Page 1

Instruction Manual

Digital Controller

FB100

RKC INSTRUMENT INC.

IMR01W16-E7

Page 2

Modbus is a registered trademark of Schneider Electric.

Company names and product names used in this manual are the trademarks or registered trademarks of

the respective companies.

All Rights Reserved, Copyright 2008, RKC INSTRUMENT INC.

Page 3

Thank you for purchasing this RKC product. In order to achieve maximum performance and ensure

proper operation of your new instrument, carefully read all the instructions in this manual. Please

place the manual in a convenient location for easy reference.

NOTICE

This manual assumes that the reader has a fundamental knowledge of the principles of electricity,

process control, computer technology and communications.

The figures, diagrams and numeric values used in this manual are only for purpose of illustration.

RKC is not responsible for any damage or injury that is caused as a result of using this instrument,

instrument failure or indirect damage.

RKC is not responsible for any damage and/or injury resulting from the use of instruments made by

imitating this instrument.

Periodic maintenance is required for safe and proper operation of this instrument. Some

components have a limited service life, or characteristics that change over time.

Every effort has been made to ensure accuracy of all information contained herein. RKC makes no

warranty expressed or implied, with respect to the accuracy of the information. The information in

this manual is subject to change without prior notice.

No portion of this document may be reprinted, modified, copied, transmitted, digitized, stored,

processed or retrieved through any mechanical, electronic, optical or other means without prior

written approval from RKC.

WARNING

!

An external protection device must be installed if failure of this instrument

could result in damage to the instrument, equipment or injury to personnel.

All wiring must be completed before power is turned on to prevent electric

shock, fire or damage to instrument and equipment.

This instrument must be used in accordance with the specifications to

prevent fire or damage to instrument and equipment.

This instrument is not intended for use in locations subject to flammable or

explosive gases.

Do not touch high-voltage connections such as power supply terminals, etc.

to avoid electric shock.

RKC is not responsible if this instrument is repaired, modified or

disassembled by other than factory-approved personnel. Malfunction can

occur and warranty is void under these conditions.

IMR01W16-E7

i-1

Page 4

CAUTION

This product is intended for use with industrial machines, test and measuring equipment.

(It is not designed for use with medical equipment and nuclear energy.)

This is a Class A instrument. In a domestic environment, this instrument may cause radio

interference, in which case the user may be required to take additional measures.

This instrument is protected from electric shock by reinforced insulation. Provide

reinforced insulation between the wire for the input signal and the wires for instrument

power supply, source of power and loads.

Be sure to provide an appropriate surge control circuit respectively for the following:

- If input/output or signal lines within the building are longer than 30 meters.

- If input/output or signal lines leave the building, regardless the length.

This instrument is designed for installation in an enclosed instrumentation panel. All

high-voltage connections such as power supply terminals must be enclosed in the

instrumentation panel to avoid electric shock by operating personnel.

All precautions described in this manual should be taken to avoid damage to the

instrument or equipment.

All wiring must be in accordance with local codes and regulations.

All wiring must be completed before power is turned on to prevent electric shock,

instrument failure, or incorrect action.

The power must be turned off before repairing work for input break and output failure

including replacement of sensor, contactor or SSR, and all wiring must be completed

before power is turned on again.

To prevent instrument damage or failure, protect the power line and the input/output lines

from high currents with a protection device such as fuse, circuit breaker, etc.

Prevent metal fragments or lead wire scraps from falling inside instrument case to avoid

electric shock, fire or malfunction.

Tighten each terminal screw to the specified torque found in the manual to avoid electric

shock, fire or malfunction.

For proper operation of this instrument, provide adequate ventilation for heat dispensation.

Do not connect wires to unused terminals as this will interfere with proper operation of the

instrument.

Turn off the power supply before cleaning the instrument.

Do not use a volatile solvent such as paint thinner to clean the instrument. Deformation or

discoloration will occur. Use a soft, dry cloth to remove stains from the instrument.

To avoid damage to instrument display, do not rub with an abrasive material or push front

panel with a hard object.

Do not connect modular connectors to telephone line.

When high alarm with hold action/re-hold action is used for Event function, alarm does not

turn on while hold action is in operation. Take measures to prevent overheating which

may occur if the control device fails.

FOR PROPER DISPOSAL

When disposing of each part used for this instrument, always follows the procedure for

disposing of industrial wastes stipulated by the respective local community.

i-2

IMR01W16-E7

Page 5

Safety Symbols:

WARNING

CAUTION

!

: This mark indicates where additional information may be located.

Character Symbols:

SYMBOLS

: This mark indicates precautions that must be taken if there is danger of electric

shock, fire, etc., which could result in loss of life or injury.

: This mark indicates that if these precautions and operating procedures are not

taken, damage to the instrument may result.

: This mark indicates that all precautions should be taken for safe usage.

: This mark indicates important information on installation, handling and operating

procedures.

: This mark indicates supplemental information on installation, handling and

operating procedures.

0 1 2 3 4 5 6 7 8 9

Minus Period

A B (b) C c D (d) E F G H I J K

L M N (n) O (o) P Q (q) R (r) S T t U u

V W X Y Z

Degree

/

Dash

Dim lighting

Bright lighting

Flashing

IMR01W16-E7

i-3

Page 6

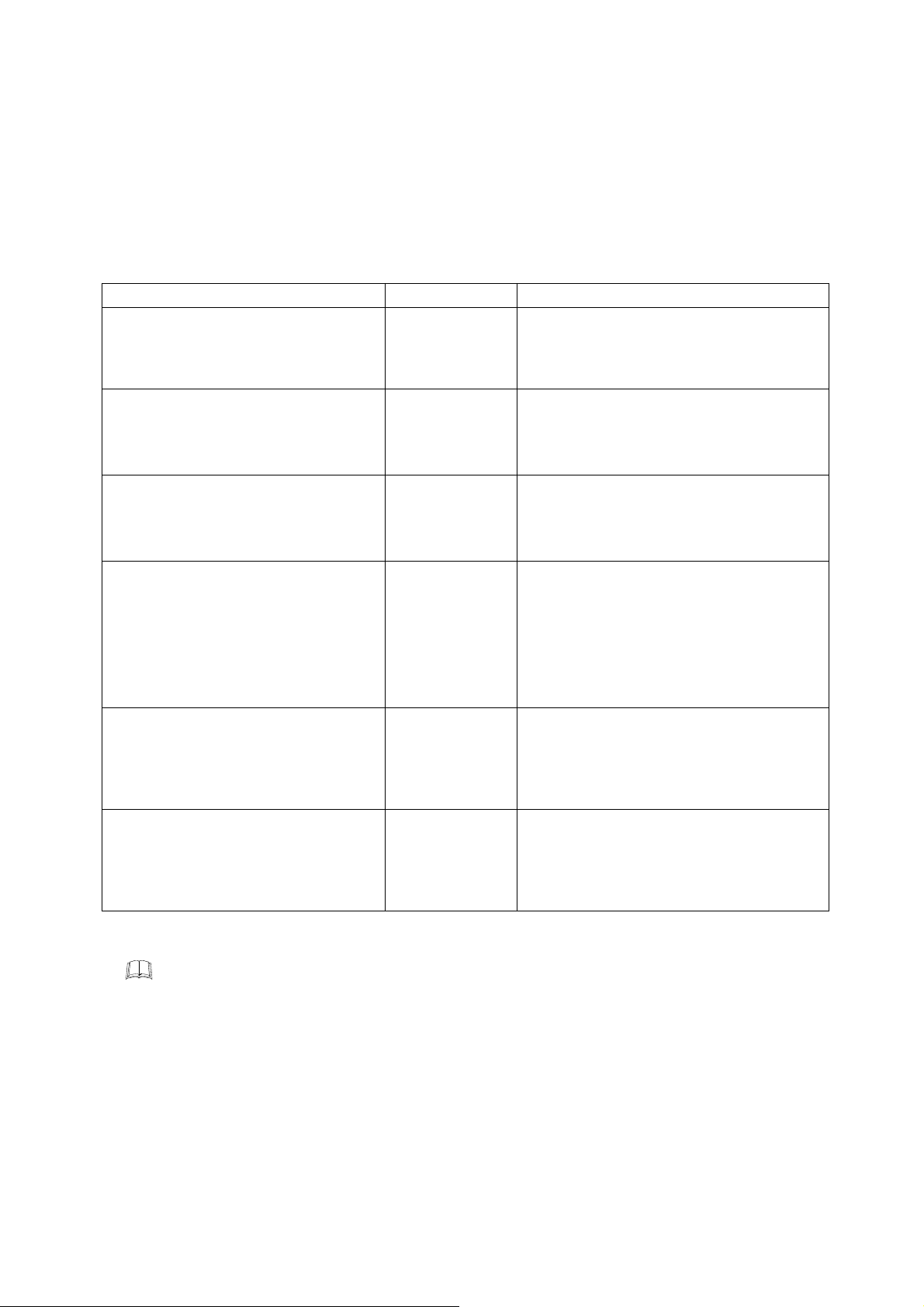

DOCUMENT CONFIGURATION

There are six manuals pertaining to this product. Please be sure to read all manuals specific to your

application requirements. If you do not have a necessary manual, please contact RKC sales office, the

agent, or download from the official RKC website.

The following manuals can be downloaded from the official RKC website:

http://www.rkcinst.com/english/manual_load.htm.

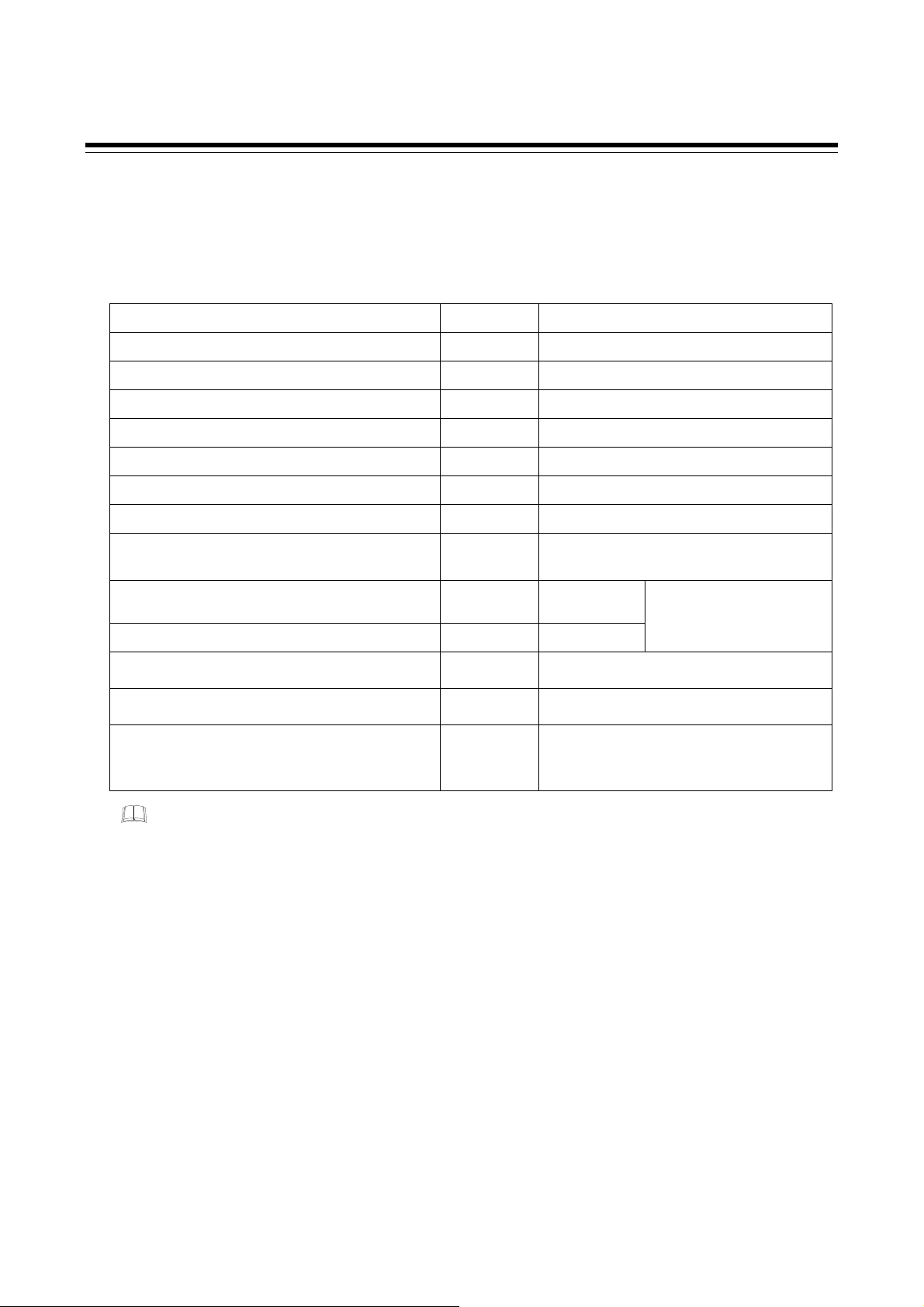

Manual Manual Number Remarks

FB100 Installation Manual IMR01W12-E

FB100 Quick Operation Manual

FB100 Parameter List

FB100 Communication Quick Manual

FB100 Instruction Manual IMR01W16-E7

FB100/FB400/FB900

Communication Instruction Manual *

* Sold separately

IMR01W13-E

IMR01W14-E

IMR01W15-E

IMR01W04-E

Read this manual carefully before operating the instrument. Please place the manual in a

convenient location for easy reference.

This manual is enclosed with instrument.

This manual explains the mounting and wiring,

front panel name, and the operation mode

outline.

This manual is enclosed with instrument.

This manual explains the basic key operation,

mode menu, and data setting.

This manual is enclosed with instrument.

This list is a compilation of the parameter data

of each mode.

This manual is enclosed with instrument.

(Only FB100 provided with the communication

function)

This manual explains the connection method

with host computer, communication

parameters, and communication data (except

for parameters in Engineering Mode).

This Manual.

This manual explains the method of

the mounting and wiring, the operation of

various functions, and troubleshooting.

This manual explains RKC communication

protocol (ANSI X3.28-1976), Modbus, and

relating to the communication parameters

setting.

i-4

IMR01W16-E7

Page 7

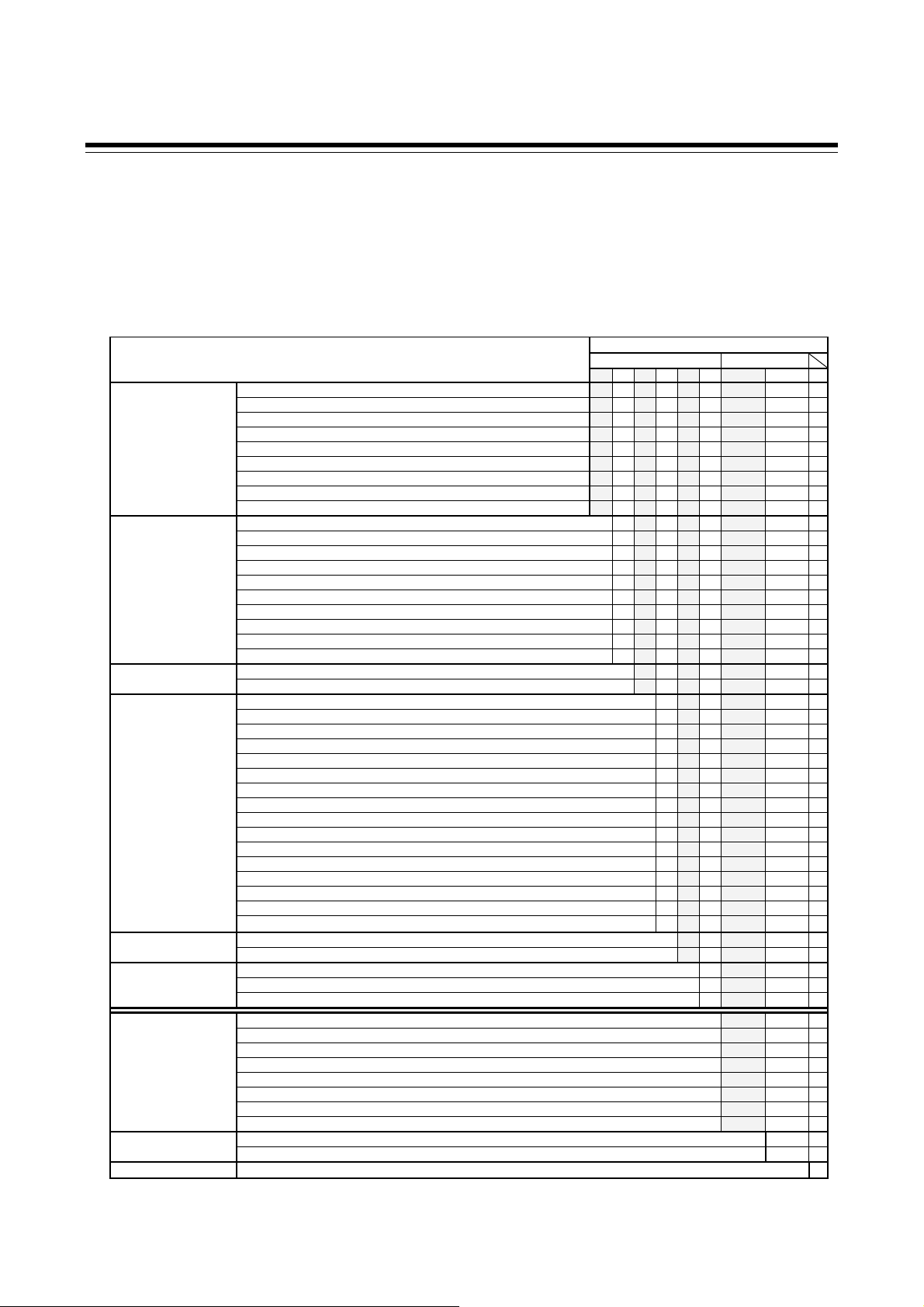

CONTENTS

1. OUTLINE ........................................................................... 1-1

1.1 Features ....................................................................................................... 1-2

1.2 Checking the Product ................................................................................... 1-3

1.3 Model Code .................................................................................................. 1-4

Suffix code .............................................................................................................. 1-4

Quick start code 2 (Initial setting code) .................................................................. 1-6

1.4 Parts Description .......................................................................................... 1-8

1.5 Input/Output Functions ............................................................................... 1-11

2. HANDLING PROCEDURE TO OPERATION .................... 2-1

Page

3. MOUNTING ........................................................................ 3-1

3.1 Mounting Cautions ........................................................................................ 3-2

3.2 Dimensions ................................................................................................... 3-3

3.3 Procedures of Mounting and Removing ....................................................... 3-4

Mounting procedures .............................................................................................. 3-4

Removing procedures ............................................................................................ 3-4

4. WIRING .............................................................................. 4-1

4.1 Wiring Cautions ............................................................................................ 4-2

4.2 Terminal Layout ............................................................................................ 4-4

Isolations of input and output.................................................................................. 4-5

4.3 Wiring of Each Terminal ............................................................................... 4-6

4.3.1 Power supply ..................................................................................................... 4-6

4.3.2 Output 1 (OUT1)/Output 2 (OUT2) .................................................................... 4-7

4.3.3 Digital output 1, 2 (DO1, DO2) .......................................................................... 4-9

4.3.4 Measured input (Thermocouple/RTD/Voltage/Current) .................................... 4-9

4.3.5 Optional ........................................................................................................... 4-10

Optional function: A [Digital input (5 points)] ..................................................... 4-10

Optional function: B [Digital input (2 points) Remote setting input (1 point)] . 4-11

Optional function: C [Digital input (2 points)

Feedback resistance input (1 point)] ................................ 4-12

Optional function: D [Digital input (2 points)

Current transformer input (2 points)] ................................ 4-13

Optional function: E [Communication (1 point) Digital input (3 points) .......... 4-14

Optional function: F [Communication (1 point) Digital input (1 point)

Current transformer input (1 point)] .................................. 4-15

Optional function: G [Communication (2 points)] .............................................. 4-16

IMR01W16-E7 i-5

Page 8

Optional function: H [Communication (1 point)

Current transformer input (2 points)] ................................ 4-17

Optional function: J [Communication (1 point) Digital input (1 point)

Remote setting input (1 point)] ......................................... 4-18

Optional function: 3, 4, 5, 6, 7, 8

[Digital input (1 point) Transmission output (1 point)

Remote setting input (1 point)] ......................................... 4-20

5. OPERATION MENU AND BASIC OPERATION ............... 5-1

5.1 Operation Menu ............................................................................................ 5-2

Input type and input range display .......................................................................... 5-3

Page

5.2 Basic Operation ............................................................................................ 5-4

5.2.1 Scrolling through parameters ............................................................................ 5-4

SV setting & monitor mode ................................................................................. 5-4

Parameter setting mode, Setup setting mode .................................................... 5-6

Operation mode .................................................................................................. 5-7

Engineering mode ............................................................................................... 5-8

5.2.2 Changing set value (SV) ................................................................................... 5-9

5.2.3 Operation of the direct key .............................................................................. 5-10

5.2.4 Data lock function ............................................................................................ 5-11

6. OPERATION ...................................................................... 6-1

6.1 Operating Precautions .................................................................................. 6-2

6.2 Monitoring Display in Operation .................................................................... 6-3

When the Direct key type is other than Monitor ...................................................... 6-3

When the Direct key type is Monitor ................................................................... 6-4

6.3 Operating Setting .......................................................................................... 6-5

6.3.1 Set the Set value (SV) ....................................................................................... 6-5

6.3.2 Set the Event set value (alarm set value) ......................................................... 6-7

6.3.3 Autotuning (AT) start ......................................................................................... 6-8

To manually set PID values ................................................................................ 6-9

6.4 RUN/STOP Transfer ................................................................................... 6-11

RUN/STOP transfer by Front key operation ......................................................... 6-11

RUN/STOP transfer by Direct key operation ........................................................ 6-12

RUN/STOP transfer by Digital input (DI) [optional] ............................................... 6-13

6.5 Autotuning (AT) .......................................................................................... 6-15

Caution for using the Autotuning (AT) .................................................................. 6-15

Requirements for Autotuning (AT) start ................................................................ 6-15

i-6 IMR01W16-E7

Page 9

Page

Requirements for Autotuning (AT) cancellation .................................................... 6-15

Autotuning (AT) start/stop operation ..................................................................... 6-16

6.6 Startup Tuning (ST) .................................................................................... 6-18

Caution for using the Startup tuning (ST) ............................................................. 6-18

Requirements for Startup tuning (ST) start ........................................................... 6-19

Requirements for Startup tuning (ST) cancellation ............................................... 6-19

Startup tuning (ST) setting .................................................................................... 6-20

6.7 Auto/Manual Transfer ................................................................................. 6-23

Auto/Manual transfer by Front key operation ....................................................... 6-24

Auto/Manual transfer by Direct key operation ...................................................... 6-25

Auto/Manual transfer by Digital input (DI) [optional] ............................................. 6-26

Procedure for setting the Manipulated output value (MV) in Manual mode .......... 6-28

6.8 Remote/Local Transfer ............................................................................... 6-29

Remote/Local transfer by Front key operation ..................................................... 6-29

Remote/Local transfer by Direct key operation .................................................... 6-30

Remote/Local transfer by Digital input (DI) [optional] ........................................... 6-31

6.9 Control Area Transfer ................................................................................. 6-33

Control area transfer by Front key operation ........................................................ 6-34

Control area transfer by Direct key operation ....................................................... 6-35

Control area transfer by Digital input (DI) [optional] ............................................. 6-36

Control area transfer by Area soak time (Ramp/Soak Control) ............................ 6-38

6.10 Interlock Release ...................................................................................... 6-39

Interlock release method by Front key operation ................................................. 6-40

Interlock release method by Digital input (DI) [optional] ....................................... 6-40

6.11 Start Action at Recovering Power Failure ................................................. 6-42

Hot/Cold start selection ........................................................................................ 6-42

Start determination point ...................................................................................... 6-42

6.12 Position Proportioning PID Control ........................................................... 6-43

Setting flowchart ................................................................................................... 6-45

Setting procedures ............................................................................................... 6-47

6.13 Ramp/Soak Control .................................................................................. 6-52

Operation flowchart .............................................................................................. 6-53

Settings before operation ..................................................................................... 6-54

Operation procedures ........................................................................................... 6-56

6.14 Group Operation by the Intercontroller Communication ........................... 6-61

6.14.1 Wiring method of the Intercontroller communication ..................................... 6-61

6.14.2 Common setting of the Intercontroller communication .................................. 6-62

6.14.3 Group RUN/STOP function ........................................................................... 6-64

IMR01W16-E7

Operation flowchart ........................................................................................... 6-64

Requirements for Group RUN/STOP ................................................................ 6-65

Group RUN/STOP operation and states ........................................................... 6-65

i-7

Page 10

Page

Settings before operation .................................................................................. 6-66

Usage example ................................................................................................. 6-69

6.14.4 Automatic temperature rise function (with learning function) ........................ 6-72

Requirements for automatic temperature rise learning start ............................. 6-73

Requirements for automatic temperature rise learning cancellation ................. 6-73

Requirements for automatic temperature rise start .......................................... 6-74

Requirements for automatic temperature rise cancellation .............................. 6-74

Operation flowchart ........................................................................................... 6-75

Settings before operation .................................................................................. 6-76

Operation procedures ....................................................................................... 6-79

6.14.5 Cascade control function ............................................................................... 6-81

Operation flowchart ........................................................................................... 6-82

Settings before operation .................................................................................. 6-83

Adjustment after control starting ....................................................................... 6-85

Operation procedures ....................................................................................... 6-88

6.14.6 Ratio setting function ..................................................................................... 6-89

Operation flowchart ........................................................................................... 6-90

Settings before operation .................................................................................. 6-91

Adjustment after control starting ....................................................................... 6-93

Operation procedures ....................................................................................... 6-96

Usage example ................................................................................................. 6-97

7. PARAMETER DESCRIPTION ........................................... 7-1

7.1 SV Setting & Monitor Mode .......................................................................... 7-2

7.1.1 Display sequence (When the Direct key type is other than Monitor) ..................... 7-2

7.1.2 Display sequence (When the Direct key type is Monitor) .................................. 7-3

7.1.3 Monitor and setting item .................................................................................... 7-4

7.2 Operation Mode .......................................................................................... 7-14

7.2.1 Display sequence ............................................................................................ 7-14

7.2.2 Operation item ................................................................................................. 7-15

7.3 Parameter Setting Mode ............................................................................. 7-22

7.3.1 Display sequence ............................................................................................ 7-23

7.3.2 Parameter setting item .................................................................................... 7-24

7.4 Setup Setting Mode .................................................................................... 7-37

7.4.1 Display sequence ............................................................................................ 7-37

7.4.2 Setup setting item ........................................................................................... 7-38

7.5 Engineering Mode ...................................................................................... 7-52

7.5.1 Display sequence ............................................................................................ 7-52

7.5.2 Precaution against parameter change ............................................................ 7-58

i-8

IMR01W16-E7

Page 11

Page

7.5.3 Engineering setting item .................................................................................. 7-65

Function block 10 (F10.) [Display] ................................................................... 7-65

Function block 11 (F11.) [Direct key] ............................................................... 7-70

Function block 21 (F21.) [Input] ....................................................................... 7-71

Function block 22 (F22.) [Remote setting input type] ...................................... 7-79

Function block 23 (F23.) [Digital input assignment] ........................................ 7-80

Function block 30 (F30.) [Output] .................................................................... 7-81

Function block 33 (F33.) [Transmission output] .............................................. 7-86

Function block 41 (F41.) [Event 1] .................................................................. 7-88

Function block 42 (F42.) [Event 2] .................................................................. 7-97

Function block 43 (F43.) [Event 3] ................................................................ 7-101

Function block 44 (F44.) [Event 4] ................................................................ 7-105

Function block 45 (F45.) [Heater break alarm 1] ........................................... 7-112

Function block 46 (F46.) [Heater break alarm 2] ........................................... 7-116

Function block 50 (F50.) [Hot/Cold start etc.] ................................................ 7-119

Function block 51 (F51.) [Control 1] .............................................................. 7-125

Function block 52 (F52.) [Control 2] .............................................................. 7-140

Function block 53 (F53.) [Position proportioning PID control] ....................... 7-152

Function block 54 (F54.) [Startup tuning] ...................................................... 7-157

Function block 55 (F55.) [Group/Automatic temperature rise] ...................... 7-159

Function block 60 (F60.) [Communication protocol] ...................................... 7-162

Function block 70 (F70.) [Time unit] .............................................................. 7-163

Function block 71 (F71.) [Setting limiter] ....................................................... 7-164

Function block 91 (F91.) [Others] .................................................................. 7-165

8. TROUBLESHOOTING ....................................................... 8-1

8.1 Error Display ................................................................................................. 8-2

Display when input error occurs ............................................................................. 8-2

Self-diagnostic error ............................................................................................... 8-3

8.2 Solutions for Problems ................................................................................. 8-4

Display .................................................................................................................... 8-5

Control .................................................................................................................... 8-6

Operation ................................................................................................................ 8-8

Event function ......................................................................................................... 8-9

Heater break alarm (HBA) .................................................................................... 8-10

9. SPECIFICATIONS ............................................................. 9-1

Measured input ................................................................................................... 9-2

Remote setting (RS) input [optional] ................................................................... 9-3

Current transformer (CT) input [optional] ............................................................ 9-4

IMR01W16-E7

i-9

Page 12

Page

Feedback resistance (FBR) input [optional] ........................................................ 9-4

Digital input (DI) [optional] .................................................................................. 9-5

Output (OUT1, OUT2) ........................................................................................ 9-5

Digital output (DO1, DO2) ................................................................................... 9-6

Transmission output (AO) [optional] ................................................................... 9-6

Performance (at the ambient temperature 23 ±2 C) .......................................... 9-7

Control ................................................................................................................ 9-8

Brilliant II PID control .......................................................................................... 9-8

Brilliant II Heat/Cool PID control ......................................................................... 9-9

Brilliant II Position proportioning PID control without FBR ................................ 9-10

Event function [optional] ................................................................................... 9-11

Control loop break alarm (LBA) [optional] ......................................................... 9-12

Heater break alarm (HBA) [time-proportional control output (optional)] ........... 9-12

Heater break alarm (HBA) [continuous control output (optional)] ..................... 9-12

Multi-memory area function [optional] ............................................................... 9-12

Loader communication ..................................................................................... 9-13

Communication [optional] ................................................................................. 9-13

Intercontroller communication function [optional] ............................................. 9-14

Self-diagnostic function ..................................................................................... 9-15

Power ................................................................................................................ 9-15

General specifications ...................................................................................... 9-16

Standard ........................................................................................................... 9-17

APPENDIX ............................................................................ A-1

A. Removing the Internal Assembly ................................................................... A-2

B. Replacing the Waterproof/Dustproof Rubber Packing ................................... A-4

C. Current Transformer (CT) Dimensions .......................................................... A-6

D. Memory Area Data List ................................................................................. A-7

E. Parameter List ............................................................................................... A-8

F. Seal [for Unit and Direct key] (accessory attached) ..................................... A-24

INDEX .................................................................................... B-1

Alphabetical Order ............................................................................................. B-2

Character Order ................................................................................................. B-5

Revisions

i-10

IMR01W16-E7

Page 13

OUTLINE

1.1 Features ........................................................................................... 1-2

1.2 Checking the Product ....................................................................... 1-3

1.3 Model Code ...................................................................................... 1-4

1.4 Parts Description .............................................................................. 1-8

1.5 Input/Output Functions ................................................................... 1-11

IMR01W16-E7 1-1

Page 14

1. OUTLINE

1.1 Features

This chapter describes features, package contents and model code, etc. The digital controller of this

high performance type has the following features:

Panel space saving: 74 mm depth

Selectable sampling time among 50ms, 100ms, and 250 ms.

Selectable sampling time makes the FB100 suitable for any application rang ing from pressure control requiring

fast response to precise control requiring highest resolution. (Factory setting: 100 ms)

Selectable PID control algorithm

PID control algorithm is selectable in the FB100 to achieve the most precise control for various applications.

PV derivative PID : suitable for fixed setpoint control (Factory setting)

Deviation derivative PID : suitable for ramp control using ramp-to-setpoint function and cascade control.

Advanced Heat/Cool PID algorithm with Undershoot Suppression

Startup tuning to eliminate time for autotuning

Mode switching can be performed directly (Direct key)

Control RUN/STOP, Auto/Manual, Remote/Local, Memory area, or monitor transfer can be selected.

(Factory set value: Auto/Manual transfer)

Up to 8 recipes (multi-memory area) or Ramp/Soak control

FB100 can store up to 8 sets of control parameters. Ramp/Soak control is available by using the memory area

function.

Easy maintenance

The internal assembly of the FB100 can be removed from the front.

NEMA4X and IP66 waterproof and dustproof protection for severe environments.

(standard)

Two communication ports (optional)

Host communication can be performed with a host computer or host device such as an operation panel.

(Communication 1)

Group operation such as cascade control and ratio setting is possible using only Intercontroller communication; it

is not necessary to use communication with a host computer or analog signals such as remote setting input and

transmission output.

(Communication 1 or Communication 2)

Easy-setup and Data Monitoring via a standard data port

The FB100 have the loader port (provided as standard) to connect to a PC USB port with Windows

2000/XP/Vista/7.

The standard port allows setup and data logging to be managed by the PC. The FB100 is recognized as an

external device on the PC.

[The communication tool (WinUCI, PROTEM2) can be downloaded from the RKC official website:

http://www.rkcinst.com/.]

1-2 IMR01W16-E7

Page 15

1. OUTLINE

1.2 Checking the Product

Before using this product, check each of the following:

Model code

Check that there are no scratches or breakage in external appearance (case, front panel, or terminal, etc.)

Check that all of the items delivered are complete. (Refer to below)

Accessories Q’TY Remarks

Instrument 1

Mounting brackets (with screw) 2

Seal (SAP-379) 1

Case rubber packing (KRB100-39) 1 For waterproof/dustproof

Installation Manual (IMR01W12-E) 1 Enclosed with instrument

Quick Operation Manual (IMR01W13-E) 1 Enclosed with instrument

Parameter List (IMR01W14-E) 1 Enclosed with instrument

Communication Quick Manual (IMR01W15-E) 1 Enclosed with instrument

(with communication function )

Instruction Manual (IMR01W16-E7) 1

Communication Instruction Manual (IMR01W04-E) 1 Sold separately

Terminal cover (KCA100-517)

Front cover (KRB100-36A)

Current transformer

(CTL-6-P-N [for 0 to 30 A] or

CTL-12-S56-10L-N [for 0 to 100 A])

Depending on the

order quantity

Depending on the

order quantity

Depending on the

order quantity

This manual

(sold separately)

Optional (sold separately)

Optional (sold separately)

Optional (sold separately)

This manual can be downloaded

from the official RKC website:

http://www.rkcinst.com/english/

manual_load.htm.

ローダツール操作説明書 (IMR01W05-J)

If any of the products are missing, damaged, or if your manual is incomplete, please contact

RKC sales office or the agent.

1

別売り

IMR01W16-E7 1-3

Page 16

1. OUTLINE

1.3 Model Code

Check that the product received is correctly specified by referring to the following model code list:

If the product is not identical to the specifications, please contact RKC sales office or the agent.

Suffix code

FB100-□ □-□*□ / □ □-□ □□□ /Y

(1) (2) (3) (4) (5) (6) (7) (8) (9)

(1) (2) (3) (4) (5) (6) (7) (8) (9)

Relay contact output M

Voltage pulse output V

Voltage output (0 to 5 V DC) 4

Voltage output (0 to 10 V DC) 5

Output 1 (OUT1)

Output 2 (OUT2)

Power supply voltage

Optional function

Case color

Quick start code

Control Method

[Quick start code 1]

Measured input and Range

[Quick start code 1]

Instrument specification

*

When the optional function code "G" is selected, the factory set value of Communication 2 becomes Intercontroller communication.

Voltage output (1 to 5 V DC) 6

Current output (0 to 20 mA DC) 7

Current output (4 to 20 mA DC) 8

Triac output T

Open collector output D

None N

Relay contact output M

Voltage pulse output V

Voltage output (0 to 5 V DC) 4

Voltage output (0 to 10 V DC) 5

Voltage output (1 to 5 V DC) 6

Current output (0 to 20 mA DC) 7

Current output (4 to 20 mA DC) 8

Triac output T

Open collector output D

24 V AC/DC 3

100 to 240 V AC 4

None N

Digital input (5 points) A

Digital input (2 points) Remote setting input B

Digital input (2 points) Feedback resistance input C

Digital input (2 points) CT input (2 points) D

Digital input (3 points) Communication (1 point) E

Digital input (1 point) Communication (1 point) CT input (1 point) F

Communication (2 points) * G

Communication (1 point) CT input (2 points) H

Communication (1 point) Digital input (1 point) Remote setting input J

Digital input (1 point) Remote setting input Transmission output [Voltage output (0 to 1 V DC) 3

Digital input (1 point) Remote setting input Transmission output [Voltage output (0 to 5 V DC) 4

Digital input (1 point) Remote setting input Transmission output [Voltage output (0 to 10 V DC) 5

Digital input (1 point) Remote setting input Transmission output [Voltage output (1 to 5 V DC) 6

Digital input (1 point) Remote setting input Transmission output [Current output (0 to 20 mA DC) 7

Digital input (1 point) Remote setting input Transmission output [Current output (4 to 20 mA DC) 8

White case N

Black case A

No quick start code (Configured to factory set value) N

Specify quick start code 1 1

Specify quick start code 1 and 2 (Refer to page 1-6) 2

Quick start code 1 is not specified No code

PID control with AT (Reverse action) F

PID control with AT (Direct action) D

Heat/Cool PID control with AT G

Heat/Cool PID control with AT (for Extruder [air cooling]) A

Heat/Cool PID control with AT (for Extruder [water cooling]) W

Position proportioning PID control without FBR (Reverse action) Z

Position proportioning PID control without FBR (Direct action) C

Quick start code 1 is not specified No code

Refer to Range Code Table.

Version symbol Y

Suffix code

Specifications

Hardware coding only Quick start code 1

1-4 IMR01W16-E7

Page 17

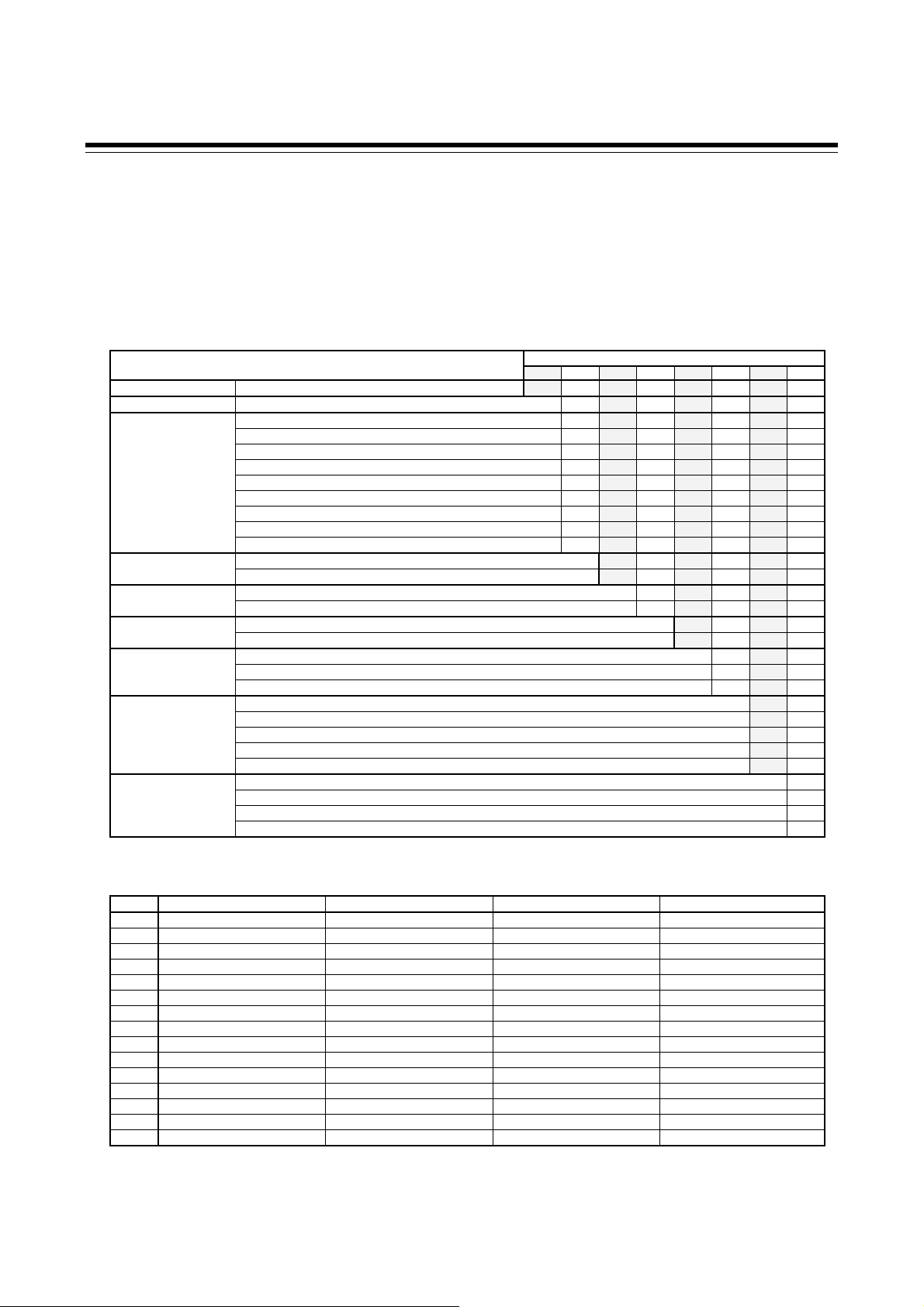

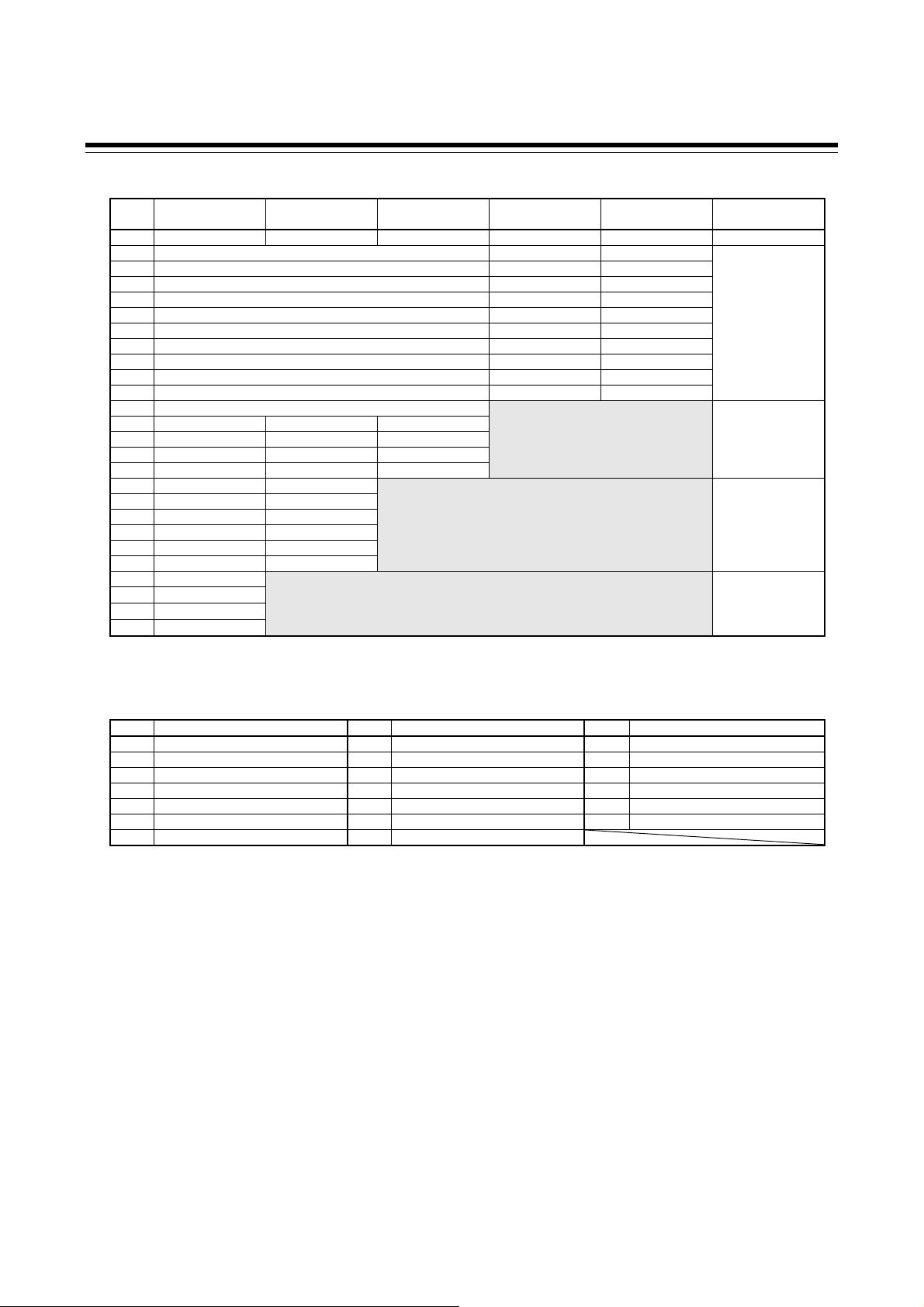

Range Code Table

[Thermocouple (TC) input, RTD input] [Voltage input, Current input]

Type Code Measured range Code Measured range Type Code Measured range

K35 200.0 to 400.0 C KC4 328.0 to 400.0 F 0 to 10 mV DC 101

K40 200.0 to 800.0 C KC6 250.0 to 800.0 F 0 to 100 mV DC 201

K41 200 to 1372 C KC5 328 to 2502 F 0 to 1 V DC 301

K K09 0.0 to 400.0 C KA4 0.0 to 800.0 F 0 to 5 V DC 401 Programmable range

K10 0.0 to 800.0 C KA1 0 to 800 F 0 to 10 V DC 501 19999 to 19999

K14 0 to 300 C KA2 0 to 1600 F 1 to 5 V DC 601 [The decimal point position is selectable]

K02 0 to 400 C 0 to 20 mA DC 701 (Factory set value: 0.0 to 100.0)

K04 0 to 800 C 4 to 20 mA DC 801

J27 200.0 to 400.0 C JC6 328.0 to 1200.0 F 100 to 100 mV DC 901

J32 200.0 to 800.0 C JC7 200.0 to 700.0 F 1 to 1 V DC 902

J15 200 to 1200 C JB9 328 to 2192 F 10 to 10 mV DC 903

J J08 0.0 to 400.0 C JB6 0.0 to 800.0 F

J09 0.0 to 800.0 C JA1 0 to 800 F

J02 0 to 400 C JA2 0 to 1600 F

J04 0 to 800 C

T T19 200.0 to 400.0 C TC2 328.0 to 752.0 F

E E21 200.0 to 700.0 C EA9 328.0 to 1292.0 F

E06 200 to 1000 C EB1 328 to 1832 F

S S06 50 to 1768 C SA7 58 to 3214 F

R R07 50 to 1768 C RA7 58 to 3214 F

B B03 0 to 1800 C BB2 0 to 3272 F

N N02 0 to 1300 C NA7 0 to 3272 F

PLII A02 0 to 1390 C AA2 0 to 2534 F

W5Re/W26Re W03 0 to 2300 C WA2 0 to 4200 F

U U04 0.0 to 600.0 C UB2 32.0 to 1112.0 F

L L04 0.0 to 900.0 C LA9 32.0 to 1652.0 F

Pt100 D34 100.00 to 100.00 C DD1 200.0 to 200.0 F

D21 200.0 to 200.0 C DC8 199.99 to 199.99 F

D35 200.0 to 850.0 C DC9 328.0 to 1562.0 F

JPt100 P29 100.00 to 100.00 C PC8 199.99 to 199.99 F

P30 200.0 to 640.0 C PC9 328.0 to 1184.0 F

PD1 200.0 to 200.0 F

1.3 Model Code

IMR01W16-E7

1-5

Page 18

1.3 Model Code

Quick start code 2 (Initial setting code)

Quick start code 2 tells the factory to ship with each parameter preset to the values detailed as

specified by the customer. Quick start code is not necessarily specified when ordering, unless the

preset is requested. These parameters are software selectable items and can be re-programmed in the

field via the manual.

□□ □□ □-□ □ □ □-□ □

(1) (2) (3) (4) (5) (6) (7) (8) (9)

Specifications

Output assignment OUT1, OUT2, DO1, DO2 (Refer to Output Assignment Code Table)

Digital input assignment DI1 to DI5 (Refer to Digital Input Assignment Code Table)

None N

Voltage input (0 to 10 mV DC) 1

Voltage input (0 to 100 mV DC) 2

Voltage input (0 to 1 V DC) 3

Remote setting input

Event function 1 (EV1)

Event function 2 (EV2)

Event function 3 (EV3)

Event function 4 (EV4)

CT type 1

Communication 1 protocol

1

If the CT type is not specified, the instrument is shipped with the CT input setting of “CTL-6-P-N.”

2

Selectable in the case of optional function codes E, F, H, and J.

Output Assignment Code Table

Code Output 1 (OUT1) Output 2 (OUT2) Digital output 1 (DO1) Digital output 2 (DO2)

01 Control output 1 Control output 2 Event output 1 (EV1) Event output 2 (EV2)

02 Control output 1 Control output 2 Event output 1 (EV1) Event output 4 (EV4)

03 Control output 1 Control output 2 Event output 1 (EV1) Heater break alarm (HBA) output

04 Control output 1 Control output 2 Event output 1 (EV1) FAIL output (De-energized)

05 Control output 1 Control output 2 Event output 4 (EV4) Heater break alarm (HBA) output

06 Control output 1 Control output 2 Event output 4 (EV4) FAIL output (De-energized)

07 Control output 1 Control output 2 Heater break alarm (HBA) output FAIL output (De-energized)

08 Control output 1 Heater break alarm (HBA) output Event output 1 (EV1) Event output 2 (EV2)

09 Control output 1 Heater break alarm (HBA) output Event output 1 (EV1) Event output 4 (EV4)

10 Control output 1 Heater break alarm (HBA) output Event output 1 (EV1) FAIL output (De-energized)

11 Control output 1 Heater break alarm (HBA) output Event output 4 (EV4) FAIL output (De-energized)

12 Control output 1 FAIL output (De-energized) Event output 1 (EV1) Event output 2 (EV2)

13 Control output 1 FAIL output (De-energized) Event output 1 (EV1) Event output 4 (EV4)

14 Control output 1 Event output 1 (EV1) Event output 2 (EV2) Event output 3 (EV3)

15 Control output 1 Event output 4 (EV4) Event output 1 (EV1) Event output 2 (EV2)

Energized/De-energized is configurable except for the FAIL output. (Factory shipment: Energized)

When Current transformer (CT) input is two-point input, Heater break alarm (HBA) output is OR output.

Invalid for a non-existing output/event function.

When used as Heat/Cool PID control, select any code of 1 to 7.

For Position proportioning PID control, output 1 (OUT1) is open-side output and output 2 (OUT2) is close-side output, regardless of the above selection.

Voltage input (0 to 5 V DC) 4

Voltage input (0 to 10 V DC) 5

Voltage input (1 to 5 V DC) 6

Current input (0 to 20 mA DC) 7

Current input (4 to 20 mA DC) 8

None N

Refer to Event Type Code Table

None N

Refer to Event Type Code Table

None N

Refer to Event Type Code Table

None N

Refer to Event Type Code Table

Control loop break alarm (LBA) 5

CT1 (none), CT2 (none) N

CT1 (CTL-6-P-N), CT2 (none) P

CT1 (CTL-12-S56-10L-N), CT2 (none) S

CT1 (CTL-6-P-N), CT2 (CTL-6-P-N) T

CT1 (CTL-12-S56-10L-N), CT2 (CTL-12-S56-10L-N) U

None N

RKC communication (ANSI X3.28-1976) 1

Modbus 2

Intercontroller communication 2 A

Quick start code 2 (Initial setting code)

(1) (2) (3) (4) (5) (6) (7) (8)

1-6

IMR01W16-E7

Page 19

Digital Input Assignment Code Table

Code

01 Unused Unused Unused Unused Unused

02 Memory area number selection (1 to 8) Memory area set RUN/STOP transfer

03 Memory area number selection (1 to 8) Memory area set Unused

04 Memory area number selection (1 to 8) Memory area set Auto/Manual transfer

05 Memory area number selection (1 to 8) Memory area set Interlock release

06 Memory area number selection (1 to 8) RUN/STOP transfer Unused

07 Memory area number selection (1 to 8) RUN/STOP transfer Auto/Manual transfer

08 Memory area number selection (1 to 8) RUN/STOP transfer Interlock release

09 Memory area number selection (1 to 8) Unused Auto/Manual transfer

10 Memory area number selection (1 to 8) Unused Interlock release

11 Memory area number selection (1 to 8) Auto/Manual transfer Interlock release

12 Memory area number selection (1 to 8)

13 RUN/STOP transfer Remote/Local transfer * Auto/Manual transfer

14 RUN/STOP transfer Remote/Local transfer * Interlock release

15 RUN/STOP transfer Auto/Manual transfer Interlock release

16 Remote/Local trans fer * Auto/Manual transfer Interlock release

17 RUN/STOP transfer Remote/Local transfer *

18 RUN/STOP transfer Auto/Manual transfer

19 RUN/STOP transfer Interlock release

20 Remote/Local trans fer * Auto/Manual transfer

21 Remote/Local tr ansfer * Interlock release

22 Auto/Manual transfer Interlock release

23 RUN/STOP transfer

24 Remote/Local tr ans fer *

25 Auto/Manual transfer

26 Interlock release

Memory area set: Switches to the memory area specified in DI1 – DI3 when the contact goes from open to closed.

Digital input 1

(DI1)

* When the optional function code A, C or D is selected, the Remote/Local transfer is invalid.

Digital input 2

(DI2)

Digital input 3

(DI3)

Digital input 4

(DI4)

Digital input 5

(DI5)

1.3 Model Code

Selectable

Optional function

A

A, E

A, B, C, D, E

A, B, C, D, E, F, J,

3, 4, 5, 6, 7, 8

Event Type Code Table

Code Type Code Type Code Type

A Deviation high H Process high V SV high

B Deviation low J Process low W SV low

C Deviation high/low K Process high with hold action 1 MV1 high [heat-side]

D Band L Process low with hold action 2 MV1 low [heat-side]

E Deviation high with hold action Q Deviation high with re-hold action 3 MV2 high [cool-side]

F Deviation low with hold action R Deviation low with re-hold action 4 MV2 low [cool-side]

G Deviation high/low with hold action T Deviation high/low with re-hold action

IMR01W16-E7

1-7

Page 20

1. OUTLINE

A

A

y

y

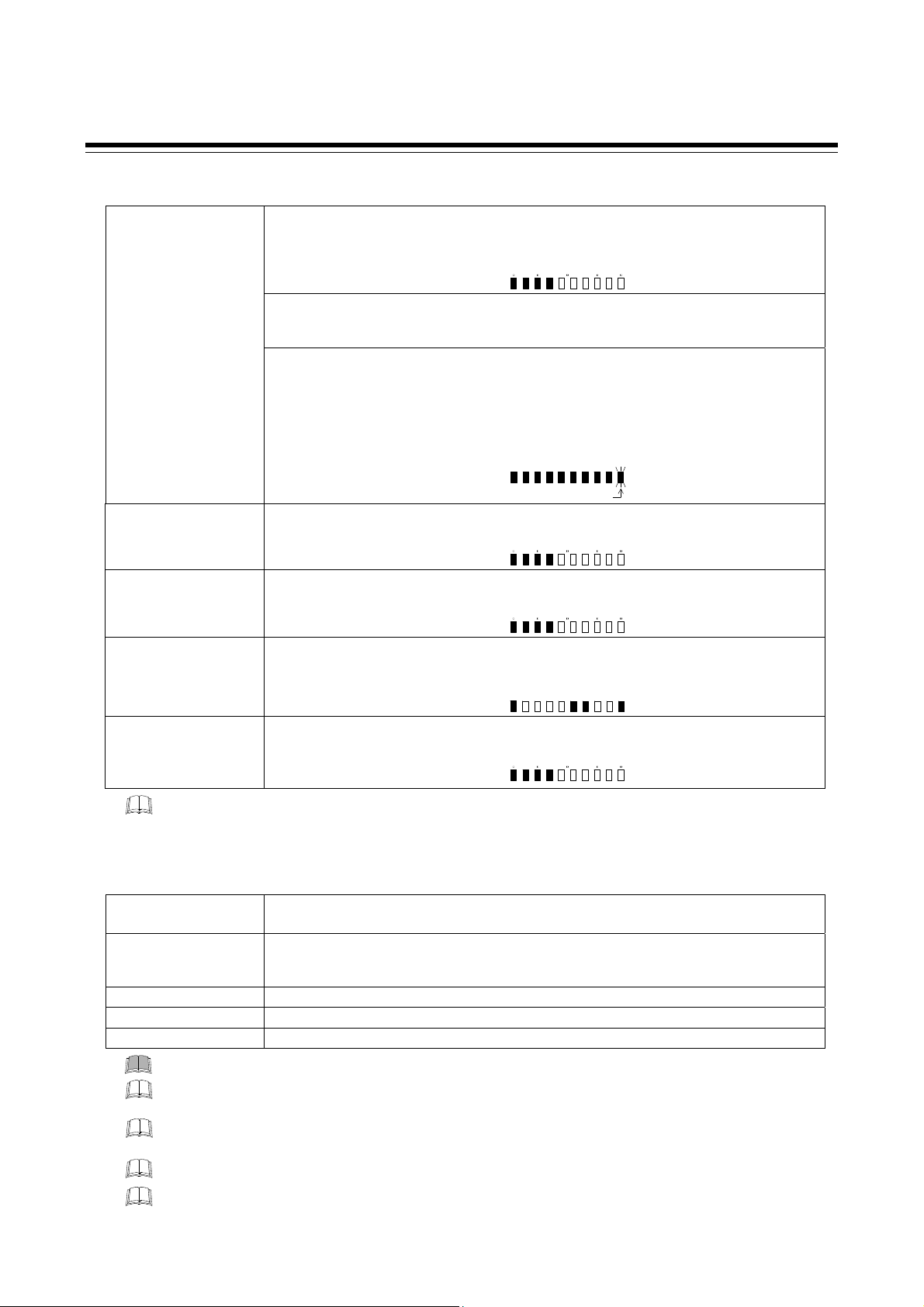

1.4 Parts Description

This section describes various display units and the key functions.

Front Panel View

Manual (MAN) mode lamp (Green)

Measured value (PV)

display

Memory area display

Manipulated output (MV)

lamp (Green)

Direct keys

Set (SET) ke

Shift ke

Display units

Measured value (PV) display [Green] Displays Measured value (PV) or various parameters’ symbols.

Remote (REM) mode lamp (Green)

utotuning (AT) lamp (Green)

Set value (SV) display

Output (OUT1, OUT2) lamp (Green)

Digital output (DO1, DO2) lamp (Green)

larm (ALM) lamp (Red)

Bar graph display

Up key

Down key

Set value (SV) display [Orange]

Memory area display [Orange] Displays memory area number (1 to 8).

Displays Set value (SV), Manipulated output value (MV) or various

parameters’ set values.

Indication lamps

Manual (MAN) mod e lamp [Green] Lights when operated in manual mode.

Remote (REM) mode lamp [Green] Lights when operated in remote mode.

Autotuning (AT) lamp [Green]

Manipulated output (MV) lamp [Green]

Output (OUT1, OUT2) lamp [Green] Lights when the output corresponding to each lamp is ON.

Digital output (DO1, DO2) lamp [Green] Lights when the output corresponding to each lamp is ON.

Alarm (ALM) lamp [Red]

These lamps work with event outputs (event function, HBA function, LBA function) which are assigned to OUT, DO

and ALM.

Flashes when Autotuning is activated.

(After autotuning is completed: AT lamp will go out)

Lights when operated in Manual mode. In this case, the Set value (SV) display

shows the Manipulated output value (MV).

Lamp indication becomes as follows for current output or voltage output:

For an output of less than 0 %: Extinguished

For an output of more than 0 % but less than 100 %: Dimly lit

For an output of more than 100 %: Lit

Lights when alarm (Event or Heater break alarm [HBA]) is turned ON.

The type of alarm which is on can be checked on the event monitor screen.

1-8 IMR01W16-E7

Page 21

0

Bar graph display [Green]

Manipulated output

values (MV1, MV2)

[Factory set value]

Heat/Cool PID control:

Position proportioning PID control:

Measured value (PV)

Displays the Manipulated output value (MV) [In the case of Position proportioning PID control,

refer to below.]. When Manipulated output value (MV) is at 0 % or less, the left-end dot of the

bar-graph flashes. When MV exceeds 100 %, the right-end dot flashes.

When both OUT1 and OUT2 light, this means overlapping, but in this case the bar graph

displays only the Manipulated output value (MV1) [heat-side].

[With FBR input]

Displays the FBR input value (0.0 to 100.0 %).

[Without FBR input]

Cannot be used as a bar graph. The bar graph displays the over-scaled state (an output of more

than 100 %). In this case, it is recommended to be set to “No display.”

Displays the Measured value (PV). Scaling is available within the input range (Input scale low to

Input scale high).

[Example]

[Example]

[Example]

050

050

Flashing

050

1.4 Parts Description

100

100

100

Set value (SV) monitor

Displays the Set value (SV). Scaling is available within the input range (Input scale low to Input

scale high). Remote mode: Displays the remote setting value.

100

Deviation value

[Example]

050

Displays the deviation between the Measured value (PV) and the Set value (SV). When the

Deviation display is selected, the dots at both ends of bar-graph light. A display resolution per

dot is settable. (Bar graph display resolution: Refer to P. 7-68)

[Example]

Current transformer 1

(CT1) input value

Current transformer 2

(CT2) input value

Displays the input value (current value) of CT1 or CT2. (Unit: A)

A display resolution per dot is settable. (Bar graph display resolution: Refer to P. 7-68)

[Example]

050

100

The factory set value of the bar graph is “Manipulated output value.” Bar graph display type can be changed by the

bar graph in the Engineering mode. (Refer to P. 7-66)

Direct keys

Pressing a direct key causes one of the operation changes below.

Auto/Manual transfer

[Factory set value]

Monitor

Memory area transfer Pressing the direct key changes to Memory area transfer screen.

Remote/Local transfer Switching the Remote/Local control mode between Remote mode and Local mode.

RUN/STOP transfer Switching the RUN/STOP mode between RUN and STOP status.

To avoid damage to the instrument, never use a sharp object to press keys.

The factory default setting is Auto/Manual transfer. The Direct key type can be set in “Direct key type” (P. 7-70)

of Engineering mode.

When the Direct key type is “Monitor”, the display of SV setting & monitor mode and the Direct key display are

different from the other types. (Refer to P. 5-4)

Use/Unused of Direct key functions is programmable. (Refer to P. 7-70)

To prevent operator error, a Direct key cannot be operated in positioning adjustment (automatic adjustment).

Switching the Auto/Manual control mode between Auto mode and Manual mode.

Use to switch the monitor screen. Pressing the direct key while any screen other than the SV

setting & monitor mode screen is being displayed returns to the Measured value (PV)/Set value

(SV) monitor screen.

IMR01W16-E7

1-9

Page 22

1.4 Parts Description

Operation keys

Set (SET) key Used for parameter calling up and set value registration.

Shift key Shift digits when settings are changed. Used to selection operation between modes.

Down key

Up key

To avoid damage to the instrument, never use a sharp object to press keys.

Bottom View

Use our communication converter COM-K (sold separately) to connect FB100 and personal

computer. Then, the cable (cable length: 1.5 meters) for connection between FB100 and our

communication converter COM-K is optional.

Side view

Decrease numerals.

Keeping pressing the DOWN key makes numeric value change faster. (Manual mode)

Increase numerals.

Keeping pressing the UP key makes numeric value change faster. (Manual mode)

Loader communication connector (Standard equipment)

1-10

Input select switch

Dip switch is used for the switching of the measured input type and

the remote setting input type.

Current input,

Voltage (low) input

To change the input type, refer to Input type (P. 7-71), Remote setting input type (P. 7-79)

For the remote setting input

For the measured input

Voltage (high) input

in the Engineering mode.

IMR01W16-E7

Page 23

1. OUTLINE

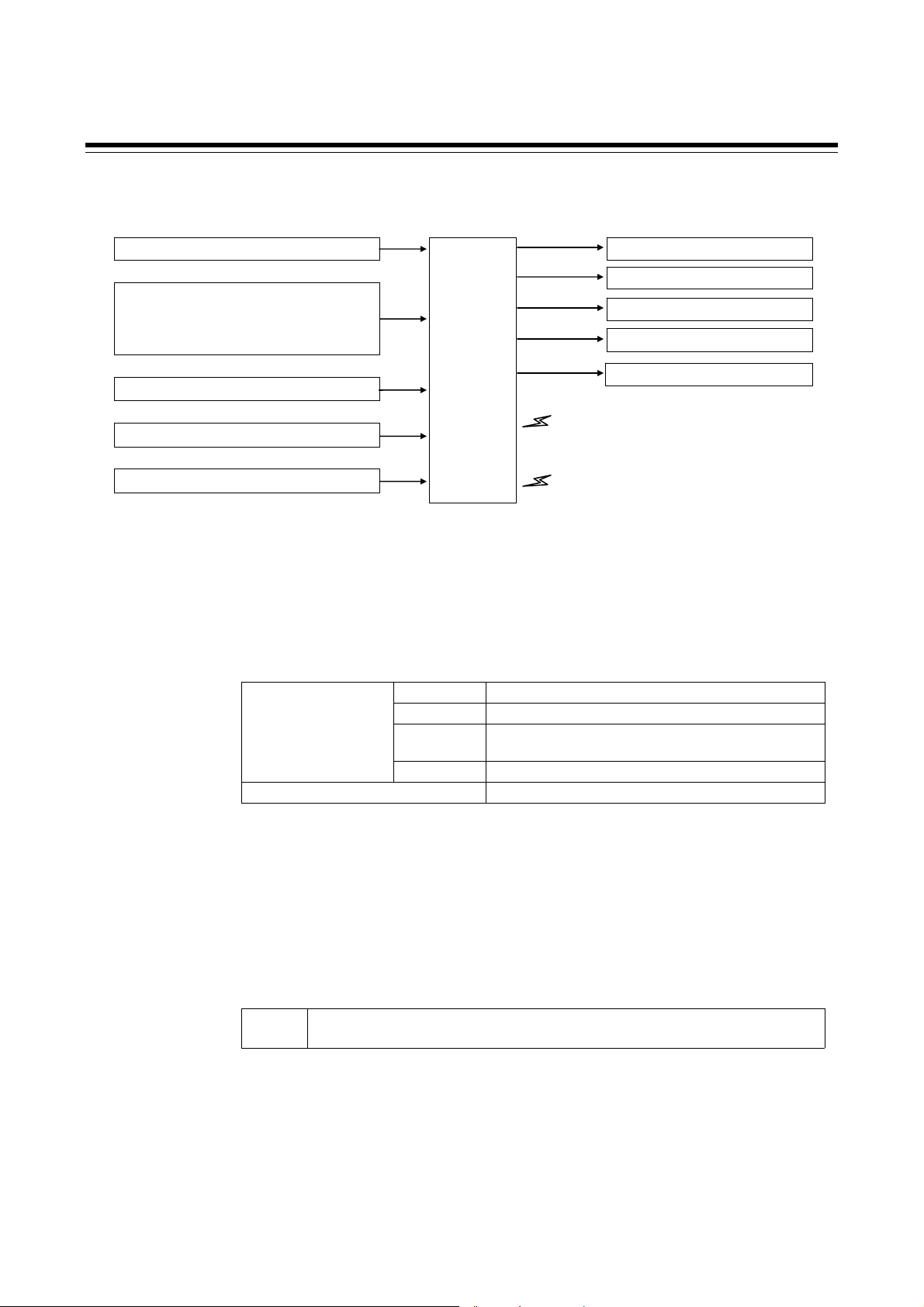

1.5 Input/Output Functions

This section describes the Input/Output functions of the instrument. To learn how to set each function,

refer to the respective page.

Measured input

Digital input DI1 to DI5 [optional]

(Memory area selection, Area set, RUN/STOP,

Remote/Local transfer, Auto/Manual transfer,

Interlock release)

Remote setting (RS) input [optional]

Current transformer (CT) input [optional]

Feedback resistance (FBR) input [optional]

Control

section

COM1 (RKC communication, Modbus, Intercontroller

COM2 (Intercontroller communication) [optional]

Loader communication

Control output 1 (Heat-side/Open-side)

Control output 2 (Cool-side/Close-side)

Output of event function

Heater break alarm output

Transmission output (AO) [optional]

communication *) [optional]

* Can only be selected when one-point

communication is used on the FB100.

Input On the FB100, Measured input, Digital input (DI), Remote setting (RS) input,

Current transformer (CT) input, and Feedback resistance (FBR) input can be used.

Measured input [universal input]:

Input groups available for measured inputs are shown in the table below. (P. 7-71)

Thermocouple K, J, E, T, S, R, B, N, PLII, W5Re/W26Re, U, L

Voltage (low) input

group

Voltage (high) input group

[Factory set value: Thermocouple K (When quick start code “N” is specified)

RTD Pt100, JPt100

Voltage (low) 0 to 1 V DC, 0 to 100 mV DC, 0 to 10 mV DC,

100 to 100 mV DC, 10 to 10 mV DC

Current 0 to 20 mA DC, 4 to 20 mA DC

1 to 1 V DC, 0 to 5 V DC, 1 to 5 V DC, 0 to 10 V DC

When the input type is changed, be sure to check the details of setting of the input

group transfer and the input type selection by the input select switch. (P. 7-71)

Digital input [DI1 to DI5] (optional)

Digital input (contact input signal from the external devices) can be used for the

following functions.

DI1 to 5

Memory area selection (number of area: 1 to 8) Area set, RUN/STOP, Remote/Local

transfer, Auto/Manual transfer, Interlock release

For function assignment to the digital input, set the Digital input (DI) assignment

(P. 7-80) in the Engineering mode.

IMR01W16-E7 1-11

Page 24

1.5 Input/Output Functions

Remote setting (RS) input [universal input] (optional)

Remote input is to change a control set point by using current or voltage input from

an external device.

Measured input is not isolated from Remote setting (RS) input.

Input groups available for Remote setting (RS) inputs are shown in the table below.

(P. 7-79)

Voltage (low) input and Current input

group

Voltage (low) input group

[Factory set value: Depend on model code]

0 to 100 mV DC, 0 to 10 mV DC, 0 to 1 V DC

0 to 20 mA DC, 4 to 20 mA DC

0 to 5 V DC, 1 to 5 V DC, 0 to 10 V DC

When using the Intercontroller communication (only slave controller of cascade

control and ratio setting), the Remote setting (RS) input function becomes invalid.

Current transformer (CT) input (optional)

CT input is used for Heater break alarm function to detect a heater break or

short-circuit.

Up to two CT inputs can be selected. (Specify when ordering)

Two types of CT available.

CTL-6-P-N (for 0 to 30 A)

CTL-12-S56-10L-N (for 0 to 100 A)

Measured input is not isolated from CT input.

If there is CT input, power frequency is automatically set by the power frequency

detection function. However, no frequency may be able to be detected if at a CT

value of less than 0.5 A.

Feedback resistance (FBR) input (optional)

When the control type is the Position proportioning PID control (with FBR input),

a valve position from the control motor can be inputted to feedback resistance.

Measured input is not isolated from Feedback resistance (FBR) input.

Feedback resistance (FBR) input cannot be used with Current transformer (CT)

input, Remote setting (RS) input and communication.

1-12

IMR01W16-E7

Page 25

1.5 Input/Output Functions

Output Up to five outputs are available. They may be used as Control output

(OUT), Digital output (DO) or Transmission output (AO) by specifying

the output type or by activating the output assignment function.

Output 1 (OUT1), Output 2 (OUT2)

The following output functions can be assigned to OUT1 and/or OUT2 at the

output assignment of the Engineering mode (P. 7-82):

- Control output,

- Heater break alarm output, or

- FAIL (De-energized fixed: contact opens under FAIL)

For Heat/Cool PID control, OUT1 corresponds to the heat-side output and OUT2

corresponds to the cool-side output.

For Position proportioning PID control, OUT1 corresponds to the open-side output

and OUT2 corresponds to the close-side output.

Output types available for OUT1 and OUT2 are shown in the table below.

(Specify when ordering)

Relay contact output 250 V AC 3 A (Resistive load), 30 V DC 1 A (Resistive load), 1a contact

Voltage pulse output 0/12 V DC (Allowable load resistance: 600 or more)

Voltage output 0 to 5 V DC, 1 to 5 V DC, 0 to 10 V DC (Allowable load resistance: 1 k or more)

Current output 0 to 20 mA DC, 4 to 20 mA DC (Allowable load resistance: 600 or less)

Triac output 0.5 A (Allowable load current)

Open collector output 30 V DC or less, 100 mA (Allowable load current), Sink type

There is not isolation between OUT1 and OUT2.

When OUT1 and OUT2 can be used for relay contact output or triac output, there

is isolation between each output (OUT1, OUT2, AO).

Digital output 1, 2 (DO1, DO2)

The following output functions can be assigned to DO1 through DO4 at the output

assignment of the Engineering mode (P. 7-82):

- Output of event function,

- Heater break alarm output, or

- FAIL (De-energized fixed: contact opens under FAIL)

The output type for DO1 and DO2 is relay only. (Specify when ordering)

Relay contact output 250 V AC 1 A (Resistive load), 30 V DC 1 A (Resistive load), 1a contact

Transmission output (AO) [optional]

Output types available for transmission output are shown in the table below.

(Specify when ordering)

Voltage output 0 to 1 V DC, 0 to 5 V DC, 1 to 5 V DC, 0 to 10 V DC

Current output 0 to 20 mA DC, 4 to 20 mA DC (Allowable load resistance: 600 or less)

Parameter values shown in the following table can be output by Transmission

output (P. 7-86). These transmission output data can be output after being scaled.

Measured value (PV) Set value (SV) monitor Deviation value

Manipulated output value (MV1)

[heat-side]

Remote setting (RS) input value

Number of output: 1 point

(Allowable load resistance: 1 k or more)

Manipulated output value (MV2)

[cool-side]

Set value (SV)

IMR01W16-E7

1-13

Page 26

1.5 Input/Output Functions

Communication

Communication 1 (optional)

In this case of one-point communication, Host communication or Intercontroller

communication can be selected. (This can be specified when the order is placed.)

In this case of two-point communication, this will be for Host communication.

Communication protocol is used for RKC communication (ANSI X3.28-1976) or

Modbus. (Specify when ordering)

With Intercontroller communication, data can be exchanged between multiple

FB100/400/900 instruments without using analog signals such as Remote setting

input or Transmission output, or communication with a host computer. (Refer to

P. 6-61)

Communication Interface:

The following four functions become usable when the Intercontroller

communication is used.

Automatic temperature rise function (with learning function)

Cascade control function

Ratio setting function

Group RUN/STOP function

For details of the Host communication, refer to the separate FB100/FB400/

FB900 Communication Instruction Manual (IMR01W04-E).

Communication 2 (optional)

This can be used only for two-point communication.

Communication 2 (COM2) is used for the Intercontroller communication. Data can

be exchanged between two or more FB100s/400s/900s without using

communication with analog signals such as Remote setting input and Analog

output as well as with the host computer. (Refer to P. 6-61.)

Interface: RS-485 only

The following four functions become usable when the Intercontroller

communication is used.

Automatic temperature rise function (with learning function)

Cascade control function

Ratio setting function

Group RUN/STOP function

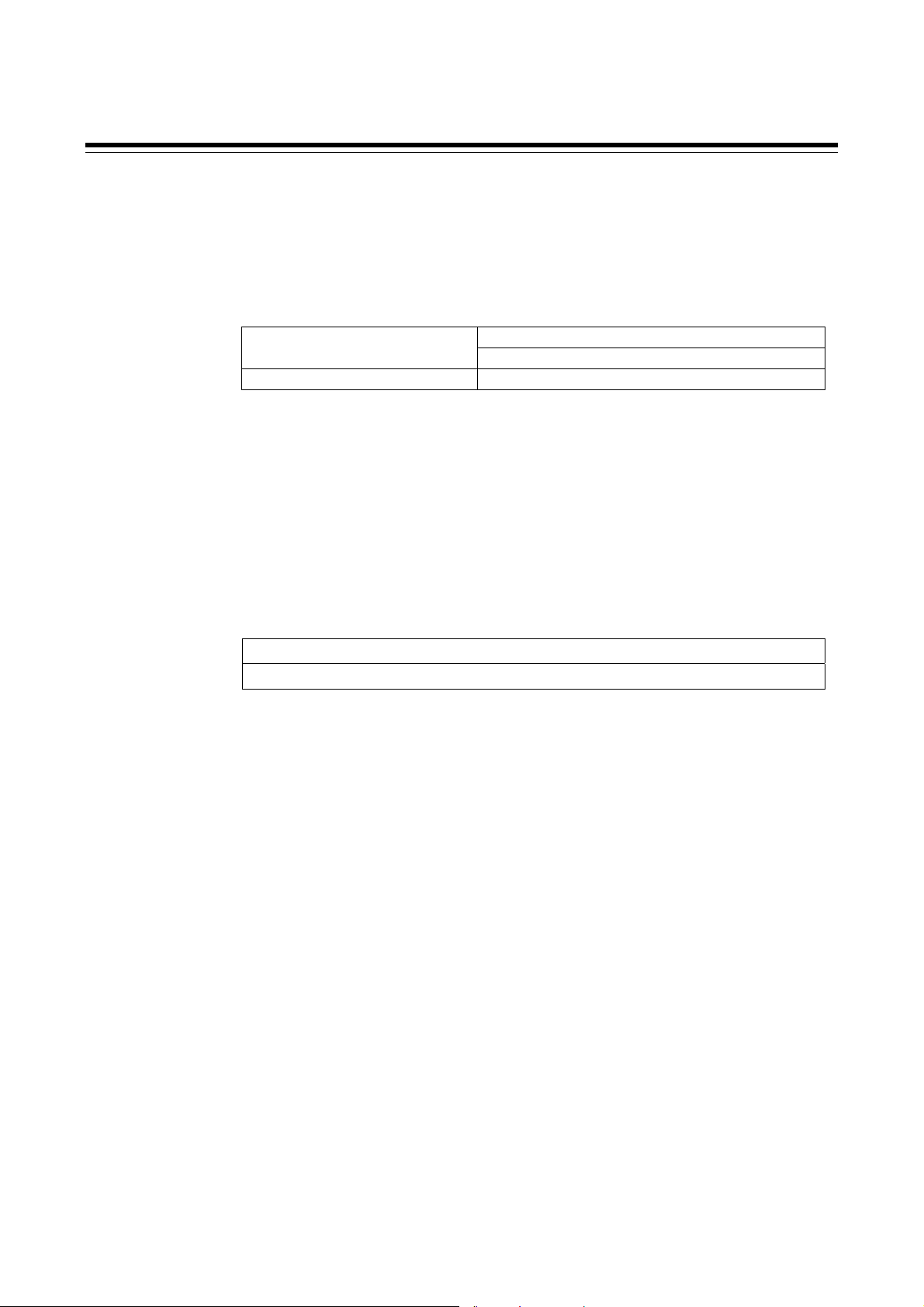

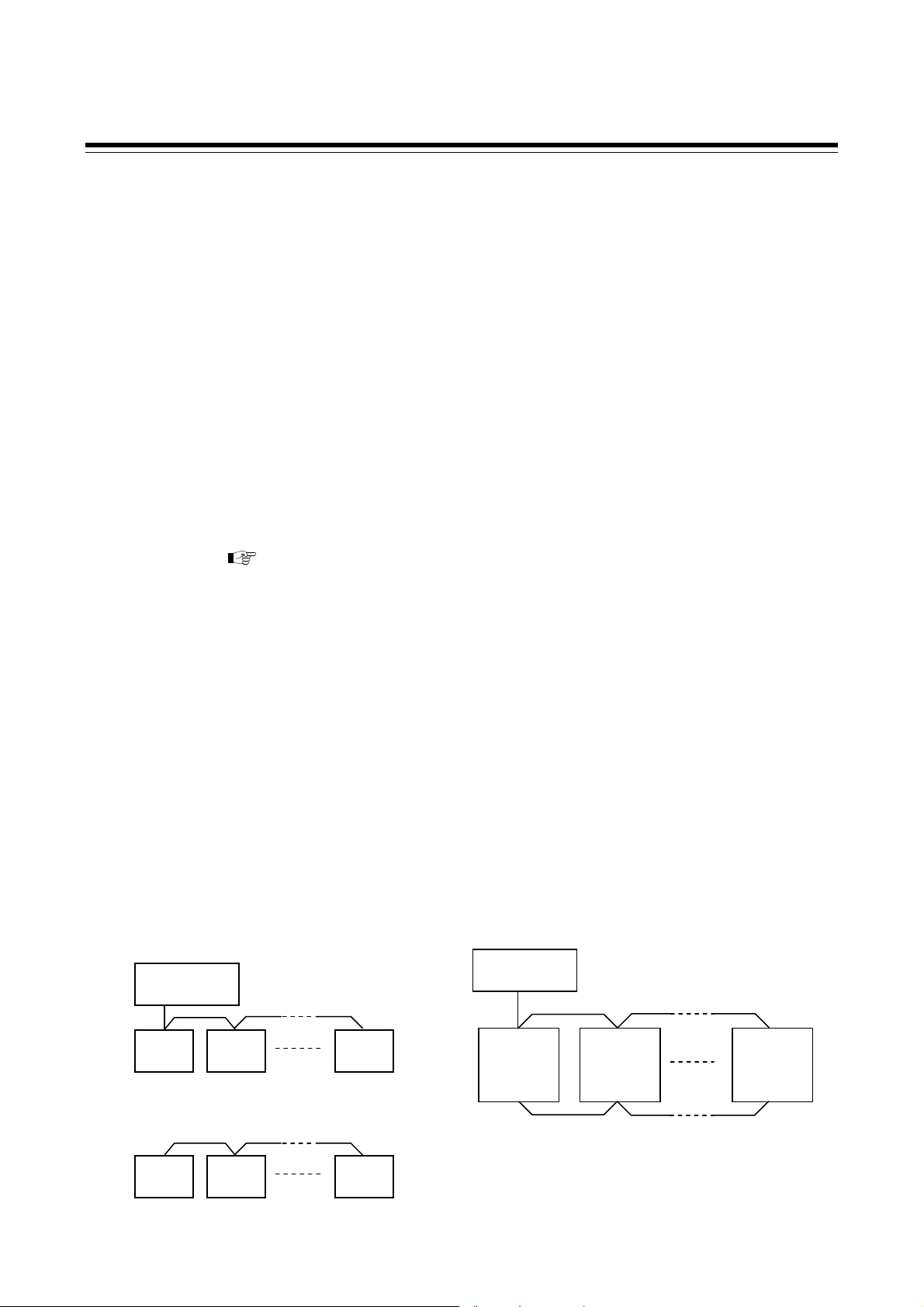

[Connection example]

When one-point communication is used When two-point communication is used

Host communication

Host

computer

FB100

COM1

FB100

COM1

FB100

COM1

Intercontroller communication

or

FB100

COM1

FB100

COM1

FB100

COM1

RS-485 only

Host

computer

COM1

FB100

COM2

Host communication

COM1

FB100

COM2

Intercontroller communication

(Cascade control, etc.)

COM1

FB100

COM2

1-14

IMR01W16-E7

Page 27

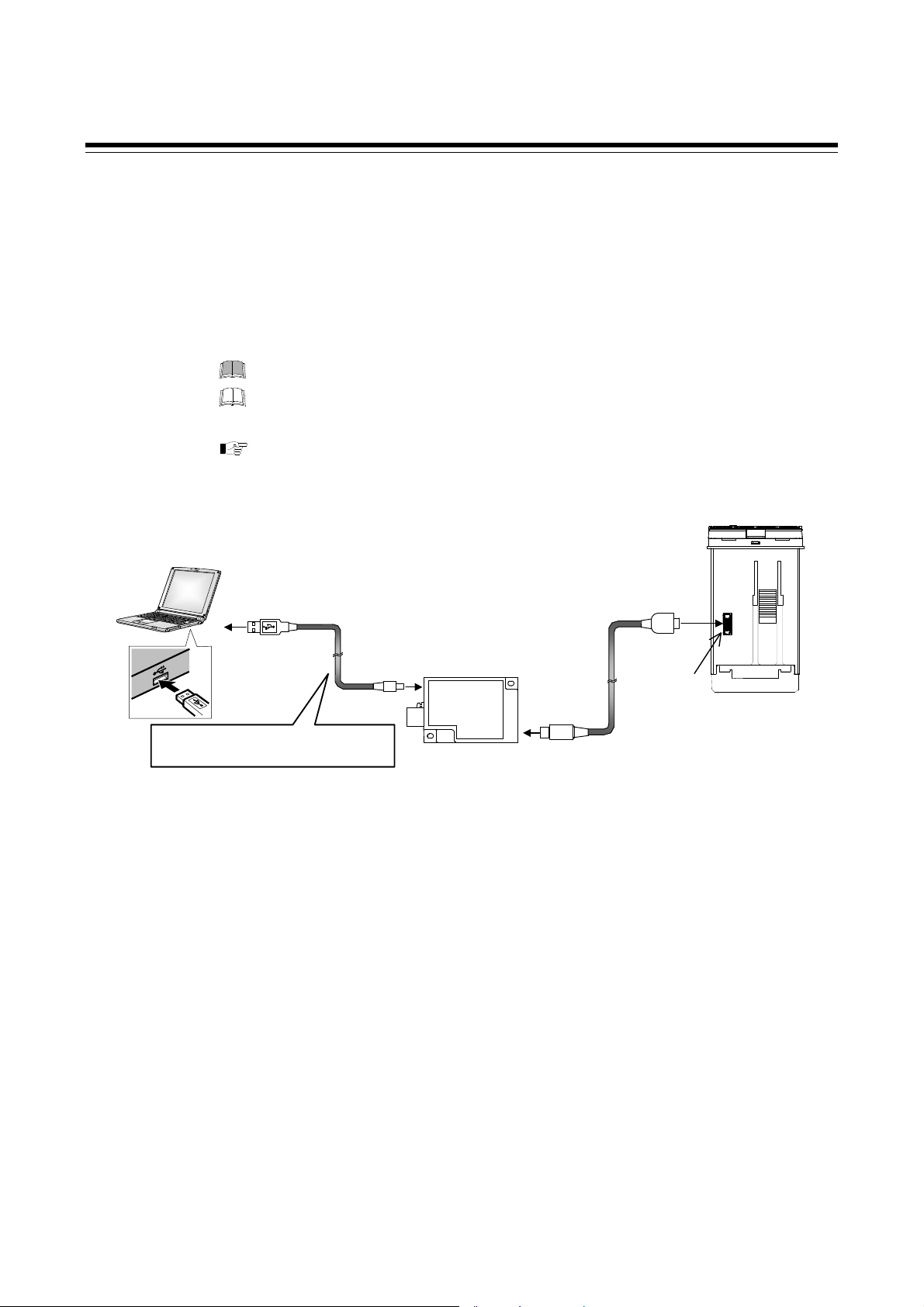

Loader communication

It is possible to manage data on the personal computer side by converting all of the

data in the FB100 into one file.

1

When starting the Loader communication, first your PC (Windows 2000/XP/

Vista/7) being used is necessary to be installed with the communication tool

http://www.rkcinst.com/.

1

Use our communication converter COM-K (sold separately) to connect FB100 and your PC.

2

The communication tool (WinUCI, PROTEM2) can be downloaded from the RKC official website:

The Loader port is only for parameter setup.

The Loader communication corresponds to the RKC communication protocol

“Based on ANSI X3.28-1976 subcategories 2.5 and A4.”

For the COM-K, refer to the COM-K Instruction Manual (IMR01Z01-E).

[Connection example]

1.5 Input/Output Functions

2

.

USB cable 1 m

(COM-K accessory)

Connected to USB

port of a personal

computer

Do not unplug the USB cable while the

power to the instrument is ON.

Communication m onitor tool WinUCI-A

Software operation environment: Windows 2000 or higher

Communication setup tool WinUCI -B for FB series

Software operation environment: Windows 2000 or higher

Communication tool PROTEM2

Software operation environment: Windows XP (Service Pack 2) or higher

PROTEM2 needs Microsoft .NET Framework 4.0 or later

Communication port of host computer

USB port: Based on USB Ver. 2.0

Communication settings on t he computer

(Values other than the communi c ation port are fixed.)

Communication speed: 38400 bps

Start bit: 1

Data bit: 8

Parity bit: Without

Stop bit: 1

Connected to

USB connecter

USB

communication

converter

COM-K

Connected to loader

communication

connector of the

FB100

Loader

communication cable

1.5 m (W-BV-01)

[COM-K optional]

Connected to loader

communication

connecter

Loader

communication

connector

The device address for

Loader communication is

fixed at “0.”

The setting of the device

address is disregarded.

FB100 bottom view

IMR01W16-E7

1-15

Page 28

MEMO

1-16 IMR01W16-E7

Page 29

HANDLING

PROCEDURE TO

OPERATION

IMR01W16-E7 2-1

Page 30

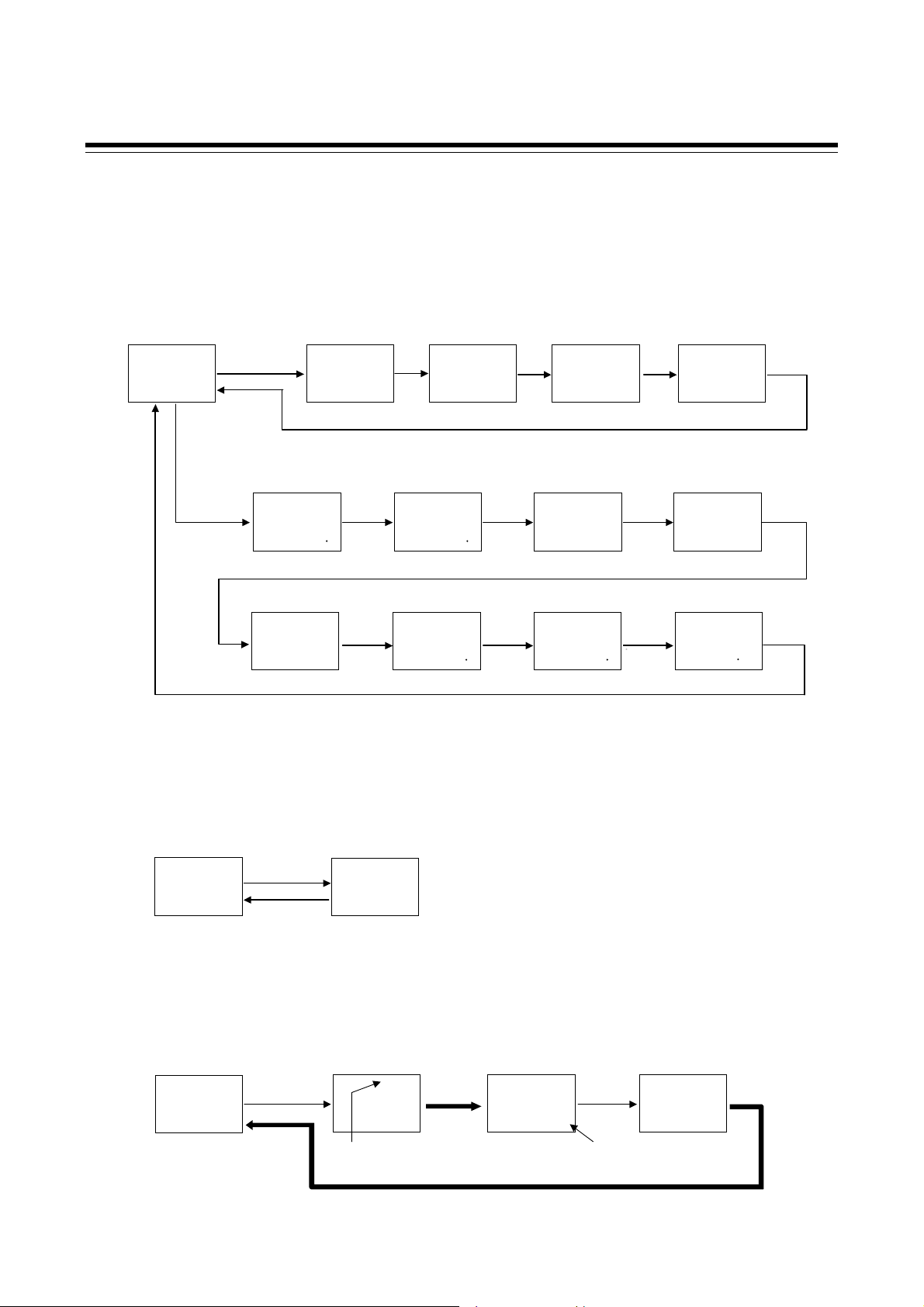

2. HANDLING PROCEDURE TO OPERATION

r

2. HANDLING PROCEDURE TO OPERATION

This chapter describes procedures to set operating conditions of a customer and parameter of various

setting modes.

Setting procedure to operation

Conduct necessary setting before operation according to the procedure described below.

Mounting and Wiring

When installing the instrument,

refer to 3. MOUNTING (P. 3-1) and

4. WIRING (P. 4-1).

When group operation by using Intercontrolle

communication is performed, refer to 6.14.1 Wiring

method of the Intercontroller communication

(P. 6-61).

Power ON

Change from RUN to STOP

The parameters in Engineering mode which should be set according to the application

are settable only when the controller is in STOP mode.

Setting of operating condition

(Engineering mode)

The parameters for controller’s basic functions in Engineering mode should be changed

according to the application before setting the parameters related to operation.

Be sure to check the parameters for the following settings and change them according to the

application if necessary. Other parameters should be also changed according to the application.

Power frequency [Factory set value 50Hz] (P. 7-78) Remote setting input type (P. 7-79) 2

Input type (P. 7-71)

Input scale high/low (P. 7-74)

Control action (P. 7-125)

Output assignment (P. 7-82)

1

This setting is not necessary when the quick start code "1" is specified.

2

This setting is not necessary when the quick start code "2" is specified.

3

This setting is not necessary when the quick start code "N" is specified.

When group operation by using Intercontroller communication is performed, set the

following setting items.

Digital input (DI) assignment (P. 7-80) 1 Automatic temperature rise group (P. 7-159) 4

External input type (P. 7-121)

Master channel selection (P. 7-122)

1

Group RUN/STOP function (P.6-64)

2

Cascade control function (P. 6-81)

Refer to 7.5. Engineering Mode (P. 7-52).

A

Entry to data sheet

Use the sheet of Appendix E,

and make record of setting

data of a customer.

Change from RUN mode to STOP mode with the RUN/STOP transfer. (P. 6-11)

Factory set value: RUN (control start)

1, 2

Event type (P. 7-88, 7-97, 7-101, 7-105)

1, 2

Transmission output type (P. 7-86) 3

1, 2

Communication protocol (P. 7-162) 3

1, 2

2, 3

RUN/STOP group (P. 7-160)

2, 3

3

Ratio setting function (P. 6-89)

4

Automatic temperature rise func tion (P. 6-72)

1, 4

2, 3

2-2 IMR01W16-E7

Page 31

2. HANDLING PROCEDURE TO OPERATION

n

e

a

A

Control action type?

Position proportioning PID control

PID control or

Heat/Cool PID control

Adjustment of the valve position

For details, refer to

page 6-43.

Setup data setting

(Setup setting mode)

Set parameters in Setup setting mode:

Heater break alarm relationships (optional),

Input correction relationships,

Communication (optional), etc.

Refer to 7.4 Setup Setting Mode

(P. 7-37).

To perform group operation by using Intercontroller communication

Set the Device address, RS

bias*, RS digital filter* and RS

ratio*.

* These parameter settings are also used for

Cascade control function (P. 6-81) and

Ratio setting function (P. 6-89).

Adjust the above parameter setting values

when finely adjustment is required.

For details, refer to

page 6-61.

Parameter data setting

To perform Ramp/Soak operation

Set parameters in Parameter setting mode:

Event function relationships,

PID and control response, etc.

Up to 8 individual sets of parameters i

Parameter setting mode and SVs can b

stored and used in Multi-memory are

function.

Refer to 7.3 Parameter Setting Mode (P. 7-22).

Set the Setting change rate

limiter, Area soak time and

Link area number.

For details, refer to

page 6-52.

Set value (SV) setting

Set the control set value (SV) which is target value of the control (refer to page 6-5).

The Set value (SV) can be stored up to 8 areas in Multi-memory area function as well as

parameters in Parameter setting mode.

B

IMR01W16-E7

2-3

Page 32

2. HANDLING PROCEDURE TO OPERATION

g

B

Is Multi-memory Area *

function used?

Yes

* Factory set value: Memory area 1

No

Control Memory Area selection

Select the Memory area in SV setting & monitor mode.

For details of memory area selection, refer to 6.9 Control Area

Transfer (P. 6-33).

Tuning type?

Startup tuning (ST)

Autotuning (AT)

[Change from STOP mode to RUN mode with the RUN/STOP transfer (P. 6-11). Operation starts as soon as

the RUN/STOP mode is changed to RUN mode.]

Change from STOP to RUN

Change from PID to AT

(Operation mode: PID/AT transfer)

Change from “oFF (PID)” to “on (AT)”

with the PID/AT transfer (P. 7-15).

AT starts as soon as the PID/AT transfer

ed to “on.”

is chan

ST type setting

(Operation mode: STU)

(P. 6-18)

AT end

When the autotuning is finished,

the controller will automatically

returns to PID control.

ST end

When the startup tuning is finished,

the controller will automatically

returns to PID control.

Operation *

* Adjust the PID constants manually when the optimum PID constants cannot be computed by Autotuning for characteristic

variations of the controlled system (refer to page 6-9).

2-4

IMR01W16-E7

Page 33

MOUNTING

3.1 Mounting Cautions. ........................................................................... 3-2

3.2 Dimensions ....................................................................................... 3-3

3.3 Procedures of Mounting and Removing ............................................ 3-4

IMR01W16-E7 3-1

Page 34

3. MOUNTING

3.1 Mounting Cautions

This chapter describes installation environment, mounting cautions, dimensions and mounting

procedures.

To prevent electric shock or instrument failure, always turn off the power before

mounting or removing the instrument.

(1) This instrument is intended to be used under the following environmental conditions. (IEC61010-1)

[OVERVOLTAGE CATEGORY II, POLLUTION DEGREE 2]

(2) Use this instrument within the following environment conditions:

Allowable ambient temperature: 10 to 50 C

Allowable ambient humidity: 5 to 95 %RH

(Absolute humidity: MAX. W. C 29.3 g/m

Installation environment conditions: Indoor use

Altitude up to 2000 m

WARNING

!

3

dry air at 101.3 kPa)

(3) Avoid the following conditions when selecting the mounting location:

Rapid changes in ambient temperature which may cause condensation.

Corrosive or inflammable gases.

Direct vibration or shock to the mainframe.

Water, oil, chemicals, vapor or steam splashes.

Excessive dust, salt or iron particles.

Excessive induction noise, static electricity, magnetic fields or noise.

Direct air flow from an air conditioner.

Exposure to direct sunlight.

Excessive heat accumulation.

(4) Mount this instrument in the panel considering the following conditions:

Provide adequate ventilation space so that heat does not build up.

Do not mount this instrument directly above equipment that generates large amount of heat (heaters,

transformers, semi-conductor functional devices, large-wattage resistors.)

If the ambient temperature rises above 50 C, cool this instrument with a forced air fan, cooler, etc.

Cooled air should not blow directly on this instrument.

In order to improve safety and the immunity to withstand noise, mount this instrument as far away as

possible from high voltage equipment, power lines, and rotating machinery.

High voltage equipment: Do not mount within the same panel.

Power lines: Separate at least 200 mm.

Rotating machinery: Separate as far as possible.

Mount this instrument in the horizontal direction for panel. If you did installation except a horizontal

direction, this causes malfunction.

(5) If this instrument is permanently connected to equipment, it is important to include a switch or