R&M Materials Handling HOIST MONITORS User Manual

English

16.9.2008

SERVICE MANUAL FOR HOIST CONTROL DEVICE

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

Read the instructions supplied with the product before installation and commissioning.

Keep the instructions in a safe place for future reference.

Table of content

1 General.......................................................... 5

1.1 Description................................................. 5

1.2 Directives, Standards and Patents............. 5

1.2.1 Directives ...................................................... 5

1.2.2 Standards...................................................... 5

1.2.3 Patent Pending.............................................. 6

1.2.4 Certificate of compliance................................ 6

2 Technical characteristics............................. 7

2.1 Description of terminals ............................. 8

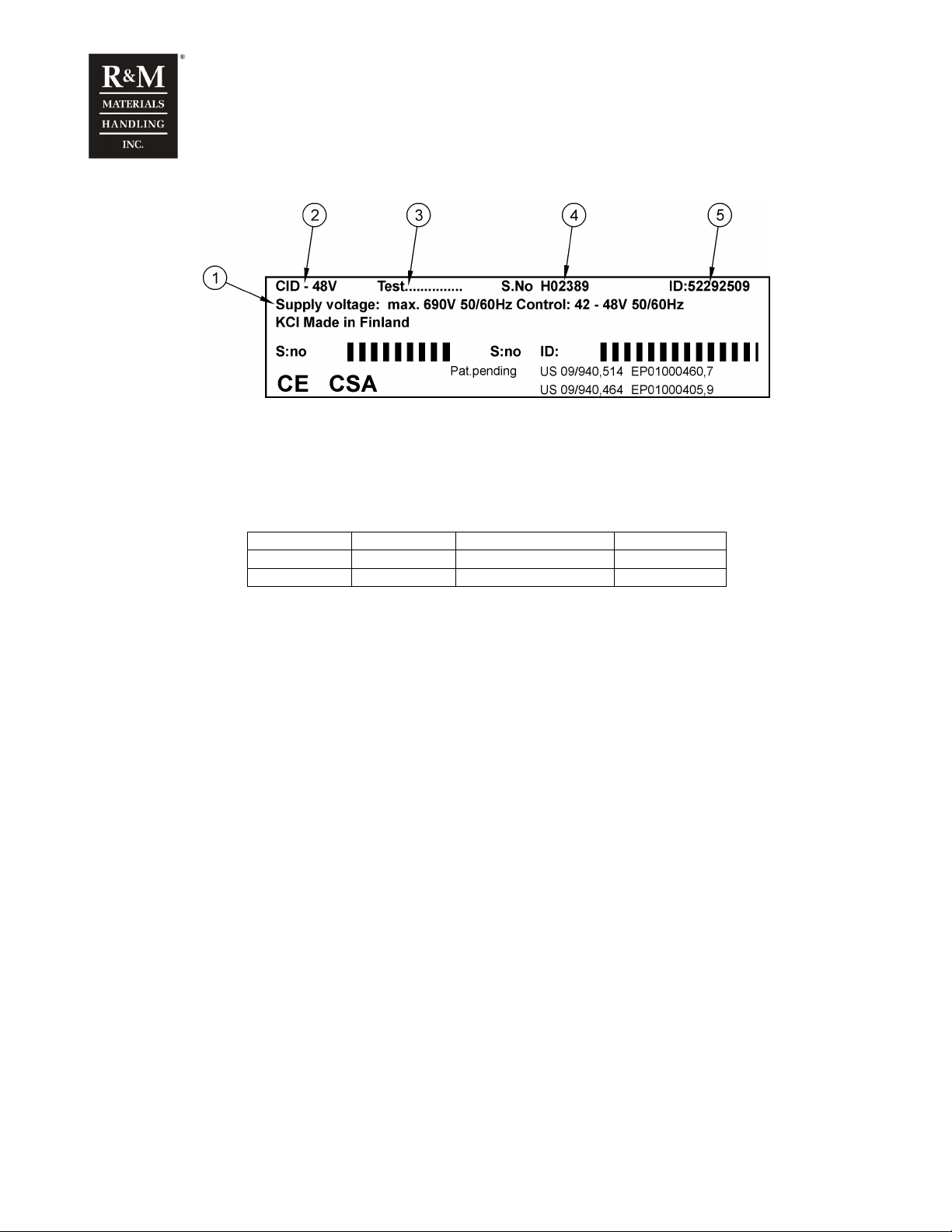

2.2 Product description sticker....................... 10

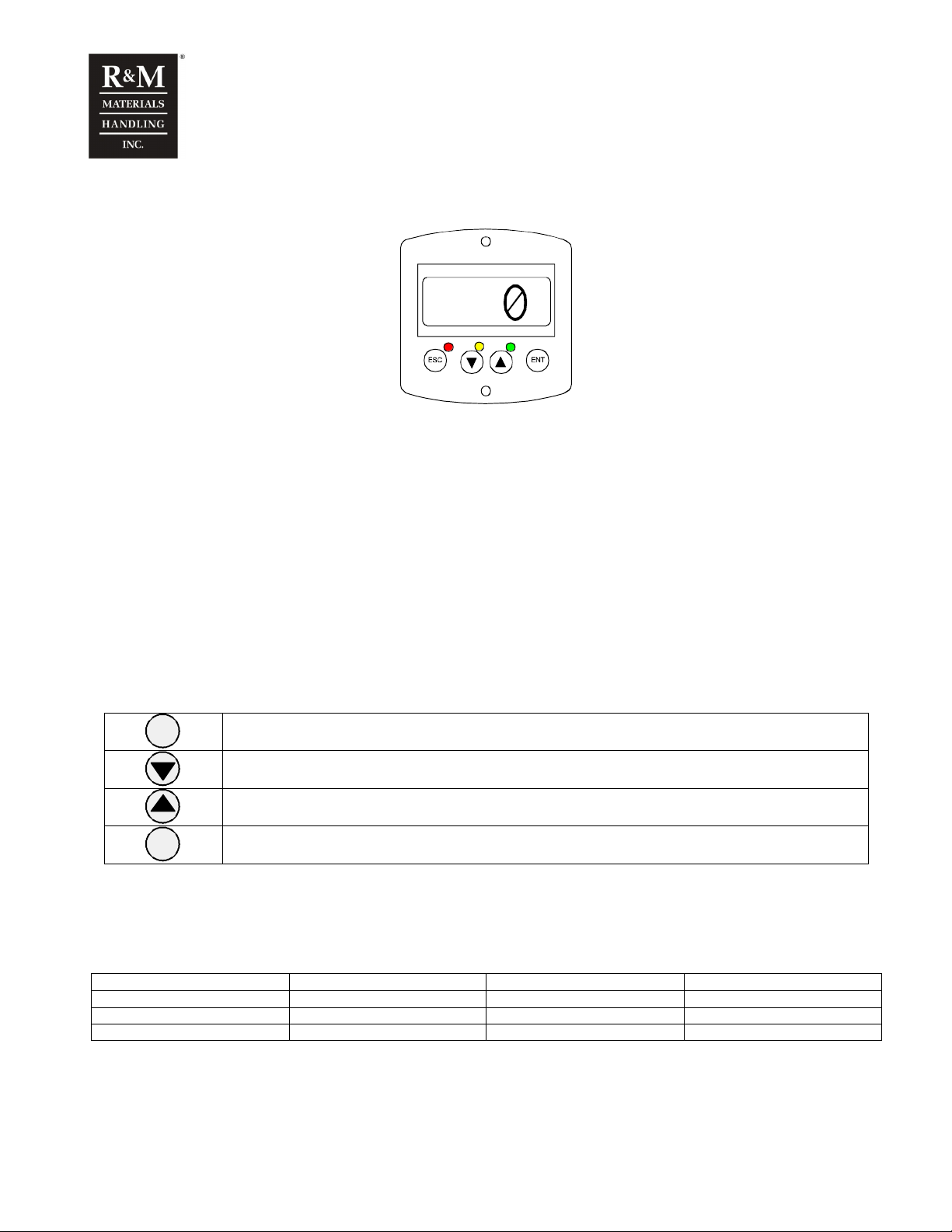

3 Display unit................................................. 11

3.1 Push-buttons............................................ 11

3.2 LEDs........................................................ 11

3.3 Display information .................................. 12

3.3.1 Tare load / actual load mode........................ 12

3.3.2 Menu Mode ................................................. 13

3.3.3 Status mode................................................ 13

3.3.4 Sum load / solo hoist load mode .................. 13

3.4 Menus...................................................... 14

3.4.1 Moving in menus ......................................... 14

3.4.2 Password .................................................... 14

3.4.3 Hoist selection (only multi-hoists)................. 14

3.5 Parameters .............................................. 15

3.5.1 Read-only parameters ................................. 15

3.5.2 Adjustable parameters................................. 15

3.6 Remote Display ....................................... 16

3.6.1 General ....................................................... 16

4 Parameters.................................................. 18

4.1 Passwords ............................................... 20

5 Basic Functions.......................................... 21

5.1 General.................................................... 21

5.2 Overload protection.................................. 22

5.3 Hoist motor overheating supervision........ 23

5.3.1 Hoist motor overheating supervision

instructions .............................................................. 25

5.4 Supply voltage phase supervision............ 26

5.4.1 Supply phase supervision instructions ......... 26

5.5 RUN and fault supervision ....................... 27

5.6 Starting and stopping through slow speed (2

speed application only) ..................................... 28

5.6.1 Starting and stopping through slow speed

instructions .............................................................. 28

5.7 Sudden load increase supervision............29

5.7.1 Sudden load increase supervision instructions

29

6 Monitoring Items......................................... 30

6.1 General.................................................... 30

6.2 Primary monitoring items ......................... 30

6.2.1 Starts counter.............................................. 31

6.2.2 Run Time counter........................................ 31

6.2.3 Safe Working Period counter (SWP%)h....... 31

6.2.4 Hoist cycles counter .................................... 32

6.2.5 Run time and start counter for trolley and

bridge 32

6.3 Measured values...................................... 33

7 Optional functions...................................... 34

7.1 General.................................................... 34

7.2 Slack rope protection ...............................34

7.2.1 Slack rope protection instructions ................ 34

7.2.2 Slack rope protection connections ............... 35

7.3 Intermediate load limits ............................ 35

7.3.1 Intermediate load limits parameters ............. 35

7.3.2 Intermediate load limits connections ............ 36

7.4 Run time and start counter for trolley and

bridge................................................................ 36

7.4.1 Run time and start counter for trolley and

bridge parameters.................................................... 37

7.4.2 Run time and start counter for trolley and

bridge connections................................................... 37

7.5 Analogue output....................................... 37

7.5.1 Analogue output parameters........................ 37

7.5.2 Analogue output connections....................... 38

7.6 Free relay output...................................... 38

7.7 Hoist brake-wear supervision................... 39

7.7.1 Hoist brake-wear supervision instructions .... 39

7.8 Load tare.................................................. 40

7.8.1 Load tare instructions .................................. 40

7.9 Levelling function ..................................... 40

7.9.1 Levelling function instructions ...................... 40

7.9.2 Levelling Function Connections ................... 41

8 Multi-hoisting.............................................. 42

8.1 General.................................................... 42

2/104

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

8.2 Multi-hoisting instructions......................... 42

8.2.1 Multi-hoisting parameters............................. 42

8.2.2 Cabling........................................................ 43

8.2.3 Menus through CAN bus.............................. 44

8.3 CAN-bus topology.................................... 45

8.3.1 Termination resistors................................... 45

8.3.2 Recommended topologies........................... 46

9 Commissioning .......................................... 47

9.1 Start-up.................................................... 47

9.2 Load measure.......................................... 47

9.2.1 Load measure type by ”Motor”, (see the

parameter 4-7-1)...................................................... 47

9.2.2 Load measure type by ”Sens.”, (see the

parameter 4-7-1)...................................................... 47

9.3 Functional checks .................................... 48

9.3.1 Multi hoisting ............................................... 48

9.3.2 Multifunction inputs...................................... 48

9.3.3 Functional free relay output ROUT............... 49

9.3.4 Analog output AOUT.................................... 50

9.3.5 Slack rope ................................................... 50

9.4 Commissioning table................................ 51

10 Overload protection – Load sensor .......... 52

10.1 Load sensor-system................................. 52

10.1.1 Load sensor set-up...................................... 52

10.2 Load sensor parameters.......................... 52

10.3 Load calibration sequence with load sensor

53

10.4 Manual load calibration............................ 54

11 Overload protection – Motor torque.......... 55

11.1 Overload protection instructions............... 55

11.1.1 Motor torque calculation-system .................. 55

11.1.2 Motor torque calculation parameters............ 55

11.2 Connections............................................. 57

11.3 Load calibration sequence with motor torque

58

11.4 Zero load calibration sequence with motor

toque 59

11.5 Manual load calibration............................ 59

12 Load sensor adjustment ............................ 61

12.1 KAE400 + Strain Gauge.......................... 61

12.1.1 General ....................................................... 61

12.1.2 Technical data............................................. 61

12.1.3 Wiring.......................................................... 61

12.1.4 Adjustment .................................................. 62

12.1.5 Dimensions ................................................. 63

12.2 ESD142 amplifier + Strain Gauge............ 63

12.2.1 ESD142 Description .................................... 63

12.2.2 Adjustment .................................................. 64

12.2.3 Zero load adjustment................................... 64

12.2.4 Adjustment with higher load......................... 64

12.2.5 Connections ................................................ 65

3/104

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

13 Faults and warnings...................................66

13.1 Faults....................................................... 66

13.1.1 Fault codes and description ......................... 66

13.2 Warnings.................................................. 67

13.2.1 General warnings ........................................ 67

13.2.2 Service warnings ......................................... 67

14 Troubleshooting ......................................... 68

14.1 Fault descriptions..................................... 68

14.1.1 Fault Hoist OL F_OL.................................. 68

14.1.2 Fault Motor OT F_OT .................................. 70

14.1.3 Fault Int. relay F_SR.................................... 70

14.1.4 Fault RUN act. F_Run ................................. 70

14.1.5 Fault Run FB – (2)..................................... 70

14.1.6 Fault Brake F_Br ......................................... 71

14.1.7 Fault Br wear F_Brw................................... 71

14.1.8 Fault Sensor ch. F_SCh .............................. 72

14.1.9 Fault Curr.meas. F_Ain................................ 72

14.1.10 Fault Supply vol F_SPh ............................... 73

14.1.11 Fault Phaseorder F_Sor .............................. 73

14.1.12 Fault CParameter F_CP .............................. 73

14.1.13 Fault MParameter F_MP.............................. 73

14.1.14 Fault CAN bus F_CAN................................. 74

14.1.15 Fault Bridge OL F_BOL ............................... 74

14.1.16 Fault Bridge RS F_Brs................................. 74

14.1.17 Fault Slack Rope – (2)................................ 74

14.2 No Signal – (2)........................................ 74

14.3 Blank display............................................ 75

14.4 The temperature sensors (NTC-wiring).... 75

14.5 Current transformers................................ 75

14.6 There is no fault, but hoist doesn’t work... 76

14.6.1 Hoisting works, but lowering is prevented .... 76

14.6.2 Hoisting and lowering prevented.................. 77

15 Replacement Instructions.......................... 78

15.1 General.................................................... 78

15.2 Ordering a new Monitoring unit ................ 78

15.3 Replacing................................................. 78

15.4 Parameters and Values............................ 78

15.5 Flow chart ................................................81

16 Menu structure............................................ 82

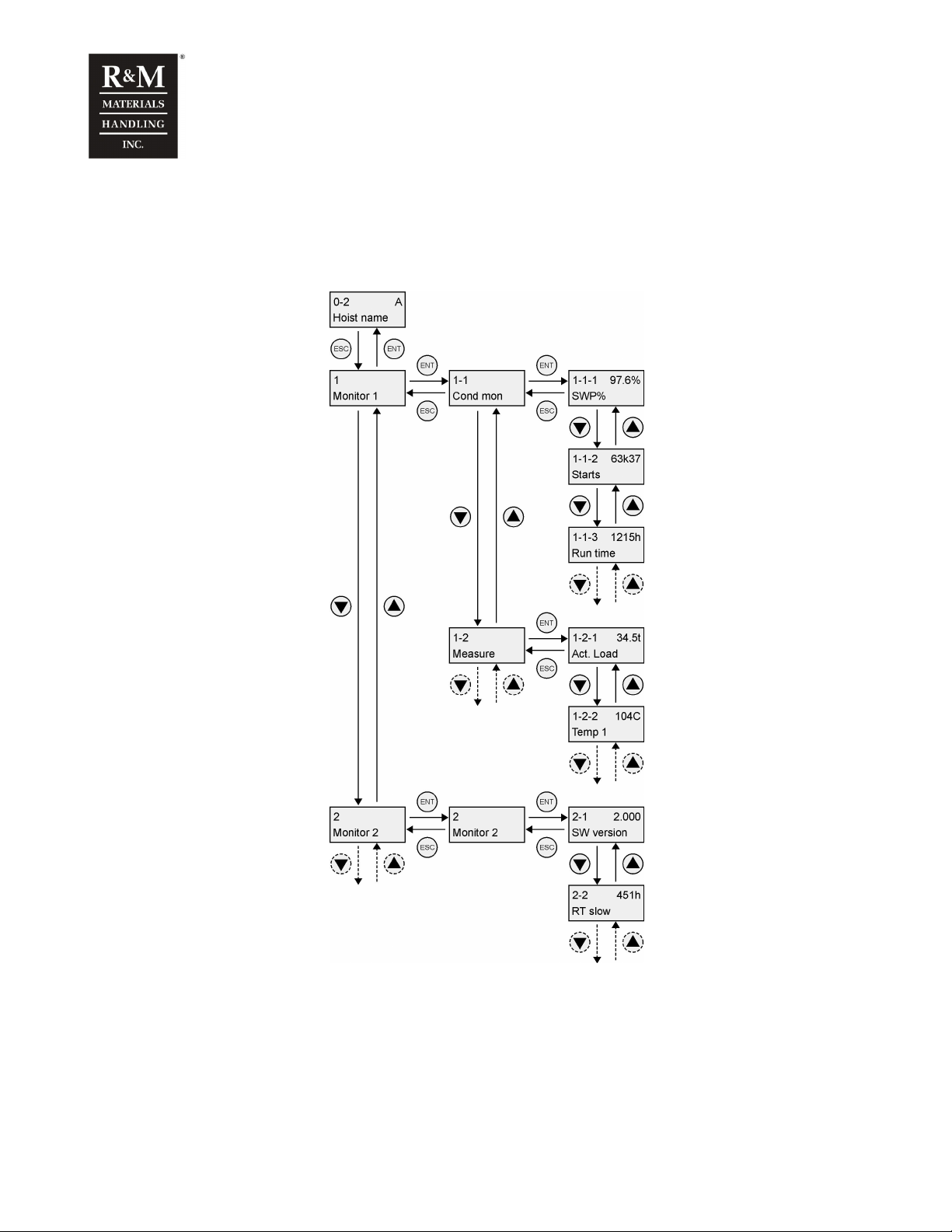

16.1 Monitor 1 (Menu 1)................................... 82

16.2 Monitor 2 (Menu 2)................................... 83

16.3 Load calibration menu (Menu 3)............... 84

16.4 Start-up menu (Menu 4)........................... 85

16.5 Service menu (Menu 5)............................ 88

16.6 Design values menu (Menu 6) ................. 88

16.7 GO –settings menu (Menu 7)................... 89

Appendix 1 - Default parameters ................... 90

Appendix 2 - Version History ......................... 91

Appendix 3 - Current Transformer’s

information ...................................................... 93

Appendix 3.1 Current transformer table........95

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

Appendix 4 - Motor temperature NTC charts 97

Appendix 5 - Example connections ............... 98

Appendix 6 - External power supply for ESD

143.................................................................. 101

Appendix 7 - Replacing the condition

monitoring unit.............................................. 103

4/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

1 General

1.1 Description

The hoist-monitoring unit is an electronic device designed to supervise and protect the hoist. The hoistmonitoring unit measures the use of the hoists and prevents hoisting or lowering in case a situation is

detected which can cause a potential dangerous situation. The hoist-monitoring unit records the use of

the hoist and calculates the remaining Safe Working Period “SWP” according to the FEM and ISO

standards.

The hoist-monitoring unit is designed to fit a wide variety of hoists and motor drives. It can be used with

variable speed control drives, as well as two speed drives. The hoist-monitoring unit contains tailored

hardware and software, especially designed for crane use.

With the display, the unit can be programmed and calibrated, and stored values can be read. The hoistmonitoring unit can be equipped and installed with many different options and additional features such

as:

• continuous load display

• tandem operation (up to five units)

• service-warning information

• hook levelling

• intermediate overload options

A service agent authorised by the manufacturer can provide detailed information and professional advice

on a tailored solution for each application.

The hoist-monitoring unit is a safety device, installed by the manufacturer. Only service

personnel authorised by the manufacturer are allowed to program and calibrate the unit.

Faulty programmed or calibrated unit may cause malfunctions that results in dangerous

situations.

Under no circumstances it is allowed to by-pass or remove the hoist-monitoring unit, as that

would disable all supervision and safety features.

1.2 Directives, Standards and Patents

1.2.1 Directives

The product conforms to the relevant safety provisions of the

• EMC Directive (2004/108/EC)

• Low Voltage Directive (2006/95/EC)

1.2.2 Standards

The product complies with the following standards:

• EN 50081-1 (1992) Generic emission standard: Residential, commercial and light industry

• EN 61000-6-2 (1999) Generic immunity standard: Industrial environment

• EN 50178 (1997) Electronic equipment for use in power installations

• EN 60204-32 (1998) Safety of machinery – Electrical equipment of machines. Part 32: Requirements

for hoisting machines

• EN 12077-2 (1998) Cranes safety. Requirements for health and safety. Part 2: Limiting and indicating

devices

5/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

1.2.3 Patent Pending

• US09/940,514 EP01000406,7

• US09/940,464 EP01000405,9

1.2.4 Certificate of compliance

• 1334676 (LR025623)

6/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

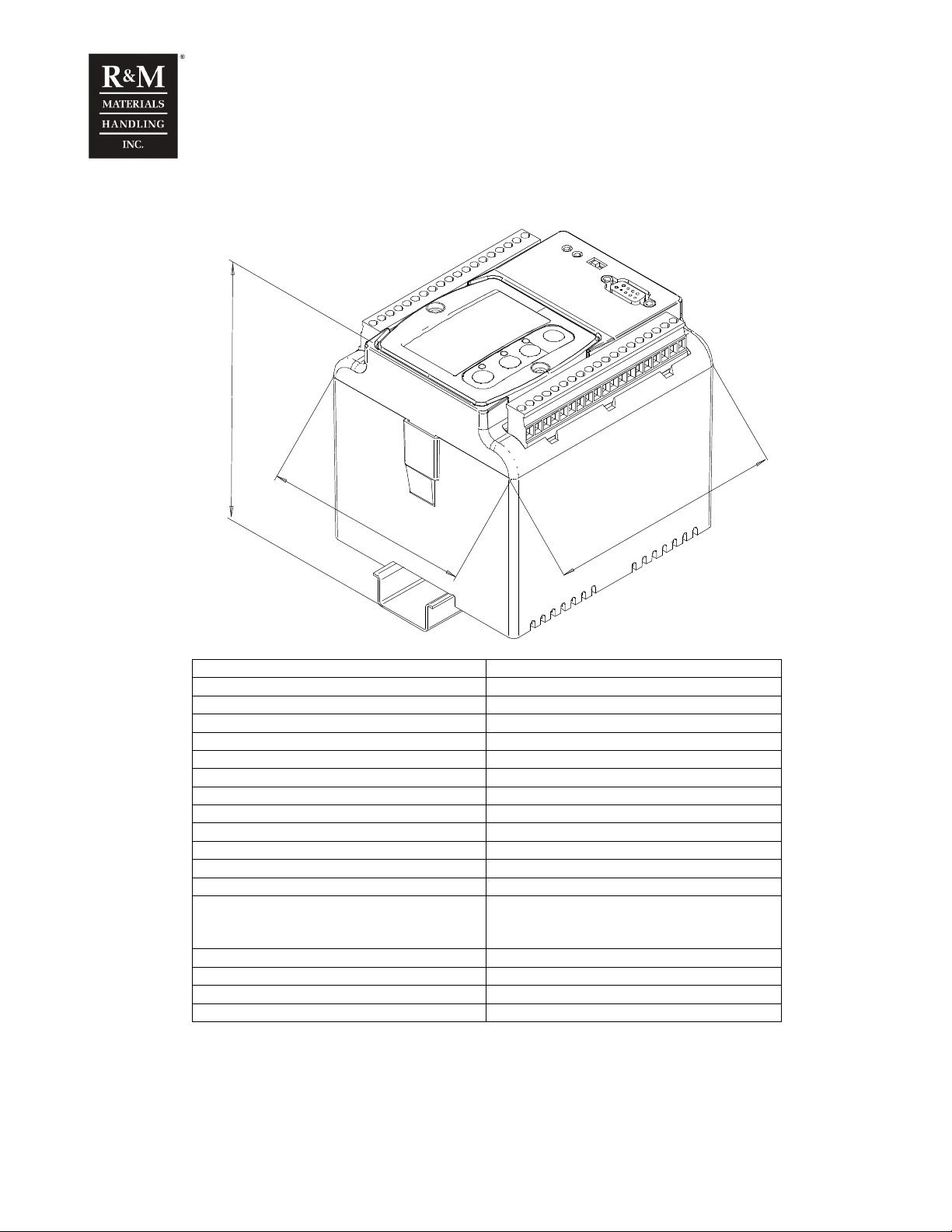

2 Technical characteristics

120.3

1

0

8

.

5

8

.

3

2

1

Signal name Technical data

Maximum supply voltage 690 VAC +10%

Nominal supply frequency 50/60 Hz

Control voltage range 42…48 VAC +/- 10% or 115…230 VAC +/- 10%

Maximum power consumption Imax = 4,5A peak value

Power consumption 6W …8W

Ambient temperature -20ºC…+65ºC; 0ºF…+150ºF

Storage temperature -40ºC…+85ºC; -40ºF…+185ºF

Humidity 0…100% RH, no condensation

Analogue output 0…10V, Rmin=1kΩ

10VDC output 10…12 VDC, Imax=50mA

Potential free relay output (Programmable) 230VAC, 3A

Current loop 12 V, I = 50…70mA

CAN 0: Ucan-H = 2.5VDC, Ucan-L = 2.5VDC

1: Ucan-H = 3.5VDC, Ucan-L = 1.5VDC

(respect to CAN-GD)

Height (including 15mm assembly rail) 120.3mm; 4.73in

Length 123.8mm; 4.87in

Width 108.5mm; 4.27in

Tightening torque of connector terminal screw 0,4 Nm – 0,6 Nm

7/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

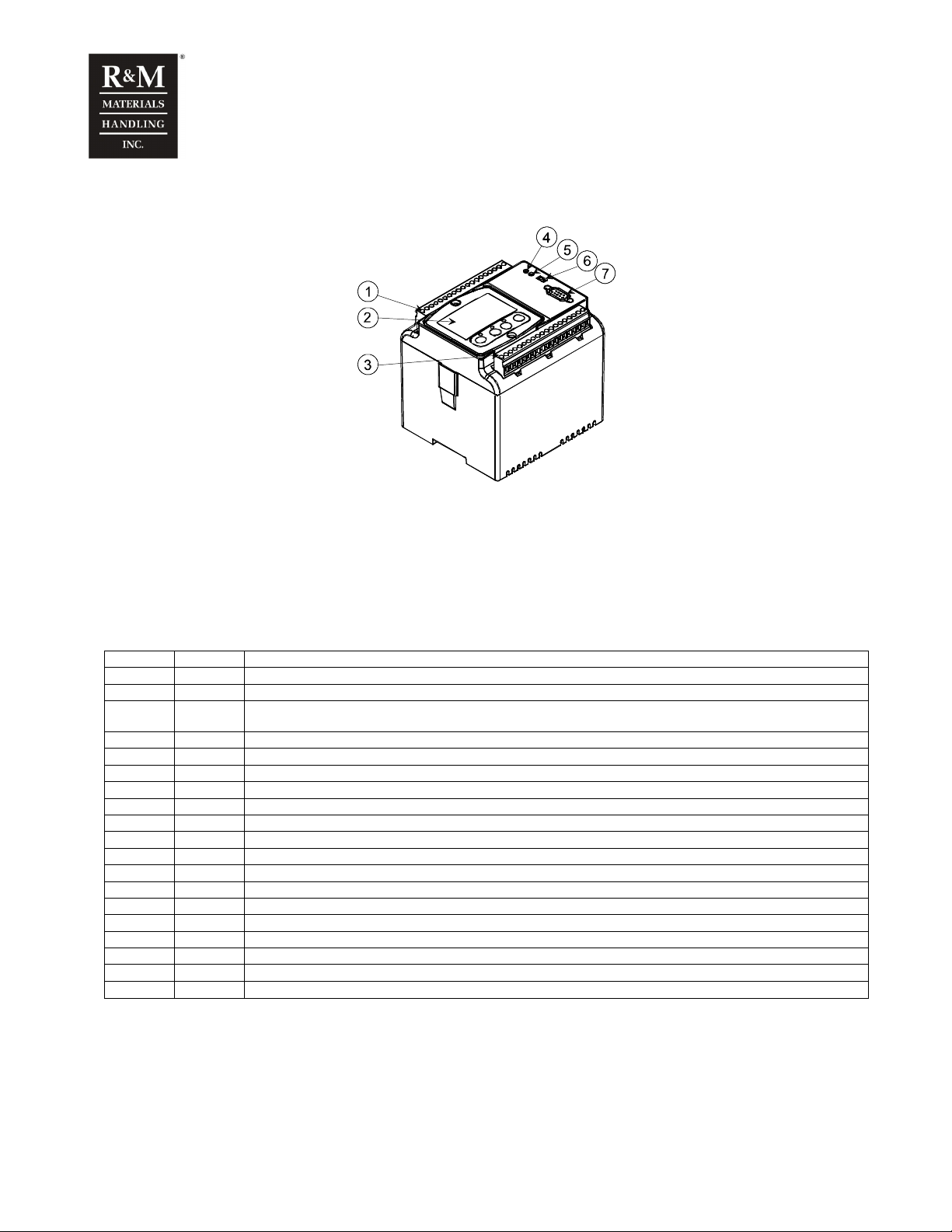

2.1 Description of terminals

c_cid1a

1. Connector X1: Terminals 1-19 for “power signals” (high voltage)

2. Display unit with pushbuttons and three indication LEDs (optional)

3. Connector X2: Terminals 20 -38 for the measurement signals (low voltages).

4. Green LED (OK and run state indication)

5. Red LED (warning and fault indication)

6. Selection switch for display location (inside the unit or remote)

7. RS232 serial link, e.g. for PC software (optional) or PLC system

Connector X1:

Terminal Signal Description

1 LOUT Provides the control voltage to lower down contactor (two step control) or lower down request. (inverter drive)

2 HOUT Provides the control voltage to hoist up contactor (two step control) or hoist up request (inverter drive)

3 FOUT

4 OL Control voltage, line

5 ON Control voltage, neutral

6 MFI2 Multifunction input 2 (programmable)

7 MFI1 Multifunction input 1 (programmable)

8 FIN Fast speed request or run feedback in inverter drive

9 LIN Lowering request

10 HIN Hoisting request

11 ROUT Relay output (programmable)

12 RIN

13 - Not used

14 - Not used

15 L3 Input voltage measurement, phase L3

16 - Not used

17 L2 Input voltage measurement, phase L2

18 - Not used

19 L1 Input voltage measurement, phase L1

Provides the control voltage to fast speed c ontactor (two step control) or fast stop control (stop limit or fault in

inverter drive)

8/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

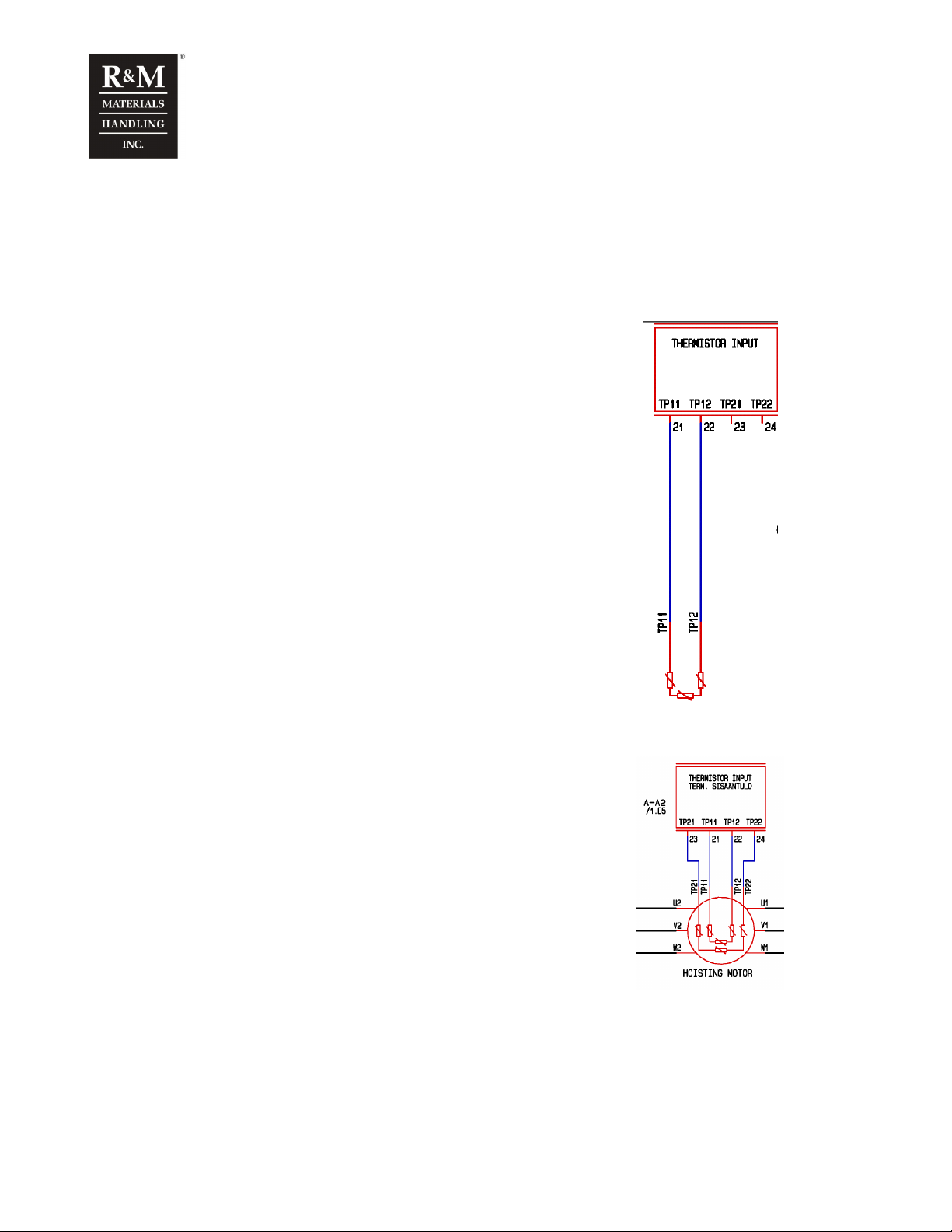

Connector X2:

Terminal Signal Description

20 PE Protective earth

21 TP11

22 TP12

23 TP21

24 TP22

25 10V Load sensor supply, 10...12 VDC

26 AIN1 Analogue input 1

27 AIN2 Analogue input 2

28 AIN3 Analogue input 3

29 IB Current transformer common

30 0V Load sensor supply, 0 V

31 - Not used

32 CL-A

33 CL-B

34 AN Analogue output

35 AN0 Analogue output, ground

36 CAN-H CAN bus, high

37 CAN-L CAN bus, low

38 CAN-GD CAN bus, neutral

Thermistor input 1

Thermistor input 2

Current loop for display

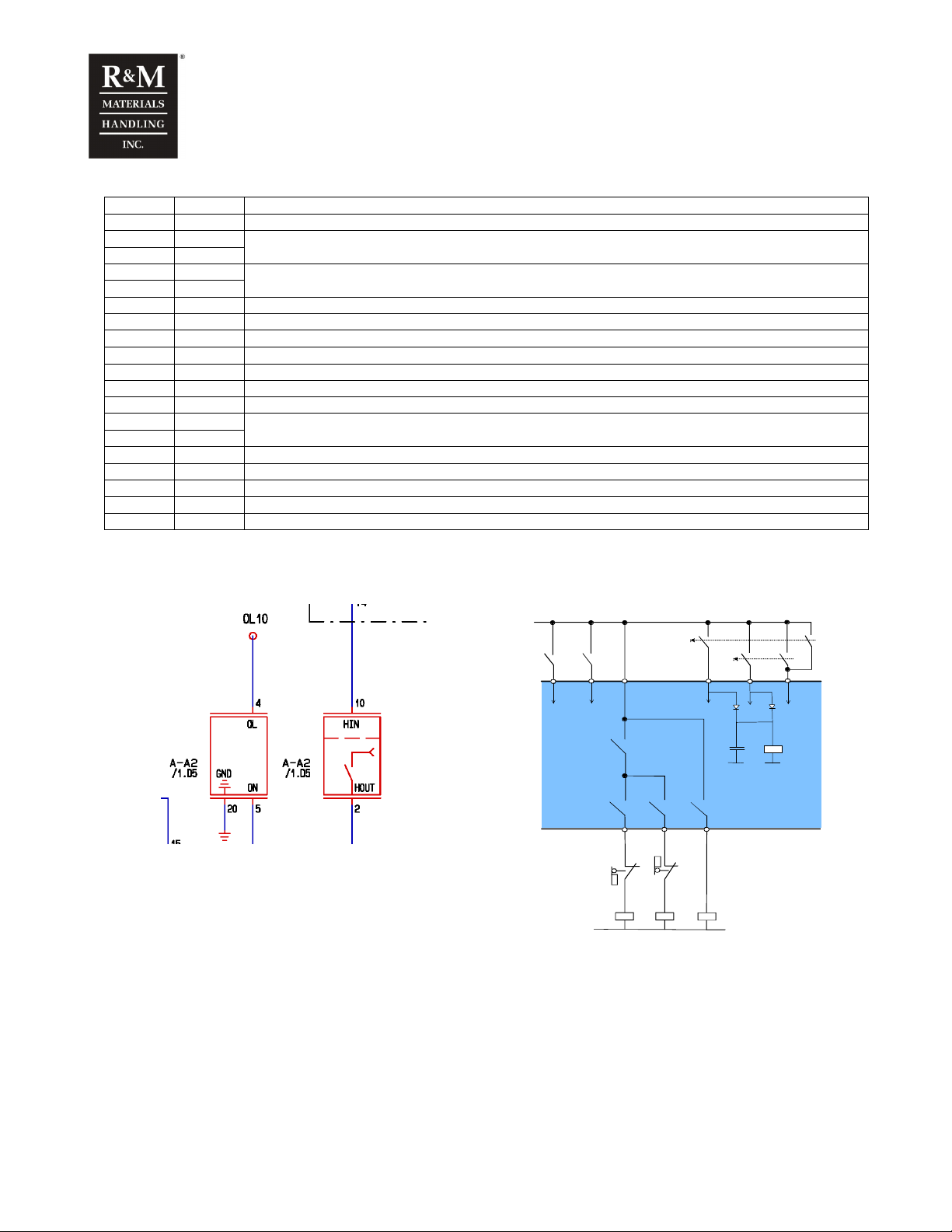

Input request is not directly connected to the output. Output voltage comes from Control

Voltage Line (OL) (via Safety Relay and Control relay). See simplified pictures.

C on trol vol ta g e

M FI 1 M FI2

OL

R S

R H R L RF

H OUT LO UT FO UT

A- K1 A -K 2

U P D OW N

A -K 4

HI N

LIN FIN

R S

Connections on eldrawings Unit’s internal connections

FAS T

9/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

2.2 Product description sticker

1.Supply voltage / Control Voltage

2.Unit type

3.Tested (year, week, tester)

4.Serial number

5.Product specific code

Unit types

Unit type Serial number Product specific code Control voltage

CID-48V Hxxxxx ID: 52292509 42-48 VAC

CID-115V Txxxxx ID: 52292510 110-230 VAC

10/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

3 Display unit

t

1 32

1. Red LED (Fault and Warning indication)

2. Orange LED (Tare load active)

3. Green LED (OK and Run indication)

The display unit shows in the large text field the actual or tared load. Also warning and fault messages

are shown in the display. Parameter values can be read and set via display unit after a correct password

has been given. Load information are displayed in a single row, other information are displayed in two

rows. If display is inside the hoist-monitoring unit, the red display selection switch must be on the local

position (up position).

Please note that the hoist-monitoring unit is designed for overload protection. The displayed load

has an accuracy of approx. ±5% of the rated load and is thus not suitable to be used as a calibrated

weighing scale.

3.1 Push-buttons

On the display are four pushbuttons for navigating and programming.

ESC

ENT

1. Zeroing of tare load. Press ESC button f or three seconds.

2. Moving from submenu to main menu and reject parameter changes

1. Toggle between actual load (orange LED off) and tare load (orange LED on)

2. Scrolling down

1. Toggle between actual load (orange LED off) and tare load (orange LED on)

2. Scrolling up

1. Entering the password level

2. Selecting a menu and accept parameter changes

3.2 LEDs

There are three LEDs inside the display unit. The left red LED is for fault or warning indication. The

orange or yellow LED in the centre is active when the tare load is selected. The right green LED is on

when the hoist-monitoring unit is OK and blinks when the hoist is running.

Action / LED Red LED (Left) Orange LED (Centre) Green LED (Right)

Illuminated continuously Fault Tare load value displayed OK, not running

Blinking Warning and Service - OK, running

Not illuminated OK Actual load value displayed Fault

OK state means that the hoist control unit is working normally and no fault or error has been detected.

When a driving output or the run feedback in inverter application is active, the green LED is blinking.

Warning means that a condition monitoring value exceeds the corresponding design value. Running the

hoist is possible, but safe using is not guaranteed.

11/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

Service-state means that a limit value set for the next service has been expired. This is indicated to the

crane user, but the hoist can still be run normally.

Fault-state means that a serious problem has been detected. Running the hoist is restricted.

3.3 Display information

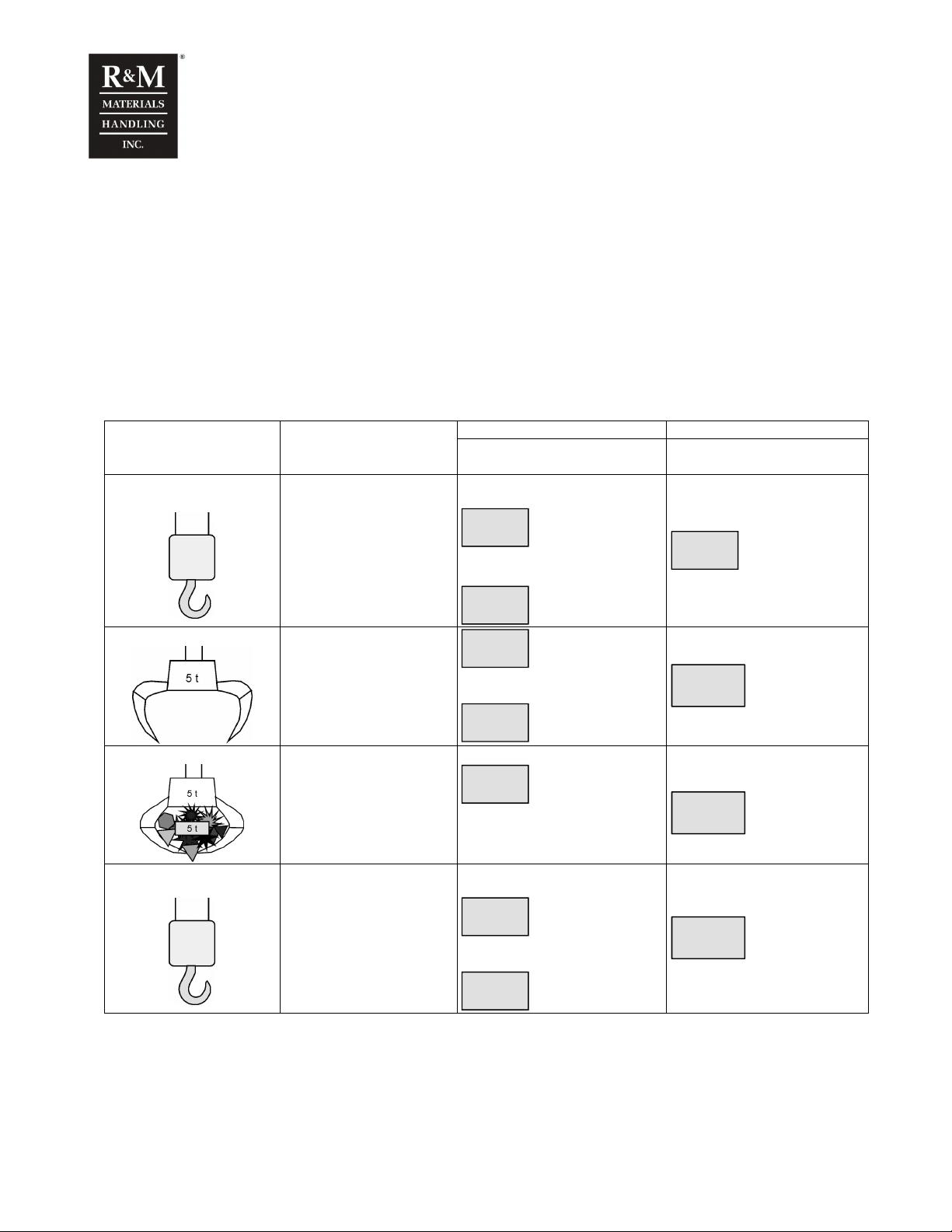

3.3.1 Tare load / actual load mode

Tare load can be used when the crane is operated with a load-handling device, such as a grab or

spreader. When no load-handling device is used, the tare load must be set to zero with empty hook.

Considering a grab crane as example the table explains the differences between tare load and actual

load. Press UP or DOWN button to toggle between tare and actual load.

Hoist application Description

10t grab without grab

Display information

Orange LED ON

TARE LOAD

Displayed value depends on last

zeroing.

Orange LED OFF

ACTUAL LOAD

10 t grab crane

10 t grab crane

10 t grab crane without grab

Only empty ropes or empty

hook block. No load in the

crane.

A grab is attached to the

ropes. Grab weight is 5 tons.

The grab is empty and not

loaded.

The grab is loaded with 5 tons

payload.

Only empty ropes or empty

hook block. No load in the

crane.

0.2 t

or zeroing press ESC f or three sec.

Display shows now

0.0 t

5.0 t

Press ESC button for three sec.

Display shows

0.0 t

Display shows

5.0 t

This is the payload of the loadhandling device.

Last zeroing was made with 5 tons

attached. Display shows

-4.8 t

Press ESC button for three sec.

Display shows

0.2 t

5.2 t

The payload + grap weight

10.2 t

0.2 t

When the display is in the load mode, the load can be tared (value set to zero) by pushing the ESC

0.0 t

button about three seconds and after that display shifts into the tare load mode.

Tare function is made for each hoist individually; means tare command is not transferred to other

units via CAN bus.

12/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

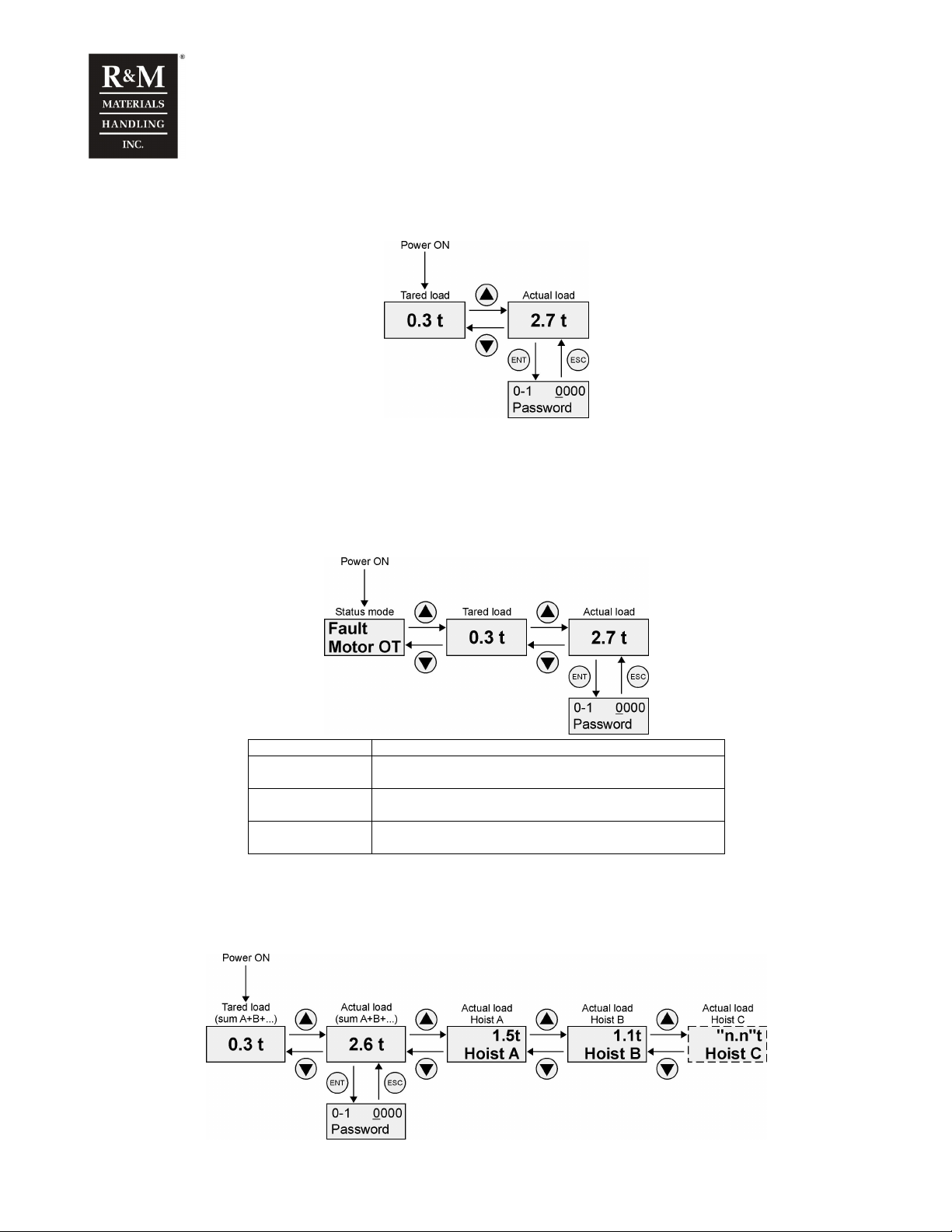

3.3.2 Menu Mode

Pushing the ENT button in the tare or actual load display mode, shifts the display into the menu mode. A

password is required in order to proceed. Pushing the ESC button returns to the actual load display.

3.3.3 Status mode

Status mode indicates all active faults, warnings and service warnings when applicable. The display

shifts automatically into the status mode when a fault or warning occurs during power ON. If more than

one fault or warning are active, all of them can be seen with arrow keys; active faults first, then warnings

and service warnings. The active fault message remains visible until the fault disappears, or the message

is removed by pushing the ENT button.

Display Description

Fault

Fault name

Warning

Warning name

Service

Service name

Status display indicating active faults status.

Status display indicating active warnings status.

Status display indicating active service status.

3.3.4 Sum load / solo hoist load mode

In multi-hoist applications, the display shows the summed tare load as the first display at power on.

Toggling between the tared sum load, the actual sum load and the actual load of each connected hoist

individually is done with the up and down buttons.

13/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

3.4 Menus

Monitoring items and parameters are presented in menus. The menus are accessible with passwords.

The right to read and/or modify parameters within a menu depends on the selected password.

3.4.1 Moving in menus

Toggling between the menus is done with the up and down arrow buttons. When the desired menu has

been selected, it is entered with the ENT-button. If there are submenus in the main menu, they are

selected and entered in the same way as described above. Returning to the higher menu level is done

with the ESC-button.

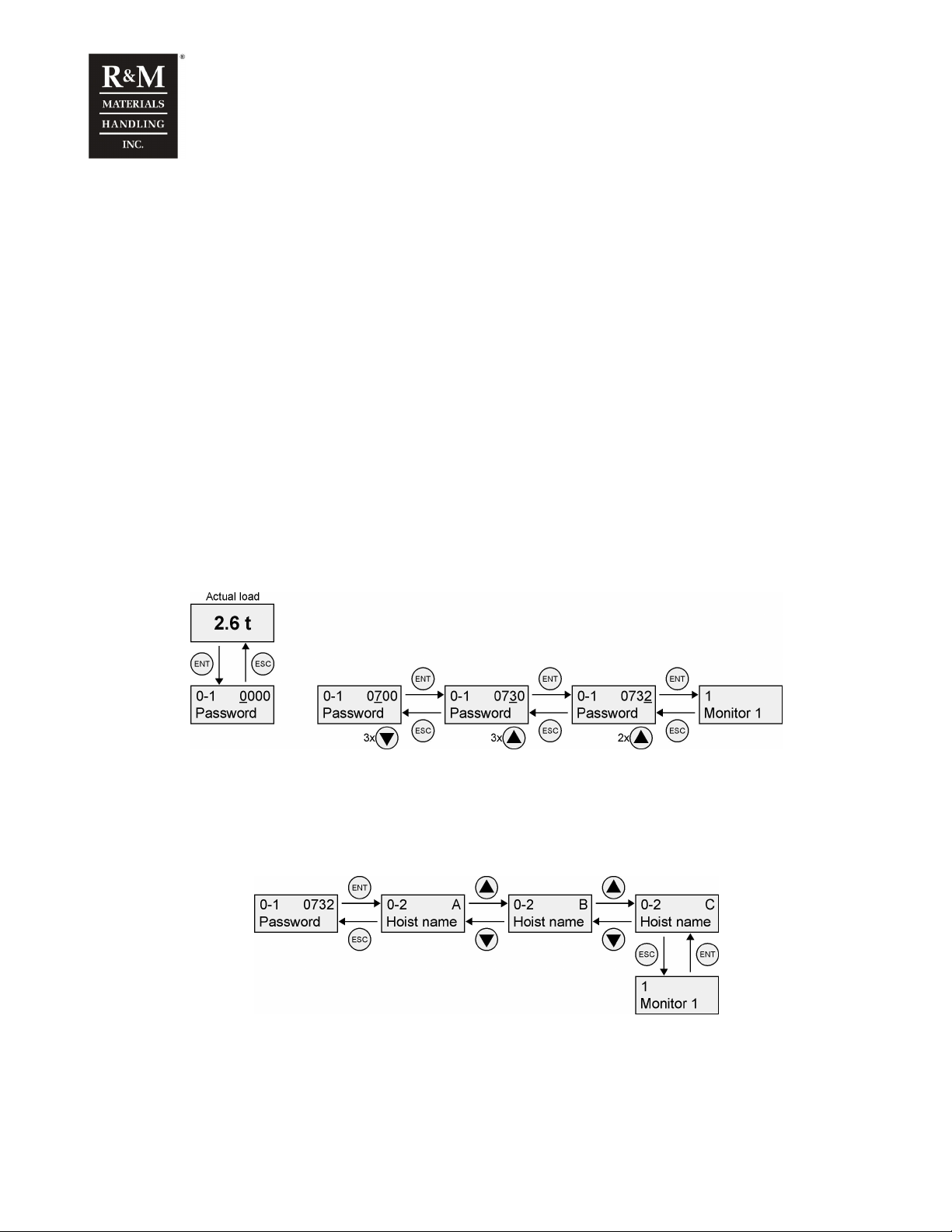

3.4.2 Password

When the ENT key is pushed the display shifts to the password request menu. With the ESC key or when

an incorrect password is given, the display shifts back to the load display.

The first display of the password select menu shows four “zeros”, with the leftmost underlined. Pushing

the up and down button will change the digit. The desired digit is selected with the ENT button, after

which the next digit will be underlined. Repeat this procedure until the correct password is given. The

display will now show the first menu “1 Monitor 1”.

(Example: Level 2 password “0732”)

3.4.3 Hoist selection (only multi-hoists)

In multi-hoist applications, where more then one unit are connected with the CAN-bus, the display will

ask to select the desired unit (A, B, C, D or E) before the display shows the first menu. This way, each

unit can be accessed via another unit. For example, all parameters and values of unit C can be displayed

and modified via unit A.

When reading data from the display in multi hoist application, verify that you are reading the data from

the correct device. The selected hoist is shown in the 0-2 display.

14/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

3.5 Parameters

3.5.1 Read-only parameters

Menu 1 (Monitor 1) and menu 2 (Monitor 2) contain read-only parameters. These menus will show the

calculated and measured values of the solo hoist, connected to the selected unit.

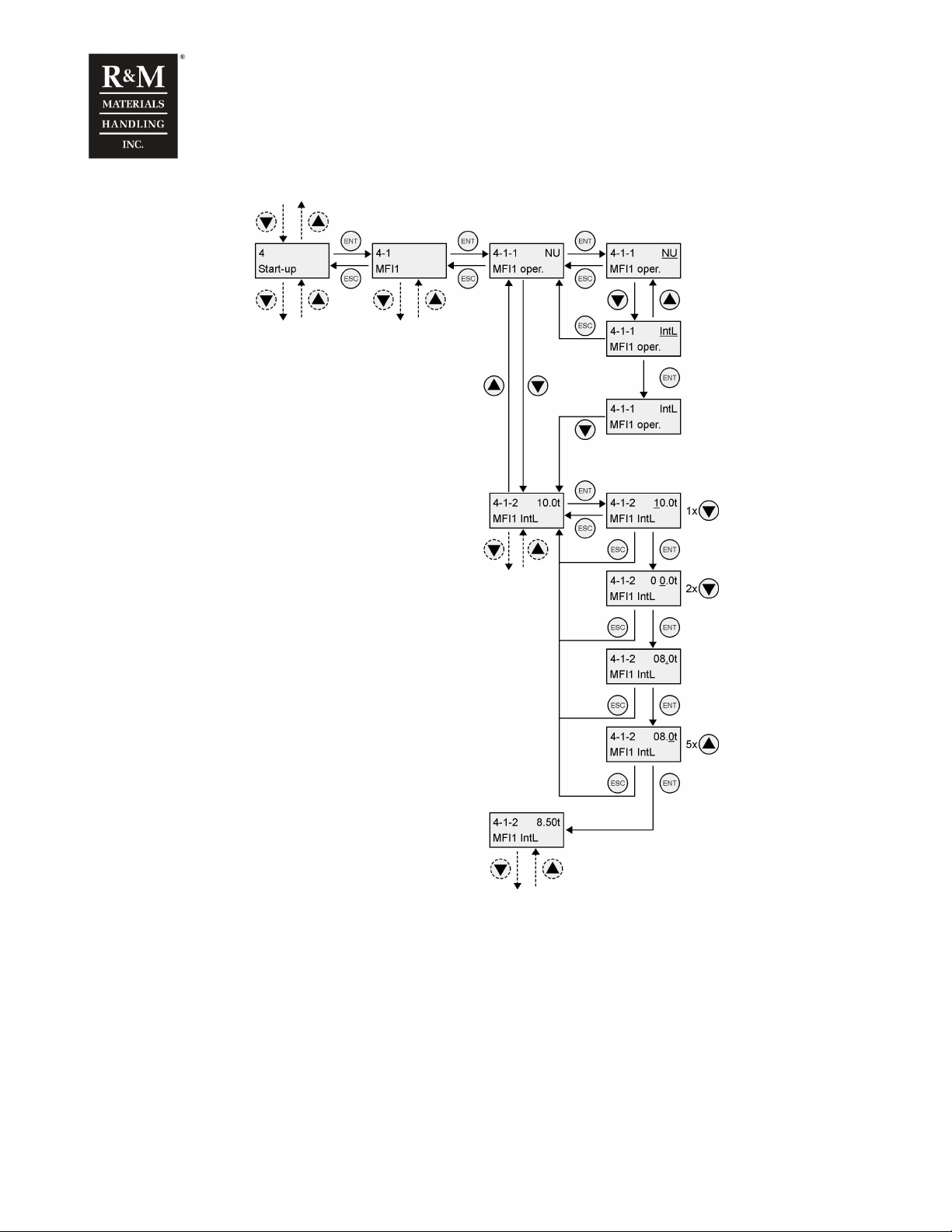

3.5.2 Adjustable parameters

There are two sorts of adjustable parameters:

• Free adjustable (within the given limits)

• Choice from option list

When a parameter has to be adjusted, first select the desired parameter. Pushing the ENT button opens

the parameter and the value can be adjusted. The free adjustable parameters will ask to adjust the digits

one at the time, whereas other parameters will give the choice between a number of options.

15/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

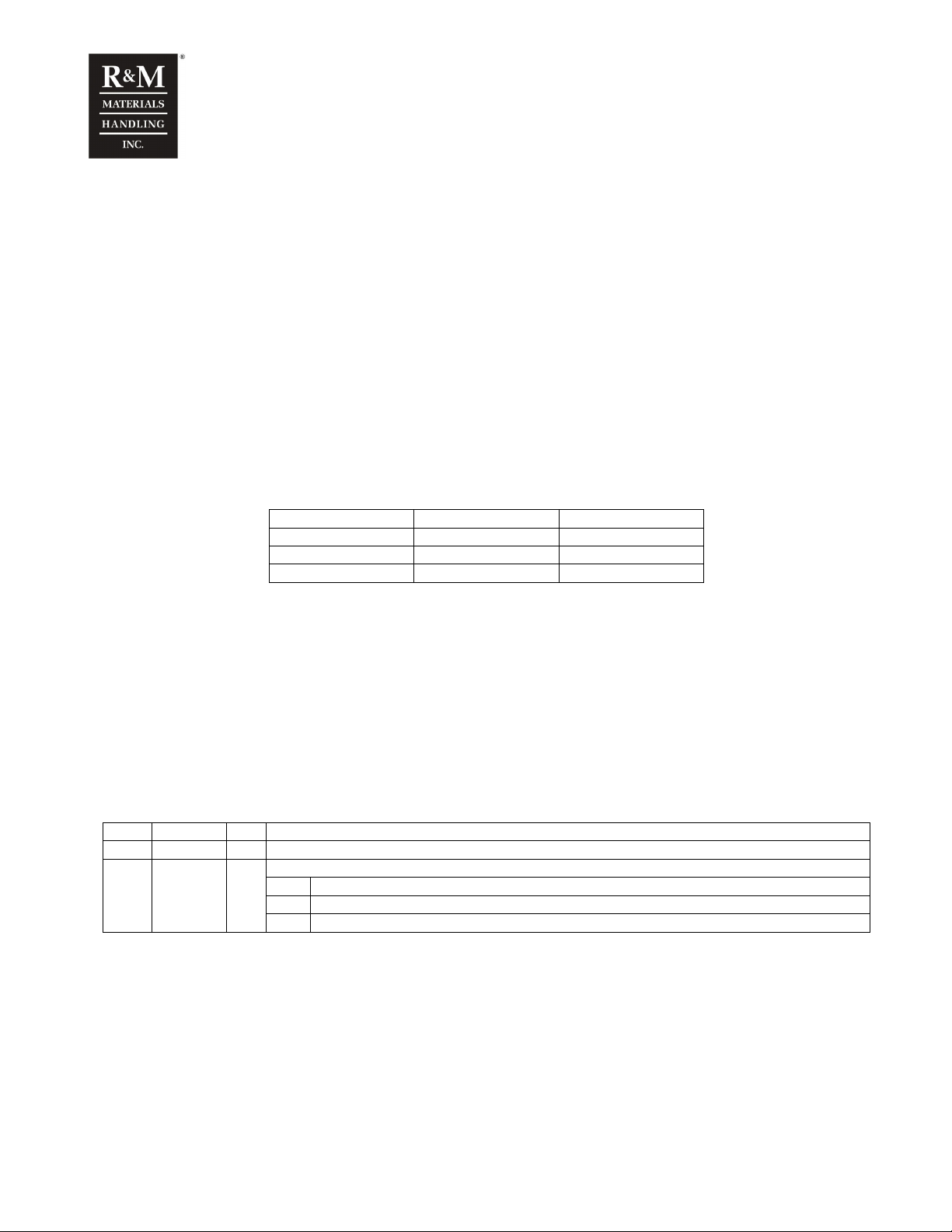

Example: selecting the MFI1 input to intermediate load function, with a load of 8.5 Tons.

3.6 Remote Display

3.6.1 General

The display can be also located at a remote location, for example in the push button station, in the

cubicle-door or in a crane driver cabin. In this way the crane operator can read load information directly

from the display. All features as well as the parameter structure are the same as when the display would

be located at the unit. The display in the remote location is a very effective tool for applications where the

crane operator needs to have a load indication when handling loads.

Please note that the hoist-monitoring unit is designed for overload protection. The displayed load

has an accuracy of approx. ±5% of the rated load and is thus not suitable to be used as a calibrated

weighing scale.

16/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

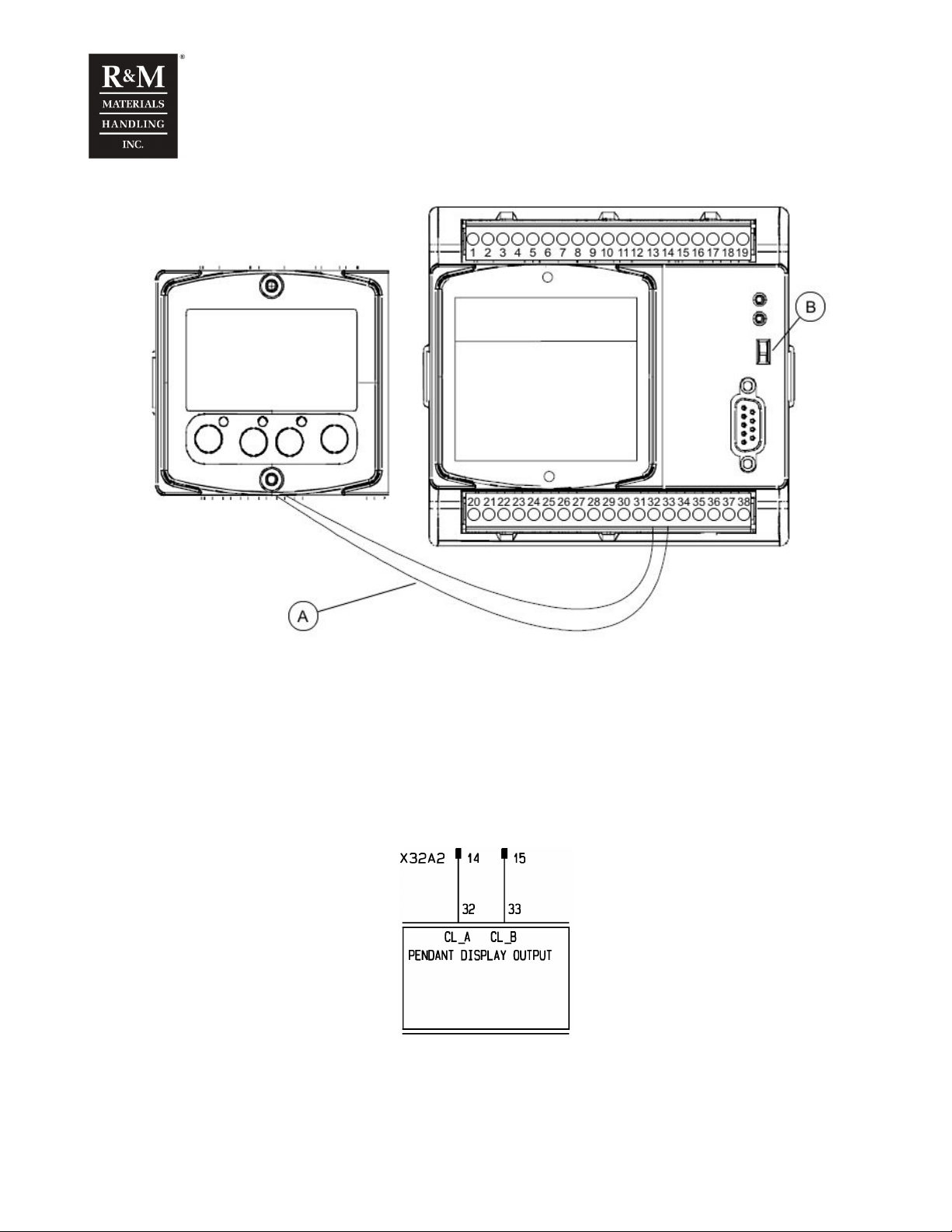

Connections and Display Selection Switch

A. Current loop to remote display

B. Display selection switch in down position for remote selection

If the display is in a remote location, the display is connected via a current loop with the hoist-monitoring

unit. The current loop is between terminals 32 (CL-A) and 33 (CL-B). Because a current loop is not

sensitive for electrical disturbances, it is not needed to use shielded cables for the display connection.

With the red display selection switch on top of the hoist-monitoring unit it is possible to switch between

the display locations. The display selection switch must be in the down position to select the remote

location active.

Remote display and display in the unit cannot work simultaneously.

17/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

Read only menu for condition monitoring values and

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

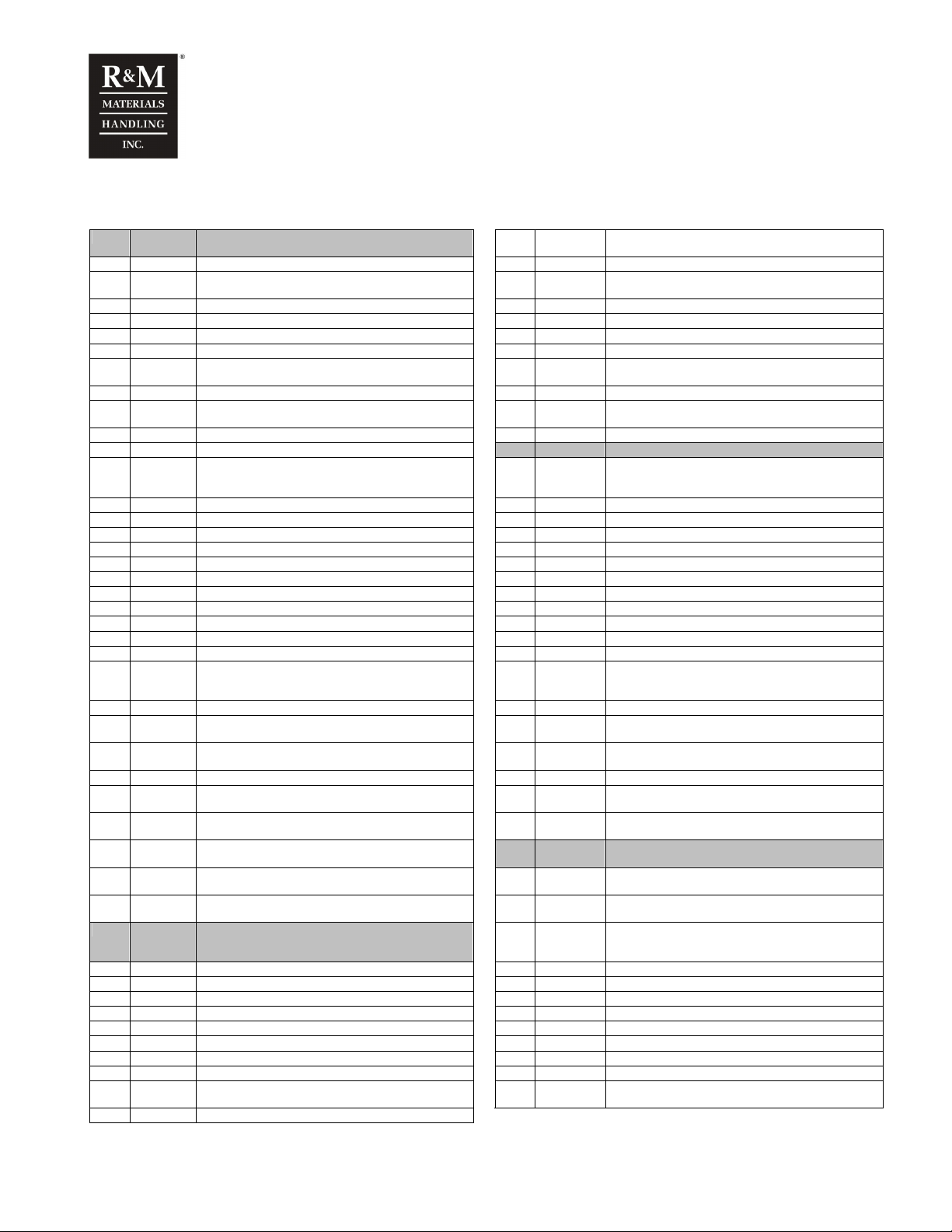

4 Parameters

1 Monitor 1

1-1 Cond mon Condition monitoring menu

1-1-1 SWP% Remaining Safe Working Period of the hoist in

1-1-2 Starts T otal number of starts 2-14 SRT8 Load sum with hoist running time, eight power

1-1-3 Run time Total running time 2-15 SWPHC% SWP% value calculated with hoist cycles

1-1-4 Cycles T otal number of hoisting cycles. 2-16 SL1 Load sum with hoist cycles, the first power (mean load)

1-1-5 Mean load Average of the handled load 2-17 SL3 Load sum with hoist cycles, the third

1-1-6 Br SWP% Remaining Safe Working Period of the brake in

1-1-7 MFI1 RT Total hours of running time, when MFI1 input is closed. 2-19 Power on The total power on time of the unit

1-1-8 MFI1 ST Total amount of starts, when MFI1 input is closed. 2-20 Temp Index Power on time of the unit, weighted with the unit’s

1-1-9 MFI2 RT Total hours of running time, when MFI2 input is closed. 2-21 Max load Maximum measured value of the load

1-1-10 MFI2 ST Total amount of starts, when MFI2 input is closed.

1-2 Measure Measurement menu

1-2-1 Act. Load The measured actual load value.

1-2-2 Temp 1 Temperature measured at thermistor input 1. 3-2-1 Load 1 The higher test load’s value

1-2-3 Temp 2 Temperature measured at thermistor input 2. 3-2-2 Mhs1 Motor torque for hoisting in slow speed, with load.

1-2-4 Supply L1 Line voltage of phase L1. 3-2-3 Mhf1 Motor torque for hoisting in fast speed, with load 1.

1-2-5 Supply L2 Line voltage of phase L2. 3-2-4 Mls1 Motor torque for lowering in slow speed, with load 1.

1-2-6 Supply L3 Line voltage of phase L3. 3-2-5 Mlf1 Motor torque for lowering in fast speed, with load 1,

1-2-7 Motor I1 Motor current of phase L1. 3-2-6 Load 2 T he lower test load’s value.

1-2-8 Motor I2 Motor current of phase L2. 3-2-7 Mhs2 Motor torque for hoisting in slow speed, with load 2.

1-2-9 Motor I3 Motor current of phase L3. 3-2-8 Mhf2 Motor torque for hoisting in fast speed, with load 2.

1-2-10 Ain1 value Measured voltage at analogue input AIN1. 3-2-9 Mls2 Motor torque for lowering in slow speed, with load 2.

1-2-11 Ain2 value Measured voltage at analogue input AIN2. 3-2-10 Mlf2 Motor torque for lowering in fast speed, with load 2.

1-2-12 Ain3 value Measured voltage at analogue input AIN3.

1-2-13 Int. temp Internal temperature of the unit.

1-2-14 Input Indicates the status of the inputs: HIN, LIN, FIN, MFI1 &

1-2-15 Output Indicates the status of the outputs: HOUT, LOUT,

1-2-16 Supply f Supply voltage frequency (50 or 60Hz) 3-4-3 Load 2 T he lower test load value

1-3 Min/Max Minimum / maximum value menu

1-3-1 Min supply Minimum measured value of the supply line voltage

1-3-2 Max supply Maximum m easured value of the supply line voltage

1-3-3 Min Int. T Minimum measured value of the internal temperature of

1-3-4 Max Int. T Maximum measured value of the internal temperature of

2 Monitor 2 Read only menu for advanced condition monitoring

2-1 SW version Software version of the unit 4-1-3 MFI1 2OLL The second load

2-2 RT slow Total run-time in slow speed 4-1-4 MFI1 CintL Bridge intermediate load limit value.

2-3 RT fast Total run-time in fast speed

2-4 No. OT Total number of hoist motor overtemperature incidents.

2-5 No. OL T otal number of overload incidents 4-2-2 MFI2 IntL T he (second) intermediate load limit value

2-6 E-stops Total number of emergency stops incidents 4-2-3 1+2 IntL T he third intermediate load limit value

2-7 ST up Total number of starts in up direction 4-2-4 MFI2 2OLL The second load limit

2-8 ST down Total number of starts in down direction 4-2-5 MFI2 CintL The (second) bridge intermediate load limit value

2-9 ST fast T otal number of starts to fast speed (counts in two

2-10 Max ED Maximum value of the calculated ED percentage

measured values.

percentage, starting from 100%.

percentage.

MFI2.

FOUT, RS & ROUT.

RMS.

RMS.

the unit.

the unit.

values and measured values. Accessible password

level 3

speed control only)

18/105

2-11 Over ED Counts the minutes when ED value has exceed the

2-12 SWPRT% SW P% value calculated with hoist running time

2-13 SRT3 Load sum with hoist running time, third power

2-18 SL8 Load sum with hoist cycles, the eight power

3 Load setup Load calibration menu. Accessible password level 2

3-1 Cal. Motor Load calibration when the motor torque based load

3-2 MC values Load calibration values for the motor torque method

3-3 Cal. Sens Load calibration when the sensor based load

3-4 SC values Load calibration values for the load sensor method

3-4-1 Load 1 T he higher test load value.

3-4-2 Input 1 T he load measurement voltage in the analogue input

3-4-4 Input 2 T he load measurement voltage in the analogue input

3-5 OL protect Set to “OFF” to temporarily by-pass of the overload

4 Start-up Start- menu. Accessible password level 4

4-1 MFI1 Multi-Functional Input 1 parameters

4-1-1 MFI1 oper. Selects the function of MFI1:

4-1-2 MFI1 IntL Interm ediate load limit value

4-2 MFI2 Multi-Functional Input 2 parameters

4-2-1 MFI2 oper. Selects the function of MFI2:

4-2-6 1+2 CintL The third bridge intermediate load limit value

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

nominal ED value

temperature

measurement is selecte. See chapter “Load

calibration sequence with motor torque”.

measurement is selected. See chapter “Load

calibration sequence with the load sensor”.

Ain1 corresponding to the higher test load

Ain1 corresponding to the lower load

protection

R&M Materials Handling, Inc.

ate for controlling the hoisting in two step

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

4-3 ROUT Relay output parameters

4-3-1 ROUT oper. Selects the function of the relay output 5-3 Reset log ? T he reset action must be confirmed by pushing the ENT

4-3-2 ROUT logic T he operation logic of the relay:

4-3-3 ROUT LoadX The load limit to switch the relay is entered here 6-1 Hoist name Identifying letter of the hoist-monitoring unit, A, B, C, D

4-3-4 TempX meas The temperature measurement operation 6-2 Unit No The serial number of the hoist.

4-3-5 TempX lim The temperature limit 6-3 Class Mechanical class for the hoist according to the FEM /

4-4 T1 Temperature measurement channel 1 parameters

4-4-1 T1 operat. Selects the function channel 1. 6-5 Nominal ED Rated ED value of the hoist

4-5 T2 Temperature measurement channel 2 parameters

4-5-1 T2 operat. Selects the function channel 1. 6-7 Max ST Maximum allowed number of starts

4-6 AOUT Analogue output parameters

4-6-1 AOUT oper. Selects the function of the analogue output 6-9 Max RT Maximum allowed run-time in hours

4-6-2 Zero load Sets the voltage level with zero-load. Range 0…10V 6-10 D SRT3 Designed running hours, power three.

4-6-3 Nom. Load Sets the voltage level with rated load. Range 0…10V 6-11 D SRT8 Designed running hours, power eight.

4-7 Load param Load calculation parameters

4-7-1 Load meas. Selects the load calculation method: 6-13 D SL8 Design constraint for hoisting cycles, power eight

4-7-2 Load rate% Load increase r

4-7-3 R0_F Resistance of fast speed windings at temperature T0 6-15 MaxRT MFI1 Max running time for MFI1.

4-7-4 R0_S Resistance of slow speed windings at temperature T 0 6-16 MaxST MFI2 Max number of MFI2 starts.

4-7-5 T0 Resistance measuring temperature T0 6-17 MaxRT MFI2 Max running time for MFI2.

4-7-6 Temp_slow Temperature measurement channel for the motor slow

4-7-7 Temp_fast T emperature measurement channel for the motor fast

4-7-8 C2F Coefficient 2 for fast speed 6-20 Password Set password level 1 (4digits).

4-7-9 C2S Coefficient 2 for slow speed

4-7-10 C1F Coefficient 1 for fast speed 7-1 Cycles Number of hoisting cycles

4-7-11 C1S Coefficient 1 for slow speed 7-2 MFI1 RT MFI1 running time

4-7-12 ki Reduction factor for current transformer [A/V] 7-3 MFI1 ST MFI1 starts

4-7-13 Acc-t slow Acceleration time from stop to slow speed. 7-4 MFI2 RT MFI2 running time

4-7-14 Acc-t fast Acceleration time from slow speed to fast speed. 7-5 MFI2 ST MFI2 starts

4-8 Hoist ctrl The selection for the hoist control method

4-9 Slack rope Slack rope function parameters

4-9-1 SR select Selects the slack rope function 7-8 No. OT Number of hoist motor overtemperature incidents.

4-9-2 Load limit The slack rope limit 7-9 No. OL Number of hoist overload incidents

4-10 Single sup 7-10 E-stops Number of emergency stops

4-10-1 OT run ? Selects the action when the motor temperature exceeds

4-10-2 OT limit When NTC type sensor is applied the limit value for the

4-10-3 Supply sup Selects the supply voltage supervision. 7-13 ST fast Number of starts to fast speed (two step control only)

4-11 Comm hoist The settings for common hoisting (multi-hoist

4-11-1 Hoist cnt The number of units connected with CAN bus. Range:

4-11-2 Run sup. Common hoisting supervision 7-16 SRT3 Load sum with hoist running time, third power

4-11-3 B OL Bridge overload protection 7-17 SRT8 Load sum with hoist running time, eight power

4-11-4 B nom load Rated load of the bridge 7-18 SL1 Load sum with hoist cycles, the first power (mean load)

5 Service Start- menu. Accessible password level 5

5-1 S limits The limit values to indicate the need for service.

5-1-1 S Run time Run time service limit 7-21 Power on The total power on time for hoist control unit

5-1-2 S starts Service limit for the number of starts 7-22 Temp Index The power on time weighted with the hoist control unit

5-1-3 S SWP% Service limit for SWP% 7-23 Max load The maximum value of the measured load

5-1-4 S Br SWP% Service limit for the hoist brake service life 7-24 Br Count T he brake wear counter.

5-2 Fault log The logger for the latest fault situations, the number

5-2-1 F_”XXX” The latest fault.

5-2-2 F_”XXX” The second latest fault.

5-2-“n” F_”XXX” The “n” latest fault (highest number is 30).

control.

speed windings.

speed windings.

the limit or when “Fault, Br wear” occurs

hoist motor overtemperature

applications)

1…5

“n” indicates the number of faults in the logger

5-3 Reset log Resets the fault log by pushing the ENT button..

6 Design Design values menu. Accessible password level 6

6-4 Nom. Load Rated load of the single hoist connected to the unit

6-6 Sp ratio Speed ratio.

6-8 Max E-stop Maximum allowed number of interrupted hoists

6-12 D SL3 Design constraint for hoisting cycles, power three

6-14 MaxST MFI1

6-18 Max Br Max number of braking actions.

6-19 Max Control Max number of Control (starts)

7 GO-setup GO-settings menu. Accessible password level 7

7-6 RT slow Run-time in slow speed

7-7 RT fast Run-time in fast speed

7-11 ST up Number of starts in up direction

7-12 ST down Number of starts in down direction

7-14 Max ED Maximum ED value

7-15 Over ED Number of cases where ED value has exceeded the

7-19 SL3 Load sum with hoist cycles, the third power

7-20 SL8 Load sum with hoist cycles, the eight power

button once more

or E.

ISO duty classes.

(emergency stops)

Max number of MFI1 starts.

rated ED value

temperature

19/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

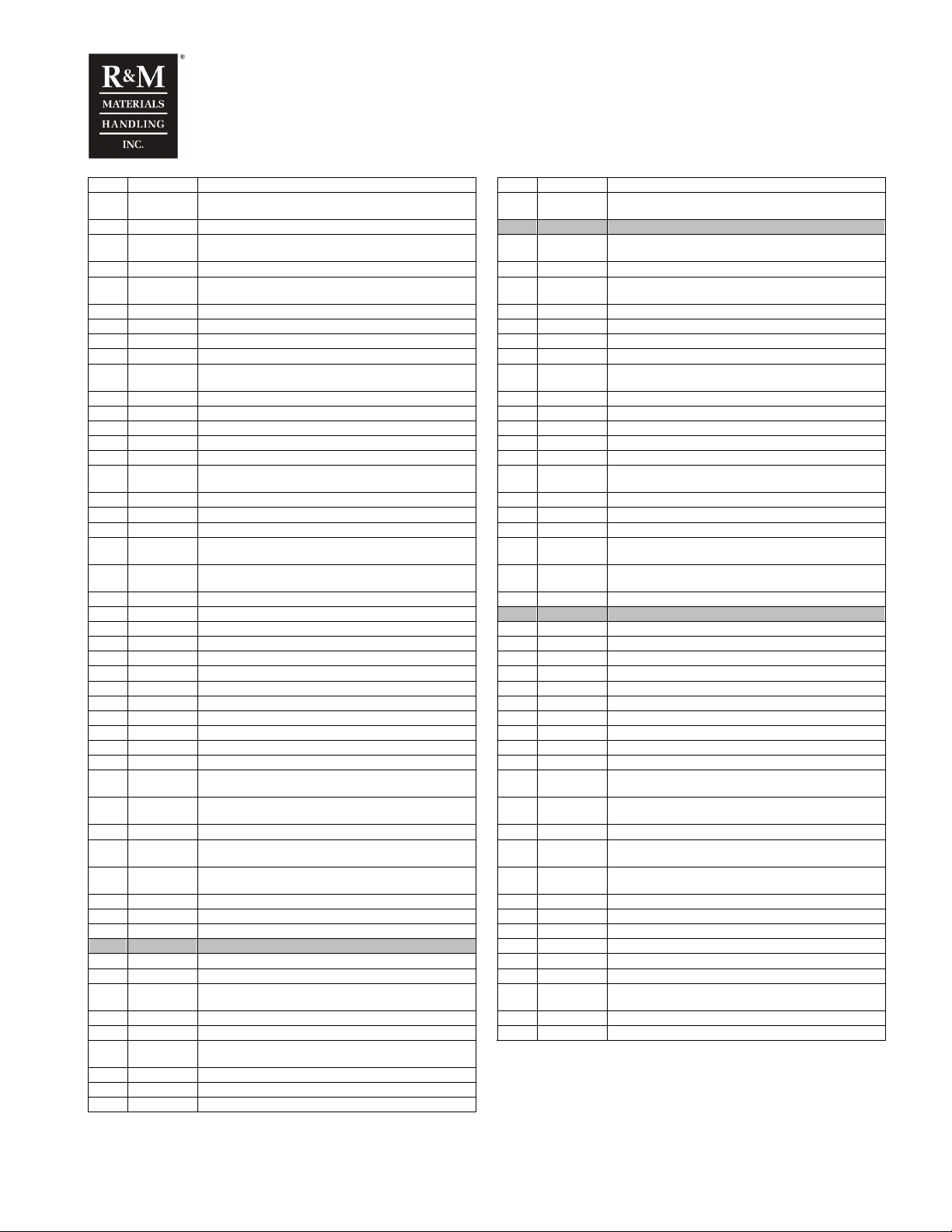

4.1 Passwords

The table below indicates the access to the menus with different password levels.

The display asks for the password when the ENT button is pushed in the main load display mode. If the

given password does not match to any of the levels, the display returns to the main load display mode. If

the given password matches to one of the levels, the user has access to the corresponding menus

according to the table below.

Main menus Level 1 Level 2 Level 3 Level 4 Level 5 Level 6 Level 7

1 Monitor 1 X X X X X X

2 Monitor 2 X X X X X

3 Load Setup X X X X X

4 Start-up X X X X

5 Service X X X

6 Design X X

7 GO-setup X

Passwords for different levels

Level Password Note

Level 1 Parameter Given with the parameter, 6–20 Password

Level 2 0732 Fixed value, can only calibrate the load measurement

Level 3 5201 Fixed value, used to read the monitoring values

Level 4 8124 Fixed value, all menus up to input/output settings and calibration

Level 5 5029 Fixed value, all menus up to service menu

Level 6 9822 Fixed value, all menus up to design limit values

Level 7 2180 Fixed value, access to all parameters

20/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

5 Basic Functions

5.1 General

The basic functions assure the safe functioning of the hoist. The hoist-monitoring unit constantly performs

a number of checks to determine if all conditions are safe in order to proceed the motion. In case the

hoist-monitoring unit detects a potentially unsafe situation, the motion will be stopped. Depending on the

kind of fault, both hoisting and lowering is prevented or in other cases driving in the opposite direction is

allowed.

In addition to the basic functions, a wide scale of optional functions can be installed. Refer to the section

“Optional functions” or contact a manufacturer’s representative for further details.

The basic functions of the hoist-monitoring unit are:

• Overload protection

• Hoist motor overtemperature supervision

• Supply phase supervision

• Run and fault supervision

• Starting and stopping through slow speed

• Sudden load increase supervision

The basic functions are factory set according to specific hoist and customer’s demand.

It is possible that few basic functions can’t be used in every hoist. (e.g. Insulated network, inverter

drive)

The additional optional functions of the hoist-monitoring unit are:

• Lifetime counters

• Remote display

• Multicare

• Multi function input Options

• Potentional Free Relay Options

• Analog Output

When during run one of the supervised safety features value exceeds the limit, the unit will stop the

motion. Re-starting is only possible after the reason for the fault is terminated. Note that some faults are

direction dependent and running in the opposite direction will terminate the fault. Refer to the sections

that describe the supervisions for details.

The hoist-monitoring unit is equipped with two LEDs that provide operational information as follows:

Action / LED Green LED Red LED

Illuminated continuously OK, not running Fault

Blinking OK, running Warning

Not illuminated Fault OK

OK state means that the hoist control unit is working normally and no fault or error has been detected.

Running the hoist is possible.

Warning means that a condition-monitoring value has exceeded the design value. Running the hoist is

possible, but safe operation can not be guaranteed.

21/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

Fault means that one (or more) of the supervised safety features values exceeds the limit. Running the

hoist is restricted.

For Run or Fault supervision, it is possible to connect an external indication device like a horn or

lamp to the relay output. Relay output must be programmed to the desired function “OK” or “Ready”

5.2 Overload protection

The overload protection can be done in two ways, either with motor torque calculation or by using a load

sensor. Regardless which system is used, the hoist-monitoring unit will prevent the hoisting motion when

the measured load exceeds 110% of the rated load for a period of time. A filtering delay is built in to

assure trouble-free lifting of a rated load. The overload protection is reset when the measured load

decreases to 80% of the rated load.

The overload protection reacts faster than the display updates the measured values. Therefore it

may happen that the movement is stopped although the display indicates a load less than 110% of

the rated load.

The motor torque calculation system uses the motor voltage, current and temperature to calculate the

motor torque and converts this into load information. This system cannot be used in combination with

frequency converters, and can only measure the load when the motor is running. In addition to the

overload protection, the hoist-monitoring unit also supervises the brake. When the calculated load value

descends under -50% of the rated load during lowering, it indicates that the brake did not open. Lowering

the hook is prevented, but lifting is still allowed.

Motors driven by a frequency converter are always equipped with a load sensor for load measurement.

Systems using a strain gauge type of sensor are also equipped with a load sensor amplifier to amplify the

signal coming from the sensor. In case a Hall-type of sensor is used, the load sensor amplifier is not

needed.

Param.

4-7 Load param Load calculation parameters

4-7-1 Load meas.

Overload level Filtering time Run-down time

140% 60 ms ~100 ms

125% 200 ms ~250 ms

110% 1000 ms ~1050 ms

Name Value Description

Selects the load calculation method:

NU Not used, the display show all time to 0,0t

Motor Motor torque calculation. Refer to chapter “Overload protection – Motor torque” of this manual

Sens. Load sensor measurement . Refer to chapter “Overload protection – Load sensor” of this manual

Load measurement tolerance is ±10% of nominal load by use motor torque calculation system and

load measurement tolerance is ±5% of nominal load by use load sensor.

22/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

thermistors are commonly used in most of the motors

thermistors will rapidly increase their

resistance when the measured temperature exceeds the

limit. The maximum allowed temperature depends on the

thermistors. The

monitoring unit will detect over temperature when the

metal switches are mounted on the motor stator

switches

the measured

temperature exceeds the limit. The maximum allowed

temperature depends on the motor and is determined by

monitoring unit will

detect overtemperature when the resistance exceeds

metal switches

monitoring unit stops

when motor torque calculation

thermistors will

decrease their resistance in an almost linear relation to

temperature increase. The actual motor temperature is

ring unit will stop the motion in case the resistance

measuring device drops below the

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

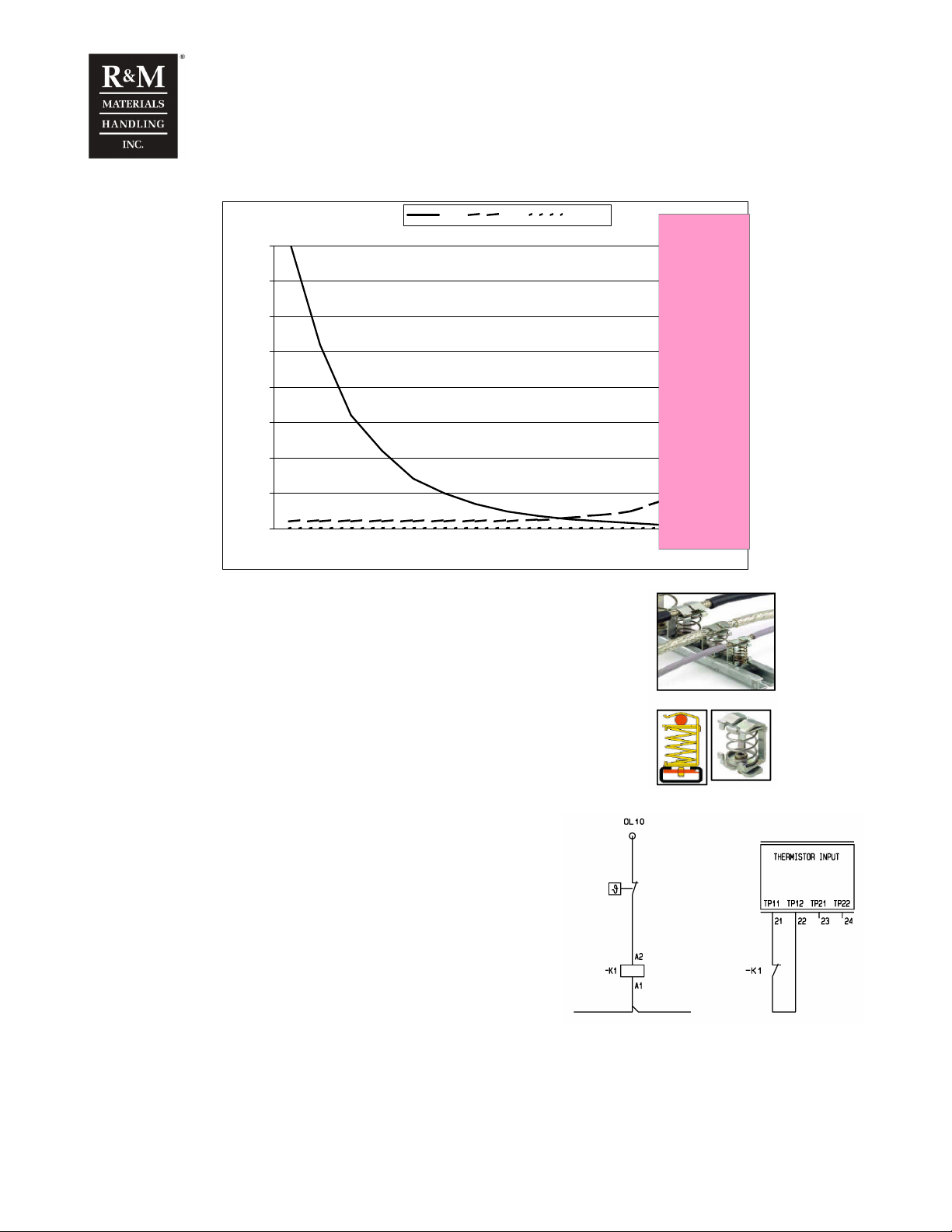

5.3 Hoist motor overheating supervision

To prevent the hoisting motor from burning up, the hoist-monitoring unit will constantly measure the

internal temperature of the motor. The motor is therefore equipped with temperature sensors; PTCthermistors, NTC-thermistors or Bi-metal switches (Klixons). The hoist-monitoring unit can be

programmed to either prevent both hoisting and lowering (default), or only the hoisting motion.

PTCin the past. PTC-

motor and is determined by the used

hoistresistance of the PTC exceeds 4.0kOhm.

Biwindings. Bi-metal switches operate as thermaland will open up the contact when

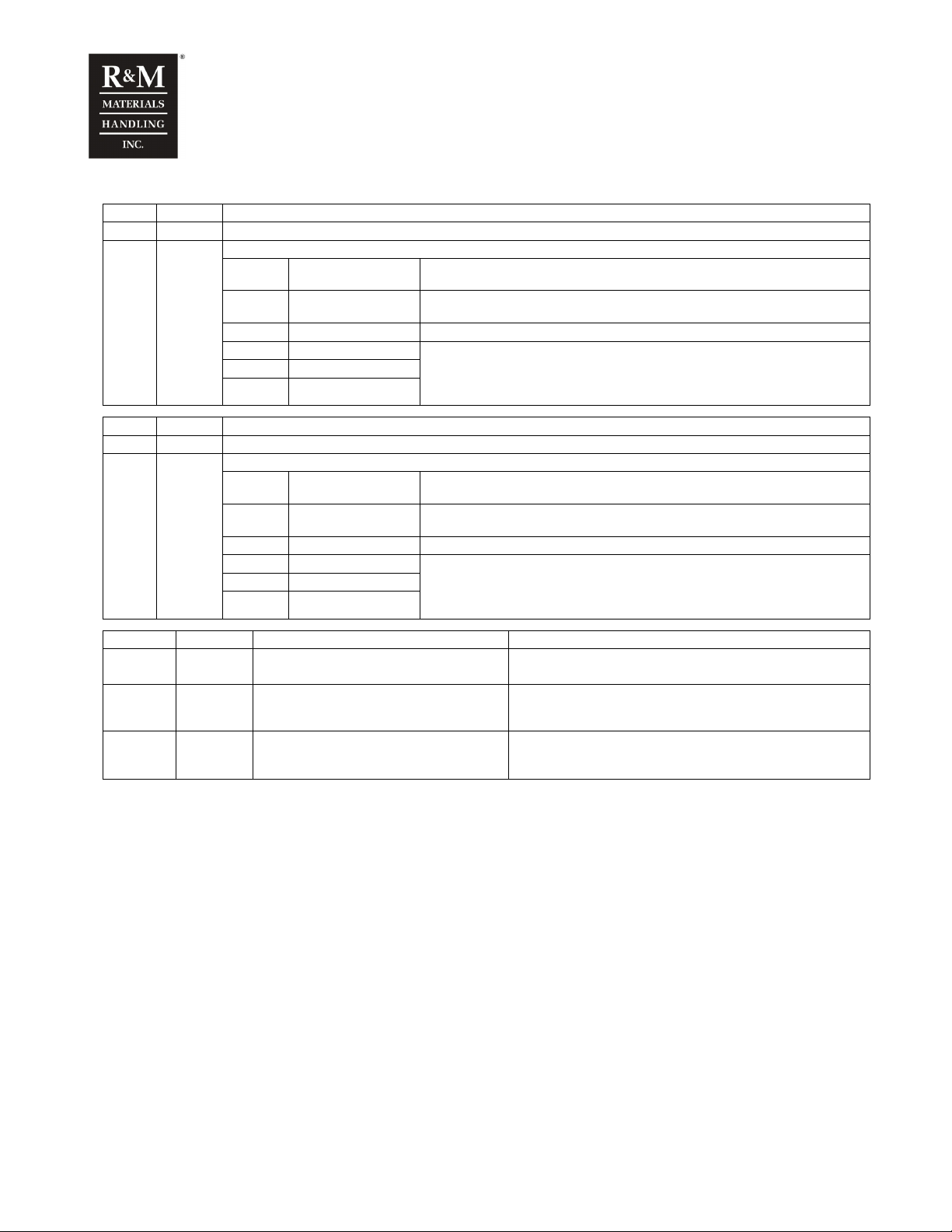

PTC-thermistor connections

the used Bi-metal switches. The hoist-

4.0kOhm (thus open contact).

In practice, PTC-thermistors and Bioperate in the same way. The hoistthe motion when the resistance of the temperaturemeasuring device exceeds 4.0kOhm.

NTC-thermistors are used

is the load measurement method. NTC-

accurately measured with NTC-thermistors and the hoistmonito

of the temperaturepreset value.

NTC-thermistors connections

23/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

Over temperature

NTC and PTC: The temperature sensor’s cable must

be shielded if the cable between the unit and the

mperature sensors is longer than 10m. The cable

shield is connected to the ground of the hoist. It is

recommended to use 360 degrees shield clamps to

metal: It is recommended to use a supplementary

the thermistor. In that

case there is no need for a shielded cable and

In case third party motors are used, please consult

with the manufacturer of the motor for thermistor

must be protected

against overheating by other means, e.g. a motor

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

Thermistors operating curve

40

35

30

25

20

kohm

15

10

5

NTC PTC Bi-metal

0

Motor Temperature

te

carry out the grounding!

Bi-

relay between the unit and

possible disturbance is limited to the minimum.

details.

Motors without thermistors

protection switch.

24/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

5.3.1 Hoist motor overheating supervision instructions

Param. Name Description

4-4 T1 Temperature measurement channel 1 parameters

4-4-1 T1 operat.

Param. Name Description

4-5 T2 Temperature measurement channel 2 parameters

4-5-1 T2 operat.

Param. Value Description Note

4-10

Single sup

4-10-1

OT run ?

4-10-2

OT limit

Selects the function of temperature measurement channel 1:

NU Not used

PTC

Bwear Brake wear sensor See section Hoist Brake- Wear supervision

A NTC Type A NTC sensor

B NTC Type B NTC sensor

C NTC Type C NTC sensor

Selects the function of temperature measurement channel 2:

NU Not used

PTC

Bwear Brake wear sensor See section Hoist Brake- Wear supervision

A NTC Type A NTC sensor

B NTC Type B NTC sensor

C NTC Type C NTC sensor

Accessible with password 4: 8124

No / Down Hoisting and lowering is prevented when the

150C Sets the tripping level of the overtemperature

Motor thermistor or

Bimetal thermal switch

Motor thermistor or

Bimetal thermal switch

overtemperature supervision trips.

supervision in degrees Celsius, steps of one

degree. Only with NTC-thermistor.

Motor without thermistors or only one sensor that is connected to the

temperature input 2.

Two speed motors typically only have one set of thermistors, for both low speed

and high speed windings.

Determines the type of thermistors in the low speed windings, connected to the

temperature input 1

Manufacturer’s hoisting motors used in motor-torque calculation overload

systems are as a standard equipped with type B NTC thermistors

Motor without thermistors or only one sensor that is connected to the

temperature input 1.

Two speed motors typically only have one set of thermistors, for both low speed

and high speed windings.

Determines the type of thermistors in the low speed windings, connected to the

temperature input 1

Manufacturer’s hoisting motors used in motor-torque calculation overload

systems are as a standard equipped with type B NTC thermistors

If, for safety reasons, local legislation or customer demands,

lowering the load is required when the temperature supervision

has tripped, set this parameter to: “Down”

Consult with the motor data sheets for the maximum allowed

temperature for the motor. Default for manufacturer’s squirrel

cage motors: 150°C

25/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

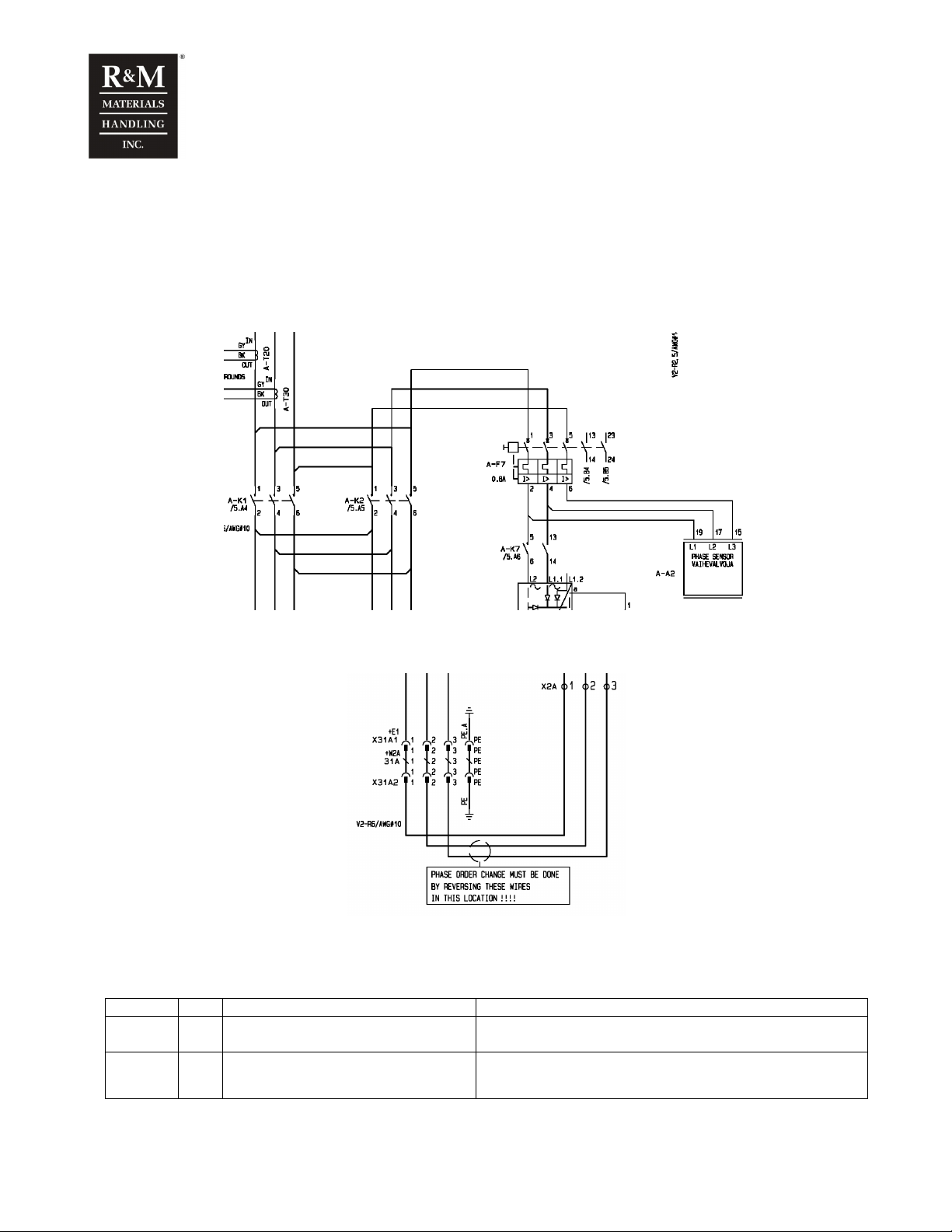

5.4 Supply voltage phase supervision

The supply voltage phase supervision consists of two functions:

- Missing supply phase detection

- Incorrect supply phase order

The three supply voltage phases are wired to the hoist-monitoring unit. Each time the unit is powered up,

the phase order is checked. The unit will continuously measure the existing of all three phases.

In case wrong direction of hoisting occurs (reversed phase condition), note that the two input power

wires are reversed at terminal X2A!

5.4.1 Supply phase supervision instructions

Supply phase supervision parameters

Param. Value Description Note

4-10

Single sup

4-10-3 Yes Switches the supply phase supervision on. W hen the hoist monitoring-unit is connected in insulated or high

Accessible with password 4: 8124

impedance grounded network, or when the supply mains are not

connected (i.e. inverter use), the setting must be “No”.

26/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

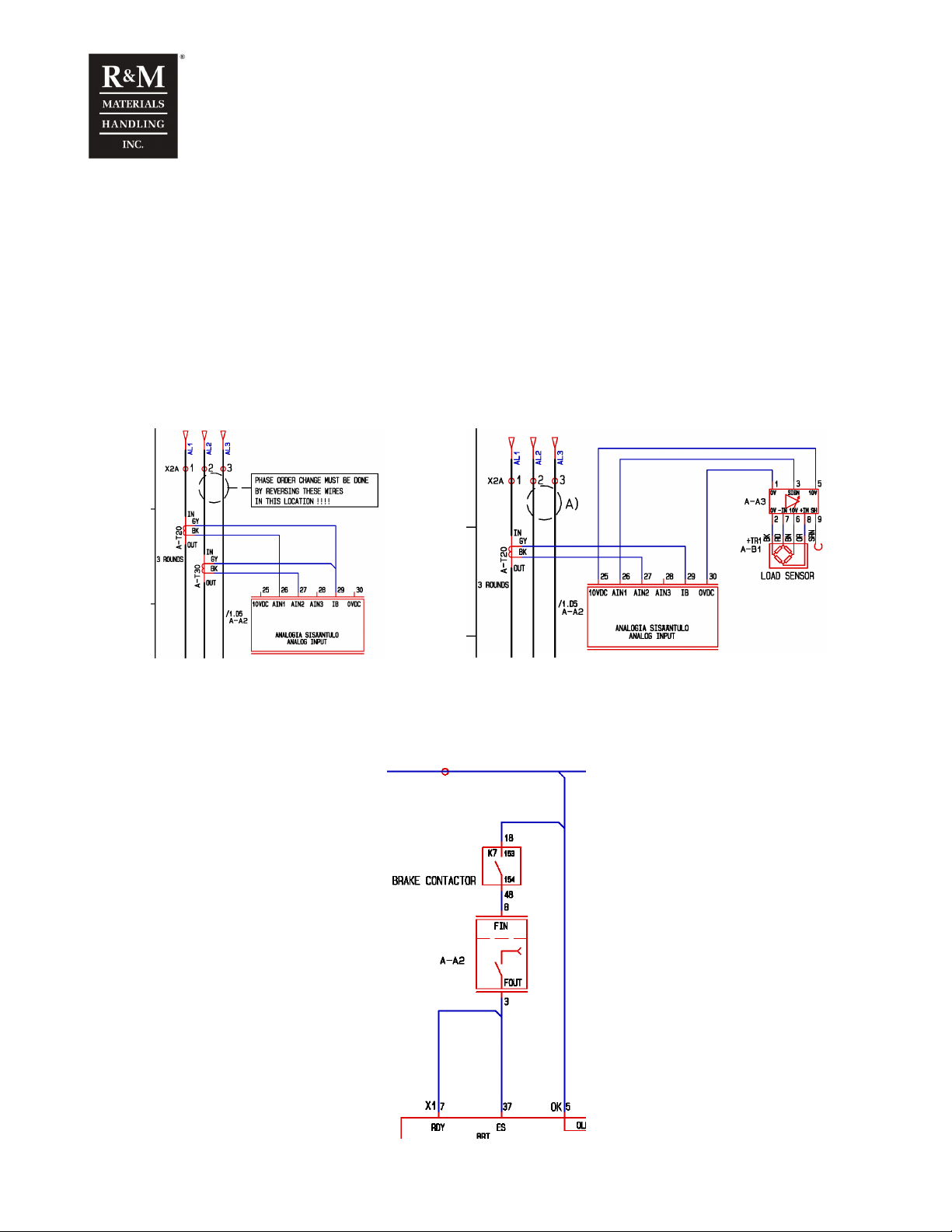

5.5 RUN and fault supervision

The hoisting and lowering request from the control station will come as an input to the hoist-monitoring

unit. Before the hoist can start the requested motion, the hoist-monitoring unit checks if it is safe to

proceed. If no limitations are detected, the hoist-monitoring unit will activate the requested output and

movement will start. The unit monitors a feedback signal. When the feedback signal drops during

running, the motion will stop immediately. During the starting sequence, the feedback signal must be on

within 200ms in contactor control, and within 800ms in inverter control.

2 Speed Hoisting: Unit monitors a feedback signal from a current transformer to analog input 2. The

current transformer measures the input current to the motor in 2 speed hoisting. During the starting

sequence, the feedback signal must be on within 200ms in contactor control. When the feedback signal

drops during running, the motion will stop immediately.

2 Speed, load measurement by motor 2 Speed, load measurement by sensor

When the unit supervises a hoist inverter application a brake contact from AK7 is connected to the FIN

input, terminal 8, to be a brake open feedback signal. If the brake contactor does not energize during

start or de-energizes during hoisting (initiated by a fault or due to brake failure) the unit will disconnect

control voltage from the FOUT signal output, terminal 3, feeding the ES and RDY inputs of the inverter.

During the starting sequence, in inverter control, the feedback signal at FIN must be on within 800ms.

27/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

5.6 Starting and stopping through slow speed (2 speed application only)

Starting the motor directly in high speed will cause a high starting current that heats up the motor quite

rapidly. To prevent the motor from overheating, the hoist-monitoring unit will always start the motion in

slow speed. After a short period of time, the hoist-monitoring unit allows driving in fast speed when

requested.

Stopping the motion directly from high speed will cause excessive brake wear. To protect the brake lining

material, the hoist-monitoring unit will initiate slow speed for a brief moment, before the mechanical brake

is closed.

This function can only be activated in two-speed systems

A. Speed

B. Position of pushbutton (0, 1, 2)

5.6.1 Starting and stopping through slow speed instructions

Starting and stopping through slow speed parameters

Param. Value Description Note

4-7Load param Load calculation menu Accessible with password 4: 8124

4-7-13 0.20s Acceleration time from stop to slow speed 0.00s – 1.00s See description below

4-7-14 0.30s Acceleration time from slow speed to fast speed 0.00s – 1.00s See description below

The parameters 4-7-13 and 4-7-14 have the following functions:

• During acceleration from zero to slow speed and deceleration from slow speed to zero, the unit will

not calculate or supervise the overload protection and current measurement for a period of time

determined by parameter 4-7-13.

• During acceleration from slow speed to fast speed and deceleration from fast speed to slow speed,

the unit will not calculate or supervise the overload protection and current measurement for a period

of time determined by parameter 4-7-14.

• The above function prevents the overload from tripping during the acceleration and deceleration

moment, especially in two-step systems with motor-torque calculation based overload protection,

since the starting currents are momentarily quite high.

• When accelerating from zero directly to fast speed, the motion starts in slow speed for a period

determined by par. 4-7-13.

• When decelerating from fast speed to slow speed, the unit will keep the fast speed active for a period

determined by par. 4-7-14.

• When decelerating from fast speed directly to zero, the unit will activate the slow speed for a fixed

period of 250ms (not adjustable by parameters!).

The above function prevents the use called as “inching”, “jogging” or “tipping” operation.

Once the slow speed output is activated, it remains active for 250ms, even if the input command

drops off within this time. This prevents the directional contactors to drop off during the high starting

currents.

28/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

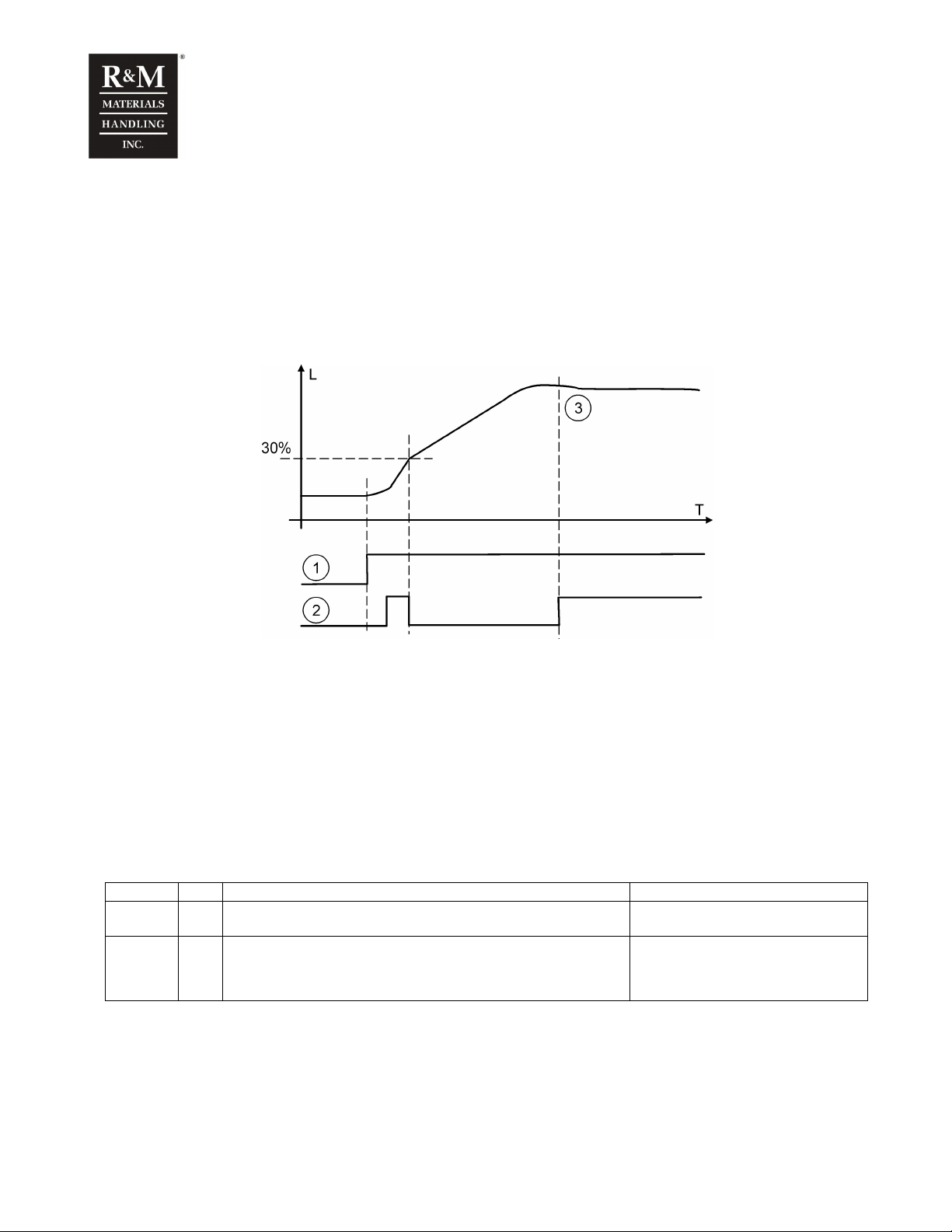

5.7 Sudden load increase supervision

In case the hoist-monitoring unit measures a sudden load increase when driving upwards in high speed,

the unit will control the hoist to low speed. A sudden load increase is considered when the load exceeds

30% of the rated load of the hoist within 200ms. High speed hoisting is allowed again when the load

increase in the last 200ms is less than the preset value, determined by parameter 4-7-2.

The function is completely reset when the measured load is less than 10% of the rated load of the hoist.

The function has no effect when the load is bigger than 30% of the rated load of the hoist. Sudden load

increase may occur e.g. due to jerky movements or starts in high speed.

L. Load

T. Time

1. First speed

2. Second speed

3. Load increase stops

This function can only be activated in two-speed application and hoist has no effect when hoisting

in low speed. Sudden load increase supervision is only activate with loads below 30% of rated load

and is activated only once.

5.7.1 Sudden load increase supervision instructions

Sudden load increase supervision parameters

Param. Value Description Note

4-7

Load param

4-7-2

Load rate%

A small value makes the hoist to drive in slow speed for a longer period, to ensure that the load is

stabilised (not stuck to the unloading platform etc. and no more vibrations caused by the ropes and/or

other mechanics).

A larger value (maximum 10) allows faster acceleration to fast speed.

Load calculation menu Accessible with password 4: 8124

10 Load increase rate for controlling the hoisting in two step control, speed

change to fast speed is allowed when actual load change within 200ms <

parameter 4-7-2.

Setting range: 0…10%, steps of 1%

0% means that the function is not applied

10% is the factory default

29/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

6 Monitoring Items

6.1 General

In order to read the monitoring items and to program the unit, the hoist-monitoring unit is equipped with a

display. The monitoring items of the hoist-monitoring unit consist of variable read-only values. These

monitoring items are of great advantage when efficiently planning maintenance, preventive repairs,

troubleshooting and general overhauls. In addition, the monitoring values will accurately show the usage

of the hoist.

The values are stored in the memory of the hoist-monitoring unit. The stored values remain also during

power-off situations. After power-off situation the previously stored values are taken into account when

new values are calculated.

The condition monitoring items can only be read after a correct password has been given. The

manufacturer will provide a personal password with each delivery that has been acquired with this

option.

1 Monitor 1

Param. Name Value Description

1-1 Cond mon Condition monitoring menu

1-1-1 SWP% “n” %

1-1-2 Starts “n” Total number of starts of the hoist in either up or down direction. *1)

1-1-3 Run time “n” h Total running time of the hoist in hours. *2)

1-1-4 Cycles “n”

1-1-5 Mean load “n.n” t Average of the handled load during the recorded cycles.

1-1-6 Br SWP% “n” %

Read only menu for condition monitoring values and measured values.

Accessible with the customer’s password.

Remaining Safe Working Period of the hoist in percentage, starting from 100%. W hen the SWP

counter descends to 0% (or even negative), a General Overhaul must be carried out.

Total number of hoisting cycles. *1). The number increases by one, when a load value increase

more than 20% of the rated load is lifted.

Remaining Safe Working Period of the brake in percentage. The SWP for the brake is calculated

according to the number of Starts and E-stops (also stops at limit switch).

6.2 Primary monitoring items

The primary monitoring items are according to the ISO and FEM regulation. Depending on the hoist duty

class, the hoist is given an initial Safe Working Period (SWP). The SWP counts down according to a

calculation, which includes the running time with a certain load. Also the total run-time (independent on

the load) and the amount of starts are directly related to the hoist’s duty class and theoretical lifetime.

The primary monitoring items, related to the FEM and ISO regulations are:

- Hoist Safe Working Period counter (SWP%)

- Starts counter

- Run Time counter

Monitoring items can only be read if the hoist-monitoring unit is equipped with a display, either

mounted on the unit or in the pushbutton station.

30/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

Loading...

Loading...