Rinnai Water Heater V65iN Parts List

Controller

|

Priority Indicator |

|

In Use Indicator |

Indicates that this |

|

controller is setting the |

||

Indicates that hot water |

||

water temperature. |

||

is being supplied. |

||

|

|

|

Priority Button |

Temperature Display |

|

When no water is |

|

being supplied, |

|

Indicates temperature |

|

|

|

pressing this button |

|

setting or flashes error |

|

|

|

allows this controller to |

|

code. |

|

|

|

set the water |

|

|

|

|

|

MC-91-2US-V |

temperature. |

Thermostat |

|

|

|

|

ON/OFF Button |

WARNING |

Do not put SW2 and 3 in DIPSW2 |

|

(white switches) in on position. |

These settings are only for commercial applications and are not compatible with V94i,V94Xi,V75i and V65i.

Diagnostic Use of the Controller

1.To display the most recent diagnostic codes press and hold the “On/Off” button for 2 seconds on the MC-91 controller.

2.To enter or exit the maintenance monitor information mode press and hold the down button for 2 seconds and without releasing it press the ON/OFF button.

No. |

Data |

Unit |

01 |

Water flow rate |

0.1 gal/min |

|

|

|

02 |

Outgoing water temperature |

Degrees Fahrenheit |

|

|

|

To Change the Temperature Scale (ºF / ºC)

With the water heater turned off, press and hold the ON/OFF button until the display changes to the other temperature scale (about 5 seconds).

To Turn Off the Controller Sound (Mute)

To turn the sound off (mute), press and hold both the ▲ and ▼ thermostat buttons until a “beep” is heard (about 5 seconds).

Locking the Controller

The MC-91-2 controller can be locked or unlocked by pressing the Priority button and the up button together for 5 seconds. A beep will sound confirming that the controller is locked. The display will alternately show “LOC”, the temperature setting, and a diagnostic code if one has been activated. All of the controllers in the system are also locked.

To unlock the controller press the Priority button and the up button together for 5 seconds.

Gas Pressure Setting

Ensure gas pressure check under Commissioning has been completed first! The regulator is electronically controlled and factory pre-set. Under normal circumstances it does not require adjustment during installation. Make adjustments only if the unit is not operating correctly and all other possible causes for incorrect operation have been eliminated.

1.Turn OFF the gas supply.

2.Turn OFF the water supply.

3.Remove the front panel (four screws).

4.Check the gas type using the data plate on the side of the unit. Confirm that the gas type switch is in the correct position (SW1 in DIPSW2 is ON for natural gas, NG, and OFF for propane gas, LPG.) Figure 1.

5.Remove the screw and attach the manometer to the burner test point located on the gas control. Figure 2.

6.Turn on the gas supply and the power supply.

7.Flow water through the water heater at the maximum flow rate obtainable. (At least 3 gallons per minute is recommended. If there is not enough water flowing, the water heater could shut off or sustain damage due to overheating.)

8.Move SW8 in DIPSW1 to ON. Figure 3.

9.Push the PC board switch A for one second. Figure 4.

10.Calibrate “Forced Low” combustion using switch A (up) and switch B (down).

11.Move SW8 in DIPSW1 to OFF and then back to ON. Figure 6.

12.Push the PC board switch B for one second. Figure 4.

13.Calibrate “Forced High” combustion using switch A (up) and switch B (down).

14.Move SW8 in DIPSW1 to OFF. Figure 5.

15.Close hot water taps.

16.Turn off gas supply and 120 V power supply.

17.Remove manometer and re-install screws.

18.Turn on the gas supply and 120 V power supply.

19.Operate the unit and check for gas leaks.

20.Install the front panel using four screws.

Gas Pressure Setting

NOTE: For additional installation and commissioning information refer to the Operation and Installation Manual.

|

|

WARNING |

This appliance must be installed, |

|||||||||||

|

|

|

|

|

|

serviced and removed by a trained |

||||||||

|

and qualified person. During pressure testing of the consumer piping, |

|||||||||||||

|

ensure gas valve is turned off before unit is shut off. Failure to do so |

|||||||||||||

|

may result in serious injury to yourself or damage to the unit. |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

APPLIANCE OPERATING PRESSURES |

Table 1 |

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

Water |

|

Gas Inlet Min./Max |

|

Forced Low |

|

Forced High |

|||||

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Inlet Max. |

|

NAT.G |

|

LPG |

|

NAT.G |

LPG |

|

NAT.G |

LPG |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Short flue length |

|

|

4"W.C. |

8"W.C. |

|

0.61”W.C. |

0.87”W.C. |

|

3.0”W.C. |

4.8”W.C. |

||

|

V94i / |

150 PSI |

|

|

|

/*2.96”W.C. |

||||||||

|

*V94Xi |

|

|

/10.5"W.C. |

/13.5"W.C. |

|

|

|

|

|

|

|||

|

Long flue length |

|

|

|

0.61”W.C. |

0.95”W.C. |

|

2.3”W.C. |

3.7”W.C. |

|||||

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

V75i |

Short flue length |

150 PSI |

|

4"W.C. |

8"W.C. |

|

0.61”W.C. |

0.87”W.C. |

|

2.5”W.C. |

3.9”W.C. |

||

|

Long flue length |

|

/10.5"W.C. |

/13.5"W.C. |

|

0.61”W.C. |

0.95”W.C. |

|

2.3”W.C. |

3.7”W.C. |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

V65i |

Short flue length |

150 PSI |

|

4"W.C. |

8"W.C. |

|

0.61”W.C. |

0.87”W.C. |

|

1.97”W.C. |

2.74”W.C. |

||

|

Long flue length |

|

/10.5"W.C. |

/13.5"W.C. |

|

0.61”W.C. |

0.95”W.C. |

|

2.04”W.C. |

2.93”W.C. |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Commissioning

With all gas appliances in operation at maximum gas rate, the flowing inlet pressure at the incoming test point on the Rinnai water heater should read 4” W.C. - 10.5” W.C. on natural gas and 8” W.C. - 13.5 W.C. on propane gas. If the pressure is lower, the gas supply is inadequate and the unit will not operate to specification. Check the gas meter regulator and pipework for correct operation/sizing and correct as required.

Burner

Test Point

DipDipSW1

DipDipSW2

Fig. 1 |

Fig. 2 |

Dip SW1

Fig. 3 |

Fig. 4 |

|

Dip SW1 |

|

Dip SW1 |

Fig. 5 |

Fig. 6 |

||

|

|

|

|

Troubleshooting |

|

|

|

|

|

|

|

Flame Rod: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

Important Safety Notes |

|

|

|

|

|

|

|

|

|

|

|

|

|

Place one lead of your meter to the flame rod and the other to ground. |

||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

With the unit running you should read between 5-150 VAC. Set your |

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||

|

There are a number of (live) tests that are required when fault |

|

|

meter to the μ amp scale and series your meter in line with the flame |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

finding this product. Extreme care should be used at all times to |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

rod. You should read 1 μ amp or greater for proper flame circuit. In |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

avoid contact with energized components inside the water heater. |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

the event of low flame circuit remove the flame rod and check for |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Only trained and qualified service technicians should attempt to |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

carbon or damage. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||

|

repair this product. Before checking for resistance readings, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

disconnect the power source to the unit and isolate the item from |

|

|

Heat Exchanger, Outgoing Water Temperature and |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

the circuit (unplug it). |

|

|

|

|

|

|

|

|

|

|

|

|

|

Inlet Thermistors: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

(SV1, SV2, SV3 , SV4 and POV) Gas valve and Modulating solenoids: (Set meter above 2K) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check all thermistors by inserting meter leads into each end of the |

||||||||||||||||||||||||||||||||||||||

|

Wire color |

|

Voltage |

Resistance |

|

Connector # |

|

|

Pin #'s |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

(Main) Black - Grey |

|

11 ~ 13 VDC |

24 ~ 28 ohms |

|

D1 |

|

|

B3 - B4 |

|

|

thermistor plug. Set your meter to the 20 K scale and read |

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||

|

(SV1) Black - Blue |

|

11 ~ 13 VDC |

36 ~ 42 ohms |

|

B3 |

|

4 - 6 |

|

|

|

|

resistance. Applying heat to the thermistor bulb should decrease |

||||||||||||||||||||||||||||||||||||||||||||||||

|

(SV2) Black - Yellow |

|

11 ~ 13 VDC |

36 ~ 42 ohms |

|

B2 |

|

4 - 7 |

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

the resistance. Applying ice to the thermistor bulb should increase |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

(SV3) Black - Red |

|

11 ~ 13 VDC |

36 ~ 42 ohms |

|

B4 |

|

4 - 5 |

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

the resistance. See below for examples of typical temperatures and |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

(SV4) Black - Orange |

|

11 ~ 13 VDC |

35 ~ 41 ohms |

|

B1 |

|

4 - 8 |

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

(POV) Pink - Pink |

|

2 ~ 15 VDC |

67 ~ 81 ohms |

|

D1 |

|

1 - 2 |

|

|

|

|

resistance readings. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

|

(M) Water Flow Control Device Servo or Geared Motor: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Example: |

|

|

59°F = 11.4 ~ 14KΩ |

|

140°F = 2.2 ~ 2.7KΩ |

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

86°F = 6.4 ~ 7.8KΩ |

|

221°F = 0.6 ~ 0.8KΩ |

|

|

|

|

|

|

||||||||||||||||||

|

Red - Pink |

|

N / A |

44 ~ 52 ohms |

|

G2 |

|

|

3 - 4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||

|

White - Blue |

|

N / A |

44 ~ 52 ohms |

|

G2 |

|

|

1 - 2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

113°F = 3.6 ~ 4.5KΩ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

|

Grey - Brown |

|

N / A |

N / A |

|

G2 |

|

|

5 - 7 |

|

|

|

|

Outgoing Water Thermistor: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

Grey - Orange |

|

N / A |

N / A |

|

G2 |

|

|

6 - 7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

White - White |

|

|

|

|

N / A |

|

|

|

|

|

|

See example above |

E5 |

|

|

|

|

|

|

2 - 3 |

|

|

||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

|

NOTE:The grey wire listed above turns to black at G connector on the PCB. |

|

|

Blue - Blue |

|

|

|

|

N / A |

|

|

|

|

|

|

See example above |

E5 |

|

|

|

|

|

|

4 - 5 |

|

|

|||||||||||||||||||||||||||||||||||

|

(QS) Water Flow Sensor: |

|

|

|

|

|

|

|

|

|

|

|

|

|

Heat Exchanger Temperature Thermistor: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Black - Red |

|

11 ~ 13 VDC |

N / A |

|

L3 |

|

|

E10 - G7 |

|

|

Pink - Pink |

|

|

|

|

N / A |

|

|

|

|

|

|

See example above |

E4 |

|

|

|

|

|

|

4 - 7 |

|

|

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

Yellow - Black |

|

4 ~ 7 VDC |

N / A |

|

L3 |

|

|

E1 - G7 |

|

|

Inlet Thermistor: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

By-pass Flow Control: |

|

|

|

|

|

|

|

|

|

|

|

|

|

White - White |

|

|

|

|

N / A |

|

|

|

|

|

|

See example above |

E7 |

|

|

|

|

|

|

4 - 9 |

|

|

||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Remote Controls: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

Red - Pink |

|

N / A |

44 ~ 52 ohms |

|

G1 |

|

|

12 - 13 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

White - Blue |

|

N / A |

|

|

|

|

G1 |

|

|

10 - 11 |

|

|

|

|

Terminals J |

|

|

|

|

10 ~ 13 VDC |

1.5 ~ 3.0 K ohms |

J |

|

|

|

|

|

|

|

1 - 2 |

|

|

||||||||||||||||||||||||||||

|

(IG) Ignition System: |

|

|

|

|

|

|

|

|

|

|

|

|

|

Frost Protection: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

Grey - Grey |

|

110 ~ 130 VAC |

N / A |

|

C1 |

|

|

1 - 3 |

|

|

|

|

This unit has frost protection heaters mounted at different points to |

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||

|

(FM) Combustion Fan Motor: |

|

|

|

|

|

|

|

|

|

|

|

|

|

protect the water heater from freezing. All of them should show a |

||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

positive resistance reading. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

Red - Black |

|

6 ~ 45 VDC |

N / A |

|

L2 |

|

|

5 - 6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||

|

White - Black |

|

5 ~ 10 VDC |

N / A |

|

L2 |

|

|

3 - 5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Yellow - Black |

|

11 ~ 13 VDC |

N / A |

|

L2 |

|

|

4 - 5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Set your meter to the hertz scale. Reading across the white and black wires at terminals 3 and 5 |

|

|

Amp Fuses: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||

|

you should read between 60 and 420 hertz. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This unit has one inline (10) amp glass fuse. Remove the fuse and |

|||||||||||||||||||||||||||||||||||||||||||||||

|

Thermal Fuse / Overheat Switch: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

check continuity through it. If you have continuity through the fuse |

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||

|

White - White |

|

11 ~ 13 VDC |

Below 1 ohms |

|

B8 |

|

|

B1 - E10 |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

then it is good. Otherwise the fuse is blown and must be replaced. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

B7 |

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dip Switches Settings |

|

|

V94i |

V94i,V94Xi |

|

|

|

V75i |

|

|

|

|

|

|

|

|

|

|

|

|

V65i |

|

|

|

|

|

|

||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

|

|

|

|

LPG |

|

NAT.G |

|

|

|

LPG |

|

|

NAT.G |

|

|

|

|

|

LPG |

|

|

NAT.G |

|

||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ON |

|

|

|

ON |

|

|

|

|

ON |

|

|

|

|

|

ON |

|

|

|

|

|

ON |

|

|

|

|

|

|

ON |

|

|||||||||

|

Adjust SW2 and 3 in DIPSW1 (upper side) depending |

|

O |

|

|

1 |

|

O |

|

|

|

1 |

|

|

O |

|

|

1 |

|

|

O |

|

|

|

|

1 |

|

|

O |

|

1 |

|

|

O |

|

|

|

|

|

1 |

|

|

|||||||||||||||||||

|

|

F |

|

|

2 |

|

F |

|

|

2 |

|

|

F |

|

|

2 |

|

|

F |

|

|

|

|

2 |

|

|

F |

|

2 |

|

|

F |

|

|

|

2 |

|

|

|||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

3 |

|

|

|

|

3 |

|

|

|

|

|

|

3 |

|

|

|

3 |

|

|

|

|

|

|

|

3 |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

on your altitude according to the table below. |

|

|

|

|

|

F |

|

|

|

F |

|

|

|

|

F |

|

|

|

|

F |

|

|

|

|

|

|

F |

|

|

|

F |

|

|

|

|

|

||||||||||||||||||||||||

|

|

|

|

|

|

|

|

4 |

|

|

|

|

4 |

|

|

|

|

4 |

|

|

|

|

|

|

4 |

|

|

|

4 |

|

|

|

|

|

|

4 |

|

|

|||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

5 |

|

|

|

|

|

5 |

|

|

|

|

|

|

|

5 |

|

|

|

|

|

5 |

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

|

|

|

|

6 |

|

|

|

|

|

6 |

|

|

|

|

|

|

|

6 |

|

|

|

|

|

6 |

|

|

|

|

|

|

|

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

|

|

|

|

7 |

|

|

|

|

|

7 |

|

|

|

|

|

|

|

7 |

|

|

|

|

|

7 |

|

|

|

|

|

|

|

7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

8 |

|

|

|

|

|

8 |

|

|

|

|

|

|

|

8 |

|

|

|

|

|

8 |

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ON |

|

|

|

ON |

|

|

|

|

ON |

|

|

|

|

|

ON |

|

|

|

|

|

ON |

|

|

|

|

|

|

ON |

|

|||||||||

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

1 |

|

O |

|

|

|

1 |

|

|

O |

|

|

1 |

|

|

O |

|

|

|

1 |

|

|

O |

|

1 |

|

|

O |

|

|

|

1 |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

F |

|

|

2 |

|

F |

|

|

|

2 |

|

|

F |

|

|

2 |

|

|

F |

|

|

|

|

2 |

|

|

F |

|

2 |

|

|

F |

|

|

|

|

|

2 |

|

|

|||

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

High Altitude |

|

|

|

|

|

|

|

|

F |

|

|

3 |

|

F |

|

|

3 |

|

|

F |

|

|

3 |

|

|

F |

|

|

|

|

3 |

|

|

F |

|

3 |

|

|

F |

|

|

|

3 |

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

4 |

|

|

|

|

4 |

|

|

|

|

|

|

4 |

|

|

|

4 |

|

|

|

|

|

|

|

4 |

|

|

|||||||||||

|

|

DIPSW1 |

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

5 |

|

|

|

|

|

5 |

|

|

|

|

|

|

|

5 |

|

|

|

|

|

5 |

|

|

|

|

|

|

|

|

5 |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

|

|

|

|

6 |

|

|

|

|

|

6 |

|

|

|

|

|

|

|

6 |

|

|

|

|

|

6 |

|

|

|

|

|

|

|

|

6 |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

|

|

|

|

7 |

|

|

|

|

|

7 |

|

|

|

|

|

|

|

7 |

|

|

|

|

|

7 |

|

|

|

|

|

|

|

7 |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

8 |

|

|

|

|

|

8 |

|

|

|

|

|

|

|

8 |

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WARNING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DO NOT adjust the other dip switches unless specifically instructed |

|

|

|||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||

|

|

DIPSW2 |

|

4 |

|

|

|

|

|

|

|

|

|

to do so. Incorrect Dip Switch Settings can cause the Rinnai water |

|

|

|||||||||||||||||||||||||||||||||||||||||||||

|

|

|

5 |

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

6 |

|

|

|

|

|

|

|

|

|

heater to operate in an unsafe condition and may damage the water |

|

|

||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

7 |

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

|

heater and void the warranty. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SW No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

2 |

|

|

|

|

|

|

|

|

Off |

|

Level 0 |

|

|

Off |

|

|

|

Level 1 |

|

|

|

On |

|

|

|

Level 2 |

|

|

On |

|

|

Level 3 |

|

|

|

|

|

|

|||||||||||||||||||||

|

|

|

|

High Altitude |

|

|

0-2000 ft |

|

|

|

|

2001-5200 ft |

|

|

|

5201-7700 ft |

|

|

|

7701-10200 ft |

|

|

|||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||

|

|

3 |

|

|

|

Off |

|

|

|

On |

|

|

|

Off |

|

|

|

On |

|

|

|

||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

(0-610 m) |

|

|

|

|

(610-1585 m) |

|

|

(1585-2347 m) |

|

|

(2347-3109 m) |

|

||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Diagnostic Codes

03Power interruption during Bath fill (Water will not flow when power returns)

• Turn off all hot water taps. Press ON/OFF twice.

10 Air Supply or Exhaust Blockage

•Ensure approved venting materials are being used.

•Check that nothing is blocking the flue inlet or exhaust.

•Check all vent components for proper connections.

•Ensure vent length is within limits.

•Verify dip switches are set properly.

•Check fan for blockage.

11 No Ignition

•Check that the gas is turned on at the water heater, meter, or cylinder.

•If the system is propane, make sure that gas is in the tank.

•Ensure appliance is properly grounded.

•Ensure gas type and pressure is correct.

•Ensure gas line, meter, and/or regulator is sized properly.

•Bleed all air from gas lines.

•Verify dip switches are set properly.

•Ensure igniter is operational.

•Check igniter wiring harness for damage.

•Check gas solenoid valves for open or short circuits.

•Remove burner cover and ensure burners are properly seated.

•Remove burner plate; inspect burner surface for condensation/debris.

•Check the ground wire for the PC board.

12 No Flame

•Check that the gas is turned on at the water heater, meter, or cylinder.

•Check for obstructions in the flue outlet.

•If the system is propane, make sure that gas is in the tank.

•Ensure gas line, meter, and/or regulator is sized properly.

•Ensure gas type and pressure is correct.

•Bleed all air from gas lines.

•Ensure proper venting material was installed.

•Ensure condensation collar was installed properly.

•Ensure vent length is within limits.

•Verify dip switches are set properly.

•Check power supply for loose connections.

•Check power supply for proper voltage and voltage drops.

•Ensure flame rod wire is connected.

•Check flame rod for carbon build-up.

•Disconnect and reconnect all wiring harnesses on unit and PC board.

•Check for DC shorts at components.

•Check gas solenoid valves for open or short circuits.

•Remove burner plate; inspect burner surface for condensation/debris.

14 Thermal Fuse

•Ensure SW5 in DIPSW2(white) is in the off position.

•Check for restrictions in air flow around unit and vent terminal.

•Check gas type of unit and ensure it matches gas type being used.

•Check for low water flow in a circulating system causing short-cycling.

•Ensure dip switches are set to the proper position.

•Check for foreign materials in combustion chamber and exhaust piping.

•Check heat exchanger for cracks or separations.

•Check heat exchanger surface for hot spots which indicate blockage due to scale build-up. Refer to instructions in manual for flushing heat exchanger. Hard water must be treated to prevent scale build up or damage to the heat exchanger.

•Measure resistance of safety circuit.

•Ensure high fire and low fire manifold pressure is correct.

•Check for improper conversion of product.

16 Over Temperature Warning

•Check for restrictions in air flow around unit and vent terminal.

•Check for low water flow in a circulating system causing short-cycling.

•Check for foreign materials in combustion chamber and exhaust piping.

•Check for blockage in the heat exchanger.

19 Electrical Grounding

• Check all components for electrical short.

32Outgoing Water Temperature Sensor

33Heat Exchanger Outgoing Temperature Sensor

34Combustion Air Temperature Sensor Fault

•Check for restrictions in air flow around unit and vent terminal.

•Check sensor wiring for damage.

•Measure resistance of sensor.

•Clean sensor of scale build up.

•Ensure fan blade is tight on motor shaft and is in good condition.

•Replace sensor.

51 Inlet Water Temperature Sensor

•Check sensor wiring for damage.

•Measure resistance of sensor.

•Clean sensor of scale build-up.

•Replace sensor.

52 Modulating Solenoid Valve Signal

•Check modulating gas solenoid valve wiring harness for loose or damaged terminals.

•Measure resistance of valve coil.

61 Combustion Fan

•Ensure fan will turn freely.

•Check wiring harness to motor for damaged and/or loose connections.

•Measure resistance of motor winding.

65 Water Flow Servo

•The water flow control valve has failed to close during the bath fill function. Immediately turn off the water and discontinue the bath fill function. Contact a licensed professional.

70 PC Board

•Check PC board DIP switches for correct positons.

•Check the connection harness at the connection on the PC board.

•Replace PC board.

71Solenoid Valve Circuit

• Replace the PC Board.

72Flame Sensing Device

•Verify flame rod is touching flame when unit fires.

•Check all wiring to flame rod.

•Remove flame rod;check for carbon build-up; clean with sand paper.

•Check inside burner chamber for any foreign material blocking flame at flame rod.

•Measure micro amp output of sensor circuit with flame present.

•Replace the PC Board.

79 Water leakage detected

• Turn off water supply and contact licenced professional.

LC# Scale Build-up in Heat Exchanger (when checking maintenance code history “00” is substituted for “LC”)

•LC0~LC9 indicates that there is scale build up in the heat exchanger and that the heat exchanger needs to be flushed to prevent damage. Refer to the flushing instructions in the manual. Hard water must be treated to prevent scale build up or damage to the heat exchanger.

•To operate the water heater temporarily until the heat exchanger can be flushed, push the On/Off button on the temperature controller 5 times. Repeated LC# codes will eventually lock out the water heater.

FF Maintenance Performed

•Indicates a service provider performed maintenance or repair. Enter this code by pressing up, down, and ON/OFF simultaneously.

No Code (Nothing happens when water flow is activated.)

•Clean inlet water supply filter.

•On new installations ensure hot and cold water lines are not reversed.

•Verify you have at least the minimum flow rate required to fire unit.

•Check for cold to hot cross over. Isolate circulating system if present.

•Turn off cold water to the unit, open pressure relief valve; if water continues to flow, there is bleed over in your plumbing.

•Verify turbine spins freely.

•Measure the resistance of the water flow control sensor.

•If the display is blank and clicking is coming from the unit, disconnect the water flow servo motor (GY, BR, O, W, P, BL, R). If the display comes on then replace the water flow servo motor.

|

|

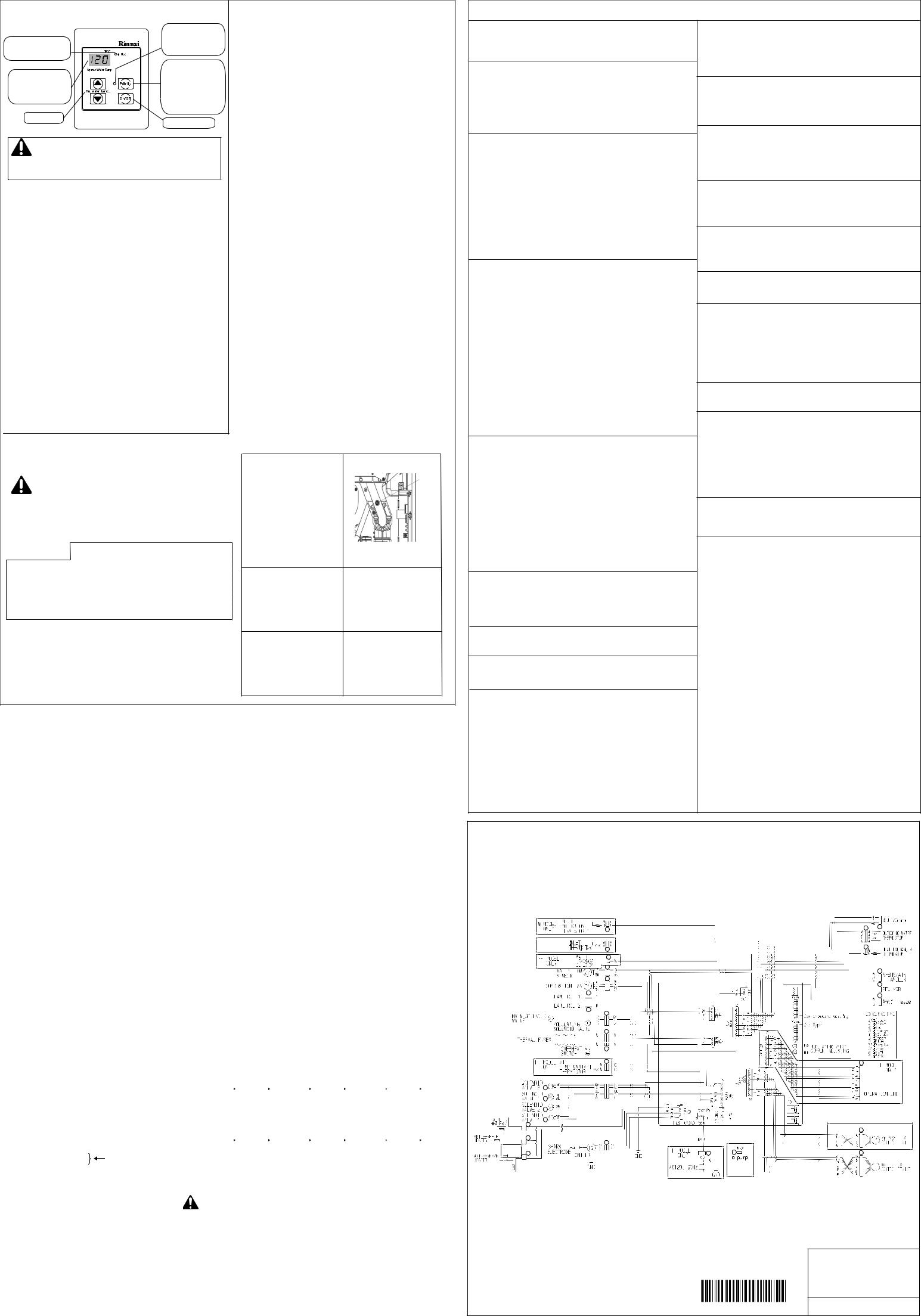

Wire Diagram |

|

|

|

|

|

|

|

Refer to EXPLODED VIEW - ELECTRICAL of technical data sheet |

|||

|

|

E6 |

|

|

E5 |

A1 |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

E4 |

|

|

|

E7 |

|

|

|

|

|

|

E8 |

|

|

|

|

|

|

L3 |

|

|

|

|

|

|

|

|

|

|

E3 |

|

|

L2 |

|

|

|

|

|

|

|

|

|

|

E2 |

|

|

L1 |

|

|

|

E1 |

|

|

|

|

|

|

|

|

|

D2 |

|

|

|

|

|

|

D1 |

|

|

|

|

|

|

B8 |

|

|

|

|

|

|

B7 |

|

|

|

|

|

|

B6 |

|

I1 |

|

|

|

|

|

|

|

|

|

|

|

B4 |

|

|

|

|

|

|

B3 |

|

|

|

|

|

|

B2 |

|

|

|

|

|

|

B1 |

|

|

|

|

|

C2 |

|

|

|

|

2837,2737 |

|

|

|

|

G1 |

|

|

|

|

|

|

|

MODEL ONLY |

|

|

|

|

|

|

|

|

|

C3 |

|

|

|

|

|

|

|

C1 |

|

|

|

|

FF MODEL |

|

|

|

|

|

|

ONLY |

C4 |

F1 |

H1 |

G2 |

|

|

|

|

|

RL MODEL |

|

|

|

|

|

|

ONLY |

|

|

|

|

|

|

|

V65i (VC2025FFU-US) |

||

|

|

|

|

V75i (VC2528FFU-US) |

||

|

|

|

|

V94Xi (VC2737FFU-US) |

||

|

|

|

|

V94i (VC2837FFU-US) |

||

|

|

|

070 00012 35700 3 |

U307-1116X02(00) |

||

Loading...

Loading...