Page 1

6

6

OPC-V

Operation Manual

Operation Panel

0

[For SRZ]

E

RKC INSTRUMENT INC.

®

IMS01T08-E1

Page 2

Modbus is a registered trademark of Schneider Electric.

Company names and product names used in this manual are the trademarks or registered trademarks of

the respective companies.

All Rights Reserved, Copyright 2006, RKC INSTRUMENT INC.

Page 3

Thank you for purchasing this RKC instrument. In order to achieve maximum performance and ensure

proper operation of your new instrument, carefully read all the instructions in this manual. Please place this

manual in a convenient location for easy reference.

SYMBOLS

WARNING

CAUTION

!

: This mark indicates where additional information may be located.

An external protection device must be installed if failure of this instrument

could result in damage to the instrument, equipment or injury to personnel.

: This mark indicates precautions that must be taken if there is danger of electric

shock, fire, etc., which could result in loss of life or injury.

: This mark indicates that if these precautions and operating procedures are not taken,

damage to the instrument may result.

: This mark indicates that all precautions should be taken for safe usage.

: This mark indicates important information on installation, handling and operating

procedures.

: This mark indicates supplemental information on installation, handling and

operating procedures.

WARNING

!

All wiring must be completed before power is turned on to prevent electric

shock, fire or damage to instrument and equipment.

This instrument must be used in accordance with the specifications to

prevent fire or damage to instrument and equipment.

This instrument is not intended for use in locations subject to flammable or

explosive gases.

Do not touch high-voltage connections such as power supply terminals, etc.

to avoid electric shock.

RKC is not responsible if this instrument is repaired, modified or

disassembled by other than factory-approved personnel. Malfunction can

occur and warranty is void under these conditions.

IMS01T08-E1

i-1

Page 4

CAUTION

This is a Class A instrument. In a domestic environment, this instrument may cause radio

interference, in which case the user may be required to take adequate measures.

This instrument is protected from electric shock by reinforced insulation. Provide reinforced

insulation between the wire for the input signal and the wires for instrument power supply,

source of power and loads.

Be sure to provide an appropriate surge control circuit respectively for the following:

- If input/output or signal lines within the building are longer than 30 meters.

- If input/output or signal lines leave the building, regardless the length.

This instrument is designed for installation in an enclosed instrumentation panel. All

high-voltage connections such as power supply terminals must be enclosed in the

instrumentation panel to avoid electric shock by operating personnel.

All precautions described in this manual should be taken to avoid damage to the instrument or

equipment.

All wiring must be in accordance with local codes and regulations.

All wiring must be completed before power is turned on to prevent electric shock, instrument

failure, or incorrect action.

The power must be turned off before repairing work for input break and output failure including

replacement of sensor, contactor or SSR, and all wiring must be completed before power is

turned on again.

To prevent instrument damage or failure, protect the power line and the input/output lines from

high currents with a protection device such as fuse, circuit breaker, etc.

Prevent metal fragments or lead wire scraps from falling inside instrument case to avoid

electric shock, fire or malfunction.

Tighten each terminal screw to the specified torque found in the manual to avoid electric shock,

fire or malfunction.

For proper operation of this instrument, provide adequate ventilation for heat dispensation.

Do not connect wires to unused terminals as this will interfere with proper operation of the

instrument.

Turn off the power supply before cleaning the instrument.

Do not use a volatile solvent such as paint thinner to clean the instrument. Deformation or

discoloration will occur. Use a soft, dry cloth to remove stains from the instrument.

To avoid damage to instrument display, do not rub with an abrasive material or push front

panel with a hard object.

Do not connect modular connectors to telephone line.

NOTICE

This manual assumes that the reader has a fundamental knowledge of the principles of electricity,

process control, computer technology and communications.

The figures, diagrams and numeric values used in this manual are only for purpose of illustration.

RKC is not responsible for any damage or injury that is caused as a result of using this instrument,

instrument failure or indirect damage.

RKC is not responsible for any damage and/or injury resulting from the use of instruments made by

imitating this instrument.

Periodic maintenance is required for safe and proper operation of this instrument. Some components

have a limited service life, or characteristics that change over time.

Every effort has been made to ensure accuracy of all information contained herein. RKC makes no

warranty expressed or implied, with respect to the accuracy of the information. The information in this

manual is subject to change without prior notice.

No portion of this document may be reprinted, modified, copied, transmitted, digitized, stored,

processed or retrieved through any mechanical, electronic, optical or other means without prior written

approval from RKC.

i-2

IMS01T08-E1

Page 5

CONTENTS

1. OUTLINE............................................................................ 1-1

1.1 Features .......................................................................................................1-2

1.2 Checking the Products .................................................................................1-4

2. PREPARATIONS ...............................................................2-1

2.1 Connections..................................................................................................2-2

2.1.1 Connection to the SRZ............................................................................................2-3

2.1.2 Installation of termination resistor ...........................................................................2-6

2.2 Communication Setting ................................................................................2-9

2.2.1 Module address setting........................................................................................... 2-9

2.2.2 Communication speed, data bit configuration and protocol setting .......................2-12

2.2.3 Confirmation of communication parameter of the OPC-V606E side .....................2-13

Page

2.3 Start-up Procedures ...................................................................................2-15

2.4 Contrast Adjustment ...................................................................................2-16

2.5 Set the Number of Connection Modules.....................................................2-18

3. SCREEN DESCRIPTIONS ................................................3-1

3.1 Screen Configuration....................................................................................3-2

3.2 Basic Operations ..........................................................................................3-6

3.2.1 Data settings ...........................................................................................................3-6

3.2.2 Text editing ...........................................................................................................3-10

3.3 Start-up Screen ..........................................................................................3-14

3.4 Operation Menu Screen .............................................................................3-17

3.4.1 Calling procedure of the operation menu screen ..................................................3-17

3.4.2 Operation menu screen.........................................................................................3-18

3.5 Monitor Screen ...........................................................................................3-19

3.5.1 Calling procedure of the monitor screen ...............................................................3-19

3.5.2 Basic configuration of monitor screen ...................................................................3-21

3.5.3 TIO monitor screen ...............................................................................................3-23

3.5.4 TIO alarm monitor screen .....................................................................................3-25

3.5.5 DIO monitor screen............................................................................................... 3-26

3.5.6 Configuration monitor menu 1 screen ...................................................................3-27

3.5.7 Configuration monitor menu 2 screen ...................................................................3-30

3.6 Trend Graph Screen...................................................................................3-33

3.6.1 Calling procedure of the trend graph screen .........................................................3-33

3.6.2 Trend graph screen...............................................................................................3-33

3.6.3 CH select screen................................................................................................... 3-35

IMS01T08-E1 i-3

Page 6

Page

3.7 Setting Screen ............................................................................................3-36

3.7.1 Calling procedure of the setting screen.................................................................3-36

3.7.2 TIO setting menu screen.......................................................................................3-38

3.7.3 Event setting menu screen....................................................................................3-39

3.7.4 PID setting menu screen.......................................................................................3-40

3.7.5 Other setting 1 menu screen.................................................................................3-41

3.7.6 Other setting 2 menu screen.................................................................................3-42

3.7.7 Basic configuration of setting screen ....................................................................3-43

3.7.8 Setting item list......................................................................................................3-44

3.8 Operation Mode Screen .............................................................................3-48

3.8.1 Calling procedure of the operation mode screen ..................................................3-48

3.8.2 Operation mode menu screen...............................................................................3-49

3.8.3 Basic configuration of operation mode screen ...................................................... 3-50

3.8.4 Operation mode item list .......................................................................................3-52

3.9 DO Setting Screen......................................................................................3-54

3.9.1 Calling procedure of the DO setting screen ..........................................................3-54

3.9.2 DO setting menu screen .......................................................................................3-54

3.9.3 Basic configuration of DO setting screen ..............................................................3-55

3.9.4 DO setting item list................................................................................................3-56

3.10 Initial Setting Screen.................................................................................3-57

3.10.1 Releasing procedure of the initial setting key protect.......................................... 3-57

3.10.2 Calling procedure of the initial setting screen......................................................3-59

3.10.3 Initial menu screen.............................................................................................. 3-63

3.10.4 Number of modules set screen ...........................................................................3-64

3.10.5 Clock set screen .................................................................................................3-65

3.10.6 Name setting menu screen .................................................................................3-66

3.10.7 Alarm message set screen..................................................................................3-67

3.10.8 TIO CH name set screen ....................................................................................3-68

3.10.9 Screen saver set screen .....................................................................................3-69

3.10.10 TIO controller initial menu screen .....................................................................3-70

3.10.11 Basic configuration of TIO controller initial screen ............................................ 3-71

3.10.12 TIO controller initial item list ..............................................................................3-73

3.10.13 DIO controller initial menu screen .....................................................................3-81

3.10.14 Basic configuration of DIO controller initial screen............................................ 3-82

3.10.15 DIO controller initial item list..............................................................................3-84

3.10.16 Password set screen......................................................................................... 3-88

i-4

3.11 Screen Setting Examples When Using DIO..............................................3-89

3.11.1 Example of using DI............................................................................................ 3-89

3.11.2 Example of using DO ..........................................................................................3-94

IMS01T08-E1

Page 7

OUTLINE

1.1 Features ...........................................................................................1-2

1.2 Checking the Products......................................................................1-4

IMS01T08-E1 1-1

Page 8

1. OUTLINE

1.1 Features

This instrument is the operation panel for module type controller SRZ. Through connection with the SRZ,

various data monitoring and setting, operation and alarm monitoring, etc. can be carried out.

This manual describes the connection with the SRZ and screen operations of the OPC-V606E.

For the mounting, power supply wiring and battery replacement of OPC-V606E, see the instruction manual

of Hakko Electronics Co., Ltd.

URL: Web site: http://www.hakko-elec.co.jp/

Manual download: http://www.hakko-elec.co.jp/eng/download/index02.html

In addition, the Model code of the MONITOUCH V606e series of operation panels (made by Hakko

Electronics Co., Ltd.) corresponding to our OPC-V606E operation panels is as listed below.

Model code correspondence list

Model code of RKC operation panel

Model code of MONITOUCH

(Hakko Electronics Co., Ltd.)

Specifications

STN monochrome,

OPC-V606E-35/ V606eM20

320 × 240 dots, 5.7 inches,

24 V DC

System configuration example

Operation panel OPC-V606E

POWER

RS-485 (Modbus)

SYSTEM

F1

F2

F3

F4

F5

Temperature control

Module type controller SRZ

modules (Z-TIO)

Digital I/O module

(Z-DIO)

[Usable SRZ modules]

• Temperature control module: Z-TIO-A (4-channel type), Z-TIO-B (2-channel type)

• Digital I/O module: Z-DIO-A (Digital input: 8 channels, Digital output: 8 channels)

[Maximum number of connected SRZ modules]

The maximum number of SRZ modules (including Z-DIO modules) on the same communication line is 31.

• Temperature control module (Z-TIO): 1 to 16 modules (Temperature control: 2 to 64 channels)

• Digital I/O module (Z-DIO): 0 to 16 modules (Digital input: 0 to 128 channels,

Digital output: 0 to 128 channels)

1-2 IMS01T08-E1

Page 9

)

r

When two or more SRZ units are connected

Operation panel OPC-V606E

POWER

RS-485 (Modbus

SYSTEM

F1

F2

F3

F4

F5

Module addr ess

Module address

Module type controller SRZ

0

1 2 3 4 5

Z-TIO module Z-DIO module

Internal communicati on line (RS-485)

Module type controller SRZ

6

7 8 9 10 11

Z-TIO module Z-DIO modul e

1.1 Features

16 17 18

19 20 21

Internal communicati on line (RS-485)

RS-485

Module type controller SRZ

Z-TIO: T emperat ure c ontrol module

Z-DIO: Digital I/O module

Module addr ess

RS-485

12

13 14 15 22 23

Z-TIO module Z-DIO modu le

Internal communicati on line (RS-485)

Termination resisto

[Usable SRZ modules]

• Temperature control module: Z-TIO-A (4-channel type), Z-TIO-B (2-channel type)

• Digital I/O module: Z-DIO-A (Digital input: 8 channels, Digital output: 8 channels)

[Maximum number of connected SRZ modules]

The maximum number of SRZ modules (including Z-DIO modules) on the same communication line is 31.

• Temperature control module (Z-TIO): 1 to 16 modules (Temperature control: 2 to 64 channels)

• Digital I/O module (Z-DIO): 0 to 16 modules (Digital input: 0 to 128 channels,

Digital output: 0 to 128 channels)

Easy operation using the transparent touch panel

By touching the transparent touch panel on the display of this operation panel OPC-V606E, operations

such as changing the settings and switching the displays can be performed. Operations can be easily carried

out using the sensation of conducting a dialog with the display.

Dustproof, Splashproof

The front OPC-V606E has a dustproof, splashproof construction equivalent to IP65 (IEC standards).

(Only the front section of the OPC-V606E mounted on the control panel.)

IMS01T08-E1

1-3

Page 10

1. OUTLINE

1.2 Checking the Products

Before using this product, check each of the following:

Model code

Check that all of the items delivered are complete.

Check that there are no scratch or breakage in external appearance (case, front panel, or terminal, etc).

If any of the products are missing, damaged, or if your manual is incomplete, please contact

RKC sales office or the agent.

Model code

OPC – V606E – 3 5 /

(1) Display method

3: STN monochrome LCD (8-step gradation)

(2) Connected equipment

5: SRZ (Modbus protcol)

(3) Language

J: Japanese

E: English

(1)(2) (3)

Accessories

• Mounting brackets.........4

• Operation panel OPC-V606E [For SRZ] Operation Manual (IMS01T08-E1)..........1

Peripheral equipment (Sold separately)

• Cable for SRZ connection Type: V6-MLT

Used for the connection of the OPC-V606E and the SRZ.

Cable length: 3 m

8-pin

• Protection sheet Package of 5 sheets Type: V606-GS

Protects the OPC-V606E surface.

SD/RD (Green)

−

SD/RD (Black)

+

SG (Red)

1-4 IMS01T08-E1

Page 11

PREPARATIONS

2.1 Connections......................................................................................2-2

2.1.1 Connection to the SRZ .............................................................................2-3

2.1.2 Installation of termination resistor............................................................. 2-6

2.2 Communication Setting.....................................................................2-9

2.2.1 Module address setting .............................................................................2-9

2.2.2 Communication speed, data bit configuration and protocol setting..........2-12

2.2.3 Confirmation of communication parameter of the OPC-V606E side........2-13

2.3 Start-up Procedures........................................................................2-15

2.4 Contrast Adjustment .......................................................................2-16

2.5 Set the Number of Connection Modules .........................................2-18

IMS01T08-E1 2-1

Page 12

2. PREPARATIONS

2.1 Connections

To prevent electric shock or instrument failure, turn off the power before

connecting or disconnecting the instrument and peripheral equipment.

CAUTION

Connect connectors correctly in the right position. If it is forcibly pushed in with pins in the

wrong positions, the pins may be bent resulting in instrument failure.

When connecting or disconnecting the connectors, do not force it too far to right and left or

up and down, but move it on the straight. Otherwise, the connector pins may be bent,

causing instrument failure.

When disconnecting a connector, hold it by the connector itself. Disconnecting connectors

by yanking on their cables can cause breakdowns.

To prevent malfunction, never touch the contact section of a connector with bare hands or

with hands soiled with oil or the like.

To prevent malfunction, connect cable connectors securely, then firmly tighten the connector

fastening screws.

To prevent damage to cables, do not bend cables over with excessive force.

If the instrument is easily affected by noise, use the ferrite core in the both ends of the

communication cable (nearest the connector).

WARNING

!

2-2 IMS01T08-E1

Page 13

2.1 Connections

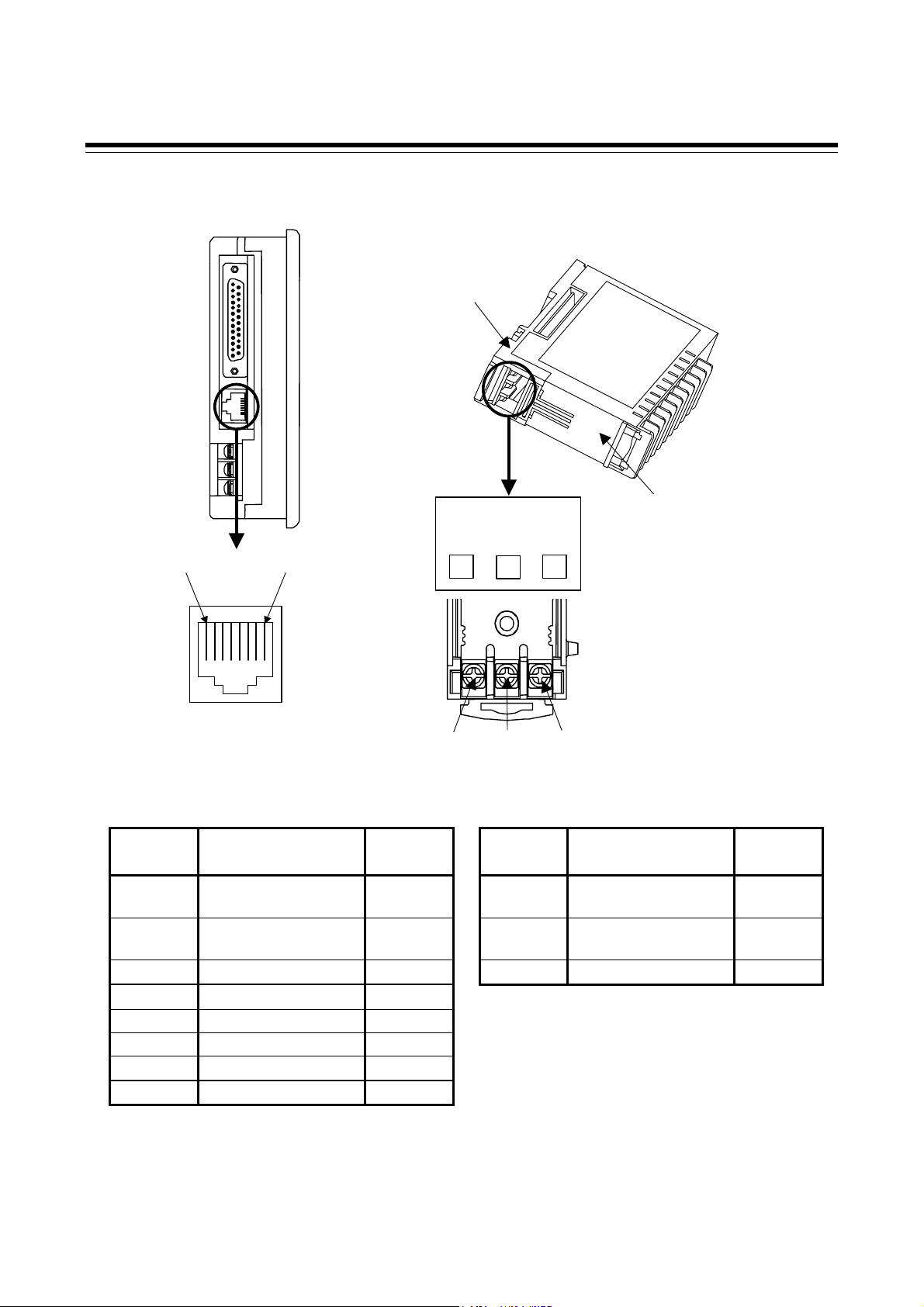

2.1.1 Connection to the SRZ

Use connection cable V6-MLT (Sold separately, Cable length: 3 m) to connect the OPC-V606E and the

SRZ.

Operation panel OPC-V606E

(Left side view)

Connect to

the [MJ1]

RS-485

Connection cable V6-MLT

Connect to the

communication terminals

SRZ module communication terminals

RS-485

T/R(A)

T/R(B)

4

SG

Module type controller SRZ

53

Base part of

the module

SRZ module

Connection cable V6-MLT

SD/RD (Green)

−

SD/RD (Black)

+

SG (Red)

Bottom of the module

For removing the base of the SRZ module, see the Z-TIO Instruction Manual (IMS01T01-E).

IMS01T08-E1 2-3

Page 14

2.1 Connections

Pin layout of connector (OPC-V606E)/Terminal configuration (SRZ)

Operation panel OPC-V606E (Left side view)

Base part of

the module

SRZ module

Bottom of the m odule

……………..

1

MJ1

RS-485

T/R(A)

8

T/R(B)

3

SG

53

4

Communication terminals

4

5

Signal details

OPC-V606E [MJ1] SRZ [Communication terminals]

Pin No. Signal name Symbol

1 RS-485

+SD/RD

send/receive data

2 RS-485

−SD/RD

send/receive data

3 Unused

4 Unused

Terminal

No.

Signal name Symbol

3 RS-485

send/receive data

4 RS-485

send/receive data

5 Signal ground SG

5 Signal ground SG

6 Signal ground SG

7 Unused

8 Unused

T/R (A)

T/R (B)

2-4 IMS01T08-E1

Page 15

Wiring contents

2.1 Connections

Module type controller SRZ

Operation panel OPC-V606E

+SD/RD

SD/RD

−

Unused

Unused

SG

SG

Unused

Unused

Modular connector

MJ1

Turns on a termination resistor

setting DIP switches (No. 6) of

OPC-V606E side modular

connector [MJ1].

Recommended modular connector

Modular connector for connect to operation panel OPC-V606E:

TM10P-88P (Manufactured by HIROSE ELECTRIC CO., LTD.)

For installation of termination resistor, see the 2.1.2 Installation of termination resistor

(P. 2-6).

1

2

3

4

5

6

7

8

Shielded twisted

Pair wire

Connectied by

the internal

communication

line

pair wire

R1: External termination

resistor (120 Ω 1/2 W)

Maximum number of connected SRZ module: 31 modules

Temperatur control module (Z-TIO): 1 to 16 modules

Digital I/O module (Z-DIO): 0 to 16 modules

R1

T/R (A)

3

4

T/R (B)

5

SG

3

4

5

T/R (A)

T/R (B)

SG

IMS01T08-E1 2-5

Page 16

2.1 Connections

2.1.2 Installation of termination resistor

Install terminating resistors to both ends of the RS-485 communication line.

Installation of termination resistor for SRZ

Mounting position

Connect a termination resistor between the communication terminals (No.3 and 4) of the module at the end

of the communication line from the host computer.

Termination resistor

(Example: 120 Ω 1/2 W)

T/R(A) T/R(B)

To operation panel OPC-V606E

When two or more module are connected

Module type controller SRZ

Internal communication line

(RS-485)

Operation

panel

OPC-V606E

RS-485

(Base)

34 5

Recommended tightening torque:

0.4 N・m (4 kgf・cm)

SG

Connect the termination

resistor to this module.

Termination

resistor

Continued on the next page.

2-6 IMS01T08-E1

Page 17

r

When two or more SRZ units are connected

Operation

panel

OPC-V606E

RS-485

RS-485

RS-485

Module type controller SRZ

Z-TIO module Z-DIO module

Internal communication line (RS-485)

Module type controller SRZ

Z-TIO module Z-DIO module

Internal communication line (RS-485)

Module type controller SRZ

Z-TIO module

Internal communication

line (RS-485)

Termination

resisto

Z-DIO module

Connect the termination

resistor to this module.

2.1 Connections

IMS01T08-E1 2-7

Page 18

2.1 Connections

Installation of termination resistor for operation panel OPC-V606E

Set the termination resistor of modular connector [MJ1] with DIP switches No. 6.

Operation panel OPC-V606E (Rear)

CN1

MJ1

+

24VDC

-

DIP switch

ON

1 2 3 4 5 6 7 8

Switch No.7 and 8 must be always OFF. Do not set to ON.

Termination resistor of modular connector [MJ1]

OFF:

If the OPC-V606E is other than a termination when connected to the MJ1 modular

connector using SRZ and RS-485.

ON:

If the OPC-V606E is a termination when connected to the MJ1 modular connector

using SRZ and RS-485.

Factory set value: ON

Switch No.1 to 5 must be always OFF. Do not set to ON.

2-8 IMS01T08-E1

Page 19

2. PREPARATIONS

2.2 Communication Setting

To prevent electric shock or instrument failure, always turn off the power

before setting the switch.

To prevent electric shock or instrument failure, never touch any section other

than those instructed in this manual.

WARNING

!

Set the communication parameter for communication between the operation panel OPC-V606E and the

SRZ.

2.2.1 Module address setting

When using two or more modules, set the desired address to each module.

Set the module address by address setting switches of front of module. For this setting, use a small blade

screwdriver.

To avoid problems or malfunction, do not duplicate an address on the same communication

line.

Set the module addresses in order from “0” without skipping any numbers. If a number is

skipped, “no response” will occur.

Setting of “Address

setting switch”

( ): Decimal number

RX/TX

Module type controller SRZ

0

1

(0)

(1)

Address setting switch

E

(14)F (15)

(2)

2

…

Setting range:

0 to F [0 to 15: Decimal numbers]

(Factory set value: 0)

D

(13)

(0)

0

1

…

(1)

(14)

E

[Temperature control module (Z-TIO)]

Set address number from the “0” sequentially.

The value obtained by adding “1” to the set

address corresponds to the address used

for the actual communication.

[Digital I/O module (Z-DIO)]

Set address number from the “0” sequentially.

The value obtained by adding “17” to the set

address corresponds to the

for the actual communication.

address used

Maximum number of connected SRZ module: 31 modules

• Temperatur control module (Z-TIO): 1 to 16 modules

• Digital I/O module (Z-DIO): 0 to 16 modules

IMS01T08-E1 2-9

Page 20

2.2 Communication Setting

Relation of module address and display channel number

Channel numbers displayed on the OPC-V606E operation panel screen are determined in order from the

“0” module address number.

[Example 1: When constructed unit with the temperature control module of 4-channel type.]

Temperature control module (Z-TIO-A: 4-channel type)

Module type controller SRZ

Address number

of module

Channel number

of module

The channel number

that is displayed on

the screen

Screen

CH3

CH3

CH4

CH4

0

CH1

CH1

CH2

CH2

CH3

CH7

CH4

CH8

1

CH1

CH5

CH2

CH6

…

…

…

CH3

CH63

CH64

15

CH4

CH61

CH1

CH2

CH62

The number of channels displayed on the screen is in accordance with the OPC-V606E initial

setting: “Number of modules set.” If “Number of modules set” is at “1” in the above system

configuration, no data on and after CH5 is displayed.

For details of number of module setting, see the 2.5 Set the Number of Connection Modules

(P. 2-18).

2-10 IMS01T08-E1

Page 21

2.2 Communication Setting

[Example 2: When constructed unit with the temperature control module of 2-channel type and

4-channel type.]

Module type controller SRZ

Address number

of module

Channel number

of module

The channel number

that is displayed on

the screen

Screen

Temperature control module

(Z-TIO-B: 2-channel type)

0

CH1

CH1

CH3

CH2

CH7

CH2

Temperature control module

(Z-TIO-A: 4-channel type)

…

…

…

CH4

CH8

1

CH1

CH2

CH5

CH6

CH3

CH63

15

CH4

CH61

CH64

CH1

CH2

CH62

When the temperature control

module of 2-channel type is

used, the display corresponding

to the CH3 and CH4 section

becomes blank.

IMS01T08-E1 2-11

Page 22

2.2 Communication Setting

p

2.2.2 Communication speed, data bit configuration and protocol setting

With the DIP switch which there is on the right side of SRZ module, select communication speed, data bit

configuration and protocol. Always make the same communication settings on the OPC-V606E and SRZ.

The data changes become valid when the power is turned on again or when changed to RUN with

“RUN/STOP transfer” of operation mode.

When two or more modules are connected on the same line, turn each switch in the DIP

switches of all of the modules to the same position. Otherwise the module may fail or

malfunction.

[Factory set value of operation panel OPC-V606E]

• Communication speed (baud rate) 19200 bps

• Data 8-bit, without parity, stop 1-bit

• Modbus protocol

See 2.2.3 Confirmation of communication parameter of the OPC-V606E side (P. 2-13).

SRZ module main frame

Z-TIO module

Z-DIO module

Right side view

[S

etting contents]

1 2 3 4 5 6 7 8

OFF ON OFF OFF ON ON OFF OFF

1 2 Communication speed

OFF OFF 4800 bps

ON OFF 9600 bps

OFF ON 19200 bps

ON ON 38400 bps

Factory set value: 19200 bps

3 4 5 Data bit configuration

OFF OFF OFF Data 7-bit, without parity, Stop 1-bit *

OFF OFF ON Data 7-bit, Even parity, Stop 1-bit *

OFF ON ON Data 7-bit, Odd parity, Stop 1-bit *

OFF OFF ON Data 8-bit, without parity, Stop 1-bit

OFF ON ON Data 8-bit, Even parity, Stop 1-bit

ON ON ON Data 8-bit, Odd parity, Stop 1-bit

* When the Modbus communication protocol is selected, this setting becomes invalid.

Factory set value: Data 8-bit, without parity, Stop 1-bit

6 7 Protocol

OFF OFF RKC communication

ON OFF Modbus

Factory set value: RKC communication

Switch No. 8: OFF fixed (Do not change this one)

DIP switch

1234567

8

OFF

Set to 19200 bps

Set to Modbus

ON

ON

Set to data 8-bit,

without parity and

sto

1-bit

2-12 IMS01T08-E1

Page 23

2.2 Communication Setting

2.2.3 Confirmation of communication parameter of the OPC-V606E side

The parameter for communication between the operation panel OPC-V606E and SRZ on the operation

panel side can be checked on the “Extension Prog. Info.” screen.

< Extension Prog. Info. screen >

Extension Prog. Info.

Temp. CTRL Drv

VER. 1.100

RKC SR-Mini/CB

Temp. CTRLComm. Param.

Signal level:

RS485

Baud Rate: 19200

Data Length: 8

Stop Bit: 1

Parity: None

Retry Time: 3

Time-out: 300msec

Send Delay: 6msec

Return Time: 10sec

Main Menu

Main Menu

Touching this key change to the “Main Menu”

screen.

Temperature control communication parameter

The parameter for communication between the

operation panel and SRZ is displayed but cannot

be set.

The parameter for communication on the OPC-V606E side is changed by the panel editor

V-SFTE. For the panel editor V-SFTE, please contact RKC sales office or the agent.

Operation procedures

1. Press and hold the [SYSTEM] switch, and press the [F5] switch at the same time.

“Main Menu” screen is displayed. The “Main Menu” screen can be changed on any screen.

SYSTEM switch

SYSTEM

F1

F2

F3

F4

Main Menu

F5

F5 switch

Continued on the next page.

IMS01T08-E1 2-13

Page 24

2.2 Communication Setting

Continued from the previous page.

2. Touch the [Extension] key. “Extension Prog. Info.” screen is displayed.

enu

Main M

Extension

Exte nsion

3. After the information is checked, touch the [Main Menu] key to call out the “Main Menu” screen.

Extension Prog. Info.

Extension Prog. Info.

Temp. CTRL Drv

VER. 1.100

Temp. CTRL Drv

RKC SR-Mini/CB

VER. 1.100

RKC SR-Mini/CB

Temp. CTRLComm. Param.

Main Men u

Main Menu

Signal level:

Temp. CTRLComm. Param .

RS485

Signal level:

Baud Rate: 19200

RS485

Data Length: 8

Baud Rate: 19200

Stop Bit: 1

Data Length: 8

Parity: None

Retry Time: 3

Stop Bit: 1

Time-out : 300msec

Parity: None

Send Delay: 6msec

Retry Time: 3

Return Time: 10sec

Time-out: 300ms ec

Send Delay: 6msec

Return Time: 10sec

Main Menu

4. Press the [SYSTEM] switch with the “Main Menu” screen being displayed. The menu is displayed at

the side of the function switch.

S

Y

SYSTEM

S

F1

M

O

D

F2

E

CT

F3

F4

Menu

F5

5. Press the [F1] switch with the menu being displayed.

Pressing the [F1] switch displays the “Opening” screen after an error is checked and then displays the

“TIO Monitor” screen.

S

Y

SYSTEM

S

F1

M

O

D

E

CT

F2

F3

The menu disappears after a certain lapse of time.

If it disappears, press the [SYSTEM] switch again.

F4

Menu

F5

2-14 IMS01T08-E1

Page 25

2.3 Start-up Procedures

Check prior to power on

Check the following items before turning on the power to the operation panel OPC-V606E.

communication setting of

Check the

mounting and wiring

Check the connections

Check the

termination resistor

Check the

SRZ

Confirms the mounting and wiring.

See the instruction manual of Hakko Electronics Co., Ltd.

Connections conform to 2.1 Connections (P. 2-2).

Termination resistor setting conforms to 2.1.2 Installation of

termination resistor (P. 2-6).

Communication setting conforms to 2.2 Communication Setting

(P. 2-9).

Power on

First, turn on the power for module type controller SRZ,

then for operation panel OPC-V606E.

Setting after power on

2. PREPARATIONS

Set the number of connection

Power on

Contrast adjustment

modules

Operations

If you changed the SRZ initial data in SRZ loader communication, turn off the power of the

OPC-V606E and then turn it back on (power reset). The initial data will be effective after

the power reset.

Adjust the contrast of the screen display.

For contrast adjustment, see the 2.4 Contrast Adjustment

(P. 2-16).

Set the number of the SRZ modules connected to an operation panel.

For the number of module connection, see the 2.5 Set the

Number of Connection Modules (P. 2-18).

IMS01T08-E1 2-15

Page 26

2. PREPARATIONS

2.4 Contrast Adjustment

The contrast adjustment can be set with the function switches.

Operation procedures

1. Press and hold the [SYSTEM] switch, and press the [F5] switch at the same time.

“Main Menu” screen is displayed. The “Main Menu” screen can be changed on any screen.

SYSTEM switch

SYSTEM

F1

F2

Main Menu

F3

F4

F5

F5 switch

Continued on the next page.

2-16 IMS01T08-E1

Page 27

2.4 Contrast Adjustment

Continued from the previous page.

2. Press the [SYSTEM] switch with the “Main Menu” screen being displayed. The menu is displayed at

the side of the function switch.

F1: Mode

Main menu mode ends.

S

Y

S

M

O

D

E

CT

CT

CT

B

K

L

T

SYSTEM

F1

F2

F3

F4

F5

F2: Contrast adjustment (dark)

This switch adjusts the contrast of LCD. When the [F2]

switch is pressed once, the LCD color becomes dark. If this

switch is held down for 1 second, the LCD color changes

rapidly into darkness.

F3: Contrast adjustment (intermediate)

This switch adjusts the contrast of LCD. When the [F3]

switch is pressed once, the LCD color becomes intermediate.

F4: Contrast adjustment (light)

This switch adjusts the contrast of LCD. When the [F4]

switch is pressed once, the LCD color becomes light. If this

switch is held down for 1 second, the LCD color changes

rapidly into lightness.

F5: Invalidity (Ignored)

Menu

3. Press the [F2] to [F4] switches with the menu being displayed. The contrast adjustment can be set.

4. Press the [F1] switch with the menu being displayed.

Pressing the [F1] switch displays the “Opening” screen after an error is checked and then displays the

“TIO Monitor” screen.

S

Y

SYSTEM

S

F1

M

O

D

E

CT

Menu

F2

F3

F4

F5

The menu disappears after a certain lapse of time.

If it disappears, press the [SYSTEM] switch again.

IMS01T08-E1

2-17

Page 28

2. PREPARATIONS

2.5 Set the Number of Connection Modules

The number of the module connection sets it after releasing an initial setting the key protection.

Operation procedures

1. Touch the [Menu] key on the “TIO Monitor” screen, to switch to the “Operation Menu” screen.

2. Touch the [Initial Setting] key on the “Operation Menu” screen, to switch to the “Password

confirmation” screen.

3. Enter the password “0000” and touch the [ENT] key.

If the password is correct, the screen will change to the “Initial Menu” screen.

The password in shipment becomes “0000.”

When changes the password, see the 3.10.16 Password set screen (P. 3-88).

Continued on the next page.

2-18 IMS01T08-E1

Page 29

2.5 Set the Number of Connection Modules

Continued from the previous page.

4. Touch the [Number of modules set] key on the “Initial Menu” screen, to switch to the “Number of

modules set” screen.

5. Set the number of the connection of the Z-TIO modules and Z-DIO modules.

Set the number of the SRZ modules connected to

an operation panel OPC-V606E.

Setting range:

Number of Z-TIO modules: 1 to 16 (Factory set value: 1)

Number of Z-DIO modules: 0 to 16 (Factory set value: 0)

Up to 31 modules including both Z-TIO module

and Z-DIO module.

6. When the number of connecting modules is changed, always reset the OPC-V606E in accordance

with any of the following procedures. The number of modules thus changed becomes valid after the

OPC-V606E is reset.

• Reset with power

Turn off the power once and then turn it on again.

• Reset with switch operations

1. Press and hold the [SYSTEM] switch, and press the [F5] switch at the same time.

2.

3. Press the [F1] switch with the menu being displayed.

IMS01T08-E1

“Main Menu” screen is displayed. The “Main Menu” screen can be changed on any screen.

Press the [SYSTEM] switch with the “Main Menu” screen being displayed. The menu is

displayed at the side of the function switch.

Pressing the [F1] switch displays the “Opening” screen after an error is checked and then

displays the “TIO Monitor” screen.

2-19

Page 30

MEMO

2-20 IMS01T08-E1

Page 31

SCREEN

DESCRIPTIONS

3.1 Screen Configuration........................................................................3-2

3.2 Basic Operations..............................................................................3-6

3.2.1 Data settings .............................................................................................3-6

3.2.2 Text editing.............................................................................................. 3-10

3.3 Start-up Screen ..............................................................................3-14

3.4 Operation Menu Screen .................................................................3-17

3.5 Monitor Screen...............................................................................3-19

3.6 Trend Graph Screen.......................................................................3-33

3.7 Setting Screen................................................................................3-36

3.8 Operation Mode Screen .................................................................3-48

3.9 DO Setting Screen .........................................................................3-54

3.10 Initial Setting Screen.....................................................................3-57

3.11 Screen Setting Examples When Using DIO..................................3-89

3.11.1 Example of using DI ..............................................................................3-89

3.11.2 Example of using DO.............................................................................3-94

IMS01T08-E1 3-1

Page 32

3. SCREEN DESCRIPTIONS

A

A

A

(

A

)

(

(

)

r

3.1 Screen Configuration

Power ON

utomatic

Check

Voltage drop of the battery

for SRAM cassette

P. 3-14

Operation

P. 3-18

Menu

utomatic

P.3-14

Opening

Error occurs

utomatic

P. 3-23

TIO Monitor

(PV/SV)

P. 3-25

TIO Alarm Monitor

E1/E2/E3/E4)

TIO Monitor

(MVH/MVC)

TIO Alarm Monitor

BO/HBA

DIO Monitor

P. 3-26

P. 3-33

CH Select Trend Graph

TIO Setting Menu

P. 3-38

For the screen list, see the TIO setting menu (P. 3-3).

Operation Mode

DO Setting Menu

P. 3-49

For the screen list, see the Operation mode menu (P. 3-3).

Menu

P. 3-54

For the screen list, see the DO setting menu (P. 3-3).

Configuration Monitor

Menu 1

Initial Menu

P. 3-27

Configuration Monito

Menu 2

P. 3-63

For the screen list, see the Initial menu (P. 3-4).

Always set the number of modules when the power was turned on for the first time is

started after the connectable number of modules changed. If no number of modules is set,

the screen may not be correctly displayed to cause malfunction. The number of modules is

set on the “Number of modules set” screen.

If you changed the SRZ initial data in SRZ loader communication, turn off the power of the

OPC-V606E and then turn it back on (power reset). The initial data will be effective after

the power reset.

P. 3-23

P. 3-25

P. 3-35

P. 3-30

P. 3-16

Warning

(Battery replacement)

P. 3-14

Error message

P. 3-24

TIO Monitor

CT/HB

For the screen list, see the

Configuration monitor menu

(P. 3-4).

3-2 IMS01T08-E1

Page 33

3.1 Screen Configuration

TIO setting menu

Screen name Page

Set value (SV) 3-44

Manual Output 3-44

Event Setting Menu Event 1 set value 3-44

Event 2 set value 3-44

Event 3 set value 3-44

Event 4 set value 3-44

PID Setting Menu Proportional band 3-45

Integral Time 3-45

Derivative Time 3-45

Proportional band [cool-side] 3-45

Integral Time [cool-side] 3-45

Derivative Time [cool-side] 3-45

Overlap/Deadband 3-45

Control response parameter 3-45

Other Setting 1 Menu HBA set value 3-46

Heater break determination point 3-46

Heater melting determination point 3-46

Proportional cycle time 3-46

Minimum ON/OFF time of proportioning cycle 3-46

Control loop break alarm (LBA) time 3-46

LBA deadband 3-46

Other Setting 2 Menu PV bias 3-47

PV digital filter 3-47

PV ratio 3-47

PV low input cut-off 3-47

Setting change rate limiter (up) 3-47

Setting change rate limiter (down) 3-47

Startup tuning (ST) ON/OFF 3-47

Communication switch for logic 3-47

Operation mode menu

Screen name Page

Operation Mode Menu Operation mode transfer 3-52

PID/AT transfer 3-52

Auto/Manual transfer 3-52

RUN/STOP transfer 3-52

Interlock release 3-52

Remote/Local transfer 3-52

DO setting menu

Screen name Page

DO Setting Menu DO RUN/STOP transfer 3-56

DO manual output 3-56

DO output distribution selection 3-56

IMS01T08-E1 3-3

Page 34

3.1 Screen Configuration

Configuration monitor menu

Screen name Page

Configuration Monitor Menu 1 Control action 3-28

Address of interacting modules 3-28

Channel selection of interacting modules 3-29

Selection switch of interacting modules 3-29

Configuration Monitor Menu 2 DO output assignment 1 3-31

DO output assignment 2 3-31

DO signal assignment module address 1 3-31

DO signal assignment module address 2 3-32

DI function assignment 3-32

Initial menu

Protection release is necessary to display each initial screen.

For details, see the 3.10.1 Releasing procedure of the initial setting key protect (P. 3-57).

Number of modules set 3-64

Clock set 3-65

Name Setting Menu Alarm Message Set 3-67

TIO CH name set 3-68

Screen Saver Set 3-69

TIO controller initial menu Input parameter menu Input type 3-73

Decimal point position 3-73

Input scale high 3-73

Input scale low 3-73

Display unit 3-73

Control parameter menu Control action 3-74

Control RUN/STOP holding setting 3-74

Event parameter menu Event 1 type 3-74

Event 1 channel setting 3-75

Event 1 hold action 3-75

Event 1 interlock 3-75

Event 1 differential gap 3-75

Event 1 delay timer 3-75

Force ON of Event 1 action 3-75

Event 2 type 3-74

Event 2 channel setting 3-75

Event 2 hold action 3-75

Event 2 interlock 3-75

Event 2 differential gap 3-75

Event 2 delay timer 3-75

Force ON of Event 2 action 3-75

Screen name

Page

Continued on the next page.

3-4 IMS01T08-E1

Page 35

3.1 Screen Configuration

Continued from the previous page.

TIO controller initial menu Event parameter menu Event 3 type 3-74

Event 3 channel setting 3-75

Event 3 hold action 3-75

Event 3 interlock 3-75

Event 3 differential gap 3-75

Event 3 delay timer 3-75

Force ON of Event 3 action 3-75

Event 4 type 3-74

Event 4 channel setting 3-75

Event 4 hold action 3-75

Event 4 interlock 3-75

Event 4 differential gap 3-75

Event 4 delay timer 3-75

Force ON of Event 4 action 3-75

Output parameter menu Output limiter (high) [heat-side] 3-76

Output limiter (low) [heat-side] 3-76

Output limiter (high) [cool-side] 3-76

Output limiter (low) [cool-side] 3-76

CT parameter menu CT ratio 3-76

CT assignment 3-76

Heater break alarm (HBA) type 3-76

Number of HBA delay times 3-76

Interacting parameter menu Address of interacting modules 3-77

Channel selection of interacting modules 3-77

Selection switch of interacting modules 3-77

ST parameter menu ST start condition 3-77

AT parameter menu AT bias 3-78

AT differential gap time 3-78

AT cycles 3-78

Output value with AT turned on 3-78

Output value with AT turned off 3-78

Communication parameter menu Interval time 3-78

Input error parameter menu Input error determination point (high) 3-79

Input error determination point (low) 3-79

Burnout direction 3-79

DIO controller initial menu DO output assignment 1 [DO1 to DO4] 3-84

DO output assignment 2 [DO5 to DO8] 3-84

DO signal assignment module address 1 [DO1 to DO4] 3-84

DO signal assignment module address 2 [DO5 to DO8] 3-84

DO energized/de-energized 3-85

Interval time 3-85

DI function assignment 3-85

Memory area setting signal 3-85

Password set Password set 3-88

Screen name

Page

IMS01T08-E1 3-5

Page 36

3. SCREEN DESCRIPTIONS

+/−

+/−

3.2 Basic Operations

3.2.1 Data settings

You directly touch the data setting or the part you want to change, the numeric keypad window appears on

the screen.

< Numeric keypad window >

Data editing section

CH

1

100.0

7 8 9

4 5 6

Close key

Close

CH

CLR

Data setting selection key

CLR key

1 2 3

ENT

0 .

ENT key

key

Data editing section: Edits the data. The cursor shows where data is input. The number of characters that

cab be edited in the data editing section depends on the number of characters that

can be input for the data.

Close key: Disappearing the numeric keypad window

Data setting selection key:

Used to select any one of the following data settings. Every time this key touched,

the data setting changes.

CH: Setting for each channel

The desired data is directly touched for its setting.

All CH: Setting for all channels

The same items related to all channels are simultaneously set to the

CLR key: Erases the input data. If you input the wrong number, touching this key.

ENT key: Enters the text displayed in the data editing section and closes the numeric keypad

window.

+/− key: The [+/−] key toggles the value between plus and minus. After inputting the

number, set the + or − with this key before touching the [ENT] key.

same numeric values.

The available setting differs depending on the setting item. If the setting

cannot be changed even when touched on the data setting selection key, that

setting cannot be used. In addition, there are some setting items in which no

data setting selection key is displayed.

3-6 IMS01T08-E1

Page 37

3.2 Basic Operations

+/−

+

Disappearing the numeric keypad window

If you accidentally touch a setting part that you do not need to change and the numeric keypad window

appears, either just press the [ENT] key without inputting a number or touch the top left section of the

numeric keypad window twice in a row to put out the numeric keypad window without changing the value.

Close

CH

1

100.0

7 8 9

CH

CLR

4 5 6

1 2 3

ENT

0 .

Setting for each channel

Example: When CH1 set value (SV) is change from 100 °C to 200 °C.

1. Touch the [TIO Setting] key on the “Operation Menu” screen, to switch to the “TIO Setting Menu”

screen.

2. Touch the [SV] key on the “TIO Setting Menu” screen, to switch to the “Setting: SV” screen.

3. From the “Setting: SV” screen, directly touch the part you want to setting (CH1 SV). The numeric

keypad window appears on the screen.

Numeric keypad window

Close

CH

1

100.0

7 8 9

CH

CLR

4 5 6

1 2 3

ENT

4. Touch the [2], [0], [0] key.

2 00

CH

1

200.0

0.

/−

IMS01T08-E1 3-7

Page 38

3.2 Basic Operations

5. Check that the data setting selection key is [CH].

CH

6. Touch the [ENT] key to enter the data. When the data is entered, the numeric keypad window

disappears.

Numeric keypad window

CH

1

200.0

7 8 9

Close

CH

CLR

4 5 6

1 2 3

ENT

0 .

If you input a number outside the valid range, when you touch the [ENT] key, the numeric

keypad window does disappear, but the value is not changed.

Setting for all channels (Batch setting)

Example: When all set value (SV) is change to 200 °C.

1. Touch the [TIO Setting] key on the “Operation Menu” screen, to switch to the “TIO Setting Menu”

screen.

2. Touch the [SV] key on the “TIO Setting Menu” screen, to switch to the “Setting: SV” screen.

3. From the “Setting: SV” screen, directly touch the part you want to setting (anywhere within the SV).

The numeric keypad window appears on the screen.

+/−

Numeric keypad window

Close

CH

100.0

7 8 9

1

CH

CLR

4 5 6

1 2 3

ENT

0.

3-8 IMS01T08-E1

+/−

Page 39

3.2 Basic Operations

4. Touch the [2], [0], [0] key.

2 00

CH

1

200.0

5. Touch the data setting selection key to change the display to the [All CH].

CH All CH

6. Touch the [ENT] key to enter the data. When the data is entered, the numeric keypad window

disappears.

Numeric keypad window

CH

1

200.0

7 8 9

Close

All CH

CLR

4 5 6

1 2 3

ENT

0 .

If you input a number outside the valid range, when you touch the [ENT] key, the numeric

keypad window does disappear, but the value is not changed.

+/−

IMS01T08-E1 3-9

Page 40

3.2 Basic Operations

z

Y

A

3.2.2 Text editing

The text editing window is used for setting names and messages. On a screen for inputting a name or

message, when you touch a section for text input, the text editing window appears.

<Text editing window>

Text editing section Editing type display

Half1 1

B C D E F G H I J

K L M N O P Q R S T

U V W X

ef

op

y

8 9

g

h i

q

r s t u v w x

0 1 2 3 4 5 6 7

Z a b c d

j

k l m n

Character

select keys

Prev Next

<< >>

DEL CLR

Text editing

BS SP

Enter

keys

Editing type display: Below is a list of the types of character editing. Editing type switches by [Prev] key,

[Next] key.

Half1: Alphabet, numeral

Half2: Symbols

Text editing section: Creates and edits the name or message. The cursor shows where characters are

input. The number of characters that can be edited in the text editing section

depends on the number of characters that can be input for the name or message.

Character selection keys:

Select the characters required for making and editing the name or message. When

you touch the character you want among those displayed, that character is

displayed at the cursor in the text editing section. The characters already at the

cursor are shifted to the rear. The contents displayed depend on the type of text

editing.

3-10 IMS01T08-E1

Page 41

3.2 Basic Operations

z

X

Y

A

Text editing keys

Prev key, Next key: Switch the type of characters required for making and editing the name or

message. These keys are used to switch the editing type display and the

character selection key display.

<< key: Moves the text editing section cursor to the left.

>> key: Moves the text editing section cursor to the right.

DEL key: Deletes the character at the cursor of the text editing section.

CLR key: Clears all the characters displayed in the text editing section.

BS key: Deletes the character to the left of the cursor of the text editing section.

SP key: Inserts a 1-byte space at the cursor of the text editing section.

Enter key: Enters the text displayed in the text editing section and closes the text editing

window.

Disappearing the text editing window

To stop text editing midway, touch the section at the top left of the text editing window twice in a row. The

text editing window disappears and the characters you were editing are thrown out.

Touch twice in a row

Harf1 1

B C D E F G H I J

K L M N O P Q R S T

U V W

e f

o p

y

8 9

Prev Next

g

h i

q

r s t u v w x

0 1 2 3 4 5 6 7

Z a b c d

j

k l m n

<< >>

BS SP

DEL CLR

Enter

IMS01T08-E1 3-11

Page 42

3.2 Basic Operations

<

<

y

0

p

q

x

g

j

A

Text editing

Example: Setting the name for TIO CH 1 (Temperature control channel 1) to “Tmp 1”

1. Calling the “TIO CH name set” screen.

For the details of calling procedure, see the 3.10.2 Calling procedure of the initial setting

screen (P. 3-59).

2. Touch the section for setting the TIO CH 1 name, the text editing window appears.

Half1 1

U V W X Y Z a b c d

e f

o

8 9

Text editing window

B C D E F G H I J

h i

r s t u v w

z

1 2 3 4 5 6 7

k l m n

>>

DEL CLRPrev Next

BS SP

Enter

3. Touch the [DEL] key or the [CLR] key to erase the text now displayed in the text editing section.

DEL CLR or

4. Touch the [T], [m], [p] keys to input “Tmp.”

T

p m

Tmp

5. Touch the [SP] key to insert a 1-byte space.

SP Tmp

6. Touch the [1] key to input “1.”

1

Tmp 1

3-12 IMS01T08-E1

Page 43

3.2 Basic Operations

漢

y

q

g

j

A

7. Touch the [Enter] key, after confirming “Tmp 1” inputted correctly in the text editing section. When

entered, the text editing window disappears and “1” is replaced with “Tmp 1.”

Half1

B C D E FG H I J

K L M N O PQ R S T

U V W X Y Z a b c d

e f

o p

8 9

Text editing window

Tmp 1

h i

r s t u v w x

z 0 1 2 3 4 5 6 7

<< >>

字

k l m n

DEL CLR

Prev Next BS SP

Enter

IMS01T08-E1 3-13

Page 44

3. SCREEN DESCRIPTIONS

t

b

3.3 Start-up Screen

When the power is turned on, first this screen is displayed, and then it is automatically changed to the next

screen (TIO Monitor screen).

<Check screen> <Opening screen>

Automatic

Automatic

To the TIO

Monitor screen

The operation panel checks whether there is an error in the SRZ configuration or hardware while the

start-up screen is displayed. If there is the error, the relevant “Error message” is displayed.

In addition, check a voltage drop of the SRAM cassette battery. If the battery voltage decreases, the

“Warning (battery replacement)” screen is displayed.

When an error occurs

<Error message screen>

Display of SRZ error

When an error occurs, the error contents are shown

in inversed display. The number of the abnormal

module is also displayed.

Display of error details of the operation panel itself

When an error occurs, the error contents are shown in

inversed display.

Back key

By touching this key, the previous screen jus

efore the error can be displayed. (If the error will

occur when the power was turned on, the screen

will return to the TIO Monitor screen.)

3-14 IMS01T08-E1

Page 45

3.3 Start-up Screen

Operation panel OPC-V606E error messages

Error messages Probable cause Solution

Parity Error

During communication, the data has

been wrongly written

Framing Error

During communication, the data has

been wrongly written

Over-Run

Problem with the taking-in of the

received data

No response from the SRZ

Breakage, wrong wiring, or imperfect

Mismatch of the setting data of

Wrong address setting

Wrong module configuration setting Configure the correct setting in the

Too much noise or surge might be

applied to the connecting cable with

SRZ.

Power supply defect of SRZ Confirm the power supply to the SRZ Time-Out

Wrong connection, no connection or

disconnection of the communication

cable

contact of the communication cable

communication speed and data bit

configuration with those of the SRZ

Investigate the wiring condition of the

connecting cable and whether there is a

noise generating source nearby, then

switch on the power again.

Confirm the connection method or

condition and connect correctly

Confirm the wiring or connector and

repair or replace the wrong one

Confirm the settings of SRZ and set

them correctly

“Number of modules set” screen of the

OPC-V606E initial settings.

SRZ error messages

Error messages Probable cause Solution

Adjust data error

• Adjustment data range is abnormal.

Data back-up error

• Back-up action is abnormal.

• Data write failure

• Response signal from A/D

converter is abnormal.

Custom data error

• There is an abnormality on logic

output data and it cannot execute.

The excessive noise, surge or strong

impact might be added to the SRZ

RAM is faulty

A/D converter is faulty A/D conversion

The excessive noise, surge or strong

impact might be added to the SRZ

The excessive noise, surge or strong

impact might be added to the SRZ

Replace the defective SRZ module

(The module whose FAIL green lamp

flashes)

IMS01T08-E1 3-15

Page 46

3.3 Start-up Screen

When a voltage drop of the SRAM cassette battery

< Warning (battery replacement) screen >

If the battery voltage for SRAM cassette has

dropped when the power is turned on, the

warning screen will be displayed.

supplied SRAM cassette, the data stored in

the SRAM cassette may be lost.

Please perform battery exchange promptly.

Replace battery: V6EM/RB

Back key

Touching this key changes to the “TIO

Monitor” screen.

If change to the “TIO Monitor” screen, no

“Warning (battery replacement)” screen is

displayed until the power is turned on again.

Data stored in the SRAM cassette:

Number of TIO modules

Number of DIO modules

Screen saver setting

Alarm message

TIO CH name

Trend graph (channel number, display scale high limit, display scale low limit)

Password

For the battery replacement, see the instruction manual of Hakko Electronics Co., Ltd.

Power not

3-16 IMS01T08-E1

Page 47

3. SCREEN DESCRIPTIONS

A

A

A

3.4 Operation Menu Screen

The operation menu screen allows the selection of each of the “Monitor,” “Setting,” “Operation Mode,”

and “Initial Set” screens.

3.4.1 Calling procedure of the operation menu screen

Warning

(Battery replacement)

Touch the

[Back] key

TIO Monitor

TIO Alarm Monitor

DIO Monitor

Trend Graph

TIO Setting Menu

Operation Mode Menu

DO Setting Menu

Configuration Monitor Menu

Voltage drop of

the battery for

SRAM cassette

Touch the [Menu] key

Power ON

utomatic

Check

utomatic

Opening

utomatic

TIO Monitor (PV/SV)

Touch the [Menu] key

Operation Menu

Touch the [Menu] key

Error occurs

Error message

Touch the

[Back] key

Initial Menu

IMS01T08-E1 3-17

Page 48

3.4 Operation Menu Screen

3.4.2 Operation menu screen

< Operation Menu screen >

Screen name

Displays the screen name.

Clock

Displays year (western calendar)/month/day

(day of the week) hour:minute. The clock can be

changed with the initial settings “Clock Set”

screen (P. 3-65).

Menu keys: Touching this key, screen can be selected.

TIO Monitor: “TIO Monitor (PV/SV)” screen

Alarm Monitor: “TIO Alarm Monitor (E1/E2/E3/E4)” screen

DIO Monitor: “DIO Monitor” screen

Trend Graph: “Trend Graph” screen

TIO Setting: “TIO Setting Menu” screen

Operation Mode: “Operation Mode Menu” screen

DO Setting: “DO Setting Menu” screen

Configuration Monitor:

“Configuration Monitor Menu” screen

Initial Setting: “Initial Menu” screen

This key is not displayed normally. Protection release is

necessary to display the key.

For details, see the 3.10.1 Releasing procedure of the initial

setting key protect (P. 3-57).

Menu keys

3-18 IMS01T08-E1

Page 49

3. SCREEN DESCRIPTIONS

(

(

)

A

(

A

)

T

r

g

[

y

[

]

3.5 Monitor Screen

Monitor screens are used to monitor the set value, measured value, control output value, alarm output, etc.

There are temperature control, alarm, DIO and configuration monitor screens.

3.5.1 Calling procedure of the monitor screen

[ ]: Key name.

Operation

menu

[TIO Monitor]

[Alarm Monitor]

[DIO Monitor]

[Configuration

Monitor]

* Touching the relevant key on the “Configuration Monitor Menu 1” screen or

“Configuration Monitor Menu 2” thus displayed calls up the setting screen.

For details, see the 3.5.6 Configuration monitor menu 1 screen (P. 3-27)

or 3.5.7 Configuration monitor menu 2 screen (P. 3-30).

Power ON

utomatic

TIO Monitor

PV/SV)

TIO Alarm Monitor

(E1/E2/E3/E4)

DIO Monitor

Configuration

Monitor Menu 1

*

*

interacting modules

*

Channel selection of

interacting modules

*

Selection switch of

interactin

Screen transfer:

TIO Monitor

MVH/MVC

Screen transfer: Touch the [Para.] key.

IO Alarm Monito

(BO/HBA)

Screen transfer: Touch the [Para.] key.

[DIO module]

Configuration

Monitor Menu 2

TIO module

Control action

Address of

modules

Touch the [Para] key

TIO Monitor

CT/HB

*

*

*

*

*

DO output

assignment 1

DO output

assignment 2

DO signal assignment

module address 1

DO signal assignment

module address 2

DI function

assignment

Screen transfer:

Touch the

Para] ke

IMS01T08-E1 3-19

Page 50

3.5 Monitor Screen

(

(

)

(

A

)

Touching the [Setting] key on the TIO monitor screen displays the respective setting screen. In

addition, touching the [Monitor] key on the setting screen displays the respective TIO monitor

screen.

TIO Monitor

TIO Monitor

MVH/MVC

TIO Monitor

PV/SV)

CT/HB

Setting screenMonitor screen

[Monitor]

Set value (SV)

[Setting]

[Monitor]

Manual Output

[Setting]

[Monitor]

[Setting]

HBA set value

3-20 IMS01T08-E1

Page 51

3.5.2 Basic configuration of monitor screen

The basic configuration of each monitor screen is as shown below.

On a temperature control 2-channel type Z-TIO module, the CH3 and CH4 displays are blank.

Example: TIO Monitor screen

Screen name

Engineering unit

Engineering unit can be

changed.

3.5 Monitor Screen

Clock

year/month/day (day of the week) hour : minute

Clock can be changed.

Monitor

item

Message

Alarm message can be changed.

Function keys

Channel name

Cannel name can be changed.

Screen name: Displays the screen name.

Engineering unit: Displays the engineering unit. The engineering unit (°C/°F) can be changed with

the TIO controller initialize “Display unit” screen (P. 3-73).

Clock: Displays year/month/day (day of the week) hour : minute. The clock can be

changed with the initial menu “Clock set” screen (P. 3-65).

Monitor item: Displays the item and data. Details of display varies depending on the each monitor

screen.

For the details of display, see the 3.5.3 TIO monitor screen (P. 3-23),

3.5.4 TIO alarm monitor screen (P. 3-25), 3.5.5 DIO monitor screen (P. 3-26),

3.5.6 Configuration monitor menu 1 screen (P. 3-27) and

3.5.7 Configuration monitor menu 2 screen (P. 3-30).

Channel name: Displays the TIO channel name. The channel name can be changed with the

initialize “TIO CH name set” screen (P. 3-68).

IMS01T08-E1 3-21

Page 52

3.5 Monitor Screen

Message: The alarm message is displayed at temperature rise completion or alarm occurrence.

Touching the message display area when an alarm occurs changes to the alarm

monitoring screen. Alarm occurring channel Nos. can be checked.

Alarm message list (Factory set value)

Item Message Priority order

BO: Burnout Burnout alarm is “ON” High

HBA: Heater break alarm Heater break alarm is “ON”

E1: Event 1 Event 1 alarm is “ON”

E2: Event 2 Event 2 alarm is “ON”

E3: Event 3 Event 3 alarm is “ON”

E4: Event 4 Event 4 alarm is “ON”

Temp.rise Temperature rise completion Low

The message of the burnout, heater break alarm, Event 1 alarm, Event 2

alarm, Event 3 alarm, Event 4 alarm and Temperature rise completion is

displayed if the relevant alarm occurs in any of the using channels. If more

than one type of alarm occurs simultaneously, the message corresponding

to the above item with higher priority is displayed. For example, if the

burnout and Event 1 alarm occur simultaneously, the burnout alarm

message is displayed.

The alarm message can be changed with the initialize “Alarm Message

Set” screen (P. 3-67).

Function keys: These key switches are assigned to match the contents of the screen.

Menu: Touching this key changes to the “Operation Menu” screen.

Setting: Touching this key changes from the monitor screen to the setting screen.

Item whose settings can be changed:

Set value (SV), manual output value (MVH), heater break alarm (HBA)

Prev.: Touching this key the display to the screen for the channel (CH) before the current

one. If there is no channel to be selected, the [Prev.] key becomes invalid.

Next: Touching this key the display to the screen for the channel (CH) after the current

one. If there is no channel to be selected, the [Next] key becomes invalid.

Para.: Every time this key is touched, the monitor screen changes. There is no this key on

the “DIO Monitor” screen.

3-22 IMS01T08-E1

Page 53

3.5 Monitor Screen

d

3.5.3 TIO monitor screen

There are PV/SV (Temperature measured value/temperature set value), MVH/MVC (Heat-side/cool-side

manipulated output value) and CT/HBA (Current transformer input measured value/heater break alarm set

value) in the TIO monitor screen. Changes the screen by touching [Para.] key.

For the function keys and other items, see the 3.5.2 Basic configuration of monitor screen (P. 3-21).

TIO monitor (PV/SV)

CH: Displays the TIO channel name.

PV: Displays the temperature measured value (PV).

Display range:

Input scale low to input scale high

SV: Displays the temperature set value (SV).

Display range:

Setting limit (low) to setting limit (high)

Touching [Setting] key changes to the “Setting: SV”

screen.

TIO monitor (MVH/MVC)

CH: Displays the TIO channel name.

MVH: Displays the heat-side manipulated output value.

Display range: −5.0 to +105.0 %

MVC: Displays the cool-side manipulated output value.

Display range: −5.0 to +105.0 %

Heating control makes the display blank.

Touching [Setting] key changes to the “Setting: Manual

Output” screen.

In heat/cool PID control, the displays of even-numbere

channels are blank.

IMS01T08-E1 3-23

Page 54

3.5 Monitor Screen

t

TIO monitor (CT/HBA)

CH: Displays the TIO channel name.

CT: Displays the current transformer (CT) inpu

measured value.

Display range: 0.0 to 100.0 A

(CTL-12-S56-10L-N) or

0.0 to 30.0 A (CTL-6-P-N)

HBA: Displays the heater break alarm set value

corresponding to current transformer (CT)

input.

Display range: 0.0 to 100.0 A

(CTL-12-S56-10L-N) or

0.0 to 30.0 A (CTL-6-P-N)

Touching [Setting] key changes to the “Setting: HBA

set value” screen.

3-24 IMS01T08-E1

Page 55

3.5 Monitor Screen

3.5.4 TIO alarm monitor screen

There are E1/E2/E3/E4 (Event status) and BO/HBA (Burnout/heater break alarm status) screens in the TIO

alarm monitor screen. Changes the screen by touching [Para.] key.

For the function keys and other items, see the 3.5.2 Basic configuration of monitor screen (P. 3-21).

TIO alarm monitor (E1/E2/E3/E4)

CH: Displays the TIO channel name.

E1: Displays the event 1 status.

Alarm occurrence: Flashes the “”

E2: Displays the event 2 status.

Alarm occurrence: Flashes the “”

E3: Displays the event 3 status.

Alarm occurrence: Flashes the “”

E4: Displays the event 4 status.

Alarm occurrence: Flashes the “”

TIO alarm monitor (BO/HBA)

CH: Displays the TIO channel name.

BO: Displays the burnout status.

Burnout occurrence: Flashes the “”

HBA: Displays the heater break alarm status.

Alarm occurrence: Flashes the “”

IMS01T08-E1 3-25

Page 56