Page 1

SR Mini HG SYSTEM

Power Supply/CPU Module

PLC Communication

H-PCP-J

Instruction Manual

[For OMRON PLC]

RKC INSTRUMENT INC.

®

IMS01J04-E1

Page 2

Modbus is a registered trademark of Schneider Electric.

The name of each programmable controller (PLC) means the products of each manufacturer.

Company names and product names used in this manual are the trademarks or registered trademarks of

the respective companies.

All Rights Reserved, Copyright 2004, RKC INSTRUMENT INC.

Page 3

Thank you for purchasing this RKC instrument. In order to achieve maximum performance and ensure

proper operation of your new instrument, carefully read all the instructions in this manual. Please

place this manual in a convenient location for easy reference.

SYMBOLS

WARNING

CAUTION

!

An external protection device must be installed if failure of this instrument

could result in damage to the instrument, equipment or injury to personnel.

: This mark indicates precautions that must be taken if there is danger of electric

shock, fire, etc., which could result in loss of life or injury.

: This mark indicates that if these precautions and operating procedures are not

taken, damage to the instrument may result.

: This mark indicates that all precautions should be taken for safe usage.

: This mark indicates important information on installation, handling and operating

procedures.

: This mark indicates supplemental information on installation, handling and

operating procedures.

: This mark indicates where additional information may be located.

WARNING

!

All wiring must be completed before power is turned on to prevent electric

shock, fire or damage to instrument and equipment.

This instrument must be used in accordance with the specifications to

prevent fire or damage to instrument and equipment.

This instrument is not intended for use in locations subject to flammable or

explosive gases.

Do not touch high-voltage connections such as power supply terminals, etc.

to avoid electric shock.

RKC is not responsible if this instrument is repaired, modified or

disassembled by other than factory-approved personnel. Malfunction can

occur and warranty is void under these conditions.

IMS01J04-E1

i-1

Page 4

CAUTION

This is a Class A instrument. In a domestic environment, this instrument may cause radio

interference, in which case the user may be required to take adequate measures.

This instrument is protected from electric shock by reinforced insulation. Provide

reinforced insulation between the wire for the input signal and the wires for instrument

power supply, source of power and loads.

Be sure to provide an appropriate surge control circuit respectively for the following:

- If input/output or signal lines within the building are longer than 30 meters.

- If input/output or signal lines leave the building, regardless the length.

This instrument is designed for installation in an enclosed instrumentation panel. All

high-voltage connections such as power supply terminals must be enclosed in the

instrumentation panel to avoid electric shock by operating personnel.

All precautions described in this manual should be taken to avoid damage to the

instrument or equipment.

All wiring must be in accordance with local codes and regulations.

All wiring must be completed before power is turned on to prevent electric shock,

instrument failure, or incorrect action.

The power must be turned off before repairing work for input break and output failure

including replacement of sensor, contactor or SSR, and all wiring must be completed

before power is turned on again.

To prevent instrument damage or failure, protect the power line and the input/output lines

from high currents with a protection device such as fuse, circuit breaker, etc.

Prevent metal fragments or lead wire scraps from falling inside instrument case to avoid

electric shock, fire or malfunction.

Tighten each terminal screw to the specified torque found in the manual to avoid electric

shock, fire or malfunction.

For proper operation of this instrument, provide adequate ventilation for heat dispensation.

Do not connect wires to unused terminals as this will interfere with proper operation of the

instrument.

Turn off the power supply before cleaning the instrument.

Do not use a volatile solvent such as paint thinner to clean the instrument. Deformation or

discoloration will occur. Use a soft, dry cloth to remove stains from the instrument.

To avoid damage to instrument display, do not rub with an abrasive material or push front

panel with a hard object.

Do not connect modular connectors to telephone line.

NOTICE

This manual assumes that the reader has a fundamental knowledge of the principles of electricity,

process control, computer technology and communications.

The figures, diagrams and numeric values used in this manual are only for purpose of illustration.

RKC is not responsible for any damage or injury that is caused as a result of using this instrument,

instrument failure or indirect damage.

RKC is not responsible for any damage and/or injury resulting from the use of instruments made by

imitating this instrument.

Periodic maintenance is required for safe and proper operation of this instrument. Some

components have a limited service life, or characteristics that change over time.

Every effort has been made to ensure accuracy of all information contained herein. RKC makes no

warranty expressed or implied, with respect to the accuracy of the information. The information in

this manual is subject to change without prior notice.

No portion of this document may be reprinted, modified, copied, transmitted, digitized, stored,

processed or retrieved through any mechanical, electronic, optical or other means without prior

written approval from RKC.

i-2

IMS01J04-E1

Page 5

CONTENTS

1. OUTLINE............................................................................... 1

2. COMMUNICATION SPECIFICATIONS................................ 3

3. CONNECTIONS.................................................................... 4

4. SETTING ON THE H-PCP-J MODULE SIDE....................... 6

4.1 PLC Data Memory Address Setting.................................................................6

Page

4.2 Protocol Selection and Communication Setting...............................................8

4.3 PLC Scanning Time Setting.............................................................................9

5. SETTING ON THE PLC SIDE............................................. 10

6. COMMUNICATION DATA .................................................. 11

6.1 Request Command and Data Transfer..........................................................11

6.2 Data Processing Precautions ........................................................................15

6.3 Communication Data List...............................................................................17

7. DATA MAP.......................................................................... 24

7.1 Reference to Data Map .................................................................................24

7.2 Data Map List ................................................................................................25

8. CURRENT TRANSFORMER (CT) MONITOR.................... 31

8.1 Setting on The H-PCP-J Module Side ...........................................................33

8.2 Setting on The PLC Side ............................................................................... 37

8.3 Communication Data List...............................................................................38

IMS01J04-E1 i-3

Page 6

MEMO

i-4 IMS01J04-E1

Page 7

r

1. OUTLINE

This manual describes the communication function of the SR Mini HG SYSTEM and the OMRON

programmable controller (hereafter called PLC).

This manual is attached when the model code of H-PCP-J module is H-PCP-J--D∗

-03E.

For details of the H-PCP-J module, see the Power Supply/CPU Module H-PCP-J

Instruction Manual (IMS01J02-E).

The SR Mini HG SYSTEM can be connected to the OMRON SYSMAC series without using any

program.

The SR Mini HG SYSTEM occupies the fixed area in the PLC data memory for each unit address.

The control unit for SR Mini HG SYSTEM consists of the H-PCP-J module and temperature control

function modules.

OMRON

SYSMAC series

PLC

RS-422A

o

RS-232C

SR Mini HG SYSTEM

control unit

Converter

RS-422A

RS-422A

SR Mini HG SYSTEM

control unit

SR Mini HG SYSTEM

control unit

RS-422A

SR Mini HG SYSTEM

control unit

(Up to 4 units)

In addition, the SR Mini HG SYSTEM can be monitored only current transformer (CT) input.

For the data, see the 8. CURRENT TRANSFORMER (CT) MONITOR (P. 31).

IMS01J04-E1 1

Page 8

1. OUTLINE

Usable units (OMRON SYSMAC series)

Name Type

High-order link unit C200H-LK202-V1, C500-LK203, C120-LK202-V1

(SYSMAC C series), etc.

CPU unit with a built in

CPU unit of SYSMAC CS1 series

communication port

Serial communication board CS1W-SCB41 (SYSMAC CS1 series), etc.

Usable modules (SR Mini HG SYSTEM)

The following function module data can be used in PLC communication (see “Data map” on page 24).

In addition, data on other modules connected (TI, AI, AO, etc.) can be used on one more

communication port (RKC communication or Modbus).

Function module Type

Temperature control module H-TIO-A H-TIO-B H-TIO-C H-TIO-D H-TIO-E

H-TIO-F H-TIO-G H-TIO-H H-TIO-J H-TIO-P

H-TIO-R

Position proportioning control

module *

Speed control module * H-SIO-A

Cascade control module * H-CIO-A

H-TIO-K

Current transformer input

H-CT-A (Up to 20 points/control unit are available)

module

* There is restriction on usable data. Only data described in 6.3 Communication Data List (P. 17)

can be used.

For the function modules, see the Hardware Instruction Manual (IMSRM15-E).

2

IMS01J04-E1

Page 9

2. COMMUNICATION SPECIFICATIONS

Interface: Based on RS-422A, EIA standard

Connection method: RS-422A: 4-wire system, multi-drop connection

Synchronous method: Start/stop synchronous type

Communication speed: 9600 bps, 19200 bps, 38400 bps

Communication speed can be selected with switch

Data bit configuration: Start bit: 1

Data bit: 7

Parity bit: Even

Stop bit: 2

Protocol: OMRON SYSMAC C mode command protocol

Unit number (Model number) 00

Usable command: C mode command

RD: Word device read for each word

WD: Word device write for each word

CPU operation mode: Program mode or monitor mode

Change it to monitor mode automatically when started with RUN mode.

Maximum connections: 4 control units per communication port of PLC

For the current transformer (CT) monitor function, 16 control units per

communication port of PLC

IMS01J04-E1 3

Page 10

3. CONNECTIONS

RS-422A

Pin layout of modular connector (RS-422A)

COM.PORT1

R (A)

1

R (B)

2

SG

3

T (B)

4

T (A)

5

SG

6

H-PCP-J module

Connector pin number and signal details (RS-422A)

Pin No. Signal name Symbol

1 Receive data R (A)

2 Receive data R (B)

3 Signal ground SG

4 Send data T (B)

5 Send data T (A)

6 Signal ground SG

4 IMS01J04-E1

Page 11

Diagram of RS-422A wiring

H-PCP-J

Pair wire

3. CONNECTIONS

PLC

OMRON

SYSMAC series

T (A)

T (B)

SG

R (A)

R (B)

SG

5

4

3

1

2

6

SDA

SDB

SG

RDA

RDB

Shielded twisted pair wire

The 6-pin type modular connector should be used for the connection to the H-PCP-J module.

Recommended model: TM4P-66P (Manufactured by HIROSE ELECTRIC CO., LTD.,)

Because there is not SG, in case of SYSMAC CS1 series, electric wiring is unnecessary.

Customer is requested to prepare a communication cable fit for the control unit to be

connected by the PLC. Connection cable W-BF-01 * (RKC product) can use to connect

PLC.

* Shields of the cable are connected to SG (No. 6 pin) of the H-PCP-J connector.

A wiring example when using our W-BF-01 connection cable is shown in the following.

Cable type: W-BF-01-3000 (RKC product, Sold separately) [Standard cable length: 3 m]

PLC

OMRON

SYSMAC series

H-PCP-J

W-BF-01

Connect to the

[COM. PORT1]

The details of the connectable connector for the PLC please also read the instruction manual

Blue

Black

White

Orange

Red

T (A)

T (B)

R (A)

R (B)

SG

SDA

SDB

RDA

RDB

SG

for the used PLC.

IMS01J04-E1

5

Page 12

4.

SETTING ON THE H-PCP-J MODULE SIDE

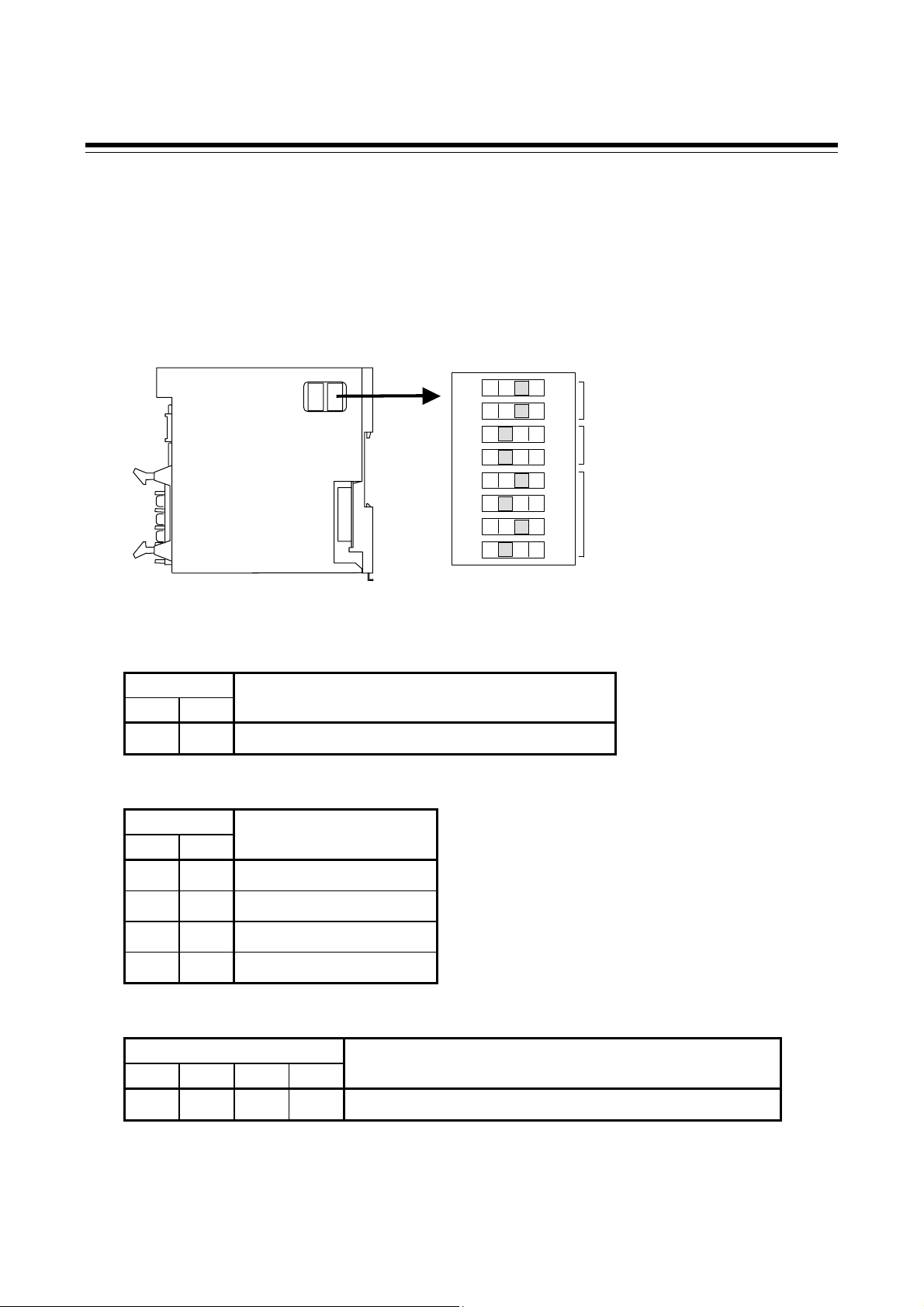

4.1 PLC Data Memory Address Setting

Set the data memory address of each control unit using the unit address setting switch at the front of

the H-PCP-J module. For this setting, use a small blade screwdriver.

H-PCP-J module

Unit address setting switch

0

1

2

F

3

E

4

D

5

C

6

B

7

A

9

8

Setting range:

0 to 15 (0 to F: hexadecimal)

Up to 4 SR Mini HG SYSTEMs can be connected to a PLC communication port. Therefore the data

memory address uses the 4 SR Mini HG SYSTEMs as a group. The SR Mini HG SYSTEMs

connected to the same PLC communication port sets the address in the same group.

Set unit address of each group including 0, 4, 8 and C by all means. 0, 4, 8 and C work

as a master of communication transfer.

Set unit address within address range of PLC (CPU unit) to use.

Group Unit address setting switch PLC data memory address

Group 1

Group 2

Group 3

Group 4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

D1000 to D1499

D1500 to D1999

D2000 to D2499

D2500 to D2999

D3000 to D3499

D3500 to D3999

D4000 to D4499

D4500 to D4999

D5000 to D5499

D5500 to D5999

D6000 to D6499

D6500 to D6999

D7000 to D7499

D7500 to D7999

D8000 to D8499

D8500 to D8999

6 IMS01J04-E1

Page 13

Setting example: When group 2 is used

PLC

SR Mini HG SYSTEM

control unit

SR Mini HG SYSTEM

control unit

SR Mini HG SYSTEM

control unit

SR Mini HG SYSTEM

control unit

4. SETTING ON THE H-PCP-J MODULE SIDE

Unit address 4

Data memory

address:

D3000 to D3499

Unit address 5

Data memory

address:

D3500 to D3999

Unit address 6

Data memory

address:

D4000 to D4499

Unit address 7

Data memory

address:

D4500 to D4999

Address in the same

group is set

IMS01J04-E1

7

Page 14

4. SETTING ON THE H-PCP-J MODULE SIDE

4.2 Protocol Selection and Communication Setting

Match the setting of data bit configuration, communication speed and communication protocol with

the PLC communication specification by COM.PORT1/COM.PORT2 setting switch (SW2).

Setting example to recommend is shown in the following.

H-PCP-J module

COM.PORT1/COM.PORT2

setting switch (SW2)

1 87 6 54 32

ON

Data bit configuration

Communication speed

(Set the same as PLC.)

Right side view

Data bit configuration

SW2

Data bit configuration

1 2

ON ON Data 7-bit, Even parity, Stop 2-bit

Communication speed Set the same as PLC.

SW2

Communication speed

3 4

OFF OFF 9600 bps

ON OFF 19200 bps

OFF ON 38400 bps

Communication protocol

Factory set value: All OFF

ON ON Don't set this one

Protocol

5 6 7 8

ON OFF ON OFF OMRON SYSMAC series special protocol

8

SW2

Protocol

IMS01J04-E1

Page 15

4. SETTING ON THE H-PCP-J MODULE SIDE

4.3 PLC Scanning Time Setting

Set the PLC scanning time (time of waiting for a response from the PLC) so as to adapt to the

environment used. The PLC scanning time is set via host communication (RKC communication

or Modbus).

PLC scanning time setting Setting range: 0 to 3000 ms (Factory set value: 10 ms)

[Setting example]

Set PLC scanning time to any value more than twice as long as the maximum scanning time of PLC.

If PLC scanning time is extremely short (When at a factory set value of 10 ms as an

example), the SR Mini HG SYSTEM may detect the time-out not conducting normal

communication processing.

The maximum scanning time of PLC differs depending on the CPU processing speed, I/O

unit configuration and the user program capacity of the PLC.

For the PLC scanning time setting (Identifier ST), see the Power Supply/CPU Module

H-PCP-J Instruction Manual (IMS01J02-E).

IMS01J04-E1

9

Page 16

5. SETTING ON THE PLC SIDE

Set the PLC as follows. (Recommend setting example)

Item Description

Serial communication mode High-order link

Unit number (Model number) 0

Start bit 1

Data bit 7

Stop bit 2

Parity bit Even

Transmission speed Set the same as SR Mini HG SYSTEM

I/O port selection RS-422A

Synchronization selection Internal synchronization

CTS selection 0 V (always ON)

5 V supply OFF

Termination resistor Termination resistor is inserted

The setting item varies depending on the PLC. The details of the setting procedure for the

PLC please also read the instruction manual for the used PLC.

10 IMS01J04-E1

Page 17

6. COMMUNICATION DATA

6.1 Request Command and Data Transfer

Data transfer between PLC and SR Mini HG SYSTEM are executed by request command.

Request command “0: Monitor (PLC ← SR Mini HG SYSTEM)”

Command which status requests the SR Mini HG SYSTEM to write data such as temperature

measured values, etc. (attribute: RO) to the PLC side.

The SR Mini HG SYSTEM always repeats data writing until “1: Setting” or “2: Set value monitor”

is set to the request command.

The PCP communication is set to “1: Writing on monitor data” during data transfer.

Request command “1: Setting (PLC → SR Mini HG SYSTEM)”

Command which requests the SR Mini HG SYSTEM to read data such as temperature set values,

etc. (attribute: RW or WO) from the PLC side. Just when “1: Setting” is set to the request

command, the SR Mini HG SYSTEM starts reading the data from the PLC side.

The PCP communication status is set to “2: Reading out setting data” during data transfer. After the

data is transferred, the request command and PCP communication status returns to “0: Monitor”

and “1: Writing on monitor data,” respectively.

Request command “2: Set value monitor (PLC ← SR Mini HG SYSTEM)”

Command which requests the SR Mini HG SYSTEM to write data such as temperature set values,

etc. (attribute: RW) to the PLC side. Just when “2: Set value monitor” is set to the request

command, the SR Mini HG SYSTEM starts writing the data to the PLC side.

The PCP communication status is set to “3: Writing on setting data” during data transfer. After the

data is transferred, the request command and PCP communication status returns to “0: Monitor”

and “1: Writing on monitor data,” respectively.

IMS01J04-E1 11

Page 18

6. COMMUNICATION DATA

p

p

R

t

t

R

Data transfer procedures

Change each set value of SR Mini HG SYSTEM from the PLC after the initial settings

are made.

If each set value of SR Mini HG SYSTEM is changed from the PLC without setting the

initial values, it is re-written to 0 with each set value of the PLC at that time set to 0.

Initial Setting (When transmit data of temperature setting values from SR Mini HG

SYSTEM to PLC)

Set “2” to the request

command

NO

PCP communication

NO

PCP communication

Start

Turn on power of

each instrument

state = 3 ?

YES

Wait time

state = 1 ?

YES

End

When 2 (Set value monitor) is set to request command,

the

SR Mini HG SYSTEM starts writing the data items

such as temperature set value, etc. (attribute: R/W) to

the PLC side.

If 3 (Writing on setting data) is set to PCP

communication state in the PLC, this indicates that

Mini HG SYSTEM data items such as temperature se

value, etc. (attribute: R/W) are being written into the

PLC.

Reserve data write time as wait time. In addition,

rocess data in each item as indefinite during this

eriod.

Waiting time (for 38400 bps):

1 second/control unit

If 1 (Writing on monitor data) is set to PCP

communication state in the PLC, this indicates tha

SRV data items such as temperature set value, etc.

(attribute: R/W) have been written to start writing

Mini HG SYSTEM data items such as temperature

measured values (PV), etc. (attribute: RO) into the

PLC.

S

S

12

IMS01J04-E1

Page 19

6. COMMUNICATION DATA

R

t

t

t

t

p

p

Data setting (When transmit data of temperature setting values from PLC to SR Mini

HG SYSTEM)

Start

Set temperature set value

(SV) and other setting data

to each register (memory)

in the PLC.

Set “1” to the request

command

[Data setting]

When 1 (Setting) is set to request command, the

Mini HG SYSTEM starts reading the temperature se

value data set to the register (memory) on the PLC

side.

NO

PCP communication

state = 2 ?

YES

If 2 (Reading out setting data) is set to PCP

communication state in the PLC, this indicates tha

temperature set values data are being read from the

PLC.

Wait time

Reserve data read time as wait time. In addition,

rocess data in each item as indefinite during this

eriod.

Waiting time (for 38400 bps):

2 seconds/control unit

NO

PCP communication

state = 1 ?

YES

If 1 (Writing on monitor data) is set to PCP

communication state in the PLC, this indicates tha

temperature set value data have been read to star

writing SR Mini HG SYSTEM data items such as

temperature measured values (PV) etc. (attribute: RO)

into the PLC.

A

Continued on the next page.

S

IMS01J04-E1

13

Page 20

6. COMMUNICATION DATA

R

t

t

p

p

Continued from the previous page.

A

Set “2” to the request

command

NO

PCP communication

state = 3 ?

YES

Wait time

NO

PCP communication

state = 1 ?

YES

End

[Confirmation of setting data]

When 2 (Set value monitor) is set to request command,

SR Mini HG SYSTEM starts writing the temperature

the

set value data set to the PLC side.

If 3 (Writing on setting data) is set to PCP

communication state in the PLC, this indicates that

Mini HG SYSTEM temperature set value data are being

written into the PLC.

Reserve data write time as wait time. In addition,

rocess data in each item as indefinite during this

eriod.

Waiting time (for 38400 bps):

1 second/control unit

If 1 (Writing on monitor data) is set to PCP

communication state in the PLC, this indicates tha

temperature set values have been written to star

writing SR Mini HG SYSTEM data items such as

temperature measured values (PV), etc. (attribute: RO)

into the PLC.

S

14

IMS01J04-E1

Page 21

6. COMMUNICATION DATA

6.2 Data Processing Precautions

With PLC communication, the maximum number of channels per unit address is 20.

Read data of unused channel and undefined address is 0.

The data type is treated as binary data with a sign and without a decimal point. For this reason,

carefully express and set the data. (excluding the TIO status)

[Example] Heat-side proportional band

Initial value of internal data: 3.0

Communication data: 30

If the data range error occurs during data setting, “Setting error” (bit 8 in the TIO status) is set to

ON in the channel where the error occurs. The SR Mini HG SYSTEM continues operation at the

present set value without updating the data.

Any attempt to write to an unused channel is not processed as an error.

The autotuning (AT) function starts its execution with PID/AT transfer and the request command

set to “1: AT operation” and “1: Setting,” respectively. After the autotuning function finishes its

execution, PID/AT transfer returns to “0: PID control operation” and thus the PID constants are

updated.

When the PLC communication status is selected by selecting the H-PCP-J module DO type

(Identifier VU), the digital output (DO) is turned on or off according to the status of

communication between the H-PCP-J module and PLC.

Communication error

When the communication is error

after the power ON immediately

When the communication is error

during operation

PLC communication status

(H-PCP-J module DO)

OFF “1: Monitor”

OFF

Operation mode

Same as mode before the

communication error

If communication between the H-PCP-J module and PLC is ready, the PLC communication status

(H-PCP-J module DO) is turned on to enable operation to continue.

The H-PCP-J module DO type selection (Identifier VU) is set by host communication. For

the host communication, see the Power Supply/CPU Module H-PCP-J Instruction

Manual (IMS01J02-E).

IMS01J04-E1

15

Page 22

6. COMMUNICATION DATA

Some communication data may become invalid depending on the module selection or the

configuration of the SR Mini HG System control unit.

If any one of the conditions listed below occurs and data items written are within the setting range,

read data becomes 0. Under these conditions, no error response message will occur.

− When heat/cool control, manual output value and auto/manual transfer are invalid.

− When heat control, cool-side manipulated output, cool-side proportional band, overlap/deadband

and cool-side proportioning cycle time are invalid.

− When ON/OFF control, cool-side manipulated output, heat-side and cool-side proportional band,

integral time, derivative time, overlap/deadband and cool-side proportioning cycle time are

invalid.

− When the H-CT-A module is not provided, current transformer input measured value 2, heater

break alarm set value 2 and CT channel setting are invalid.

16

IMS01J04-E1

Page 23

6.3 Communication Data List

• Name

: Item stored in the memory area.

[ ]: The functional module name that data becomes valid is written.

• Attributes

RO: At the time of request command “0: Monitor,” SR Mini HG SYSTEM writes in data.

(SR Mini HG SYSTEM → PLC)

R/W: At the time of request command “1: Setting,” SR Mini HG SYSTEM read out data.

At the time of request command “2: Set value monitor,” SR Mini HG SYSTEM

writes in data. (SR Mini HG SYSTEM ↔ PLC)

WO: At the time of request command “1: Setting,” SR Mini HG SYSTEM read out data.

(SR Mini HG SYSTEM ← PLC)

• Structure

C: Data for each channel U: Data for each unit address

Name

Attri-

bute

Struc-

ture

Data range

6. COMMUNICATION DATA

Factory

set value

Temperature set value

(SV)

[H-TIO-, H-CIO-A]

R/W C

TC/RTD input:

Within input range (Within setting limiter)

Current/voltage input:

Within display scale range

(Within setting limiter)

Motor speed set value

[H-SIO-A]

Alarm 1 set value

[H-TIO-, H-CIO-A,

H-SIO-A]

Alarm 2 set value

R/W C

R/W C

Within display scale range

(Within setting limiter)

TC/RTD input:

Within input range or span range

Current/voltage input, H-SIO-A:

Within display scale range or span range

[H-TIO-, H-CIO-A,

H-SIO-A]

* Factory set value table of Alarm 1/Alarm 2 set value

Input type Alarm type Alarm 1 set value Alarm 2 set value

TC/RTD input

Current/voltage input

Process low alarm 0.0 % 0.0 %

Deviation high alarm, Deviation

Deviation low alarm

No alarm function 100.0 % 0.0 %

Process high alarm Input range (high limit) Input range (high limit)

Process low alarm Input range (low limit) Input range (low limit)

Deviation high alarm, Deviation

high/low alarm, Band alarm

Deviation low alarm

No alarm function Input range (high limit) Input range (low limit)

Process high alarm 100.0 % 100.0 %

high/low alarm, Band alarm

50 °C 50 °C

−50 °C −50 °C

50 % 50 %

−50 % −50 %

Continued on the next page.

0

The position

of the decimal

point differs

depending on

the input

range.

See Factory

set value

table of

Alarm 1/

Alarm 2

set value *

IMS01J04-E1

17

Page 24

6. COMMUNICATION DATA

Continued from the previous page.

Name

Attri-

bute

Struc-

ture

Data range

Factory

set value

Heater break alarm

set value

[H-CT-A]

Operation mode transfer

[H-TIO-, H-CIO-A,

H-SIO-A]

R/W C

R/W C

0.0 to 100.0 A or 0.0 to 30.0 A

For the current transformer (CT) input of the

H-CT-A module.

Allocates the channels for H-TIO- module

to the input channels of H-CT-A module by

CT channel setting.

For the CT channel setting, see the Power

Supply/CPU Module H-PCP-J Instruction

Manual (IMS01J02-E).

0: Unused

If set to “Unused,” no control, monitor or

alarm monitor is performed.

1: Monitor

If set to “Monitor,” only the monitor is

performed. No control or alarm monitor is

performed.

2: Alarm

If set to “Alarm,” monitor or alarm

monitor is performed. No control is

performed.

3: Normal

Selected to normal mode to perform

control, monitor or alarm monitor.

0.0

3

Auto/Manual transfer

[H-TIO-, H-CIO-A]

Manual output value

[H-TIO-, H-CIO-A]

Overlap/deadband

[H-TIO-, H-CIO-A]

Heat-side proportional

band

[H-TIO-, H-CIO-A,

H-SIO-A]

Cool-side proportional

band

[H-TIO-, H-CIO-A]

R/W C

0: Auto

0

1: Manual

Setting will be invalid in ON/OFF control

and heat/cool control.

R/W C

−5.0 to +105.0 %

0.0

Setting will be invalid in ON/OFF control

and heat/cool control.

R/W C −10.0 to +10.0 % of span 0.0

R/W C 0.1 to 1000.0 % of span

H-TIO-,

H-CIO-A:

3.0

H-SIO-A:

300.0

R/W C 0.1 to 1000.0 % of span 3.0

Continued on the next page.

18

IMS01J04-E1

Page 25

Continued from the previous page.

Name

Attri-

bute

Struc-

ture

Data range

6. COMMUNICATION DATA

Factory

set value

Integral time

[H-TIO-, H-CIO-A,

H-SIO-A]

R/W C 1 to 3600 seconds

H-TIO-,

H-CIO-A:

240

H-SIO-A:

2

Derivative time

[H-TIO-, H-CIO-A,

H-SIO-A]

R/W C 0 to 3600 seconds (0: PI action)

H-TIO-,

H-CIO-A:

60

H-SIO-A:

0

PID/AT transfer *

[H-TIO-, H-CIO-A,

H-SIO-A]

R/W C

0: PID control operation

1: AT (Autotuning) operation

The autotuning (AT) function starts its

0

execution with PID/AT transfer and the

request command set to “1: AT operation”

and “1: Setting,” respectively. After the

autotuning function finishes its execution,

PID/AT transfer returns to “0: PID control

operation.”

* Autotuning (AT) is the function which automatically measures, calculates and sets the optimum PID

constants according to the set temperature.

Caution for using the Autotuning (AT)

When a temperature change (UP and/or Down) is 1C or less per minute during

Autotuning, Autotuning may be cancelled before calculating PID values. In that case,

adjust the PID values manually. It is possible to happen when the set value is around

the ambient temperature or is close to the maximum temperature achieved by the load.

The following is the conditions necessary to carry out autotuning and the conditions which will cause

the autotuning to stop.

Conditions necessary for autotuning:

The autotuning should be executed after satisfying all of the following conditions:

• Operation mode conditions:

− Auto/Manual transfer → Auto mode

− PID/AT transfer → PID control mode

− Control RUN/STOP transfer → Control RUN mode

• The measured value (PV) is without input error range [Input error determination point (high) >

Measured value (PV) > Input error determination point (low)].

• The output limiter high limit should be more than 0.1 % and the output limiter low limit should be

less than 99.9 %.

• When operation mode is set to “Normal (Can be controlled ).”

When the autotuning is finished, the display of each channel automatically returns to “0: PID control

operation.”

Continued on the next page.

IMS01J04-E1

19

Page 26

6. COMMUNICATION DATA

Continued from the previous page.

Conditions which will cause the autotuning to stop:

• When the temperature set value (SV) is changed.

• When the memory area is changed.

• When the PV bias value is changed.

• When the AT bias value is changed.

• When transfer to Manual mode using the Auto/Manual transfer.

• When the measured value (PV) goes to input error range [Measured value (PV) ≥ Input error

determination point (high) or Input error determination point (low) ≥ Measured value (PV)].

• When the power is cut off.

• When FAIL occurs in the module whose channel is under the autotuning. Otherwise, when FAIL

occurs in the H-PCP-J module.

• When transfer to the PID control mode by the PID/AT transfer.

• When operation mode is set to “Unused,” “Monitor” or “Alarm.”

• When the Control RUN/STOP function is changed to the “Control STOP” function.

When the above-mentioned conditions to stop the autotuning occurs, the autotuning is

immediately stopped and switch over to the PID control mode. The PID constants

return to the values at the start of the autotuning.

20

Continued on the next page.

IMS01J04-E1

Page 27

Continued from the previous page.

Name

Attri-

bute

Struc-

ture

Data range

6. COMMUNICATION DATA

Factory

set value

Temperature measured

value (PV)

[H-TIO-, H-CIO-A]

Motor speed measured

value

[H-SIO-A]

Heat-side manipulated

output value

[H-TIO-, H-CIO-A]

Cool-side manipulated

output value

[H-TIO-, H-CIO-A]

Current transformer

input measured value

[H-CT-A]

TIO status

[H-TIO-, H-CIO-A,

H-SIO-A]

Set value monitor

[H-TIO-, H-CIO-A,

H-SIO-A]

RO C

TC/RTD input:

Current/voltage input:

RO C

RO C

RO C

Within display scale range

−0.5 to +105.0 %

−0.5 to +105.0 %

0.0 to 100.0 A or 0.0 to 30.0 A

Current transformer (CT) input measured

value of the H-CT-A module.

Allocates the channels for H-TIO- module

to the input channels of H-CT-A module by

CT channel setting.

For the CT channel setting, see the Power

Supply/CPU Module H-PCP-J Instruction

Manual (IMS01J02-E).

RO C

Each operation status is assigned as a bit

image in binary numbers.

Bit data

Data 0: OFF 1: ON

Bit image: 0000000000000000

[Decimal number: 0 to 509]

RO C

TC/RTD input:

Current/voltage input:

Within input range

Within display scale range

bit 0: Heat-side manipulated output status

bit 1: Unused

bit 2: Alarm 1 status

bit 3: Alarm 2 status

bit 4: Burnout status

bit 5: Heater break alarm status

bit 6: Control loop break alarm (LBA) status

bit 7: Temperature rise completion status

bit 8: Setting error

bit 9 to 15: Unused

bit 15·························· bit 0

Within input range

Within display scale range

Continued on the next page.

IMS01J04-E1

21

Page 28

6. COMMUNICATION DATA

Continued from the previous page.

Name

Attri-

bute

Struc-

ture

Data range

Factory

set value

Request command

[H-PCP-J]

R/W U

0: Monitor

Command which requests the SR Mini HG

SYSTEM to write data such as temperature

measured values, etc. (attribute: RO) to the

PLC side.

The SR Mini HG SYSTEM always repeats

data writing until “1: Setting” or “2: Set

value monitor” is set to the request

command. The PCP communication status

is set to “1: Writing on monitor data”

during data transfer.

1: Setting

Command which requests the SR Mini HG

SYSTEM to read data such as temperature

set values, etc. (attribute: RW or WO)

from the PLC side. Just when “1: Setting”

is set to the request command, the SR Mini

HG SYSTEM starts reading the data from

the PLC side.

The PCP communication status is set to

“2: Reading out setting data” during data

transfer. After the data is transferred, the

request command and PCP communication

status returns to “0: Monitor” and

“1: Writing on monitor data,” respectively.

2: Set value monitor

Command which requests the SR Mini HG

SYSTEM to write data such as temperature

set values, etc. (attribute: RW) to the PLC

side. Just when “2: Set value monitor” is

set to the request command, the SR Mini

HG SYSTEM starts writing the data to the

PLC side.

The PCP communication status is set to

“3: Writing on setting data” during data

transfer. After the data is transferred, the

request command and PCP communication

status returns to “0: Monitor” and

“1: Writing on monitor data,” respectively.

0

PCP communication

status

[H-PCP-J]

22

RO U

1: Writing on monitor data

2: Reading out setting data

3: Writing on setting data

During monitor data of attribute RO is

written to PLC

During setting data of attribute R/W or

WO is read from PLC

During setting data of attribute R/W is

written to PLC

Continued on the next page.

IMS01J04-E1

Page 29

Continued from the previous page.

Name

Attri-

bute

PCP normal

communication flag

[H-PCP-J]

Memory area number

[H-TIO-, H-CIO-A,

H-SIO-A]

Control RUN/STOP

transfer *

[H-PCP-J]

PV bias

[H-TIO-, H-CIO-A,

H-SIO-A]

RO

Struc-

ture

U

The numbers 0 and then 1 are repeated in

Data range

every communication period.

The SR Mini HG SYSTEM rewrites 0 and 1

in this area alternately like 0 → 1 → 0 in

every communication period. It is possible to

determine whether or not the SR Mini HG

SYSTEM makes communication by

monitoring this area periodically using the

PLC program.

WO U

1 to 8

Data reading is always made from the PLC

regardless of the request command. Any

numeric value other than 1 to 8 becomes

invalid.

Changing the memory area automatically

writes each set value to the PLC.

WO U

0: Control STOP

1: Control RUN

R/W C −5.00 to +5.00 % of span

ZK-1103 specification:

−Input span to +Input span

6. COMMUNICATION DATA

Factory

set value

0.00

ZK-1103:

a

0

Setting change rate

R/W C 0.0 to 100.0 % of span/minute 0.0

limiter

[H-TIO-, H-CIO-A,

H-SIO-A]

When the control RUN/STOP holding setting is set to “Not hold” or “Hold”:

*

The control RUN/STOP transfer setting is always read from the PLC regardless of the request

command. Any numeric value other than 0 and 1 becomes invalid.

When the control RUN/STOP holding setting is set to “Start-up from control RUN status”:

As the control RUN/STOP transfer setting is always set to “1: Control RUN,” any value set to the

control RUN/STOP transfer becomes invalid.

The Control RUN/STOP holding (Identifier X1) is set by host communication. For the host

communication, see the Power Supply/CPU Module H-PCP-J Instruction Manual

(IMS01J02-E).

a

Unit (°C, °F, etc.) and decimal point position (No decimal place, One decimal place, Two decimal

places or Three decimal places) depends on input range type.

IMS01J04-E1

23

Page 30

7. DATA MAP

7.1 Reference to Data Map

This data map summarizes the data (data memory) addresses, channels and names that can be used

with PLC. For details on each data range, see the 6.3 Communication Data List (P. 17).

(a)

(c)

Unit

address

0

D1000 to

D1019

D1020 to

D1039

Unit

address

1

D1500 to

D1519

D1520 to

D1539

Unit

address

2

D2000 to

D2019

D2020 to

D2039

Unit

address

3

D2500 to

D2519

D2520 to

D2539

(a) Unit address: Unit address of SR Mini HG SYSTEM

(b) Name: Data names

(c) Address: Data (data memory) addresses

Data memory address is expressed in decimal number

Temperature set value (SV)

CH1 to CH20

Alarm 1 set value CH1 to CH20

(b)

Name

24 IMS01J04-E1

Page 31

7.2 Data Map List

Unit address 0 to 3 (Group 1)

7. DATA MAP

Unit

address

0

D1000 to

D1019

D1020 to

D1039

D1040 to

D1059

D1060 to

D1079

D1080 to

D1099

D1100 to

D1119

D1120 to

D1139

D1140 to

D1159

D1160 to

D1179

D1180 to

D1199

D1200 to

D1219

D1220 to

D1239

D1240 to

D1259

D1260 to

D1279

D1280 to

D1299

D1300 to

D1319

D1320 to

D1339

D1340 to

D1359

D1360 to

D1379

D1380 D1880 D2380 D2880 Request command

D1381 D1881 D2381 D2881 PCP communication status

D1382 D1882 D2382 D2882 PCP normal communication flag

Unit

address

1

D1500 to

D1519

D1520 to

D1539

D1540 to

D1559

D1560 to

D1579

D1580 to

D1599

D1600 to

D1619

D1620 to

D1639

D1640 to

D1659

D1660 to

D1679

D1680 to

D1699

D1700 to

D1719

D1720 to

D1739

D1740 to

D1759

D1760 to

D1779

D1780 to

D1799

D1800 to

D1819

D1820 to

D1839

D1840 to

D1859

D1860 to

D1879

Unit

address

2

D2000 to

D2019

D2020 to

D2039

D2040 to

D2059

D2060 to

D2079

D2080 to

D2099

D2100 to

D2119

D2120 to

D2139

D2140 to

D2159

D2160 to

D2179

D2180 to

D2199

D2200 to

D2219

D2220 to

D2239

D2240 to

D2259

D2260 to

D2279

D2280 to

D2299

D2300 to

D2319

D2320 to

D2339

D2340 to

D2359

D2360 to

D2379

Unit

address

3

D2500 to

D2519

D2520 to

D2539

D2540 to

D2559

D2560 to

D2579

D2580 to

D2599

D2600 to

D2619

D2620 to

D2639

D2640 to

D2659

D2660 to

D2679

D2680 to

D2699

D2700 to

D2719

D2720 to

D2739

D2740 to

D2759

D2760 to

D2779

D2780 to

D2799

D2800 to

D2819

D2820 to

D2839

D2840 to

D2859

D2860 to

D2879

Name

Temperature set value (SV) CH1 to CH20

Alarm 1 set value CH1 to CH20

Alarm 2 set value CH1 to CH20

Heater break alarm set value CH1 to CH20

(H-CT-A module)

Operation mode transfer CH1 to CH20

Auto/Manual transfer CH1 to CH20

Manual output value CH1 to CH20

Overlap/deadband CH1 to CH20

Heat-side proportional band CH1 to CH20

Cool-side proportional band CH1 to CH20

Integral time CH1 to CH20

Derivative time CH1 to CH20

PID/AT transfer CH1 to CH20

Temperature measured value (PV) CH1 to CH20

Heat-side manipulated output value CH1 to CH20

Cool-side manipulated output value CH1 to CH20

Current transformer input measured value

(H-CT-A module) CH1 to CH20

TIO status CH1 to CH20

Set value monitor CH1 to CH20

Continued on the next page.

IMS01J04-E1 25

Page 32

7. DATA MAP

Continued from the previous page.

Unit

address

0

D1383 to

D1389

Unit

address

1

D1883 to

D1889

Unit

address

2

D2383 to

D2389

Unit

address

3

D2883 to

D2889

Do not use this address range

D1390 D1890 D2390 D2890 Memory area number

D1391 D1891 D2391 D2891 Control RUN/STOP transfer

D1392 to

D1399

D1400 to

D1419

D1420 to

D1439

D1440 to

D1499

D1892 to

D1899

D1900 to

D1919

D1920 to

D1939

D1940 to

D1999

D2392 to

D2399

D2400 to

D2419

D2420 to

D2439

D2440 to

D2499

D2892 to

D2899

D2900 to

D2919

D2920 to

D2939

D2940 to

D2999

Do not use this address range

PV bias CH1 to CH20

Setting change rate limiter CH1 to CH20

Do not use this address range

Unit address 4 to 7 (Group 2)

Name

Unit

address

4

D3000 to

D3019

D3020 to

D3039

D3040 to

D3059

D3060 to

D3079

D3080 to

D3099

D3100 to

D3119

D3120 to

D3139

D3140 to

D3159

D3160 to

D3179

D3180 to

D3199

D3200 to

D3219

D3220 to

D3239

Unit

address

5

D3500 to

D3519

D3520 to

D3539

D3540 to

D3559

D3560 to

D3579

D3580 to

D3599

D3600 to

D3619

D3620 to

D3639

D3640 to

D3659

D3660 to

D3679

D3680 to

D3699

D3700 to

D3719

D3720 to

D3739

Unit

address

6

D4000 to

D4019

D4020 to

D4039

D4040 to

D4059

D4060 to

D4079

D4080 to

D4099

D4100 to

D4119

D4120 to

D4139

D4140 to

D4159

D4160 to

D4179

D4180 to

D4199

D4200 to

D4219

D4220 to

D4239

Unit

address

7

D4500 to

D4519

D4520 to

D4539

D4540 to

D4559

D4560 to

D4579

D4580 to

D4599

D4600 to

D4619

D4620 to

D4639

D4640 to

D4659

D4660 to

D4679

D4680 to

D4699

D4700 to

D4719

D4720 to

D4739

Name

Temperature set value (SV) CH1 to CH20

Alarm 1 set value CH1 to CH20

Alarm 2 set value CH1 to CH20

Heater break alarm set value CH1 to CH20

(H-CT-A module)

Operation mode transfer CH1 to CH20

Auto/Manual transfer CH1 to CH20

Manual output value CH1 to CH20

Overlap/deadband CH1 to CH20

Heat-side proportional band CH1 to CH20

Cool-side proportional band CH1 to CH20

Integral time CH1 to CH20

Derivative time CH1 to CH20

Continued on the next page.

26

IMS01J04-E1

Page 33

Continued from the previous page.

Unit

address

4

D3240 to

D3259

D3260 to

D3279

D3280 to

D3299

D3300 to

D3319

D3320 to

D3339

D3340 to

D3359

D3360 to

D3379

Unit

address

5

D3740 to

D3759

D3760 to

D3779

D3780 to

D3799

D3800 to

D3819

D3820 to

D3839

D3840 to

D3859

D3860 to

D3879

Unit

address

6

D4240 to

D4259

D4260 to

D4279

D4280 to

D4299

D4300 to

D4319

D4320 to

D4339

D4340 to

D4359

D4360 to

D4379

Unit

address

7

D4740 to

D4759

D4760 to

D4779

D4780 to

D4799

D4800 to

D4819

D4820 to

D4839

D4840 to

D4859

D4860 to

D4879

Name

PID/AT transfer CH1 to CH20

Temperature measured value (PV) CH1 to CH20

Heat-side manipulated output value CH1 to CH20

Cool-side manipulated output value CH1 to CH20

Current transformer input measured value

(H-CT-A module) CH1 to CH20

TIO status CH1 to CH20

Set value monitor CH1 to CH20

D3380 D3880 D4380 D4880 Request command

D3381 D3881 D4381 D4881 PCP communication status

D3382 D3882 D4382 D4882 PCP normal communication flag

D3383 to

D3389

D3883 to

D3889

D4383 to

D4389

D4883 to

D4889

Do not use this address range

D3390 D3890 D4390 D4890 Memory area number

D3391 D3891 D4391 D4891 Control RUN/STOP transfer

D3392 to

D3399

D3400 to

D3419

D3420 to

D3439

D3440 to

D3499

D3892 to

D3899

D3900 to

D3919

D3920 to

D3939

D3940 to

D3999

D4392 to

D4399

D4400 to

D4419

D4420 to

D4439

D4440 to

D4499

D4892 to

D4899

D4900 to

D4919

D4920 to

D4939

D4940 to

D4999

Do not use this address range

PV bias CH1 to CH20

Setting change rate limiter CH1 to CH20

Do not use this address range

Unit address 8 to B (Group 3)

7. DATA MAP

Unit

address

8

D5000 to

D5019

D5020 to

D5039

D5040 to

D5059

D5060 to

D5079

IMS01J04-E1

Unit

address

9

D5500 to

D5519

D5520 to

D5539

D5540 to

D5559

D5560 to

D5579

Unit

address

A

D6000 to

D6019

D6020 to

D6039

D6040 to

D6059

D6060 to

D6079

Unit

address

B

D6500 to

D6519

D6520 to

D6539

D6540 to

D6559

D6560 to

D6579

Name

Temperature set value (SV) CH1 to CH20

Alarm 1 set value CH1 to CH20

Alarm 2 set value CH1 to CH20

Heater break alarm set value CH1 to CH20

(H-CT-A module)

Continued on the next page.

27

Page 34

7. DATA MAP

Continued from the previous page.

Unit

address

8

D5080 to

D5099

D5100 to

D5119

D5120 to

D5139

D5140 to

D5159

D5160 to

D5179

D5180 to

D5199

D5200 to

D5219

D5220 to

D5239

D5240 to

D5259

D5260 to

D5279

D5280 to

D5299

D5300 to

D5319

D5320 to

D5339

D5340 to

D5359

D5360 to

D5379

Unit

address

9

D5580 to

D5599

D5600 to

D5619

D5620 to

D5639

D5640 to

D5659

D5660 to

D5679

D5680 to

D5699

D5700 to

D5719

D5720 to

D5739

D5740 to

D5759

D5760 to

D5779

D5780 to

D5799

D5800 to

D5819

D5820 to

D5839

D5840 to

D5859

D5860 to

D5879

Unit

address

A

D6080 to

D6099

D6100 to

D6119

D6120 to

D6139

D6140 to

D6159

D6160 to

D6179

D6180 to

D6199

D6200 to

D6219

D6220 to

D6239

D6240 to

D6259

D6260 to

D6279

D6280 to

D6299

D6300 to

D6319

D6320 to

D6339

D6340 to

D6359

D6360 to

D6379

Unit

address

B

D6580 to

D6599

D6600 to

D6619

D6620 to

D6639

D6640 to

D6659

D6660 to

D6679

D6680 to

D6699

D6700 to

D6719

D6720 to

D6739

D6740 to

D6759

D6760 to

D6779

D6780 to

D6799

D6800 to

D6819

D6820 to

D6839

D6840 to

D6859

D6860 to

D6879

Name

Operation mode transfer CH1 to CH20

Auto/Manual transfer CH1 to CH20

Manual output value CH1 to CH20

Overlap/deadband CH1 to CH20

Heat-side proportional band CH1 to CH20

Cool-side proportional band CH1 to CH20

Integral time CH1 to CH20

Derivative time CH1 to CH20

PID/AT transfer CH1 to CH20

Temperature measured value (PV) CH1 to CH20

Heat-side manipulated output value CH1 to CH20

Cool-side manipulated output value CH1 to CH20

Current transformer input measured value

(H-CT-A module) CH1 to CH20

TIO status CH1 to CH20

Set value monitor CH1 to CH20

D5380 D5880 D6380 D6880 Request command

D5381 D5881 D6381 D6881 PCP communication status

D5382 D5882 D6382 D6882 PCP normal communication flag

D5383 to

D5389

D5883 to

D5889

D6383 to

D6389

D6883 to

D6889

Do not use this address range

D5390 D5890 D6390 D6890 Memory area number

D5391 D5891 D6391 D6891 Control RUN/STOP transfer

D5392 to

D5399

D5400 to

D5419

D5420 to

D5439

D5440 to

D5499

D5892 to

D5899

D5900 to

D5919

D5920 to

D5939

D5940 to

D5999

D6392 to

D6399

D6400 to

D6419

D6420 to

D6439

D6440 to

D6499

D6892 to

D6899

D6900 to

D6919

D6920 to

D6939

D6940 to

D6999

Do not use this address range

PV bias CH1 to CH20

Setting change rate limiter CH1 to CH20

Do not use this address range

28

IMS01J04-E1

Page 35

Unit address C to F (Group 4)

7. DATA MAP

Unit

address

C

D7000 to

D7019

D7020 to

D7039

D7040 to

D7059

D7060 to

D7079

D7080 to

D7099

D7100 to

D7119

D7120 to

D7139

D7140 to

D7159

D7160 to

D7179

D7180 to

D7199

D7200 to

D7219

D7220 to

D7239

D7240 to

D7259

D7260 to

D7279

D7280 to

D7299

D7300 to

D7319

D7320 to

D7339

D7340 to

D7359

D7360 to

D7379

Unit

address

D

D7500 to

D7519

D7520 to

D7539

D7540 to

D7559

D7560 to

D7579

D7580 to

D7599

D7600 to

D7619

D7620 to

D7639

D7640 to

D7659

D7660 to

D7679

D7680 to

D7699

D7700 to

D7719

D7720 to

D7739

D7740 to

D7759

D7760 to

D7779

D7780 to

D7799

D7800 to

D7819

D7820 to

D7839

D7840 to

D7859

D7860 to

D7879

Unit

address

E

D8000 to

D8019

D8020 to

D8039

D8040 to

D8059

D8060 to

D8079

D8080 to

D8099

D8100 to

D8119

D8120 to

D8139

D8140 to

D8159

D8160 to

D8179

D8180 to

D8199

D8200 to

D8219

D8220 to

D8239

D8240 to

D8259

D8260 to

D8279

D8280 to

D8299

D8300 to

D8319

D8320 to

D8339

D8340 to

D8359

D8360 to

D8379

Unit

address

F

D8500 to

D8519

D8520 to

D8539

D8540 to

D8559

D8560 to

D8579

D8580 to

D8599

D8600 to

D8619

D8620 to

D8639

D8640 to

D8659

D8660 to

D8679

D8680 to

D8699

D8700 to

D8719

D8720 to

D8739

D8740 to

D8759

D8760 to

D8779

D8780 to

D8799

D8800 to

D8819

D8820 to

D8839

D8840 to

D8859

D8860 to

D8879

Name

Temperature set value (SV) CH1 to CH20

Alarm 1 set value CH1 to CH20

Alarm 2 set value CH1 to CH20

Heater break alarm set value CH1 to CH20

(H-CT-A module)

Operation mode transfer CH1 to CH20

Auto/Manual transfer CH1 to CH20

Manual output value CH1 to CH20

Overlap/deadband CH1 to CH20

Heat-side proportional band CH1 to CH20

Cool-side proportional band CH1 to CH20

Integral time CH1 to CH20

Derivative time CH1 to CH20

PID/AT transfer CH1 to CH20

Temperature measured value (PV) CH1 to CH20

Heat-side manipulated output value CH1 to CH20

Cool-side manipulated output value CH1 to CH20

Current transformer input measured value

(H-CT-A module) CH1 to CH20

TIO status CH1 to CH20

Set value monitor CH1 to CH20

D7380 D7880 D8380 D8880 Request command

D7381 D7881 D8381 D8881 PCP communication status

D7382 D7882 D8382 D8882 PCP normal communication flag

D7383 to

D7389

D7883 to

D7889

D8383 to

D8389

D8883 to

D8889

Do not use this address range

Continued on the next page.

IMS01J04-E1

29

Page 36

7. DATA MAP

Continued from the previous page.

Unit

address

C

Unit

address

D

Unit

address

E

Unit

address

F

D7390 D7890 D8390 D8890 Memory area number

D7391 D7891 D8391 D8891 Control RUN/STOP transfer

D7392 to

D7399

D7400 to

D7419

D7420 to

D7439

D7440 to

D7499

D7892 to

D7899

D7900 to

D7919

D7920 to

D7939

D7940 to

D7999

D8392 to

D8399

D8400 to

D8419

D8420 to

D8439

D8440 to

D8499

D8892 to

D8899

D8900 to

D8919

D8920 to

D8939

D8940 to

D8999

Do not use this address range

PV bias CH1 to CH20

Setting change rate limiter CH1 to CH20

Do not use this address range

Name

30

IMS01J04-E1

Page 37

8.

CURRENT TRANSFORMER (CT) MONITOR

Current transformer (CT) monitor function monitors only current transformer input.

Control unit is configured with H-PCP-J module and H-CT-A module to do current transformer (CT)

monitor. Data of functional module other than the H-CT-A module cannot be used. In addition, set the

communication protocol to “OMRON SYSMAC series special protocol [Current transformer (CT)

monitor].”

Maximum number of current transformer input points

Maximum 60 points/control unit

Maximum 960 points/communication port of PLC

This section describes the system configuration, switch setting and communication data of

current transformer (CT) monitor. For the communication specifications and connections,

see the following section.

• For the communication specifications, see the 2. COMMUNICATION

SPECIFICATIONS (P. 3).

• For the connections, see the 3. CONNECTIONS (P. 4).

IMS01J04-E1 31

Page 38

8. CURRENT TRANSFORMER (CT) MONITOR

Current transformer (CT) monitor dedicated system configuration

OMRON SYSMAC series

PLC

RS-422A

RS-422A

SR Mini HG SYSTEM control unit

H-PCP-J

module

SR Mini HG SYSTEM control unit

H-PCP-J

module

H-CT-A module

(10 modules max.)

H-CT-A module

(10 modules max.)

RS-422A

Up to 16 control units per communication port of PLC

Maximum number of H-CT-A modules that can be connected to one control unit:

10 modules/control unit

Maximum number of control units that can be connected to one communication port

of PLC:

16 control units/communication port of PLC

Usable units (OMRON SYSMAC series)

Name Type

High-order link unit C200H-LK202-V1, C500-LK203, C120-LK202-V1

(SYSMAC C series), etc.

CPU unit with a built in

CPU unit of SYSMAC CS1 series

communication port

Serial communication board CS1W-SCB41 (SYSMAC CS1 series), etc.

32

IMS01J04-E1

Page 39

8. CURRENT TRANSFORMER (CT) MONITOR

8.1 Setting on The H-PCP-J Module Side

PLC data memory address setting

Set the data memory address of each control unit using the unit address setting switch at the front of

the H-PCP-J module. For this setting, use a small blade screwdriver.

H-PCP-J module

Unit address setting switch

0

1

2

F

3

E

4

D

5

C

6

B

7

A

9

8

Setting range:

0 to 15 (0 to F: hexadecimal)

Up to 16 SR Mini HG SYSTEMs can be connected to a PLC communication port.

Set unit address within address range of PLC (CPU unit) to use.

Unit address

setting

switch

0

1

2

3

4

5

PLC data

memory

Communication item

address

D9000 to

D9059

Unit address 0 Current transformer input measured value

CT1 to CT60

D9961 Unit address 0 PCP normal communication flag

D9060 to

D9119

Unit address 1 Current transformer input measured value

CT1 to CT60

D9962 Unit address 1 PCP normal communication flag

D9120 to

D9179

Unit address 2 Current transformer input measured value

CT1 to CT60

D9963 Unit address 2 PCP normal communication flag

D9180 to

D9239

Unit address 3 Current transformer input measured value

CT1 to CT60

D9964 Unit address 3 PCP normal communication flag

D9240 to

D9299

Unit address 4 Current transformer input measured value

CT1 to CT60

D9965 Unit address 4 PCP normal communication flag

D9300 to

D9359

Unit address 5 Current transformer input measured value

CT1 to CT60

D9966 Unit address 5 PCP normal communication flag

Continued on the next page.

IMS01J04-E1

33

Page 40

8. CURRENT TRANSFORMER (CT) MONITOR

Continued from the previous page.

Unit address

setting

switch

PLC data

memory

address

Communication item

6

7

8

9

A

B

C

D

E

F

D9360 to

D9419

D9967 Unit address 6 PCP normal communication flag

D9420 to

D9479

D9968 Unit address 7 PCP normal communication flag

D9480 to

D9539

D9969 Unit address 8 PCP normal communication flag

D9540 to

D9599

D9970 Unit address 9 PCP normal communication flag

D9600 to

D9659

D9971 Unit address A PCP normal communication flag

D9660 to

D9719

D9972 Unit address B PCP normal communication flag

D9720 to

D9779

D9973 Unit address C PCP normal communication flag

D9780 to

D9839

D9974 Unit address D PCP normal communication flag

D9840 to

D9899

D9975 Unit address E PCP normal communication flag

D9900 to

D9959

D9976 Unit address F PCP normal communication flag

Unit address 6 Current transformer input measured value

CT1 to CT60

Unit address 7 Current transformer input measured value

CT1 to CT60

Unit address 8 Current transformer input measured value

CT1 to CT60

Unit address 9 Current transformer input measured value

CT1 to CT60

Unit address A Current transformer input measured value

CT1 to CT60

Unit address B Current transformer input measured value

CT1 to CT60

Unit address C Current transformer input measured value

CT1 to CT60

Unit address D Current transformer input measured value

CT1 to CT60

Unit address E Current transformer input measured value

CT1 to CT60

Unit address F Current transformer input measured value

CT1 to CT60

Data memory address D9960, D9977 to D9999: Do not use this address range

34

IMS01J04-E1

Page 41

8. CURRENT TRANSFORMER (CT) MONITOR

Protocol selection and communication setting

Match the setting of data bit configuration, communication speed and communication protocol with

the PLC communication specification by COM.PORT1/COM.PORT2 setting switch (SW2).

Setting example to recommend is shown in the following.

H-PCP-J module

COM.PORT1/COM.PORT2

setting switch (SW2)

1 87 6 54 32

ON

Data bit configuration

Communication speed

(Set the same as PLC.)

Right side view

Data bit configuration

SW2

Data bit configuration

1 2

ON ON Data 7-bit, Even parity, Stop 2-bit

Communication speed Set the same as PLC.

SW2

Communication speed

3 4

OFF OFF 9600 bps

ON OFF 19200 bps

OFF ON 38400 bps

Communication protocol

Factory set value: All OFF

ON ON Don't set this one

Protocol

5 6 7 8

OFF ON ON OFF

IMS01J04-E1

SW2

Protocol

OMRON SYSMAC series special protocol

[Current transformer (CT) monitor]

35

Page 42

8. CURRENT TRANSFORMER (CT) MONITOR

PLC scanning time setting

Set the PLC scanning time (time of waiting for a response from the PLC) so as to adapt to the

environment used. The PLC scanning time is set via host communication (RKC communication

or Modbus).

PLC scanning time setting Setting range: 0 to 3000 ms (Factory set value: 10 ms)

[Setting example]

Set PLC scanning time to any value more than twice as long as the maximum scanning time of PLC.

If PLC scanning time is extremely short (When at a factory set value of 10 ms as an

example), the SR Mini HG SYSTEM may detect the time-out not conducting normal

communication processing.

The maximum scanning time of PLC differs depending on the CPU processing speed, I/O

unit configuration and the user program capacity of the PLC.

For the PLC scanning time setting (Identifier ST), see the Power Supply/CPU Module

H-PCP-J Instruction Manual (IMS01J02-E).

36

IMS01J04-E1

Page 43

8. CURRENT TRANSFORMER (CT) MONITOR

8.2 Setting on The PLC Side

Set the PLC as follows. (Recommend setting example)

Item Description

Serial communication mode High-order link

Unit number (Model number) 0

Start bit 1

Data bit 7

Stop bit 2

Parity bit Even

Transmission speed Set the same as SR Mini HG SYSTEM

I/O port selection RS-422A

Synchronization selection Internal synchronization

CTS selection 0 V (always ON)

5 V supply OFF

Termination resistor Termination resistor is inserted

The setting item varies depending on the PLC. The details of the setting procedure for the

PLC please also read the instruction manual for the used PLC.

IMS01J04-E1

37

Page 44

8. CURRENT TRANSFORMER (CT) MONITOR

8.3 Communication Data List

Attributes

RO: SR Mini HG SYSTEM writes in data. (SR Mini HG SYSTEM → PLC)

If the power is turned on, SR Mini HG SYSTEM always writes data to PLC. As for the

setting of request command from PLC, there is not requirement.

The data type is treated as binary data with a sign and without a decimal point.

[Example] Current transformer input measured value

Initial value of internal data: 12.3

Communication data: 123

Name

Attri-

bute

Struc-

ture

Data range

Factory

set value

Current transformer

input measured value

PCP normal

communication flag

RO C 0.0 to 100.0 A or 0.0 to 30.0 A

Current transformer (CT) input measured

value of the H-CT-A module.

RO

U

The numbers 0 and then 1 are repeated.

The SR Mini HG SYSTEM rewrites 0 and 1

in this area alternately like 0 → 1 → 0. It is

possible to determine whether or not the SR

Mini HG SYSTEM makes communication

by monitoring this area periodically using

the PLC program.

When SR Mini HG SYSTEM did not

communicate, flag does not change.

38

IMS01J04-E1

Page 45

The first edition: SEP. 2004 [IMQ00]

The fifth edition: OCT. 2003 [IMQ00]

Page 46

RKC INSTRUMENT INC.

HEADQUARTERS: 16-6, KUGAHARA 5-CHOME, OHTA-KU TOKYO 146-8515 JAPAN

PHONE: 03-3751-9799 (+81 3 3751 9799)

E-mail: info@rkcinst.co.jp

FAX: 03-3751-8585 (+81 3 3751 8585)

IMS01J04-E1 SEP. 2004

Loading...

Loading...