Page 1

M

-

RKC INSTRUMENT INC.

®

Communication Converter

CO

E

Instruction Manual

IMS01C01-E7

Page 2

MONITOUCH V6 series are products manufactured by Hakko Electronics Co., Ltd.

The respective products of the programmable controller (PLC) are products manufactured by

the respective companies.

Other names of products or manufacturers used in this manual are trademarks or registered

trademarks of the respective companies.

All Rights Reserved, Copyright 2000, RKC INSTRUMENT INC.

Page 3

t

Thank you for purchasing the RKC instrument. In order to achieve maximum performance and ensure

proper operation of your new instrument, carefully read all the instructions in this manual. Please

place this manual in a convenient location for easy reference.

SYMBOLS

WARNING

CAUTION

!

: This mark indicates where additional information may be located.

An external protection device must be installed if failure of this instrument

could result in damage to the instrument, equipment or injury to personnel.

: This mark indicates precautions that must be taken if there is danger of electric

shock, fire, etc., which could result in loss of life or injury.

: This mark indicates that if these precautions and operating procedures are no

taken, damage to the instrument may result.

: This mark indicates that all precautions should be taken for safe usage.

: This mark indicates important information on installation, handling and operating

procedures.

: This mark indicates supplemental information on installation, handling and

operating procedures.

WARNING

!

All wiring must be completed before power is turned on to prevent electric

shock, fire or damage to instrument and equipment.

This instrument must be used in accordance with the specifications to

prevent fire or damage to instrument and equipment.

This instrument is not intended for use in locations subject to flammable or

explosive gases.

Do not touch high-voltage connections such as power supply terminals, etc.

to avoid electric shock.

RKC is not responsible if this instrument is repaired, modified or

disassembled by other than factory-approved personnel. Malfunction can

occur and warranty is void under these conditions.

IMS01C01-E7

i-1

Page 4

CAUTION

This is a Class A instrument. In a domestic environment, this instrument may cause radio

interference, in which case the user may be required to take adequate measures.

This instrument is protected from electric shock by reinforced insulation. Provide

reinforced insulation between the wire for the input signal and the wires for instrument

power supply, source of power and loads.

Be sure to provide an appropriate surge control circuit respectively for the following:

- If input/output or signal lines within the building are longer than 30 meters.

- If input/output or signal lines leave the building, regardless the length.

This instrument is designed for installation in an enclosed instrumentation panel. All

high-voltage connections such as power supply terminals must be enclosed in the

instrumentation panel to avoid electric shock by operating personnel.

All precautions described in this manual should be taken to avoid damage to the

instrument or equipment.

All wiring must be in accordance with local codes and regulations.

All wiring must be completed before power is turned on to prevent electric shock,

instrument failure, or incorrect action.

The power must be turned off before repairing work for input break and output failure

including replacement of sensor, contactor or SSR, and all wiring must be completed

before power is turned on again.

To prevent instrument damage or failure, protect the power line and the input/output lines

from high currents with a protection device such as fuse, circuit breaker, etc.

Prevent metal fragments or lead wire scraps from falling inside instrument case to avoid

electric shock, fire or malfunction.

Tighten each terminal screw to the specified torque found in the manual to avoid electric

shock, fire or malfunction.

For proper operation of this instrument, provide adequate ventilation for heat dispensation.

Do not connect wires to unused terminals as this will interfere with proper operation of the

instrument.

Turn off the power supply before cleaning the instrument.

Do not use a volatile solvent such as paint thinner to clean the instrument. Deformation or

discoloration will occur. Use a soft, dry cloth to remove stains from the instrument.

To avoid damage to instrument display, do not rub with an abrasive material or push front

panel with a hard object.

Do not connect modular connectors to telephone line.

NOTICE

This manual assumes that the reader has a fundamental knowledge of the principles of electricity,

process control, computer technology and communications.

The figures, diagrams and numeric values used in this manual are only for purpose of illustration.

RKC is not responsible for any damage or injury that is caused as a result of using this instrument,

instrument failure or indirect damage.

Periodic maintenance is required for safe and proper operation of this instrument. Some

components have a limited service life, or characteristics that change over time.

Every effort has been made to ensure accuracy of all information contained herein. RKC makes no

warranty expressed or implied, with respect to the accuracy of the information. The information in

this manual is subject to change without prior notice.

No portion of this document may be reprinted, modified, copied, transmitted, digitized, stored,

processed or retrieved through any mechanical, electronic, optical or other means without prior

written approval from RKC.

i-2

IMS01C01-E7

Page 5

CONTENTS

1. OUTLINE .............................................................................. 1

1.1 Product Outline...............................................................................................1

1.2 Confirmation of the Model Code .....................................................................3

1.3 Parts Description ............................................................................................4

2. SPECIFICATIONS ................................................................ 6

3. MOUNTING ......................................................................... 10

3.1 Mounting Environment................................................................................... 10

Page

3.2 Dimensions....................................................................................................11

3.3 Mounting the Mother Block............................................................................12

3.4 Mounting the Module Mainframe ...................................................................14

3.5 Removing the Module Mainframe..................................................................14

4. WIRING .............................................................................. 15

4.1 Wiring ............................................................................................................15

4.2 Connection....................................................................................................17

4.2.1 Connection to PLC ............................................................................................ 17

4.2.2 Connection to the RKC temperature controller ................................................. 23

4.2.3 Connection to host computer ............................................................................ 28

4.2.4 Connection to operation panel .......................................................................... 29

5. PLC COMMUNICATION ..................................................... 31

5.1 Rotary Switch Setting ....................................................................................31

5. 2 PLC Setting ...................................................................................................32

5.2.1 YOKOGAWA FA-M3 series............................................................................... 32

5.2.2 MITSUBISHI MELSEC A series (A, AnA, AnU types)/Q series/QnA series...... 33

5.2.3 OMRON SYSMAC CS1 series.......................................................................... 34

5.3 The RKC Temperature Controller Setting .....................................................35

5.4 Communication Data ....................................................................................36

5.4.1 Request command and data transfer................................................................36

5.4.2 Communications status check...........................................................................38

5.4.3 Caution for handling communication data.........................................................39

IMS01C01-E7 i-3

Page 6

5.5 Communication Items List............................................................................. 40

5.5.1 Reference to communication items list..............................................................40

5.5.2 CB100/CB400/CB500/CB700/CB900 ............................................................... 41

5.5.3 REX-F400/REX-F700/REX-F900 ...................................................................... 44

5.5.4 SA200................................................................................................................ 46

5.6 Table of Register Area Numbers vs. Register Numbers ...............................49

6. HOST COMMUNICATION ................................................. 53

6.1 Protocol.........................................................................................................53

6.1.1 Communication data structure ..........................................................................53

6.1.2 Polling................................................................................................................ 54

6.1.3 Selecting............................................................................................................ 59

Page

6.2 Communication Identifier List........................................................................62

6.2.1 CB100/CB400/CB500/CB700/CB900 ............................................................... 62

6.2.2 REX-F400/REX-F700/REX-F900 ...................................................................... 64

6.2.3 SA200................................................................................................................ 65

7. USAGE EXAMPLE ............................................................ 66

7.1 Configuration Instrument .............................................................................. 66

7.2 Handling Procedures ....................................................................................67

7.3 Connection of Each Instrument..................................................................... 68

7.4 Communication Items and Assignment of PLC Register ..............................69

7.5 Setting in Each Instrument............................................................................70

7.6 Initial Setting .................................................................................................73

7.7 Data Setting .................................................................................................. 75

8. TROUBLESHOOTING ....................................................... 77

9. ASCII 7-BIT CODE TABLE................................................ 81

i-4

IMS01C01-E7

Page 7

A

A

A

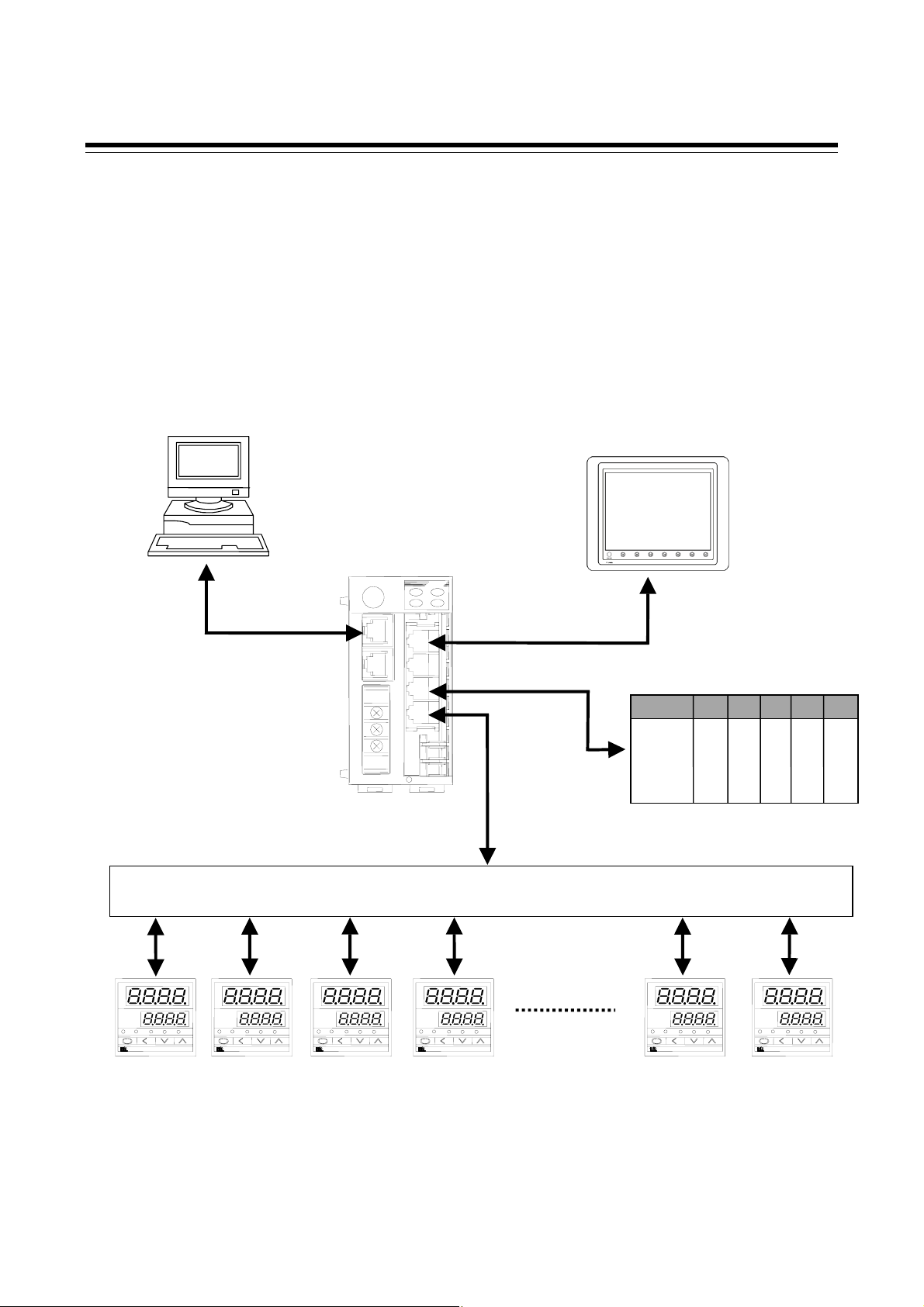

1. OUTLINE

This manual describes the specifications, mounting, wiring, connection, rotary switch setting and data

details of the COM-E.

1.1 Product Outline

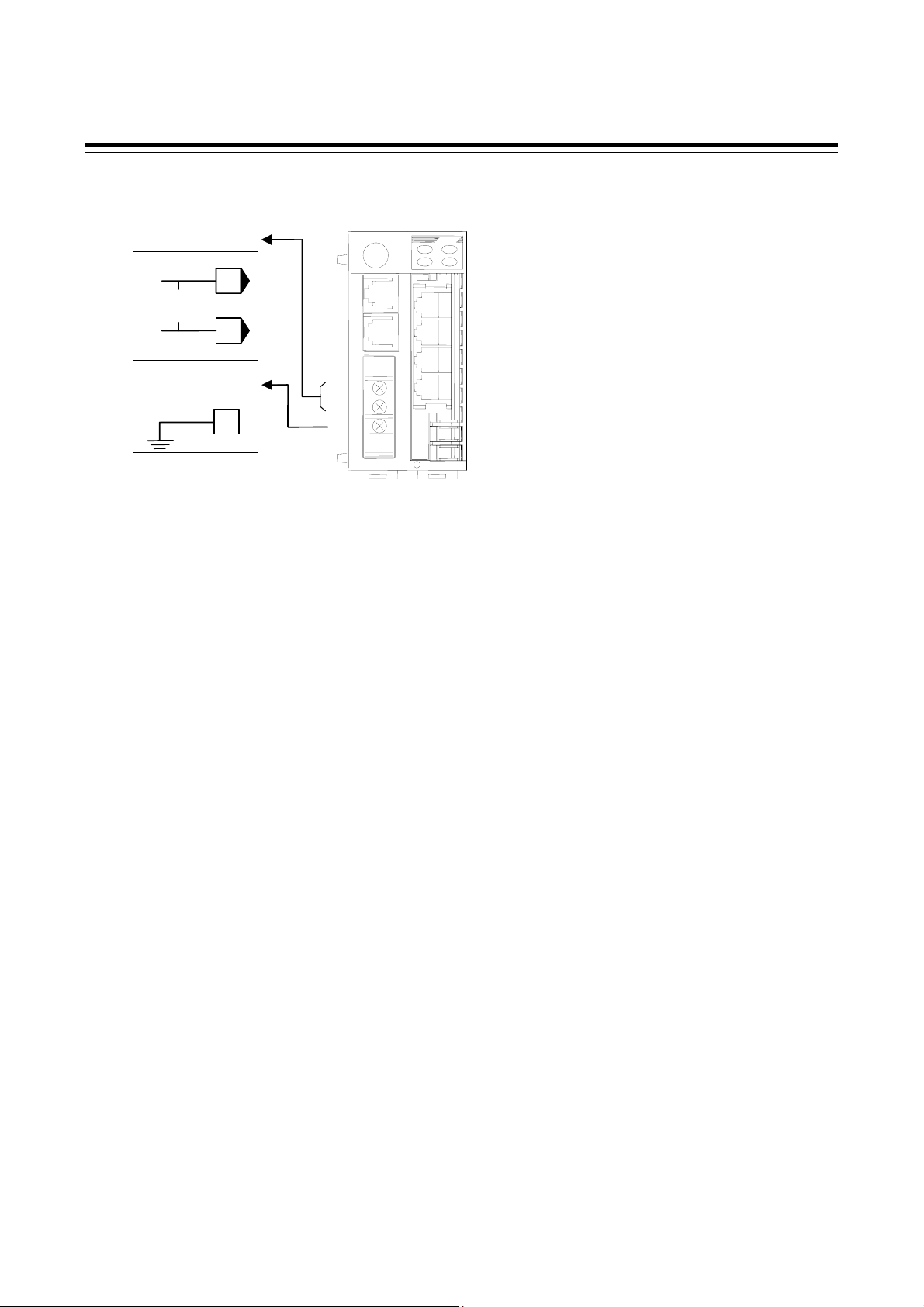

The COM-E communication converter (hereinafter called the COM-E) is a product to connect the

RKC temperature controller with communication function and the programmable controller (PLC) .

Also, COM-E has the host communication port and the operation panel (MONITOUCH V6 series

made by Hakko Electronics Co., Ltd) port as the additional function.

Host computer

Communication converter

COM-E

RS-232C

RS-422

RS-485

or

RS-422

Junction terminals

CB100 CB100 CB100 CB100 CB100 CB100

RKC temperature controller

Up to 20

controllers

Operation panel

MONITOUCH V6 series

RS-422

Programmable controller

(PLC)

RKC temperature controller

IMS01C01-E7 1

Page 8

1. OUTLINE

Communication port

COM-E has the following four kinds of communication ports.

PLC communication port

COM-E connects the RKC temperature controller and PLC, and works as the communication protocol

converter. The PLC can connect one COM-E, using modular connector.

For a specification of connecting PLC, please also read the instruction manual for the used

PLC.

The RKC temperature controller communication port

This is RKC standard communication port used in the RKC temperature controller.

COM-E can connect the maximum twenty controllers in multi-drop wiring.

Host computer communication port

Host computer to be connected to host communication port can monitor, operate and control the

system. The host computer can connect one COM-E, using modular connector.

Operation panel communication port

COM-E connects the RKC temperature controller and operation panel, and works as the

communication protocol converter. The operation panel can connect one COM-E, using modular

connector.

For the operation panel communication, please also read the instruction manual for the V6

series of Hakko Electronics Co., Ltd.

2

IMS01C01-E7

Page 9

1.2 Confirmation of the Model Code

When unpacking your new instrument, please confirm that the following products are included.

If the product you received is not the one ordered, please contact RKC sales office or the agent.

Communication converter

COM-E-- 01

(1) (2)

(1) PLCs

01: YOKOGAWA PLC FA-M3 series

02: MITSUBISHI MELSEC A series (A, AnA, AnU type) / Q series / QnA series of PLCs

03: OMRON PLC SYSMAC CS1 series

(2) Corresponding to the RKC temperature controller

1. OUTLINE

01: REX-F400/REX-F700/REX-F900

CB100/CB400/CB500/CB700/CB900

SA200

A model code label is attached to the left side of the COM-E.

Modular connector cables (Sold separately)

W-BF-01-

“” are filled with cable length in mm. Please specify the length on your purchasing order. The

standard length is “3000.”

W-BF-01: Used to connect the RKC temperature controller, PLC, or the operation panel.

Terminal converter (Sold separately: Hakko Electronics Co., Ltd)

TC485

The TC485 is a converting connector for connecting the operation panel.

It is used together with the modular connector cable (W-BF-01-).

Cable to connect the host computer

The customer is requested to prepare a communication cable (cable with connector) for the COM-E to

be connected by the host computer.

IMS01C01-E7

3

Page 10

1. OUTLINE

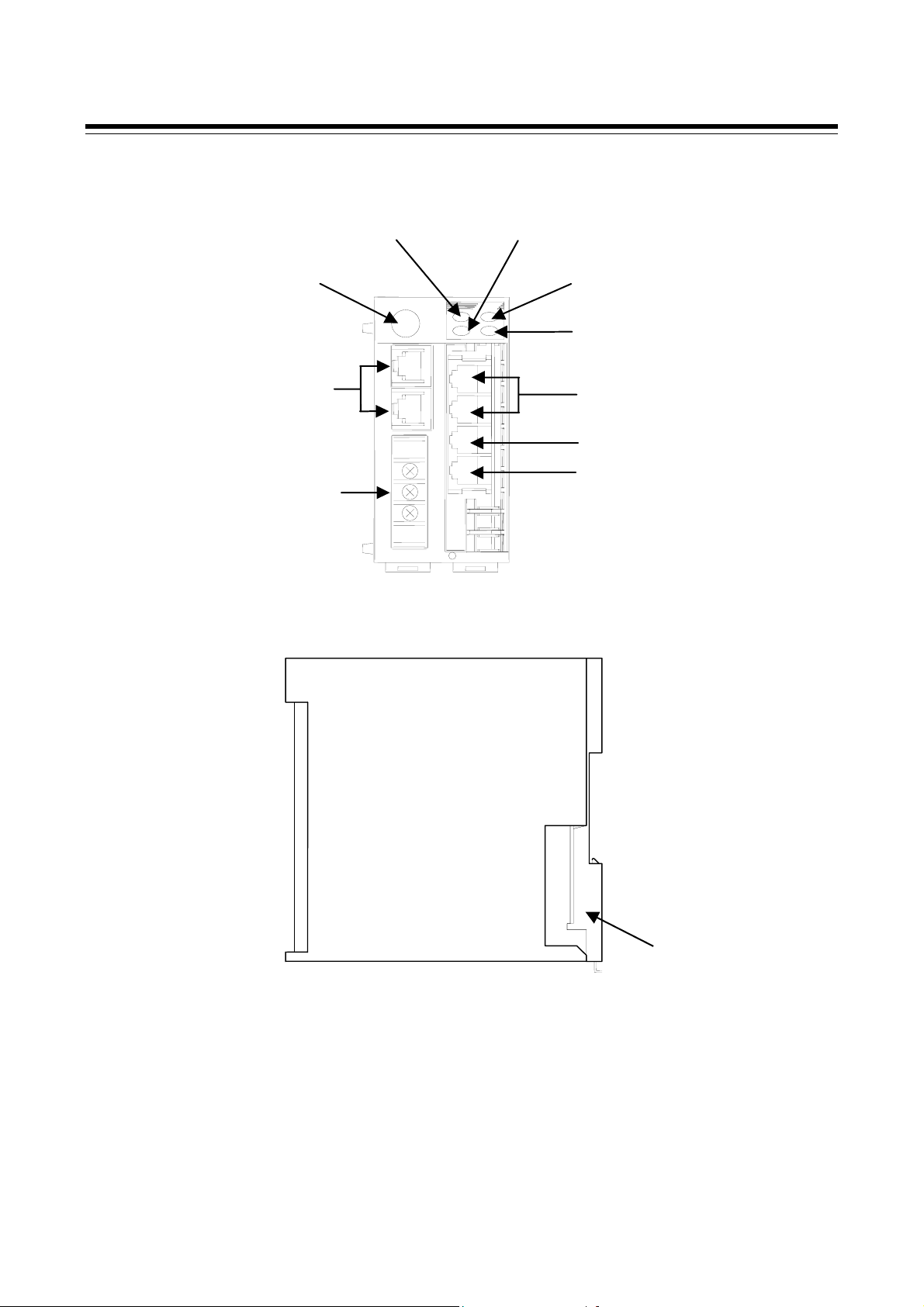

1.3 Parts Description

4.

Rotary switch

3.

Operation lamp 1

5.

Operation lamp 2

6.

Operation lamp 3

7. Operation lamp 4

2.

Modular connector COM1

1.

Power and ground terminals

8.

Modular connector COM2

9. Modular connector COM3

10.

Modular connector COM4

Front view

Module mainframe

Side view

11.

Mother block

4

IMS01C01-E7

Page 11

1. OUTLINE

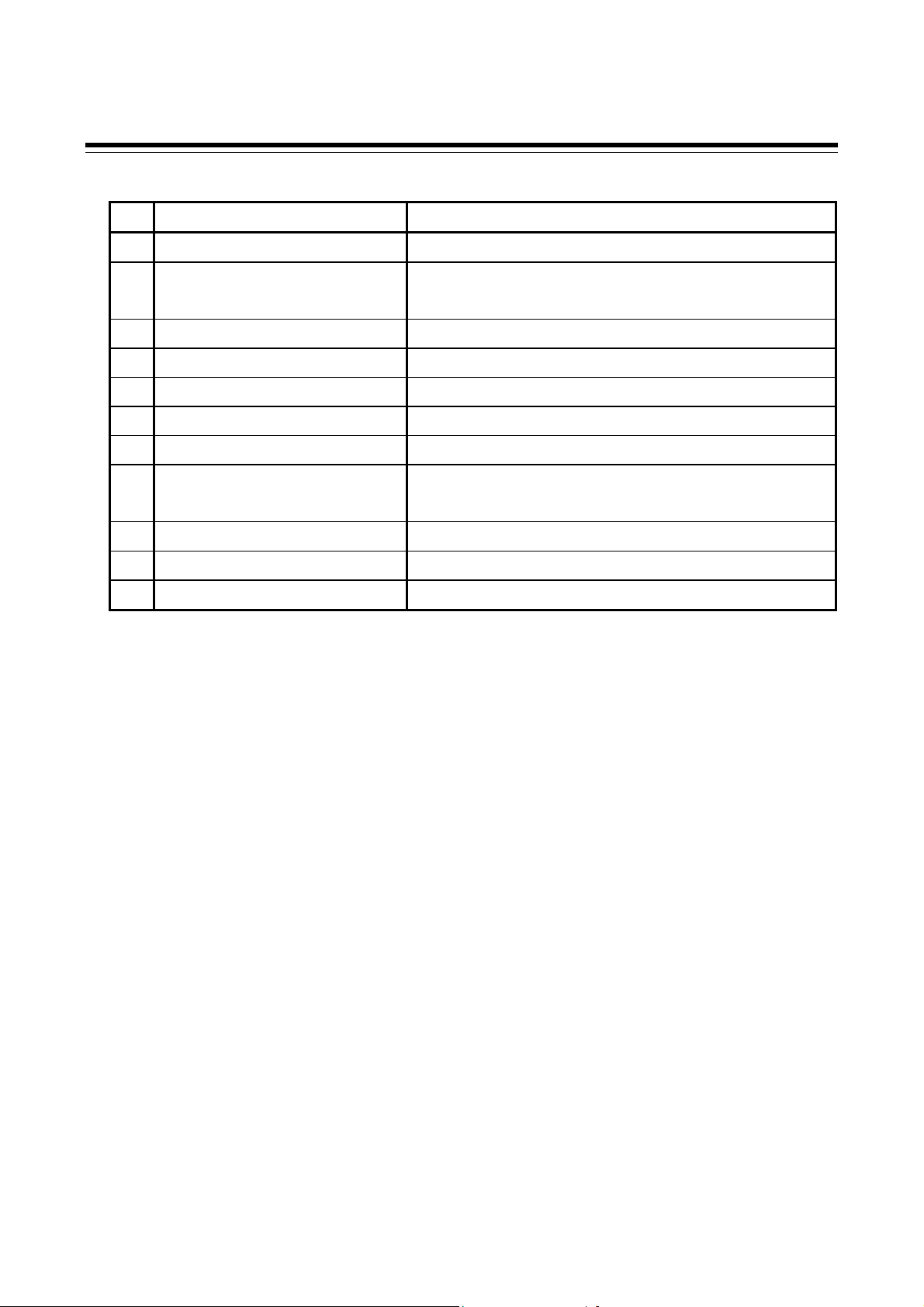

No. Name Description

1 Power and ground terminals Power supply (24 V DC) and ground terminals

2 Modular connector COM1 Upper: Host communication port (for RS-232C)

Lower: Unused communication port

3 Rotary switch Register number selector of PLC

4 Operation lamp 1 (Yellow LED) ON: Host communication is operating.

5 Operation lamp 2 (Yellow LED) ON: Operation panel communication is operating.

6 Operation lamp 3 (Yellow LED) * ON: PLC communication is operating.

7 Operation lamp 4 (Yellow LED) * ON: Controllers communication is operating.

8 Modular connector COM2 Upper: Operation panel communication port (for RS-422A)

Lower: Unused communication port

9 Modular connector COM3 PLC communication port (for RS-422A)

10 Modular connector COM4 The RKC temperature controller communication port

11 Mother block Module DIN rail mounting connector

* LED flashes on and off regardless of presence of junction of PLC and temperature controller as soon

as the power is turned on.

IMS01C01-E7

5

Page 12

2. SPECIFICATIONS

PLC communication

Communication interface: Based on RS-422A, EIA standard

Communication method: Four-wire system, multi-drop connection

Protocol: PLC standard communication

Synchronous method: Start-stop synchronous type

Communication speed: 9600 bps, 19200 bps (Factory set value: 19200 bps)

(Selectable)

It is necessary that connect the operation panel when the setting is

changed.

Data bit configuration: Start bit: 1

Data bit: 8

Parity bit: Without or Even*

Stop bit: 1

*

For OMRON PLC SYSMAC CS1 series

Communication code: ASCII 7-bit code

Number of connection: One PLC per COM-E

The RKC temperature controller communication

Communication interface: Based on EIA standard RS-485 or EIA standard RS-422A *

*

Communication method: Two-wire system, multi-drop connection (RS-485)

Four-wire system, multi-drop connection (RS-422A)

Protocol: RKC standard communication

(Based on ANSI X 3.28 subcategory 2.5, B1)

Synchronous method: Start/stop synchronous type

Communication speed: 9600 bps, 19200 bps (factory set value: 19200 bps)

(Selectable)

It is necessary that connect the operation panel when the setting is

changed.

Data bit configuration: Start bit: 1

Data bit: 8

Parity bit: Without

Stop bit: 1

Communication code: ASCII 7-bit code

Number of connection: 20 controllers max. per COM-E

RS-422A is only for REX-F400/REX-F700/REX-F900

6 IMS01C01-E7

Page 13

2. SPECIFICATIONS

Host communication

Communication interface: Based on RS-232C, EIA standard

Communication method: RS-232C point-to-point connection

Protocol: Based on ANSI X3.28 subcategory 2.5, B1

Polling/selecting type

Error control: Horizontal parity

Synchronous method: Start-stop synchronous type

Communication speed: 9600 bps, 19200 bps (factory set value: 19200 bps)

(Selectable)

It is necessary that connect the operation panel when the setting is

changed.

Data bit configuration: Start bit: 1

Data bit: 8

Parity bit: Without

Stop bit: 1

Block length: 128 bytes or less

Communication code: ASCII 7-bit code

Control codes: ENQ (05H), EOT (04H), STX (02H), ETB (17H), ETX (03H),

ACK (06H), NAK (15H)

Codes in brackets ( ) are in hexadecimal.

Time out time: 3 seconds

Number of connection: One host computer per COM-E

Signal voltage and Logic: RS-232C

Signal voltage Logic

+ 3V or more 0 (Space status)

− 3V or less 1 (Mark status)

IMS01C01-E7 7

Page 14

2. SPECIFICATIONS

Operation panel communication

Communication interface: Based on RS-422A, EIA standard

Communication method: Four-wire system, multi-drop connection

Protocol: Based on MITSUBISHI AnA communication protcol

Synchronous method: Start-stop synchronous type

Communication speed: 9600 bps, 19200 bps, 38400 bps (factory set value: 19200 bps)

(Selectable)

It is necessary that connect the operation panel when the setting is

changed.

Data bit configuration: Start bit: 1

Data bit: 8

Parity bit: Without

Stop bit: 1

Communication code: ASCII 7-bit code

Number of connection: One operation panel per COM-E

Power supply

Power supply voltage: 21.6 to 26.4 V DC (Rating: 24V DC)

Ripple noise: 10 % or less (peak to peak)

Current consumption: 85 mA max. (24 V DC)

Diagnostic functions

Check item: ROM/RAM check

Watchdog timer

If error occurs in self-diagnosis, the message is displayed on the operation

panel display.

Data storage functions

Memory backup: Lithium battery for RAM backup, approximate 10 years life for data

retention.

*

and storage and operating environments.

However, the above life differs depending on the product storage period,

8

IMS01C01-E7

Page 15

2. SPECIFICATIONS

Calendar functions

Precision: Within ± 2.3 seconds per day

Setting method: Time set with the operation panel screen

Display: Western (Gregorian) calendar year, month, day, day of the week,

hour, minute display

The operation panel is necessary for the use of calendar functions.

General specifications

Insulation resistance: Between power and ground terminals: 20 MΩ or more at 500 V DC

Between output and ground terminals: 20 MΩ or more at 500 V DC

Withstand voltage: Between power and ground terminals: 1 minute at 1500 V AC

Between output and ground terminals: 1 minute at 1000 V AC

Withstand noise: 1500 V (peak to peak)

Pulse width: 1 µs

Rise time: 1 ns

By noise simulator

Ambient temperature range: 0 to 50 °C

Ambient humidity range: 45 to 85 % RH (Non condensing)

Ambient operating atmosphere:

There should be neither corrosive gases nor much dust.

Storage temperature range: −10 to +60 °C

Storage humidity range: 95 % RH or less (Non condensing)

Dimensions: 48 (W) × 96 (H) × 100 (D) mm

Weight: Approx. 300 g

IMS01C01-E7

9

Page 16

3. MOUNTING

To prevent electric shock or instrument failure, always turn off the power

before mounting or removing the instrument.

WARNING

!

3.1 Mounting Environment

(1) This instrument is intended to be used under the following environmental conditions. (IEC61010-1)

[OVERVOLTAGE CATEGORY II, POLLUTION DEGREE 2]

(2) Avoid the following when selecting the mounting location:

Ambient temperature less than 0 °C or more than 50 °C.

Ambient humidity of less than 45 % or more than 85 % RH.

Rapid changes in ambient temperature which may cause condensation.

Corrosive or inflammable gases.

Direct vibration or shock to the mainframe.

Water, oil, chemicals, vapor or steam splashes.

Excessive dust, salt or iron particles.

Excessive induction noise, static electricity, magnetic fields or noise.

Direct air flow from an air conditioner.

Exposure to direct sunlight.

Excessive heat accumulation.

10 IMS01C01-E7

Page 17

A

3.2 Dimensions

External dimensions

4

3. MOUNTING

(Unit: mm)

47.5

96

100

3.5

48

Module mounting depth (Mounting on the DIN rail)

The mounting depth of each module is 108 mm from the mounting surface inside the panel to the front

of the module with the module mounted on the DIN rail. However, when modular connector cables are

plugged in, additional depth is required.

pprox.

50

108

(Unit: mm)

DIN rail

IMS01C01-E7

11

Page 18

3. MOUNTING

3.3 Mounting the Mother Block

The mother block can be mounted to a panel or DIN rail.

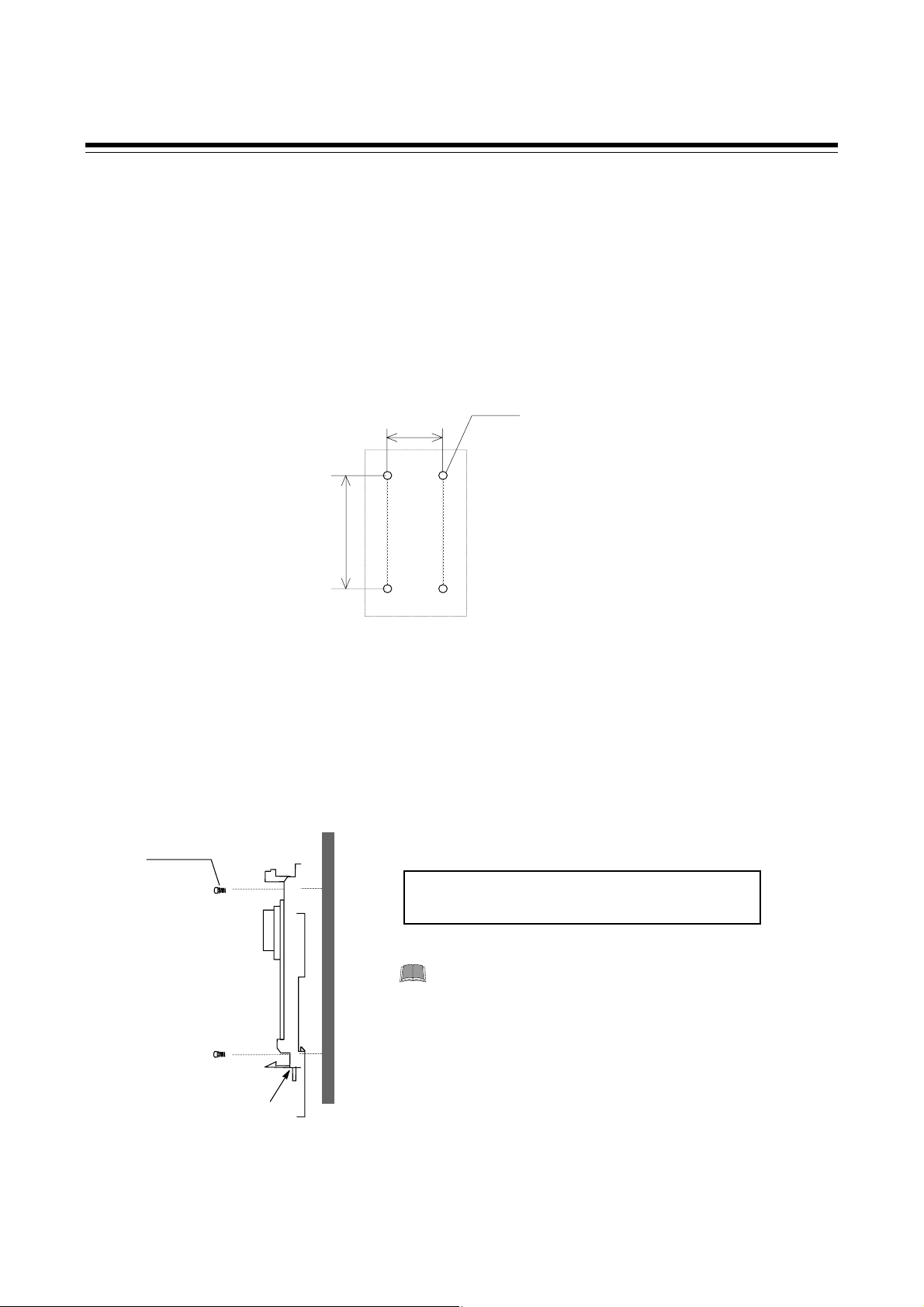

Panel mounting directions

1. Refer to both the panel mounting dimensions below and the external dimensions in previous

section when selecting the location.

(Unit: mm)

4-M3

24

77

2. Remove the module from the mother block. For details of removing the module, see

3.5 Removing the module (P. 14).

3. Connect the mother blocks together before tightening the screws on the panel.

(Customer must provide the set screws)

M3 × 10

Recommended tightening torque:

0.3 Nm (3 kgfcm)

When the mother block is mounted on the panel,

50 mm or more space is required at the top and

bottom of the mother block to attach the

module mainframe.

Mother block

12

IMS01C01-E7

Page 19

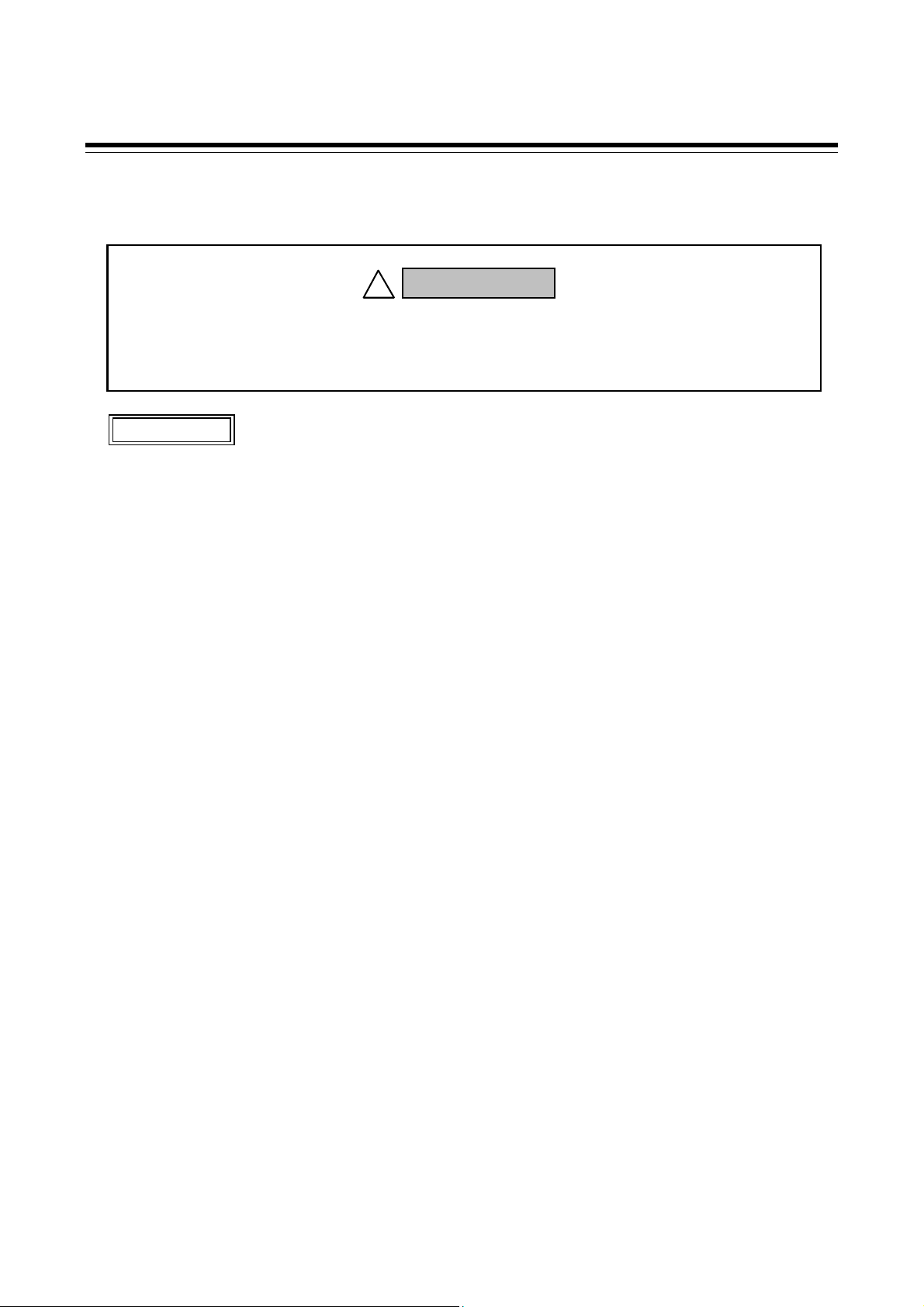

3. MOUNTING

DIN rail mounting directions

1. Remove the module mainframe from the mother block. For details of removing the module

mainframe, see 3.5 Removing the Module Mainframe (P. 14).

2. Pull down both locking devices at the bottom of the mother block.

3. Attach the top bracket of the mother block to the DIN rail and push the lower section into place

on the DIN rail. (B)

4. Slide the locking devices up to secure the mother block to the DIN rail. (C)

(A)

When the mother block is mounted on panel, 50 mm or more space is required at the

top and bottom of the mother block to attach the module mainframe.

Locking device

A

B

C

IMS01C01-E7

13

Page 20

3. MOUNTING

3.4 Mounting the Module Mainframe

It engages the module with the mother block that is mounted on DIN rail or a panel.

1. Place the module mainframe opening on top of the mother block tab. (A)

2. Snap the lower part of module mainframe on to the mother block. (B)

Opening at top of module

A snapping sound will be heard when module mainframe is securely connected to mother

block.

A

Tab at top of mother

B

3.5 Removing the Module Mainframe

To separate the module mainframe from the mother block, press the bottom on the module, lifting

upward, to release connection.

Mother block

Module mainframe

Press bottom of module

and lift upward to release

Module mainframe

Upper

section

Lower

section

Mother block

14

IMS01C01-E7

Page 21

4. WIRING

4.1 Wiring

To prevent electric shock or instrument failure, do not turn on the power until all

the wiring is completed.

CAUTIONS

Power supply wiring:

WARNING

!

Use a power supply is within the power supply voltage variation range.

For power supply wires, use twisted wires with low voltage drop.

Separate each of the instrument power supply line, input/output circuit power supply line,

equipment and motor power supply line, and operating circuit power supply line.

If a noise source is near the instrument and could affect the instrument, use a noise

filter.

− Shorten the distance between twisted power supply wire pitches. The shorter the

distance between the pitches, the more effective for noise reduction. In addition,

always ground noise filter.

− Always install the noise filter on the grounded panel. Also minimize the wiring distance

between the noise filter output side and instrument power supply terminals to ensure

the effectiveness of the noise filter.

− Do not connect fuses or switches on the wiring of the noise filter output side, since

these may reduce the effectiveness of the noise filter.

− To obtain a satisfactory noise filter effect, select the most suitable type after due

consideration of instrument power supply voltage and filter frequency characteristics.

To the instrument with power supply of 24 V, please be sure to supply the power from

SELV circuit.

Grounding wire wiring:

Ground the instrument separately from other equipment. The grounding resistance should

be 100 Ω or less. Use grounding wires with a cross section area of 2.0 mm

IMS01C01-E7 15

2

or more.

Page 22

4. WIRING

Power supply and ground wiring

Power terminals

DC +

24 V

Ground terminal

12

13

-

11

12

14

13

14

15

Terminal screw

Screw size: M3

Recommended tightening torque:

0.4 N⋅m (4 kgf⋅cm)

Power supply

21.6 to 26.4 V DC (Rating: 24V DC)

Ripple noise: less than 10 % (peak to peak)

Ground

Ground the instrument separately from other equipment. The grounding resistance should be 100 Ω or

less. Use grounding wires with a cross section area of 2.0 mm

2

or more.

16

IMS01C01-E7

Page 23

(B)

4.2 Connection

To prevent electric shock or instrument failure, turn off the power before

connecting or disconnecting the instrument and peripheral equipment.

4.2.1 Connection to PLC

Customer is requested to prepare a communication cable fit for the COM-E to be connected by PLC.

YOKOGAWA FA-M3 series

WARNING

!

4. WIRING

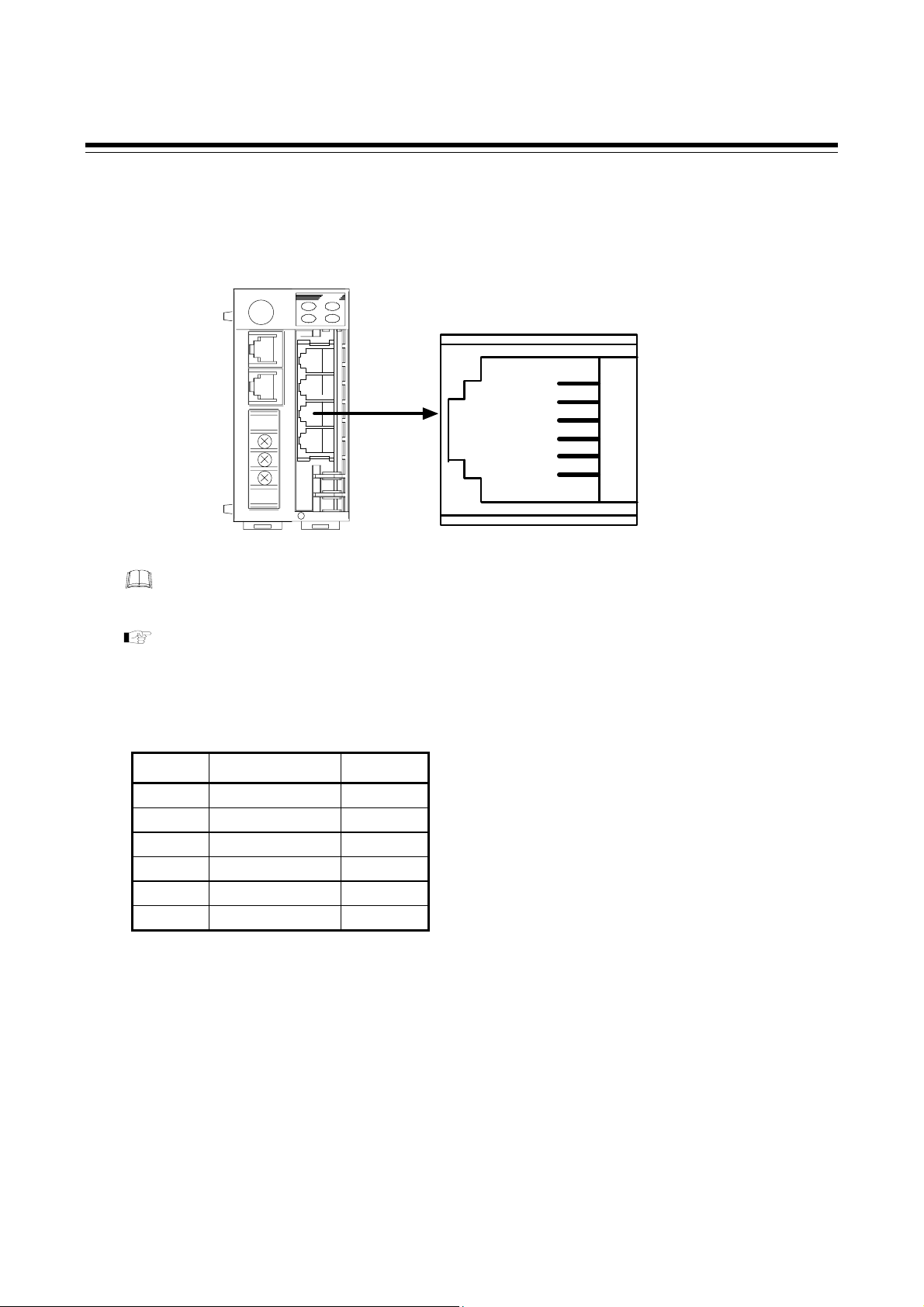

Pin layout of COM3

COM-E

The 6-pin type modular connector should be used for the connection to the COM-E.

Pin number and signal name (RS-422A)

(Recommended manufacturer and model : Hirose Electric, TM4P-66P)

The details of the connectable connector for the PLC please also read the instruction manual

for the used PLC.

Pin No. Signal Name Symbol

PLC communication port : COM3

T (A)

T (B)

SG 3

R

R (A)

SG

1

2

4

5

6

1 Send Data T (A)

2 Send Data T (B)

3 Signal Ground SG

4 Receive Data R (B)

5 Receive Data R (A)

IMS01C01-E7

6 Signal Ground SG

17

Page 24

4. WIRING

(

)

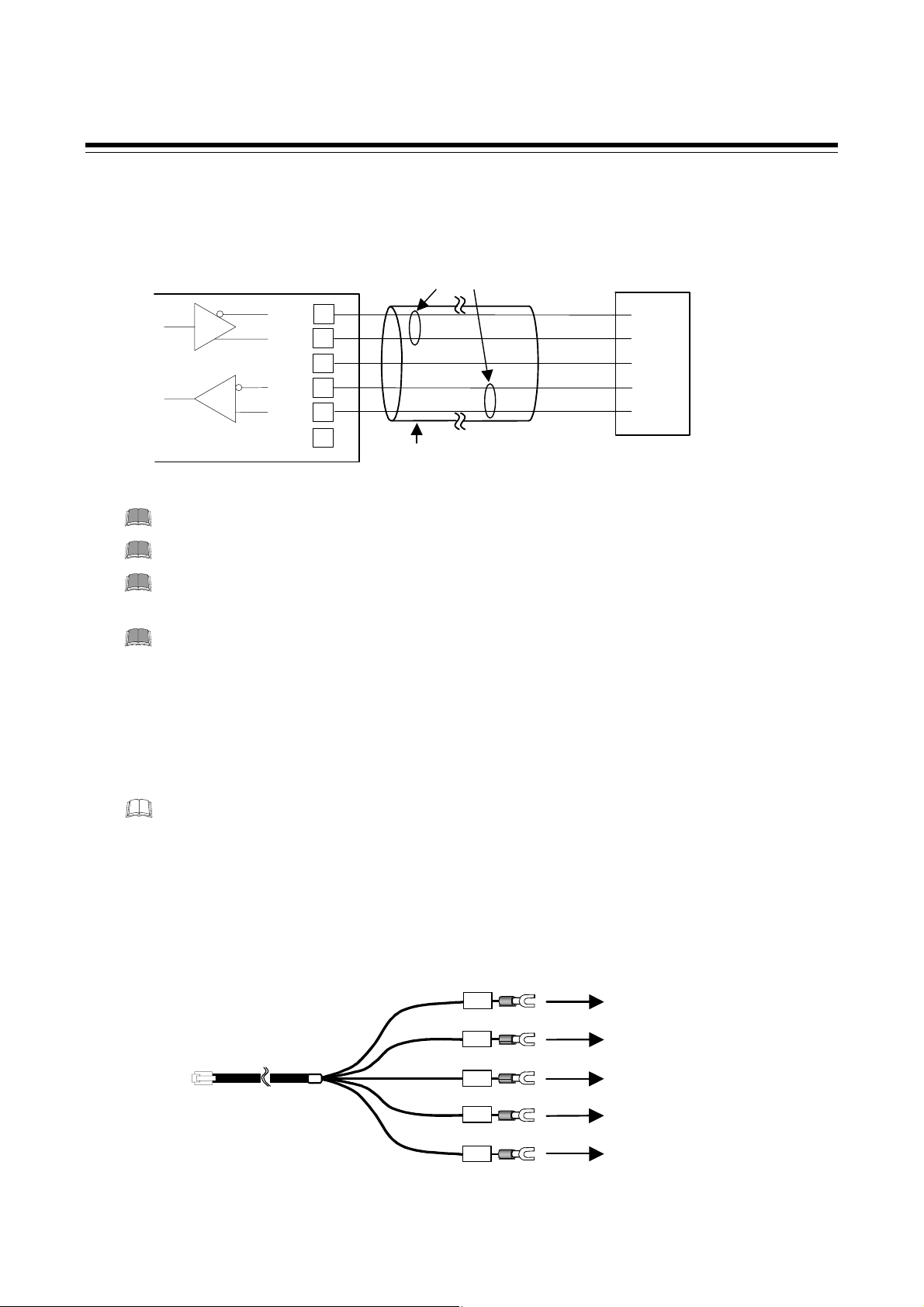

Diagram of RS-422A communication cable wiring

COM-E

1

T (A)

T (B)

SG

R (B)

R (A)

SG

2

3

4

5

6

RS-422A

Paired wire

Twisted pair wire

with shield

YOKOGAWA FA-M3 series

PLC

RDA

RDB

SG

SDB

SDA

Modular connector cable W-BF-01 * can use to connect PLC.

*

Shields of the cable are connected to SG (No. 6 pin) of the COM-E connector.

A wiring example when using our W-BF-01 connection cable is shown in the following.

Cable type: W-BF-01-3000 (RKC product, Sold separately)

[Standard cable length: 3 m]

Orange

YOKOGAWA FA-M3 series

R(B)

PLC

SDB

White

R(A)

SDA

W-BF-01

Black

Blue

Red

T(B)

T(A)

SG

RDB

RDA

SG

18

IMS01C01-E7

Page 25

)

MITSUBISHI MELSEC A series (A, AnA, AnU types)/Q series/QnA series

Pin layout of COM3

COM-E

PLC communication port : COM3

4. WIRING

The 6-pin type modular connector should be used for the connection to the COM-E.

(Recommended manufacturer and model : Hirose Electric, TM4P-66P)

The details of the connectable connector for the PLC please also read the instruction manual

for the used PLC.

Pin number and signal name (RS-422A)

Pin No. Signal Name Symbol

1 Send Data T (A)

2 Send Data T (B)

3 Signal Ground SG

4 Receive Data R (B)

5 Receive Data R (A)

6 Signal Ground SG

T (A)

T (B)

1

2

SG 3

R (B

R (A)

SG

4

5

6

IMS01C01-E7

19

Page 26

4. WIRING

A

A

Diagram of RS-422A communication cable wiring

RS-422A

COM-E

T (A)

T (B)

SG

R (B)

R (A)

SG

1

2

3

4

5

6

Paired wire

Twisted pair wire

(with shield)

MITSUBISHI MELSEC

A series (A, AnA, AnU types)/

Q series/QnA series

PLC

RDB

RDA

SG

SD

SDB

For connection with the COM-E, use the Computer link unit.

Cannot connect to the PLCs CPU-port.

As communication protocol, the type 4 protocol control procedure only for

MITSUBISHI is used.

When preparing a cable of connecting the Computer link unit belonging to the

MITSUBISHI MELSEC A series of PLCs to our COM-E, cross each pair of wires as

shown in Fig.4-14 as the A and B terminal positions on their terminal boards are not

symmetrical.

Example: Connect the COM-E T (A) send data terminal to the RDB receive data terminal

on the Computer link unit belonging to the MITSUBISHI MELSEC A series of

PLCs.

Modular connector cable W-BF-01 * can use to connect PLC.

*

Shields of the cable are connected to SG (No. 6 pin) of the COM-E connector.

A wiring example when using our W-BF-01 connection cable is shown in the following.

Cable type: W-BF-01-3000 (RKC product, Sold separately)

[Standard cable length: 3 m]

Orange

R(B)

White

W-BF-01

Black

Blue

Red

R(A)

T(B)

T(A)

SG

MITSUBISHI MELSEC

A series (A, AnA, AnU types)/

Q series/QnA series

20

PLC

SDA

SDB

RD

RDB

SG

IMS01C01-E7

Page 27

(B)

OMRON SYSMAC CS1 series

Pin layout of COM3

COM-E

4. WIRING

PLC communication port : COM3

The 6-pin type modular connector should be used for the connection to the COM-E.

Pin number and signal name (RS-422A)

(Recommended manufacturer and model : Hirose Electric, TM4P-66P)

The details of the connectable connector for the PLC please also read the instruction manual

for the used PLC.

Pin No. Signal Name Symbol

1 Send Data T (A)

2 Send Data T (B)

3 Signal Ground SG

4 Receive Data R (B)

5 Receive Data R (A)

6 Signal Ground SG

T (A)

T (B)

SG 3

R

R (A)

SG

1

2

4

5

6

IMS01C01-E7

21

Page 28

4. WIRING

(

)

A

Diagram of RS-422A communication cable wiring

COM-E

1

T (A)

T (B)

SG

R (B)

R (A)

SG

2

3

4

5

6

RS-422A

Paired wire

Twisted pair wire

with shield

OMRON SYSMAC CS1 series

PLC

RDA

RDB

SDB

SDA

Modular connector cable W-BF-01 * can use to connect PLC.

*

Shields of the cable are connected to SG (No. 6 pin) of the COM-E connector.

A wiring example when using our W-BF-01 connection cable is shown in the following.

Cable type: W-BF-01-3000 (RKC product, Sold separately)

[Standard cable length: 3 m]

OMRON SYSMAC CS1 series

PLC

Orange

White

R(B)

R(A)

SDB

SDA

W-BF-01

Black

Blue

Red

T(B)

T(A)

SG

RDB

RD

22

IMS01C01-E7

Page 29

•

•

4.2.2 Connection to the RKC temperature controller

For the connection cable, use the RKC product (Sold separately).

Cable type: W-BF-01-3000 [Standard cable length: 3 m] (RKC product, Sold separately)

When using one RKC temperature controller

COM-E

Connection cable

W-BF-01

RKC temperature controller

PV

SV

R/S

CB100

CB100

4. WIRING

When the communication interface of RKC temperature controller is RS-422A

W-BF-01

Connect according to the label names as they are without crossing the wires.

Orange

White

Black

Blue

Red

R(B)

R(A)

T(B)

T(A)

SG

RKC temperature

controller terminals

R (B)

R (A)

T (B)

T (A)

SG

When the communication interface of RKC temperature controller is RS-485

In RS-485, connect the signal line T (A) and R (A). And, connect the signal line T (B) and R (B) in

the same way.

W-BF-01

Orange

Black

White

Blue

Red

R(B)

T(B)

R(A)

T(A)

SG

When using the RKC temperature controller, always set addresses of them to 0.

When using the RKC temperature controller, set communication interval time period

for them to 25 ms or more.

For details on setting communication with the RKC temperature controller, see the

Communications instruction manual for the RKC temperature controller.

RKC temperature

controller terminals

T/R (B)

T/R (A)

SG

IMS01C01-E7

23

Page 30

4. WIRING

When using two or more RKC temperature controllers

COM-E

When the communication interface of RKC temperature controller is RS-422A

W-BF-01

Connection cable

W-BF-01

Junction terminals

Orange

White

Black

Blue

Red

R(B)

R(A)

T(B)

T(A)

SG

RKC temperature controllers

PV

SV

R/S

CB100

PV

SV

R/S

CB100

Up to 20 controllers

Junction terminals

RKC temperature

controller terminals

R (B)

R (A)

T (B)

T (A)

SG

Connect according to the label names as they are without crossing the wires.

24

R (B)

R (A)

T (B)

T (A)

SG

Up to 20 controllers

Continued on the next page.

IMS01C01-E7

Page 31

•

•

Continued from the previous page.

When the communication interface of RKC temperature controller is RS-485

In RS-485, connect the signal line T (A) and R (A). And, connect the signal line T (B) and R (B) in

the same way.

W-BF-01

Orange

Black

White

Blue

Red

R(B)

T(B)

R(A)

T(A)

SG

Junction terminals

RKC temperature

controller terminals

4. WIRING

T/R (B)

T/R (A)

SG

T/R (B)

T/R (A)

SG

Up to 20 controllers

When using the RKC temperature controller, always use their addresses from address

number 0 in succession.

When using the RKC temperature controller, set communication interval time period

for them to 25 ms or more.

Prepare cables for connecting the junction branch box to the temperature controllers on your

side. (No cables included in the instrument)

For details on setting communication with the RKC temperature controller, see the

Communications instruction manual for the RKC temperature controller.

IMS01C01-E7

25

Page 32

4. WIRING

(B)

(B)

Pin layout of COM4

COM-E

RKC temperature controller

communication port: COM4

The 6-pin type modular connector should be used for the connection to the COM-E.

(Recommended manufacturer and model : Hirose Electric, TM4P-66P)

Pin number and signal name (RS-422A)

Pin No. Signal Name Symbol

1 Receive Data R (A)

2 Receive Data R (B)

3 Signal Ground SG

4 Send Data T (B)

5 Send Data T (A)

6 Signal Ground SG

R (A)

R

SG 3

T

T (A)

SG

1

2

4

5

6

26

IMS01C01-E7

Page 33

Diagram of communication cable wiring

RS-485

4. WIRING

COM-E

In RS-485, connect the signal line T (A) and R (A). And, connect the signal line T (B) and

R (B) in the same way.

RS-422A

R (A)

R (B)

SG

T (B)

T (A)

SG

COM-E

RS-485

Paired wire

1

2

3

RKC temperature

controller

T/R (A)

T/R (B)

SG

4

5

6

Twisted pair wire

(with shield)

RS-422A

Paired wire

RKC temperature

controller

R (A)

R (B)

T (B)

T (A)

SG

SG

1

2

3

4

5

6

Twisted pair wire

(with shield)

T (A)

T (B)

SG

R (A)

R (B)

Modular connector cable W-BF-01 * can use to connect RKC temperature controller.

*

Shields of the cable are connected to SG (No. 6 pin) of the COM-E connector.

IMS01C01-E7 27

Page 34

4. WIRING

4.2.3 Connection to the host computer

Customer is requested to prepare a communication cable fit for the COM-E to be connected by the

host computer.

Pin layout of COM1

COM-E

Host communication port:

COM1

Pin number and signal name (RS-232C)

Pin No. Signal Name Symbol

1

Unused

2 Send Data SD (TXD)

3 Signal Ground SG

4 Receive Data RD (RXD)

5

6 Signal Ground SG

Unused

Diagram of RS-232C communication cable wiring

Unused 1

SD 2

SG 3

RD 4

Unused 5

SG 6

28

COM-E

SD (TXD)

SG (GND)

RD (RXD)

SG (GND)

RS-232C

2

3

4

6

Shielded wire

Host Computer

SD (TXD)

SG (GND)

RD (RXD)

*

RS (RTS)

CS (CTS)

* Short circuit between RS-CS

pin in the connector.

IMS01C01-E7

Page 35

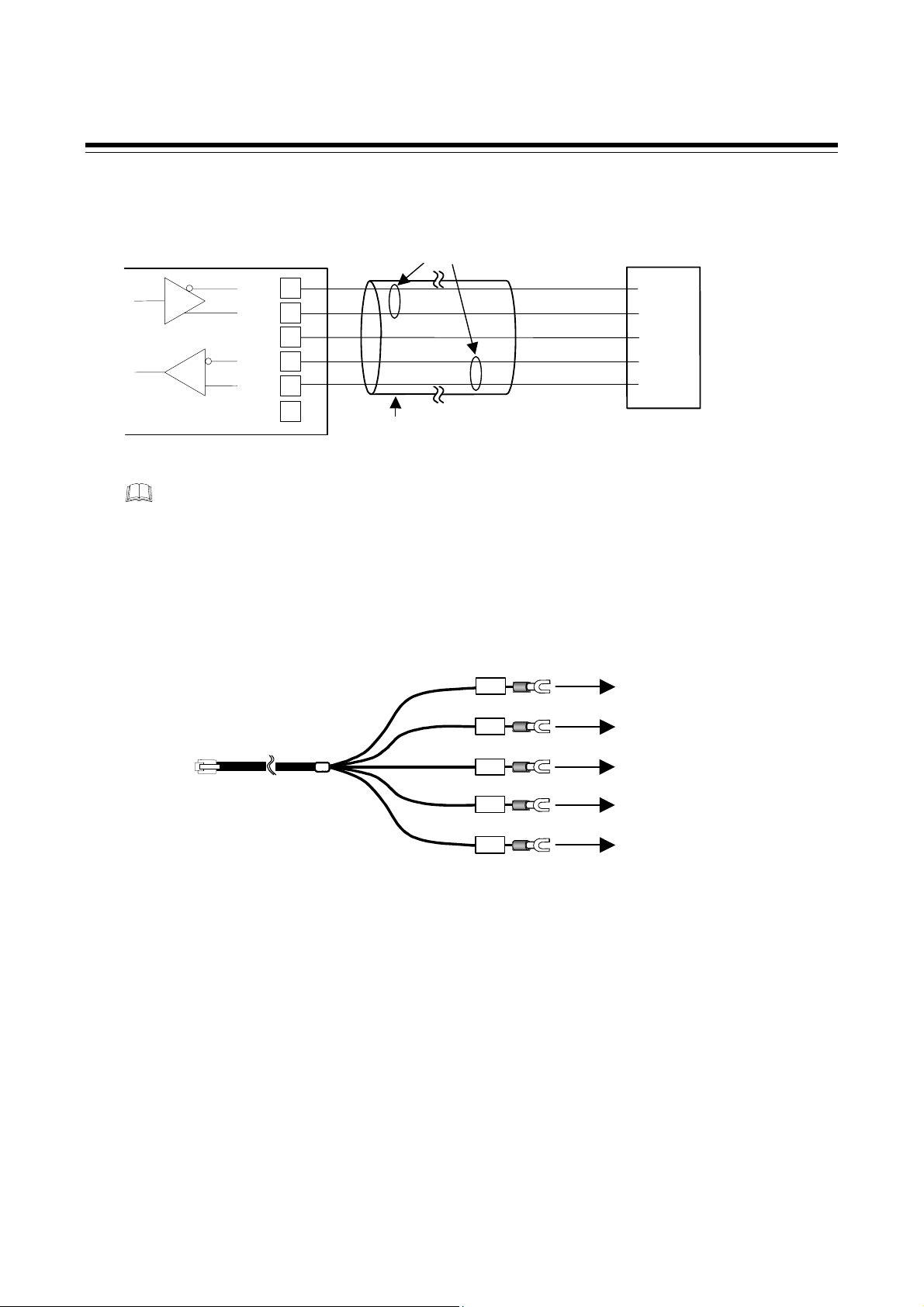

4.2.4 Connection to operation panel

For the connection cable, use the RKC product (Sold separately).

Cable type: W-BF-01-3000 [Standard cable length: 3 m]

COM-E

RS-422A

Terminal

converter

4. WIRING

Operation panel (front)

MONITOUCH V6 series

Connection cable

W-BF-01

TC485

Cable type: W-BF-01-3000 (RKC product, Sold separately)

[Standard cable length: 3 m]

Terminal converter

Orange

R(B)

White

Black

Blue

Red

R(A)

T(B)

T(A)

SG

W-BF-01

For connection of the operation panel with the connection cable, the TC485 terminal

converter connector (sold separately: Hakko Electronics Co., Ltd) is required.

The details of the connectable connector for the operation panel, please also read the

instruction manual for the V6 series of Hakko Electronics Co., Ltd.

TC485

SD

+

SD

-

RD

+

RD

-

SG

IMS01C01-E7

29

Page 36

4. WIRING

(

)

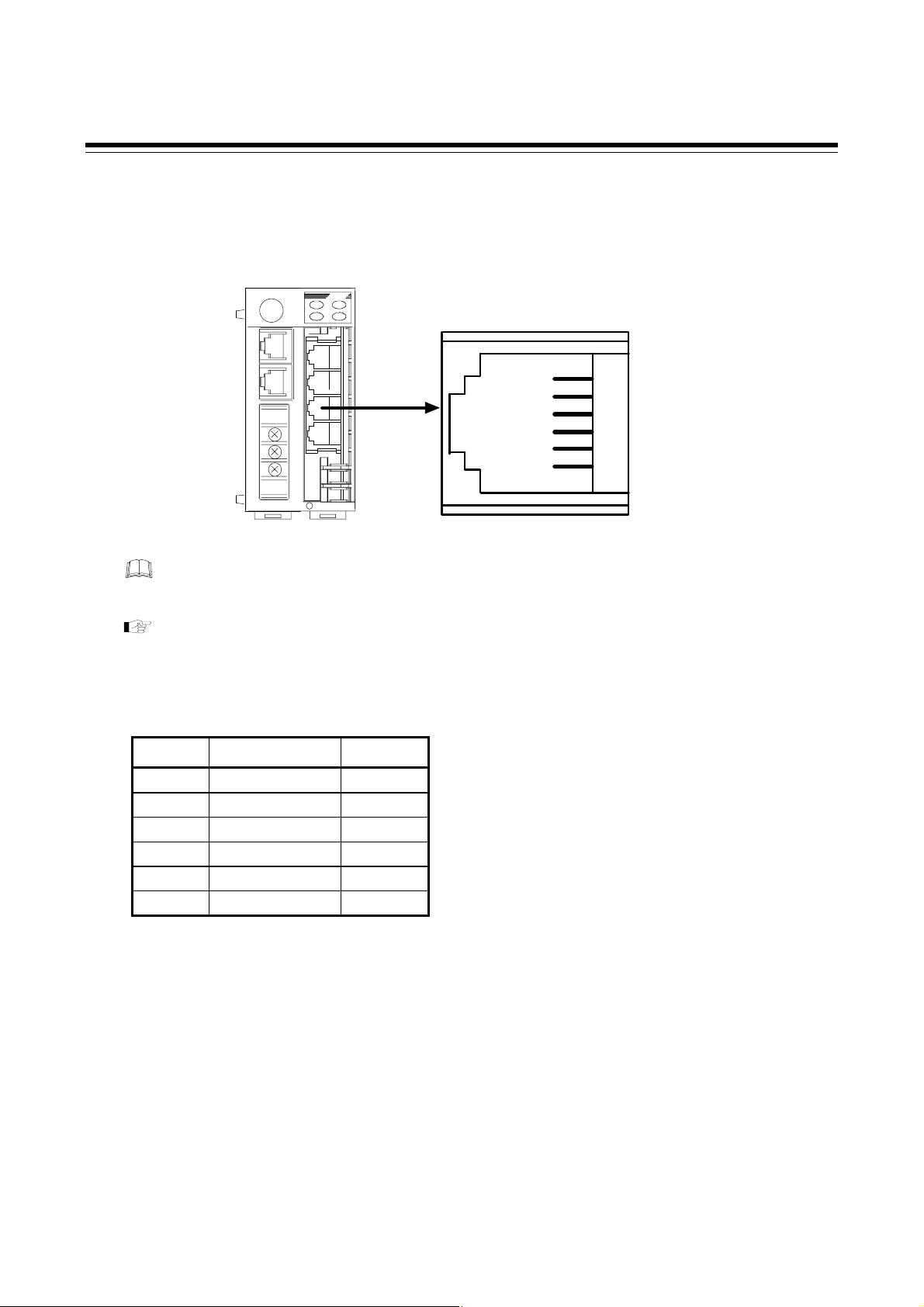

Pin layout of COM2

COM-E

Operation panel

communication port: COM2

The 6-pin type modular connector should be used for the connection to the

(Recommended manufacturer and model: Hirose Electric, TM4P-66P)

The details of the connectable connector for the operation panel, please also read the

instruction manual for the V6 series of Hakko Electronics Co., Ltd.

Pin number and signal name (RS-422A)

Pin No. Signal Name Symbol

R (A)

R (B)

SG

T (B)

T (A)

SG

1

2

3

4

5

6

COM-E.

1 Receive Data R (A)

2 Receive Data R (B)

3 Signal Ground SG

4 Send Data T (B)

5 Send Data T (A)

6 Signal Ground SG

Diagram of RS-422A communication cable wiring

COM-E

R (A)

R (B)

T (B)

T (A)

SG

SG

1

2

3

4

5

6

Modular connector cable W-BF-01 * can use to connect the operation panel.

Shields of the cable are connected to SG (No. 6 pin) of the COM-E connector.

*

RS-422A

Paired wire

Twisted pair wire

with shield

Operation panel

-SD

+SD

SG

+RD

-RD

30

IMS01C01-E7

Page 37

5. PLC COMMUNICATION

5.1 Rotary Switch Setting

The COM-E rotary switch can set the PLC register area.

For this setting, use a small blade screwdriver.

COM-E

It is prohibited to set the rotary switch to the “B” position.

Select the setting of rotary switch after confirming the PLC register area.

Rotary switch

0

1

2

F

3

E

4

D

5

C

6

B

7

A

9

8

Setting range: 0 to F (hexadecimal)

Factory set value: 8: OMRON SYSMAC CS1 series

9: MITSUBISHI MELSEC A series/

Q series/QnA series

A: YOKOGAWA FA-M3 series

IMS01C01-E7

31

Page 38

5. PLC COMMUNICATION

5.2 PLC Setting

5.2.1 YOKOGAWA FA-M3 series

Please turn on number 1 only and turn off numbers 2 to 8 of the data format

configuration switch, which there is in personal computer link module F3LC11-2N

belonging to the YOKOGAWA FA-M3 series of PLCs. When the data format

configuration switch turn on number 1 only and turn off numbers 2 to 8 , these come to

the following data format.

• Data bit: 8

• Parity bit: Without

• Stop bit: 1

• Checksum: Without

• Final character specification: Without

• Protection function: Without

For details on setting with the PLC, please also read the instruction manual for the used PLC.

Rotary switch Number of COM-E and PLC register area

Rotary

switch No.

PLC register area Remarks

0 Area available in D register D1000 to D1399

1 Area available in D register D1500 to D1899

2 Area available in D register D2000 to D2399

3 Area available in D register D2500 to D2899

4 Area available in D register D3000 to D3399

5 Area available in D register D3500 to D3899

6 Area available in D register D4000 to D4399

7 Area available in D register D4500 to D4899

8 Area available in D register D5000 to D5399

9 Area available in D register D5500 to D5899

A Area available in D register D6000 to D6399

B Interdict from setting (the default mode)

C Area available in W register W0000 to W0399 Not usable

D Area available in W register W0500 to D0899

E Area available in D register D0000 to D0399 Not usable

F Area available in D register D0500 to D0899

32

IMS01C01-E7

Page 39

5. PLC COMMUNICATION

5.2.2 MITSUBISHI MELSEC A series (A, AnA, AnU types)/Q series/QnA

series

Please set the Computer link unit belonging to the MITSUBISHI MELSEC series of

PLCs as follows.

• Protocol: MITSUBISHI MELSEC series special protocol type 4

• Data bit: 8

• Parity bit: Without

• Stop bit: 1

• Sum check code: Provided

• Writing during RUN: ON

• Station number: 00

• PC number: FF

For details on setting with the PLC, please also read the instruction manual for the used PLC.

Rotary switch Number of COM-E and PLC register area

Rotary

switch No.

0

1

2

3

4

5

6

7

8

9

A

B

C

PLC register area Remarks

Area available in D register D1000 to D1399

Area available in D register D1500 to D1899

Area available in D register D2000 to D2399

Area available in D register D2500 to D2899

Area available in D register D3000 to D3399

Area available in D register D3500 to D3899

Area available in D register D4000 to D4399

Area available in D register D4500 to D4899

Area available in D register D5000 to D5399

Area available in D register D5500 to D5899

Area available in D register D6000 to D6399

Interdict from setting (the default mode)

Area available in W register W0000 to W018F

Corresponding to AnA/AnU

type CPU, Q series and QnA

series.

Corresponding to the instrument

model which uses the QR/QW

command as a communication

command.

Corresponding to A type CPU. *

D

E

F

* A type CPU model code: A1S, A1SJ, A0J2H, A1, A1N, A2 (S1), A2N (S1), A2S, A2A (S1), A2U, A2US,

A2C, A52G, A3, A3N, A3A, A3U, A4U, A3H, A3M, A73 or A7LMS-F

IMS01C01-E7

Area available in W register W0200 to D038F

Area available in D register D0000 to D0399

Area available in D register D0500 to D0899

Corresponding to the instrument

model which uses the WR/WW

command as a communication

command.

33

Page 40

5. PLC COMMUNICATION

5.2.3 OMRON SYSMAC CS1 series

Please set the CPU unit belonging to the OMRON SYSMAC CS1 series of PLCs as

follows.

• Serial communication mode: high-order link method

• Data bit: 8

• Parity bit: Provided (even)

• Stop bit: 1

• Unit number (Model number) : 00

For details on setting with the PLC, please also read the instruction manual for the used PLC.

Rotary switch Number of COM-E and PLC register area

Rotary

switch No.

PLC register area Remarks

0 Area available in D register D1000 to D1399

1 Area available in D register D1500 to D1899

2 Area available in D register D2000 to D2399

3 Area available in D register D2500 to D2899

4 Area available in D register D3000 to D3399

5 Area available in D register D3500 to D3899

6 Area available in D register D4000 to D4399

7 Area available in D register D4500 to D4899

8 Area available in D register D5000 to D5399

9 Area available in D register D5500 to D5899

A Area available in D register D6000 to D6399

B Interdict from setting (the default mode)

C Area available in D register D7000 to D7399

D Area available in D register D7500 to D7899

E Area available in D register D0000 to D0399

F Area available in D register D0500 to D0899

34

IMS01C01-E7

Page 41

5. PLC COMMUNICATION

5.3 The RKC Temperature Controller Setting

Please set the RKC temperature controller side as follows.

CB100/CB400/CB500/CB700/CB900

Setting items Description

Communication speed 19200 bps

Data bit 8

Stop bit 1

Parity bit Without

Communication interval time 15 or more (25 ms or more)

Device address Always use their addresses from address number 0 in

succession.

REX-F400/REX-F700/REX-F900

Setting items Description

Communication speed 19200 bps

Data bit 8

Stop bit 1

Parity bit Without

Communication interval time 25 ms or more

Device address Always use their addresses from address number 0 in

succession.

SA200

Setting items Description

Communication speed 19200 bps

Data bit 8

Stop bit 1

Parity bit Without

Communication interval time 25 ms or more

Device address Always use their addresses from address number 0 in

succession.

For details on setting communication with the RKC temperature controller, see the

Communications instruction manual

for the RKC temperature controller.

IMS01C01-E7

35

Page 42

5. PLC COMMUNICATION

5.4 Communication Data

5.4.1 Request command and data transfer

Data transfer between the PLC and RKC temperature controller are excuted by the request

command (Register area No. 20).

Request command “0: Monitor”

Command which requests the RKC temperature controller to write data items such as temperature

measured values, etc. (attribute: RO) to the PLC side. The COM-E always repeats data writing until

“1: Setting” or “2: Set value monitor” is set to the request command. The COM-E communication

status is set to “1: Writing on monitor data” during data transfer.

Data transfer procedures

[Example]

• Set “0: Monitor” to the request command on the PLC side.

• If the request command is set, the COM-E writes our temperature controller data items such as

temperature measured values, etc. (attribute: RO) into the PLC.

• The COM-E communication status is set to “1: Writing on monitor data” during data transfer.

PLC

1. The COM-E reads the request

command “0: Monitor” from the PLC.

COM-E

The COM-E always repeats

data read.

RKC temperature

controller

2. The COM-E writes RKC temperature

controller data items such as

temperature measured values, etc.

into the PLC.

Request command “1: Setting”

This is the command of making a request to our temperature controller for writing data items such as

temperature set values, etc. (attribute: RW) set to the resister on the PLC side (memory).

Data transfer procedures

[Example]

• Data items such as temperature set values, etc. (attribute: RW) are set to the resister on the PLC

side (memory).

• Set “1: Setting” to the request command on the PLC side.

Continued on the next page.

36

IMS01C01-E7

Page 43

5. PLC COMMUNICATION

Continued from the previous page.

•

If the request command is set, the COM-E starts reading data items such as temperature set values,

etc. (attribute: RW) on the PLC side. The COM-E communication status is set to “2: Reading out

setting data” during data read on the PLC side.

• If the COM-E finishes reading data items from the PLC, it starts writing the data items read to our

temperature controller. The COM-E communication status is set to “2: Reading out setting data”

even during data write into our temperature controller.

• After the data is transferred, the request command and COM-E communication status returns

to “0: Monitor” and “1: Writing on monitor data,” respectively.

PLC

1. The COM-E reads the request

command “1: Setting” from the PLC.

COM-E

3. The COM-E writes data

items read from the PLC

side.

RKC temperature

controller

2. The COM-E reads data items such as

temperature set values, etc.

on the PLC side.

Request command “2: Set value monitor”

Command which requests the RKC temperature controller to write data items such as temperature set

values, etc. (attribute: RW) to the PLC side.

Data transfer procedures

[Example]

• Set “2: Set value monitor” to the request command on the PLC side.

• If the request command is set, the COM-E writes our temperature controller data items such as

temperature set values, etc. (attribute: RW) into the PLC.

The COM-E communication status is set to “3: Writing on setting data” during data transfer.

• After the data is transferred, the request command and COM-E communication status returns

to “0: Monitor” and “1: Writing on monitor data,” respectively.

PLC

1. The COM-E reads the request

command “2: Set value monitor” from

the PLC.

COM-E

The COM-E always repeats

data read.

RKC temperature

controller

IMS01C01-E7

2. The COM-E writes RKC temperature

controller data items such as temperature

set values, etc. into the PLC.

37

Page 44

5. PLC COMMUNICATION

5.4.2 Communication status check

The communication status between the PLC and COM-E is confirmed by the COM-E communication

status (Register area No. 21).

The COM-E always writes data on the COM-E communication status into the PLC.

COM-E communication status “0: Communication failure”:

“0: Communication failure” represents that communication between the COM-E and PLC is abnormal.

If communication between the COM-E and PLC is normal, the COM-E communication status

always becomes 1, 2, or 3.

COM-E communication status “1: Writing on monitor data”:

“1: Writing on monitor data” represents that data items such as temperature measured values, etc.

(attribute: RO) are being written into the PLC.

COM-E communication status “2: Reading out setting data”:

“2: Reading out setting data” represents that data items such as temperature set values, etc. (attribute:

RW) are being read from the PLC.

COM-E communication status “3: Writing on setting data”:

“3: Writing on setting data” represents that data items such as temperature set values, etc. (attribute:

RW) are being written into the PLC.

Communication status check procedures

[Example]

When the COM-E communication status is “1: Writing on monitor data”

1. “0: Communication failure” is set to the register on the PLC side (COM-E communication

status).

Conduct this setting only when checking the communication status.

2. After setting, take appropriate wait time.

Wait time differs depending on the connectable number of our temperature controllers.

It is about 1 second/controller.

3. After a lapse of wait time, confirm that the value in the register on the PLC side (COM-E

communication status) is “1: Writing on monitor data.”

38

IMS01C01-E7

Page 45

5.4.3 Caution for handling communication data

(1) The alarm status in each channel is expressed for each bit.

[b0] : Unused

[b1] : Unused

[b2] : Alarm 1 status (0: OFF 1: ON)

*

[b3] : Alarm 2 status or HBA (Heater break alarm) status

[b4] : Burnout status (0: OFF 1: ON)

[b5] : Unused

[b6] : Unused

[b7] : Unused

[b8] : Error flag (0: Normality 1: Abnormality of instrument or communication)

[b9] to [b15] : Unused

*

Remove REX-F400/REX-F700/REX-F900

(0: OFF 1: ON)

5. PLC COMMUNICATION

[Example] The following expressions are when alarm 1 is turned on.

• Binary digit: 00000000 00000100

• Hexadecimal numeral: 0004H

• Decimal numeral: 4

(2) The data type is treated as binary data with a sign and without a decimal point. For this reason,

carefully express and set the data.

[Example] Proportional band setting

Initial value of internal data: 3.0

Communication data: 30

(3) Any item whose attribute is RO (Read only) is always written to the PLC from the

COM-E.

During data write, “1: Writing on monitor data” is written to “COM-E communication status.”

(The RKC temperature controller

→ COM-E → PLC)

(4) Any item whose attribute is R/W (Read and Write) is read only when “Request command” is set to

“1: Setting.”

→ COM-E → The RKC temperature controller)

(PLC

(5) Any item whose attribute is R/W (Read and Write) is written only when “Request command” is set

to “2: Set value monitor.” After finish writing, “COM-E communication status” is set to “1:

Writing on monitor data”, “Request command” is set to “0: Monitor.”

(The RKC temperature controller

→ COM-E → PLC)

(6) The autotuning (AT) function is activated when “AT startup/stop” is set to “1: Autotuning (AT)

startup” and “A request for reading out set value” is set to “1: Reading out set value.” After the

autotuning (AT) function is finished, the

COM-E sets “2: Writing on set value” to “A request for

reading out set value” to write each set value to the PLC. At this time, “AT startup/stop” returns

to “0: Autotuning (AT) end or stop” to change the PID constants.

IMS01C01-E7

39

Page 46

5. PLC COMMUNICATION

5.5 Communication Items List

5.5.1 Reference to communication items list

This communication items list summarizes the register area numbers of the PLC, communication items,

data, setting ranges and attributes.

(1) (2) (3) (4) (5)

Register

area No.

Communication items Data Setting range Attribute

1

2 Alarm set value 1 20

3 Alarm set value 2 20

(1) Register area No.: It is written in register area numbers of the PLC that can be used with each

communication item. Check the register number which will be actually

used in

Before operation, always set “The total number of RKC temperature controllers” in

register area number 22 to the desired number.

(2) Communication items: It is written in each communication item

(3) Data: It is written in data of each communication item.

(4) Setting range: It is written in setting ranges of each communication item.

(5) Attribute: It is written in attributes of each communication item.

Never set any item whose attribute is RO (Read only).

Set value (SV)

5.6 Table of register area numbers vs. register numbers (P. 49).

20: The maximum number of RKC temperature controllers which can be

connected to the

1: It is a common data of RKC temperature controllers which be

connected to the

ROs indicate monitor items which are read from the RKC temperature

controller by the PLC .

R/Ws indicate items which are read from and written to the RKC

temperature controller by the PLC.

20 Within input range R/W

Temperature input

Process alarm, deviation alarm,

SV alarm:

-1999 to +9999

-199.9 to +999.9

Voltage/ current inputs

Deviation alarm: -span to +span

(Within 9999)

Process alarm, SV alarm:

Within input range

COM-E.

COM-E.

°C [°F] or

°C [°F]

R/W

R/W

40

IMS01C01-E7

Page 47

5.5.2 CB100/CB400/CB500/CB700/CB900

(Attribute RO: Read only R/W: Read and Write)

5. PLC COMMUNICATION

Register

area No.

1

2 Alarm 1 set value 20

Communication items Data Setting range Attribute

Set value (SV)

20 Within input range R/W

Temperature input

Process alarm, deviation alarm,

SV alarm:

−1999 to +9999 °C [°F] or

−199.9 to +999.9 °C [°F]

3 Alarm 2 set value 20

Voltage/ current inputs

Deviation alarm:

−span to +span

(Within 9999)

Process alarm, SV alarm:

Within input range

4 Heater break alarm (HBA) 1

set value

1

20 0.0 to 100.0 A R/W

5 RUN/STOP function 20 0: RUN

1: STOP

6 User unusable province

7 User unusable province

8 Overlap/Deadband

2

20

- - -

- - -

Temperature input:

−10 to +10 °C [°F] or

−10.0 to +10.0 °C [°F]

Voltage/current inputs:

−10.0 to +10.0 % of span

9 Heat-side proportional band

3

20

Temperature input:

1 (0.1) to span or

9999 (999.9)

°C [°F]

Voltage/current inputs :

0.1 to 100.0 % of span

(ON/OFF action control when set to

10 Cool-side proportional band

0 or 0.0)

2

20 1 to 1000 % of heat-side proportional

band

(0 can not be set)

11 Integral time (I) 3 20 0 to 3600 second (0: PD control) R/W

12 Derivative time (D) 3 20 0 to 3600 second (0: PI control) R/W

1

Valid only when heater break alarm is available

2

Valid only for heat/cool PID action with autotuning (Water cooling/Air cooling)

3

Cannot be set while the self-tuning (ST) function is activated. Only polling can be made.

Continued on the next page.

R/W

R/W

R/W

R/W

R/W

R/W

IMS01C01-E7

41

Page 48

5. PLC COMMUNICATION

Continued from the previous page.

Register

area No.

13 Autotuning (AT) 20

Communication items Data Setting range Attribute

0: Autotuning (AT) end or stop

1: Autotuning (AT) startup

Change to 0 automatically at the end

of Autotuning

14 Measured value (PV) 20 Within input range RO

15 User unusable province

16 User unusable province

17 Current transformer input 1

18 Alarm status

2

20 0: OFF

- - -

- - -

1

20 0.0 to 100.0 A RO

1: ON

19 User unusable province

- - -

20 Request command 1 0: Monitor

Command which requests the RKC

temperature controller to write data

items such as temperature

measured values, etc. (attribute:

RO) to the PLC side.

1: Setting

This is the command of making a

request to our temperature

controller for writing data items

such as temperature set values, etc.

(attribute: RW) set to the resister

on the PLC side (memory).

2: Set value monitor

Command which requests the RKC

temperature controller to write data

items such as temperature set

values, etc. (attribute: RW) to the

PLC side.

R/W

RO

R/W

1

Valid only when heater break alarm is available

2

For details, see 5.4.3 Caution for Handling Communication Data (P. 39).

42

Continued on the next page.

IMS01C01-E7

Page 49

Continued from the previous page.

5. PLC COMMUNICATION

Register

area No.

Communication items Data Setting range Attribute

21 COM-E communication

status

22 The connectable number of

RKC temperature controllers

23 User unusable province

1 0: Communication failure

R/W

1: Writing on monitor data

During monitor data of attribute

RO is written to PLC

2: Reading out setting data

During setting data of attribute

R/W is read from PLC

3: Writing on setting data

During setting data of attribute

R/W is written to PLC

1 1 to 20 R/W

- - -

IMS01C01-E7

43

Page 50

5. PLC COMMUNICATION

5.5.3 REX-F400/REX-F700/REX-F900

(Attribute RO: Read only R/W: Read and Write)

Register

area No.

1

2 First alarm set value 20

Communication items Data Setting range Attribute

Set value (SV)

20 Within input range R/W

Process alarm:

Within input range

Deviation alarm: −span to +span

3 Second alarm set value 20

−1999 to +9999,

or

High/low alarm, band alarm:

0 to span (or 9999)

4 Heater break alarm (HBA)

set value

1

20 0.0 to 100.0 A R/W

5 RUN/STOP transfer 20 0: RUN

1: STOP

6 User unusable province

7 User unusable province

8 Overlap/Deadband

2

20

9 Proportional band

(Heat-side)

10 Proportional band

(Cool-side)

2

- - -

- - -

−10.0 to +10.0 % of span

20 0.1 to 999.9 % of span

20 0.1 to 999.9 % of span

11 Integral time (I) 20 1 to 3600 second R/W

12 Derivative time (D) 20 0 to 3600 second (0: PI control) R/W

13 PID control/Autotuning (AT) 20

0: AT end or PID control

1: AT startup

Change to 0 automatically at the end

of Autotuning

14 Measured value (PV) 20 Within input range RO

15 User unusable province

16 User unusable province

17 Feedback resistance input

measured value

18 Alarm status

3

4

20 0: OFF

- - -

- - -

20 0.0 to 100.0 % RO

1: ON

1

Valid only when heater break alarm is available

2

Valid only for heat/cool PID action (including “with autotuning for extruder”)

3

Valid only for position proportioning PID action

4

For details, see 5.4.3 Caution for Handling Communication Data (P. 39).

Continued on the next page.

R/W

R/W

R/W

R/W

R/W

R/W

R/W

RO

44

IMS01C01-E7

Page 51

Continued from the previous page.

5. PLC COMMUNICATION

Register

area No.

19 Current transformer input

Communication items Data Setting range Attribute

20 0.0 to 100.0 A RO

value

1

20 Request command 1 0: Monitor

21 COM-E communication

1 0: Communication failure

status

22 The connectable number of

1 1 to 20 R/W

RKC temperature controllers

23 User unusable province

1

Valid only when heater break alarm is available

- - -

R/W

Command which requests the RKC

temperature controller to write data

items such as temperature

measured values, etc. (attribute:

RO) to the PLC side.

1: Setting

This is the command of making a

request to our temperature

controller for writing data items

such as temperature set values, etc.

(attribute: RW) set to the resister

on the PLC side (memory).

2: Set value monitor

Command which requests the RKC

temperature controller to write data

items such as temperature set

values, etc. (attribute: RW) to the

PLC side.

R/W

1: Writing on monitor data

During monitor data of attribute

RO is written to PLC

2: Reading out setting data

During setting data of attribute

R/W is read from PLC

3: Writing on setting data

During setting data of attribute

R/W is written to PLC

IMS01C01-E7

45

Page 52

5. PLC COMMUNICATION

5.5.4 SA200

(Attribute RO: Read only R/W: Read and Write)

Register

area No.

1

2 First alarm set value (AL1) 20

Communication items Data Setting range Attribute

Set value (SV)

20 Within input range R/W

Process alarm, SV alarm:

R/W

setting limiter (low limit) to

setting limiter (high limit)

3 Second alarm set value (AL2) 20

Deviation alarm: −span to +span

Within

−1999 to +9999 °C [°F] or

R/W

−199.9 to +999.9 °C [°F]

4 User unusable province

5 RUN/STOP function 20 0: RUN

- - -

R/W

1: STOP

6 User unusable province

7 User unusable province

8 Overlap/Deadband

3

20

- - -

- - -

−span to +span

Within

−1999 to +9999 °C [°F] or

R/W

−199.9 to +999.9 °C [°F]

9 Heat-side proportional band

(P)

20

Temperature input:

0 (0.0) to span or

9999 (999.9)

°C [°F]

R/W

Voltage/current inputs :

0.1 to span

(ON/OFF action control when set to

0 or 0.0)

10 Cool-side proportional band

3

20 1 to 1000 % of heat-side proportional

R/W 4

band

11 Integral time (I) 20 1 to 3600 second (0: PD action) R/W 5

12 Derivative time (D) 20 1 to 3600 second (0: PI action) R/W 5

1

If no alarm for first alarm or control loop break alarm is selected, the attribute becomes

RO (Read only).

2

If no alarm for second alarm is selected, the attribute becomes RO (Read only).

3

Valid only for heat/cool PID action with autotuning (Water cooling/Air cooling)

4

If heat/cool PID control with autotuning (water cooling/air cooling) for control type is not selected,

the attribute becomes RO (Read only).

5

If the self-tuning (ST) function is on, the attribute becomes RO (Read only).

Continued on the next page.

1

2

4

5

46

IMS01C01-E7

Page 53

Continued from the previous page

5. PLC COMMUNICATION

Register

area No.

13 AT startup/stop 20

Communication items Data Setting range Attribute

0: Autotuning (AT) end or stop

1: Autotuning (AT) startup

Change to 0 automatically at the

end of Autotuning

14 Measured value (PV) 20 Within input range RO

15 User unusable province

16 User unusable province

17 User unusable province

18 Alarm status

1

20 0: OFF

- - -

- - -

- - -

1: ON

19 User unusable province

- - -

20 Request command 1 0: Monitor

Command which requests the

RKC temperature controller to

write data items such as

temperature measured values,

etc. (attribute: RO) to the PLC

side.

1: Setting

This is the command of making

a request to our temperature

controller for writing data items

such as temperature set values,

etc. (attribute: RW) set to the

resister on the PLC side

(memory).

2: Set value monitor

Command which requests the

RKC temperature controller to

write data items such as

temperature set values, etc.

(attribute: RW) to the PLC side.

R/W

RO

R/W

1

For details, see 5.4.3 Caution for Handling Communication Data (P. 39).

IMS01C01-E7

Continued on the next page.

47

Page 54

5. PLC COMMUNICATION

Continued from the previous page

Register

area No.

Communication items Data Setting range Attribute

21 COM-E communication

status

22 The connectable number of

RKC temperature controllers

23 User unusable province

1 0: Communication failure

R/W

1: Writing on monitor data

During monitor data of attribute

RO is written to PLC

2: Reading out setting data

During setting data of attribute

R/W is read from PLC

3: Writing on setting data

During setting data of attribute

R/W is written to PLC

1 1 to 20 R/W

- - -

48

IMS01C01-E7

Page 55

5. PLC COMMUNICATION

5.6 Table of Register Area Numbers vs. Register Numbers

The register number used for the PLC differs depending on the rotary switch number of the COM-E.

In the following table, any register number which will be actually used can be checked by referring to

“Rotary switch No.” and “Register area No.” in 5.5 Communication Items List (P. 40).

For the Rotary switch No. 0 to 7

Register

area No.

1

2

3

4

5

6

7

8

9

10

11

0 1 2 3 4 5 6 7

D1000 D1500 D2000 D2500 D3000 D3500 D4000 D4500

to to to to to to to to

D1019 D1519 D2019 D2519 D3019 D3519 D4019 D4519

D1020 D1520 D2020 D2520 D3020 D3520 D4020 D4520

to to to to to to to to

D1039 D1539 D2039 D2539 D3039 D3539 D4039 D4539

D1040 D1540 D2040 D2540 D3040 D3540 D4040 D4540

to to to to to to to to

D1059 D1559 D2059 D2559 D3059 D3559 D4059 D4559

D1060 D1560 D2060 D2560 D3060 D3560 D4060 D4560

to to to to to to to to

D1079 D1579 D2079 D2579 D3079 D3579 D4079 D4579

D1080 D1580 D2080 D2580 D3080 D3580 D4080 D4580

to to to to to to to to

D1099 D1599 D2099 D2599 D3099 D3599 D4099 D4599

D1100 D1600 D2100 D2600 D3100 D3600 D4100 D4600

to to to to to to to to

D1119 D1619 D2119 D2619 D3119 D3619 D4119 D4619

D1120 D1620 D2120 D2620 D3120 D3620 D4120 D4620

to to to to to to to to

D1139 D1639 D2139 D2639 D3139 D3639 D4139 D4639

D1140 D1640 D2140 D2640 D3140 D3640 D4140 D4640

to to to to to to to to

D1159 D1659 D2159 D2659 D3159 D3659 D4159 D4659

D1160 D1660 D2160 D2660 D3160 D3660 D4160 D4660

to to to to to to to to

D1179 D1679 D2179 D2679 D3179 D3679 D4179 D4679

D1180 D1680 D2180 D2680 D3180 D3680 D4180 D4680

to to to to to to to to

D1199 D1699 D2199 D2699 D3199 D3699 D4199 D4699

D1200 D1700 D2200 D2700 D3200 D3700 D4200 D4700

to to to to to to to to

D1219 D1719 D2219 D2719 D3219 D3719 D4219 D4719

Rotary switch No.

Continued on the next page.

IMS01C01-E7

49

Page 56

5. PLC COMMUNICATION

Continued from the previous page.

Register

area No.

12

13

14

15

16

17

18

19

20

21

22

23

Rotary switch No.

0 1 2 3 4 5 6 7

D1220 D1720 D2220 D2720 D3220 D3720 D4220 D4720

to to to to to to to to

D1239 D1739 D2239 D2739 D3239 D3739 D4239 D4739

D1240 D1740 D2240 D2740 D3240 D3740 D4240 D4740

to to to to to to to to

D1259 D1759 D2259 D2759 D3259 D3759 D4259 D4759

D1260 D1760 D2260 D2760 D3260 D3760 D4260 D4760

to to to to to to to to

D1279 D1779 D2279 D2779 D3279 D3779 D4279 D4779

D1280 D1780 D2280 D2780 D3280 D3780 D4280 D4780

to to to to to to to to

D1299 D1799 D2299 D2799 D3299 D3799 D4299 D4799

D1300 D1800 D2300 D2800 D3300 D3800 D4300 D4800

to to to to to to to to

D1319 D1819 D2319 D2819 D3319 D3819 D4319 D4819

D1320 D1820 D2320 D2820 D3320 D3820 D4320 D4820

to to to to to to to to

D1339 D1839 D2339 D2839 D3339 D3839 D4339 D4839

D1340 D1840 D2340 D2840 D3340 D3840 D4340 D4840

to to to to to to to to

D1359 D1859 D2359 D2859 D3359 D3859 D4359 D4859

D1360 D1860 D2360 D2860 D3360 D3860 D4360 D4860

to to to to to to to to

D1379 D1879 D2379 D2879 D3379 D3879 D4379 D4879

D1380 D1880 D2380 D2880 D3380 D3880 D4380 D4880

D1381 D1881 D2381 D2881 D3381 D3881 D4381 D4881

D1382 D1882 D2382 D2882 D3382 D3882 D4382 D4882

D1383 D1883 D2383 D2883 D3383 D3883 D4383 D4883

to to to to to to to to

D1399 D1899 D2399 D2899 D3399 D3899 D4399 D4899

50

IMS01C01-E7

Page 57

For the Rotary switch No. 8 to F

(However, the position of the rotary switch: B interdict from setting)

Register

area No.

1

2

3

4

5

6

7

8

9

10

11

8 9 A B

D5000 D5500 D6000 W0000 W0200 D0000 D0500