Page 1

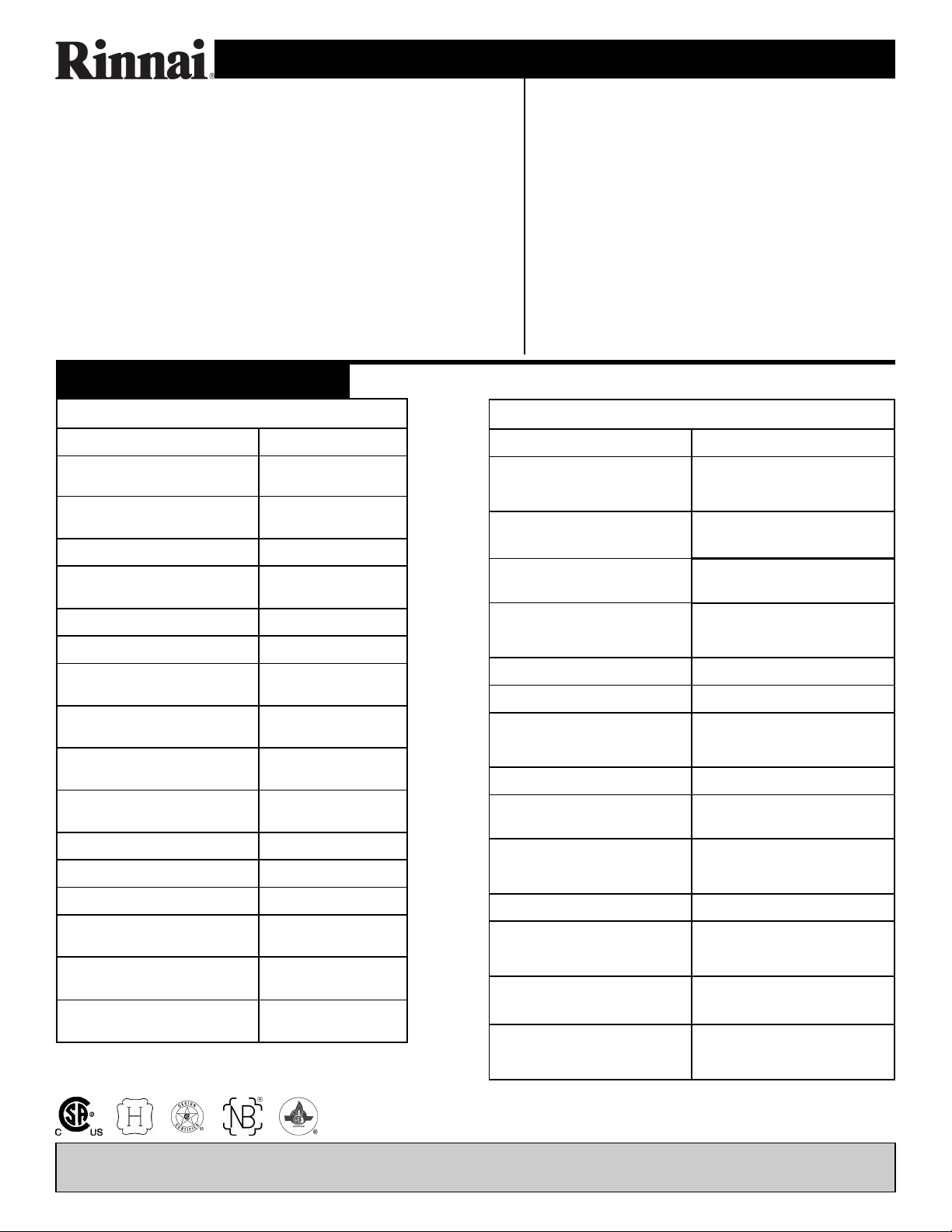

Q175C Condensing Boiler

Standard Features

Factory Installed Boiler/System Modulating Pump

Onboard Outdoor Reset Control System with Sensor Standard

Priority Domestic Hot Water (DHW) Standard

Built in DHW 6.6 Gallon Indirect Tank

Modulating Ceramic Premix Burner

5.0:1 Turndown Ratio

Spark Ignition

Exceeds SCAQMD 1146.2 Low NO

Requirements

x

Stainless Steel Water Tube Condensing Heat Exchanger

Direct Vent Sealed Combustion

Concentric and Twin Pipe Venting Adapters Included

Approved for Room and Closet Installations

SPECIFICATIONS

General Specifications

Water Content (Heating) 1.8 Gal / 7.0 L

Water Content (DHW) 3.7 Gal / 14 L

Max Supply Boiler

Temperature

Max Operating Pressure 45 PSI / 310 kPa

176 °F / 80 °C

Optional Accessories

RS100 Single Zone Controller

Flue Gas Temperature Sensor

Room Air Filter

NG to LP Conversion Kit

NG to LP Conversion Kit

Performance Specifications

Fuel Types NG and LP

Input (Heating) 175 MBH / 51.0 kWh

Heating Capacity

162 MBH / 47.5 kWh

Relief Valve Rating 375 MBH / 110 kWh

Relief Valve Pressure Rating 30 PSI / 207 kPa

Unit Weight 196 lbs / 89 kg

Min Inlet Gas Pressure NG 4.0" WC / 10.0 mbar

Max Inlet Gas Pressure NG 10.5" WC / 26.2 mbar

Min Inlet Gas Pressure LP 8.0" WC / 19.9 mbar

Max Inlet Gas Pressure LP 13.5” WC / 33.6 mbar

Electrical Voltage Mains 120 V / 60 Hz

Electrical Voltage Controls 24 V

Power Consumption Max Load 210 W

Power Consumption Standby

Load

Recommended Circuit Breaker

Rating

Sound Level 54 dB

14 W

15 A

Input (DHW) 175 MBH / 51.0 kWh

Minimum Input

Turndown Ratio 5.0:1 / 2.4:1 TDR

System Pump Model UPER 20-78

Max Head Pressure at Flow

Rate

AFUE 95.0%

DHW Flow Rate 75°F ΔT

DHW Minimum Activation N/A

Flow Restrictor Color N/A

Max Equivalent Exhaust Vent

Length

Max Equivalent Combustion

Air Vent Length

Approved Venting Materials

NG: 35 MBH / 10.3 kWh

LP: 74 MBH / 21.7 kWh

15.9 ft at 5.0 GPM

4.8 m at 18.9 LPM

4.1 GPM / 15.5 LPM

80 ft / 24.4 m

80 ft / 24.4 m

Polypropylene, Stainless Steel,

PVC, CPVC

Rinnai is continually updating and improving products; therefore, specifications are subject to change without prior

notice. Local, state, provincial and federal codes must be adhered to prior to installation.

© 2017 Rinnai Corporation

Q175C-SP-2 8/2017

Page 2

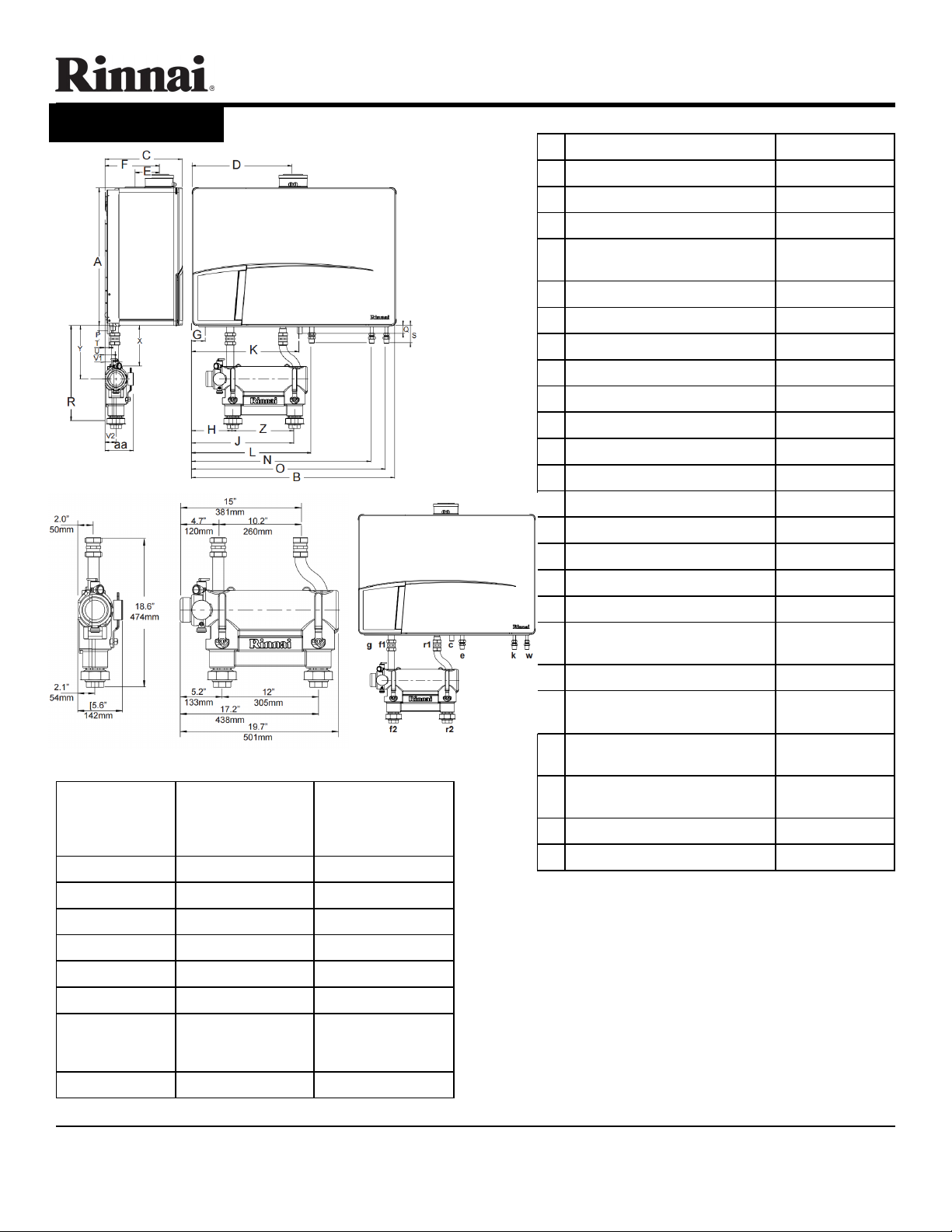

DIMENSIONS

Q175C Condensing Boiler

A Height

B Width 39.4” / 1000 mm

C Depth 15.2” / 385 mm

D Left Side / Vent 19.5” / 495 mm

Center to Center / Vent and Air

E

Supply

F Back / Vent 10.6” / 270 mm

G Left Side / Gas Pipe 2.6” / 65 mm

H Left Side / Supply Pipe 7.8” / 199 mm

J Left Side / Return Pipe 19.8” / 504 mm

K Left Side / Condensate Pipe 20.9” / 530 mm

L Left Side / Expansion Tank 23.2” / 590 mm

N Left Side / Cold Water Pipe 34.8” / 885 mm

O Left Side / Hot Water Pipe 37.6” / 955 mm

P Pipe Length of G 0.7” / 18 mm

Q Pipe Length of C 2” / 50 mm

R Pipe Length of F and R 18.5” / 470 mm

T Back / Center of Pipe C 1” / 25 mm

U Back / Center of Pipe G 1.6” / 40 mm

Back / Center of Pipes f1, e, k,

V1

r1, and w

V2 Back/ Center of Pipes f2 and r2 2.1” / 54 mm

26.8” / 680 mm

4.7” / 121 mm

2” / 50 mm

Pipe Length Vent Co-axial

W

Pipe Length Vent Parallel

Bottom Side Boiler to Center

X

Clearances

Minimum required

Top 2” / 50 mm 10” / 250 mm

Back 0 0

Front 6” / 150 mm 24” / 600 mm

Left side 2” / 50 mm 2” / 50 mm

Right side 2” / 50 mm 2” / 50 mm

Floor / Ground 12” / 300 mm 30” / 762 mm

Floor / Ground to

bottom of Low

Loss Header

Vent 0 0

Rinnai Corporation • 103 International Drive • Peachtree City, GA 30269 • Toll-Free: 1-800-621-9419 • Fax: 678-364-8643 • www.rinnai.us

clearance to

combustibles and

non-combustibles

0 12” / 300 mm

Recommended

service clearances

Pressure Relief Valve

Bottom Side Boiler to Center

Y

Low Loss Header

Z Center to Center of f2 and r2 12” / 305 mm

aa Depth of Low Loss Header 5.6” / 142 mm

2.6” / 65 mm

5.8” / 147 mm

8” / 200 mm

10.4” / 265 mm

© 2017 Rinnai Corporation

Q175C-SP-2 8/2017

Loading...

Loading...