Page 1

Owner’s Operation and Installation Manual for the

RHFE-750ETR

Direct Vent Fireplace

Table of Contents .......... 2

Safety Information.......... 2

Operating Instructions.... 6

Care and Maintenance... 11

Fault Codes ................... 14

Installation Instructions .. 15

Consumer Support......... 36

WARNING: If the information in these instructions are not

followed exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

— Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in

your building.

• Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

— Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

Page 2

This appliance may be installed in an aftermarket, permanently located, manufactured home

(USA only) or mobile home, where not prohibited by local codes.

This appliance is only for use with the type of gas indicated on the rating plate. This

appliance is not convertible for use with other gases, unless a certified kit is used.

Table of Contents

Consumer Safety Information

Safety Definitions........................................ 2

Safety Behaviors and Practices.................. 3

Safety Features........................................... 3

Specifications................................................. 4

Features ..................................................... 5

Dimensions................................................. 5

Flue Manifolds............................................. 5

Operating Instructions

Front Panel ................................................ 6

Remote Control Features ........................... 7

Remote Control Care..................................7

Sequence of Operations............................. 8

Basic Fireplace Operations

Turning ON and OFF............................. 8

Remote Control Operation..................... 8

Adjusting the Temperature .................... 9

Obstruction of Warm Air Discharge ....... 9

Lock Function ........................................ 9

Flame Function ...................................... 9

Auto Off Function................................... 9

Timers

Programming the Clock and Timers .... 10

Using the Timers.................................. 10

Using the Override............................... 10

Pre-heat ............................................... 10

Care and Maintenance

Maintenance ........................................ 11

Filters ................................................... 11

Visual Inspection of Flame .................. 11

Care of Exterior.................................... 12

Cleaning Combustion Chamber Glass 12

Troubleshooting........................................13

Fault Codes............................................... 14

Installation Instructions

General Instructions..................................15

Clearances to Combustibles.....................15

Flue Terminal Clearances................... 16, 17

Location ..............................................18, 19

Drilling Flue and Gas Supply Holes..........20

Flue Manifold Installation.................... 20, 21

Extension Kit Installation..................... 22, 23

Connections........................................ 24, 25

Final Assembly

Install the Logs..................................... 26

Open the Air Guide Vanes................... 27

Install the Front Panel.......................... 27

Operating Instructions............................... 28

Wiring and Schematic Diagram................29

Parts List..............................................30-36

Consumer Support

................................. 36, 37

Consumer Safety Information

Safety Definitions

This is the safety alert symbol. This symbol alerts you to potential hazards that can kill or hurt you and

others.

DANGER

WARNING

CAUTION

2 Rinnai Corporation RHFE-750ETR

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in minor or

moderate injury. It may also be used to alert against unsafe practices.

Page 3

Safety Behavior and Practices

WARNING

• Keep the area around the appliance clear and free

from combustible materials, gasoline, and other

flammable vapors and liquids.

• Do not use this appliance if any part has been

under water. Immediately call a qualified service

technician to inspect the appliance and to replace

any part of the control system and any gas control

which has been under water.

CAUTION

• Do not block the warm air discharge. Do not allow

anyone to sleep directly in front of the appliance.

• Due to high temperatures, the appliance should be

located out of traffic and away from furniture and

draperies.

• Children and adults should be alerted to the

hazards of high surface temperature and should

stay away to avoid burns or clothing ignition. Hand

or body contact with the warm air discharge louvers

and glass must be avoided.

• Young children should be carefully supervised

when they are in the same room as the appliance.

• Do not operate appliance with the glass front

removed, cracked, or broken. Replacement of the

glass should be performed by a licensed or

qualified service technician.

• Broken or damaged components should be

removed or repaired by a licensed or qualified

service technician.

• Never store liquid propane containers indoors.

• Do not spray aerosols near the appliance while it is

operating. Most aerosols contain butane gas which

is flammable.

• Do not place items on or against the appliance. If

there is a power failure while the appliance is ON

then the overheat vent on top of the panel may

open to release internal heat. An item placed on

top of the appliance could prevent the overheat

vent from opening resulting in damage to the

appliance.

• Any safety filter or guard removed for servicing

must be replaced prior to operating the appliance.

• Clothing or other flammable material should not be

placed on or near the appliance.

• Do not insert items into the louvers.

Safety Features

• Overheat: The appliance will automatically shut

down when the appliance exceeds a predetermined

temperature.

• Flame Failure: The appliance will automatically

shut down if the burner flame is extinguished.

• Power Failure: The appliance will cut off the gas if

it loses electrical power.

• Power Surge Fuse: A glass fuse power supply

harness protects against overcurrent. If the fuse

blows then all indicator lamps will be off.

• Spark Detector: The appliance automatically

shuts down if there is an abnormal spark at ignition.

Rinnai Corporation RHFE-750ETR 3

Page 4

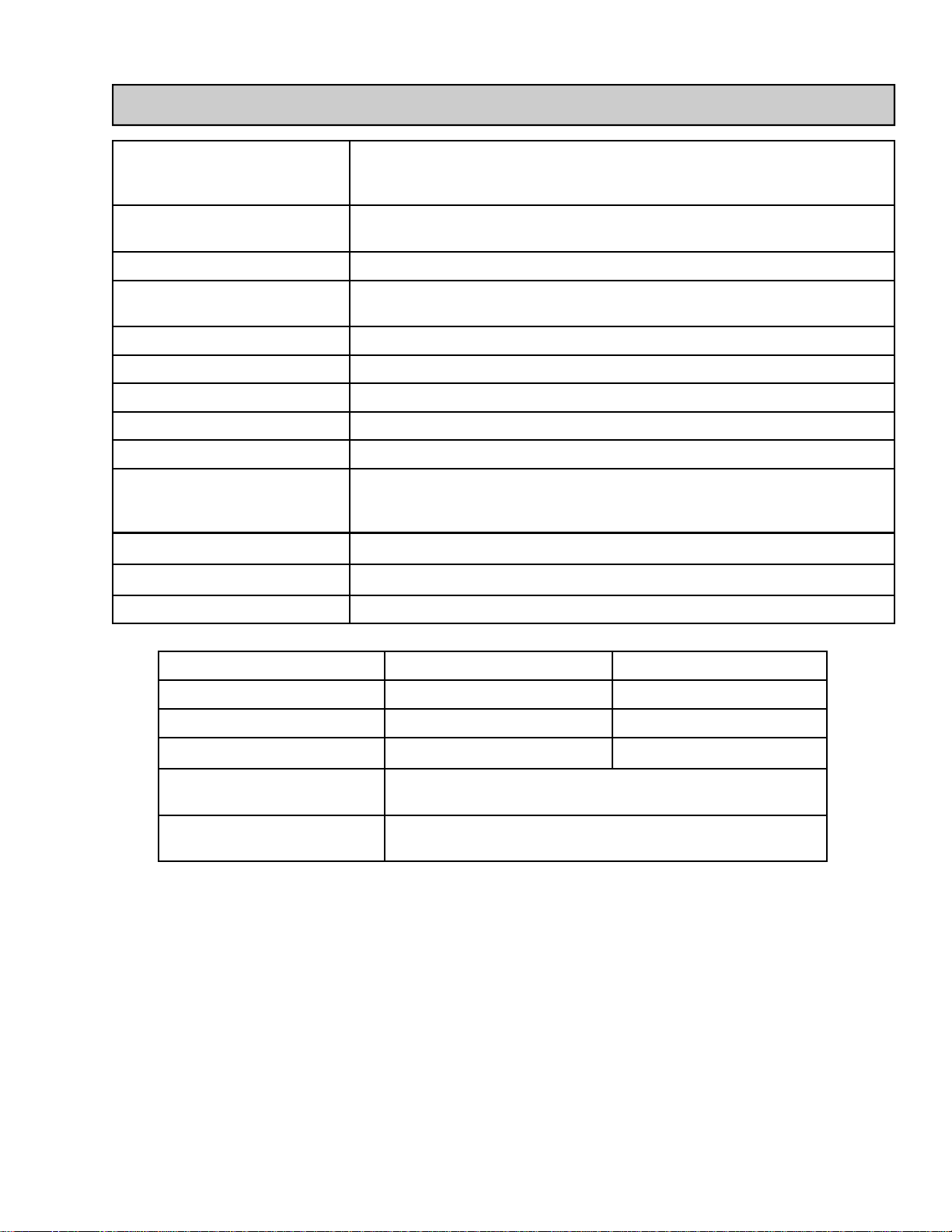

Specifications

Application Inbuilt only; for residential installation, commercial setting, or manufactured

home;

not designed for installation in a solid-fuel burning fireplace

General Description Inbuilt convector, glass and steel fronted, ceramic log space heater with

forced convection and power flue system

Operation Push button electronic / remote control

Gas Connection Flex line is 3/8 inch flare nut;

ball valve is 1/2 inch female x 3/8 inch flare

Gas Control Electronic

Burners Flame burners

Temperature Control Electronic thermostat

Logs Ceramic

Ignition System Electronic spark ignition

Flue System The flue must be terminated to atmosphere. Only flue components listed with

the appliance’s certification can be used. Warranty will be voided if non-listed

components are installed.

Electrical Connection AC 120V, 60 Hz

Fan 3 speed

Weight 154.3 lb (70 kg)

Minimum supply gas pressure 4.3 in (109 mm) W.C. 9.8 in (249 mm) W.C.

Maximum supply gas pressure 10.5 in (267 mm) W.C. 13.0 in (330 mm) W.C.

Manifold test pressure Factory Set Factory Set

BTU/hour input Natural Gas: Low - 10000 BTU/h; High - 29000 BTU/h

Propane: Low - 10000 BTU/h; High - 28000 BTU/h

BTU/hour output Natural Gas: Low - 7850 BTU/h; High - 21900 BTU/h

Propane: Low - 8050 BTU/h; High - 21840 BTU/h

Rinnai is continually updating and improving products. Therefore, specifications are subject to change without

prior notice.

Natural Gas Propane Gas

4 Rinnai Corporation RHFE-750ETR

Page 5

Features

• Direct Vent: Intake air is taken from the outside

and the combustion products are exhausted to the

outside. Therefore the furnace has no effect on the

quality of the indoor air.

• Push Button Ignition: Only one push of the

STANDBY/ON switch is all that is required to

operate the heater.

• Lock: The buttons on the remote control can be

locked to prevent any unintended operation.

• Dual Timer: The appliance can be programmed to

operate at two separate periods during the day.

• Pre-heat: The appliance will turn on before the

programmed ON time and begin raising the room

temperature to that of the programmed temperature

by the ON time.

• Memory: The computer memory records preset

temperatures, timer programming, and, operational

modes.

• Remote Control: The appliance has a fully

functioning cordless remote control.

• Auto-Off Function: You have the option of having

the flame display remain on or off once the room

temperature reaches the temperature setting.

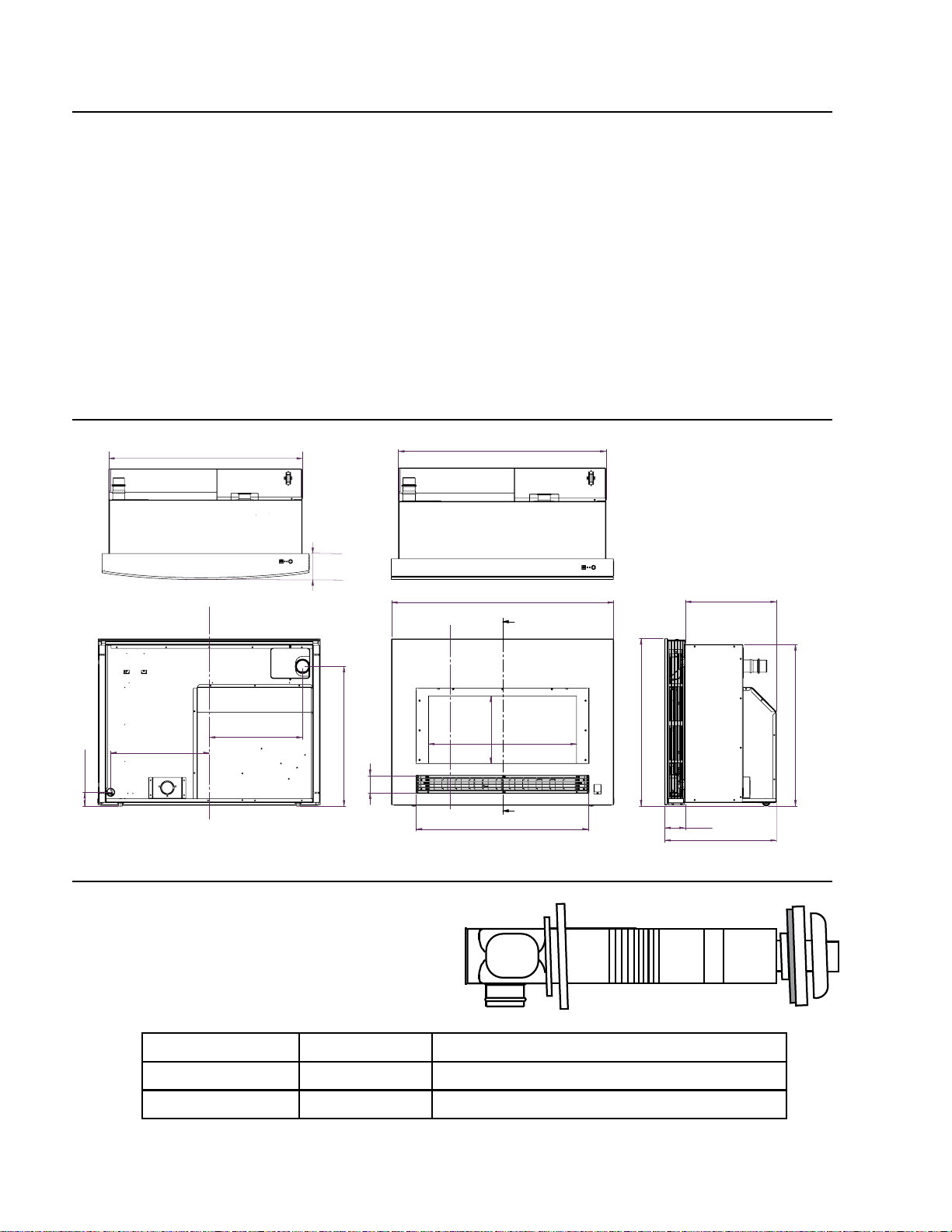

Dimensions

33 3/16 (842)

33 3/16 (842)

GAS CONNECTION

2 1/4 (57)

15 3/4 (400)

FLUE CONNECTION

14 7/8 (378)

4 15/16 (126)

21 5/16 - 23 5/16 (542 - 592)

2 15/16 (71)

35 7/16 (900)

B

23 5/8 (600)

10 13/16 (274)

B

27 9/16 (700)

26 3/4 (679)

14 1/2 (369)

25 13/16 (655)

3 5/16 (84)

17 13/16 (453)

Flue Manifolds

See the installation instructions for the parts list of the

vent kit.

The “A” Vent Kit is included with the appliance.

The following flue manifold sizes are available:

Name Kit No. fits walls

A Vent Kit FOT-203 4 1/3 - 9 1/2 inch (110 - 240 mm)

B Vent Kit FOT-204 9 1/2 - 15 3/4 inch (240 - 400 mm)

Rinnai Corporation RHFE-750ETR 5

Page 6

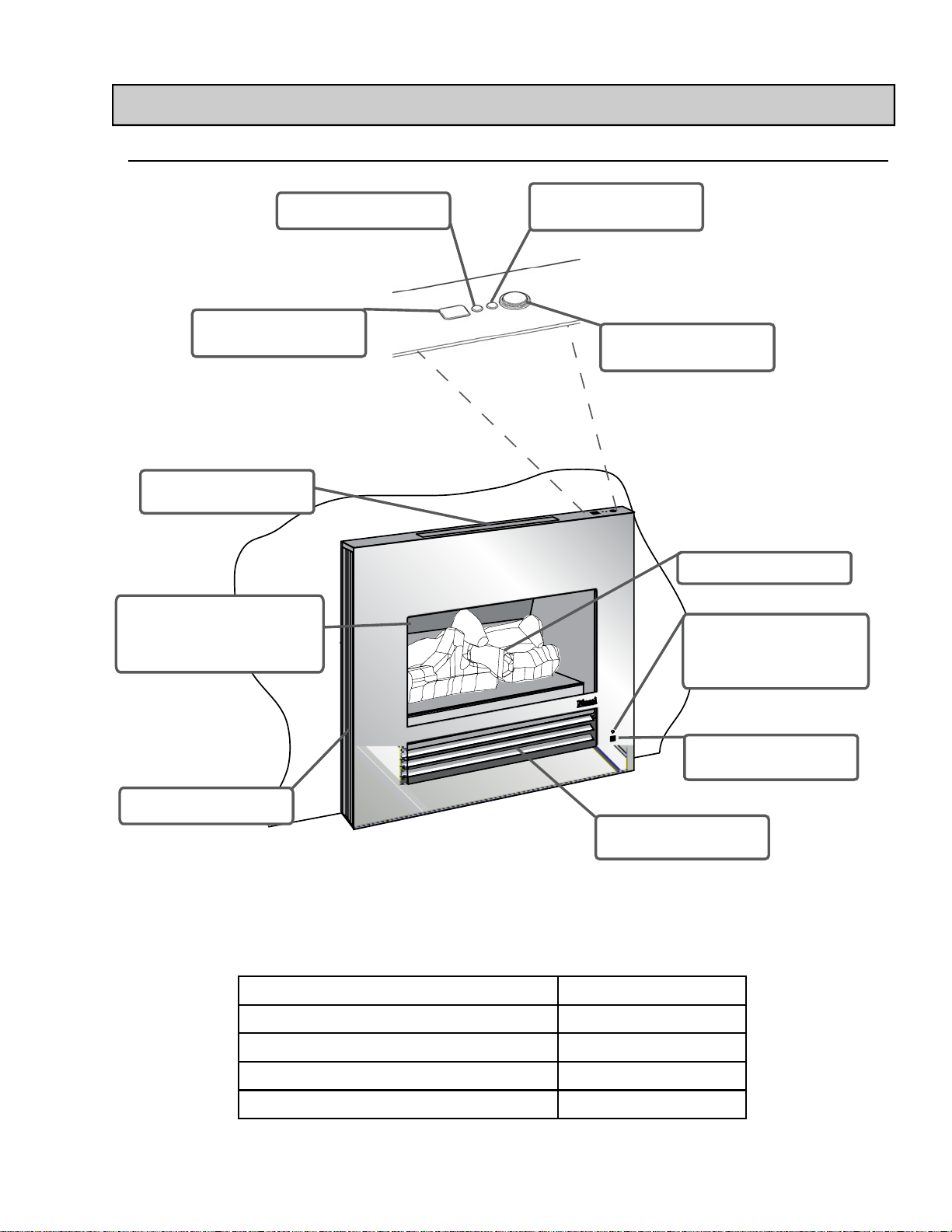

Operating Instructions

Front Panel

FAULT CODE DISPLAY

OVERHEAT

DISCHARGE VENT

TEMPERED GLASS IN THE

FRONT PANEL

CERAMIC GLASS PAN EL AT

THE COMBUSTION CHAM BER

TIMER INDICATOR

OPERATION INDICATOR

ON/OFF BUTTON

CONTROL PANEL

LOG SET

BLOCKAGE INDICATOR

for FILTERS (flashes red)

for WARM AIR DISCHARGE

(glows red)

REMOTE CONTROL

RECEIVER WINDOW

ROOM AIR RETURN

LOUVER, WARM

AIR DISCHARGE

Front Panel

(features are the same for flat and cu rved models)

Front Panel Models

Description Part Number

Flat Metal - Black Front R2700

Flat Metal - Stainless Steel Front R2701

Radius (curved) Glass - Silver Front R2702

Radius (curved) Glass - Black Front R2703

6 Rinnai Corporation RHFE-750ETR

Page 7

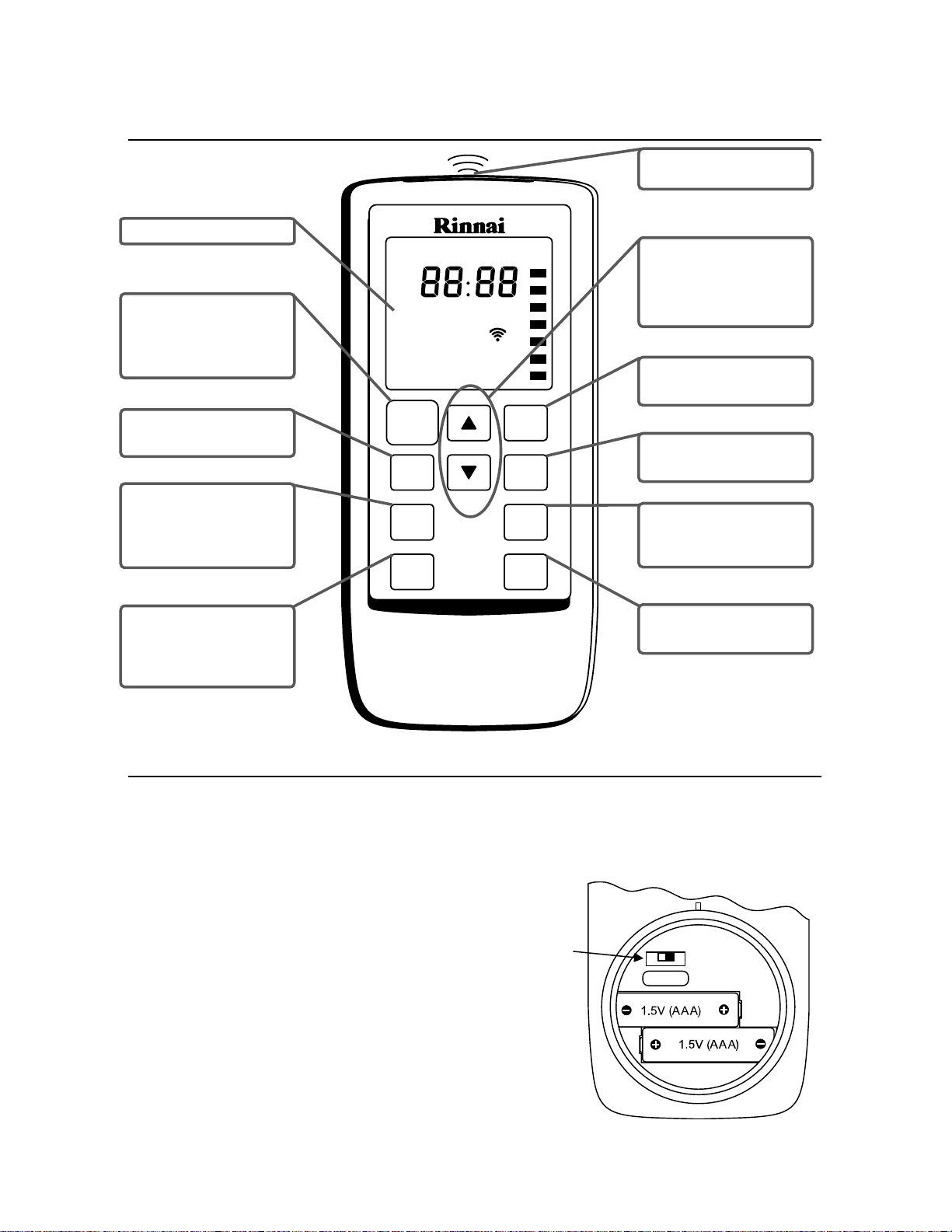

Remote Control Features

INFRA RED

EMITTER

DISPLAY

UP and DOWN

BUTTONS

Changes temperature,

flame level, or time

TIMER 1 BUTTON

Sets timer program 1

TIMER 2 BUTTON

Sets timer program 2

OVERRIDE BUTTON

Overrides timer

operation

STANDBY / ON

BUTTON

Stops and operates the

heater remotely

FLAME BUTTON

Controls the flame level

AUTO OFF

AUTO OFF BUTTON

Turns the flame off when

the temperature setting is

reached.

Lo ck

Override Aut o Off

AM

PM

Te m p e r a t u r e

Se t

Cl o c k

Ti m e r 1

Se t O N O FF

STA N D B Y

ON

Fl a m e

Auto

Off

Lock

Fl a m e

Ti m e

ON OFFTi m e r 2 Set

Ti mer 1

Ti mer 2

Overrid e

Ti m e

Se t

LOCK BUTTON

Locks out control to

prevent unintended

operation

TIME SET BUTTON

Sets the clock and timers

Remote Control Care

• Use two 1.5V AAA batteries.

• To replace batteries unscrew the battery

compartment cover located on the back of the

remote control counter clockwise. Ensure that

the correct polarity is observed. The polarity is

engraved into the battery compartment.

Replace the cover by turning clockwise until a

soft click is heard.

• To avoid damage from leaking batteries,

remove batteries if the remote control is not

going to be used for a long period.

• Some fluorescent lights may interfere with the

transmission of remote control signals.

• Do not place it close to the warm air discharge

louvers.

• Avoid dropping the remote control or getting it

wet.

Celsius (0)/

Fahrenheit (1)

switch

0

1

O - I

• Avoid leaving the remote control in direct

sunlight.

Rinnai Corporation RHFE-750ETR 7

Page 8

Sequence of Operations

The combustion fan will run for several seconds

before ignition to purge the combustion chamber of

any gas.

If the front burner fails to ignite the appliance will turn

off and fault code 11 will be displayed. If the rear

burner fails to ignite the appliance will turn off and

make another attempt to ignite. If this second attempt

fails, the appliance will automatically turn off and fault

code 11 will be displayed. This may occur when using

the appliance for the first time or if it has not been

used for a while. Try operating the appliance again.

The appliance may make noises after ignition or

extinction of the flame. This is normal and is due to

the thermal expansion or contraction of its

components.

If the ON/OFF or the STANDBY/ON button is pressed

immediately after the flame has been extinguished,

the appliance will delay ignition for about 1 minute.

The normal ignition sequence is as follows:

1. When the ON/OFF or the STANDBY/ON button is

pressed the Operation Indicator LED will glow red

and the combustion fan will rotate to purge the

combustion chamber.

2. Electric ignitor operates.

3. Gas is allowed to flow to the pilot when a spark is

sensed.

4. When the pilot flame is established gas will flow to

the front burners and then to the rear burners.

5. When all burners are established the appliance

will automatically maintain the temperature

setting.

NOTE: The appliance will wait until the heat

exchanger is warmed up before discharging

air. This ensures that any discharge air will be

warm and not cold.

Basic Fireplace Operations

Turning ON and OFF

Remote Control Operation

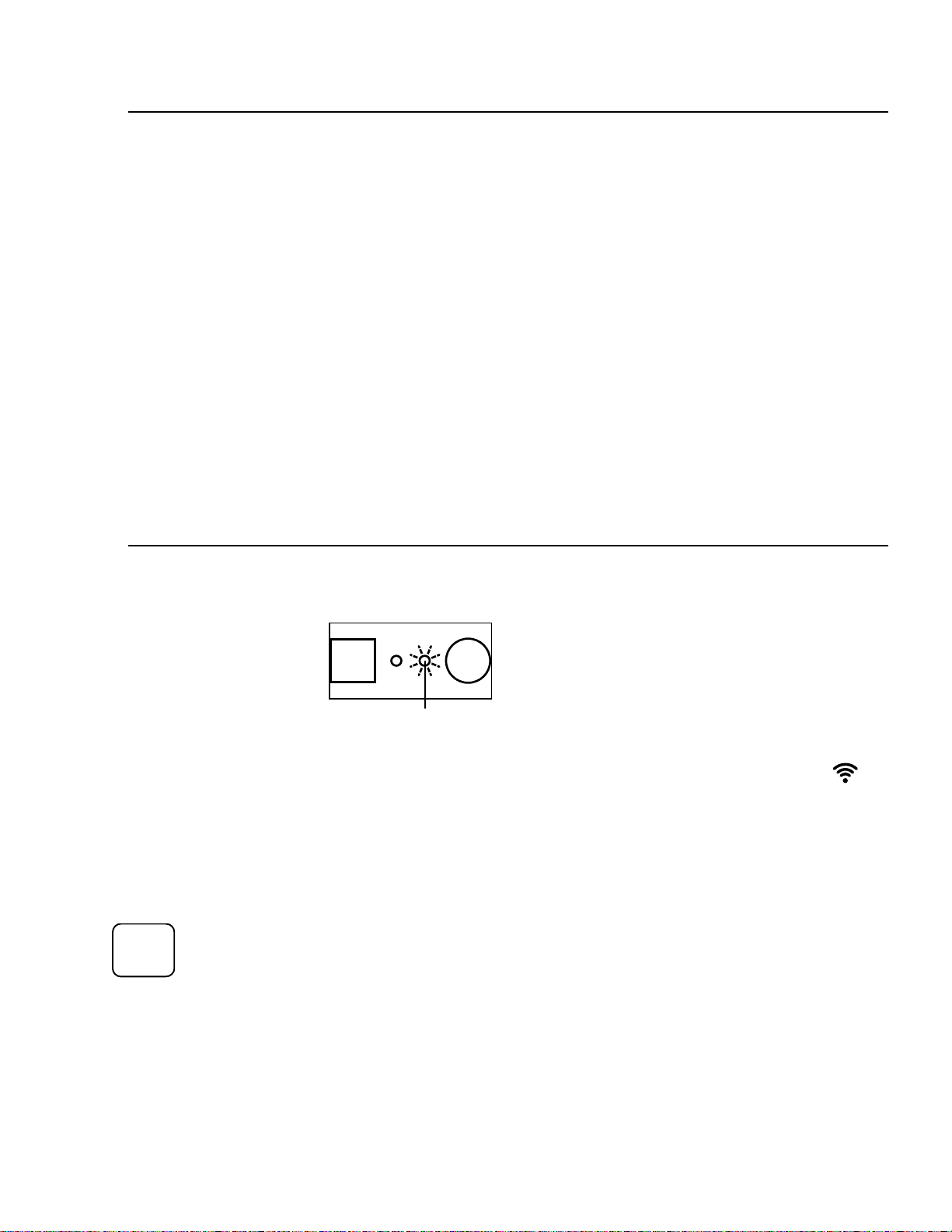

The Operation Indicator will glow red when the

appliance is ON.

The appliance will turn ON and attempt ignition:

• when you press the ON/

OFF button on the

appliance panel while the

appliance is OFF.

• when you press the STANDBY/ON button on the

remote control while the appliance is in

STANDBY.

• at the TIMER setting after you have activated the

TIMER and while the appliance is in STANDBY.

Pressing the STANDBY/ON button on the remote

control while the appliance is ON will put the

appliance in STANDBY mode, extinguishing

STA N D BY

ON

appliance is ON or in STANDBY will turn the

appliance OFF.

all flames and cause the Operation Indicator

to glow green.

Pressing the ON/OFF button while the

Operation Indicator

The remote control emits an infrared (IR) signal and

must be aimed at the receiver located to the right of

the warm air discharge louvers. The normal

operating range is about 16 feet (4.9 m) with an angle

of about 40 degrees to the horizontal. This range will

vary depending on the position of the installation and

the strength of the remote control batteries.

Signal transmissions are confirmed by

• a brief illumination of the Transmission

Signal Indicator on the Remote Display

• a flash by the Remote Control Receiver to the

right of the louvers

• a beep from the appliance

The remote control transmits information whenever a

button is pressed except as follows:

• when the lock function is activated

• when setting the timers, timer information is

transmitted only when the “TIME SET” button is

pressed

8 Rinnai Corporation RHFE-750ETR

Page 9

Basic Fireplace Operations

Adjusting the Temperature

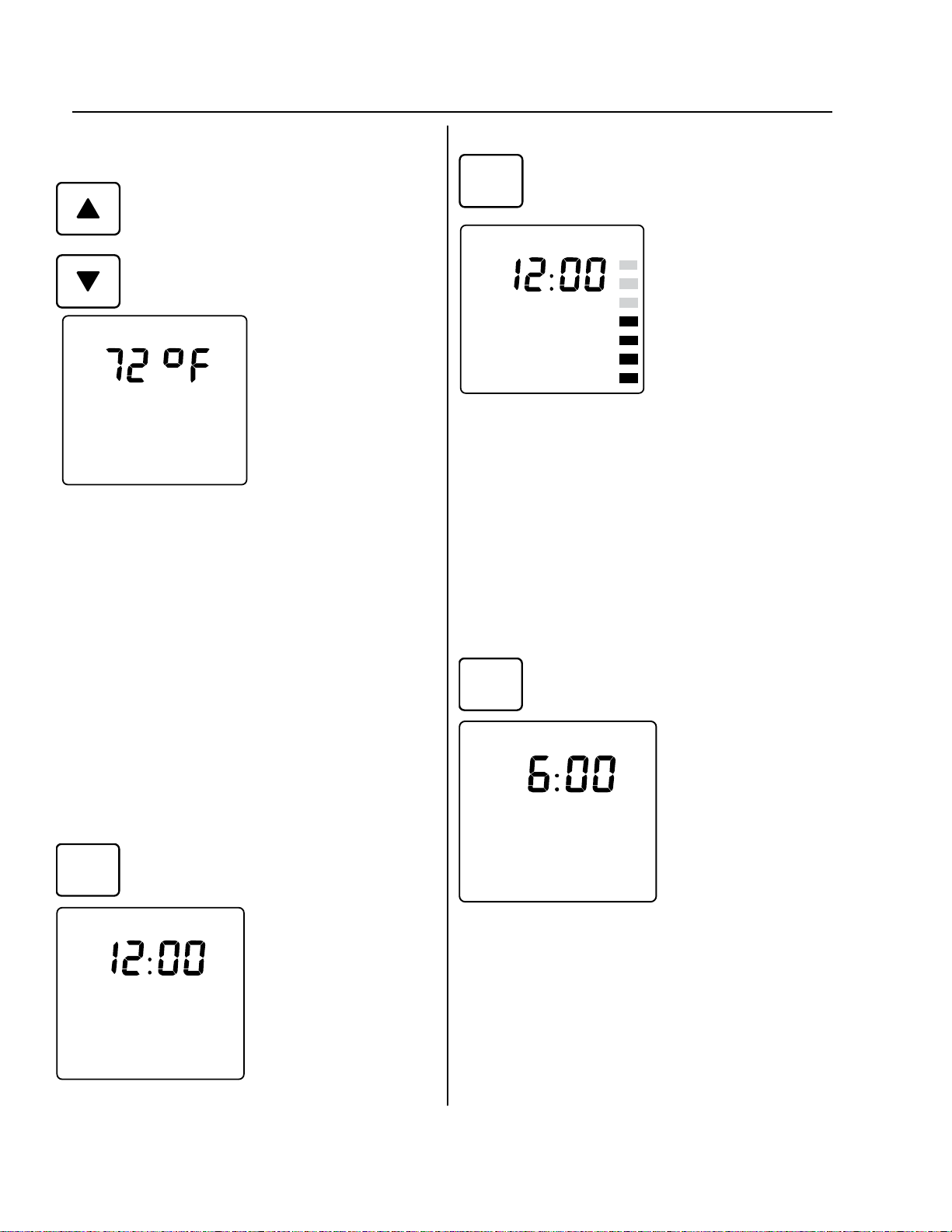

Pressing the UP and DOWN buttons will change the

temperature setting by 2 degree (F)

increments. The display will show

“Temperature” and the new temperature as

confirmation.

The temperature can be set to:

• L (Low) - burner is on minimum

combustion

Lock

Override Auto Off Flam e

PM

Te m p e r a t u r e

Cl o c k

Se t

Ti mer 1

Se t O N O F F

ON OFFTi mer 2 Set

The temperatures 16-26° C are available in one

degree increments. To return to Fahrenheit scale

move the switch toward “1”.

• 60° F - 80° F in two

degree increments

• H (High) - burner is

on maximum combustion

To use Celsius scale,

open the battery

compartment and move

the switch toward “0”.

Obstruction of Warm Air Discharge

Obstructing the louvers for the warm air discharge will

cause the appliance to operate inefficiently.

When an obstruction is detected the Blockage

Indicator LED above the Receiver Window will glow

red and combustion reduces to front burner, low

operation only.

To restore normal operation, remove the obstruction,

turn the appliance OFF and then ON.

Lock Function

Pressing the LOCK button will cause all

Lock

Lock

AM

PM

functions of the remote control to be locked

except for the STANDBY/ON button.

Override

Te m p e r a t u r e

Ti me

The remote control

display will show the word

“Lock” in the top left

corner.

To cancel the Lock

function press down and

hold the LOCK button for

3 seconds.

Flame Function

Press the FLAME button to control the flame

Fl am e

Lock

AM

PM

Cl o c k

Ti me r 1

flame automatically.

If the room temperature reaches 104° F (40° C) while

the flame function is on then the appliance will turn off

automatically as a safety precaution.

The FLAME function is not available during TIMER

operation.

level. There are seven levels of flame

available.

The display will show the

Over ri d e

Te m p e r a t u r e

Se t

Se t ON O FF

ON OFFTi me r 2 Set

Ti m e

Fl am e

word “Flame” and a series

of short bars (one for each

flame level).

Use the UP or DOWN

buttons to select the

desired flame level.

Pressing the FLAME

button again will allow the

appliance to control the

Auto Off Function

When the appliance is not in AUTO OFF mode and

the room temperature reaches the temperature

setting the appliance will reduce the gas

Aut o

Off

Lock

AM

PM

Cl o ck

Ti m e r 1

mode press the AUTO OFF button. The words “Auto

Off” will be displayed above the time. To exit this

mode press the AUTO OFF again.

Whether this mode is on or off, the appliance will

attempt to maintain the temperature setting.

flow and maintain the flame on the lowest

flame level. The temperature may continue

to rise even on this low setting. If the

temperature reaches

Override Aut o Off

Te m p e r a t u r e

Ti m e

Se t

Se t ON O FF

ON OFFTi m e r 2 Set

Fl a m e

104° F (40° C) then the

appliance will

automatically shut down

with fault code 16.

In AUTO OFF mode the

gas flow will be reduced

to pilot operation with no

visible flame when the

temperature setting is

reached. To enter this

Rinnai Corporation RHFE-750ETR 9

Page 10

Timers

Programming the clock and timers

The clock must be set before the timers will operate.

The temperature setting during timer operation is the

temperature last used when the appliance was on.

During the steps below, if no button is pressed for 90

seconds then the screen will return to the current time

display.

Ti me

Se t

Lock

AM

Cl o ck

Ti me r 1

Lock

AM

PM

Cl o ck

Ti me r 1

1. Press the TIME SET button. The display

will show the words “Clock Set” and “AM

12:00” or the time.

2. Use the UP or DOWN buttons to set the

desired clock time.

NOTE: If you do not want to set the timers

now then press the TIME SET button five

more times to finish setting the clock.

3. Press the TIME SET button. “Timer 1

Set ON” and “AM 6:00” or

Override Aut o Of f

Te m p e r a t u r e

Se t

Se t O N OFF

ON OFFTi me r 2 Set

Override Aut o Of f

Te m p e r a t u r e

Se t

Se t O N O FF

ON OFFTi me r 2 Set

and Timer 1.

Ti me

Ti me

the last programmed time

Fl a m e

will be displayed. Use the

UP or DOWN buttons to

set the desired on time.

When finished press the

TIME SET button.

4. “Timer 1 Set OFF” and

“AM 9:00” or the last

programmed time will be

displayed. Use the UP or

DOWN buttons to set the

Fl a m e

desired off time. When

finished press the TIME

SET button.

5. To set Timer 2 repeat

steps 3 and 4. If finished

press the TIME SET

button two more times to

complete setting the clock

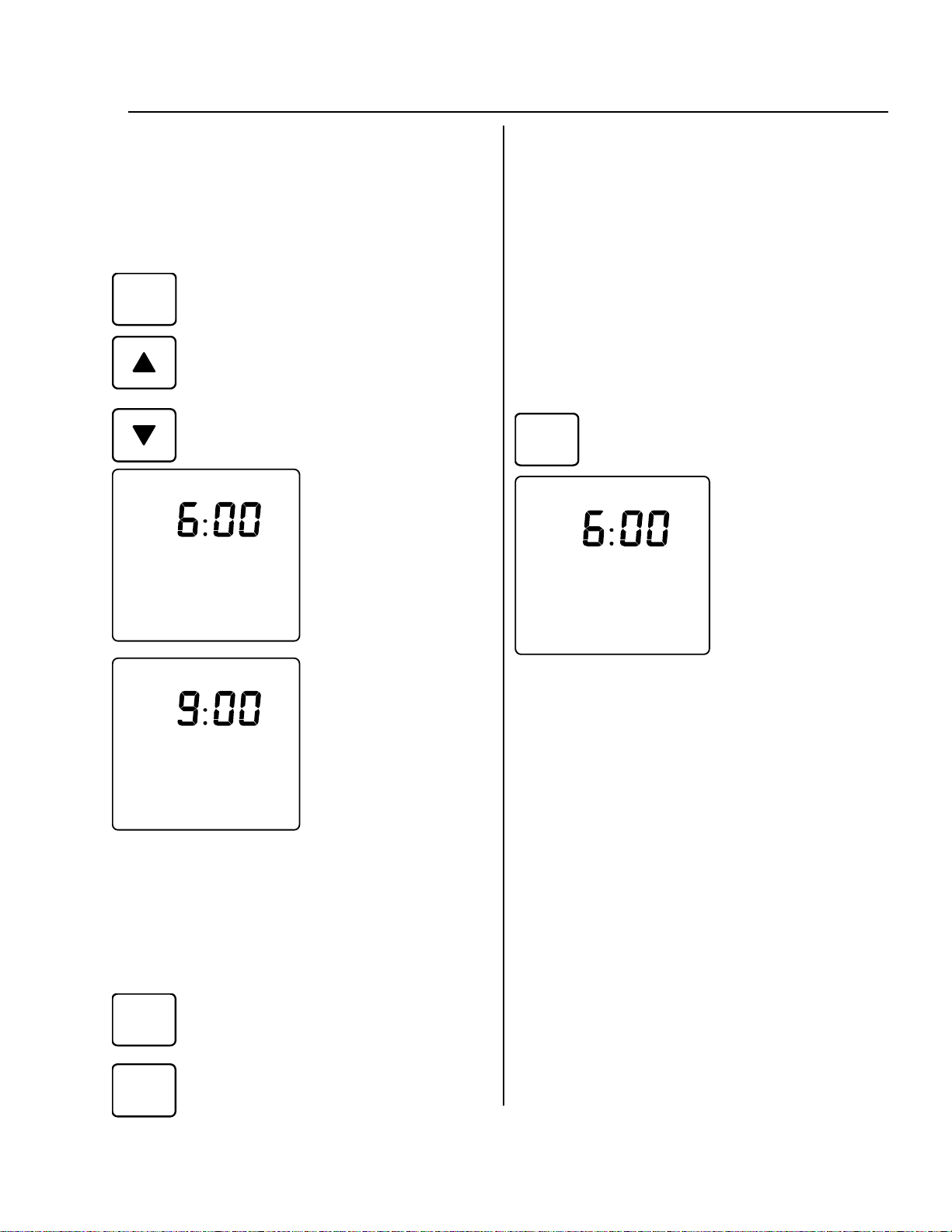

Using the Timers

Check the temperature setting before using the

timers.

go into standby mode and the Timer Indicator will

glow green.

To turn the timers off press the appropriate timer

button again. If the appliance was on, it will return to

standby mode and the Operation Indicator will glow

green.

The Timer Indicator will not display if both timers are

turned off.

Using the Override

This function is used to manually override

Override

Lock

AM

PM

Cl o ck

Ti me r 1

for operation then pressing OVERRIDE will turn the

appliance ON.

OVERRIDE does not change the programmed times.

Timer programmed operation.

If the appliance is

Override Auto Off

Te m p e r a t u r e

Ti m e

Se t

Se t O N OFF

ON OFFTi me r 2 Set

Fl am e

operating in Timer mode

then pressing

OVERRIDE will turn the

it OFF and cause the

word “Override” to be

displayed for 10

seconds.

If the appliance is in

Timer mode but outside

of the programmed time

Pre-heat

The appliance may operate up to one hour before the

programmed ON time in order to allow the room to

reach the desired temperature by the programmed

ON time. The pre-heat time (how long before the

programmed ON time that the appliance will provide

heat) is determined by the difference between the

temperature setting and the room temperature one

hour before the programmed ON time.

One or both timers can be used. To allow

Ti m er 1

Ti m er 2

10 Rinnai Corporation RHFE-750ETR

the appliance to operate during the preprogrammed times press the TIMER 1 and/

or TIMER 2 button. The display will briefly

show the “on” and “off” times for each timer.

If the current time is outside of the

programmed times then the appliance will

Page 11

Care and Maintenance

Maintenance

Repairs should be performed by a qualified service

technician. The appliance should be inspected

annually by a qualified service agency.

More frequent cleaning may be required due to

excessive lint from carpeting, bedding material, etc. It

is imperative that control compartments, burners, and

circulating air passage ways of the appliance be kept

clean.

When the appliance has cooled off, gain access by

removing the front panel, combustion chamber glass

panel, and ceramic logs. Refer to the Parts List and

the sections Cleaning Combustion Chamber Glass

and Final Assembly for disassembly / assembly

instructions. Vacuum, use pressurized air, and then

vacuum again to remove dust from the burners,

compartments, and convection fan.

Any filter or guard removed for servicing the

appliance must be replaced prior to operating the

appliance.

The vent should be inspected annually for blockages

or damage.

Motors are permanently lubricated and do not need

periodic lubrication. Keep fan and motor free of dust

and dirt by cleaning annually.

Verify proper operation after servicing.

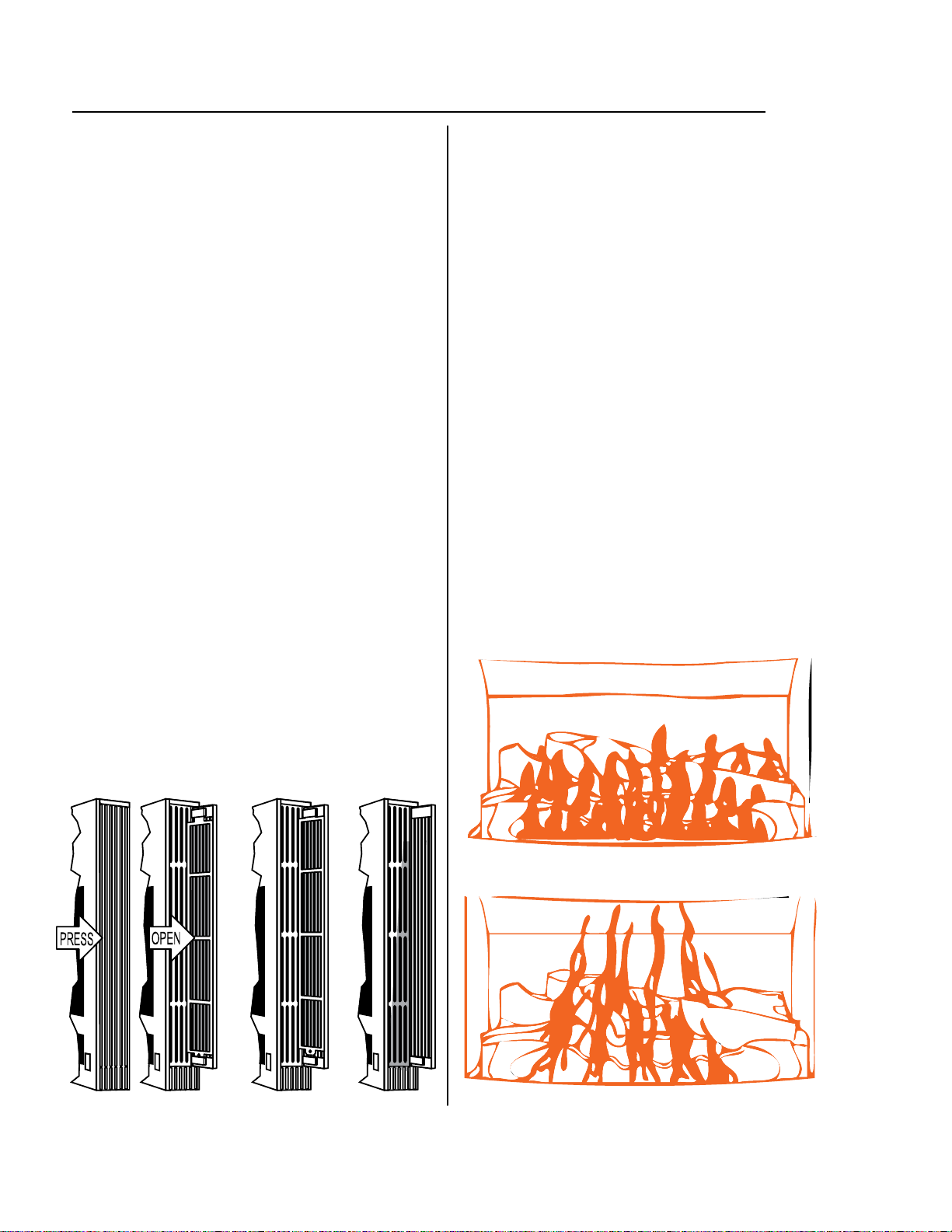

ability to produce heat. The filters should be cleaned

once a week during the heating season. If the filters

become blocked the blockage indicator will flash red.

The filters should be cleaned whenever the blockage

indicator flashes red. If not cleaned the appliance

may turn off and display fault code 14 (overheat) on

the control panel display.

To clean the filters, the appliance should be OFF and

cool. Open the louver by pushing inward and

releasing. Slide the filter upwards until the bottom tab

clears the lower retaining slot. Then slide the filter

down and away to remove. Clean the filter using a

soft dry cloth or vacuum.

Visual Inspection of Flame

Check that the pilot and burner flames are operating

normally.

If flames appear either very short or very long and

streaky or are producing smoke or soot deposits then

there may be a problem with the appliance or gas

supply.

The appliance should not be used if you suspect

there is a problem. Call a qualified service technician

to inspect the appliance.

The burners are designed to produce two rows of

yellow flame but not smoke or soot.

Filters

This appliance has two filters which are behind the

louvers on either side of the heater. The louvers are

hinged to allow access to the filters.

Dirty filters reduce the air flow and the appliance’s

NORMAL

ABNORMAL

Rinnai Corporation RHFE-750ETR 11

Page 12

Care and Maintenance

Over time combustion products may leave a film on

the combustion chamber glass. Continued use of the

appliance may permanently stain the glass. If filming

occurs, this glass panel needs to be removed,

cleaned, and installed only by a qualified service

technician.

WARNING

Do not clean glass when hot.

Do not clean glass with abrasive cleaners.

12 Rinnai Corporation RHFE-750ETR

Page 13

Troubleshooting

Problem Possible Solutions or Explanation

No display on remote Replace the remote control batteries.

No ignition or no panel indications Ensure the appliance has power.

Press the control panel ON/OFF button.

Burners fail to ignite Air may need to be purged from the gas line. Several

ignition attempts may purge the gas line.

Turn on the gas supply.

Combustion stops during operation Remove any obstructions from the louvers.

Turn on the gas supply.

Smell of gas Follow the instructions in the warning block on the front of

this manual.

Remote control does not work Ensure the appliance has power.

Press the control panel ON/OFF button.

Press the LOCK button for 3 seconds if LOCK is displayed.

Press the STANDBY/ON button.

Warm air does not start immediately after burner

lights

Smoke or odors are produced when first operated This is caused by grease or oil on the heat exchanger or by

Clicking noises at ignition or shutdown Internal components are cooling (contracting) or heating up

Clunking noise when the thermostat operates This is the sound of the solenoid gas valves opening and

Convection fan continues to run after appliance is

turned OFF

Steam is discharged from the flue outside Steam discharge is normal.

Does not start while in STANDBY and the

temperature is below the setting

Timers do not turn the appliance ON or OFF Timers may be turned off or incorrectly programmed.

Timer turns the appliance ON briefly and then the

appliance turns OFF before the OFF time setting.

The appliance will wait until the heat exchanger is warmed

up before discharging air. This ensures that any discharge

air will be warm and not cold.

dust and should stop after a short time.

(expanding) at different rates.

closing to regulate the gas flow.

The fan will continue to run to prevent internal components

from over heating.

Timers must be turned off (or press OVERRIDE) for

manual operation.

The room temperature may be higher than the temperature

setting.

Rinnai Corporation RHFE-750ETR 13

Page 14

Fault Codes

If there is a malfunction the appliance may shut down as a safety precaution and display a fault code to assist in

diagnosing the problem. The fault code will flash in the Fault Code Display window and the Operation Indicator

will flash green.

Code Fault Remedy

Confirm that the gas supply is turned on. Switch appliance to

11 Ignition failure

12 Incomplete combustion Service call

14 Filter blocked or Overheat

16 Room overheat

31 Room temperature sensor faulty Service call

STANDBY and then ON again. If ignition failure continues

then a Service call is required.

Clean filters

If overheating continues then a service call is required to

determine the cause.

Thermal fuse; a qualified service technician must replace the

fuse following the procedure below.

The temperature has reached 104° F (40° C). Turn the

appliance off or engage the AUTO OFF function to prevent the

display of flame. See AUTO OFF section.

32 Overheat temperature sensor faulty Service call

53 Spark sensor faulty Service call

61 Fan motor faulty Service call

71 Solenoids faulty Service call

72 Flame detection circuit fault Service call

73 Communication fault Service call

99 Flue block Check around flue terminal for obstructions to air flow

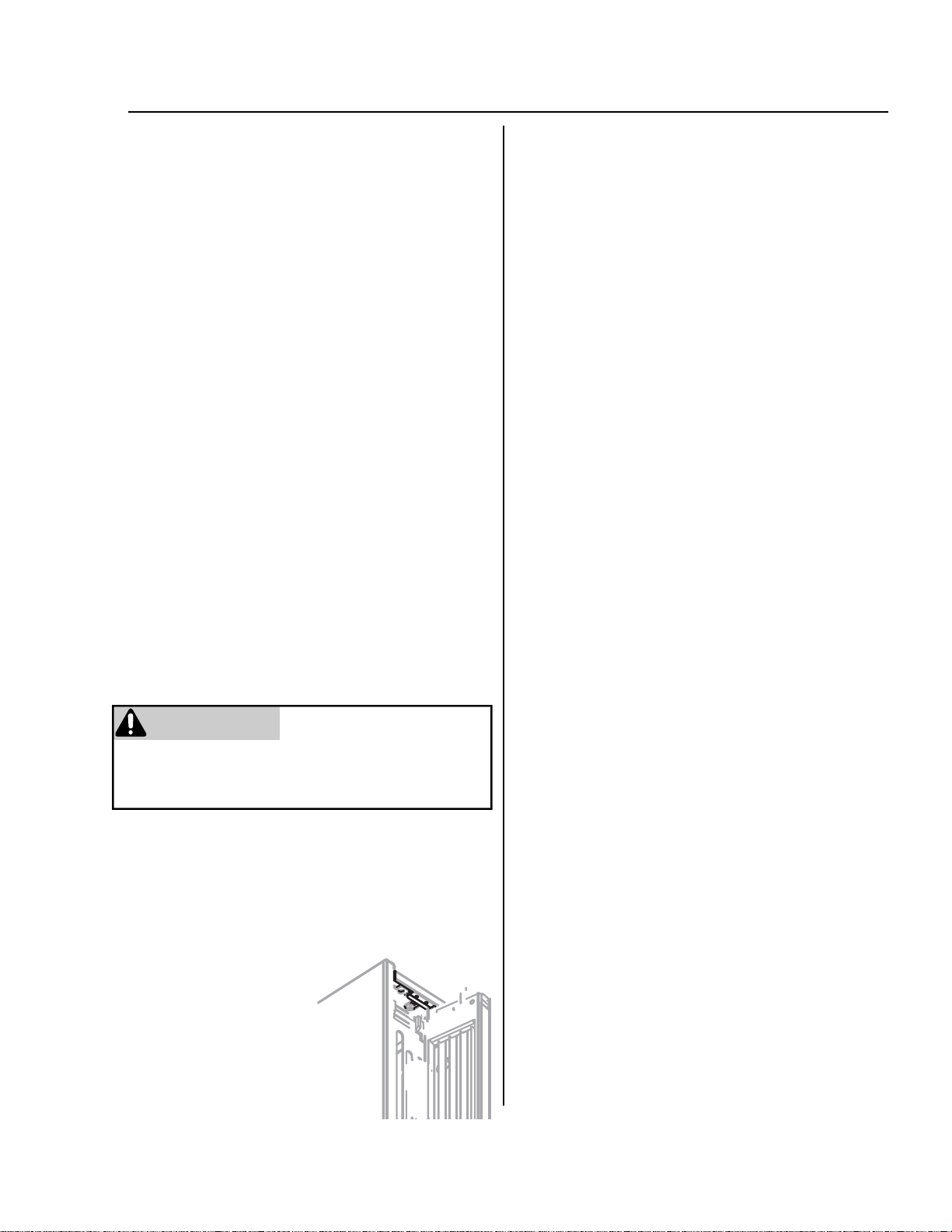

Replacement of Thermal Fuse

The cause of the overheat condition needs to be

determined and remedied before replacing the

thermal fuse.

A qualified service technician needs to:

1. Disconnect the appliance from the power supply.

2. Remove the right hand side panel to allow access

to the gas control and main PCB.

3. Unplug the thermal fuse harness (including the

control plug for the POV on the gas control) and

unscrew thermal fuse.

Thermal Fuse

PCB

POV

4. Re-assemble with replacement thermal fuse.

14 Rinnai Corporation RHFE-750ETR

Page 15

Installation Instructions

General Instructions

The appliance must not be connected to a chimney

WARNING

Do not use substitute materials.

Use only parts certified with the appliance.

A qualified service technician should install the

appliance and inspect it before use.

The installation must conform with local codes or, in

the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1/NFPA 54, or the Natural Gas and

Propane Installation Code, CSA B149.1.

A manufactured home (USA only) must conform with

the Manufactured Home Construction and Safety

Standard, Title 24 CFR, Part 3280, or, when such a

standard is not applicable, the standard for

Manufactured Home Installations, ANSI/NCSBCS

A225.1, or the standard for Gas Equipped

Recreational Vehicles and Mobile Housing, CSA

Z240.4.

The appliance, when installed, must be electrically

grounded in accordance with local codes or, in the

absence of local codes, with the National Electrical

Code, ANSI/NFPA 70, or the Canadian Electrical

Code, CSA C22.1.

Two 1/8 in test plugs are provided for testing of

manifold differential pressure.

flue serving a separate solid-fuel burning appliance.

The appliance and its appliance main gas valve must

be disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of 1/2 psi (3.5 kPa).

The appliance must be isolated from the gas supply

piping system by closing its equipment shutoff valve

during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 psi

(3.5 kPa).

If the flooring is carpet, tile, or other combustible

material other than wood, then the appliance must be

installed on a metal or wood panel extending the full

width and depth of the appliance.

This appliance discharges a large volume of warm air

next to the floor. Any particles in the air such as

cigarette smoke could cause discoloration in carpet.

The warm air flow could discolor nylon carpets

containing dyes or vinyl surfaces. To prevent

discoloration of the floor covering place a mat under

the appliance which extends about 30 inches in front

of it.

Refer to the conversion manual for high altitude

installations.

Clearances to Combustibles

The clearances to combustibles as stated on the

rating plate and as shown in the figures must be

followed. Also refer to the Safety Behaviors and

Practices section.

combustible projections (ex. mantles)

Wall

1"

3"

2"

3"

5"

4"

Top Panel of Fireplace

4"

45°

CLEARANCES FROM THE SIDES

Rinnai Corporation RHFE-750ETR 15

CLEARANCES

FROM THE TOP

45°

Top Front

Edge

6"

4"

5"

3"

4"

2"

1"

Wall

3"

Page 16

X

Flue Terminal Clearances

K

M

I

INSIDE

H

AIR SUPPLY INLET

VENT TERMINAL AREA WHERE

TERMINAL IS NOT

PERMITTTED

V

B

FIXED

CLOSED

OPERABLE

B

G

CORNER D ETAI L

A

J

A

B

B

FIXED

CLOSED

OPERABLE

C

B

F

B

L

E

D

16 Rinnai Corporation RHFE-750ETR

Page 17

Flue Terminal Clearances

terminate directly above

a sidewalk or paved

driveway that is located

between two single

family dwellings and

serves both dwellings.

veranda, porch, deck,

or balcony is fully open

on a minimum of two

sides beneath the floor.

specified in ANSI

Z223.1/NFPA 54 or

CSA B149.1,

clearances are in

accordance with local

installation codes and

the requirements of the

gas supplier.

1 A vent shall not

12 inches (30 cm) 12 inches (30 cm)

12 inches (30 cm) 9 inches (23 cm)

Canadian Installations US Installations

2 Permitted only if

* For clearances not

*

within 10 feet (3 m)

3 feet (91 cm) above if

* *

above the meter/

3 feet (91 cm) within a

height 15 feet (4.57 m)

regulator assembly

12 inches (30 cm) 9 inches (23 cm)

6 feet (1.83 m)

horizontally

7 feet (2.13 m) 1 *

12 inches (30 cm) 2 *

Description

Clearance above grade, veranda, porch,

A

Ref

deck, or balcony

Clearance to window or door that may be

opened

B

Vertical clearance to ventilated soffit,

located above the terminal within a

horizontal distance of 2 feet (61 cm) from

the center line of the terminal

C Clearance to permanently closed window * *

D

E Clearance to unventilated soffit * *

Rinnai Corporation RHFE-750ETR 17

Clearance to each side of center line

extended above meter/regulator assembly

F Clearance to outside corner * *

G Clearance to inside corner * *

H

Clearance to nonmechanical air supply

inlet to building or the combustion air inlet

to any other appliance

I Clearance to service regulator vent outlet 3 feet (91 cm) *

J

Clearance to a mechanical air supply inlet

K

Clearance above paved sidewalk or

paved driveway located on public property

L

Clearance under veranda, porch, deck, or

balcony

M

Page 18

Location

This appliance has a cool outer casing that allows it to

be installed in a recessed application consisting of

combustible materials such as wood and plaster.

The location needs to have a level surface that allows

the appliance to be rolled in or out of the enclosure.

If the surface is elevated and there is not enough

room for it to be rolled out then a base and joists may

be used as shown.

The appliance will have to be rolled out for

maintenance. After installation do not place any

permanent fixtures that would prevent pulling the

appliance out for access. To pull the appliance

completely out of the enclosure a minimum of 15

inches from the front panel would be needed.

Do not vent the exhaust into ‘natural draft’ flue pipes

or a chimney flue.

The enclosure must be within these limits:

Enclosure Dimensions

Width (w) 33.8 in (860 mm)

Height (h) 26.0 - 26.2 in (660-665 mm)

Depth (d) 15.0 - 16.9 in (380-430 mm)

The front panel extends below the surface on which

the appliance rests. Ensure that clearance is

maintained in order to install the front panel.

LEFT

WHEEL

JOIST JOIST

28.3 in (720 mm)

RIGHT

WHEEL

w

h

d

For installation in the corner of the room refer to the

diagram at the right and the table below for

dimensions. These dimensions are the minimum

required if using the minimum width, height, and

depth dimensions above.

Enclosure Dimensions in a Corner

x

x 63.8 in (1620 mm)

y 45.1 in (1146 mm)

z 31.9 in (810 mm)

z

18 Rinnai Corporation RHFE-750ETR

y

Page 19

Location

Use the adjustment feet so that the appliance is level

and not tilted. They are initially installed immediately

behind the side louvers but can be moved forward for

better access in hearth or floor installations.

The hearth should not block the appliance.

Correct Floor

Level Installation

Wall Lining

Particle Board, MDF, Plywood etc.

Rinnai Corporation RHFE-750ETR 19

Wall Lining

Particle Board, MDF, Plywood etc.

Wall Lining

Particle Board, MDF, Plywood etc.

Page 20

Drilling Flue and Gas Supply Holes

Check for water and gas pipes as well as electric

cables. Use the template supplied to mark the wall

locations for the flue manifold and the gas supply.

Drill the flue hole using a 3 1/2 inch (90 mm) drill.

For weatherboard walls, drill through the center of the

weatherboard from the outside first and then through

the plasterboard.

Flue Manifold Installation

1. Disassemble the Flue Manifold

The flue consists of 3 parts:

• sleeve

• inside connection

• terminal

Disassemble the flue manifold by first pulling

out the inside connection. To remove the

outer terminal pull and release the two

internal ties and then pull out the outer

terminal.

Clearance to combustibles for the sleeve and

flanges is zero inches.

2. Assemble and Adjust the Sleeve Length

Measure wall thickness through previously drilled

3 1/2 inch (90 mm) hole.

Inside Connection

Sleeve

Terminal

The end of the sleeve should protrude 3/16 - 3/8

inch (5-10 mm) from the outside wall.

a

In the “A” vent kit there are 4 parts provided with

which to assemble the sleeve. Use the table to

determine which pieces to assemble.

In both the “A” and “B” vent kits, two parts are

threaded for additional adjustment.

Adjust the sleeve length to wall thickness plus

3/16 - 3/8 inch (5-10 mm).

For wall thickness plus 3/16 - 3/8 in (5-10 mm) Assemble these parts (“A” Vent Kit)

4 1/3 - 6 1/8 in (110 - 155 mm)

6 1/8 - 7 3/4 in (155 - 195 mm)

7 3/4 - 9 1/2 in (195 - 240 mm)

a

++c+

a

b

Sleeve Parts

+

a

++

b

b

b

c

c

c

20 Rinnai Corporation RHFE-750ETR

Page 21

Flue Manifold Installation

3. Attach the sleeve

Attach to the inside wall using 3 screws arranging

the flange so that the marking “TOP” is at the top.

The flange is offset 2° to allow the condensate to

drain to the outside.

3 screws

4. Install the Terminal

Check that the terminal seal is in place. For

weatherboard or vinyl siding, add the second seal

next to the terminal seal to compensate for the

angle.

From the outside insert the terminal into the

sleeve with the marking “TOP” at the top. The left

hand side locking tie should be marked “LEFT”.

sleeve should extend

3/16 - 3/8 in (5-10 mm)

Terminal seal

Terminal

5. Lock the ties

Pulling hard on the left and right hand ties, clip

the ties over the notches inside the sleeve. You

should be able to pull the ties 2 or 3 notches past

the starting point. Cut the ties, leaving about 3/4

inch (20 mm) past the notch. Bend the ties back

into the sleeve and parallel to the wall.

6. Attach Inside Connection Assembly

Push the assembly into the terminal tube.

Attach the inside connection with 3 screws. The

inside connection can still be turned if necessary.

Locking tie

Locking ties

Sleeve

Rinnai Corporation RHFE-750ETR 21

Page 22

Extension Kit Installation

If necessary, extension kits are available to extend the exhaust line and air line between the manifold and the

appliance. The maximum extension allowed is shown in the table below and is based on the number of 90°

elbows used. Vertical extensions are not allowed.

maximum vent length 7.2 ft (2.2 m) 6.5 ft (2.0 m) 5.9 ft (1.8 m)

no elbows 1 elbow 2 elbows

Clamps

Both the exhaust line and air intake hose are

supported by clamps which are attached to the wall.

A wall fixture can be used to offset the clamp from the

wall. If the wall fixture is not used then use Screw A

and the nut to attach the clamp to the wall.

The air line should always be underneath the exhaust

line so that in case the air line sags it will not come

into contact with the exhaust line.

Installing the Exhaust Line

The exhaust line is connected between the joint pipe

at the rear of the heater and the exhaust port on the

flue pipe.

Slope the exhaust line 3° to the outside so that any

condensate will drain away from the appliance. The

figures below show two examples of horizontal

exhaust line extensions.

1. Attach the clamp with one screw to secure the

extension pipe to the flue manifold.

2. Use pipe stopper A to clamp the connections with

all other components.

3. Use pipe stopper B to fix the length on the

adjustable exhaust pipes. Do not extend these

pipes beyond the red line.

Pipe Clamp and

Wall Fixture

Screw B

Air Line

Flue

Manifold

Exhaust Line

Air Line

Screw A

Pipe Stopper A

Tie

Pipe Stopper B

Clamp

Example with One Elbow

4. Do not cut the exhaust pipe.

5. To bend the elbow, insert exhaust pipes into both

ends for additional leverage. Bend to desired

angle.

Example with No Elbows (straight out)

6.5 ft (2m) Maximum

7.2 ft(2.2 m)Maximum

3° SLOPE

3° SLOPE

22 Rinnai Corporation RHFE-750ETR

Page 23

Extension Kit Installation

Connecting the Air Line

The air line is connected between the air connection

at the rear of the heater and the air intake port on the

flue manifold.

Push the air intake hose onto the flue manifold and

secure with the plastic cable tie.

Join air intake hoses by screwing the hose joint half of

its length into the air intake hose and then screwing

another air intake hose into the hose joint.

Clearances

exhaust pipe to combustibles 1 inch (25.4 mm)

exhaust pipe to non-combustibles zero

Extension Kits and Parts

The hose can be cut to the required length. Deburr all

rough edges.

Support the air line with pipe clamps.

Description FOT-102 FOT-103 FOT-114 FOT-115

Exhaust Pipe (adjustable)

11.4-20.3 in (290-515 mm)

Exhaust Pipe (adjustable)

21.0-39.6 in (533-1005 mm)

Exhaust Pipe

40 in (1016 mm)

Air Intake Hose

29.5 in (750 mm)

Air Intake Hose

49.2 in (1.25 m)

Air Intake Hose

90.6 in (2.3 m)

Elbow (flexible) 1

Hose Joint 1 1 1

Pipe Stopper A 1 1 2 2

Pipe Stopper B 1 1 1

Top Stopper 1 1 1

Pipe Clamp 2 sets 3 sets 4 sets

1

1 1

1

1

1

1

Wall Fixture 2 3 4

Nut 2 3 4

Screw A 2 3 4

Screw B 4 6 8

Rinnai Corporation RHFE-750ETR 23

Page 24

Connections

1. Carefully remove the packaged ceramic logs and

place in a safe location.

2. To ensure the correct positioning, terminate the

gas supply so that it is 5.9 inches (150 mm) from

the front of the enclosure.

3. Gain access to the gas connection by removing

the right hand side access panel by unscrewing

the four retaining screws. Pry the front edge of

the panel open to the right and pull forwards.

4. Position the appliance in front of the enclosure so

that the end of the gas supply aligns with the gas

fitting opening. Connect the flexible gas

connection to the gas supply.

5. Replace the right hand panel and secure with the

four retaining screws.

remove 4

screws to

remove

side

panel

6. Unscrew the flue access panel held by two

screws located inside the top left-hand corner of

the appliance. Slide this panel to the right behind

the convection fan.

7. Attach the electrical connection and place in the

junction box.

8. Leak test the gas connection using a soapy

solution. Do not allow the soapy solution to

contact electrical components. Remove any

residue.

gas fitting opening gas connection

24 Rinnai Corporation RHFE-750ETR

Page 25

Connections

9. Remove clamp L and slide the vertical pipe M

down into the lower elbow N to remove parts J

and K. Separate J and K.

10. Attach pipe J to the flue manifold with clamp and

screw. (If using extension pipes, attach pipe J to

the extension pipe using pipe stopper A.)

11. Push the air intake line onto the flue manifold and

secure with the plastic cable tie. Make sure the

hose does not kink. (This may have been done

when installing extension pipes.)

13. Slide tube M up into elbow K and clamp together

with clamp L.

14. Slide the flue access panel back into position and

attach with two screws.

15. Open both of the air return louvers on both sides.

Secure the appliance using the four mounting

points.

12. Carefully slide the appliance into the enclosure

lining up the gas supply and exhaust pipe. Fit

elbow K to pipe J making sure that the clip in

elbow K goes beyond the groove in the pipe. The

gas supply flexible hose is designed to coil inside

the appliance as it is pushed into the enclosure.

Rinnai Corporation RHFE-750ETR 25

Page 26

s

Final Assembly

Install the Logs

The log set consists of seven pieces as follows:

• rear

• left hand middle

• right hand middle

• center top

1. Remove the two retaining screws that secure the

combustion chamber glass panel.

2. Rotate and lift the combustion chamber glass clear

of the combustion chamber and place in a safe

location.

• right hand top

• left hand front

• right hand front

retaining screw

J

Step 3

3. Seat the rear log into the combustion chamber

onto its location pins.

4. Seat the left hand middle log onto its location pins.

5. Seat the right hand middle log onto its location

pins.

6. Seat the center top log onto the location pins.

7. Seat the right hand top log onto the location pins.

8. Place the left hand front log and the right hand

front log on the pins.

9. Install the glass panel with two retainer screws at

the top of the panel.

Steps

6 & 7

left hand front

right hand front

Step 8

26 Rinnai Corporation RHFE-750ETR

Page 27

Install the Front Panel

1. Install the front panel by hooking the top into the

body and rotating the bottom towards the

appliance.

Air Guide Vanes

To move the air flow more to the right or to the left,

bend the air guide vanes using only light hand

pressure.

Do not bend repeatedly (no more than 5 times) or

else the vane will break.

2. Secure the front panel to the appliance using

two screws through the front of the warm air

discharge louvers.

Rinnai Corporation RHFE-750ETR 27

Page 28

Operating Instructions

If you do not follow these instructions exactly, a fire or explosion

WARNING

A. This appliance is equipped with an ignition device

that automatically lights the pilot. Do not

light the burner by hand.

B. BEFORE OPERATING smell all around the

appliance area for gas. Be sure to smell next to

the floor because some gas is heavier than air and

will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any

phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

1. STOP! Read the safety information above.

FOR YOUR SAFETY READ BEFORE OPERATING

may result causing property damage, personal injury or loss of life.

try to

OPERATING INSTRUCTIONS

On/Off Button Error Code

• If you cannot reach your gas supplier, call the

fire department.

C. Use only your hand to push the gas control

buttons. Never use tools. If the knob will not push

in or turn by hand, don’t try to repair it, call a

qualified service technician. Force or attempted

repair may result in a fire or explosion.

D. Do not use this appliance if any part has been

under water. Immediately call a qualified service

technician to inspect the appliance and to replace

any part of the control system and any gas control

which has been under water.

4. If the appliance does not light it will automatically

shut down and an error code will display. Check

the this manual for error code definitions.

5. To re-attempt ignition, press the On/Off button

twice.

2. Wait five (5) minutes to clear out any gas. Then

smell for gas, including near the floor. If you smell

gas, STOP! Follow “B” in the safety information

above. If you don’t smell gas, go to the next step.

3. Press the On/Off button on the top panel on the

appliance. This will start the ignition sequence.

Turn off electric power to the appliance using the On/

Off button located on the control panel. The fan will

continue to operate until the appliance is cool. Once

the fan has stopped operating, isolate the appliance

power by unplugging it from the wall or turning off the

isolating breaker switch.

TO TURN OFF GAS TO APPLIANCE

6. To adjust the heat, press the up▲ or down▼

buttons on the remote control to adjust the

thermostat.

7. To turn the unit off, press the On/Off button on the

top control panel.

8. If the appliance will not operate, follow the

instructions “To Turn Off Gas To Appliance” and

call your service technician or gas supplier. See

this manual for additional information.

NOTE: Do not turn the appliance off by unplugging it

from the wall. Keep burner and control

compartment clean. See installation and

operating instructions.

28 Rinnai Corporation RHFE-750ETR

Page 29

Wiring and Schematic Diagrams

CAUTION

Label all wires prior to disconnection when servicing controls.

Wiring errors can cause improper and dangerous operation.

If any of the original wire as supplied with the

appliance must be replaced, it must be replaced with

type 18 AWG wire or its equivalent.

Rinnai Corporation RHFE-750ETR 29

Page 30

Parts List

For replacement parts call Rinnai at 1-800-621-9419.

30 Rinnai Corporation RHFE-750ETR

Page 31

Parts List

Rinnai Corporation RHFE-750ETR 31

Page 32

Parts List

32 Rinnai Corporation RHFE-750ETR

Page 33

Parts List

ITEM QTY PART NO. DESCRIPTION COMMENTS

1 1 10201 PANEL BASE RHFE750ETR

2 2 10777 FOOT KIT RHFE

3 1 BRACKET COMB CHAMBER SUPPORT RH R750 NON SERVICEABLE PART

4 1 BRACKET COMB CHAMBER SUPPORT LH R750 NON SERVICEABLE PART

5 2 10458 BRACKET FRONT MOUNT RHFE

6 2 10751 WHEEL KIT RHFE750/IBOF

7 2 10778 GLASS RETAINER SPRING KIT RHFE750

8 1 10232 PANEL AIR DIVERTER RH RHFE750

9 1 10231 PANEL AIR DIVERTER LH RHFE750

10 1 10209Z PANEL LOWER AIR GUIDE POWDER COAT RHFE

11 1 COMBUSTION CHAMBER ASSEMBLY PAINTED R750 NON SERVICEABLE PART

12 2 10780 GLASS RETAINER SLIDE ASSEMBLY RHFE750

13 2 10390 GLASS RETAINER SLIDE COVER RHFE750

14 1 10224Z PANEL BURNER SHIELD PAINTED R750

15 1 10204 PANEL HEAT SHIELD REAR RHFE750

16 1 10202 PANEL HEAT SHIELD RH RHFE750

17 1 10203 PANEL HEAT SHIELD LH RHFE750

18 1 10262 PANEL COMB FAN FLUE DIVIDER

19 1 10208 PANEL FAN INFILL RHFE750

20 1 10205 PANEL OUTER RH RHFE750ETR

21 1 10206 PANEL OUTER LH RHFE750ETR

22 1 10263 PANEL COMB FAN INLET "A"

23 1 10264 PANEL REAR AIR INLET "B"

24 1 10781 COMBUSTION FAN COVER RHFE750

25 1 10213 PANEL COVER FLUE OUTLET

26 1 10412 PANEL COVER TRANS RHFE

27 1 10207 TOP PANEL RHFE ENGINE ASSEMBLY

28 1 10296Z LOUVRE SIDE SUPPORT RH BLACK 750

29 1 10297Z LOUVRE SIDE SUPPORT LH BLACK 750

30

31

32 1 10750 DOOR LATCH KIT CONTAINS 4 x LATCHES

33 1 10782 COMB CHAMBER GLASS ASSEMBLY RHFE750

34 2 10783 LOUVRE SIDE ASSEMBLY RHFE750

35 2 10784 SCREEN KIT RHFE750

36 1 10785 WAX ELEMENT ASSEMBLY RHFE750

37 1 10786 MAIN PCB BRACKET ASSEMBLY RHFE750

38 1 10418 BRACKET REAR BURNER SUPPORT RHFE

39 1 10255 BRACKET RECEIVER RHFE750

40 1 10226 BRACKET INJECTOR SUPPORT RHFE750

41 3 10462 PACKING INJECTOR BLOCK

42 2 10753 INJECTOR BLOCK KIT REAR RHFE750

43 1 10754 INJECTOR BLOCK KIT FRONT RHFE750

44 2 7185 INJECTOR 1.45 NG **

44 2 5436 INJECTOR 0.9 LPG **

45 1 5425 INJECTOR 1.75 NG **

45 1 5548 INJECTOR 1.05 LPG **

46 1 10413 BRACKET TRANSFORMER MOUNT RHFE

47 1 10275A BURNER BRAY 450 NG + BUSH NG **

47 1 10277A BURNER BRAY 450 LP Ø5.0 LPG **

2 10752 LOUVRE HINGE KIT

** Always refer to the data plate for correct information.

KIT CONTAINS 1 x UPPER AND

1 x LOWER HINGE

Rinnai Corporation RHFE-750ETR 33

Page 34

Parts List

ITEM QTY PART NO. DESCRIPTION COMMENTS

48 2 10359F BURNER ASSEMBLY BRAY 250 Ø3.0 x 2 NG LEFT AND RIGHT **

48 1 10359B BURNER ASSEMBLY BRAY 250 Ø6.0 x 2 LPG LEFT ONLY **

48 1 10359G BURNER ASSEMBLY BRAY 250 Ø6.5 x 2 LPG RIGHT ONLY **

49 1 10764 PILOT ASSEMBLY RHFE750

INCLUDES DOUBLE

50 1 10772 PILOT ELECTRODE KIT RHFE750

51 1 10419 BRACKET REAR BURNER CLAMP RHFE

52 1 10212 PANEL BURNER SURROUND REAR BLACK

53 1 10549 PANEL BURNER SURROUND FRONT BLACK

54 1 10760 AERATION PLATE SET RHFE750 NG US NG **

54 1 10761 AERATION PLATE SET RHFE750 LPG US LPG **

55 1 10757 LOG PIN SET RHFE US

56 1 10215 PANEL AIR INLET COVER RHFE750

57 2 10211 BRACKET BURNER EXP PLATE RHFE750

58 1 7795 INJECTOR NG 62 NG **

58 1 7873 INJECTOR NG 35 LPG **

59 1 10272 PILOT CONVERTIBLE HOOD 3 FLAME

60 1 10425 BRACKET CROSS LIGHTING RHFE NG NG **

60 1 10426 BRACKET CROSS LIGHTING RHFE LPG LPG **

61 1 10288 GAS SUPPLY TUBE PILOT B

62 1 10787 REGULATOR ASSEMBLY RHFE750 7~13 mbar US NG **

62 1 10788 REGULATOR ASSEMBLY RHFE750 15~25 mbar US LPG **

63 1 10267 BRACKET REGULATOR MOUNT RHFE750

64 1 6313 GAS TUBE RETAINER

65 1 10287 GAS SUPPLY TUBE ASSEMBLY PILOT A

66 1 10248 GAS SUPPLY TUBE FRONT RHFE750

67 1 10247 GAS SUPPLY TUBE RR RHFE750

68 1 10249A GAS SUPPLY TUBE ASSEMBLY RL RH RHFE

69 1 10249B GAS SUPPLY TUBE ASSEMBLY RL LH R750

70 1 10520 JOINER 8MM

71

72

73

74 1 10774 GAS CON SUB ASSEMBLY RHFE750ETR INCLUDES WIRING HARNESS

75 1 10518 TEST POINT CC US RHFE750ETR

76 1 10355 US LOG SET NZ/AU RHFE750ETR US

77 1 FRONT HEAT EXCHANGER ASSEMBLY NON SERVICEABLE PART

78 1 HEAT EXCHANGER REAR RHFE750 NON SERVICEABLE PART

79 1 10227 BRACKET HEAT EXCHANGER TOP R750

80 1 10794 COMBUSTION FAN ASSEMBLY RHFE750 US INCLUDES THERMISTOR (134)

81 1 10341 TUBE COMB EXHAUST LOWER RHFE

82 1 10345 BRACKET EXHAUST TUBE RHFE

83 1 4326 EXHAUST AIR SIDE

84 1 10279 EXHAUST ELBOW RHFE750ETR

85 1 10270 EXHAUST STRAIGHT RHFE750ETR

86 1 10478 CLAMP FLUE 50MM

87 1 10530 FLUE ASSEMBLY RHFE750ETR

88 1 10550 BRACKET FLUE RETAINER RHFE750ETR

1 10756

O-RING KIT RHFE750

** Always refer to the data plate for correct information.

ELECTRODE, FLAME ROD AND

CLAMPS

6 x LONG PINS + SCREWS

4 x SHORT SCREWS

KIT INCLUDES 8 ASSORTED

ORINGS AND INSTRUCTION

SHEET

34 Rinnai Corporation RHFE-750ETR

Page 35

Parts List

ITEM QTY PART NO. DESCRIPTION COMMENTS

89 1 10234 AIR INLET BOX FRONT RHFE750ETR

90 1 10271 PACKING FOR AIR INLET BOX

91 1 10278 PACKING COMB FAN RHFE750ETR

92 1 10796 AIR INLET ASSEMBLY RHFE750 US

93 1 10349 AIR INLET HOSE

94 1 4328 AIR INLET ELBOW B 50x50

95 1 10330 HOSE SS 10 530 3/8SAE RHFE750

96 1 10567 VALVE 3/8" SAEM-FLARE 1/2"NPTF

97 1 10797 PCB ASSEMBLY RHFE750

98 1 10768 FLAME ROD KIT RHFE750 CONTAINS 3 x FLAME RODS

99 1 10770 FLAME ROD BRACKET KIT RHFE750 CONTAINS 3 x BRACKETS

100 1 10792 CONVECTION FAN ASSEMBLY RHFE750 US

101 1 10769 FLAME ROD SLEEVE KIT RHFE750 CONTAINS 3 x SLEEVES

102 1 10798 RECEIVER ASSEMBLY RHFE750

103 1 10765 CONTROL PCB KIT RHFE750 CONTAINS 4 x PCB SPACERS

104 1 10771 BODY PLUG KIT RHFE750 CONTAINS 2 x BODY PLUGS

105 1 10253 PCB DISPLAY RHFE750ETR

106 1 10256 PRESSURE SWITCH RHFE US

107 1 10528 TUBE SILICON BLACK 7x4x1200

108 1 10527 TUBE SILICON CLEAR 6x3x700

109 1 10377 ELECT JUNCTION BOX BODY R750

110 1 7972 ELECTRICAL JUNCTION BOX COVER

111 1 9073 SCREW M4 X 20 PAN PHIL ZINC

112 1 9233 WASHER SPRING M4 ZP

113 2 9186 NUT M4 ZP

114 2 9231 WASHER FLAT M4 ZP

115 1 10378 HARNESS FUSED POWER USA RHFE

116 1 10281 HARNESS FLAME ROD

117 1 10282 HARNESS THERMISTOR

118 1 10283 HARNESS OHS THERMAL FUSE

119 1 10284 HARNESS CONTROL PANEL

120 1 10285 HARNESS RECEIVER

121 1 10286 HT LEAD

122 1 10289 HARNESS COMB FAN

123 1 10348 HARNESS MAIN RHFE750ETR

124 1 10480 HARNESS COMB FAN SPEED

125 1 10539 HARNESS PRESSURE SW US

126 1 10507 HARNESS COMB FAN THERMISTOR FLY

127

128

129 1 10776 PLASTIC CLIP KIT RHFE750

130 1 10766 SPARKER KIT RHFE750 INCLUDES PCB SPACERS

131 1 10773 CONTROL PAN COVER KIT RHFE750 INCLUDES BUTTON

132 1 10259 TRANSFORMER US RHFE750ETR

133 1 10563 CABLE CLAMP RHFE750 USA

134 1 10506 HARNESS COMB FAN THERMISTOR

1 10767

GROMMET KIT RHFE750

** Always refer to the data plate for correct information.

CONTAINS 4 x Ø4 AND

2 x 2Ø1.8 HOLED GROMMETS

ALSO COMES AS PART OF

COMBUSTION FAN

Rinnai Corporation RHFE-750ETR 35

Page 36

Consumer Support

Warranty Information

The installer is responsible for your heater’s correct installation.

Please complete the information below to keep for your records:

Purchased from: ___________________________________________________________

Address: _____________________________ Phone: ___________________________

_____________________________

Date of Purchase: __________________________________

Model No.: ________________________________________

Serial No.: ________________________________________

Installed by: ___________________________ Installer’s License No.: _________________

Address: _____________________________ Phone: _____________________________

Date of Installation: __________________________________

Limited Warranty

RHFE-750ETR Direct Vent Fireplace

What is covered?

This Warranty covers any defects in materials or workmanship, subject to the terms stated below. This Warranty

extends to the original purchaser and subsequent transferees, but only while the product remains at the site of

the original installation. This Warranty only extends through the first installation of the product and terminates if

the product is moved or reinstalled at a new location.

How long does coverage last?

All parts…………………..2 years from date of purchase

What will Rinnai do?

Rinnai will repair any part or component that is defective in materials or workmanship as set forth as follows. All

repair parts must be genuine Rinnai parts. All repairs or replacements must be performed by an individual or

servicing company that has been authorized by Rinnai.

Replacement of the product may be authorized by Rinnai only. Rinnai does not authorize any person or

company to assume for it any obligation or liability in connection with the replacement of a product. If Rinnai

determines that repair of a product is not possible, Rinnai will replace the product with a comparable product, at

Rinnai’s discretion.

36 Rinnai Corporation RHFE-750ETR

Page 37

Limited Warranty - continued

How do I get service?

You must contact a qualified/authorized service provider for the repair of a product under this Warranty. For the

name of a qualified/authorized service provider please contact your place of purchase, visit the Rinnai website

(www.rinnai.us

Georgia 30269.

Proof of purchase is required. You may show proof of purchase with a dated sales receipt, or by completing and

mailing the enclosed Registration card within 30 days of purchasing the product. Please complete the enclosed

Registration card and mail it to Rinnai at the address shown on the card. Receipt of this card by Rinnai will

constitute proof-of-purchase for this product. However, return of the Registration card is not necessary in order

to validate this Warranty.

What is not covered?

This Warranty does not cover any failures or operating difficulties due to accident, abuse, misuse, alteration,

misapplication, force majeure, improper installation, improper conversion, improper maintenance or service, or

for any other causes other than defects in materials or workmanship. This Warranty does not apply to any

product whose serial number or manufacture date has been defaced.

Rinnai is not liable for any special, incidental, indirect or consequential damages that may arise, including

damage to person or property, loss of use, or inconvenience. Some states do not allow the exclusion or

limitation of incidental or consequential damages, so the above limitation may not apply to you.

Limitation on implied warranties

), call Rinnai at 1-800-621-9419 or write to Rinnai at 103 International Drive, Peachtree City,

Any implied warranties of merchantability and fitness arising under state law are limited in duration to the period

of coverage provided by this limited Warranty, unless the period provided by state law is less. Some states do

not allow limitations on how long an implied Warranty lasts, so the above limitation may not apply to you.

This Warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Rinnai Corporation RHFE-750ETR 37

Page 38

Notes

38 Rinnai Corporation RHFE-750ETR

Page 39

Notes

Rinnai Corporation RHFE-750ETR 39

Page 40

Manufactured by

Rinnai New Zealand LTD

691 Mt Albert Road

Royal Oak, Auckland

For information on Rinnai’s products contact

103 International Drive

Peachtree City, GA 30269

Phone: 1-800-621-9419

Fax: 1-888-474-6624

15237 (Issue B)

Loading...

Loading...