Page 1

Direct Vent Wall Furnace

Installation and Operation Manual

— Do not store or use gasoline or other ammable vapors and liquids in the vicinity of this or any other

appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instrucons.

• If you cannot reach your gas supplier, call the re department.

— Installaon and service must be performed by a licensed professional.

If the informaon in these instrucons is not followed exactly, a re or explosion

may result causing property damage, personal injury or death.

WARNING

READ ALL OF THE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR OPERATING

THIS HEATER.

This manual provides information on the installation, operation, and maintenance of the heater. For

proper operation and safety, it is important to follow the instructions and adhere to the safety

precautions.

A licensed professional must install the fan convection heater according to the exact instructions

within this manual.

The consumer must read the entire manual to properly operate the heater and to have regular

maintenance performed.

EX38CT............... (RHFE-1005FTA2)

Installer: Leave this manual with the appliance.

Consumer: Retain this manual for future reference.

Register your product at www.rinnairegistration.com or call 1-866-RINNAI1 (746-6241)

Page 2

2 Rinnai Corporation EX38CT Manual

Table of Contents

Important Safety Information

Safety Definitions

This is the safety alert symbol. This symbol alerts you to potential hazards that can kill or hurt you and

others.

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in minor or

moderate injury. It may also be used to alert against unsafe practices.

DANGER

CAUTION

WARNING

Table of Contents ............................................. 2

Safety Definitions ............................................. 2

Safety Behaviors and Practices for the Consumer

and Installer ...................................................... 3

Installation Instructions

(for the licensed professional)

State Regulations ............................................. 4

Included Installation and Vent Components .... 5

Installation Instructions..................................... 6

Prepare for Installation ..................................... 7

Determine Installation Location ........................ 7

Flue Terminal Clearances ................................ 8

Clearances to Combustibles ............................ 9

Checklist to Determine Installation Location .... 9

Drilling Flue Hole ............................................ 10

Attach Wall Brackets ...................................... 10

Attach Back Spacers ...................................... 10

Flue Manifold Installation ............................... 11

Extension Kit Installation ................................ 13

Connecting the Appliance .............................. 16

Gas Connection ............................................. 17

Adjust Gas Pressure Settings ........................ 17

Dimensions .................................................... 21

Specifications ................................................. 22

Direct Vent Furnace Operation Instructions

Safe Operation .............................................. 24

Getting to Know Your Appliance .................... 25

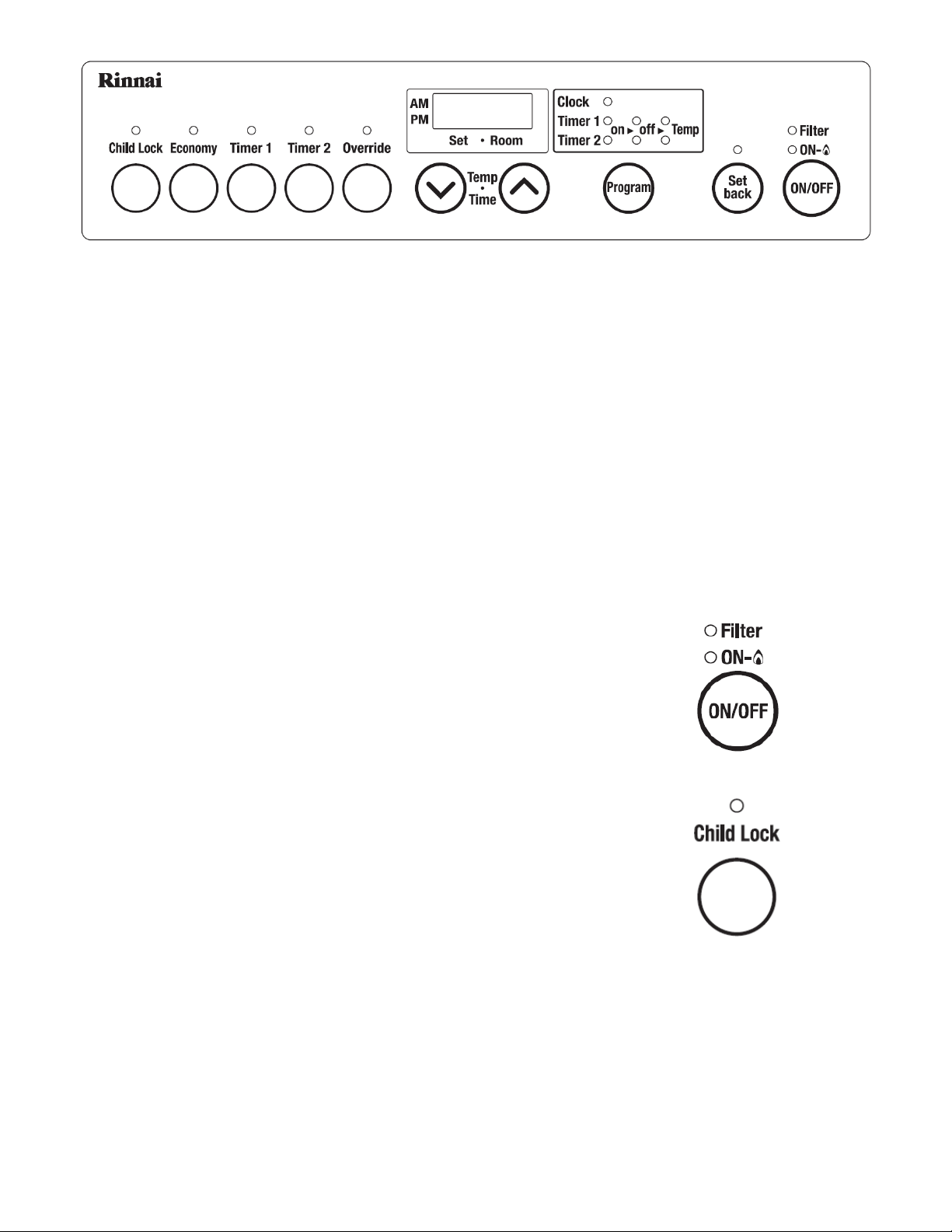

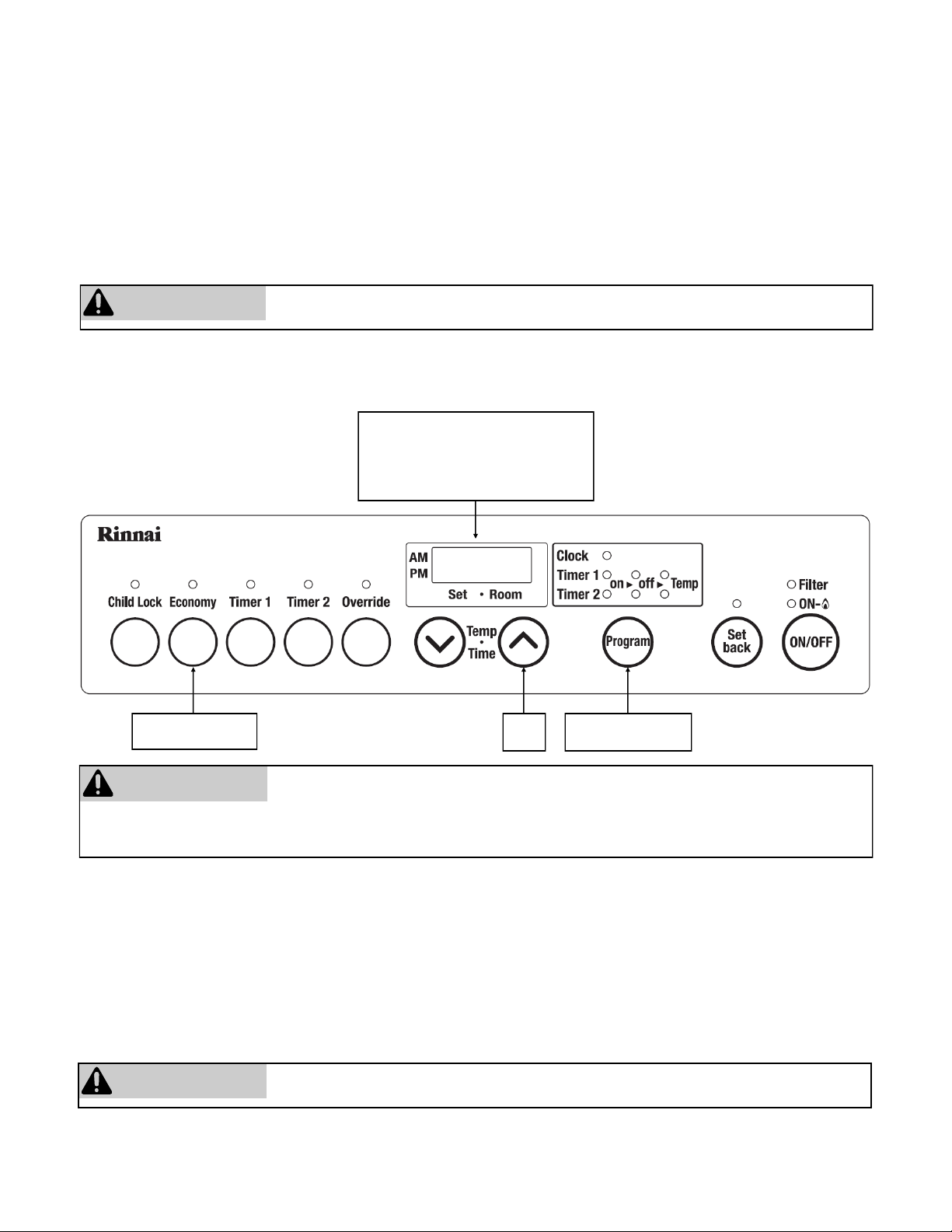

Control Panel ................................................. 26

ON / OFF ........................................................ 26

Child Lock ...................................................... 26

Remote Thermostat Mode

(Optional Accessory) ..................................... 27

Setting the Clock ............................................ 28

Setting and Operating the Timers .................. 28

Override Function .......................................... 29

Economy (Energy Saving Mode) ................... 29

Set Back ......................................................... 29

Humidifier and Air Flow Direction .................. 30

Required Care and Maintenance

Care and Maintenance .................................. 31

Before Making a Service Call ........................ 32

Diagnostic Codes Remedies ......................... 33

Restart Function............................................. 34

Troubleshooting ............................................. 34

Cut-Away Diagram ......................................... 35

Wiring Diagram .............................................. 36

Ladder Diagram ............................................. 37

Parts List ........................................................ 38

Consumer Information

Warranty ........................................................ 46

French Version............................................... 49

NOTICE: Rinnai sometimes shares customer contact information with businesses that we believe provide

products or services that may be useful to you. By providing this information, you agree that we can

share your contact information for this purpose. If you prefer not to have your information shared with

these businesses, please contact customer service and ask not to have your information shared. We will

however, continue to contact you with information relevant to the product(s) you registered and/or your

account with us.

If you have any questions or feel that the manual is incomplete contact Rinnai at 1-800-621-9419.

Page 3

Rinnai Corporation EX38CT Manual 3

WARNING

CAUTION

Safety Behaviors and Practices for the Consumer and Installer

• Do not block the warm air discharge. Do not allow

anyone to sleep directly in front of the appliance.

• Due to high temperatures, the appliance should be

located out of traffic and away from furniture and

draperies.

• Children and adults should be alerted to the hazards

of high surface temperature and should stay away

to avoid burns or clothing ignition.

• Young children should be carefully supervised when

they are in the same room as the appliance.

• Clothing or other flammable material should not be

placed on or near the appliance.

• Any safety screen or guard removed for servicing

must be replaced prior to operating the appliance.

• Do not insert items into the louvers.

• Do not spray aerosols near the appliance while it is

operating. Most aerosols contain butane gas which

is flammable.

• Do not unplug the appliance while it is operating or

while the fans are on.

• Do not use bare hands to touch the front louvers

due to high temperatures which may cause burns.

• Wear hand protection when touching the side back

covers, front louver, and rear intake for the

convection fan.

• Prevent dust from accumulating on the power cord,

side covers, and parts behind the appliance.

• Do not sit on the heater.

• Do not place containers of liquid on top of the

heater. Water spillage can cause extensive

damage to the appliance and may result in electric

shock.

• Repairs should be performed by a qualified service

technician.

• Keep the area around the appliance clear and free

from combustible materials, gasoline, and other

flammable vapors and liquids.

• Never store liquid propane containers indoors.

• Do not use this appliance if any part has been under

water. Immediately call a qualified service

technician to inspect the appliance and to replace

any part of the control system and any gas control

which has been under water.

• This appliance is equipped with a three-prong plug

for your protection against shock hazard and should

be plugged directly into a properly grounded threeprong receptacle. Do not cut or remove the ground

prong from this plug.

• Any alteration to the appliance or its controls can be

dangerous.

• Do not operate appliance with the panels removed,

cracked or broken. Replacement of the panels

should be done by a licensed or qualified service

person.

WARNING

California law requires this notice to be provided:

California Proposition 65:

This product can expose you to chemicals including Di (2-ethylhexyl) phthalate (DEHP) and carbon bisulfide

which are known to the State of California to cause cancer, birth defects or other reproductive harm. For more

information, visit www.P65Warnings.ca.gov.

Page 4

4 Rinnai Corporation EX38CT Manual

Installation Instructions (for the licensed professional)

State Regulations

NOTICE BEFORE INSTALLATION: Rinnai direct-vent appliance must be installed by a state qualified or licensed contractor and

a properly trained Rinnai Installer. If you are not properly trained, you must not install this unit.

IMPORTANT: In the State of Massachusetts (248 CMR 4.00 & 5.00)

For all side wall horizontally vented gas fueled equipment installed in every dwelling, building or structure used in whole or in

part for residential purposes, including those owned or operated by the Commonwealth and where the side wall exhaust vent

termination is less than seven (7) feet above finished grade in the area of the venting, including but not limited to decks and

porches, the following requirements shall be satisfied:

1. INSTALLATION OF CARBON MONOXIDE DETECTORS. At the time of installation of the side wall horizontal vented gas

fueled equipment, the installing plumber or gasfitter shall observe that a hard wired carbon monoxide detector with an alarm

and battery back-up is installed on the floor level where the gas equipment is to be installed. In addition, the installing

plumber or gasfitter shall observe that a battery operated or hard wired carbon monoxide detector with an alarm is installed

on each additional level of the dwelling, building or structure served by the side wall horizontal vented gas fueled equipment.

It shall be the responsibility of the property owner to secure the services of qualified licensed professionals for the

installation of hard wired carbon monoxide detectors

a. In the event that the side wall horizontally vented gas fueled equipment is installed in a crawl space or an attic, the hard

wired carbon monoxide detector with alarm and battery back-up may be installed on the next adjacent floor level.

b. In the event that the requirements of this subdivision can not be met at the time of completion of installation, the owner

shall have a period of thirty (30) days to comply with the above requirements; provided, however, that during said thirty

(30) day period, a battery operated carbon monoxide detector with an alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS. Each carbon monoxide detector as required in accordance with the

above provisions shall comply with NFPA 720 and be ANSI/UL 2034 listed and IAS certified.

3. SIGNAGE. A metal or plastic identification plate shall be permanently mounted to the exterior of the building at a minimum

height of eight (8) feet above grade directly in line with the exhaust vent terminal for the horizontally vented gas fueled

heating appliance or equipment. The sign shall read, in print size no less than one-half (1/2) inch in size, "GAS VENT

DIRECTLY BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS".

4. INSPECTION. The state or local gas inspector of the side wall horizontally vented gas fueled equipment shall not approve

the installation unless, upon inspection, the inspector observes carbon monoxide detectors and signage installed in

accordance with the provisions of 248 CMR 5.08(2)(a)1 through 4.

When an existing Category I heater is removed or replaced, the original venting system may no longer be sized to properly vent

the attached appliances. Instructions shall also indicate effects of an improperly sized venting system (formation of condensate,

leakage, spillage, etc.) and shall specify the following test procedure.

WARNING: CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each appliance connected to the venting system being placed into operation could

result in carbon monoxide poisoning or death.

The following steps shall be followed for each appliance connected to the venting system being placed into operation, while all

other appliances connected to the venting system are not in operation:

1. Seal any unused openings in the venting system.

2. Inspect the venting system for proper size and horizontal pitch, as required in the National Fuel Gas Code, ANSI Z223.1/

NFPA 54 or the Natural Gas and Propane Installation Code, CSA B149.1 and these instructions. Determine that there is no

blockage or restriction, leakage, corrosion and other deficiencies which could cause an unsafe condition.

3. As far as practical, close all building doors and windows and all doors between the space in which the appliance(s)

connected to the venting system are located and other spaces of the building.

4. Close fireplace dampers.

5. Turn on clothes dryers and any appliance not connected to the venting system. Turn on any exhaust fans, such as range

hoods and bathroom exhausts, so they are operating at maximum speed. Do not operate a summer exhaust fan.

6. Follow the lighting instructions. Place the appliance being inspected into operation. Adjust the thermostat so appliance is

operating continuously.

7. Test for spillage from draft hood equipped appliances at the draft hood relief opening after 5 minutes of main burner

operation. Use the flame of a match or candle.

8. If improper venting is observed during any of the above tests, the venting system must be corrected in accordance with the

National Fuel Gas Code, ANSI Z223.1/NFPA 54 and/or Natural Gas and Propane Installation Code, CSA B149.1.

9. After it has been determined that each appliance connected to the venting system properly vents when tested as outlined

above, return doors, windows, exhaust fans, fireplace dampers and any other gas-fired burning appliance to their previous

conditions of use.

WARNING

Page 5

Rinnai Corporation EX38CT Manual 5

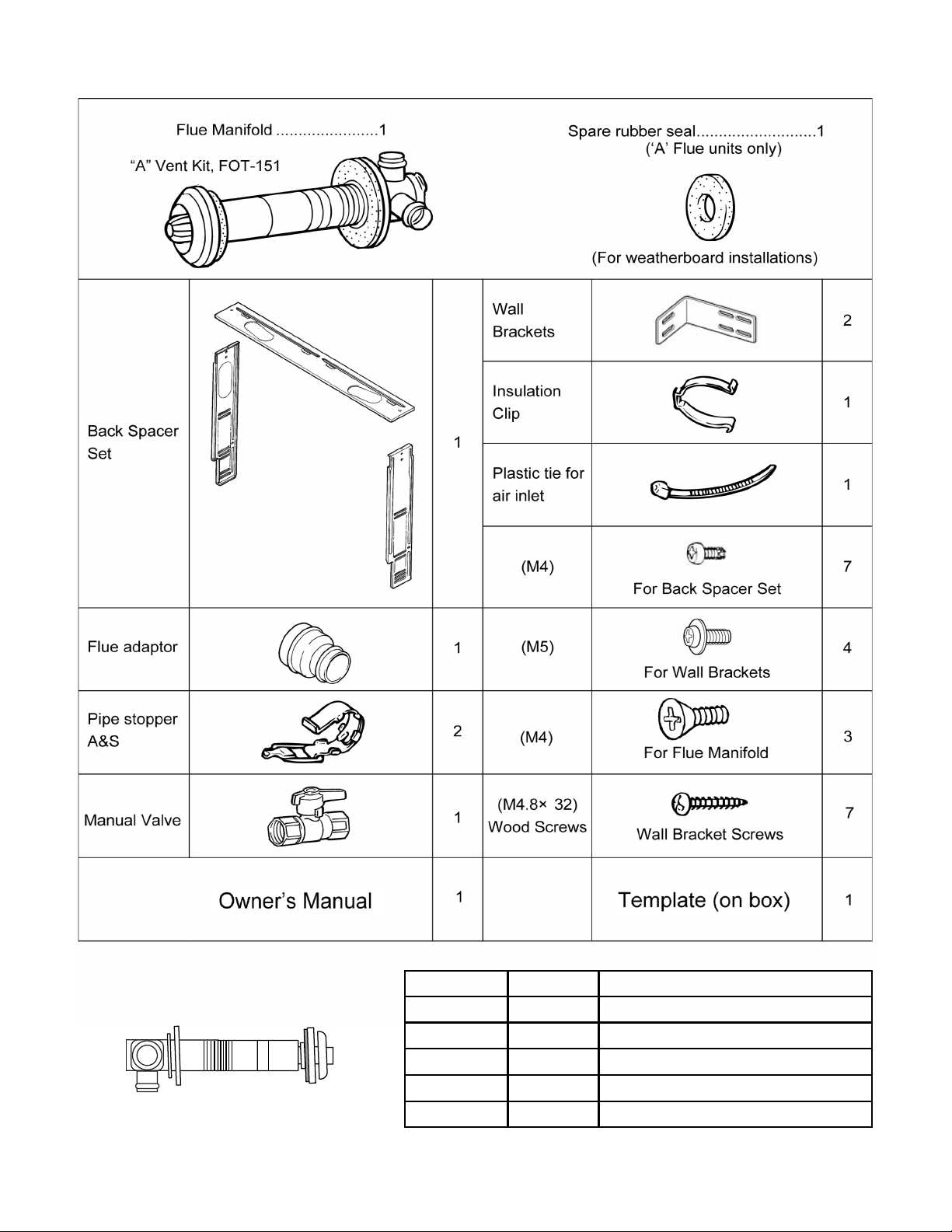

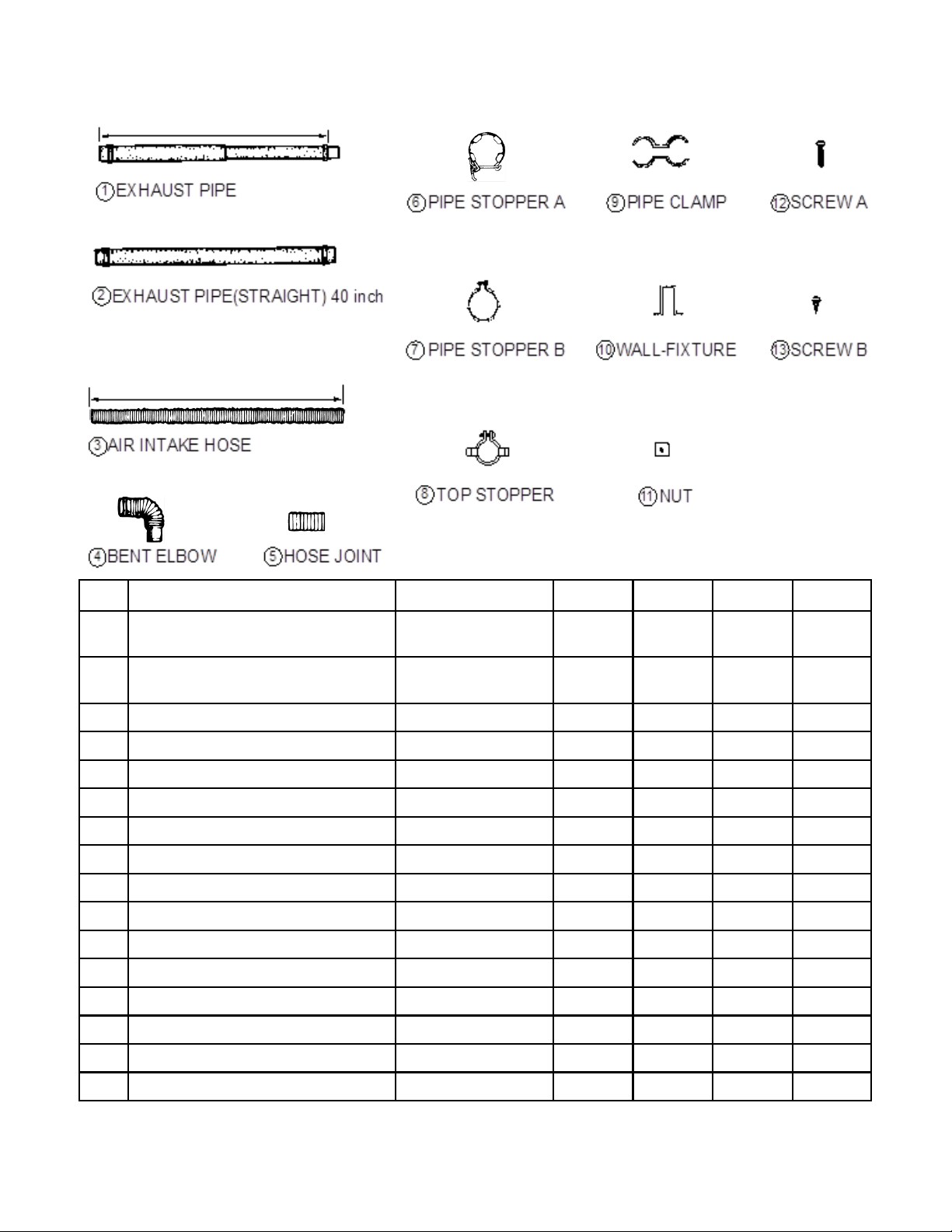

Included Installation and Vent Components

The following items are included with the appliance:

(Attached to unit)

The following flue manifold sizes are

available for different wall thicknesses:

Name Kit No. fits walls

S Vent Kit FOT-150 3 - 4 1/2 in (75 - 115 mm)

A Vent Kit FOT-151 4 1/2 - 9 1/2 in (115 - 240 mm)

B Vent Kit FOT-152 9 1/2 - 15 3/4 in (240 - 400mm)

C Vent Kit FOT-153 15 3/4 - 23 5/8 in (400 - 600 mm)

D Vent Kit FOT-154 23 5/8 - 31 1/2 in (600 - 800 mm)

Flue Manifolds

Vent A Kit is included with the appliance.

Page 6

6 Rinnai Corporation EX38CT Manual

This appliance may be installed in an aftermarket,

permanently located, manufactured home (USA only)

or mobile home, where not prohibited by local codes.

This appliance is only for use with the type of gas

indicated on the rating plate. This appliance is not

convertible for use with other gases, unless a certified

kit is used.

Installation Instructions

This appliance may be installed as an OEM

installation in a manufactured home (USA only) or

mobile home and must be installed in accordance with

the manufacturer’s instructions and the Manufactured

Home construction and Safety Standard, Title 24

CFR, Part 3280, in the United States, or the Mobile

Home Standard, CAN/CSA Z240 MH Series, in

Canada.

If installation is at a location above

2001 ft (610 m), then follow the Adjust

Gas Pressure Settings procedure.

Appliance input ratings are based on

sea level operation and need not be

changed for operation up to 2000 ft

(610 m) elevation.

NOTICE

A licensed professional must install the appliance,

inspect it, and leak test it before use. The warranty

will be voided due to any improper installation.

The installer should have skills such as:

• Gas sizing.

• Connecting gas lines, valves, and electricity.

• Knowledge of applicable national, state, and local

codes.

• Installing venting through a wall.

• Training in installation of direct vent furnaces.

(Training can be accessed on-line at

www.trainingevents.rinnai.us)

Installer Qualifications

General Instructions

Type of installaon

• For installation in residential and commercial

applications.

• Certified for installation in manufactured (mobile)

homes.

MUST DO

• If you move, check the gas type in your new area.

The local gas authority will be able to advise on

local regulations.

• The installation must conform with local codes or, in

the absence of local codes, with the National Fuel

Gas Code, ANSI Z223.1/NFPA 54, or the Natural

Gas and Propane Installation Code, CSA B149.1.

• A manufactured home (USA only) or mobile home

OEM installation must conform with the

Manufactured Home Construction and Safety

Standard, Title 24 CFR, Part 3280, or, when such a

standard is not applicable, the standard for

Manufactured Home Installations, ANSI Z225.1, or

the standard for Gas Equipped Recreational

Vehicles and Mobile Housing, CSA Z240.4.

• The appliance, when installed, must be electrically

grounded in accordance with local codes or, in the

absence of local codes, with the National Electrical

Code, ANSI/NFPA 70, or the Canadian Electrical

Code, CSA C22.1.

• The appliance and its appliance main gas valve

must be disconnected from the gas supply piping

system during any pressure testing of that system

at test pressures in excess of 1/2 psi (3.5 kPa).

• The appliance must be isolated from the gas supply

piping system by closing its equipment shutoff valve

during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2

psi (3.5 kPa).

• If the flooring is carpet or other combustible material other than wood, then the appliance must be installed on a metal or wood panel extending the full

width and depth of the appliance.

• This appliance is only for use with the type of gas

indicated on the rating plate. This appliance is not

convertible for use with other gases unless a certified kit is used. If conversion of the unit is needed,

conversions must be performed by a qualified service provider at the owner’s expense.

• The appliance should be correctly sized for the

space it is required to heat. It is recommended that

an Industry standard BTU Heat Loss Calculation be

conducted to determine the proper sizing.

• Follow the installations instructions and those in

Care and Maintenance for adequate combustion

and ventilation air.

• This appliance discharges a large volume of warm

air next to the floor. Any particles in the air such as

cigarette smoke could cause discoloration in nylon

carpets containing dyes or vinyl surfaces.

• Rinnai suggests that a dedicated electrical circuit

with a 120VAC, 60 Hz, 10 amp power source be

used.

• A test plug is provided for testing of manifold

differential pressure. It is located on the modulating

gas valve.

Page 7

Rinnai Corporation EX38CT Manual 7

WARNING

Do not use substitute materials.

Use only parts certified with the appliance.

DO NOT

• This appliance is not designed to built in.

• This appliance must not be connected to a chimney

flue serving a separate solid-fuel burning appliance.

• The flow of combustion and ventilation air shall not

be obstructed.

Prepare for Installation

Tools needed

Materials needed

• Pipe wrenches (2)

• Adjustable pliers

• Screwdrivers (2)

• Wire cutters

• Gloves

• Safety glasses

• Level

Tools that might be needed

• Hammer drill with

concrete bits

• Saw

• Threading machine with

heads and oiler

• Core drill with diamond

head

• Torch set

• Copper tubing cutter

• Steel pipe cutter

Materials that may be needed

• Soap or gas leak

detector solution

• Approved venting

• Teflon tape

(recommended) or pipe

compound

• Heat tape

• Pipe insulation

• Concrete wall anchors

• Optional pipe cover

• Optional temperature

controller

• 2 conductor 22 AWG

wire for controller

• Single gang electrical

box

• Wire nuts

Determine Installation Location

You must ensure that clearances will be met and that

the vent length will be within required limits. Consider

the installation environment. Requirements for the

gas line and electrical connection can be found in their

respective installation sections of this manual.

Environment

Air surrounding the venting, and vent termination(s) is

used for combustion and must be free of any

compounds that cause corrosion of internal

components. These include corrosive compounds

that are found in aerosol sprays, detergents, bleaches,

cleaning solvents, oil based paints/ varnishes, and

refrigerants.

The furnace, venting, and vent termination(s) should

not be installed in any areas where the air may

contain these corrosive compounds. If it is necessary

for a furnace to be located in areas that may contain

corrosive compounds, the following

instructions are strongly recommended.

IMPORTANT CONSIDERATIONS FOR:

• DO NOT Install in areas where air for combustion

might be contaminated with chemicals.

• Before installation, consider where air has the

ability to travel within the building to the furnace.

• Terminate the unit as far away as possible from

any air inlet vents. Corrosive fumes may be

released through these vents when air is not

being brought in through them.

• Chemicals that are corrosive in nature should not

be stored or used near the furnace or vent

termination.

Damage and repair due to corrosive compounds in the

air is not covered by warranty.

Page 8

8 Rinnai Corporation EX38CT Manual

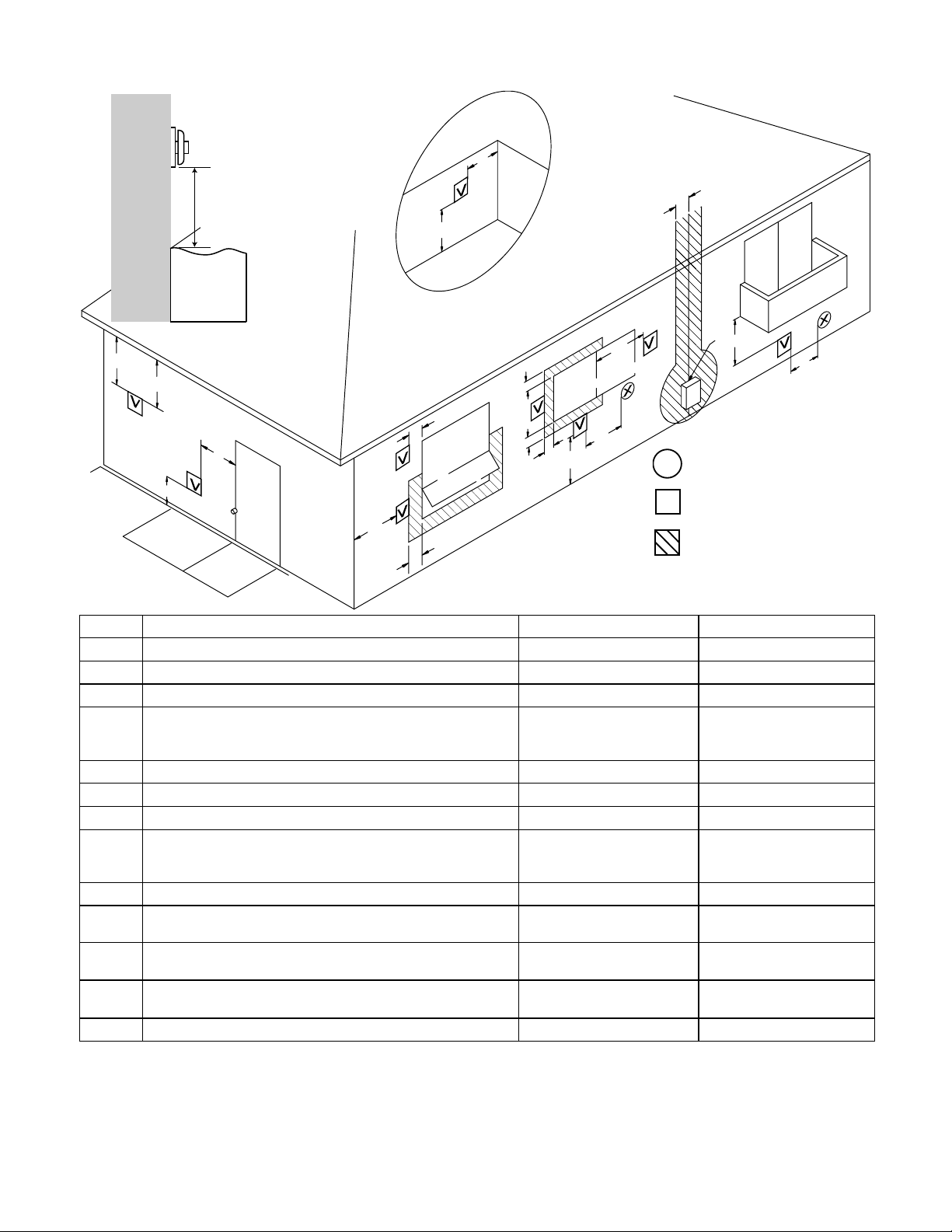

Flue Terminal Clearances

INSIDE

CORNER DE

TAIL

FIXED

CLOSED

OPERABLE

FIXED

CLOSED

OPERABLE

B

B

B

A

J

B

M

C

F

B

B

E

D

L

G

A

H

K

I

[1] A vent shall not terminate directly above a sidewalk or paved

driveway that is located between two single family dwellings and

serves both dwellings.

[2] Permitted only if veranda, porch, deck, or balcony is fully open on

a minimum of two sides beneath the floor.

For clearances not specified in ANSI Z223.1/NFPA 54, clearances

are in accordance with local installation codes and the requirements

of the gas supplier.

Clearance to opposite wall is 24 inches (60 cm).

X

V

AIR SUPPLY INLET

VENT TERMINAL

AREA WHERE

TERMINAL IS NOT

PERMITTTED

Ref

Description

Canadian Installations US Installations

A Clearance above grade, veranda, porch, deck, or balcony 12 inches (30 cm) 12 inches (30 cm)

B Clearance to window or door that may be opened 12 inches (30 cm) 9 inches (23 cm)

C Clearance to permanently closed window * *

D

Vertical clearance to ventilated soffit, located above the terminal

within a horizontal distance of 2 feet (61 cm) from the center line

of the terminal

* *

E Clearance to unventilated soffit * *

F Clearance to outside corner * *

G Clearance to inside corner * *

H

Clearance to each side of center line extended above meter/

regulator assembly

3 feet (91 cm) within a height

15 feet (4.5 m) above the

meter/regulator assembly

*

I Clearance to service regulator vent outlet 36 inches (91 cm) *

J

Clearance to nonmechanical air supply inlet to building or the

combustion air inlet to any other appliance

12 inches (30 cm) 9 inches (23 cm)

K Clearance to a mechanical air supply inlet 6 feet (1.83 m)

3 feet (91 cm) above if within

10 feet (3 m) horizontally

L

Clearance above paved sidewalk or paved driveway located on

public property

7 feet (2.13 m) *

M Clearance under veranda, porch, deck, or balcony 12 inches (30 cm) *

SNOW

TERMINATION

Clearance in

Ref. A also

applies to

anticipated

snow line

Clearance in

Ref. A also

applies to

anticipated

snow line

Page 9

Rinnai Corporation EX38CT Manual 9

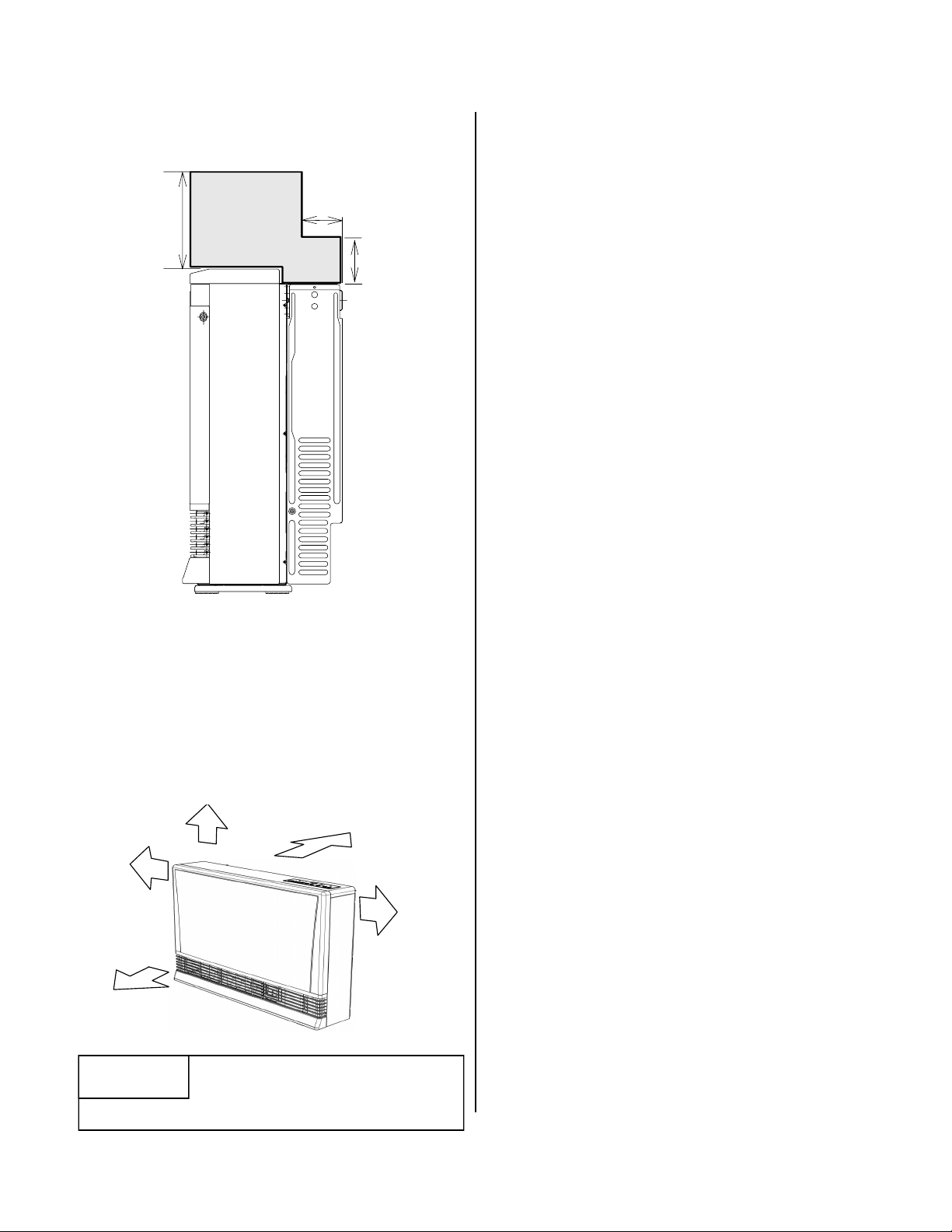

When determining where to install the appliance the

clearances to combustibles shown in the figure must

be followed. Also refer to the Safety Behaviors and

Practices section.

Rinnai recommends 10” (254 mm) clearance from the

top and on both sides for servicing.

The 40 inch (1 meter) clearance from the

front of the appliance does not include

flooring material or carpeting that is less

than 1.2 inches (30 mm) in height.

NOTICE

clearance for

maintenance

10"(250mm)

0"

2"

(50mm)

2"

(50mm)

40" (1m)

0” (0 mm)

10”

(254 mm)

3”

(76 mm)

6”

(153 mm)

Clearances to Combustibles

Checklist to Determine Installation

Location

□ The furnace is not exposed to corrosive

compounds in the air.

□ The furnace location complies with the clearances.

□ The planned venting will not exceed the maximum

length for the number of elbows used.

□ The planned venting termination/air intake location

meets the clearances.

□ Indoor air is not being used for combustion.

□ A standard 3 prong 120 VAC, 60 Hz properly

grounded wall outlet.

□ The installation must conform with local codes or,

in the absence of local codes, with the National

Fuel Gas Code, ANSI Z223.1/NFPA 54, or the

Natural Gas and Propane Installation Code, CSA

B149.1. If installed in a manufactured home, the

installation must conform with the Manufactured

Home Construction and Safety Standard, Title 24

CFR, Part 3280 and/or CAN/SCA Z240 MH

Series, Mobile Homes.

□ Leave the entire manual with the consumer.

Additional Clearances

Clearances to access the appliance during servicing

are 10 inches (254 mm) from the sides, 40 inches

(1 m) from the front, and the area shown above the

appliance in the picture.

Page 10

10 Rinnai Corporation EX38CT Manual

Ensure that there are no gas lines, or electrical

circuits in the wall location where the flue hole is to

be drilled.

Drill the flue hole using a 3 1/8 inch (80 mm) drill. A

template is provided on the appliance carton/box.

The center of the hole must be located anywhere

within the shaded area, unless extension kits are

used. See the dimensions diagram.

For weatherboard walls, drill through the center of

the weatherboard from the outside first and then

through the plasterboard.

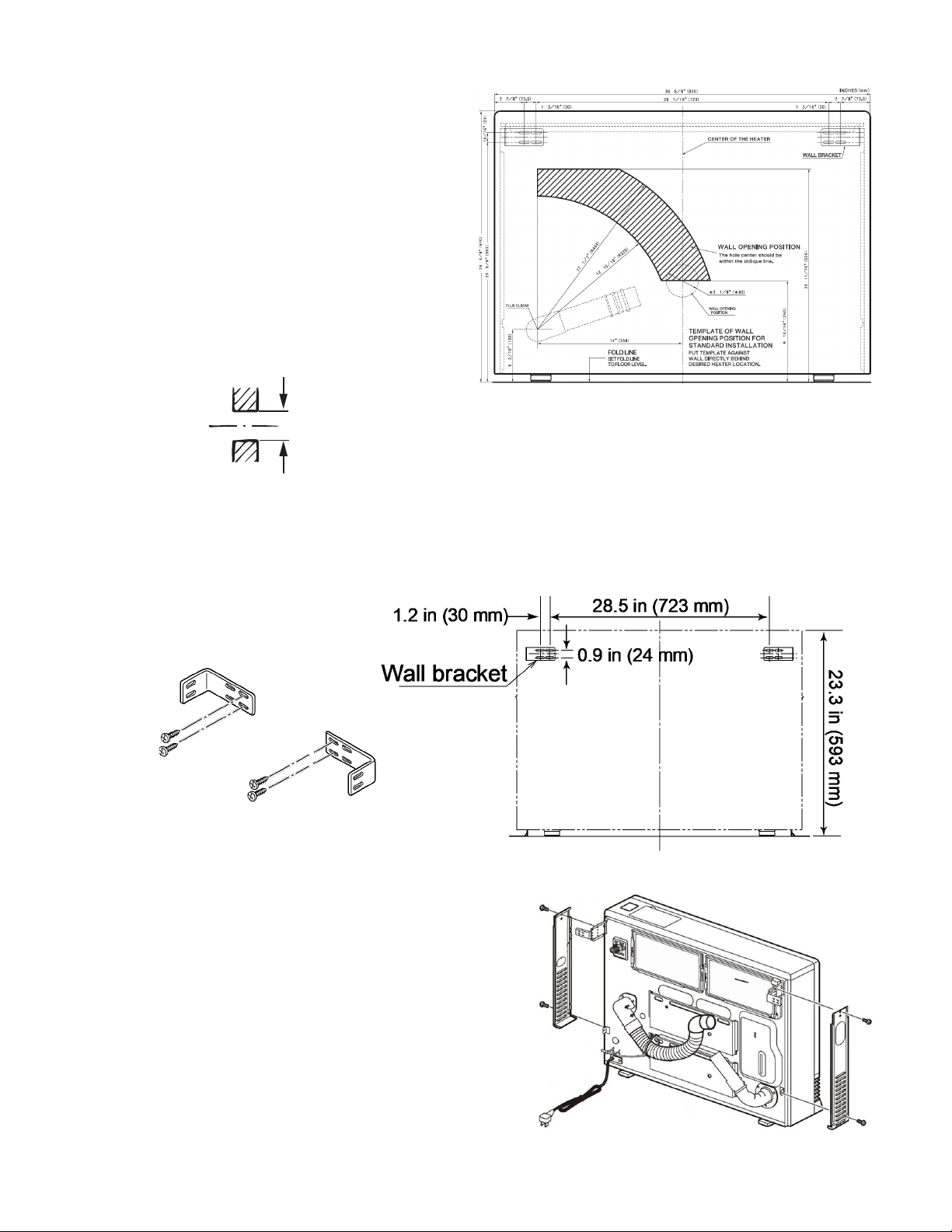

Flue Hole

3 1/8"

(80 mm)

8 7/16"

(214 mm)

R11"

(R27

9

mm

)

R8.0"

(R206 mm

)

8 9/16"

(217 mm)

11"

(280 mm)

Cavity Opening

Attach the wall brackets as shown. A template is

provided.

Attach side back spacers to both sides of the

appliance with 2 screws each.

Template is on the appliance carton/box.

Drilling Flue Hole

Attach Wall Brackets

Attach Back Spacers

Page 11

Rinnai Corporation EX38CT Manual 11

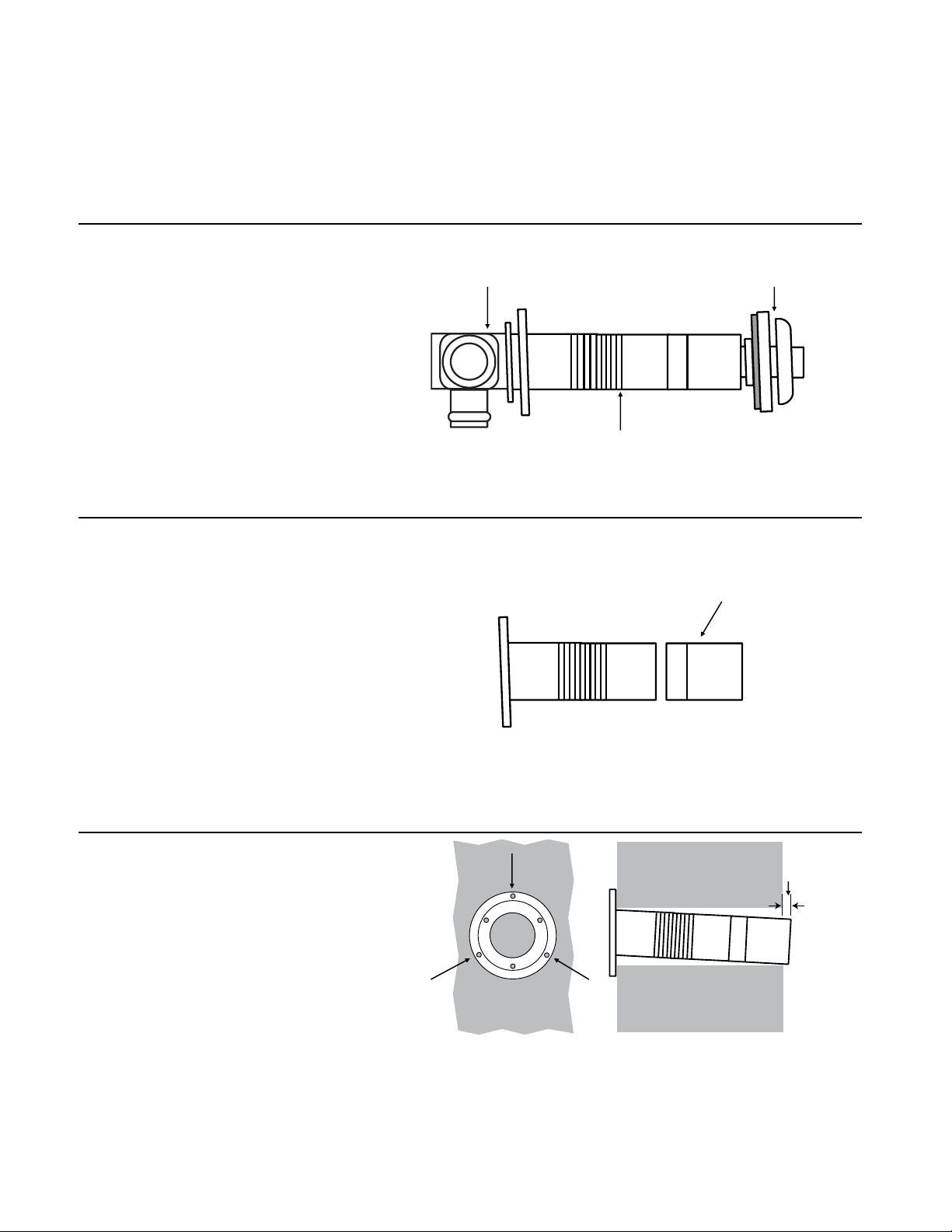

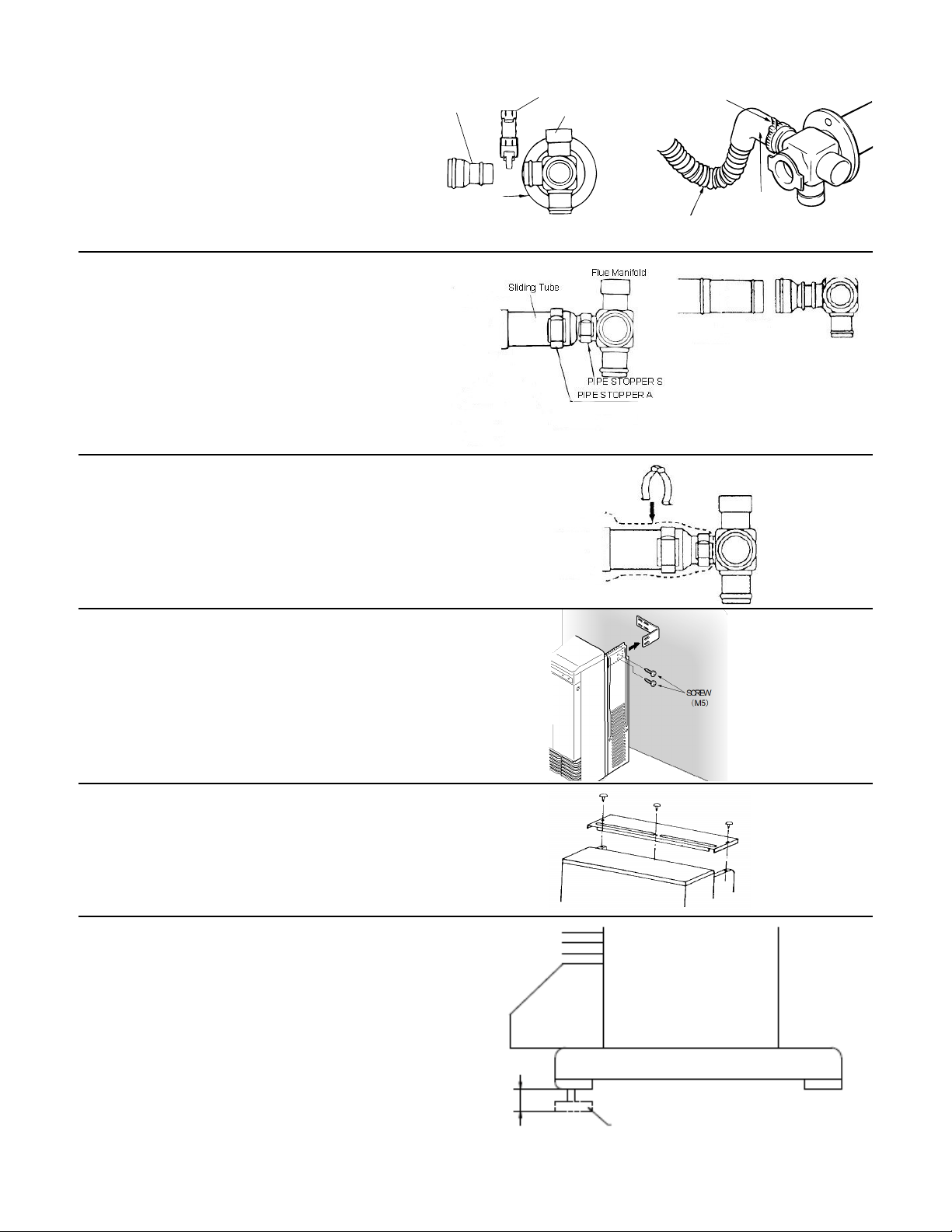

1. Disassemble the flue manifold

The flue consists of 3 parts:

• sleeve

• inside connection

• outside terminal

Disassemble the flue manifold by first pulling

out the inside connection. To remove the

outer terminal pull and release the two

internal ties and then pull out the outer

terminal.

Clearance to combustibles for the sleeve and

flanges is zero inches.

2. Adjust the sleeve length

Measure wall thickness through previously

drilled 3 1/8 inch (80 mm) hole.

The end of the sleeve should protrude 3/16 3/8 inch (5-10 mm) from the outside wall.

The sleeve is threaded for adjustment. Adjust

the sleeve length to wall thickness plus 3/16 3/8 inch (5-10 mm).

NOTE: Do not extend beyond the red line.

For other than the “S” type flue manifold, if a

shorter length is necessary an extension can

be removed. Cut the plastic and remove the

extension.

• The flue manifold must exhaust to the outside. Do

not exhaust into other rooms.

• The flue manifold is not designed to be positioned

under floors or below the furnace.

• The termination cannot be vertical.

• This appliance can only be used with one of the

five types of Rinnai flue kits. The flue kits and their

dimensions are listed on the previous page.

• Refer to the Flue Terminal Clearances section.

3 screws

sleeve should extend

3/16 - 3/8 in (5-10 mm)

3. Attach the sleeve

Attach to the inside wall using 3 screws

arranging the flange so that the marking

“TOP” is at the top.

The flange is offset 2° to allow the

condensate drain to the outside.

Inside Connection

Sleeve

Terminal

Remove extension

if necessary

Flue Manifold Installation

Page 12

12 Rinnai Corporation EX38CT Manual

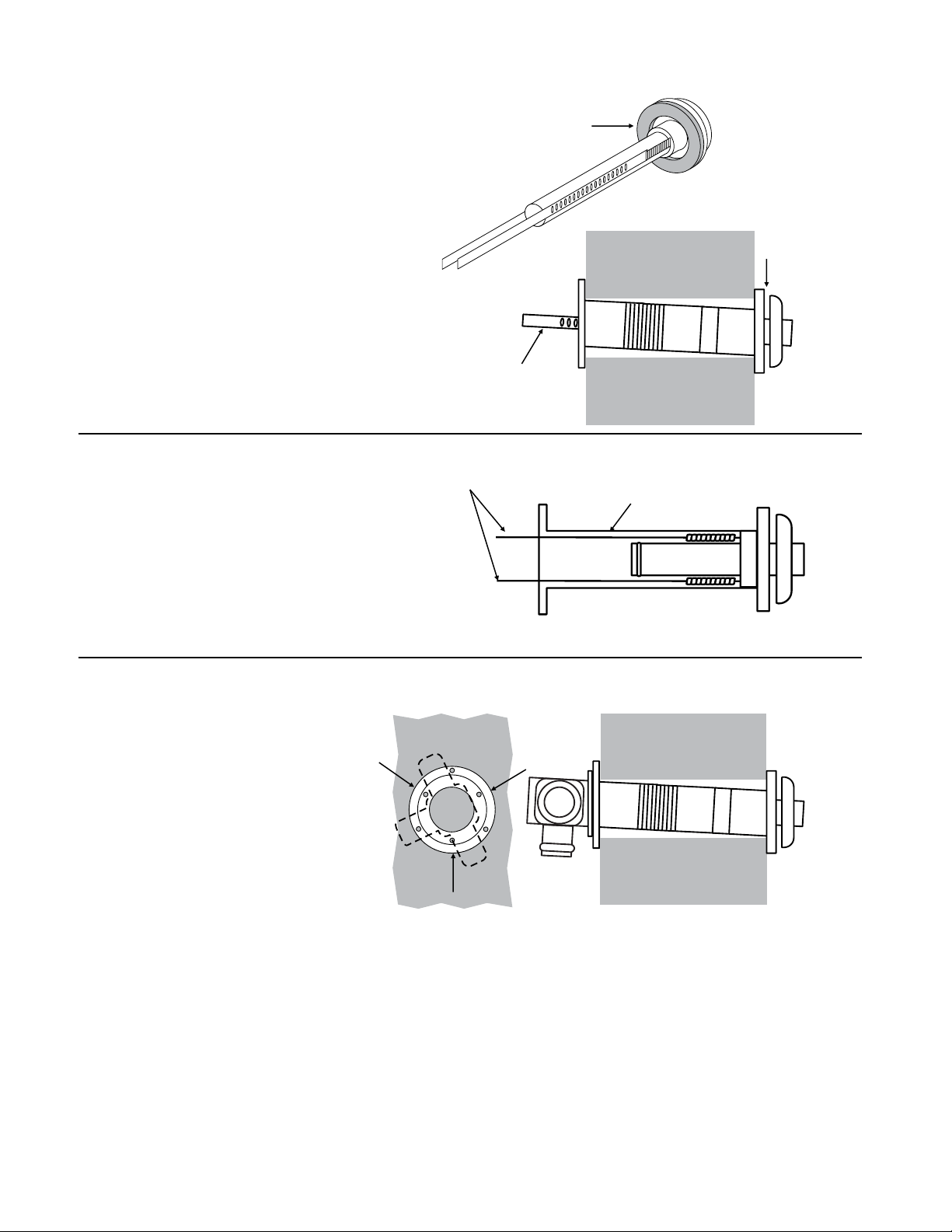

5. Lock the ties

Pulling hard on the left and right hand ties,

clip the ties over the notches inside the

sleeve. You should be able to pull the ties 2

or 3 notches past the starting point. Cut the

ties, leaving about 3/4 inch (20 mm) past the

notch. Bend the ties back into the sleeve and

parallel to the wall.

6. Insert Inside Connection Assembly

Push the assembly into the terminal tube,

ensuring that the seal is in place on the

inner tube.

Attach the inside connection with 3

screws. The inner connection can still

be turned to install the screws.

4. Install the Terminal

Check that the terminal seal is in place. For

weatherboard walls, add the second seal next

to the terminal seal to compensate for

weather board angle.

From the outside insert the terminal into the

sleeve with the marking “TOP” at the top.

The left hand side locking tie should be

marked “LEFT”.

Terminal seal

Locking tie

Terminal

Locking ties

Sleeve

3 screws

Flue Manifold Installation

Page 13

Rinnai Corporation EX38CT Manual 13

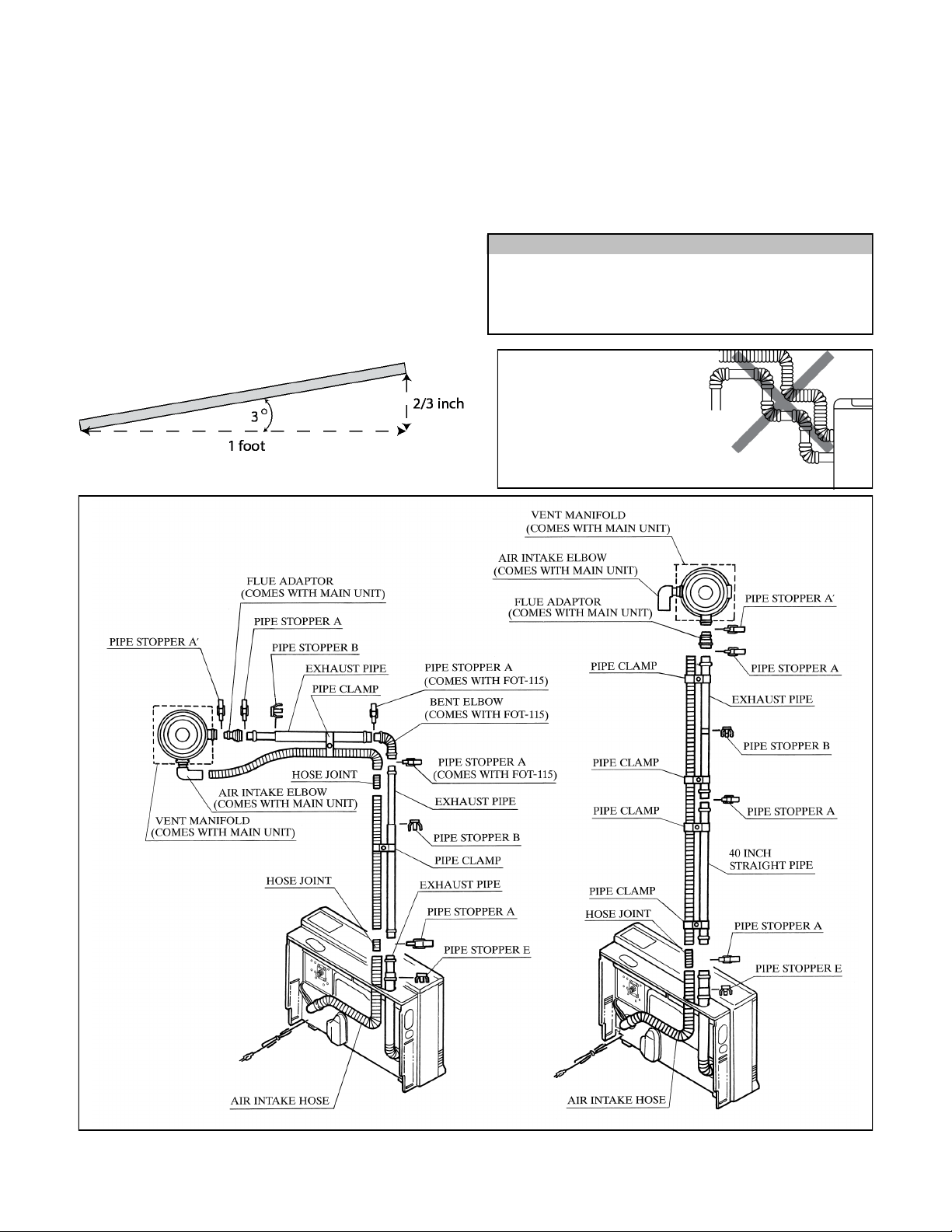

If necessary, extension kits are available to extend the

exhaust line and air intake hose between the manifold

and the appliance. The maximum vent length is 13 feet

(4 m) with 2 bends. The bent pipe attached to the

appliance does not count toward the max limit of 2

bends.

Horizontal sections should be sloped 3º to drain

condensate. (3º equals 2/3 inch drop per foot of vent.)

The direction should be to the outside (if local codes

allow) or toward the appliance. Do not allow any low

points in the exhaust line where condensate will collect.

Vent extensions installed in unconditioned air space

must be insulated with high temperature insulation and

must be accessible.

Vent extensions must not be concealed per NFPA 54

and must be accessible allowing inspection and repair.

Decorative covers are available from Rinnai.

INCORRECT

• Too many bends (limit is 2)

• Air intake hose is above

exhaust pipe

CORRECT

Slope horizontal sections 3º (2/3 inch drop per foot of vent.)

NOTE

The EX38CT is capable of two vent length settings:

Short Vent: 0 - 7ft + 1 elbow

Long Vent: 7ft + 1 elbow - 13ft + 2 elbows

Extension Kit Installation

Page 14

14 Rinnai Corporation EX38CT Manual

Clearances

exhaust pipe to combustibles 1 inch (25.4 mm)

exhaust pipe to non-combustibles zero

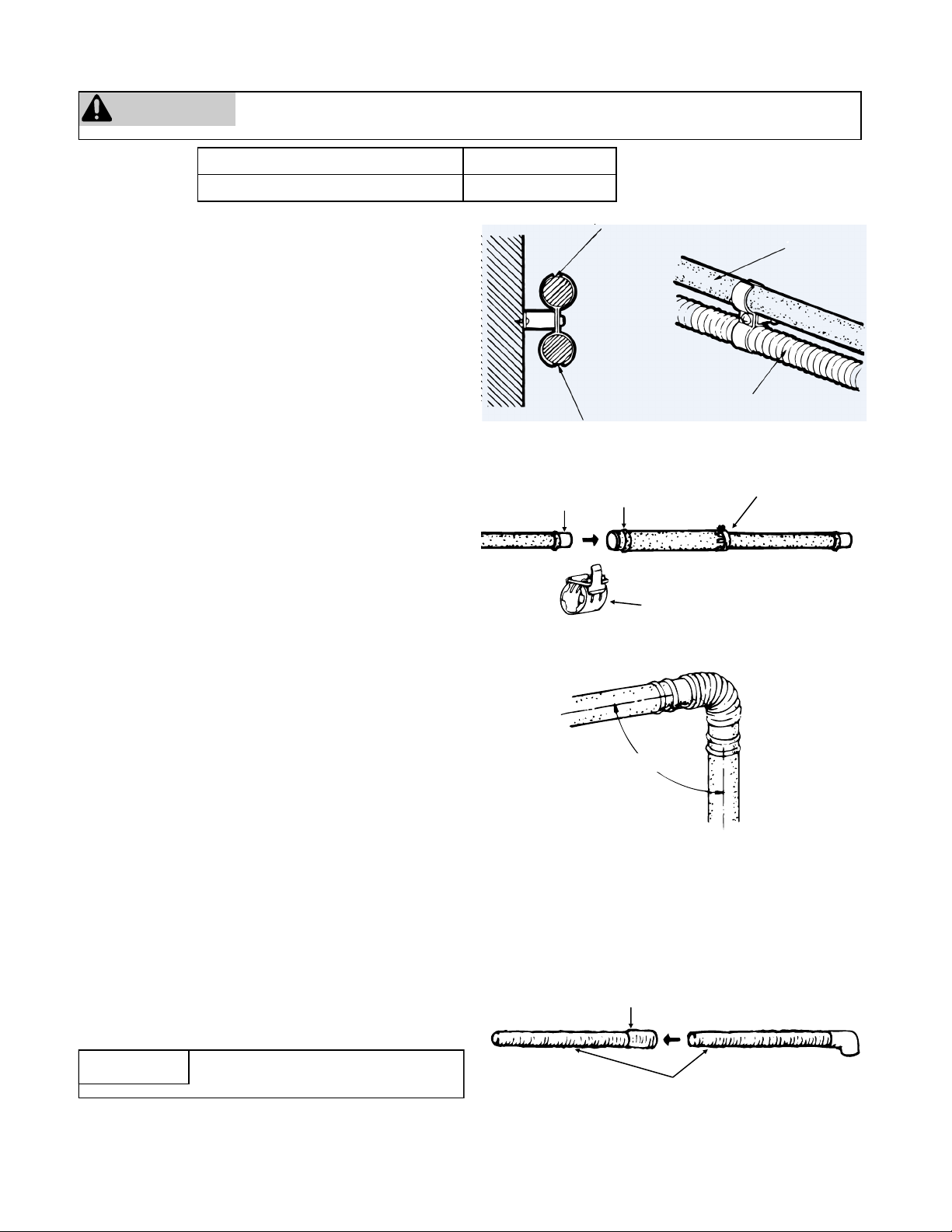

Both the exhaust line and air intake hose are

supported by clamps which are attached to the wall.

A wall fixture can be used to offset the clamp from the

wall. Use Screw B to attach the wall fixture to the

wall. If the wall fixture is not used then use Screw A

and the nut to attach the clamp to the wall.

The air intake hose should always be underneath the

exhaust line so that in case the air intake hose sags it

will not come into contact with the exhaust line.

Clamps

The exhaust line is connected between the bent pipe

at the rear of the furnace and the exhaust port on the

flue manifold.

Installing the Exhaust Line

To connect exhaust pipes with other straight pipes or

bends, fit the male end into the female end. Use pipe

stopper A to clamp the connection.

Use pipe stopper B to fix the length on the adjustable

exhaust pipes. Do not extend these pipes beyond the

red line.

Do not cut the exhaust pipe. Use the adjustable

pipes if necessary.

To bend the elbow, insert exhaust pipes into both

ends for additional leverage. Bend to desired angle.

Do not straighten the bent pipe attached to the

appliance.

Pipe stopper A

Pipe stopper B

Male end

Female end

Adjust the angle

Connecting the Air Intake Hose

The air intake hose is connected between the air

connection at the rear of the furnace and the air intake

port on the flue manifold.

Push the air intake hose onto the flue manifold and

secure with the plastic cable tie.

Join air intake hoses by screwing the hose joint half of

its length into the air intake hose and then screwing

another air intake hose into the hose joint.

The lengths of the air intake hose and the exhaust

pipe must be the same in order for the appliance to

operate properly. The hose can be cut to the required

length. Deburr all rough edges. Do not cut the hose

attached to the appliance.

Support the air intake hose with pipe clamps.

Hose joint

air intake hoses

CAUTION

Use the pipe stoppers, connectors, clamps, and screws according to these instructions in

order to ensure no leakage of exhaust gases.

Do not cut the intake hose. Cutting

the intake hose may result in noise.

NOTICE

Extension Kit Installation

Exhaust pipe

Exhaust pipe

Air intake hose

Air intake hose

Page 15

Rinnai Corporation EX38CT Manual 15

Item Description Part No. FOT-102 FOT-103 FOT-114 FOT-115

1 Exhaust Pipe (adjustable)

12.2-21.1 in (311-536 mm)

FOT 111-1 1

1 Exhaust Pipe (adjustable)

21.9-40.4 in (556-1026 mm)

FOT 112-1 1 1

2 Exhaust Pipe - 39.4 in (1000 mm) FOT 114-3 1

3 Air Intake Hose - 29.5 in (750 mm) RHF 1000-130-e 1

3 Air Intake Hose - 51.2 in (1.3 m) RHF 1000-130-b 1

3 Air Intake Hose - 90.6 in (2.3 m) RHF 1000-130-f 1

4 Bent Elbow FOT 025-4 1

5 Hose Joint RFOT 226-001 1 1 1

6 Pipe Stopper A 1001F-250 1 1 2 2

7 Pipe Stopper B FOT 111-6 1 1 1

8 Top Stopper FOT 062-7 1 1 1

9 Pipe Clamp FOT 064-11 2 sets 3 sets 4 sets

10 Wall Fixture FOT 064-12 2 3 4

11 Nut FOT 062-10 2 3 4

12 Screw A ZAA0420SC 2 3 4

13 Screw B CP-30408 4 6 8

Extension Kits and Parts

A FOT-102 (12.2-21.1 inch)

B FOT-103 (21.9-40.4 inch)

A FOT-102 (21.1 inch)

B FOT-103 (51.2 inch)

C FOT-114 (90.6 inch)

Extension Kit Installation

Page 16

16 Rinnai Corporation EX38CT Manual

1. Attach flue adapter to the flue manifold with

pipe stopper S.

2. Attach the air inlet hose to the flue manifold.

Secure with plastic tie. The unused inlet is

plugged with the rubber cap supplied on the

manifold.

3. Connect the vent sliding tube with pipe

stopper S and E. The sliding tube should

not be extended beyond the red line. The

red line should not be visible after sliding

the tube into the vent outlet.

4. Slide the insulation sleeve up to the flue

manifold and slip the securing clip over the

sleeve as shown.

5. Attach the appliance to the wall brackets,

using 2 screws at each bracket.

6. Attach the back spacer with 3 screws to the

top of the appliance.

Inlet hose

Inlet elbow

Plastic tie

7. If necessary, the appliance can be leveled

using the adjustable legs under the front

right and left legs.

Pipe stopper S

Flue Manifold

Flue Adapter

Connecting the Appliance

Up to

3/8” (10mm)

Adjustable Leg

Page 17

Rinnai Corporation EX38CT Manual 17

When connecting the gas valve or other gas

components in the gas line, use a backup wrench to

ensure the connection is gas tight.

WARNING

Gas Connection

□ Verify proper clearances around the vents and air

intakes.

□ Ensure you have used the correct venting

products for the model installed and that you have

completely followed the venting manufacturer’s

installation instructions and these installation

instructions.

□ Verify that the vent system does not exceed the

maximum length for the number of elbows used.

Checklist for Venting

• The gas supply line shall be gas tight, sized and so

installed as to provide a supply of a gas sufficient to

meet the maximum demand of the furnace without

loss of pressure.

• A shut off valve and appliance connector valve

should be installed in the upstream of the gas line

to permit servicing.

• Flexible pipe and any appliance connector valve

used for gas piping shall be types approved by

nationally recognized agencies.

• Any compound used on the threaded joint of the

gas piping shall be a type which resists the action

of liquefied petroleum gas (propane).

• After completion of gas pipe connections all joints

including the furnace must be checked for gas

tightness by means of leak detector solution, soap

and water, or an equivalent nonflammable solution,

as applicable. (Since some leak test solutions,

including soap and water, may cause corrosion or

stress cracking, the piping shall be rinsed with

water after testing, unless it has been determined

that the leak test solution is non-corrosive.)

• Check the gas supply pressure immediately

upstream at a location provided by the gas

company. Supplied gas pressure must be within

the limits shown in the Specifications section.

• Refer to an approved pipe sizing chart if in doubt

about the size of the gas line.

Adjust Gas Pressure Settings

Complete these instructions for altitude and vent

length. (Default altitude: 0ft - 2,000ft. Default vent length:

0 - 7ft+1 elbow )

For high altitude installations in Canada, the conversion

shall be carried out by a manufacturer’s authorized

representative, in accordance with the requirements of

the manufacturer, provincial or territorial authorities

having jurisdiction and in accordance with the

requirements of CAN/CGA-B149.1 or CAN/CGA-B149

installation codes.

CAUTION

Do not touch any other areas on the PC board

besides the “SW” switches while power is supplied to

the appliance. Parts of the PC board are supplied

with 120 volts AC.

CAUTION

Do not insert hands or objects into the circulation fans

while they are running. Injury or mechanical

malfunction may occur.

CAUTION

Do not touch the areas at or near the exhaust. This

area becomes very hot and could cause burns.

The regulator has been factory pre-set. If the

pressure is incorrect, check the supply pressure first,

before making any adjustments to the appliance.

Also, if the low control pressure cannot be obtained,

adjust the adjustment screw on the proportional valve

to roughly set pressure and then recheck both the low

and high fire pressures.

NOTICE

Page 18

18 Rinnai Corporation EX38CT Manual

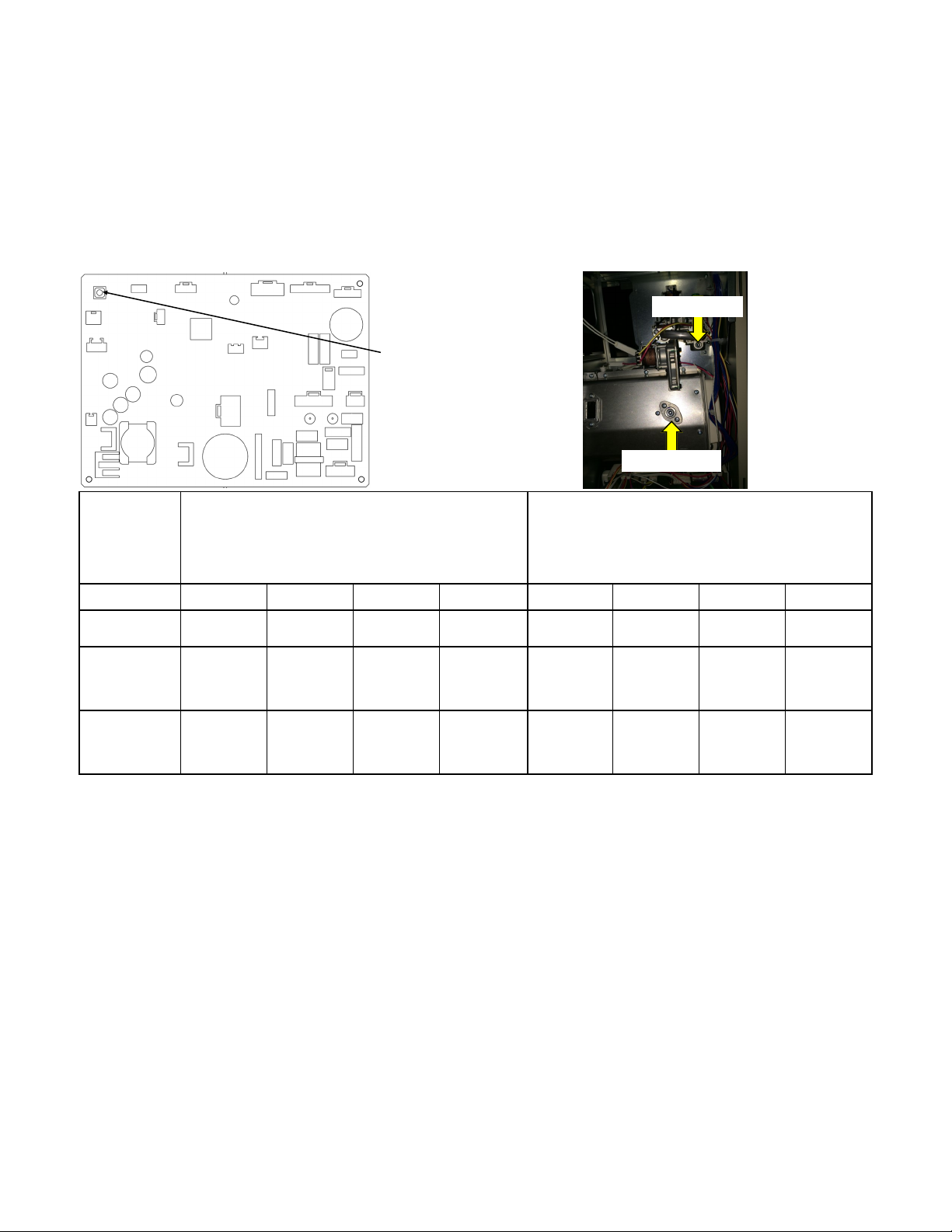

1. Turn off the gas and the power supply.

2. Remove test port screws (1/8 NPT tap) with 3/16 Allen wrench located at gas valve and burner cover. Attach

dual port manometer to these test ports as shown. Ensure that the manometer is properly calibrated.

3. Turn on the gas and power supply to the appliance.

4. Ensure “Set Back” feature has been deactivated. (“Set Back” feature is active by default.)

5. With the unit in the Off position, press the SW1 switch at the top of PC board until it beeps.

6. Select the correct code for gas type, altitude, and vent length on the LED display using ▲ and ▼ buttons:

Natural Gas

Short Vent Lengths: 0 - 7ft+1 elbow

(A1 - A4)

Long Vent lengths: 7ft +1 elbow - 13ft + 2 elbows

(A5 - A8)

Propane Gas

Short Vent Lengths: 0 - 7ft+1 elbow

(L1 - L4)

Long Vent lengths: 7ft +1 elbow - 13ft + 2 elbows

(L5 - L8)

Code

A1 / A5 A2 / A6 A3 / A7 A4 / A8 L1 / L5 L2 / L6 L3 / L7 L4 / L8

Altitude

0-2000 ft

0-610 m

2001-5200 ft

611-1585 m

5201-7700 ft

1586-2347 m

7701-10200 ft

2348-3109 m

0-2000 ft

0-610 m

2001-5200 ft

611-1585 m

5201-7700 ft

1586-2347 m

7701-10200 ft

2348-3109 m

Manifold test

pressure -

W.C. Low

1.69 in

(43 mm)

1.59 in

(40 mm)

1.49 in

(38 mm)

1.43 in

(36 mm)

3.21 in

(82 mm)

3.01 in

(76 mm)

2.85 in

(72 mm)

2.73 in

(69 mm)

Manifold test

pressure -

W.C. High

3.77 in

(96 mm)

2.99 in

(76 mm)

2.69 in

(68 mm)

2.45 in

(62 mm)

6.38 in

(162 mm)

5.62 in

(143 mm)

5.06 in

(129 mm)

4.58 in

(116 mm)

PCB Test Switch

Positive Port

Negative Port

Adjust Gas Pressure Settings

7. Press the SW1 switch twice to enter the gas code into memory.

8. Press the ON/OFF button to operate the appliance.

9. Press the SW1 switch. The LED will display a “7”.

10. Press the SW1 switch again to change to the low pressure mode. The LED will display “PL”.

11. Compare the pressure reading on the manometer to the correct table for your gas type. If necessary adjust

the low fire pressure using the ▲ and ▼ buttons. Press the SW1 switch again.

12. The LED will display “PH” indicating high fire mode.

13. Compare the pressure reading on the manometer to the correct table for your gas type. If necessary adjust

the high fire pressure using the ▲ and ▼ buttons.

14. Press the ON/OFF button again. The LED display turns blank and the appliance returns to the normal OFF

The LED display turns blank and the unit returns to the normal off mode. You are now ready to

program in your correct low fire and high fire gas pressure setting. Follow the procedure below for

setting the manifold gas pressure. Do not adjust gas pressure on this appliance using the screw on

top of the gas valve.

Page 19

Rinnai Corporation EX38CT Manual 19

Normal Operating Sequence

When you press the ON/OFF button, the LED display

will illuminate, the combustion fan will begin to run,

and the spark will ignite the main burner.

This furnace has an automatic ignition system. When

the main burner has lit, the combustion lamp will glow

red, and the spark will stop.

1. Install the front panel and bottom cover.

2. Place the conversion plate (label) on the front

cover.

Final Assembly

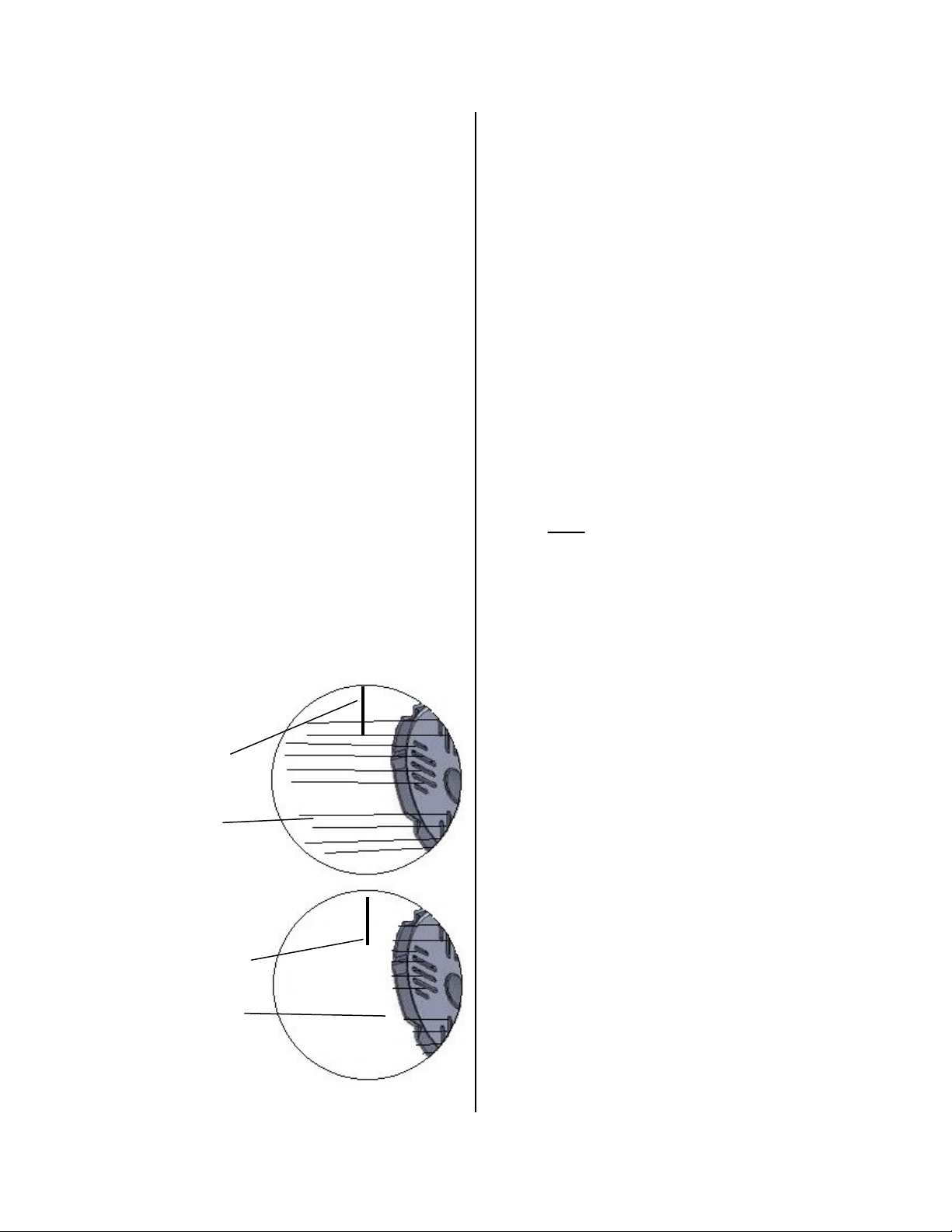

Visual Inspection of Flame

Check that the burner flames are operating normally.

The flame can be seen through the circular window.

When operating normally the burner flame should

appear as long, clear, blue, stable, streaks. Yellow

flames or an orange color is abnormal and

maintenance is required.

NORMAL

Flame Rod

Long, clear, blue,

stable flames

ABNORMAL

Yellow flames or

orange color

Flame Rod

• check the normal operating sequence

• visually inspect the flame

• check for gas leaks at the test points

NOTE: If the LED display shows “HF” or “LF” do not

touch the ▲ and ▼ buttons or Economy button.

In this case push SW1.

Adjust Gas Pressure Settings

Checklist for Gas and Electricity

□ A manual gas control valve is placed in the gas

line to the heater.

□ Check the gas lines and connections for leaks.

□ Confirm that the gas inlet pressure is within limits.

□ Confirm that the heater is rated for the gas type

supplied.

□ Confirm that the electricity is supplied from 120

VAC, 60 Hz power source and is in a properly

grounded circuit.

□ Confirm that an extension cord or an adapter plug

has NOT been used with the heater.

mode.

15. Remove manometer and install Allen head screws.

Operate the unit and

16. Return unit to normal functioning.

Page 20

20 Rinnai Corporation EX38CT Manual

Final Checklist

□ The heater is not subject to corrosive compounds

in the air.

□ Clearances from the heater unit are met.

□ Clearances from the vent termination are met.

□ Ensure you have used the correct venting

products for the model installed and that you have

completely followed the venting manufacturer’s

installation instructions and these installation

instructions.

□ Verify that the vent system does not exceed the

maximum length for the number of elbows used.

□ A manual gas control valve has been placed in the

gas line to the heater.

□ Check the gas lines and connections for leaks.

□ Confirm that the gas inlet pressure is within limits.

□ Confirm that the heater is rated for the gas type

supplied.

□ Confirm that the electricity is supplied from a 120

VAC, 60 Hz power source, is in a properly

grounded circuit, and turned on.

□ Verify the system is functioning correctly by

connecting your manometer to the gas pressure

test port on the water heater. Operate all gas

appliances in the home or facility at high fire. The

inlet gas pressure at the heater must not drop

below that listed on the rating plate.

□ Install the front panel.

□ Explain to the customer the importance of not

blocking the vent termination.

□ Explain to the customer the operation of the

heater, safety guidelines, maintenance, and

warranty.

□ The installation must conform with local codes or,

in the absence of local codes, with the National

Fuel Gas Code, ANSI Z223.1/NFPA 54, or the

Natural Gas and Propane Installation Code, CSA

B149.1. If installed in a manufactured home, the

installation must conform with the Manufactured

Home Construction and Safety Standard, Title 24

CFR, Part 3280 and/or CAN/SCA Z240 MH

Series, Mobile Homes.

□ Leave the entire manual with the consumer.

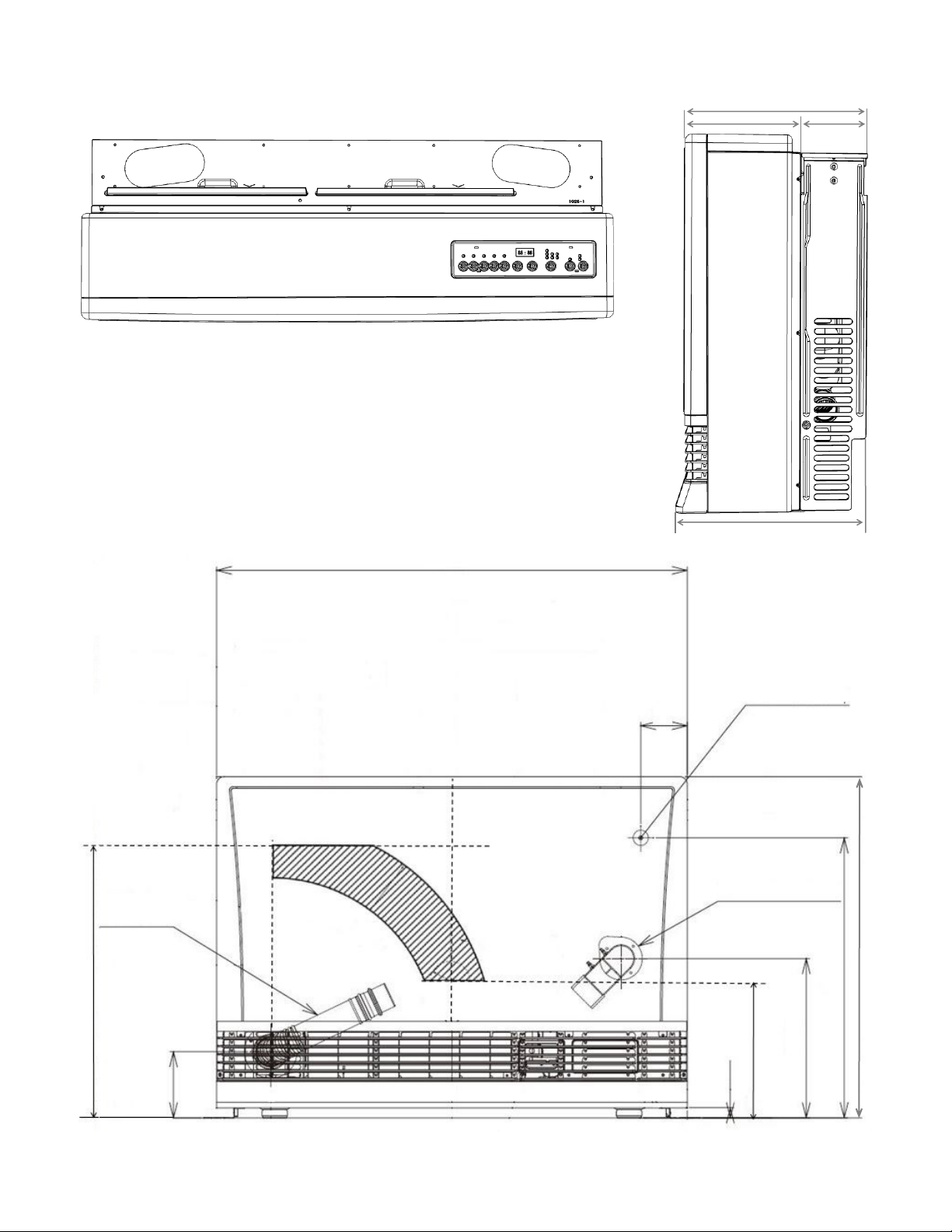

Page 21

Rinnai Corporation EX38CT Manual 21

inches (mm)

12.63 (320)

8.1 (205)

4.5 (113)

36.63 (930)

Gas Connection

3.63 (92)

13 (330)

Air Inlet

21.63 (550)

12.31 (313)

9.31 (250)

.31 (20)

Exhaust Pipe

5.13 (130)

20.69 (526)

26.38 (670)

Dimensions

Page 22

22 Rinnai Corporation EX38CT Manual

Specifications

Rinnai is continually updating and improving products. Therefore, specifications are subject to change without

prior notice.

The efficiency rating of this appliance is a product thermal efficiency rating determined under continuous operating

conditions and was determined independently of any installed system.

Safety Features

• Overheat: The appliance will automatically shut

down when the appliance exceeds a predetermined

temperature.

• Flame Failure: The appliance will automatically

shut down if the burner flame is extinguished.

• Power Failure: The appliance will cut off the gas if

it loses electrical power.

• Power Surge Fuse: A glass fuse on the PC board

protects against overcurrent. If the fuse blows then

all indicator lamps will be off.

• Spark Detector: The appliance automatically shuts

down if there is an abnormal spark at ignition.

• Fusible Link: In case the overheat feature

prevents the temperature from rising then the fusible

link will break shutting off the appliance.

Appliance Specifications

EX38CT

Application

Approved for manufactured home (USA only) or mobile home or residential installation

convertible for use with natural gas and liquefied petroleum gases (propane) when

provision is made for the simple conversion from one gas to the other.

Approved for commercial setting.

Approved for installation at altitudes up to 10,200 feet (3109 m).

Natural Gas Propane Gas

Min. Supply Gas Pressure

3.5 in (89 mm) W.C. 8.0 in (203 mm) W.C.

Max. Supply Gas Pressure 10.5 in (267 mm) W.C. 13.0 in (330 mm) W.C.

BTU/hour input Low 13,200 High 38,400 Low 13,200 High 36,500

General Description Forced combustion, forced convection, flued gas furnace

Operation Push button electronic

Gas Connection 1/2 in NPT

Gas Control Electronic

Burners Stainless steel Bunsen burner

Temperature Control Electronic thermostat

Temperature Range Low, 60 - 80°F (in 2°F increments), High

Ignition System Electronic spark ignition

Flue System

The flue must be terminated to atmosphere with only flue components listed with the

appliance’s certification. Warranty will be voided if non listed components are installed.

Humidifier Tray Capacity - 6.3 pints (3000 cc)

Electrical Connection AC 120V, 60 Hz, 117 watts

Weight 88 lbs (40 kg)

Noise Level 39 - 46dB

Page 23

Rinnai Corporation EX38CT Manual 23

Direct Vent Furnace Operaon Instrucons

Important Facts about your Direct Vent Furnace

Thank you for purchasing a Rinnai Direct Vent Furnace. For proper operation and safety, it is

important to follow the instructions and adhere to all safety precautions.

Read all of the instructions and the warranty thoroughly before operating this heater. Keep this

manual in a safe place.

NOTICE: Rinnai sometimes shares customer contact information with businesses that we believe provide

products or services that may be useful to you. By providing this information, you agree that we can

share your contact information for this purpose. If you prefer not to have your information shared with

these businesses, please contact customer service and ask not to have your information shared. We will

however, continue to contact you with information relevant to the product(s) you registered and/or you

account with us.

— Do not store or use gasoline or other ammable vapors and liquids in the vicinity of this or any

other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s

instrucons.

• If you cannot reach your gas supplier, call the re department.

— Installaon and service must be performed by a licensed professional.

If the informaon in these instrucons is not followed exactly, a re or

explosion may result causing property damage, personal injury, or death.

WARNING

EX38CT .............. (RHFE-1005FTA2)

Page 24

24 Rinnai Corporation EX38CT Manual

FOR YOUR SAFETY READ BEFORE OPERATING

WARNING

If you do not follow these instructions exactly, a fire or explosion

may result causing property damage, personal injury or loss of life.

A. This appliance does not have a pilot. It is

equipped with an ignition device which

automatically lights the burner. Do not try to

light the burner by hand.

B. BEFORE OPERATING smell all around the

appliance area for gas. Be sure to smell next

to the floor because some gas is heavier than

air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call

the fire department.

C. Use only your hand to push in or turn the gas

control knob. Never use tools. If the knob will

not push in or turn by hand, do not try to

repair it, call a qualified service technician.

Force or attempted repair may result in a fire

or explosion.

D. Do not use this appliance if any part has been

under water. Immediately call a qualified

service technician to inspect the appliance

and to replace any part of the control system

and any gas control which has been under

water.

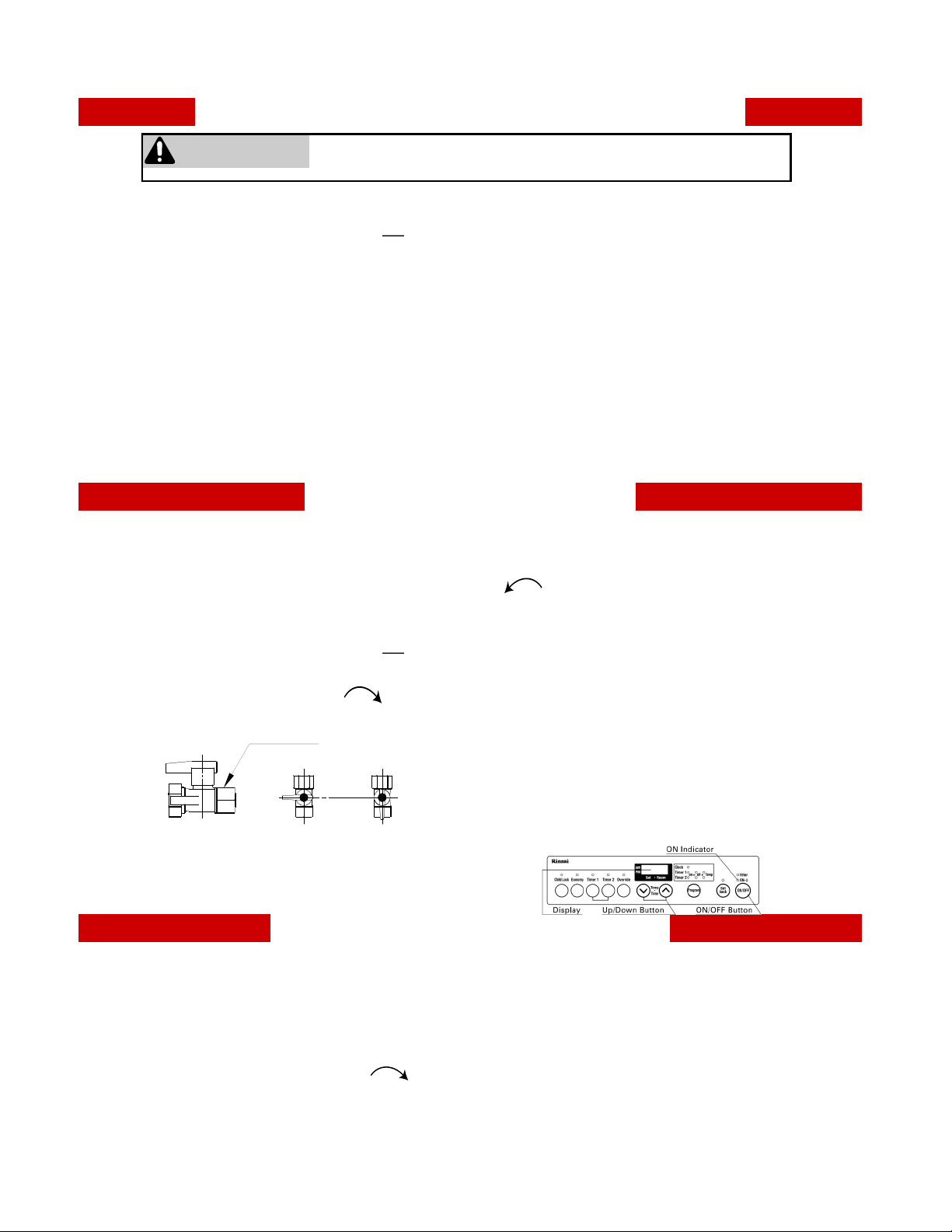

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat to lowest setting.

2. Turn off all electric power to the appliance if

service is to be performed (Using the ON/OFF

button located on control panel.)

3. Locate the manual gas valve.

4. Turn the manual valve clockwise to the

full OFF position.

NOTE: The fan will continue to operate until the

appliance is cool. Do not turn the

appliance off by unplugging it from the

wall. Keep burner and control

compartment clean. See installation and

operating instructions.

OPERATING INSTRUCTIONS

STOP! Read the safety information above.

2. Set the thermostat to lowest setting.

3. Turn off all electric power to the appliance

using the ON/OFF button on the control panel.

4. This appliance does not have a pilot. It is

equipped with an ignition device which

automatically lights the burner. Do not try to

light the burner by hand.

5. Turn Manual valve clockwise to the full

OFF position.

6. Wait five (5) minutes to clear out any gas.

Then smell for gas, including near the floor.

If you smell gas, STOP ! Follow “B” in the

safety information above. If you don’t smell

gas go to the next step.

7. Turn the manual gas valve counterclockwise

to the full ON position.

8. Turn on all electric power to the appliance

using the ON/OFF button.

9. Set the thermostat to desired setting.

10. Burner is lit when indicator lamp “ON” turns

red.

11. “ON” indicator and fault code 11, flash when

burner fails to ignite.

12. If the appliance will not operate, follow the

instructions “To Turn Off Gas To Appliance”

and call your service technician or gas

supplier. See manual for additional

information.

CLOSE

Manual Valve

OPEN

Safe Operation

Page 25

Rinnai Corporation EX38CT Manual 25

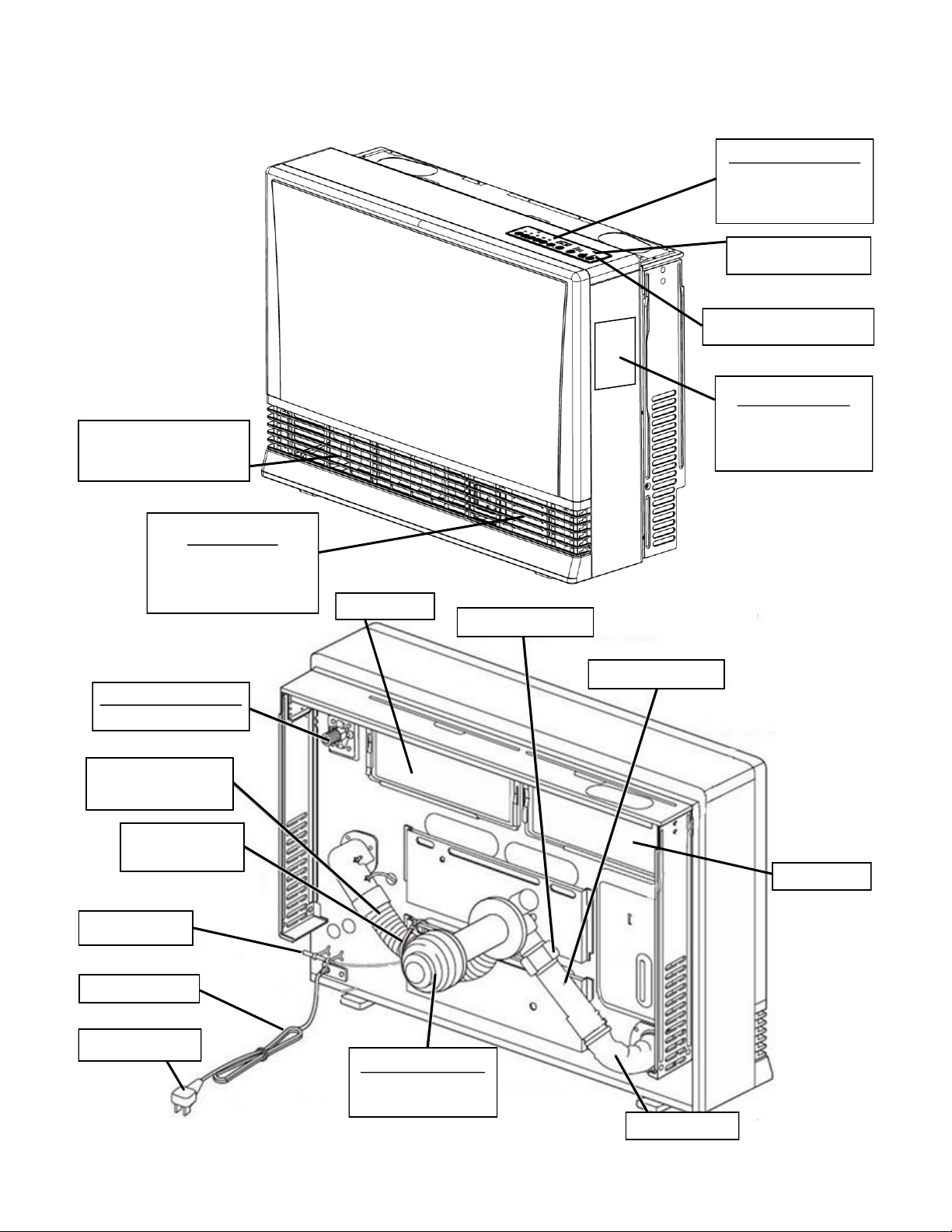

Getting to Know Your Appliance

GAS CONNECTION

1/2” NPT

PLASTIC TIE

FOR AIR INLET

POWER CORD

PLUG 120V AC

AIR FILTER

VENT TERMINAL

COMBUSTION /

EXHAUST

EXHAUST PIPE

COMBUSTION AIR

INTAKE HOSE

AIR FILTER

PIPE STOPPER

THERMISTOR

BENT ELBOW

WARM AIR OUTLET

HUMIDIFIER

OPEN THE DOOR

AND POUR WATER

INTO THE TRAY

CONTROL PANEL

OPERATION /

TEMPERATURE

CONTROL DISPLAY

FILTER LAMP

OPERATION LAMP

RATING PLATE

MODEL NUMBER,

SERIAL NUMBER,

GAST TYPE, ETC.

Page 26

26 Rinnai Corporation EX38CT Manual

Sensible Temperature Control

The Child Lock will help to prevent accidental operation of the appliance and to

prevent children from operating the appliance.

To activate Child Lock, press the Child Lock button. The indicator will light and a beep

will sound.

To deactivate the Child Lock, press the Child Lock button and hold for about 2

seconds. The indicator light will go out and a beep will sound.

• The lock can be activated when the furnace is ON or OFF.

• If activated while the furnace is ON, all controls other than the OFF switch will be

locked.

• If activated while the furnace is OFF, then all controls will be locked.

• If the furnace is turned off while the Child Lock is activated, it cannot be turned on

again until the lock is deactivated.

• Deactivating the lock releases the control buttons.

The sensible temperature control feature allows

comfortable heating which matches the conditions in

the room.

Based on the information collected by the room

temperature thermistor when the heating starts, the

heating capacity is automatically adjusted to achieve a

comfortable heating effect and to reach the

temperature setting quickly.

Occasionally, the room temperature may briefly exceed

the temperature setting due to the layout of the room or

heating area.

Press the ON/OFF button to operate the furnace. The ON indicator will glow green.

Once the burner ignites, the ON indicator will glow red. When the furnace warms up,

the convection fan will automatically start.

To turn the furnace off, press the ON/OFF button. The ON indicator light will go out.

The fan will continue to operate for several minutes after the burner has gone out in

order to cool the furnace. Do no unplug the furnace while the fan is running.

Display

After the furnace is turned on and begins operating, the display will dim. The display will turn off when the furnace is

turned off. While programming the timers the display will turn off for several seconds after a button is last pushed.

Fahrenheit or Celsius (Factory default is °F)

1. The furnace must be turned off.

2. Press the Timer 1 and Timer 2 button at the same time for about 5 seconds. The display will show “°C” or “°F”.

3. Use the arrow keys to select the temperature scale.

4. Press the ON/OFF button.

Control Panel

ON / OFF

Child Lock

Page 27

Rinnai Corporation EX38CT Manual 27

Remote Thermostat Mode (Optional Accessory)

ECONOMY UP PROGRAM

A remote thermostat can be installed for the furnace with the Remote Thermostat Installation Kit (Part # 204000045

for U.S. installations, Part # 204000048 for Canadian Installations). Once installed, the furnace must be placed in

Remote Thermostat mode by following the steps below:

1. Ensure the furnace is plugged in but is turned OFF.

2. Ensure the Set back feature is turned OFF.

3. Press and hold the Economy + Up + Program buttons for 2.5 seconds and then release (00 appears in the

display).

4. Press the UP button (01 appears in the display).

5. Press the ON/OFF button; the display will go blank. The furnace is now in Remote Thermostat mode.

Note: To return the furnace back to Control Panel mode, repeat steps 1-3. At step 4, press the UP button until 02

appears in the display. Next, press the ON/OFF button; the display will go blank. The furnace is now in Control

Panel mode.

00 - Default Factory Setting

01 - Remote Thermostat Mode

02 - Control Panel Mode

The following control panel buttons/indicators will remain functional in both modes (Remote Thermostat and

Control Panel modes)

• ON/OFF button

• Filter indicator

• ON indicator

• Display (the display will be blank except in the event of an error code. All error codes will appear on the

display in either mode. Error codes will not appear on the remote thermostat even when the furnace is in

Remote Thermostat mode.)

ATTENTION

DO NOT place the furnace back into 00 (default factory setting) without the wall thermostat connection

components. Failure to do so may cause the furnace to not function properly.

ATTENTION

Do not unplug the furnace within two hours of entering Remote Thermostat

mode. This will cause the furnace to revert back to Control Panel mode (default).

ATTENTION

The remote thermostat will NOT control the heaters ability to power on or power down.

This must still be done by using the ON/OFF button of the heater.

Page 28

28 Rinnai Corporation EX38CT Manual

Operating the Furnace Manually

1. Press the “Program” button.

2. The light next to “Clock” should be

flashing. Press the up and down arrows to set the

time. Holding down either of the arrow keys will

change the time more quickly.

3. Press the “Program” button

until none of the time options are flashing up.

Confirm the clock is correct.

NOTE: The clock will have to

be reset in case of a power

failure. However the timers will

retain their settings.

The furnace will start before

the programmed starting time

in order to heat the room by the

programmed starting time.

The timers can be set while the

furnace is on or off. To operate

the timer, the furnace must be

on.

Setting the timers:

1. Press the “Program” button twice to set Timer 1.

2. The light next to “Timer 1 on” should be flashing.

Press the up or down arrows to set the start time.

Holding down either of the arrow keys will change

the time more quickly.

3. Press the “Program” button again so that the

Timer 1 off position is flashing. Press the up or

down arrows to set the end time. Holding down

either of the arrow keys will change the time more

quickly.

4. Press the “Program” button again so that the

Timer 1 Temp Position is flashing. Press the up or

down arrows to set the temperature.

5. Press the “Program” button again to set the times

for Timer 2. Follow the same steps above to set

the start and end times.

6. Press the “Program” button until none of the time

options are flashing up.

Operating the timers:

To operate the furnace using a Timer, press the ON/

OFF button and the appropriate Timer button. The

furnace will operate from the start to end times you

have entered for that Timer. It will operate at the

temperature setting that has been set for the furnace.

The timer can be set while the furnace is operating.

1. Turn the furnace on by pressing the “ON/OFF”

button.

2. Press the up or down arrows to set the

temperature. The left display shows the

temperature setting. The right display shows the

room temperature.

The thermostat automatically modulates the burner

and the fan to maintain the temperature setting.

The temperature settings available are:

• LO - burner is on minimum combustion

• 60° F - 80° F in one degree increments

• HI - burner is on maximum combustion

While in standby, the timer LED will be on with a solid

light. When operating the LED will be flashing.

Setting the Clock

Setting and Operating the Timers

Page 29

Rinnai Corporation EX38CT Manual 29

This function is used only when the furnace

is in Timer operation.

It allows you to “override” the reset timer

setting until the beginning of the next Timer

period.

For example, if the furnace is ON, pressing

the “Override” button will turn the furnace

OFF until the next period. If the furnace is OFF,

pressing the “Override” button will turn the furnace

ON, and allow you to select a temperature setting,

until the next period. The furnace will remain on until

the next timer period or until the Override function is

turned off.

When in override function, pressing the “Override”

button will return the furnace to the operation of the

current timer period.

The Economy mode can only be set while

the furnace is operating (heating). Once it

is set, it will remain in the system memory

until deactivated.

1. To turn the Economy mode on, press

the “Economy” button. The Economy

indicator is lit.

• The Economy mode now remains in the system

memory.

• If the appliance is turned off manually, or stops

heating as a result of an OFF timer period, the

“Economy “ indicator will go out.

• Whenever the appliance starts heating again,

the “Economy” indicator will light.

2. To turn the Economy mode off, press the

“Economy” button. The “Economy “ indicator will

go out.

• The Economy mode can only be turned off while

the furnace is operating (heating) and when the

“Economy” indicator is lit.

This function allows a minimum room temperature to

be pre-set, between 38ºF and 78ºF (in 1ºF

increments). This temperature should be set below

the room temperature setting. The default setting is

60ºF. Once the Set back function is selected the

appliance will start heating whenever the room

temperature falls below the selected temperature,

regardless of timer or manual settings.

Follow these steps to set and operate the

Set back feature:

1. Make sure the furnace is turned OFF.

2. Press the “Set back” button. The light

above the button will come on.

Economy Mode Information

After the room is heated initially, the air temperature

may be dropped to a lower level without affecting

comfort. The Economy Mode reduces the

temperature by 2 ºF, 30 minutes after the room

temperature setting is reached. After another 30

minutes, it reduces the temperature setting by another

2 ºF, effectively saving energy. The room temperature

setting will drop up to a total of 4 ºF.

The Economy Mode will not operate if the furnace is

under capacity for the room size.

Override Function

Economy (Energy Saving Mode)

Set Back

3. Press the up and down

buttons to set the minimum

temperature.

When the “Set back” indicator is on, frost protection is

operating, and will always prevent the room

temperature from falling below the pre-set minimum

temperature (as long as electric power and gas is

supplied).

To turn this feature off, press the “Set back” button.

The unit will retain its ON or OFF setting after a power

failure. (Set Back feature is on by factory default. For

feature to be active unit must be in OFF position.)

NOTICE

The Set Back feature is intended to prevent the

installation location from falling below a specified

temperature. It is not intended as an alternate

thermostat, but rather a preventative measure against

freezing.

Page 30

30 Rinnai Corporation EX38CT Manual

Adjusting Air Flow Direction

The vertical louvers may be adjusted to move the air

flow more to the right or to the left.

Use a screw driver or similar object to bend each

louver to the desired position.

Do not bend repeatedly (no more than 5 times) or else

the louver may break.

The horizontal louvers (which determines the vertical

air flow direction) are fixed and cannot be adjusted.

CAUTION

Do not adjust the air flow

louvers while warm air is

flowing.

Adding Water to the Humidifier

Access Door

Max. Fill Line

Humidifier Tray

Filler Spout

Do not force door open too far.

Close door during operation.

Pull

To fill the tray, open the door as shown in the diagram

and pour water into the tray up to the Max Fill Line

using the spout built into the door. The air will be

humidified as it passes over the water in the tray.

During operation a small amount of condensation is

produced in the flue system and drains into the

humidifier tray.

CAUTION

Do not fill the tray while the

appliance is in operation.

Close the door after filling.

The humidifier tray and

surrounding area are hot

when the appliance is on.

Humidifier and Air Flow Direction

Page 31

Rinnai Corporation EX38CT Manual 31

Filters

Dirty filters reduce the air flow and the appliance’s

ability to produce heat. The filters should be cleaned

frequently during the heating season. If the filters

become blocked the filter indicator lamp will flash and

the appliance will beep. Eventually the appliance will

turn off and the Temperature Level lamp 14 will light,

indicating a fault code.

To clean the filters, the

appliance should be OFF

and cool. Remove the

filter and clean it using a

soft dry cloth or vacuum.

If the filter is greasy

wash with warm soapy

water, rinse, and dry

completely.

Do not use the appliance

without the filters installed.

Care and Maintenance

All maintenance and service is to be performed by a

qualified service technician, preferably one who has

attended Rinnai service training classes on the Direct

Vent products.

The appliance should be inspected annually by a

qualified service technician. More frequent cleaning

may be required due to excessive lint from carpeting,

bedding material, etc. It is imperative that control

compartments, burners, and circulating air passage

ways of the appliance be kept clean.

Any screen or guard removed for servicing the

appliance must be replaced prior to operating the

appliance. Clean as follows:

1. Turn heat off. Allow to cool for one hour.

2. Remove the front panel by removing three screws.

3. Use pressurized air to remove dust from the main

burner, heat exchanger, and fan blades.

4. Use soft dry cloth to wipe cabinet.

Do not use wet cloth or spray cleaners on the burner.

The flue should be inspected annually for blockages or

damage.

Motors are permanently lubricated and do not need

periodic lubrication. Keep fan and motor free of dust

and dirt by cleaning annually.

Verify proper operation after servicing.

When attaching the front panel, take care not to clip or

pinch any electric cords to prevent electric shock.

Care of Exterior

Dampen soft cloth with warm water. Wring water out

well and wipe the unit.

Do not use volatile substances such as benzene or

thinners. They cause fading of the paint and

deformation of the resin.

AIR FILTERS

CAUTION

Prevent dust from accumulating on the power cord,

side covers, and parts behind the appliance.

Visual Inspection of Flame

Check that the burner flames are operating normally.

The flame can be seen through the circular window.

When operating normally the burner flame should

appear as long, clear, blue, stable, streaks. Yellow

flames or an orange color is abnormal and

maintenance is required.

NORMAL

Flame Rod

Long, clear, blue,

stable flames

ABNORMAL

Yellow or orange

flames

Flame Rod

CAUTION

Keep the area around flue terminal free of snow and

ice. The appliance will not function properly if the intake air or exhaust is impeded by obstructions.

Refer to the Flue Terminal Clearances. The clearance

in Ref. A should be maintained from any snow

accumulation.

Required Care and Maintenance

Page 32

32 Rinnai Corporation EX38CT Manual

Before making a service call please check the following:

At Ignition:

Heater does not operate.

Warm air does not flow when the burner

lights.

Smoke or strange smells are produced

on the first trial light up after installation.

Sharp clicking noises at ignition, or when

unit cuts down on the thermostat, or goes

out.

During Combustion:

Clunking noise when the thermostat

operates.

Unit is not heating room.

Air filter is blocked or the louvers are

blocked or obstructed.

Heater will not re-ignite after overheating.

When the unit is turned off.

Convection fan continues to run after

turning OFF.

Other Points:

Steam is discharged from the flue terminal .

Unit cuts off without apparent reason.

Power Failure.

Is the heater plugged in?

Have the fuses or breaker blown at the fuse box / breaker panel?

Is there a power failure?

Is the air filter blocked?

Is anything blocking the outlet for the hot air?

Is the flue blocked?

The fan is started automatically after a short delay.

This is to allow the heat exchanger to warm up, helping to avoid cold draughts.

This is caused by grease or oil and dust on the heat exchanger and will stop

after a short time.

This is simply expansion noise from the heat exchanger.

This is the sound of the solenoid gas valves opening and closing.

Is the air filter blocked?

Is the set temperature high enough?

Is the warm air outlet blocked by anything?

Are the doors and windows of the room closed?

Was the appliance correctly sized for the space?

Allow heater to cool, clean air filter, operate again.

Even after unit has cooled down, the heater does not ignite again. Repair is

necessary.

Contact a qualified / authorized service provider.

This is to remove the residual heat from the heat exchanger. The fan will stop

when the heater cools down.

High efficiency appliances tend to discharge water vapor on cold days. This

is normal.

Check whether filters are blocked. Dirty filters will cause the heater to overheat.

Switch OFF, then ON again when power is restored to re-set controls.

Before Making a Service Call

Page 33

Rinnai Corporation EX38CT Manual 33

[1] If the fusible link needs replacement, it must be done by a qualified service agency. In addition, the cause of

the overheat needs to be determined. The fusible link is a one use safety device that breaks to shut off the

appliance.

[2] Remove any obstructions. The flue needs to be kept clear to expel exhaust gases. If the appliance fails to

operate contact a qualified service agency.

[3] Only this code is dimly lit.

CODE DISPLAYED FAULT REMEDY

11 [3] No Ignition

Check that gas is turned ON.

Check that the vent termination is not blocked.

Refer to the Restart Function explanation.

Service call if repeated.

14 Overheat

Clean filter.

Service call if repeated. [1]

16 Room Overheat Lower room temperature to less than 104°F (40°C).

Service call.

30

Overheat Temperature Thermistor 2

Disconnection (open circuit)

31

Room Temperature Thermistor

Disconnection (Open Circuit)

32

Room Temperature Thermistor

Short Circuit

33

Overheat Thermistor 1

Disconnection (Open Circuit)

34

Overheat Thermistor 1

Short Circuit

35

Overheat Temperature Thermistor 2

Short Circuit

49 Sensor Breakdown

53 Sparker

61 Combustion Fan

62 Convection Fan

70 ON/OFF Switch or “Set Back” Switch

71 Solenoids

72 Flame Rod

73 Communication Error Turn furnace OFF, then ON again.

81 Solenoid Valve Service Call