Page 1

4

r

RKC INSTRUMENT INC.

®

HA

HA401/HA901

Operation Manual

Digital Controlle

00/HA900

IMR01N02-E6

Page 2

Modbus is a registered trademark of Schneider Electric.

DeviceNet is a registered trademark of Open DeviceNet Vender Association, Inc.

Company names and product names used in this manual are the trademarks or registered trademarks of

the respective companies.

All Rights Reserved, Copyright 2002, RKC INSTRUMENT INC.

Page 3

Thank you for purchasing this RKC instrument. In order to achieve maximum performance and ensure

proper operation of your new instrument, carefully read all the instructions in this manual. Please

place this manual in a convenient location for easy reference.

NOTICE

This manual assumes that the reader has a fundamental knowledge of the principles of electricity,

process control, computer technology and communications.

The figures, diagrams and numeric values used in this manual are only for purpose of illustration.

RKC is not responsible for any damage or injury that is caused as a result of using this instrument,

instrument failure or indirect damage.

Periodic maintenance is required for safe and proper operation of this instrument. Some

components have a limited service life, or characteristics that change over time.

Every effort has been made to ensure accuracy of all information contained herein. RKC makes no

warranty expressed or implied, with respect to the accuracy of the information. The information in

this manual is subject to change without prior notice.

No portion of this document may be reprinted, modified, copied, transmitted, digitized, stored,

processed or retrieved through any mechanical, electronic, optical or other means without prior

written approval from RKC.

WARNING

!

An external protection device must be installed if failure of this instrument

could result in damage to the instrument, equipment or injury to personnel.

All wiring must be completed before power is turned on to prevent electric

shock, fire or damage to instrument and equipment.

This instrument must be used in accordance with the specifications to

prevent fire or damage to instrument and equipment.

This instrument is not intended for use in locations subject to flammable or

explosive gases.

Do not touch high-voltage connections such as power supply terminals, etc.

to avoid electric shock.

RKC is not responsible if this instrument is repaired, modified or

disassembled by other than factory-approved personnel. Malfunction can

occur and warranty is void under these conditions.

IMR01N02-E6

i-1

Page 4

CAUTION

This is a Class A instrument. In a domestic environment, this instrument may cause radio

interference, in which case the user may be required to take adequate measures.

This instrument is protected from electric shock by reinforced insulation. Provide

reinforced insulation between the wire for the input signal and the wires for instrument

power supply, source of power and loads.

Be sure to provide an appropriate surge control circuit respectively for the following:

- If input/output or signal lines within the building are longer than 30 meters.

- If input/output or signal lines leave the building, regardless the length.

This instrument is designed for installation in an enclosed instrumentation panel. All

high-voltage connections such as power supply terminals must be enclosed in the

instrumentation panel to avoid electric shock by operating personnel.

All precautions described in this manual should be taken to avoid damage to the

instrument or equipment.

All wiring must be in accordance with local codes and regulations.

All wiring must be completed before power is turned on to prevent electric shock,

instrument failure, or incorrect action.

The power must be turned off before repairing work for input break and output failure

including replacement of sensor, contactor or SSR, and all wiring must be completed

before power is turned on again.

To prevent instrument damage or failure, protect the power line and the input/output lines

from high currents with a protection device such as fuse, circuit breaker, etc.

Prevent metal fragments or lead wire scraps from falling inside instrument case to avoid

electric shock, fire or malfunction.

Tighten each terminal screw to the specified torque found in the manual to avoid electric

shock, fire or malfunction.

For proper operation of this instrument, provide adequate ventilation for heat dispensation.

Do not connect wires to unused terminals as this will interfere with proper operation of the

instrument.

Turn off the power supply before cleaning the instrument.

Do not use a volatile solvent such as paint thinner to clean the instrument. Deformation or

discoloration will occur. Use a soft, dry cloth to remove stains from the instrument.

To avoid damage to instrument display, do not rub with an abrasive material or push front

panel with a hard object.

Do not connect modular connectors to telephone line.

i-2

IMR01N02-E6

Page 5

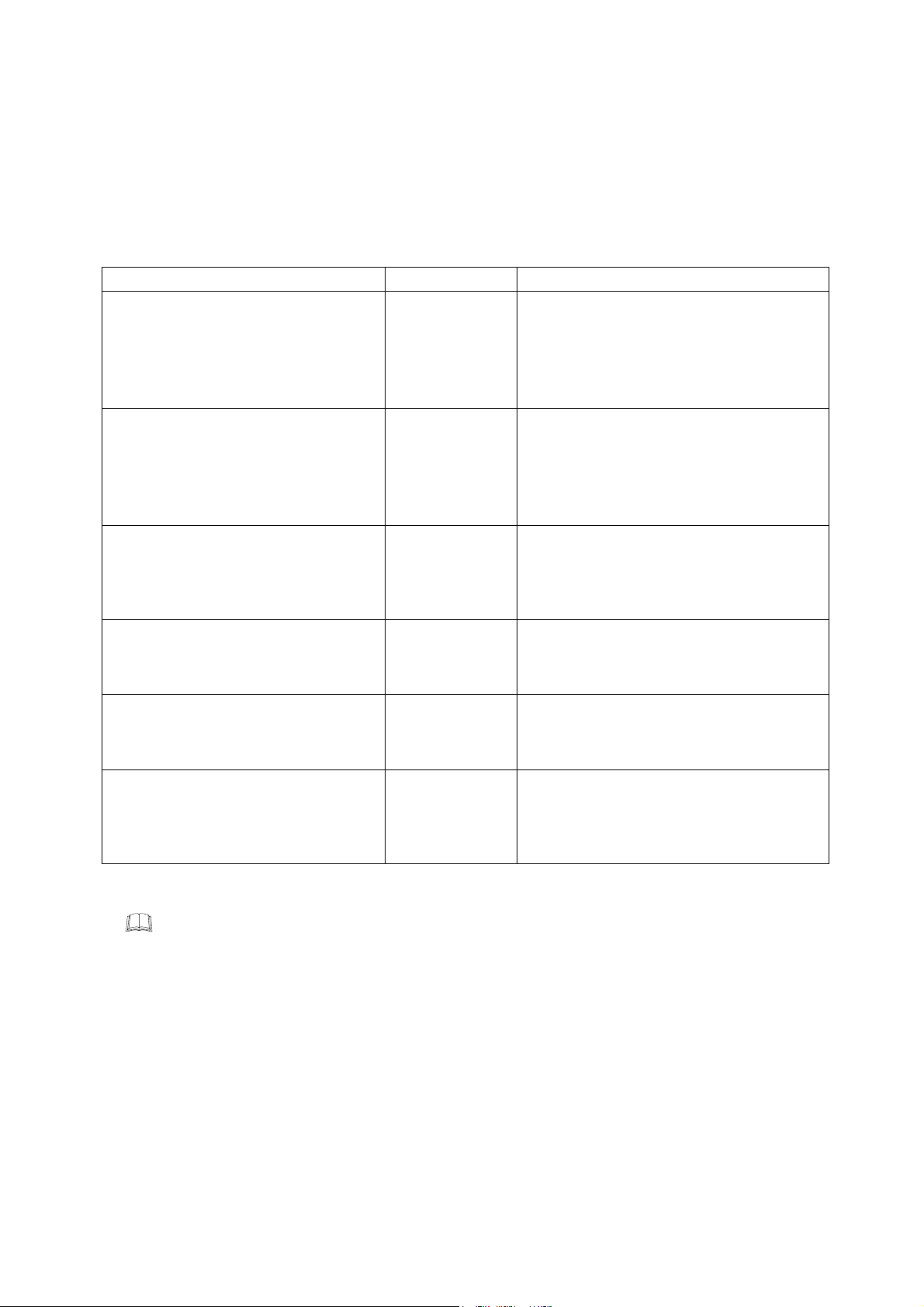

DOCUMENT CONFIGURATION

As for the document related to this product, there are six manuals including this manual. According to

application of a customer, please read a manual related together. When you do not have a necessary manual,

please contact RKC sales office or the agent.

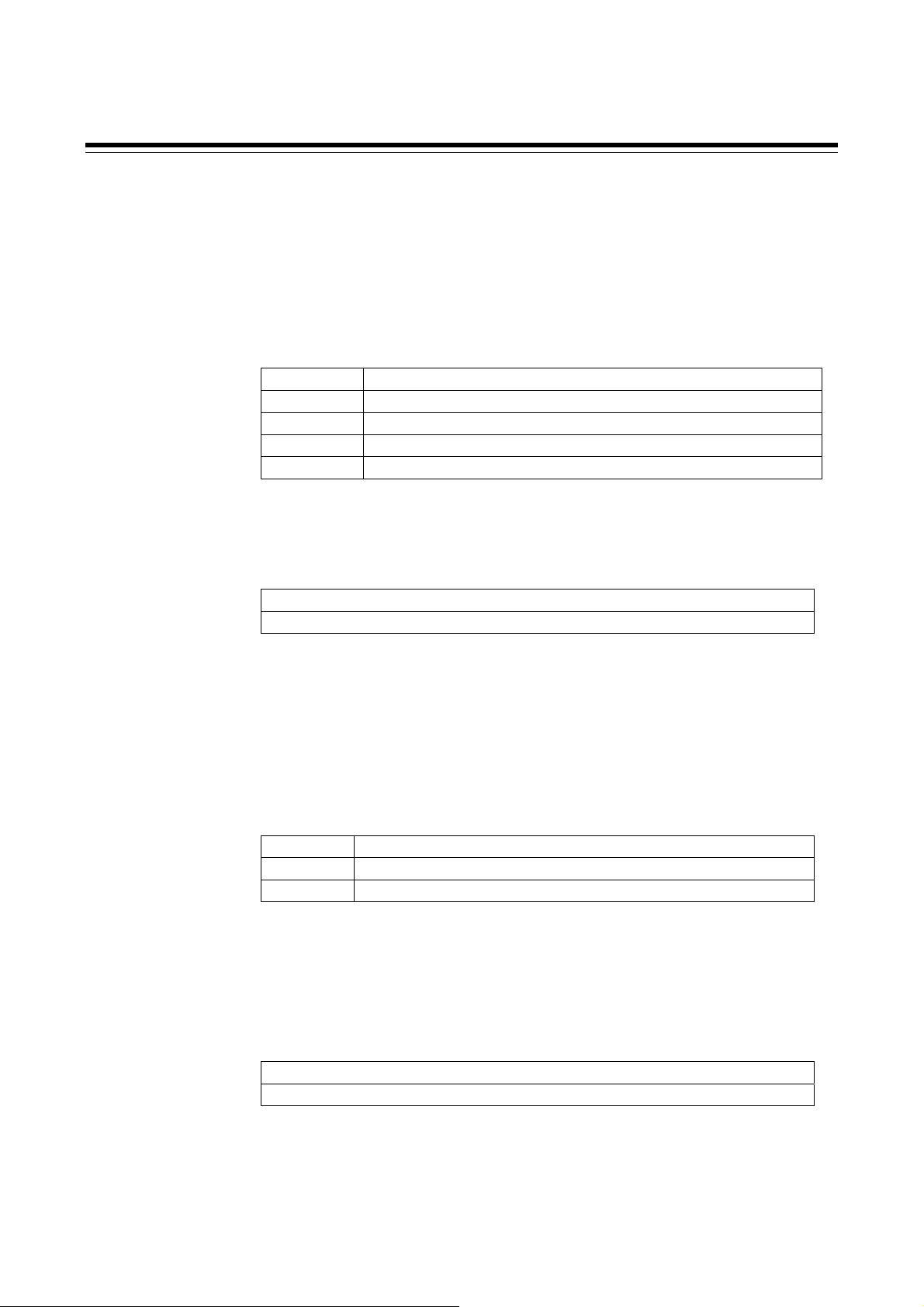

Manual Manual Number Remarks

HA400/HA900/HA401/HA901

Instruction Manual

HA400/HA900/HA401/HA901

Operation Manual

HA400/HA900/HA401/HA901

Communication Instruction Manual *

[RKC communication/MODBUS]

HA400/HA900/HA401/HA901

Communication Instruction Manual *

[PROFIBUS]

IMR01N01-E A product box contains this manual.

This manual explains the mounting and wiring,

a name of the front panel, and outline of

the operation mode of the product.

IMR01N02-E6

IMR01N03-E This manual explains RKC communication

IMR01N04-E This manual explains PROFIBUS

This Manual.

This manual explains the method of

the mounting and wiring, the operation of

various functions, and troubleshooting.

protocol, MODBUS, and relating to

the communication parameters setting.

communication connection and configuration.

HA400/HA900/HA401/HA901

Communication Instruction Manual *

[DeviceNet]

Infrared Communication Software RKCIR

for HA Series Controller

PDA INSTALL GUIDE

* Optional function

Read this manual carefully before operating the instrument. Please place this manual in a convenient

location for easy reference.

IMR01N05-E This manual explains DeviceNet

communication connection and node address

setting.

IMT01C01-E This manual describes downloading of the

"RKCIR infrared communication software" and

installation of this software to the PDA.

IMR01N02-E6

i-3

Page 6

t

Safety Symbols

WARNING

CAUTION

: This mark indicates precautions that must be taken if there is danger of electric

shock, fire, etc., which could result in loss of life or injury.

: This mark indicates that if these precautions and operating procedures are no

taken, damage to the instrument may result.

!

: This mark indicates that all precautions should be taken for safe usage.

: This mark indicates important information on installation, handling and operating

procedures.

: This mark indicates supplemental information on installation, handling and

operating procedures.

: This mark indicates where additional information may be located.

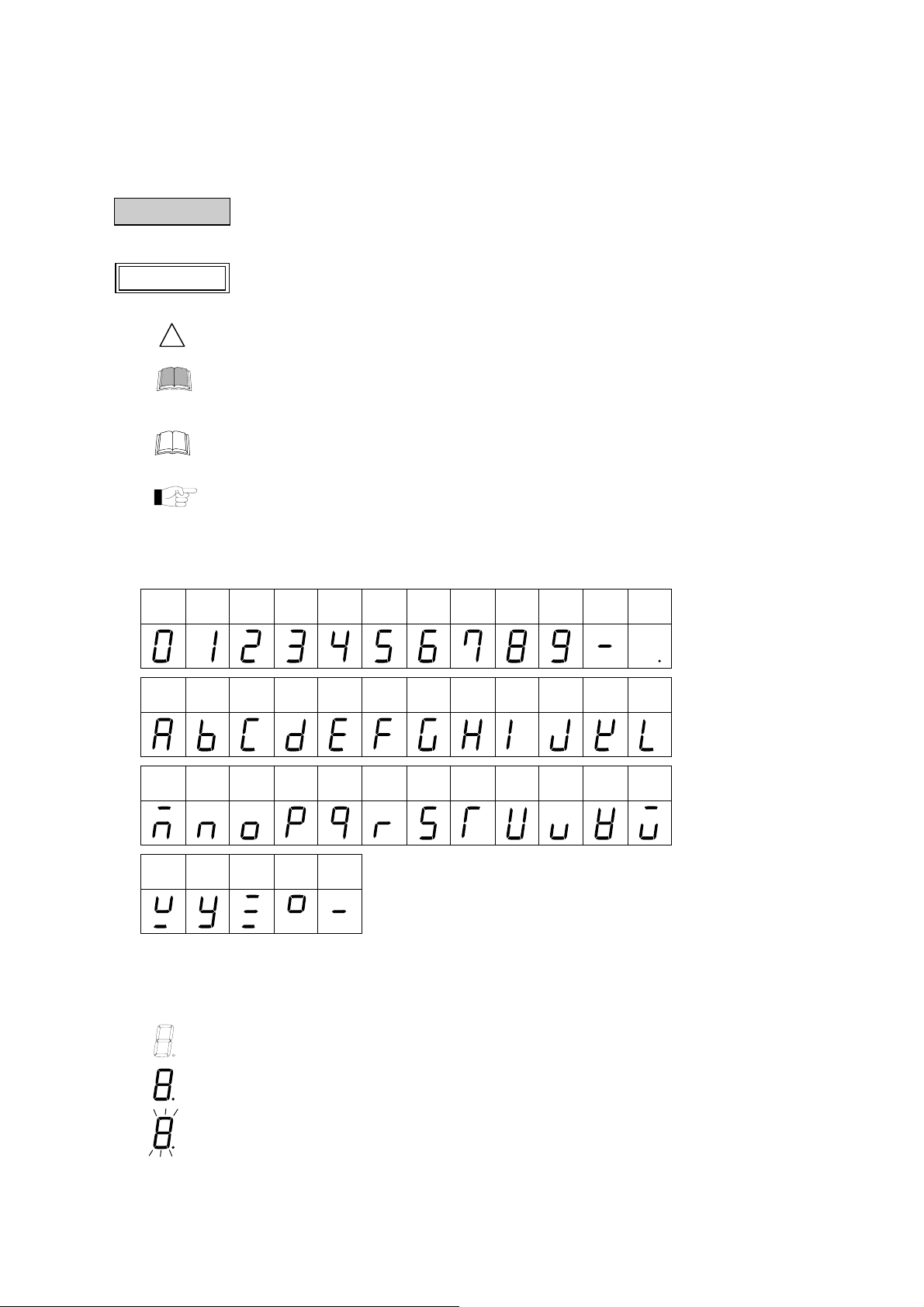

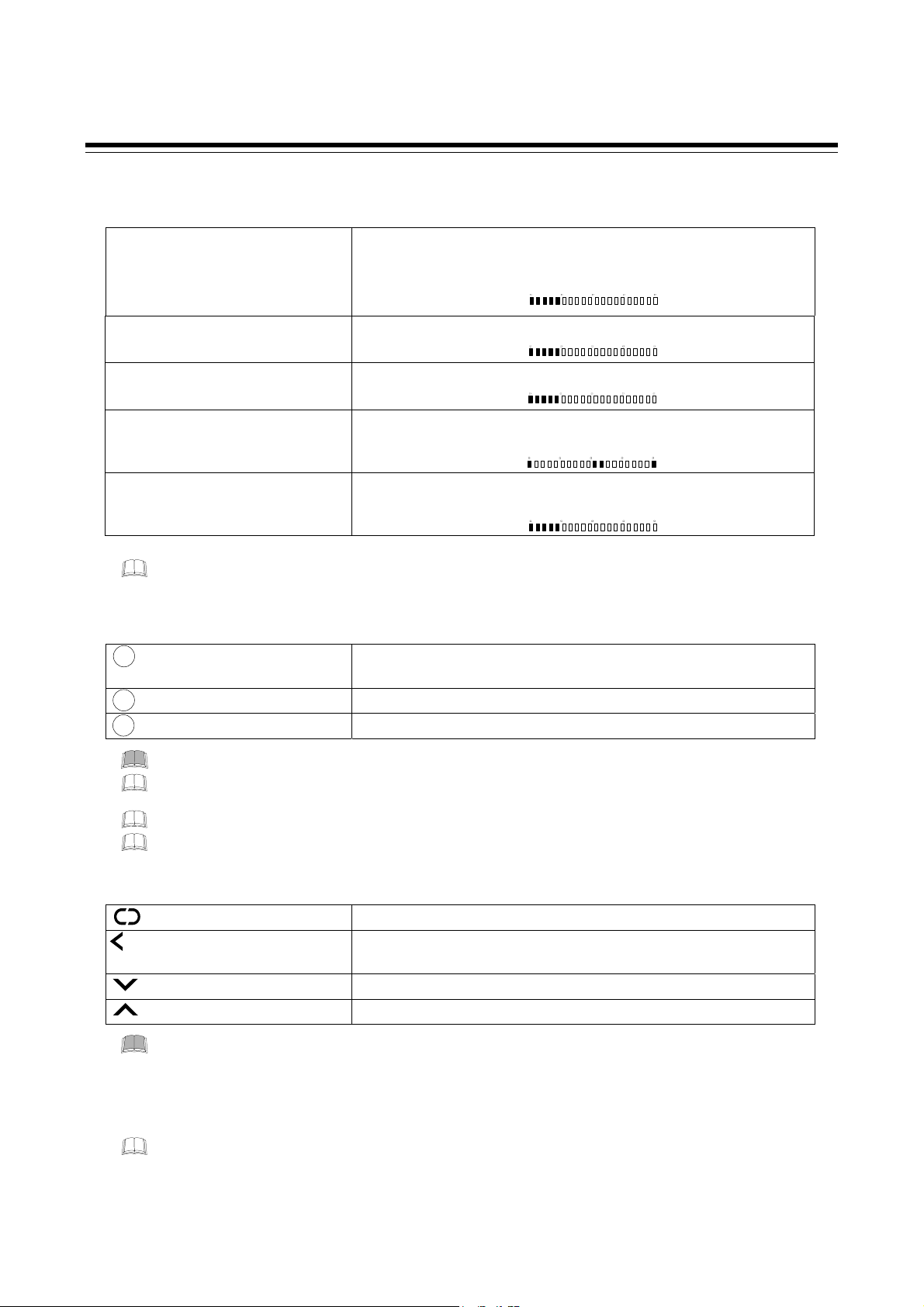

Character Symbols

SYMBOLS

0 1 2 3 4 5 6 7 8 9

Minus Period

(b)

B

A C E F G H I J K L

D

(d)

N O

M P S T U u V W

(n) (o)

Q R

(q) (r)

X Y Z /

Degree

Character LED lighting state:

: Dim lighting

: Bright lighting

: Flashing

i-4

IMR01N02-E6

Page 7

CONTENTS

1. OUTLINE.............................................................................. 1

1.1 Checking the Product ......................................................................................1

1.2 Model Code .....................................................................................................2

1.3 Input/Output Functions ....................................................................................5

1.4 Parts Description .............................................................................................8

2. MOUNTING......................................................................... 11

2.1 Mounting Environment................................................................................... 11

2.2 Mounting Cautions.........................................................................................11

Page

2.3 Dimensions....................................................................................................12

HA400/HA401 ......................................................................................................... 12

HA900/HA901 ......................................................................................................... 12

2.4 Procedures of Mounting and Removing ........................................................13

Mounting procedures............................................................................................... 13

Removing procedures .............................................................................................13

3. WIRING ............................................................................... 14

3.1 Wiring Cautions .............................................................................................14

3.2 Terminal Layout.............................................................................................15

1-input controller...................................................................................................... 15

2-input controller...................................................................................................... 15

3.3 Wiring of Each Terminal ................................................................................16

Power supply........................................................................................................... 16

Output 1 to 3 (OUT1 to OUT3) ................................................................................17

Output 4 to 5 (OUT4 to OUT5) ................................................................................17

Measured input........................................................................................................ 18

Remote input (optional) ........................................................................................... 19

Event input (optional)............................................................................................... 19

CT input/Power feed forward input/Feedback resistance input (optional)............... 20

Communication 1/Communication 2 (optional)........................................................ 20

IMR01N02-E6 i-5

Page 8

4. SETTING............................................................................. 22

4.1 Setting Procedure to Operation .....................................................................22

4.2 Operation Menu.............................................................................................24

Input type and input range display........................................................................... 25

4.3 Key Operation................................................................................................26

Scrolling through parameters................................................................................... 26

Changing set value (SV).......................................................................................... 26

Data Lock Function.................................................................................................. 27

How to restrict operation of the direct keys.............................................................. 27

4.4 Changing Parameter Settings........................................................................28

Change Settings ...................................................................................................... 28

Page

5. SV SETTING & MONITOR MODE...................................... 30

5.1 Display Sequence..........................................................................................30

5.2 Procedure for Set Value (SV) Setting .................................................................31

6. PARAMETER SETTING MODE .........................................32

6.1 Display Sequence..........................................................................................32

6.2 Parameter List ...............................................................................................34

6.3 Description of Each Parameter......................................................................35

Event 1 set value (EV1)/Event 2 set value (EV2)/Event 3 set value (EV3)/

Event 4 set value (EV4)........................................................................................... 35

Control loop break alarm (LBA) time (LbA1, LbA2) ................................................. 35

LBA deadband (Lbd1, Lbd2) ...................................................................................36

Proportional band (1. P, 2. P) for PI/PID control...................................................... 37

Integral time (1. I, 2. I) for PI/PID control ................................................................. 37

Derivative time (1. d, 2. d) for PID control ...............................................................37

Control response parameter (1. rPT, 2. rPT)........................................................... 37

Setting change rate limiter (up) (1.SVrU, 2.SVrU) ................................................38

Setting change rate limiter (down) (1.SVrd, 2.SVrd) .............................................38

Area soak time (AST) .............................................................................................. 39

Link area number (LnKA) ........................................................................................39

i-6

IMR01N02-E6

Page 9

7. SETUP SETTING MODE .................................................... 40

7.1 Display Sequence..........................................................................................40

7.2 Parameter List ...............................................................................................41

7.3 Description of Each Parameter......................................................................42

Heater break alarm 1 (HBA1) set value (HbA1)

Heater break alarm 2 (HBA2) set value (HbA2) ......................................................42

Heater break determination point 1 (HbL1)

Heater break determination point 2 (HbL2) ............................................................. 44

Heater melting determination point 1 (HbH1)

Heater melting determination point 2 (HbH2) .......................................................... 44

PV bias (1. Pb, 2. Pb) ............................................................................................. 44

PV digital filter (1. dF, 2. dF) ...................................................................................44

PV ratio (1. Pr, 2. Pr)............................................................................................... 45

PV low input cut-off (1. PLC, 2. PLC)...................................................................... 45

Proportional cycle time (1. T, 2. T) ..........................................................................45

Device address 1 (Slave address 1) (Add1) .........................................................46

Communication speed 1 (bPS1).............................................................................. 46

Data bit configuration 1 (bIT1)................................................................................. 46

Interval time 1 (InT1) ...............................................................................................47

Device address 2 (Slave address 2) (Add2) .........................................................47

Communication speed 2 (bPS2).............................................................................. 47

Data bit configuration 2 (bIT2)................................................................................. 48

Interval time 2 (InT2) ...............................................................................................48

Infrared communication address (Add3) .................................................................49

Infrared communication speed (bPS3) .................................................................... 49

Set lock level (LCK)................................................................................................. 49

Page

8. ENGINEERING MODE ....................................................... 50

8.1 Display Sequence..........................................................................................50

8.2 Parameter List ............................................................................................... 54

8.3 Precaution Against Parameter Change .........................................................58

8.4 Screen Configuration (F10) .........................................................................63

STOP display selection (SPCH) ............................................................................. 63

Bar graph display selection (dE).............................................................................. 64

Bar graph resolution setting (dEUT)........................................................................ 64

8.5 Direct key (F11).............................................................................................65

Auto/Manual transfer key operation selection (Fn1)................................................ 65

Remote/Local transfer key operation selection (Fn2).............................................. 65

RUN/STOP transfer key operation selection (Fn3) ................................................. 65

IMR01N02-E6

i-7

Page 10

Page

8.6 Input 1 (F21)/Input 2 (F22).............................................................................66

Input type selection (1. InP, 2. InP) .........................................................................66

Display unit selection (1. UnIT, 2. UnIT).................................................................. 67

Decimal point position (1. PGdP, 2. PGdP).............................................................67

Input scale high (1. PGSH, 2. PGSH)...................................................................... 67

Input scale low (1. PGSL, 2. PGSL) ........................................................................ 68

Input error determination point (high) (1. PoV, 2. PoV)......................................... 68

Input error determination point (low) (1. PUn, 2. PUn)........................................68

Burnout direction (1. boS, 2. boS) ........................................................................... 69

Square root extraction selection (1. SQr, 2. SQr)....................................................69

Power supply frequency selection (PFrQ) ............................................................... 69

8.7 Event Input (F23)...........................................................................................70

Event input logic selection (dISL) ............................................................................ 70

8.8 Output (F30) .................................................................................................. 73

Output logic selection (LoGC) .................................................................................73

Output timer setting (oTT1 to oTT5)........................................................................ 74

Alarm lamp lighting condition setting (ALC1, ALC2)................................................ 74

8.9 Transmission Output 1 (F31)/ Transmission Output 2 (F32)/

Transmission Output 3 (F33)......................................................................... 75

Transmission output type selection (Ao1, Ao2, Ao3)............................................... 75

Transmission output scale high (AHS1, AHS2, AHS3) ...........................................75

Transmission output scale low (ALS1, ALS2, ALS3)............................................... 75

8.10 Event 1 (F41)/Event 2 (F42)/Event 3 (F43)/Event 4 (F44)..........................76

Event type selection (ES1, ES2, ES3, ES4)............................................................76

Event hold action (EHo1, EHo2, EHo3, EHo4)........................................................ 78

Event differential gap (EH1, EH2, EH3, EH4) .........................................................79

Event action at input error (EEo1, EEo2, EEo3, EEo4)...........................................80

Event assignment (EVA1, EVA2, EVA3, EVA4)......................................................80

8.11 Current Transformer (CT1) Input (F45)/

Current Transformer (CT2) Input (F46).......................................................81

CT ratio (CTr1, CTr2) ..............................................................................................81

Heater break alarm (HBA) type selection (HbS1, HbS2)......................................... 81

Number of heater break alarm (HBA) delay times (HbC1, HbC2)...........................82

CT assignment (CTA1, CTA2)................................................................................. 82

i-8

8.12 Control (F50) ...............................................................................................83

Hot/Cold start selection (Pd).................................................................................... 83

Input 2_use selection (CAM) ................................................................................... 84

Cascade ratio (CAr)................................................................................................. 84

Cascade bias (CAb) ................................................................................................85

SV tracking (TrK) ....................................................................................................86

IMR01N02-E6

Page 11

Page

8.13 Control 1 (F51)/Control 2 (F52) ...................................................................87

Control action type selection (1. oS, 2. oS) ............................................................. 87

Integral/derivative time decimal point position (1.IddP, 2.IddP)............................... 87

Derivative gain (1. dGA, 2.dGA) ............................................................................ 87

ON/OFF action differential gap (upper) (1. oHH, 2. oHH) ..................................... 88

ON/OFF action differential gap (lower) (1. oHL, 2. oHL).......................................88

Action at input error (high) (1.AoVE, 2.AoVE)....................................................... 89

Action at input error (low) (1.AUnE, 2.AUnE)........................................................89

Manipulated output value at input error (1. PSM, 2. PSM) ...................................... 89

Output change rate limiter (up) (1. orU, 2. orU) ....................................................90

Output change rate limiter (down) (1. ord, 2. ord)................................................. 91

Output limiter (high) (1. oLH, 2. oLH).................................................................... 91

Output limiter (low) (1. oLL, 2. oLL)..................................................................... 91

Power feed forward (1. PFF, 2. PFF) ......................................................................92

Power feed forward gain (1. PFFS, 2. PFFS)..........................................................93

8.14 Autotuning 1 (AT1) (F53) /Autotuning 2 (AT2) (F54) ............................. 93

AT bias (1. ATb, 2. ATb).......................................................................................... 93

AT cycle (1. ATC, 2. ATC) ...................................................................................... 94

AT differential gap time (1. ATH, 2. ATH) ...............................................................95

8.15 Position Proportioning PID Action (F55) ......................................................96

Open/close output neutral zone (Ydb) ................................................................96

O

pen/close output differential gap (YHS) ...........................................................97

Action at feedback resistance (FBR) input error (Ybr)............................................. 97

Feedback resistance (FBR) input assignment (PoSA) ............................................ 97

Feedback adjustment preparation screen (PoS)..................................................... 98

8.16 Communication Function (F60) ...................................................................99

Communication protocol selection (CMPS1, CMPS2) ............................................99

8.17 Set Value (SV) (F70).................................................................................99

Setting change rate limiter unit time (SVrT)............................................................. 99

Soak time unit selection (STdP) .............................................................................. 99

8.18 Set Value 1 (SV1) (F71) /Set Value 2 (SV2) (F72)...............................100

Setting limiter (high) (1. SLH, 2. SLH).................................................................100

Setting limiter (low) (1. SLL, 2. SLL) .................................................................100

8.19 System Information Display (F91) .............................................................101

9. OPERATION ..................................................................... 102

9.1 Control RUN and STOP ..............................................................................102

Operation under control RUN mode ...................................................................... 102

Display at control STOP ........................................................................................ 102

9.2 Configuration of Operation Mode.................................................................103

IMR01N02-E6

i-9

Page 12

Page

9.3 Monitoring Display in Operation...................................................................104

9.4 Autotuning (AT) ...........................................................................................107

Requirements for AT start .....................................................................................107

Requirements for AT cancellation .........................................................................107

9.5 Auto/Manual Transfer .................................................................................. 108

Auto/Manual transfer by front key operation.......................................................... 108

Auto/Manual transfer by direct key (A/M) operation ..............................................109

Auto/Manual transfer by event input......................................................................109

Procedure for setting the manipulated output value (MV) in Manual mode........... 109

9.6 Remote/Local Transfer ................................................................................ 110

Remote/Local transfer by front key operation........................................................ 110

Remote/Local transfer by direct key (R/L) operation ............................................. 110

Remote/Local transfer by event input....................................................................111

9.7 RUN/STOP Transfer.................................................................................... 111

RUN/STOP transfer by front key operation ...........................................................111

RUN/STOP transfer by direct key (R/S) operation ................................................112

RUN/STOP transfer by event input .......................................................................112

9.8 Control Area Transfer .................................................................................. 113

Control area transfer by front key operation.......................................................... 113

Control area transfer by event input ...................................................................... 113

9.9 Start Operation when Power Failure Recovers............................................114

9.10 Ramp/Soak Control ...................................................................................115

10. ERROR DISPLAYS ........................................................ 119

10.1 Overscale and Underscale ........................................................................119

10.2 Self-diagnostic Error .................................................................................. 120

11. TROUBLESHOOTING.................................................... 121

11.1 Display....................................................................................................... 121

11.2 Control.......................................................................................................122

11.3 Operation...................................................................................................123

11.4 Other .........................................................................................................124

12. REMOVING THE INTERNAL ASSEMBLY .................... 125

i-10

IMR01N02-E6

Page 13

APPENDIX

A. Setting Data List ............................................................. A-1

A-1. SV Setting & Monitor Mode........................................................................ A-1

A-2. Setup Setting Mode ................................................................................... A-2

A-3. Parameter Setting Mode ............................................................................ A-5

A-4. Engineering Mode (F10 to F91) ................................................................. A-7

B. Specifications................................................................ A-26

C. Trans Dimensions for Power Feed Forward .............. A-33

Page

D. Current Transformer (CT) Dimensions ....................... A-34

E. Memory Area Data List ................................................. A-35

INDEX.................................................................................... B-1

IMR01N02-E6

i-11

Page 14

MEMO

i-12 IMR01N02-E6

Page 15

1. OUTLINE

This Chapter describes features, package contents and model code, etc.

The digital controller of this high performance type has the following features:

High-speed sampling time (25 ms)

Suitable for fast responding control systems.

Autotuning function corresponding to fast response

• The HA400/HA900 is best suited for applications that reach setpoint quickly (within 30 seconds). *

• The HA401/HA901 is best suited for applications that take more than 30 seconds to reach setpoint. *

* Autotuning a process with a fast response may produce PID constants that would fluctuate the process excessively. If the process is less than

5 minutes to setpoint, RKC recommends adjusting the AT differential gap to less than 10 seconds (default value in the HA401/HA901) prior

to autotuning.

Up to two inputs, 2-loop control in one instrument

Control mode is selectable from 1 loop control, 2-loop control (2 input type only) and cascade control.

Direct function keys

Three Direct Function Keys on the front panel are provided for one-key operation to switch Auto/Manual,

Remote/Local, and RUN/STOP.

Up to 16 memory areas or ramp/soak control

HA400/HA900/HA401/HA901 can store up to 16 sets of control parameters. Ramp/Soak control is available by

using the memory area function.

Two communication ports (optional)

HA400/HA900/HA401/HA901 incorporates a maximum of two communication ports to communicate with a

computer, operation panel, programmable controller, etc.

1.1 Checking the Product

Before using this product, check each of the following:

Model code

Check that there are no scratch or breakage in external appearance (case, front panel, or terminal, etc).

Check that all of the items delivered are complete. (See below)

Instrument 1

Mounting brackets Each 2 Waterproof/dustproof options: each 4

Instruction Manual (IMR01N01-E) 1 Enclosed with instrument

Operation Manual (IMR01N02-E6) 1 This Manual

Communication Instruction Manual (IMR01N03-E)

[RKC communication/Modbus]

Communication Instruction Manual (IMR01N04-E)

[PROFIBUS]

Communication Instruction Manual (IMR01N05-E)

[DeviceNet]

PDA Install Guide (IMT01C01-E) 1 Infrared communication software “RKCIR”

Power feed transformer (100V type or 200V type) 1 Optional

Current transformer (CTL-6-P-N or CTL-12-S56-10L-N) 1 or 2 Optional (sold separately)

If any of the products are missing, damaged, or if your manual is incomplete, please contact RKC sales

office or the agent.

Accessories Q’TY Remarks

Optional

1

With RKC communication or Modbus

Optional

1

With PROFIBUS

Optional

1

With DeviceNet

IMR01N02-E6 1

Page 16

1. OUTLINE

1.2 Model Code

Check whether the delivered product is as specified by referring to the following model code list. If the product

is not identical to the specifications, please contact RKC sales office or the agent.

High-speed AT type:

HA400

HA400-□ □-□ □-□*□ □-□ □ □ □-□/□/Y

HA900

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11) (12) (13) (14)

Standard AT type:

HA401

HA900-□ □-□ □-□*□ □-□ □ □ □-□/□/Y

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11) (12) (13) (14)

(1) Input 1 type

K : K thermocouple J : J thermocouple T : T thermocouple S : S thermocouple R : R thermocouple

A : PLII thermocouple N : N thermocouple E : E thermocouple B : B thermocouple W : W5Re/W26Re

D : RTD (3-wire) [Factory set value: Pt100] 1 C : RTD (4-wire) [Factory set value: Pt100]

3 : Voltage (low) input group (0 to 10 mV, 0 to 100 mV, 0 to 1 V) [Factory set value: 0 to 1 V] 1

6 : Voltage (high) input group (0 to 5 V, 1 to 5 V, 0 to 10 V) [Factory set value: 1 to 5 V]

8 : Current input group (0 to 20 mA, 4 to 20 mA) [Factory set value: 4 to 20 mA]

1

To change the input type, see 8. ENGINEERING MODE (P. 50).

2

Not available as a two-input specification.

(2) Input 2 type

0 : None

K : K thermocouple J : J thermocouple T : T thermocouple S : S thermocouple R : R thermocouple

A : PLII thermocouple N : N thermocouple E : E thermocouple B : B thermocouple W : W5Re/W26Re

D : RTD (3-wire) [Factory set value: Pt100] 1

3 : Voltage (low) input group (0 to 10 mV, 0 to 100 mV, 0 to 1 V) [Factory set value: 0 to 1 V] 1

6 : Voltage (high) input group (0 to 5 V, 1 to 5 V, 0 to 10 V) [Factory set value: 1 to 5 V]

8 : Current input group (0 to 20 mA, 4 to 20 mA) [Factory set value: 4 to 20 mA]

HA901

1

1

1

1

1, 2

Non-isolated type (for remote input) 2

G : Voltage (low) input group (0 to 10 mV, 0 to 100 mV, 0 to 1 V) [Factory set value: 0 to 1 V] 1

V : Voltage (high) input group (0 to 5 V, 1 to 5 V, 0 to 10 V) [Factory set value: 1 to 5 V]

Y : Current input group (0 to 20 mA, 4 to 20 mA) [Factory set value: 4 to 20 mA]

1

To change the input type, see 8. ENGINEERING MODE (P. 50).

2

When 4-wire RTD is selected for input 1, only remote input (no-isolation) can be selected for input 2.

Continued on the next page.

2

1

1

IMR01N02-E6

Page 17

1. OUTLINE

(3) Output 1 (OUT1)

N : None T : Triac output 6 : Voltage output (1 to 5 V DC)

M : Relay contact output 4 : Voltage output (0 to 5 V DC) 7 : Current output (0 to 20 mA DC)

V : Voltage pulse output 5 : Voltage output (0 to 10 V DC) 8 : Current output (4 to 20 mA DC)

(4) Output 2 (OUT2)

N : None T : Triac output 6 : Voltage output (1 to 5 V DC)

M : Relay contact output 4 : Voltage output (0 to 5 V DC) 7 : Current output (0 to 20 mA DC)

V : Voltage pulse output 5 : Voltage output (0 to 10 V DC) 8 : Current output (4 to 20 mA DC)

(5) Power supply voltage

3 : 24 V AC/DC 4 : 100 to 240 V AC

(6) Output 3 (OUT3)

N : None T : Triac output 6 : Voltage output (1 to 5 V DC)

M : Relay contact output 4 : Voltage output (0 to 5 V DC) 7 : Current output (0 to 20 mA DC)

V : Voltage pulse output 5 : Voltage output (0 to 10 V DC) 8 : Current output (4 to 20 mA DC)

(7) Output 4 (OUT4)/Output 5 (OUT5)

N : None

1 : OUT4 (Relay contact output) OUT5 (No output)

2 : OUT4 (Relay contact output) OUT5 (Relay contact output)

(8) Event input (optional)

N : None

1 : Event input [Dry contact input (5 points): for memory area selection]

Continued on the next page.

IMR01N02-E6

3

Page 18

1. OUTLINE

(9) CT input/Power feed forward input/Feedback resistance input (optional)

N : None S : CT 1 point (CTL-12-S56-10L-N)

F : Feedback resistance input T : CT 2 points (CTL-6-P-N)

P : CT 1 point (CTL-6-P-N) U : CT 2 points (CTL-12-S56-10L-N)

1 : Power feed forward input (one 100-120 V AC transformer included)

2 : Power feed forward input (one 200-240 V AC transformer included)

3 : CT 1 point (CTL-6-P-N) + Power feed forward input (one 100-120 V AC transformer included)

4 : CT 1 point (CTL-6-P-N) + Power feed forward input (one 200-240 V AC transformer included)

5 : CT 1 point (CTL-12-S56-10L-N) + Power feed forward input (one 100-120 V AC transformer included)

6 : CT 1 point (CTL-12-S56-10L-N) + Power feed forward input (one 200-240 V AC transformer included)

(10) Communication 1/Event input (optional)

N : None 6 : RS-485 (Modbus)

1 : RS-232C (RKC communication) 8 : RS-232C (Modbus)

5 : RS-485 (RKC communication) D : Event input [Dry contact input (2 points): for operation mode transfer]

(11) Communication 2 (optional)

N : None 6 : RS-485 (Modbus) A : DeviceNet

1 : RS-232C (RKC communication) 7 : RS-422A (Modbus) B : PROFIBUS

4 : RS-422A (RKC communication) 8 : RS-232C (Modbus)

5 : RS-485 (RKC communication)

(12) Waterproof/dustproof (optional)

N : None 1 : Waterproof/dustproof

(13) Case color

N : White A : Black

(14) Instrument version

Y : Version symbol (Infrared communication function included)

4

IMR01N02-E6

Page 19

1. OUTLINE

1.3 Input/Output Functions

This section describes the input/output functions of the instrument. To learn how to set each function, see the

respective page.

INPUT In addition to measured input, 5 optional input functions are available.

Measured input: 1-input or 2-input. (Specify when ordering)

Input types available for measured inputs are shown in the table below.

Thermocouple * K, J, T, S, R, E, B, PLII, N, W5Re/W26Re

RTD * Pt100, JPt100 [Factory set value: Pt100]

Voltage (low) * 0 to 100 mV DC, 0 to 10 mV DC, 0 to 1 V DC [Factory set value: 0 to 1 V DC]

Voltage (High) * 0 to 5 V DC, 1 to 5 V DC, DC 0 to 10 V DC [Factory set value: 1 to 5 V DC]

Current * 0 to 20 mA DC, 4 to 20 mA DC [Factory set value: 4 to 20 mA DC]

*

To change the input type, see 8. ENGINEERING MODE (P. 50).

The second measured input can be used as isolated remote input.

Event input: Optional Event Input hardware is necessary. (Specify when ordering)

Event Input can be used for the following functions. (See P. 70.)

Memory area selection (Number of areas: 1 to 16 or 1 to 8)

Operation mode transfer (RUN/STOP, Remote/Local, Auto/Manual.)

Remote input (non-isolated type):

Remote input is to change a control setpoint by using current or voltage input from an

external device.

Remote input is available with 1-input controller. (Specify when ordering)

Measured input at Input 1 is not isolated from remote input at Input 2. If isolated remote

input is necessary, specify 2-input controller when ordering, and use the second input for

remote input.

Any one of the following input types can be selected. (See P. 66.)

Voltage (low) 0 to 100 mV DC, 0 to 10 mV DC, 0 to 1 V DC

Voltage (High) 0 to 5 V DC, 1 to 5 V DC, DC 0 to 10 V DC

Current 0 to 20 mA DC, 4 to 20 mA DC

CT input: CT input is used for Heater Break Alarm function to detect a heater break or short-circuit.

Up to two CT inputs can be selected. (Specify when ordering)

Only one CT input is available when power feed forward input is selected.

Measured input is not isolated from CT input.

CT inputs accept signal from dedicated current transformers (CT).

Two types of CT available. (See P. 81.)

CTL-6-P-N (for 0 to 30 A)

CTL-12-S56-10L-N (for 0 to 100 A)

IMR01N02-E6

5

Page 20

1. OUTLINE

Power feed forward (PFF) input:

Power feed forward input is used for Power Feed Forward function to achieve accurate

control. PFF monitors power supply voltage variation on a device and compensates

control output from the controller.

Two types of dedicated transformer is available. (Specify either of them when ordering)

PFT-01 100 V type transformer (100 to 120 V AC)

PFT-02 200 V type transformer (200 to 240 V AC)

Feedback resistance input:

Feedback resistance input is used to monitor a valve position when position proportioning

PID control is selected as control action.

Measured input is not isolated from feedback resistance input.

OUTPUT Up to five outputs are available. They may be used as control output, event output or

transmission output by specifying the output type or by activating the output logic

function (output logic selection).

Output1 to 3 (OUT1 to OUT3):

Control output, event output, HBA alarm output, or transmission output can be allocated

to output 1 to 3. (See P. 73 to 80.)

Number of outputs and output types must be specified when ordering.

Output types available for OUT1 to OUT3 are shown in the table below.

Relay contact output 250 V AC, 3A (Resistive load), 1a contact

Voltage pulse output 0/12 V DC (Load resistance: 600 Ω or more)

Triac output 0.4 A (Rated current)

Voltage output 0 to 5 V DC, 1 to 5 V DC, 0 to 10 V DC (Load resistance: 1 kΩ or more)

Current output 0 to 20 mA DC, 4 to 20 mA DC (Load resistance: 600 Ω or less)

OUT3 is isolated from both OUT1 and OUT2.

OUT1 and OUT2 are not isolated from each other except for relay or triac output.

When relay or triac output is used, there is isolation between outputs.

There is isolation between input and output.

There is isolation between output and power supply terminals.

Output 4 to 5 (OUT4 to OUT5):

The output type for OUT4 and OUT5 is relay only. OUT4 and OUT5 can be used for

event output and/or HBA alarm output. (See P. 73 to 80.)

Relay contact output 250 V AC, 1A (Resistive load), 1a contact

Event output function (EV1 to EV4)

The following event types can be selected for EV1 to EV4.

Deviation high Band SV high

Deviation low

Deviation high/low

Process high SV low

Process low LBA (Only EV3 and EV4 can be selected)

6

The maximum number of event output is four.

Output allocation is necessary to output the event state from output terminals. (See P. 73.)

IMR01N02-E6

Page 21

1. OUTLINE

Transmission output 1 to 3 (AO1 to AO3):

Maximum three transmission output can be allocated to OUT1, OUT2, and OUT3.

Maximum number of output available for transmission output varies by other output use

for control output and event output. Parameter values shown in the following table can be

output by transmission output. (See P. 75.)

Input 1 side Measured value (PV), Set value (SV), Manipulated output value (MV),

Deviation (PV−SV)

Input 2 side Measured value (PV), Set value (SV), Manipulated output value (MV),

Deviation (PV−SV)

Output logic function:

Output logic function allocates output functions to output terminals. Logic output such as

OR/AND is available for event output. The following signals are allocated by output logic

function. Transmission output needs to be allocated separately. (See P. 70 to 73.)

Input Analog signal: Control output value (max. 2 points)

Digital signal: Event action state (4 points), HBA action state (max. 2 points),

Position proportioning output state (2 points),

Contact input state (max. 7 points), Control area number (4 points)

Operation state (3points): LOC/MAN/REM

Output Computed output from OUT1 to OUT5.

COMMUNICATION

Communication 1, Communication 2 (optional):

Up to two communication ports are available to communicate with a computer or

programmable controller. When DI 6 and 7 are used, communication port 1 is not

available. (Specify when ordering)

The protocols available for each port are shown in the table below.

Interface *

Protocol *

Open Network *

* Specify when ordering.

Infrared communication:

Infrared communication can be used when sending and receiving data between this

controller and the PDA installed with the RKCIR software.

Communication 1 function * Communication 2 function *

RS-485, RS-232C RS-485, RS-232C, RS-422A

RKC communication, Modbus RKC communication, Modbus

−

PROFIBUS, DeviceNet

IMR01N02-E6

7

Page 22

1. OUTLINE

A

A

AREA

A

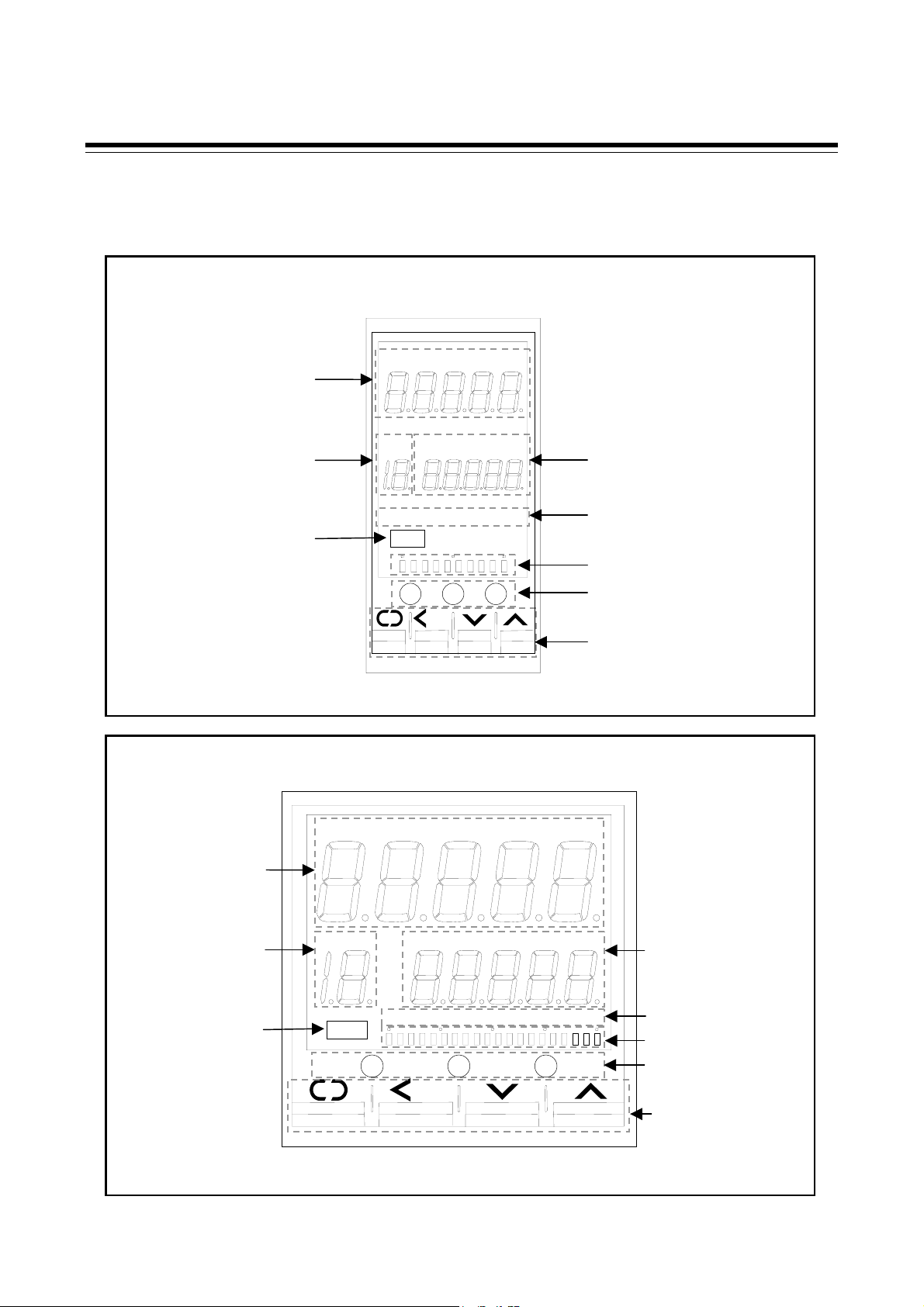

1.4 Parts Description

This chapter describes various display units and the key functions.

HA400/HA401

HA900/HA901

Upper display

rea display

Infrared port

Upper display

rea display

Infrared port

PV1

SET

PV1 PV2 MAN REM AT

AREA PV2 MAN REM AT SV

OUT1 OUT2 OUT3 OUT4 OUT5 ALM

A/M R/L R/S

MODE

SET

PV2 MAN

/M R/L R/S

PV2 MAN REM AT SV

OUT1 OUT2 OUT3 OUT4 OUT5 ALM

MODE

REM

Lower display

Output/Alarm lamp

Bar gragh display

Direct keys

Operation keys

AT

Lower display

Output/Alarm lamp

Bar gragh display

Direct keys

Operation keys

8

IMR01N02-E6

Page 23

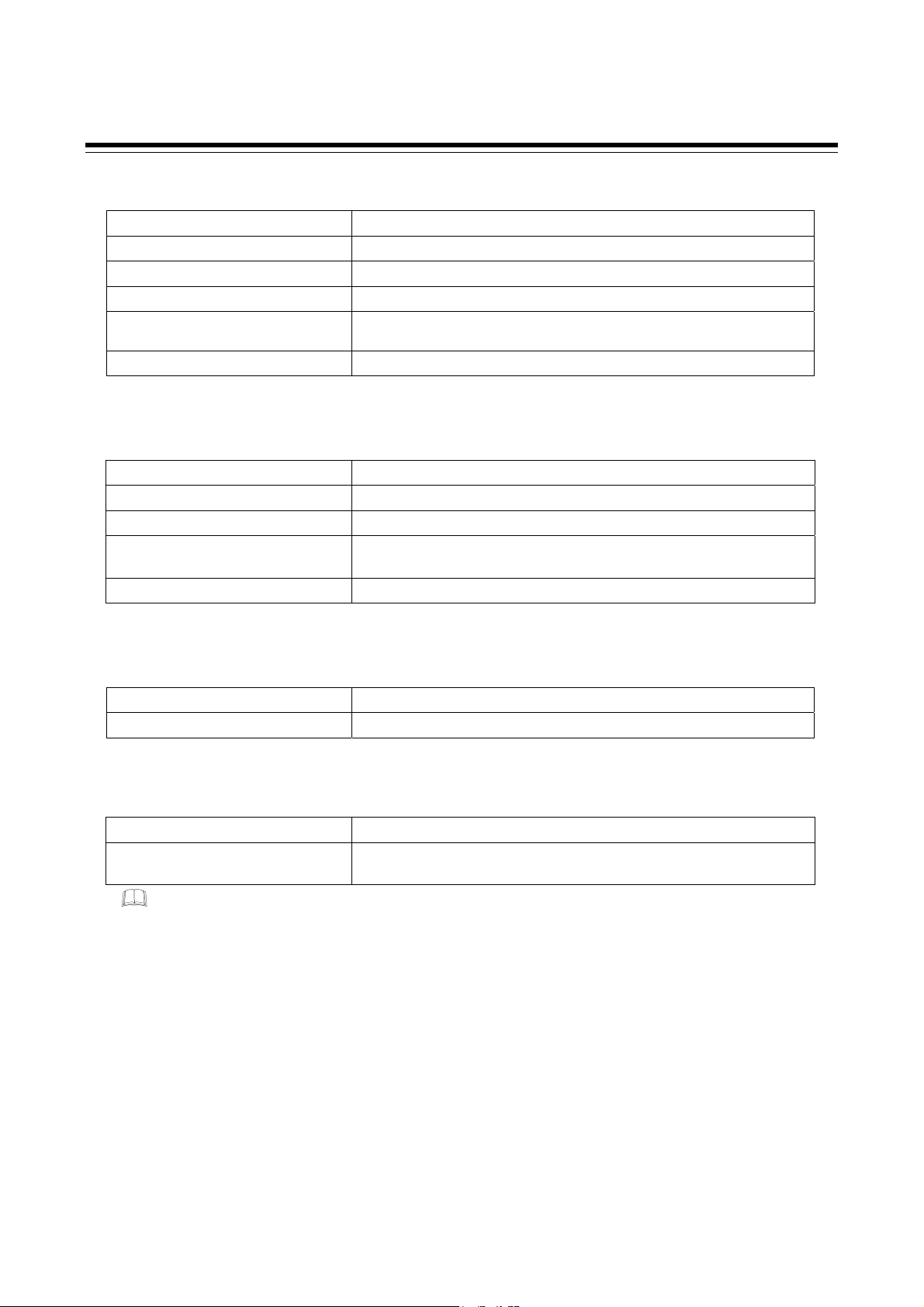

Upper display

Measured value 1 (PV1) lamp [Green] Lights when measured value 1 is displayed on the PV1/PV2 display unit.

Measured value 2 (PV2) lamp * [Green] Lights when measured value 2 is displayed on the PV1/PV2 display unit.

Manual (MAN) mode lamp [Green] Lights when operated in manual mode.

Remote (REM) mode lamp [Green] Lights when remote setting function is activated.

Autotuning (AT) lamp [Green]

Measured value (PV1/PV2) display Displays PV1, PV2 or various parameters’ symbols.

* This lamp is activated only with 2-input controller.

Flashes when autotuning is activated.

(After autotuning is completed: AT lamp will become OFF)

Lower display

Measured value 2 (PV2) lamp * [Green] Lights when measured value 2 is displayed on the SV display unit.

Set value (SV) lamp [Green] Lights when set value (SV) is displayed on the SV display unit.

Manual (MAN) mode lamp * [Green] Lights when operated in manual mode.

Autotuning (AT) lamp * [Green] Flashes when autotuning is activated.

(After autotuning is completed: AT lamp will become OFF)

Set value (SV) display Displays SV, PV2 or various parameters’ set values.

* This lamp is activated only with 2-input controller.

Area display

1. OUTLINE

Area (AREA) lamp [Green] Lights when memory area number is displayed.

Memory area display Displays memory area number (1 to 16).

Output/Alarm lamp

Output (OUT1 to OUT5) lamp [Green] Lights when the output corresponding to each lamp is ON.

Alarm (ALM) lamp [Red] Lights when alarm (Event or HBA function) is turned on.

The type of alarm which is on can be checked on the event monitor display.

These lamps works with outputs (control, alarm, retransmission) which are assigned to OUT1 through OUT5.

For assignment of outputs to OUT1 through OUT5, see Transmission Output Type Selection (P.75) and Output Logic

Selection (P.73).

IMR01N02-E6

9

Page 24

1. OUTLINE

−

+

Bar graph display [Green] *

One of the displays shown in the table below can be selected for the bar-graph.

Manipulated output value (MV) display

Measured value display

Set value display Displays the set value (SV). Scaling is available within the input range.

Deviation display

Feedback resistance input value (POS)

display

* The number of dots: 10 dots (HA400/HA401) 20 dots (HA900/HA901)

Displays the manipulated output value (MV). When manipulated output value (MV) is

at 0 % or less, the left-end dot of the bar-graph flashes. When MV exceeds 100 %, the

right-end dot flashes.

[Example]

050

100

Displays the measured value (PV). Scaling is available within the input range.

[Example]

050

100

[Example]

050

100

Displays the deviation between the measured value (PV) and the set value (SV).

When the Deviation display is selected, the dots at both ends of bar-graph light.

[Example]

0

Displays the feedback resistance input value (POS).

(Available with position proportioning PID control)

[Example]

050

100

The bar-graph function is not activated at the factory unless the controller is specified as position proportioning PID controller

when ordered Bar graph display can be selected in the Engineering Mode. See selecting the bar graph display (P.64).

Direct keys

A/M

Auto/Manual transfer key Switching the Auto/Manual control mode between Auto (PID control) mode and Manual

mode.

R/L

Remote/Local transfer key Switching the Remote/Local control mode between Remote control and Local control.

R/S

RUN/STOP transfer key Switching the RUN/STOP mode between RUN and STOP.

To avoid damage to the instrument, never use a sharp object to press keys.

For the Auto/Manual transfer key, it is possible to select among Auto/Manual transfer for (1) Input1, (2) Input2, or (3) both

Input 1 and Input 2. (See P. 65.)

Use/Unuse of Direct Key function are programmable. (See P. 65.)

To prevent operator error, a direct key cannot be operated in positioning adjustment (automatic adjustment).

Operation keys

SET

Set (SET) key Used for parameter calling up and set value registration.

MODE

Shift key Shift digits when settings are changed.

Used to selection operation between modes.

Down key Decrease numerals.

Up key Increase numerals.

To avoid damage to the instrument, never use a sharp object to press keys.

Infrared port

Used when sending and receiving data between this controller and the PDA installed with the RKCIR software.

The RKCIR software can be downloaded from our home page. For this purpose, user registration address and password are required.

For details, PDA INSTALL GUIDE (IMT01C01-E).

10

IMR01N02-E6

Page 25

2. MOUNTING

This chapter describes installation environment, mounting cautions, dimensions and mounting procedures.

To prevent electric shock or instrument failure, always turn off the power before

mounting or removing the instrument.

WARNING

!

2.1 Mounting Environment

(1) This instrument is intended to be used under the following environmental conditions. (IEC61010-1)

[OVERVOLTAGE CATEGORY II, POLLUTION DEGREE 2]

(2) Use this instrument within the following ambient temperature and ambient humidity.

• Allowable ambient temperature: −10 to +50 °C

• Allowable ambient humidity: 5 to 95 % RH

(Absolute humidity: MAX. W. C 29 g/m

(3) Avoid the following conditions when selecting the mounting location:

• Rapid changes in ambient temperature which may cause condensation.

• Corrosive or inflammable gases.

• Direct vibration or shock to the mainframe.

• Water, oil, chemicals, vapor or steam splashes.

• Excessive dust, salt or iron particles.

• Excessive induction noise, static electricity, magnetic fields or noise.

• Direct air flow from an air conditioner.

• Exposure to direct sunlight.

• Excessive heat accumulation.

3

dry air at 101.3 kPa)

2.2 Mounting Cautions

Take the following points into consideration when mounting this instrument in the panel.

• Provide adequate ventilation space so that heat does not build up.

• Do not mount this instrument directly above equipment that generates large amount of heat (heaters,

transformers, semi-conductor functional devices, large-wattage resistors).

• If the ambient temperature rises above 50 °C, cool this instrument with a forced air fan, cooler, or the like.

However, do not allow cooled air to blow this instrument directly.

• In order to improve safety and the immunity to withstand noise, mount this instrument as far away as possible

from high voltage equipment, power lines, and rotating machinery.

High voltage equipment: Do not mount within the same panel.

Power lines: Separate at least 200 mm.

Rotating machinery: Separate as far as possible.

• Mount this instrument in the horizontal direction for panel. If you did installation except a horizontal direction,

this causes malfunction.

IMR01N02-E6 11

Page 26

2. MOUNTING

+

+

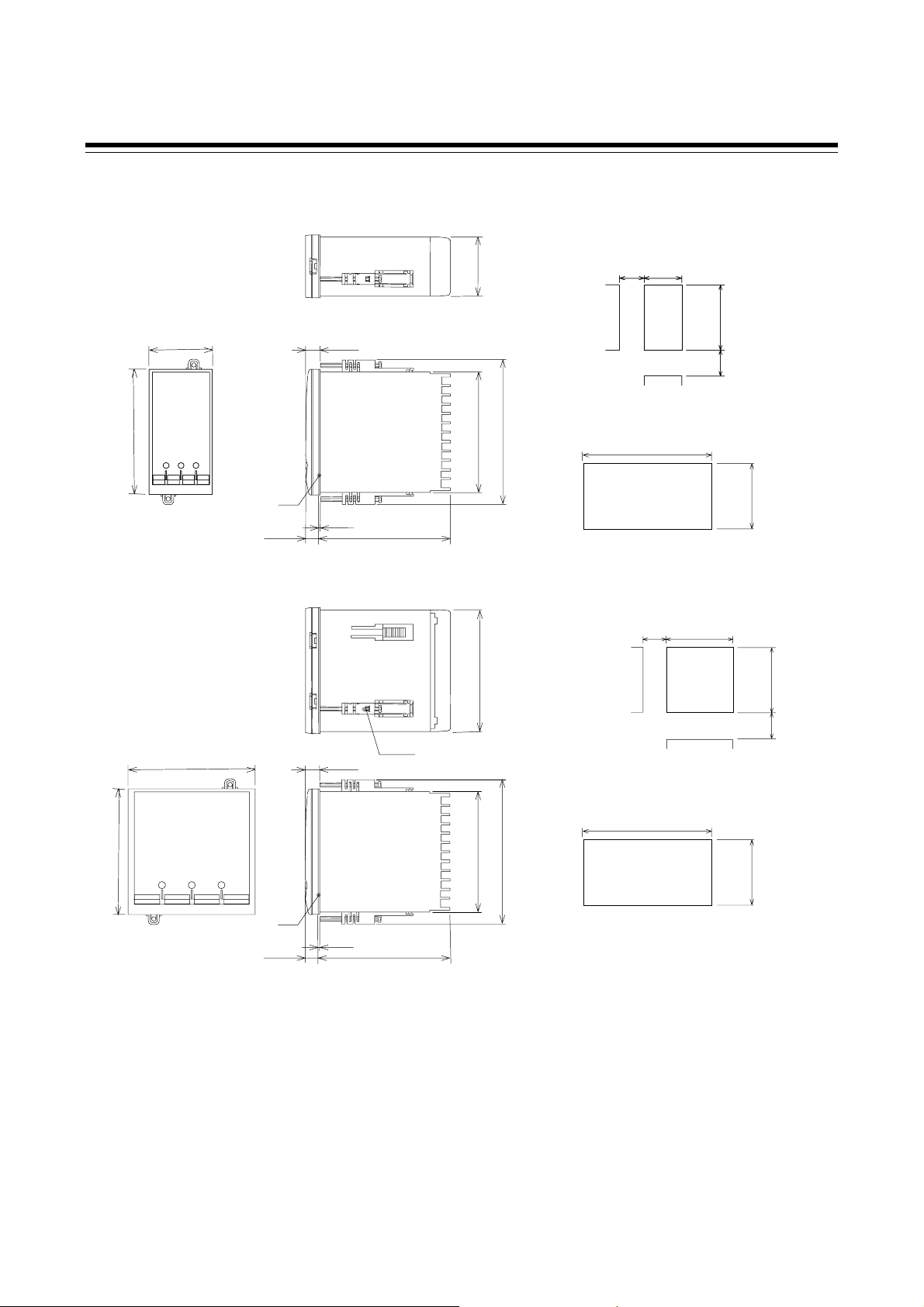

2.3 Dimensions

HA400/HA401

(Unit: mm )

48

44.8

11.1

Individual mounting

+0.6

+0.6

45

45

25

25

+0

+0

+0.8

+0

+0.8

+0

92

92

30

*3, *4

30

96

91.8

110.8

Close mounting

0.6

L

+0

*1

10.1 100

(1)

+0.8

+0

92

L = 48×n-3 n: Number of units (2 ≤ n ≤ 6)

HA900/HA901

Individual mounting

(Unit: mm )

25

91.8

96

11.1

*2

96

91.8

110.8

Close mounting

0.8

L

+0

*1

10.1

(1)

L = 96×n-4 n: Number of units (2 ≤ n ≤ 6)

100

*1 Rubber (Option)

*2 Up to 4 mounting brackets may be used.

*3 If the HA400/HA401s or HA900/HA901s have waterproof/dustproof options, protection will be compromised and not

meet IP65 by close mounting.

*4 When controllers are closely mounted, ambient temperature must not exceed 50 °C.

For mounting of the HA400/HA401 or HA900/HA901, panel thickness must be between 1 to 10 mm. When mounting

multiple HA400/HA401s or HA900/HA901s close together, the panel strength should be checked to ensure proper

support.

92

*3, *4

+0.8

+0

0.8

0

92

30

+0.8

+0

92

12

IMR01N02-E6

Page 27

2. MOUNTING

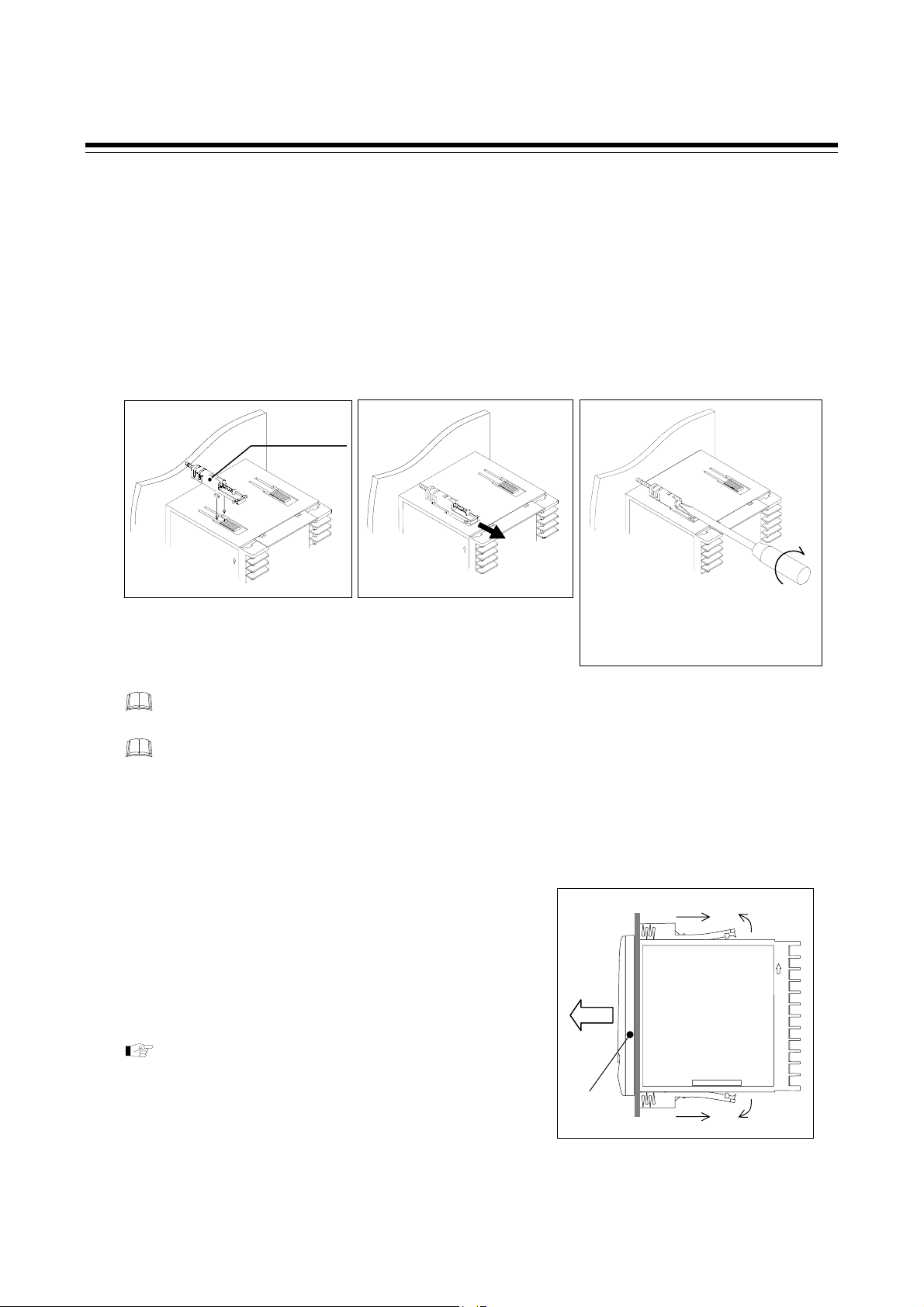

2.4 Procedures of Mounting and Removing

Mounting procedures

1. Prepare the panel cutout as specified in 2.3 Dimensions. (Panel thickness: 1 to 10 mm)

2. Insert the instrument through the panel cutout.

3. Insert the mounting bracket into the mounting groove of the instrument. (Fig. 1)

4. Pull till click sounds to the direction shown by the arrow. (Fig. 2)

5. Tighten up the screw. (Fig. 3)

6. The other mounting bracket should be installed the same way described in 3. to 5.

Fig. 1

HA900/HA901 is used in the above figures for explanation, but

the same mounting procedures also apply to HA400/HA401.

When the instrument is mounted, always secure with two mounting brackets so that upper and lower

mounting brackets are positioned diagonally.

The waterproof/dustproof option on the front of the instrument conforms to IP65 when mounted on the

panel. For effective waterproof/dustproof, the gasket must be securely placed between instrument and

panel without any gap. If gasket is damaged, please contact RKC sales office or the agent.

Removing procedures

Mounting

bracket

Fig. 2

Fig. 3

When using the mounting

screws, only turn one full

revolution after the screw

touches the panel.

1. Loosen the screw of the mounting bracket.

2. Remove the mounting bracket from the case. (Fig. 4)

3. Pull out the instrument from the mounting cutout while

holding the front panel frame of this instrument.

When pulling out only the internal assembly from

the instrument case after being wired, see

12. REMOVING THE INTERNAL ASSEMBLY

(P. 125).

IMR01N02-E6

Fig.4

Pull out

Front panel

frame

13

Page 28

3. WIRING

This chapter describes wiring cautions, wiring layout and wiring of terminals.

To prevent electric shock or instrument failure, do not turn on the power

until all the wiring is completed.

WARNING

!

3.1 Wiring Cautions

• For thermocouple input, use the appropriate compensation wire.

• For RTD input, use low resistance lead wire with no difference in resistance between the three or four lead

wires.

• To avoid noise induction, keep input signal wire away from instrument power line, load lines and power lines

of other electric equipment.

• If there is electrical noise in the vicinity of the instrument that could affect operation, use a noise filter.

− Shorten the distance between the twisted power supply wire pitches to achieve the most effective noise

reduction.

− Always install the noise filter on a grounded panel. Minimize the wiring distance between the noise filter

output and the instrument power supply terminals to achieve the most effective noise reduction.

− Do not connect fuses or switches to the noise filter output wiring as this will reduce the effectiveness of the

noise filter.

• About five seconds are required as preparation time for contact output every time the instrument is turned on.

Use a delay relay when the output line is used for an external interlock circuit.

• Power supply wiring must be twisted and have a low voltage drop.

• For an instrument with 24 V power supply, supply power from a SELV circuit.

• This instrument is not furnished with a power supply switch or fuse. Therefore, if a fuse or power supply

switch is required, install close to the instrument.

Recommended fuse rating: Rated voltage 250 V, Rated current 1 A

Fuse type: Time-lag fuse

• Use the solderless terminal appropriate to the screw size.

Screw size: M3 × 6 (With 5.8 × 8 square washer )

Recommended tightening torque: 0.4 N・m (4 kgf・cm)

Recommended dimension:

6 mm

5.9 mm MAX

3.2 mm MIN

14 IMR01N02-E6

Page 29

3. WIRING

3.2 Terminal Layout

The terminal layout is as follows. HA400/HA401 is used in the figures for explanation, but the same terminal

layouts also apply to HA900/HA901.

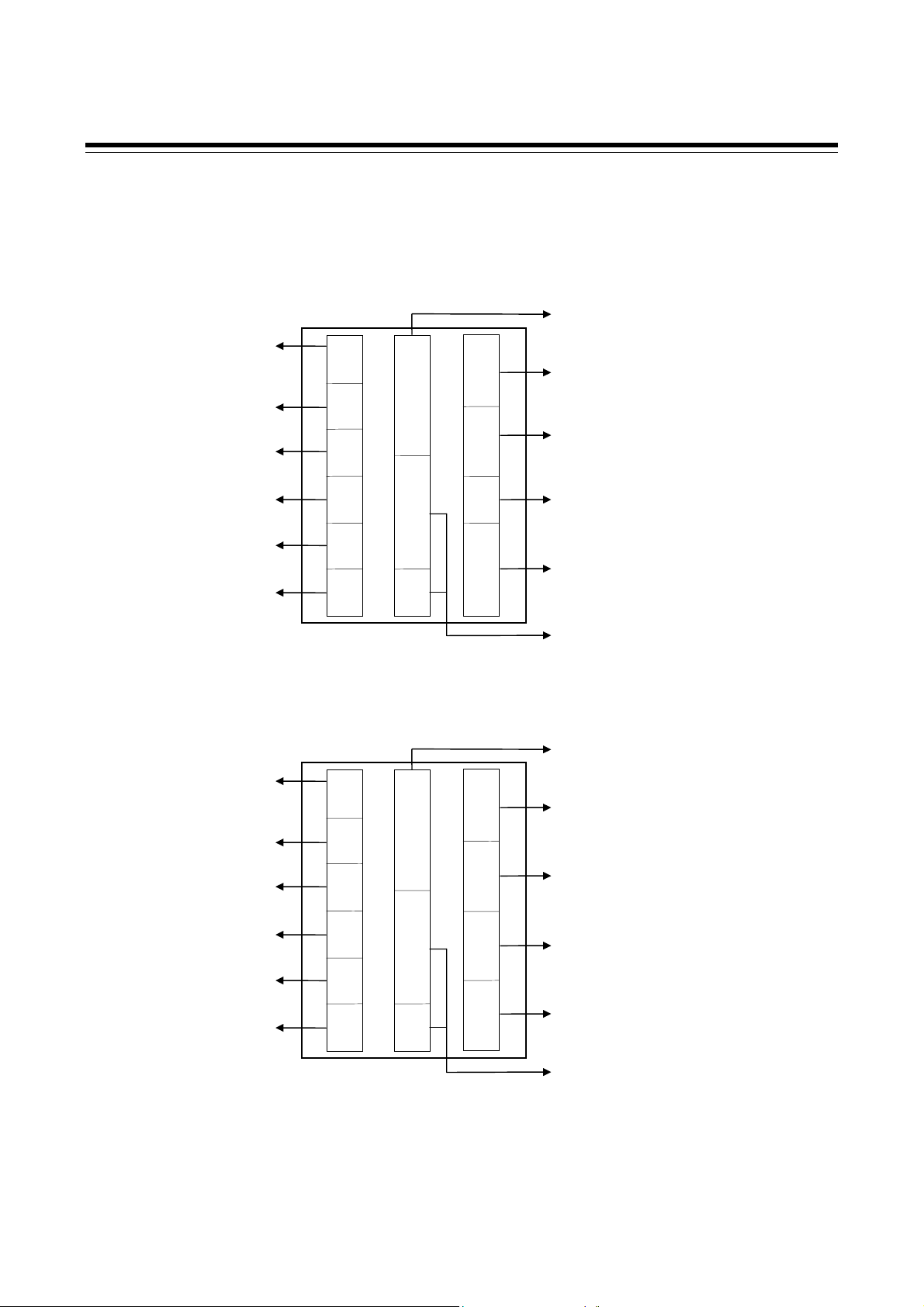

1-input controller

Power supply voltage

100 to 240 V AC

24 V AC

24 V AC

Output 5 (OUT5)

Output 4 (OUT4)

Output 3 (OUT3)

Output 2 (OUT2)

Output 1 (OUT1)

2-input controller

1

2

3

4

5

6

7

8

9

10

11

12

25

26

27

28

29

30

31

32

33

34

35

36

13

14

15

16

17

18

19

20

21

22

23

24

Optional

Communication 2

Optional

Communication 1

Event input (DI6 to DI7)

Optional

CT input

Feedback resistance input

Power feed forward input

Optional

Remote input (non-isolated type)

Measured input

Thermocouple/RTD/Voltage/Current

Optional

Event input (DI1 to DI4, DI5)

Power supply voltage

100 to 240 V AC

24 V AC

24 V AC

Output 5 (OUT5)

Output 4 (OUT4)

Output 3 (OUT3)

Output 2 (OUT2)

Output 1 (OUT1)

1

2

3

4

5

6

7

8

9

10

11

12

25

26

27

28

29

30

31

32

33

34

35

36

13

14

15

16

17

18

19

20

21

22

23

24

Optional

Communication 2

Optional

Communication 1

Event input (DI6 to DI7)

Optional

CT input

Feedback resistance input

Power feed forward input

Measured input 2

Thermocouple/RTD/Voltage/Current

Measured input 1

Thermocouple/RTD/Voltage/Current

Optional

Event input (DI1 to DI4, DI5)

IMR01N02-E6

15

Page 30

3. WIRING

A

A

+

−

3.3 Wiring of Each Terminal

Prior to conducting wiring, always check the polarity of each terminal.

The terminal nameplate of this instrument and its descriptions are shown in the following.

Symbols on the input terminal block

correspond to the type of external input

connected to the instrument

Thermocouple Relay contact output

+

TC

−

[Example]

Instrument

inside

23

Relay

24

23

24

Symbols on the output terminal block

NO

correspond to the type (state) of output

sent from the instrument.

Power supply

• Connect the power to terminal numbers 1 and 2.

L

C

100-240 V

100-240 V AC power

supply type

1

2

N

24 V AC power supply type

• The power supply types must be specified when ordering. Power supply voltage for the controller must be

within the range shown below for the controller to satisfy the control accuracy in the specifications.

Power supply type Power consumption

90 to 264 V AC [Power supply voltage range], 50/60 Hz,

(Rating 100 to 240 V AC)

21.6 to 26.4 V AC [Power supply voltage range],

50/60 Hz, (Rating 24 V AC)

21.6 to 26.4 V DC [Power supply voltage range],

(Rating 24 V DC)

• If there is electrical noise in the vicinity of the instrument that could affect operation, use a noise filter.

• Power supply wiring must be twisted and have a low voltage drop.

• For an instrument with 24 V power supply, supply power from a SELV circuit.

• This instrument is not furnished with a power supply switch or fuse. Therefore, if a fuse or power supply

switch is required, install close to the instrument.

Recommended fuse rating: Rated voltage 250 V, Rated current 1 A

Fuse type: Time-lag fuse

L

C

24 V

1

2

N

HA400/HA401: 16.5 VA max. (at 100 V AC), 22.5 VA max. (at 240 V AC)

HA900/HA901: 17.5 VA max. (at 100 V AC), 24.0 VA max. (at 240 V AC)

HA400/HA401: 15.0 VA max. (at 24 V AC)

HA900/HA901: 16.0 VA max. (at 24 V AC)

HA400/HA401: 430 mA max. (at 24 V DC)

HA900/HA901: 470 mA max. (at 24 V DC)

DC

24 V DC power supply type

1

24 V

2

16

IMR01N02-E6

Page 31

11

+

−

+

−

∼

Output 1 to 3 (OUT1 to OUT3)

• Terminal 11 and 12 are for output 1 (OUT1); Terminal 9 and 10 are for output 2 (OUT2); and Terminal 7 and

8 are for output 3 (OUT3).

• Connect an appropriate load according to the output type.

Relay contact output:

11

12

OUT1

NO

9

10

OUT2

NO

7

8

OUT3

NO

Voltage pulse output/Voltage output/Current output

OUT1

12

OUT2

9

+

−

10

OUT3

7

+

−

8

• Number of outputs and output types must be specified when ordering. Control output, event output, HBA

alarm output, or transmission output can be allocated to output 1 to 3. The specifications of each output are as

follows.

Output type Specifications

Relay contact output 250 V AC, 3A (Resistive load), 1a contact Electrical life 300,000 times or more (Rated load)

Voltage pulse output 0/12 V DC (Load resistance: 600 Ω or more)

Triac output 0.4 A (Rated current)

Voltage output

Current output

0 to 5 V DC, 1 to 5 V DC, 0 to 10 V DC (Load resistance: 1 kΩ or more)

Output resolution: 11 bits or more

0 to 20 mA DC, 4 to 20 mA DC (Load resistance: 600 Ω or less)

Output resolution: 11 bits or more

Triac output:

OUT1

11

SSR

12

Example of wiring is as follows:

Inside of

instrument

NO

OUT2

9

10

Load

SSR

OUT3

7

+

SSR

−

8

3. WIRING

+

−

• OUT3 is isolated from both OUT1 and OUT2.

• OUT1 and OUT2 are not isolated from each other except for relay or triac output. When relay or triac output is

used, there is isolation between outputs.

• There is isolation between input and output.

• There is isolation between output and power supply terminals.

Output 4 to 5 (OUT4 to OUT5)

• Terminal 5 and 6 are for output 4 (OUT4); and Terminal 3 and 4 are for output 5 (OUT5).

• Output type is only relay contact output.

Relay contact output 250 V AC, 1A (Resistive load), 1a contact Electrical life 300,000 times or more (Rated load)

• OUT4 and OUT5 can be used for event output and/or HBA alarm output.

5

6

OUT4

NO

3

4

OUT5

NO

IMR01N02-E6

17

Page 32

3. WIRING

+

−

24

22

22

22

+

−

+

−

22

Measured input

• For the 1-input controller, terminals 21 through 24 are allocated to the measured input.

Thermocouple

+

23

TC

24

−

RTD input

A

A

RTD

B

B

21

3-wire

system

22

23

or

4-wire

system

Voltage input Current input

+

23

IN

24

23

IN

24

−

• For the 2-input controller, terminals 22 through 24 are allocated to Input 1, and terminals 19 through 21 are

allocated to Input 2.

Thermocouple Voltage input Current input

RTD input

19

+

20

TC2

21

−

+

23

TC1

24

−

RTD2

RTD1

A

19

B

20

B

21

IN2

19

19

+

20

21

20

IN2

21

−

A

B

23

B

24

23

IN1

24

+

23

IN1

24

−

• The input types needs to be specified when ordering. The input types are as follows.

Thermocouple: K, J, T, S, R, E, B, PLII, N, Voltage (low): 0 to 100 mV DC, 0 to 10 mV DC, 0 to 1 V DC

W5Re/W26Re Voltage (high): 0 to 5 V DC, 1 to 5 V DC, 0 to 10 V DC

RTD: Pt100, JPt100 Current: 0 to 20 mA DC, 4 to 20 mA DC

• For thermocouple input, use an appropriate compensation wire. For RTD input, use the same low resistance

lead wires for all connections.

18

IMR01N02-E6

Page 33

Remote input (optional)

• With non-isolated remote input option, terminals 19 to 20 are allocated to Remote Input.

3. WIRING

+

19

RS

20

−

Any one of the following input types can be selected.

Voltage (low): 0 to 100 mV DC, 0 to 10 mV DC, 0 to 1 V DC

Voltage (high): 0 to 5 V DC, 1 to 5 V DC, 0 to 10 V DC

Current: 0 to 20 mA DC, 4 to 20 mA DC

• Input 2 of the 2-input controller can be used as isolated Remote Input.

• Measured input is not isolated from remote input (non-isolated type).

Event input (optional)

• With Event Input option, terminals 13 through 15 and 30 through 36 are allocated to event input. Event input

option must be specified when ordering.

Dry contact input Dry contact input

COM

DI1

DI2

DI3

DI4

30

31

32

33

34

COM

DI6

DI7

13

14

15

COM

35

DI5

36

• Event Input option can not be selected if Communication 1 function is specified. Use Communication 2

function if both event inputs and communications are necessary.

• Contact input from external devices or equipment should be dry contact input. If it is not dry contact input, the

input should have meet the specifications below.

Contact resistance: At OFF (contact open): 500 kΩ or more At ON (contact closed) 10 Ω or less

• The following functions can be assigned to event inputs.

Memory area selection, RUN/STOP transfer, Remote/Local transfer, Auto/Manual transfer

To assign functions to event inputs, see 8. ENGINEERING MODE (P. 50).

IMR01N02-E6

19

Page 34

3. WIRING

A

+

28

−

28

28

CT input/Power feed forward input/Feedback resistance input (optional)

• With CT input, Power Feed Forward input or feedback resistance input, terminals 16 through 18 are allocated

to the specified input.

• When using CT input, connect CTs to the relevant terminals.

• When using Power Feed Forward input, connect the dedicated transformer included.

• When using feedback resistance input, connect a potentiometer to the relevant terminals.

CT input (1 point)

COM

16

CT1

17

18

CT input (2 points)

COM

16

CT1

CT2

17

18

Power feed forward

input

16

PFF

17

18

CT input +

Power feed forward input

COM

16

CT1

PFF

17

18

Feedback resistance

input

O

16

17

W

18

C

llowance resistance range:

100Ω to 10 kΩ (Standard 135 Ω)

• CT input and feedback resistance input are not isolated between measured input.

Communication 1/Communication 2 (optional)

• With Communication function 1, terminals 13 through 15 are allocated to Communication 1.

• With Communication function 2, terminals 25 through 29 are allocated to Communication 2.

• Communication 1 option can not be selected if Event Input function is specified.

• Conduct wiring to the relevant terminals meeting the specified communication interface. For details of wiring,

see Communication Instruction Manual (IMR01N03-E).*

* See Communication Instruction Manual (IMR01N04-E) for PROFIBUS and Communication Instruction Manual (IMR01N05-E)

for DeviceNet.

[Communication 1]

RS-232C

RS-485

SG

SD

13

14

SG

T/R (A)

13

14

RD

15

T/R (B)

15

[Communication 2]

RS-232C

RS-485

RS-422A

DeviceNet

PROFIBUS

SG

SD

25

26

SG

T/R (A)

25

26

SG

T (A)

V

25

26

CAN-H

25

26

VP

RxD/TxD-P

25

26

RD

27

T/R (B)

27

T (B)

R (A)

27

Drain

CAN-L

27

RxD/TxD-N

DGND

27

R (B)

29

V

29

20

IMR01N02-E6

Page 35

3. WIRING

Example 1: Connection to the RS-232C port of the host computer (master)

HA400/HA900

(Slave)

SG (GND)

SD (TXD)

RD (RXD)

Number of connection: 1 instrument

13

14

15

RS-232C

Shielded wire

Host computer (master)

SG (GND)

SD (TXD)

RD (RXD)

*

RS (RTS)

CS (CTS)

* Short RS and CS within connector

Example 2: Connection to the RS-485 port of the host computer (master)

HA400/HA900

(Slave)

SG

T/R (A)

T/R (B)

SG

T/R (A)

T/R (B)

13

14

15

13

14

15

*R

RS-485

Shielded twisted

*R: Termination resistors (Example: 120Ω 1/2 W)

Paired wire

pair wire

Host computer (master)

SG

T/R (A)

T/R (B)

*R

Maxmum connections: 32 instruments maximum including a host computer

Example 3: Connection to the RS-422A port of the host computer (master)

HA400/HA900

(Slave)

25

SG

T (A)

26

T (B)

27

R (A)

28

R (B)

29

25

SG

T (A)

26

T (B)

27

R (A)

28

R (B)

29

Maxmum connections: 32 instruments maximum including a host computer

RS-422A

Shielded twisted

Paired wire

pair wire

Host computer (master)

SG

T (A)

T (B)

R (A)

R (B)

IMR01N02-E6

21

Page 36

a

4. SETTING

This chapter describes procedures to set operating conditions of a customer and parameter of various setting

modes.

4.1 Setting Procedure to Operation

Conduct necessary setting before operation according to the procedure described below.

Mounting & Wiring

When installing the instrument,

see 2. MOUNTING (P.11) and

3. WIRING (P. 14).

Power ON

Change from RUN to STOP

Factory set value: RUN (Control start)

Press the direct key (R/S) to change the RUN/STOP status from RUN mode to STOP mode.

The parameters in Engineering Mode which should be set according to the application are

settable only when the controller is in STOP mode.

Setting of operating condition

The parameters for controller’s basic functions in Engineering Mode should be changed

according to the application before setting the parameters related to operation.

Be sure to check the parameters for the following settings and change them according to the

application if necessary. Other parameters should be also changed according to the application.

• Input type (RTD input/voltage input/current input specified when the instrument is ordered)

• Power frequency (50 Hz or 60 Hz) [Factory set value: 50 Hz]

• Control action (Direct action or Reverse action) [Factory set value: Reverse action]

• Output logic selection (Output function assignment from OUT1 to OUT5)

[Factory set value: 1-input controller: 1, 2-input controller: 5]

For details of the engineering mode, see 8. ENGINEERING MODE (P. 50).

Setup data setting

Set parameters in Setup Setting Mode:

• Heater break alarm set value (option)

• PV bias, PV digital filter, PV low input cut-off

• Proportional cycle time for control output (Expect voltage and current output)

• Communication (option)

For details of the setup setting mode, see 7. SETUP SETTING MODE (P. 40).

A

Entry to data sheet

Use the sheet of Appendix E, and

make record of setting data of

customer.

22 IMR01N02-E6

Page 37

4. SETTING

r

n

A

Parameter data setting

Set parameters in Parameter Setting Mode:

• Event output/event input function

• PID and control response, etc.

Up to 16 individual sets of parameters in Paramete

Setting Mode and SVs can be stored and used i

Multi-memory Area function.