Page 1

-

3

RKC INSTRUMENT INC.

®

Three-phase Thyristor Unit

400 V AC Type

THW

Instruction Manual

IMR01V02-E1

Page 2

Company names and product names used in this manual are the trademarks or registered trademarks of

the respective companies.

All Rights Reserved, Copyright 2005, RKC INSTRUMENT INC.

Page 3

t

Thank you for purchasing this RKC instrument. In order to achieve maximum performance and ensure

proper operation of your new instrument, carefully read all the instructions in this manual. Please

place this manual in a convenient location for easy reference.

SYMBOLS

WARNING

CAUTION

!

An external protection device must be installed if failure of this instrument

could result in damage to the instrument, equipment or injury to personnel.

: This mark indicates precautions that must be taken if there is danger of electric

shock, fire, etc., which could result in loss of life or injury.

: This mark indicates that if these precautions and operating procedures are no

taken, damage to the instrument may result.

: This mark indicates that all precautions should be taken for safe usage.

: This mark indicates important information on installation, handling and operating

procedures.

: This mark indicates supplemental information on installation, handling and

operating procedures.

: This mark indicates where additional information may be located.

WARNING

!

All wiring must be completed before power is turned on to prevent electric

shock, fire or damage to instrument and equipment.

This instrument must be used in accordance with the specifications to

prevent fire or damage to instrument and equipment.

This instrument is not intended for use in locations subject to flammable or

explosive gases.

Do not touch the high-voltage sections such as power supply terminals,

power supply lines and input/output terminals. If touched, electric shock or

injury may result.

Do not enter the hand into the opening of this instrument. If entered, electric

shock or injury may result.

RKC is not responsible if this instrument is repaired, modified or

disassembled by other than factory-approved personnel. Malfunction can

occur and warranty is void under these conditions.

IMR01V02-E1

i-1

Page 4

CAUTION

This is a Class A instrument. In a domestic environment, this instrument may cause radio

interference, in which case the user may be required to take adequate measures.

This instrument is protected from electric shock by reinforced insulation. Provide

reinforced insulation between the wire for the input signal and the wires for instrument

power supply, source of power and loads.

Be sure to provide an appropriate surge control circuit respectively for the following:

- If input/output or signal lines within the building are longer than 30 meters.

- If input/output or signal lines leave the building, regardless the length.

This instrument is manufactured on the assumption that it is mounted within a control

panel. All high-voltage connections such as power supply terminals must be enclosed in

the control panel to avoid electric shock by operating personnel.

All precautions described in this manual should be taken to avoid damage to the

instrument or equipment.

All wiring must be in accordance with local codes and regulations.

Always use this product at the rated power supply voltage, load current and power

frequency.

All wiring must be completed before power is turned on to prevent electric shock,

instrument failure, or incorrect action.

To prevent instrument damage or failure, protect the power line and the input/output lines

with a protection device such as fuse, etc.

If this product is used for phase control, higher harmonic noise may be generated.

Therefore in this case, take such measures as installing an isolation transformer and

separating the power line from the high-voltage line for load drive.

Prevent metal fragments or lead wire scraps from falling inside instrument case to avoid

electric shock, fire or malfunction.

Tighten each terminal screw to the specified torque found in the manual to avoid electric

shock, fire or malfunction.

For proper operation of this instrument, provide adequate ventilation for heat dispensation.

Do not connect wires to unused terminals as this will interfere with proper operation of the

instrument.

Turn off the power supply before cleaning the instrument.

Do not use a volatile solvent such as paint thinner to clean the instrument. Deformation or

discoloration will occur. Use a soft, dry cloth to remove stains from the instrument.

To avoid damage to instrument display, do not rub with an abrasive material or push front

panel with a hard object.

NOTICE

This manual assumes that the reader has a fundamental knowledge of the principles of electricity,

process control, computer technology and communications.

The figures, diagrams and numeric values used in this manual are only for purpose of illustration.

RKC is not responsible for any damage or injury that is caused as a result of using this instrument,

instrument failure or indirect damage.

RKC is not responsible for any damage and/or injury resulting from the use of instruments made by

imitating this instrument.

Periodic maintenance is required for safe and proper operation of this instrument. Some

components have a limited service life, or characteristics that change over time.

Every effort has been made to ensure accuracy of all information contained herein. RKC makes no

warranty expressed or implied, with respect to the accuracy of the information. The information in

this manual is subject to change without prior notice.

No portion of this document may be reprinted, modified, copied, transmitted, digitized, stored,

processed or retrieved through any mechanical, electronic, optical or other means without prior

written approval from RKC.

i-2

IMR01V02-E1

Page 5

CONTENTS

1. OUTLINE .............................................................................. 1

1.1 Checking the Product ......................................................................................2

1.2 Parts Description ............................................................................................. 4

2. MOUNTING ........................................................................... 6

2.1 Mounting Environment.....................................................................................6

2.2 Mounting Cautions...........................................................................................7

2.3 Dimensions......................................................................................................8

2.4 Mounting Procedures ....................................................................................11

Page

3. WIRING ............................................................................... 12

3.1 Circuit Block Diagram ....................................................................................12

3.2 Wiring of Main Circuit ....................................................................................13

3.3 Wiring of the Step-Down Transformer ...........................................................15

3.4 Wiring of Controller (Auto Mode) ................................................................... 16

3.4.1 Wiring of the current input ..................................................................................17

3.4.2 Wiring of the voltage input or voltage pulse input ..............................................17

3.4.3 Wiring of the series connection (For current input) ............................................ 18

3.4.4 Wiring of the parallel connection (For voltage input or voltage pulse input)....... 18

3.5 Wiring for Input/Output Connector .................................................................19

3.5.1 Input/output connector pin number and details ..................................................19

3.5.2 Caution for wiring input/output connector (plug) ................................................20

3.5.3 Wiring of external manual setter ........................................................................20

3.5.4 Wiring of external gradient setter ....................................................................... 20

3.5.5 Wiring of external contact input.......................................................................... 21

3.5.6 Wiring of Auto mode (with gradient setter)......................................................... 21

3.5.7 Wiring of Auto/Manual mode selection............................................................... 22

3.5.8 Wiring of Auto/Manual mode selection (with gradient setter)............................. 22

3.5.9 Wiring of alarm output ........................................................................................ 23

3.5.10 Wiring of contact input...................................................................................... 23

3.5.11 Wiring of ON/OFF control................................................................................. 24

IMR01V02-E1 i-3

Page 6

4. SETTING ............................................................................. 25

4.1 Mode Menu....................................................................................................25

4.2 Monitor Mode 1..............................................................................................27

4.2.1 Display sequence............................................................................................... 27

4.2.2 Description of each monitor item........................................................................ 28

(1) Input signal monitor 1 (InS1)............................................................................ 28

(2) Phase angle ratio monitor (PHAr).................................................................... 30

(3) Current value monitor (CT) .............................................................................. 30

(4) Voltage value monitor (Vo) .............................................................................. 30

(5) Power value monitor (PoW)............................................................................. 30

4.3 Monitor Mode 2..............................................................................................31

4.3.1 Display sequence............................................................................................... 31

4.3.2 Description of each monitor item........................................................................ 32

(1) Power frequency monitor (IFrq) ....................................................................... 32

(2) Input signal monitor 2 (InS2)............................................................................ 32

(3) External gradient set value monitor (EGr) .......................................................32

(4) External manual set value monitor (EMAn) ..................................................... 32

(5) Contact input state monitor (dIST)................................................................... 32

Page

4.4 Setting Mode .................................................................................................33

4.4.1 Display sequence............................................................................................... 33

4.4.2 Changing parameter settings ............................................................................. 34

4.4.3 Description of each parameter ........................................................................... 36

(1) Internal manual set value (IMAn)..................................................................... 36

(2) Internal gradient set value (IGr) ....................................................................... 36

(3) Soft-start time (SoFS) ...................................................................................... 36

(4) Soft-down time (SoFd)..................................................................................... 36

(5) Maximum load current set value for alarm (MAXC)......................................... 37

(6) Heater break alarm 1 set value setting (HbA1)................................................ 37

(7) Thyristor break-down set value setting (THb).................................................. 38

(8) Heater break alarm 2 set value setting (HbA2)................................................ 38

(9) Current limiter value setting (CT)..................................................................... 39

(10) Set data lock setting (LCK) ............................................................................39

4.5 Engineering Mode .........................................................................................40

4.5.1 Transfer to engineering mode ............................................................................ 40

4.5.2 Display sequence............................................................................................... 42

i-4

IMR01V02-E1

Page 7

Page

4.5.3 Description of each parameter ........................................................................... 43

(1) Function block 24 (F24.) .................................................................................. 43

Contact input action (dISL)............................................................................. 43

(2) Function block 30 (F30.) .................................................................................. 43

Output mode for phase control (oS)............................................................... 43

Alarm 1 output logic (LGA1), Alarm 2 output logic (LGA2)............................. 44

(3) Function block 45 (F45.) .................................................................................. 44

Number of heater break alarm 1 delay times (HbC1) .................................... 44

Heater break alarm 1 type (AS1) ................................................................... 45

Alarm interlock (ILS)....................................................................................... 45

(4) Function block 46 (F46.) .................................................................................. 45

Number of heater break alarm 2 delay times (HbC2) .................................... 45

Heater break alarm 2 type (AS2) ................................................................... 45

(5) Function block 51 (F51.) .................................................................................. 46

Control method (ConT) .................................................................................. 46

RUN/STOP action (rSA)................................................................................. 46

Input signal (InSS).......................................................................................... 46

(6) Function block 52 (F52.) .................................................................................. 47

Output limiter (high) (oLH).............................................................................. 47

Output limiter (low) (oLL)................................................................................ 47

Output limiter (high) at operation start (SoLH) ............................................... 47

Output limiter (high) time at operation start (SoLT)........................................ 47

Base-up set value (bAUP).............................................................................. 47

(7) Function block 60 (F60.) .................................................................................. 48

(8) Function block 91 (F91.) .................................................................................. 48

ROM version .................................................................................................. 48

Integrated operating time [upper 2 digits] (WTH) ........................................... 48

Integrated operating time [lower 4 digits] (WTL) ............................................ 48

5. FUNCTIONS........................................................................ 49

5.1 Control Method ..............................................................................................49

5.2 Ramp Function (Soft-Start/Soft-Down Function) ...........................................49

5.3 Gradient Setting Function.............................................................................. 50

5.4 Output Limiter (High and Low).......................................................................50

5.5 Output Limiter (High) at Operation Start ........................................................51

5.6 Base-Up Setting Function.............................................................................. 52

5.7 Output Mode for Phase Control .....................................................................53

IMR01V02-E1

i-5

Page 8

Page

5.8 Current Limiter Function ................................................................................56

5.9 Automatic Power Frequency Detection

and Power Frequency Monitoring Function ................................................... 56

5.10 Alarm Interlock Function.............................................................................. 57

5.11 Heater Break Alarm 1 (HBA1), Heater Break Alarm 2 (HBA2)

and Thyristor Break-Down Alarm.................................................................57

5.11.1 Number of alarm delay times ........................................................................... 57

5.11.2 Heater break alarm for phase control (Type 1) ................................................ 58

5.11.3 Heater break alarm for phase control (Type 2) ................................................ 64

5.11.4 Heater break alarm for zero-cross control........................................................ 65

5.12 FAIL Alarm...................................................................................................68

5.13 Negative Phase Sequence Alarm................................................................68

5.14 Over Current Alarm (optional)......................................................................68

5.15 Fuse Break Alarm (optional) ........................................................................68

5.16 Set Data Lock Function ...............................................................................68

5.17 External Contact Input (DI) Function ...........................................................69

6. MAINTENANCE .................................................................. 70

6.1 Daily Inspection .............................................................................................70

6.2 Troubleshooting.............................................................................................71

6.3 Replacement of the Fast-Blow Fuse.............................................................. 72

6.3.1 Replacement of the fast-blow fuse (without microswitch) .................................. 72

6.3.2 Replacement of the fast-blow fuse (with microswitch) ....................................... 75

7. SPECIFICATIONS .............................................................. 77

APPENDIX .............................................................................. 81

How to fix the terminal cover (optional).......................................................... 81

Description of terms ....................................................................................... 82

Character symbols ......................................................................................... 82

i-6

IMR01V02-E1

Page 9

A

A

A

1. OUTLINE

This instrument is a three-phase thyristor unit for power supply voltage 400 V AC.

It is possible to adjust power supplied to heaters, etc. by setting the signal from the controller, setter

(potentiometer) or front keys.

Gradient setter

Manual setter

Switch, etc.

Alarmer, etc

External gradient setting

External manual mode

External contact input:

uto mode/Manual mode,

RUN/STOP,

larm interlock release

larm output:

Heater break, Thyristor break-down,

etc.

Step-down

transformer

(Heater, etc)

Three-phase power supply

THW-3

Load

Front keys

Internal manual mode,

Internal gradient setting,

Alarm setting, etc.

Controller

Auto mode

The rated currents of six types are available.

Power supply voltage

Rated current

20 A 30 A 45 A 60 A 80 A 100 A

400 V AC

The input signal and set value can be checked on the display unit.

The display unit can check the input signal, phase angle, power frequency, current and set value of

each parameter, etc.

The front keys can set the gradient setting and manual setting.

In addition to the setting by an ordinary setter (potentiometer), it is possible to set internal gradient

setting and internal manual setting values by the front keys while checking these numeric values

shown on the display unit.

Automatic power frequency detection

The instrument automatically detects a power supply frequency (50/60 Hz) when the power is turned

on.

The control of three types can be selected.

It is possible to select by the front keys and then use any one of phase control, zero-cross control

(continuous) and zero-cross control (input synchronous type).

IMR01V02-E1 1

Page 10

1. OUTLINE

*

1.1 Checking the Product

Before using this product, check each of the following:

• Model code

• Check that there are no scratch or breakage in external appearance (case, heat radiation fin, front

panel, or terminal, etc).

• Check that all of the items delivered are complete. (See below)

THW - 3 4 PZ - ∗

(1) (2) (3) (4) (5) (6) (7) (8)

-

*

The code shown in (8) is printed on the nameplate when the relevant accessory is specified as an option.

(1) Power supply

4: Three-phase 400 to 440 V AC

(2) Control method

PZ: Phase control/Zero-cross control (configurable)

(3) Rated current

020: 20 A 060: 60 A

030: 30 A 080: 80 A

045: 45 A 100: 100 A

(4) Input signal

4: Voltage input 0 to 5 V DC 7: Current input 0 to 20 mA DC

5: Voltage input 0 to 10 V DC 8: Current input 4 to 20 mA DC

6: Voltage input 1 to 5 V DC

(5) Output mode

N: Standard (Proportional phase angle to input, Proportional voltage to input, Proportional square

voltage (electric power) to input)

6: Standard and Constant voltage control (No heater break alarm)

V: Standard and Constant voltage control (With heater break alarm and current limiter function *)

E: Standard and Constant current control (With heater break alarm and current limiter function *)

W: Standard and Constant power control (With heater break alarm and current limiter function *)

* When the Heater break alarm and Current limiter are provided, the Over current and Thyristor break-down

alarm are available.

2

IMR01V02-E1

Page 11

(6) Fuse

N: No fast-blow fuse is provided

F: Built-in fast-blow fuse

S: Built-in fast-blow fuse (With microswitch)

(7) Option function

N: No function

(8) Accessories

1: Setter (potentiometer, knob and scale plate) [1 set] and Input/Output connector (plug)

2: Setter (potentiometer, knob and scale plate) [2 set] and Input/Output connector (plug)

9: Input/Output connector (plug)

A: Terminal cover

Accessories (Order Separately)

1. OUTLINE

THVP-S01: Setter (potentiometer, knob and scale plate)

THWP-C01: Input/Output connector (plug)

THWP-T01: Step-down transformer (for instrument power supply)

THWP-F22: Fast-blow fuse for 20 A

THWP-F32: Fast-blow fuse for 30 A

THWP-F42: Fast-blow fuse for 45 A and 60 A

THWP-F82: Fast-blow fuse for 80 A

THWP-FA2: Fast-blow fuse for 100 A

THWP-F23: Fast-blow fuse for 20 A (With microswitch)

THWP-F33: Fast-blow fuse for 30 A (With microswitch)

THWP-F43: Fast-blow fuse for 45 A and 60 A (With microswitch)

THWP-F83: Fast-blow fuse for 80 A (With microswitch)

THWP-FA3: Fast-blow fuse for 100 A (With microswitch)

THWP-A02: Terminal cover for 20 A, 30 A, 45 A and 60 A

THWP-A03: Terminal cover for 80 A and 100 A

The accessories attached to product

Instruction Manual (IMR01V02-E1)................................................................... 1

Short bar (The short bar is connected to the “input terminals.”)......................... 1

Step-down transformer (for instrument power supply: THWP-T01).................. 1

If any of the products are missing, damaged, or if your manual is incomplete, please contact

RKC sales office or the agent.

IMR01V02-E1

3

Page 12

1. OUTLINE

1.2 Parts Description

(1) Main circuit terminals (power supply side)

(13) Power

terminals

(2) Power lamp

(3) Display

(4) SET key

(5) Shift key

(6) DOWN key

(7) UP key

(12) Input/output

connector

(8) Indication

lamps

(9) Input terminals

(10) Grounding

terminal

(11) Main circuit terminals (load side)

The name is the same as for each type (20 to 100 A).

No. Name Description No. Name Description

(1) Main circuit terminals

(power supply side)

(1/L1, 3/L2, 5/L3)

(2) Power lamp (green) Lit when the power is turned

(3) Display • Display (upper):

• Display (lower):

(4)

(5)

• Shift digits when settings

(6)

(7)

(SET key)

(Shift key)

(DOWN key)

(UP key)

Used to connect three-phase

power supply.

on.

Display the parameters

symbols and numeric value.

Display the input signal value

and each set value.

Used for parameter calling up

and set value registration.

• Used to select the mode. (12) Input/Output

are changed.

• Used to select the monitor

item and function block

(F).

• Decrease numerals.

• Used to select the monitor

item and function block

(F).

• Increase numerals.

(8) Indication lamps

(red)

(9) Input terminals Used to connect input signal

(10) Grounding terminal Used to connect the

(11) Main circuit terminals

(load side)

(2/T1, 4/T2, 6/T3)

connector (socket)

[Optional] contact or controller.

(13) Power terminals

(7/l1, 8/l2, 9/l3)

Lights when any error occurs.

For details, see the Description

of Indication lamp (P. 5).

wires (controller, etc.).

grounding terminal.

Used to connect the load.

Used to connect with a setter

(potentiometer), external

In addition, used to alarm

output.

Used to connect the power

supply of THW-3.

4

IMR01V02-E1

Page 13

Description of indication lamp

If an error occurs, the indication lamp lights.

INDICATION LAMP

FAIL

FREQ

PHASE

HBA1

THY.B

HBA2

OCR

FUSE

1. OUTLINE

THW-3

The name is the same as for each type (20 to 100 A).

Symbol Description

FAIL

(Board error)

FREQ

(Power frequency error)

PHASE

(negative phase sequence)

HBA1

(Heater break alarm 1)

THY.B

(Thyristor break-down alarm)

HBA2

(Heater break alarm 2)

OCR

(Over current)

FUSE

(Fuse break)

This lamp lights if a board error of this instrument is detected by

the self-diagnosis function.

This lamp lights if power frequency is out of the allowable range

(detecting range) when power is turned on or during operation.

This lamp lights if negative phase sequence or the open phase

is detected.

Lights when Heater break alarm 1 output is turned on.

HBA1 is not available when heater break alarm is not provided.

Lights when thyristor break-down alarm output is turned on.

Thyristor break-down alarm is not available when heater break

alarm is not provided.

Lights when Heater break alarm 2 output is turned on.

HBA2 is not available when heater break alarm is not provided.

This lamp lights if the current of more than 1.2 times the rating

of this instrument flows.

when heater break alarm is not provided.

This lamp lights if the fast-blow fuse in this instrument blew.

Fuse break alarm is not available when the fast-blow fuse (with

microswitch) is not provided.

The over current alarm is not available

Action taken when

an error occurs

Thyristor output OFF

Thyristor output OFF

The output can be turned

ON when the error is

canceled.

Thyristor output OFF

Control is continued.

Control is continued.

When shorted:

Thyristor output continues

to be turned ON.

When broken:

Thyristor output OFF

Control is continued.

Thyristor output OFF

Thyristor output OFF

IMR01V02-E1

5

Page 14

2. MOUNTING

In order to prevent electric shock or instrument failure, always mount or remove

this instrument after power supplied to the entire system is turned off.

As the temperature of this instrument becomes high, mount the instrument on

a non-inflammable material (metal plate, etc.).

As this instrument generates a large amount of heat, it is cooled by circulating

air by convection. Therefore, if mounted in any direction other than specified,

accident or failure may result.

When carrying this instrument, hold the heat radiation fin. In addition, always

carry it with the heat radiation fin cooled.

WARNING

!

2.1 Mounting Environment

Avoid the following conditions when selecting the mounting location:

• Ambient temperature of less than 0 °C or more than 40 °C.

(The rated current drops when the ambient temperature exceeds 40 °C.)

Load current (%)

100

80

60

40

20

0

10 20 30 40 50 55

Temperature characteristic of load current

• Ambient humidity of less than 5 % or more than 95 % RH.

(Absolute humidity: MAX. W. C 29 g/m

3

dry air at 101.3 kPa)

• Rapid changes in ambient temperature which may cause condensation.

• Corrosive or inflammable gases.

Temperature (°C)

60

• Such a place where there are inflammable materials near this instrument.

• Direct vibration or shock to the mainframe.

• Water, oil, chemicals, vapor or steam splashes.

• Excessive dust, salt or iron particles.

• Excessive induction noise, static electricity, magnetic fields or noise.

• Exposure to direct sunlight.

• Excessive heat accumulation.

6 IMR01V02-E1

Page 15

2.2 Mounting Cautions

Take the following points into consideration when mounting this instrument.

Mount this instrument in the direction shown below.

Vertical

direction

Upper

2. MOUNTING

THW-3

Provide adequate heat radiation space so that heat does not build up.

At least 20 mm is necessary on the left and right and at least 100 mm on the top and bottom.

If the panel inside temperature rises due to self-generation of heat, install a forced circulation fan

so that the panel inside is fully ventilated with the open air.

Unit: mm

100

or more

THW-3 THW-3

20 or more20 or more

100 or more

100

or more

20 or more

THW-3 THW-3

100 or more 100 or more

IMR01V02-E1 7

Page 16

2. MOUNTING

r

r

2.3 Dimensions

Dimensions

A

2-φ6

8 7

2-φ12

B C

D *

* Dimensions when the connecto

plug (optional) is connected.

When connecting the connecto

plug, install the thyristor by taking

6

R3

enough space for its wiring into

account.

Unit: mm

Dimensions

Types

A B C D

20 A, 30 A, 45 A and 60 A types

80 A and 100 A types

8

314.0 200.0 203.0 212.0

347.0 230.0 235.0 244.0

IMR01V02-E1

Page 17

Mounting dimensions

20 A, 30 A, 45 A and 60 A types 80 A and 100 A types

2. MOUNTING

単位: mm

4-M5

±0.2

302.0

±0.2

183.0

Setter (Potentiometer, Knob and Scale plate)

10

φ6

φ

2.8

18.7

φ

16.1

Knob

2

M9 × 0.75

φ24

13.5

10 10

Potentiometer

(Resistance 5 kΩ, variation characteristic: B)

±0.2

335.0

4-M5

213.0

40

30

20

10

0

Scale plate

±0.2

50

48

60

100

70

80

90

THW-3

Unit: mm

48

IMR01V02-E1

10

0

Set the potentiometer full counterclockwise and combine with

a scale plate.

When setting the knob on the scale plate, align the arrow on

the knob with 0 on the scale plate.

9

Page 18

2. MOUNTING

φ

Fast-blow fuse (For 20 A, 30 A, 45 A and 60 A)

18.5

Code:

THWP-F22 (20 A)

THWP-F32 (30 A)

THWP-F42 (45 A/60 A)

62.0

47

17.5

12.0

φ

25.0

Unit: mm

34.5

27.0

76.0

Without microswitch With microswitch

Fast-blow fuse (For 80 A and 100 A)

34.0

Code:

THWP-F82 (80 A)

THWP-FA2 (100 A)

Without microswitch With microswitch

70.0

40.0

95.0

30.0

25.0

φ

Step-down transformer (THWP-T01)

117

22

Code: THWP-F23 (20 A)

THWP-F33 (30 A)

THWP-F43 (45 A/60 A)

47.0

33.5

Code:

THWP-F83 (80 A)

THWP-FA3 (100 A)

Unit: mm

39.5

Unit: mm

60

L1 L2 L3 I1 I2 I3

40

5-4

73

50

31

46

10

IMR01V02-E1

Page 19

2. MOUNTING

2.4 Mounting Procedures

1. Prepare the holes as specified in 2.3 Dimensions.

2. Place the instrument in mounting position.

3. Insert the mounting screws into the holes, and then tighten them with a screwdriver. Customer

must provide the set of screws.

Screw size Recommended tighten torque

M5 3.6 N⋅m (36 kgf⋅cm)

Mounting hole Mounting hole

IMR01V02-E1

Mounting hole Mounting hole

The Figure shows the type of 20 A to 60 A. However, the mounting procedure is the same as

for the type of 80 A/100 A.

11

Page 20

A

A

r

3. WIRING

To prevent electric shock or instrument failure, do not turn on the power until all

the wiring is completed.

WARNING

!

3.1 Circuit Block Diagram

Step-down transforme

External gradient setting

3

2

1

External

manual mode

RUN/STOP transfer

larm interlock release

3

2

1

uto mode/Manual

mode transfer

L1 L2 L3 I1 I2 I3

1

2

3

4

5

6

7

Power terminals

Connecter

CT/PT

circuit

RST

1/L1 3/L2 5/L3

7/I18/I29/I3

Snubber

circuit

Fast-blow

fuse

Snubber

circuit

Three-phase

400 to 440 V AC

(50/60 Hz)

Fast-blow

fuse

Snubber

circuit

Fast-blow

fuse

NFB

10

11

12

8

9

Input

terminals

2/T1 4/T2 6/T3

UVW

Load

4 to 20 mA DC

(Auto mode)

1 2 3

Controller

Grounding

terminal

−+

24 V DC

NC

Alarm 1

Relay

Alarm 2

+

−

Relay

The fast blow-fuse, CT and PT are optional.

12 IMR01V02-E1

Page 21

3.2 Wiring of Main Circuit

Conduct wiring by referring to the wiring diagram and the tightening torque table.

CAUTION

Always conduct wiring so that the R, S and T phases of 3-phase power coincide

with the main circuit terminals (power side), 1/L1, 3/L2 and 5/L3 on this instrument,

respectively. Otherwise the instrument may not function properly or the load may

be damaged.

R → Connect to the 1/L1 terminal. T → Connect to the 5/L3 terminal.

S → Connect to the 3/L2 terminal.

Always coincide the main circuit terminals (load side), 2/T1, 4/T2 and 6/T3 on this

instrument with the U, V and W phases of the load, respectively. Otherwise the

instrument may not function properly or the load may be damaged.

2/T1 terminal → Connect to the U. 6/T3 terminal → Connect to the W.

4/T2 terminal → Connect to the V.

When controlling the primary side of the transformer, do not open its secondary side of

circuit during operation. In addition, do not operate the instrument below the minimum

load current.

When controlling the primary side of the transformer, set magnetic field density of the

transformer to about 0.8T (8,000-gauss). If the transformer is saturated, overcurrent

flows through it to cause the thyristor to be damaged.

Imbalance between each phase of the load may result in a large error of the input/output

characteristic.

No power switch is provided in this instrument. Therefore install the switches near the

instrument, if necessary.

To avoid noise induction, keep input signal wire of controller away from instrument

power line, load lines and power lines of other electric equipment. If wiring near

high-voltage power is unavoidable, use shielded wires.

For safety, always ground the grounding terminal.

Tighten the hexagon headed bolts on the main circuit terminals using a torque wrench.

Always tighten each of them by contacting the diagonal surfaces of the wrench with

those of each hexagon head.

Recommended tool: Manufactured by TOHNICHI MFG. CO., LTD.

Model code of adjustable type torque wrench with

ratchet head

20 A/30 A QL3N M4

45 A/60 A QL6N M6

80 A/100 A QL12N M8

Use wires satisfying the rated current capacity.

Firmly tighten each terminal hexagon headed bolt with the tightening torque specified

below. Otherwise, electric shock, fire or heat generation may result.

Terminal hexagon bolt size and tightening torque list

Hexagon bolt size M4 M6 M8

Recommended tightening torque 1.6 N⋅m (16.31 kgf⋅cm) 3.8 N⋅m (38.74 kgf⋅cm) 9.0 N⋅m (91.77 kgf⋅cm)

Main circuit terminal (1/L1 to 5/L3 and 2/T1 to 6/T3)

20 A/30 A 45 A/60 A 80 A/100 A

Socket size

3. WIRING

Continued on the next page.

IMR01V02-E1 13

Page 22

3. WIRING

φ

Continued from the previous page.

When using a solderless terminal lug, use ring type.

Ring type solderless terminal size

Ring type solderless terminal

D

Main circuit terminal (1/L1 to 5/L3 and 2/T1 to 6/T3)

20 A/30 A 45 A/60 A 80 A/100 A

φ

dimension 4.3 mm or more 6.4 mm or more 8.4 mm or more

D dimension 9.5 mm or less 12.0 mm or less 22.0 mm or less

Wiring of the main circuit

Table of calorific values

(400 to 440V AC)

1/L1 3/L2 5/L3

2/T1 4/T2 6/T3

Three-phase

400 to 440 V AC

(50/60 Hz)

R S T

U V W

NFB

Rated current Calorific values

20 A 82 W

30 A 118 W

45 A 172 W

60 A 226 W

80 A 298 W

100 A 370 W

Load

14

IMR01V02-E1

Page 23

φ

3.3 Wiring of the Step-Down Transformer

CAUTION

Use the step-down transformer only for stepping down the voltage of power supplied to

this instrument.

Always coincide the R, S and T phases of 3-phase power with the step-down

transformer terminals (primary side: L1, L2 and L3, and secondary side: I1, I2 and

I3) and the power terminals, 7/I1, 8/I2 and 9/I3 of this instrument, respectively.

Otherwise the instrument may not function properly or the load may be damaged.

R Connect to the L1 terminal l1 terminal Connect to the 7/l1 terminal

S Connect to the L2 terminal I2 terminal Connect to the 8/l2 terminal

T Connect to the L3 terminal I3 terminal Connect to the 9/l3 terminal

3. WIRING

Use wires satisfying the rated current capacity.

When using a solderless terminal lug, use ring type.

Ring type solderless terminal size

Ring type solderless terminal

D

Power terminal (L1, L2, L3 and l1, l2, l3)

φ

dimension 3.2 mm or more

D dimension 6.5 mm or less

Recommended tightening torque 0.6 to 0.9 N⋅m (6.1 to 9.1 kgf⋅cm)

Wiring of the step-town transformer

Primary side

L1 L2 L3 l1 l2 l3

Step-down transformer

Secondary side

Three-phase

400 to 440 V AC (50/60 Hz)

RST

1/L1 3/L2 5/L3

NFB

Power terminals

7/l18/l29/l3

IMR01V02-E1

15

Page 24

3. WIRING

φ

A

3.4 Wiring of Controller (Auto Mode)

When using a solderless terminal lug, use ring type.

Ring type solderless terminal size

φ

D dimension

Recommended tightening torque

Ring type

D

solderless terminal

Input terminal (1, 2 and 3)

dimension

3.2 mm or more

5.5 mm or less

0.4 N⋅m (4 kgf⋅cm)

On input signal change

The input signal is set as specified when ordering at the time of being unpacked. When changing the

input signal, conduct the following two settings.

• Set the type of input signal by Input signal by Input signal (InSS) in Engineering mode. (See P. 46)

• Change the position of the short bar to match the input type. (See the next page.)

In addition, the input signal is divided into two pieces of hardware. The input signal in the same

hardware is selectable but the input signal in the other hardware cannot be selected.

Current input 0 to 20 mA DC

Voltage input 0 to 5 V DC

Current input 4 to 20 mA DC

Voltage input 1 to 5 V DC

Voltage pulse input 0/12 V DC

Hardware 1 Hardware 2

Cannot be selected to the input

signal in the other hardware.

Voltage input 0 to10 V DC

Voltage pulse input 0/12 V DC

Voltage pulse input 0/24 V DC

n input type change may

only be made within the

hardware groups.

16

IMR01V02-E1

Page 25

+

−

+

−

−

3.4.1 Wiring of the current input

For current input (0 to 20 mA DC, 4 to 20 mA DC), short terminal No.1 with terminal No.2.

Current input

0 to 20 mA DC, 4 to 20 mA DC

+ −

12 3

THW-3 input terminal

Input impedance: 100 Ω

Short

3. WIRING

Short bar

Controller: 0 to 20 mA DC,

4 to 20 mA DC output

3.4.2 Wiring of the voltage input or voltage pulse input

For voltage input (0 to 5 V DC, 1 to 5 V DC or 0 to 10 V DC) or voltage pulse input (0/12 V DC, 0/24

V DC), short terminal No.2 with terminal No.3.

Voltage input: 0 to 5 V DC, 1 to 5 V DC, 0 to 10 V DC

Voltage pulse input: 0/12 V DC, 0/24 V DC

+

1 2 3

THW-3 input terminal

Input impedance:

Hardware 1 (0 to 5 V DC, 1 to 5 V DC and 0/12 V DC): 30 kΩ

Hardware 2 (0 to 10 V DC, 0/12 V DC and 0/24 V DC): 68 kΩ

Short

Short bar

Controller: 0 to 5 V DC, 1 to 5 V DC,

0 to 10 V DC, 0/12 V DC,

0/24 V DC output

IMR01V02-E1

17

Page 26

3. WIRING

f

3.4.3 Wiring of the series connection (For current input)

Current input: 0 to 20 mA DC, 4 to 20 mA DC

+ −

1 2 3

THW-3 input terminal

Input impedance: 100 Ω

THW-3 THW-3 THW-3

The number of thyristor that can be connected

depends on the resistance of temperature controller

being used. For resistance of controller, see controller

instruction manual.

3.4.4 Wiring of the parallel connection (For voltage input or voltage pulse input)

Voltage input: 0 to 5 V DC, 1 to 5 V DC, 0 to 10 V DC Voltage pulse input: 0/12 V DC, 0/24 V DC

+ −

1 2 3

THW-3 input terminal

Input impedance:

Hardware 1 (0 to 5 V DC, 1 to 5 V DC, 0/12 V DC): 30 kΩ

Hardware 2 (0 to 10 V DC, 0/12 V DC, 0/24 V DC): 68 kΩ

THW-3 THW-3 THW-3

The number of thyristor that can be connected

depends on the resistance of temperature

controller being used. For resistance o

controller, see controller instruction manual.

Controller

0 to 20 mA DC,

4 to 20 mA DC output

−

+

18

Controller:

0 to 5 V DC,

1 to 5 V DC,

0 to 10 V DC,

0/12 V DC or

0/24 V DC outputs

−

+

IMR01V02-E1

Page 27

3.5 Wiring for Input/Output Connector

The input/output connector is used for the following wiring.

• External manual setting

• External gradient setting

• External contact input (Auto/Manual mode transfer, RUN/STOP transfer, alarm interlock release)

• Alarm output

3.5.1 Input/Output connector pin number and details

Pin No. Details

+5 V output

0 V

External gradient setting input

(0 to 5 V input by the gradient setter)

External manual setting input

(0 to 5 V input by the manual setter)

External contact input (DI)

Auto/Manual mode transfer: Contact closed: Manual mode

Contact open: Auto mode

External contact input (DI)

RUN/STOP transfer: Contact closed: RUN

Contact open: STOP

When using RUN/STOP transfer, it is necessary to set

RUN/STOP action (rSA) to “1: Used.”

(See P. 46)

External contact input (DI)

Alarm interlock release: Closing the contact releases the

alarm interlock

Unused

24 V DC (+)

Alarm 1: Open collector output

In order to output an alarm, it is necessary to select the type

of alarm by Alarm 1 output logic (LGA1).

(See P. 44)

Alarm 2: Open collector output

In order to output an alarm, it is necessary to select the type

of alarm by Alarm 2 output logic (LGA2).

(See P. 44)

0 V

1

2

3

4

5

6

7

8

9

10

11

12

Pin number

1

2

3

4

5

6

7

8

9

10

11

12

3. WIRING

IMR01V02-E1

19

Page 28

3. WIRING

3.5.2 Caution for wiring input/output connector (plug)

• Use stranded wire of size 0.14 to 0.5 mm2 for the leadwires.

• Strip off the sheath from 8 mm from the leadwire end.

8 mm

Size 0.14 to 0.5 mm

(AWG28-20)

Input/output connector (plug)

2

3.5.3 Wiring of external manual setter

3

External

manual setter

2

Short

1

10

11

12

3.5.4 Wiring of external gradient setter

THW-3

1

2

3

4

5

6

Input/Output connector

7

8

9

20

External

gradient setter

THW-3

3

2

1

1

2

3

4

5

6

Input/Output connector

7

8

9

10

11

12

IMR01V02-E1

Page 29

A

A

A

A

A

+

−

3.5.5 Wiring of external contact input

3. WIRING

uto/Manual mode

transfer

RUN/STOP transfer

larm interlock

release

uto/Manual mode transfer

Contact closed: Manual mode

Contact open: Auto mode

RUN/STOP transfer

Contact closed: RUN

Contact open: STOP

larm interlock release

Contact closed: Alarm interlock release

1

2

3

4

5

6

Input/Output connector

7

8

9

10

11

12

THW-3

3.5.6 Wiring of Auto mode (with gradient setter)

External

gradient setter

3

2

1

1

2

3

4

5

6

7

8

9

10

11

12

For controller wiring,

see page 16.

THW-3

Input/Output connector

Controller

Input

terminal

uto mode

IMR01V02-E1

21

Page 30

3. WIRING

A

A

+

−

A

+

−

A

3.5.7 Wiring of Auto/Manual mode selection

External

manual setter

uto/Manual mode transfer

Contact closed: Manual mode

Contact open: Auto mode

3

2

1

1

2

3

4

5

6

Input/Output connector

7

8

9

10

11

12

For controller wiring,

see page 16.

THW-3

Input

terminal

Controller

uto mode

3.5.8 Wiring of Auto/Manual mode selection (with gradient setter)

External

gradient setter

External

manual setter

uto/Manual mode transfer

Contact closed: Manual mode

Contact open: Auto mode

3

2

1

3

2

1

THW-3

1

2

3

4

5

6

Input/Output connector

7

8

9

10

11

12

Input

terminal

For controller wiring,

see page 16.

Controller

uto mode

22

IMR01V02-E1

Page 31

3.5.9 Wiring of alarm output

A diode should be used and connected as show in the diagram, when using a relay.

+

24 V DC

−

Alarm 1

3.5.10 Wiring of contact input

Alarm 2

THW-3

1

2

3

4

5

6

Input/Output connector

7

8

9

10

11

12

3. WIRING

Controller

ON/OFF signal

(Relay contact output)

Controller

C: Common

NO: Normally open

The thyristor output is turned

on/off by the ON/OFF signal

from the controller.

C

NO

+5 V output

Short

1

2

3

4

5

6

Input/Output connector

7

8

9

10

11

12

THW-3

IMR01V02-E1

23

Page 32

3. WIRING

3.5.11 Wiring of ON/OFF control

ON/OFF control

ON/OFF signal

(Relay contact output)

Controller

NO: Normally open

NC: Normally closed

C: Common

NO

NC

C

Low limit setter

3

2

1

High limit setter

3

2

1

Short

THW-3

1

2

3

4

5

6

Input/Output connector

7

8

9

10

11

12

24

IMR01V02-E1

Page 33

A

4. SETTING

This chapter describes various monitor screens, parameters or setting method. Set any mode necessary

for customer’s operation. When setting the mode for the first time, set it in the order of Engineering

mode and Setting mode.

4.1 Mode Menu

THW-3 has four different modes, and all settable parameters belongs to one of them. The following

chart show how to access different mode.

Monitor mode 1: The Input signal, Phase angle ratio, Current and other values can be

monitored.

Monitor mode 2: The Power frequency, External gradient, External manual and other values

can be monitored.

Setting mode: The parameters (Soft-start/Soft-down, Internal gradient, Set data lock and

others) can be set.

Engineering mode: This is the mode to set parameters which are almost unrequired to be

changed hereafter as far as normally used, it set once so as to meet the

operating condition.

Power ON

The rated current and

specifications are displayed.

(Display for

approx. 2 seconds)

Monitor mode 1

(See P. 27)

Press the SET key

for 2 seconds.

Display (upper): The rated current is displayed.

Display (lower): Specification is displayed. (See next page)

Press the shift key.

Monitor mode 2

(See P. 31)

Press the SET key

for 2 seconds.

Setting mode

(See P. 33)

This instrument returns to

the monitor mode 1 if no

key operation is performed

for more than 1 minute.

Engineering

(See P. 40)

fter the set data lock is released, press the

shift key while pressing the SET key.

If the engineering mode is

locked, the engineering mode

mode

is not displayed. For details on

releasing the lock, see on the

page 40.

IMR01V02-E1 25

Page 34

4. SETTING

The rated current and specification display

THW-3 immediately confirms the rated current and specification following power ON.

Power ON

(1) The rated current display

Parameter Rated current

Display changes

automatically

Input signal monitor 1

(1) Rated

current

(2) Specification

20 A

30 A

45 A

60 A

80 A

100 A

(2) Specification display

0 fixed

Fuse

0: Without fast-blow fuse

1: Built-in fast-blow fuse

(without microswitch)

2: Built-in fast-blow fuse

(with microswitch)

Output mode

0: Constant voltage and constant power

controls are not provided.

1: Constant voltage control is provided.

2: Constant power control is provided.

Heater break alarm

0: Heater break alarm is not provided.

1: Heater break alarm is provided.

26

IMR01V02-E1

Page 35

4. SETTING

4.2 Monitor Mode 1

When the power is turned on, THW-3 goes to this mode after self-diagnostics. The following items are

displayed in the monitor mode 1.

• Input signal value • Current value • Power value

• Phase angle ratio value • Voltage value

4.2.1 Display sequence

To go to the next monitor screen, press UP or DOWN key. To go back to the first monitor screen,

keep pressing the keys until it is displayed again.

Press the UP key.

Input signal monitor 1

(InS1)

Phase angle ratio monitor

Current value monitor *

Voltage value monitor *

Press the DOWN key.Press the UP key.

(PHAr)

Press the DOWN key.Press the UP key.

(CT)

Press the DOWN key.Press the UP key.

(Vo)

Press the DOWN key.Press the UP key.

Power value monitor *

(PoW)

Press the DOWN key.

* These parameters may not be displayed depending on the specification.

IMR01V02-E1

27

Page 36

4. SETTING

4.2.2 Description of each monitor item

(1) Input signal monitor 1 ( )

Select and then display one input signal value from among three input signal values. The type of input

signal to be displayed can be selected by the external contact input.

Input signal type: Auto set value (Value of Auto mode)

External manual set value

Display range: 0 to 100 %

The internal manual set value displayed on Input signal monitor 1 is that whose digits

following the decimal point are truncated.

Application (Procedure required until the internal manual set value is displayed)

Internal manual set value

Wiring of Auto/Manual mode transfer

Wiring of controller

Select the Setting mode.

Unlock the Engineering mode.

Select the Engineering mode.

Select the contact input action.

Set the “1: Internal manual mode ↔ Auto

mode.”

Select the Setting mode.

A

When not wired, see the following page.

Wiring of Controller (P. 16)

Wiring of Auto/Manual mode selection (P. 22)

See P. 25

See P. 39

See P. 25

See P. 42

See P. 43

See P. 25

28

IMR01V02-E1

Page 37

A

Lock the Engineering mode.

See P. 39

Select the input signal monitor 1.

See P. 25 and 27

Display the internal

manual set value.

No (Display the auto set value

1

)

YES

Close the contact of Auto/Manual

mode transfer.

Open the contact of Auto/Manual

mode transfer.

1

Auto set value: Input signal from controller

2

The internal manual set value

is displayed.

If the internal manual set value or auto set value display is selected, control is also performed at the set value

thus selected.

2

The auto set value is displayed. 2

When necessary to display any other input signal, first select the external contact action by

referring to the following table and then select the external contact.

State of External contact

Contact input action

0: External manual mode

↔ Auto mode

1: Internal manual mode

↔ Auto mode

2: Internal manual mode

(fixed)

Displays the External manual set

value.

Displays the Internal manual set

value.

Contact closed

(Manual mode)

Displays the Internal manual set value.

Contact open

(Auto mode)

Displays the Auto set value.

4. SETTING

0: External manual mode ↔ Auto mode

1: Internal manual mode ↔ Auto mode

2: Internal manual mode (fixed) Displays the Internal manual set value.

IMR01V02-E1

When no wiring of “Auto mode/Manual mode transfer” is conducted, the contact keeps opening

and as a result Input signal monitor 1 displays the input signal value in the following table.

Contact input action

State of contact

(Contact open: Auto mode)

Displays the Auto set value.

29

Page 38

4. SETTING

(2) Phase angle ratio monitor ( )

Displays the phase angle of the trigger point by percentage. Phase angle is obtained by performing

such computation as Soft-start/Soft-down time, Gradient setting, Output limiter setting or Base up

setting to the input signal.

Display range: 0 to 100 %

Display the 0 % when the phase angle is 210°.

Display the 100 % when the phase angle is 0°.

Phase angle

0°

100 %

Output

waveform

Phase angle

°

90

Phase angle

°

210

57 %

0 %

Displays this value.

(3) Current value monitor ( )

Displays the current value (Input value of CT). The display range varies depending on the instrument

specification.

Display range: 20 A type: 0.0 to 26.0 A

30 A type: 0.0 to 39.0 A

45 A type: 0 to 58 A

60 A type: 0 to 78 A

80 A type: 0 to 104 A

100 A type: 0 to 130 A

The current value monitor is not displayed when the heater break alarm function is not

provided.

(4) Voltage value monitor ( )

Displays the voltage value (Input value of PT).

Display range: 0 to 500 V

The voltage value monitor is not displayed when the constant voltage control is not provided.

(5) Power value monitor ( )

Displays the power value.

Display range: 0.0 to 84.0 kW

The power value monitor is not displayed when the constant power control is not provided.

30

IMR01V02-E1

Page 39

4. SETTING

4.3 Monitor Mode 2

The following items are displayed in the monitor mode 2.

• Power frequency • Auto set value (value of auto mode)

• External gradient set value • External manual set value

• State of contact (open/closed state)

4.3.1 Display sequence

To go to the next monitor screen, press UP or DOWN key. To go back to the first monitor screen,

keep pressing the keys until it is displayed again.

Press the UP key.

Power frequency monitor

(IFrq)

Input signal monitor 2

External gradient set value monitor

External manual set value monitor

Press the DOWN key.Press the UP key.

(InS2)

Press the DOWN key.Press the UP key.

(EGr)

Press the DOWN key.Press the UP key.

(EMAn)

IMR01V02-E1

Press the DOWN key.Press the UP key.

Contact input state monitor

(dIST)

Press the DOWN key.

31

Page 40

4. SETTING

4.3.2 Description of each monitor item

(1) Power frequency monitor ( )

Displays the power frequency.

Display range: 0 to 70 Hz

The automatic power frequency detection and power frequency monitoring function is

available with the THW-3. For details, see the function description (P. 56).

(2) Input signal monitor 2 ( )

Displays the Auto set value (value of auto mode).

Display range: 0 to 100 %

(3) External gradient set value monitor ( )

Displays the external gradient set value.

Display range: 0 to 100 %

(4) External manual set value monitor ( )

Displays the external manual set value.

Display range: 0 to 100 %

(5) Contact input state monitor ( )

Displays the state of the contact input.

Display item: 0: Contact open

1: Contact closed

Contact input state monitor

Auto/Manual mode transfer

0: Contact open (Auto mode)

1: Contact closed (Manual mode)

32

RUN/STOP transfer

0: Contact open (STOP)

1: Contact closed (RUN)

Alarm interlock release

0: Contact open

1: Contact closed (alarm interlock release)

IMR01V02-E1

Page 41

4. SETTING

4.4 Setting Mode

In Setting mode, the following operations are possible.

• Internal gradient can be set. • Soft-start time and Soft-down time can be set.

• Heater break alarm set value can be set. • Current limit value can be set.

• Maximum load current set value for alarm, etc.

4.4.1 Display sequence

To go to the next parameter (setting item), press SET key. To go back to the first setting item, keep

pressing SET keys until it is displayed again.

Internal manual

set value

Internal gradient

set value

Soft-start time

Soft-down time

Press the SET key.

Press the SET key.

Press the SET key.

(IMAn)

(IGr)

(SoFS)

(SoFd)

Thyristor break-

(THb)

down set value

setting *

Press the SET key.

Heater break

(HBA2)

alarm 2 set

value setting *

Press the SET key.

Current limit

(CL)

value setting *

Press the SET key.

Set data lock

(LCK)

setting

Maximum load

current set

value for alarm

Heater break

alarm 1 set

value setting *

IMR01V02-E1

Press the SET key.

(MAXC)

Press the SET key.

(HbA1)

Press the SET key.

Press the SET key.

Return to internal manual set value

* These parameters may not be displayed

depending on the specification.

33

Page 42

4. SETTING

4.4.2 Changing parameter settings

When set the internal gradient set value to “0.50”

1. Press the SET key for 2 seconds to change to Setting mode.

Monitor mode 1

Setting mode

Internal manual set value

SET SET

2. Press the SET key to enter the Internal gradient set value.

Setting mode

Internal manual set value

Internal gradient

set value

SET SET

3. Press the shift key to high-light the one decimal place on display (lower).

Internal gradient

set value

Internal gradient

set value

SET SET

4. Press the DOWN key to change the number to “0.5.”

Internal gradient

set value

SET SET

34

Internal gradient

set value

IMR01V02-E1

Page 43

5. Press the SET key to store the new value. The display goes to the next parameter.

4. SETTING

Internal gradient

set value

Soft-start time

SET SET

To store a new value for the parameter, always press the SET key. A new value will not be

stored without pressing SET key after the new value is displayed on the display.

After a new value has been displayed by using the UP and DOWN keys, the SET key must

be pressed within one minute, or the new value is not stored and the display will return to the

monitor mode 1.

If the following setting is tried to be set, no set value is registered even if the SET key is

pressed. In addition, it does not go to the next parameters.

• When in zero-cross control, it is tried to set constant current control, constant voltage

control or constant power control.

• When in constant current control, constant voltage control or constant power control, it is

tried to set zero-cross control.

Other parameters can be set in the same way as the example above.

Every time the shift key is pressed, the high-lighted digit moves as follows.

IMR01V02-E1

35

Page 44

4. SETTING

4.4.3 Description of each parameter

(1) Internal manual set value ( )

Use to set the Internal set value.

Setting range: 0.0 to 100.0 %

Factory set value: 0.0

(2) Internal gradient set value ( )

Use to set the Internal gradient set value.

Setting range: 0.00 to 1.00 Internal gradient is 0 % when set 0.00.

Internal gradient is 100 % when set 1.00

Factory set value: 1.00

For the gradient output characteristic, see page 50.

(3) Soft-start time ( )

Use to set the Soft-start time.

CAUTION

If a load generating large rush current is used, thyristor break-down may occur when

no soft-start time is appropriately set. In zero-cross control, no rush current can be

suppressed even if the Soft-start time is set.

Setting range: 0.0 to 99.9 seconds

Factory set value: 0.1

For the function description, see page 49.

(4) Soft-down time ( )

Use to set the Soft-down time.

Setting range: 0.0 to 99.9 seconds

Factory set value: 0.1

For the function description, see page 49.

36

IMR01V02-E1

Page 45

4. SETTING

(5) Maximum load current set value for alarm ( )

Use to set the maximum heater current value (maximum load current value) for Heater break alarm.

The maximum load current value means a current value which flows through the heater at an output of

100 % (phase angle: 0°). After the wiring is complete, check a current value which flows through the

heater at an output of 100 % (phase angle: 0°) on the current monitor (see P. 30).

Phase angle can be checked on the Phase angle ratio monitor (see P. 30).

Always set the maximum load current value if the heater break alarm function is

provided.

If the maximum current value which flows through the heater changes due to heater

secular change or deterioration, change the maximum load current value.

Setting range: 20 A type: 0.0 to 22.0 A Factory set value: 20 A type: 20.0

30 A type: 0.0 to 33.0 A 30 A type: 30.0

45 A type: 0 to 50 A 45 A type: 45

60 A type: 0 to 66 A 60 A type: 60

80 A type: 0 to 88 A 80 A type: 80

100 A type: 0 to 110 A 100 A type: 100

This parameter is not displayed when the heater break alarm function is not provided.

For the application, see 5.11 Heater Break Alarm 1 (HBA1), Heater Break Alarm

(HBA2) and Thyristor Break-down Alarm (see P. 57).

(6) Heater break alarm 1 set value setting ( )

Use to set the heater break alarm 1 set value. For the heater break alarm 1 set value, make the setting

as follows.

When the control method is Phase Control, RKC recommends:

Set the heater break set value to approximately 20 % of the maximum load current value for heater

break alarm Type 1.

Set the heater break set value to approximately 5 % of the maximum load current value for heater

break alarm Type 2.

When the control method is Zero-cross Control, RKC recommends:

Set the heater break alarm set value to approximately 80 % of the reading of current transformer

input. Set the heater break alarm set value to a slightly smaller value to prevent a false alarm when

power supply variation is large. Set the heater break alarm set value to a slightly larger value to

detect a failure of one heater when more than one heaters are connected in parallel. But the set value

should be less than the maximum reading of current transformer input.

Setting range: 0 to 100 % (0: Heater break alarm 1 unused)

Factory set value: 20

This alarm value is the deviation setting when the heater break alarm 1 type is type 1.

This parameter is not displayed when the heater break alarm function is not provided.

For the function description, see P. 57.

IMR01V02-E1 37

Page 46

4. SETTING

(7) Thyristor break-down set value setting ( )

Use to set the thyristor break-down set value. For the thyristor break-down set value, make the setting

as follows.

When the control method is Phase Control, RKC recommends:

Set the heater break set value to approximately 20 % of the maximum load current value for heater

break alarm Type 1.

Set the heater break set value to approximately 5 % of the maximum load current value for heater

break alarm Type 2.

When the control method is Zero-cross Control, RKC recommends:

Set the heater break set value to approximately 30 % of the maximum load current value.

Setting range: 0 to 100 % (0: Thyristor break-down alarm unused)

Factory set value: 20

This alarm value is the deviation setting when the heater break alarm 1 type is type 1.

This parameter is not displayed when the heater break alarm function is not provided.

For the function description, see P. 57.

(8) Heater break alarm 2 set value setting ( )

Use to set the heater break alarm 2 set value. For the heater break alarm 2 set value, make the setting

as follows.

When the control method is Phase Control and heater break alarm Type 1 is selected, RKC

recommends:

Set the value must be equal or less than the heater break alarm 1 set value.

When the control method is Phase Control and heater break alarm Type 2 is selected:

For the type 2, this item is not available. Set the “0: Heater break alarm 2 unused.”

When the control method is Zero-cross Control is selected:

For the zero-cross control, this item is not available. Set the “0: Heater break alarm 2 unused.”

Setting range: 0 to 100 % (0: Heater break alarm 2 unused)

Factory set value: 15

This alarm value is the deviation setting when the heater break alarm 2 type is type 1.

This parameter is not displayed when the heater break alarm function is not provided.

For the function description, see P. 57.

38

IMR01V02-E1

Page 47

(9) Current limiter value setting ( )

Use to set the current limiter value.

Setting range: 20 A type: 0.0 to 22.0 A

30 A type: 0.0 to 33.0 A

45 A type: 0 to 50 A

60 A type: 0 to 66 A

80 A type: 0 to 88 A

100 A type: 0 to 110 A

Factory set value: 20 A type: 22.0

30 A type: 33.0

45 A type: 50

60 A type: 66

80 A type: 88

100 A type: 110

If a current limit value is set to its maximum value, the current limit function is deactivated.

Factory set value is deactivation state.

This parameter is not displayed when the heater break alarm function is not provided.

For the function description, see P. 56.

(10) Set data lock setting ( )

4. SETTING

The Set Lock Function limits access of unauthorized personnel to the parameter and prevents

parameter change by mistake. Parameters of Setting mode and Engineering mode can be locked.

Setting range:

Set data lock

Setting mode

0: Setting mode unlock

1: Setting mode lock

Engineering mode

0: Engineering mode lock

1: Engineering mode unlock

Unused

Unused

Factory set value: 0000

If the parameters of Engineering mode are locked, those parameters are not displayed.

IMR01V02-E1

39

Page 48

4. SETTING

4.5 Engineering Mode

Parameters in Engineering mode should be set according to the application before

setting any parameter related to operation. Once the Parameters in the Engineering

mode are set correctly, those parameters are not necessary to be changed for the same

4.5.1 Transfer to engineering mode

When changing to the Engineering mode, it is necessary to unlock the Engineering mode lock.

1. Change to setting mode.

application under normal conditions.

All parameters of the engineering mode are displayed regardless of the instrument

specification.

Setting mode (Internal manual set value )

SET

2. Press the SET key several times to change to the set data lock setting.

Set data lock setting

SET

3. Press the shift key to high-light the tens digit of display (lower).

Set data lock setting

40

SET

IMR01V02-E1

Page 49

4. Press the UP key to change 0 to 1 in the tens digit.

Set data lock setting

Set value

0000: Engineering mode lock

0010: Engineering mode unlock

SET

5. Press the SET key to unlock the engineering mode. The display goes to the first parameter in

engineering mode.

Set data lock setting

Internal manual

set value

4. SETTING

SET SET

6. Press the shift key while pressing the SET key to change to the engineering mode. The display

goes to the function block 24.

Internal manual

set value

SET SET

Engineering mode

Function block 24

IMR01V02-E1

41

Page 50

4. SETTING

y

y

y

y

y

y

y

y

4.5.2 Display sequence

Setting items are classified into groups (function block: F) within the Engineering mode.

• Change to the function block (F.): To go to the next function block, press UP or DOWN keys.

• Change to parameter: To go to the next parameter, press SET key.

To function block 91 (F91.)

(F24.)

(F30.)

(F45.)

(F46.)

(F51.)

(F52.)

DOWN key

Contact input

(P. 43)

SET key

DOWN key UP ke

(P. 43)

SET key

DOWN key UP ke

(P. 44) (P. 44) (P. 45) (P. 45)

DOWN key UP ke

(P. 45) (P. 45) (P. 45)

DOWN key UP ke

(P. 46) (P. 46) (P. 46) (P. 46)

DOWN key UP ke

(P. 47) (P. 47) (P. 47) (P. 47) (P. 47)

action

Output mode for

phase control

Number of heater break

alarm 1 delay times

Number of heater break

alarm 2 delay times

Control method

Output limiter

(high)

(P. 43)

SET key

(dISL)

(P. 43) (P. 44) (P. 44)

SET key

(oS) (LGA1) (LGA2)

SET keySET key SET key

(HbC1) (AS1) (ILS)

SET key SET keySET key

(HbC2) (AS2)

SET key SET keySET key

(ConT) (rSA)

SET key SET keySET key

Return to F24.

Alarm 1

output logic

Heater break

alarm 1 type

Heater break

alarm 2 type

RUN/STOP

action

Output limiter

(low)

SET key

Output limiter (high)

output logic

Alarm interlock

Return to F46.

Input signal

at operation start

Alarm 2

SET key

SET key

SET key

(InSS)

Output limiter (high)

time at operation start

SET key

Return to F30.

Return to F45.

Return to F51.

SET key

Function block 24

Function block 30

Function block 45

Function block 46

Function block 51

Function block 52

(oLH) (oLL) (SoLH) (SoLT)

Base-up

DOWN key UP ke

Function block 60

(F60.)

Function block 91

(F91.)

UP ke

To function block 24 (F24.)

(P. 48)

This item cannot be used.

DOWN key UP ke

(P. 48) (P. 48) (P. 48) (P. 48)

ROM version

Integrated operating

time (upper 2 digits)

SET key

set value

Return to F 52.

Integrated operating

time (lower 4 digits)

SET keySET key

(WTH ) (WTL )

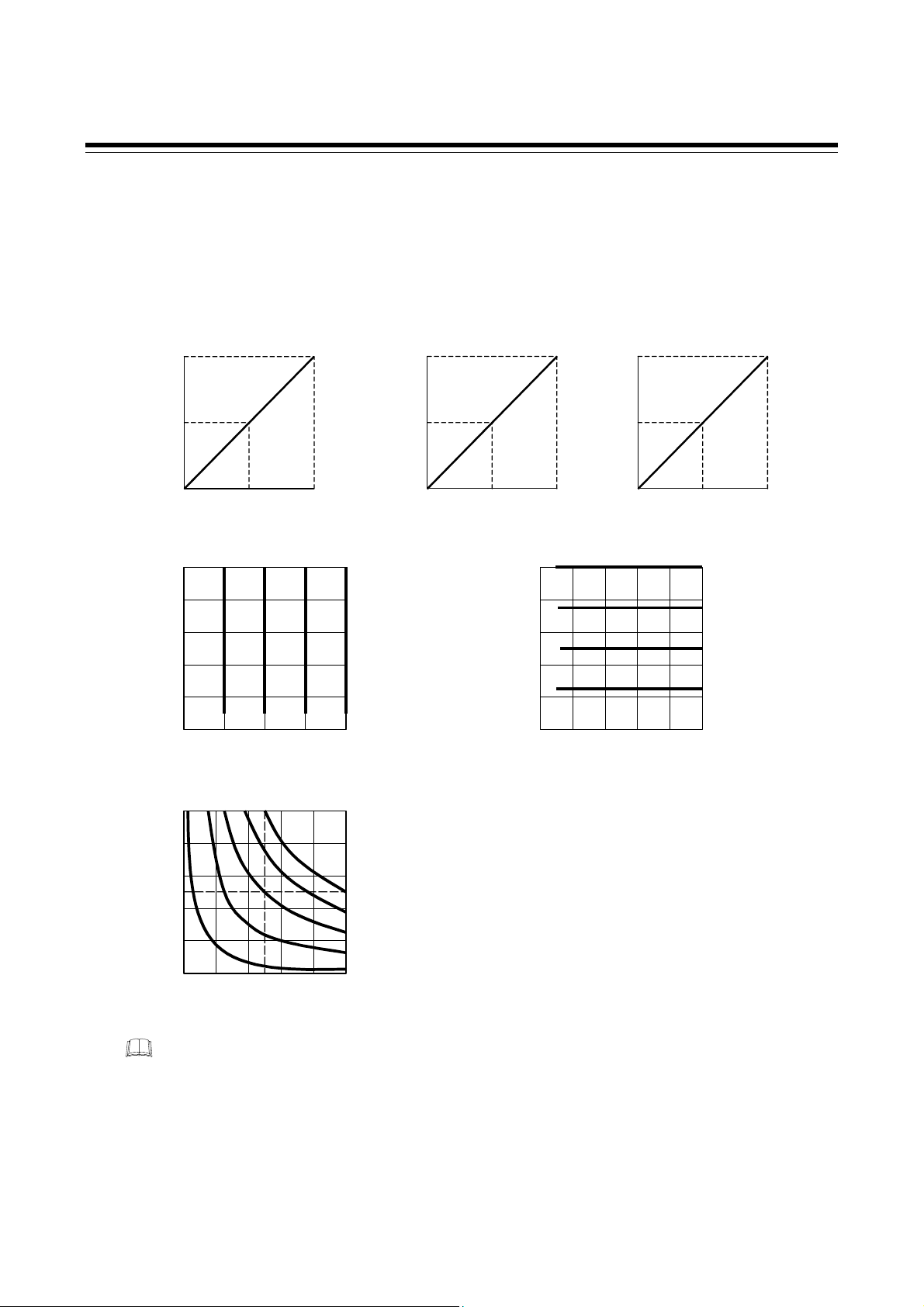

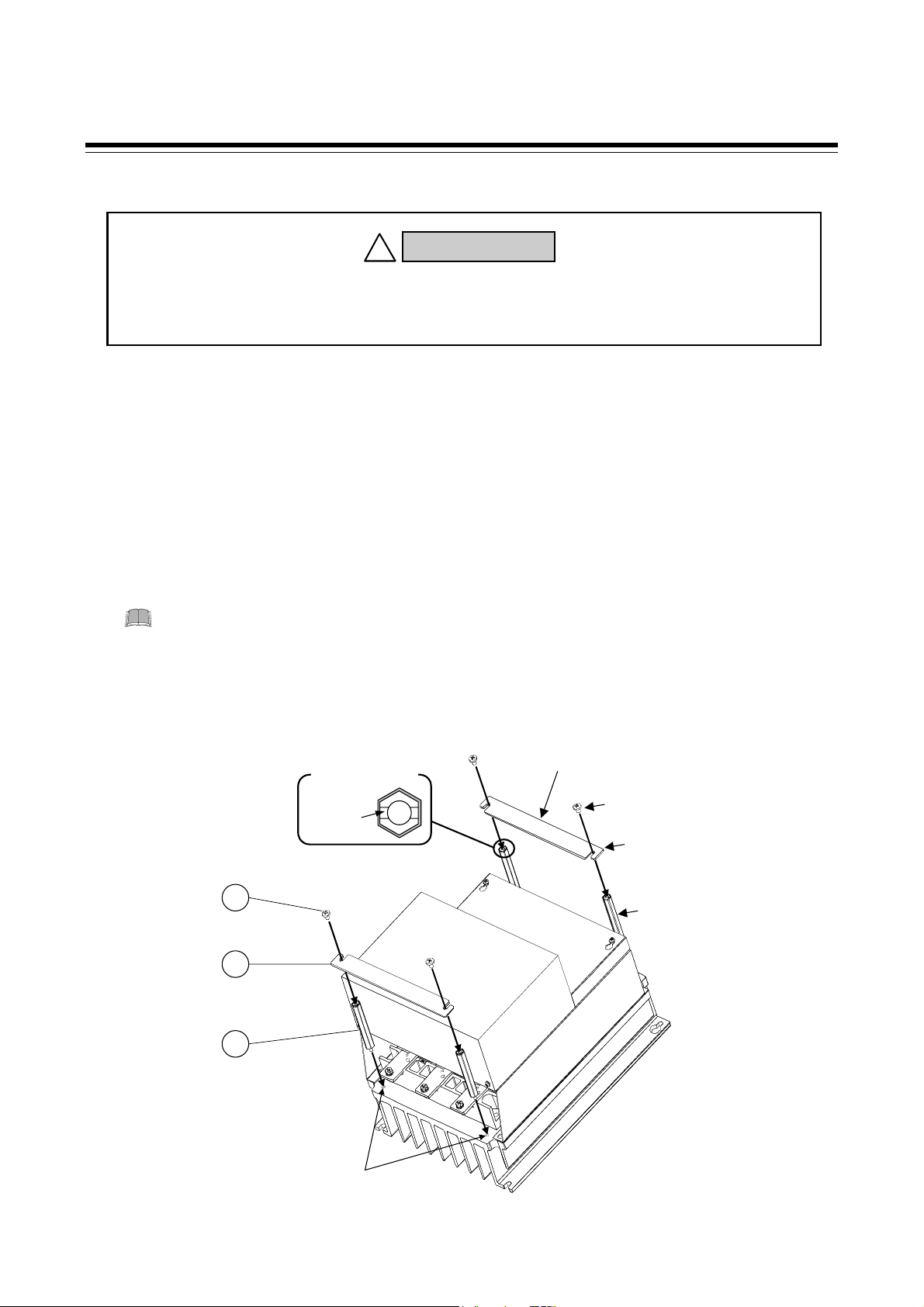

SET key