Page 1

The Twin Fire

Unitary Infrared Heater

Submittal: TF-Series

Job:

Location:

Engineer:

Gas Specs:

Date:

QTY. MODEL NO. TF UNIT INPUT BTU/HR

QTY. MODEL NO. TF UNIT INPUT BTU/HR

QTY. MODEL NO. TF UNIT INPUT BTU/HR

QTY. MODEL NO. TF UNIT INPUT BTU/HR

TOTAL INPUT BTU/HR

Important

Before installation and operation of heating equipment, read and understand the

Installation, Operation and Service Manual.

ROBERTS GORDON® products are to be installed only in accordance with local laws, codes and regulations, and only by a contractor qualified in

the installation and service of gas-fired heating equipment.

1250 William Street 241 South Service Road West

P.O. Box 44 Grimsby, Ontario L3M 1Y7

Buffalo, New York 14240-0044 Canada

Telephone: 716.852.4400 Telephone: 905.945.5403

Fax: 716.852.0854 Fax: 905.945.0511

Toll Free: 800.828.7450

www.rg-inc.com

Applications, engineering and detailed guidance on systems design, installation and product performance is available upon request.

Roberts-Gordon Roberts-Gordon Canada Inc.

© Copyright 2001 Roberts-Gordon

P/N190600NA 06/01

Page 2

Page 3

TABLE OF CONTENTS

STANDAR D PARTS LIST............................................. 1

Contents of TF-Series Burner Carton ..................... 1

Contents of Core and Extension Packages............. 1

GENERAL SPECIFICATIONS ...................................... 2

Material Specification .............................................. 2

Reflectors ................................................................ 2

Heater Specifications............................................... 2

Ignition .....................................................................2

Suspension Specifications....................................... 2

Controls Specifications............................................ 2

Gas Pressure at Manifold:.......................................2

Dimensions:............................................................. 2

Pipe Connection:..................................................... 2

Gas Inlet Pressure:.................................................. 2

Electrical Rating (all Models): .................................. 2

Standard Reflector.................................................. 3

One Side Reflector .................................................. 3

Two Side Reflectors ................................................ 3

45° Tilt Reflector ...................................................... 4

U-Tube, Standard Reflector..................................... 4

U-Tube, Full 45° ...................................................... 4

U-Tube, Opposite 45° Reflector .............................. 5

2-Foot Deco Grille, 1-Foot Deco Grille and

Protective Grille....................................................... 5

Lower Clearance Shield*.........................................5

Venting .................................................................... 6

TF-SERIES ASSEMBLY OVERVIEW........................... 7

Major Component Descriptions ............................... 7

TF-Series Linear Assembly Overview ................... 8

HEATER INSTALLATION............................................. 9

Critical Hanger Placement....................................... 9

TF-Series Linear Layout Overview ......................... 10

TF-Series Linear Layout Overview

(Continued).............................................................. 11

BBurner Tube Installation........................................ 12

Burner Installation.................................................... 12

Tube Clamp Package Installation............................ 13

Coupling and Tube Assembly.................................. 13

Coupling and Tube Assembly (Continued).............. 14

Turbulator Installation .............................................. 15

Reflector Installation................................................ 15

Reflector, U-Clip and Reflector Support

Installation ............................................................... 16

OPTIONAL HEATER ACCESSORIES.......................... 17

TF-Series U-Tube Assembly Overview .................. 17

TF-Series U-Tube Layout Overviews ..................... 18

TF-Series U-Tube Layout Overviews

(Continued).............................................................. 19

ELBOW PACKAGE CONFIGURAT ION........................20

Elbow Installation.....................................................20

Elbow Installation (continued) ..................................20

Reflector Joint Installation........................................20

Reflector Joint Detail................................................21

REFLECTOR SIDE EXTENSION..................................22

Bracket Installation...................................................22

Side Reflector Installation........................................22

LOWER CLEARANCE SHIELD INSTALLATION.........23

Shield Support Strap Assembly...............................23

TWO-FOOT DECORATIVE GRILLE INSTALLATION..23

Grille Installation......................................................23

Frame Shield Installation .........................................24

Reflector Side Extension Installation ......................24

ONE-FOOT DECORATIVE GRILLE INSTALLATION..25

One-Foot Decorative Grille Bracket.........................25

Decorative Grille......................................................25

Joint Piece and Reinforcement................................25

End Piece and Reflector End Cap...........................26

90° Elbow.................................................................26

PROTECTIVE GRILLE INSTALLATION.......................27

Silicone Cap Installation...........................................27

Grille End Cap Installation .......................................27

Grille Installation......................................................27

VENTING........................................................................28

Horizontal Ventilation 4" (10 cm) Pipe .....................28

Vertical Ventilation 4" (10 cm) Pipe..........................28

CFlexible Boot Installation (Single Vent)..................29

Common Sidewall Venting.......................................29

Vertical Ventilation 6" (15 cm) Pipe .........................30

Flexible Boot Installation (Common Vent)................30

OUTSIDE COMBUSTION AIR SUPPLY.......................31

Vertical Outside Air Supply .....................................31

Horizontal Outside Air Supplly.................................31

GAS PIPING...................................................................32

WIRING..........................................................................33

Line Voltage Thermostat Wiring...............................33

Low Voltage Thermostat and Relay Wiring..............34

Electrical Connection to the Burner .........................36

INTERNAL BURNER DIAGRAM...................................37

THE ROBERTS GORDON® VANTAGE® TF LIMITED

WARRANTY...................................................................38

© 2004

All rights reserved. No part of this work covered by the copyrights herein may be reproduced

or copied in any form or by any means - graphic, electronic, or mechanical, including

photocopying, recording, taping or information storage and retrieval systems - without the

written permission of Roberts-Gordon.

Printe d in U.S.A.

Page 4

Page 5

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

STANDARD PARTS LIST

Contents of TF-Series Burner Carton

Part No. Descrip tion TF-120 TF-160 TF-200 TF-250 TF-300 TF-350 TF-380

090XXXXX TF Burner Assembly (Rate and Fuel Varies) 1 1 1 1 1 1 1

02568200 Gasket 1 1 1 1 1 1 1

190100NA Installation, Operation and Service Manu al 1 1 1 1 1 1 1

94273914 Hex Head Bolts 5/ 16-18 Rolok 8 8 8 8 8 8 8

96411600 Split Lock washer 8 8 8 8 8 8 8

91412203 Flexible Gas Connector Assembly - 3/ 4" NPT 1 1 1 1 1 1 1

03051503 Turbulator Adapter 2 2 2 - - - 03051504

Turbulator 2.5

'

(76 cm) Aluminized Steel

884----

91412800 Flexible Boot 2 2 2 2 2 2 2

91901300 Boot Clamp 4 4 4 4 4 4 4

09080000 Vent Sleeve 2 2 2 2 2 2 2

Contents of Core and Extension Packages

Core Packages Extension Packages

Hot Rolled

with

Aluminum

Reflector

Alu minized

with

Aluminum

Refl ector

Aluminized

with

Stainless

Steel

Hot Rolled

with

Aluminum

Reflector

Aluminized with

Aluminum

Reflector

Aluminized with

Sta inless Steel

Refle ctor

Reflector

Part No. Description

91409300

91409408

03051101

Tube, Hot Rolled Steel, 10

'

(3m)

Tube, HT Aluminized, 10' (3 m)

Burner Tube, ALUMI-THERM® Steel, 10' (3m)

20

'

30

'

40

'

20

'

30

'

40

'

20

'

30

'

40

'

10

'

20

'

30

'

40

'

10

'

20

'

30

'

40

'

10

'

20

'

30

'

(6m)

(9m )

(12m)

(6 m )

(9m)

(12m)

(6m)

(9 m )

(12m)

(3m)

(6 m )

(9m)

(12m

(3m)

(6 m )

(9m)

(12m

(3m)

(6 m )

(9m)

40

(12m

123------1234--------

- - -123123--- -12341234

111111111------------

'

01312700 Coupling Assembly 1 23123123123412341234

02750303

Standard Reflector, 8

'

(3.5m)

346346-- -23462346- -- -

02750800 End Cap 2 22222--------------027503SS Stainless Steel Reflector, 8’ (3.5m) ------346--------2346

027508SS Stainless Steel End Cap ------222-----------03090100 Tube and Reflector Hanger 3 45345345123412341234

91907302 S-Hook 6 8 10 6 8 10 6 8 10 2 4 6 824682468

03050010 Reflector Support Package

235235457234623462346

(Strap, Wire Form, Screws)

91107720 U-Clip Package 1 11111111111111111111

90502700 Vent Adapter (Not required for TF Models) 1 11111111-----------01318901 Tube Clamp Package 1 11111222------------

Part Number

CP20HRS

CP30HRS

© 2004 Roberts-Gordon

CP40HRS

CP20ALUM

CP30ALUM

CP40ALUM

CP 20 AL U MSS

APPLICATION S, ENGI NEERING AND DETAILE D GUIDANCE ON S YSTEMS DES IGN, INSTALLATION AND P RODUCT PE RFORMANC E IS AVAILABLE UP ON REQUEST. ROB ERTS GORDON® PRODUCT S ARE T O BE

INSTALLED ONL Y IN ACCORDA NCE WI TH LOC AL LAWS , CODES AND REGUL AT IONS, AND ONLY BY A C ONTRACTOR QUA LIFIED I N THE I NSTALLATION AND SERV ICE OF GAS- FIRED HEATING EQUIPMENT.

CP 30 AL U MSS

CP 40 AL U MSS

EXP10HRS

EXP20HRS

EXP30HRS

EXP40HRS

EXP10ALUM

EXP20ALUM

EXP30ALUM

EXP40ALUM

EXP10ALUMSS

EXP20ALUMSS

EXP30ALUMSS

EXP40ALUMSS

Page 6

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

GENERAL SPECIFICATIONS

Material Specification

Reflectors

.024 Aluminum

Heater Specifications

Ignition

Automatic direct spark ignition with safety shut-off.

Suspension Specifications

Hang heater with materials with a minimum working

load of 75 lbs (33 kg).

Controls Specifications

Time switches, thermostats, etc. can be wired into

the electrical supply. External controls supplied as an

optional extra.

General Specifications for TF-Series heaters are as follows:

Side View

Reflector

23.5"

(60 cm)

End View

13.75"

(35 cm)

Length "A"

9.5"

(24 cm)

Length "A"

Length “A” Each Side Recommended

Heat Input

Rate

Minimum Maximum

Minimum Mounting

Height*

Model (BTUH X1000) Linear U-Tube Linear U-Tube Space Spot

TF-120 120 20' (6 m) 11'6" (4 m) 20' (6 m) 11'6" (4 m) 12' (4 m) 9' (3 m)

TF-160 160 20' (6 m) 11'6" (4 m) 30' (9 m) 16'6" (5 m) 15' (5 m) 11' (3 m)

TF-200 200 30' (9 m) 16'6" (5 m) 40' (12 m) 21'6" (7 m) 15' (5 m) 12' (4 m)

TF-250 250 40' (12 m) 21’ 6" (7 m) 50' (15 m) 26'6" (8 m) 20' (6 m) 15' (5 m)

TF-300 300 50' (15 m) 26'6" (8 m) 60' (18 m) 31'6" (10 m) 20' (6 m) 20' (6 m)

TF-350 350 50' (15 m) 26'6" (8 m) 70' (21 m) 36'6" (11 m) 25' (8 m) 23' (7 m)

TF-380 380 60' (18 m) 31'6" (10 m) 80' (24 m) 41'6" (13 m) 25' (8 m) 23' (7 m)

Gas Pressure at Manifold:

Natural Gas: 3.5" w.c.

LP Gas: 10.5" w.c.

Dimensions:

Vent Connection Size:

4" (10 cm) or 6" (15 cm)

Outside Air Connection Size:

4" (10 cm) or 6" (15 cm)

Refer to figure above for dimensional information.

© 2004 Roberts-Gordon

APPLI CATIONS, ENGINEERING AND DE TAILE D GUIDANCE ON S YSTEMS DE SIGN, INS TALLA TION A ND PRODUCT PE RFORMANCE IS AVAILABLE UPO N REQUEST. ROBERTS GO RDON® PRODUCTS ARE TO BE

INSTALLED ONLY I N ACCOR DANC E WITH L OCAL L AW S, C ODES AND RE GULATIONS, AND ONLY BY A CONTRACTO R QUALIFIED IN THE INST ALLAT ION AND SERVICE OF GAS-F IRED HEATING EQUIPMEN T.

Pipe Connection:

3/4" NPT

Gas Inlet Pressure:

Natural Gas: 5.0" w.c. Minimum

16.0" w.c. Maximum

LP Gas: 12.0" w.c. Minimum

16.0" w.c. Maximum

Electrical Rating (all Models):

120V - 60 Hz., 1.0 Amp

Page 7

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

NOTE: 1. All dimensions are from the surfaces of all tubes, couplings and elbows.

2. Clearances B, C and D can be reduced by 50% after 25' (7.5 m) of tubing downstream

from where the burner and burner tube connect.

Standard Reflector

(inches) (centimeters)

Model ABCDABCD

A

B

C

D

One Side Refle ctor

A

B

C

D

TF-120 6 35 63 35 16 89 161 89

TF-160 6 38 66 38 16 97 168 97

TF-200 6 40 71 40 16 102 181 102

TF-250 6 46 77 46 16 117 196 117

TF-300 6 50 80 50 16 127 204 127

TF-350 8 52 82 52 21 133 209 133

TF-380 8 52 82 52 21 133 209 133

(inches) (centimeters)

Model ABCDABCD

TF-120 6 9 63 47 16 23 161 120

TF-160 6 9 70 54 16 23 178 138

TF-200 6 9 77 59 16 23 196 150

TF-250 6 9 83 65 16 23 211 166

TF-300 6 9 86 69 16 23 219 176

TF-350 8 9 88 73 21 23 224 186

TF-380 8 9 88 73 21 23 224 186

Two Si de Reflectors

A

B

C

D

© 2004 Roberts-Gordon

(inches) (centimeters)

Model ABCDABCD

TF-120 6 23 66 23 16 59 168 59

TF-160 6 25 72 25 16 64 183 64

TF-200 6 27 78 27 16 69 199 69

TF-250 6 32 84 32 16 82 214 82

TF-300 6 35 88 35 16 89 224 89

TF-350 8 40 91 40 21 102 232 102

TF-380 8 40 91 40 21 102 232 102

APPLICATION S, ENGI NEERING AND DETAILE D GUIDANCE ON S YSTEMS DES IGN, INSTALLATION AND P RODUCT PE RFORMANC E IS AVAILABLE UP ON REQUEST. ROB ERTS GORDON® PRODUCT S ARE T O BE

INSTALLED ONL Y IN ACCORDA NCE WI TH LOC AL LAWS , CODES AND REGUL AT IONS, AND ONLY BY A C ONTRACTOR QUA LIFIED I N THE I NSTALLATION AND SERV ICE OF GAS- FIRED HEATING EQUIPMENT.

Page 8

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

NOTE: 1. All dimensions are from the surfaces of all tubes, couplings and elbows.

2. Clearances B, C and D can be reduced by 50% after 25' (7.5 m) of tubing downstream

from where the burner and burner tube connect.

45

° Tilt Reflector

(inches) (centimeters)

Model ABCDABCD

A

C

B

D

U-Tube, Standard Reflector

A

C

DB

TF-120 8 8 60 54 21 21 153 138

TF-160 8 8 66 60 21 21 168 153

TF-200 10 8 74 64 26 21 188 163

TF-250 10 8 78 69 26 21 199 176

TF-300 12 8 84 74 31 21 214 188

TF-350 12 8 85 79 31 21 216 201

TF-380 12 8 85 79 31 21 216 201

(inches) (centimeters)

Model ABCDABCD

TF-120 6 35 63 30 16 89 161 77

TF-160 6 38 69 37 16 97 176 94

TF-200 6 40 76 39 16 102 194 100

TF-250 6 46 79 43 16 117 201 110

TF-300 6 50 84 47 16 127 214 120

TF-350 8 54 87 51 21 138 221 130

TF-380 8 54 87 51 21 138 221 130

U-Tube, Full 45°

A

B

D

C

© 2004 Roberts-Gordon

(inches) (centimeters)

Model ABCDABCD

TF-120 8 8 60 42 21 21 153 107

TF-160 8 8 66 46 21 21 168 117

TF-200 8 8 74 52 21 21 188 133

TF-250 8 8 78 61 21 21 199 155

TF-300 8 8 84 66 21 21 214 168

TF-350 8 8 85 70 21 21 216 178

TF-380 8 8 85 70 21 21 216 178

APPLI CATIONS, ENGINEERING AND DE TAILE D GUIDANCE ON S YSTEMS DE SIGN, INS TALLA TION A ND PRODUCT PE RFORMANCE IS AVAILABLE UPO N REQUEST. ROBERTS GO RDON® PRODUCTS ARE TO BE

INSTALLED ONLY I N ACCOR DANC E WITH L OCAL L AW S, C ODES AND RE GULATIONS, AND ONLY BY A CONTRACTO R QUALIFIED IN THE INST ALLAT ION AND SERVICE OF GAS-F IRED HEATING EQUIPMEN T.

Page 9

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

NOTE: 1. All dimensions are from the surfaces of all tubes, couplings and elbows.

2. Clearances B, C and D can be reduced by 50% after 25' (7.5 m) of tubing downstream

from where the burner and burner tube connect.

U-Tube, Opposite 45

° Reflector

(inches) (centimeters)

Model ABCDABCD

A

B

C

D

TF-120 8 54 60 22 21 138 153 56

TF-160 8 60 66 22 21 153 168 56

TF-200 10 64 74 22 26 163 188 56

TF-250 10 70 78 22 26 178 199 56

TF-300 12 74 84 22 31 188 214 56

TF-350 12 76 85 22 31 194 216 56

TF-380 12 76 85 22 31 194 216 56

2-Foot Deco Grille, 1-Foot Deco Grille and Protective Grille

(inches) (centimeters)

Model ABCDABCD

A

C

B

D

TF-120 6 35 63 35 16 89 161 89

TF-160 6 38 66 38 16 97 168 97

TF-200 6 40 71 40 16 102 181 102

TF-250 6 46 77 46 16 117 196 117

TF-300 6 50 80 50 16 127 204 127

TF-350 8 52 82 52 21 133 209 133

TF-380 8 52 82 52 21 133 209 133

Lower Clearance Shield*

(inches) (centimeters)

Model ABCDABCD

TF-120 6 39 33 39 16 100 84 100

A

TF-160 6 40 38 40 16 102 97 102

TF-200 6 50 44 50 16 127 112 127

TF-250 6 54 48 54 16 138 122 138

B

C

D

TF-300 6 55 50 55 16 140 127 140

TF-350** Unapproved

Unapproved

TF-380** Unapproved Unapproved

*When installed in the first 20’ (6 m) on each side of the burner.

**Roberts-Gordon prohibits the installation of this heater for all unapproved applications.

© 2004 Roberts-Gordon

APPLICATION S, ENGI NEERING AND DETAILE D GUIDANCE ON S YSTEMS DES IGN, INSTALLATION AND P RODUCT PE RFORMANC E IS AVAILABLE UP ON REQUEST. ROB ERTS GORDON® PRODUCT S ARE T O BE

INSTALLED ONL Y IN ACCORDA NCE WI TH LOC AL LAWS , CODES AND REGUL AT IONS, AND ONLY BY A C ONTRACTOR QUA LIFIED I N THE I NSTALLATION AND SERV ICE OF GAS- FIRED HEATING EQUIPMENT.

Page 10

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

NOTE: 1. All dimensions are from the surfaces of all tubes, couplings and elbows.

2. Clearances B, C and D can be reduced by 50% after 25' (7.5 m) of tubing downstream

from where the burner and burner tube connect.

Venting

A

E

Unvented

Infrared Tubes

Vented

Vent

Pipes

F

(inches) (centimeters)

Model A E F A E F

TF-120 14 18 18 36 46 46

TF-160 20 24 18 51 61 46

TF-200 20 24 18 51 61 46

TF-250 20 24 18 51 61 46

TF-300 20 30 18 51 77 46

TF-350 20 30 18 51 77 46

TF-380 20 30 18 51 77 46

© 2004 Roberts-Gordon

APPLI CATIONS, ENGINEERING AND DE TAILE D GUIDANCE ON S YSTEMS DE SIGN, INS TALLA TION A ND PRODUCT PE RFORMANCE IS AVAILABLE UPO N REQUEST. ROBERTS GO RDON® PRODUCTS ARE TO BE

INSTALLED ONLY I N ACCOR DANC E WITH L OCAL L AW S, C ODES AND RE GULATIONS, AND ONLY BY A CONTRACTO R QUALIFIED IN THE INST ALLAT ION AND SERVICE OF GAS-F IRED HEATING EQUIPMEN T.

Page 11

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

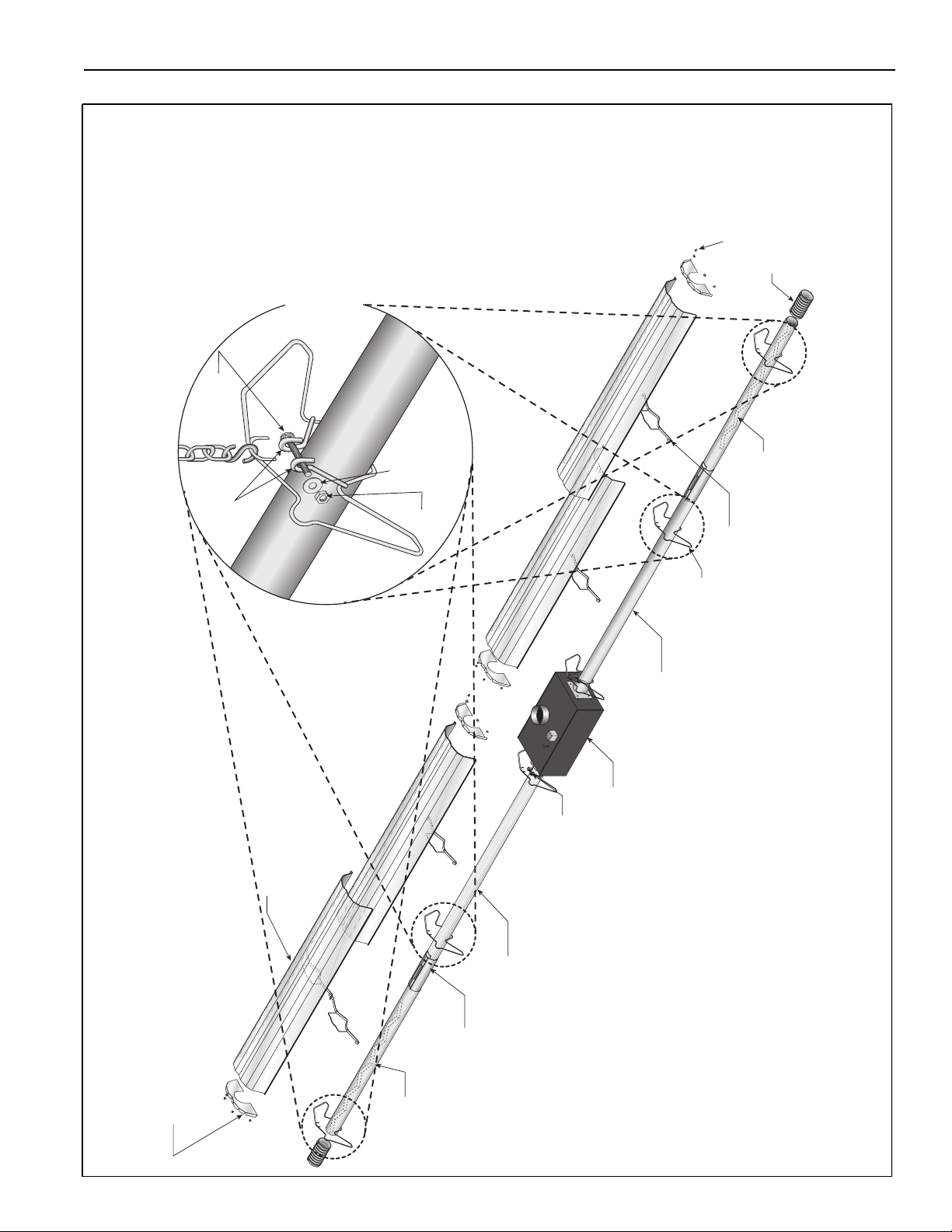

TF-SERIES ASSEMBLY OVERVIEW

Major Component Descriptions

Burner with Tube Gasket

Must be installed with the

flame observation

window facing down.

Burner Tube

Supplied in 10

'

(3 m) lengths. Burner

tube is always the first tube

after the burner.

Refle ctor E nd Cap

Punch out center

section to

accommodate heat

exchanger tube.

Reflector

(Aluminum or

Stainless

Steel)

Alternate overlap as

shown on overview and

on Page 10, Figure .

Minimum overlap is 7” (18 cm).

Tube

Hot Rolled or Heat

Treated Aluminized Tube

Supplied in 10’ (3 m) lengths.

Coupling Assembly

with Lock

Tube and Reflector Hanger

with Clamp Package

Position this hanger no more

than 4” (10 cm) away from

the burner.

Tube and Reflector Hanger

Suspend system from these

hangers.

Reflector Support Strap &

Wire Form

Flex Gas Line with

Shut Off Cock

Flexible Boot

Flexible boot is used to

connect the last tube to

the vent.

Vent Sleeve

Vent Sleeve installed

inside flexible boot.

Turbulator

Turbulator must be

installed in the last standard

section of tube. Turbulator is

not required on the TF-250/

300/350/380. For installation

see Page 15, Section .

© 2004 Roberts-Gordon

APPLICATION S, ENGI NEERING AND DETAILE D GUIDANCE ON S YSTEMS DES IGN, INSTALLATION AND P RODUCT PE RFORMANC E IS AVAILABLE UP ON REQUEST. ROB ERTS GORDON® PRODUCT S ARE T O BE

INSTALLED ONL Y IN ACCORDA NCE WI TH LOC AL LAWS , CODES AND REGUL AT IONS, AND ONLY BY A C ONTRACTOR QUA LIFIED I N THE I NSTALLATION AND SERV ICE OF GAS- FIRED HEATING EQUIPMENT.

Page 12

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

F

la

t

W

a

s

h

e

r

Nut

(Tor

que

120 in/lb

13.56

Nm

)

Tube

Clamp

B

o

lt

TF-Series Linear Assembly Overview

on each side of the burner.

used at the two farthest hangers

For shorter than minimum

suspension lengths,

tube clamps must be

U-Clips

Flexible Boot

Reflector

Turbulator

Reflector Support

Burner Tube

Tube and Reflector Hanger

Burner

Tube Clamp Package

Reflector End Cap

© 2004 Roberts-Gordon

APPLI CATIONS, ENGINEERING AND DE TAILE D GUIDANCE ON S YSTEMS DE SIGN, INS TALLA TION A ND PRODUCT PE RFORMANCE IS AVAILABLE UPO N REQUEST. ROBERTS GO RDON® PRODUCTS ARE TO BE

INSTALLED ONLY I N ACCOR DANC E WITH L OCAL L AW S, C ODES AND RE GULATIONS, AND ONLY BY A CONTRACTO R QUALIFIED IN THE INST ALLAT ION AND SERVICE OF GAS-F IRED HEATING EQUIPMEN T.

Tube

Burner Tube

Coupling

Page 13

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

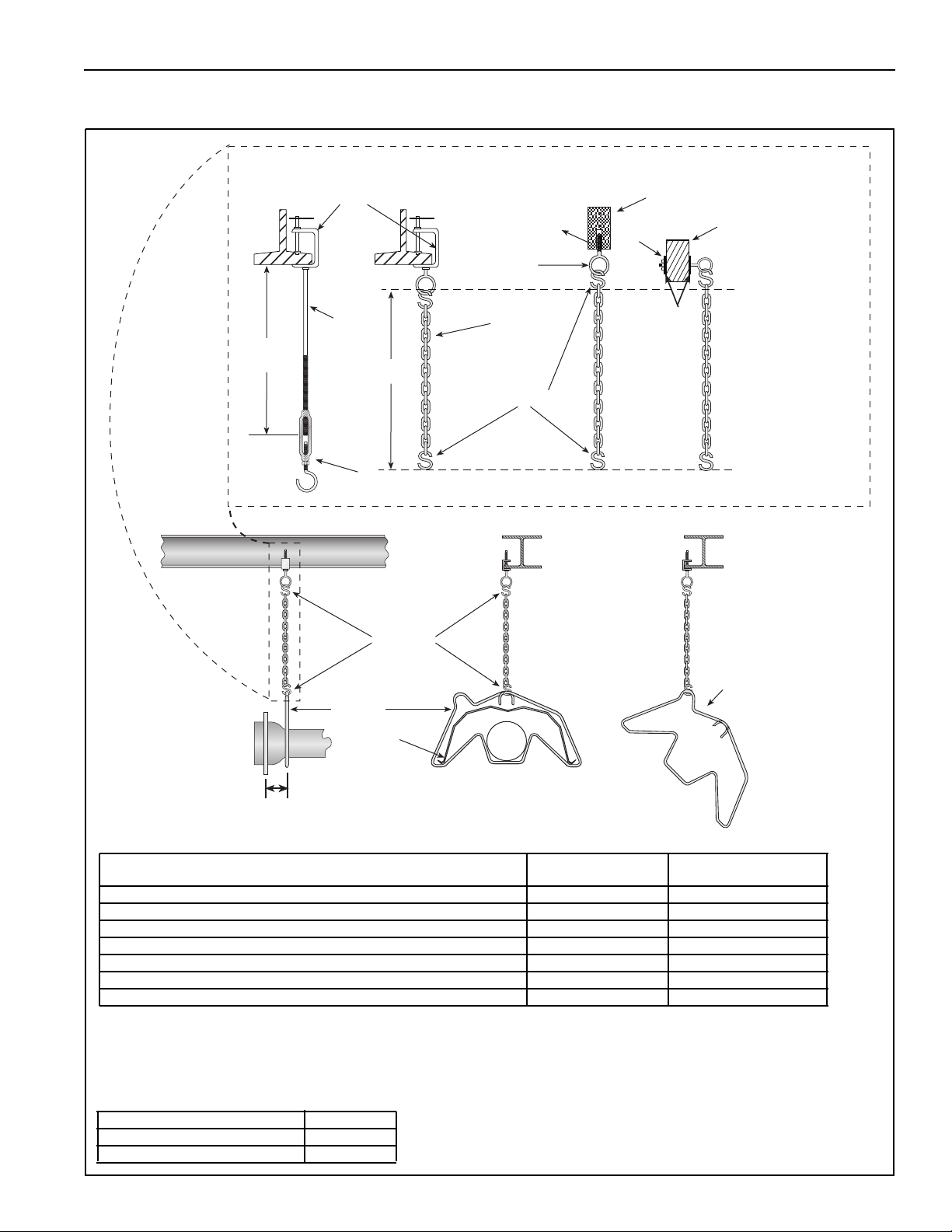

HEATER INSTALLATION

Critical Hanger Placement

Typical Suspension Details

24" min.*

(61 cm)

Beam Clamp

Rod (3/8")

X*

Turnbuckle

Not Included

S Hooks

Concrete Beam

Anchor

Locknut

Screw Hook

(3/8")

Chain size

3/16" minimum

Washers

S Hooks

* Allows for thermal expansion of system

Wood Beam

Side View

Hanger

Hanger

Reflector

Must Be Within 4" (10 cm) Front View

Total Straight Length (both sides) or Length from U-Tube to U-Tube

in a Double "U" Layout

0’ - 50’ ±1” (3 cm) 12” (31 cm)

51’ - 60’ ±2” (5 cm) 18” (46 cm)

61’ - 80’ ±3” (8 cm) 24” (61 cm)

81’ - 100’ ±4” (10 cm) 30" (76 cm)

101’ - 120’ ±5” (13 cm) 36" (91 cm)

121’ - 140’ ±6” (15 cm) 42" (107 cm)

141’ - 160’ ±7” (18 cm) 48" (122 cm)

Typical Expansion

Each Si de

45° Angle

Minimum “X” Length

If the installation requires a shorter suspension length than the minimum listed, the suspension

length may be reduced by 6" (16 cm). In this case tube clamps MUST be used at the two farthest

hangers on each side of the burner. See Page 8, Figure .

Description Part Number

S-Hoo k 9190 7302

Tube/Refl ecto r Hanger 0309 01 00

© 2004 Roberts-Gordon

APPLICATION S, ENGI NEERING AND DETAILE D GUIDANCE ON S YSTEMS DES IGN, INSTALLATION AND P RODUCT PE RFORMANC E IS AVAILABLE UP ON REQUEST. ROB ERTS GORDON® PRODUCT S ARE T O BE

INSTALLED ONL Y IN ACCORDA NCE WI TH LOC AL LAWS , CODES AND REGUL AT IONS, AND ONLY BY A C ONTRACTOR QUA LIFIED I N THE I NSTALLATION AND SERV ICE OF GAS- FIRED HEATING EQUIPMENT.

Page 14

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

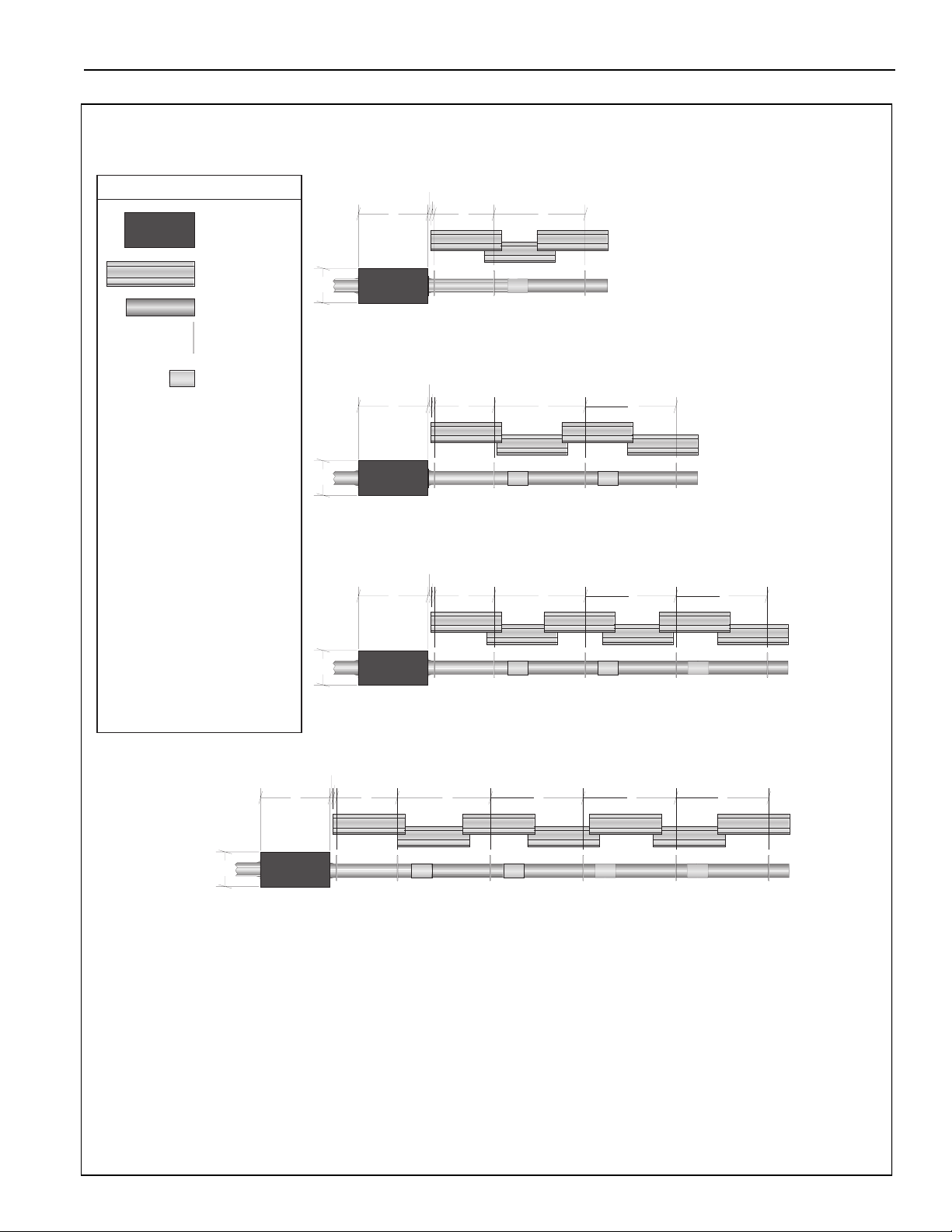

TF-Series Linear Layout Overview

Linear layouts showing one side. Use same measurements for the other side.

LEGEND

Burner

Reflector

Tube

Tube/Reflector

Hanger

Coupling

Assembly

a = 14" (36 cm)

reflector width (not shown)

b = 2" (5 cm)

end cap to burner

c = 2" (5 cm)

end cap to hanger

d = 7'6" (229 cm)

distance first hanger

e = 10' (305 cm)

distance between hangers

f = 9.5" (24 cm)

burner height

b

c

g

f

TF-120

de

20' (6m) Tube Length (each side)

TF-160

b

c

g

f

TF-160

de

30' (9m) Tube Length (each side)

e

TF-200

b

c

g

de

e e

g = 23.5" (60 cm)

burner length

f

TF-200

40' (12m) Tube Length (each side)

TF-250

b

c

g

f

de

TF-250

50' (15m) Tube Length (each side)

e e e

TF-300

TF-350

© 2004 Roberts-Gordon

APPLI CATIONS, ENGINEERING AND DE TAILE D GUIDANCE ON S YSTEMS DE SIGN, INS TALLA TION A ND PRODUCT PE RFORMANCE IS AVAILABLE UPO N REQUEST. ROBERTS GO RDON® PRODUCTS ARE TO BE

INSTALLED ONLY I N ACCOR DANC E WITH L OCAL L AW S, C ODES AND RE GULATIONS, AND ONLY BY A CONTRACTO R QUALIFIED IN THE INST ALLAT ION AND SERVICE OF GAS-F IRED HEATING EQUIPMEN T.

Page 15

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

TF-Series Linear Layout Overview (Continued)

b

c

g

f

de

e e e e

TF-300

60' (18m) Tube Length (each side)

TF-350

TF-380

b

c

g

de

e e e e e

b

f

TF-350

70' (21m) Tube Length (each side)

TF-380

b

c

g

de

b

e e e e e

f

TF-380

© 2004 Roberts-Gordon

80' (24m) Tube Length (each side)

APPLICATION S, ENGI NEERING AND DETAILE D GUIDANCE ON S YSTEMS DES IGN, INSTALLATION AND P RODUCT PE RFORMANC E IS AVAILABLE UP ON REQUEST. ROB ERTS GORDON® PRODUCT S ARE T O BE

INSTALLED ONL Y IN ACCORDA NCE WI TH LOC AL LAWS , CODES AND REGUL AT IONS, AND ONLY BY A C ONTRACTOR QUA LIFIED I N THE I NSTALLATION AND SERV ICE OF GAS- FIRED HEATING EQUIPMENT.

Page 16

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

7' 6" ± 1'

(229 cm ± 25 cm)

S

Hook

Burner Tube

Hanger

29"± 2"

(73 cm ± 5 cm)

BBurner Tube Installation

NOTE:

Tubing requires a downward

slope of 1/2" (13 mm)

per 20' (6 m) away

from burner.

Description Par t Numbe r

Burn er Tu be 03051 XXX

S-Hook 9190 7302

Tube/Ref le cto r Ha nger 0309 0100

Offset mounting

hole must be

to the top

Weld Seam

must be to the

bottom of the tube.

Burner Installation

Description Part Number

Bolt 9427 3914

Lock Wash er 96 41160 0

Gasket 02568200

Burn er 090XX XXX

© 2004 Roberts-Gordon

APPLI CATIONS, ENGINEERING AND DE TAILE D GUIDANCE ON S YSTEMS DE SIGN, INS TALLA TION A ND PRODUCT PE RFORMANCE IS AVAILABLE UPO N REQUEST. ROBERTS GO RDON® PRODUCTS ARE TO BE

INSTALLED ONLY I N ACCOR DANC E WITH L OCAL L AW S, C ODES AND RE GULATIONS, AND ONLY BY A CONTRACTO R QUALIFIED IN THE INST ALLAT ION AND SERVICE OF GAS-F IRED HEATING EQUIPMEN T.

Bolt

Lock Washer

Gasket

Burner

Page 17

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

Bolt

Flat

Washer

Tube Clamp

Tube Clamp Package Installation

Nut

(Tor

que

120 in/lb

13.56 Nm

)

Description Part Number

Tube Clamp Package 01318901

Tube Clamp 01396801

Bolt 97113940

Flat Washer 95211600

Nut 921 13900

Coupling a nd Tube Asse mbly

Close coupling

A

with tab

Open

Closed

Insert tubes into coupling

C

Tab

Start Slide bar/Coupling Lock

B

onto coup ling

3" (8 cm) to

4" (10 cm)

Tighte n coupling to join tube s

D

Slide Bar/Coupling Lock

Wide end

Coupling

© 2004 Roberts-Gordon

Slide Bar/Coupling Lock

Orient coupling so that

the impact block is in the

2:00 or 10:00 oclock

positions

Tube

Tube

APPLICATION S, ENGI NEERING AND DETAILE D GUIDANCE ON S YSTEMS DES IGN, INSTALLATION AND P RODUCT PE RFORMANC E IS AVAILABLE UP ON REQUEST. ROB ERTS GORDON® PRODUCT S ARE T O BE

INSTALLED ONL Y IN ACCORDA NCE WI TH LOC AL LAWS , CODES AND REGUL AT IONS, AND ONLY BY A C ONTRACTOR QUA LIFIED I N THE I NSTALLATION AND SERV ICE OF GAS- FIRED HEATING EQUIPMENT.

Descr ipti on Part Number

Coupling 013 29600

Slide bar/Coupling Lock 01329700

Tube 91 409X XX

Tube

Coupling

Page 18

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

Coupling and Tube Assembly (Continued)

Tighten slide bar as shown below

Drive Slide Bar until tight.

End of Slide Bar should be

within tolerance listed below.

± 2" (5 cm)

Correct Slide Bar

dimensions

Incorrect Slide Bar

position

• Repeat A - D until all tubes are assembled.

Coupling and Tube Assembly (Continued)

Tube Length Per Side

Model

TF-120 20’ (6 m) 20’ (6 m)

TF-160 20’ (6 m) 30’ (9 m)

TF-2 00 3 0’ ( 9 m ) 40 ’ (12 m)

TF-2 50 40 ’ (12 m) 50 ’ (15 m)

TF-3 00 50 ’ (15 m) 60 ’ (18 m)

TF-3 50 50 ’ (15 m) 70 ’ (21 m)

TF-3 80 60 ’ (18 m) 80 ’ (24 m)

Minimum Maximum

See recommended venting lengths

on Page 28, Section , when using

maximum tube lengths.

© 2004 Roberts-Gordon

7' 6" ± 1'

(229 cm ± 25 cm)

10' Typ. ± 1'

(254 cm Typ ± 25 cm)

APPLI CATIONS, ENGINEERING AND DE TAILE D GUIDANCE ON S YSTEMS DE SIGN, INS TALLA TION A ND PRODUCT PE RFORMANCE IS AVAILABLE UPO N REQUEST. ROBERTS GO RDON® PRODUCTS ARE TO BE

INSTALLED ONLY I N ACCOR DANC E WITH L OCAL L AW S, C ODES AND RE GULATIONS, AND ONLY BY A CONTRACTO R QUALIFIED IN THE INST ALLAT ION AND SERVICE OF GAS-F IRED HEATING EQUIPMEN T.

Page 19

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

Turbulator Installation

Turbulator

2.5' Section

Turbulator must be installed in

the last standard section of

tube.

T

w

i

s

t

Turbulator

Adapter

Description Part Number

Tu r bul a tor Section 1 03051 50 3

Tu r bul a tor Section 2 03051 50 4

Tube 91409XXX

Reflector Installation

Tab

Pull String

Fold tab around outside

of tube nearest to the vent to hold turbulator

in place. Where a vent sleeve

is used, do not fold tab.

NOTE: All tube surfaces must be covered

by a reflector, except for a U-Tube.

Burner

Hanger

Burner Tube

Description Part Number

Tube/ Reflector Hang er 030 901 00

Bur ne r Tu be 0305 1XX X

Ref lector 027 50303

© 2004 Roberts-Gordon

APPLICATION S, ENGI NEERING AND DETAILE D GUIDANCE ON S YSTEMS DES IGN, INSTALLATION AND P RODUCT PE RFORMANC E IS AVAILABLE UP ON REQUEST. ROB ERTS GORDON® PRODUCT S ARE T O BE

INSTALLED ONL Y IN ACCORDA NCE WI TH LOC AL LAWS , CODES AND REGUL AT IONS, AND ONLY BY A C ONTRACTOR QUA LIFIED I N THE I NSTALLATION AND SERV ICE OF GAS- FIRED HEATING EQUIPMENT.

Reflector

Page 20

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

Reflector, U-Clip and Reflector Support Installation

The pictorial drawings of the heater construction in

this Section are schematic only and provide a general guideline of where hangers, reflector supports

and U-clips are to be installed.

1. The first reflector after the burner must be affixed in

the middle of the reflector with a reflector support and

tight screws.

Reflector

End Cap

First Reflector

U-Clips

To ensure proper expansion and contraction movement of the reflectors, a combination of U-clips and

reflector supports are used. The positioning of reflector supports and U-clips depend on the individual

installation. The following rules must be observed.

Tight

Sheet Metal

Wire Form

Reflector Support

Strap

Screw

Overlap must be a

minimum of 6" (16 cm)

6"

(16 cm)

2. The overlap at the first and second reflector is a slip overlap.

Thereafter, every third reflector joint is a slip overlap. A slip

overlap is achieved by either:

a.) both reflectors lay inside a hanger.

(no reflector support needed).

b.) using a reflector support with

loose screws at the reflector

overlap.

3. The remaining reflector overlaps require a non-slip

overlap connection. To affix the reflectors together in

a non-slip overlap either:

a.) use reflector support and tight screws.

b.) if both reflectors lay inside a hanger, u-clips or

sheet metal screws may be used.

This section of three reflectors joined together must

be affixed to the tube with at least one reflector support

with tight screws.

Option B

Non-Slip Overlap

Option A

Slip Overlap

Option B

Slip Overlap

Option A

Non-Slip Overlap

Reflector

Reflector

Support

Loose screws

loosened 1/16"

(2 mm) to allow

slippage.

Reflector

Tight

screws

Description Part Number

Reflector Suppor t Package 03050010

Wir e Form 91 90 8004

Reflect or Supp ort S trap 030500 00

Screw #8 x 3/4 94320812

U-Clip Package 91107720

Reflector End Cap 027508XX

© 2004 Roberts-Gordon

APPLI CATIONS, ENGINEERING AND DE TAILE D GUIDANCE ON S YSTEMS DE SIGN, INS TALLA TION A ND PRODUCT PE RFORMANCE IS AVAILABLE UPO N REQUEST. ROBERTS GO RDON® PRODUCTS ARE TO BE

INSTALLED ONLY I N ACCOR DANC E WITH L OCAL L AW S, C ODES AND RE GULATIONS, AND ONLY BY A CONTRACTO R QUALIFIED IN THE INST ALLAT ION AND SERVICE OF GAS-F IRED HEATING EQUIPMEN T.

U-Clip

(2 clips per

non-slip overlap

inside a hanger)

Page 21

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

OPTIONAL HEATER ACCESSORIES

TF-Series U-Tube Assembly Overview

Reflector End Cap

Coupling

Burner Tube

U-Tube Support

Bracket Assembly

U-Tube, Standard

1 2

U-Tube, Full 45°

Tube Clamp Package

Burner

Reflector

Turbulator

Reflector Support

Description Part Number

U-Tube Pac kage 0301 100 0

180° U - Tub e 01 33590 1

Tube a nd Re flect or H an ger 0309 0100

Coupling 0131 2700

Reflect or End Ca p (2) 0275 080 0

U-Tube Support Bracket 03020501

4" (10 cm) U-Bolts (2) 90912500

Reflector Suppor t Set 03050010

S-Hook 9190 7302

Hex Nut 92113000

Lock Wash er 9641 150 0

U-Clips

180° U-Tube

18" (45.7 cm)

Center to Center

Tube

2

1

U-Tube, Opposite 45°

1 2

Tight U-Bolt

1 2

4" (10 cm) U-Bolt,

secured to Burner Tube

with 1/4" (6 mm)

Lockwashers and

1/4-20 Hex Nuts

Loose U-Bolt

4" (10 cm) U-Bolt,

secured to Bracket with

1/4" (6 mm) Lockwashers

and 1/4-20 Hex Nuts on

top and bottom to

allow for tube expansion

and contraction

U-Bolt

Nut

Lock Washer

Lock Washer

Nut

© 2004 Roberts-Gordon

APPLICATION S, ENGI NEERING AND DETAILE D GUIDANCE ON S YSTEMS DES IGN, INSTALLATION AND P RODUCT PE RFORMANC E IS AVAILABLE UP ON REQUEST. ROB ERTS GORDON® PRODUCT S ARE T O BE

INSTALLED ONL Y IN ACCORDA NCE WI TH LOC AL LAWS , CODES AND REGUL AT IONS, AND ONLY BY A C ONTRACTOR QUA LIFIED I N THE I NSTALLATION AND SERV ICE OF GAS- FIRED HEATING EQUIPMENT.

Page 22

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

TF-Series U-Tube Layout Overviews

U-tube layouts showing one side. Use same measurements for the other side.

LEGEND

Burner

Reflector

Tube 10' (3m)

Tube 5' (1.5m)**

Tube/Reflector

Hanger

Coupling

Assembly

U-Tube

a = 14" (36 cm)

reflector width (not shown)

b = 2" (5 cm)

end cap to burner

c = 2" (5 cm)

end cap to hanger

d = 7'6" (229 cm)

distance first hanger

b

c

g

h

TF-120

20' (6m) Tube Length* (each side)

e

TF-160

b

c

g

h

TF-160

d

30' (9m) Tube Length**(each side)

f

TF-200

b

c

g

de

e = 10' (305 cm)

distance between hangers

f = 5' (153 cm)

distance between last full tube

hanger and half tube hanger

g = 17.5" (44 cm)

burner length

h = 9.5" (24 cm)

burner height

*Requires the last reflector

before the U-Tube to be cut

in half for use on both sides.

**Requires the last tube before

the U-Tube to be cut in half for

use on both sides.

h

TF-200

40' (12m) Tube Length (each side)

TF-250

b

c

g

h

TF-250

de

50' (15m) Tube Length* ** (each side)

f

TF-300

TF-350

© 2004 Roberts-Gordon

APPLI CATIONS, ENGINEERING AND DE TAILE D GUIDANCE ON S YSTEMS DE SIGN, INS TALLA TION A ND PRODUCT PE RFORMANCE IS AVAILABLE UPO N REQUEST. ROBERTS GO RDON® PRODUCTS ARE TO BE

INSTALLED ONLY I N ACCOR DANC E WITH L OCAL L AW S, C ODES AND RE GULATIONS, AND ONLY BY A CONTRACTO R QUALIFIED IN THE INST ALLAT ION AND SERVICE OF GAS-F IRED HEATING EQUIPMEN T.

Page 23

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

TF-Series U-Tube Layout Overviews (Continued)

b

c

g

h

de

e

TF-300

60' (18m) Tube Length (each side)

TF-350

b

c

g

h

TF-350

de

70' (21m) Tube Length** (each side)

e

f

TF-380

b

c

g

h

de

e

e

TF-380

© 2004 Roberts-Gordon

80' (24m) Tube Length** (each side)

APPLICATION S, ENGI NEERING AND DETAILE D GUIDANCE ON S YSTEMS DES IGN, INSTALLATION AND P RODUCT PE RFORMANC E IS AVAILABLE UP ON REQUEST. ROB ERTS GORDON® PRODUCT S ARE T O BE

INSTALLED ONL Y IN ACCORDA NCE WI TH LOC AL LAWS , CODES AND REGUL AT IONS, AND ONLY BY A C ONTRACTOR QUA LIFIED I N THE I NSTALLATION AND SERV ICE OF GAS- FIRED HEATING EQUIPMENT.

Page 24

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

ELBOW PACKAGE CONFIGURATION

Elbow Installation

Tube

Description P art Number

Elbow Pa ckage 02718 70 2

90° Elbow 01335 801

Coupling 01312 700

Reflecto r End Cap 02 75080 0

Reflecto r Joint Piece 02 75090 0

U-Clip Pa ck age 9110772 0

Elbow Installation (continued)

Coupling

90° Elbow

Reflector Joint Installation

Reflector

Tube

Coupling

Reflector

Joint

Reflector Joi29

© 2004 Roberts-Gordon

Scribe

Flatten Edge

Contour

1" (2.5 cm)

maximum

APPLI CATIONS, ENGINEERING AND DE TAILE D GUIDANCE ON S YSTEMS DE SIGN, INS TALLA TION A ND PRODUCT PE RFORMANCE IS AVAILABLE UPO N REQUEST. ROBERTS GO RDON® PRODUCTS ARE TO BE

INSTALLED ONLY I N ACCOR DANC E WITH L OCAL L AW S, C ODES AND RE GULATIONS, AND ONLY BY A CONTRACTO R QUALIFIED IN THE INST ALLAT ION AND SERVICE OF GAS-F IRED HEATING EQUIPMEN T.

Page 25

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

nt Installation

Reflector Joint Detail

Cut away contour

with tin snips.

Punch/Drill six 3/32" (2 mm) holes

Install Reflector

End Cap

Reflector Joint Detail

Attach Reflector Joint

with six #8 sheet

metal screws

Reflector

Reflector

Joint

© 2004 Roberts-Gordon

APPLICATION S, ENGI NEERING AND DETAILE D GUIDANCE ON S YSTEMS DES IGN, INSTALLATION AND P RODUCT PE RFORMANC E IS AVAILABLE UP ON REQUEST. ROB ERTS GORDON® PRODUCT S ARE T O BE

INSTALLED ONL Y IN ACCORDA NCE WI TH LOC AL LAWS , CODES AND REGUL AT IONS, AND ONLY BY A C ONTRACTOR QUA LIFIED I N THE I NSTALLATION AND SERV ICE OF GAS- FIRED HEATING EQUIPMENT.

Page 26

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

REFLECTOR SIDE EXTENSION

Bracket Installation

Tube

Description Part Number

Reflector Side Extension Package 02712700

Reflector Side Extension 01368000

Retainer Clips 02751200

Shee t Metal Screws 94 1181 06

Reflector

Tube and Reflector Hanger

Reflector Support

Reflector Side

Extension Bracket

(2 per reflector)

Use additional supports

in high air movement

applications.

Order Separately

Reflector Side Extension 01329910

Side Reflector Installation

#8 x 3/8" Sheet Metal Screw

© 2004 Roberts-Gordon

Retainer Clip

(2 per side)

Reflector Side Extension

APPLI CATIONS, ENGINEERING AND DE TAILE D GUIDANCE ON S YSTEMS DE SIGN, INS TALLA TION A ND PRODUCT PE RFORMANCE IS AVAILABLE UPO N REQUEST. ROBERTS GO RDON® PRODUCTS ARE TO BE

INSTALLED ONLY I N ACCOR DANC E WITH L OCAL L AW S, C ODES AND RE GULATIONS, AND ONLY BY A CONTRACTO R QUALIFIED IN THE INST ALLAT ION AND SERVICE OF GAS-F IRED HEATING EQUIPMEN T.

Page 27

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

Washers

Screws

Locknuts

LOWER CLEARANCE SHIELD INSTALLATION

Shield Support Strap Assembly

12"

17.1"

(434 mm)

Align pilot holes

(300 mm)

Reflector

Lower Clearance Shield

TWO-FOOT DECORATIVE GRILLE INSTALLATION

Grille Installation

Reflector

Tube

Descr ipti on Part N u mber

Lower C lea rance S hiel d Pack age 0139 7501

Shield Support Strap 01397500

Lower Clear an ce Shie ld 0279 300 0

Locknu t #8 92 31140 0

Fl at Wash er #8 9531 080 0

Scr ew #8 x 3/8" 9351 1406

Tube and Reflector

Hanger

Suspended Ceiling Frame

© 2004 Roberts-Gordon

61 x 122 cm Aluminium Grille

Description Part Number

Aluminium Grille 2’ x 4’ 91407000

APPLICATION S, ENGI NEERING AND DETAILE D GUIDANCE ON S YSTEMS DES IGN, INSTALLATION AND P RODUCT PE RFORMANC E IS AVAILABLE UP ON REQUEST. ROB ERTS GORDON® PRODUCT S ARE T O BE

INSTALLED ONL Y IN ACCORDA NCE WI TH LOC AL LAWS , CODES AND REGUL AT IONS, AND ONLY BY A C ONTRACTOR QUA LIFIED I N THE I NSTALLATION AND SERV ICE OF GAS- FIRED HEATING EQUIPMENT.

Page 28

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

Frame Shield Installation

Shield

Reflector Side Extension Installation

NOTE: If the Decorative Grille system is to

be installed in an area with considerable

air movement, it is recommended that one

#8 x 3/8 (3.9 x 9.5mm) sheet metal screw

be installed per reflector extension to

prevent it from blowing over.

Descr ipti on Part Number

Deco Grille Shield 01365900

Cut Relief Notches for Tube

and Reflector Hangers

Insert Screw

here

A

Reflector Side

Extension

Distance "A" Extension

Minimum Maximum Par t No. Width

2" (4 cm) 6" ( 15 cm) 013 70408 8" (20 cm)

6" ( 15 cm) 10" (26 cm) 0 13704 12 12" (30 cm)

10" (26 cm) 14" (37 cm) 0 13704 16 16" (40 cm)

© 2004 Roberts-Gordon

APPLI CATIONS, ENGINEERING AND DE TAILE D GUIDANCE ON S YSTEMS DE SIGN, INS TALLA TION A ND PRODUCT PE RFORMANCE IS AVAILABLE UPO N REQUEST. ROBERTS GO RDON® PRODUCTS ARE TO BE

INSTALLED ONLY I N ACCOR DANC E WITH L OCAL L AW S, C ODES AND RE GULATIONS, AND ONLY BY A CONTRACTO R QUALIFIED IN THE INST ALLAT ION AND SERVICE OF GAS-F IRED HEATING EQUIPMEN T.

Description P art N umber

Reflecto r Side Ext ensio n 01 37041 2

Page 29

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

Spread apart brackets

and install

Decorative Grille.

#8 Sheet Metal Screws

Joint Piece

Reinforcement

Slip joint piece into

support bracket

and fasten to

bracket on one side

of the joint only.

Joint Piece

ONE-FOOT DECORATIVE GRILLE INSTALLATION

One-Foot Decorative Grille Bracket

#8 Sheet Metal Screws

In order to maintain reflector shape, do

not fasten brackets together. Do not

fasten bracket to adjoining reflectors.

Maintain same slipjoint position as

reflectors.

Decorative Grille Bracket

Description Part Number

Bracket 0136 3003

Decorative Grille

Description Part Number

Decor at ive Gr i lle 8’ x 1 ’ 9140 6700

Joint Piece and Reinforcement

Cut relief notches for

supports and hangers.

2"

Minimum

Bracket

Overlap

Description Par t Numbe r

Joint Piece 01365903

Reinforcement 01365902

© 2004 Roberts-Gordon

APPLICATION S, ENGI NEERING AND DETAILE D GUIDANCE ON S YSTEMS DES IGN, INSTALLATION AND P RODUCT PE RFORMANC E IS AVAILABLE UP ON REQUEST. ROB ERTS GORDON® PRODUCT S ARE T O BE

INSTALLED ONL Y IN ACCORDA NCE WI TH LOC AL LAWS , CODES AND REGUL AT IONS, AND ONLY BY A C ONTRACTOR QUA LIFIED I N THE I NSTALLATION AND SERV ICE OF GAS- FIRED HEATING EQUIPMENT.

Page 30

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

Fasten end piece

to brackets using two

#8 sheet metal screws

and replace reflector end cap.

Insert end piece

between grille and

brackets.

End Piece

Reflector

End Cap

Insert

End Piece

between

grille and

brackets.

Joint Piece

Cut grille bracket at

reflector joint piece.

Grille Brackets

Inside

Corner

Decorative Grille

Brackets

Joint Piece

End Piece and Reflector End Cap

90° Elbow

Descr ipti on Part Number

End Piece 013 65 901

© 2004 Roberts-Gordon

APPLI CATIONS, ENGINEERING AND DE TAILE D GUIDANCE ON S YSTEMS DE SIGN, INS TALLA TION A ND PRODUCT PE RFORMANCE IS AVAILABLE UPO N REQUEST. ROBERTS GO RDON® PRODUCTS ARE TO BE

INSTALLED ONLY I N ACCOR DANC E WITH L OCAL L AW S, C ODES AND RE GULATIONS, AND ONLY BY A CONTRACTO R QUALIFIED IN THE INST ALLAT ION AND SERVICE OF GAS-F IRED HEATING EQUIPMEN T.

Page 31

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

PROTECTIVE GRILLE INSTALLATION

Silicone Cap Installation

Silicone Cap

Grille

Finger

Description Part Number

Grille Se ction 0 80500 01

Grille En d Cap 0 80 50002

Silicone Cap 91915951-6P

Grille End Cap Installation

A

Grille

Grille End Cap

B

CD

Bend up 90°

Pull outward

Grille Installation

40 "

(101 cm)

© 2004 Roberts-Gordon

Reflector

Final Grille

Section

Grille

Grille

End Cap

APPLICATION S, ENGI NEERING AND DETAILE D GUIDANCE ON S YSTEMS DES IGN, INSTALLATION AND P RODUCT PE RFORMANC E IS AVAILABLE UP ON REQUEST. ROB ERTS GORDON® PRODUCT S ARE T O BE

INSTALLED ONL Y IN ACCORDA NCE WI TH LOC AL LAWS , CODES AND REGUL AT IONS, AND ONLY BY A C ONTRACTOR QUA LIFIED I N THE I NSTALLATION AND SERV ICE OF GAS- FIRED HEATING EQUIPMENT.

Page 32

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

VENTING

Horizontal Ventilation 4" (10 cm) Pipe

Burner

Flexible

Boot

Combustible or

Non-Combustible

Wall

Vent Terminal

Description Part Number

Fl exible B oot 9141 2800

Boot Clamp 91901300

Vent Termina l (Com b. Wall) 90 50 21 00

Vent Terminal (Non-Comb Wall) 02537801-1P

Wall Thimble 90505600

Vent Sleeve 09 08 0000

Vertical Ventilation 4" (10 cm) Pipe

Vent Cap

4" (10cm)

Roof

Secure all

joints with (3)

#8 x 3/8 Sheet

Metal Screws

Tube

Install with boot

extended

Boot Clamp

Burner

Single Wall

Vent Pipe

4" (10 cm) Single Wall Pipe

Non-Combustible

Wall

4" (10 cm) Single Wall Pipe

Single Wall

Flexible

Boot

(Type 'B' vent pipe

must be used for

pipe exiting building)

Wall

Thimble

Metalbestos

Cap

18" (46 cm)

Min.

Vent Terminal

Vent Pipe

Description Part Number

Vent Cap 4" (10 cm) 90502300

© 2004 Roberts-Gordon

APPLI CATIONS, ENGINEERING AND DE TAILE D GUIDANCE ON S YSTEMS DE SIGN, INS TALLA TION A ND PRODUCT PE RFORMANCE IS AVAILABLE UPO N REQUEST. ROBERTS GO RDON® PRODUCTS ARE TO BE

INSTALLED ONLY I N ACCOR DANC E WITH L OCAL L AW S, C ODES AND RE GULATIONS, AND ONLY BY A CONTRACTO R QUALIFIED IN THE INST ALLAT ION AND SERVICE OF GAS-F IRED HEATING EQUIPMEN T.

Tube

Flexible

Boot

Page 33

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

Boot Clamp

Single Wall

Vent Pipe

Flexible

Boot

Tube

Bead

2 min.

(5 cm)

CFlexible Boot Installation (Single Vent)

Flexible Boot Installation

for Single Vent

Vent

3"

(8 cm)

2"

(5 cm)

Expansion

Gap

3"

(8 cm)

Tube

Bead

Flexible Boot

Description Part Number

Rolled Sleeve 090 80 000

Fle xible B oot 4" ( 10 cm) 914 12 800

Boot Clamp 4" ( 10 cm) 9 1901 300

Common Sidewall Venting

Burner

Vent Sleeve

Boot Clamp

6" (15 cm) Single Wall Pipe

Vent Terminal

Plan View

Description Part Number

Vent Tee 91 91610 0

Vent Ter minal 6" ( 15 cm) 90 50210 1

© 2004 Roberts-Gordon

APPLICATION S, ENGI NEERING AND DETAILE D GUIDANCE ON S YSTEMS DES IGN, INSTALLATION AND P RODUCT PE RFORMANC E IS AVAILABLE UP ON REQUEST. ROB ERTS GORDON® PRODUCT S ARE T O BE

INSTALLED ONL Y IN ACCORDA NCE WI TH LOC AL LAWS , CODES AND REGUL AT IONS, AND ONLY BY A C ONTRACTOR QUA LIFIED I N THE I NSTALLATION AND SERV ICE OF GAS- FIRED HEATING EQUIPMENT.

Tube

* IMPORTANT

Compress boot on installation

to allow at least 2" (5 cm) of

movement on each side for

thermal expansion of tube

away from the tee.

Combustible or

Non-Combustible

Wall

Vent Tee

Flexible

Boot*

Boot

Clamp

6" (15 cm)

Vent Pipe

Page 34

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

Vertical Ventilation 6" (15 cm) Pipe

Vent Terminal

6" (15 cm) Single

Wall Pipe

Burner

Description Part Number

Vent C ap 6 " (15 cm) 905 02302

Tube

Roof

Vent Pipe

Flexible

Boot

*

Boot Clamp

Vent Tee

* IMPORTANT

Compress boot on installation to allow at least

2" (5 cm) of movement on each side for thermal

expansion of tube away from the tee.

Plan View

6" (15 cm)

Flexible Boot Installation (Common Vent)

Rolled Sleeve Installation

8" ( 20 cm) long Flexible

Tube

Expansion

Direction

3"

(8 cm)

Description Part Number

Rolled Sleeve 09080000

Fl exible Boot 4 " (10 cm) 9 14128 00

Boot Clamp 4 " (10 cm) 919 013 00

Vent Te e - 4" Dia . x 4 " D ia . x 6" Dia. 9 19161 00

for Common Vent

Boot Compressed

to 6" (15 cm) long

6" (15 cm)

3/4" (2 cm)

3.5"

(9 cm)

3"

(8 cm)

11"

18"

6"

Vent Tee

© 2004 Roberts-Gordon

APPLI CATIONS, ENGINEERING AND DE TAILE D GUIDANCE ON S YSTEMS DE SIGN, INS TALLA TION A ND PRODUCT PE RFORMANCE IS AVAILABLE UPO N REQUEST. ROBERTS GO RDON® PRODUCTS ARE TO BE

INSTALLED ONLY I N ACCOR DANC E WITH L OCAL L AW S, C ODES AND RE GULATIONS, AND ONLY BY A CONTRACTO R QUALIFIED IN THE INST ALLAT ION AND SERVICE OF GAS-F IRED HEATING EQUIPMEN T.

Page 35

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

OUTSIDE COMBUSTION AIR SUPPLY

Vertical Outside Air Supply

Approved

Vent Cap

Secure with (3)

#8 x 3/8 Sheet

Metal Screws

Minimum of

18" (46 cm)

Suggestion: Wrap pipe

with insulation to prevent

condensation from forming

on outside of pipe.

Single Wall

Vent Pipe

Burner

Description Part Number

Vent Cap 5" (13 cm) 90 50230 1

Horizontal Outside Air Supplly

Secure with (3)

#8 x 3/8 Sheet

Metal Screws

Tube

Single Wall

Vent Pipe

Burner

Approved

Vent Cap

Description Part Number

Vent C ap 5" (1 3 cm) 90502 30 1

© 2004 Roberts-Gordon

Tube

APPLICATION S, ENGI NEERING AND DETAILE D GUIDANCE ON S YSTEMS DES IGN, INSTALLATION AND P RODUCT PE RFORMANC E IS AVAILABLE UP ON REQUEST. ROB ERTS GORDON® PRODUCT S ARE T O BE

INSTALLED ONL Y IN ACCORDA NCE WI TH LOC AL LAWS , CODES AND REGUL AT IONS, AND ONLY BY A C ONTRACTOR QUA LIFIED I N THE I NSTALLATION AND SERV ICE OF GAS- FIRED HEATING EQUIPMENT.

Page 36

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

GAS PIPING

FIGURE 1: Gas Connection with Stainless Steel Flex Connector

Hold gas nipple securely

with pipe wrench when

attaching the flex gas

connector.

Failure to follow these

instructions can result in

product damage.

3/4" NPT Pipe

Shut-Off Valve

(included

with connector)

12"

2" (5 cm)

Shut-Off Valve must be parallel to

burner gas inlet. The 2" (5 cm)

displacement shown is for the cold

condition. This displacement may

reduce when the system is fired.

(30 cm)

Stainless

Steel Flex

90° Pipe Elbow (not supplied)

Burner

Gas Connector

Description Part Number

1/2” Flex Gas Line 91412200

3/4” Flex Gas Line 91412203

90°

45°

0°

45°

© 2004 Roberts-Gordon

APPLI CATIONS, ENGINEERING AND DE TAILE D GUIDANCE ON S YSTEMS DE SIGN, INS TALLA TION A ND PRODUCT PE RFORMANCE IS AVAILABLE UPO N REQUEST. ROBERTS GO RDON® PRODUCTS ARE TO BE

INSTALLED ONLY I N ACCOR DANC E WITH L OCAL L AW S, C ODES AND RE GULATIONS, AND ONLY BY A CONTRACTO R QUALIFIED IN THE INST ALLAT ION AND SERVICE OF GAS-F IRED HEATING EQUIPMEN T.

Page 37

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

WIRING

WARNING

Electrical Shock Hazard

Disconnect electrical power and gas supply before

servicing.

This appliance must be connected

to a properly grounded electrical source.

Failure to follow these instructions can result in

death or electrical shock.

Li ne Volt age Thermos tat Wir ing

Line Voltage Thermostat

120V-60Hz

Supply Circut

L1

L2

Gnd.

N H

Gnd.

Burner 1 Burner 2

N H

Additional

Burners

Gnd.

Maximum 2 to 8 burners

per thermostat, depending on

thermostat chosen (see thermostat

manufacturers specifications).

© 2004 Roberts-Gordon

APPLICATION S, ENGI NEERING AND DETAILE D GUIDANCE ON S YSTEMS DES IGN, INSTALLATION AND P RODUCT PE RFORMANC E IS AVAILABLE UP ON REQUEST. ROB ERTS GORDON® PRODUCT S ARE T O BE

INSTALLED ONL Y IN ACCORDA NCE WI TH LOC AL LAWS , CODES AND REGUL AT IONS, AND ONLY BY A C ONTRACTOR QUA LIFIED I N THE I NSTALLATION AND SERV ICE OF GAS- FIRED HEATING EQUIPMENT.

Page 38

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

WARNING

Electrical Shock Hazard

Disconnect electrical power and gas supply before

servicing.

This appliance must be connected

to a properly grounded electrical source.

Failure to follow these instructions can result in

death or electrical shock.

Low Voltage Thermostat and Relay Wiring

SPDT Transformer Relay

P/N 90417600

Black

FRONT VIEW BACK VIEW

1

2

4

COIL COIL

5

Low Voltage

3

6

R C

W G Y

Thermostat

120V-60Hz

Supply Circuit

L1

L2

Gnd.

Black

White

Burner 1 Burner 2

Red

N H

Gnd.

N H

Additional

Burners

Gnd.

Maximum 6 burners

per relay (see thermostat

manufacturers specifications).

© 2004 Roberts-Gordon

APPLI CATIONS, ENGINEERING AND DE TAILE D GUIDANCE ON S YSTEMS DE SIGN, INS TALLA TION A ND PRODUCT PE RFORMANCE IS AVAILABLE UPO N REQUEST. ROBERTS GO RDON® PRODUCTS ARE TO BE

INSTALLED ONLY I N ACCOR DANC E WITH L OCAL L AW S, C ODES AND RE GULATIONS, AND ONLY BY A CONTRACTO R QUALIFIED IN THE INST ALLAT ION AND SERVICE OF GAS-F IRED HEATING EQUIPMEN T.

Page 39

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

0.1 TF-Series Internal Wiring

PRESSURE

SWITCH

BLU

DOOR

SWITCH

BLK

WHT

BLK

GRN

TRANSFORMER

3

4

WHT

1

5

BLU

BLK

BLK

YEL

GRN

VALVE

BLOWER

MODULE

GRN

BRN

ELECTRODE

YEL

SPARK 2

SPARK 1

BLU

24VAC

GND

BLK

VALVE

VALVE

ALARM

ALARM

ELECTRODE

BLK

SENSE 2

SENSE 1

0.2 TF-Series Ladder Diagram

L1 L2

BLOWER

120V

PRESSURE SWITCHES

24V

IGNITION MODULE

GROUND

ELECTRODE

POWER

SENSE

GAP GAP

SPARK

VALVE

ELECTRODE

LIGHT

GAS VALVE

© 2004 Roberts-Gordon

APPLICATION S, ENGI NEERING AND DETAILE D GUIDANCE ON S YSTEMS DES IGN, INSTALLATION AND P RODUCT PE RFORMANC E IS AVAILABLE UP ON REQUEST. ROB ERTS GORDON® PRODUCT S ARE T O BE

INSTALLED ONL Y IN ACCORDA NCE WI TH LOC AL LAWS , CODES AND REGUL AT IONS, AND ONLY BY A C ONTRACTOR QUA LIFIED I N THE I NSTALLATION AND SERV ICE OF GAS- FIRED HEATING EQUIPMENT.

Page 40

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

Electrical Connection to the Burner

Electrical Cord or

Flexible Conduit

Burner

Connect wires together with

suitable approved wire connections.

Green

White

Black

Green to Gnd.

White to L2

Black to L1

Internal Wire Bundle

L1

L2

Wire Connector

Conduit Hole

Gnd.

© 2004 Roberts-Gordon

APPLI CATIONS, ENGINEERING AND DE TAILE D GUIDANCE ON S YSTEMS DE SIGN, INS TALLA TION A ND PRODUCT PE RFORMANCE IS AVAILABLE UPO N REQUEST. ROBERTS GO RDON® PRODUCTS ARE TO BE

INSTALLED ONLY I N ACCOR DANC E WITH L OCAL L AW S, C ODES AND RE GULATIONS, AND ONLY BY A CONTRACTO R QUALIFIED IN THE INST ALLAT ION AND SERVICE OF GAS-F IRED HEATING EQUIPMEN T.

Page 41

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

INTERNAL BURNER DIAGRAM

Burner Cup

Door

Switch

Blower with

Blower with

Screen and Gasket

Screen and Gasket

Viewer Window

Electrode

Pressure

Switch

Transformer

Electrode

Gasket

Gas Valve

Air Collar

Burner

Tube

Gasket

Pressure

Switch

© 2004 Roberts-Gordon

Indicator Light

APPLICATION S, ENGI NEERING AND DETAILE D GUIDANCE ON S YSTEMS DES IGN, INSTALLATION AND P RODUCT PE RFORMANC E IS AVAILABLE UP ON REQUEST. ROB ERTS GORDON® PRODUCT S ARE T O BE

INSTALLED ONL Y IN ACCORDA NCE WI TH LOC AL LAWS , CODES AND REGUL AT IONS, AND ONLY BY A C ONTRACTOR QUA LIFIED I N THE I NSTALLATION AND SERV ICE OF GAS- FIRED HEATING EQUIPMENT.

Ignition Module

Page 42

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

THE ROBERTS GORDON® VANTAGE® TF LIMITED WARRANTY

ROBERTS-GORDON WILL PAY FOR:

Within 42 months from date of shipment from RobertsGordon, replacement parts will be provided free of charge

for any pa rt of the controlle r which fai ls due to a

manufacturing or material defect.

Roberts-Gordon will require the part in question to be

returned to the factory. Roberts-Gordon w ill, at its sole

discretion, repair or replace after determining the nature of

the defect and disposition of part in question.

ROBERTS GORDON® Replacem ent Parts are warranted

for a period of 18 months from date of shipment from

Roberts-Gordon or the remaining ROBERTS GORDON®

VANTAGE® TF warranty.

ROBERTS-GORDON WILL NOT PAY FOR:

Service trips, service calls and labor charges.

Shipment of replacement parts.

Claims where the total price of the goods have not

been paid.

Damage due to:

• Imprope r installatio n, oper ation o r ma intenance .

• Misuse, abuse, neglect, or modification of the

ROBERTS GORDON® VAN TAGE® TF in any way.

• Use of the ROBERTS GORDON® VANTAGE® TF for

other than its intended purpose.

• Incorrect gas or electrical supply, accident, fire, floods,

acts of God, war, terrorism, or other casualty.

• Improper service, use of replacement parts or accesso ries not spe cified by Robe rts- Gord on.

• Failure to install or maintain the ROBERTS GORD ON®

VANTAGE® TF as directed in the Installation, Operation and Service manual.

• Relocation of the ROBERTS GORDON® VAN TAG E®

TF after initial installation

• Th e use of th e ROBERTS GORD ON® VANTAGE® TF

in a corrosive atmosphere containing contaminants.

• Th e use of th e ROBERTS GORD ON® VANTAGE® TF

in the vicinity of a combustible or explosive material.

• Any defect in the ROBERTS GORDON® VAN TAG E®

TF arising from a drawing, design, or specification

supplied by or on behalf of the consumer.

• Damage incurred duri ng shipment. Claim must be filed

with carrier.

WARRANTY IS VOID IF:

The ROBERTS GORDON® VAN TAG E® TF is not installed

by an contractor qualified in the installation and service of

gas-fired heating equipment.

Yo u cannot prove ori ginal purchase d ate and re quired

annual maintenance history.

The data plate and/or serial number are removed,

defaced, modified or altered in any way.

Th e ownersh ip o f the ROBERTS GORD ON® VANTAGE®

TF is moved or transferred. This warranty is

nontransferable.

Roberts-Gordon is not permitted to inspect the damaged

controller and/or component parts.

READ YOUR INSTALLATION, OPERATION AND

SERVICE MANUAL

If you have questions about your controller, contact your

installing professional. Should you need Replacement

Parts or have additional questions, call or write RobertsGord on:

U. S . A.

1250 Will iam Stre et

P.O. Box 44

Buffalo, New York 14240-0044

716.852.4400

Canada

76 Main Street West, Unit 10

Grimsby, On tari o L3 M 1R6

905.945.5403

On the web at: www.rg-inc.com

Roberts-Gordon's liability, and your exclusive remedy,

under this warranty or any implied warranty (including

the implied warranties of merchantability and fitness

for a particular purpose) is limited to providing

replacement parts during the term of this warranty.

Some jurisdictions do not allow limitations on how long an

implied warranty lasts, so this limitation may not apply to

you. There ar e n o ri ghts, warranties or co nditions,

expressed or implied, statutory or otherwise, other than

those contained in this warranty.

Roberts-Gordon shall in no event be responsible for

incidental or consequential damages or incur liability

for d amages in excess of the amount paid by you for

the ROBERTS GORDON® VANTAGE® TF. Some

jurisdictions do not allow the exclusion or limitation of

incidental or consequential damages, so this lim itation or

exclusion may not apply to you. This warranty gives you

specific legal rights, and you may also have other rights

which vary from jurisdiction to jurisdiction.

Roberts-Gordon sh al l no t be r esponsibl e for fail ure to

perfor m under the terms of this warranty if caused by

ci rcumstances out of its control, including but not limited to

war, fire, floo d, strike, government or cour t or ders, a cts of

God, ter ror ism , una vailabi lity of suppl ies, par ts or power.

No person is authorized to assume for Roberts-Gordon

any o ther war ra nty, o bl iga tion or liabili ty.

LIMITATIONS ON AUTHORITY OF

REPRESENTATIVES:

No representative of Roberts-Gordon, other than an

Executive Officer, has authority to change or extend these

provisions. Chan ges or extensi ons shall be bin ding on ly if

confirmed in writing by Roberts-Gordon's duly authorized

Executive Offi cer.

© 2004 Roberts-Gordon

APPLI CATIONS, ENGINEERING AND DE TAILE D GUIDANCE ON S YSTEMS DE SIGN, INS TALLA TION A ND PRODUCT PE RFORMANCE IS AVAILABLE UPO N REQUEST. ROBERTS GO RDON® PRODUCTS ARE TO BE

INSTALLED ONLY I N ACCOR DANC E WITH L OCAL L AW S, C ODES AND RE GULATIONS, AND ONLY BY A CONTRACTO R QUALIFIED IN THE INST ALLAT ION AND SERVICE OF GAS-F IRED HEATING EQUIPMEN T.

Page 43

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

© 2004 Roberts-Gordon

APPLICATION S, ENGI NEERING AND DETAILE D GUIDANCE ON S YSTEMS DES IGN, INSTALLATION AND P RODUCT PE RFORMANC E IS AVAILABLE UP ON REQUEST. ROB ERTS GORDON® PRODUCT S ARE T O BE

INSTALLED ONL Y IN ACCORDA NCE WI TH LOC AL LAWS , CODES AND REGUL AT IONS, AND ONLY BY A C ONTRACTOR QUA LIFIED I N THE I NSTALLATION AND SERV ICE OF GAS- FIRED HEATING EQUIPMENT.

Page 44

ROBERTS GORDON® TF-SERIES SUBMITTAL SHEET

© 2004 Roberts-Gordon

APPLI CATIONS, ENGINEERING AND DE TAILE D GUIDANCE ON S YSTEMS DE SIGN, INS TALLA TION A ND PRODUCT PE RFORMANCE IS AVAILABLE UPO N REQUEST. ROBERTS GO RDON® PRODUCTS ARE TO BE

INSTALLED ONLY I N ACCOR DANC E WITH L OCAL L AW S, C ODES AND RE GULATIONS, AND ONLY BY A CONTRACTO R QUALIFIED IN THE INST ALLAT ION AND SERVICE OF GAS-F IRED HEATING EQUIPMEN T.

Loading...

Loading...