Page 1

DeviceNet Communication Converter

A

M

-JH

t

Communication

CO

ll Rights Reserved, Copyright 2007, RKC INSTRUMENT INC.

[For SRZ]

Data Lis

IMR01Y32-E1

This manual describes the communication data of the COM-JH. For the installation, the

detail handling procedures and various function settings, please refer to the following

separate manuals.

• COM-JH [For SRZ] Installation Manual (IMR01Y24-E): Enclosed with COM-JH

• COM-JH [For SRZ] Quick Instruction Manual (IMR01Y28-E): Enclosed with COM-JH

• COM-JH [For SRZ] Instruction Manual (IMR01Y36-E): Separate

(Download or sold separately)

The above manuals can be downloaded from our website:

URL: http://www.rkcinst.com/english/manual_load.htm

1. USAGE OF COMMUNICATION DATA ITEMS

“Communication items,” the “Number of communication controllers” and the “Number of

communication words” necessary for polling I/O communication are set via Explicit message

communication or using the configuration tool.

Communication items

The measured data item (IN) and setting data item (OUT) communicating via polling I/O

communication set the attribute ID, “Controller object (0x64: 64Hex, 0x65: 65Hex, 0x66:

66Hex)” to object instance 1 corresponding to the device profile, “Controller communication

item setting object (0xC7: C7Hex).”

Number of communication controllers

The number of communication controllers means the number of controllers connected to the

COM-JH.

The number of communication controllers is set to attribute ID: 236 of the Z-TIO module

object (0x64: 64Hex).

Number of communication words

The number of communication words means the number of words corresponding to the

measured data item (IN) and setting data item (OUT) communicating via polling I/O

communication.

The number of communication words is set to attribute ID: 240 [Measured data item (IN)]

and 241 [Setting data item (OUT)] of the Z-TIO module object (0x64: 64Hex)

The number of communication words can be calculated from the following equation.

Number of communication words

For Explicit message communication and the configuration tool, see COM-JH

[For SRZ] Instruction Manual (IMR01Y36-E).

For “Controller communication item setting object (0xC7: C7Hex)” and “Controller

object (0x64: 64Hex, 0x65: 65Hex, 0x66: 66Hex),” see 3. DEVICE PROFILES

and the COM-JH [For SRZ] Instruction Manual (IMR01Y36-E).

The number of communication controllers can be set even by the communication

environment setting made by the COM-JH rotary switch.

• For details of the number of communication controllers, see COM-JH [For

SRZ] Instruction Manual (IMR01Y36-E).

• For communication environment setting made by the rotary switch, see

COM-JH [For SRZ] Quick Instruction Manual (IMR01Y28-E).

= (Number of words of first communication item for one module

+ Number of words of next communication item for one module

• • •

+ Number of words of last communication item for one module)

× Number of communication controllers + Fixed communication date items: 5 words *

* Measured data items (IN)

Receive counter: 1 word, Alarm state: 2 words, RUN/STOP state: 2 words

Setting data items (OUT)

Setting state selection: 3 words, RUN/STOP transfer: 2 words

The number of communication words can be set even by the communication

environment setting made by the COM-JH rotary switch.

• For details of the number of communication words, see COM-JH [For SRZ]

Instruction Manual (IMR01Y36-E).

• For communication environment setting made by the rotary switch and fixed

communication data items, see COM-JH [For SRZ] Quick Instruction

Manual (IMR01Y28-E).

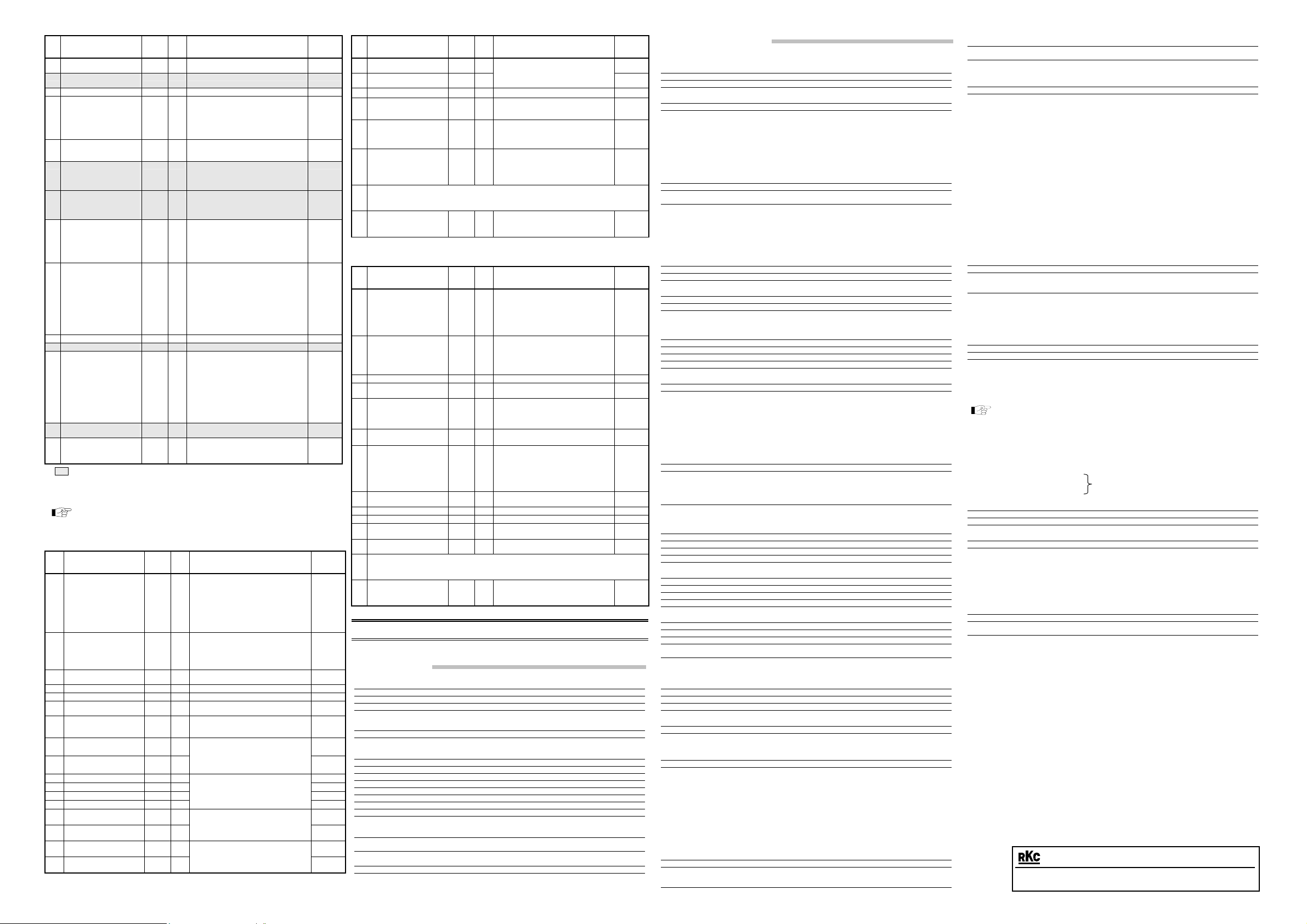

2. CONTROLLER OBJECT DATA ITEMS

The controller objects consist of the three types below. The content of each object is

indicated by the order of the attribute IDs.

• Z-TIO module object (0x64: 64Hex)

• Z-TIO module extended object (0x65: 65Hex)

• Z-DIO module object (0x66: 66Hex)

• ID: Attribute ID

• Number of data items: 1: Only object instance 1 is valid

2: Only object instance 1 and 2 are valid

16: Valid for object instance 1 to 16

31: Valid for object instance 1 to 31

64: Valid for object instance 1 to 64

128: Valid for object instance 1 to 128

• Attribute: RO: Only reading data is possible (Get: Yes, Set: No)

R/W: Reading and writing data is possible (Get: Yes, Set: Yes)

• Data range: For 16-bit data

For details of data item, see COM-JH [For SRZ] Instruction Manual

(IMR01Y36-E).

Z-TIO Module Object (0x64: 64Hex)

ID Name

1 Measured value (PV) 64 RO Input scale low to Input scale high

2 Current transformer (CT)

input value monitor

3 Unused

4 Set va lue (SV) mo nitor 64 RO Setting limiter (low) to Setting limiter (high )

5 Remote setting (RS) input

value monitor

6 Burnout state monitor 64 RO 0: OFF

7 Unused

8 Event 1 state monitor 64 RO

9 Event 2 state monitor 64 RO

10 Event 3 state monitor

11 Event 4 state monitor 64 RO

12 Heater break alarm (HBA)

state monitor

13 Unused

14 Manipulated output value

(MV) monitor [heat-side]

15 Manipulated output value

(MV) monitor [cool-side]

16 Error code 16 RO Bit data

17 Unused

18 Output state monitor 16 RO Bit data

19 Operation mode state

monitor

20 Memory area soak time

monitor

21 Integrated operating time

monitor

22 Holding peak value ambient

temperature monitor

23 Unused

24 Backup memory state

monitor

25

Unused

•

•

•

32

PID/AT transfer 2

33

34 Auto/Manual transfer 64 R/W 0: Auto mode

35 Remote/Local transfer 64 R/W 0: Local mode

36 RUN/STOP transfer 16 R/W 0: STOP (control stop)

1

If the Event 3 type is temperature rise completion, check the temperature rise completion state in the

comprehensive event state [Z-TIO module extended object (0x65: 65Hex) ID: 1]. (The Event 3 state

monitor does not turn ON.)

2

When using PID/AT transfer by polling I/O communication, it is necessary to set action mode selection to

"PID/AT transfer by polling I/O communication is valid."

1

64 RO

…………….……………………

b15

Number

Attri-

of data

bute

items

64 RO CTL-6-P-N: 0.0 to 30.0A

64 RO Setting limiter (low) to Setting limiter (high )

64 RO 0: OFF

64 RO PID control or heat/cool PID control:

64 RO −5.0 to +105.0 %

64 RO Bit data

64 RO 0 to 11999 seconds or 0 to 5999 minutes

16 RO 0 to 19999 hours

64 RO −10.0 to +100.0 °C or 14 to 212 °F

16 RO 0: The content of the backup memory

64 R/W 0: PID control

CTL-12-S56-10L-N: 0.0 to 100.0 A

1: ON

0: OFF

1: ON

1: ON

−5.0 to +105.0 %

Position proportioning control with feedback

resistance (FBR) input:

0.0 to 100.0 %

b0: Adjustment data error

b1: Data back-up error

b2: A/D conversion error

b3, b4: Unused

b5: Logic output data error

b6 to b15: Unused

Data 0: OFF 1: ON

[Decimal number: 0 to 39]

b0: OUT1 state b2: OUT3 state

b1: OUT2 state b3: OUT4 state

b4 to b15: Unused

Data 0: OFF 1: ON

[Decimal number: 0 to 15]

b0: Control STOP

b1: Control RUN

b2: Manual mode

b3: Remote mode

b4 to b15: Unused

Data 0: OFF 1: ON

[Decimal number: 0 to 15]

Data range of Area soak time can be

selected on the Soak time unit.

does not coincide with that of the RAM.

1: The content of the backup memory

coincides with that of the RAM.

1: Autotuning (AT) *

Automatically reverts to 0 after autotuning ends.

*

1: Manual mode

1: Remote mode

1: RUN (control start)

Data range

b0

Factory

set value

0

0

0

0

ID Name

37 Memory area transfer 64 R/W 1 to 8 1

38 Interlock release 64 R/W 0: Normal state

39 Event 1 set value ★ 64 R/W 50

40 Event 2 set value ★ 64 R/W 50

41 Event 3 set value ★ 64 R/W 50

42 Event 4 set value ★ 64 R/W

43 Control loop break alarm

(LBA) time ★

44 LBA deadband ★ 64 R/W 0 (0.0) to Input span 0 (0.0)

45 Set value (SV) ★ 64 R/W Setting limiter (low) to

46 Proportional band

[heat-side] ★

47 Integral time [heat-side] ★ 64 R/W PID control or heat/cool PID control:

48 Derivative time [heat-side] ★ 64 R/W

49 Control response

parameter ★

50 Proportional band

[cool-side] ★

51 Integral time [cool-side] ★ 64 R/W

52 Derivative time [cool-side] ★ 64 R/W

53 Overlap/Deadband ★ 64 R/W TC/RTD inputs:

54 Manual reset ★ 64 R/W −100.0 to +100.0 % 0.0

55 Setting change rate limiter

(up) ★

56 Setting change rate limiter

(down) ★

57 Area soak time ★ 64 R/W 0 to 11999 seconds or 0 to 5999 minute s

58 Link area number ★ 64 R/W 0 to 8 (0: No link) 0

59 Heater break alarm (HBA)

set value

60 Heater break

determination point

61 Heater melting

determination point

62 Unused

63 Unused

64 Unused

65 PV bias 64 R/W −Input span to + Input span 0

66 PV digital filter 64 R/W 0.0 to 100.0 seconds (0.0: Unused) 0.0

67 PV ratio 64 R/W 0.500 to 1.500 1.000

68 PV low input cut-off 64 R/W 0.00 to 25.00 % of input span 0.00

69

70

71

72 Proportional cycle time 64 R/W 0.1 to 100.0 seconds

73 Unused

74 Manual manipulated output

★: Data related to multi-memory area function

1

Varies with the setting of the integral/derivative time decimal point position selection.

2

The RS bias, RS ratio, and RS digital filter are data for cascade control and proportion setting control.

2

RS bias

RS digital filter 2

RS ratio 2

value

It is possible to change only the data of the control area which is selected by the memory area transfer (ID: 37).

Number

Attri-

of data

bute

items

1: Interlock release execution

Deviation action, Deviation action

between channels, Temperature rise

completion range *:

−Input span to +Input span

Process action, SV action:

Input scale low to Input scale high

Manipulated output value (MV):

−5.0 to +105.0 %

* When temperature rise completion is

64 R/W 0 to 7200 seconds (0: Unused) 480

64 R/W TC/RTD inputs:

64 R/W 0: Slow

64 R/W TC/RTD inputs:

64 R/W 0 (0.0)

64 R/W

64 R/W CTL-6-P-N:

64 R/W 0.0 to 100.0 % of HBA set value

64 R/W 0.0 to 100.0 % of HBA set value

64 R/W −Input span to + Input span 0

64 R/W 0.0 to 100.0 seconds (0.0: Unused) 0.0

64 R/W 0.001 to 9.999 1.000

64 R/W PID control:

selected at Event 3 action type.

Setting limiter (high)

0 (0.0) to Input span (Unit: °C [°F])

Voltage (V)/current (I) inputs:

0.0 to 1000.0 % of Input span

(0, 0.0: ON/OFF action)

0 to 3600 seconds or

0.0 to 1999.9 seconds 1

(0, 0.0: PD action)

Position proportioning control:

1 to 3600 seconds or

0.1 to 1999.9 seconds 1

0 to 3600 seconds or

0.0 to 1999.9 seconds

(0, 0.0: PI action)

1: Medium

2: Fast

[P or PD action: 2 (Fast) fixed]

1 (0.1) to Input span (Unit: °C [°F])

Voltage (V)/current (I) inputs:

0.1 to 1000.0 % of Input span

0 to 3600 seconds or

0.0 to 1999.9 seconds 1

(0, 0.0: PD action)

00 to 3600 seconds or

0.0 to 1999.9 seconds 1

(0, 0.0: PI action)

−Input span to +Input span (Unit:°C [°F])

Voltage (V)/current (I) inputs:

−100.0 to +100.0 % of Input span

Minus (−) setting results in overlap.

0 (0.0) to Input span/unit time *

0 (0.0): Unused

* Unit time: 60 seconds (f actory set value)

Data range of Area soak time can be

selected on the Soak time unit

0.0 to 30.0 A (0.0: Unused)

CTL-12-S56-10L-N:

0.0 to 100.0 A (0.0: Unused)

(0.0: Heater break determination is invalid)

(0.0: Heater melting determination is invalid)

M: Relay contact output

V: Voltage pulse output

T: Triac output

D: O pen collector output

Output limiter (low) to Output limiter (high)

Heat/cool PID control:

−Output limiter (high) to

+Output limiter (high)

Position proportioning control with

feedback resistance (FBR) input:

Output limiter (low) to

Output limiter (high)

Position proportioning control

(without FBR input):

0: Close-side output OFF,

Open-side output OFF

1: Close-side output ON,

Open-side output OFF

2: Close-side output OFF,

Open-side output ON

Data range

1

Factory

set value

TC/RTD

inputs: 0 °C

V/I inputs:

0.0 %

TC/RTD

inputs: 30

V/I inputs:

30.0

240

PID control,

Position

proportioning

control: 0

Heat/cool

PID control: 2

TC/RTD

inputs: 30

V/I inputs:

30.0

240

0 (0.0)

0.0

30.0

30.0

M output:

20.0

V, T, D

output: 2.0

0.0

0

50

60

60

0

0

ID Name

75

Unused

•

•

•

82

83

•

Engineering setting data

•

•

For the data, see COM-JH [For SRZ] Instruction Manual (IMR01Y36-E).

203

204 Startup tuning (ST) 64 R/W 0: Startup tuning (ST) unused

205

•

Engineering setting data

•

•

For the data, see COM-JH [For SRZ] Instruction Manual (IMR01Y36-E).

209

210 Automatic temperature rise

learning

211

•

Engineering setting data

•

•

For the data, see COM-JH [For SRZ] Instruction Manual (IMR01Y36-E).

224

225 Controller state 1 31 RO Bit data

226 Controller state 2 31 RO Bit data

227

Unused

•

•

•

230

231

Comprehensive alarm

state 1

232

Controller alarm state

Error state

RUN/STOP 1

1

233

234

1

Valid only when Explicit message communication is used.

Number

of data

items

64 R/W 0: Unused

1 RO Bit data

1

2 RO Bit data

2 RO Bit data

2 R/W Bit data

Attribute

1: Execute once *

2: Execute always

* Automatically reverts to 0 after Startup tuning

(ST) ends.

1: Learning *

* Automatically reverts to 0 after automatic

temperature rise learning ends.

Z-TIO module:

b0: Burnout state

b1: Unused

b2: Event 1 state

b3: Event 2 state

b4: Event 3 state

b5: Event 4 state

b6: Heater break alarm (HBA) state

b7 to b15: Unused

OR data for each Z-TIO module.

Z-DIO module:

b0 to b15: Unused

Data 0: OFF 1: ON

[Decimal number: 0 to 125]

Z-TIO module:

b0: Adjustment data error

b1: Data back-up error

b2: A/D conversion error

b3: Unused

b4: Unused

b5: Logic output data error

b6 to b14: Unused

b15: Controller communication error

Z-DIO module:

b0: Unused

b1: Data back-up error

b2 to b14: Unused

b15: Controller communication error

Data 0: OFF 1: ON

[Decimal number: 0 to 32807]

b0: Burnout state

b1: Unused

b2: Event 1 state

b3: Event 2 state

b4: Event 3 state

b5: Event 4 state

b6: Heater break alarm (HBA) state

b7 to b15: Unused

Data 0: OFF 1: ON

[Decimal number: 0 to 125]

Object instance 1:

b0 to b15: Controller 1 to 16

Object instance 2:

b0 to b14: Controller 17 to 31

Data 0: OFF 1: ON

[Decimal number: 0 to 65535]

OR of Controller state 1 (ID: 225)

Object instance 1:

b0 to b15: Controller 1 to 16

Object instance 2:

b0 to b14: Controller 17 to 31

Data 0: OFF 1: ON

[Decimal number: 0 to 65535]

OR of Controller state 2 (ID: 226)

Object instance 1:

b0 to b15: Controller 1 to 16

Object instance 2:

b0 to b14: Controller 17 to 31

Data:

RUN/STOP state is depending on the value

of RUN/STOP logic selection (ID: 242)

• ID: 242 = 0 0: RUN (control start),

1: STOP (control stop)

• ID: 242 = 1 0: STOP (control stop),

1: RUN (control start)

[Decimal number: 0 to 65535]

Link RUN/STOP transfer (ID: 36)

Data range

(Continued on the next page )

Factory

set value

0

0

1

Page 2

A

)

e

ID Name

235 Setting update flag

236 Number of polling I/O

communication controllers

237

Unused

238 COM-JH error code

239 Number of connected

controller in controller

communication 1

240 Number of communication

measured data items (IN)

when conducting polling I/O

communication

241 Number of communication

setting data items (OUT)

when conducting polling I/O

communication

242 RUN/STOP logic

selection

243 Setting validity selection

244

Unused

245 Controller address setting

246 Action mode selection

247 Automatic acquisition of

controller address

248

Unused

•

•

•

255

: It is possible to set in the communication environment setting by the rotary switch of COM-JH or

configuration tool.

♦: Communication environment setting by rotary switch of COM-JH is possible.

1

Valid only when Explicit message communication is used.

2

The setting is validated when the power is turned off once after the setting is changed and it is turned on again.

1, 2

1, 2

1, 2

For communication environment setting by the rotary switch, see COM-JH [For SRZ] Quick Instruction

Manual (IMR01Y28-E).

Number

Attri-

of data

bute

items

1

1 RO 0: Setting update is completed

1 R/W 1 to 31 10

1

1

1 RO Bit data

1 RO 0 to 31

1 R/W 0: Depends on the DIP switch setting

1, 2

1 R/W 0: Depends on the DIP switch setting

1 R/W 0: RUN = 0, STOP = 1

1

1 R/W 0: The setting is validated when the power

1, 2

1 R/W 0 to 32 (0: No communication) 1 to 31

1, 2

♦ 1 R/W Bit data

1 R/W 0: Do not execute the automatic acquisition

1: During setting update

b0: Back-up error

b1: Controller communication error

b2 to b15: Unused

Data 0: OFF 1: ON

[Decimal number: 0 to 3]

1 to 5: 5 words

6 to 200: 6 to 200 words

1 to 5: 5 words

6 to 200: 6 to 200 words

1: RUN = 1, STOP = 0

Valid to RUN/STOP (ID: 234) and the 4th

word and the 5th word in the polling I/O

communication setting item (OUT). However,

invalid to the RUN/STOP transfer (ID: 36).

is turned off once after the setting is

changed and it is turned on again.

1: The setting is validated just after the

setting is changed.

Object data

• The data of “Controller communication

item setting object (0xC7)”

• The data of “Number of polling I/O

communication controllers (ID: 236)”

b0: Address setting method transfer

0: Continuous setting

1: Free setting

b1: PID/AT transfer by polling I/O

communication

0: Invalid

1: Valid

b2 to b15: Unused

[Decimal number: 0 to 3]

1: Execute the automatic acquisition

Data range

Factory

set value

Z-TIO Module Extended Object (0x65: 65Hex)

Number

Attri-

ID Name

1 Comprehensive event state 64 RO Bit data

2 Logic output monitor 16 RO Bit data

3 Output distribution selection 64 R/W 0: Control output

4 Output distribution bias 64 R/W −100.0 to +100.0 % 0.0

5 Output distribution ratio 64 R/W −9.999 to +9.999 1.000

6 Minimum ON/OFF time

of proportioning cycle

7 Area soak time stop function 64 R/W 0: No function 3: Event 3

8 EDS mode (for disturbance 1) 64 R/W 0

9 EDS mode (for disturbance 2) 64 R/W

10 EDS value 1 (for disturbance 1) 64 R/W 0.0

11 EDS value 1 (for disturbance 2) 64 R/W 0.0

12 EDS value 2 (for disturbance 1) 64 R/W 0.0

13 EDS value 2 (for disturbance 2) 64 R/W

14 EDS transfer time

(for disturbance 1)

15 EDS transfer time

(for disturbance 2)

16 EDS action time

(for disturbance 1)

17 EDS action time

(for disturbance 2)

of data

items

bute

b0 to b3: Event 1 state to Event 4 state

b4: Heater break alarm state

b5: Temperature rise completion

b6: Burnout

b7 to b15: Unused

Data 0: OFF 1: ON

[Decimal number: 0 to 127]

b0 to b7: Logic output 1 to 8

b8 to b15: Unused

Data 0: OFF 1: ON

[Decimal number: 0 to 255]

Data range

1: Distribution output

64 R/W 0 to 1000 ms 0

1: Event 1 4: Event 4

2: Event 2

0: No function

1: EDS function mode

2: Learning mode

3: Tuning mode

EDS function: External disturbance suppression function

−100.0 to +100.0 %

64 R/W 0

0 to 3600 seconds or 0.0 to 1999.9 seconds

64 R/W

64 R/W 600

1 to 3600 seconds

64 R/W

Factory

set value

ID Name

18 EDS action wait time

(for disturbance 1)

19 EDS action wait time

(for disturbance 2)

20 EDS value learning times 64 R/W 0 to 10 times (0: No learning mode) 1

21 EDS start signal 64 R/W 0: EDS start signal OFF

22 Operation mode 64 R/W 0: Unused

23 Communication switch for

0

0

1

logic

24

•

Engineering setting data

•

•

For the data, see COM-JH [For SRZ] Instruction Manual (IMR01Y36-E).

42

43

Unused

•

•

•

255

Z-DIO Module Object (0x66: 66Hex)

0

ID Name

1 Digital input (DI) state 16 RO Bit data

2 Digital output (DO) state 16 RO Bit data

1

3 Error code 16 RO 2: Data back-up error

4 Inte grated operating time

monitor

5 Backup memory state

monitor

0

6 RUN/STOP transfer 16 R/W 0: STOP (Control stop)

7 DO manual output 16 R/W Bit data

8 DO output distribution

selection

9 DO output distribution bias 128 R/W −100.0 to +100.0 % 0.0

10 DO output distribution ratio 128 R/W −9.999 to +9.999 1.000

11 DO proportional cycle time 128 R/W 0.1 to 100.0 seconds Depends on

12 DO minimum ON/OFF time

of proportional cycle

13

•

Engineering setting data

•

•

For the data, see COM-JH [For SRZ] Instruction Manual (IMR01Y36-E).

26

27

Unused

•

•

•

255

3. DEVICE PROFILES

A device profile is the specification that defined each necessary parameter with DeviceNet.

3.1 Basic Data

0

General Device Data

Conforms to DeviceNet specification Volume I - Release 2.0, Volume II - Release 2.0

Vendor name RKC INSTRUMENT INC. (Vendor ID = 394)

Device profile name Generic Device

Product catalog number

0

Product revision 2.1

Physical Conformance Data

0

Network power consumption 2 mA @ 11 V DC, 4 mA @ 24 V DC

Connector type Open-style connector or Micro-style connector

Insulated physical layer Provided

LEDs supported Module, Network

MAC ID setting Rotary switch (Node address setting)

0.0

600

Default MAC ID 63

Communication speed setting Rotary switch (DeviceNet communication sp eed setting)

Communication speed supported 125 kbps, 250 k bps, 500 kbps

0

Communication Data

Predefined master/slave connection

set

Dynamic connection supported

(UCMM)

Fragmented Explicit Messaging None

Number

Attri-

of data

bute

items

64 R/W 0.0

0.0 to 600.0 seconds

Data range

64 R/W

1: EDS start signal ON (for disturbance 1)

2: EDS start signal ON (for disturbance 2)

1: Monitor

2: Monitor + Event function

16 R/W Bit data

Number

of data

items

3: Control

b0 to b3: Communication switch 1 to 4

b4 to b15: Unused

Data 0: OFF 1: ON

[Decimal number: 0 to 15]

Attribute

b0 to b7: DI1 to DI8

b8 to b15: Unused

Data 0: Contact open

1: Contact closed

[Decimal number: 0 to 255]

b0 to b7: DO1 to DO8

b8 to b15: Unused

Data 0: OFF 1: ON

[Decimal number: 0 to 255]

Data range

Factory

set value

0.0

Factory

set value

16 RO 0 to 19999 hours

16 RO 0: The content of the backup memory

does not coincide with that of the RAM.

1: The content of the backup memory

coincides with that of the RAM.

1: RUN (Control start)

b0 to b7: DO1 manual output to

DO8 manual output

b8 to b15: Unused

Data 0: OFF 1: ON

128 R/W 0: DO output

128 R/W 0 to 1000 ms 0

Instruction manual number:

Japanese: IMR01Y24-J, IMR01Y28-J, IMR01Y32-J, IMR01Y36-J

English: IMR01Y24-E, IMR01Y28-E, IMR01Y32-E, IMR01Y36-E

Group 2 Only server

Not supported

[Decimal number: 0 to 255]

1: Distribution output

specifications

3.2 Object Mounting

Identity Object (0x01: 01Hex)

Object class

Attributes Not supported

Services Not supported

Object instance 1

0

ID Description Get Set Type Value

Attributes 1 Vendor Yes No UINT 39 4

2 Product type Yes No UINT 0

3

3 Product code Yes No UI NT 5

4 Revision

0

5 Status (bits supported) Yes No WORD Note

6 Serial number Yes No UDINT

7 Product name

DeviceNet service Parameter option

Services 0x05 Reset 0

0x0E Get_Attribute_Single None

Note bit 0: Owned

bit 7:

Set to 1 when a self-diagnostic error occurs.

Self-diagnostic error: When attribute ID: 238 (COM-JH error code) of the controller object (0x64)

is set to 1, a self-diagnostic error occurs.

bit 1 to 6 and bit 8 to 15: Unused

Message Router Object (0x02: 02Hex)

Object class

Attributes Not supported

Services Not supported

Object instance

Attributes Not supported

Services Not supported

DeviceNet Object (0x03: 03Hex)

Object class

ID Description Get Set Type Value

Attributes 1 Revision Yes No UINT 2

DeviceNet service Parameter option

Services 0x0E Get_Attribute_Single None

Object instance 1

ID Description Get Set Type Value

Attributes 1 MAC ID Yes No UINT 0 to 63

2 Baud rate Yes No UINT 0 to 2

3 BOI Yes No BOOL 0

4 Bus-off counter Yes Yes USINT

5 Allocation information

0

6 MAC ID switch changed Yes No BOOL 0, 1

7 Baud rate switch changed Yes No BOOL 0, 1

0

8 MAC ID switch value Yes No USINT 0 to 63

9 Baud rate switch value Yes No USI NT 0 to 2

DeviceNet service Parameter option

Services 0x0E Get_Attribute_Single None

0x10 Set _Attribute_Single None

0x4B Allocate_Master/Slave_

0

0x4C Release_Group_2_Identifire_Set None

Assembly Object (0x04: 04Hex)

Object class

ID Description Get Set Type Value

Attributes 1 Revision Yes No UINT 2

DeviceNet service Parameter option

Services 0x0E Get_Attribute_Single None

Object instance 100

ID Description Get Set Type Value

Attributes 3 Data Yes No INT CH1: Measured value (PV)

DeviceNet service Parameter option

Services 0x0E Get_Attribute_Single None

Object instance 101

ID Description Get Set Type Value

Attributes 3 Data Yes Yes INT C H1: Set value (SV)

DeviceNet service Parameter option

Services 0x0E Get_Attribute_Single None

0x10 Set _Attribute_Single None

Connection Object (0x05: 05Hex)

Object class

Attributes Not supported

Services Not supported

Number of maximum possible active connection 1

Object instance 1

Section Information

Instance type Explicit Message 1

Production trigger Cyclic

Transport type Server

Transport class 3

ID Description Get Set Type Value

Attributes 1 State Yes No USINT

2 Instance type Yes No U SINT 0x00

3 Transport class trigger Y es No BYTE 0x83

4 Produced connection ID Yes No UINT

5 Consumed connection ID Yes No UINT

6 Initial comm. Characteristics Yes No BYTE 0x21

7 Produced connection size Yes No UINT 7

8 Consumed connection size Yes No UINT 7

9 Expected packet rate Yes Yes UINT Def ault: 2500

12 Watchdog time-out act ion Yes Yes USINT 1, 3

13 Produced connection pat h length Yes No UINT 0

14 Produced connection pat h Yes No (null)

15 Consumed connection path length Yes No UINT 0

16 Consumed connection pat h Yes No (null)

DeviceNet service Parameter option

Services 0x05 Reset None

0x0E Get_Attribute_Single None

0x10 Set _Attribute_Single None

Major revision

Minor revision

Length

Name

Allocation choice byte

Master’s MAC ID

Connection_Set

Yes No

Yes No

Yes No

None

UINT

2

UINT

1

UINT

5

STRING

COM01

BYTE

USINT

Number of maximum instance

Object instance 2

Instance type Polled I/O 1

Production trigger Cyclic

Transport type Server

Transport class 3

ID Description G et Set Type Value

Attributes 1 State Yes No U SINT

2 Instance type Yes No U SINT 0x01

3 Transport class trigger Yes N o BYTE 0x82

4 Produced connection ID Yes No UINT

5 Consumed connection ID Yes No UINT

6 Initial comm. Characteristics Yes No BYT E 0x01

7 Produced connection size Yes No UI NT Note

8 Consumed connection size Yes No UINT Note

9 Expected packet rate Yes Yes UINT Default: 0

12 Watchdog t ime-out action Yes No USINT 0

13 Produced co nnection path length Yes No UINT 6

14 Produced co nnection path

15 Consumed connect ion path length Yes N o UINT 6

16 Consumed connect ion path

DeviceNet service Parameter option

Services 0x05 Reset None

0x0E Get_Attribute_Single None

0x10 Set _Attribute_Single None

Note: Make the setting by any of the f ollowing methods. (The value is validated with the power turned on)

Section Information

Logic Segment, Class

Class Number

Logic Segment, Instance

Instance Number

Logic Segment, Attributes

Attributes Number

Logic Segment, Class

Class Number

Logic Segment, Instance

Instance Number

Logic Segment, Attributes

Attributes Number

• Select with the DIP s witch [14 (7 words), 50 (25 words), 90 (45 words), 200 (100 words)]

• Set with number setting ( attribute ID: 240 and 241) of communication data of controller object (0x64).

Yes No

Yes No

USINT

USINT

USINT

USINT

USINT

USINT

USINT

USINT

USINT

USINT

USINT

USINT

Number of

maximum instance

0x20

0x04

0x24

0x64

0x30

0x03

0x20

0x04

0x24

0x65

0x30

0x03

Controller Object (0x64: 64Hex, 0x65: 65Hex, 0x66: 66Hex)

Object class

Attributes Not supported

Services Not supported

Object instance (: 1 to 64): Z-TIO module object

Object instance (: 1 to 64): Z-TIO module extended object

Object instance (: 1 to 128): Z-DIO module object

For details of object instance, see 2. CONTROLLER OBJECT DATA ITEMS.

Controller Communication Item Setting Object (0xC7: C7Hex)

Measured data item (IN) and setting data item (OUT) communicating via polling I/O

communication are set by the attribute ID in “Controller object (0x64 to 0x66).”

0x64: 64Hex: Attributes ID

0x65: 65Hex: Attributes ID + 1000

0x66: 66Hex: Attributes ID + 2000

When setting the communication items of a object (0x65

or (0x66), set the attribute ID number with the appropriat

offset value (1000 or 2000) added.

Object class

Attributes Not supported

Services Not supported

Object instance 1

ID Description Get Set Type Value *

Attributes 1 Measured data item (IN) 1 Yes Yes UINT 1: Measured value (PV)

2 Measured data item (IN) 2 Yes Yes UINT 0

•

32 Measure d data item (IN) 32 Yes Yes UINT 0

33 Sett ing data item (OUT) 1 Yes Yes UINT 45: Set value (SV)

34 Sett ing data item (OUT) 2 Yes Yes UINT 0

•

64 Sett ing data item (OUT) 32 Yes Yes UINT 0

DeviceNet service Parameter option

Services 0x0E Get_Attribute_Single None

0x10 Set _Attribute_Single None

* Attribute ID 2 to 32 and Attribute I D 34 to 64: 0 (factory set value)

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

DeviceNet is a registered trademark of Open DeviceNet Vendor Association, Inc.

Modbus is a registered trademark of Schneider Electric.

Company names and product names used in this manual are the trademarks or registered

trademarks of the respective companies.

This product has been self-tested by RKC at DeviceNet Protocol Conformance Test Software

Version

-17.

RKC INSTRUMENT INC.

®

HEADQUARTERS: 16-6, KUGAHARA 5-CHOME, OHTA-KU TOKYO 146-85 15 JAPAN

PHONE: 03-3751-9799 (+81 3 3751 9799) E-mail: info@rkcinst.co.jp

FAX: 03-3751-8585 (+81 3 3751 8585) JUN. 2007

The first edition: JUN. 2007 [IMQ00]

Loading...

Loading...