Page 1

r

A

A

A

Pressure Indicator

PG500

ll Rights Reserved, Copyright 2007, RKC INSTRUMENT INC.

Thank you for purchasing this RKC product. In order to achieve maximum performance

and ensure proper operation of your new instrument, carefully read all the instructions in

this manual. Please place this manual in a convenient location for easy reference.

This manual describes the communication function of the PG500. For the installation, the

parts description, the specifications and the operation method, please read if necessary

the following separate manuals.

• PG500 Installation Manual (IMR02F01-E): Enclosed with PG500

• PG500 Operation Manual (IMR02F02-E): Enclosed with PG500

Communication

Instruction Manual

IMR02F03-E2

The above manuals can be downloaded from our website:

URL: http://www.rkcinst.com/english/manual_load.htm

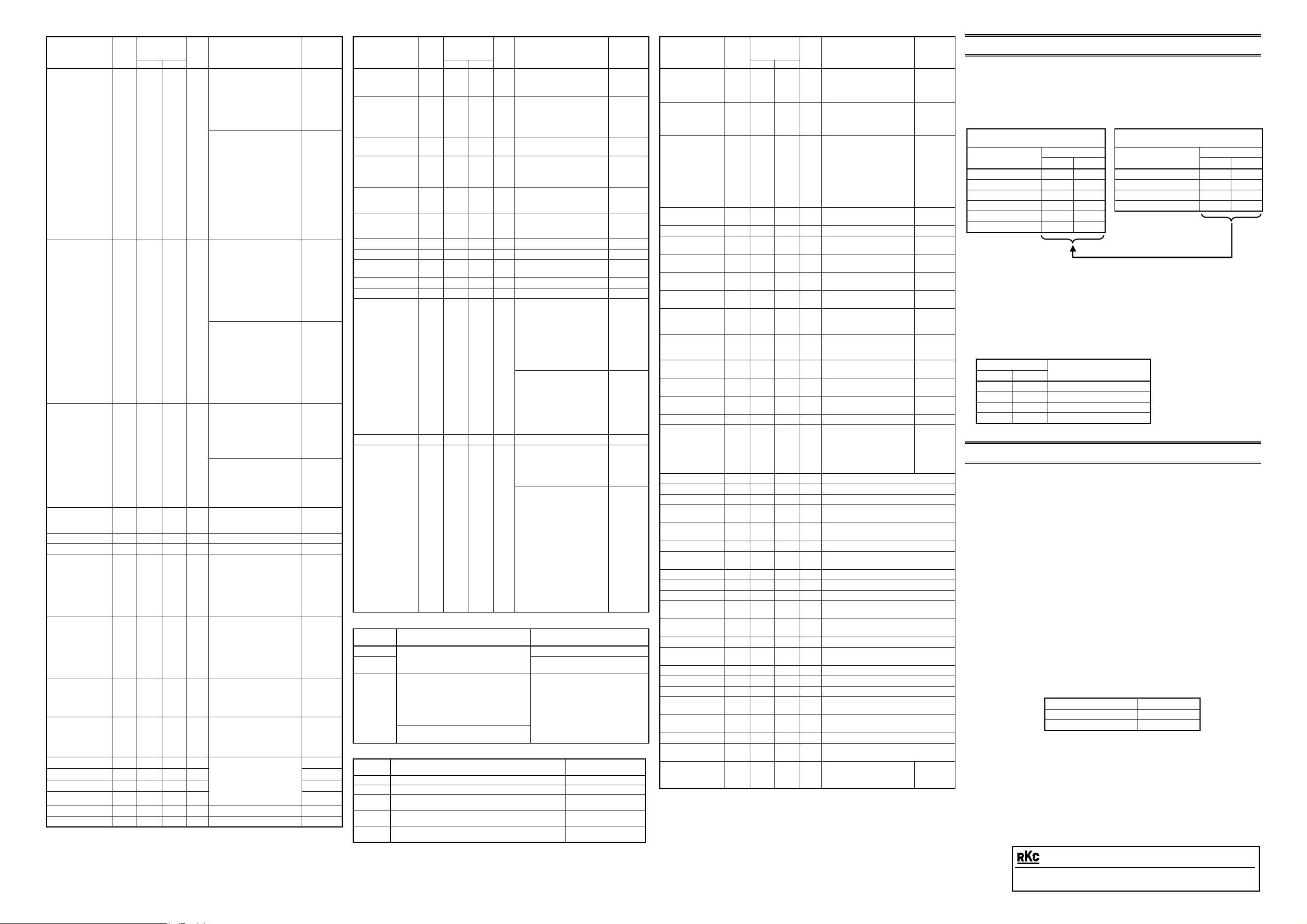

1. CONNECTION TO HOST COMPUTER

To prevent electric shock or instrument failure, turn off the power before

connecting or disconnecting the instrument and peripheral equipment.

The cable must be provided by the customer.

1.1 RS-485

Communication terminal number and signal details

Terminal No. Signal name Symbol

25 Signal ground SG

26 Send/Receive data T/R (A)

27 Send/Receive data T/R (B)

When the interface of host computer (Master) is RS-485

PG500 (Slav e)

SG

(−)

(+)

PG500 (Slav e)

(−)

(+)

When the host computer (Master) has a USB connector

Connect the USB communication converter between the host computer and the PG500.

PG500 (Slav e)

(−)

(+)

PG500 (Slav e)

(−)

(+)

25

T/R (A)

26

T/R (B)

27

SG

25

T/R (A)

26

T/R (B)

27

*R

SG

25

T/R (A)

26

T/R (B)

27

SG

25

T/R (A)

26

T/R (B)

27

*R

For the COM-K, see the COM-K Instruction Manual (IMR01Z01-E).

WARNING

!

Paired wire

RS-485

Shielded twisted

pair wire

Screw size: M3×7 (with 5.8×5.8 square washer)

Recommended tighteni ng torque:

0.4 N・m (4 kgf・cm)

Recommended solderless termi nals:

Manufactured by J.S.T MFG CO., LTD.

Circular term inal with isolat ion V1.25-MS3

(M3 screw, width 5.9 mm, hole diameter 3. 2 mm)

*R: Terminati on resistors (Exampl e: 120 Ω 1/2 W)

Maximum connections: Up to 31 instr uments

Paired wire

RS-485

Shielded twisted

pair wire

Screw size: M3×7 (with 5.8×5.8 square washer)

Recommended tighteni ng torque:

0.4 N・m (4 kgf・cm)

Recommended solderless termi nals:

Manufactured by J.S.T MFG CO., LTD.

Circular term inal with isolat ion V1.25-MS3

(M3 screw, width 5.9 mm, hole diameter 3. 2 mm)

*R: Terminati on resistors (Exampl e: 120 Ω 1/2 W )

Maximum connections: Up to 31 instruments

Host computer (Master)

SG

T/R (A)

T/R (B)

*R

Host computer (Master)

(COM-K accessory)

SG

1

T/R (A)

2

T/R (B)

3

Unused

4

Unused

5

USB communication convert er

COM-K (RKC product)

(−)

(+)

Connect to

USB port

USB cable

Connect to

USB connector

of COM-K

The termination

resistor is built-in

to the COM-K.

1.2 RS-422A

Communication terminal number and signal details

Terminal

Signal name Symbol

No.

25 Signal ground SG 28 Receive data R (A)

26 Send data T (A) 29 Receive data R (B)

27 Send data T (B)

Terminal

No.

Signal name Symbol

When the interface of host computer (Master) is RS-422A

PG500 (Slav e)

PG500 (Slav e)

(−)

(+)

(−)

(+)

SG

25

T (A)

26

T (B)

27

(−)

R(A)

28

R(B)

29

(+)

SG

25

T (A)

26

T (B)

27

(−)

R(A)

28

R(B)

29

(+)

Shielded twisted

Screw size: M3×7 (with 5.8×5.8 square washer)

Recommended t ightening to rque:

0.4 N・m (4 kgf・cm)

Recommended sol derless termi nals:

Manufactured by J.S.T MFG CO., LTD.

Circular terminal with isolati on V1.25-MS3

(M3 screw, width 5.9 mm , hole diam eter 3.2 mm)

Maximum connections: Up to 31 instruments

RS-422A

pair wire

Paired wire

Host computer (Master)

SG

(−)

T (A)

T (B)

(+)

(−)

R (A)

R (B)

(+)

When the host computer (Master) has a USB connector

Connect the USB communication converter between the host computer and the PG500.

PG500 (Slav e)

SG

(−)

(+)

PG500 (Slav e)

(−)

(+)

25

T (A)

26

T (B)

27

(−)

R(A)

28

R(B)

29

(+)

SG

25

T (A)

26

T (B)

27

(−)

R(A)

28

R(B)

29

(+)

For the COM-K, see the COM-K Instruction Manual (IMR01Z01-E).

RS-422A

Shielded twisted

pair wire

Screw size: M3×7 (with 5.8×5.8 square washer)

Recommended t ightening to rque:

0.4 N・m (4 kgf・cm)

Recommended sol derless termi nals:

Manufactured by J.S.T MFG CO., LTD.

Circular terminal with isolati on V1.25-MS3

(M3 screw, width 5.9 mm , hole diam eter 3.2 mm)

Maximum connections: Up to 31 instruments

Host computer ( Master)

Paired wire

(COM-K accessory)

SG

1

T (A)

2

T (B)

3

R (A)

4

R (B)

5

USB communi cation conv erte

COM-K (RKC product)

Connect to

USB port

USB cable

Connect to

USB connector

of COM-K

The term ination

resistor is bui lt-in

to the COM-K.

2. SETTING

To establish communication parameters between host computer and PG500, it is

necessary to set the following parameters.

When all communication parameter settings have been completed, turn the power

off and then on to make the new set values take effect.

This section describes the parameters to need setting for communication. For the

mode/parameters transfer and data setting, see the PG500 Operation Manual

(IMR02F02-E).

Description of each parameters

Engineering mode F60

Symbol Name Data range Description

Communication

CMP

protocol

(CMP)

Setup setting mode

Symbol Name Data range Description

Device address

Add

(Slave address)

(Add)

Communication

BPS

speed

(bPS)

0: RKC communication

1: Modbus

0 to 99

Maximum

connections:

Up to 31

instruments

1.2: 1200 bps

2.4: 2400 bps

4.8: 4800 bps

9.6: 9600 bps

19.2: 19200 bps

38.4: 38400 bps

Do not use the same device

address for more than one

instrument in multi-drop

connection. Each instrument

must have a unique address in

multi-drop connection.

In Modbus communication,

communication is not possible

when the address is 0.

Set the same communication

speed for both the PG500 (slave)

and the host computer (master).

Use to select a protocol of

communication function.

Factory

set value

0

Factory

set value

0

9.6

Symbol Name Data range Description

Data bit

BIT

configuration

(bIT)

Interval time 0 to 250 ms

InT

(InT)

Data bit configuration table

Set

Data bit

value

8n1

8n2

8E1

8E2

8o1

8o2

Interval time:

The interval time for the PG500 should be set to provide a time for host computer to finish

sending all data including stop bit and to switch the line to receive status for the host. If the

interval time between the two is too short, the PG500 may send data before the host

computer is ready to receive it. In this case, communication transmission cannot be

conducted correctly.

3. COMMUNICATION REQUIREMENTS

8 Without 1

8 Without 2

8 Even 1

8 Even 2

8 Odd 1

8 Odd 2

* When the Modbus communication protocol selected, this setting becomes invalid.

Parity

bit

See Data bit

configuration

table

Stop bit

Set the same data bit

configuration for both the PG500

(slave) and the host computer

(master).

The interval time for the PG500

should be set to provide a time

for host computer to finish

sending all data including stop bit

and to switch the line to receive

status for the host.

Set

Data bit

value

7n1

* 7 Without 1

7n2

* 7 Without 2

7E1

* 7 Even 1

7E2

* 7 Even 2

7o1

* 7 Odd 1

7o2

* 7 Odd 2

Parity

bit

Processing times during data send/receive

When the host computer is using either the polling or selecting procedure for

communication, the following processing times are required for PG500 to send data:

- Response wait time after PG500 sends BCC in polling procedure

- Response wait time after PG500 sends ACK or NAK in selecting procedure

Response send time is time at having set interval time in 0 ms.

RKC communication (Polling procedure)

Response send time after PG500 receives ENQ 3 ms max.

Response send time after PG500 receives ACK 3 ms ma x.

Response send time after PG500 receives NAK 3 ms ma x.

Response send time after PG500 sends BCC 1 ms max.

RKC communication (Selecting procedure)

Response send time after PG500 receives BCC 34 ms max.

Response wait time after PG500 sends ACK 1 ms max.

Response wait time after PG500 sends NAK 1 ms max.

Modbus

Read holding registers [03H]

Response send time after the slave receives the query message (When 125

registers are collectively read)

Preset single register [06H]

Response send time after the slave receives the query message

Diagnostics (loopback test) [08H]

Response send time after the slave receives the query message

Preset multiple registers [10H]

Response send time after the slave receives the query message (When 123

registers are collectively write)

RS-485 (2-wire system) send/receive timing

RS-485 communication is conducted through two wires, therefore the transmission and

reception of data requires precise timing.

Polling procedure

Host

computer

PG500

a

: Response send time after the controller receives [ENQ] + Interval time

b: Response send time after the controller sends BCC

c: Response send time after the controller receives [ACK] + Interval time or

Response send time after the controller receives [NAK] + Interval tim

Selecting procedure

Host

computer

PG500

a: Response send time after the controllerreceives BCC + Interval time

b: Response wait time after the controller sends ACK or Response wait time after the controller sends NAK

Send data

(Possible/Impossible)

Sending status

Send data

(Possible/Impossible)

Sending status

Send data

(Possible/Impossible)

Sending status

Send data

(Possible/Impossible)

Sending status

To switch the host computer from transmission to reception, send data must be on

line.

Procedure details Time

Procedure details Time

Procedure details Time

360 ms max.

25 ms max.

15 ms max.

360 ms max.

(RKC communication)

Possible

Impossible

Possible

Impossible

Possible

Impossible

Possible

Impossible

E

E

- - - - -

N

O

Q

T

S

T

X

e

B

S

C

T

- - - - C

X

C

K

- - - - -

or

bc a

B

C

C

ba

N

A

K

Factory

set value

8n1

Stop bit

N

or

C

A

K

K

10

The following processing times are requires for the PG500 to process data.

- In Polling procedure, Response wait time after the PG500 sends BCC

- In Selecting procedure, Response wait time after the PG500 sends ACK or NAK

RS-422A/RS-485 fail-safe

A transmission error may occur with the transmission line disconnected, shorted or set to

the high-impedance state. In order to prevent the above error, it is recommended that the

fail-safe function be provided on the receiver side of the host computer. The fail-safe

function can prevent a framing error from its occurrence by making the receiver output

stable to the MARK (1) when the transmission line is in the high-impedance state.

Modbus data processing precautions

• The numeric range of data used in Modbus protocol is 0000H to FFFFH. Only the set

value within the setting range is effective.

FFFFH represents −1.

• Data with decimal point is treated as data without decimal point on the Modbus protocol.

• If data (holding register) exceeding the accessible address range is accessed, an error

response message is returned.

• Read data of unused item is a default value.

• Any attempt to write to an unused item is not processed as an error. Data can not be

written into an unused item.

• If data range or address error occurs during data writing, it is not processed as an error.

Except the data that error occurred, normal data is written in data register. Therefore, it

is necessary to confirm data after the end of setting data.

• Communication data includes data that becomes RO (read only) depending on the

specification. No error occurs even if data is written when set to RO. However in this

case, no data is written.

• Send the next command message at time intervals of 30 bits after the master receives

the response message.

• Error code

Problem Probable cause Solution

Error

code 1

Error

code 2

Error

code 3

Error

code 4

Function cod error (Specifying

nonexistent function code)

When the mismatched address is

specified

When the specified number of data

items in the query message

exceeds the maximum number of

data items available

Self-diagnostic error Turn off the power to the instrument.

Confirm the function code

Confirm the address of holding

register

Confirm the setting data

If the same error occurs when the

power is turned back on, please

contact RKC sales office or the agent.

4. COMMUNICATION DATA LIST

The communication data map shows data which can be used for communication between

the host computer and PG500.

Explanation of data map items

• Modbus register address

HEX: Hexadecimal DEC: Decimal

• Attribute (A method of how communication data items are read or written when

viewed from the host computer is described)

RO: Only reading data is possible (Host computer

R/W: Reading and writing data is possible (Host computer

• Data

RKC communication

ASCII code data of 6 digits

Modbus

16-bit data

….…....

RKC

Identifier

Least significant

digit

Modbus

register

address

HEX DEC

Attribute

Most significant

digit

Name

Model code ID RO Model character code

ROM version

monitor

Measured value

(PV)

Burnout state

monitor

Alarm 1 state

monitor

Alarm 2 state

monitor

Alarm 3 state

monitor

Alarm 4 state

monitor

VR RO Version of ROM built-in the

M1 00E0 224 RO Pressure display low to

B1 00E1 225 RO 0: OFF 1: ON

AA 00E2 226 RO

AB 00E3 227 RO

AC 00E4 228 RO

AD 00E5 229 RO

…………….……………………

b15

Data range

(32-digit)

instrument (8-digit)

Pressure display high

0: OFF 1: ON

Unused 00E6 230

Unused 00E7 231

Peak hold monitor HP 00E8 232 RO

Bottom hold

monitor

HQ 00E9 233 RO

Pressure display low to

Pressure display high

At input break:

Display range limit

←

↔

PG500)

PG500)

set value

b0

Factory

Continued on the rear page

Page 2

Name

Error code ER 00EA 234 RO

Digital input (DI)

state monitor

Alarm output state

monitor

Integrated

operating time

monitor

Modbus

RKC

register

Iden-

address

tifier

HEX DEC

L1 00EB 235 RO

Q1 00EC 236 RO

Attribute

Data range

RKC communication

1: Adjustment data error

2: Back-up error

4: A/D conversion error

16: Auto zero/auto

calibration error

128: Watchdog timer error

256: Program error (stack)

2048: Program error (busy)

Modbus (Bit data)

b0: Adjustment data error

b1: Back-up error

b2: A/D conversion error

b3: Unused

b4: Auto zero/auto calibration

error

b5, b6: Unused

b7: Watchdog timer error

b8: Program error (stack)

b9: Unused

b10: Unused

b11: Program error (busy)

b12 to b15: Unused

Data 0: OFF 1: ON

[Decimal number: 0 to 2439]

RKC communication

Least significant digit:

The state of auto zero (DI1)

2nd digit:

The state of hold reset (DI2)

3rd digit:

The state of Interlock release

(DI3)

4th digit to Most significant digit:

Unused

Data 0: Contact open

1: Contact closed

Modbus (Bit data)

b0:

The state of auto zero (DI1)

b1:

The state of hold reset (DI2)

b2:

The state of Interlock release

(DI3)

b3 to b15: Unused

Data 0: Contact open

1: Contact closed

[Decimal number: 0 to 7]

RKC communication

Least significant digit to 4th

digit:

The state of alarm 1 output

to alarm 4 output

5th digit to Most significant digit:

Unused

Data 0: OFF 1: ON

Modbus (Bit data)

b0 to b3:

The state of alarm 1 output

to alarm 4 output

b4 to b15: Unused

Data 0: OFF 1: ON

[Decimal number: 0 to 15]

Factory

set value

UT 00ED 237 RO 0 to 19999 hours

Unused 00EE 238

Unused 00EF 239

Auto zero AZ 00F0 240 R/W 0: Normal state

Auto calibration 1

FS 00F1 241 R/W 0: Normal state

Hold reset HR 00F2 242 R/W 0: Hold reset execution

Interlock release 2

Alarm 1 set value 3

Alarm 2 set value 3

Alarm 3 set value 3

Alarm 4 set value 3

IR 00F3 243 R/W 0: Interlock release execution

A1 00F4 244 R/W 50

A2 00F5 245 R/W 0

A3 00F6 246 R/W 50

A4 00F7 247 R/W

1: Auto zero execution

When “1” is written, auto zero

starts. When done, the value

reverts to “0.”

3: Error

When “0” is written, returns to a

normal state.

1: Auto calibration execution

When “1” is written, auto

calibration starts. When done, the

value reverts to “0.”

3: Error

When “0” is written, returns to a

normal state.

1: Hold state

When “0” is written, the hold

reset is performed. When done,

the value reverts to “1.”

1: Interlock state

When “0” is written, the interlock

is released. When done, the

value reverts to “1.”

Pressure display low to

Pressure display high

Signals are output from the

alarm outputs (ALM1 to

ALM4) if exceeding the

alarm set value.

0

0

1

1

50

Unused 00F8 248

Unused 00F9 249

1

This item is valid when using resistance for sensitivity adjustment built-in pressure

sensor.

2

This item is invalid when the alarm 1 to 4 Interlock are set to “0: Unused.”

3

This item is invalid when the alarm type is set to “0: None.”

Name

Input type XI 00FA 250 R/W 0 to 4

Gain setting GA 00FB 251 R/W 0.500 to 4.000 mV/V or

Display unit PU 00FC 252 R/W

Input decimal point

position

Pressure display

high

Pressure display

low

Modbus

RKC

register

Iden-

address

tifier

HEX DEC

XU 00FD 253 R/W

XV 00FE 254 R/W Pressure display low to 19999

XW 00FF 255 R/W 0 to Pressure display high

Attribute

Data range

See Input type and factory

set value table.

0.5000 to 1.9999 mV/V *

(Varies with the setting of the

gain setting decimal point

position)

2

0: Kgf/cm

1: MPa 3: psi

0: No decimal place

1: One decimal place

2: Two decimal places

3: Three decimal places

(Varies with the setting of the

input decimal point position)

(Varies with the setting of the

input decimal point position)

2: bar

Factory

set value

Depends

on model

code.

See Input

type and

factory set

value

table

50

Linearizing type LI 0100 256 R/W 0 to 20 * 0

PV bias PB 0101 257 R/W −Input span to +Input span 0

PV digital filter F1 0102 258 R/W 0.0 to 100.0 seconds

(0.0: Unused)

PV ratio PR 0103 259 R/W 0.500 to 1.500 * 1.000

Unused 0104 260

Set lock level LK 0105 261 R/W RKC communication

Least significant digit:

Items other than alarm set

value.

2nd digit: Alarm set value

3rd digit to Most significant

digit: Unused

Data 0: Unlock

1: Lock

Modbus (Bit data)

b0: Items other than alarm

set value.

b1: Alarm set value

b2 to b15: Unused

Data 0: Unlock

1: Lock

[Decimal number: 0 to 3]

Display timer TL 0106 262 R/W 0.1 to 10.0 seconds 0.1

PV display

condition

* The setting value varies depending on using pressure sensor.

Data name

Gain setting Set the appropriate gain setting value.

Linearizing

type

PV ratio

Input type and factory set value table

Set value Input type

0 Our CZ-100P/CZ-200P (Standard) 1.500

1 Our CZ-100P/CZ-200P (Explosionproof) 1.500

2

3

4

DU 0107 263 R/W RKC communication

When using

our CZ-100P or CZ-200P

See Gain setting and linearizing type of

PG500 Operation Manual (IMR02F02-E).

[Explosionproof specification type]

Set the desired correction factor of our safety

barrier RZB-001 to the PV ratio (Pr). Thus,

an indicated error caused by the use of the

safety barrier is corrected. The correction

factor is described in the nameplate attached

to the safety barrier (RZB-001).

[Non-explosionproof specification type]

Use a factory set value of “1.000.”

Our CZ-100P/CZ-200P (Standard)

[Loose nut: 0.0 to 0.5 MPa, Fixed nut: 0 to 5 MPa]

Our CZ-100P/CZ-200P (Explosionproof)

[Loose nut: 0.0 to 0.5 MPa, Fixed nut: 0 to 5 MPa]

3.33 mV/V output type

(Pressure sensor made by other companies)

0 to 63 (Decimal)

Set the bit data (See

Modbus) after converting it

to decimal.

Modbus (Bit data)

b0: Minus display of PV value

b1: Input error

b2: Alarm 1 occurs

b3: Alarm 2 occurs

b4: Alarm 3 occurs

b5: Alarm 4 occurs

b6 to b15: Unused

Data

b0 の場合

0: Minus display

1: Non-minus display

b1 to b5

0: Non-flashing display

1: Flashing display

[Decimal number: 0 to 63]

When using resistance for sensitivity

adjustment built-in pressure sensor

Use a factory set value of “0.”

The result obtained by auto calibration is

reflected to the PV ratio (Pr). Manual full

scale adjustment can be performed by

changing this PV ratio value.

Factory set value

of gain setting (mV/V)

0.650

0.650

3.330

Name

Input error

determination point

(high)

Input error

determination point

(low)

1

Burnout direction IB 010A 266 R/W 0: Upscale

0

0

Gain setting decimal

point position

Unused 010C 268

Shunt resistance

output value

0

0

Transmission

output scale high

Transmission

output scale low

Transmission

output timer

1

Alarm 1 type XA 0111 273 R/W 0: None

Alarm 1 hold action WA 0112 274 R/W 0: OFF

Alarm 1 interlock QA 0113 275 R/W 0: Unused (OFF)

0

Alarm 1 energized/

de-energized

Alarm 1 differential

gap

Alarm 1 delay timer TD 0116 278 R/W 0.0 to 600.0 seconds 0.0

Alarm 1 action at

input error

0

Alarm 2 type XB 0118 280 R/W Same as Alarm 1 type

0

Alarm 2 hold action WB 0119 281 R/W Same as Alarm 1 hold action

Alarm 2 interlock QB 011A 282 R/W Same as Alarm 1 interlock

Alarm 2 energized/

de-energized

Alarm 2 differential

gap

Alarm 2 delay timer TG 011D 285 R/W Same as Alarm 1 delay timer

Alarm 2 action at

input error

Alarm 3 type XC 011F 287 R/W Same as Alarm 1 type

Alarm 3 hold action WC 0120 288 R/W Same as Alarm 1 hold action

Alarm 3 interlock QC 0121 289 R/W Same as Alarm 1 interlock

Alarm 3 energized/

de-energized

Alarm 3 differential

gap

Alarm 3 delay timer TH 0124 292 R/W Same as Alarm 1 delay timer

Alarm 3 action at

input error

Alarm 4 type XD 0126 294 R/W Same as Alarm 1 type

Alarm 4 hold action WD 0127 295 R/W Same as Alarm 1 hold action

Alarm 4 interlock QD 0128 296 R/W Same as Alarm 1 interlock

Alarm 4 energized/

de-energized

Alarm 4 differential

gap

Alarm 4 delay timer TI 012B 299 R/W Same as Alarm 1 delay timer

Alarm 4 action at

input error

Unused 012D

1

This item is valid when using resistance for sensitivity adjustment built-in pressure

sensor.

2

When not specifying: Alarm 1: Process high (without hold action) Alarm 3: No alarm

Alarm 2: Process low (without hold action) Alarm 4: No alarm

Modbus

RKC

register

Iden-

address

tifier

HEX DEC

AV 0108 264 R/W Pressure display low −

AW 0109 265 R/W Pressure display low −

GS 010 B 267 R/W 3: Three decimal places

OR 010D 269 R/W

HV 010E 270 R/W Transmission output scale

HW 010F 2 71 R/W Pressure display low to

Attribute

Data range

(5 % of input span) to

Pressure display high +

(5 % of input span)

(5 % of input span) to

Pressure display high +

(5 % of input span)

1: Downscale

Setting of a barn out

direction select switch is

necessary to select a barn

out direction.

For the switch setting, see

the PG500 Installation

Manual (IMR02F01-E).

4: Four decimal places

40.0 to 100.0 %

low to Pressure display high

Transmission output scale high

Factory

set value

53

−2

0

3

80.0

50

0

TO 0110 272 R/W 0.1 to 10.0 seconds 0.1

1: Process high

2: Process low

1: Hold action ON

1: Used

NA 0114 276 R/W 0: Energized

1: De-energized

Depends

on model

code

Depends

on model

code

0

0

HA 0115 277 R/W 0 to Input span 2

OA 0117 279 R/W 0: Normal alarm action

1: Forced alarm ON when

temperature measured

value exceeds the input

error determination point

(high or low limit).

0

NB 011B 283 R/W Same as Alarm 1 energized/ de-energized

HB 011C 284 R/W Same as Alarm 1 differential gap

OB 011E 286 R/W Same as Alarm 1 action at input error

NC 0122 290 R/W Same as Alarm 1 energized/ de-energized

HC 0123 291 R/W Same as Alarm 1 differential gap

OC 0125 293 R/W Same as Alarm 1 action at input error

ND 0129 297 R/W Same as Alarm 1 energized/ de-energized

HD 012A 298 R/W Same as Alarm 1 differential gap

OD 012C 300 R/W Same as Alarm 1 action at input error

301

•

•

•

314

013A

•

•

•

5. HOW TO USE MODBUS DATA MAPPING

In this communication, it is possible to continuously read/write data by freely specifying 16

sets of data.

Register address to specify mapping data: 1000H to 100FH

Register address to actually read/write data: 1500H to 150FH

Register address of data which can be mapped: See 4. COMMUNICATION DATA LIST.

Example: When mapping Measured value (PV), Alarm 1 state monitor, Alarm 2 state monitor

and Alarm output state monitor to the register addresses from 1500H to 1503H

For data mapping

Factory set value: (−1: No mapping)

Name

Register address Register address

HEX DEC

Mapping data

Name

Setting 1 (For 1500H) 1000 4096 Measured value (PV) 00E0 224

Setting 2 (For 1501H) 1001 4097 Alarm 1 state monitor 00E2 226

Setting 3 (For 1502H) 1002 4098 Alarm 2 state monitor 00E3 227

Setting 4 (For 1503H) 1003 4099 Alarm output state monitor 00EC 236

•

•

•

Setting 16 (For 150FH) 100F 4111

•

•

•

•

•

•

Write to 1000H to 1003H.

1. The register address, “00E0H” of the “Measured value (PV)” to be mapped is written to

register address setting 1 (1000H).

2. The register address, “00E2H” of the “Alarm 1 state monitor” to be mapped is written to

register address setting 2 (1001H).

3. The register address, “00E3H” of the “Alarm 2 state monitor” to be mapped is written to

2

2

register address setting 3 (1002H).

4. The register address, “00ECH” of the “Alarm output state monitor” to be mapped is

written to register address setting 4 (1003H).

5. The assignment of the register addresses from 1500H to 1503H from/to which data is

actually read/written becomes as follows.

Register address

HEX DEC

1500 5376 Measured value (PV)

1501 5377 Alarm 1 state monitor

1502 5378 Alarm 2 state monitor

1503 5379 Alarm output state monitor

Name

High-speed communication

is performed by reading or

writing data in the

consecutive register

addresses from 1500H to

1503H.

6. COMMUNICATION SPECIFICATIONS

Interface: Based on RS-422A or RS-485, EIA standard

Synchronous method: Start-stop synchronous type

Communication speed: 1200 bps, 2400 bps, 4800 bps, 9600 bps, 19200 bps, 38400 bps

Data bit configuration: Start bit: 1

Connection method: RS-422A: 4-wire system, half-duplex multi-drop connection

RS-485: 2-wire system, half-duplex multi-drop connection

Protocol: • RKC communication (ANSI X3.28-1976 subcategory 2.5, A4)

Maximum connections: Up to 31 instruments

Termination resistor: Externally connected (Example: 120 Ω 1/2W)

Data mapping function: Up to 16 items (Only Modbus)

Interval time: 0 to 250 ms

Signal logic: RS-422A, RS-485

Data bit: RKC communication: 7 or 8

Modbus: 8

Parity bit: Without, Odd or Even

Stop bit: 1 or 2

Error control: Vertical parity (With parity bit selected)

Horizontal parity (BCC check)

Communication code: ASCII 7-bit code

Xon/Xoff control: None

• Modbus

Signal transmission mode:

Remote Terminal Unit (RTU) mode

Function code: 03H (Read holding registers)

06H (Preset single register)

08H (Diagnostics: loopback test)

10H (Preset multiple registers)

Error check method: CRC-16

Signal voltage Logic

V (A) − V (B) ≥ 2 V 0 (SPACE)

V (A) − V (B) ≤ −2 V 1 (MARK)

Voltage between V (A) and V (B) is the voltage

of (A) terminal for the (B) terminal.

Modbus is a registered tradema rk of Schneider Electric.

Company names and product names used i n this manual are the trademark s or registered

trademarks of the respective companies.

RKC INSTRUMENT INC.

®

HEADQUARTERS: 16-6, KUGAHARA 5-CHOME, OH TA-KU TOKYO 146-8515 JAPAN

PHONE: 03-3751-9799 (+81 3 3751 9799) E-mail: info@rk cinst.co.jp

FAX: 03-3751-8585 (+81 3 3751 8585) JAN. 2008

The first edition: OCT. 2007 [IMQ00]

The second edition: JAN. 2008 [IMQ00]

HEX DEC

Loading...

Loading...