rmo2015-008-777_a

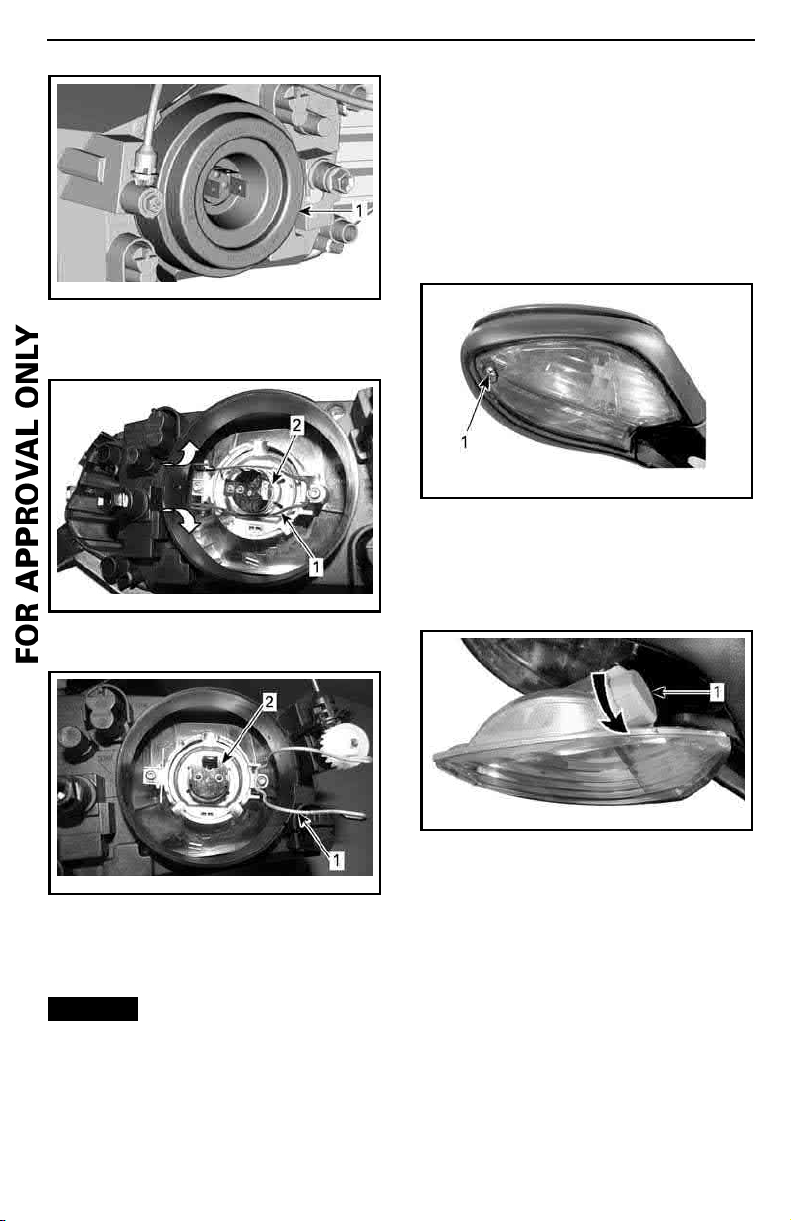

1. Housing cap

11. Unclip light bulb retaining spring.

rmo2015-008-761_a

1. Bulb retaining spring

2. Bulb housing

HOW TO REPLACE FUSES AND LIGHTS

14. Install the connector onto light

bulb.

15. Properly reinstall the parts in the

reverse order of their removal.

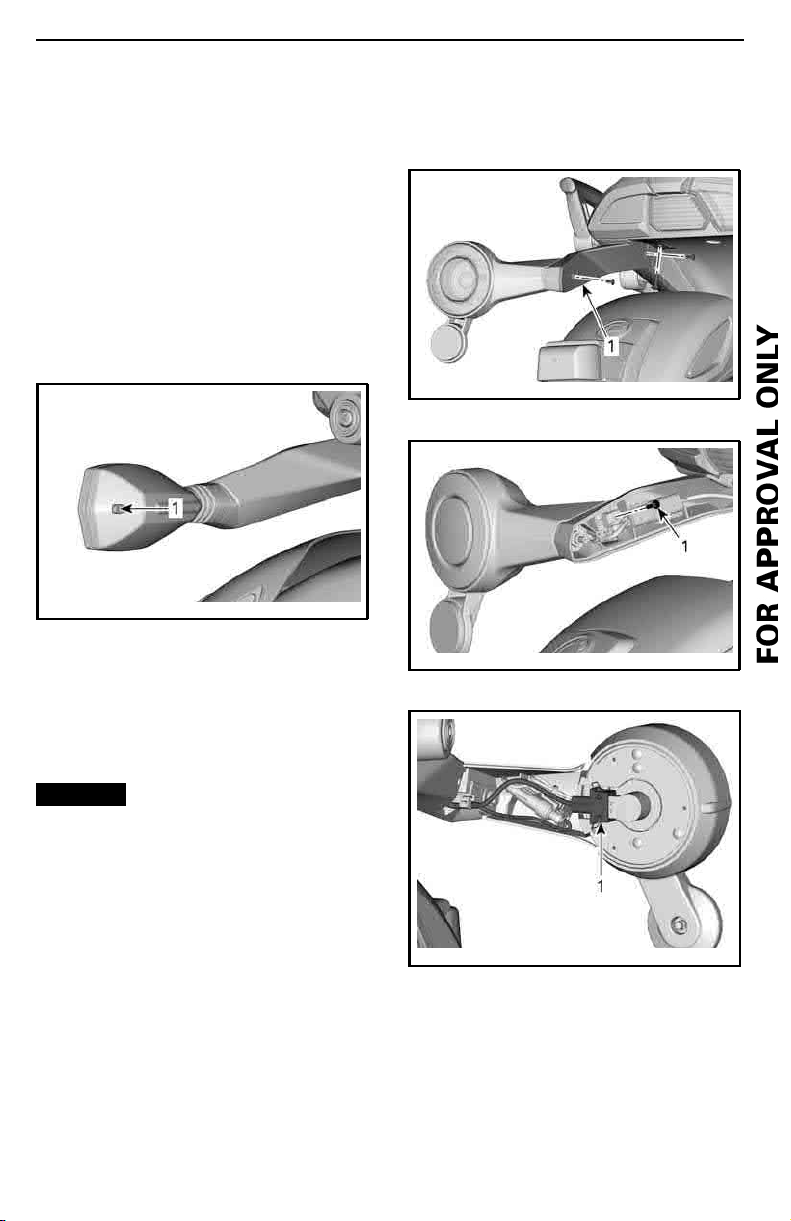

Turn Signal Light — Front - F3 Base

and F3-S Models

1. Remove the lens.

rmo2008-001-103_a

TYPICAL

1. Front turn signal lens screw

2. Turn the connector counterclock-

wise as indicated below and remove

lens.

rmo2015-008-762_a

1. Bulb retaining spring

2. Bulb housing

12. Install the new bulb in placeand secure with retaining spring.

NOTICE

Never touch glass portion

of a halogen bulb with bare fingers,

it shortens its operating life. If glass

is touched, clean it with isopropyl alcohol and a clean cloth.

13. Reinstall housing cap.

______________

rmo2008-001-104_a

TYPICAL

1. Front turn signal light connector

3. Remove the bulb by pushing it in

and turning counterclockwise.

4. Install the new bulb by pushing it in

and turning clockwise.

5. Properly reinstall the parts in the reverse order of their removal.

147

HOW TO REPLACE FUSES AND LIGHTS

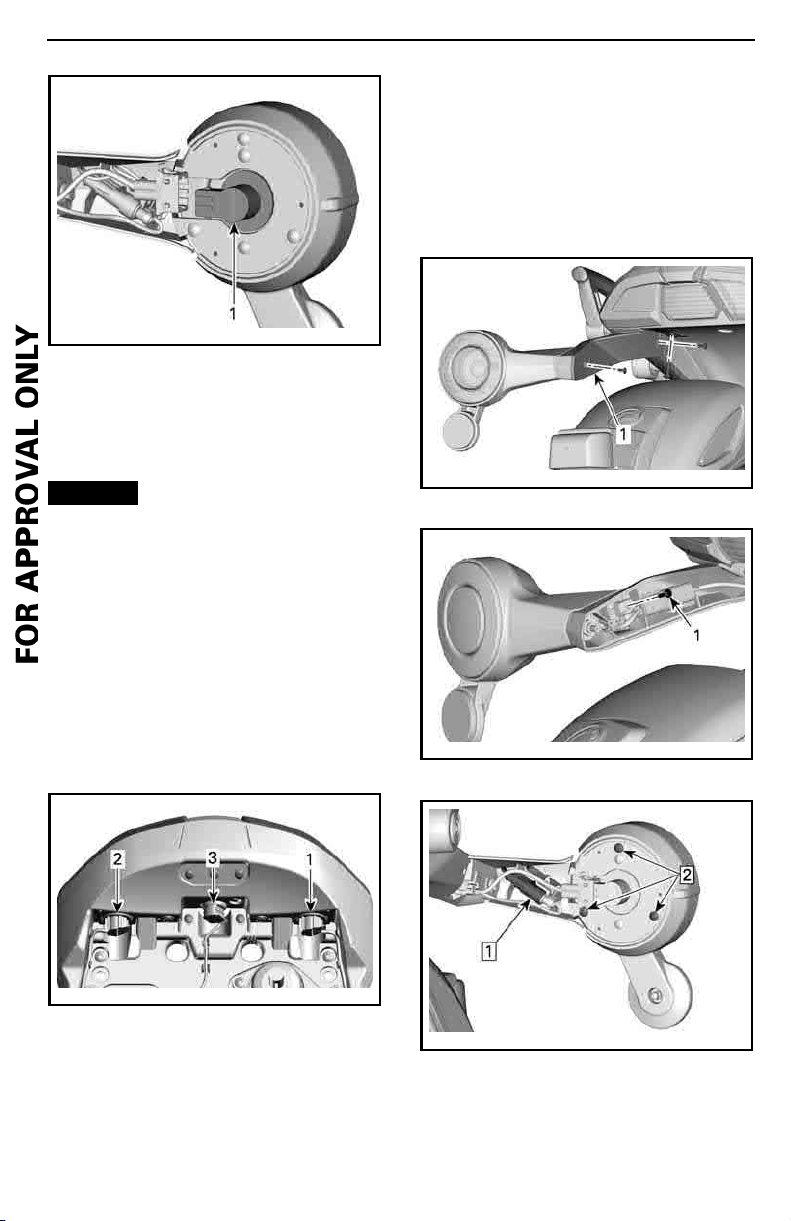

Turn Signal - Front - LED Unit (F3

Limited and F3-T Models)

The turn signal lights are built with

LEDs (light emitting diode) and this

technology proved to be reliable. In

the unlikely event they do not work,

have them checked by an authorized

Can-Am roadster dealer.

Turn Signal Light — Rear (F3 Base

and F3-S Models - Australian and

European Models)

1. Remove the lens

rmr2015-133-026_a

1. Rear turn signal lens screw

2. Remove the bulb by pus hin g in an d

turning counterclockwise.

3. Install the new bulb by pushing and

turning it clockwise.

4. Reinstall the lens.

NOTICE

At installation, tighten

screws finger tight.

Turn Signal Light — R ear (F3

Base and F3-S Models - Japanese

Models)

rmr2015-133-027_a

1. Remove this cover

rmo2016-009-005_a

1. Remove this screw

______________

148

rmr2015-133-031_a

1. Disconnect signal light connector

rmr2015-133-032_a

1. Turn the bulb holder to release it

Removethebulbbypushingitinand

turning counterclockwise.

Reverse these steps for installation of

bulbandremovedparts.

NOTICE

At installation, tighten

screws finger tight.

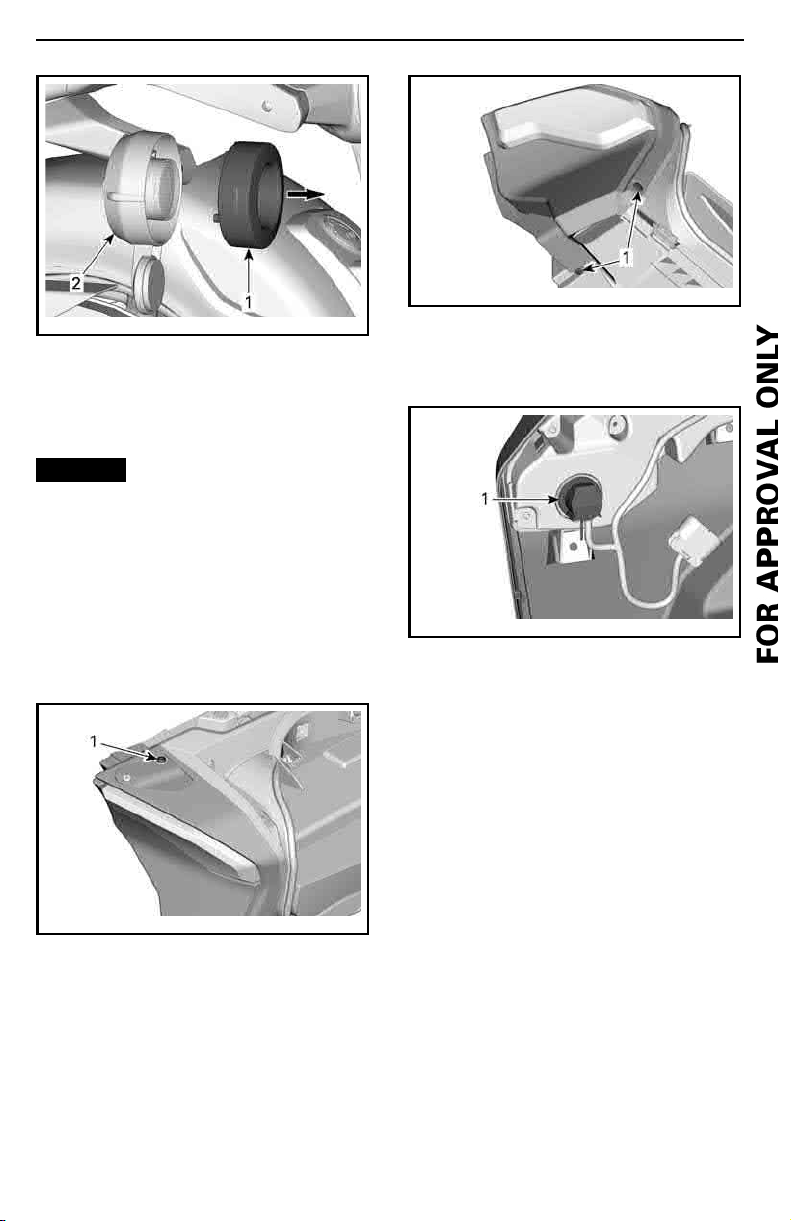

Taillight/Brake Light (F3 Base

and F3-S Models - Australian and

European Models)

1. Remove passenger seat. Refer to

OPENING SEATinEQUIPMENT

2. Rotate the bulb socket to remove it

from the vehicle.

NOTE: Rotate the center and left bulb

sockets counterclockwise. Rotate the

right bulb socket clock wise.

HOW TO REPLACE FUSES AND LIGHTS

4. Install the new bulb by pushing it in

and turning clockwise.

5. Install seat

Taillight/Brake Light LED Unit (F3

Base and F3-S Models - Japanese

Models)

rmr2015-133-027_a

1. Remove this cover

rmo2016-009-005_a

1. Remove this screw

rmo2015-008-041_b

1. LH taillight/brake light

2. RH taillight/brake light

3. Back-up light

3. Remove the bulb by pushing it in

and turning counterclockwise.

______________

rmr2015-133-029_a

Step 1: Disconnect taillight connector

Step 2: Remove these screws

149

HOW TO REPLACE FUSES AND LIGHTS

rmr2015-133-030_a

1. LED taillight unit

2. Taillight housing

Reverse these steps for installation

of new LED taillight unit and removed

parts.

NOTICE

At installation, tighten

screws finger tight.

Turn Signal - Rear - (F3 Limited and

F3-T Models - All Countries)

Remove saddlebag from vehicle. Refer to

AND F3-T MODELS)

SADDLEBAGS (F3 LIMITED

.

Remove upper retaining screw securing taillight support to s ad dleb ag .

rmo2016-010-016_a

1. Lower retaining screws to remove

Remove bulb holder from taillight support.

rmo2016-010-018_a

1. Turn the bulb holder to release it

Removethebulbbypushingitinand

turning counterclockwise.

Reverse these steps for installation of

bulbandremovedparts.

rmo2016-010-017_a

1. Upper retaining screw to remove

Remove lower retaining screws securing taillight support to sadd le bag and

remove taillight support from saddlebag.

______________

150

Taillight/Brake Light LED Unit (F3

Limited and F3-T Models)

The position lights are built with LEDs

(light emitting diode) and this technology proved to be reliable. In the

unlikely event they do not work,

have them checked by an authorized

Can-Am roadster dealer.

Position Light

F3 Base Models

1. Push then hold lens towards rear of

fender.

rmo2008-003-001_a

TYPICAL

2. Lift front portion of lens with your

thumb or a small screwdriver to release.

rmo2008-003-002

TYPICAL

3. Turn the bulb holder clockwise and

remove it from the connector.

HOW TO REPLACE FUSES AND LIGHTS

rmo2008-001-087_a

TYPICAL

1. Pull out bulb

5. Insert a new bulb in the holder.

6. Properly reinstall the parts in the reverse order of their removal.

F3-S, F3-T and F3 Limited Models

The position lights are built with LEDs

(light emitting diode) and this technology proved to be reliable. In the

unlikely event they do not work,

have them checked by an authorized

Can-Am roadster dealer.

F3 Limited Models

The high mounted are built with LEDs

(light emitting diode) and this technology proved to be reliable. In the

unlikely event they do not work,

have them checked by an authorized

Can-Am roadster dealer.

License Plate Light

rmo2008-001-086_a

TYPICAL

1. Turn clockwise

4. Pull bulb out of the holder as indicated below.

______________

License Plate Light Replacement (F3

Base and F3-S Models)

1. Remove light cover.

151

HOW TO REPLACE FUSES AND LIGHTS

rmr2015-133-009_a

TYPICAL

1. License plate light

2. Cover screw

2. Remove the bulb by pushing it in

and turning counterclockwise.

rmo2016-010-013_a

TYPICAL

1. License plate light

2. Cover screws

2. Remove the bulb by pushing it in

and dislodging it from support.

rmo2016-010-014_a

1. Light bulb

rmr2015-133-010_a

1. Light bulb

3. Install the new bulb by pushing and

turning it clockwise.

4. Confirm light operation.

5. Reinstall light cover.

License Plate Light Replacement (F3

Limited and F3-T Models)

1. Remove light cover.

______________

152

3. Install the new bulb by pushing it

into place.

4. Confirm light operation.

5. Reinstall light cover.

Back-up Light

Refer to procedure in

TURN SIGNAL

LIGHT — REAR (AUSTRALIAN AND

EUROPEAN MODELS)

.

TRANSPORTING THE VEHICLE

If your vehicle needs to be transported,

it should be carried on a flatbed trailer

of the proper size and capacity.

CAUTION If you need to push

the vehicle, do it from the right-hand

side to be able to reach the brake

pedal.

When pulling the vehicle backwards, be careful that the front

wheel does not roll over your feet.

NOTICE

Do not tow the Spyder

roadster — towing can seriously

damage the vehicle drive system.

When contacting a towing or transporting service, be sure to ask if they

have a flatbed trailer, loading ramp or

power ramp to safely lift the vehicle

and tie-down straps. Ensure the vehicle is properly transported as specified

in this section.

NOTICE

Avoid using chains to tie

the vehicle — they may damage

the surface finish or plastic components.

To load the vehicle for transport, proceed as follows:

1. Shift the vehicle into NEUTRAL (N).

2. Remove the key from the ignition

switch.

3. Put a strap around the lower arm of

each front suspension.

4. Attach the straps to the winch cable.

If possible, use chains or additional

straps to attach the straps to the

winch c able as indicated below to

avoid damaging the bumper cover.

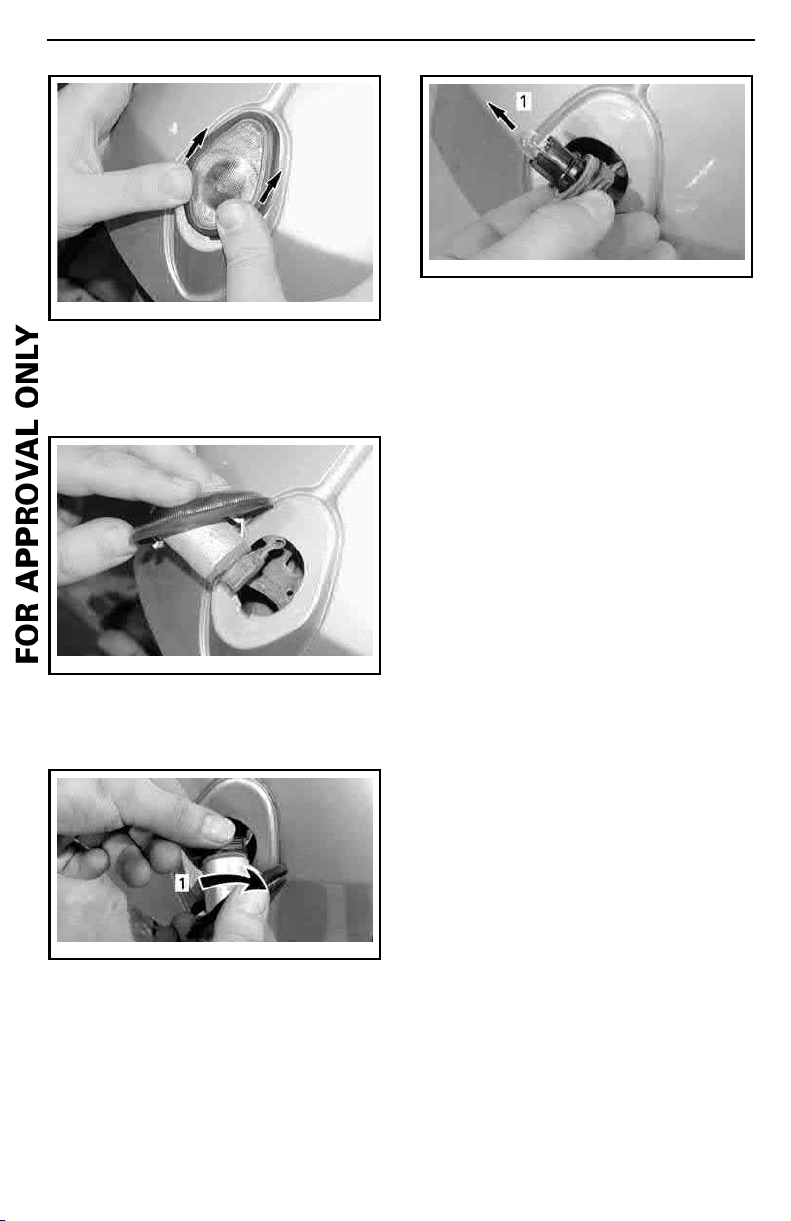

rmo2008-001-066_a

TYPICAL

1. Strap around front suspension lower arms

2. Chains to avoid damaging the bumper cover

3. Winch cable

5. Ensure that the parking brake is released.

6. Pull the vehicle on the flatbed trailer

with the winch.

7. Engage the parking brake.

8.EnsurethatthevehicleisinNEUTRAL (N).

9. Strap the front tires by using one the

following methods indicated below.

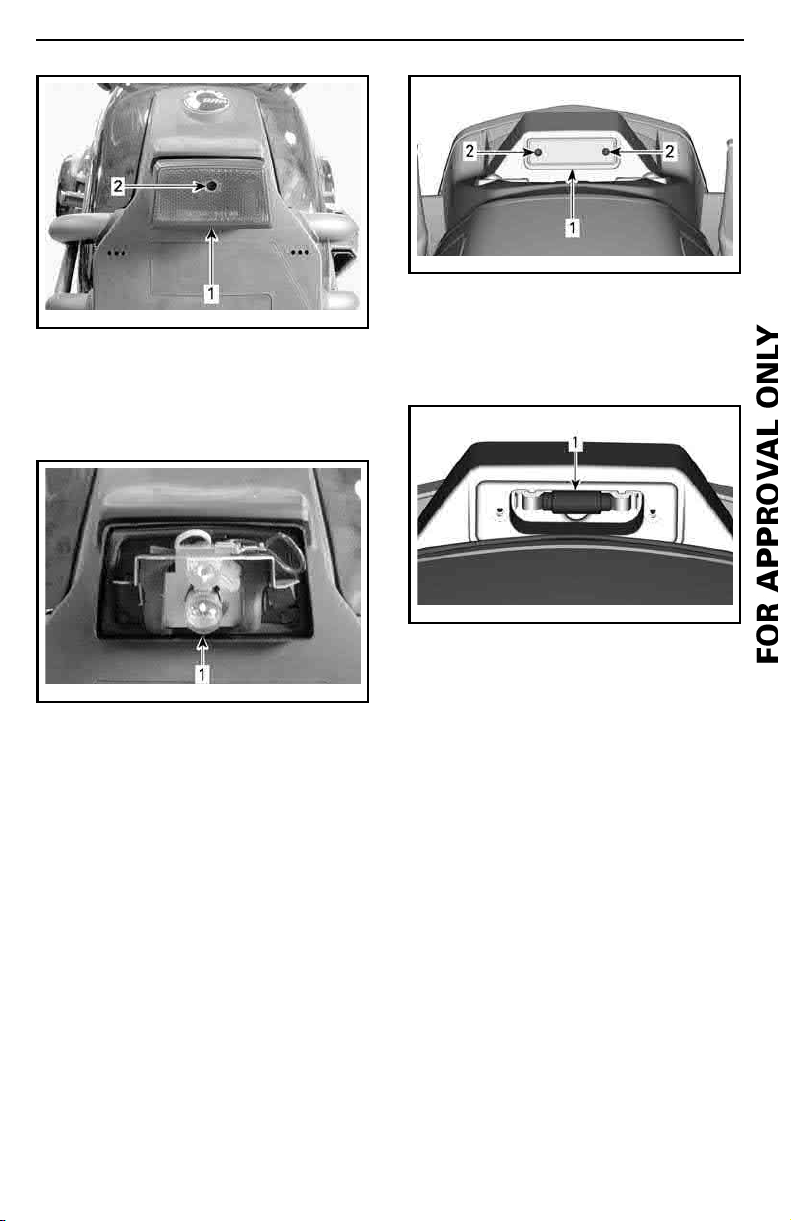

rmo2008-001-065_a

TYPICAL

1. Strap

2. Lower suspension arm

______________

153

TRANSPORTING THE VEHICLE

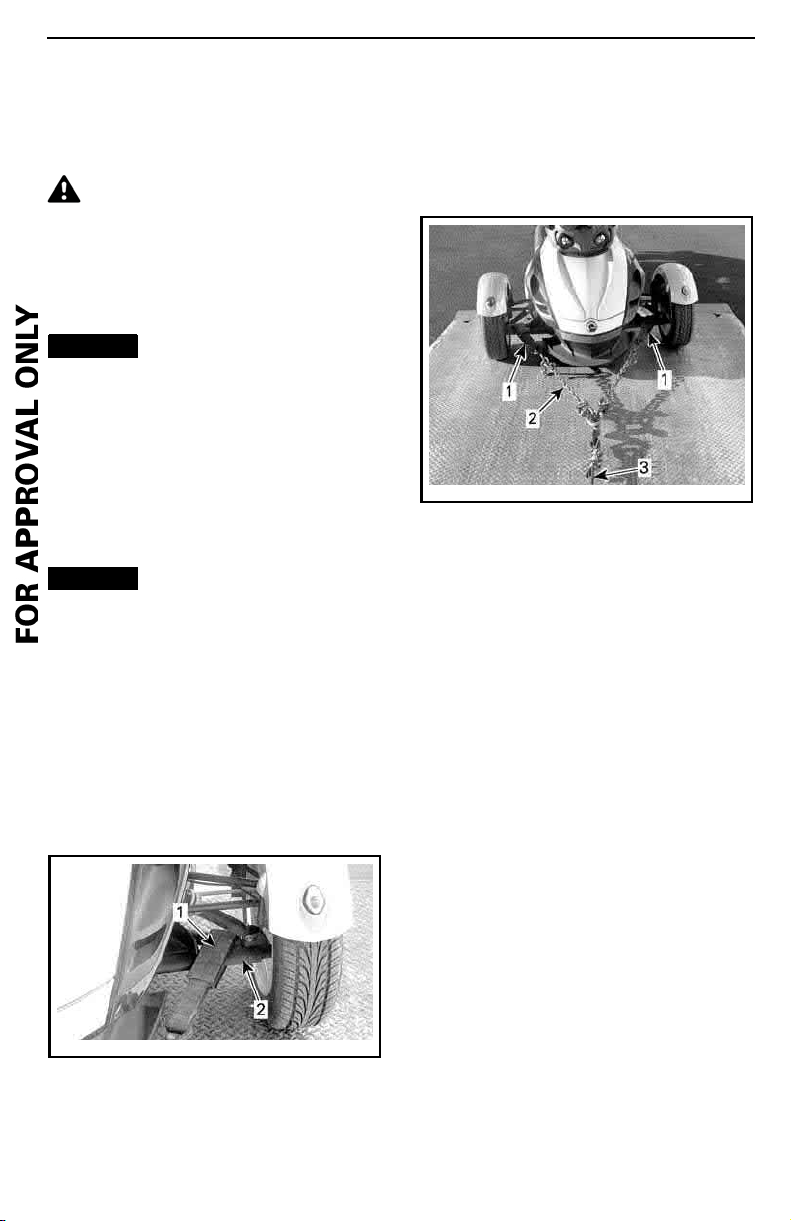

rmo2008-001-069_a

FRONT WHEELS ATTACHMENT — TYPICAL

METHOD 1

1. Strap around the rim of each front wheel

and attached to the front of trailer

rmo2008-001-067_a

REAR WHEEL ATTACHMENT - TYPICAL

1. Tie-down strap

2. Inside rear wheel rim ONLY

11. Firmly attach the rear wheel

tie-down strap to the rear of the

trailer with a ratchet.

12. Ensure that both the front and rear

wheelsarefirmlyattachedtothe

trailer.

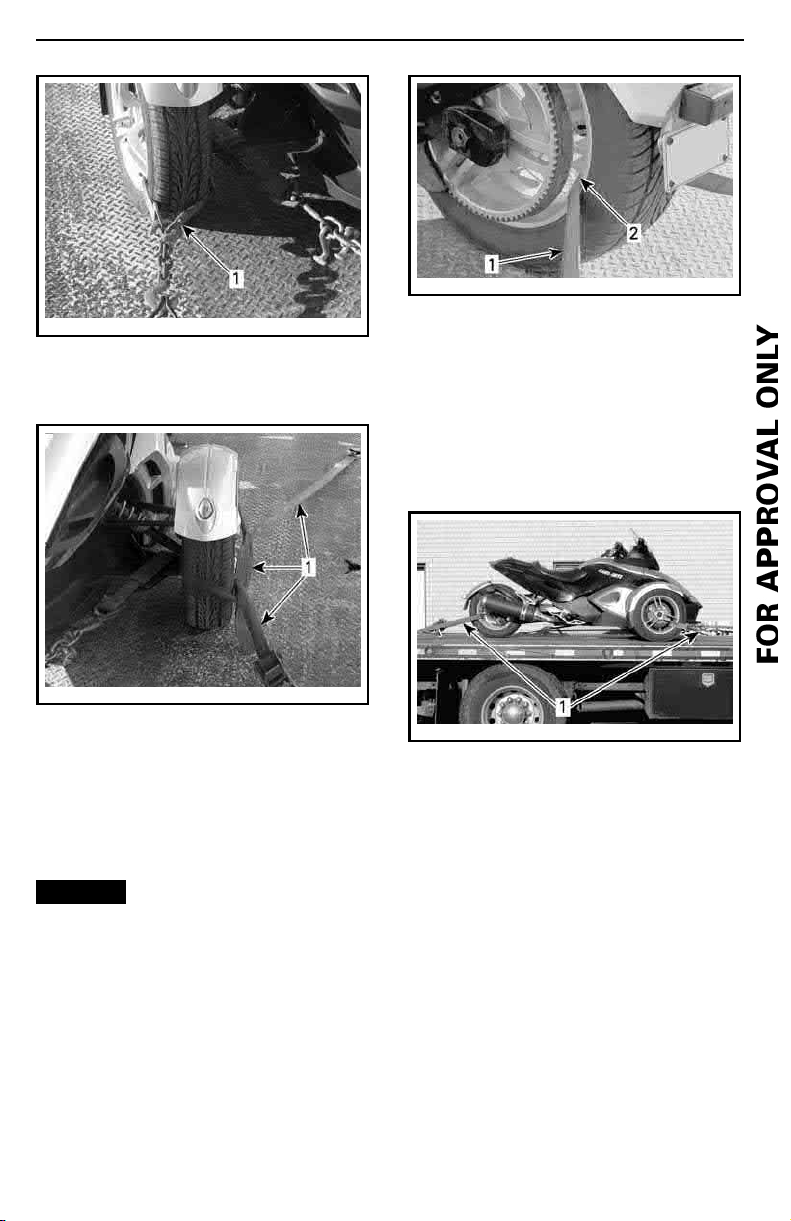

rmo2008-001-073_a

FRONT WHEELS ATTACHMENT — TYPICAL

METHOD 2

1. Strap around each wheel and fixed to the

front and rear of trailer

10. Pass a tie-down strap inside the

rear wheel rim only. Do not pass

the tie-down strap inside the rear

sprocket.

NOTICE

Passing the tie-down

strap inside the rear sprocket may

seriouslydamagethedrivesystem.

______________

154

rmo2008-001-072_a

TYPICAL - VEHICLE FACING TOWARDS

FRONT OF TOWING

1. Front and rear wheel firmly attached to

trailer

TECHNICAL

INFORMATION

______________

155

VEHICLE IDENTIFICATION

BRP A

USTR

ALIA PT

Y L

TD

The main components of your vehicle

(engine and frame) are identified by

different serial numbers. It may sometimes become necessary to locate

these numbers for w arranty purposes

or to trace your vehicle in the event of

loss. These numbers are required by

the authorized Can-Am roadster dealer

to complete warranty claims properly.

We strongly recommend that you take

note of all the serial numbers on your

vehicle and supply them to your insurance company.

Vehicle Identification

Number

North American Models

Bombardier Recreational Products Inc.

121

CAN TYPE : TRI

CAN ICES-2/NMB-2

V.I.N. / N.I.V. :

DATE :

GAWR/PNBE :FR/AV : kg ( lb )

GVWR/PNBV : kg ( lb )

CURB WEIGHT / POIDS EN ORDRE DE MARCHE : kg ( lb )

THIS VEHICLE CONFORMS TO ALL APPLICABLE U.S. FEDERAL MOTOR VEHICLE SAFETY

STANDARDS (FMVSS) IN EFFECT ON THE DATE OF MANUFACTURE SHOWN ABOVE.

U.S. TYPE : MOTORCYCLE

MOD:

RR/AR : kg ( lb )

ASSEMBLED IN / ASSEMBLÉ AU CANADA

704904865

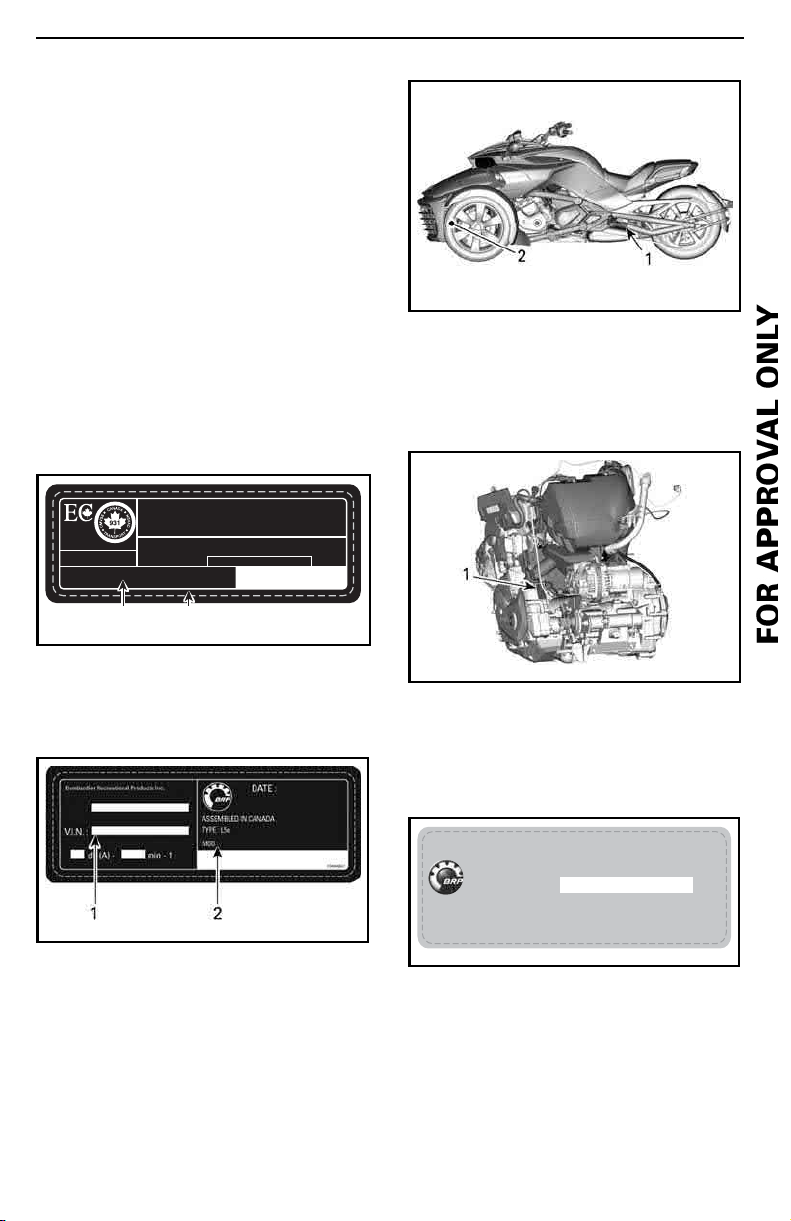

rmo2015-008-207_a

TYPICAL - LOCATION OF VIN

1. Swing arm (VIN label)

2. Lower frame (VIN stamped on the right side)

Engine Identification

Number

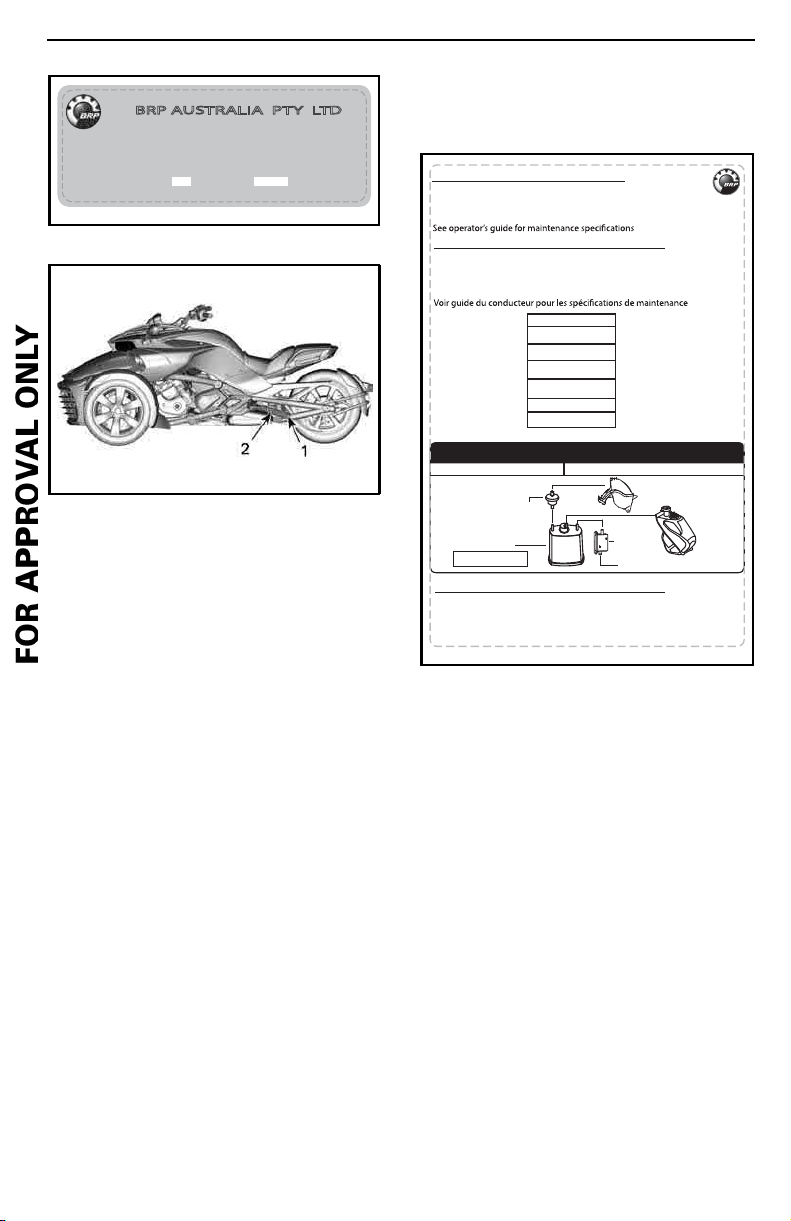

rmo2015-008-210_b

1

VEHICLE SERIAL NUMBER LABEL

1. VIN (Vehicle Identification Number)

2. Model number

2

European Models

rmo2015-009-800_a

TYPICAL - VEH ICLE SERIAL NUMBER LABEL

1. VIN (Vehicle Identification Number)

2. Model number

______________

156

rmo2015-008-208_a

TYPICAL

1. EIN (Engine Identification Number) location

Compliance Labels

Australian Models

APPROVAL No: 38891 CATEGORY LEM2

12/09

THIS VEHICLE WAS MANUFACTURED TO COMPLY

WITH THE MOTOR VEHICULE STANDARD ACT 1989

rmo2015-009-301

TYPICAL - AUSTRALIA ADR LA BEL

BRP

UST

BRP CAN AM SPYDER

VIN

ALIA P

XXXXXXXXXXXXXXXXX

Y

TD

VEHICLE IDENTIFICATION

BRP AUSTRALIA PTY LTD

CAN AM SPYDER

STATIONARY NOISE INFORMATION

TESTED : dB(A) @ RPM

rmo2015-009-302

Part No: BRP CA 07

TYPICAL - AUSTRALIA NOISE LABEL

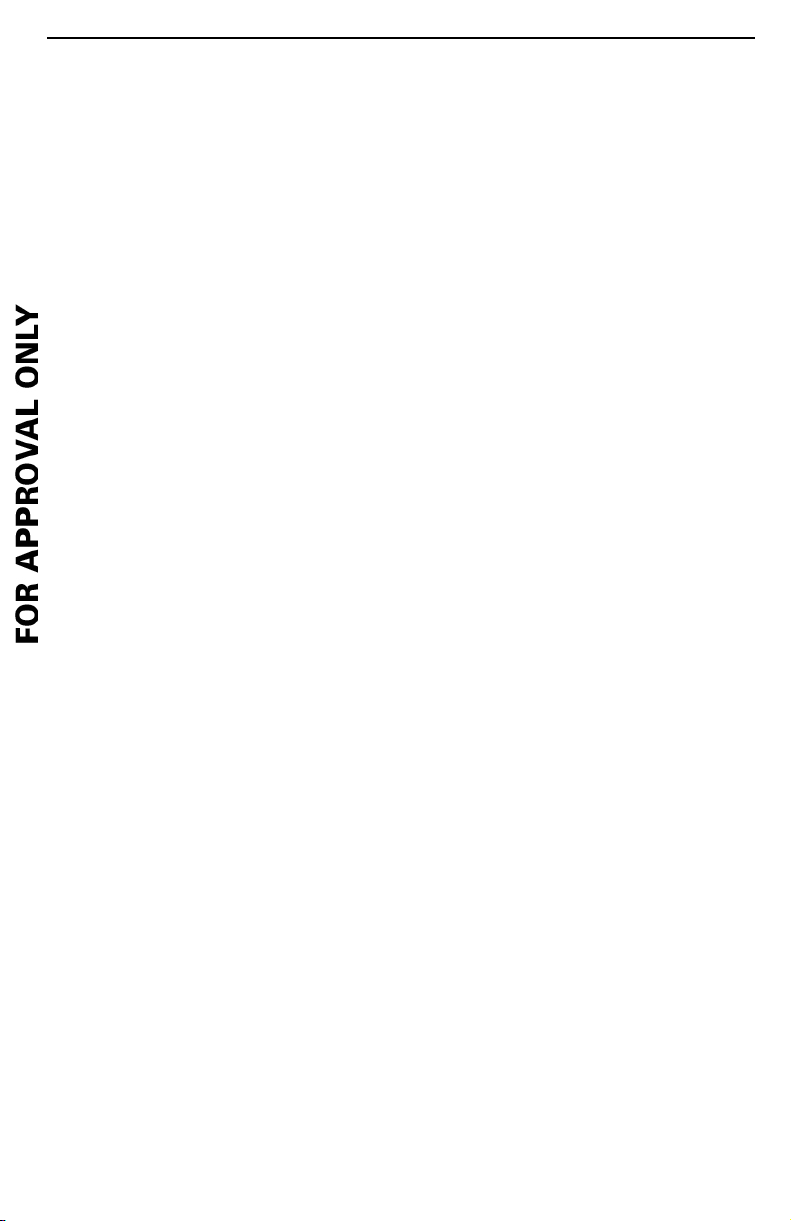

rmo2015-008-207_b

TYPICAL - LOCATION OF COMPLIANCE

LABELS

1. Australia ADR Label

2. Australia Noise Label

EPA Compliance Label

(North American Models)

VEHICLE EMISSION CONTROL INFORMATION

BOMBARDIER RECREATIONAL PRODUCTS INC.

THIS VEHICLE CONFORMS TO U.S. EPA AND CALIFORNIA REGULATIONS

APPLICABLE TO MODEL YEAR NEW MOTORCYCLES AND IS CERTIFIED

TO AN HC+NOx EMISSION STANDARD OF GRAM/KILOME TER.

RENSEIGNEMENT SUR LE DISPOSITIF ANTIPOLLUTION

BOMBARDIER PRODUITS RÉCRÉATIFS INC.

CE VÉHICULE EST CONFORME AUX RÈGLEMENTS DE L'EPA DES É.U. ET DE LA

CALIFORNIE APPLICABLES AUX MOTOCYCLETTES NEUVES DE L'ANNÉE

MODÈLE ET EST CERTIFIÉ À LA NORME D'ÉMISSIONS HC+NOx de

GRAMME/KILOMÈTRE.

Engine Displacement

Engine Family

Permeation Family

Evaporation Family

Exhaust Emission

Control System

Idle Speed

Fuel

VACUUM HOSE ROUTING

ENGINE FAMILY:

EVAP PURGE CONTROL

SOLENOID VALVE

EVAP CANISTER

MOTORCYCLE NOISE EMISSION CONTROL INFORMATION

THIS , , MEETS U.S EPA NOISE EMISSION

REQUIREMENTS OF dB (A) AT RPM BY THE FEDERAL TEST PROCEDURE.

MODIFICATIONS WHICH CAUSE THIS MOTORCYCLE TO EXCEED FEDERAL NOISE

STANDARDS ARE PROHIBITED BY FEDERAL LAW. SEE OPERATOR’S GUIDE.

704904887

TYPICAL - NORTH AMERICAN MODELS

LOCATION - FRONT STORAGE

COMPARTMENT

Cylindrée

Famille de moteur

Famille de perméation

Famille d’évaporation

Système de contrôle

des émissions

Ralenti moteur

Essence

EVAPORATION FAMILY:

AIR FILTER

TO OPEN AIR

INTAKE PLENUM

FUEL TANK

704904887

______________

157

NOISE EMISSION CONTROL SYSTEM REGULATION

Tampering with Noise Control System Is Prohibited!

U.S. Federal law and Canadian provincial laws may prohibit the following

acts or the causing there of:

1. The removal or rendering inoperative by any person other than for

purposes of maintenance, repair or

replacement of any device or element of design incorporated into

any new vehicle for the purpose of

noise control prior to its sale or delivery to the ultimate purchaser or

while it is in use or

2. The use of the vehicle after such

device or element of design has

been removed or rendered inoperative by any person.

Among those Acts Presumed to

Constitute Tampering Are the Ac ts

Listed Below:

1. Removal or alteration or the puncturing of the muffler or any engine

component which conducts removal of engine exhaust gases.

2. Removal or alteration or the puncturing of any part of the intake system.

3. Replacing any moving parts of the

vehicle or p arts of the exhaust or

intake s ystem, with non-compliant

part.

4. Lack of proper maintenanc e.

______________

158

RADIO FREQUENCY DIGITALLY ENCODED

SECURITY SYSTEM (RF D.E.S.S. KEY)

This device complies with FCC Part 15

and Industry Canada license exempt

RSS standard(s). Operation is subject

to the following two conditions: (1) this

device may not cause interference,

and (2) this device must accept any interference, including in te rfere nc e that

may cause undesired operation of the

device.

Changes or modifications not expressly approved by the party responsible for compliance could void the

user’s authority to operate the equipment.

IC Registration Number: 11538A246416

FCC ID: 2ABBF-246416

______________

159

RADIO FREQUENCY M ULTIFUNCTION GAUGE (F3

LIMITED AND F3-T MODELS)

This device complies with FCC Part 15

and Industry Canada license exempt

RSS standard(s). Operation is subject

to the following two conditions: (1) this

device may not cause interference,

and (2) this device must accept any interference, including interference that

may c ause undesired operation of the

device.

Changes or modifications not expressly approved by the party responsible for compliance could void the

user’s authority to operate the equipment.

IC Registration Number: 22868 - VDIBRHS01

FCC ID: 2AMJS - VDIBRHS01

RF exposure:

1. The equipment complies with FCC

RF exposure limits set forth for an

uncontrolled environment.

2. This equ ip ment must be installed

and operated with a separation distance of at least 20 cm from all persons.

3. The antenna(s) used for this transmitter must not be co- located or

operating in conjunction with any

other antenna or transmitter.

______________

160

SPECIFICATIONS

NOTE: Because of our ongoing commitment to product quality and innovation,

BRP reserves the right, at any time, to make changes in design and specifications

and/or to make additions to, or improvements in its products without imposing

any obligation upon itself to install them on its previously manufactured products.

ENGINE

®

1330 ACE, 4-stroke,

ROTAX

Engine type

Number of cylinders

Number of valves

Bore 84 mm (3.31in)

Stroke 80 mm (3.15in)

Displacement 1 330 cm³ (81.16 in³)

Compression ratio

Type Dry sump with separate oil tank and oil cooler

Engine BRP Rotax m icroglass fibre type, replaceable

Oil filter

Lubrication

Clutch

Exhaust system

Air filter Paper element

Engine oil

capacity

Recommended engine oil

Type

Fluid

Type

Engagement Approximately 1100 RPM

Stall

Transmission/HCM SE6

Oil change with new

engine filter

Oil change with new

engine filter

Oil change with new

engine and HCM

filters

SM6 4.5 L (4.8 qt (U.S. liq.))

SE6

SM6

SE6

Dual Over Head Camshaft (DOHC),

BRP Rotax multi-layer surface filter,

Use

OIL (P/N 293 600 121)

semi-synthetic or synthetic motorcycle oil

meeting the requirements for API service SJ,

SL, SM or SN classification and JASO MA2

Wet, multi-plate, manual operation

Hydraulic clutch + wet multi-plate clutch

automatically controlled by TCM

Approximately 2800 +/- 200 RPM

(automatically controlled by TCM)

3 into 1 manifold, primary muffler with

catalytic converter, with secondary muffler

liquid cooled

3

12

12:1

replaceable

4.7 L (5 qt (U.S. liq.))

4.9 L (5.2 qt (U.S. liq.))

XPS 4-STROKE SYNTH. BLEND

or a 5W-40

through a hydraulic piston

DOT4brakefluid

______________

161

SPECIFICATIONS

GEARBOX

SM6

Type

SE6

COOLING SYSTEM

Type Liquid cooled, double radiator with cooling fans

Coolant

ELECTRICAL SYSTEM

Ignition system type Electronic ignition with dual output coil

Ignition timing Not adjustable

Engine RPM limiter setting Forward

Battery

Headlight Hi/Low

Taillight/brake light

Typ e

Capacity 4.2 L (1.1U.S. gal.)

Quantity

Make and type NGK MR7BI-8 (iridium) or equivalentSpark plug

Gap 0.7 mm - 0.8 mm (.028 in - .031 in)

Type Yuasa YTX24HL-BS

Voltage 12 volts

Nominal rating 21 A•h

Recommended charging rate 2 A

CE Models

Other Models Halogen, 2 x 55/60 W (type HB2)

All models

except

Japanese, F3-T

and F3 Limited

Models

F3-T Models 2X 0,26W/2,4W

F3 Limited

Models CU

All F3 Limited

models except

F3 Limited CU

F3-S Japanese

models

Sequential Manual 6-speed (SM6) with remote

Sequential Electronic 6-speed (SE6) with remote

See

electronic reverse interlock

electronic reverse interlock

ENGINE COOLANT

PROCEDURES

8100 RPM with engaged drivetrain

7500 RPM with open clutch or on neutral

High Beam: Halogen, 2 x 60 W (type HB2)

Low Beam: Halogen, 2 x 55 W (type H7)

2X 0,26W/2,4W + 0.14W/2.6W

2X 0,26W/2,4W + 2.6W

2x21W+LED3.1W

in the

MAINTENANCE

section of this guide

3

2x5/21W

______________

162

ELECTRICAL SYSTEM

F3 Models

F3-S Model

Front

Turn signal lights

Rear

Front

Position lights

Rear

License plate light

Back-up light 21 W

Fuses

F3-T

F3 Limited

Models

F3-S CE Models 2 x 21 W

F3-S Other

Countries

F3-T Models 2 x 10 W

F3-S Model

F3-T Model

Japanese Model LED 0.6 W

F3-T Model

F3 Limited

Models

Other Countries 2 x 5 W

F3-S Model 10 W

F3-T Model

F3 Limited

Models

Refer to

2x21W

2x3.2W

2x10W

LED 2 x 1 W

2 x 0.26 W

5W

FUSESinHOW TO REPLACE

FUSES AND LIGHTS

SPECIFICATIONS

FUEL SYSTEM

Multi-point Electronic Fuel Injection (EFI)

Fuel delivery Type

Fuel pump Type Electrical module in fuel tank

Idle speed

Type Premium unleaded gasoline

Fuel - Refer to

FUEL REQUIRE-

Minimum octane

MENTS

Recommended octane

Fuel tank capacity 27 L (7.1 U.S. gal.)

with ETC (Electronic Throttle Control)

Single throttle body (54 m m ) with an actuator

900 RPM

Electronically controlled, not adjustable

87 Pump Posted AKI (RON+MON)/2

92 RON

91 Pump Posted AKI (RON+MON)/2

95 RON

______________

163

SPECIFICATIONS

DRIVE SYSTEM

Final drive type Carbon reinforced drive belt

F3 Base models

North America

Final drive ratio

Europe

Japan

Australia

STEERING

Type Dynamic Power Steering (DP S)

FRONT SUSPENSION

Suspension type Double A-arm with anti-sway bar

Suspension travel 129 mm (5.07in)

Shock absorber

Spring preload adjustment Type

F3 Limited models

F3-S models

F3-T models

All F3 models 79/28

Qty

Typ e

F3-S

models

F3 Base

models

F3-T

models

F3

Limited

models

All

models

except

F3 Base

models

FOX PODIUM mono-tube coil cover

79/28

89/28

2

SACHS "Big Bore"

Threaded rings

REAR SUSPENSION

All models except F3

Limited and F3-T models

Suspension type

Suspension travel 132 mm (5.2 in)

______________

164

F3-T models

F3 Limited models

Swing arm with monoshock

Air ride with manual pressure adjustment

Swing arm with monoshock

Air controlled suspension with

automatic self leveling adjustment

Swing arm with monoshock

REAR SUSPENSION

Shock absorber

Spring preload adjustment

BRAKES

Type

Front brake

Rear brake

Brake fluid

Parking brake

Minimum brake pad thickness 1 mm (.04in)

Minimum brake disc thickness 6.4 mm (.252 in)

Maximum brake disc warpage 0.100 mm (.004 in)

Qty

Type SACHS twin-tube coil-over

All models except F3-T

models

F3-T models

Capacity 480 ml (16.2U.S. oz)

Typ e DO T 4

Adjustable air pressure: 105 kPa to 515 kPa

Foot actuated, fully integrated hydraulic 3 wheel

braking system with ABS and EBD

270 mm (11 in) rigid discs,

radially mounted Brembo monobloc

with 4 piston calipers, 2-pad

270 mm (11 in) disc

with 1 piston floating caliper with

Mechanical, e lectrically actuated to the

1

No adjustment

(15 PSI to 75 PSI)

Dual

Single

integrated parking

rear caliper

SPECIFICATIONS

TIRES

Type (use only radial tires

recommended by BRP)

Pressure

Minimum tire tread depth

Front Kenda KR31 165/55R15

Rear Kenda KR21A 225/50R15

Nominal.: 103 kPa (15 PSI)

Min.: 89 kPa (13 PSI)

Front

Rear

Front 2.5 mm (3/32in)

Rear 4.0 mm (5/32in)

NOTE: The pressure difference between the

left and right side tire should not exceed 3.4 kPa

(.5 PSI).

Max.: 117 kPa (17 PSI)

Nominal.: 193 kPa (28 PSI)

Min.: 179 kPa (26 PSI)

Max.: 207 kPa (30 PSI)

______________

165

SPECIFICATIONS

WHEELS

Size (diameter X width)

Front wheel nuts torque

Rear drive axle nut torque

DIMENSIONS

Overall length

Overall width 1 497 mm (58.9 in)

Overall height

Seat (top) height 675 mm (26.6 in)

Wheel base 1 709 mm (67.3 in)

Front wheel track 1 308 mm (51.5 in)

Front 381 mm (15 in) x 127 mm (5 in)

Rear 381 mm (15 in) x 178 mm (7in)

105 N•m to 113 N•m

(77 lbf•ft to 83 lbf•ft)

210 N•m to 240 N•m

(155 lbf•ft to 177 lbf•ft)

All models except F3 Limited and

F3-T models

F3-T models 2 596 mm (102.2 in)

F3 Limited 2 820 mm (111 in)

All models except F3 Limited and

F3-T models

F3 Limited and F3-T models 1 241 mm (48.9 in)

2 642 mm (104 in)

1 099 mm (43.3 in)

Ground clearance, front and under engine 115 mm (4.5 in)

WEIGHT AND LOADING CAPACITY

F3 Base models 408 kg (899.5 lb)

F3-S models 408 kg (899.5 lb)

Dry weight

Front storage compartment

Saddlebags (If equipped)

Rear center storage (if equipped)

______________

166

F3-T models 430 kg (948 lb)

F3 Limited models 448 kg (987.7 lb)

Capacity 24.4 L (6.45U.S. gal.)

Maximum load 6.8 kg (15 lb)

Right saddlebag capacity 26 L (6.87 U.S. gal.)

Maximum load 6.8 kg (15 lb)

Left saddlebag capacity 24 L (6.34 U.S. gal.)

Maximum load 6.8 kg (15 lb)

Capacity 60 L (15.85U.S. gal.)

Maximum load 6.8 kg (15 lb)

WEIGHT AND LOADING CAPACITY

Total vehicle load allowed

(including operator, all other loads

and added accessories)

Gross vehicle weight rating

(GVWR)

Gross axle weight rating (GAWR)

SPECIFICATIONS

All models except F3

Limited models

F3 Limited models 209 kg (460.8 lb)

F3 Base models

F3-S models

F3-T models 648 kg (1,429lb)

F3 Limited models 677 kg (1,493 lb)

All models

Front

Rear

except F3-T

models

F3-T models 340 kg (750 lb)

F3 Base

models

F3-S models

F3-T models 310 kg (683 lb)

F3 Limited

models

199 kg (438 lb)

627 kg (1,382 lb)

336 kg (741 lb)

291 kg (642 lb)

341 kg (752 lb)

______________

167

SPECIFICATIONS

______________

168

WARRANTY

______________

169

BRP LIMITED WARRANTY — USA AND CANADA:

2018 Can-Am

1. SCOPE OF THE LIMITED WARRANTY

Bombardier Recreational Products Inc. (“BRP”)* warrants its 2018 Can-Am

Spyder Roadsters ("Roadster") sold by authorized Can-Am Roadster Dealers (as

defined below) in the United States of America and in Canada from defects in

material or workmanship for the period and under the conditions described below.

This limited warranty will become null and void if: (1) Roadster was used for racing

or any other competitive activity, at any point, even by a previous owner; (2) the

odometer was removed or has been tampered with; (3) the Roadster was used

off-road; or (4) the Roadster has been altered or modified in such a way so as to

adversely affect its operation, performance or durability, or has been altered or

modified to change its intended use.

Non-factory installed parts and accessories are not covered under this limited warranty. Please refer to the applicable parts and accessories limited warranty text.

2. LIMITATIONS OF LIABILITY

THIS WARRANTY IS EXPRESSLY GIVEN AND ACCEPTED IN LIEU OF ANY

AND ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING

WITHOUT LIMITATION ANY WARRANTY OF M ERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TO THE EXTENT THAT THEY CANNOT

BE DISCLAIMED, THE IMPLIED WARRANTIES ARE LIMITED IN DURATION

TO THE LIFE OF THE EXPRESS WARRANTY. INCIDENTAL AND CONSEQUENTIAL DAMAGES ARE EXCLUDED FROM COVERAGE U NDER THIS

WARRANTY. SOME STATES/PROVINCES DO NOT ALLOW FOR THE DISCLAIMERS, LIMITATIONS AND EXCLUSIONS IDENTIFIED ABOVE, AS A

RESULT, THEY MAY NOT APPLY TO YOU. THIS WARRANTY GIVES YOU

SPECIFIC RIGHTS, AND YOU MAY ALSO HAVE OTHER LEGAL RIGHTS

WHICH MAY VARY FROM STATE TO STATE, OR PROVINCE TO PROVINCE.

Neither the distributor, any Dealer nor any other person has been authorized to

make any affirmation, representation or warranty regarding the Roadster, other

than those contained in this limited wa rran ty, and if made, shall not be enforceable

against BRP. BRP reserves the right to modify this limited warranty at any time,

being understood that such modification will not alter the warranty conditions

applicable to the Roadsters sold while this limited warranty is in effect.

®

SPYDER®ROADSTER

3. EXCLUSIONS — ARE NOT WARRANTED

The following are not warranted under any circumstances:

– Replacement of routine maintenance items such as, without limitation, oil, lu-

bricants, fluids, filters and spark plugs.

– Normal wear and tear, such as, without limitation, wear and tear of the tires, bat-

tery,generator brushes, sealed beams and light bulbs, clutch plates and facings,

drive belt, brake pads, brake linings and rotors and sprockets.

– Tune ups and adjustments including without limitation adjustments of belt,

alignment and wheel balance.

– Damages related to the appearance of the Roadster, including without limitation

scratches, dents, fading, flaking, peeling and damages to seat cover material.

– D amage caused by failure to provide proper maintenance or storage, as de-

scribedinthe

______________

170

OPERATOR'S GUIDE

.

– Damage resulting from removal of parts, improper repairs, improper service or

improper maintenance, modifications, alterations that are outside of the original

specifications of the Roadster, or damage resulting from repairs done by a person that is not an authorized servicing D ealer.

– D amage resulting from the installation of parts with specifications that differ

from the original Roadster parts, such as, without limitation, different tires,

exhaust system, wheels or brakes.

– Damage resulting from abuse, abnormal use, neglect or operation of the Road-

ster in a manner inconsistent with the recommendations of the

GUIDE

– Damage resulting from water ingestion, accident, road hazards, submersion,

fire, theft, vandalism or any act of God.

– D amage resulting from operation with fuels, oils or fluids with specifications dif-

ferent than as recommended in the

– Damage resulting from corrosion from road salts, battery acid, environmental

influences or treatment contrary to the

– Incidental or consequential damages, including without limitation towing,

storage, telephone, rental, taxi, inconvenience, insurance coverage, loan

payments, loss of time or loss of inc ome.

.

OPERATOR'S GUIDE

.

OPERATOR'S GUIDE

OPERATOR'S

.

4. WARRANTY COVERAGE PERIOD

This limited warranty will be in effect from the date of delivery to the first retail

consumer or the date the Roadster is first put into use, whichever occurs first and

for the following periods:

1.

For private, recreational use, TWENTY FOUR (24) CONSECUTIVE MONTHS,

except for the items covered in points (2) to (5) below; and for commercial

use TWELVE (12) CONSECUTIVE MONTHS, except for the items covered in

points (2) to (5) below.

A Roadster is used commercially when it is us ed in connection with any work

or employment that generates income during any part of the warranty period.

A Roadster is also used commercially when, at any point during the warranty

period, it is licensed for commercial use. T his is a minimal warranty period

which can be extended by any applicable warranty promotional program, as

the case may be

2.

For the battery, SIX (6) CONSECUTIVE MONTHS.

3.

For the tires, 6 CONSECUTIVE MONTHS or un til t i res a re worn to the last

three thirty-seconds of an inch (3/32 ") (2.38 millimeters) for the front tires and

the last five thirty-seconds of an inch (5/32 ") (3.97 millime ter s) for the rear tire,

whichever occurs first.

4.

For emission-related components; please also refer to the

PERFORMANCE WARRANTY

contained herein.

US EPAEMISSIONS

______________

171

5.

For Roadsters produced for sale in the state of California, that are originally

sold to residents or subsequently warranty registered to residents in the

state of California, please also refe r t o the applicable California Emissions

Control Warranty Statement.

The repair or replacement of parts or the performance of service under this

warranty does not extend the life of this warranty beyond its original expiration

date.

5. CONDITIONS TO HAVE WARRANTY COVERAGE

This warranty coverage is available only if each of the following conditions has

been fulfilled:

– The 2018 Roadster must be purchased as new and unused by its first owner

from a Spyder Roadster dealer authorized to distribute Roadsters in the country

in which the sale occurred (“Dealer” ).

– The BRP-specified pre-delivery inspection process must be completed, docu-

mented and signed by the purchaser.

– The Roadster must have undergone proper warranty registration by an autho-

rized Dealer.

– The Roadster must be purchased in the country in which th e purchaser resides.

– Routine maintenance must be performed as indicated in the

GUIDE

proof of proper maintenance.

BRP will not honor this limited warranty to any private use owner or commercial

use owner if the preceding conditions have not been met. Such limitations are

necessary in order to allow BRP to preserve both the safety of its products, and

also that of its consumers and the general public.

. BRP reserves the right to make warranty coverage contingent upon

OPERATOR'S

6. WHAT TO DO TO OBTAIN WARRANTY COVERAGE

The customer must cease using the Roadster upon the appearance of an anomaly. The customer m ust notify a servicing Dealer within three (3) days of the

appearance of a defect, and provide it with reasonable access to the product

and reasonable opportunity to repair it. The customer must also present to the

authorized Dealer proof of purchase of the product and must sign the repair/work

order prior to starting the repair in order to validate the warranty repair. All parts

replaced under this limited warranty become the property of BRP.

7. WHAT BR P WILL DO

BRP’s obligations under this warranty are limited to, at its sole discretion, repairing

parts found defective under normal use, maintenance and service, or replacing

such parts with new genuine Roadster parts without charge for parts and labor, at

any authorized Dealer durin g the warranty coverage p eriod. BRP's responsib ility

is limited to mak ing the required rep airs or replacements of parts. No claim of

breach of warranty shall be cause for cancellation or rescission of the sale of the

Roadster to the owner.

______________

172

In the event that service is required outside of the country of original sale, the

owner will bear responsibility for any additional charges due to local practices

and conditions, such as, but not limited to, freight, insurance, taxes, license fees,

import duties, and any and all other financial charges, including those levied by

governments, states, territories and their respective agencies.

BRP reserves the right to improve or modify products from time to time without assuming any obligation to modify any products manufactured.

8. TRANSFER

If the ownership of a product is transferred during the warranty coverage period,

this limited warranty, subject to its terms and conditions, shall also be transferred

and be valid for the remaining coverage period provided BRP or an authorized

Distributor/Dealer receives a proof that the former owner agreed to the transfer of

ownership, in addition to the co-ordinates of the new owner.

9. CONSUMER ASSISTANCE

In the event of a controversy or a dispute in connection w ith this limited warranty,

BRP suggests that you try to resolve the issue at the dealership level. We recommend discussing the issue with the authorized Dealer's service manager or owner.

If the matter still remains unresolved, contact BRP by filling out the customer contact form at www.brp.com or contact BRP by mail at one of the addresses listed

under the

CONTACT US

section of this guide.

______________

173

US EPA EMISSIONS PERFORMANCE WARRANTY

Bombardier Recreational Products Inc. ("BRP')* warrants that if:

1. The vehicle is maintained and operated in accordance with the written instructions for proper maintenance and use, and

2. The vehicle fails to conform at any time during its useful life to the applicable

emission standards or family emission limits as determined by an EPA-approved emission test, a nd

3. Such nonconformity results or will result in the vehicle owner having to bear

any penalty or other sanction (including the denial of the right to use the vehicle)

under local, State or Federal law, then BRP shall remedy the nonconformity at

no cost to the owner; except that, if the vehicle has been in operation for more

than 5 years or 30,000 kilometers (18,641 miles). BRP shall be required to

remedy only those nonconformities resulting from the failure of components

whichhavebeeninstalledinoronthevehicleforthesoleorprimarypurpose

of reducing vehicle emissions and that were not in general use prior to model

year 1968.

The warranty period begins o n the da te the veh icle is delive re d to its ultimate purchase, or if the vehicle is first placed in service as a “demonstrator” or “company”

motorcycle prior to delivery, on the date it is first placed in service.

Items which are covered by the Emissions Performance Warranty for the full useful life of the vehicle:

Fuel System and Air Admission Systems

– Fuel Injectors, Fuel Pump Module, Fuel Filter Ass’y, Throttle Body (Including

Throttle Position Sensor), Air Intake Manifold

Ignition Components and Sensors

– Engine Control Module (ECM), Engine Wiring Harness, Ignition Coils, Spark

Plugs (covered only up to the first maintenance replacement), Noise Sen so r

(Knock Sensor), Camshaft Position Sensor, Crankshaft Position Sensor, Temperature Sensor (Coolant), Pressure And Temperature Sensor, Oxygen Sensors

Exhaust System

– Primary Muffler (Containing Catalytic Converter), Exhaust Manifolds

– Clamps, Gaskets and Seals (from Engine up to Primary Muffler)

Crankcase Ventilation System

– Crankcase Vent Breather, Crankcase Vent Hose, Oil Filler Cap

Evaporative Emission Control System

– Fuel Tank, Fuel Cap, Fuel Hose, Vapor Canister, Vapor Canister Mounting

Bracket, Bleed Valve (Purge Valve), Check Valve, Filters, Evaporative Components Mounting Brackets

– Clamp, Seal, Gasket and Fitting (associated with fuel system assembly)

See maintenance information section in this operator’s guide for proper maintenance. This operator’s guide contains information for proper use of the vehicle.

Under the Emissions Performance Warranty, BRP shall be liable for the total cost

of the remedy for any vehicle validly presented for repair to any authorized Can-Am

roadster dealer, unless for emergency repairs as required by item 2 of the following list. State o r local limitations as to the extent of the penalty or sanction imposed

upon an owner of a failed vehicle shall have no bearing on this liability.

______________

174

In no case may BRP deny an emission performance warranty claim on the basis of:

1. Warranty work or predelivery service performed by any facility autho rized by

BRP to perform such work or service; or

2. Work performed in an emergency situation to rectify an unsafe condition,

including an unsafe driveability condition, attributable to BRP, provided the vehicle owner has taken steps to put the vehicle back in a conforming condition

in a timely manner; or

3. The use of a ny uncertified part or non-compliance with any written instruction

for proper maintenance and use w hic h is not relevant to the reason that the vehicle failed to comply with applicable emission standards; or

4. Any cause attributable to BRP; or

5. The use of any fuel which is commonly available in the geographical area in

which the vehicle is located, unless the written instructions for proper maintenance and use specify that the use of that fuel would adversely affect the

emission control devices and systems of the vehicle, and there is commonly

available information for the owner to identify the proper fuel to be used. See

maintenance information section and fuel requirements of fueling section.

Except as stated in the previous items; BRP may deny an emission performance

warranty claim on the basis of an uncertified aftermarket part used in the maintenance or repair of a vehicle if the use of the uncertified part caused the vehicle’s

failure to meet emission standards. The use of parts not equivalent to the original

parts or uncertified aftermarket parts may have a negative impact on the effectiveness of the emission control system and results in the vehicle’s failure to

meet emission standards. The use of certified parts does not affect the emission

performance warranty. Maintenance, replacement, or repair of the emission

control devices and systems m ay be performed by any motorcycle repair

establishment or individual using any certified part.

As soon as you become aware of a defect; you are responsible for presenting your

vehicle to an authorized Can-Am roadster dealer. Authorized Can-Am roadster

dealer will proceed w ith the warranty claim.

In the case an authorized Can-Am roadster dealer in unable (for reasons not attributable to the vehicle owner or events beyond the control of BRP or an authorized

Can-Am roadster dealer) to repair a vehicle within 30 days after the initial presentation of the vehicle to an authorized Can-Am roadster dealer, then the owner shall

be entitled to have the warranty remedy performed, at the expense of BRP, by any

repair facility of the owner’s choosing.

All defective parts replaced under this warranty become the property of BRP.

Contact the Director, Field Operations and Support Division (6406J), Environmen-

tal Protection Agency, 401 “M” Street, SW., Washington, DC 20460 (Attention:

Warranty Claim) for further information concerning the Emissions Performance

Warranty or to report a violations of the terms of the Emissions Performance

Warranty.

______________

175

Bombardier Recreational Products Inc. (“BRP”)* also warrants to the ultimate purchaser and each subsequent purchaser that this new vehicle, including all parts of

its exhaust emission-control system and its evaporative emission-control system,

meets two conditions:

– It is designed, built, and equipped so it conforms at the time of sale to the ulti-

mate p urch aser with the requirements of 40 CFR 86 and with the evaporative

emission standards of 40 CFR 1051, as applicable to onroad motorcycles.

– It is free from defects in materials and workmanship that may keep it from meet-

ing the requirements of 40 CFR 86 and with the evaporative emission standards

of 40 CFR 1051, as applicable to onroad motorcycles.

Where a warrantable condition exists, BRP will repair or replace, as it elects, any

part or component with a defect in materials or workmanship that would increase

the engine’s emissions of any regulated pollutant within the stated warranty

period at no cost to the owner, including expenses related to diagnosing and

repairing or replacing emission-rela ted parts.

The emission-related warranty is valid for the following p eriod whichever comes

first:

KILOMETERS/MILES YEARS

Exhaust and Evaporative emission-related

components

30,000/18,641

5

US EPA FEDERAL NOISE EMISSION WARRANTY

Bombardier Recreational Products Inc. (“BRP”)* warrants to the ultimate purchaser and each subsequent purchaser that this new vehicle, at time of sale,

was designed, built and equipped to meets all applicable US EPA Federal noise

control standards and is free from defects in materials and workmanship that may

keep it, when properly maintained and used, from meeting the requirements of

all applicable US EPA Federal noise standards for the following period whichever

comes first:

KILOMETERS/MILES YEAR

6,000/3,730

* In the USA, products are distributed and serviced by BRP US Inc.

______________

176

1

CALIFORNIA EMISSION CONTROL WARRANTY

STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS:

The California Air Resources Board and BRP US Inc. ("BRP")*, on behalf of

Bombardier Recreational Products Inc., are pleased to explain the emission

control system warranty on your 2018 Can-Am Spyder Roadster. In California,

new motor vehicles must be designated, built and equipped to meet the State's

stringent anti-smog standards. BRP must warrant the emission control system

on your Roadster for the periods of time listed below provided there has been no

abuse, neglect or improper maintenance of your Roadster.

Your emission control system may include parts such as the fuel-injection sys tem,

ignition system, catalytic converter and engine computer. Also included may be

hoses, connectors and other emission-related assemblies. Where a warrantable

condition exists, BRP will repair your Roadster at no cost to you including diagnosis, parts and labor.

MANUFACTURER'S WARRANTY COVERAGE

– For 5 years or 30 000 kilometers (18,641 miles), whichever occurs first.

OWNER'S WARRANTY RESPONSIBILITIES:

As the Roadster owner, you are responsible for the performance of the required

maintenance listed in your

retain all receipts covering maintenance on your Roadster, but BRP cannot deny

warranty solely for the lack of receipts or foryour failure to ensurethe performance

of all scheduled maintenance.

You are responsible for presenting your Roadster to a Dealer as soon as a problem

exists. The warranty repairs should be completed in a reasonable amount of time,

not to exceed 30 days.

As the Roadster owner, you should also be aware that BRP may deny you warranty

coverage if your Roadster or a part has failed due to abuse, neglect, improper maintenance or unapproved modifications.

If you have any questions regarding your warranty rights and responsibilities, you

should contact BRP's customer assistance center at 1 715 848-4957 or the California Air Resource Board at 9528 Telstar Avenue, El Monte, CA 91731.

OPERATOR'S GUIDE

. BRP recommends that you

*IntheUSA,productsaredistributedandservicedbyBRPUSInc.

©

2017 Bombardier Recreational Products Inc. All rights reserved.

®

Registered Trademarks of Bombardier Recreational Products Inc. or its affiliates.

______________

177

BRP LIMITED WARRANTY OUTSIDE USA AND

CANADA: 2018 Can-Am

1. SCOPE OF THE LIMITED WARRANTY

Bombardier Recreational Products Inc. (“BRP”)* warrants its 2018 Can-Am

Spyder roadsters (the "Products") sold by authorized Can-Am Spyder roadster

distributors or dealers located in the EEA (the "EEA" or "European Economic Area"

shall mean the countries member of the European Union plus Norway, Iceland

and Liechtenstein) or elsewhere, except in the USA and Canada** (the "Distributors/Dealers") from defects in material or workmanship for the period and under

the conditions described below. This limited warranty will become null and void if:

(1) the Product was used for racing or any other competitive activity, at any point,

even by a previous owner; or (2) the odometer was removed or has been tampered with; (3) the Product was used off-road; or (4) the Product has been altered

or modified in such a way so as to adversely affect its operation, performance or

durability, or has been altered or modified to change its intended use.

Non-factory installed parts and accessories are not covered under this limited warranty. Please refer to the applicable parts and accessories limited warranty text.

2. LIMITATIONS OF LIABILITY

JURISDICTIONS TO THE EXTENT PERMITTED BY LAW. THIS WARRANTY IS

EXPRESSLY GIVEN AND ACCEPTED IN LIEU OF ANY A ND ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WITHOUT LIMITATION

ANY WARRANTY OF M ER CHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TO THE EXTENT THAT THEY CANNOT BE DISCLAIMED,

THE IMPLIED WARRANTIES ARE LIMITED IN DURATION TO THE LIFE OF

THE EXPRESS WARRANTY. ALL INCIDENTAL, CONSEQUENTIAL, DIRECT,

INDIRECT OR OTHER DAMAGES OF ANY KIND ARE EXCLUDED FROM

COVERAGE UNDER THIS WARRANTY. SOME JURISDICTIONS DO NOT

ALLOW FOR THE DISCLAIMERS, LIMITATIONS O F IN CIDE NTAL OR CONSEQUENTIAL DAMAGES OR OTHER EXCLUSIONS IDENTIFIED ABOVE.

AS A RESULT, THEY MAY NOT APPLY TO YOU. THIS WARRANTY GIVES

YOU SPECIFIC RIGHTS, AND YOU MAY ALSO HAVE OTHER LEGAL RIGHTS

WHICH MAY VARY FROM COUNTRY TO COUNTRY, OR JURISDICTION TO

JURISDICTION. (FOR PRODUCTS PURCHASED IN AUSTRALIA SEE CLAUSE

4BELOW).

Neither the authorized Distributors/Dealers nor any other person has been authorized t o make any affirmation, representation or warranty regarding the Product,

other t han those contained in this limited warranty, and if made, shall not be enforceable against BRP. BRP reserves the right to modify this warranty at any time,

being understood that such modification will not alter the warranty conditions

applicable to the Products sold while this warranty is in effect.

®

SPYDER®ROADSTER

3. EXCLUSIONS — ARE NOT WARRANTED

The following are not warranted under this limited policy under any circumstances:

– R eplacement of routine maintenance items such as, without limitation, oil and

lubricants, filters and spark plugs.

– Normal wear and tear, such as, without limitation, wear and tear of the tires, bat-

tery,generator brushes, sealed beams and light bulbs, clutch plates and facings,

drive belt, brake pads, brake linings and rotors and sprockets.

______________

178

– Tune ups and adjustments including without limitation adjustments of belt,

alignment and wheel balance.

– Damages related to the appearance of the Product, including without limitation

scratches, dents, fading, flaking, peeling and damages to seat cover material.

– Damage caused by negligence or failure to provide proper maintenance and/or

storage, as described in the

– Damage resulting from removal of parts, improper repairs, improper service

or improper maintenance, modifications, alterations that are outside of the

original specifications of the Product, or damage resulting from use of parts

or accessories not manufactured or approved by BRP which in its reasonable

judgement are either incompatible with the product or adversely affect its

operation, performance or durability or resulting from repairs done by a person

that is not an authorized servicing Distributor/Dealer.

– D amage resulting from the installation of parts with specifications that differ

from the original Product parts, such as, without limitation, different tires,

exhaust system, wheels or brakes.

– Damage resulting from abuse, abnormal use, neglect, racing or operation

of the Product in a manner inconsistent with the recommend ations of the

OPERATOR'S GUIDE

– Damage resulting from water ingestion, accident, road hazards, submersion,

fire, theft, vandalism or any act of God.

– Damage resulting from operation with fuels, oils or lubricants with specifica-

tions different than as recommended in the

– Damage resulting from corrosion from road salts, battery acid, environmental

influences or treatment contrary to the

– Incidental or consequential damages, including without limitation, expense

for gasoline, expense for transporting the Product to and from the authorized

Distributor/Dealer, mechanic’s travel time, trailering or towing, storage, t elephone, cell phone, fax or telegram charges, rental of a like or replacement

Product during w arranty services or down time, taxi, travel, lodging, loss of or

damage to personal property, inconvenience, cost of insurance coverage, loan

payments, loss of time, loss of income, revenue or profits, or loss of enjoyment

or use of Product.

OPERATOR'S GUIDE

.

.

OPERATOR'S GUIDE

OPERATOR'S GUIDE

.

.

4. WARRANTY COVERAGE PERIOD

This warranty will be in effect from the date of delivery to the first retail consumer

or the date the Product is first put into use, whichever occurs first and for the following periods:

a.

For private, recreational use, TWENTY-FOUR (24) CONSECUTIVE

MONTHS, except for the items covered in points (2) and 3) below; and

for commercial use TWELVE (12) CONSECUTIVE MONTHS, except for the

items covered in points (2) and (3) below.

The Product is used commercially when it is used in connection with any

work or employment that generates income, during any part of the warranty

period. The Product is also used comm ercially when, at any point during the

warranty period, it is licensed for commercial use;

______________

179

b.

For the battery, SIX (6) CONSECUTIVE MONTHS;

c.

For the tires, 6 CONSECUTIVE MONTHS or until tires are worn to the last

three thirty-second of an inch (3/32 ") (2.38 millimeters) for the front tires and

the last five thirty-second of an inch (5/32 ") (3.97 millimeters) for the rear tire,

whichever occurs first.

The repair or replacement of parts or the performance of service under this warranty does not extend the life of this warranty beyond its original expiration date.

Note that the duration and any other modalities of the warranty coverage are subject to the applicable national or local legislation in the custom er's country.

FOR PRODUCTS SOLD IN AUSTRALIA ONLY

Nothing in these Warranty terms and conditions should be taken to exclude,

restrict or modify the application of any condition, warranty, guarantee, right or

remedy conferred or implied under the Competition and Consumer Act 2010

(Cth), including the Australian Consumer Law or any other law, where to do so

would contravene that law, or cause any part of these terms and conditions to be

void. The benefits given to you under this limited warranty are in addition to other

rights and remedies that you hav e under Australian law.

Our goods come with guarantees that cannot be excluded under the Australian

Consumer Law. You are entitled to a replacement or refund for a major failure

and for compensation for any other reasonably foreseeable loss or damage. You

are also entitled to have the goods repaired or replaced if the goods fail to be of

acceptable quality and the failure does not amount to a major failure.

5. CONDITIONS TO HAVE WARRANTY COVERAGE

This warranty coverage is available only if each of the following conditions has

been fulfilled:

– The Product must be purchased as new and unused by its first owner from a

Distributor/Dealer authorized to distribute the Product in the country or unio n

of countries in which the sale occurred;

– The BRP specified pre-delivery inspection process has been completed and

documented by the purchaser and the authorized Distributor/Dealer and signed

by the purchaser;

– The Product must have undergone proper warranty registration by an autho-

rized Distributor/Dealer;

– The Product must be purchased in the country or union of countries in which the

purchaser resides.

– Routine maintenance as outlined in the

formed in a timely manner. BRP reserves the right to make warranty coverage

contingent upon proof of proper maintenance.

BRP will not honour this limited warranty to any private use owner or commercial

use owner if one of the preceding conditions has not been met. Such limitations

are necessary in order to allow BRP to preserve both the safety of its products, and

also that of its consumers and the general public.

______________

180

OPERATOR'S GUIDE

must be per-

6. WHAT TO DO TO OBTAIN WARRANTY COVERAGE

The customer must cease using the Product upon the appearance of an anomaly.

The customer must notify an authorized servicing Distributor/Dealer within two

(2) months of the appearance of a defect, and provide it with reasonable access

to the Product and reasonable opportunity to repair it. The customer must also

present to the authorized Distributor/Deale r, proof of purchase of the Product and

must sign the repair/work order prior to starting the repair in orde r to validate the

warranty repair. All parts replaced under this limite d warranty become the property of BRP. Note that the notification period is subject to the applicable national

or local legislation in customer's country.

7. WHAT BRP WILL DO

To the extent permitted by law, BRP’s obligations under this warranty are limited to, at its sole discretion, repairing parts found defective under normal use,

maintenance and service, or replacing such parts with new genuine Product parts

without charge for parts and labour, at any authorized Distributor/Dealer during

the warranty coverage period under the conditions described herein. BRP’s

responsibility is limited to making the required repairs or replacements of parts.

No claim of breach of warranty shall b e cause for cancellation or rescis sion of the

sale of the Product to the owner. You may have other legal rights which may vary

from country to country.

In the event that service is required outside of the country of original sale, or

for EEA residents, if service is required outside of the EEA, the owner will bear

responsibility for any additional charges due to local practices and condition s, such

as, but not limited to, freight, insurance, taxes, license fees, import duties, and

any and all other financial charges, including those levied by governments, states,

territories and their respective agencies.

BRP reserves the right to improve or modify products from time to time without assuming any obligation to modify all pro du cts previo usly manufactured.

8. TRANSFER

If the ownership of a Product is transferred during the warranty coverage period,

this limited warranty, subject to its terms and conditions, shall also be transferred

and be valid for the remaining coverage period provided BRP or an authorized

Distributor/Dealer receives a proof that the former owner agreed to the transfer of

ownership, in addition to the co-ordinates of the new owner.

9. CONSUMER ASSISTANCE

In the event of a controversy or a dispute in connection w ith this limited warranty,

BRP suggests that you try to resolve the issue at the Distributor/Dealer level. We

recommend discussing the issue with the authorized Distributor/D ealer's service

manager or owner.

If the matter still remains unresolved, contact BRP by filling out the customer contact form at www.brp.com or contact BRP by mail at one of the addresses listed

under the

CONTACT US

section of this guide.

______________

181

ADDITIONAL TERMS AND CONDITIONS FOR FRANCE

ONLY

The following terms and conditions are applicable to products sold in France only:

The seller shall deliver goods that are complying with the contract and shall be re-

sponsible for defects existing upon delivery. The seller shall also be responsible for

defects resulting from packaging, assembling instructions or the installation when

it is its responsibility per the contract or if accomplished under its responsibility. To

be compliant with the contract, the good shall:

1. Be fit for normal use for goods similar thereto and, if applicable:

1.1 Correspond to the description provided by the seller and have the qualities

presented to the buyer though sample or model;

1.2 Have the qualities that a buyer may legitimately expect considering the

public declarations of the seller, the manufacturer of its representative,

including in advertising or labeling; o r

2. Have the characteristics mutually agreed upon as between the parties or be fit

for the specific use intended by the buyer and brought to the attention of the

seller and which accepted.

The action for failure to comply is prescribed after two years after delivery of the

goods. The seller is responsible for the warranty for hidden defects of the good

sold if such hidden defects are rendering the good unfit for the intended use, or

if they diminish its use in such a way that the buyer would not have acquired the

good or would have given a lesser price, had he known. The action for such hidden

defects shall be taken by the buyer within 2 years of the discovery of the defect.

* In the European Economic Area and elsewhere, Products are distribute d and serviced by

BRP European Distribution S.A. and other subsidiaries of BRP.

** The BRP limited warranty offered on Products sold in the USA and Canada is different

than the one offered in the EEA and elsewhere.

©

2017 Bombardier Recreational Products Inc. All rights reserved.

®

Registered Trademarks of Bombardier Recreational Products Inc. or its affiliates.

______________

182

CUSTOMER

INFORMATION

______________

183

PRIVACY INFORMATION

BRP wishes to inform you that your coordinates will be used for safety and warranty related purpos es . Furthermore, BRP and its affiliates may use its customer

list to distribute marketing and promotional information about BRP and related

products.

To exercise your right to consult or correct your data, or to be removed from the addressee-list for direct marketing, please contact BRP.

By E-mail: privacyofficer@brp.com

By mail:

BRP

Senior Legal Counsel-Privacy Officer

726 St-Joseph

Valcourt QC

Canada,

J0E 2L0

______________

184

CONTACT US

www.brp.com

North America

565 de la Montagne Street

Valcourt (Québec) J0E 2L0

Canada

Sturtevant, Wisconsin, U.S.A.

10101 Science Drive

Sturtevant, Wisconsin

53177

U.S.A.

Sa De Cv, Av. Ferrocarril 202

Parque Ind. Querétaro, Lote2-B

76220

Santa Rosa Jáuregui, Qro., Mexico

Europe

Skaldenstraat 125

B-9042 Gent

Belgium

Itterpark 11

D-40724 Hilden

Germany

ARTEPARC Bâtiment B

Route de la côte d'Azur, Le Canet

13590 Meyreuil

France

Ingvald Y stgaardsvei 15

N-7484 Trondeim

Norway

Isoaavantie 7

PL 8040

96101 Rovaniemi

Formvägen 16

S-90621Umeå

Sweden

Avenue d’Ouchy 4-6

1006 Lausanne

Switzerland

South America

Rua James Clerck Maxwell, 230

TechnoPark Campinas SP 13069-380

Brazil

Asia

15/F Parale Mitsui Building,8

Higashida-Cho, Kawasaki-ku

Kawasaki 210-0005

Japan

Room Dubai, level 12, Platinum Tower

233 Tai Cang Road

Xintiandi, Lu Wan District

Shanghai 200020

PR China

Oceania

6 Lord Street

Lakes Business Park

Botany, NSW 2019

Australia

______________

185

CHANGE OF ADDRESS/OWNERSHIP

If your address has changed or if you are the new owner of the vehicle, be sure to

notify BRP by either:

– Notifying an authorized Can-Am roadster dealer.

– North America Only: calling at 1-888-272-922 2;

– Mailing o ne of the change of address cards on the following pages at one of the

BRP addresses indicated in the

In case of change of ownership, please join a proof that the former owner agreed

to the transfer.

Notifying BRP, even after the expiration of the limited warranty, is v ery important

as it enables BRP to reach the vehicle owner if necessary, like w hen safety recalls

are initiated. It is the owner’s responsibility to notify BRP.

STOLEN UNITS: If your personal vehicle is stolen, you should notify BRP or an authorized Can-Am roadster d e ale r. We will ask you to provide your name, address,

phone number, the vehicle identification number and the date it was stolen.

CONTACT US

section of this guide.

______________

186

CHANGE OF ADDRESS/OWNERSHIP

______________

187

CHANGE OF ADDRESS/OWNERSHIP

This page is

intentionally blank

______________

188

CHANGE OF ADDRESS/OWNERSHIP

______________

189

CHANGE OF ADDRESS/OWNERSHIP

This page is

intentionally blank

______________

190

NOTES

CHANGE OF ADDRESS/OWNERSHIP

______________

191

CHANGE OF ADDRESS/OWNERSHIP

NOTES

______________

192

Loading...

Loading...