Page 1

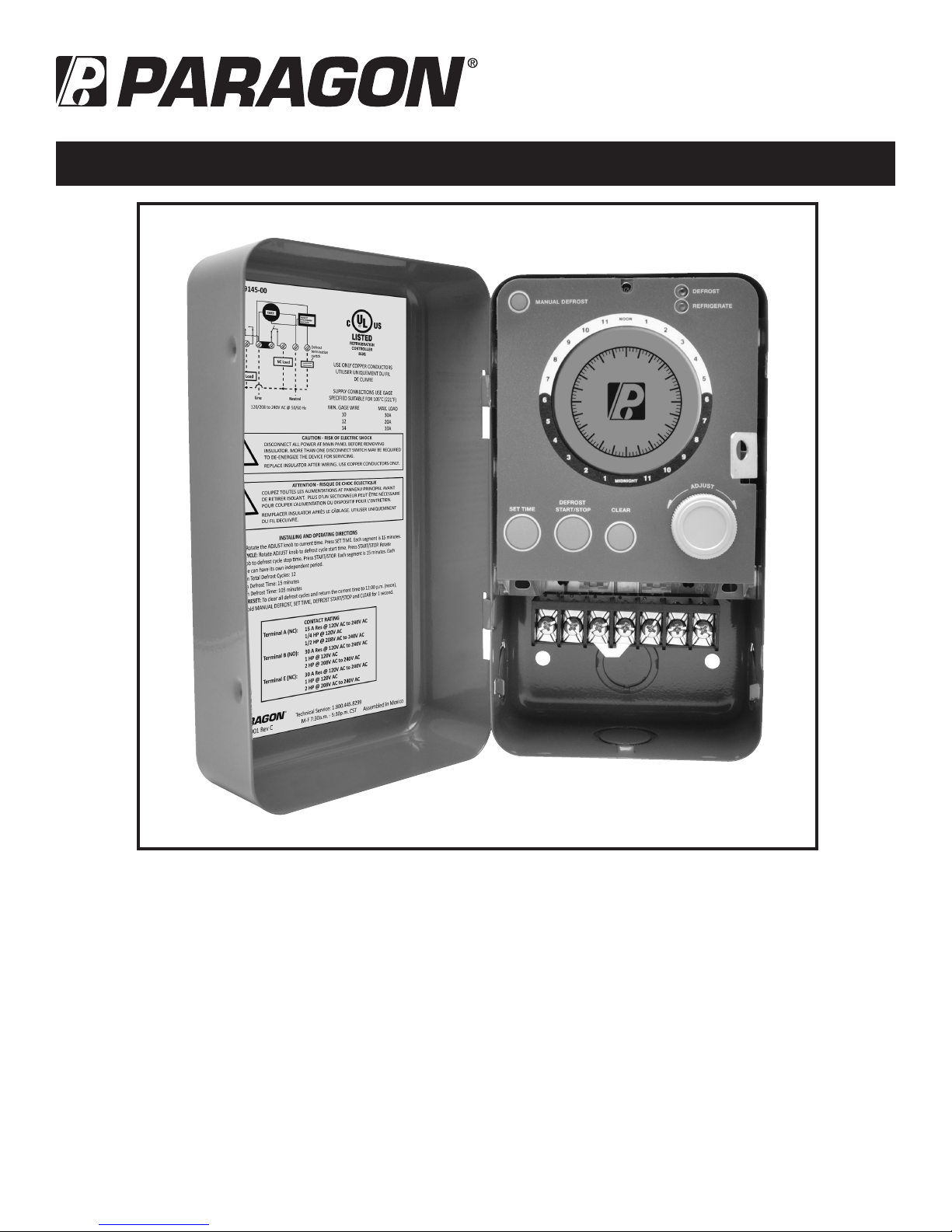

UDT - Universal Defrost Timer

Universal Defrost Timer (UDT)

The Universal Defrost Timer family consists of two models: electric defrost and off-cycle defrost. Both models can

be wired directly to 120V AC, 208V AC or 240V AC power sources. The timers can be used in place of traditional

electromechanical defrost time clocks. Users should review this document, including terminal specifications, to ensure

compatibility with the application.

The timer maintains and displays the current time and each defrost cycle. The user can glance at the display and

immediately determine what time it is as well as see the defrost settings (start time and duration). In

addition, colored LEDs indicate the current system mode (refrigeration or defrost).

1

Page 2

Operation and Functions

The Paragon® Universal Defrost Timer series is designed to accept power supply voltages of 120V AC, 208V AC

or 240V AC directly connected to the power terminals. This is accomplished without the use of jumpers or

switches. It is designed to be as easy to use as similar electromechanical defrost time clocks.

• Dial style clock face

• Current time indicated by flashing segment

• Scheduled defrosts and defrost duration indicated by solid segments

• Simple programming using three buttons and a rotating dial

Features not found on traditional electromechanical defrost time clocks include:

• System status indicators – LED for refrigeration and defrost

• Manual defrost initiation with a single button press

• Terminal G (defrost termination wiring connection) diagnostics

Features / Benefits

Universal Voltage ��������������������������������������������� Directly connect to 120V AC, 208V AC or 240V AC power supply.

Electronic User Interface .................................... Easy-to-read time of day. Simple defrost cycle programming. No

complicated dials and hard-to-use pins.

Program Carryover ............................................. Maintains clock up to 100 hours and program indefinitely in case of

power outage. When power restores, the program detects the current

time and program status and continues as programmed.

Backlit Display..................................................... Easy to see in poorly lighted spaces.

System Status Indicators .................................... Green LED indicates refrigeration. Red LED indicates defrost.

Manual Defrost ................................................... User-initiated 15 minute manual defrost cycle.

Non-Volatile Memory ......................................... The programmed parameters will remain in the memory.

Capacitor Carryover for the Clock ...................... Maintains the correct time-of-day for a minimum of 100 hours.

Microprocessor-Based Electronics ..................... High reliability and repeatability.

Agency Listings:

File number SA512 (9045-00 and 9145-00)

File number SA512 (9045-00M and 9145-00M)

The devices are listed as Refrigeration Controllers.

FCC Compliance*

This device complies with CFR 47, Part 15, Subpart B, Class A.

Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this

device must accept any interference received, including interference that may cause undesired

operation. Changes or modifications not expressly approved by Robertshaw Controls could void the user’s authority to

operate the equipment.

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses and

can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

2

Page 3

interference, in which case the user will be required to correct the interference at his own expense.

Canadian Compliance*

This Class A digital apparatus meets all of the Industry Canada, ICES-003 requirements (Canadian Interference-Causing

Equipment Regulations).

Cet appareil numerique de la classe A respecte toutes les ezigences du Reglement sur le material brouilleur du Canada.

*NOTE: These compliance statements apply to NEMA 1 enclosed models only� All modular units are the

responsibility of the purchaser to obtain the compliance�

Installation Instructions

IMPORTANT

• All UDT series controls are designed as operating controls only� If an operating control failure could result in

personal injury or loss of property, a separate safety control and/or alarm should be installed�

• The schematic drawings and other information included in these instructions are for the purpose of

illustration and general reference only.

• These instructions do not expand, reduce, modify or alter the Robertshaw Terms in any way. No warranty or

remedy in favor of the customer or any person arises out of these instructions.

• The 9045 and 9145 controls have been certified by Underwriters Laboratories Inc. The certification does not

extend to their use for any other purpose. Robertshaw assumes no responsibility for any

unconventional application of its control unless such application has been approved in writing

by Robertshaw.

• It is the responsibility of the installer and the user to assure that the application and use of Robertshaw products

are in compliance with all federal, state and local requirements, including, without limitation, all requirements

imposed under the National Electric Code and any applicable

building codes.

CAUTION

To prevent possible electric shock or equipment damage,

disconnect electrical power to the unit before and during

installation. DO NOT restore electrical power to the unit until the

control is properly installed and the cover is assembled. DO NOT

locate the control in an explosive atmosphere as a safety hazard

can result due to possible spark generation in the control. Controls

are not to be located in areas of significant moisture, dirt or dust,

or in a corrosive, explosive atmosphere. Using a control in such

environments may result in injury or damage to persons or property

(or both) and are likely to shorten the control life. DO NOT connect

the supply (as shown connected to terminal F in Figures 4 and 6)

directly to any other terminal. DO NOT remove jumpers between

terminals C and D on model 9145 or between terminals B, C and D

on model 9045.

Robertshaw assumes no responsibility for any such use�

Pour prévenir les chocs électriques ou les dommages aux

équipements, couper l’alimentation électrique de l’unité avant

et pendant l’installation. NE PAS ali-menter le thermostat avant

que la commande ne soit correctement installée et le couvercle

assemblé. NE PAS placer le thermostat dans une atmosphère explosive car une étincelle dans le thermostat représente un danger. Les

thermostats ne doivent pas être placés dans des zones très humides,

poussiéreuses ou sales, ou dans une atmosphère corrosive et

explosive. Si le thermostat est utilisé dans de tels environnements,

des préjudices aux personnes ou des dommages aux biens (ou les

deux) peuvent survenir et sont susceptibles de raccourcir la durée

de vie du thermostat. NE PAS brancher l’électricité (comme branché

à la borne F dans les figures 4 et 6) directement à n’importe quelle

autre borne. NE PAS retirer les cavaliers entre les bornes C et D sur le

modèle 9145 ou entre les bornes B, C et D sur le modèle 9045.

Robertshaw n’assume aucune responsabilité pour de telles utilisations�

MISE EN GARDE

Mounting

Mount these controls to a wall or any flat surface using the three holes in the metal case (models

9045-00 and 9145-00). The control’s components are not position sensitive, but should be mounted so they can be

easily wired and adjusted. The models that do not come in a metal case must be mounted inside an enclosure (Nema 1

type or better).

NOTE: The manufacturer recommends removal of the electronic controller prior to mounting the metal

case to a wall or any flat surface to facilitate installation and the installation of conduit fittings and conduit installation.

3

Page 4

NOTE: For models 9045-00M and 9145-00M: Place the peel-and-stick label (3.25” x 7”), over the old label on the inside

cover of the metal enclosure used by the 8100 or 8200 series of products.

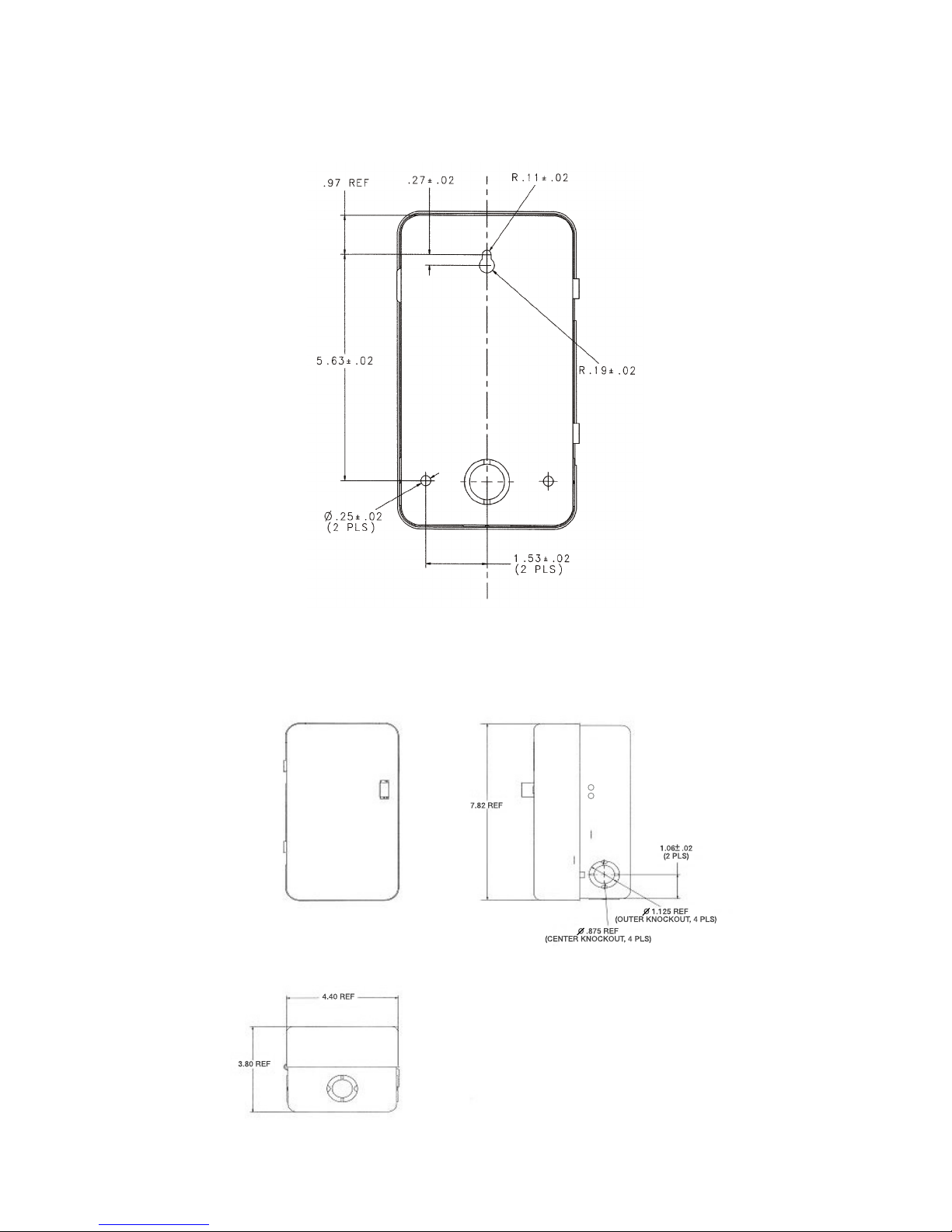

Mounting Dimensions – Metal Case

Overall Dimensions

Fig. 1

Fig. 2

4

Page 5

Representative Wiring Installation Procedure Model 9045

Connecting the refrigeration / defrost equipment (See Figures 3 and 4)

NOTE: Rated input power 120/208-240V AC 50/60 Hz (+10,-15%)

1. Turn off the AC power.

2. Open the metal case to access the control connectors.

3. Connect the wires from the compressor to terminal A.

4. Connect the defrost device (heater or hot gas solenoid) to terminal E.

5. Connect the wire from L1 - 120V AC or 208-240V AC line - to terminal C.

6. Jumper terminal C to terminals B and D.

7. Connect the wire from L2/N to terminal F.

A B C D E F G

Fig. 3 Load / AC Input Connectors Terminal Block Model 9045

Fig. 4 Model 9045

5

Page 6

Control Wiring

All wiring should conform to the National Electric Code and local regulations.

NOTE: Use copper conductors only!

• Electrical leads should not be taut; allow slack for temperature change and vibration.

• The manufacturer suggests removal of the electronic controller prior to mounting the metal case to

a wall or any flat surface to facilitate installation and the installation of conduit fittings and conduit installation.

Terminal Detail: 9045

Representative Wiring Installation Procedure Model 9145

Terminal A B C D E F G

Relay

Contact

Relay Rating

Device

Connections

SPST #1

NC Contact

30A resistive @ 120V AC

to 240V AC

1HP @ 120V AC,

2HP @ 208V AC to 240V

AC

Compressor (Typical) Defrost Device (Typical)

SPST #1

COMM

Contact

L1

Power in

to timer

SPST #2

NO Contact

SPST #2

COMM Contact

30A resistive @ 120V AC

to 240V AC

1HP @ 120V AC,

2HP @ 208V AC to 240V

AC

Connecting the refrigeration / defrost equipment (See Figures 5 and 6�)

NOTE: Rated input power 120/208-240V AC 50/60 Hz (+10,-15%)

1. Turn off the AC power.

2. Open the metal case to access the control connectors.

3. Connect the wires from the compressor to terminals A or E.

4. Connect the defrost device (heater or hot gas solenoid) to terminal B.

5. Connect the wire from L1 - 120V AC or 208-240V AC line - to terminal C.

6. Jumper terminal C to terminal D.

7. Connect the wire from L2/N to terminal F.

8. Connect the fan wires to terminals A or E.

9. If a defrost termination switch is present, connect its wire to terminal G.

L2/N

Power in

to timer

No

Connection

Control Wiring Model 9145

A B C D E F G

Fig. 5 Load / AC Input Connectors

Terminal Block Model 9145

Fig. 6 Model 9145

6

Page 7

A

A

A

A

All wiring should conform to the National Electric Code and local regulations.

NOTE: Use copper conductors only!

• Electrical leads should not be taut; allow slack for temperature change and vibration.

• The manufacturer suggests removal of the electronic controller prior to mounting the metal case to a wall or

any flat surface to facilitate installation and the installation of conduit fittings and conduit installation.

Terminal Detail: Model 9145

Technical Specifications

Terminal A B C D E F G

Relay

Contact

Relay Rating

SPDT

NC Contact

15A resistive @

120V AC to 240V AC

1/4HP @ 120V AC,

1/2HP @ 208V AC to

240V AC

SPDT

NO Contact

30A resistive @

120V AC to 240V

AC

1HP @ 120V AC,

2HP @ 208V AC to

240V AC

SPDT

COMM

Contact

L1 Power

to timer

and to

Defrost

Termination

Device

Connections

Fan (Typical)

Compressor

(Optional)

Defrost Device

(Typical)

Device

Wiring Conversion from 8000 Series to 9000 Series

SPST

NO

Contact

SPST

COMM Contact

30A resistive @

120V AC to 240V AC

1HP @ 120V AC,

2HP @ 208V AC

to 240V AC

Compressor

(Typical)

Fan (Optional)

L2/N

Power in

to timer

Defrost

Termination

Device Input

L2/N side

Defrost

Termination

Switch

Convert 8041 to 9145

8041 N 1 4

3 2 X

9145

8145 3 4 X

9145

B C D E F G

Convert 8145 to 9145

1 2 N

B C D E F G

Convert 8141 to 9145

8141 N 1 4

3 2 X

9145 A B C D E F G

Convert 8045 to 9045

8045 2 N 1

4 3 X

9045

B C D E F

Convert 8143 to 9145

8143 1 N 2

3 4 X

9145

B C D E F G

7

Page 8

Input Power: 120/208-240V AC 50/60 Hz (+10,-15%)

Power Consumption: 6 VA max

Defrost termination switch (terminal G) input impedance to terminal C: 85kΩ +/- 5%

Operating Voltage: 120V AC (+10%, -15%) @ 50/60Hz

208V AC to 240V AC (+10%, -15%) @ 50/60Hz

NOTE: There are no user-required adjustments to switch between the high and low voltage.

Ambient Operating Conditions: -40°F to 131°F (-40°C to 55°C); 0 to 95% RH (non-condensing)

NOTE: While the display is not harmed at temperatures as low as -40°C, it is not visible at -30°C and below. The display

is visible when the ambient temperature is above -30°C.

Storage Temperature: -40°F to 140°F (-40°C to 60°C)

Outside Dimensions: Individual Unit: 4.40”W x 7.82”H x 3.80”D

Individual Unit (in shipping box): 4.75”W x 8.875”H x 4.75” D

Individual Case Shipping Weight: 3.2 lb

Agency Approvals:

Listed Product – Models 9045-00 and 9145-00

Recognized Component – Models 9045-00M and 9145-00M

Ratings:

9145

Terminal A: 15A resistive @ 120V AC to 240V AC

1/4HP @ 120V AC, 1/2HP @ 208V AC to 240V AC

Terminal B: 30A resistive @ 120V AC to 240V AC

1HP @ 120V AC, 2HP @ 208V AC to 240V AC

Terminal E: 30A resistive @ 120V AC to 240V AC

1HP @ 120V AC, 2HP @ 208V AC to 240V AC

9045

Terminal A: 30A resistive @ 120V AC to 240V AC

1HP @ 120V AC, 2HP @ 208V AC to 240V AC

Terminal E: 30A resistive @ 120V AC to 240V AC

1HP @ 120V AC, 2HP @ 208V AC to 240V AC

NOTE: SPST normally closed (SPST NC) relays assume the normally closed state when power is applied. When power is

lost, the relay will return to the de-energized (NO) state.

8

Page 9

Graphic Description / Dimensions

MODEL 9145

Display Layout

Initiate 15

Minute

Manual

Defrost

Display

shows

defrost start

time and

duration

System Status

Indicators

Lighted Display

Easy

Set Up

Set Time,

Set Defrost

Start

and Defrost End

Direct Connect

Line Voltage –

120/208/240V AC

9

Page 10

Programming

Upon initial power up the flashing segment should be at 12:00 pm (noon). Turning the ADJUST knob will

activate the programming cursor and momentarily turn off the time. If any of the other segments are on

(lit), they may be related to a previous program. The display backlight will turn on when the ADJUST knob is turned. The

backlight remains lighted for 10 seconds after the last activity.

Program Reset

Program reset deletes any existing program and returns the clock to 12:00 pm (noon).

1. Press and hold the following (4) buttons at the same time for 1 second: MANUAL DEFROST, SET TIME, DEFROST

START/STOP and CLEAR.

2. Lighted segments showing any program will turn off, and the time segment will show 12:00 pm (noon).

Set the Time

The flashing segment shows the actual time.

1. Rotate ADJUST knob until the correct time is shown. Each segment is 15 minutes.

2. Press the SET TIME button to set the time.

Program a Defrost Cycle

1. Refer to original equipment manufacturer’s operating instructions for recommended defrost schedule.

2. Rotate ADJUST to move the cursor to desired defrost start time.

3. Press DEFROST START/STOP once. This indicates a timed defrost start time.

4. Rotate ADJUST to move the cursor to the desired time terminated or backup termination time.

5. Press DEFROST START/STOP once. This shows the termination time.

All the segments between the start and stop times will be lit.

• Number of defrost cycles user may set: 12

• Defrost periods: minimum 15 minutes, maximum 105 minutes (each segment is 15 minutes) Each defrost

cycle can have its own independent period.

• Minimum time between defrost cycles: 15 minutes

Clear

To remove a defrost cycle:

1. Rotate ADJUST to the start time.

2. Press CLEAR once.

3. Defrost cycle is deleted. (All the lit segments linked with the defrost cycle, turn off.)

To remove part of the defrost cycle:

1. Rotate ADJUST to a segment within a defrost cycle.

2. Press CLEAR once.

3. The segments from the cursor location to the termination time are deleted. (The lit segments will turn off.)

Manual Defrost

Press the MANUAL DEFROST button to begin a manual defrost at any time during a refrigeration cycle. A manual

defrost lasts 15 minutes.

If a programmed automatic defrost is scheduled to start during a manual defrost, the control will automatically switch

from the manual defrost mode to the automatic defrost mode. The automatic defrost will end normally (time or

temperature).

If a manual defrost is started so that the refrigeration ON time between the end of the manual defrost

and the start of the next scheduled defrost violates the Short Cycle ON time requirement (see below),

the manual defrost period will be lengthened to the start of the scheduled defrost. Manual defrosts

occurring after ascheduled defrost that violate the Short Cycle OFF time requirement will initiate the

manual defrost immediately.

10

Page 11

Short Cycle Protection

The control will not schedule a compressor run (ON) time shorter than five minutes. The control will not schedule a

compressor OFF time shorter than thirty seconds except for loss of power situations.

The operator can stop or start the compressor at any time.

Program Carryover

Time will be retained for a minimum of 100 hours; program retention is indefinite.

During loss of power, the display will be blank, the indicating lights are off and the relay(s) is/are

de-energized. When power is restored (less than 100 hours), the time and program will pick up where

the program is as if there had been no loss of power.

NOTE: After 100 hours, if the clock is lost the time is set to noon, and the program resumes.

Troubleshooting

Problem Solution

The display backlight will turn on when the ADJUST knob

Backlight is not on.

is turned and will remain on for 10 seconds after the last

activity.

The display segments and backlight are not on.

All the display segments and LEDs are flashing.

The display is flashing a

G during normal operation.

1. Verify proper voltage is applied to the correct

terminals.

2. Perform PROGRAM RESET.

3. Replace timer.

The control has detected a catastrophic or

programming failure. If possible the UDT will return to

refrigerate.

1. Verify proper voltage is applied to the correct

terminals.

2. Verify wiring of the device.

3. Perform PROGRAM RESET.

4. If problem clears, reprogram the device.

5. If indication remains, replace the timer.

Indicates a shorted defrost termination switch on

Terminal G. The control will default to its timed

termination point.

1. Verify wiring of defrost termination switch.

2. Verify switch operation, and replace defrost

termination switch if necessary.

3. Once the defrost termination switch is operating

normally, the flashing G will reset automatically.

(This may take one defrost cycle to reset.)

11

Page 12

Customer Service Telephone 1.800.304.6563

Customer Service Facsimile 1.800.426.0804

HVACCustomerService@robertshaw.com

For Technical Service

Telephone 1.800.445.8299

TechnicalService@robertshaw.com

Robertshaw®, Ranco®, Paragon® and Uni-Line® are

trademarks of Robertshaw, its subsidiaries and/or

affiliated companies. All other brands mentioned

may be the trademarks of their respective owners.

www.robertshaw.com

©2016 Robertshaw

09/16 –352-00006-001 RevE

Loading...

Loading...