Page 1

r

RKC INSTRUMENT INC.

®

Module Type Controlle

SRV

Ethernet [Modbus/TCP]

Communication

Instruction Manual

IMS01P09-E4

Page 2

Ethernet is a registered trademark of Xerox Corp.

Modbus is a registered trademark of Schneider Electric.

Windows and Microsoft Internet Explorer are registered trademark of Microsoft Corporation in the

U.S.A. and other countries.

Company names and product names used in this manual are the trademarks or registered trademarks of

the respective companies.

All Rights Reserved, Copyright 2004, RKC INSTRUMENT INC.

Page 3

t

Thank you for purchasing this RKC instrument. In order to achieve maximum performance and ensure

proper operation of your new instrument, carefully read all the instructions in this manual. Please

place this manual in a convenient location for easy reference.

SYMBOLS

WARNING

CAUTION

!

An external protection device must be installed if failure of this instrument

could result in damage to the instrument, equipment or injury to personnel.

: This mark indicates precautions that must be taken if there is danger of electric

shock, fire, etc., which could result in loss of life or injury.

: This mark indicates that if these precautions and operating procedures are no

taken, damage to the instrument may result.

: This mark indicates that all precautions should be taken for safe usage.

: This mark indicates important information on installation, handling and operating

procedures.

: This mark indicates supplemental information on installation, handling and

operating procedures.

: This mark indicates where additional information may be located.

WARNING

!

All wiring must be completed before power is turned on to prevent electric

shock, fire or damage to instrument and equipment.

This instrument must be used in accordance with the specifications to

prevent fire or damage to instrument and equipment.

This instrument is not intended for use in locations subject to flammable or

explosive gases.

Do not touch high-voltage connections such as power supply terminals, etc.

to avoid electric shock.

RKC is not responsible if this instrument is repaired, modified or

disassembled by other than factory-approved personnel. Malfunction can

occur and warranty is void under these conditions.

IMS01P09-E4

i-1

Page 4

CAUTION

This is a Class A instrument. In a domestic environment, this instrument may cause radio

interference, in which case the user may be required to take adequate measures.

This instrument is protected from electric shock by reinforced insulation. Provide

reinforced insulation between the wire for the input signal and the wires for instrument

power supply, source of power and loads.

Be sure to provide an appropriate surge control circuit respectively for the following:

- If input/output or signal lines within the building are longer than 30 meters.

- If input/output or signal lines leave the building, regardless the length.

This instrument is designed for installation in an enclosed instrumentation panel. All

high-voltage connections such as power supply terminals must be enclosed in the

instrumentation panel to avoid electric shock by operating personnel.

All precautions described in this manual should be taken to avoid damage to the

instrument or equipment.

All wiring must be in accordance with local codes and regulations.

All wiring must be completed before power is turned on to prevent electric shock,

instrument failure, or incorrect action.

The power must be turned off before repairing work for input break and output failure

including replacement of sensor, contactor or SSR, and all wiring must be completed

before power is turned on again.

To prevent instrument damage or failure, protect the power line and the input/output lines

from high currents with a protection device such as fuse, circuit breaker, etc.

Prevent metal fragments or lead wire scraps from falling inside instrument case to avoid

electric shock, fire or malfunction.

Tighten each terminal screw to the specified torque found in the manual to avoid electric

shock, fire or malfunction.

For proper operation of this instrument, provide adequate ventilation for heat dispensation.

Do not connect wires to unused terminals as this will interfere with proper operation of the

instrument.

Turn off the power supply before cleaning the instrument.

Do not use a volatile solvent such as paint thinner to clean the instrument. Deformation or

discoloration will occur. Use a soft, dry cloth to remove stains from the instrument.

To avoid damage to instrument display, do not rub with an abrasive material or push front

panel with a hard object.

Do not connect modular connectors to telephone line.

NOTICE

This manual assumes that the reader has a fundamental knowledge of the principles of electricity,

process control, computer technology and communications.

The figures, diagrams and numeric values used in this manual are only for purpose of illustration.

RKC is not responsible for any damage or injury that is caused as a result of using this instrument,

instrument failure or indirect damage.

RKC is not responsible for any damage and/or injury resulting from the use of instruments made by

imitating this instrument.

Periodic maintenance is required for safe and proper operation of this instrument. Some

components have a limited service life, or characteristics that change over time.

Every effort has been made to ensure accuracy of all information contained herein. RKC makes no

warranty expressed or implied, with respect to the accuracy of the information. The information in

this manual is subject to change without prior notice.

No portion of this document may be reprinted, modified, copied, transmitted, digitized, stored,

processed or retrieved through any mechanical, electronic, optical or other means without prior

written approval from RKC.

i-2

IMS01P09-E4

Page 5

CONTENTS

1. OUTLINE .............................................................................. 1

2. COMMUNICATION SPECIFICATIONS ................................ 2

3. SETTING PROCEDURE TO OPERATION .......................... 3

4. COMMUNICATION SETTING .............................................. 6

4.1 Module Address Setting ..................................................................................6

Page

4.2 Internal Communication Setting.......................................................................8

4.3 Termination Resistor Setting of Internal communication ...............................10

5. WIRING ............................................................................... 12

5.1 Wiring Configuration ......................................................................................12

5.2 Wiring Details ................................................................................................14

6. IP ADDRESS SETTING ...................................................... 16

6.1 Setting by Telnet............................................................................................16

6.2 Setting by the Web Browser .......................................................................... 21

6.3 Setting by the DIP Switch .............................................................................. 24

7. MODBUS/TCP PROTOCOL ............................................... 28

7.1 Message Configuration.................................................................................. 28

7.2 Function Code ...............................................................................................30

7.3 Server (SRV) Responses ..............................................................................30

7.4 Message Format............................................................................................32

7.4.1 Read holding registers [03H].............................................................................. 32

7.4.2 Write single register [06H].................................................................................. 34

7.4.3 Diagnostics (Loopback test) [08H] ..................................................................... 35

7.4.4 Write multiple registers [10H] ............................................................................. 36

7.4.5 Read/write multiple registers [17H] .................................................................... 38

IMS01P09-E4 i-3

Page 6

7.5 Data Configuration.........................................................................................40

7.5.1 Data processing with decimal points.................................................................. 40

7.5.2 Data processing precautions.............................................................................. 42

7.6 Data Map....................................................................................................... 43

7.6.1 Normal setting data items ..................................................................................43

7.6.2 Initial setting data items...................................................................................... 51

8. COMMUNICATION DATA DESCRIPTION ........................ 56

8.1 Normal Setting Data Items.............................................................................57

8.2 Initial Setting Data Items................................................................................ 86

Page

9. TROUBLESHOOTING ........................................................ 99

APPENDIX A. HARDWARE................................................ 102

A.1 Terminal Configuration................................................................................ 102

A.2 Pin Layout of Connector.............................................................................. 103

A.3 Indication Lamp...........................................................................................104

A.4 Product Specifications................................................................................. 106

APPENDIX B. DATA PROCESSING TIME......................... 115

INDEX OF DATA ITEMS ...................................................... 117

i-4

IMS01P09-E4

Page 7

1. OUTLINE

This manual describes Modbus/TCP protocol communication when the temperature control module

for Ethernet V-TIO-P or V-TIO-Q (hereafter called the V-TIO-P/V-TIO-Q module) for the module

type controller SRV is used.

• The V-TIO-P/V-TIO-Q module has one modular connector (RJ-45) for connection to Ethernet.

• Up to 30 temperature control modules (V-TIO-A, B, C or D) can be connected to one

V-TIO-P/V-TIO-Q module.

Modbus/TCP is an open field network provided with the Modbus protocol on the TCP/IP

protocol of Ethernet.

The data request side is called “client” (such as computer) and the data response (supply)

side is called “server” (SRV).

Basically, one client corresponds to one server (SRV) (i.e. one to one). However, one client

can communicate with two or more servers depending on the program on the client side, but

two or more clients cannot communicate with one server.

For specification, parts description and wiring of the V-TIO-P/V-TIO-Q module, see

Temperature Control Module for Ethernet V-TIO-P/V-TIO-Q Instruction Manual

(IMS01P08-E).

Computer

(Client)

Network Hub

Ethernet

Ethernet

Temperature control

module for Ethernet

V-TIO-P/V-TIO-Q

(Server)

Usable modules:

•

Temperature control (TIO) module

[Basic type]: V-TIO-A, V-TIO-C

•

Temperature control (TIO) module

[Extension type]: V-TIO-B, V-TIO-D

(Up to 30 modules)

IMS01P09-E4 1

Page 8

2. COMMUNICATION SPECIFICATIONS

Ethernet communication

Physical layer: Ethernet

10BASE-T/100BASE-TX automatic recognition

Application layer: Modbus/TCP

Communication data: Based on Modbus message format

Connector type: RJ-45

Maximum connections: Up to 30 temperature control modules can be connected to one

V-TIO-P/V-TIO-Q module.

(Maximum number of temperature control point: 62 channels)

Modbus/TCP message configuration

Modbus ADU (Application Data Unit) on TCP/IP

MBAP Header: Transaction Identifier: 2 bytes

MBAP Header

7 bytes

Modbus TCP/IP ADU

Protocol Identifier: 2 bytes

Data Length: 2 bytes

Unit Identifier: 1 byte

(MBAP: Modbus Application Protocol)

PDU (Protocol Data Unit)

2 to 255 bytes

PDU (Protocol Data Unit):

Function code: 1 byte

Data: 1 to 254 bytes

03H: Read holding registers

06H: Write single register

08H: Diagnostics (loopback test)

10H: Write multiple registers

17H: Read/write multiple registers

2 IMS01P09-E4

Page 9

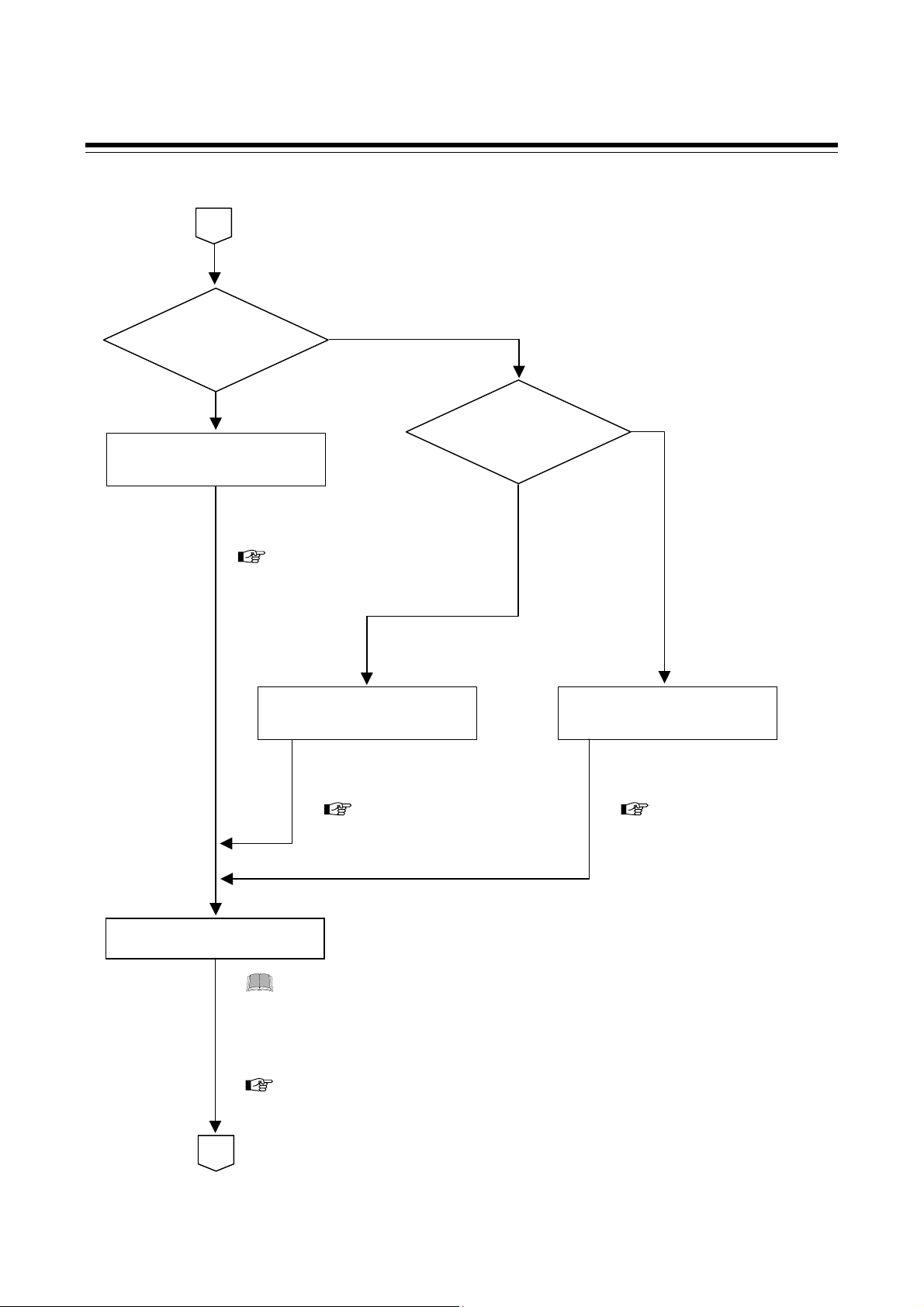

3. SETTING PROCEDURE TO OPERATION

Conduct necessary setting before operation according to the procedure described below.

Address setting

Set the module address.

See 4.1 Module Address Setting (P. 6).

Internal communication

setting

Set the communication speed and data bit configuration.

See 4.2 Internal Communication Setting (P. 8).

Wiring of SRV

Wire a power supply and input/output of SRV (server).

For the V-TIO-P/V-TIO-Q module, see APPENDIX A.1 Terminal

Configuration (P. 102).

For other modules, see the Instruction Manual of each module.

Connection of

communication line

Connect SRV (server) to client.

See 5. Wiring (P. 12).

Power ON

Turn on the power supply of SRV (server) and client.

The V-TIO-P/V-TIO-Q module starts collecting data on each module

connected from the time when the power is turned on. At this time, the

RUN lamp corresponding to indication lamp 2 flashed at very short

intervals.

After data collection is finished and communication becomes enabled *,

the RUN lamp keeps lighting.

* Time required for enabling communication differs depending on the number

of modules connected.

A

Continued on the next page.

IMS01P09-E4 3

Page 10

3. SETTING PROCEDURE TO OPERATION

y

Continued from the previous page.

A

Do execute

IP address setting

by a Telnet ?

NO

YES

IP address setting

by a Telnet

The IP address is set by using

Telnet.

See 6.1 Setting by Telnet

(P. 16).

IP address setting

by a web browser

The IP address is set by using

a web browser.

See 6.2 Setting by the

Web Browser (P. 21).

Initial setting data setting

Set the Input scale high/low limit, Input range decimal point position, Control

t

Before setting operation data items, always set initial setting data

items so as to satisfy the specification used.

pe, Event type etc.

For initial setting data items, see 7.6.2 Initial setting data items (P. 51) or

8.2 Initial Setting Data Items (P. 86).

B

Do execute

IP address setting by a

web browser ?

YES

NO

IP address setting

by the DIP switches

The IP address is set by using

the DIP switches.

See 6.3 Setting by the

DIP Switch (P. 24).

Continued on the next page.

4

IMS01P09-E4

Page 11

Continued from the previous page.

B

Power ON again

The initial setting data items thus set are registered by turning on the

SRV power supply again.

Operation data setting

Set data to be related to the control.

Operation mode setting

Select the operation mode in the Auto/Manual transfer.

(Factory set value: AUTO)

Control RUN

Set the control RUN/STOP transfer to the “RUN.”

(Factory set value: STOP)

Operation start

3. SETTING PROCEDURE TO OPERATION

For data, see 7.6.1 Normal setting data items (P. 43) or 8.1 Normal

Setting Data Items (P. 57).

IMS01P09-E4

5

Page 12

4. COMMUNICATION SETTING

To prevent electric shock or instrument failure, always turn off the power

before setting the switch.

WARNING

!

To prevent electric shock or instrument failure, never touch any section other

than those instructed in this manual.

CAUTION

Do not separate the module mainframe from the terminal base with the power turned on. If

separated, adjusted data may be destroyed; control be stopped, and no return can be made.

Set the following communication setting before operation.

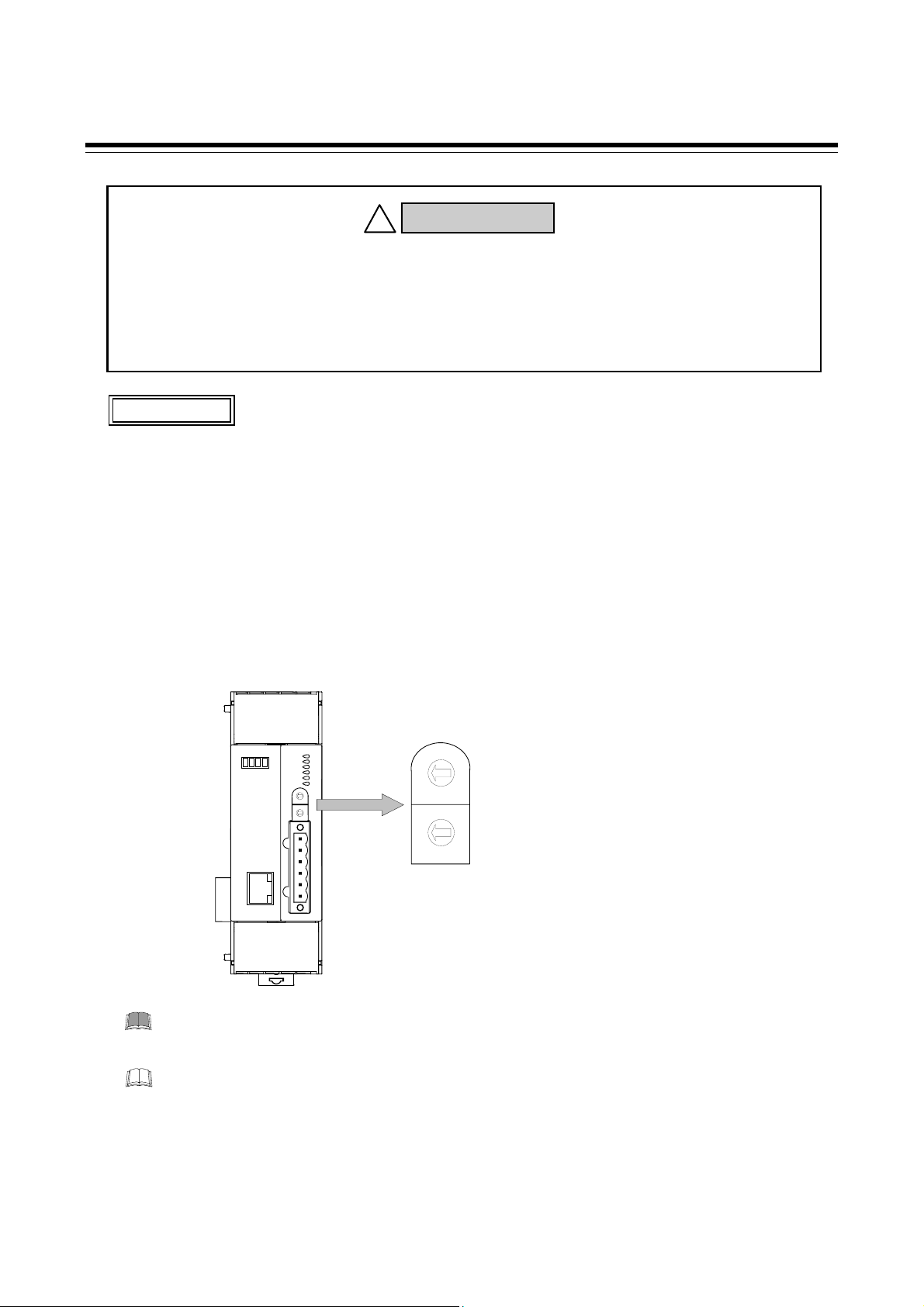

4.1 Module Address Setting

When using two or more modules, set the desired address to each module.

Set the module address by address setting switch of front of module. For this setting, use a small blade

screwdriver.

Address setting switch

FAIL/RUN

RX/TX

EVENT1

EVENT2

EVENT3

EVENT4

3

2

4

1

5

5 5

0

6

9

7

8

3

2

4

1

5

0

6

9

7

8

Setting range: 0 to 30

(Factory set value: 0)

Set the module address such that it is different to the other addresses in the same unit.

Otherwise, problems or malfunction may result.

3

2

4

1

5

5 5

0

9

8

3

2

1

0

9

8

High-order digit setting

6

7

(set value × 10)

4

5

Low-order digit setting

6

7

(set value × 1)

The above figure is V-TIO-P/V-TIO-Q module. The figure of other TIO module is the same

as a V-TIO-P/V-TIO-Q module.

6 IMS01P09-E4

Page 13

4. COMMUNICATION SETTING

The channel number for the module address

The module address can be freely set with any numbers from 0 to 30.

In addition, to each module address, the relevant temperature control channel is assigned. Each

temperature control channel number can be calculated from the following equation.

Temperature control channel number of communication

[Setting example]

V-TIO-P module

= (Module address × 2) + Temperature control channel number of module

Temperature control module [extension type] V-TIO-B

Module

address

30

CH1

CH61

CH2

CH62

Temperature contr ol

channel num ber of

module

Temperature contr ol

channel num ber of

communication

CH1

CH1

CH2

CH2

CH1

CH3

CH2

CH4

CH1

CH21

CH2

CH22

CH1

CH23

CH2

CH24

CH1

CH41

CH2

CH42

21201110 10

CH1

CH2

CH43

CH44

For heat/cool control, data in the second channel of each module becomes invalid.

[Example] If module addresses of one V-TIO-Q module and six V-TIO-D modules which

are heat/cool temperature control modules are set as follows by the free setting,

data in odd channels is used because data in even channels is invalid.

Valid channel number: 1, 3, 21, 23, 41, 43, 61

Invalid channel number: 2, 4, 22, 24, 42, 44, 62

V-TIO-Q module

Temperature control module [extension type] V-TIO-D

Module

address

Valid channel

Invalid channel

IMS01P09-E4

CH1

CH1

CH2

CH2

CH1

CH3

CH2

CH4

CH1

CH21

CH2

CH22

CH1

CH23

CH2

CH24

CH1

CH41

CH2

CH42

CH1

CH43

212011101 0

CH2

CH44

CH1

CH61

30

CH2

CH62

Temperature control

channel number of

module

Temperature control

channel number of

communication

7

Page 14

4. COMMUNICATION SETTING

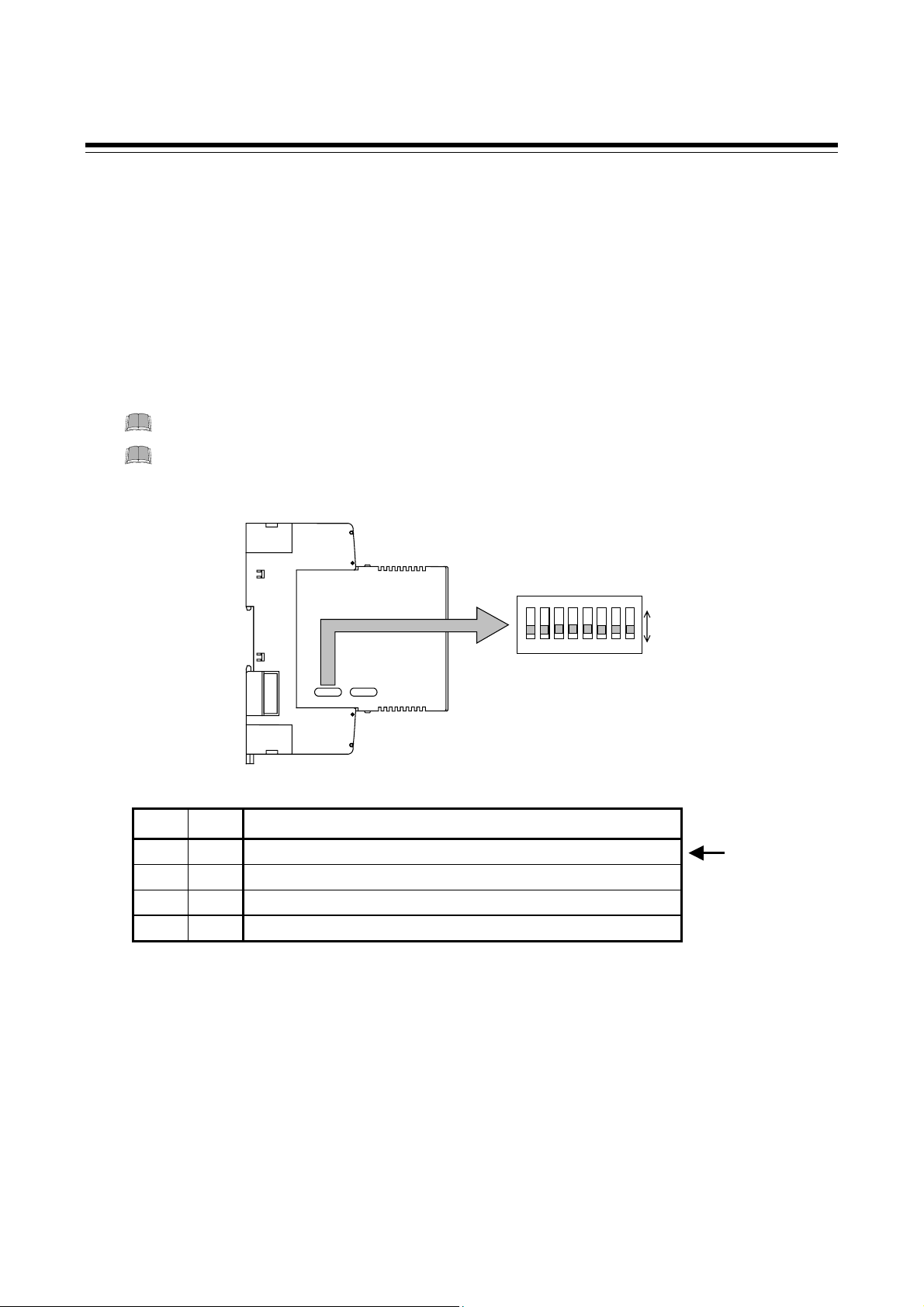

4.2 Internal Communication Setting

Internal communication is used for data transfer between modules within the SRV unit.

The setting is made on the Ethernet communication and temperature control sides of the

V-TIO-P/V-TIO-Q module.

Setting of Ethernet communication side

With the DIP switch 1 which there is on the left side of V-TIO-P/V-TIO-Q module, select internal

communication speed.

Switch No. 3 to 8: OFF fixed (Don’t change this one)

Set the communication speed to the same value as the setting on the temperature

control side (DIP switch 3).

Left side view

1 2 Communication speed

OFF OFF

ON OFF

OFF ON

ON ON

38400 bps

9600 bps

19200 bps

38400 bps

DIP switch 1

ON

ON

1234567 8

1234567 8

ON

OFF

Factory

set value

8

IMS01P09-E4

Page 15

4. COMMUNICATION SETTING

Setting of temperature control side

With the DIP switch 3 which there is on the right side of V-TIO-P/V-TIO-Q module, select internal

communication speed and data bit configuration.

Switch No. 6: ON fixed (Don’t change this one)

Switch No. 7, 8: OFF fixed (Don’t change this one)

Set the communication speed to the same value as the setting on the Ethernet

communication side (DIP switch 1).

When connecting two or more modules (V-TIO-A, V-TIO-B, V-TIO-C or V-TIO-D) to

the V-TIO-P/V-TIO-Q module, match all of their communication speed and data bit

configuration settings with the internal settings of the V-TIO-P/V-TIO-Q module.

Right side view

1 2 Communication speed

OFF OFF

ON OFF

OFF ON

ON ON

9600 bps

19200 bps

38400 bps

Don’t set this one

3 4 5 Data bit configuration

OFF OFF OFF

OFF OFF ON

Don’t set this one

OFF ON OFF

OFF ON ON

ON OFF OFF

Data 8-bit, without parity, Stop 1-bit

ON OFF ON

ON ON OFF

Don’t set this one

ON ON ON

DIP switch 3

ON

ON

12345678

12345678

ON

OFF

Factory

set value

Factory

set value

IMS01P09-E4

9

Page 16

4. COMMUNICATION SETTING

4.3 Termination Resistor Setting of Internal communication

Procedure for setting a termination resistor to internal communication (RS-485) and its setting position

are described in the following.

Termination resistor setting position

Set a termination resistor to the communication line termination in the module located in the position

farthermost from the V-TIO-P/V-TIO-Q module.

V-TIO-P/V-TIO-Q module

Temperature control module

[extension type] V-TIO- B/V-TIO-D

Setting procedure of termination resistor

SRV unit

Internal communication

(RS-485)

Turn on the termination

resistor of this module.

As no termination resistor is externally connected to the temperature control (TIO) module [extension

type] V-TIO-B (or V-TIO-D), the termination resistor built in the module is connected by switch

selection.

1. Turn off the power supply of the module.

Do not separate the module mainframe from the terminal base with the power turned on. If

separated, adjusted data may be destroyed; control be stopped, and no return can be made.

2. Pull out the module mainframe itself toward you while pushing the locks at its top and bottom,

and then separate it from the terminal base.

Upper-side lock

Top view

Terminal base

Module mainframe

(1) Push

(2) Pull out

Lower-side lock

10

Bottom view

(1) Push

Removing the module mainframe

IMS01P09-E4

Page 17

Ω

3. Turn on the termination resistor transfer switch in the terminal base.

Termination resistor transfer switch

4. COMMUNICATION SETTING

Termination resistor ON (120

1/2 W)

Termination resistor OFF

Factory set value: OFF

A terminal base of the state which removed module mainframe

4. Push the module mainframe thus separated in the terminal base until firmly locked.

Terminal base

Module mainframe

Push the module

mainframe until

firmly locked

Mounting the module mainframe

IMS01P09-E4

11

Page 18

(

5. WIRING

To prevent electric shock or instrument failure, turn off the power before

connecting or disconnecting the instrument and peripheral equipment.

WARNING

!

CAUTION

Connect connectors correctly in the right position. If it is forcibly pushed in with pins in

the wrong positions, the pins may be bent resulting in instrument failure.

When connecting or disconnecting the connectors, do not force it too far to right and left

or up and down, but move it on the straight. Otherwise, the connector pins may be bent,

causing instrument failure.

When disconnecting a connector, hold it by the connector itself. Disconnecting

connectors by yanking on their cables can cause breakdowns.

To prevent malfunction, never touch the contact section of a connector with bare hands

or with hands soiled with oil or the like.

To prevent malfunction, connect cable connectors securely, then firmly tighten the

connector fastening screws.

To prevent damage to cables, do not bend cables over with excessive force.

If the instrument is easily affected by noise, use the ferrite core in the both ends of the

communication cable (nearest the connector).

5.1 Wiring Configuration

When directly connected to client

Computer

(Client)

Internal Communication

Ethernet

V-TIO-P/V-TIO-Q module

Server)

Up to 30 temperature control modules can be connected to one V-TIO-P/V-TIO-Q module.

SRV unit

(RS-485)

TIO module [extension type]

V-TIO-B/V-TIO-D

12 IMS01P09-E4

Page 19

(

)

When use network hub

Computer

(Client)

Network Hub

Ethernet

Up to 30 temperature control modules can be connected to one V-TIO-P/V-TIO-Q module.

Basically, one client corresponds to one server (SRV) (i.e. one to one). However, one client

can communicate with two or more servers depending on the program on the client side, but

two or more clients cannot communicate with one server.

Ethernet

V-TIO-P/V-TIO-Q module

Server

5. WIRING

SRV unit

Internal Communication

(RS-485)

TIO module [extension type]

V-TIO-B/V-TIO-D

Computer

(Client)

V-TIO-P/V-TIO-Q module

(Server)

Network Hub

Ethernet

Ethernet

SRV unit

Ethernet

SRV unit

V-TIO-P/V-TIO-Q module

(Server)

TIO module [extension type]

V-TIO-B/V-TIO-D

IMS01P09-E4 13

Page 20

5. WIRING

r

t

5.2 Wiring Details

Pin layout of modular connector

Modular connecto

for Etherne

V-TIO-P/V-TIO-Q module

RJ-45

8: Unused

7: Unused

6: RX−

5: Unused

4: Unused

3: RX+

2: TX−

1: TX+

Connector pin number and signal details

Pin No. Signal name Symbol

1

2

3

4 Unused

5 Unused

6

7 Unused

8 Unused

The cable is provided by the customer.

Used cable: The cable is based on the 10BASE-T or the 100BASE-TX standard of

Used connector: RJ-45 type

Send data + TX+

Send data − TX−

Receive data + RX+

Receive data − RX−

Ethernet.

14

IMS01P09-E4

Page 21

+TX−RX+

−

Wiring example

When directly connected to client

Use a cross cable when directly connected to the client (such as computer).

Computer

V-TIO-P/V-TIO-Q

5. WIRING

module

TX

+

TX

−

RX

+

RX

−

Cross cable

When use network hub

Use straight cables when connected to the network hub.

Computer

TX

TX

RX

RX

+

−

+

−

Network Hab

TX+

TX−

RX+

RX−

TX

RX

TX+

TX−

RX+

RX−

V-TIO-P/V-TIO-Q

module

TX+

TX−

RX+

RX−

IMS01P09-E4

Straight cable Straight cable

Cross cables may be used depending on the connecting device used. Therefore, follow the

instructions for the respective device.

15

Page 22

6. IP ADDRESS SETTING

Set an IP address of a V-TIO-P/V-TIO-Q module.

Three types of IP address setting are available: “setting by Telnet,” “setting by Web browser” and

“setting by DIP switch.”

Confirm the IP address number to the network administrator of the network (LAN) to

which the V-TIO-P/V-TIO-Q module is connected.

6.1 Setting by Telnet

Set the IP address by the software “Telnet” attached to Windows.

Preparations before setting

When setting the IP address by Telnet, it is necessary to coincide the 1st to 3rd bytes and masking

range of the IP address of the client (computer) which starts Telnet with those of the IP address of the

V-TIO-P/V-TIO-Q module.

1. Connect the V-TIO-P/V-TIO-Q module and client, and then turn on the power.

For wiring procedure, see 5. WIRING (P. 12).

2. The IP address of the V-TIO-P/V-TIO-Q module is set to a factory set value of “192.168.1.1.”

As it is necessary to coincide the 1st to 3rd byte values of this IP address with those of the IP

address of the client, change the IP address of the client to “192.168.1.” (: Any value in the

range of 0 to 255, but other than 1).

3. As the subnet mask of the V-TIO-P/V-TIO-Q module is “255.255.255.0,” also change the subnet

mask of the client to “255.255.255.0.”

After the IP address of the server is set, return the present IP address of the client to the

original address or change to the address meeting the network to be connected.

It is possible to set the IP address of the V-TIO-P/V-TIO-Q module using the client already

connected to the network. However, as the IP address of the client is changed, that client is

disconnected from the network so far connected.

In addition, when setting the IP address by this method, confirm to the network administrator

whether or not no problem arises.

16 IMS01P09-E4

Page 23

6. IP ADDRESS SETTING

Setting example

An example of setting the IP address to “192.168.1.3” is shown in the following.

1. Display the MS-DOS prompt (command prompt); enter the following command and then press

the Enter key.

C:¥>telnet 192.168.1.1 9999

2. Device information on the module (V-TIO-P/V-TIO-Q module) whose IP address is

“192.168.1.1” is displayed. Finally, as the message “Press Enter to go into Setup Mode” is

displayed, press the Enter key to go into Setup Mode.

MAC address 00204A8064BD

Software version 01.3 (030612) XPTE

Press Enter to go into Setup Mode

If the timing of pressing the Enter key is late, the message “Connection with Host was cut

off” is displayed and thus the client is disconnected from the V-TIO-P/V-TIO-Q module.

Therefore if the message “Press Enter to go into Setup Mode” is displayed, immediately

press the Enter key.

If disconnected, try again from “1.”

3. If entered into Setup Mode, the present Ethernet information is displayed.

Finally, eight choices are displayed as “Change Setup:.” Therefore enter “0” after “Your

choice ?” and then press the Enter key.

*** basic parameters

Hardware: Ethernet TPI

IP addr 192.168.1.1, no gateway set,netmask 255.255.255.000

*************** Security ***************

SNMP is enabled

SNMP Community Name: public

Telnet Setup is enabled

TFTP Download is enabled

Port 77FEh is enabled

Web Server is enabled

ECHO is disabled

Enhanced Password is disabled

*************** Channel 1 **************

Baudrate 38400, I/F Mode 7C, Flow 00

Port 00502

Remote IP Adr: --- none ---, Port 00000

Connect Mode: C0 Disconn Mode: 00

Flush Mode: 80

Pack Cntrl : 00

Continued on the next page.

IMS01P09-E4

17

Page 24

6. IP ADDRESS SETTING

Continued from the previous page.

*************** Expert *****************

TCP Keepalive : 45s

ARP cache timeout: 600s

*************** E-mail *****************

Mail server: 0.0.0.0

Unit :

Domain :

Recipient 1:

Recipient 2:

*** Trigger 1

Serial Sequence: 00,00

CP1: X

CP2: X

CP3: X

Message:

Priority : L

Min. notification interval: 1 s

Re-notification interval : 0 s

*** Trigger 2

Serial Sequence: 00,00

CP1: X

CP2: X

CP3: X

Message:

Priority : L

Min. notification interval: 1 s

Re-notification interval : 0 s

*** Trigger 3

Serial Sequence: 00,00

CP1: X

CP2: X

CP3: X

Message:

Priority : L

Min. notification interval: 1 s

Re-notification interval : 0 s

Change Setup:

0 Server configuration

1 Channel 1 configuration

3 E-mail settings

5 Expert settings

6 Security

7 Factory defaults

8 Exit without save

9 Save and exit Your choice ? 0

Enter “0” (Server configuration),

and press the Enter key.

18

IMS01P09-E4

Page 25

4. Selecting “0: Server configuration” makes ready to set the IP address.

Enter the IP address one byte by one byte.

As the following display appears, enter “192” into the first byte and then press the Enter key.

IP Address : (192) 192

Next, enter “168” into the second byte and then press the Enter key.

IP Address : (192) 192.(168) 168

Enter “1” into the third byte and then press the Enter key.

IP Address : (192) 192.(168) 168.(001) 1

6. IP ADDRESS SETTING

Enter “3” into the fourth byte and then press the Enter key.

IP Address : (192) 192.(168) 168.(001) 1.(001) 3

5. After the IP address is entered, the following display appears. Therefore press the Enter key to

proceed to the next.

IP Address : (192) 192.(168) 168.(001) 1.(001) 3

Set Gateway IP Address (N) N

In addition, as one line is displayed, press the Enter key to proceed to the next.

IP Address : (192) 192.(168) 168.(001) 1.(001) 3

Set Gateway IP Address (N) N

Netmask: Number of Bits for Host Part (0=default) (16)

Further, as more one line is displayed, press the Enter key to proceed to the next.

IP Address : (192) 192.(168) 168.(001) 1.(001) 3

Set Gateway IP Address (N) N

Netmask: Number of Bits for Host Part (0=default) (16)

Change telnet config password (N) N

IMS01P09-E4

19

Page 26

6. IP ADDRESS SETTING

6. As “Change Setup:” is displayed again, enter “9” after “Your choice ?” and then press the Enter

key.

Change Setup:

0 Server configuration

1 Channel 1 configuration

3 E-mail settings

5 Expert settings

Enter “9” (Save and exit),

and press the Enter key.

6 Security

7 Factory defaults

8 Exit without save

9 Save and exit Your choice ? 9

7. “Parameters stored ...” is displayed and thus the setting is finished.

Parameters stored ...

Connection with Host was cut off

20

IMS01P09-E4

Page 27

6. IP ADDRESS SETTING

6.2 Setting by the Web Browser

It is possible to set the IP address by using the Web browser (such as Internet Explorer).

Preparations before setting

When setting the IP address by Web browser, it is necessary to coincide the 1st to 3rd bytes and

masking range of the IP address of the client (computer) which starts Web browser with those of the

IP address of the V-TIO-P/V-TIO-Q module.

1. Connect the V-TIO-P/V-TIO-Q module and client, and then turn on the power.

For wiring procedure, see 5. WIRING (P. 12).

2. The IP address of the V-TIO-P/V-TIO-Q module is set to a factory set value of “192.168.1.1.”

As it is necessary to coincide the 1st to 3rd byte values of this IP address with those of the IP

address of the client, change the IP address of the client to “192.168.1. ” (: Any value in the

range of 0 to 255, but other than 1).

3. As the subnet mask of the V-TIO-P/V-TIO-Q module is “255.255.255.0,” also change the subnet

mask of the client to “255.255.255.0.”

After the IP address of the server is set, return the present IP address of the client to the

original address or change to the address meeting the network to be connected.

It is possible to set the IP address of the V-TIO-P/V-TIO-Q module using the client already

connected to the network. However, as the IP address of the client is changed, that client is

disconnected from the network so far connected.

In addition, when setting the IP address by this method, confirm to the network administrator

whether or not no problem arises.

IMS01P09-E4

21

Page 28

6. IP ADDRESS SETTING

Setting example

An example of setting the IP address to “192.168.1.3” is shown in the following.

1. Start the Web browser; enter the present IP address “192.168.1.1” into the address bar and then

press the Enter key.

2. The initial setting applet starts. “Selected Channel: 1” is displayed on the main display with “Port

Properties” selected on the Menu display on the left side of the screen.

Under this condition, click the Server Properties button on the Menu display.

Do not change the contents of “Selected Channel: 1.” If changed, device failure or

error may result.

Click

22

IMS01P09-E4

Page 29

6. IP ADDRESS SETTING

3. Display the Server Properties screen.

Set “192.168.1.3” in IP Address.

Set

192.168.1.3

Do not change any items other than the IP Address. If so, device failure or error

may result.

4. Clicking the Update Settings button on the Menu display updates the setting to display the

following message.

Click

5. Enter the new IP address “192.168.1.3” into the address bar as instructed by message and then

press the Enter key. Thus, a new IP address setting screen appears to end the setting.

IMS01P09-E4

23

Page 30

6. IP ADDRESS SETTING

6.3 Setting by the DIP Switch

It is possible to set the IP address by DIP switch with Ethernet not connected.

DIP switches used are “DIP switch 1” and “DIP switch 2” on the left side of the module.

DIP switch 1

DIP switch 2

Left side view of V-TIO-P/V-TIO-Q module

Factory set value of an IP address of a V-TIO-P/V-TIO-Q module is “192.168.1.1.”

Setting example

An example of setting the IP address to “192.168.1.3” is shown in the following.

1. Setting preparations

Turn on No. 6 and off No. 7 of DIP switch 1 with the power turned off.

It does not matter whether Nos. 1 to 5 and No. 8 of DIP switch 1 is turned on or off.

2. Power ON

Turning the power on goes to IP address setup mode. Thus, the FAIL lamp lights.

In addition, the first byte (most significant byte) of the IP address is set to the entry wait state.

(RUN lamp: ON, TX lamp: ON, RX lamp: OFF)

DIP switch 1

ON

ON

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

ON

OFF

FAIL lamp

ON

No. 6: ON

No. 7: OFF

RUN lamp

ON

RX lamp

OFF

TX lamp

ON

24

IMS01P09-E4

Page 31

3. Input the first byte “192”

Enter the first byte (most significant byte) by DIP switch 2. As the first byte (most significant

byte) is entered with “192,” this number corresponds to a binary number of “11000000.”

Conduct the following setting with No. 8 of DIP switch 2 set to the most significant bit.

DIP switch 2

ON

ON

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

4. Decision of the first byte input

In order to establish the setting of DIP switch 2, turn off No. 6 of DIP switch 1.

In addition, the second byte of IP address is set to the entry wait state.

(RUN lamp: ON, TX lamp: OFF, RX lamp: OFF)

DIP switch 1

ON

ON

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

5. Input the second byte “168”

Enter the second byte by DIP switch 2. As the second byte is entered with “168,” this number

corresponds to a binary number of “10101000.” Conduct the following setting with No. 8 of DIP

switch 2 set to the most significant bit.

DIP switch 2

ON

ON

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

6. Decision of the second byte input

In order to establish the setting of DIP switch 2, turn on No. 6 of DIP switch 1.

In addition, the third byte of IP address is set to the entry wait state.

(RUN lamp: OFF, TX lamp: ON, RX lamp: OFF)

DIP switch 1

ON

ON

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

No. 6

OFF

No. 6

ON

ON

No. 1 to 6: OFF

No. 7, 8: ON

OFF

ON

No. 1, 2, 3, 5, 7: OFF

No. 4, 6, 8: ON

OFF

FAIL lamp

ON

FAIL lamp

ON

6. IP ADDRESS SETTING

RUN lamp

ON

RUN lamp

OFF

TX lamp

OFF

TX lamp

ON

RX lamp

OFF

RX lamp

OFF

IMS01P09-E4

25

Page 32

6. IP ADDRESS SETTING

7. Input the third byte “1”

Enter the third byte by DIP switch 2. As the third byte is entered with “1,” this number

corresponds to a binary number of “00000001.” Conduct the following setting with No. 8 of DIP

switch 2 set to the most significant bit.

DIP switch 2

ON

ON

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

8. Decision of the third byte input

In order to establish the setting of DIP switch 2, turn off No. 6 of DIP switch 1.

In addition, the fourth byte of IP address is set to the entry wait state.

(RUN lamp: OFF, TX lamp: OFF, RX lamp: OFF)

DIP switch 1

ON

ON

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

9. Input the fourth byte “3”

Enter the fourth byte by DIP switch 2. As the fourth byte is entered with “3,” this number

corresponds to a binary number of “00000011.” Conduct the following setting with No. 8 of DIP

switch 2 set to the most significant bit.

DIP switch 2

ON

ON

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

10. Decision of the fourth byte input

In order to establish the setting of DIP switch 2, turn on No. 6 of DIP switch 1. Thus, the IP

address setting is finished and the FAIL lamp goes off.

(RUN lamp: OFF, TX lamp: OFF, RX lamp: OFF)

DIP switch 1

ON

ON

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

No. 6

OFF

No. 6

ON

ON

No. 1: ON

No. 2 to 8: OFF

OFF

ON

No. 1, 2: ON

No. 3 to 8: OFF

OFF

FAIL lamp

ON

FAIL lamp

OFF

RUN lamp

OFF

RUN lamp

OFF

RX lamp

OFF

TX lamp

OFF

RX lamp

OFF

TX lamp

OFF

26

IMS01P09-E4

Page 33

11. Decision of the IP address

After a lapse of a few seconds, the RUN lamp lights and the IP address is established.

The FAIL, TX and RX lamps flash until the IP address is established and they go off after the IP

address is established.

12. Power OFF

Turn the power off and also turn off No. 6 of DIP switch 1. In addition, turn off all Nos. of DIP

switch 2.

If the power is turned on, operation starts at the IP address thus set.

FAIL lamp

Flashing

FAIL lamp

OFF

RUN lamp

OFF

RUN lamp

ON

6. IP ADDRESS SETTING

RX lamp

Flashing

TX lamp

Flashing

A few seconds later

RX lamp

OFF

TX lamp

OFF

IMS01P09-E4

27

Page 34

7. MODBUS/TCP PROTOCOL

Modbus/TCP is an open field network provided with the Modbus protocol on the TCP/IP protocol of

Ethernet.

The data request side is called “client” (such as computer) and the data response (supply) side is called

“server” (SRV).

7.1 Message Configuration

Modbus ADU (Application Data Unit) on TCP/IP is in the following configuration.

MBAP Header

Transaction

Identifier

2 bytes

MBAP Header

7 bytes

Modbus TCP/IP ADU

Function code

1 byte

Protocol

Identifier

2 bytes

PDU (Protocol Data Unit)

2 to 255 bytes

Data

1 to 254 bytes

Data Length

2 bytes

Unit Identifier

1 byte

MBAP (Modbus Application Protocol) header contains the following fields: Transaction Identifier,

Protocol Identifier, Data Length and Unit Identifier.

Fields Length Request (Client) Response (Server)

Transaction

Identifier

2 bytes

Unused

However, data corresponding to

Returns data from the client as is

two bytes is sent

Protocol

2 bytes

Identifier

Data Length 2 bytes

Unit Identifier 1 byte

“0” fixed

(Modbus protocol = 0)

The total number of bytes of

Unit Identifier and PDU

(256 bytes max.)

Unused

Returns data from the client as is

The total number of bytes of

Unit Identifier and PDU

(256 bytes max.)

Returns data from the client as is

However, data corresponding to

one byte is sent

28 IMS01P09-E4

Page 35

PDU

PDU (Protocol Data Unit) consists of two blocks: function codes and data.

Fields Length Request (Client) Response (Server)

7. MODBUS/TCP PROTOCOL

Function code 1 byte

Data 1 to 254

bytes

03H: Read holding registers

06H: Write single register

08H: Diagnostics (loopback test)

10H: Write multiple registers

17H: Read/write multiple

registers

Data meeting the function code

Normal response

Returns data from the client as is

Error response

80H + Function code

Normal response

Data meeting the function code

Error response

Exception code

01H: Illegal function code

02H: Illegal register address

03H: Illegal data value

04H: Server failure

06H: Server busy

IMS01P09-E4 29

Page 36

7. MODBUS/TCP PROTOCOL

7.2 Function Code

Function code contents

Function code

Function Contents

03H

06H

08H

10H

Read holding registers

Write single register Set value, PID constants, event set value, etc.

Diagnostics (loopback test) Loopback test

Write multiple registers Set value, PID constants, event set value, etc.

Measured value, Control output value, Current

transformer input value, Event status, etc.

Measured value, Control output value, Current

17H

Read/write multiple registers

transformer input value, Event status, Set value,

PID constants, event set value, etc.

Message (PDU) length of each function [Unit: byte]

Function code Function

Request message Response message

Min Max Min Max

03H

06H

08H

10H

17H

Read holding registers

Write single register

Diagnostics (loopback test)

Write multiple registers

Read/write multiple registers

5 5 4 252

5 5 5 5

5 5 5 5

8 252 5 5

12 246 4 238

7.3 Server (SRV) Responses

Normal response

• In the response message of the read holding registers, the server (SRV) returns the “Function

code,” “Number of data items” and the “Read out data” as the response message.

• In the response message of the write single register and diagnostics (loopback test), the server

(SRV) returns the same message as the request message.

• In the response message of the write multiple registers, the server (SRV) returns the “Function

code,” the “Register address number” and the “Number of register” as the response message.

• In the response message of the read/write multiple registers, the server (SRV) returns the “Function

code,” “Number of write data items” and the “Read out data” as the response message.

30

IMS01P09-E4

Page 37

Defective message response

7. MODBUS/TCP PROTOCOL

• If the request message from the client is defective, except for

Function code

transmission error, the server (SRV) returns the exception response

message without any action.

• If the self-diagnostic function of the server (SRV) detects an error,

the server will return an exception response message to all request

Exception code

Exception response

message

messages.

• The function code of each exception response message is obtained by adding “80H” to the function

code of the request message.

Exception

code

Contents Causes

01H Illegal function code An unsupported function code was specified

02H Illegal register address When the mismatched register address is specified.

03H Illegal data value

• The number of specified data points was out of the

following range during data read or write.

Function code 03H: 1 to 125

Function code 10H: 1 to 123

Function code 17H: 1 to 118

• When the data written exceeds the setting range

04H Server failure

State under which the server cannot normally

respond (An error occurred in the server)

06H Server busy

State under which the server cannot immediately

respond (The server is being initialized)

Exception code priority order

01H > 03H > 02H > 04H > 06H

• Order of a no response in PDU data length error

When Specified PDU data length < Received PDU data length:

01H > No response in PDU data length error > 03H

When Specified PDU data length > Received PDU data length:

No response in PDU data length error > 01H

• Order when reading/writing the register contents

When there is 02H or 03H only for read processing:

01H > 04H > 06H > 03H > 02H

• Order when out of the setting range

For 03H when out of the setting range: 01H > 02H > 04H > 06H > 03H

No response

The server (SRV) ignores the request message and does not respond when:

• The IP address does not coincide.

• The server (SRV) is not connected to the network.

• The PDU (Protocol Data Unit) data length is abnormal.

When the PDU data length specified by the request message does not coincide with the number of

bytes received as one TCP packet.

SRV determines whether or not communication messages correspond to one packet by time-out

(approx. 12 ms) between characters.

IMS01P09-E4

31

Page 38

7. MODBUS/TCP PROTOCOL

N

7.4 Message Format

7.4.1 Read holding registers [03H]

The request message specifies the starting register address number and quantity of register addresses

to be read.

The contents of the registers are entered in the response message as data, divided into two parts: the

high-order eight bits and low-order eight bits, arranged in the order of the register numbers.

Example: The contents of the three registers from 0000H to 0002H are the read out.

Request message [Client]

Transaction Identifier High 00H

Low 00H

Protocol Identifier High 00H

Low 00H

Data Length High 00H

Low 06H

Unit Identifier 00H

Function code 03H

Register address High 00H

Low 00H

Quantity High 00H

(Number of words) Low 03H

MBAP Header

First register address

The setting must be between 1 (0001H) and

125 (007DH).

Normal response message [Server]

Transaction Identifier High 00H

Low 00H

Protocol Identifier High 00H

Low 00H

MBAP Header

Data Length High 00H

Low 09H

Unit Identifier 00H

Function code 03H

Number of data (byte) 06H

umber of registers × 2

First register High 00H

contents Low 78H

Next register High 00H

contents Low 00H

Next register High 00H

contents Low 14H

32

IMS01P09-E4

Page 39

Exception response message [Sever]

Transaction Identifier High 00H

Low 00H

Protocol Identifier High 00H

Low 00H

MBAP Header

Data Length High 00H

Low 03H

Unit Identifier 00H

80H + Function code 83H

Exception code 03H

When the data exceeds the setting range

7. MODBUS/TCP PROTOCOL

IMS01P09-E4

33

Page 40

7. MODBUS/TCP PROTOCOL

7.4.2 Write single register [06H]

The request message specifies data to be written into the designated register.

Write data items are arranged in the request message in order starting from the smallest register

address number. In addition, each register address is assigned in the order of high-order eight bits and

low-order eight bits, respectively.

Example: When 100 (64H) is written to the register 0010H

Request message [Client]

Transaction Identifier High 00H

Low 00H

Protocol Identifier High 00H

Low 00H

Data Length High 00H

Low 06H

Unit Identifier 00H

Function code 06H

Register address High 00H

Low 10H

Write data High 00H

Low 64H

Normal response message [Server]

Transaction Identifier High 00H

Low 00H

Protocol Identifier High 00H

Low 00H

Data Length High 00H

Low 06H

Unit Identifier 00H

Function code 06H

Register address High 00H

Low 10H

Write data High 00H

Low 64H

Exception response message [Sever]

Transaction Identifier High 00H

Low 00H

Protocol Identifier High 00H

Low 00H

Data Length High 00H

Low 03H

Unit Identifier 00H

80H + Function code

86H

Exception code 03H

MBAP Header

Any data within the range

Contents will be the same as request message data

MBAP Header

When the data exceeds the setting range

34

IMS01P09-E4

Page 41

7. MODBUS/TCP PROTOCOL

7.4.3 Diagnostics (Loopback test) [08H]

The client's request message will be returned as the response message from the server.

This function checks the communication system between the client and server.

Example: Loopback test

Request message [Client]

Transaction Identifier High 00H

Low 00H

Protocol Identifier High 00H

Low 00H

Data Length High 00H

Low 06H

Unit Identifier 00H

Function code 08H

Test code High 00H

Low 00H

Data High 1FH

Low 34H

Normal response message [Server]

Transaction Identifier High 00H

Low 00H

Protocol Identifier High 00H

Low 00H

Data Length High 00H

Low 06H

Unit Identifier 00H

Function code 08H

Test code High 00H

Low 00H

Data High 1FH

Low 34H

Exception response message [Sever]

Transaction Identifier High 00H

Low 00H

Protocol Identifier High 00H

Low 00H

Data Length High 00H

Low 03H

Unit Identifier 00H

80H + Function code

88H

Exception code 06H

MBAP Header

Test code must be set to 00H

Any pertinent data

Contents will be the same as request message data

MBAP Header

When server is busy

IMS01P09-E4

35

Page 42

7. MODBUS/TCP PROTOCOL

N

7.4.4 Write multiple registers [10H]

Each data is written to registers in specified quantities starting from the specified register address.

Write data items are arranged in the request message in order starting from the smallest register

address number. In addition, each register address is assigned in the order of high-order eight bits and

low-order eight bits, respectively.

Example: When 100 (64H) and 30 (1EH) are written to the register 0010H and 0011H (two in

total)

Request message [Client]

Transaction Identifier High 00H

Low 00H

Protocol Identifier High 00H

Low 00H

Data Length High 00H

Low 0BH

Unit Identifier 00H

Function code 10H

Register address High 00H

Low 10H

Quantity High 00H

(Number of words) Low 02H

Number of data (byte) 04H

Data to first High 00H

register Low 64H

Data to next High 00H

register Low 1EH

MBAP Header

First register address

The setting must be between 1 (0001H) and

123 (007BH).

umber of registers × 2

Normal response message [Server]

Transaction Identifier High 00H

Low 00H

Protocol Identifier High 00H

Low 00H

MBAP Header

Data Length High 00H

Low 06H

Unit Identifier 00H

Function code 10H

Register address High 00H

Low 10H

First register address

Quantity High 00H

(Number of words) Low 02H

36

IMS01P09-E4

Page 43

Exception response message [Sever]

Transaction Identifier High 00H

Low 00H

Protocol Identifier High 00H

Low 00H

MBAP Header

Data Length High 00H

Low 03H

Unit Identifier 00H

80H + Function code 90H

Exception code 03H

When the data exceeds the setting range

7. MODBUS/TCP PROTOCOL

IMS01P09-E4

37

Page 44

7. MODBUS/TCP PROTOCOL

N

N

7.4.5 Read/write multiple registers [17H]

The contents of consecutive registers in specified quantities are read starting from the specified

register address. Each data is written to registers in specified quantities starting from the specified

register address.

Example: When data is read from the register 0000H (one in total) and then 100 (64H) and 30

(1EH) are written to the register 0010H and 0011H (two in total)

Request message [Client]

Transaction Identifier High 00H

Low 00H

Protocol Identifier High 00H

Low 00H

Data Length High 00H

Low 0FH

Unit Identifier 00H

Function code 17H

Read register High 00H

address Low 00H

Read quantity High 00H

(Number of words) Low 01H

Write register High 00H

address Low 10H

Write quantity High 00H

(Number of words) Low 02H

Number of write data (byte) 04H

Written data to first High 00H

register Low 64H

Written data to next High 00H

register Low 1EH

MBAP Header

First read register address

The setting must be between 1 (0001H) and

118 (0076H).

First write register address

The setting must be between 1 (0001H) and

118 (0076H).

umber of write registers × 2

Normal response message [Server]

Transaction Identifier High 00H

Low 00H

Protocol Identifier High 00H

Low 00H

MBAP Header

Data Length High 00H

Low 05H

Unit Identifier 00H

Function code 17H

Number of write data (byte) 04H

Read register

High 00H

umber of write registers × 2

contents Low 78H

38

IMS01P09-E4

Page 45

Exception response message [Sever]

Transaction Identifier High

Low

Protocol Identifier High

Low

Data Length High

Low

Unit Identifier

80H + Function code

Exception code

00H

00H

00H

00H

00H

03H

00H

97H

03H

7. MODBUS/TCP PROTOCOL

MBAP Header

When the data exceeds the setting range

IMS01P09-E4

39

Page 46

7. MODBUS/TCP PROTOCOL

7.5 Data Configuration

The numeric range of data used in this protocol is 0000H to FFFFH. Only the set value within the

setting range is effective.

FFFFH represents −1.

7.5.1 Data processing with decimal points

Data without decimal points

Comprehensive event state DO1 setting

Burnout state DO2 setting

Error code DO state

Event 1 state Event interlock release

Event 2 state Temperature rise completion soak time

Heater break alarm state TIO state

Control loop break alarm (LBA) state V-TIO-P/V-TIO-Q module error code

Temperature rise completion state Number of connected TIO modules

Integral time Number of connected TIO channels

Derivative time Initial setting mode

Control response parameters Control loop break alarm (LBA) use selection

Operation mode Control loop break alarm (LBA) time

PID/AT transfer Input rang number

Auto/Manual transfer Input range decimal point position

Heat-side proportional cycle time Temperature unit selection

Cool-side proportional cycle time Control type selection

Digital filter Event 1 type selection

Number of heater break alarm delay times Event 2 type selection

Control RUN/STOP transfer Event 1 action selection

Input error determination point (high) Event 2 action selection

Input error determination point (low) Event delay timer

AT differential gap time TIO module internal communication

Event LED mode setting Transmission transfer time setting

DI setting Operation mode holding setting

DI state

Example: When input range number is 18, 18 = 12H

Input range number

High

00H

Low 12H

40

IMS01P09-E4

Page 47

7. MODBUS/TCP PROTOCOL

Data with decimal points

This protocol does not recognize data with decimal points during communication.

Data with one decimal place

Heat-side manipulated output value Manual output value

Cool-side manipulated output value Output limiter (high)

Current transformer input measured value Output limiter (low)

Heater break alarm set value Manipulated output value at input error

Example: When heater break alarm set value 1 is 20.0 A, 20.0 is processed as 200,

200 = C8H

Heater break alarm

High

00H

set value Low C8H

Data whose decimal point’s presence and/or position depends on input

range

The position of the decimal point changes depending on the input range type because this protocol

does not recognize data with decimal points during communication.

Type of decimal points position

Temperature input: No decimal place and one decimal place

Voltage/current input: No decimal place, one decimal place, two decimal places, and thee decimal

places

Input measured value (PV) Input error determination point (low)

Set value (SV) AT bias

Set value monitor Control loop break alarm (LBA) deadband

Heat-side proportional band Temperature rise completion range

Cool-side proportional band Input scale high limit

Overlap/Deadband Input scale low limit

Setting change rate limiter ON/OFF control differential gap (upper)

PV bias ON/OFF control differential gap (lower)

Event 1 set value Event 1 differential gap

Event 2 set value Event 2 differential gap

Input error determination point (high)

Example: When the set value is −20.0 °C, −20.00 is processed as −200,

−200 = 0000H − 00C8H = FF38H

IMS01P09-E4

Set value

High

FFH

Low 38H

41

Page 48

7. MODBUS/TCP PROTOCOL

7.5.2 Data processing precautions

With this protocol, the maximum number of channels is 62.

If data range or address error occurs during data writing, the data written before error is in effect.

Some communication data may become invalid depending on the module selection or the

configuration of the server (SRV).

Under conditions listed below, no error response message will occur.

− When ON/OFF control, proportional band, integral time and derivative time are invalid.

− When current/voltage output, proportioning cycle time are invalid.

− When only the heater break alarm function is provided, current transformer input measured value,

heater break alarm status, heater break alarm set value and number of heater break alarm delay

times are valid.

− When only the control loop break alarm (LBA) function is provided, control loop break alarm

(LBA) status, use selection, time and deadband are valid.

Do not write data to any address which is not described in a list of data maps.

42

IMS01P09-E4

Page 49

7.6 Data Map

For heat/cool control, data in the second channel of temperature control module

7.6.1 Normal setting data items

becomes invalid.

Register address numbers which are not described are those unused.

7. MODBUS/TCP PROTOCOL

Register

Name

address

HEX DEC

Measured value (PV) 0000

·

·

·

003D

Comprehensive event

state

0040

·

·

·

007D

Heat-side manipulated

output value

0080

·

·

·

00BD

Set value monitor 00C0

·

·

·

00FD

0

·

·

·

61

64

·

·

·

125

128

·

·

·

189

192

·

·

·

253

RO: Read only R/W: Read and Write

No. of

data

Attri-

bute

62 RO TC/RTD input:

Within input range

Voltage (V)/Current (I)

input:

Input scale low limit to

Input scale high limit

62 RO

Bit data

b0: Burnout

b1: Event 1 state

b2: Event 2 state

b3: Heater break alarm

(HBA) state

b4: Control loop break

alarm (LBA) state

b5 to b7:

Unused

Data 0: OFF 1: ON

[Decimal numbers

expression: 0 to 31]

62 RO

−5.0 to +105.0 %

62 RO TC/RTD input:

Within input range

Voltage (V)/Current (I)

input:

Input scale low limit to

Input scale high limit

Data range

Factory

set

value

Refer-

ence

page

57

57

58

58

IMS01P09-E4

Continued on the next page.

43

Page 50

7. MODBUS/TCP PROTOCOL

Continued from the previous page.

Name

Error code

(Data of each module)

Cool-side manipulated

output value

Current transformer (CT)

input value

01BD

Burnout state 0200

Event 1 state 0240

Event 2 state 0280

02BD

Heater break alarm

(HBA) state

Control loop break

alarm (LBA) state

Temperature rise

completion state

Operation mode 03C0

Register

address

HEX DEC

0100

·

·

·

011E

0140

·

·

·

017D

0180

·

·

·

256

·

·

·

286

320

·

·

·

381

384

·

·

·

445

512

·

·

·

023D

·

·

·

027D

·

·

·

·

·

·

573

576

·

·

·

637

640

·

·

·

701

02C0

·

·

·

02FD

0300

·

·

·

033D

0340

·

·

·

037D

·

·

·

03FD

704

·

·

·

765

768

·

·

·

829

832

·

·

·

893

960

·

·

·

1021

No. of

data

Attri-

bute

31 RO

62 RO

62 RO

62 RO 0: OFF

62 RO 0: OFF

62 RO 0: OFF

62 RO

62 RO 0: OFF

62 RO

62 R/W

Data range

Bit data

b0: Memory backup error

b1: Unused

b2: Internal communication

error

b3: Adjustment data error

b4: Input error

b5: Current transformer

(CT) input error

b6: Temperature

compensation error

b7: Unused

Data 0: OFF 1: ON

[Decimal numbers

expression: 0 to 127]

−5.0 to +105.0 %

0.0 to 30.0 A or

0.0 to 100.0 A

1: ON

1: ON

1: ON

0: OFF

1: Heater break

2: Relay welding

1: ON

0: Temperature rise not

complete

1: Temperature rise

completion

0: Unused

1: Monitor 1

2: Monitor 2

3: Control

Continued on the next page.

Factory

set

value

Refer-

ence

page

59

58

59

59

60

60

60

61

61

3 62

44

IMS01P09-E4

Page 51

Continued from the previous page.

Name

Set value (SV) 0400

Heat-side proportional

band

Integral time

04BD

Derivative time 04C0

04FD

Control response

parameters

PV bias

Event 1 set value 0580

05BD

Event 2 set value 05C0

05FD

Register

address

HEX DEC

1024

·

·

·

043D

0440

·

·

·

047D

0480

·

·

·

·

·

·

1085

1088

·

·

·

1149

1152

·

·

·

1213

1216

·

·

·

·

·

·

1277

0500

053D

0540

057D

·

·

·

·

·

·

·

·

·

1280

·

·

·

1341

1344

·

·

·

1405

1408

·

·

·

1469

1472

·

·

·

·

·

·

1533

No. of

data

Attri-

bute

62 R/W

62 R/W

62 R/W

62 R/W

62 R/W 0: Slow

62 R/W

62 R/W

62 R/W

7. MODBUS/TCP PROTOCOL

Data range

TC/RTD input:

Within input range

Voltage (V)/Current (I)

input:

Input scale low limit to

Input scale high limit

TC/RTD input:

0 (0.0) to Input span

Voltage (V)/Current (I)

input:

0.0 to 100.0 % of input

span

0 (0.0): ON/OFF action

1 to 3600 seconds

0 to 3600 seconds

0: Derivative action OFF

(PI action)

1: Medium

2: Fast

−Input span to +Input span

Deviation high/Deviation

low: −Input span to

+Input span

Deviation high/low, Band:

0 (0.0) to Input span

Process high/Process low:

TC/RTD input:

Within input range

Voltage (V)/Current (I)

input:

Input scale low limit to

Input scale high limit

Factory

set

value

Refer-

ence

page

0 (0.0) 62

TC/RTD:

63

30 °C

(30.0 °C)

or 30 °F

(30.0 °F)

V/I:

30.0 %

of input

span

240 64

60 64

0 65

0 65

0 66

0 66

IMS01P09-E4

Continued on the next page.

45

Page 52

7. MODBUS/TCP PROTOCOL

Continued from the previous page.

Name

Cool-side proportional

band

Overlap/Deadband

07BD

Setting change rate

limiter

07FD

PID/AT transfer 0800

Auto/Manual transfer 0840

Manual output value

08BD

Output limiter (high) 08C0

08FD

Output limiter (low) 0900

Heat-side proportional

cycle time

Cool-side proportional

cycle time

09BD

Digital filter

09FD

Heater break alarm

(HBA) set value

0A3D

Register

address

HEX DEC

·

·

·

·

·

·

1792

·

·

·

1853

1920

·

·

·

0700

073D

0780

1981

07C0

·

·

·

1984

·

·

·

2045

2048

·

·

·

083D

·

·

·

087D

0880

·

·

·

·

·

·

2109

2112

·

·

·

2173

2176

·

·

·

2237

2240

·

·

·

·

·

·

2301

2304

·

·

·

093D

0940

·

·

·

097D

0980

·

·

·

·

·

·

2365

2368

·

·

·

2429

2432

·

·

·

2493

09C0

·

·

·

2496

·

·

·

2557

0A00

·

·

·

2560

·

·

·

2621

No. of

data

Attri-

bute

Data range

62 R/W TC/RTD input:

1 (0.1) to Input span

Voltage (V)/Current (I)

input:

0.1 to 100.0 % of input

span

62 R/W

−Input span to +Input span

62 R/W 0 (0.0) to

Input span/minute

0 (0.0): Setting change

rate limiter OFF

62 R/W 0: PID control operation

1: AT (Autotuning)

operation

62 R/W 0: Auto mode

1: Manual mode

62 R/W

−5.0 to +105.0 %

62 R/W Output limiter (low) to

105.0 %

62 R/W

−5.0 % to

Output limiter (high)

62 R/W 1 to 100 seconds

62 R/W 1 to 100 seconds

62 R/W 0 to 100 seconds

0: Digital filter OFF

62 R/W 0.0 to 30.0 A or

0.0 to 100.0 A

Factory

set

value

Refer-

ence

page

TC/RTD:

30 °C

(30.0 °C)

or 30 °F

(30.0 °F)

V/I:

30.0 %

of input

span

0 (0.0) 66

0 (0.0) 67

0 68

0 69

0.0 69

100.0 69

0.0 69

Relay

contact

output:

20

Voltage

pulse

output: 2

0 70

0.0 71

Continued on the next page.

63

70

70

46

IMS01P09-E4

Page 53

Continued from the previous page.

Name

Number of heater break

alarm (HBA) delay times

0A7D

Control RUN/STOP

transfer

(Data of each module)

0C1E

Input error determination

point (high)

0C7D

Input error determination

point (low)

0CBD

Action at input error

0CC0

(high)

0CFD

Action at input error

(low)

0D3D

Manipulated output value

at input error

0D7D

AT differential gap time 0D80

0DBD

AT bias

0E3D

Event LED mode setting

(Data of each module)

Register

address

HEX DEC

·

·

·

2624

·

·

·

0A40

2685

0C00

·

·

·

3072

·

·

·

3102

·

·

·

3136

·

·

·

0C40

3197

0C80

·

·

·

3200

·

·

·

3261

3264

·

·

·

·

·

·

3325

0D00

·

·

·

3328

·

·

·

3389

0D40

·

·

·

3392

·

·

·

3453

3456

·

·

·

·

·

·

3517

0E00

·

·

·

3584

·

·

·

3645

0F00

0F1E

·

·

·

3840

·

·

·

3870

7. MODBUS/TCP PROTOCOL

Factory

value

No. of

data

Attri-

bute

Data range

62 R/W 1 to 255 times 5 72

31 R/W 0: Control STOP

1: Control RUN

62 R/W TC/RTD input:

Within input range

Voltage (V)/Current (I)

input:

Input scale low limit to

Input scale high limit

TC/RTD:

Input

range

high

limit

V/I:

Input

scale

high

limit

62 R/W TC/RTD input:

Within input range

Voltage (V)/Current (I)

input:

Input scale low limit to

Input scale high limit

TC/RTD:

Input

range

low limit

V/I:

Input

scale

low limit

62 R/W 0: Normal control

1: Manipulated output

value at input error