Rinnai RHFE-557FTR, RHFE-309FT, RHFE-556FTR, RHFE-556FDT, RHFE-559FT Installation Manual

...

To Suit Models:

RHFE-308FTR

RHFE-309FT

RHFE-556FTR

RHFE-556FDT

RHFE-557FTR

RHFE-559FT

RHFE-1004FTR

RHFE-1004FDT

Energysaver Space Heater

Co-Axial Flue System

Installation Manual

These components shall be installed in accordance with:

• Manufacturer’s Installation Instructions

• Current AS/NZS 3000, AS/NZS 3500 & AS 5601

• Local Regulations and Municipal Building Codes

THESE COMPONENTS MUST BE INSTALLED, SERVICED AND REMOVED BY AN AUTHORISED PERSON!

ONLY THE FLUE SYSTEM COMPONENTS SPECIFIED IN THIS MANUAL MUST BE USED. COMPONENTS

NOT SPECIFIED IN THIS MANUAL, WHETHER MANUFACTURED BY RINNAI OR OTHERWISE, ARE NOT

COMPATIBLE AND “MUST NOT” BE USED!

The Rinnai Energysaver® Co-Axial flue is certified as part of the

Rinnai Energysaver space heaters that have the designation ‘RHFE’ in

the model number .

Only an authorised person must install, service and remove the

Rinnai Energysaver® space heater & flue system.

Only the flue system components described in this manual must be

used.

Components that are not described in this manual, whether

manufactured by Rinnai or otherwise, are not compatible and must

not be used. Rinnai appliance warranty conditions may be voided if

non Rinnai flue components are fitted.

Rinnai New Zealand Ltd. i ES Flue Installation Manual

CONVENTIONS USED IN THIS MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

REGULATIONS, CLEARANCES & GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

FLUE TRANSITION CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

LOCATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

LUBRICATING INNER PIPE COMPONENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

INSTALLATION CONFIGURATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

WALL PENETRATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

FLUE KIT COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

FLUE COMPONENT ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

CREATING A “DIRECT” FLUE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

CREATING A “DIRECT EXTENDED” FLUE INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

CREATING AN “EXTERNAL WALL” FLUE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

CREATING A “SIDEWAYS” FLUE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

CREATING AN “UNDER FLOOR” FLUE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

CUTTING ~ ESDFK

, ESPIPE900 & ESROOFCOWL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

COMPONENT ASSEMBLY & CONNECTION ~ ESPIPE900 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

ASSEMBLING WALL TERMINAL ~ ESDFK & ESPIPE900. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

ASSEMBLING AN ON-WALL TERMINAL ~ ESWTERM, ESBEND & ESPIPE900. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

COMPONENT ASSEMBLY & CONNECTION ~ ESBEND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

COMPONENT ASSEMBLY & CONNECTION ~ ESCONDK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

COMPONENT ASSEMBLY & CONNECTION ~ ESROOFCOWL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

CREATING AN “IN-WALL” FLUE INSTALLATION ~ ESFKIT03 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

CONNECTING HEATER EXHAUST & AIR SUPPLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

CONNECTING HEATER EXHAUST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

CONNECTING COMBUSTION AIR HOSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

CONTACT INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

TABLE OF CONTENTS

Rinnai New Zealand Ltd. 1 ES Flue Installation Manual

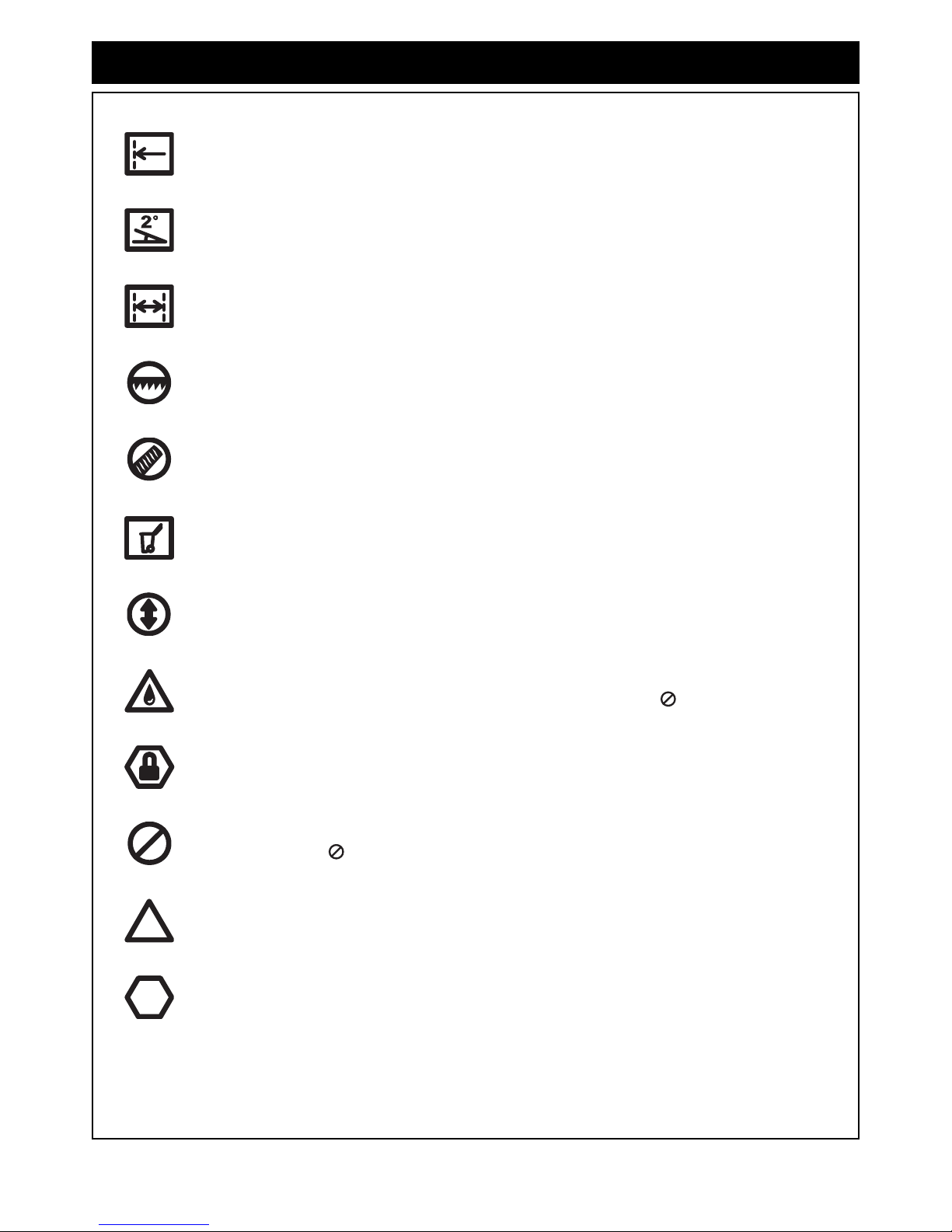

CONVENTIONS USED IN THIS MANUAL

The following symbols are used to highlight sp ecic requirements during installation steps.

The heater and the flue system shall be installed in accordance with the following:

CLEARANCES

Where required clearances will be provided and must be observed.

FALL

Ensure that the specified 2° fall is maintained to either the terminal or condensate trap.

MEASURE

Required measurements will be provided and MUST BE observed for correct installation.

CUT

Cut as required to the specified measurements.

FINISH

Ensure that burrs and swarf are removed from all cut ends.

DISCARD

Denotes items that are not required for the specific installation.

OBSERVE CORRECT ORIENTATION

Where specified ensure that components are installed with the correct vertical or horizontal

orientation.

LUBRICATE

Use the supplied container of silicon grease to lubricate components. DO NOT use other

lubricants as these may damage the flue components.

SECURE

Where specified secure components with either install

er provided or component supplied fixings.

DO NOT

Failure to observe DO NOT instructions will void the warranty of an appliance and may cause

injury or death.

NOTE / IMPORTANT

Important notes or general hints and guides provided to ease the installation.

CAUTION

Caution notes and or warnings that MUST BE observed for safe and correct installations.

!

!

Rinnai New Zealand Ltd. 2 ES Flue Installation Manual

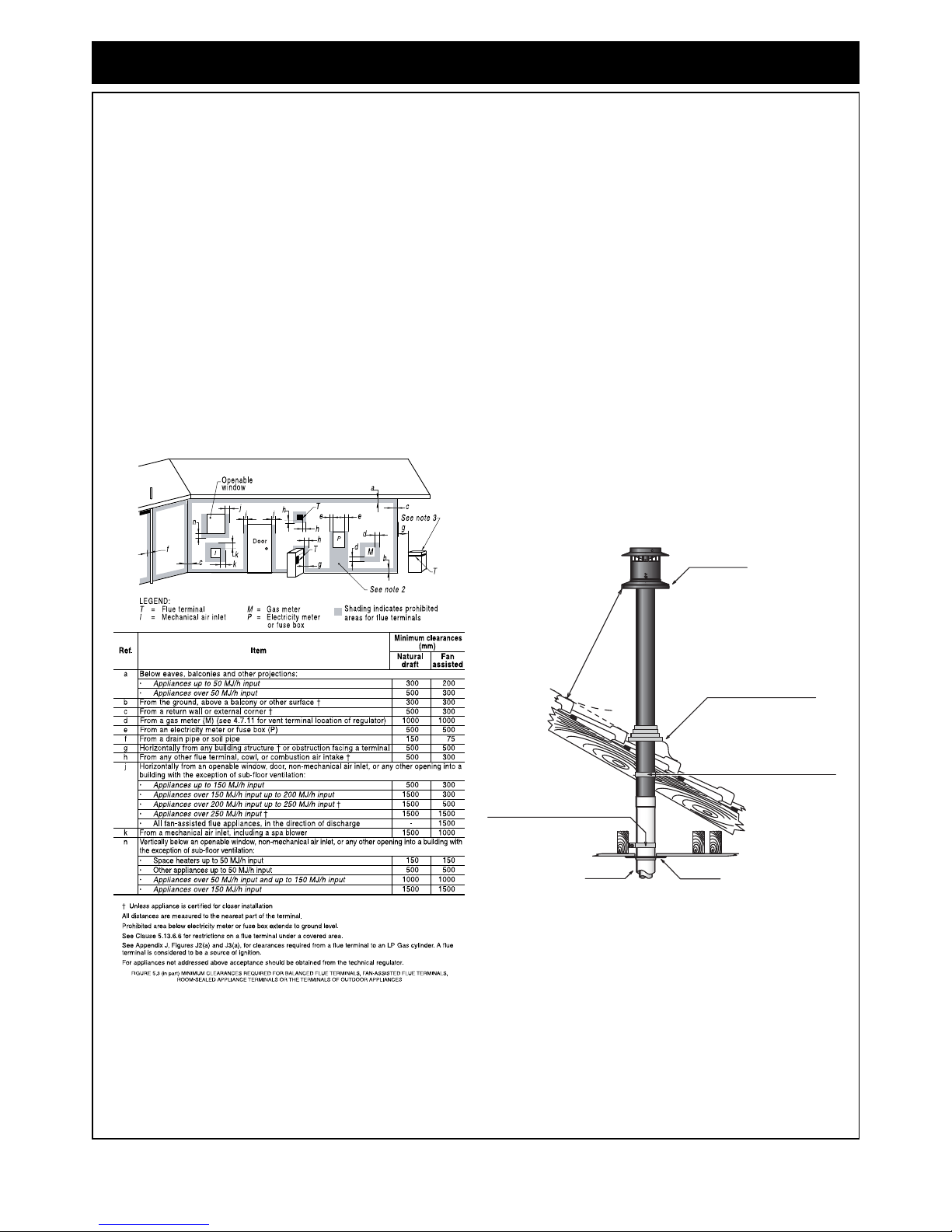

REGULATIONS, CLEARANCES & GENERAL INFORMATION

• The requirements of the current version of AS 5601 (Gas Installations)

Note that AS 5601-2004 is referred to in this instruction and was current at the time of printing, but may have

since been superseded. It is the Installer’s responsibility to ensure that requirements of the current version of

AS 5601 are met.

• Manufacturers installation instructions.

Before commencing an installation, read the installation sections of the ‘Customer and Installation Manual’

supplied with the heater.

• Local & Municipal building codes.

• Any other relevant Statutory Regulation.

• Rinnai Energysaver space heater when co rrectly installed with Rin nai a pproved flue components are roomsealed appliances and no internal ventilation is required.

• Rinnai Energysaver space heater is fan-assisted. Therefore the fan assisted flue clearance dimensions from

AS 5601 extract shown on this page must be used.

• The o uter pla stic se ction o f the Co-Axial flue complies with temperature ha zard requirements an d ca n be

installed with zero clearance to combustible material.

• Vertical clearances when using a roof terminal (ESROOFCOWL) are shown in Fig.1.

If in doubt contact Rinnai.

Horizontal Clearances (Extract AS 5601-2004 5.13.6.5 Fig. 5.3)

Vertical Clearances Fig.1

Minimum Clearance 500 mm

ESROOFCOWL

Decktite or lead collar flashing

ESPLATE

ESPIPE900

Flue pipe clip supplied with ESPIPE900

Flue pipe clip supplied with ESROOFCOWL

Rinnai New Zealand Ltd. 3 ESFlue Installation Manual

REGULATIONS, CLEARANCES & GENERAL INFORMATION

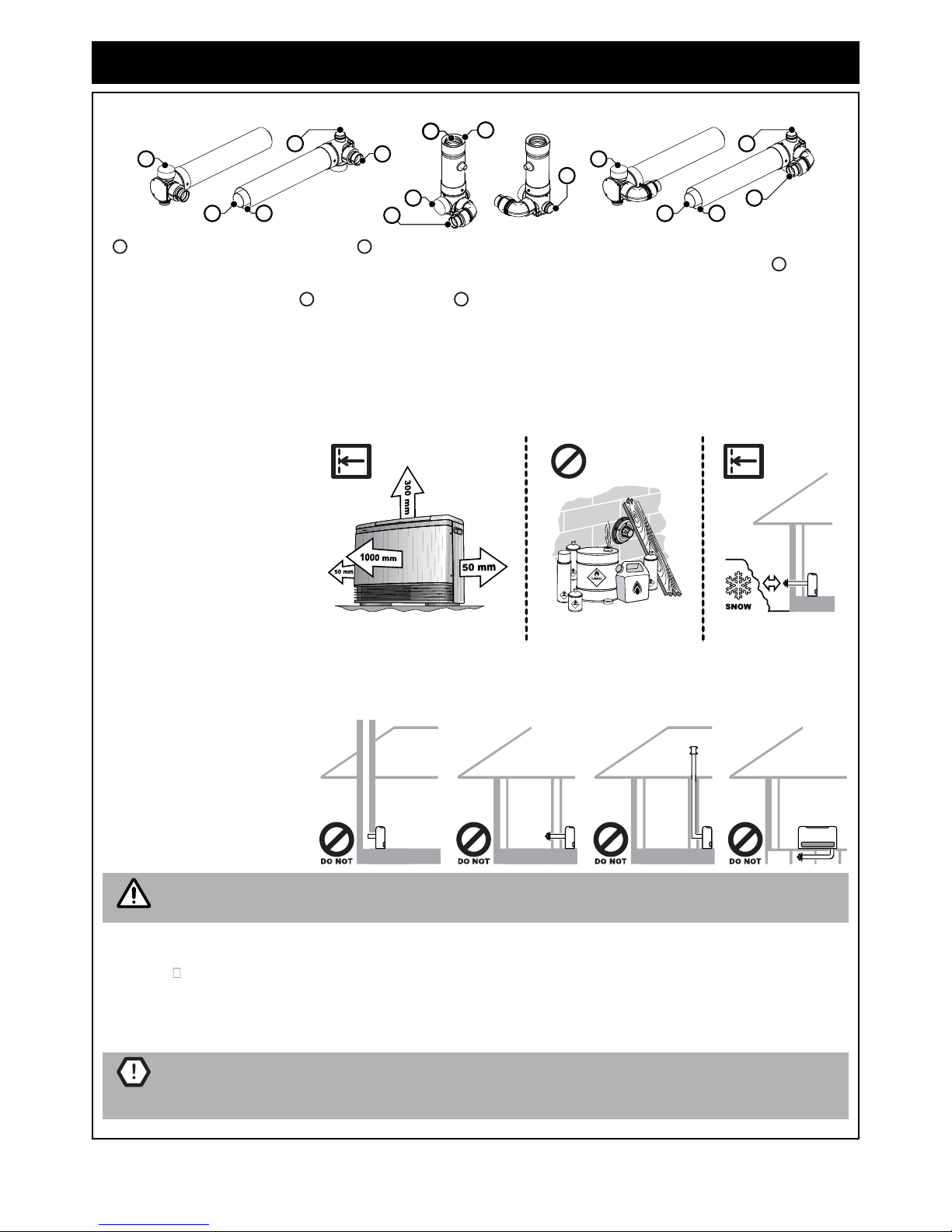

FLUE TRANSITION CONNECTIONS

Flue exhaust connection to heater. Combustion air inlet connection to heater (Right hand ~ Small connection

for models 308, 309, 556, 557, 559 heaters. Left hand ~ Large connection for model 1004 heaters). Rubber

combustion air inlet cap (when fitted) is designed to fit both the large and small combustion air inlet and MUST

cover the air inlet not in use. Combustion air inlet. Exhaust outlet.

LOCATION

LUBRICATING INNER PIPE COMPONENTS

The inner

ue pipe joints are sealed with an “O” ringseal.

To help ensure a good seal and to ease assembly, a small tub of silicone grease is provided with the Direct Flue

Kit (ESDFK) and the In-Wall Transition Kit (ESKIT03). Use this silicone grease tolubricatethe “O” ring on the inner

pipes prior to assembly.

This appliance is NOT suitable for inbuilt installations.

This appliance MUST NOT be installed where curtains or other combustible materials could come into contact with

it. In some cases curtains may need restraining.

Heat emanating from the front

of this appliance may over time

affect t

he appearance of some

materials used for flooring such

as carpet, vinyl, cork or timber.

This effect may be amplified if

the air in the room contains

cooking vapours or cigarette

smoke. To avoid this possibility

it is recommended that a mat be

placed in front of the appliance,

extending at least 750 mm in

front of it.

The flue terminal MUST BE positioned away from flammable materials.

In areas subject to heavy snowfall, keep snow clear of flue terminal at all times.

• DO NOT flue into natural

draught flues or fireplaces.

• DO NOT flue into other

rooms, roof spaces or into

under floor spaces.

• DO NOT install the heater

an unusually dust

y area.

For other important information regarding the location of the heater refer to the instructions

supplied with the appliance.

Use ONLY the supplied silicone based “O Ring” seal lubricant.

DO NOT use petroleum based lubricants such as petroleum jelly. Petroleum jelly or similar

petroleum based lubricants will cause deterioration of the ‘O’ ring seals.

2

1

3

1

3

5

4

3

1

4

2

5

2

5

4

1 2

3

4 5

DO NOT

IMPORTANT

CAUTION

Rinnai New Zealand Ltd. 4 ES Flue Installation Manual

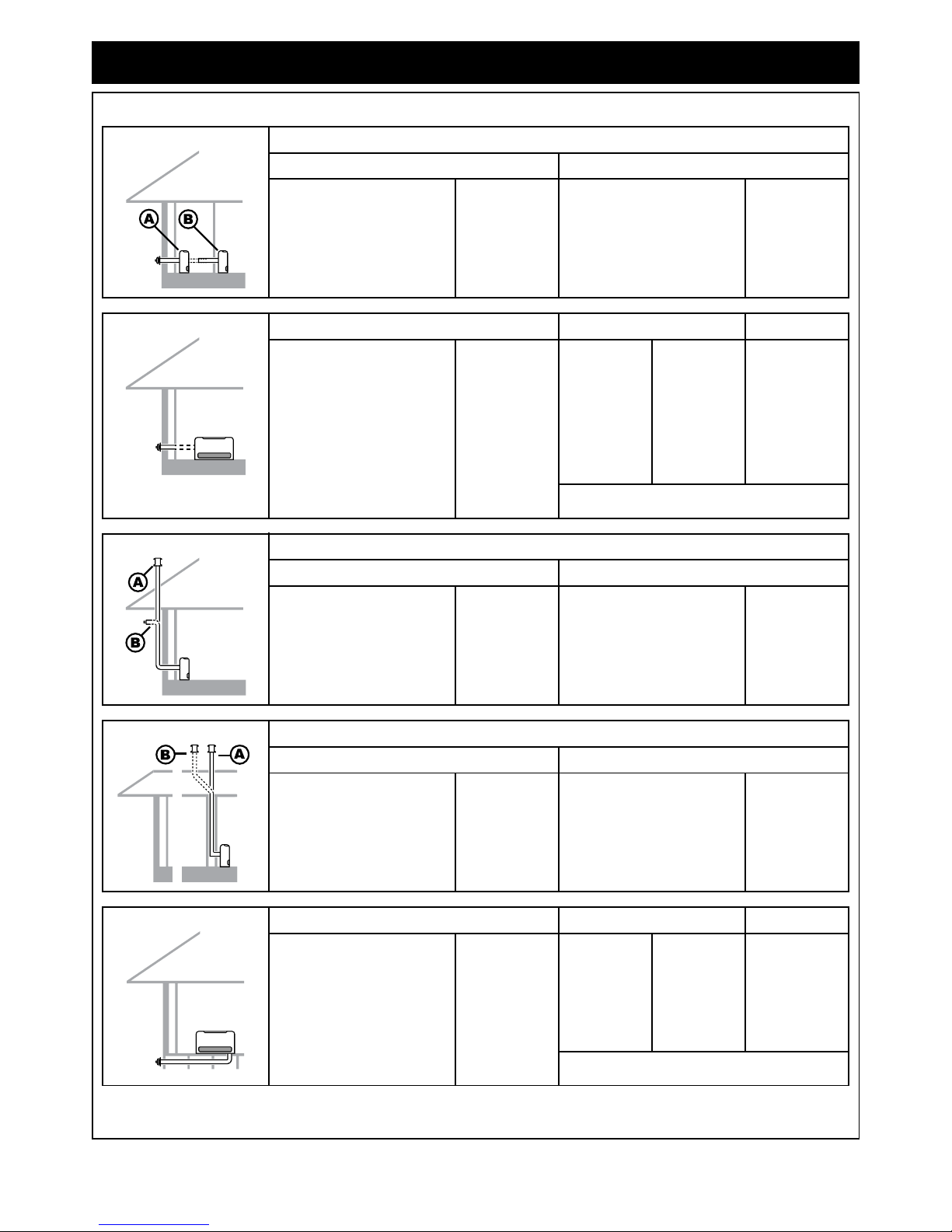

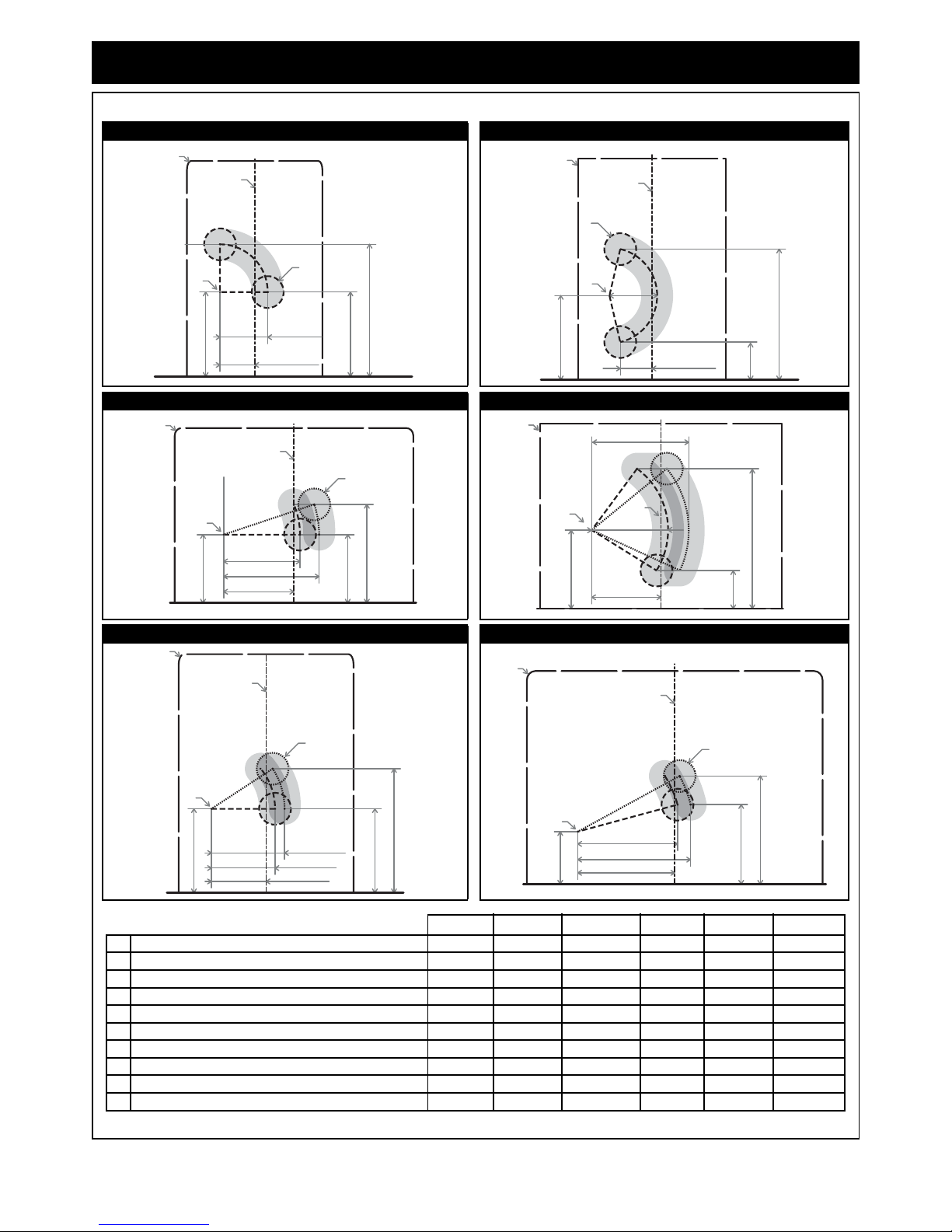

INSTALLATION CONFIGURATIONS

The following configurations are currently available. For alternative configurations contact Rinnai.

DIRECT/EXTENDED Components

Option A (Direct) Option B (Direct Extended)

Direct Flue Kit ESDFK Direct Flue Kit

Co-Ax Pipe 900mm (Optional) #

ESDFK

ESPIPE900

SIDEWAYS Components Back Cover Kit Depth

Direct Flue Kit

Co-Ax Pipe 900mm #

Back Cover Kit

ESDFK

ESPIPE900

(refer page 8 for Kit

contents)

308

309

556

557

559

1004

ESBSKA

ESBSKE

ESBSKB

ESBSKC

ESBSKF

ESBSKD

200 mm

205 mm

200 mm

200 mm

205 mm

200 mm

A Back Cover Kit is required when the flue system is installed

in a sideways configuration.

EXTERNAL WALL Components

Option A (Vertical Termination) Option B (On Wall Termination)

Direct Flue Kit

Co-Ax Pipe 900mm #

Bend (2 x 45º)

Condensate Trap

Roof Cowl

ESDFK

ESPIPE900

ESBEND

ESCONDK

ESROOFCOWL

Direct Flue Kit

Co-Ax Pipe 900mm #

Bend (45º) x2

Condensate Trap

Wall Terminal Kit

ESDFK

ESPIPE900

ESBEND

ESCONDK

ESWTERM

IN-WALL Components

Option A (Direct) Option B (Offset)

Vertical Adaptor Kit §

Co-Ax Pipe 900mm #

Roof Cowl

ESKIT03

ESPIPE900

ESROOFCOWL

Vertical Adaptor Kit §

Co-Ax Pipe 900mm #

Bend (45º) x2

Roof Cowl

ESKIT03

ESPIPE900

ESBEND

ESROOFCOWL

UNDER FLOOR Components Back Cover Kit Depth

Direct Flue Kit

Co-Ax Pipe 900mm #

Bend (2 x 45º)

Wall Terminal Kit

Back Cover Kit

ESDFK

ESPIPE900

ESBEND

ESWTERM

(refer page 8 for Kit

contents)

308

309

556

557

559

1004

ESBSKA

ESBSKE

ESBSKB

ESBSKC

ESBSKF

ESBSKD

200 mm

205 mm

200 mm

200 mm

205 mm

200 mm

A Back Cover Kit is required when the flue system is installed

in a under floor configuration.

# Order lengths as required § Includes Condensate Trap (ESCONDK)

Rinnai New Zealand Ltd. 5 ES Flue Installation Manual

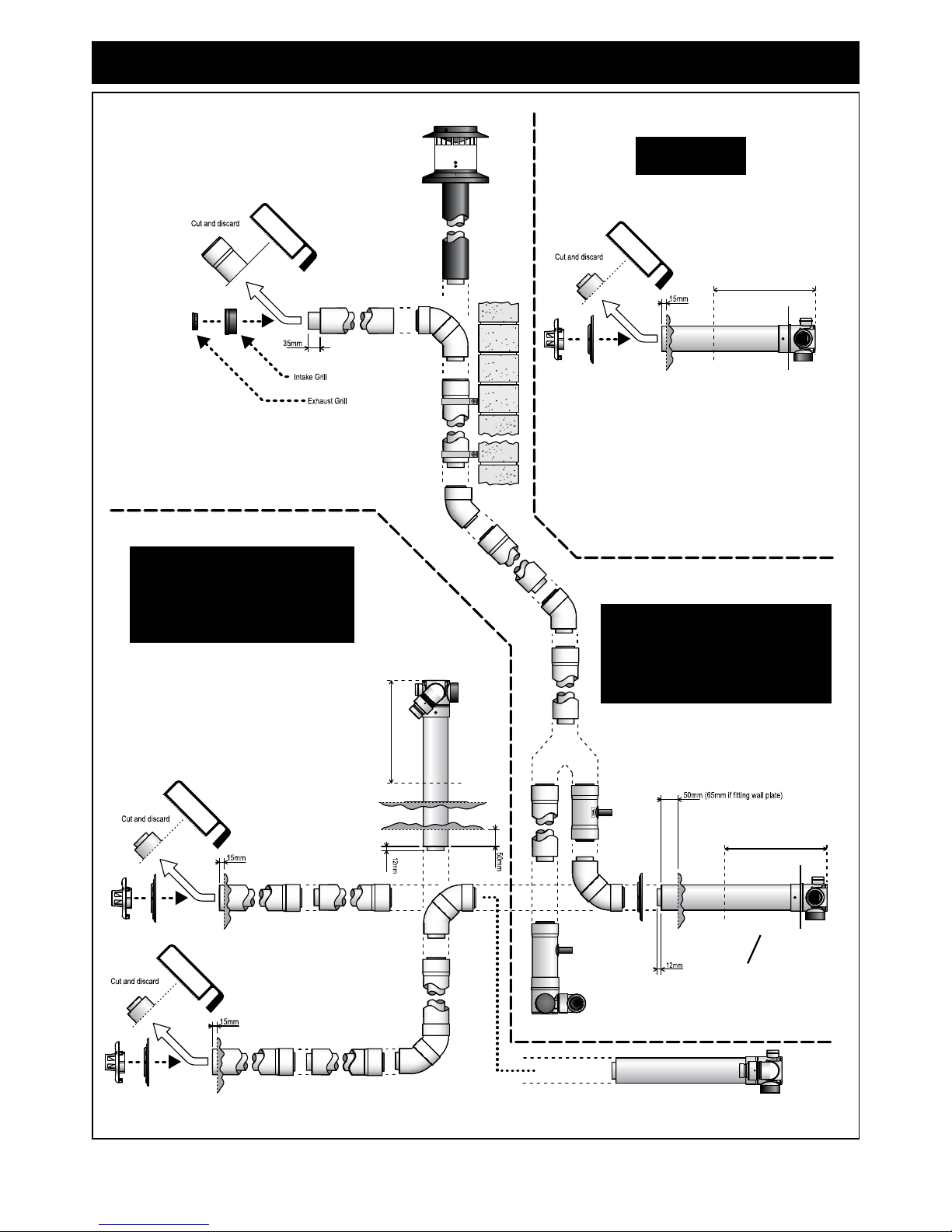

INSTALLATION CONFIGURATIONS

When cutting the flue transition

for joining to other components

the minimum total length is not

to be less than 300mm!

When cutting the flue transition

for joining to other components

the minimum total lengthis not

to be less than 300mm!

• DIRECT EXTENDED

• EXTERNAL WALL

• IN-WALL

• DIRECT EXTENDED

• UNDER FLOOR

•SIDEWAYS

SIDEWAYS

IN-WALL

EXTERNAL

WALL

DIRECT

EXTENDED

UNDER FLOOR

When cutting the flue transition

for joining to other components

the minimum total length is not

to be less than 300mm!

DIRECT

•DIRECT

Rinnai New Zealand Ltd. 6 ES Flue Installation Manual

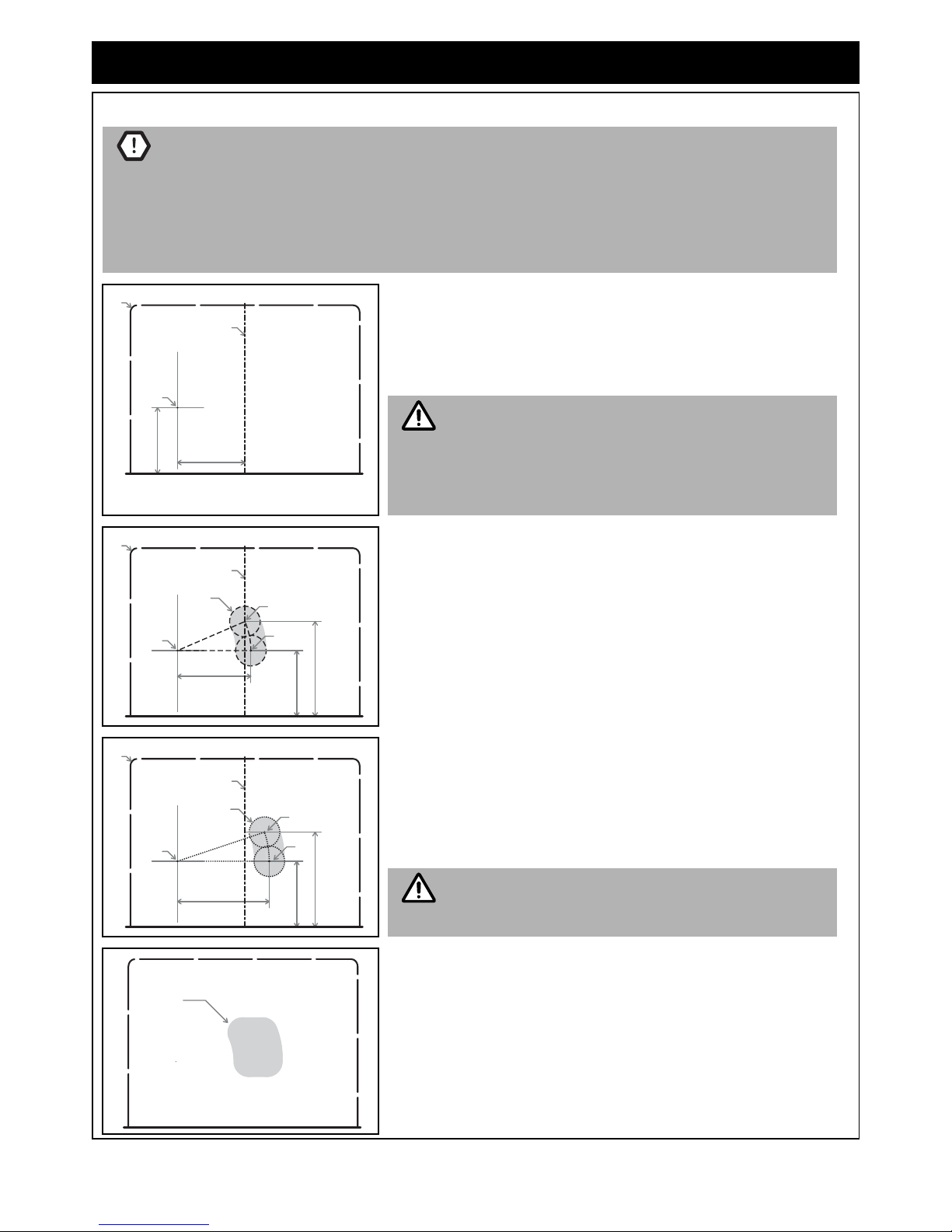

WALL PENETRATIONS

It is critical that any wall penetrations are located correctly.

Ensure there are no wall studs, noggins, wiring or other obstruction within the wall cavity where

the flue is proposed to penetrate.

Ensure the location of the flue terminal can comply with the requirements of AS 5601. Figure 5.3

from AS 5601-2004 and additional information is shown on page 2.

Especially relevant is the requirement to have a minimum of 300mm clearance between the flue

terminal a nd t he finish ed ground lev el. It is not pe rmissible to excavate a ho le t o ob tain the

required 300mm clearance, unless there is sufficient drainage provision.

1. Select the desired location i for the Energysaver Heater.

2. Find th e v ertical ce ntre lin e of the a ppliance ii an d mar k th is

location on the wall.

3. Using Measurements A & B from Table 1, mark off the arc centre

iii on the wall.

The arc centre iii corresponds to the pivot point centre

of the telescopic flue elbow on the heater.

The RHFE-308 and RHFE-309 have a fixed length nontelescopic flue elbo w. Hen ce ac curate marking of th e

penetration a rc a nd a ssociated a rea are th erefore

especially critical.

4. From the arc axis iii use the measurements C, D & E from Table

1. to draw an arc on the wall.

The lowe r end poin t of th e ar c iv will be the lower limit of the

minimum horizontal and vertical centre of penetration G.

The upper end point of the arc v will the be the upper limit of the

minimum horizontal and vertical centre of penetration G.

5. From the arc axis iii use the measurements F, D & E from Table

1. to draw an arc on the wall.

The lowe r end poin t of th e ar c vi will be the lower limit of the

maximum horizontal and vertical centre of penetration G.

The upper end point of the arc vii will be the upper limit of the

maximum horizontal and vertical centre of penetration G.

Due to the fixed length non-telescopic flue elbow of the

RHFE-308 and RHFE-309 model heaters measurements

C & F are the same for these model only.

6. The penetration may be mad e anywhere within the confines of

the shaded minimum and maximum areas viii defined by the two

arcs.

CAUTION

B

A

iii

i

ii

IMPORTANT

G

D

E

C

iii

iv

v

i

ii

D

E

F

iii

vi

vii

G

i

ii

IMPORTANT

viii

Rinnai New Zealand Ltd. 7 ES Flue Installation Manual

WALL PENETRATIONS

Below are diagrams and associated dimension tables for wall penetrations for each Energysaver heater model.

Table 1.

RHFE 308 RHFE 309

RHFE 556 RHFE 559

RHFE 557 RHFE 1004

All dimension are in millimetres

RHFE 308 RHFE 309 RHFE 556 RHFE 557 RHFE 559 RHFE 1004

i Width of appliance 426 465 750 550 760 930

ii Centre-Line of appliance 213 233 375 275 380 465

iii Arc axis (Axis point of the flue elbow) — — — — — —

A Horizontal distance from Centre-Line to arc centre 110 100 220 172 217 305

B Vertical distance from base to arc centre 265 265 215 264 247 165

C Minimum horizontal limit of arc 150 150 240 200 240 325

D Minimum vertical limit of arc 265 120 215 264 120 250

E Maximum vertical limit of arc 415 410 310 390 440 340

F Maximum horizontal limit of arc 150 150 300 230 305 365

G Penetration diameter 100 100 100 100 100 100

D

B

E

A

i

ii

G

C & F

iii

i

C & F

iii

ii

B

D

E

A

G

D

B

E

A

C

F

G

ii

I

iii

A

iI

ii

C

F

D

E

B

iii

D

B

E

A

C

F

G

ii

i

iii

D

B

E

A

F

C

G

ii

i

iii

Loading...

Loading...