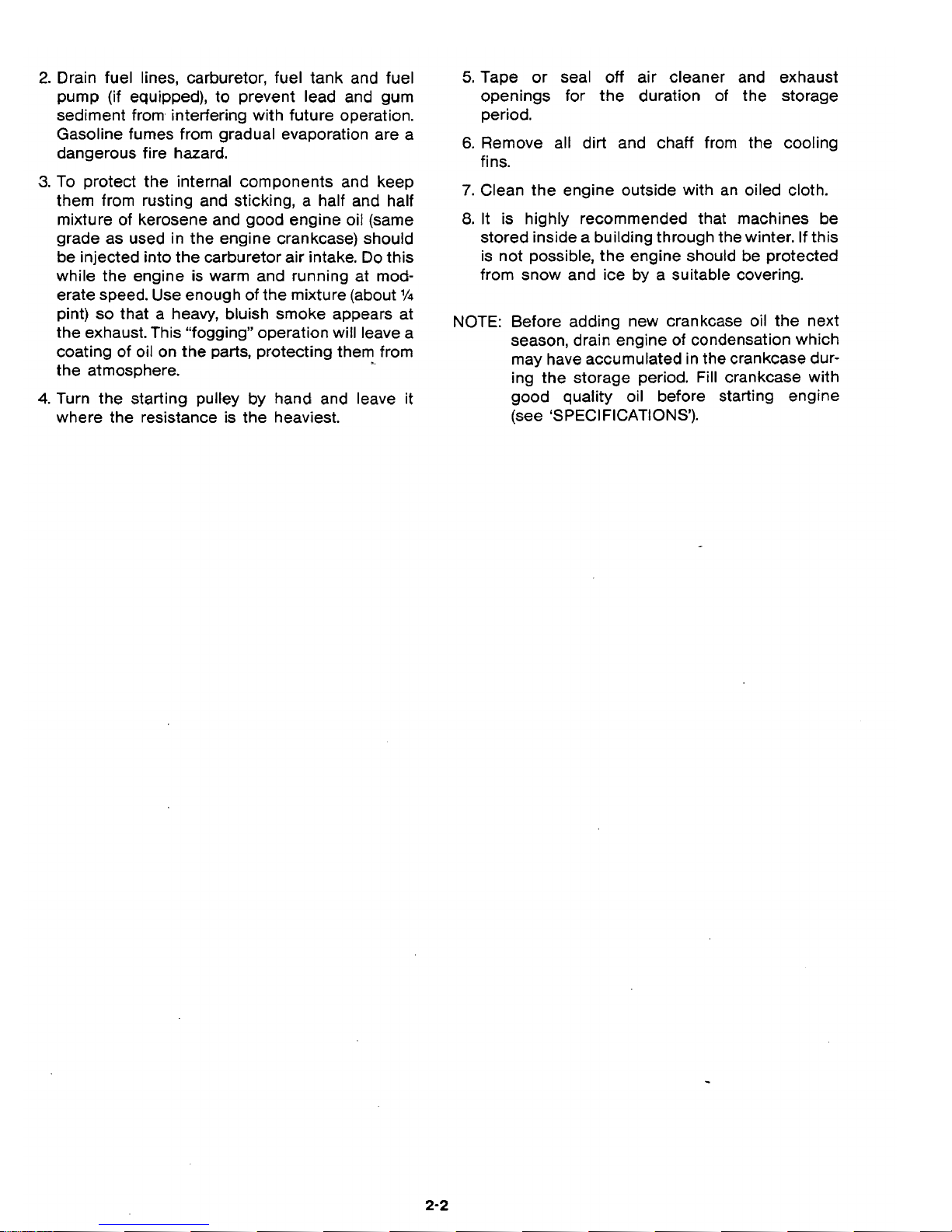

2.

Drain fuel lines, carburetor, fuel tank and fuel

pump

(if

equipped), to prevent lead and gum

sediment from. interfering with future operation.

Gasoline fumes from gradual evaporation are a

dangerous fire hazard.

3.

To

protect the internal components and keep

them from rusting and sticking, a half and half

mixture of kerosene and good engine oil (same

grade as used in the engine crankcase) should

be injected into the carburetor air intake.

Do

this

while the engine

is

warm and running at mod-

erate speed. Use enough of the mixture (about

l/4

pint)

so

that a heavy, bluish smoke appears at

the exhaust. This “fogging” operation will leave a

coating of oil on the parts, protecting them from

the atmosphere.

4.

Turn the starting pulley by hand and leave it

where the resistance is the heaviest.

5.

Tape

or

seal

off

air cleaner and exhaust

openings for the duration

of

the storage

period.

6.

Remove all dirt and chaff from the cooling

fins.

7.

Clean the engine outside with an oiled cloth.

8.

It

is highly recommended that machines be

stored inside a building through the winter.

If

this

is not possible, the engine should be protected

from snow and ice by a suitable covering.

NOTE: Before adding new crankcase oil the next

season, drain engine

of

condensation which

may have accumulated in the crankcase during the storage period. Fill crankcase with

good quality oil before starting engine

(see ‘SPECIFICATIONS).

2-2

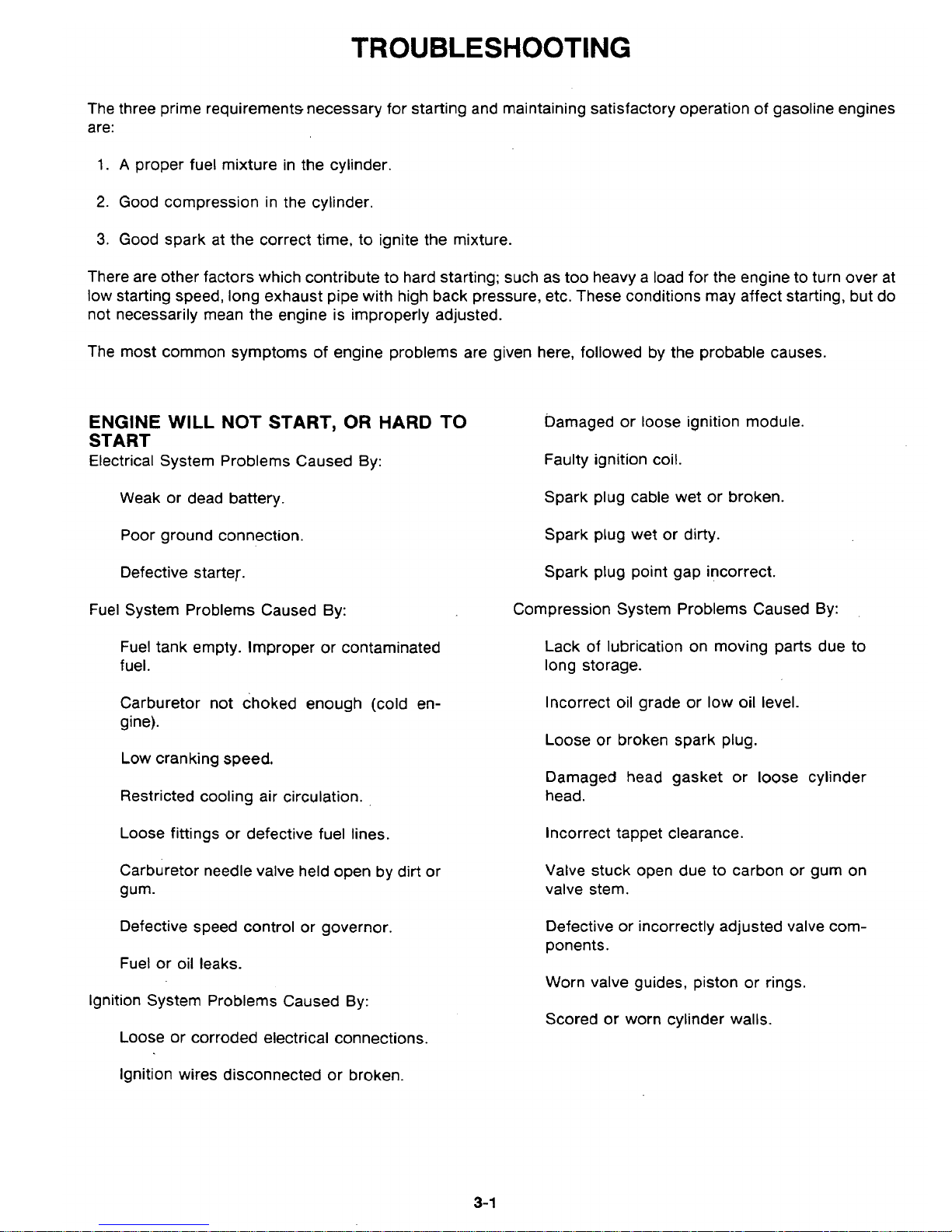

The three prime requirements necessary for starting and maintaining satisfactory operation

of

gasoline engines

are:

1.

A

proper fuel mixture in the cylinder

2.

Good compression in the cylinder.

3.

Good spark at the correct time, to ignite the mixture.

There are other factors which contribute to hard starting; such as too heavy a load for the engine to turn over at

low starting speed, long exhaust pipe with high back pressure, etc. These conditions may affect starting, but do

not necessarily mean the engine is improperly adjusted.

The most common symptoms of engine problems are given here, followed by the probable causes.

ENGINE

WILL

NOT

START, OR HARD

TO

START

Electrical System Problems Caused By:

Weak or dead battery.

Poor ground connection.

Defective starter.

Fuel System Problems Caused By:

Fuel tank empty. Improper or contaminated

fuel.

Carburetor not choked enough (cold engine).

Low

cranking

speed.

Restricted cooling air circulation.

Loose fittings or defective fuel lines.

Carburetor needle valve held open by dirt or

gum.

Defective speed control or governor.

Fuel or oil leaks.

Ignition System Problems Caused By:

Loose

or

corroded electrical connections.

Ignition wires disconnected or broken.

Damaged or loose ignition module.

Faulty ignition coil.

Spark plug cable wet or broken.

Spark plug wet or dirty.

Spark ptug point gap incorrect.

Compression System Problems Caused By:

Lack of lubrication on moving parts due to

long storage.

Incorrect oil grade or

low

oil

level.

Loose or broken spark plug.

Damaged head gasket or loose cylinder

head.

Incorrect tappet clearance.

Valve stuck open due to carbon or gum on

valve stem.

Defective or incorrectly adjusted valve com-

ponents.

Worn valve guides, piston or rings.

Scored or worn cylinder walls.

3-1

ENGINE

MISFIRES

Incorrect spark plug gap.

Ignition cable leaking.

Weak spark

Ignition wires loose.

Water or dirt in gasoline.

Insufficient compression.

ENGINE

STOPS

Fuel tank empty.

Water, dirt, gum, etc. in gasoline.

Vapor lock (gasoline evaporating in fuel lines

due to excessive heat around engine).

Vapor lock in fuel lines or carburetor

due to incorrect fuel.

Engine scored

or

stuck due to lack of oil.

Air vent hole in the fuel tank cap plugged.

Magneto or ignition coil faulty.

ENGINE OVERHEATS

Crankcase oil level

low.

Spark timing incorrect.

Low

grade gasoline used.

Engine overloaded.

Cooling air restricted from dirt

or

debris.

Engine operated in confined space where cooling air is continually recirculated.

Restricted exhaust.

Heavy load

at

low engine speed.

0

ENGINE KNOCKS

Low quality gasoline.

Engine operating under heavy load at

low

speed.

Carbon or lead deposits in cylinder head

or

on piston.

Spark timing incorrect.

Worn

or

damaged connecting rod bearing.

Worn or damaged piston pin.

ENGINE BACKFIRES THROUGH

CARBURETOR

Water or dirt in gasoline, or poor grade

gasoline.

Intake valve stuck

Valves overheated,

or

particles in combustion

chamber.

Engine cold.

ENGINE SURGES

OR

GALLOPS

Carburetor flooded.

Governor rod installed wrong, or governor out

of adjustment.

High speed jet

in

carburetor partially

restricted.

/?

3-2

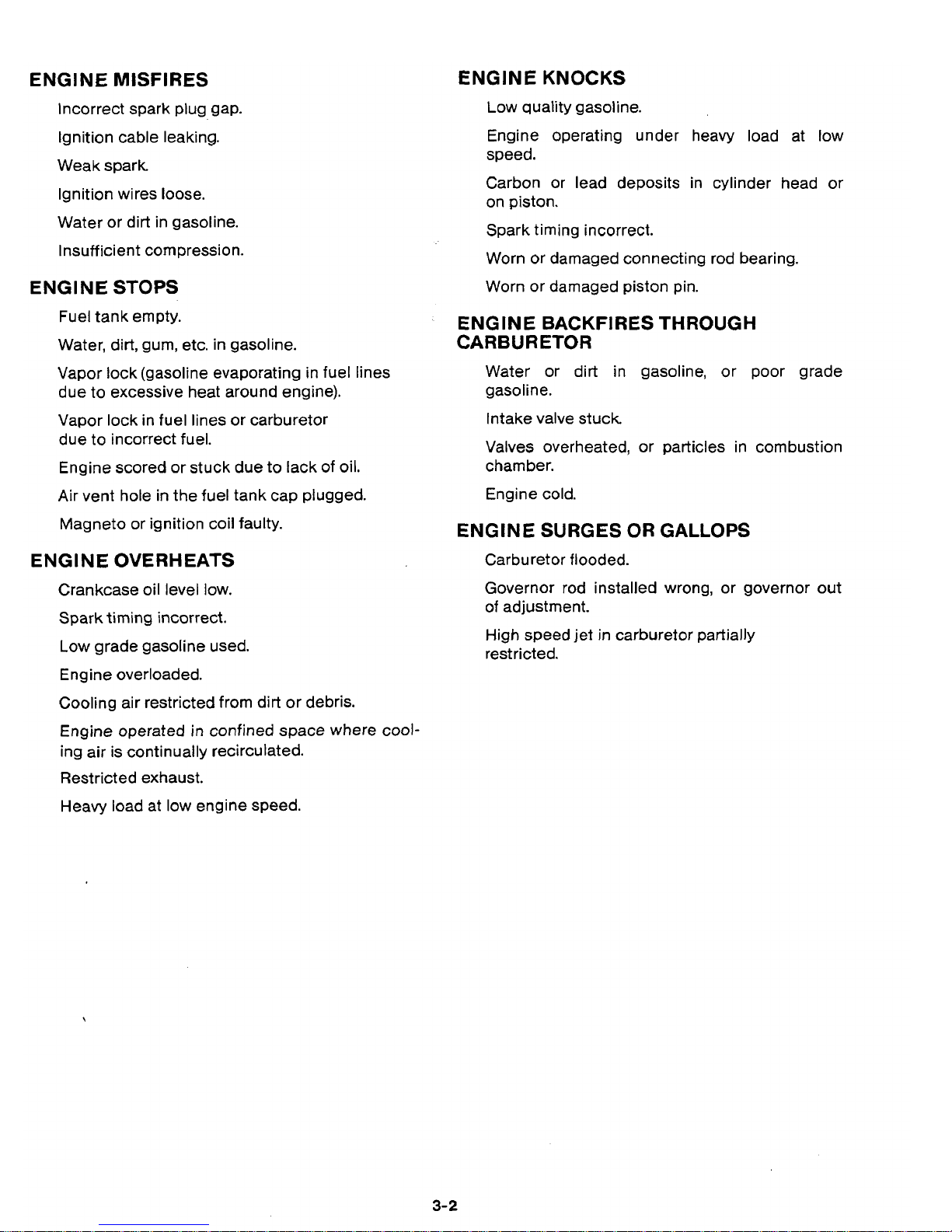

IGNITION

The standard ignition system for engines

WO1-115,

150

and

210

is a magneto ignition system called

T.I.C. (Transistor Ignition Circuit). T.I.C. consists

of

an

ignition coil with a built-in transistor mounted on

the flywheel.

For initial excitation, a Solid State Ignition is an available option for these engines.

SYSTEM

OPERATION

Figures

4-1

and

4-2

Revolution

of

the flywheel generates electricity on

the primary side

of

the ignition coil, and the electric

SYSTEM

current

(A)

runs.

(A)

makes the power transistor

"ON"

and the electric current

(B)

passes.

The flywheel goes round further, and at the time

of

ignition the electric current (C) runs, then the electric

current

(D)

runs

to

the signal transistor, by which the

electric current

(B),

passing through the power transistor, is abruptly cut; and as a result, the high

voltage electricity

is

generated on the secondary

side

of

the ignition coil and it sparks at the plug.

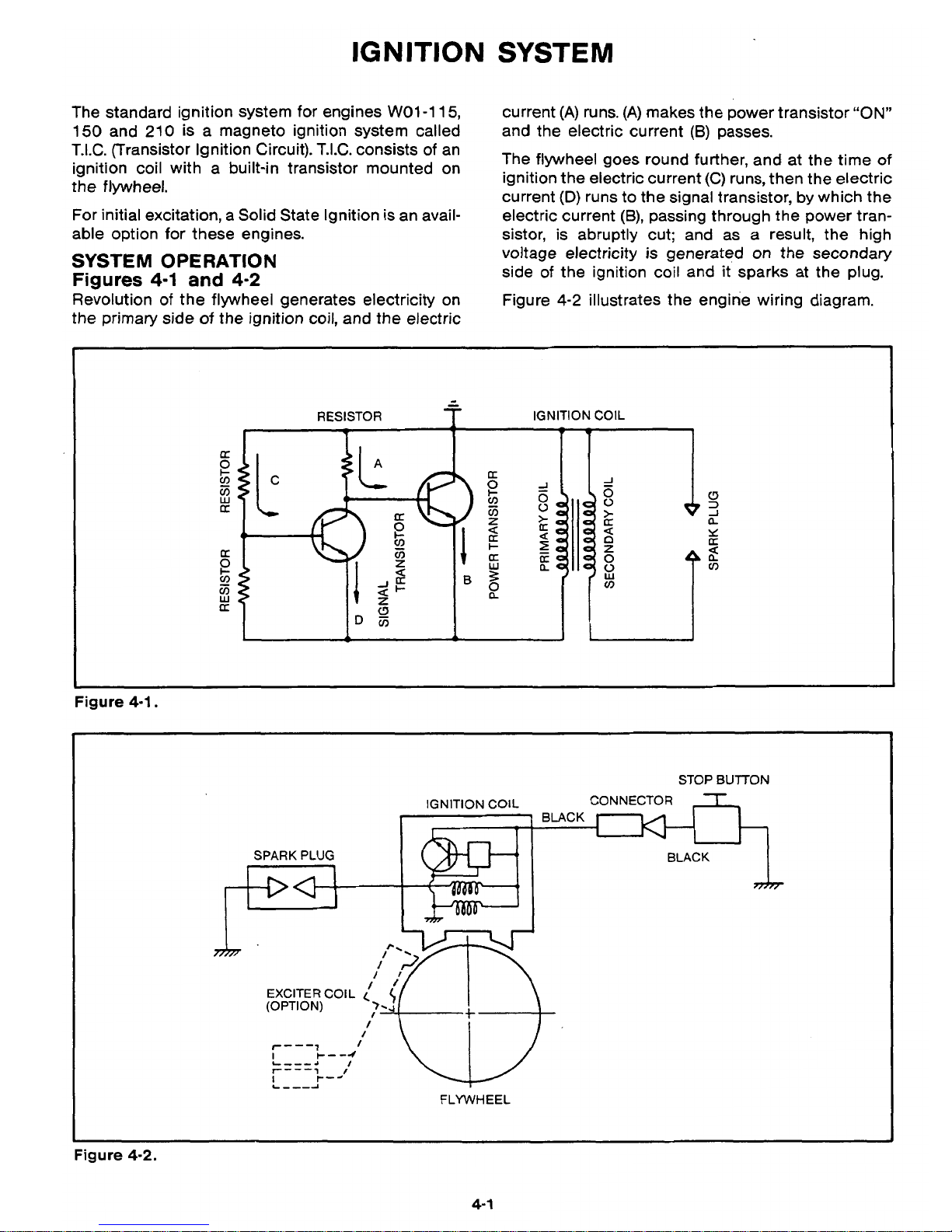

Figure

4-2

illustrates the engine wiring diagram.

-

RESISTOR

f

IGNITION

COIL

Figure

4-1.

STOP

BUlTON

IGNITION COIL CONNECTOR

-r

SPARK

PLUG BLACK

mrr

(OPTION)

EXCITER

COIL

(

I

I

l""1

I

i

FLYWHEEL

Figure

4-2.

4-

1

Loading...

Loading...