Page 1

Multi-point Digital Controller

MA900/MA901

Initial Setting Manual

RKC INSTRUMENT INC.

®

IMR01H03-E4

Page 2

!"Modbus is a registered trademark of Schneider Electric.

!"Company names and product names used in this manual are the trademarks or registered trademarks of

the respective companies.

All Rights Reserved, Copyright 2001, RKC INSTRUMENT INC.

Page 3

Thank you for purchasing this RKC instrument. In order to achieve maximum performance and ensure

proper operation of your new instrument, carefully read all the instructions in this manual. Please

place this manual in a convenient location for easy reference.

SYMBOLS

WARNING

CAUTION

!

: This mark indicates precautions that must be taken if there is danger of electric

shock, fire, etc., which could result in loss of life or injury.

: This mark indicates that if these precautions and operating procedures are not

taken, damage to the instrument may result.

: This mark indicates that all precautions should be taken for safe usage.

: This mark indicates important information on installation, handling and operating

procedures.

: This mark indicates supplemental information on installation, handling and

operating procedures.

: This mark indicates where additional information may be located.

WARNING

!

An external protection device must be installed if failure of this instrument

!"

could result in damage to the instrument, equipment or injury to personnel.

All wiring must be completed before power is turned on to prevent electric

!"

shock, fire or damage to instrument and equipment.

This instrument must be used in accordance with the speci fications to pr ev ent

!"

fire or damage to instrument and equipment.

This instrument is not intended for use in locations subject to flammable or

!"

explosive gases.

Do not touch high-voltage connections such as power supply terminals, etc.

!"

to avoid electric shock.

RKC is not responsible if this instrument is repaired, modified or

!"

disassembled by other than factory-approved personnel. Malfunction can

occur and warranty is void under these conditions.

IMR01H03-E4

i-1

Page 4

CAUTION

This is a Class A instrument. In a domestic environment, this instrument may cause radio

!

interference, in which case the user may be required to take adequate measures.

This instrument is protected from electric shock by reinforced insulation. Provide

!

reinforced insulation between the wire for the input signal and the wires for instrument

power supply, source of power and loads.

Be sure to provide an appropriate surge contr ol cir c uit r espectively for the following:

!

- If input/output or signal lines within the building are longer than 30 mete r s.

- If input/output or signal lines leave the building, regardless the length.

This instrument is designed for installat ion in an enclosed instrument ation panel. All high-

!

voltage connections such as power supply terminals must be enclosed in the

instrumentation panel to avoid electric shock by operating personnel.

All precautions described in this manual should be taken to avoid damage to the

!

instrument or equipment.

All wiring must be in accordance with local codes and regulations.

!

All wiring must be completed before power is turned on to prevent electric shock,

!

instrument failure, or incor r ect action.

The power must be turned off before repairing work for input break and output failure

including replacement of sensor, contactor or SSR, and all wiring must be completed

before power is turned on again.

To prevent instrument damage or f ailure, protect t he power line and the input/output lines

!

from high currents with a protect ion device such as f use, circuit breaker, etc.

Prevent metal fragment s or lead wire scraps from falling inside instrum ent case to avoid

!

electric shock, fire or malfunction.

Tighten each terminal screw t o the specified torq ue found in the manual to avoid electric

!

shock, fire or malfunction.

For proper operation of this instrument, provide adequate ventilation for heat dispensation.

!

Do not connect wires to unused terminals as this will interf er e with proper operation of the

!

instrument.

Turn off the power supply befor e cleaning the instrument.

!

Do not use a volatile solvent such as paint thinner to clean the inst rum ent. Def ormat ion or

!

discoloration will occur. Use a soft, dry cloth to rem ove stains from the instrument.

To avoid damage to instrument display, do not rub with an abrasive material or push f ront

!

panel with a hard object.

Do not connect modular connectors to telephone line.

!

NOTICE

!

This manual is written for RKC service engineers or qualified technicians. This manual is also

prepared especially for readers who already have a fundamental knowledge of electricity, control,

computer and communication.

!

The figures, diagrams and numeric values used in this manual are only for purpose of illustration.

!

RKC is not responsible for any damage or injury that is caused as a result of using this instrument,

instrument failure or indirect damage.

!

Periodic maintenance is required for safe and proper operation of this instrument. Some

components have a limited service life, or characteristics that change over time.

!

Every effort has been made to ensure accuracy of all information contained herein. RKC makes no

warranty expressed or implied, with respect to the accuracy of the information. The information in

this manual is subject to change without prior notice.

!

No portion of this document may be reprinted, modified, copied, transmitted, digitized, stored,

processed or retrieved through any mechanical, electronic, optical or other means without prior

written approval from RKC.

i-2

IMR01H03-E4

Page 5

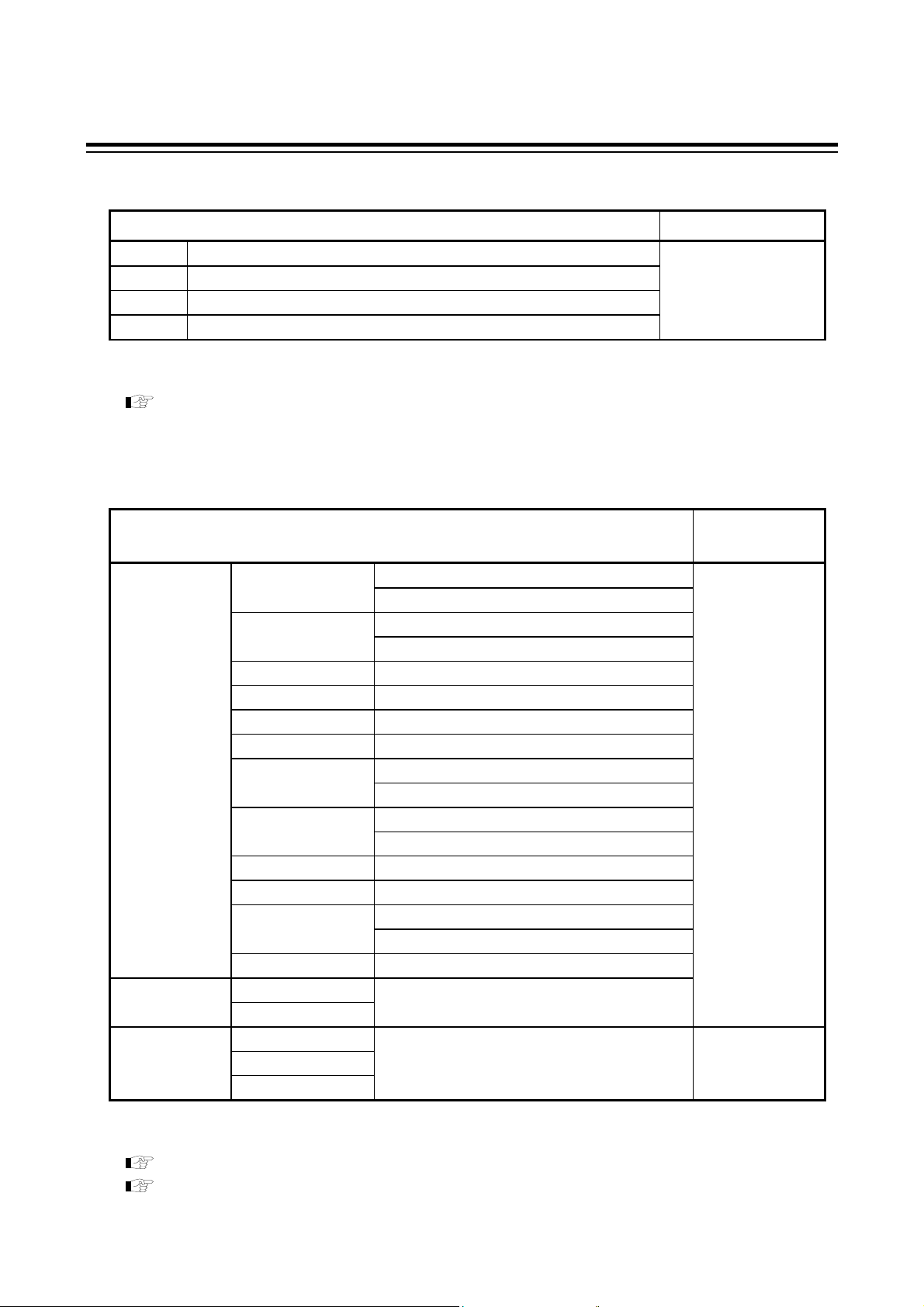

CONTENTS

Page

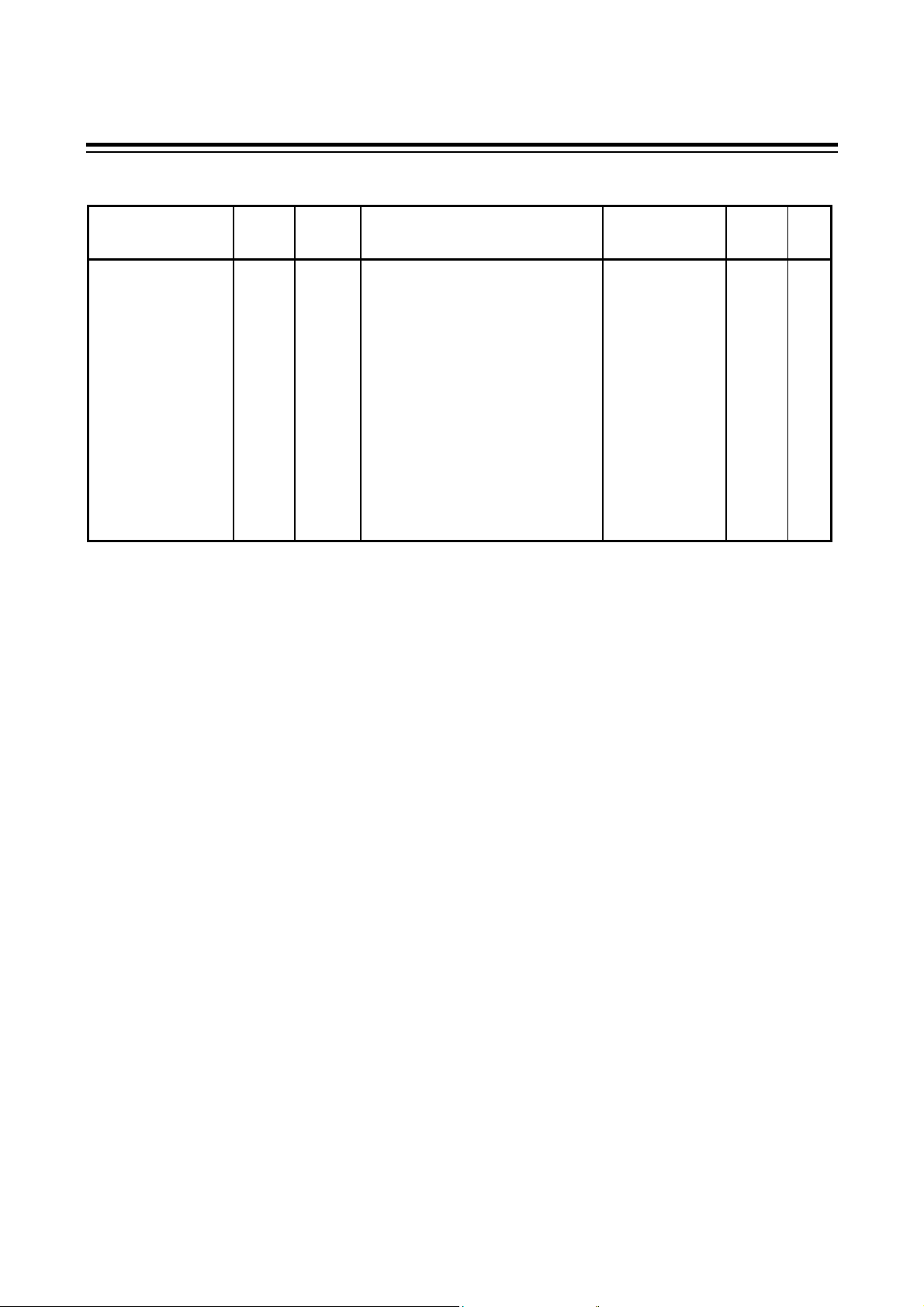

1. PROCEDURE FOR INITIALIZATION....................................1

1. 1 Transfer to Engineering Mode.........................................................................2

1.2 Procedure for Parameter Setting.....................................................................4

1.3 End of Engineering Mode................................................................................9

2. DETAILS OF PARAMETER SETTING ...............................10

2.1 Attention Items in Setting...............................................................................12

2.2 F10 Display function......................................................................................17

2.3 F21 Input Specification..................................................................................18

2.4 F22 Current Transformer (CT) Input Specification ........................................20

2.5 F24 Contact Input Specification.....................................................................22

2.6 F31 Output Function......................................................................................24

2.7 F32 Alarm Output Function............................................................................26

2.8 F41 Alarm 1 Function/F42 Alarm 2 Function/F43 Alarm 3 Function..............27

2.9 F51 Control Action.........................................................................................29

2.10 F61 Communication Function......................................................................30

2.11 F91 Displayed for Maintenance Information................................................31

3. INITIALIZE COMMUNICATION DATA................................32

3.1 RKC Communication Protocol.......................................................................32

3.2 Modbus Communication Protocol..................................................................42

3.2.1 Communication data list ...................................................................................42

3.2.2 Data map..........................................................................................................49

4. INPUT RANGE TABLES.....................................................55

IMR01H03-E4

i-3

Page 6

MEMO

i-4

IMR01H03-E4

Page 7

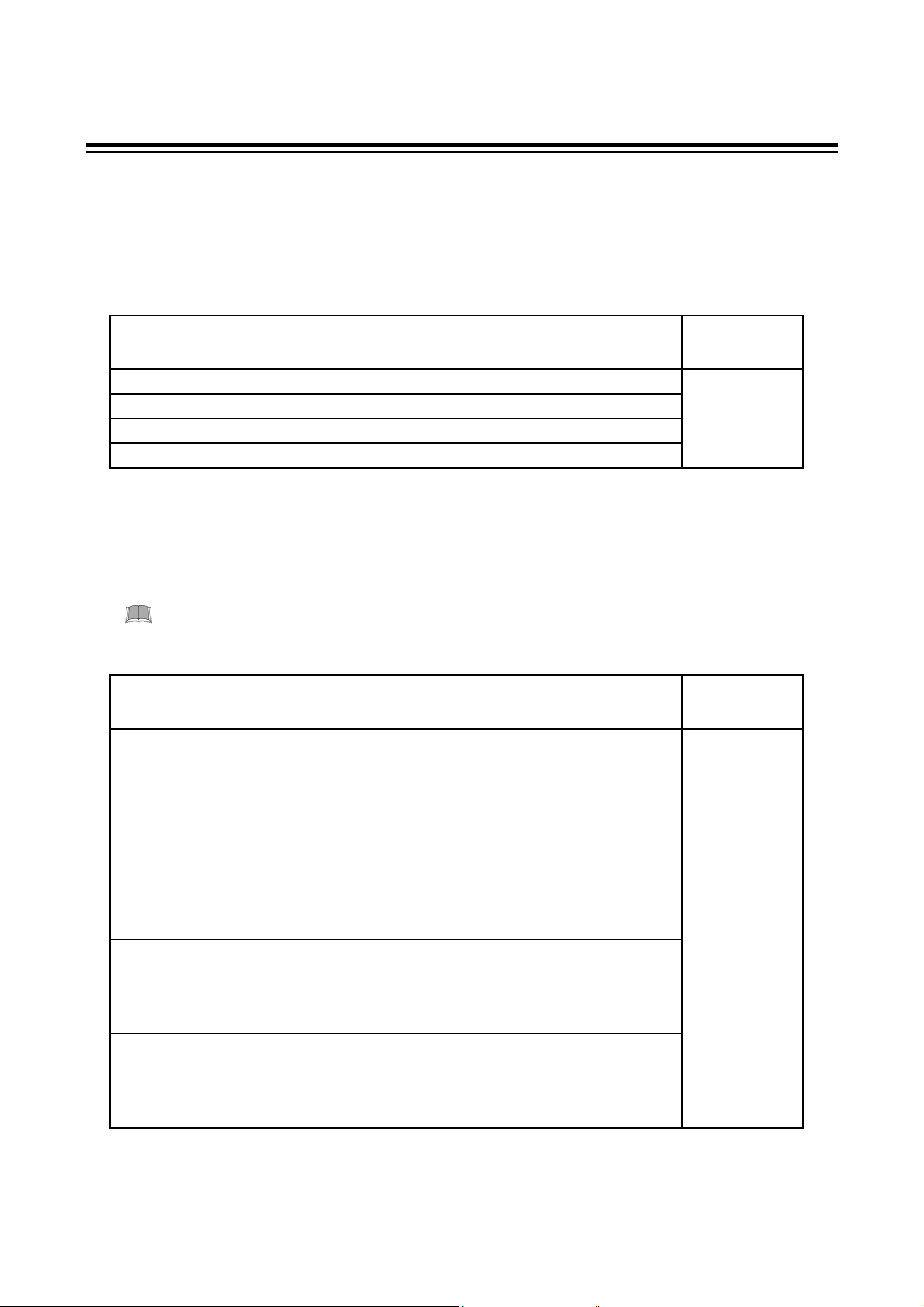

1. PROCEDURE FOR INITIALIZATION

Initialization is to set parameters relating to instrument specifications (input type, input range, alarm

type, etc.). Engineering mode that can do this setting.

Initialization flowchart

!"

Power ON

1.1 Transfer to Engineering Mode.

Change from RUN to STOP

See

Unlock the engineering mode

Setting the initial parameter

Lock the engineering mode

End of initialization

1.1 Transfer to Engineering Mode.

See

1.2 Procedure for Paramet er Setting

See

2. DETAILS OF PARAMETER SETTING

See

1.3 End of Engineering Mode

See

.

.

.

IMR01H03-E4

1

Page 8

1. PROCEDURE FOR INITIALIZATION

1.1 Transfer to Engineering Mode

MA900 is used in the below figures for explanation, but the same setting procedures also

apply to MA901.

The parameter of engineering mode can be changed only in the control STOP state.

1. Press the <R/S key with states of the PV/SV monitor mode for 1 second, to change the STOP

from RUN.

PV

CH

SV

AREA

SET

CH

MA900

R/S

STOP display

If set to the STOP state (dSTP) by the contact input, no parameters in Engineering mode

can be changed. They can be changed in case of the following.

• The instrument changed the STOP state (KSTP) by the key operation.

• The instrument changed the STOP state by both the key operation and contact input

operation.

For the RUN/STOP transfer, see the Instruction Manual (IMR01H01-E

####

)

2. Press the <R/S key while pressing the SET key with the PV/SV monitor mode change the

instrument to setup setting mode.

For the setup setting mode, see Instruction Manual (IMR01H01-E

####

).

3. Press the SET key several times to change to the lock level 2 display (LCK2).

4. Press the <R/S key to light brightly the hundreds digit on the SV display.

CH

PV

SV

AREA

SET

CH

MA900

R/S

Lock level 2 display

2

IMR01H03-E4

Page 9

1. PROCEDURE FOR INITIALIZATION

5. Press the UP key to change 0 to 1 in the hundreds digit.

CH

PV

AREA

SV

Set value

0000: Lock

0100: Unlock

SET

CH

MA900

R/S

Lock level 2 display

6. Press the SET key to unlock the engineering mode. The display changes to the first parameter in

setup setting mode.

AREA

PV

CH

SV

SET

CH

MA900

R/S

AREA

PV

CH

SV

SET

CH

MA900

R/S

Lock level 2 display Autotuning display

7. Press the <R/S key for 2 seconds while pressing the SET key to change the engineering mode.

The display changes to the function block F10.

AREA

CH

PV

SV

SET

CH

MA900

R/S

AREA

CH

PV

SV

SET

CH

MA900

R/S

Autotuni ng d isplay

Function block F10 display

Engineering mode

IMR01H03-E4

3

Page 10

1. PROCEDURE FOR INITIALIZATION

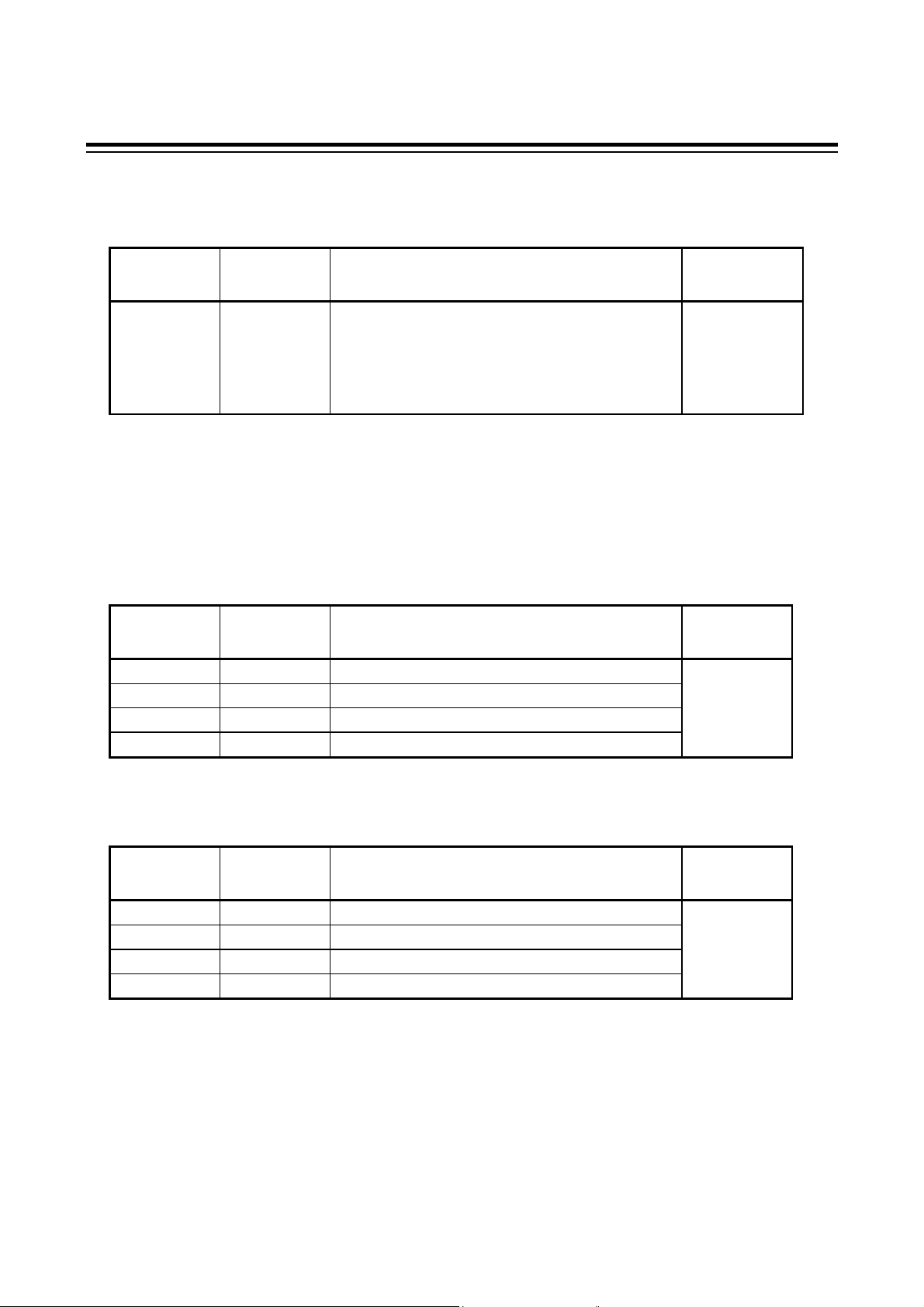

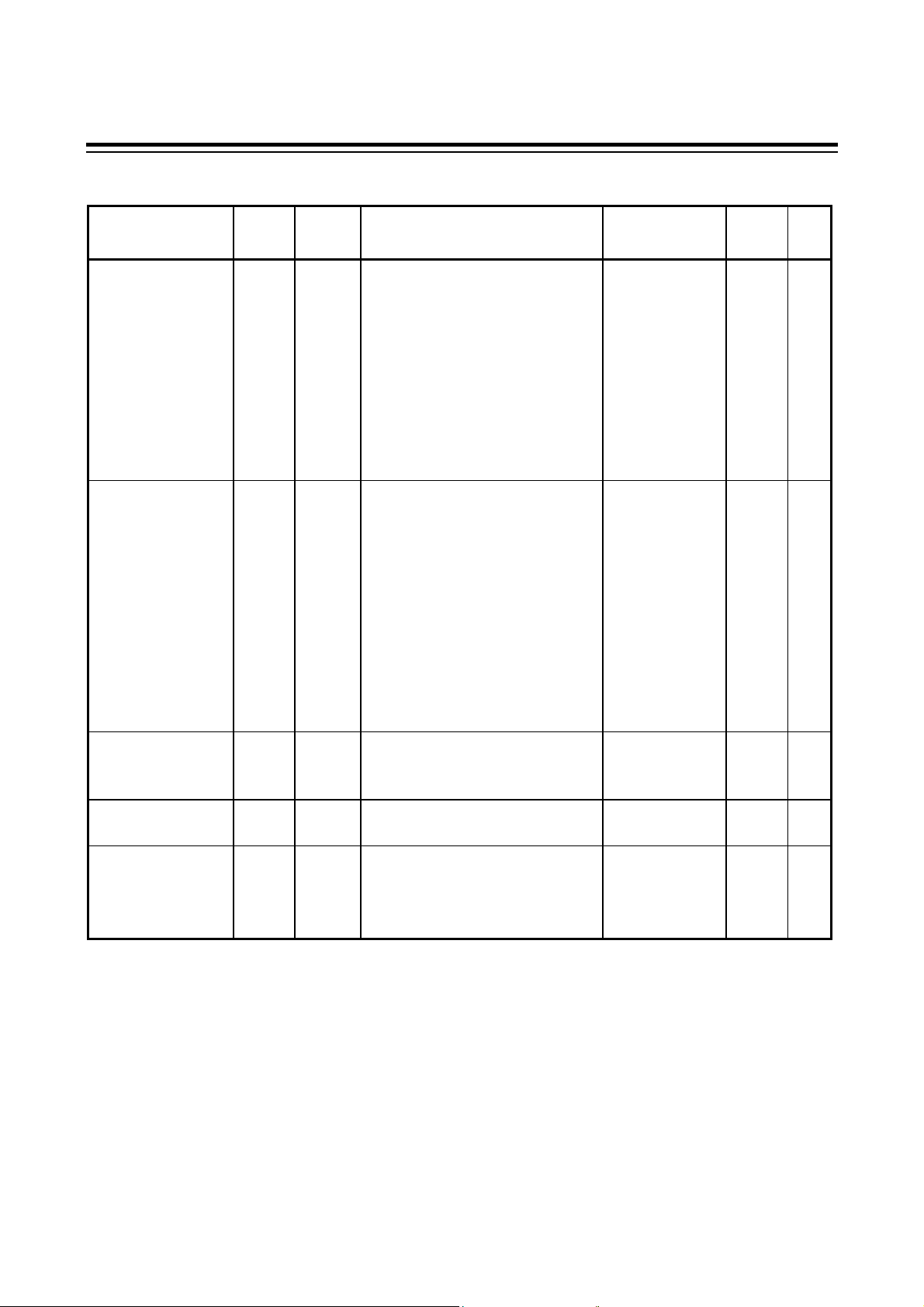

1.2 Procedure for Parameter Setting

Flowchart of displaying parameter items

!"

!"

!"!"

Display flowcharts in engineering mode are shown in the following.

[ : Press the SET key : Press the UP or DOWN key]

STOP display

selection

PV

SV

(F10.)

(SPCH)

Return to the

F10

Input type

selection

(F21.)

(F22.)

(F24.)

(F31.) (LGo1) (LGo2)

(InP) (UnIT) (PGdP) (SLH) (SLL)

CT ratio 1

selection

(CTr1)

Contact input

logic selection

(dlSL)

Control output

logic selection 1

Alarm output

logic selection

Display unit

selection

CT ratio 2

selection

(CTr2)

Return to the

Control output

logic selection 2

F24

.

Decimal point

position setting

Return to the

Return to the

F22

F31

.

.

Setting limiter

(high limit) setting

Setting limiter

(low limit) setting

Return to the

F21

Any parameter whose channel number is

displayed can be set for each channel.

(Check the channel number on the

channel display of instrument.)

All of the channels can be

simultaneously s et as the same value.

All the setting item is displayed regard

less of the contents of the instrument

specification.

.

A B

4

(F32.)

(F41.)

Return to the

(LGA)

Alarm type

selectionAlarm 1

(AS1) (AHo1) (AH1) (ALT1) (AEo1)

Alarm hold

action selection

F32

.

Alarm differential

gap setting

Alarm timer

setting

Action selection at

input error

Return to the

.

F41

IMR01H03-E4

Page 11

1. PROCEDURE FOR INITIALIZATION

A

(F42.) (AS2)

(F43.) (AS3)

(F61.) (CMPS)

B

Alarm 2

Alarm 3

Alarm type

selection

Alarm type

selection

Control action

type selection

(oS) (oH)(F51.)

Communication

protocol selection

ROM version

display

Alarm hold

action selection

(AHo2)

Alarm hold

action selection

(AHo3)

ON/OFF action

differential gap setting

RUN/STOP transfer

logic selection

(CMLG)

Integrated operating

time display

(Upper 3 digits)

Alarm differential

gap setting

(AH2)

Alarm differential

gap setting

(AH3)

Return to the

Return to the

F51

F61

Integrated operating

time display

(Lower 4 digits)

Alarm timer

setting

(ALT2)

Alarm timer

setting

(ALT3)

.

.

Holding peak ambient

temperature display

Action selection at

input error

(AEo2)

Action selection at

input error

(AEo3)

Return to the

.

F42

Return to the

.

F43

(F91.) ( E261) (WTH)

(WTL) (TCJ)

Return to the

F91

.

IMR01H03-E4

5

Page 12

1. PROCEDURE FOR INITIALIZATION

!"

!"Example of changing the setting

!"!"

As setting procedure example, show procedure at setting with each channel (Usual setting) and

channel common (Batch setting).

MA900 is used in the below figures for explanation, but the same setting procedures also

apply to MA901.

Example 1:

The following procedure is for changing the CH1 input type from “K” to “J.” (Usual setting)

1. Press the UP key to change the display to F21.

PV

CH

SV

AREA

SET

CH

MA900

R/S

Function block display

2. Press the SET key to change to input type selection (InP).

PV

CH

SV

AREA

SET

CH

MA900

Input type selection

R/S

3. Press the UP key to enter 1 in the least significant digit of the set value (SV) display.

PV

CH

SV

AREA

SET

CH

MA900

Input type selection

6

R/S

IMR01H03-E4

Page 13

1. PROCEDURE FOR INITIALIZATION

4. Press the SET key to register the value thus set. The display changes to the next parameter.

AREA

CH

PV

SV

SET

CH

MA900

R/S

AREA

CH

PV

SV

SET

CH

MA900

R/S

Display unit selection Input type selection

Example 2:

The following procedure is for changing all channels of the input type from “K” to “J.” (Batch

setting)

1. Press the UP key to change the display to F21.

PV

CH

SV

AREA

SET

CH

MA900

Function block display

R/S

2. Press the SET key to change to input type selection (InP).

PV

CH

SV

AREA

SET

CH

MA900

Input type selection

R/S

IMR01H03-E4

7

Page 14

1. PROCEDURE FOR INITIALIZATION

3. Press the CH key several times. Display the character A on th e CH d isp lay and “ ----” on the SV

display. The character A indicates that the batch setting.

PV

CH

SV

AREA

SET

CH

MA900

R/S

Input type selection

Every time the CH key is pressed, the channel number changes as follows.

4. Press the UP key several times to enter 1 in the least significant digit of the set value (SV)

display.

PV

CH

SV

AREA

SET

CH

MA900

Input type selection

R/S

5. Press the SET key to register the value thus set. The display changes to the next parameter.

Press the CH key to return to the usual setting from the batch setting.

CH

PV

AREA

SV

SET

CH

MA900

R/S

Input type selection

CH

PV

AREA

SV

SET

CH

MA900

R/S

Display unit selection

(Batch setting)

CH

PV

AREA

SV

SET

CH

MA900

R/S

Display unit selection

(Usual setting)

If the selected parameter corresponds to the setting item in common to all channels, the

simultaneous setting state returns to the normal setting state.

8

IMR01H03-E4

Page 15

1. PROCEDURE FOR INITIALIZATION

1.3 End of Engineering Mode

MA900 is used in the above figures for explanation, but the same setting procedures also

apply to MA901.

##

1. Transfer to function block symbol display (F

2. Press the <R/S key for 2 seconds while pressing the SET key to change to the PV/SV monitor

mode from the engineering mode.

3. Press the <R/S key while pressing the SET key with the PV/SV monitor mode change the

instrument to setup setting mode.

4. Press the SET key several times to change to the lock level 2 display (LCK2).

5. Press the <R/S key to light brightly the hundreds digit on the SV display.

) after each parameter is set.

6. Press the DOWN key to change 1 to 0 in the hundreds digit.

PV

AREA

CH

SV

Set value

0000:Lock

0100: Unlock

SET

CH

MA900

Lock lev el 2 display

R/S

7. Press the SET key to lock the engineering mode. The display changes to the first parameter in

setup setting mode.

PV

AREA

CH

SV

SET

CH

MA900

R/S

AREA

PV

CH

SV

SET

CH

MA900

R/S

Lock level 2 display

Autotuning display

8. Press the <R/S key while pressing the SET key to change to the PV/SV monitor mode from the

setup setting mode. Thus, the initialization ends.

IMR01H03-E4

9

Page 16

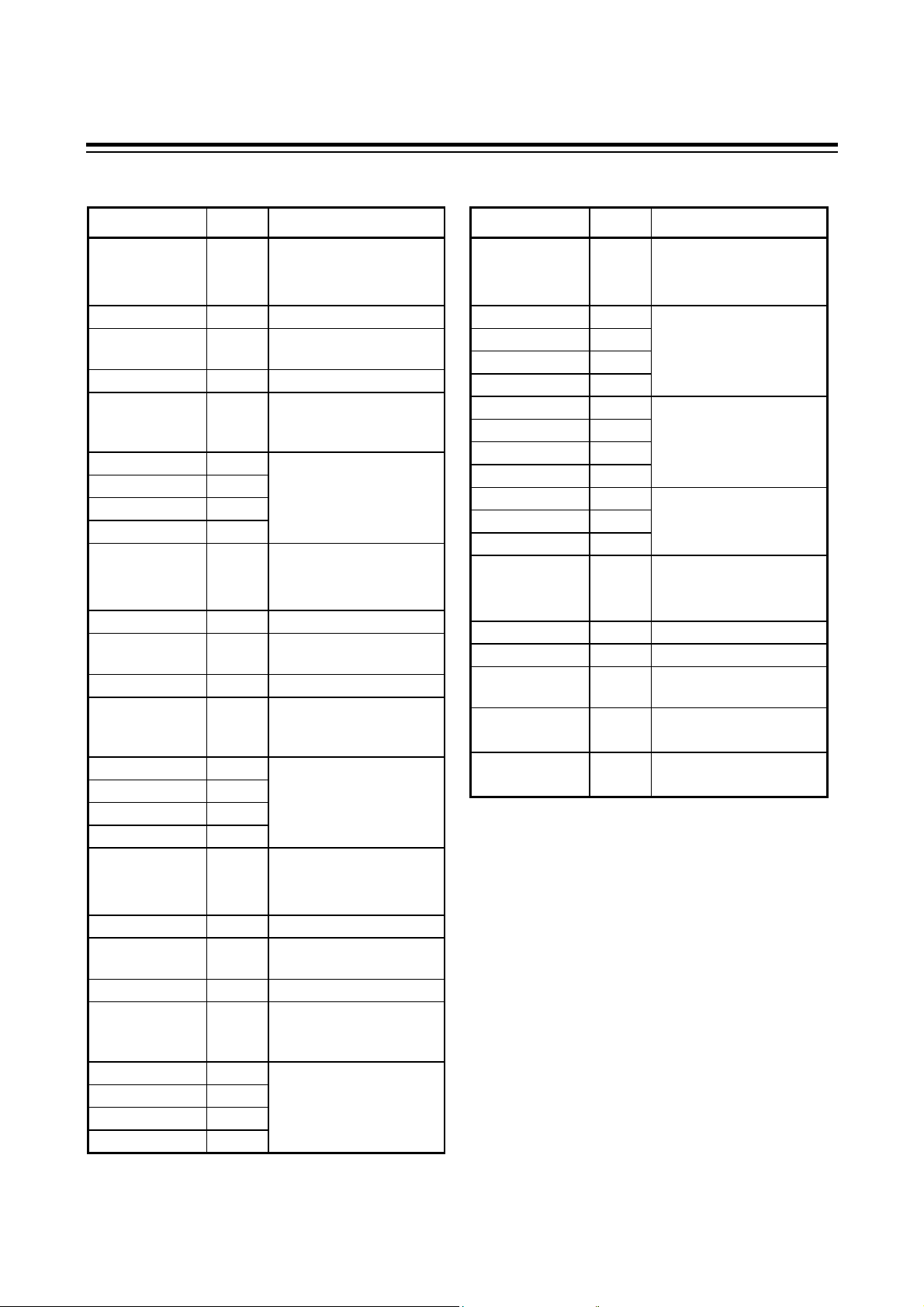

2. DETAILS OF PARAMETER SETTING

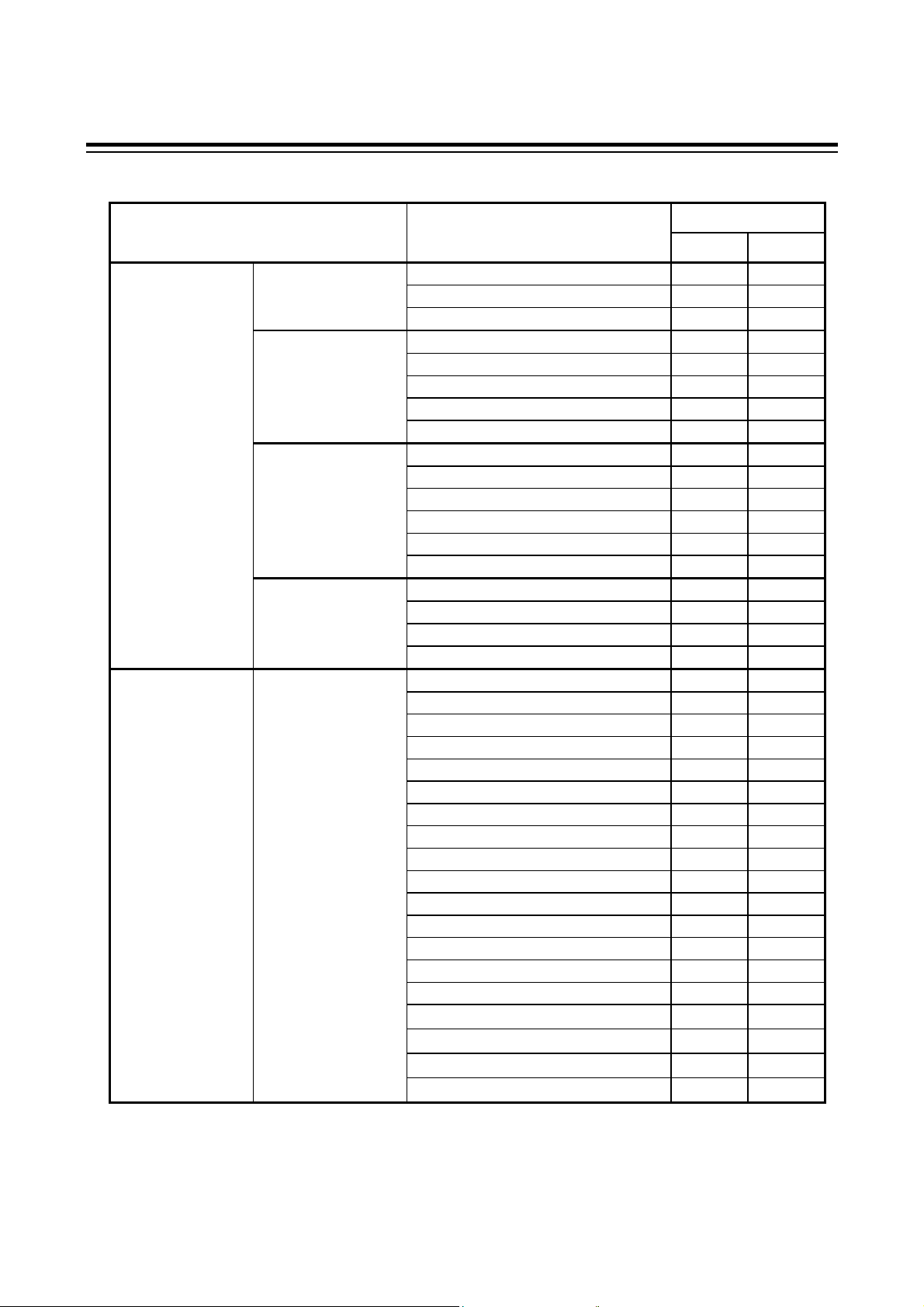

!"Parameter list

Function block Parameter Page

Display function STOP display selection (SPCH) P. 17

(F10.)

(F21.)

Input

specification

Input type selection (InP) P. 18

Display unit selection (UnIT)

Decimal point position selection (PGdP) P. 19

(F22.)

(F24.)

(F31.)

(F32.)

(F41.)

Setting limiter (high limit)

(SLH)

setting

Setting limiter (low limit)

(SLL)

setting

Current

CT ratio 1 selection (CTr1) P. 20

transformer (CT)

input

CT ratio 2 selection (CTr2)

specification

Contact input

Contact input logic selection (dISL) P. 22

specification

Output function Control output logic selection 1 (LGo1) P. 24

(MA900)

Control output logic selection 2 (LGo2) P. 25

(MA901)

Alarm output

Alarm output logic selection (LGA) P. 26

function

Alarm 1

Alarm 1 type selection (AS1) P. 27

function

Alarm 1 hold action selection (AHo1)

Alarm 1 differential gap setting (AH1) P.28

10

Alarm 1 timer setting (ALT1)

Alarm 1 action selection at

(AEo1) P. 29

input error

Continued on the next page.

IMR01H03-E4

Page 17

Continued from the previous page.

Function block Parameter Page

2. DETAILS OF PARAMETER SETTING

(F42.)

(F43.)

(F51.)

(F61.)

(F91.)

Alarm 2

Alarm 2 type selection (AS2) P. 27

function

Alarm 2 hold action selection (AHo2)

Alarm 2 differential gap setting (AH2) P. 28

Alarm 2 timer setting (ALT2)

Alarm 2 action selection at

(AEo2) P. 29

input error

Alarm 3

Alarm 3 type selection (AS3) P. 27

function

Alarm 3 hold action selection (AHo3)

Alarm 3 differential gap setting (AH3) P. 28

Alarm 3 timer setting (ALT3)

Alarm 3 action selection at

(AEo3) P. 29

input error

Control action Control action type selection (oS1) P. 29

ON/OFF action differential gap

(oH)

setting

Communication

function

Communication protocol

selection

RUN/STOP transfer logic

(CMPS) P. 30

(CMLG)

selection

Displayed for

ROM version display (E261) P. 31

maintenance

information Integrated operating time

(WTH)

(Upper 3 digits) display

Integrated operating time

(WTL)

(Lower 4 digits) display

Holding peak ambient

(TCJ)

temperature display

IMR01H03-E4

11

Page 18

2. DETAILS OF PARAMETER SETTING

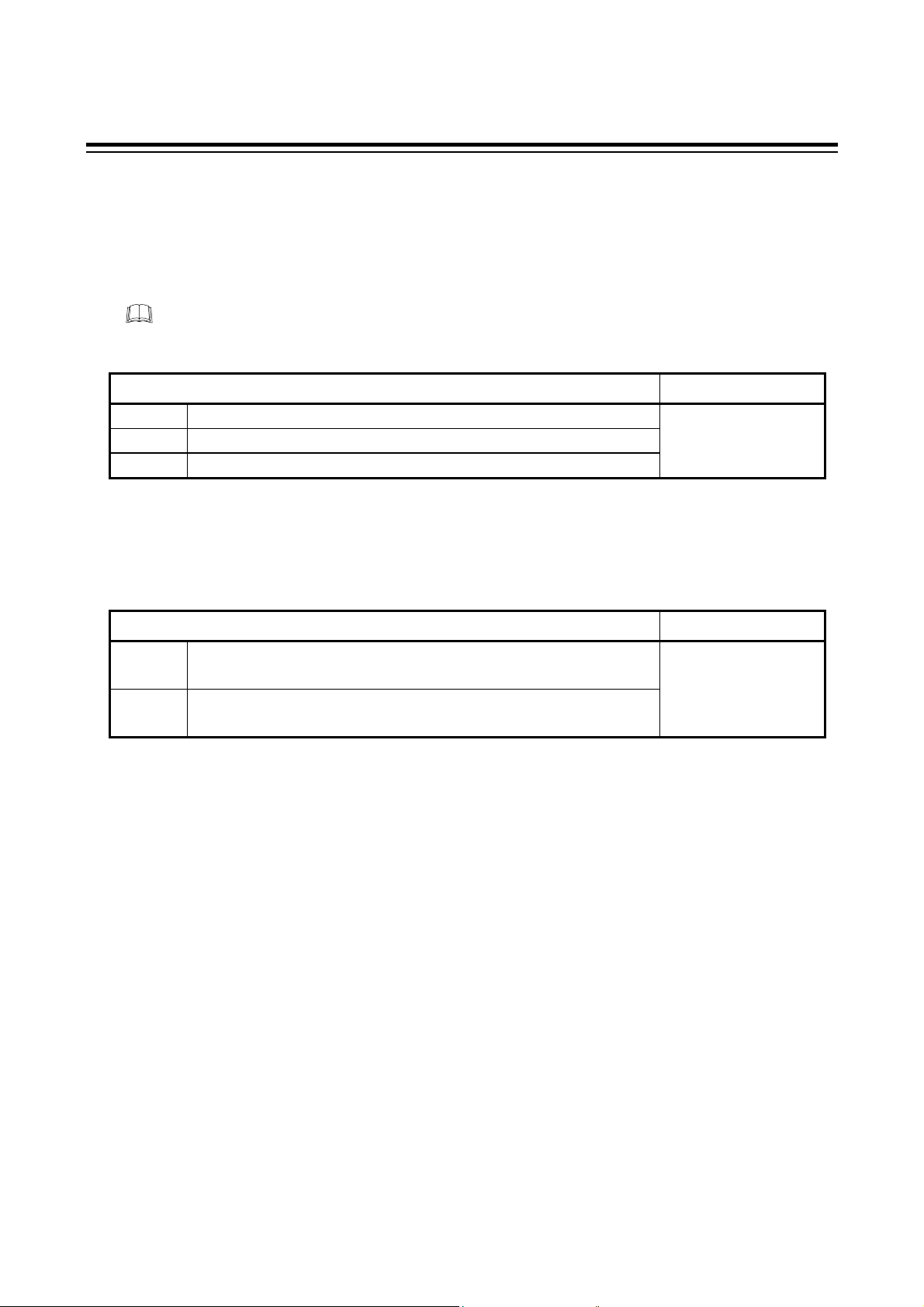

2.1 Attention Items in Setting

If any of the following parameter is changed, the relevant set value is initialized or is automatically

converted.

Before changing the set values, always record all of them (SV setting & CT monitor mode,

setup setting mode, parameter setting mode and engineering mode).

After changing the set values, always check all of them (SV setting & CT monitor mode,

setup setting mode, parameter setting mode and engineering mode).

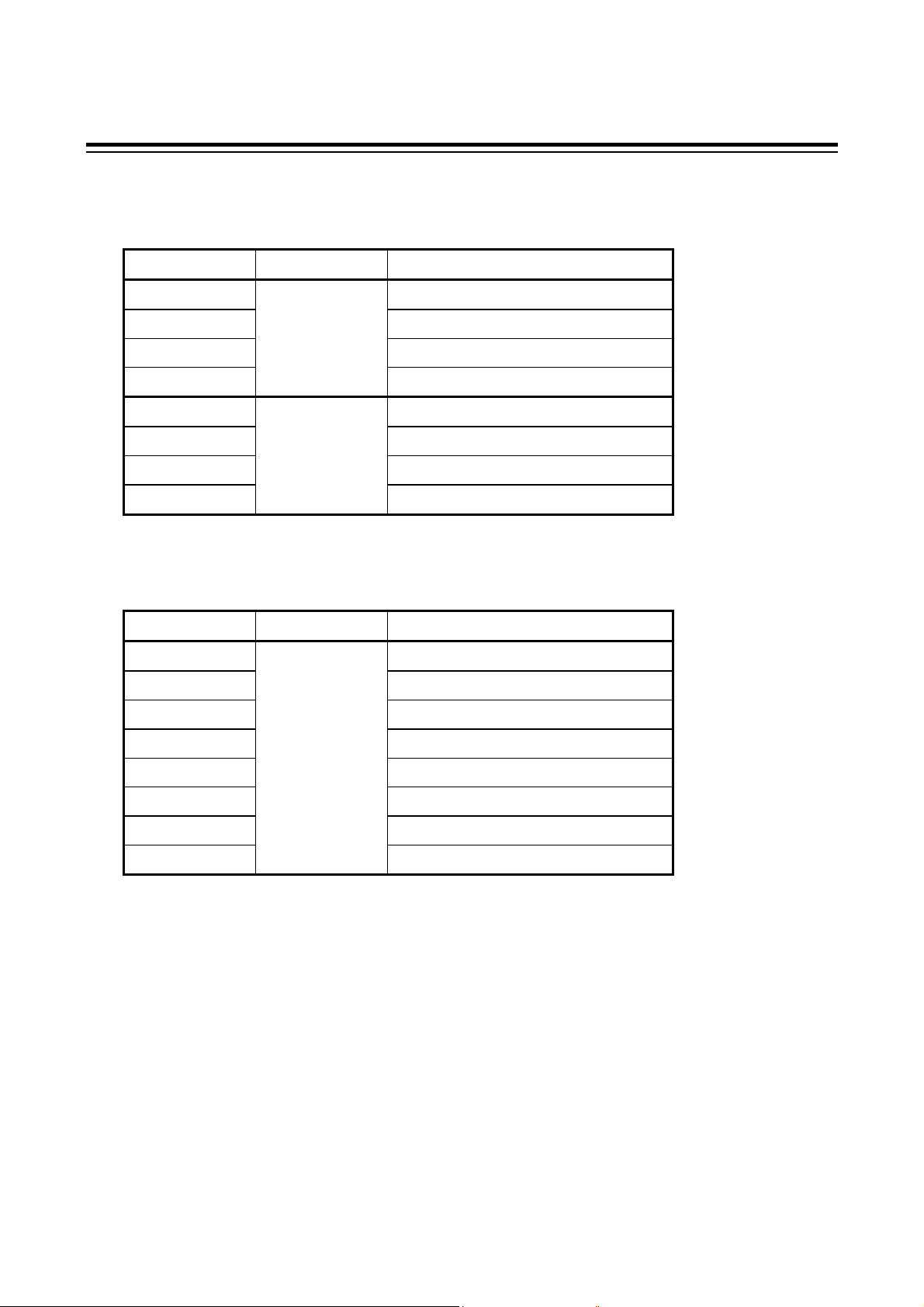

When changed parameter of input type selection or engineering unit setting

!"

!"

!"!"

When change a input type and unit, all the set value of a list shown below is initialized. Set it in value

to use once again.

Mode Description Default value

TC input RTD input Voltage input

Decimal point position 0

1

1

2

Setting limiter [high limit] Maximum settable value 100.0 %

Setting limiter [low limit] 0.0 %

Alarm 1 hold action

0 (Without alarm hold action)

Alarm 1 differential gap 2 °C [°F] 2.0 °C [°F] 0.2 % of span

Alarm 1 action at input error 0 (Without action at input error)

Engineering Alarm 2 hold action 0 (Without alarm hold action)

mode Alarm 2 differential gap 2 °C [°F] 2.0 °C [°F] 0.2 % of span

Alarm 2 action at input error 0 (Without action at input error)

Alarm 3 hold action 0 (Without alarm hold action)

Alarm 3 differential gap 2 °C [°F] 2.0 °C [°F] 0.2 % of span

Alarm 3 action at input error 0 (Without action at input error)

ON/OFF action differential gap 2 °C [°F] 2.0 °C [°F] 0.2 % of span

Heater break alarm 1 OFF

Setup setting Heater break alarm 2

3

OFF

mode PV bias 0 °C [°F] 0.0 °C [°F] 0.0 %

Digital filter OFF

1

0: No digit below decimal point

2

1: 1 digit below decimal point

3

In case of MA901, this item is not provided.

12

Continued on the next page.

IMR01H03-E4

Page 19

2. DETAILS OF PARAMETER SETTING

Continued from the previous page.

Mode Description Default value

TC input RTD input Voltage input

Control loop break alarm 8.0 minutes

Control loop break alarm

0 °C [°F] 0.0 °C [°F] 0.0 %

deadband

Alarm 1 50 °C [°F] 50.0 °C [°F] 5.0 % of span

Alarm 2

Parameter Alarm 3

setting mode Heat-side proportional band 30 °C [°F] 30.0 °C [°F] 3.0 % of span

Integral time 240 seconds

Derivative time 60 seconds

Anti-reset windup 100 %

Cool-side proportional band * 100 % of heat-side proportional band

Overlap/deadband * 0 °C [°F] 0.0 °C [°F] 0.0 %

Setting changing rate limiter OFF

SV setting &

Set value (SV) 0 °C [°F] 0.0 °C [°F] 0.0 %

CT monitor

mode

* In case of MA901, these items are not provided.

IMR01H03-E4

13

Page 20

2. DETAILS OF PARAMETER SETTING

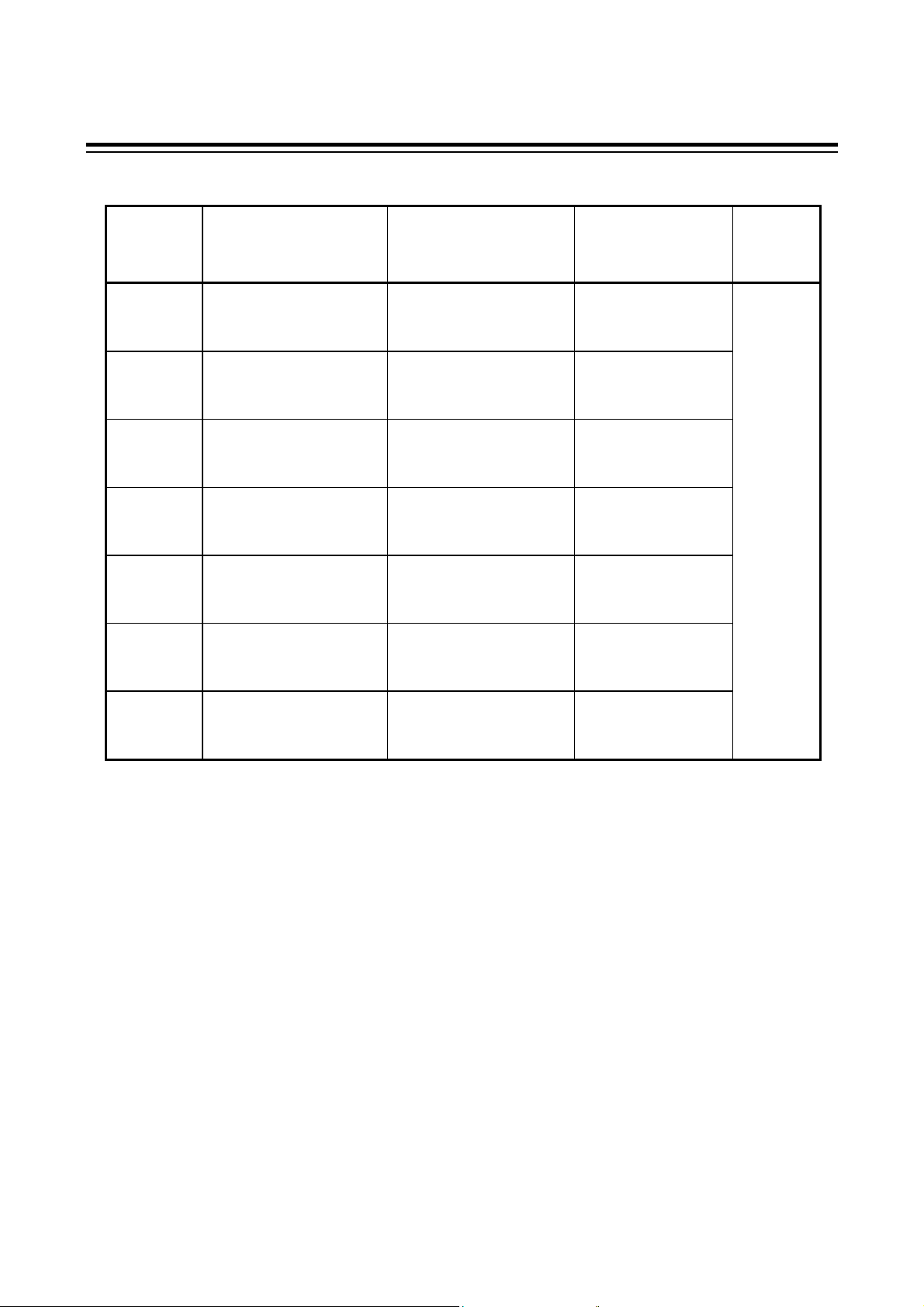

When changed parameter of decimal point position setting

!"

!"

!"!"

When change a decimal point position, it is converted into about set value of a list shown below

automatically. However, the set value may change as a result of changing the position of the decimal

point. Therefore in that case, re-set it to the value to be used.

Mode Description

Setting limiter [high limit]

Setting limiter [low limit]

Engineering mode Alarm 1 differential gap

Alarm 2 differential gap

Alarm 3 differential gap

ON/OFF action differential gap

Setup setting mode PV bias

Control loop break alarm deadband

Alarm 1

Alarm 2

Parameter setting mode Alarm 3

Heat-side proportional band

Overlap/deadband *

Setting changing rate limiter

SV setting & CT monitor mode Set value (SV)

* In case of MA901, this item is not provided.

Example and caution of automatic conversion

• Decimal point location moves in accordance with it when increases decimal point location.

Example: When the position of the decimal point changed from 0 to 1 with SLH set to 800 °C.

(Changed from 800 to 800.0)

(SLH)(SLH)

• If the setting range is not between −1999 and +9999 regardless of the position of the decimal point,

it is limited by the range from −1999 to +9999.

Example: Suppose set SLH is 1372 °C, if change decimal point position from 0 to 1.

SLH becomes 999.9 as it exceeds the setting range.

(SLH)(SLH)

14

Continued on the next page.

IMR01H03-E4

Page 21

2. DETAILS OF PARAMETER SETTING

Continued from the previous page.

• If the number of digits below the decimal point is changed in the decreasing direction, the decreased

number of digits is omitted.

Example: Suppose set SLH is 99.99, if change decimal point position from 0 to 2.

The figures below the decimal point are omitted,

and as a result SLH becomes 99.

(SLH) (SLH)

In the above example, it the position of the decimal point is returned to 2 from 0, SLH

becomes 99.00.

• Set SLL and SLH so that SLL may not be equal to SLH when the position of the decimal point is

changed. Otherwise malfunction may result.

Example: When the position of the decimal point is changed to 0 at SLL=999.1 and SLH=999.9

(SLL) (SLH) (SLL)

When changed parameter of setting limiter [high limit/low limit]

!"

!"

!"!"

(SLH)

When change setting limiter [high limit/low limit], all the set value of a list shown below is initialized.

Set it in value to use once again. However no change is made if the set value is within the range

changed.

Mode Description

Alarm 1 differential gap

Engineering mode Alarm 2 differential gap

Alarm 3 differential gap

ON/OFF action differential gap

Setup setting mode PV bias

Control loop break alarm deadband

Alarm 1

Alarm 2

Parameter setting mode Alarm 3

Heat-side proportional band

Overlap/deadband *

Setting change rate limiter

SV setting & CT monitor mode Set value (SV)

* In case of MA901, this item is not provided.

Example: For temperature input, voltage/current inputs

If the setting is made so that the span becomes narrower, there may be a case where the related set

value becomes smaller or 0.

IMR01H03-E4

15

Page 22

2. DETAILS OF PARAMETER SETTING

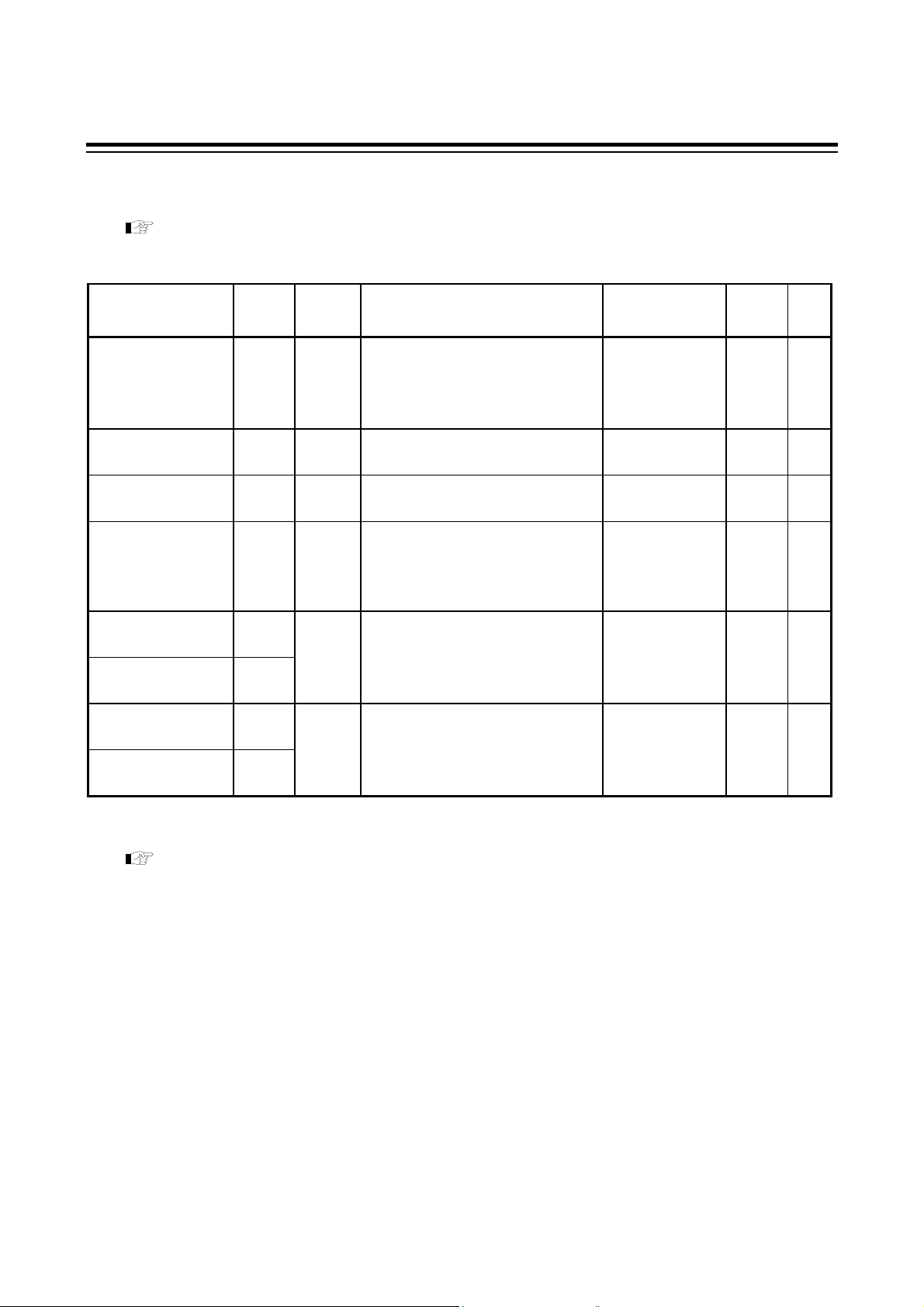

When changed parameter of alarm type selection

!"

!"

!"!"

When change alarm 1 type and alarm 2 type, all the set value of a list shown below is initialized. Set it

in value to use once again.

Mode Description Default value

TC input RTD input Voltage input

Alarm 1 hold action 0 (Without alarm hold action)

Alarm 1 differential gap 2 °C [°F] 2.0 °C [°F] 0.2 % of span

Alarm 1 action at input error 0 (Without action at input error)

Alarm 2 hold action 0 (Without alarm hold action)

Engineering Alarm 2 differential gap 2 °C [°F] 2.0 °C [°F] 0.2 % of span

mode Alarm 2 action at input error 0 (Without action at input error)

Alarm 3 hold action 0 (Without alarm hold action)

Alarm 3 differential gap 2 °C [°F] 2.0 °C [°F] 0.2 % of span

Alarm 3 action at input error 0 (Without action at input error)

Setup setting Heater break alarm 1 OFF

mode Heater break alarm 2 * OFF

Control loop break alarm 8.0 minutes

Control loop break alarm

Parameter

setting mode Alarm 1 50 °C [°F] 50.0 °C [°F] 5.0 % of span

deadband

Alarm 2

Alarm 3

0 °C [°F] 0.0 °C [°F] 0.0 %

* In case of MA901, this item is not provided.

16

IMR01H03-E4

Page 23

2. DETAILS OF PARAMETER SETTING

2.2 F10 Display function

(1) STOP display selection (SPCH)

Details of setting Factory set value

0000 STOP is displayed on the PV display unit. (TYPE 1) 0000

0001 STOP is displayed on the SV display unit. (TYPE 2)

Displays in the STOP mode become as follows.

TYPE 1

(SPCH=0000)

TYPE 2

(SPCH=0001)

PV

SV

PV

SV

(KSTP)

(KSTP)

PV

SV

PV

SV

(dSTP)

(dSTP)

(SToP)

PV

SV

PV

SV

(SToP)

IMR01H03-E4

17

Page 24

2. DETAILS OF PARAMETER SETTING

2.3 F21 Input Specification

The setting items (InP, UnIT, PGdP, SLH and SLL) in the function block F21 are set for each channel.

In addition, they can be set simultaneously for all channels.

(1) Input type selection (InP)

Details of setting Factory set value

0000 K Factory set value

0001 J varies depending on

0002 R the input type.

0003 S

0004 B

0005 E Thermocouple *

0006 N (TC)

0007 T

0008 W5Re/W26Re

0009 PL II

0010 U

0011 L

0012 Pt100 RTD *

0013 JPt100

0014 0 to 5 V DC Voltage *

0015 1 to 5 V DC

0016 0 to 10 V DC

* Input type cannot be changed because the hardware is different.

See 2.1 Attention Items in Setting (P. 12).

(2) Display unit selection (UnIT)

Details of setting Factory set value

0000 °C 0000

0001 °F

The invalidity in case of the voltage inputs.

See 2.1 Attention Items in Setting (P. 12).

18

IMR01H03-E4

Page 25

2. DETAILS OF PARAMETER SETTING

(3) Decimal point position setting (PGdP)

Details of setting Factory set value

0000 No digit below decimal point (!!!!) Note 1

0001 1 digit below decimal point (!!!.!)

0002 2 digits below decimal point (!!.!!) *

0003 3 digits below decimal point (!.!!!) *

* When input type is thermocouple and RTD, no setting can be changed.

Note 1 Factory set value varies depending on the instrument specification.

See. 2.1 Attention Items in Setting (P. 12).

(4) Setting limiter [high limit] (SLH)

Setting limiter [low limit] (SLL)

Details of setting Factory set

K −199 to +1372 °C (−326 to +2502 °F) Factory set

−199.9 to +999.9 °C (−199.9 to +999.9 °F) value varies

J −199 to +1200 °C (−326 to +2192 °F) depending on

−199.9 to +999.9 °C (−199.9 to +999.9 °F) the instrument

R 0 to 1769 °C (0 to 3216 °F) specification.

S 0 to 1769 °C (0 to 3216 °F)

B 0 to 1820 °C (0 to 3308 °F)

E 0 to 1000 °C (0 to 1832 °F)

Thermocouple N 0 to 1300 °C (0 to 2372 °F)

0 to 999.9 °C (0 to 999.9 °F)

T −199 to +400 °C (−326 to +752 °F)

−199.9 to +400.0 °C (−199.9 to +752.0 °F)

W5Re/W26Re 0 to 2320 °C (0 to 4208 °F)

PL II 0 to 1390 °C (0 to 2534 °F)

U −199 to +600 °C (−326 to +1112 °F)

−199.9 to +600.0 °C (−199.9 to +999.9 °F)

L 0 to 900 °C (0 to 1652 °F)

RTD Pt100 (JIS/IEC 1) −199.9 to +649.0 °C

JPt100 (JIS) (−199.9 to +999.9 °F)

0 to 5 V DC −1999 to +9999 SLH: 100.0

Voltage

2

1 to 5 V DC (programmable scale) SLL: 0.0

0 to 10 V DC

1

IEC (International Electrotechnical Commission) is equivalent to JIS, DIN and ANSI.

2

In case of voltage/current inputs, SLH can be set below SLL.

Set the setting limiter referring to the 4. INPUT RANGE TABLES (P. 55).

See. 2.1 Attention Items in Setting (P. 12).

value

IMR01H03-E4

19

Page 26

2. DETAILS OF PARAMETER SETTING

2.4 F22 Current Transformer (CT) Input Specification

If the heater break alarm is selected as the alarm 2, the number of turns * of the current transformer

(CT) used is set for each channel. In addition, it can be set simultaneously for all channels.

* The number of turns = CT ratio

The heater break alarm for three-phase heater can not be specified with MA901.

When the MA901 instrument specification corresponds to contact input or communication

function, the heater break alarm can't be added. Therefore, do not use this parameter.

CT ratio 1 selection (CTr1) [Heater break alarm for single-phase heater or

"#

"#

"#"#

heater break alarm for three-phase heater (Z-168) ]

CT ratio 2 selection (CTr2) [Heater break alarm for three-phase heater

(Z-168) ]

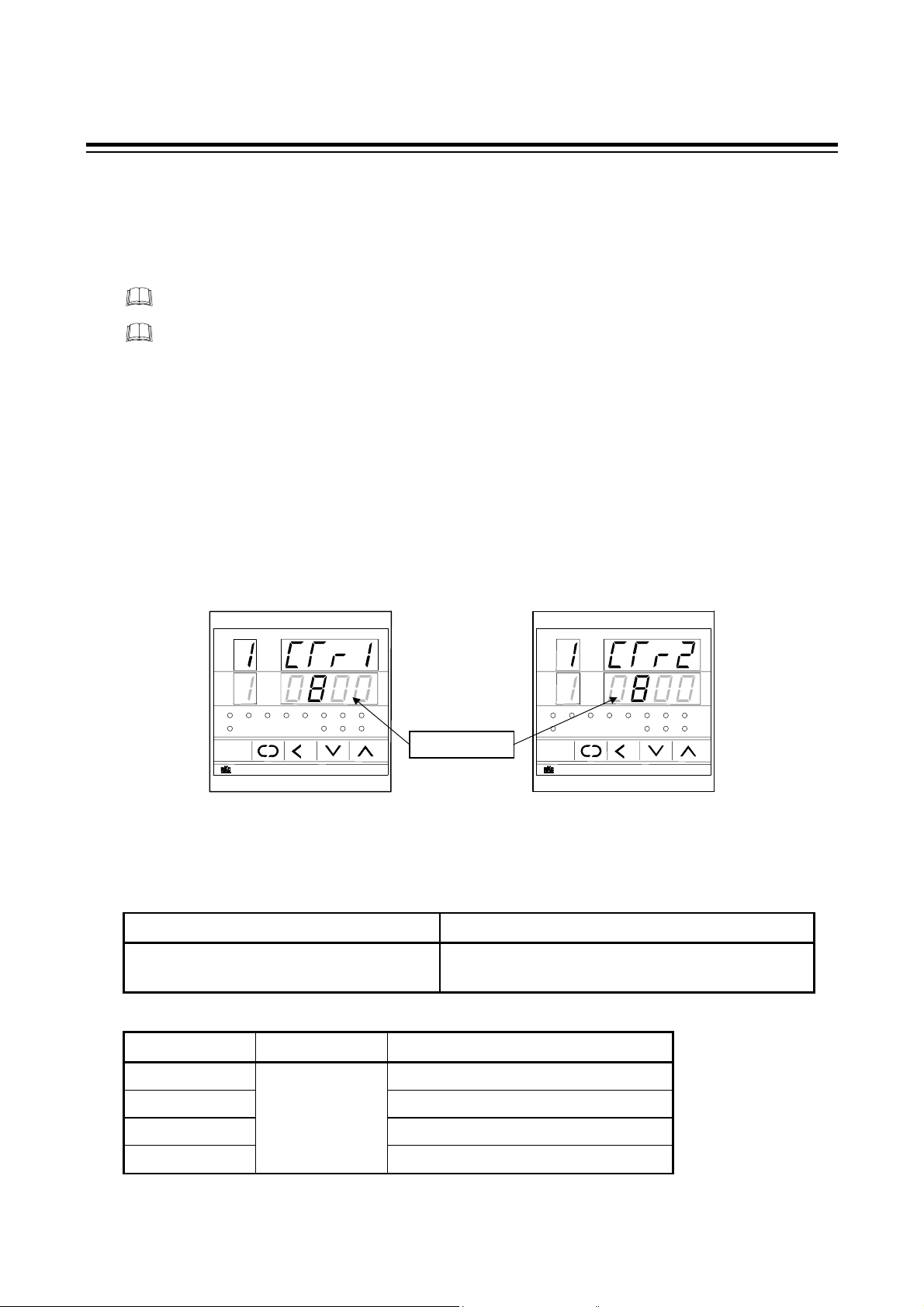

The setting the CT ratio from CT1 to CT4 can be made when the CT ratio 1 (CTr1) of MA900 is

selected.

The setting the CT ratio from CT1 to CT8 can be made when the CT ratio 1 (CTr1) of MA901 is

selected.

The setting the CT ratio from CT5 to CT8 can be made when the CT ratio 2 (CTr2) is selected.

PV

SV

SET

CH

MA900

R/S

AREA

CH

PV

SV

SET

CH

MA900

R/S

Set the CT ratio.

CH

AREA

CT ratio 2 selecti on (CTr 2) CT ratio 1 selecti on (CTr 1)

Setting method

When the CTL-6-P-N current transformer is used, set the CT ratio to 800.

When the CTL-12-S56-10L-N current transformer is used, set the CT ratio to 1000.

Details of setting Factory set value

0 to 9999 CTL-6-P-N: 800

CTL-12-S56-10L-N: 1000

MA900 (Heater break alarm for sing le- phase heater)

CH display PV display Details of setting

1 CTr1 Set the CT ratio of CT1.

2 Set the CT ratio of CT2.

3 Set the CT ratio of CT3.

4 Set the CT ratio of CT4.

Continued on the next page.

20

IMR01H03-E4

Page 27

Continued from the previous page.

MA900 (Heater break alarm for thr ee- phase heat er)

CH display PV display Details of setting

1 CTr1 Set the CT ratio of CT1.

2 Set the CT ratio of CT2.

3 Set the CT ratio of CT3.

4 Set the CT ratio of CT4.

1 CTr2 Set the CT ratio of CT5.

2 Set the CT ratio of CT6.

3 Set the CT ratio of CT7.

2. DETAILS OF PARAMETER SETTING

4 Set the CT ratio of CT8.

The CT ratio 2 selection (CTr2) is displayed when the instrument specification is

three-phase heater.

MA901 (Heater break alarm for sing le- phase heater)

CH display PV display Details of setting

1 CTr1 Set the CT ratio of CT1.

2 Set the CT ratio of CT2.

3 Set the CT ratio of CT3.

4 Set the CT ratio of CT4.

5 Set the CT ratio of CT5.

6 Set the CT ratio of CT6.

7 Set the CT ratio of CT7.

8 Set the CT ratio of CT8.

IMR01H03-E4

21

Page 28

2. DETAILS OF PARAMETER SETTING

2.5 F24 Contact Input Specification

Setting is common to all channels.

When the MA901 instrument specification corresponds to heater break alarm, the contact

input can't be added. Therefore, do not use this parameter.

Contact input logic selection (diSL)

"#

"#

"#"#

The contact input logic selection sets the set value about the following contents.

STOP selection

•

Selected whether to stop when the contact is opened or when the contact is closed.

Memory area selection

•

Memory area selection 1 to 8: These contents are selected when any of the memory areas from 1

to 8 is selected by the contact input.

Memory area selection 1 to 7: For example, when a digital switch starting from “0” is used,

select the memory area number when the memory area number

must match the digital switch number.

If the selection of the memory areas from 1 to 7 is chosen, no memory area 8 can be

selected by the contact input. In this case, select the memory area by the front key.

Used/unused of DI SET term inal (No. 43)

•

The method of establishment is set when the memory area is selected.

When the DI SET terminal (No. 43) is used:

Select the area 0.5 seconds after the DI SET terminal is closed.

When the DI SET terminal (No. 43) is not used:

Select the memory area 2 seconds after the area is selected.

Details of

setting

0000 When contact input

0001 When contact input

0002 When contact input

STOP selection Memory area

selection

Memory area transfer

(RUN/STOP transfer)

opens, stop.

Memory area transfer

(RUN/STOP transfer)

opens, stop.

Memory area transfer

(RUN/STOP transfer)

opens, stop.

1 to 8

1 to 8

1 to 7

Used/unused of

DI SET terminal

(No. 43)

Used 0000

Unused

Used

Factory

set value

22

Continued on the next page.

IMR01H03-E4

Page 29

Continued from the previous page.

2. DETAILS OF PARAMETER SETTING

Details of

STOP selection Memory area

setting

0003 When contact input

(RUN/STOP transfer)

opens, stop.

0004 When contact input

(RUN/STOP transfer)

opens, stop.

0005 When contact input

(RUN/STOP transfer) is

closed, stop.

0006 When contact input

(RUN/STOP transfer) is

closed, stop.

0007 When contact input

(RUN/STOP transfer) is

closed, stop.

0008 When contact input

(RUN/STOP transfer) is

closed, stop.

0009 When contact input

(RUN/STOP transfer) is

closed, stop.

selection

Memory area transfer

1 to 7

There is no memory

area transfer function.

Memory area transfer

1 to 8

Memory area transfer

1 to 8

Memory area transfer

1 to 7

Memory area transfer

1 to 7

There is no memory

area transfer function.

Used/unused of

DI SET terminal

(No. 43)

Unused

Unused

Used 0000

Unused

Used

Unused

Unused

Factory

set value

IMR01H03-E4

23

Page 30

2. DETAILS OF PARAMETER SETTING

2.6 F31 Output Function

"#

"#

MA900

"#"#

(1) Control output logic selection 1 (LGo1)

This data is 0000 fixation. This data must not set the set value besides 0000.

Channel

display

1OUT1

2OUT2

3OUT3

4OUT4

Output

number

Details of setting Factory set

value

0000: Heat-side control output of CH1 0000

0000: Heat-side control output of CH2

0000: Heat-side control output of CH3

0000: Heat-side control output of CH4

(2) Control output logic selection 2 (LGo2)

Select the output logic of the output 2 (OUT5 to OUT8).

The channel number displayed on the CH display unit corresponds to the relevant output number.

The setting is made for each channel number. In addition, OUT5 to OUT8 can be simultaneously set.

Conduct setting so as to meet the instrument specification.

An incorrect setting may cause a malfunction.

Channel

display

1OUT5

2OUT6

3OUT7

1

Setting becomes effective at the time of heat/cool control.

2

Not output when alarm 3 corresponds to the FAIL alarm.

Output

number

Details of setting Factory set

0000: No output

0001: Cool-side control output of CH1

0002: No output

0003: No output

0004: Alarm 3 of CH1

0005: Alarm 3 of CH2

0006: Alarm 3 of CH3

0007: Alarm 3 of CH4

2

2

2

2

0008 to 0011: No output

0000: No output

0001: Cool-side control output of CH2

0002 to 0007: Same as OUT5

0008 to 0011: No output

0000: No output

0001: Cool-side control output of CH3

0002 to 0007: Same as OUT5

0008 to 0011: No output

value

Factory set

1

value varies

depending on

the instrument

specification.

1

1

Continued on the next page.

24

IMR01H03-E4

Page 31

Continued from the previous page.

MA900

Channel

display

Output

number

2. DETAILS OF PARAMETER SETTING

Details of setting Factory set

value

4OUT8

0000: No output

0001: Cool-side control output of CH4

*

0002 to 0007: Same as OUT5

0008 to 0011: No output

*

Setting becomes effective at the time of heat/cool control.

"#

"#

MA901

"#"#

(1) Control output logic selection 1 (LGo1)

This data is 0000 fixation. This data must not set the set value besides 0000.

Channel

display

1OUT1

2OUT2

3OUT3

4OUT4

Output

number

Details of setting Factory set

0000: Heat-side control output of CH1 0000

0000: Heat-side control output of CH2

0000: Heat-side control output of CH3

0000: Heat-side control output of CH4

Factory set

value varies

depending on

the instrument

specification.

value

(2) Control output logic selection 2 (LGo2)

This data is 0000 fixation. This data must not set the set value besides 0000.

Channel

display

1OUT5

2OUT6

3OUT7

4OUT8

Output

number

Details of setting Factory set

0000: Heat-side control output of CH5 0000

0000: Heat-side control output of CH6

0000: Heat-side control output of CH7

0000: Heat-side control output of CH8

value

IMR01H03-E4

25

Page 32

2. DETAILS OF PARAMETER SETTING

2.7 F32 Alarm Output Function

Alarm output logic selection (LGA)

"#

"#

"#"#

Select the alarm output logic of alarm 1 (Normal equipment), alarm 2 (Option) and alarm 3 (Option).

The channel number displayed on the CH display unit corresponds to the relevant alarm. The setting

is made for each channel number. In addition, output logic of alarm 1 to alarm 3 can be

simultaneously set.

Conduct setting so as to meet the instrument specification.

An incorrect setting may cause a malfunction.

Channel

display

1ALM1

2ALM2

3ALM3

Alarm Detail s of set t i ng Factory

[Alarm 1]

[Alarm 2]

[Alarm 3]

set value

0000: FAIL alarm

0001: Logical OR of alarm 1 in all channels (E

0002: Logical OR of alarm 2 in all channels (E

0003: Logical OR of alarm 3 in all channels (E

0004: Logical OR of alarm 1 and alarm 2 in all channels

nergized

(E

0005: Logical OR of alarm 1 and alarm 3 in all channels

nergized

(E

0006: Logical OR of alarm 2 and alarm 3 in all channels

nergized

(E

0007: Logical OR of alarm 1, alarm 2 and alarm 3 in all

channels (E

0008: Logical OR of alarm 1 in all channels (De-e

0009: Logical OR of alarm 2 in all channels (De-e

0010: Logical OR of alarm 3 in all channels (De-e

0011: Logical OR of alarm 1 and alarm 2 in all channels

(De-e

0012: Logical OR of alarm 1 and alarm 3 in all channels

(De-e

0013: Logical OR of alarm 2 and alarm 3 in all channels

(De-e

0014: Logical OR of alarm 1, alarm 2 and alarm 3 in all

channels (De-e

0000 to 0014: Same as ALM1 0002

0000 to 0014: Same as ALM1 0003

)

)

)

nergized

nergized

nergized

nergized

)

)

)

)

nergized

)

nergized

nergized

nergized

nergized

nergized

nergized

)

)

)

)

)

)

0001

26

Alarm output is only relay contact output.

IMR01H03-E4

Page 33

2. DETAILS OF PARAMETER SETTING

2.8 F41 Alarm 1 Function F42 Alarm 2 Function F43 Alarm 3 Function

(1) Alarm type selection (AS1, AS2, AS3)

Details of setting Factory set value

0000 Alarm not provided

0001 SV high alarm varies depending

0002 SV low alarm on the instrument

0003 Process high alarm specification.

0004 Process low alarm

0005 Deviation high alarm

0006 Deviation low alarm

0007 Deviation high/low alarm

0008 Band alarm

0009 Control loop break alarm

0010 Heater break alarm

1

When instrument specification is failure alarm, set 0000.

2

When control action type is heat/cool control, do not select.

3

When control output is current output, do not select.

4

When the contact input or the communication function is selected as instrument specifications of

MA901, the heater break alarm can’t be added.

See 2.1 Attention Items in Setting (P. 12).

1

3, 4

Factory set value

2

(2) Alarm hold action selection (AHo1, AHo2, AHo3)

Details of setting Factory set value

0000 Without alarm hold action

0001 Effective when the power is turned on, or operation is changed

from STOP to RUN.

0002 Valid when:

• the power is turned on,

• operation is changed from STOP to RUN,

• the SV is changed, or

• the memory area (control area) is changed.

The alarm hold action function can not be added to the FAIL alarm, SV alarm, control loop

break alarm and heater break alarm.

IMR01H03-E4

Without alarm hold

action: 0000

With alarm hold

action: 0002

27

Page 34

2. DETAILS OF PARAMETER SETTING

t

(3) Alarm differential gap setting (AH1, AH2, AH3)

Set the alarm differential gap for each channel. In addition, they can be set simultaneously for all

channels.

Details of setting Factory set value

Thermocouple 0 (0.0) to span Note 1

RTD

Voltage

Note 1 TC and RTD inputs: 2 °C [°F] or 2.0 °C [°F]

Voltage inputs: 0.2 % of span

(4) Alarm timer setting (ALT1, ALT2, ALT3)

Set the time until an alarm is actually output after being set to the alarm state.

Details of setting Factory set value

0 to 6000 seconds 0

Setting is common to all channels.

The alarm timer function:

The alarm timer function regards the period until the alarm timer is set after measured value

(PV) or deviation exceeds the alarm set value as a non-alarm state and outputs an alarm after

the alarm timer setting time elapses.

The alarm timer starts being activated if the alarm is turned on. In addition, if the alarm state

is released while the alarm timer is being activated, no alarm is output.

Example: When set the alarm timer for 100 seconds

Measur ed v al ue (P V)

Alarm set value

Set value (SV)

28

Alarm out p u

Alarm timer

(100 seconds)

Alarm state

ON

Alarm timer

seconds)

(100

Alarm state

When instrument specification is FAIL alarm, the alarm timer function does not operate.

IMR01H03-E4

Page 35

2. DETAILS OF PARAMETER SETTING

(5) Action selection at input error (AEo1, AEo2, AEo3)

Set the alarm action in input abnormality by input break (when the input is over-scaled or

underscaled).

Details of setting Factory set value

0000 Normal processing:

0000

The alarm action set by alarm type selection (AS1/AS2) is taken

even if the input is abnormal.

0001 Forcibly turned on when abnormal:

The alarm is forcibly turned on regardless of the alarm action set

by alarm type selection (AS1/AS2) when the input is abnormal.

For a voltage input of 0 to 5 V DC or 0 to 10 V DC, as over-scale or underscale does not

occur when the input breaks, no alarm is turned on.

2.9 F51 Control Action

The setting items (oS and oH) in the function block F51 are set for each channel. In addition, they can

be set simultaneously for all channels.

(1) Control action type selection (oS1)

Match the setting with the instrument specification. Otherwise malfunction may result.

The MA901 does not perform heat/cool control.

Details of setting Factory set value

0000 D type: PID control with autotuning (Direct action)

0001 F type: PID control with autotuning (Reverse action)

0002 W type: Heat/cool PID control with autotuning (Water cooling)

0003 A type: Heat/cool PID control with autotuning (Air cooling)

1

When instrument specification corresponds to heat/cool control, this set value can’t be set.

2

When instrument specification corresponds to heat control, this set value can’t be set.

1

1

2

2

Note 1 Factory set value varies depending on the instrument specification.

(2) ON/OFF action differential gap setting (oH)

Details of setting Factory set value

Thermocouple 0 (0.0) to span Note 1

RTD

Voltage

Note 1 TC and RTD inputs: 2 °C [°F] or 2.0 °C [°F]

Voltage inputs: 0.2 % of span

Note 1

IMR01H03-E4

29

Page 36

2. DETAILS OF PARAMETER SETTING

2.10 F61 Communication Function

(1) Communication protocol selection (CMPS)

If the protocol is selected, always turn the power on again or select RUN from STOP.

When the MA901 instrument specification corresponds to heater break alarm, the

communication function can't be added. Therefore, do not use this parameter.

Details of setting Factory set value

0000 RKC communication protocol (Multi-point mode)

0001 Modbus communication protocol Note 1

0002 RKC communication protocol (Single mode)

Note 1 Factory set value varies depending on the instrument specification.

(2) RUN/STOP transfer logic selection

Select the logic of RUN/STOP transfer in the communication mode.

Details of setting Factory set value

0000 Set in 0: STOP mode

Set in 1: RUN mode

0001 Set in 0: RUN mode

Set in 1: STOP mode

0000

30

IMR01H03-E4

Page 37

2. DETAILS OF PARAMETER SETTING

2.11 F91 Displayed for Maintenance Information

Only displayed for the F91 function block.

(1) ROM version displayed (E261)

Display the version of loading software.

(2) Integrated operating time display (WTH) [upper 3 digits]

Display the integrated operating time (upper 3 digits) of instrument.

Details of display : 0 to 100 (Resolution of display: 10,000 hours)

Up to 1,000,000 from 0 including the upper and lower digits can be displayed.

(3) Integrated operating time display (WTL) [lower 4 digits]

Display the integrated operating time (lower 4 digits) of instrument.

However, as the integral time is increments by 1 when the power is turned on or off.

If the total integrated operating time exceeds 9,999 hours, these digits move to the integrated

operating time display (upper 3 digits).

Details of display : 0 to 9999 (Resolution of display: 1 hours)

(4) Holding peak value ambient temperature display (TCJ)

The maximum ambient temperature on the rear terminal board of the instrument is stored and

displayed on the set value (SV) display.

Details of display : −10 to +100 °C [°F] (Resolution of display: 1°C [°F])

IMR01H03-E4

31

Page 38

3. INITIALIZE COMMUNICATION DATA

3.1 RKC Communication Protocol

Reference to communication identifier list

!"

!"

!"!"

(1) (2) (3) (4) (5) (6) (7)

Name Iden-

tifier

STOP display

selection

Input type

selection

(1) Name: A name of identifier is written.

(2) Identifier: The code to identify the data is written.

(3) No. of digits: The number of maximum digits is written.

(4) Data range: The range of reading or writing data is written.

(5) Factory set value: The factory set value of data is written.

(6) Attribute: The data accessing direction is written.

(7) CH: ×: Identifier with channel

DX 1 0: It makes display “STOP” in

XI 6 0 to 16 (See P. 18)Note 1R/W×

No. of

digits

PV display.

1: It makes display “STOP” in

SV display.

RO: Read only (Data direction: Controller → Host computer)

R/W: Read and Write (Data direction: Controller ↔ Host computer)

−: Identifier without channel

Data range Factory set

Attri-

value

0R/W−

bute

CH

Data sending during polling

!"

!"

!"!"

Each time the host computer sends ACK (acknowledgement), the controller sends data corresponding

to the respective identifier in the order specified in a list of communication identifiers.

Communication is not possible when an identifier is specified that the controller can not

recognize.

To be send in this order.

32

Name Iden-

STOP display

selection

Input type

selection

tifier

DX 1 0: It makes display “STOP”

XI 6 0 to 16 (See P. 18)

No. of

digits

Data range

PV display.

1: It makes display “STOP”

SV display.

IMR01H03-E4

Page 39

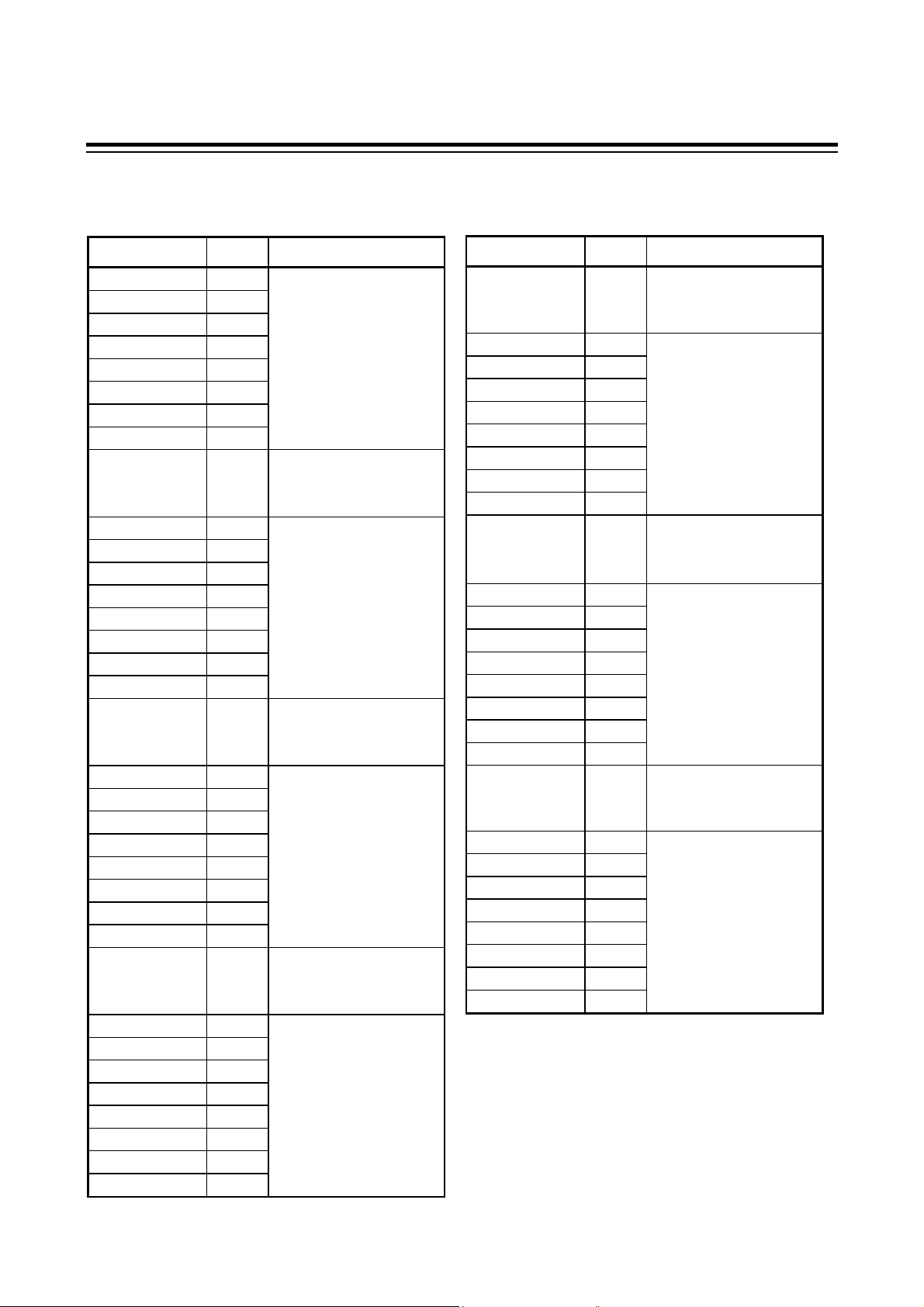

!"Communication identifier list

For details on the structure of communication data, see Communication Instruction

Manual (IMR01H02-E#).

3. INITIALIZE COMMUNICATION DATA

Name Iden-

STOP display

selection

tifier

DX 1 0: It makes display “STOP” in

No. of

digits

Data range Factory set

PV display.

Attri-

value

bute

0R/W−

1: It makes display “STOP” in

SV display.

Input type

XI 6 0 to 16 (See P. 18)Note 1R/W×

selection

Display unit

selection

Decimal point

position setting

PU 10: °C

1: °F

XU 1 0: No digit below decimal point

1: 1 digit below decimal point

0R/W×

Note 2 R/W ×

2: 2 digits below decimal point

3: 3 digits below decimal point

Setting limiter

XV 6 Within input range. Note 3 R/W ×

[high limit] setting

Setting limiter

[low limit] setting

CT ratio 1

1

XW See 4. INPUT RANGE

TABLES (P. 55)

XR 6 0 to 9999 (See P. 20)Note 4R/W×

selection

CT ratio 2

1, 2

XS

selection

1

When selecting CT ratio 1 or 2, as a channel number specified after the identifier, specify the

channel number corresponding to the CT ratio selection.

For the CT ratio selection channel number, see the 2.4 F22 Current Transformer (CT)

Input Specification (P. 20).

2

Do not use CT ratio 2 for the MA901.

Note 1 Factory set value varies depending on the input type.

Note 2 Factory set value varies depending on the instrument specification. However, factory set value

of a case of voltage input is 1.

Note 3 Factory set value varies depending on the instrument specification. However, factory set value

of a case of voltage input is 100.0 (high limit) and 0.0 (low limit).

Note 4 CTL-6-P-N: 800

CTL-12-S56-10L-N: 1000

CH

IMR01H03-E4

Continued on the next page.

33

Page 40

3. INITIALIZE COMMUNICATION DATA

Continued from the previous page.

Name Iden-

Contact input

logic selection *

tifier

XK

No. of

digits

1 0 to 9

Data range Factory set

See contact input logic tables

* This is the identifier effective when the contact input is provided.

Contact input logic tables

Set value STOP selection Memory area

selection

0 When contact input (RUN/STOP

transfer) opens, stop.

1 When contact input (RUN/STOP

transfer) opens, stop.

2 When contact input (RUN/STOP

transfer) opens, stop.

3 When contact input (RUN/STOP

transfer) opens, stop.

4 When contact input (RUN/STOP

transfer) opens, stop.

Memory area

transfer 1 to 8

Memory area

transfer 1 to 8

Memory area

transfer 1 to 7

Memory area

transfer 1 to 7

There is no

memory area

transfer function.

5 When contact input (RUN/STOP

transfer) is closed, stop.

6 When contact input (RUN/STOP

transfer) is closed, stop.

7 When contact input (RUN/STOP

transfer) is closed, stop.

8 When contact input (RUN/STOP

transfer) is closed, stop.

9 When contact input (RUN/STOP

transfer) is closed, stop.

Memory area

transfer 1 to 8

Memory area

transfer 1 to 8

Memory area

transfer 1 to 7

Memory area

transfer 1 to 7

There is no

memory area

transfer function.

value

Attri-

bute

CH

0R/W

Used/Unused of

DI SET terminal (No.43)

Used

Unused

Used

Unused

Unused

Used

Unused

Used

Unused

Unused

×

34

For details of the selection item, see the 2.5 F24 Contact Input Specification (P. 22).

Continued on the next page.

IMR01H03-E4

Page 41

Continued from the previous page.

3. INITIALIZE COMMUNICATION DATA

Name Iden-

Control output

logic selection 1

tifier

E0

No. of

digits

6

Data range Factory set

OUT1

0: Heat-side control output of

CH1

*

OUT2

0: Heat-side control output of

*

CH2

OUT3

0: Heat-side control output of

*

CH3

OUT4

0: Heat-side control output of

*

CH3

* This data is 0 fixation. This data must not set the set value besides 0.

Attri-

value

bute

0R/W

CH

×

IMR01H03-E4

Continued on the next page.

35

Page 42

3. INITIALIZE COMMUNICATION DATA

Continued from the previous page.

Name Iden-

Control output

logic selection 2

tifier

No. of

digits

Data range Factory set

E1 6 •••• MA900 (OUT5 to OUT8)

OUT5

0: No output

1: Cool-side control output of

CH1

1

2: No output

3: No output

4: Alarm 3 of CH1

5: Alarm 3 of CH2

6: Alarm 3 of CH3

7: Alarm 3 of CH4

2

2

2

2

8 to 11: No output

OUT6

0: No output

1: Cool-side control output of

CH2

1

2 to 11: Same as OUT5

OUT7

0: No output

1: Cool-side control output of

CH3

1

2 to 11: Same as OUT5

OUT8

0: No output

1: Cool-side control output of

CH4

1

2 to 11: Same as OUT5

value

Factory set

value varies

depending on

the instrument

specification.

Attri-

bute

R/W ×

CH

•••• MA901 (OUT5 to OUT8)

OUT5

0: Heat-side control output of

3

CH5

OUT6

0: Heat-side control output of

3

CH6

OUT7

0: Heat-side control output of

3

CH7

OUT8

0: Heat-side control output of

3

CH8

1

Setting becomes effective at the time of heat/cool control.

2

Not output when alarm 3 corresponds to the FAIL alarm.

3

This data is 0 fixation. This data must not set the set value besides 0.

36

Continued on the next page.

IMR01H03-E4

Page 43

Continued from the previous page.

3. INITIALIZE COMMUNICATION DATA

Name Iden-

Alarm output

logic selection *

tifier

No. of

digits

Data range Factory set

EA 6 0: FAIL alarm

1: Logical OR of alarm 1 in all

channels (Energized)

2: Logical OR of alarm 2 in all

channels (Energized)

3: Logical OR of alarm 3 in all

channels (Energized)

4: Logical OR of alarm 1 and

alarm 2 in all channels

(Energized)

5: Logical OR of alarm 1 and

alarm 3 in all channels

(Energized)

6: Logical OR of alarm 2 and

alarm 3 in all channels

(Energized)

7: Logical OR of alarm 1,

alarm 2 and alarm 3 in all

channels (Energized)

8: Logical OR of alarm 1 in all

channels (De-energized)

9: Logical OR of alarm 2 in all

channels (De-energized)

10: Logical OR of alarm 3 in all

channels (De-energized)

11: Logical OR of alarm 1 and

alarm 2 in all channels

(De-energized)

12: Logical OR of alarm 1 and

and 3 of all channels

(De-energized)

13: Logical OR of alarm 2 and

alarm 3 in all channels

(De-energized)

14: Logical OR of alarm 1,

alarm 2 and alarm 3 in all

channels (De-energized)

value

Alarm 1: 1

Alarm 2: 2

Alarm 3: 3

Attri-

bute

R/W

CH

−

* The logic of alarm output can be set for each alarm (alarm 1 to alarm 3). When selecting the logic,

as a channel number specified after the identifier, specify any of the following numbers.

Alarm 1: 01 Alarm 2: 02 Alarm 3: 03

For the data structure, see the Communication Instruction Manual (IMR01H02-E

Continued on the next page.

IMR01H03-E4

####

.

)

37

Page 44

3. INITIALIZE COMMUNICATION DATA

Continued from the previous page.

Name Iden-

Alarm 1 type

selection

1

tifier

XA 6 0: No alarm

No. of

digits

Data range Factory set

1: SV high alarm

2: SV low alarm

3: Process high alarm

4: Process low alarm

value

Factory set

value varies

depending on

the instrument

specification.

Attri-

bute

R/W −

5: Deviation high alarm

6: Deviation low alarm

7: Deviation high/low alarm

8: Band alarm

2

Without

R/W −

alarm hold

action: 0

With alarm

hold action: 2

Alarm 1

hold action

selection

9: Control loop break alarm

WA 1 0: Without alarm hold action

3

1: Effective when the power is

turned on, or operation is

changed from STOP to RUN.

2: Valid when:

• the power is turned on,

• operation is changed from

STOP to RUN,

• the SV is changed, or

• the memory area (control

area) is changed.

Alarm 1

HA 6 0 (0.0) to span Note 1 R/W ×

differential gap

setting

Alarm 1

TD 6 0 to 6000 seconds (See P. 28)0R/W−

timer setting

Alarm 1

action selection at

input error

OA 1 0: Normal processing

1: Forcibly turned on when

abnormal

0R/W−

(See P. 29)

1

When using the FAIL alarm, always set the alarm type to “0:No alarm.”

2

Control loop break alarm can not be specified in case of heat/cool control.

3

The alarm hold action can not be added to the FAIL alarm, SV high alarm, SV low alarm, control

loop break alarm and heater break alarm.

Note 1 TC and RTD inputs: 2 °C [°F] or 2.0 °C [°F]

Voltage input: 0.2 % of span

CH

38

Continued on the next page.

IMR01H03-E4

Page 45

Continued from the previous page.

3. INITIALIZE COMMUNICATION DATA

Name Iden-

Alarm 2 type

selection

1

tifier

XB 6 0: No alarm

No. of

digits

Data range Factory set

1: SV high alarm

2: SV low alarm

3: Process high alarm

4: Process low alarm

value

Factory set

value varies

depending on

the instrument

specification.

Attri-

bute

R/W −

5: Deviation high alarm

6: Deviation low alarm

7: Deviation high/low alarm

8: Band alarm

9: No alarm

2, 3

Without

alarm hold

action: 0

With alarm

hold action: 2

R/W −

Alarm 2

hold action

selection

10: Heater break alarm

WB 1 0: Without alarm hold action

4

1: Effective when the power is

turned on, or operation is

changed from STOP to RUN.

2: Valid when:

• the power is turned on,

• operation is changed from

STOP to RUN,

• the SV is changed, or

• the memory area (control

area) is changed.

Alarm 2

HB 6 0 (0.0) to span Note 1 R/W ×

differential gap

setting

Alarm 2

TG 6 0 to 6000 seconds (See P. 28)0R/W−

timer setting

Alarm 2

action selection at

input error

OB 1 0: Normal processing

1: Forcibly turned on when

abnormal

0R/W−

(See P. 29)

1

When using the FAIL alarm, always set the alarm type to “0:No alarm.”

2

When the control output is current output, no setting can be changed.

3

When the contact input or the communication function is selected as instrument specifications of

MA901, the heater break alarm cannot be added.

4

The alarm hold action can not be added to the FAIL alarm, SV high alarm, SV low alarm, control

loop break alarm and heater break alarm.

Note 1 TC and RTD inputs: 2 °C [°F] or 2.0 °C [°F]

Voltage input: 0.2 % of span

CH

IMR01H03-E4

Continued on the next page.

39

Page 46

3. INITIALIZE COMMUNICATION DATA

Continued from the previous page.

Name Iden-

Alarm 3 type

selection

1

Alarm 3

hold action

selection

2

Alarm 3

differential gap

setting

tifier

XC

WC

HC

No. of

digits

6 0: No alarm

1: SV high alarm

2: SV low alarm

3: Process high alarm

4: Process low alarm

Data range Factory set

value

Factory set

value varies

depending on

the instrument

specification.

5: Deviation high alarm

6: Deviation low alarm

7: Deviation high/low alarm

8: Band alarm

1 0: Without alarm hold action

1: Effective when the power is

turned on, or operation is

changed from STOP to RUN.

2: Valid when:

Without

alarm hold

action: 0

With alarm

hold action: 2

• the power is turned on,

• operation is changed from

STOP to RUN,

• the SV is changed, or

• the memory area (control

area) is changed.

6 0 (0.0) to span Note 1 R/W

Attri-

bute

R/W

R/W

CH

−

−

×

Alarm 3

timer setting

Alarm 3

action selection at

input error

TH

OC

6 0 to 6000 seconds

(See P. 28)

1 0: Normal processing

1: Forcibly turned on when

abnormal

0R/W

0R/W

(See P. 29)

1

When using the FAIL alarm, always set the alarm type to “0:No alarm.”

2

The alarm hold action can not be added to the FAIL alarm, SV high alarm, SV low alarm, control

loop break alarm and heater break alarm.

Note 1 TC and RTD inputs: 2 °C [°F] or 2.0 °C [°F]

Voltage input: 0.2 % of span

Continued on the next page.

40

−

−

IMR01H03-E4

Page 47

Continued from the previous page.

3. INITIALIZE COMMUNICATION DATA

Name Iden-

ON/OFF action

differential gap

tifier

IV 6 0 (0.0) to span

No. of

digits

Data range Factory set

However, 9999 digits of less

setting

Control action

type selection

ROM version

display

Integrated

operating time

XE 1 0: PID control (Direct action)

1: PID control (Reverse action)

2: Heat/cool action

(Water cooling)

2

3: Heat/cool action

(Air cooling)

2

VR 10 Display the version of loading

software.

UT 6 0000 to 0100

(See P. 31)

1

Factory set

1

value varies

depending on

the instrument

specification.

display

[upper 3 digits]

Integrated

operating time

UU 6 0000 to 9999

(See P. 31)

display

[lower 4 digits]

Holding peak

HP 6 −10 to +100 RO −

ambient

temperature

display

Communication

protocol selection

IS 1 0: RKC communication protocol

(Multi-point mode)

1: Modbus communication

protocol

2: RKC communication protocol

Factory set

value varies

depending on

the instrument

specification.

(Single mode)

RUN/STOP

transfer

RS 1 0: 0 (STOP) 1 (RUN)

1: 0 (RUN) 1 (STOP)

logic selection

1

When the instrument specification is heat/cool control, no setting can be changed.

2

When the instrument specification is only heat control, no setting can be changed.

The MA901 does not perform heat/cool control.

Note 1 TC and RTD inputs: 2 °C [°F] or 2.0 °C [°F]

Voltage input: 0.2 % of span

value

Attri-

bute

CH

Note 1 R/W ×

R/W ×

RO −

RO −

RO −

R/W −

0R/W−

IMR01H03-E4

41

Page 48

3. INITIALIZE COMMUNICATION DATA

3.2 Modbus Communication Protocol

3.2.1 Communication data list

The communication data list summarizes names, descriptions, factory set values and attributes.

Attribute (RO: Read only, R/W: Read and Write)

The communication data whose name is marked with ! indicates that corresponding to the

memory area.

Name Data range Factory set value Attri-

bute

Setting change rate

limiter !

Setting limiter

[high limit] setting

Setting limiter

[low limit] setting

Digital filter 0 to 100 seconds

Input type selection 0 to 16 (See P. 18)Note 2R/W

Display unit selection 0: °C 1: °F0R/W

Decimal point position

setting

CT ratio 1 selection 0 to 9999 (See P. 20)Note 4R/W

CT ratio 2 selection *

ON/OFF action

differential gap setting

0 (0.0) to span/minute

(0: Setting change rate limiter OFF)

Within input range.

See 4. INPUT RANGE TABLES (P. 55)

(0: No digital filter function)

0: No digit below decimal point

1: 1 digit below decimal point

2: 2 digits below decimal point

3: 3 digits below decimal point

0 (0.0) to span

However, 9999 digits of less

0R/W

Note 1 R/W

0R/W

Note 3 R/W

Note 5 R/W

* Do not use CT ratio 2 for the MA901.

Note 1 Factory set value varies depending on the instrument specification. However, factory set value

of a case of voltage input is 100.0 (high limit) and 0.0 (low limit).

Note 2 Factory set value varies depending on the input type.

Note 3 Factory set value varies depending on the instrument specification. However, factory set value

of a case of voltage input is 1.

Note 4 CTL-6-P-N: 800

CTL-12-S56-10L-N: 1000

Note 5 TC and RTD inputs: 2 °C [°F] or 2.0 °C [°F]

Voltage input: 0.2 % of span

Continued on the next page.

42

IMR01H03-E4

Page 49

Continued from the previous page.

Name Data range Factory set value Attri-

Control action type

selection

0: PID control (Direct action)

1: PID control (Reverse action)

2: Heat/cool control (Water cooling)

3: Heat/cool control (Air cooling)

3. INITIALIZE COMMUNICATION DATA

bute

1

1

2

2

Note 1 R/W

Alarm 1 type

selection

3

0: No alarm

1: SV high alarm

2: SV low alarm

3: Process high alarm

Factory set value

varies depending on

the instrument

specification.

R/W

4: Process low alarm

5: Deviation high alarm

6: Deviation low alarm

7: Deviation high/low alarm

8: Band alarm

4

Without alarm hold

R/W

action: 0

With alarm hold

action: 2

Alarm 1 hold action

selection

5

9: Control loop break alarm

0: Without alarm hold action

1: Effective when the power is turned on,

or operation is changed from STOP to

RUN.

2: Valid when:

• the power is turned on,

• operation is changed from STOP to

RUN,

• the SV is changed, or

• the memory area (control area) is

changed.

Alarm 1 timer setting 0 to 6000 seconds (See P. 28)0R/W

Alarm 1

action selection at

input error

Alarm 1

0: Normal processing

1: Forcibly turned on when abnormal

(See P. 29)

0 (0.0) to span Note 2 R/W

0R/W

differential gap setting

1

When the instrument specification is heat/cool control, no setting can be changed.

2

When the instrument specification is only heat control, no setting can be changed.

The MA901 does not perform heat/cool control.

3

When using the FAIL alarm, always set the alarm type to “0: No alarm.”

4

Control loop break alarm can not be specified in case of heat/cool control.

5

The alarm hold action can not be added to the FAIL alarm, SV high alarm, SV low alarm, control

loop break alarm and heater break alarm.

Note 1 Factory set value varies depending on the instrument specification.

Note 2 TC and RTD inputs: 2 °C [°F] or 2.0 °C [°F]

Voltage input: 0.2 % of span

IMR01H03-E4

Continued on the next page.

43

Page 50

3. INITIALIZE COMMUNICATION DATA

Continued from the previous page.

Name Data range Factory set value Attri-

bute

Alarm 2 type

selection

1

0: No alarm

1: SV high alarm

2: SV low alarm

3: Process high alarm

Factory set value

varies depending on

the instrument

specification.

R/W

4: Process low alarm

5: Deviation high alarm

6: Deviation low alarm

7: Deviation high/low alarm

8: Band alarm

9: No alarm

2, 3

Without alarm hold

action: 0

With alarm hold

action: 2

R/W

Alarm 2 hold action

selection

4

10: Heater break alarm

0: Without alarm hold action

1: Effective when the power is turned on,

or operation is changed from STOP to

RUN.

2: Valid when:

• the power is turned on,

• operation is changed from STOP to

RUN,

• the SV is changed, or

• the memory area (control area) is

changed.

Alarm 2 timer setting 0 to 6000 seconds (See P. 28)0R/W

Alarm 2

action selection at

input error

Alarm 2

0: Normal processing

1: Forcibly turned on when abnormal

(See P. 29)

0 (0.0) to span Note 1 R/W

0R/W

differential gap setting

1

When using the FAIL alarm, always set the alarm type to “0: No alarm.”

2

When the control output is current output, no setting can be changed.

3

When the contact input or the communication function is selected as instrument specifications of

MA901, the heater break alarm cannot be added.

4