R&M Materials Handling WIRE ROPE PACKAGES User Manual

English

31.12.2008

COMPLETE ASSEMBLY INSTRUCTION FOR CRANES

-

-

-

-

-

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

Read the instructions supplied with the product before installation and commissioning.

Keep the instructions in a safe place for future reference.

Table of content

Crane components........................................4

1

1.1 Single girder crane (Wire rope hoist)..........4

1.2 Double girder crane (Wire rope hoist).........5

1.3 Double girder crane with a service

platform (Wire rope hoist) ....................................6

1.4 Single girder crane, underrunning end

carriages (Wire rope hoist)...................................7

1.5 Single girder crane (Chain hoist)................8

1.6 Solo hoist, pendant in festoon (Wire rope

hoist) 9

1.7 Solo hoist, pendant fixed in hoist (Wire

rope hoist)..........................................................10

2 Festoon assembly.......................................11

2.1 Single girder crane (Wire rope hoist)........11

2.2 C-rail assembly of hoist power supply;

Single girder crane (Wire rope hoist) .................13

2.3 Single girder crane (Chain hoist)..............14

2.4 C-rail assembly of hoist power supply;

Single girder crane (Chain hoist) .......................16

2.5 Solo hoist with moveable pendant (Wire

rope hoist)..........................................................17

2.6 Solo hoist ,pendant fixed to hoist (Wire

rope hoist)..........................................................18

2.7 Double girder crane (Wire rope hoist).......19

3 Traveling machinery assembly..................21

3.1 Machinery sizes 3-5..................................21

3.2 Machinery size 3, 8 wheels.......................22

3.3 Machinery size 3, 4 wheels.......................23

3.4 Machinery size 2, 8 wheels.......................24

4 Crane towing arm assembly.......................25

4.1 Crane Towing Arm....................................25

4.2 Crane Towing Arm, 8 wheels end carriage

and I-beam frame...............................................26

4.3 Crane Towing Arm, 4 wheels end carriage

and 8 wheels end carriage with Hat-profile........27

5 Hoist power towing arm assembly............28

5.1 Normal headroom hoist, girder height

≤400 mm (Wire rope hoist) ................................28

5.2 Normal headroom hoist, girder height

>400 mm (Wire rope hoist) ................................29

5.3 Low headroom hoist (drum diam. 303 mm

or 355 mm), girder height ≤500 mm (Wire rope

hoist) 29

2/76

5.4 Low headroom hoist (drum diam. 303 mm

or 355 mm), girder height >500 mm (Wire rope

hoist) 30

5.5 Low headroom hoist (drum diam. 406 mm)

(Wire rope hoist).................................................31

5.6 Double girder trolley (Wire rope hoist)......32

5.7 Normal headroom hoist (Chain hoist).......33

6 Traveling limit switch assembly.................34

6.1 Double girder trolley (Wire rope hoist)......34

6.2 Normal headroom trolley (Wire rope hoist)35

6.3 Low headroom hoist (drum diam. 406 mm)

(Wire rope hoist).................................................36

6.4 Low headroom hoist (drum diam. 303 mm

or 355 mm), girder height ≤ 500 mm (Wire rope

hoist) 37

6.5 Low headroom hoist (drum diam. 303 mm

or 355 mm), girder height > 500 mm (Wire rope

hoist) 38

6.6 Normal headroom trolley (Chain hoist).....39

6.7 Crane limit switch assembly, top running

end carriages .....................................................40

6.8 Crane limit switch assembly, underrunning

end carriages (Wire rope hoist)..........................41

7 Bridge panel assembly ...............................42

7.1 Single girder crane (Wire rope hoist)........42

7.2 Double girder crane (Wire rope hoist).......43

7.3 Double girder crane with a service

platform (Wire rope hoist)...................................44

7.4 Single girder crane (Chain hoist) ..............45

8 Horn assembly.............................................46

8.1 Crane........................................................46

8.2 Solo hoist..................................................47

9 Buffer stop assembly for single girder

crane 48

9.1 Wire rope hoist..........................................48

9.2 Chain hoist................................................49

10 Joint plate assembly...................................50

10.1 Joint plate assembly, top running end

carriages ............................................................50

10.2 Joint plate assembly, underrunning end

carriages ............................................................51

11 Load display assembly...............................52

12 Crane light assembly ..................................53

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

12.1 I-Valo light, fixing to a flange of a main

girder 53

12.2 Titano light, fixing to a flange of a main

girder 54

13 Flashing light assembly..............................55

13.1 Flashing light assembly, top running end

carriages............................................................55

13.2 Flashing light assembly, underrunning end

carriages............................................................56

14 Radio assembly...........................................57

15 Radio assembly (solo)................................58

16 Cable plugs and paths................................59

16.1 Single girder crane plug layout and cable

paths (Wire rope hoist).......................................59

16.2 Single girder crane plug layout and cable

paths, two hoists (Wire rope hoist).....................60

16.3 Single girder crane plug layout and cable

paths, three hoists (Wire rope hoist)..................61

16.4 Double girder crane plug layout and cable

paths (Wire rope hoist).......................................62

16.5 Double girder crane plug layout and cable

paths, two hoists (Wire rope hoist).....................63

16.6 Double girder crane plug layout and cable

paths, three hoists (Wire rope hoist)..................64

16.7 Plug diagram, (Wire rope hoist)................65

16.8 Plug diagram, two hoists (Wire rope hoist)66

16.9 Plug diagram, three hoists (Wire rope

hoist) 67

16.10 Single girder crane plug layout and cable

paths (Chain hoist).............................................68

16.11 Plug diagram (Chain hoist) .......................69

16.12 Solo hoist with moveable pendant plug

layout and cable paths (Wire rope hoist)............70

16.13 Solo hoist with fixed pendant plug layout

and cable paths (Wire rope hoist)......................71

16.14 Plug diagram, movable pendant (Wire

rope hoist)..........................................................72

16.15 Plug diagram, fixed pendant (Wire rope

hoist) 73

17 Crane cable ways ........................................74

17.1 Assembly examples..................................74

17.2 Common assembly methods ....................75

3/76

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

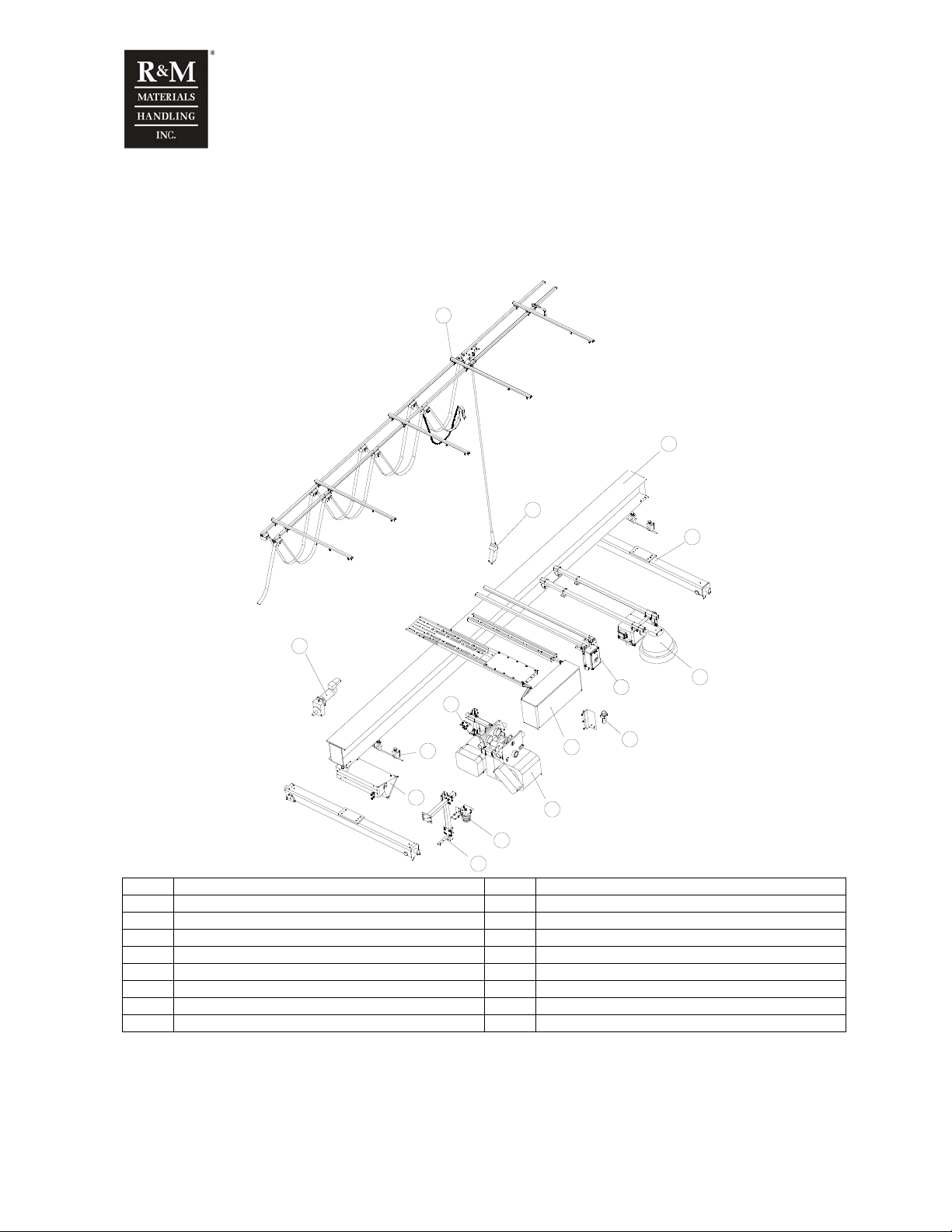

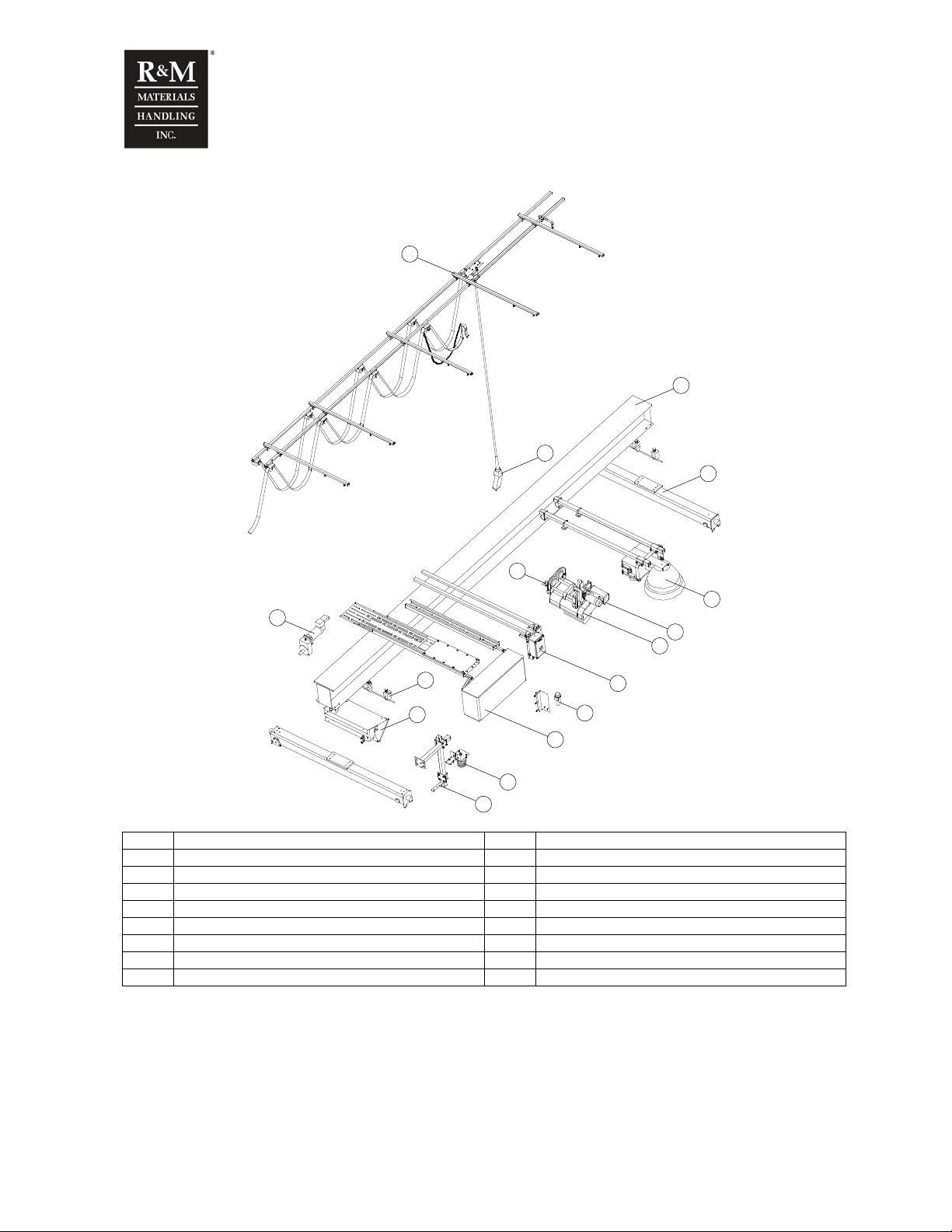

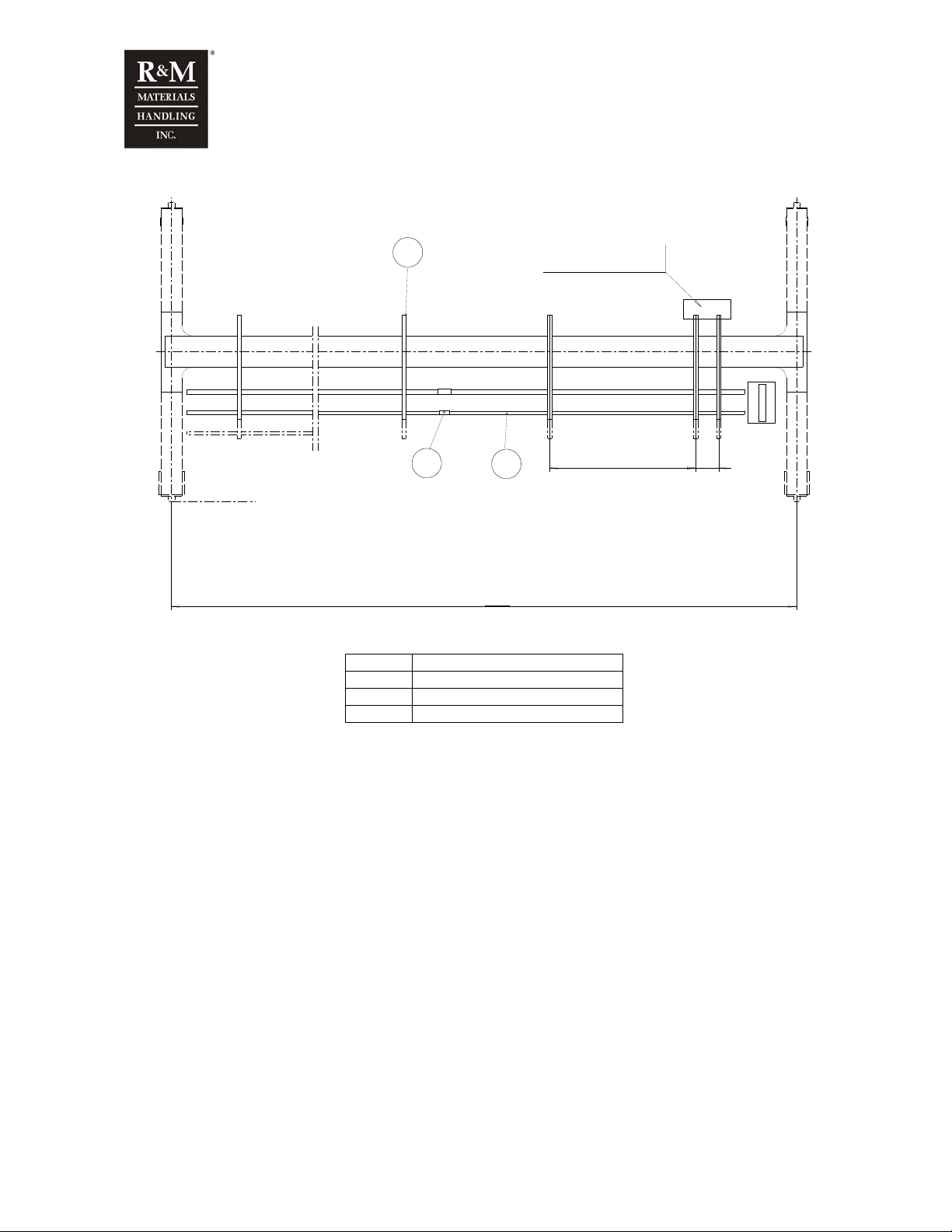

1 Crane components

1.1 Single girder crane (Wire rope hoist)

1

5

4

14

15

2

13

12

11

10

8

9

3

c-osat-1-gb

Pos. Name Pos. Name

1 Festoon assembly 9 Hoist

2 Hoist power towing arm 10 Crane power towing arm

3 Horn (option) 11 Flashing light (option)

4 Pendant (option) 12 Load display (option)

5 Main girder 13 Buffer stop

6 End carriage 14 Bridge traveling machinery

7 Light (option) 15 Radio (option)

8 Bridge panel

6

7

4/76

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

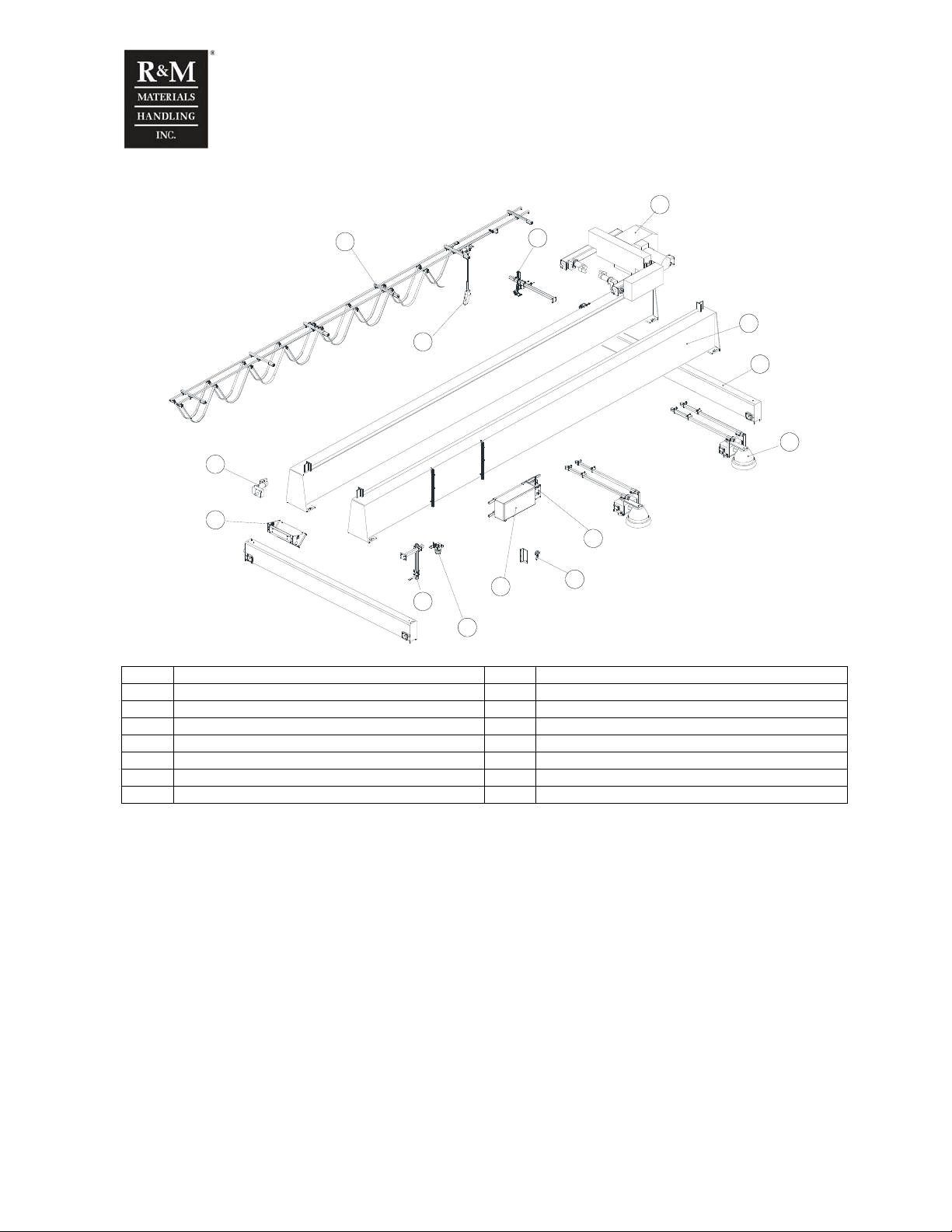

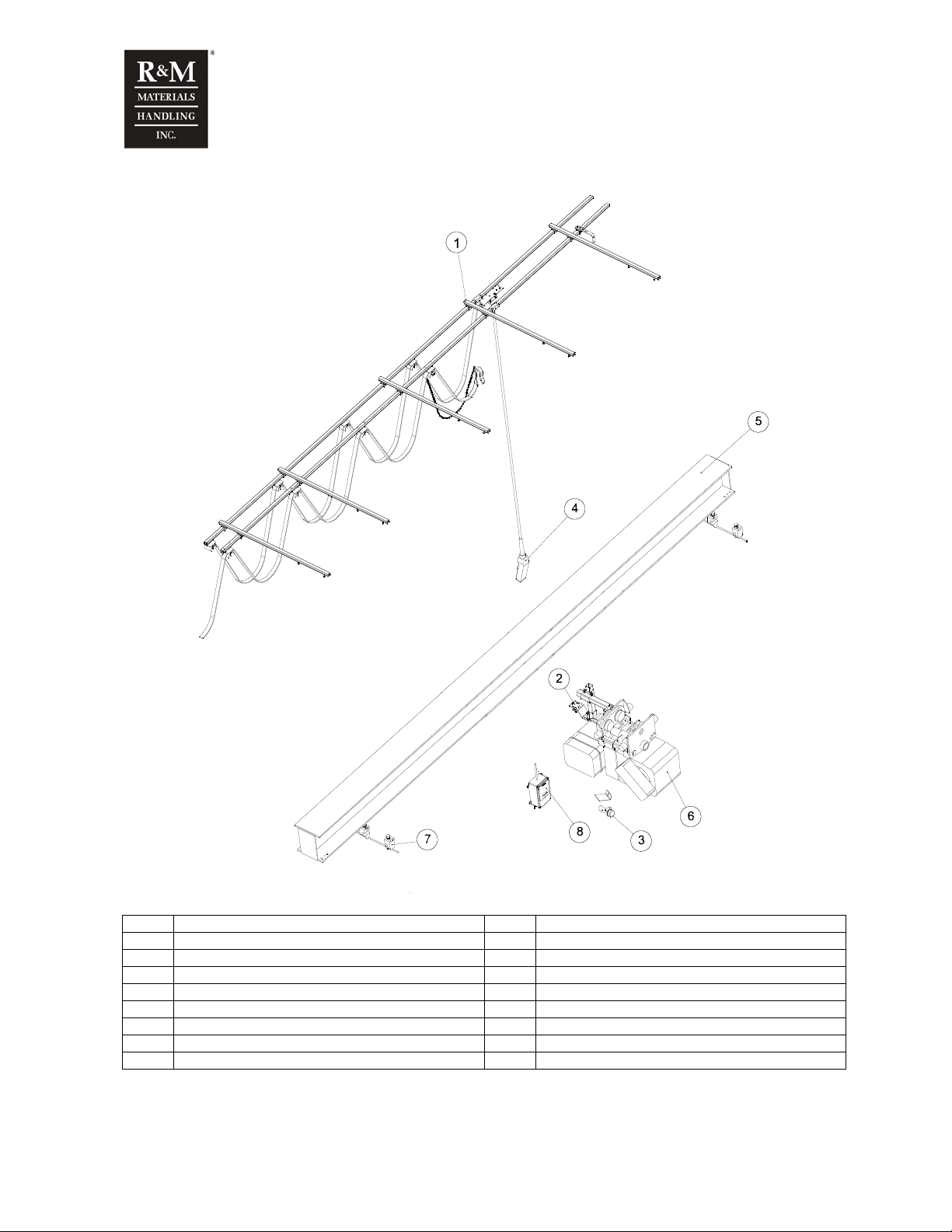

1.2 Double girder crane (Wire rope hoist)

5

1

4

3

13

12

14

9

8

11

10

Pos. Name Pos. Name

1 Festoon assembly 8 Horn (option)

2 Main girders 9 Bridge panel

3 Pendant (option) 10 Flashing light (option)

4 Hoist power towing arm 11 Crane power towing arm

5 Hoist 12 Load display (option)

6 End carriage 13 Bridge traveling machinery

7 Light (option) 14 Radio (option)

2

6

7

c-osat-2-gb

5/76

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

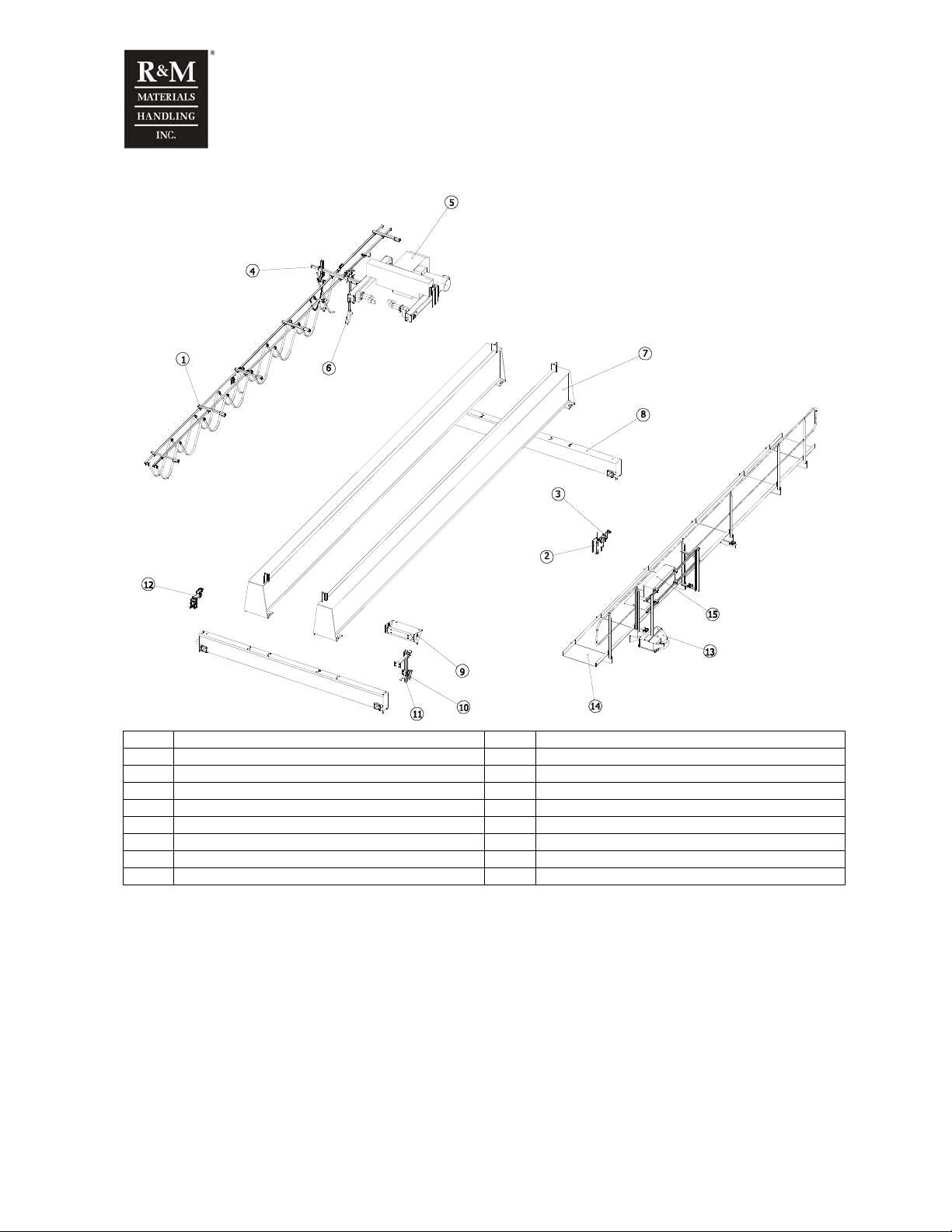

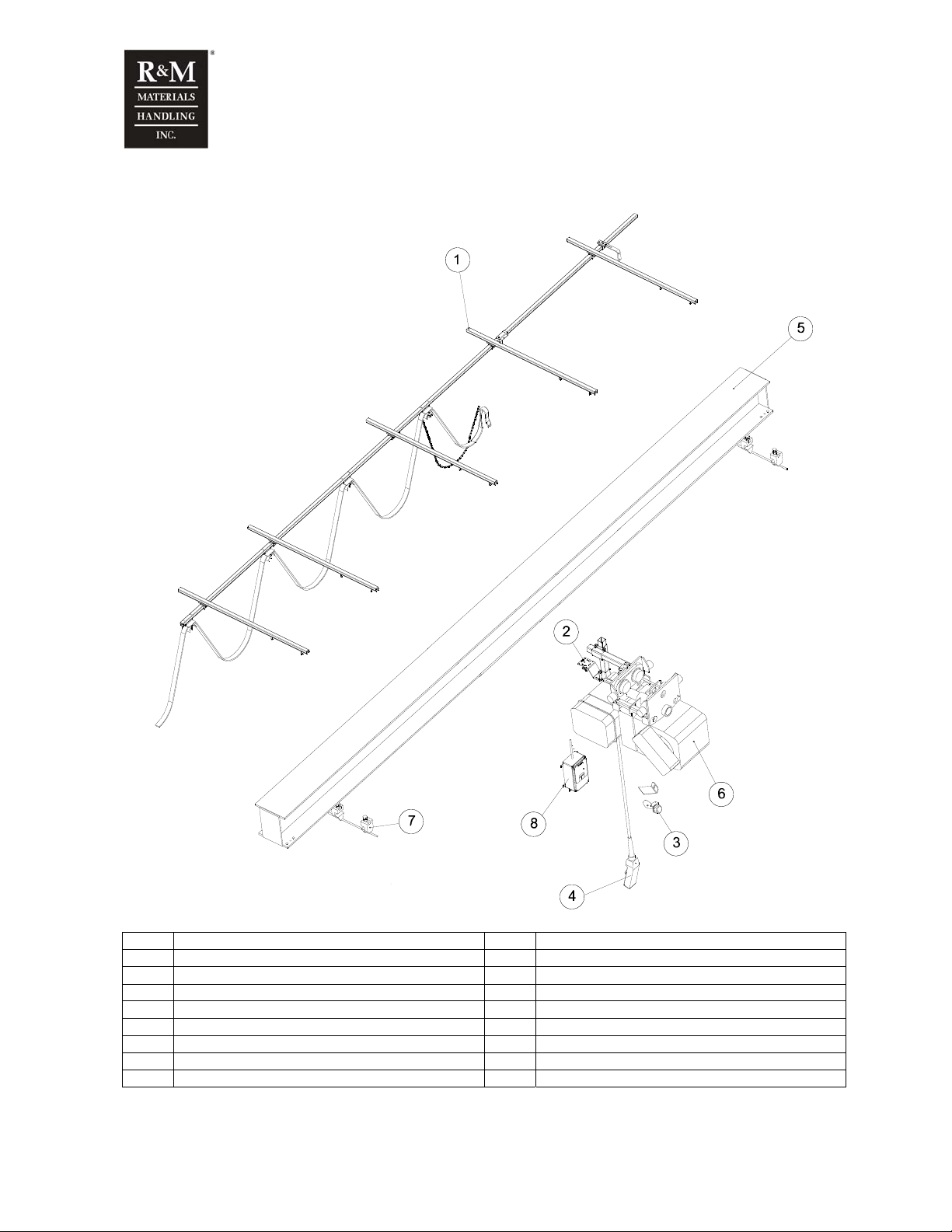

1.3 Double girder crane with a service platform (Wire rope hoist)

Pos. Name Pos. Name

1 Festoon assembly 9 Load display (option)

2 Radio (option) 10 Flashing light (option)

3 Horn (option) 11 Crane power towing arm

4 Hoist power towing arm 12 Bridge traveling machinery

5 Hoist 13 Light

6 Pendant (option) 14 Service platform (option)

7 Main girders 15 Bridge panel

8 End carriage

6/76

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

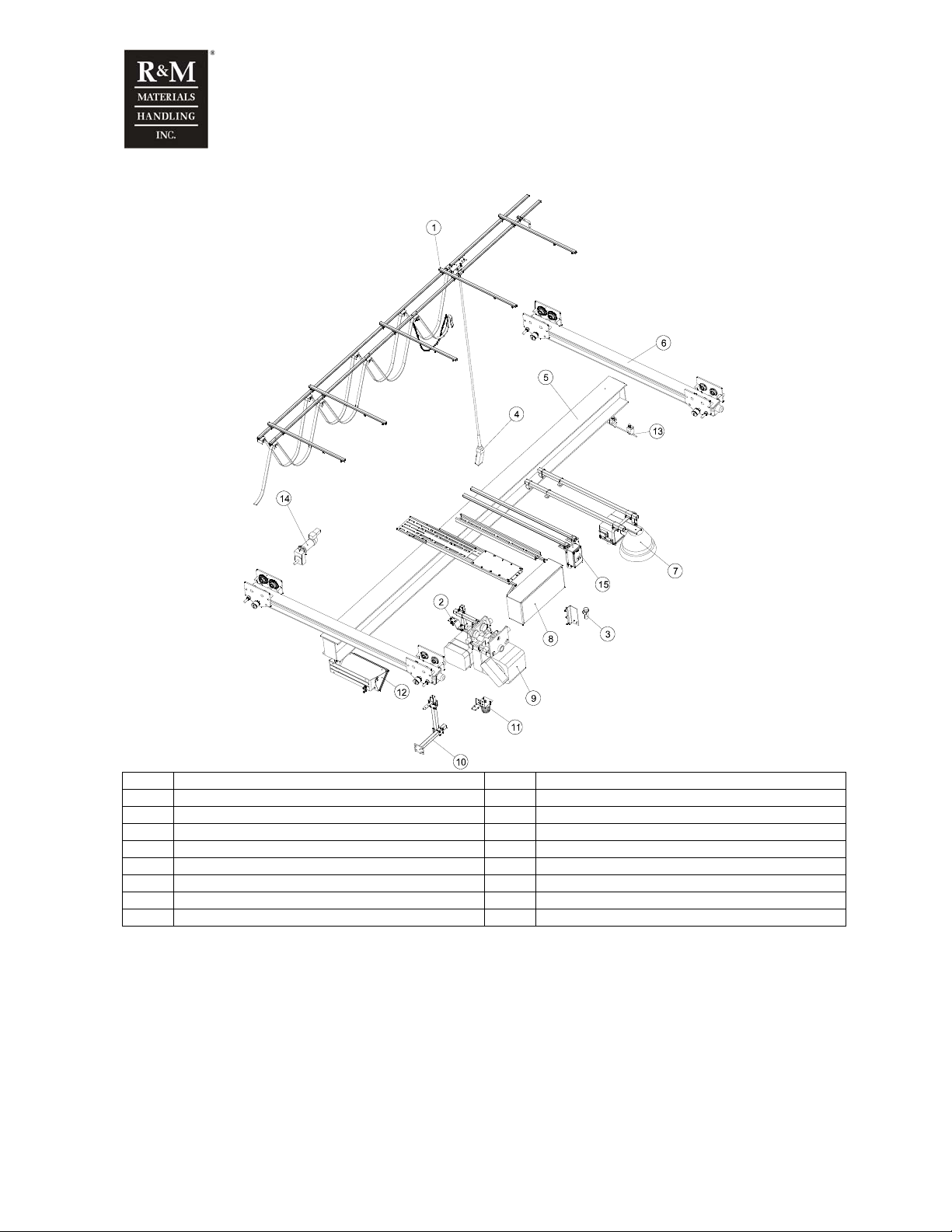

1.4 Single girder crane, underrunning end carriages (Wire rope hoist)

C_under01a

Pos. Name Pos. Name

1 Festoon assembly 9 Hoist

2 Hoist power towing arm 10 Crane power towing arm

3 Horn (option) 11 Flashing light (option)

4 Pendant (option) 12 Load display (option)

5 Main girder 13 Buffer stop

6 End truck 14 Bridge traveling machinery

7 Light (option) 15 Radio (option)

8 Bridge panel

7/76

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

d

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

1.5 Single girder crane (Chain hoist)

1

5

4

6

2

14

13

12

8

11

10

c-chain1

15

3

16

9

Pos. Name Pos. Name

1 Festoon assembly 9 Hoist

2 Hoist power towing arm 10 Crane power towing arm

3 Horn (option) 11 Flashing light (option)

4 Pendant (option) 13 Buffer sto p

5 Main girder 14 Bridge traveling machinery

6 End carriage 15 Radio (option)

7 Light (option) 16 Travelling limit switch (option)

8 Bridge panel

7

8/76

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

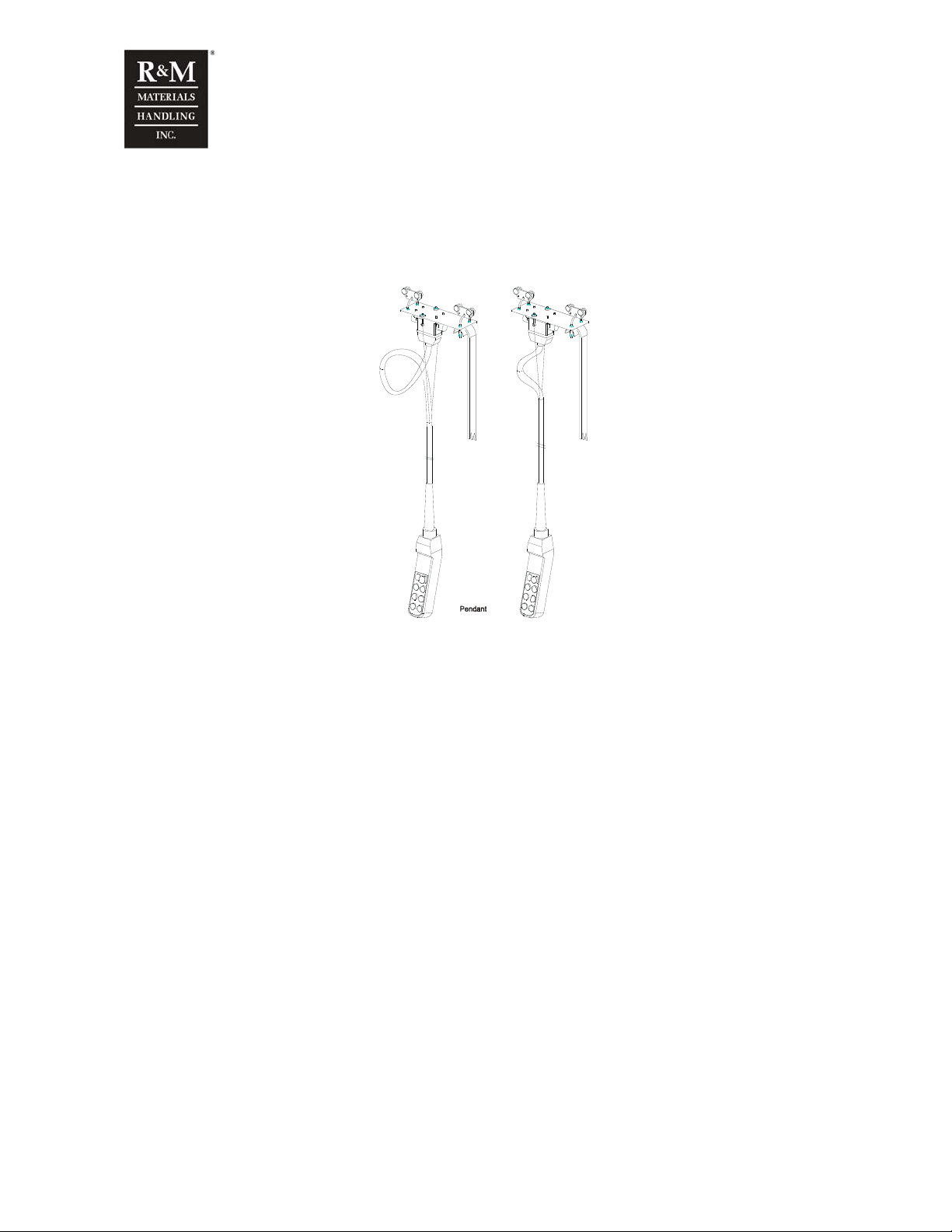

1.6 Solo hoist, pendant in festoon (Wire rope hoist)

Pos. Name

1 Festoon assembly

2 Hoist power towing arm

3 Horn (option)

4 Pendant (option)

5 Main girder

6 Hoist

7 Buffer stop

8 Radio (option)

9/76

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

c-solo1a

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

1.7 Solo hoist, pendant fixed in hoist (Wire rope hoist)

Pos. Name

1 Festoon assembly

2 Hoist power towing arm

3 Horn (option)

4 Pendant (option)

5 Main girder

6 Hoist

7 Buffer stop

8 Radio (option)

10/76

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

c-solo2a

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

2 Festoon assembly

2.1 Single girder crane (Wire rope hoist)

Pos. Name Specification Amount

1 Beam clip KC-020181 or KC-020180

2 End stop KC-023215

3 Track coupler KC-024105 or KC-023210

4 Track support bracket KC-023226 or KC-024122

5 Pendant trolley (option)

6 Cable trolley

7 Hoist towing arm assembly

8 Limit switch trigger and adapter QA-L210W30 and KC-023201

Part number seven (7) is an assembly, which includes a current collector, a cable saddle, two pieces

of arced fasteners, a chain and a plate for a cable trolley.

11/76

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

To notice when assembling a festoon

• Make sure that the joint (part no. 3) is smooth for trolley (part no. 6) to travel.

• Pendant trolley will be assembled in the outer c-rail from the crane.

• Tighten strain relief wires on both sides of the plug so that the pendant cable is either on loop or

on pleat. When looped, there will be better possibilities on adjusting the cable length.

• Tighten the wire clamp.

Pendant

12/76

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

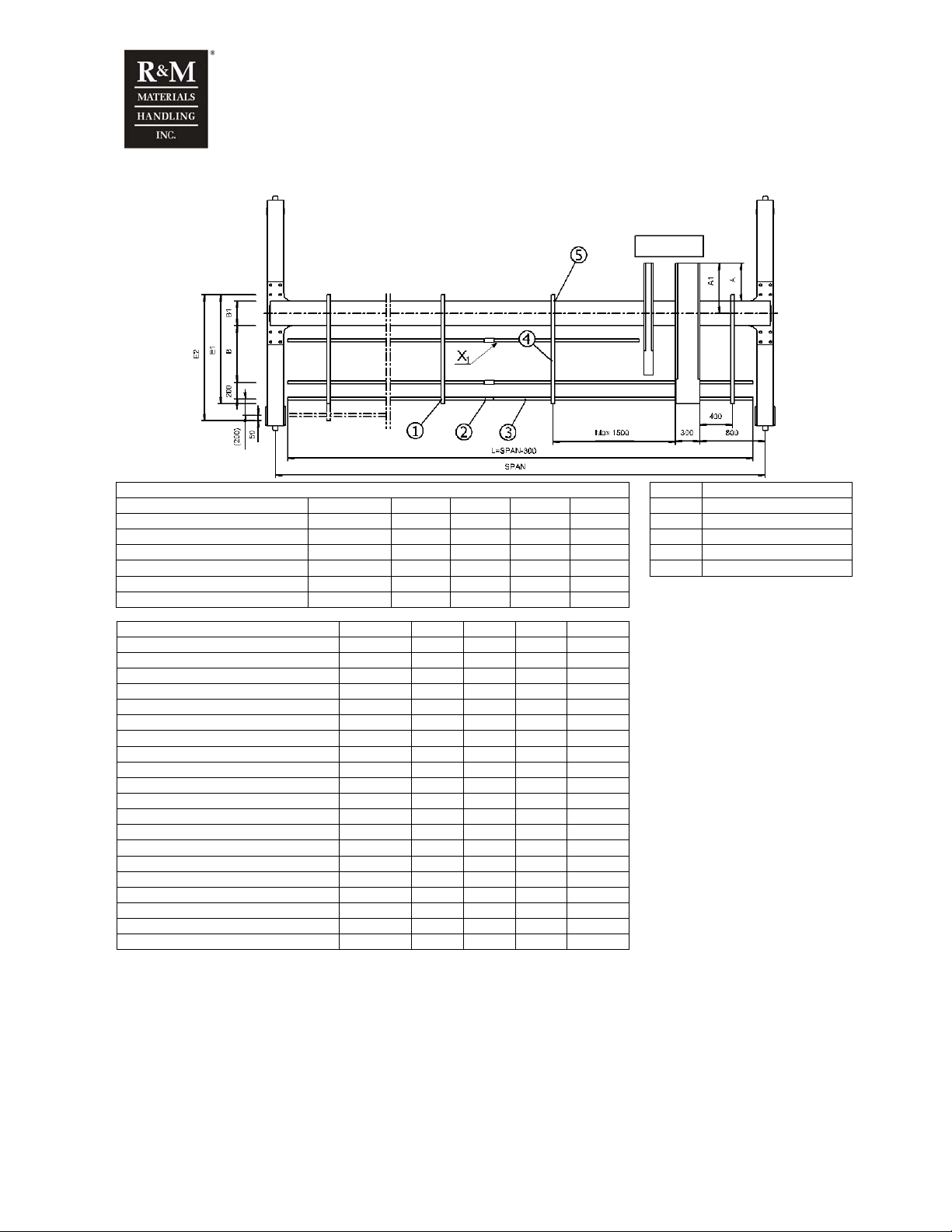

2.2 C-rail assembly of hoist power supply; Single girder crane (Wire rope hoist)

Low headroom hoist Pos. Name

Hoist Flange B1 A B E1 E2 1 Track support

Drum diam. 303 mm ≤250 560 620 1340 1520 2 Track joint

Drum diam. 303 mm >250 560 620 1520 1800 3 C-rail

Drum diam. 355 mm ≤300 630 640 1340 1520 4 Support arm

Drum diam. 355 mm >300 630 640 1520 1800 5 Beam clip

Drum diam. 406 mm ≤360 730 730 1520 1800

Drum diam. 406 mm >360 730 730 1800 2000

Normal headroom hoist

Hoist - Ropes Flange B1 A1 B E1 E2

Drum diam. 303 mm -R2/R4 ≤270 530 660 1340 1520

Drum diam. 303 mm -R2/R4 >270 530 660 1520 1800

Drum diam. 355 mm -R2/R4 ≤270 600 720 1340 1520

Drum diam. 355 mm -R2/R4 >270 600 720 1520 1800

Drum diam. 406 mm -R2x ≤270 750 840 1520 1800

Drum diam. 406 mm -R2x >270 750 840 1800 2000

Drum diam. 608 mm -R4/R24/R26/R28 ≤360 1020 950 1800 2000

Drum diam. 608 mm -R4/R24/R26/R28 >360 1020 950 2000 2200

Drum diam. 608 mm -R6/R8 ≤450 1050 920 1800 2000

Drum diam. 608 mm -R6/R8 >450 1050 920 2000 2200

Drum diam. 608 mm -R2/R22 ≤360 970 1000 1800 2000

Drum diam. 608 mm - R2/R22 >360 970 1000 2000 2200

Hoist - Ropes Flange B1 A1 B E1 E2

Drum diam. 355 mm -R6/R8 ≤270 720 660 1340 1520

Drum diam. 355 mm -R6/R8 >270 720 660 1520 1800

Drum diam. 406 mm –R2/R4 ≤270 720 720 1340 1520

Drum diam. 406 mm - R2/R4 >270 720 720 1520 1800

Drum diam. 406 mm -R6/R8 ≤270 790 810 1520 1800

Drum diam. 406 mm -R6/R8 >270 790 810 1800 2000

X1) Optional C-rail for an alternative route of the cable of traveling machinery

13/76

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

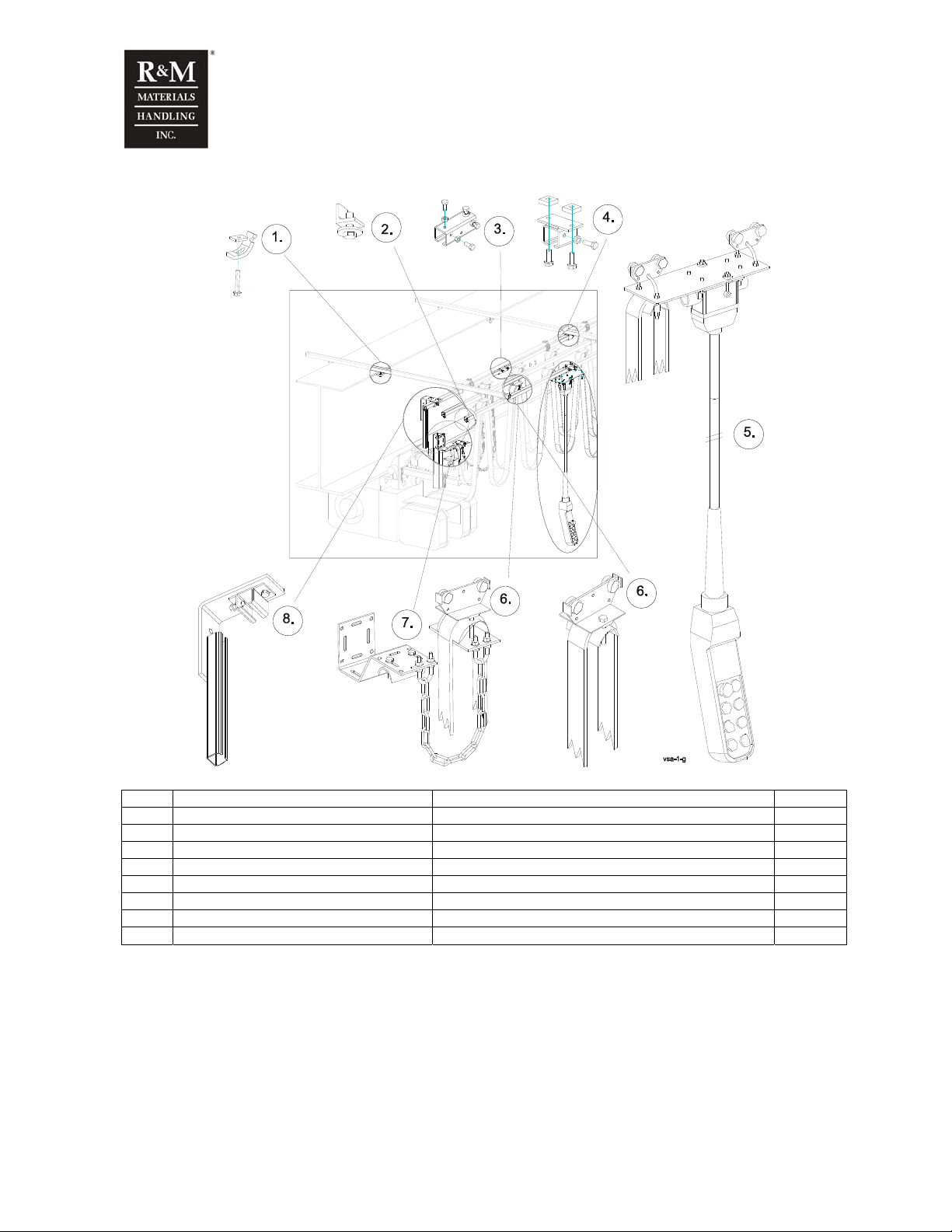

2.3 Single girder crane (Chain hoist)

1

2

3 4

5

667

vsa-3-gb

Pos. Name Specification Amount

1 Beam clip KC-020181 or KC-020180

2 End stop KC-023215

3 Track coupler KC-024105 or KC-023210

4 Track support bracket KC-023226 or KC-024122

5 Pendant trolley (option)

6 Cable trolley

7 Towing arm assembly

Part number seven (7) is an assembly, which includes a current collector, a cable saddle, two pieces

of arced fasteners, a chain and a plate for a cable trolley.

14/76

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

To notice when assembling a festoon

• Make sure that the joint (part no. 3) is smooth for trolley (part no. 6) to travel.

• Pendant trolley will be assembled in the outer c-rail from the crane.

• Tighten strain relief wires on both sides of the plug so that the pendant cable is either on loop or

on pleat. When looped, there will be better possibilities on adjusting the cable length.

• Tighten the wire clamp.

Pendant

15/76

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

2.4 C-rail assembly of hoist power supply; Single girder crane (Chain hoist)

1

2

3

SPAN

Optional radio assembly.

El-cubicle

220Max spacing 1400

Pos. Name

1 Track support

2 Track joint

3 C-rail

16/76

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

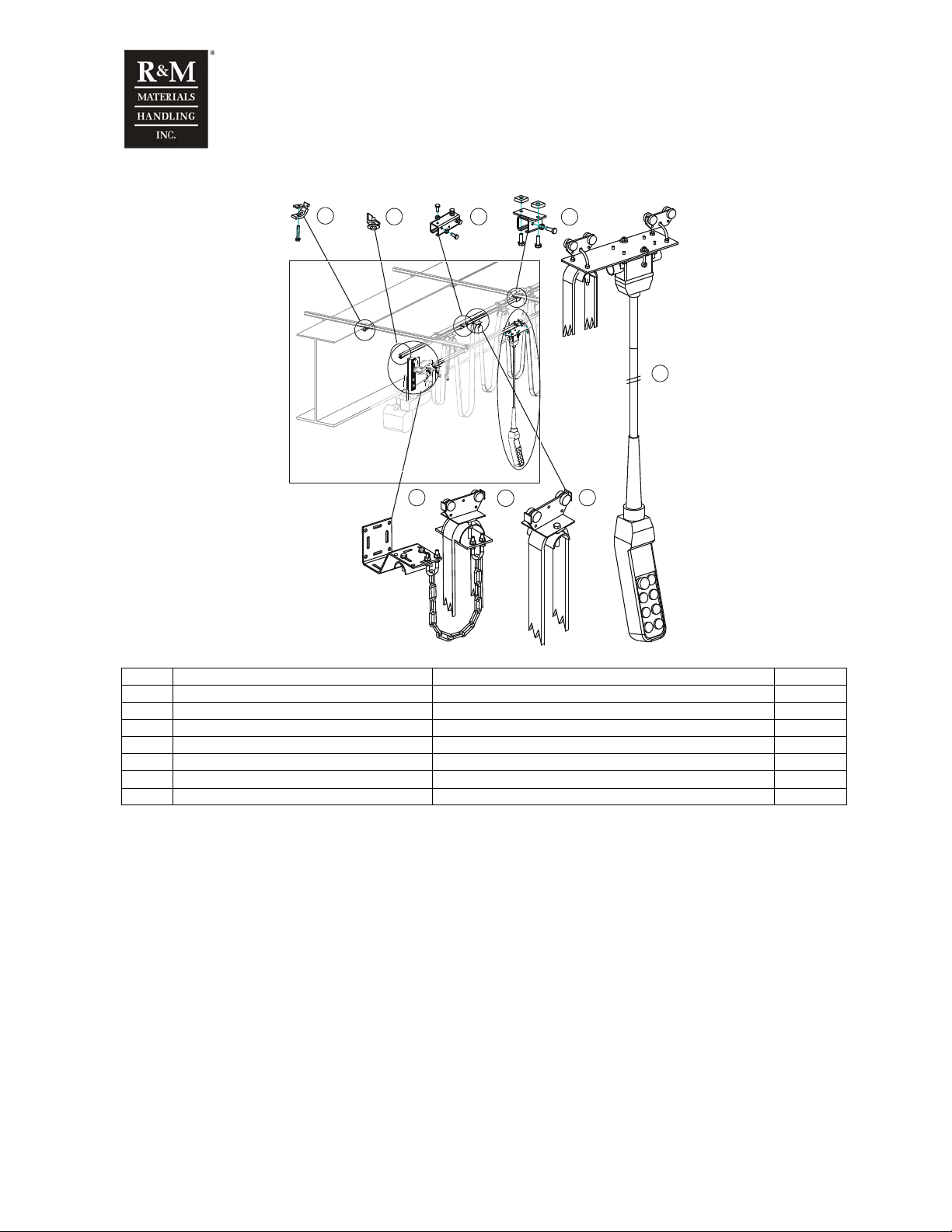

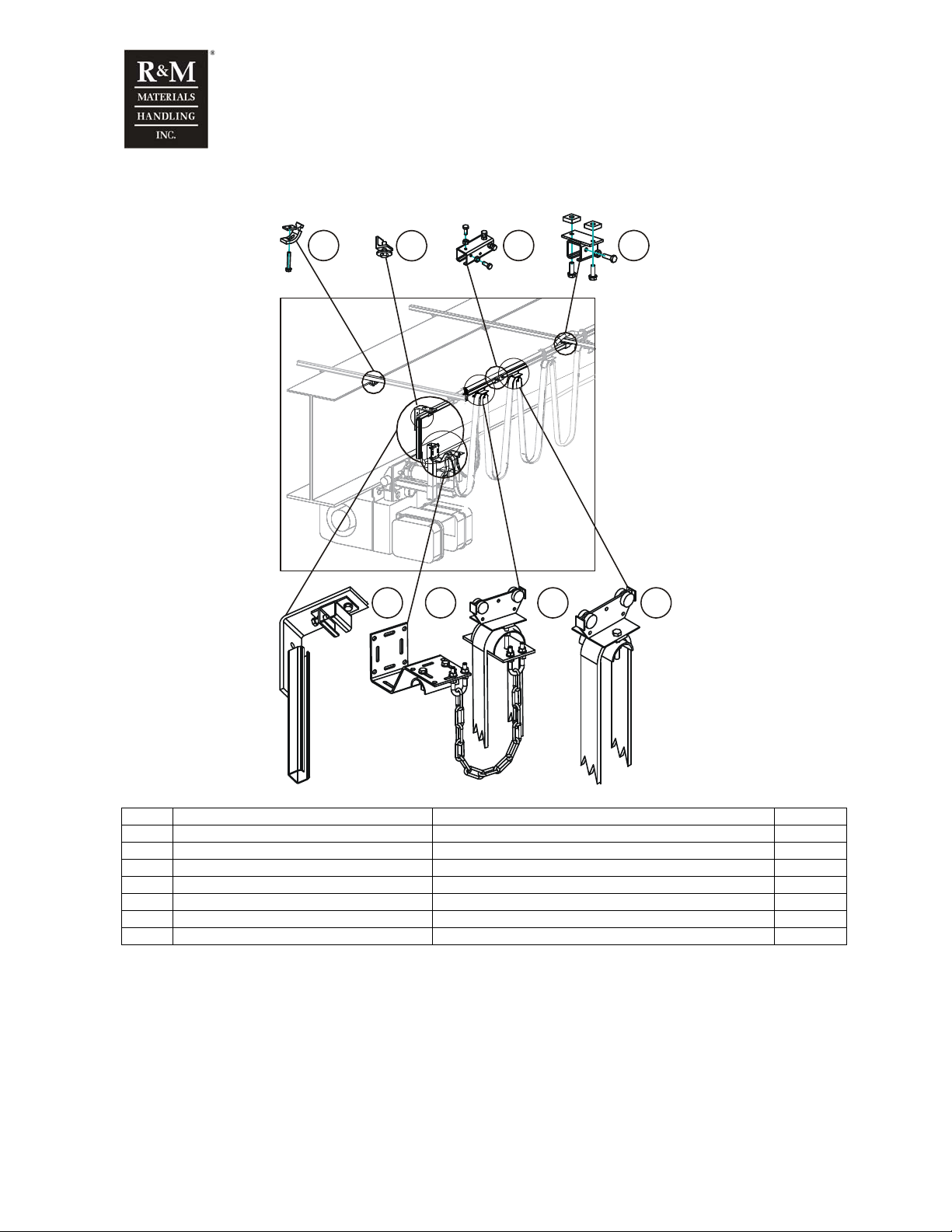

2.5 Solo hoist with moveable pendant (Wire rope hoist)

Pos. Name Specification Amount

1 Beam clip KC-020181 or KC-020180

2 End stop KC-023215

3 Track joint KC-024105 or KC-023210

4 Track support bracket KC-023226 or KC-024122

5 Pendant trolley (option)

6 Cable trolley

7 Towing arm assembly

8 Limit switch trigger and adapter QA-L210W30 and KC-023201

Part number seven (7) is an assembly, which includes a current collector, a cable saddle, two pieces

of fixing plates, a chain and a plate for a cable trolley.

17/76

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

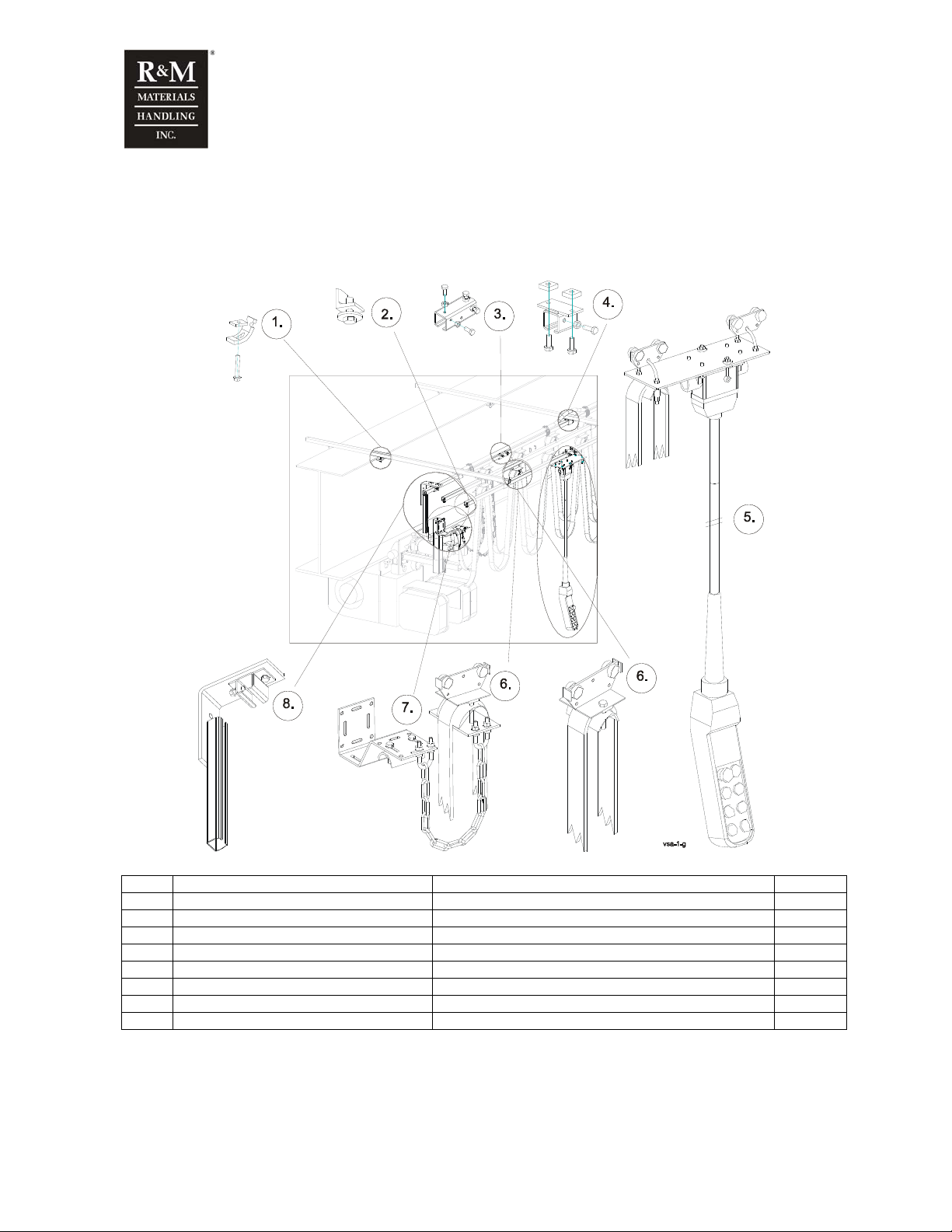

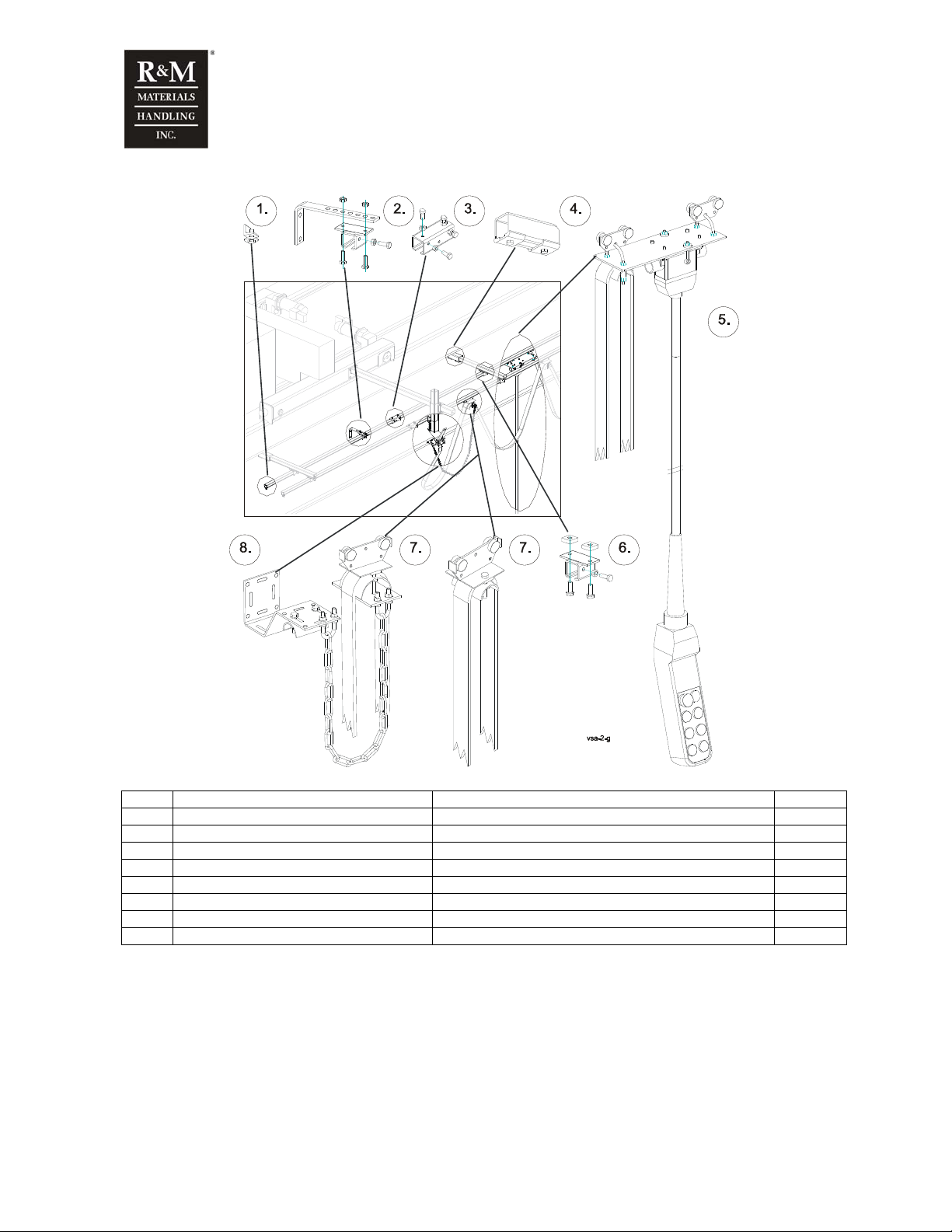

2.6 Solo hoist ,pendant fixed to hoist (Wire rope hoist)

1.

2.

3. 4.

6.6.8. 7.

vsa-5-ga

Pos. Name Specification Amount

1 Beam clip KC-020181 or KC-020180

2 End stop KC-023215

3 Track joint KC-024105 or KC-023210

4 Track support bracket KC-023226 or KC-024122

6 Cable trolley

7 Towing arm assembly

8 Limit switch trigger and adapter QA-L210W30 and KC-023201

Part number seven (7) is an assembly, which includes a current collector, a cable saddle, two pieces

of fixing plates, a chain and a plate for a cable trolley.

18/76

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

2.7 Double girder crane (Wire rope hoist)

Pos. Name Specification Amount

1 End stop KC-023215

2 Limit switch trigger QA-L210W30 and KC-023201

3 Track joint KC-024105 or KC-023210

4 Bracket for support arm KC-020286

5 Pendant trolley (option)

6 Track support bracket KC-023226 or KC-024122

7 Cable trolley

8 Towing arm assembly

• Part number eight (8) is an assembly, which includes a current collector, a cable saddle, two

pieces of fixing plates, a chain and a plate for a cable trolley.

• Part number 4 is not included in standard delivery

19/76

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

To notice when assembling a festoon

• Make sure that the joint (part no. 3) is smooth for trolley (part no. 7) to travel.

• Pendant trolley will be assembled in the inner c-rail from the crane.

• Tighten strain relief wires on both sides of the plug so that the pendant cable is either on loop or

on pleat. When looped, there will be better possibilities on adjusting the cable length.

• Tighten the wire clamp.

20/76

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

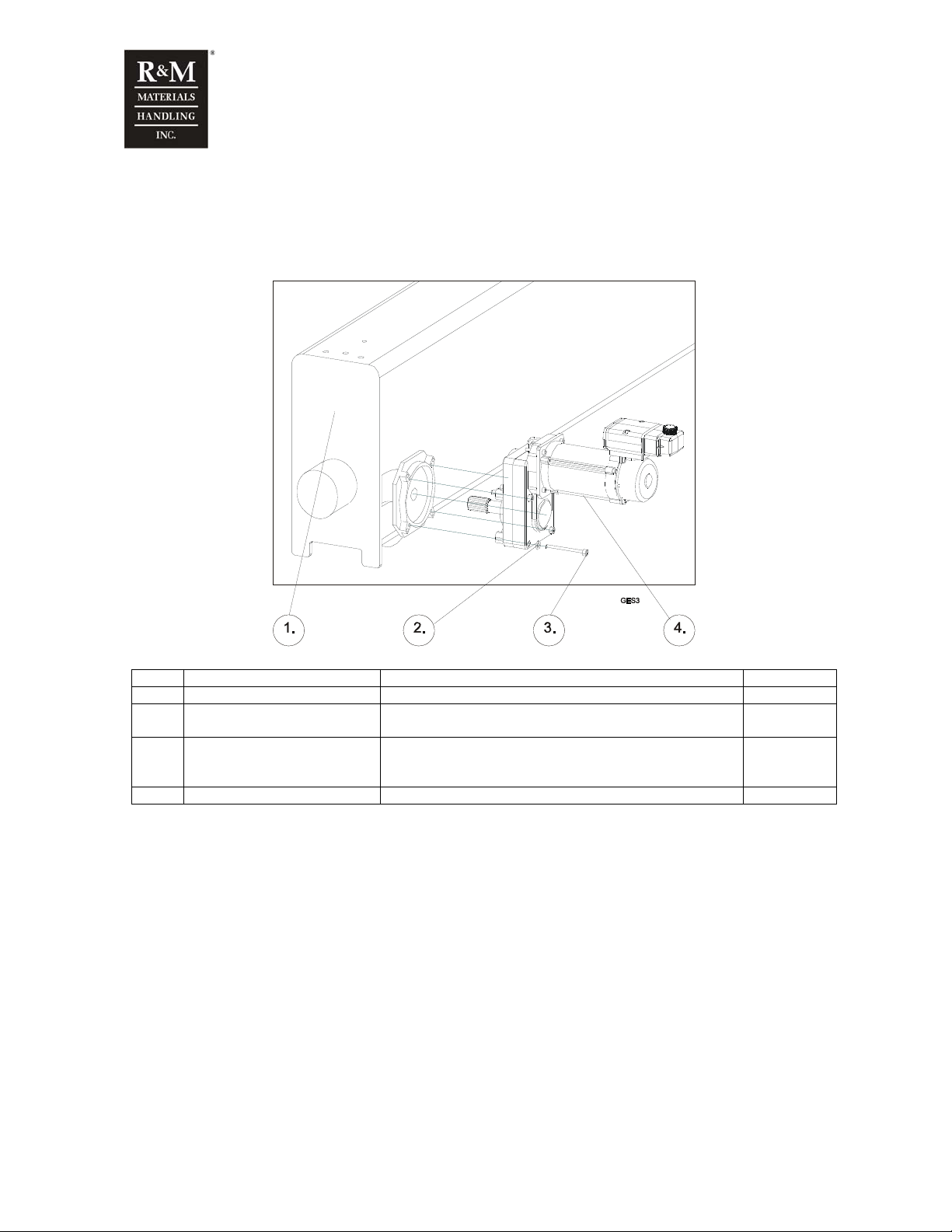

3 Traveling machinery assembly

3.1 Machinery sizes 3-5

Pos. Name Specification Amount

1 End carriage 2

2 Washer DIN125-A8-A3G (Machinery sizes 3 and 4)

DIN6796-A12-A3G (Machinery size 5)

3 Screw DIN912-M8x85-8.8-A3G (Machinery size 3)

DIN912-M8x100-8.8-A3G (Machinery size 4)

DIN912-M12x140-8.8-A3G (Machinery size 5)

4 Traveling machinery 2

8+8

8+8

• Clean splines and mounting flanges from dirt and rust protection wax and grease the shaft lightly

before assembly.

• You can use a plastic hammer to slide drive in. Do not use any metal or lead hammer.

• Tightening torques M8-8.8 23 Nm, M12-8.8 77 Nm.

• Remove the protection pin from the breather plug.

21/76

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

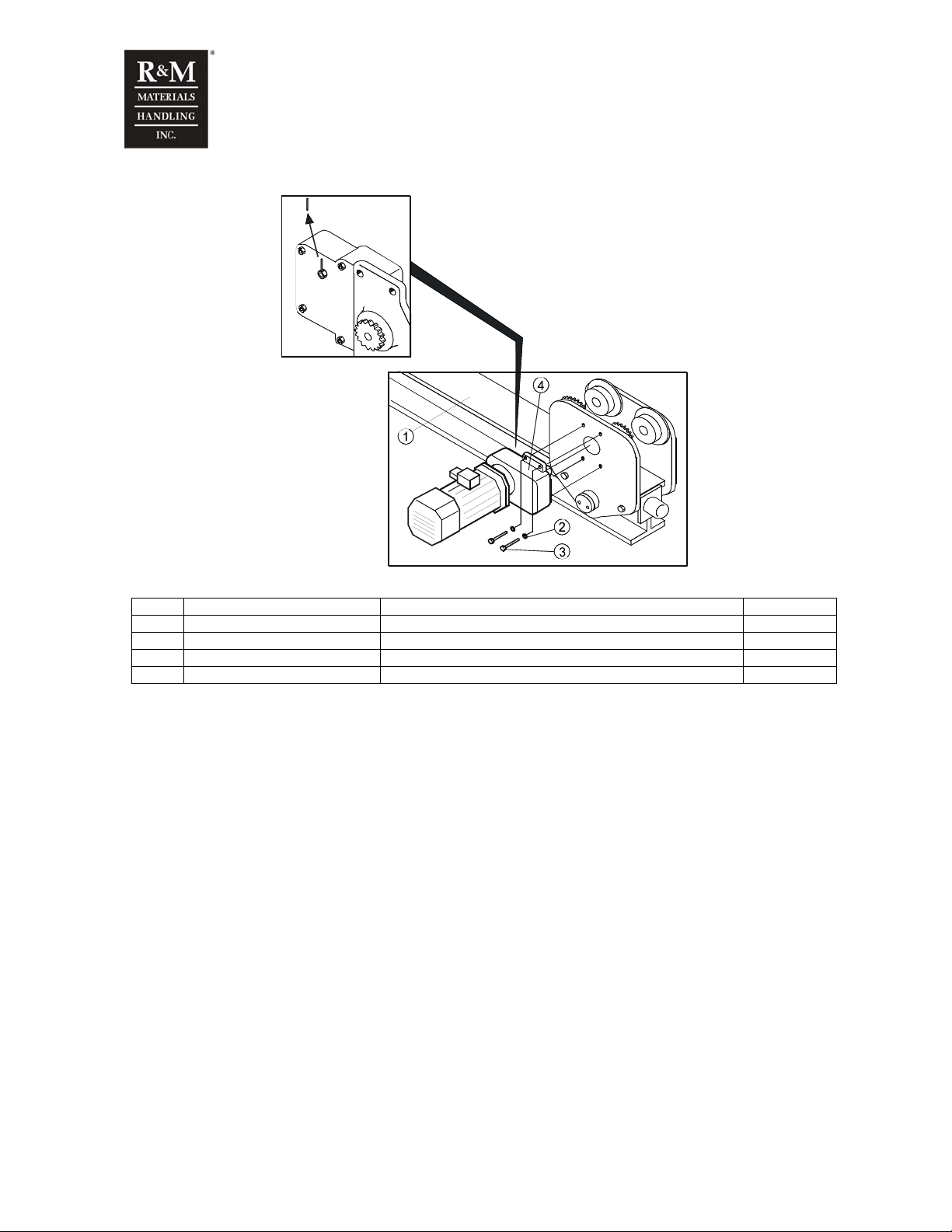

3.2 Machinery size 3, 8 wheels

1

c_usgs01a

Pos. Name Specification Amount

1 End truck 2

2 Washer 11DIN126-A3G 4+4

3 Socket head cap screw M10X35DIN933-8.8A3G 4+4

4 Traveling machinery 2

• Clean splines and mounting flanges from dirt and rust protection wax and grease the shaft lightly

before assembly.

You can use a plastic hammer to slide drive in. Do not use any metal or lead hammer.

•

• Tightening torques M10-8.8 40 Nm

• Remove the protection pin from the breather plug.

22/76

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

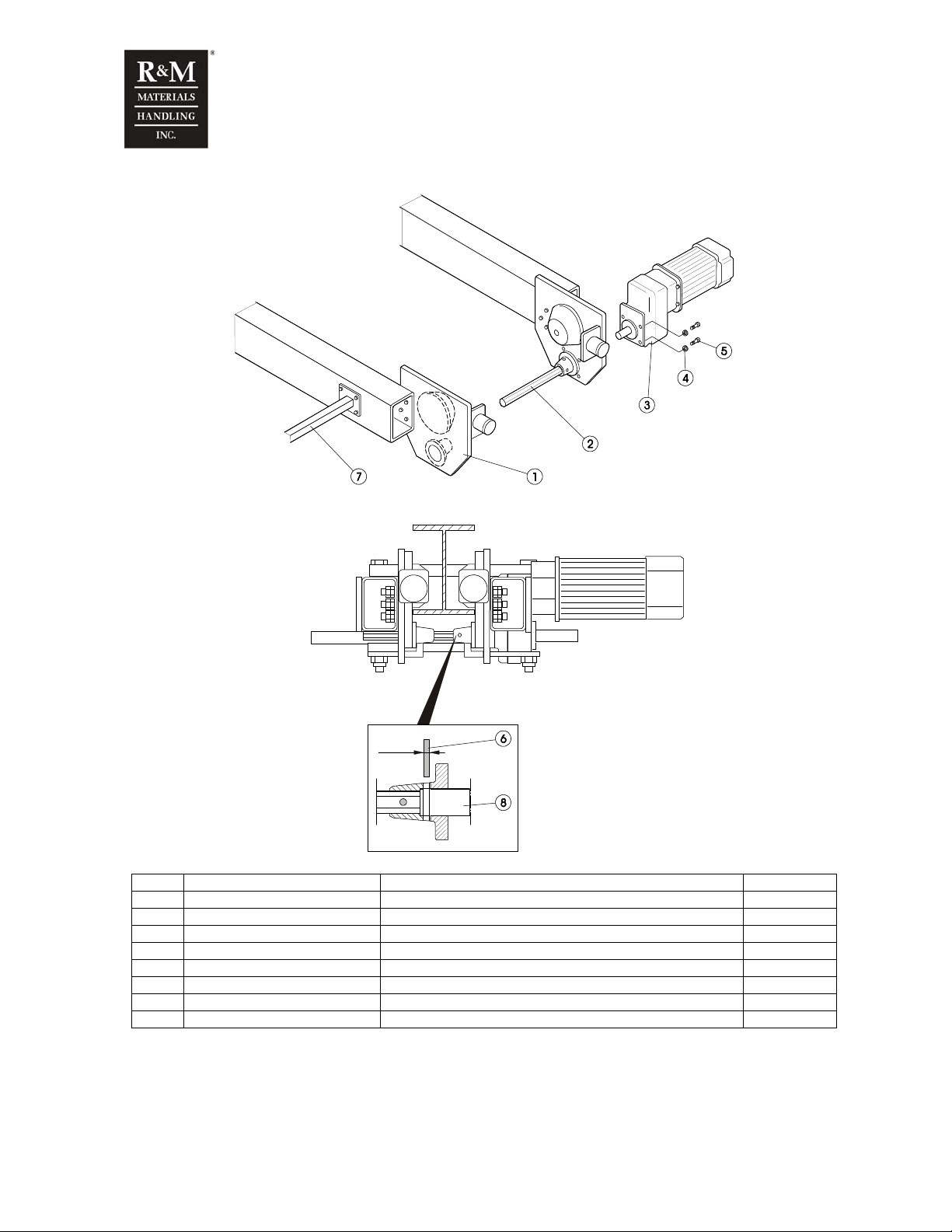

3.3 Machinery size 3, 4 wheels

Ø

8

c_ulgs01a

Pos. Name Specification Amount

1 End truck 2

2 Axle ILBD00-6 A 2

3 Traveling machinery 2

4 Washer 11DIN126-A3G 4+4

5 Socket head cap screw M10X35DIN933-8.8A3G 4+4

6 Split pin DIN1481-8X32 1+1

7 Crane power towing arm 1

8 Gear shaft

• Drill 8 mm hole for pin through gear wheel and traveling machinery shaft, use predrilled hole!

Install split pin!

• Do not fix axle to the idle wheel! Make sure that axle moves horizontally freely through gear

wheel!

• Remove the protection pin from the breather plug!

23/76

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

Loading...

Loading...