Page 1

SERVICE

MANUAL

Model

EH025/EH035

ENGINE

PUB-ES1740

Rev. 05/03

Page 2

940 Lively Blvd. • Wood Dale, IL 60191 • Phone: 630-350-8200 • Fax: 630-350-8212

e-mail: sales@robinamerica.com • www.robinamerica.com

© Copyright 2003 Robin America, Inc.

Page 3

CONTENTS

Section Title Page

1. SPECIFICATIONS....................................................................................................... 1

2. PERFORMANCE ........................................................................................................ 2

2-1 MAXIMUM OUTPUT........................................................................................................ 2

2-2 CONTINUOUS RATED OUTPUT .................................................................................... 2

2-3 MAXIMUM TORQUE AND FUEL CONSUMPTION WITH MAXIMUM OUTPUT............. 2

2-4 PERFORMANCE CURVES ............................................................................................. 3

3. FEATURES.................................................................................................................. 5

3-1 THE SMALLEST AND LIGHTEST 4-STROKE ENGINE IN THE MARKET..................... 5

4-STROKE ENGINE ALLOWING OPERATION IN THE TILTED POSITION,

3-2

REQUIRED IN BRUSH CUTTING WORK AND OTHER SIMILAR APPLICATIONS ......................

4. GENERAL DESCRIPTION OF ENGINE COMPONENTS .......................................... 8

4-1 CYLINDER BLOCK AND CRANKCASE.......................................................................... 8

4-2 CRANKSHAFT AND CONNECTING ROD ...................................................................... 8

4-3 PISTON............................................................................................................................ 8

4-4 PISTON RINGS ...............................................................................................................9

4-5 CAM GEAR...................................................................................................................... 9

4-6 COOLING SYSTEM......................................................................................................... 9

4-7 LUBRICATION SYSTEM ................................................................................................. 9

4-8 IGNITION SYSTEM ....................................................................................................... 10

4-9 CARBURETOR.............................................................................................................. 10

4-10 AIR CLEANER ............................................................................................................. 10

4-11 DECOMPRESSION SYSTEM.......................................................................................11

4-12 SECTIONAL VIEW OF ENGINE.................................................................................. 12

5

5. DISASSEMBLY AND REASSEMBLY ....................................................................... 14

5-1 PREPARATIONS AND SUGGESTIONS........................................................................ 14

5-2 SPECIAL TOOLS ........................................................................................................... 14

5-3 DISASSEMBLY PROCEDURES.................................................................................... 14

5-4 REASSEMBLY PROCEDURES..................................................................................... 26

6. MAGNETO ................................................................................................................ 41

6-1 FLYWHEEL MAGNETO................................................................................................. 41

6-2 IGNITION OF MAGNETO.............................................................................................. 41

7. AUTOMATIC DECOMPRESSION SYSTEM............................................................. 42

7-1 FUNCTION AND MECHANISM..................................................................................... 42

7-2 INSPECTION .................................................................................................................42

Page 4

Section Title Page

8. CARBURETOR ........................................................................................................ 43

8-1 OPERATION AND CONSTRUCTION............................................................................43

8-2 DISASSEMBLY AND REASSEMBLY.............................................................................44

9. RECOIL STARTER .................................................................................................. 47

9-1 HOW TO DISASSEMBLE..............................................................................................47

9-2 HOW TO REASSEMBLE...............................................................................................49

9-3 CHECK AFTER REASSEMBLE ....................................................................................50

9-4 OTHER GUIDES............................................................................................................50

10. TROUBLESHOOTING ........................................................................................... 51

10-1 STARTING DIFFICULTIES ..........................................................................................51

10-2 ENGINE MISFIRES .....................................................................................................52

10-3 ENGINE STOPS ..........................................................................................................52

10-4 ENGINE OVERHEATS ................................................................................................53

10-5 ENGINE KNOCKS .......................................................................................................53

10-6 ENGINE BACKFIRES THROUGH CARBURETOR.....................................................53

11. INSTALLATION ..................................................................................................... 54

11-1 INSTALLING.................................................................................................................54

11-2 VENTILATION..............................................................................................................54

11-3 EXHAUST GAS DISCHARGE .....................................................................................54

11-4 POWER TRANSMISSION TO DRIVEN MACHINES...................................................54

12. SERVICE DATA ...................................................................................................... 55

12-1 CLEARANCE DATA AND LIMITS ................................................................................55

12-2 TORQUE SPECIFICATIONS .......................................................................................58

12-3 OIL GRADE CHART ....................................................................................................59

13. MAINTENANCE AND STORAGE.......................................................................... 60

13-1 DAILY MAINTENANCE................................................................................................60

13-2 INITIAL 20 HRS. MAINTENANCE ...............................................................................60

13-3 EVERY 50 HRS. (10 DAYS) MAINTENANCE .............................................................60

13-4 EVERY 100-200 HRS. (MONTHLY) MAINTENANCE .................................................61

13-5 ENGINE STORAGE.....................................................................................................61

Page 5

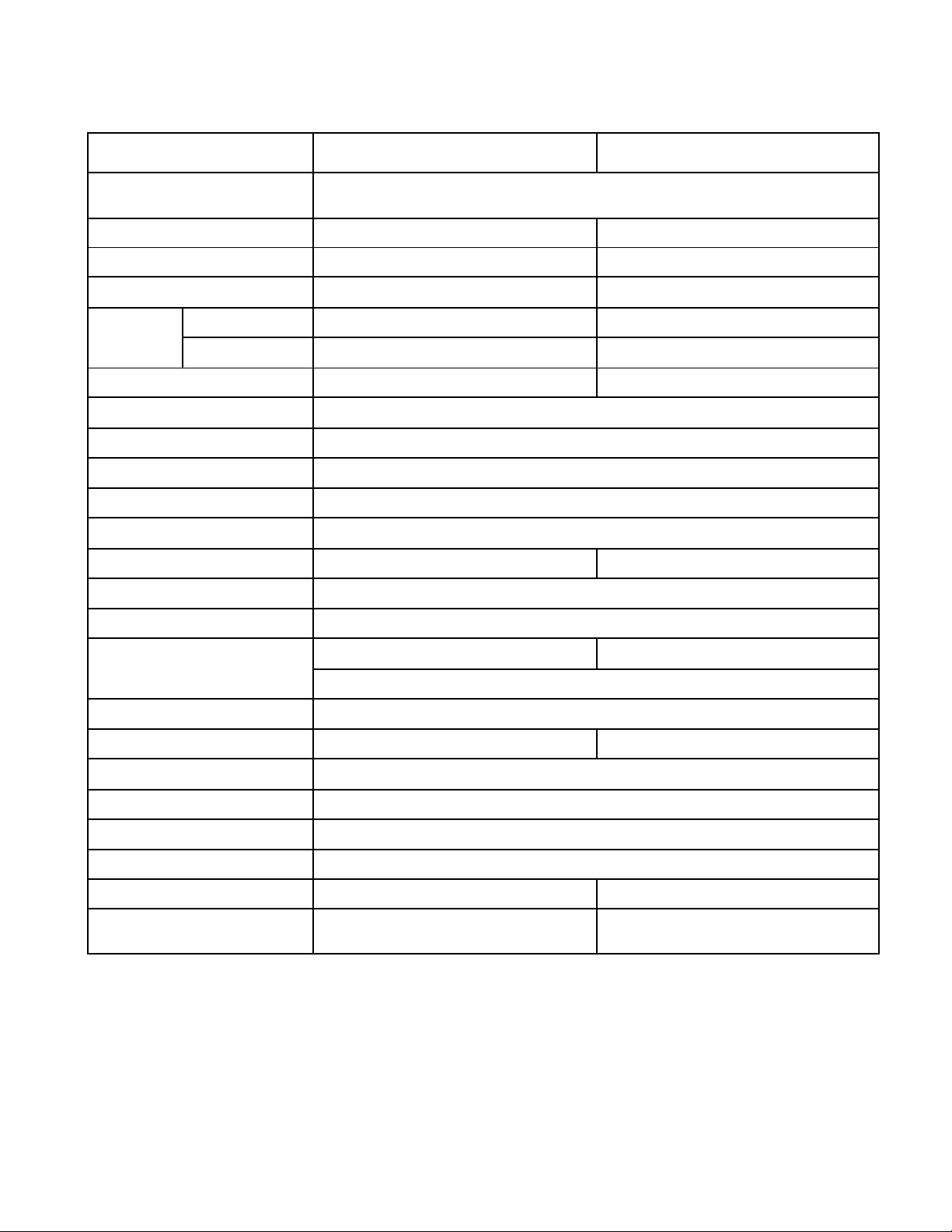

1. SPECIFICATIONS

MODEL EH025 EH035

Type

Bore x Stroke 34 x 27 mm (1.34 x 1.06 in.) 39 x 28 mm (1.54 x 1.10 in.)

Piston Displacement 24.5 cm

Compression Ratio 8.3 8.6

Output

Max. Torque 1.18 N

Direction of Rotation Counterclockwise As Viewed From P.T.O. Shaft Side

Cooling system Forced Air Cooling

Valve Arrangement Overhead Valve

Lubrication Forced Lubrication

Lubricant Automotive Oil SAE #20, #30 or 10W-30 ; Class SF or higher

Capacity of Lubricant 0.08 liters (0.021 U.S. gal.) 0.10 liters (0.026 U.S. gal.)

Carburetor Diaphragm Type

Fuel Automotive Unleaded Gasoline

Continuous 0.55 kW (0.75 HP) /7000 r.p.m. 0.81 kW (1.10 HP) /7000 r.p.m.

Max. 0.81 kW (1.10 HP) /7000 r.p.m. 1.18 kW (1.60 HP) /7000 r.p.m.

・

m (0.12 kgf・m) /5000 r.p.m. 1.76 N・m (0.18 kgf・m) /5000 r.p.m.

Air-Cooled, 4-Cycle, Single-Cylinder,

Horizontal P.T.O. Shaft, Gasoline Engine

3

(1.49 cu.in.) 33.5 cm3(2.04 cu.in.)

Fuel Consumption Ratio

Fuel Feed System Diaphragm Pump

Fuel Tank Capacity 0.5 liters (0.13 U.S. gal.) 0.65 liters (0.17 U.S. gal.)

Ignition System Flywheel Magneto (Solid State)

Spark Plug NGK CMR6A (M10 x 1.0)

Starting System Recoil Starter

Air Cleaner Semi-Wet Type

Dry Weight 2.8 kg (6.17 lb.) 3.5 kg (7.72 lb.)

Dimensions (L x W x H)

408 g/kW

170 mm x 213 mm x 225 mm

(6.69 in. x 8.39 in. x 8.86 in.)

・

h (300 g/HP・h) 340 g/kW・h (250 g/HP・h)

At Continuous Rated Output

191 mm x 234 mm x 246 mm

(7.52 in. x 9.21 in. x 9.69 in.)

Specifications are subject to change without notice.

- 1 -

Page 6

2. PERFORMANCE

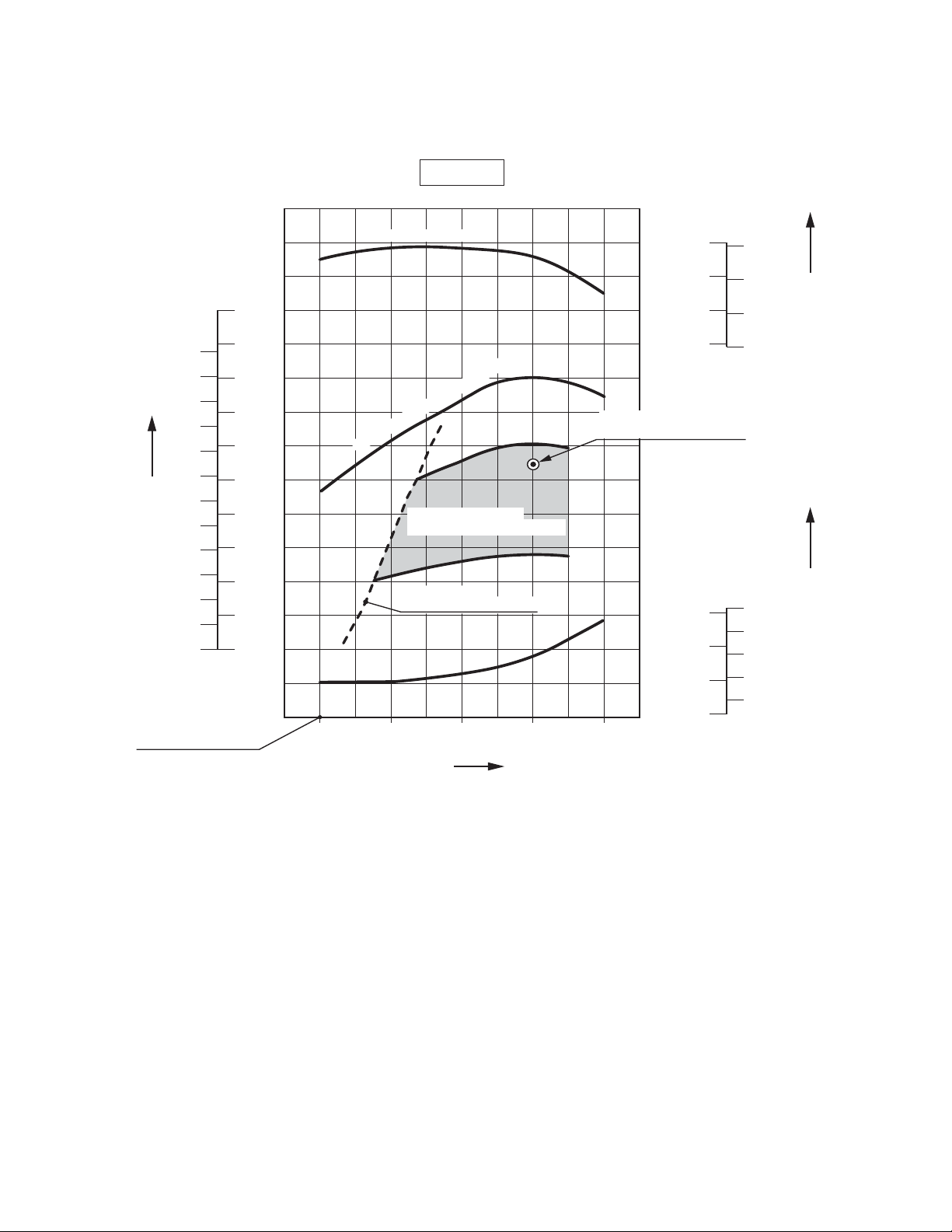

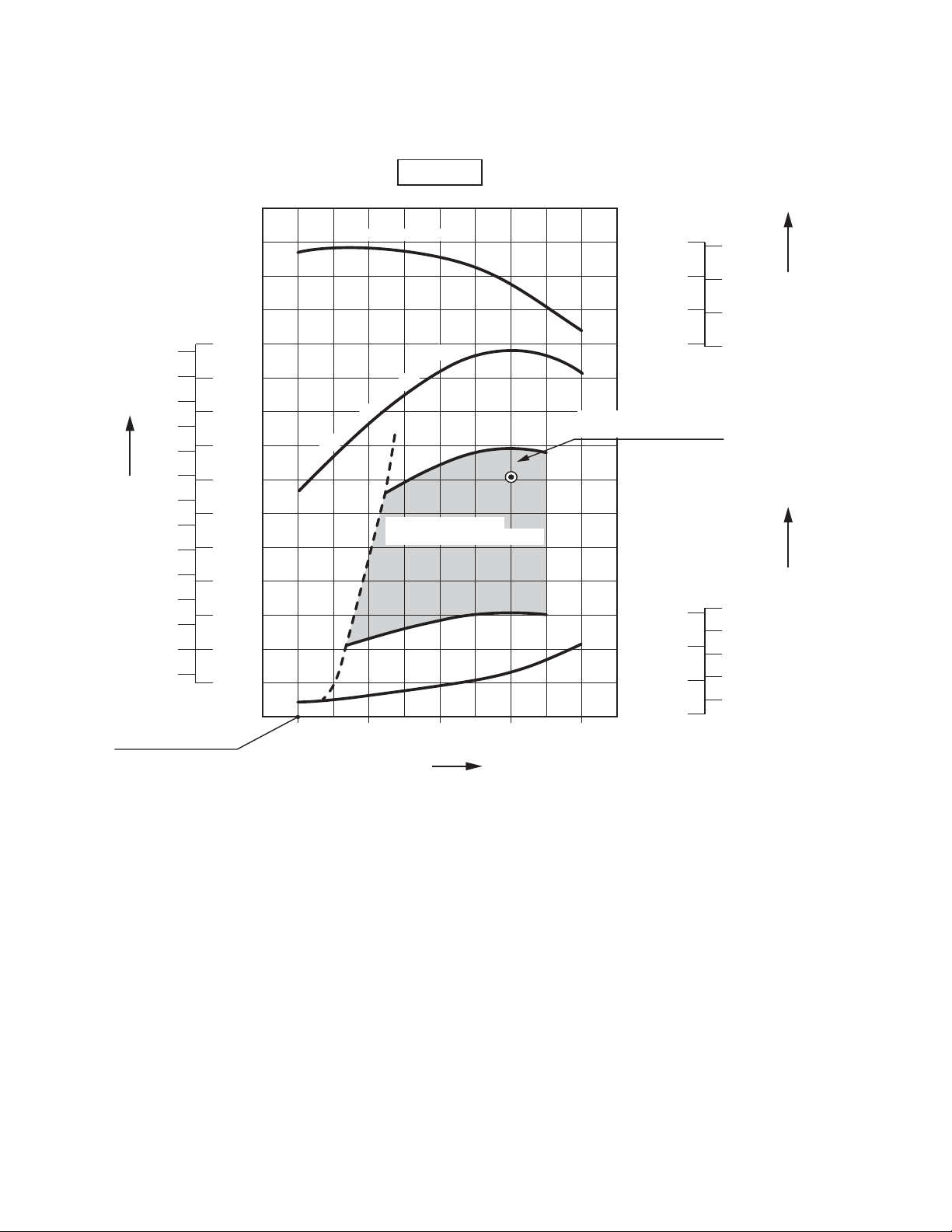

2-1 MAXIMUM OUTPUT

The maximum output is the output of an engine with its throttle valve fully opened under the condition that

all the moving parts are properly broken in after the initial break-in period. A new engine may not produce

full maximum output while its moving parts are still not broken-in.

2-2 CONTINUOUS RATED OUTPUT

The continuous rated output is the output of an engine at optimum governed speed which is most favorable from the view point of engine's life and fuel consumption. When the engine is installed on a certain

equipment, it is recommended that the continuous output required from the equipment should be kept

below this continuous rated output.

2-3 MAXIMUM TORQUE AND FUEL CONSUMPTION WITH MAXIMUM OUTPUT

The maximum torque is the torque at the output shaft when the engine is producing maximum output at

certain revolution. The fuel consumption rate is the amount of fuel in grams consumed per horsepowerhour when the engine is working at continuous rated output.

- 2 -

Page 7

2-4 PERFORMANCE CURVES

EH025

(PS)

(kW

1.2

1.0

0.8

0.6

OUTPUT

0.4

0.2

0

CLUTCH MEET

4000 - 4400 r.p.m.

1.0

0.8

0.6

0.4

0.2

0

(Nm)

MAXIMUM TORQUE

)

(kg-m

1.2

1.0

0.8

0.6

CONTINUOUS RATED

HORSEPOWER

MAXIMUM HORSEPOWER

RECOMMENDED

HORSEPOWER RANGE

600

) (

g/PSh

CLUTCH

CHARACTERISTICS

(g/kWh

)

0.12

0.10

0.08

TORQUEFUEL CONSUMPTION RATE

0.06

)

450

400

500

400

350

300

250

300

4000 5000 6000 7000

(r.p.m.)Revolution

8000

- 3 -

Page 8

EH035

(PS)

(kW

1.6

1.4

1.2

1.0

OUTPUT

0.8

0.6

0.4

CLUTCH MEET

4000 - 4400 r.p.m.

1.2

1.0

0.8

0.6

0.4

0.2

(Nm)

MAXIMUM TORQUE

(kg-m

1.8

1.6

)

1.4

1.2

CONTINUOUS RATED

HORSEPOWER

MAXIMUM HORSEPOWER

RECOMMENDED

HORSEPOWER RANGE

(g/kWh

) (

g/PSh

600

)

0.18

0.16

0.14

TORQUEFUEL CONSUMPTION RATE

0.12

)

450

400

500

400

350

300

250

300

4000 5000 6000 7000

(r.p.m.)Revolution

8000

- 4 -

Page 9

3. FEATURES

3-1 THE SMALLEST AND LIGHTEST 4-STROKE ENGINE IN THE MARKET

1) Small-sized lubricant oil tank, thanks to the Robin original lubrication system.

2) Compact construction because of the optimum design, not taking any bore-up into consideration.

3) Shorter shaft length at the output side (magneto side), by arranging the cam gear unit at the opposite

side of the magneto.

4) Light weight construction, because of the resin made came gear, rocker cover and other parts.(EH025)

And because of the resin made came gear, other parts.(EH035)

5) Parts of the valve driving system with thoroughgoing light weight construction

3-2 4-STROKE ENGINE ALLOWING OPERATION IN THE TILTED POSITION, REQUIRED IN

BRUSH CUTTING WORK AND OTHER SIMILAR APPLICATIONS

1) Robin's original lubricating system

Small-sized lubrication system with high reliability , that makes it possible to operate the engine in tilted

position.

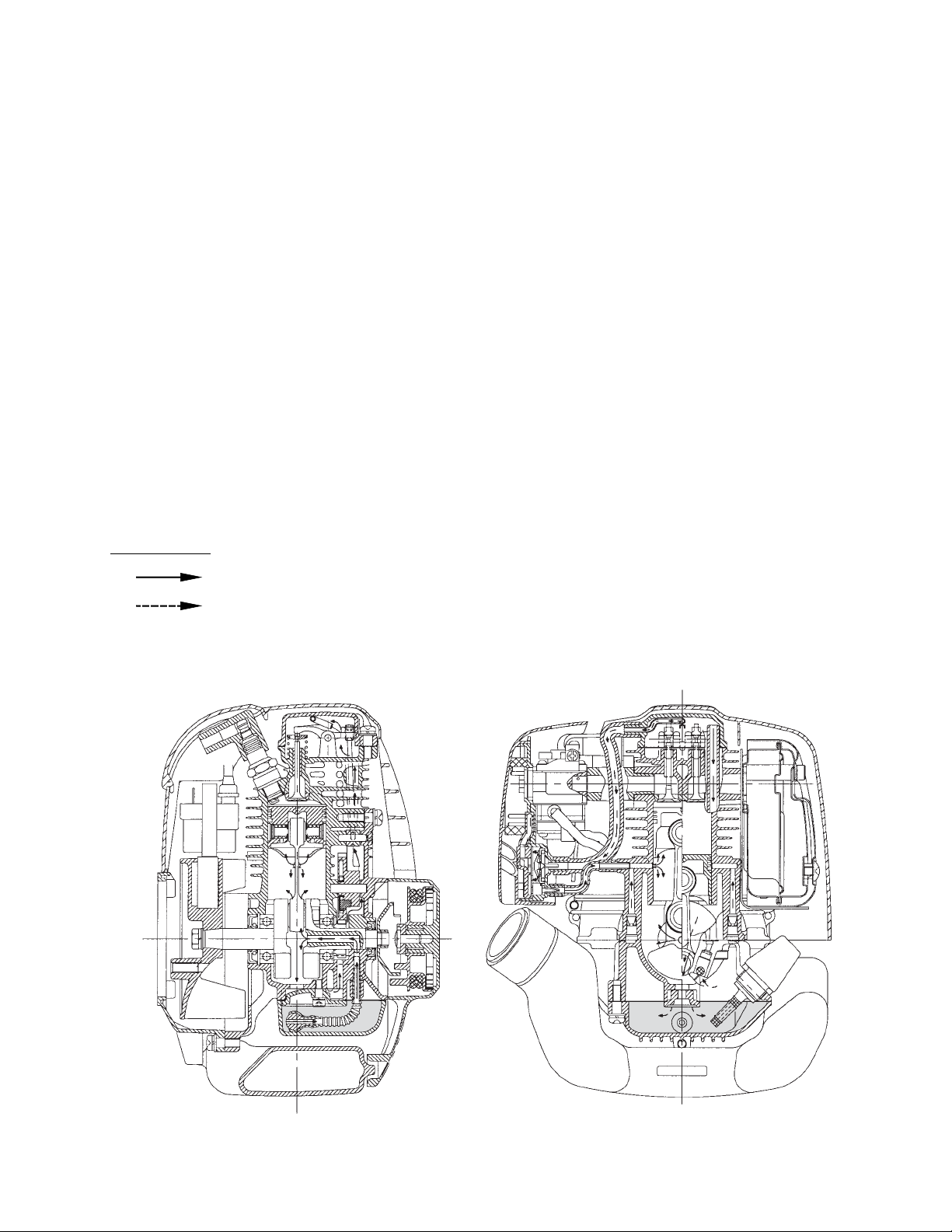

Basic system

Oil flow

Blow-by air (including fresh air) and oil mist

Fig. 3-1

- 5 -

Page 10

(a) Since Robin lubricating system makes use of the pressure fluctuations in the crankcase, a lead valve

is arranged at the lower part of the crankcase. By utilizing the negative pressure that occurs during

the piston rising stroke, lubricant oil is supplied from the oil tube (located inside the oil tank, that is

separated from the crankcase) to the crankcase, through the oil passage of the crankshaft which has

rotary valve that opens and shuts with an appropriate timing.

(b) At the same time, fresh air and blow-by air containing oil mist coming from the rocker arm compart-

ment are sucked through the two assist holes that open at the piston top dead center.

(c) The supplied oil is diffused by the crank arm and other parts, thereby transforming in mist.

That diffused oil mist is compressed during the piston lowering stroke, and an appropriate quantity of

the compressed oil mist is pumped to the cam gear compartment and to the rocker arm compartment

through the lead valve, and oil pasage. Thus, it lubricates the various parts of the engine. The remaining oil mist returns to the oil tank via bypass hole.

(d) The oil tank has two pressure relief holes located at its left and right sides which are connected to the

assist hole of the cylinder unit. These pressure relief holes have the function to keep the pressure of

the oil tank constant.

(e) Oil inside the rocker arm compartment is sucked back to the crankcase by the strong negative pres-

sure inside the crankcase, through the two return paths located at the left and right sides.

(f) The blow-by gas and a small amount of oil mist flow from the rocker arm compartment to the oil

separator inside the air cleaner, through the breather pipe. Then separated into blow-by gas and oil

mist.

(g) The separated oil mist returns into the crankcase, passing through the assist hole of the cylinder.

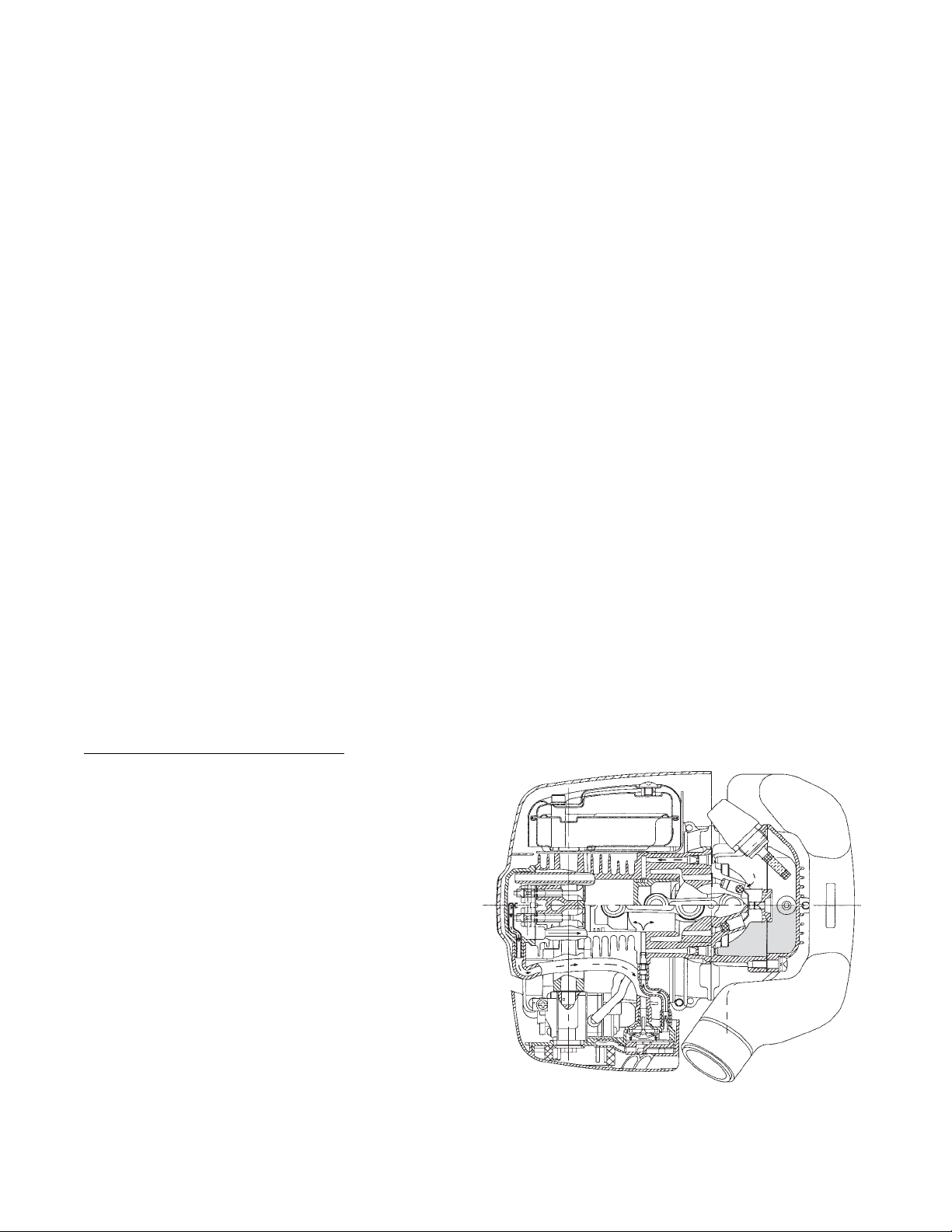

Engine operation in tilted positions

(a) When the engine is tilted carburetor side down.

The return path at the carburetor side inside

the rocker arm compartment comes to the

lower position. Then, the stagnant oil is sucked

back to the crankcase. At that time, the check

valve of the pressure relief hole prevents oil

from flowing back, because the carburetor side

pressure relief hole, located inside the oil tank,

is in the oil.

- 6 -

Fig. 3-2

Page 11

(b) When the engine is tilted muffler side down.

In the same way as that of the carburetor side

down, the return path in the rocker arm compartment and the pressure relief hole operate

and return the stagnant oil into the crankcase.

(c) Engine tilted back and forth

The breather hole located inside the rocker arm

compartment is arranged approximately at the

center of the rocker arm compartment, so as

to prevent stagnant lubricant oil from being

gushed out at either back or forth inclined position. The stagnant oil is sucked back into the

crankcase through the return path.

(d) Upside down position

Fig. 3-3

Basically, it is presumed that the engine is not

used (is not required to operate) continuously

in the upside down position, and only the practical tilted positions are taken into consideration

as priorities. Measures are adopted, however,

so that the engine can be run for a short time

in upside down positions during the work and/

or during idling.

The oil return passage tube at the muffler side

is extended up to the rocker arm cover in order to suck the oil that stagnates in the rocker

arm compartment while the engine is in the

upside down position. At that time, the pressure relief hole located inside the oil tank is

closed by the check ball, so as to prevent oil

from back flowing from the oil tank.

Fig. 3-4

Lubrication inside the cylinder is carried out with a sufficient volume of oil, irrespective of the position of

the engine, and there is no risk of engine seizure, wear and other similar problems caused by improper

lubrication. The oil volume supplied into the cam gear compartment and into the rocker arm compartment is limited to an appropriate amount, to minimize the oil consumption.

- 7 -

Page 12

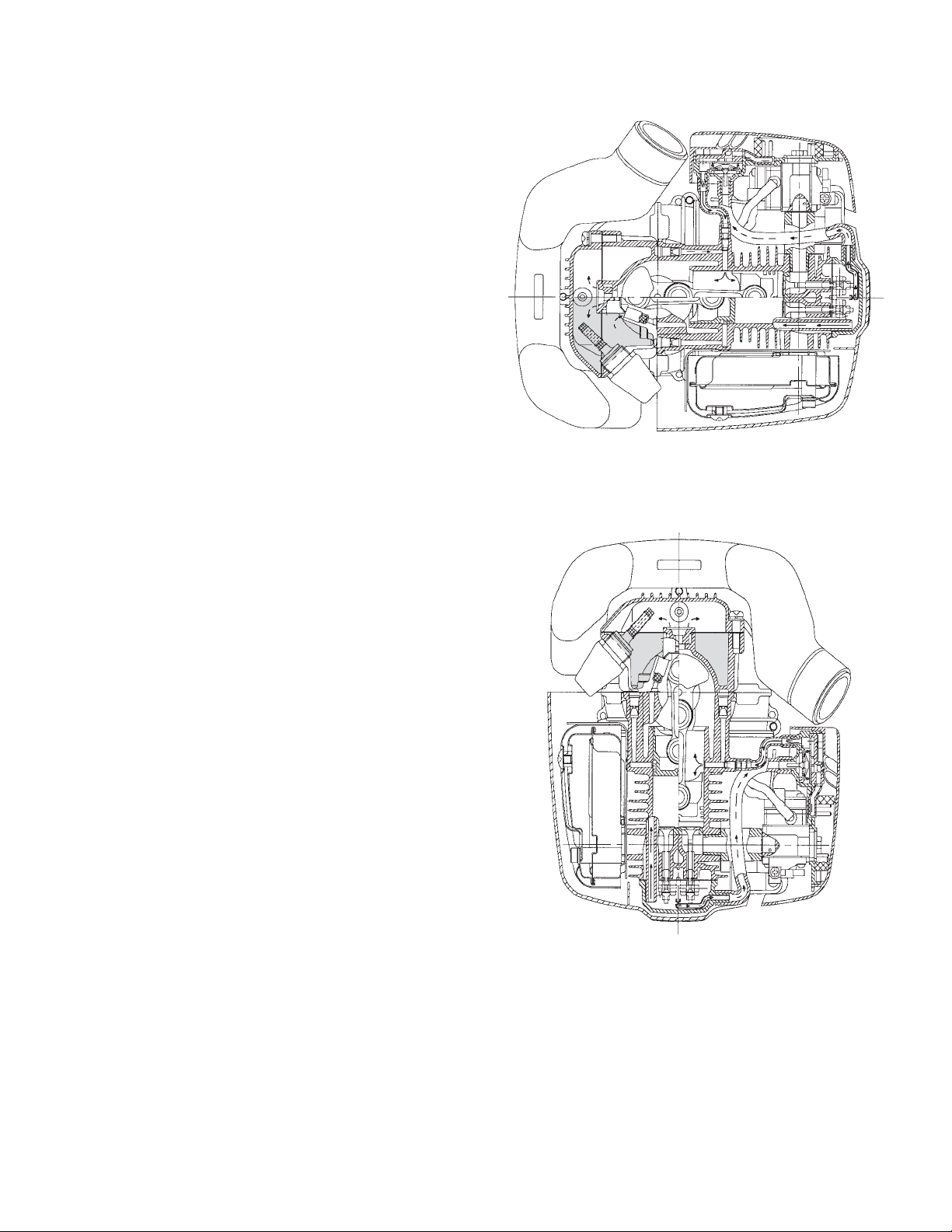

4. GENERAL DESCRIPTION OF ENGINE COMPONENTS

4-1 CYLINDER BLOCK AND CRANKCASE

The cylinder block and crankcase are aluminum

die-castings split in upper and lower parts.

The cylinder block and the cylinder head are a

single piece. The valve seats are molded and the

valve guides (intake valves and exhaust valves)

and the valve stem seal (intake side only) are

press fitted. The cylinder bore is finished with hard

chromium plating.

Fig. 4-1

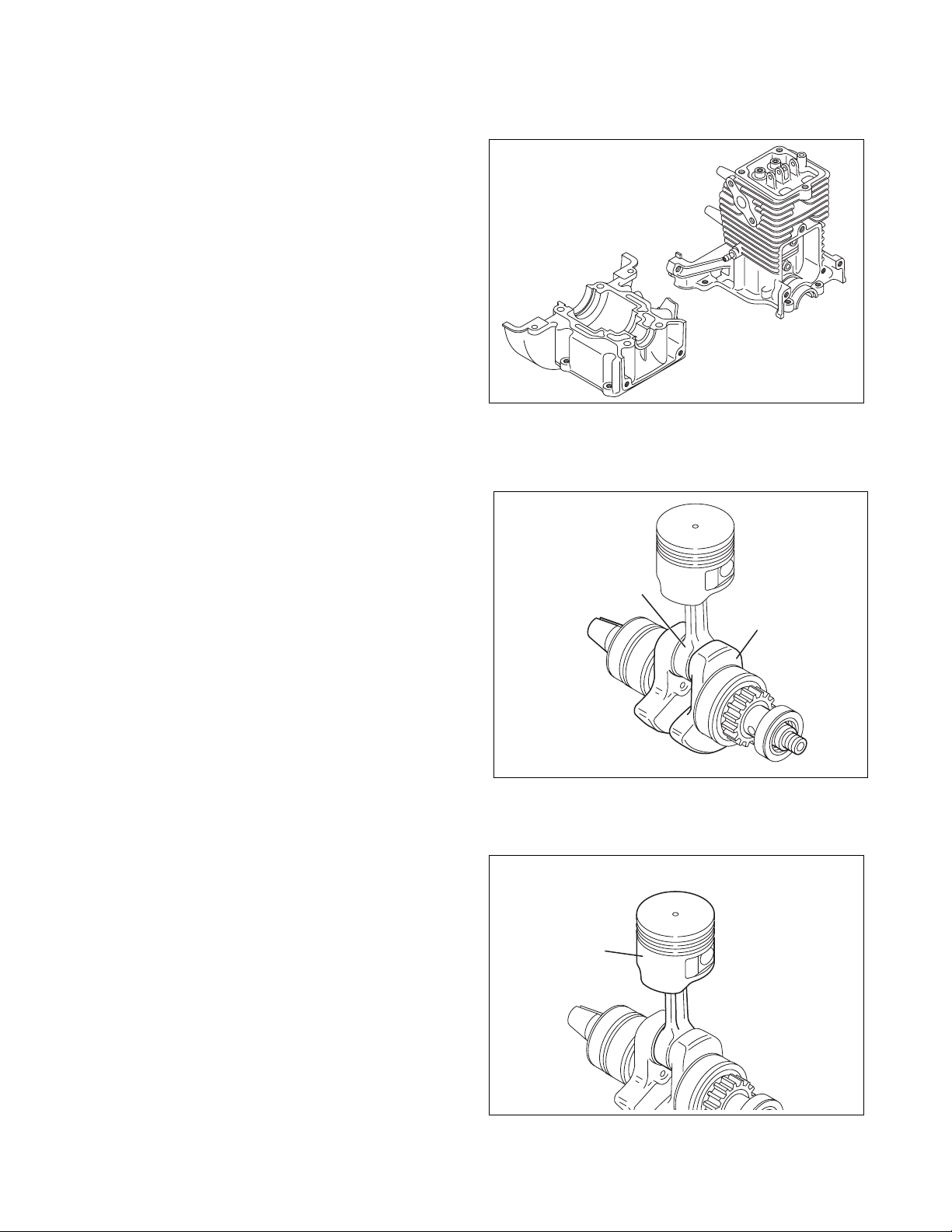

4-2 CRANKSHAFT AND CONNECTING ROD

The crankshaft is made of malleable cast iron, and

the entire crank pin surface is hardened by cementation.

The crank gear is press fitted at the opposite side

to the P.T.O..

CONNECTING ROD

CRANKSHAFT

The connecting rod is a carbon steel casting, and

needle roller bearings are press fitted in the large

and small ends.

4-3 PISTON

The piston is made of high silicon alminun, and

measures are taken to improve its wearing resistance.

Fig. 4-2

PISTON

- 8 -

Fig. 4-3

Page 13

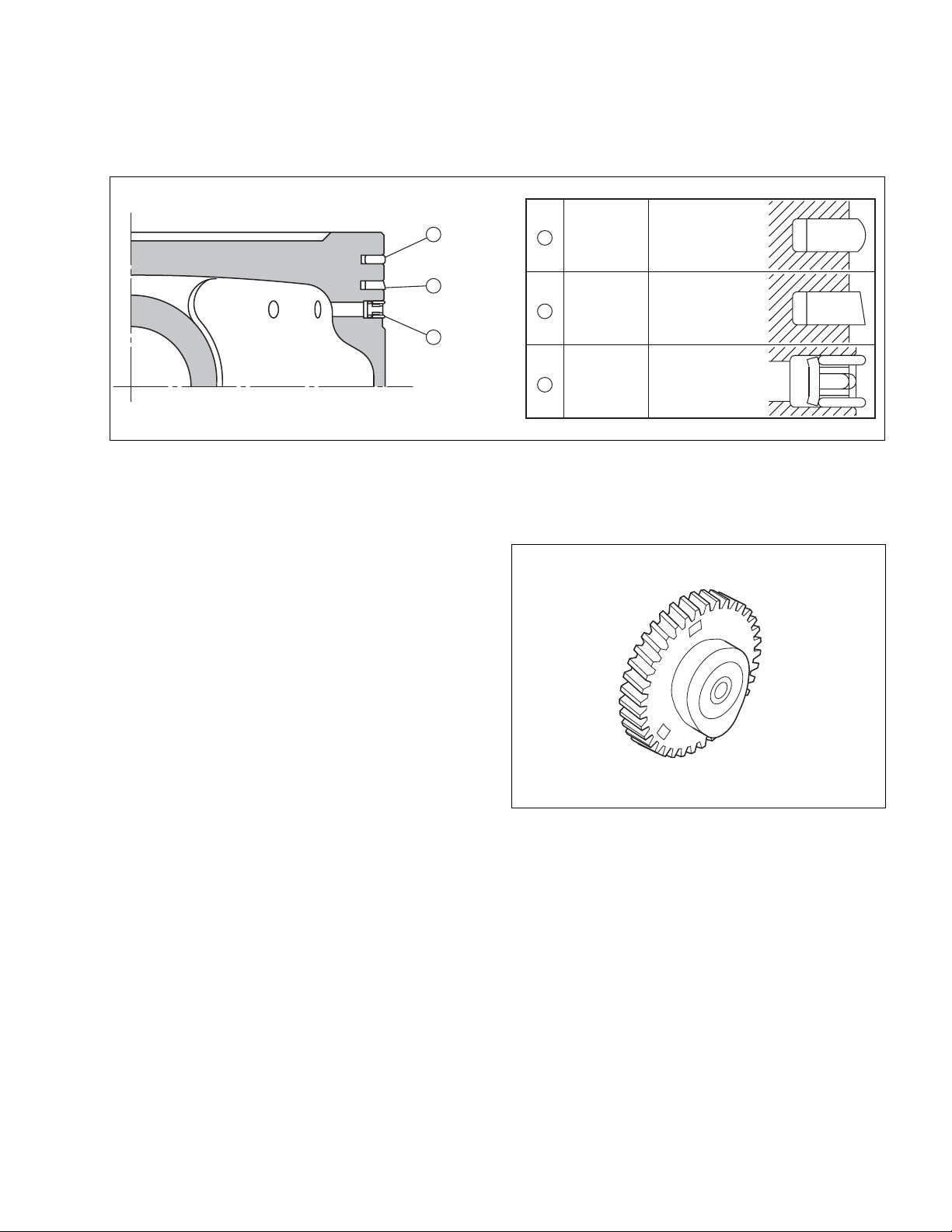

4-4 PISTON RINGS

The piston rings are made of special cast iron. The top ring is a barrel face type, the second ring is a

tapered one, and the oil ring consists of three pieces, so as to reduce the oil consumption.

4-5 CAM GEAR

The cam gear consists of the combination of the

cam and the gear. The cam is a sintered component, widely used in this kind of application. The

gear is made of synthetic resin to reduce both

weight and gear noise.

1

2

3

Fig. 4-4

1

2

3

TOP

RING

SECOND

RING

OIL RING

BARREL

TAPER

THREE-PIECE

ASSEMBLY

4-6 COOLING SYSTEM

Fig. 4-5

This engine adopts the forced air-cooled system, where cooling air is sent to the cylinder block by an

even-pitched cooling fan that works as a flywheel as well. This cooling air is guided properly to the

cylinder block by the baffle plate.

4-7 LUBRICATION SYSTEM

The rotary parts and the sliding parts of the engine are lubricated by lubricant oil, which is forcibly supplied by utilizing the pressure generated by the up-down movement of the piston. Moreover, the oil

compartment is provided separately in order to prevent lubricant oil from flowing directly into the cylinder.

- 9 -

Page 14

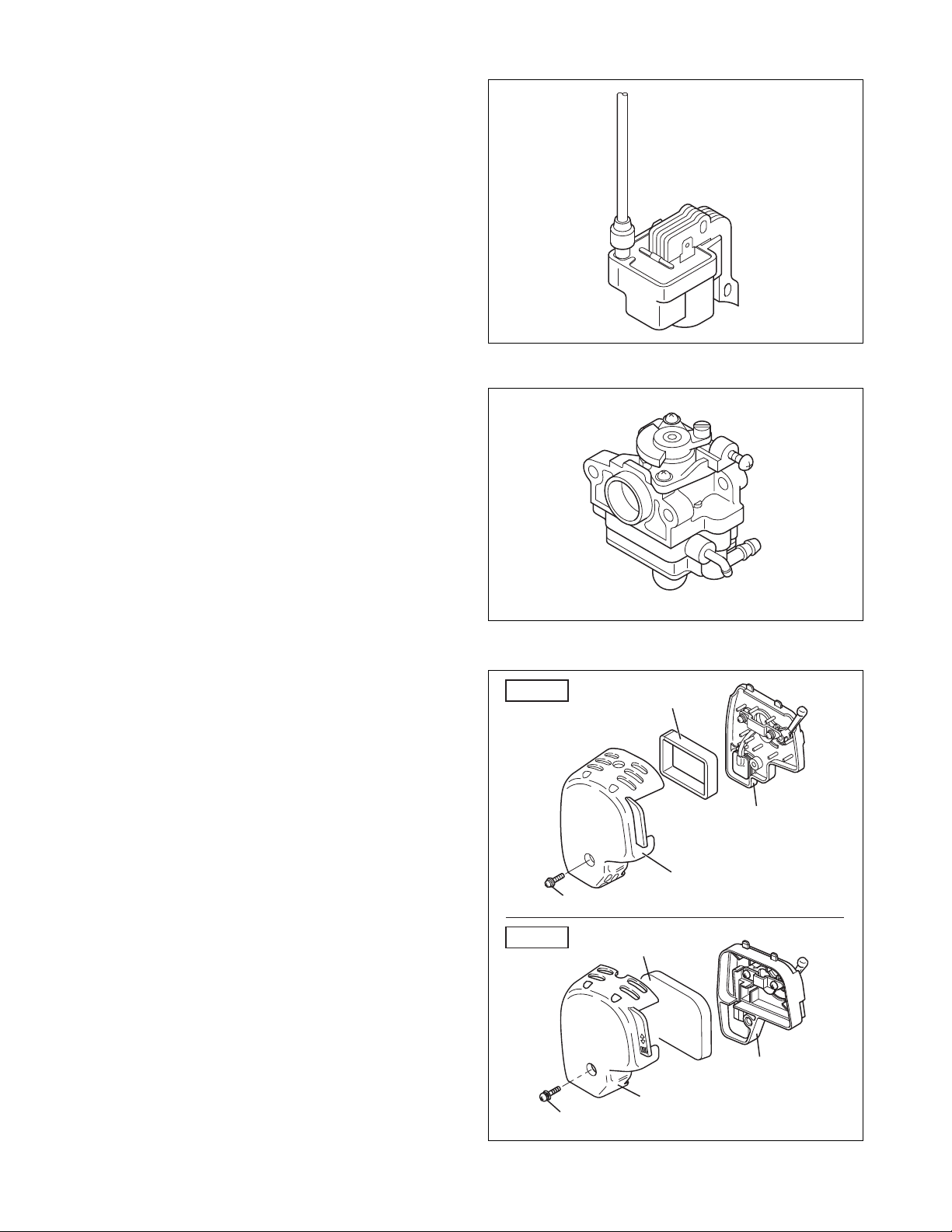

4-8 IGNITION SYSTEM

The ignition system is a TIC flywheel magneto

type. The ignition timing is 25 degrees before the

top dead center.

The magneto consists of the flywheel and the ignition coil. The flywheel (that works as a cooling

fan as well) is mounted on the crankshaft and the

ignition coil is mounted directly on the cylinder

block.

4-9 CARBURETOR

This engine adopts a diaphragm type carburetor.

The carburetor is calibrated carefully for easy starting, good acceleration, low fuel consumption and

sufficient output.

Fig. 4-6

4-10 AIR CLEANER

The air cleaner element is urethane foam (semiwet type).

This air cleaner has a compartment that separates

blow-by gas from lubricant oil.

EH025

EH035

Fig. 4-7

ELEMENT

PLATE

AIR CLEANER COVER

FIXING BOLT

ELEMENT

PLATE

AIR CLEANER COVER

FIXING BOLT

Fig. 4-8

-

10

-

Page 15

4-11 DECOMPRESSION SYSTEM

The decompression equipment is installed inside

the gear of the cam-gear unit. The decompression equipment opens the intake valve before the

compression top to relieve the compression pressure for easy start.

CAMLIFTER

WEIGHT

CRESCENT CAM

Fig. 4-9

-

11

-

Page 16

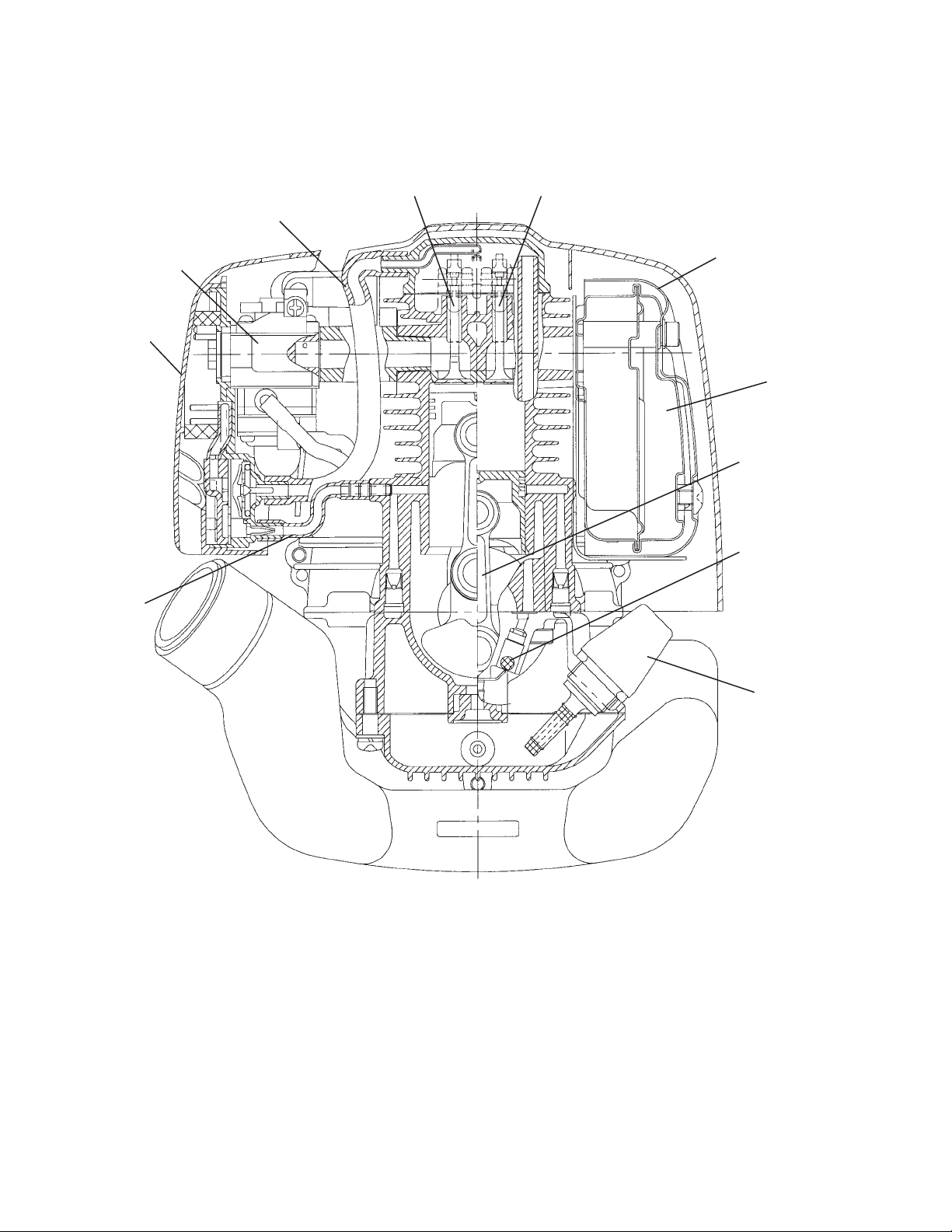

4-12 SECTIONAL VIEW OF ENGINE

CARBURETOR

AIR

CLEANER

RETURN

PIPE

BREATHER PIPE

INTAKE VALVE

EXHAUST VALVE

MUFFLER COVER

MUFFLER

CONNECTING

ROD

CHECK BALL

Fig. 4-10

OIL GAUGE

-

12

-

Page 17

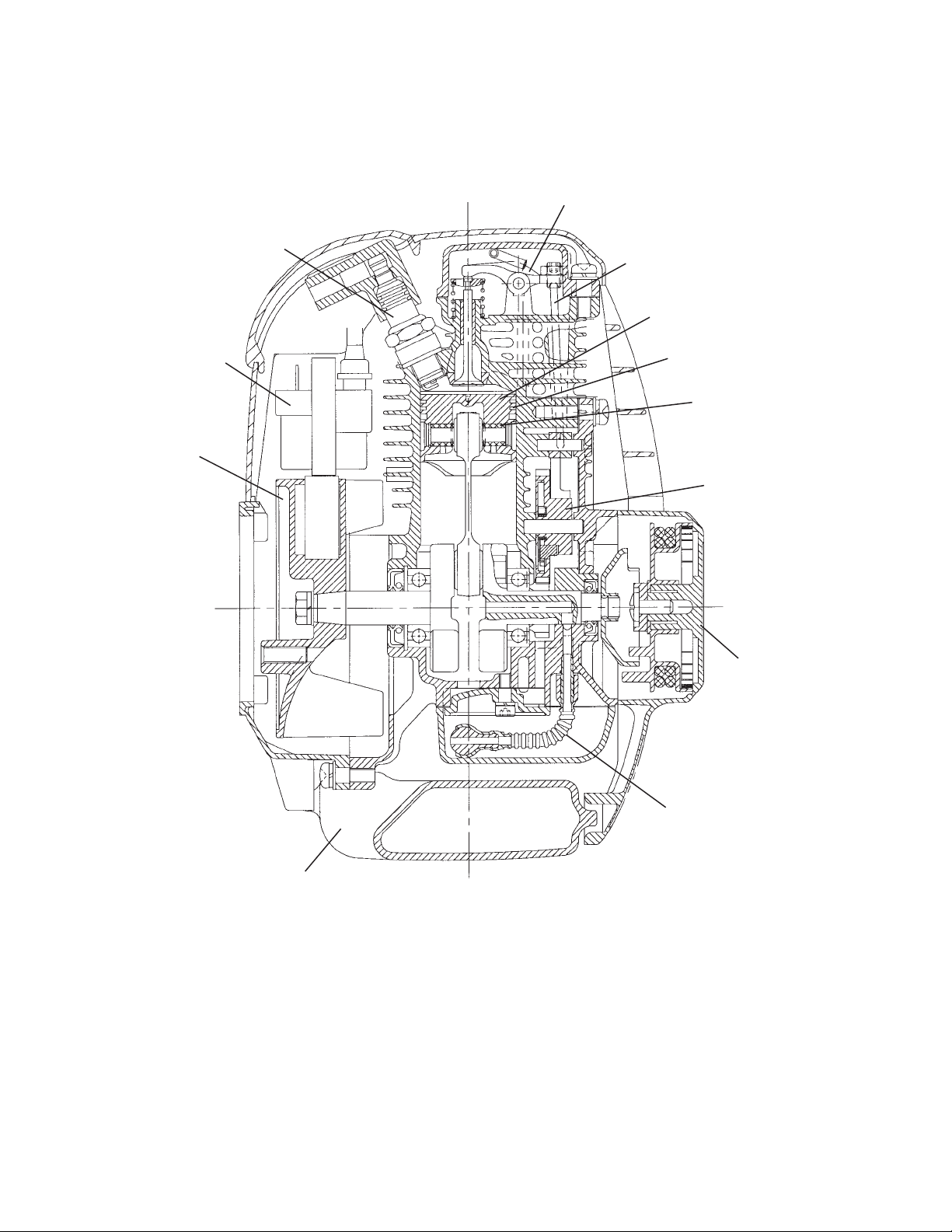

SPARK PLUG

ROCKER ARM

PUSH ROD

PISTON

IGNITION COIL

FLYWHEEL

PISTON RING

PISTON PIN

CAM GEAR

RECOIL

STARTER

FUEL TANK

Fig. 4-11

-

13

-

OIL TUBE

Page 18

5. DISASSEMBLY AND REASSEMBLY

5-1 PREPARATIONS AND SUGGESTIONS

1) When disassembling the engine, memorize the locations of individual parts so that they can be

reassembled correctly. If you are uncertain of identifying some parts, it is suggested attach tags to

them.

2) Have boxes ready to keep disassembled parts by group.

3) To prevent losing and misplacing, temporarily assemble each group of disassembled parts.

4) Carefully handle disassembled parts, and clean them with washing oil if necessary.

5) Use the correct tools in the correct way.

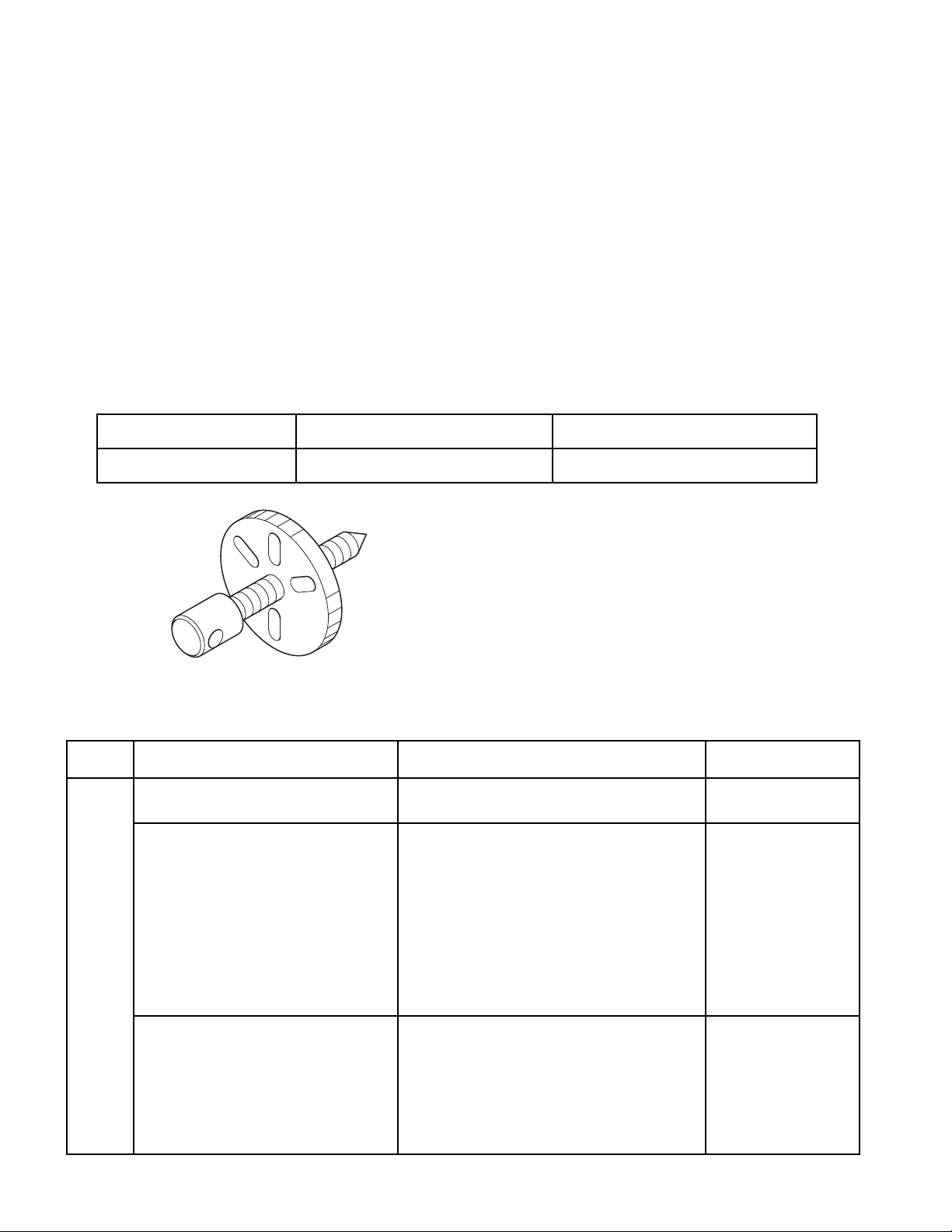

5-2 SPECIAL TOOLS (EH025 ONLY)

Tool No. Tool Use

560-90020-00 Flywheel puller For pulling off the flywheel

Fig. 5-1

5-3 DISASSEMBLY PROCEDURES

Step Parts to remove Remarks and procedures Fasteners

Engine oil drain Remove the oil gauge.

Plug cover, plug cap, stop switch 1)

1

Engine cover Remove engine cover from blower

Remove plug cover from engine

cover.

Remove the plug cap.

2)

Disconnect lead wire of stop

3)

switch from ignition coil

(Except Stop switch : EH035)

*Hold lead wire with plier and pull

it out straight.

housing and recoil.

M5x8 mm: 1 pce.

(EH035)

M5x12 mm: 2 pcs.

(EH025)

M4x16 mm: 2 pcs.

(EH025)

M5x12 mm: 3 pcs.

(EH035)

-

14

-

Page 19

OIL GAUGE

EH025

PLUG COVER

Fig. 5-2

Fig. 5-3

Fig. 5-4

M5 x 8 SCREW : 1 pce.

STOP SWITCH

EH035

PLUG COVER

STEP 1 STEP 1

ENGINE COVER

ENGINE COVER

LEAD WIRE

M5 x 12 SCREW AND

WASHER AY : 1 pce.

M5 SCREW AND

WASHER : 2 pcs.

Fig. 5-5

M4 SCREW AND

WASHER : 2 pcs.

M5 x 12 SCREW AND

WASHER AY : 2 pcs.

-

15

-

Fig. 5-6

Page 20

Step Parts to remove Remarks and procedures Fasteners

Air cleaner, insulator, insulator

carburetor

2

*Breather unit of the air cleaner (plate

separator, check valve)

*Disassemble the breather unit

only if necessary.

1)

Remove air cleaner cover and air

cleaner element.

2)

Remove fuel tube from carburetor,

and then remove breather pipe and

return pipe from cylinder.

It is convenient to use a small-sized

screwdriver to remove tubes.

3)

Remove air cleaner plate.

The air cleaner plate is fastened

together with the carburetor.

4)

Remove insulator and insulator

carburetor.

1)

Remove the plate separator.

Make sure of removing the plate

separator by holding its edge.

When holds the square pipe, there is

risk of damaging the pipe.

2)

Remove the check valve plate

(fastened together with the check

valve) with a small-sized screwdriver.

It is recommendable to pry the hook

of the check valve plate with a screwdriver to remove the plate.

3)

Remove the check valve (1).

M5 x 14 mm ; 1 pc.

M5 x 68 mm; 2 pcs.

M5 x 18 mm ; 2pcs.

M5 x 12 mm ; 1pce.

-

16

-

Page 21

EH025

CHOKE PLATE

PLATE

M5 x 40

SCREW : 2 pcs.

CHOKE LEVER

AIR CLEANER

PLATE

O-RING

CARBURETOR

AIR CLEANER

COVER

M5 x 14 SCREW

AND WASHER

: 1 pce.

PLATE,

SEPARATOR

STEP 2

INSULATOR,

CARBURETOR

GASKET,

CARBURETOR

ELEMENT

CHECK

VALVE

CHECK VALVE

PLATE

GASKET,

SEPARATOR

INSULATOR

M5 x 12 SCREW

AND WASHER : 1 pce.

BREATHER PIPE

CHECK

VALVE (1

O-RING

GASKET,

INSULATOR

M5 x 18

SCREW AND

WASHER : 2 pcs.

SPACER

RETURN

PIPE

)

RETURN PIPE

Fig. 5-8

Fig. 5-9

EH035

CHOKE PLATE

PLATE

M5 x 40

SCREW : 2 pcs.

AIR CLEANER

COVER

M5 x 14 SCREW

AND WASHER

: 1 pce.

PLATE,

SEPARATOR

Fig. 5-7

STEP 2

CHOKE LEVER

CARBURETOR

ELEMENT

O-RING

CHECK VALVE PLATE

CHECK VALVE

GASKET, SEPARETOR

INSULATOR,

CARBURETOR

GASKET,

CARBURETOR

O-RING

AIR CLEANER

PLATE

RETURN PIPE

CHECK VALVE (1

GASKET,

INSULATOR

INSULATOR

M5 x 18 SCREW AND WASHER : 2 pcs.

M5 x 12 SCREW AND WASHER : 1 pce.

)

Fig. 5-10

Fig. 5-11

-

17

-

Page 22

Step Parts to remove Remarks and procedures Fasteners

Muffler and Muffler cover Remove the muffler cover from the

muffler.

The muffler and the muffler cover are

fastened together with two M5 x 40 mm

socket head bolts.

Recoil starter Remove recoil starter from crankcase.

3

Fuel tank Remove fuel tank from housing blower.

Pulley Remove the pulley from the crank-

shaft. Utilize the hole of the pulley, and

remove the pulley by tapping it with a

metallic rod and a hammer. (The thread

is clockwise).

M5 x 5mm; 1 pc.

M5 x 40mm

socket head bolt ;

2 pcs.

M4 x16mm; 2 pcs.

(EH025)

M5 x14mm; 4 pcs.

(EH035)

M5 SOKET HEAD

BOLT : 2 pcs.

HOLE OF THE PULLEY

Fig. 5-12

FUEL

TANK

EH025

Fig. 5-13

STEP 3

PULLEY

M4 SCREW AND

WASHER : 2 pcs.

MUFFLER

GASKET

RECOIL

STARTER

M5 SCREW : 1 pc.

MUFFLER

COVER

MUFFLER

EH035

RECOIL

STARTER

PULLEY

M5 SCREW AND

WASHER : 4 pcs.

-

18

-

Page 23

Step Parts to remove Remarks and procedures Fasteners

Blower housing Remove blower housing from cylinder

and crankcase

4

Clutch Remove the clutch from the flywheel.

EH025

M5 SCREW AND

WASHER : 3 pcs.

BLOWER HOUSING

M6 BOLT,

CLUTCH : 2 pcs.

STEP 4

SPRING

M5 x18mm; 3 pcs.

(EH025)

M5 x16mm; 4 pcs.

(EH035)

M6 x23mm; 2 pcs.

(EH025)

M8 x23.5mm; 2 pcs.

(EH035)

EH035

M5 SOCKET

HEAD BOLT : 4 pcs.

BLOWER HOUSING

CLUTCH

M8 BOLT,

CLUTCH : 2 pcs.

STEP 4

SPRING

CLUTCH

Fig. 5-14

-

19

-

Page 24

Step Parts to remove Remarks and procedures Fasteners

Flywheel 1) Remove flywheel from crankshaft.

*Use the flywheel puller as shown

in the Figure, and remove the flywheel by rotating the center shaft

5

Ignition coil

clockwise.

Remove ignition coil from cylinder

block.

M4 x 20 mm ;

2 pcs.

Spark plug

Remove the spark plug from the cylinder block

SPARK PLUG

STEP 5

IGNITION COIL

Fig. 5-15

M4 SCREW AND

WASHER : 2 pcs.

FLYWHEEL

Fig. 5-16

-

20

-

M6 BOLT AND

WASHER : 1 pce.

Page 25

Step Parts to remove Remarks and procedures Fasteners

Oil case 1)2)Remove oil case from crankcase.

Remove the oil case from the

recoil side of the crankcase, by

tapping the oil case with a plastic

or wooden hammer.

Oil tube and Retainer plate 1)2)Pull out the oil tube, by holding its

6

base. It is recommendable to pry

the oil tube with a small-sized

screwdriver.

Remove retainer plate from crank-

case. When removing the retainer

plate, take care not to lose the

lead valve.

M5 x18 mm;

4 pcs.

M4 x10 mm; 1 pc.

OIL TUBE

LEAD VALVE

RETAINER PLATE

M4 SOCKET HEAD

BOLT : 1 pce.

Fig. 5-18

STEP 6

GASKET, CASE

OIL CASE

M5 SCREW AND

WASHER : 4 pcs.

Fig. 5-17

OIL TUBE

OIL WEIGHT

-

21

-

Page 26

Step Parts to remove Remarks and procedures Fasteners

Rocker cover Remove rocker cover from cylinder

block.

Cam gear cover Remove cam gear cover from cylinder

block.

Cam lifter, Cam gear and

Push rod

7

1)

Position the cam peak portion

down, then remove the cam lifter

shaft, and remove the cam lifter.

2)

Remove the cam gear shaft, and

remove the cam gear.

3)

Remove the push rod.

Rocker arm Remove the rocker arm shaft, then re-

move the rocker arm. Hold the rocker

arm shaft, that can be seen between

the intake and exhaust rocker arm,

with pincers, then remove the shaft.

M5 SCREW AND

WASHER : 3 pcs.

M5 x 16mm ; 3 pcs.

(EH025)

M5 x 16mm ; 4 pcs.

(EH035)

M5 x 14mm ; 3 pcs.

ROCKER ARM

ADJUSTING SCREW

STEP 7

GASKET,

ROCKER COVER

ROCKER SHAFT

ROCKER COVER

PUSH ROD

GASKET,

CAMGEAR COVER

CAMGEAR COVER

CAMLIFTER

SHAFT

M5 SCREW AND

WASHER : 3 pcs.

CAMLIFTER

CAMGEAR

Fig. 5-19

CAMGEAR SHAFT

Fig. 5-20

-

22

-

Page 27

Step Parts to remove Remarks and procedures Fasteners

Crankcase Remove the crankcase from the

cylinder block by tapping it with a

plastic or wooden hammer from the

recoil side. Take care not to lose the

check balls (2 pcs.) that are held by

8

the washer of the screw.

Crankshaft Remove crankshaft from cylinder

block. When removing the crankshaft

from the cylinder block, take care not

to damage the oil seal.

M5 x 14mm ; 8 pcs.

(EH025)

M5 x 16mm ; 4 pcs.

(EH035)

M5 x 33mm ; 4 pcs.

(EH035)

M5 SOCKET HEAD

BOLT : 8 pcs.

Fig. 5-21

CYLINDER BLOCK

STEP 8

CRANKSHAFT

CRANKCASE

Fig. 5-22

-

23

-

Page 28

Step Parts to remove Remarks and procedures Fasteners

Valve, Valve spring and

9

Spring retainer

Hold the valve from the inner side of the

cylinder, then push the spring retainer

and remove it by sliding.

SPRING RETAINER

VALVE SPRING

STEP 9

INTAKE VALVE

EXHAUST VALVE

Fig. 5-23

SPACER

Fig. 5-24

-

24

-

Page 29

Step Parts to remove Remarks and procedures Fasteners

Piston and Piston ring 1)2)Remove the two piston clips, take

out the piston pin, and then

remove the piston from the small

end of the connecting rod.

When removing the piston, take

care to prevent dust from getting in

the bearing at the connecting rod

10

small end.

To remove the two piston rings

and the oil ring, open wide the

open end of the rings and remove

them from the piston.

Take care not to widen the open

end of the rings too much, or the

rings may break.

CLIP

PISTON

STEP 10

PISTON RING

PISTON PIN

CLIP

CRANKSHAFT

Fig. 5-25

-

25

-

Page 30

5-4 REASSEMBLY PROCEDURES

● PRECAUTIONS FOR REASSEMBLY

1) Clean parts thoroughly before reassembly.

Pay most attention to cleanliness of piston, cylinder, crankshaft, connecting rod and bearings.

2) Scrape off all carbon deposits from cylinder head, piston top and piston ring grooves.

3) Check lip of oil seals. Replace oil seal if the lip is damaged. Apply oil to the lip before reassembly.

4) Replace all the gaskets with new ones.

5) Replace keys, pins, bolts, nuts, etc., if necessary.

6) Torque bolts and nuts to specification referring to the "TORQUE SPECIFICATIONS".

7) Apply oil to rotating and sliding portions.

8) Check and adjust clearances and end plays where specified in this manual.

9) Check resistance and/or noise by rotating parts by hand, when reassemble main parts.

5-4-1 CYLINDER BLOCK, VALVE SPRING AND SPRING RETAINER

(1) Before reassemble, apply 4 cycle engine oil

(10W-30) to cylinder inner surface, piston slide

face and valve guide holes.

SPRING RETAINER

(2) Install valve spring and spring retainer as

shown in Fig. 5-26. Push spring retainer down

until valve stem comes through the hole of

spring retainer, then slide the spring retainer.

1.INSERT THE

VALVE SPRING

2.SLIDE THE

SPRING RETAINER

SPRING

RETAINER

VALVE

SPRING

Fig. 5-26

VALVE SPRING

SPACER MOUNTING

POSITION

INTAKE VALVE

SPACER

EXHAUST VALVE

Fig. 5-27

-

26

-

Page 31

5-4-2 CONNECTING ROD, PISTON AND PISTON RINGS

Install the piston on the connecting rod

(1) After installing the piston rings, apply 4-cycle engine oil to the rings.

NOTE ;

Install the top ring and the second ring with their open ends displaced by 180 degrees. When installing a

new ring, place the white mark at the right-hand side, and when reassembling a used one, install it with

the contact face down.

WHITE MARK

CLIP

PISTON

1

2

3

PISTON RING

PISTON PIN

CLIP

Fig. 5-28

1

2

3

TOP

RING

SECOND

RING

OIL RING

BARREL

TAPER

THREE-PIECE

ASSEMBLY

CRANKSHAFT

APPLY GREASE

ON THE INNER FACE

Fig. 5-29

-

27

-

Page 32

5-4-3 CYLINDER BLOCK AND CRANKCASE

Installing cylinder block and crankcase

Make sure that the liquid packing (Three Bond 1216) is evenly applied on the crankcase before installing

the cylinder block.

Tightening torque of the hexagonal socket head bolts (8 pce.) of the lower part of the crankcase :

Tightening torque : 4.5 - 6.5 N・m

(45 - 65 kgf・cm)

(3.3 - 4.7 ft・lb.)

M5 SOCKET HEAD

BOLT : 8 pcs.

CYLINDER

BLOCK

CRANKCASE

LOWER PART

Tightening order

6

1

Fig. 5-30

4

7

Fig. 5-31

2

LIQUID PACKING

(THREE BOND 1216)

8

3

5

M5 SOCKET HEAD

BOLT : 8 pcs.

DO NOT APPLY LIQUID

PACKING IN EXCESS

CRANKCASE

M5 x 16 SOCKET

HEAD BOLT : 4 pcs.

Fig. 5-32

M5 x 33 SOCKET

HEAD BOLT : 4 pcs.

-

28

Fig. 5-33

-

Page 33

5-4-4 OIL CASE

Install the lead valve with the cutout facing to the

oil filling port.

Retainer plate M4 x 10 mm hexagonal socket head

bolt (1 pc.)

Oil case M5 x 18 mm screw, and washer (4 pcs.)

Tightening torque

M4 BOLT M5 SCREW

3 - 4 N・m

(30 - 40 kgf・cm)

(2.2 - 2.9 ft・lb.)

4 - 5.5 N・m

(40 - 55 kgf・cm)

(2.9 - 4.0 ft・lb.)

M4 SOCKET HEAD

BOLT : 1 pce.

RETAINER PLATE

LEAD VALVE

CUTOUT

OIL CASE

GASKET, CASE

M5 SCREW AND

WASHER : 4 pcs.

OIL WEIGHT

OIL TUBE

*ASSEMBLE

SEPARATELY

CRANKCASE

LOWER PART

Fig. 5-34

-

29

-

Page 34

5-4-5 FLYWHEEL

Installing the flywheel

Degrease the crankshaft and the tapered portion

of the flywheel perfectly when installing them.

Align the flywheel key with the crankshaft key

groove.

Flywheel tightening bolt M6 x 16 mm, with spring

washer :

Tightening torque : 9 - 12 N・m

(90 - 120 kgf・cm)

(6.5 - 8.8 ft・lb.)

Fig. 5-35

FLYWHEEL

5-4-6 IGNITION COIL

Installing the ignition coil (Air gap adjustment)

Air gap :0.3 mm

Ignition coil tightening torque

M4 x 20 mm, with washer and spring washer

(2 pcs.)

NOTE :

Measure the air gap between the flywheel magnet and the ignition coil.

Tightening torque : 2 - 4 N・m

(20 - 40 kgf・cm)

(1.4 - 2.9 ft・lb.)

M6 BOLT AND

WASHER : 1 pc.

Fig. 5-36

PLUG CAP

THICKNESS GAUGE

IGNITION

COIL

FLYWHEEL

Fig. 5-37

-

30

-

Page 35

5-4-7 BLOWER HOUSING

Installing the blower housing.

Blower housing tightening torque

M5 x 18 mm Screw : 3 pcs. (EH025)

M5 x 16 mm Socket hesd bolt : 4 pcs. (EH035)

Tightening torque : 4 - 5.5 N・m

(40 - 55 kgf・cm)

(2.9 - 4.0 ft・lb.)

5-4-8 CAM GEAR

Installing the cam gear.

(1) Align the mark punched on the flywheel (key

position groove) with the timing mark on the

ignition coil.

M5 SCREW AND

WASHER : 3 pcs.

BLOWER HOUSING

Fig. 5-38

TIMING MARK

(2) Install the cam gear with the cam top facing

down vertically (use the timing mark for

reference).

TIMING MARK

Fig. 5-40

Fig. 5-39

CAMGEAR

SHAFT,

CAMGEAR

Fig. 5-41

-

31

-

Page 36

5-4-9 PUSH ROD, CAMLIFTER AND ROCKER ARM

Installing the push rod, cam lifter and rocker arm

(1) Apply sufficient oil in the rocker shaft hole.

(2) Install the cam lifter.

(3) Pass the push rod through the hole of the cyl-

inder block. Align the push rod end with the

cam lifter ball groove.

APPLY A SUFFICIENT AMOUNT OF OIL

Fig. 5-42

ADJUSTING SCREW

BALL

GROOVE

PUSH ROD

BALL

GROOVE

(4) Install the rocker arm assembly. Align the push

rod end with the ball groove of the adjusting

screw.

-

32

CAM LIFTER

Fig. 5-43

ROCKER

ARM

ADJUSTING

SCREW

PUSH ROD

CAM LIFTER SHAFT

CAM LIFTER

Fig. 5-44

-

Page 37

5-4-10 CAMGEAR COVER

Installing the cam gear cover

Before installing the cam gear cover, apply oil on

the camgear and the cam lifter sliding surface.

Camgear cover tightening torque M5 x 14 mm

screw (3 pcs.)

Tightening torque : 4 - 5.5 N・m

(40 - 55 kgf・cm)

(2.9 - 4.0 ft・lb.)

CAMGEAR COVER

Fig. 5-45

GASKET,

CAMGEAR COVER

CAMGEAR COVER

5-4-11 VALVE CLEARANCE ADJUSTMENT

Loosen the nut and adjust the valve clearance by

rotating the adjusting screw with a hexagon bar

wrench. Adjust the valve clearance at the compression top dead center.

After the adjustment, tighten the nut firmly.

Valve clearance : 0.15 mm

(0.0059 in.)

Tightening torque : 5 - 6.5 N・m

(50 - 65 kgf・cm)

(3.6 - 4.7 ft・lb.)

M5 SCREW AND

WASHER : 3 pcs.

Fig. 5-46

THICKNESS GAUGE

ADJUSTING SCREW

Fig. 5-47

-

33

-

Page 38

5-4-12 ROCKER COVER

Before installing the rocker cover, apply oil on the

sliding surfaces of the rocker arm and the valve

stems.

Rocker cover tightening torque

ROCKER COVER

M5 SCREW AND

WASHER : 3 pcs.

M5 x 16 mm screw : 3 pcs. (EH025)

M5 x 16 mm screw : 4 pcs. (EH035)

GASKET,

ROCKER COVER

Tightening torque : 4 - 5.5 N・m

(40 - 55 kgf・cm)

(2.9 - 4.0 ft・lb.)

5-4-13 PULLEY, FUEL TANK AND RECOIL STARTER

Install the pulley on the crankshaft.

Pulley tightening torque :

Tightening torque : 4 - 5.5 N・m

(40 - 55 kgf・cm)

(2.9 - 4.0 ft・lb.)

Install the tank on the main bearing cover.

Install the recoil on the crankcase.

Recoil tightening torque

M4 x 16 mm screw : 2 pcs. (lower side) (EH025)

Tightening torque : 1 - 2.5 N・m

(10 - 25 kgf・cm)

(0.7 - 1.8 ft・lb.)

M5 x 14 mm screw : 4 pcs. (EH035)

PLATE

PLATE

Fig. 5-48

M5 SOCKET HEAD BOLT : 2 pcs.

MUFFLER COVER

M5 SCREW

: 1 pce.

MUFFLER

GASKET, MUFFLER

A

FUEL TANK

Tightening torque : 1 - 2.5 N・m

(10 - 25 kgf・cm)

(0.7 - 1.8 ft・lb.)

5-4-14 MUFFLER AND MUFFLER GASKET

Install the gasket, muffler and muffler cover on

the cylinder head exhaust port.

M5 x 40 mm socket head bolt (2 pcs.)

M5 x 5 mm screw (1 pc.)

Tightening torque

M5 BOLT M5 SCREW

7 - 9 N・m

(70 - 90 kgf・cm)

(5.1 - 6.5 ft・lb.)

3 - 5 N・m

(30 - 50 kgf・cm)

(2.2 - 3.6 ft・lb.)

DAMPER

EH025

PULLEY

RECOIL

STARTER

A

M4 SCREW AND

WASHER : 2 pcs.

Fig. 5-49

-

34

-

EH035

A

PULLEY

M5 SCREW AND

WASHER : 4 pcs.

RECOIL

STARTER

Page 39

5-4-15 INSULATOR AND INSULATOR CARBURETOR

Cover the insulator on the insulator carburetor and

tighten them together.

M5 x 18 mm screw : 2 pcs. (EH025, EH035)

M5 x 12 mm screw : 1 pc. (EH025, EH035)

Tightening torque : 4 - 5.5 N・m

(40 - 55 kgf・cm)

(2.9 - 4.0 ft・lb.)

NOTE :

The end face of the adjustment screw shall be

aligned with the insulator end face (no protrusion).

The angular side of the gasket shall face up.

EH025

INSULATOR,

CARBURETOR

M5 x12

SCREW AND

WASHER : 1 pc.

EH035

INSULATOR,

CARBURETOR

INSULATOR

GASKET,

INSULATOR

INSULATOR

M5 x 18 SCREW AND

WASHER : 2 pcs.

GASKET,

INSULATOR

M5 x12 SCREW AND

WASHER : 1 pc.

Approx. 2 mm

M5 x 18 SCREW AND

WASHER : 2 pcs.

Fig. 5-50

Alignment

Fig. 5-51

-

35

-

Page 40

5-4-16 CARBURETOR AND AIR CLEANER

(a) Assemble the plate, choke plate, air cleaner plate, carburetor, gasket carburetor, spacer, o-ring,

breather pipe and return pipe.

NOTE :

When installing the choke plate, keep the choke lever fully closed. (lever touching the upper stopper).

Apply grease or silicone on the choke plate after installing it.

Air cleaner tightening torque Air cleaner tightening torque

M5 x 68 mm screw : 2 pcs. M5 x 14 mm screw : 1 pce.

Tightening torque : 2 - 4 N・m

(20 - 40 kgf・cm)

(1.4 - 2.9 ft・lb.)

EH025

CHOKE LEVER

CHOKE PLATE

PLATE

M5 SCREW

: 2 pcs.

AIR CLEANER

COVER

M5 SCREW

AND WASHER

: 1 pce.

PLATE,

SEPARATOR

ELEMENT

CHECK VALVE

GASKET, SEPARATOR

AIR CLEANER

PLATE

CHECK

VALVE (1

O-RING

CHECK VALVE

PLATE

GASKET,

CARBURETOR

CARBURETOR

O-RING

SPACER

BREATHER PIPE

RETURN

PIPE

)

Tightening torque : 0.5 - 1 N・m

(5 - 10 kgf・cm)

(0.35 - 0.7 ft・lb.)

EH035

CHOKE PLATE

PLATE

M5 SCREW

: 2 pcs.

AIR CLEANER

COVER

M5 SCREW AND

WASHER : 1 pce.

PLATE,

SEPARATOR

CHOKE LEVER

CARBURETOR

O-RING

ELEMENT

CHECK VALVE (1

O-RING

CHECK VALVE

PLATE

CHECK VALVE

GASKET, SEPARATOR

GASKET,

CARBURETOR

AIR CLEANER

PLATE

BREATHER PIPE

RETURN PIPE

)

Fig. 5-52

STOPPER (UPPER)

-

36

-

STOPPER

(LOWER)

STOPPER (UPPER)

STOPPER

(LOWER)

CHOKE OPENCHOKE CLOSE

Fig5-53

Page 41

(b) Connect the fuel tank tube to the fuel joint of

the carburetor. (Check the bent of the tube).

(c) Connect the return pipe to the pipe joint at the

center of the cylinder.

BREATHER PIPE

HOSE CLAMP

AIR CLEANER PLATE

UPPER CLAW

(d) Connect the breather pipe to the pipe on the

rocker cover and fasten it with the hose clamp.

(e) Install the air cleaner cover after hooking it on

the upper claw of the air cleaner plate.

5-4-17 SPARK PLUG

Installing the spark plug.

Tightening torque : 9 - 13 N・m

(90 - 130 kgf・cm)

(6.5 - 9.4 ft・lb.)

RETURN

PIPE

TUBE

TUBE

Fig. 5-54

5-4-18 CLUTCH

Install the clutch with the “← ”(EH025),

“R”(EH035) mark on the clutch shoe at the front

side (facing the assembly worker).

Bolt (clutch)

M6 x 23mm : 2 pcs. (EH025)

M8 x 23.5mm : 2 pcs. (EH035)

Tightening torque : 7.5 - 10 N・m

(75 - 100 kgf・cm)

(5.4 - 7.2 ft・lb.)

M6 BOLT : 2 pcs. (EH025)

M8 BOLT : 2 pcs. (EH035)

SPRING

CLUTCH

Fig. 5-55

-

37

-

Page 42

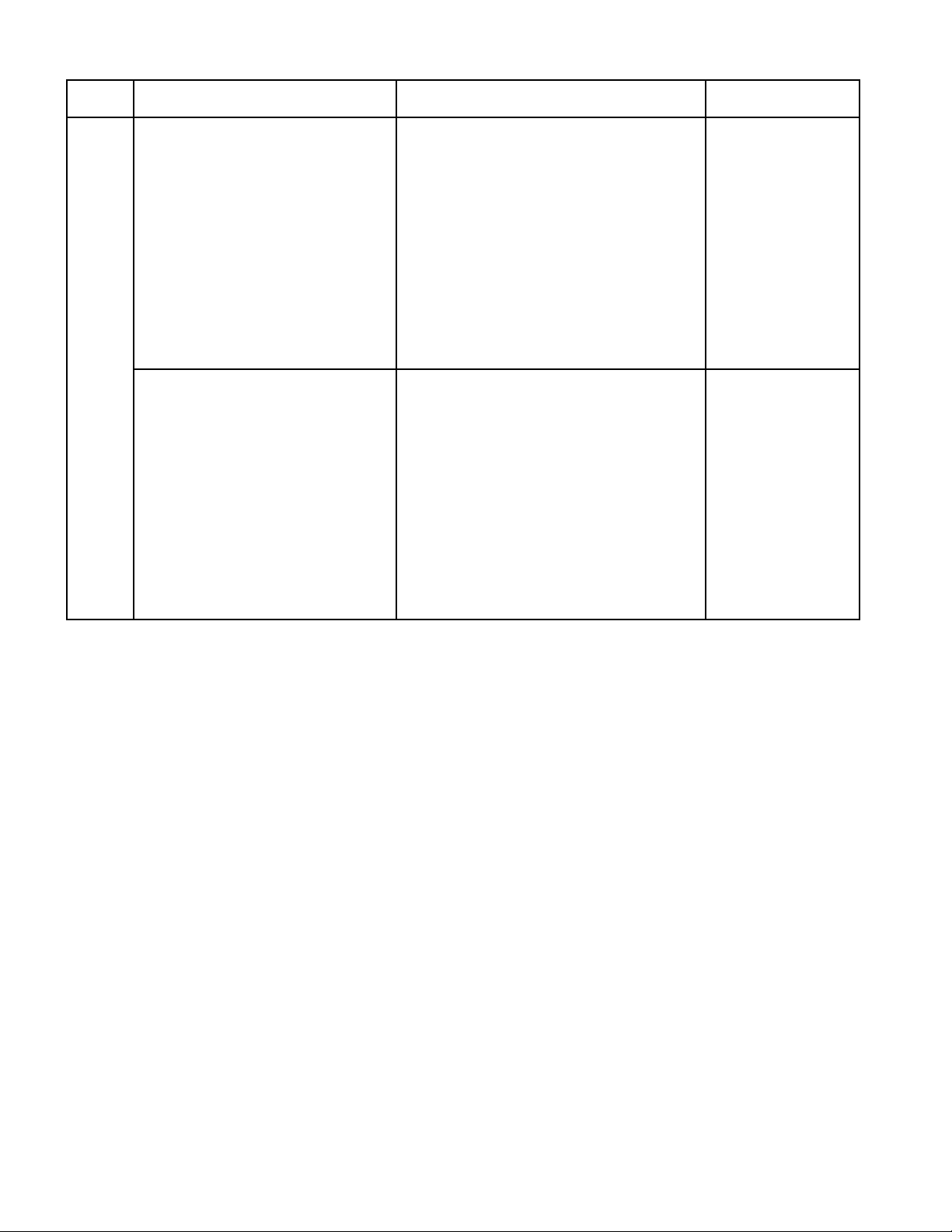

5-4-19 ENGINE COVER, STOP SWITCH AND PLUG COVER

Installing the engine cover, stop switch and plug

cover.

(1) Assemble the stop switch on the engine cover

in advance. Connect the stop switch wire to

the terminal of the switch. (EH025)

(2) Faston terminals (2 places) from the stop

switch. (EH025)

Either Faston terminal can be connected with

the coil terminal. (EH025)

Faston terminals (2 places) of the coil. (EH025)

The cylinder side is the grounding terminal.

(EH025)

※ Install the engine cover by placing it on the

engine from above, and screw its front side

on the blower housing (two places) and its rear

side on the crankcase (two places). (screw the

rear side together with the recoil).

MUFFLER

NOTE :

When installing the engine cover, make sure that

there is no coil terminal disconnected and no high

voltage cord bent.

ENGINE COVER

Fig. 5-56

THE INSULATOR CARBURETOR

SHALL BE PLACED INSIDE.

Fig. 5-57

-

38

-

Page 43

(4) Install the plug cover by hooking the lower claw on

the engine cover first and then fitting its upper part.

M5 x 12 mm screw (2 pcs.) (EH025,EH035)

Tightening torque : 2 - 4 N・m

(20 - 40 kgf・cm)

(1.4 - 2.9 ft・lb.)

M5 x 8 mm screw (1 pce.) (EH035)

Tightening torque : 1.5 - 3 N・m

(15 - 30 kgf・cm)

(1.1 - 2.1 ft・lb.)

M4 x 16 mm screw (2 pcs.) (EH025) M5 x 14 mm screw (1 pce.) (EH035)

Tightening torque : 1 - 2 N・m

(10 - 20 kgf・cm)

(0.7 - 1.4 ft・lb.)

EH025

PLUG COVER

STOP SWITCH

ENGINE COVER

EH035

PLUG COVER

ENGINE COVER

Tightening torque : 1 - 2 N・m

(10 - 20 kgf・cm)

(0.7 - 1.4 ft・lb.)

M5 x 8 SCREW : 1 pce.

M5 x 14 SCREW

AND WASHER

M5 x 12 SCREW AND

WASHER : 2 pcs.

M4 x 16 SCREW AND

WASHER : 2 pcs.

Fig. 5-58

-

M5 x 12 SCREW AND

WASHER AY : 2 pcs.

39

-

Page 44

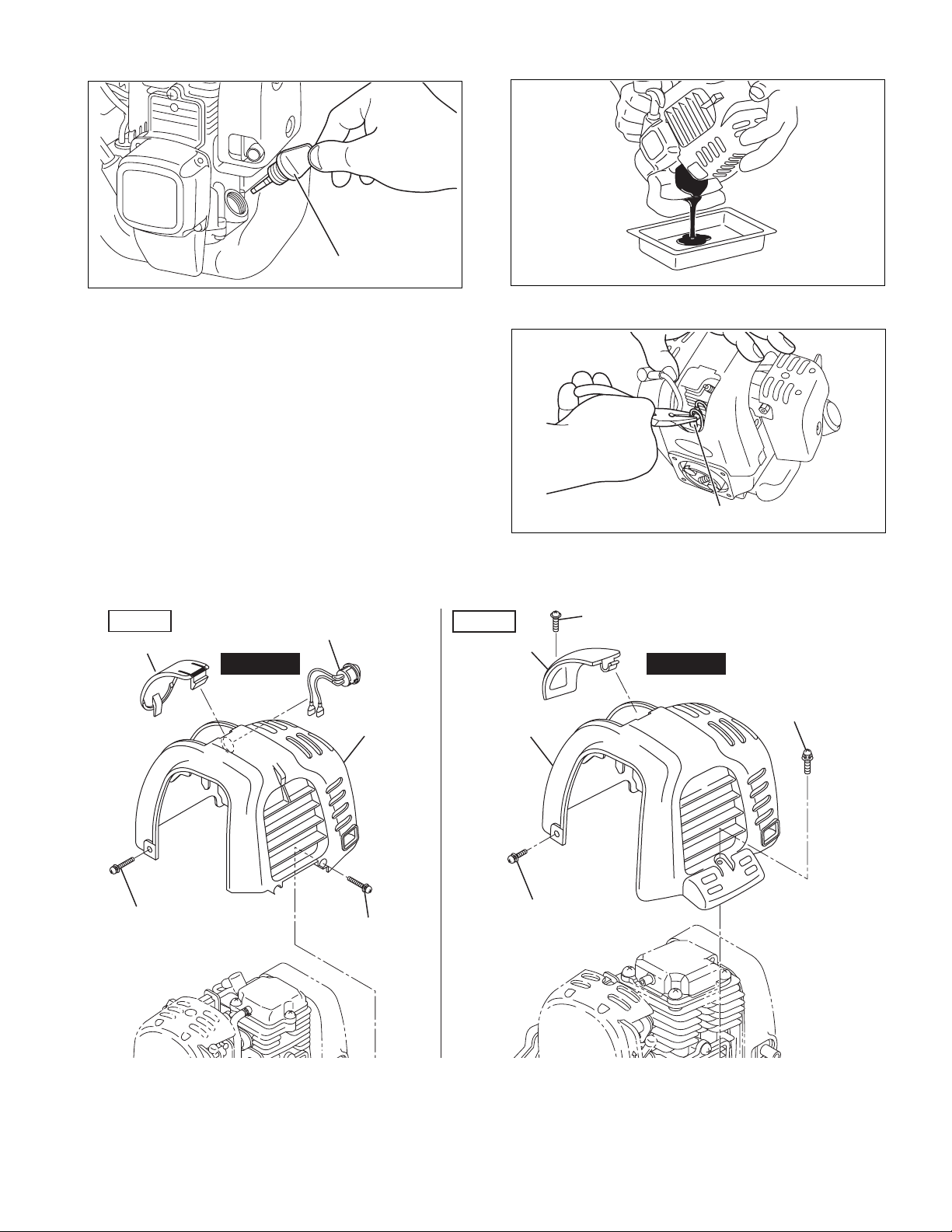

5-4-20 ENGINE OIL, OIL GAUGE

(1) Place the engine horizontally and fill oil from

the oil filling port up to the threaded mouth.

Use Robin genuine oil or engine oil class SF

or higher.

Oil capacity : EH025 0.08L (80 cc)

EH035 0.10L (100 cc)

(2) After filling oil, tighten the oil gauge.

(3) Test run

An engine that has been completely overhauled should be thoroughly RUN-IN, especially when the cylinder, piston rings, valves,

etc., have been changed with new ones.

-

End of the reassembly

-

OIL GAUGE

Fig. 5-59

Fig. 5-60

UPPER LIMIT

(

MOUTH OF THE OIL

CHARGING PORT

OIL LEVEL

)

-

40

-

Page 45

6. MAGNETO

6-1 FLYWHEEL MAGNETO

The ignition system of the EH025 is the T.I.C. (Transistor, Igniter, Circuit) point less ignition system.

6-2 IGNITION OF MAGNETO

When the engine does not start, has difficulty in starting or does not run correctly, carry out the following

checks for magneto failure.

(1) Check carefully the high voltage wiring for damage and short-circuit.

(2) Check the spark.

1) Remove the spark plug from the cylinder and connect the spark plug with the plug cap and ground

it to the cylinder. (The electrode gap of the spark plug should be 0.7 to 0.8 mm.)

2) Rotate the flywheel by pulling the recoil starter and check the spark and examine the intensity of

the spark.

3) If the plug does not spark, remove the spark plug and the plug cap, place the high voltage wire end

a few millimeters away from the cylinder, pull the recoil starter and check whether the high voltage

wire end sparks.

-

41

-

Page 46

7. AUTOMATIC DECOMPRESSION SYSTEM

7-1 FUNCTIONS AND MECHANISM

The decompression system is installed on the cam in order to open the intake valve and relieve the

compression pressure at the first half of the engine compression cycle. The flyweight installed inside the

cam gear has an appropriate shape (weight) to have the effect of the centrifugal force, and the end of the

rotary shaft has a crescent cam shape. Since the gravity force on the weight is larger than the centrifugal

force on the weight at the low cam gear revolution when starting, the crescent cam projects the cam

profile and lifts up the follower of the cam lifter, opens the intake valve.

FLYWEIGHT

CAMLIFTER

CRESCENT

CAM

ROTATION

Fig. 7-1

When the engine is running, the crescent cam is retracted into the camshaft profile because the centrifugal force applied onto the flyweight becomes larger than the gravity force and the decompression turns

OFF.

FLYWEIGHT

CAMLIFTER

CRESCENT

CAM

ROTATION

Fig. 7-2

7-2 INSPECTION

(1) When assembling the cam gear assembly, be sure that the spring hook is hooked on the flyweight.

(2) Be sure that the flyweight moves smoothly.

-

42

-

Page 47

8. CARBURETOR

8-1 OPERATION AND CONSTRUCTION

8-1-1 FUNCTIONS AND CONSTRUCTION OF THE DIAPHRAGM SYSTEM

This engine is equipped with a diaphragm type carburetor.

Since the fuel level is kept constant, irrespective of the tilting angle of the engine, it can be operated at

any position. The float chamber is provided with a diaphragm and is covered with a cover . When negative

pressure is generated in the air intake, the diaphragm bulges up, thereby pushing up the metering lever

and opening the inlet needle valve. When the negative pressure disappears, the spring forces the valve

shut. Therefore, fuel flow rate can be controlled by appropriately determining the diaphragm area and the

spring load.

AIR INTAKE

INLET NEEDLE VALVE

JET

DIAPHRAGM

ASSEMBLY

Fig. 8-1

FUEL

METERING LEVER

FUEL

-

43

-

Page 48

8-2 DISASSEMBLY AND REASSEMBLY

14

13

3

15

16

20

21

22

23

24

17

18

19

12

2

1

4

5

6

8

9

10

11

25

1. Screw

2. Plug

3. Swivel

4. Washer

5. Ring, spring retaining

6. Valve assembly, throttle

7. Body assembly, carburetor

8. O-ring

Fig. 8-2

9. Jet

10. Gasket, pump

11. Diaphragm, pump

12. Spring, pump

13. Body assembly, pump

14. Inlet screen

15. Metering lever spring

16. Metering lever pin

-

44

-

17. Inlet needle valve

18. Metering lever

19. Screw, metering lever pin

20. Metering diaphragm gasket

21. Diaphragm assembly, metering

22. Body assembly air purge

23. Primer pump

24. Primer pump cover

25. Screw

Page 49

8-2-1 PRECAUTIONS

(1) Wash the carburetor with clean gasoline before disassembly.

(2) Disassemble and reassemble the carburetor by referring to the exploded view.

(3) Refrain from disassembling the throttle valve assy. (6), pump body assy. (13) and the main body.

8-2-2 DISASSEMBLY AND REASSEMBLE PROCEDURES

(1) Removes the screw (25) and the primer pump cover (24). Remove dust or foreign matter stuck on the

primer pump (23), if any.

(2) Remove the pump body assy. (13) from the main body (Be careful not to lose the spring (15)).

Remove dust or foreign matter caught in the inlet screen (14), if any.

(3) Remove the jet (19) from the main body.

(4) Remove the screw (1) and remove the throttle valve assy. (6) from the main body.

(5) When assembling the carburetor, be sure that the jet (9) and the spring (12) are firmly installed.

8-2-3 PRECAUTIONS FOR INSPECTION

(1) Wash the main body with gasoline and blow it clean with compressed air.

(2) Check the jet for dust stuck on the surface, corrosion, etc. If there is dust stuck on the jet, wash it and

blow it clean with compressed air. If the jet is corroded, replace it with a new one. (NOTE : When

replacing a jet, be sure of using a new one with the same number).

(3) Check the gasket for deformation and damage. If it is deformed or damaged, change with a new one.

(4) The pump (diaphragm) should not be hardened nor damaged.

(5) The inlet valve and the outlet valve should be flat and not bent.

(6) The diaphragm assy. should be free of any hardening, damage or bent.

(7) After assembling the pump body assy.,check it for deformation of the metering lever and metering

spring, height of the metering lever, dust stuck on the inlet screen, valve leakage, etc. To check the

main check valve for correct operation, connect a vinyl or rubber hose to the check valve portion from

the jet side and breathe it with your mouth. If the valve stops when blown and closes when sucked,

the valve is working normally. If there is any abnormality , immerse it in gasoline for approximately 10

minutes and then blow and suck it repeatedly. If the valve can not be fixed even by doing so, replace

it with a new pump body assy.

(NOTE : Refrain from blowing the main check valve with compressed air. When using an air gun,

keep them approximately 30 cm apart of each other when the compressed air has a pressure of 6 kg/

2

cm

).

(8) Check the primer pump for any hole, damage or abnormal hardening. Be sure that the combination

valve is working normally.

-

45

-

Page 50

8-2-4 MARKS ON THE CARBURETOR

Marks are stamped as shown in the figure at the

right.

11

1 Model No.

11

22

2 Date of manufacture

22

Example

11

1 : 116 ---------- WYL116 (Walbro model No.)

11

22

2 : 914

22

week 14 (May. 29-Apr. 2)

1

1999

2

Fig. 8-3

-

46

-

Page 51

9. RECOIL STARTER

9-1 HOW TO DISASSEMBLE

The recoil starter rarely have problem under normal use. When it fails, however, or when greasing,

disassemble and reassemble it according to the following procedure.

Tools : Screwdriver and pincers (pliers)

(1) Remove the recoil starter from the engine.

(2) Pull out the starter knob, hold the rotary reel

with your thumb as shown in Figure 9-1 when

the reel notch gets aligned with the starter rope

outlet, and pull the starter rope to inside the

recoil starter with a screwdriver.

Hook the starter rope to the notch, and rewind

the reel to the arrow direction until it stops, by

controlling the rotation of the reel with your

thumb.

NOTCH

Fig. 9-1

-

47

-

Page 52

(3) Remove the parts as shown in Fig. 9-2.

Remove the reel slowly while turning it back and forth gently, otherwise the spiral spring may escase

from the case which may invite danger. (It the spiral spring escapes, put it in the case by following

procedure shown in Fig. 9-6.)

Untie the starter rope knot at the reel end and withdraw it to complete disassembling.

EH025

SET SCREW

EH035

SWING ARM

COLLAR

STARTER KNOB

REEL

SPIRAL SPRING

STARTER SHAFT

REEL

SPIRAL SPRING

SET SCREN

STARTER KNOB

Fig. 9-2

-

48

-

Page 53

9-2 HOW TO REASSEMBLE

(1) Pass the starter rope through the starter knob

and make an overhand knot as shown in Fig.

9-3. Pass the opposite side of the starter rope

from the starter case to the reel, and make a

knot in the same way, then put the rope end

securely into the rope housing in the reel.

Then, apply a small amount of grease on the

starter shaft and on the spiral spring.

(2) Check that the spring is securely set in the

reel and form the spring end to have 1 to 2

mm clearance between inner end of the spring

and the reel bush so that the inner end catches

the hook securely as shown in Fig. 9-4. The

shape of spring inner end (approx. 10 cm from

the end) can be adjusted with plier if neces-

sary.

(3) Prior to installing the reel in the starter case,

wind the starter rope to the reel in the arrow

direction of Figure 9-5, take out the third turn

of the starter rope from the reel notch and then

install the reel securely inside the starter case

so that the spiral spring inner end catches the

hook. Next, hold the starter rope as shown in

Figure 9-5, and rotate the reel 4 to 5 turns in

the arrow direction by utilizing the reel notch.

After winding the reel, hold it securely to pre-

vent it from reverse turn and pull out the starter

knob to stretch the rope tight and then release

the knob slowly. Rassemble the parts in re-

verse order of disassembling shown in Fig.

9-2. Tighten the setscrew securely.

REEL

APPLY

GREASE

REEL BUSH

Fig. 9-3

SPIRAL SPRING END

SPIRAL SPRING

1 to 2 mm

Fig. 9-4

APPROX.

10 mm

APPROX.

10 mm

INNER END

STARTER SHAFT

REEL

HOOK

*Be sure to check the following to make sure

that the parts are securely installed.

-

49

Fig. 9-5

-

Page 54

9-3 CHECK AFTER REASSEMBLE

(1) Pull the starter knob a few times to check if:

A. The starter knob is too heavy to pull, check that each part has been assembled as specified.

B. The ratchet fails to function, check is parts such as friction spring have been missing.

(2) Pull out the starter knob to extend the rope to its extreme to see if:

A. The starter rope still remains in the rope slot of the reel, unwind the rope by 1 to 2 turns as shown

in Fig. 9-1, as the spring may be over-stressed.

B. The starter rope is found weak to recoil or droops in halfway, apply grease or mobile oil to the

rotating part and to the friction parts. If it persists, wind-up the spring by 1 to 2 turns. (In this case,

check that the spring is not over-stressed.)

C. The spring escapes with a sound and the starter rope fails to spring back to its original position,

reassemble the starter from the beginning.

9-4 OTHER GUIDES

(1) When the spring escapes from the reel :

Make a ring having a rather small diameter

than spring housing using a thin wire.

Hook the outer end of the spring onto a part of

the ring and re-wind the spring into the wire

ring as shown in Fig.9-6 then put it into the

housing.

Remove the ring slowly while holding down

the spring to avoid getting out of place.

The ring can easily be removed by prying it

with the tip of a screwdriver.

Refer to Fig.9-4 for which way the spiral spring

must be placed.

(2) When it is lubricated :

WIRE RING

SPRING

Fig. 9-6

Lubricate the starter shaft and spring with a

grease (If possible, heat-resistant type is preferable) or a mobile oil when the starter is being disassembled and prior to long-term storage.

(3) When the swing arm does not move smoothly:

Apply grease (Alevin No. 3) or mobile oil on it.

-

50

-

Page 55

10. TROUBLESHOOTING

The following three conditions must be fulfilled for satisfactory engine start.

1. The cylinder filled with a proper fuel-air mixture.

2. Good compression in the cylinder.

3. Good spark, properly timed, to ignite the mixture.

The engine cannot be started unless these three conditions are met. There are also other factors which

make engine start difficult, e. g., a heavy load on the engine when it is about to start at low speed, and a

high back pressure due to a long exhaust pipe.

The most common causes of engine troubles are given below :

10-1 STARTING DIFFICULTIES

10-1-1 FUEL SYSTEM

(1) No gasoline in the fuel tank.

(2) The carburetor is not choked sufficiently especially when the engine is cold.

(3) Water, dust or gum in the gasoline interfering the fuel flow to the carburetor.

(4) Inferior grade gasoline or poor quality gasoline not vaporized enough to produce the correct fuel-air

mixture.

(5) If the carburetor overflows, excessive fuel runs into the cylinder when starting the engine, making the

fuel-air mixture too rich to burn. If this happens, remove the spark plug, and turn the starting pulley a

few turns in order to let the rich fuel-air mixture out of the spark plug hole into the atmosphere.

Keep the choke valve open during this operation.

Dry the spark plug well, screw it into place, and try to start again.

10-1-2 COMPRESSION SYSTEM

If starting difficulties and loss of power are not due to the fuel system or ignition system, the following

must be checked for possible lack of compression.

(1) Engine inside is completely dried up because of a long period of storage.

(2) Loose or broken spark plug. This causes a hissing noise made by mixture gas running out of cylinder

in compression stroke during cranking.

(3) Damaged head gasket or loose cylinder head. A similar hissing noise is produced during compres-

sion stroke.

(4) Incorrect Valve clearance

If the correct compression is not obtained even after remedying the above, disassemble the engine

and check further as follows :

a) Valve stuck open due to carbon or gum on the valve stem.

b) If the piston rings are stuck on the piston, remove the piston and connecting rod from the engine.

Clean or replace the parts.

-

51

-

Page 56

10-1-3 IGNITION SYSTEM

Check the followings for lack of spark.

(1) Wires of the ignition coil, spark plug or contact breaker disconnected.

(2) Ignition coil damaged and shorted.

(3) Spark plug cable wet or soaked with oil.

(4) Spark plug dirty or wet.

(5) Spark plug electrode gap incorrect.

(6) Spark plug electrode is connected or bridged.

(7) Incorrect spark timing.

10-2 ENGINE MISFIRES

(1) Incorrect spark plug electrode gap. Adjust it to anywhere between 0.7 and 0.8 mm.

(2) Ignition cable worn and leaking.

(3) Sparks weak.

(4) Ignition wire connections loose.

(5) Water in gasoline.

(6) Insufficient compression.

10-3 ENGINE STOPS

(1) Fuel tank empty. Water, dirt, gum, etc. in gasoline.

(2) Vapor lock, i. e., gasoline evaporating in the fuel lines due to overheat around the engine.

(3) Vapor lock in the fuel lines or carburetor due to the use of too volatile winter gas in the hot season.

(4) Air vent hole in the fuel tank cap plugged.

(5) Bearing parts seized due to lack of oil.

(6) Magneto or ignition coil faulty.

-

52

-

Page 57

10-4 ENGINE OVERHEATS

(1) Crankcase oil level low. Add oil immediately.

(2) Spark timing incorrect.

(3) Low grade gasoline is used, or engine is overloaded.

(4) Cooling air circulation restricted.

(5) Cooling air path misdirected causes loss of cooling efficiency.

(6) Cylinder head cooling fins clogged up with dirt.

(7) Engine operated in an enclosed space without sufficient cooling air.

(8) Exhaust gas discharge restricted, or carbon deposits in the combustion chamber.

(9) Engine running on low-octane gasoline detonates due to heavy load at low speed.

10-5 ENGINE KNOCKS

(1) Poor quality gasoline.

(2) Engine operating under heavy load at low speed.

(3) Carbon or lead deposits in the cylinder head.

(4) Spark timing incorrect.

(5) Loose connecting rod bearing due to wear.

(6) Loose piston pin due to wear.

(7) Curses of engine overheat.

10-6 ENGINE BACKFIRES THROUGH CARBURETOR

(1) Water or dirt in gasoline, or low-grade gasoline.

(2) Intake valve stuck.

(3) Valves overheated, or hot carbon particles in the combustion chamber.

(4) Engine cold.

-

53

-

Page 58

11. INSTALLATION

Engine life, ease of maintenance and inspection, frequency of checks and repairs, and operating cost all

depend on the way in which the engine is installed. Review the following instructions carefully for installing the engine.

11-1 INSTALLING

When mounting the engine, carefully examine its position, the method of connecting it to a machine, the

foundation, and the method of supporting the engine.

When determining its mounting position, in particular, make sure that gasoline and oil can easily be

supplied and checked, the spark plug can easily be checked, the air cleaner can easily be serviced, and

that the oil can easily be discharged.

11-2 VENTILATION

Fresh air is necessary for cooling the engine and burning the fuel.

In the case the engine is operated under a hood or in a small room, temperature rise in the engine room

can cause vapor lock, oil deterioration, increased oil consumption, loss of power, piston seizure, shorter

engine life, etc., making it impossible to operate the engine properly . It is necessary, therefore, to provide

a duct or baffle to guide cooling air to the engine to prevent recirculation of the hot air used for engine

cooling, and temperature rise of the machine. Keep the engine room temperature below 50°C even in the

hottest period of the year.

11-3 EXHAUST GAS DISCHARGE

Exhaust gas is noxious. When operating the engine indoors, be sure to discharge the exhaust gas

outdoor. If a long exhaust pipe is used in such a case, the internal resistance increases causing loss of

engine power. Thus pipe inside diameter must be increased in proportion to exhaust pipe length.

Exhaust pipe : Less than 3 m long, pipe inside diameter 30 mm ,

Less than 5 m long, pipe inside diameter 33 mm.

11-4 POWER TRANSMISSION TO DRIVEN MACHINES

11-4-1 BELT DRIVE

Take the following notes into consideration.

* V-belts are preferable to flat belts.

* The driving shaft of the engine must be parallel to the driven shaft of the machine.

* The driving pulley of the engine must be in line with the driven pulley of the machine.

* Install the engine pulley as close to the engine as possible.

* If possible, span the belt horizontally.

* Disengage the load when starting the engine.

If no clutch is used, use a belt tension pulley or the like.

11-4-2 FLEXIBLE COUPLING

When using a flexible coupling, run out and misalignment between the driven shaft and engine shaft

must be minimized. Run out and misalignment tolerance are specified by the coupling manufacturer.

-

54

-

Page 59

12. SERVICE DATA

12-1 CLEARANCE DATA AND LIMITS

Unit : mm (in)

CYLINDER

*Valve guide inside dia.

*Inside dia.

ITEM

EH025

EH035

STD

EH025

EH035

STD Limit

3.005 - 3.025

(0.118 - 0.119)

3.505 - 3.525

(0.138 - 0.139)

34.00 - 34.02

(1.3386 - 1.3394)

39.00 - 39.02

(1.5354 - 1.5362)

3.1

(0.122)

3.6

(0.142)

34.06

(1.3409)

39.06

(1.5378)

-

55

-

Page 60

Unit : mm (in)

ITEM

PISTON

* Piston size (At skirt in thrust direction)

*Ringgroove side clearance

8.2 mm

-

4.5

STD

2nd

Oil ring

EH025

EH035

Top

EH025

EH035

STD Limit

33.959

(1.3370

38.959

(1.5338

-

33.980

-

1.3378)

-

38.980

-

1.5346)

0.03 - 0.07

(0.0012 - 0.0028)

0.02 - 0.06

(0.0008 - 0.0024)

0.03 - 0.07

(0.0012 - 0.0028)

0.04 - 0.14

(0.0016 - 0.0055)

33.940

(1.3362)

38.940

(1.5331)

0.12

(0.005)

0.12

(0.005)

0.20

(0.008)

* Piston pin hole

* Piston pin outside dia.

* Piston ring end gap

EH025

EH035

EH025

EH035

Top

2nd

EH025

EH035

EH025

EH035

7.996 - 8.005

(0.3148 - 0.3152)

9.996 - 10.005

(0.3935 - 0.3939)

7.994 - 8.000

(0.3147 - 0.3149)

9.994 - 10.000

(0.3935 - 0.3937)

0.1-0.25

(0.0039-0.0098)

0.1 - 0.25

(0.0039 - 0.0098)

8.03

(0.3161)

10.03

(0.3949)

7.988

(0.3145)

9.988

(0.3932)

0.8

(0.0315)

0.8

(0.0315)

Oil

ring

-

EH025

EH035

56

-

0.1 - 0.6

(0.0039 - 0.0236)

0.8

(0.0315)

Page 61

Unit : mm (in)

CAMSHAFT

*Cam height (IN. and EX.)

* Journal outside dia.

D

2

VALVE

*Valve stem outside dia.

ITEM

STD Limit

EH025

23.20 - 23.30

(0.9134 - 0.9173)

EH035

D

1

EH025

D

1

EH035

EH025

D

2

EH035

EH025

5.01 - 5.06

(0.1972 - 0.1992)

4.99 - 5.00

(0.1965 - 0.1969)

2.975 - 2.990

(0.1171 - 0.1177)

IN.

EH035

EH025

3.475 - 3.490

(0.1368 - 0.1374)

2.950 - 2.965

(0.1161 - 0.1167)

EX.

EH035

3.450 - 3.465

(0.1358 - 0.1364)

22.65

(0.8917)

-----------

-----------

2.9

(0.1142)

3.4

(0.1339)

2.9

(0.1142)

3.4

(0.1339)

*Clearance between valve stem dia. and valve

guide.

*Valve clearance

*Valve lift

*Valve spring free length (IN. and EX.)

IN.

EX.

IN. / EX.

(cold)

IN. / EX.

EH025

EH035

EH025

EH035

EH025

EH035

0.015 - 0.050

(0.0006 - 0.0020)

0.017 - 0.050

(0.0007 - 0.0020)

0.040 - 0.075

(0.0016 - 0.0030)

(0.0051 - 0.0067)

3.0 - 3.2

(0.1181 - 0.1260)

17.7

(0.6969)

21.0

(0.8268)

0.2

(0.0079)

0.2

(0.0079)

0.13 - 0.17

2.6

(0.1024)

-----------

-----------

-

57

-

Page 62

12-2 TORQUE SPECIFICATIONS

Tightening Torque

ITEMS

N-m Kg-cm ft-lb.

Retainer plate (Crankcase) 3 - 4 30 - 40 2.2 - 2.9

Cylinder block (Crankcase) 4.5 - 6.5 45 - 65 3.3 - 4.7

Oil case (Crankcase) 4 - 5.5 40 - 55 2.9 - 4.0

Cam gear cover 4 - 5.5 40 - 55 2.9 - 4.0

Ignition coil 2 - 4 20 - 40 1.4 - 2.9

Flywheel 9 - 12 90 - 120 6.5 - 8.8

Clutch 7.5 - 10 75 - 100 5.4 - 7.2

Rocker arm (adjust screw) 5 - 6.5 50 - 65 3.6 - 4.7

Rocker cover 4 - 5.5 40 - 55 2.9 - 4.0

Muffler 7 - 9 70 - 90 5.1 - 6.5

Muffler cover 3 - 5 30 - 50 2.2 - 3.6

Insulator carburetor

(insulator&crankcase)

Recoil starter 1 - 2.5 10 - 25 0.7 - 1.8

Blower housing (engine cover) 2 - 4 20 - 40 1.4 - 2.9

Spark plug 9 - 13 90 - 130 6.5 - 9.4

Cover (air cleaner) 0.5 - 1 5 - 10 0.04 - 0.7

Air cleaner plate 2 - 4 20 - 40 1.4 - 2.9

Pulley 4 - 5.5 40 - 55 2.9 - 3.9

Plug cover EH035 1.5 - 3 15 - 30 1.1 - 2.2

4 - 5.5 40 - 55 2.9 - 4.0

-

58

-

Page 63

12-3 OIL GRADE CHART

Use oil classified SF or higher.

Multi-grade oil tends to increase its consumption at high ambient temperature.

Comparison between oil viscosity and temparature

5W

10W

Specified

Lubricant

Quality

Single

grade

Multi-

grade

20W

#20

#30

#40

10W-30

10W-40

20W-40

-

-

20

4

-

10

14

32

0

10

50

20

68

30

86

40 °C

104 °F

-

59

-

Page 64

13. MAINTENANCE AND STORAGE

The following maintenance jobs apply when the engine is operated correctly under normal conditions.

The indicated maintenance intervals are by no means guarantees for maintenance free operations during these intervals.

For example, if the engine is operated in extremely dusty conditions, the air cleaner should be cleaned

every day instead of every 50 hours.

13-1 DAILY MAINTENANCE

MAINTENANCE ITEMS REMARKS

1) Clean away dust and chaff from engine. Governor linkage is especially sensitive to dust.

2) Check fuel leakage from fuel system. If any,

retighten fasteners or replace necessary parts.

3) Inspect for loose hardware and retighten if

necessary.

4) Check oil level and add up to full mark.

Loose bolts and nuts may come off and result in

breakage of other parts.

13-2 INITIAL 20 HRS. MAINTENANCE

MAINTENANCE ITEMS REMARKS

1) Change crankcase oil. To remove sludge from run-in operation.

13-3 EVERY 50 HRS. (10 DAYS) MAINTENANCE

MAINTENANCE ITEMS REMARKS

1) Change crankcase oil. Contaminated oil quickens wear.

2) Clean air cleaner.

3) Check and clean spark plug.

-

60

-

Page 65

13-4 EVERY 100-200 HRS. (MONTHLY) MAINTENANCE

SMETIECNANETNIAMSKRAMER

.knatleufdnaretlifleufnaelC)1

.ffahcdnatridevomerdnametsysgnilooctcepsnI)2

.enigneluahrevO)3

.raeyaecnosenilleufecalpeR)4 .egakaelleufybdesuacsdrazahdiovA

.gnisuohdna

.straptcerrocdnanaelC

.strapyrassecenrehtodnasgnirnotsipecalpeR

13-5 ENGINE STORAGE

(1) Perform the above 13-1 and 13-2 maintenance jobs.

(2) Drain fuel from the fuel tank and carburetor.

(3) To prevent rust in the cylinder bore, apply oil through the spark plug hole and turn the crankshaft

several turns by hand. Reinstall the plug.

(4) Turn the starting pulley by hand and leave it where the resistance is the heaviest.

(5) Clean outside of the engine with oiled cloth.

(6) Put a plastic cover or the like over the engine and store the engine in dry place.

snifneewtebpunaelcdnagnisuohrewolbevomeR

-

61

-

Page 66

PRINTED IN THE USA

Loading...

Loading...