Rinnai RHFE1000, RHFE0800, RHFE1500 Installation Manual

Models: RHFE0800, RHFE1000, RHFE1500

Linear collection gas fireplaces

Installation guide

Important

Appliance must be installed with a Rinnai approved ue

system.

This appliance shall be installed in accordance with:

- Manufacturer’s installation instructions

Current:

- AS/NZS 5601 Gas Installations

- AS/NZS 5263 Gas Appliances General Requirements

- AS/NZS 3000 Electrical Standards

- AS/NZS 3500 Plumbing and Drainage Standards

Installation, servicing and repair shall be carried out only by

authorised personnel.

Warning

Improper installation, adjustment, alteration, service or

maintenance can cause property damage, personal injury or

loss of life.

For more information about buying, using, and servicing of

Rinnai appliances call: 0800 RINNAI (0800 746 624).

Rinnai New Zealand Limited

105 Pavilion Drive, Mangere, Auckland

PO Box 53177, Auckland Airport, Auckland 2150

Phone: (09) 257 3800

Email: info@rinnai.co.nz

Web: www.rinnai.co.nz

www.youtube.com/rinnainz

www.facebook.com/rinnainz

Installer please note

When completing the installation it is ideal to have the homeowner present to test the Wi-Fi

connectivity and correct operation of the re.

Contents

Before you start ....................................................4

Specication .........................................................5

Unit dimensions (mm)...........................................6

Clearances from combustibles .............................7

Hearths .................................................................9

TV installation .......................................................10

Installation overview .............................................11

Cavity ventilation ..................................................12

Framing dimensions .............................................13

Gas supply............................................................17

Room thermistor ...................................................17

Electrical supply....................................................18

Flue terminal position ...........................................18

Installing the Linear into the cavity .......................19

Removing the glass front ......................................20

Commissioning .....................................................21

Wiring diagram .....................................................25

Burn media installation .........................................26

Test operation and lighting sequence ...................27

Check Wi-Fi connection........................................28

Installing the wall lining .........................................29

Flueing

General ueing guidelines ....................................36

Flueing options .....................................................38

Air hose connection ..............................................44

Linear ue components ........................................45

Before you start

H

Unpack the appliance and components and check for damage. DO NOT install any damaged

items. Check all components have been supplied, refer table below, and that you have the

correct gas type.

Read these instructions to get an overview of the steps required before starting the installation.

Failure to follow these instructions could cause a malfunction of the appliance. This could result in

serious injury and/or property damage. There are also some sections in this guide that are crtical

to a successful installation, for example:

• Preline instructions regarding combustible and non-combustible materials

pages 7, 9, 29-35

• Cavity ventilation considerations page 12

• Framing dimensions in order to centre the glass of the re pages 13-16

Linear boxed dimensions

Linear 800 Linear 1000 Linear 1500

Height

Width

Depth

W

D

Weight

1156 mm

1350 mm

530 mm

120 kg

931 mm

1550 mm

530 mm

125 kg

931 mm

2050 mm

530 mm

140 kg

With the Linear engine comes the:

- Glass front

- Remote control (batteries included)

- Flue lock bracket and truss screws (x2)

- Operation and Installation guides

- Burn media installation guide

- Colour burn media placement sheet (attached to the glass frame)

- Commissioning sheet (in a plastic pouch inside the unit)

- Reducing are

- Linear 800 FlameTech or standard log set (inside the engine)

The burn media for the Linear 1000 and 1500 models will come packaged separately

in one large box.

Flue components and accessory items are ordered separately.

Installer please note

The Linear carton has a unit protection cutout that can be xed to the appliance to protect the

re from damage, debris, and dust, until nal commissioning can be completed.

4 | Linear installation guide 13563-H 08-19

Specication

Inbuilt power ued convection fan re operated by a simple infra-red remote, or by the Rinnai Wi-Fi

app that allows full thermostatic control as well as other features such as timers. Dierent burn media

options available.

Specication summary

Input Output* Heating area**

800 15-35 MJ/h 3.1-7.5 kW 70-120 m

800FT 15-35 MJ/h 3.1-7.7 kW 71-123 m

1000 14-34 MJ/h 3.1-7.4 kW 69-118 m

1500 14-40 MJ/h 3.1-8.5 kW 79-135 m

2

2

2

2

Eciency = > 75% (all models on high)

Gas type = NG or ULPG

* Will vary according to gas type and ue conguration

** Will vary depending on geographical location in NZ

Suitability

Ideal for living rooms and open plan areas.

Versatile power ue system makes for easy

installation in almost any living space, including

bedrooms.

The Linear is ideal for a new build installation.

Installation considerations

Room size—smaller rooms will heat up quickly,

and due to the eciency of the appliance, if in

thermostatic mode, will reduce to a low ame

prole.

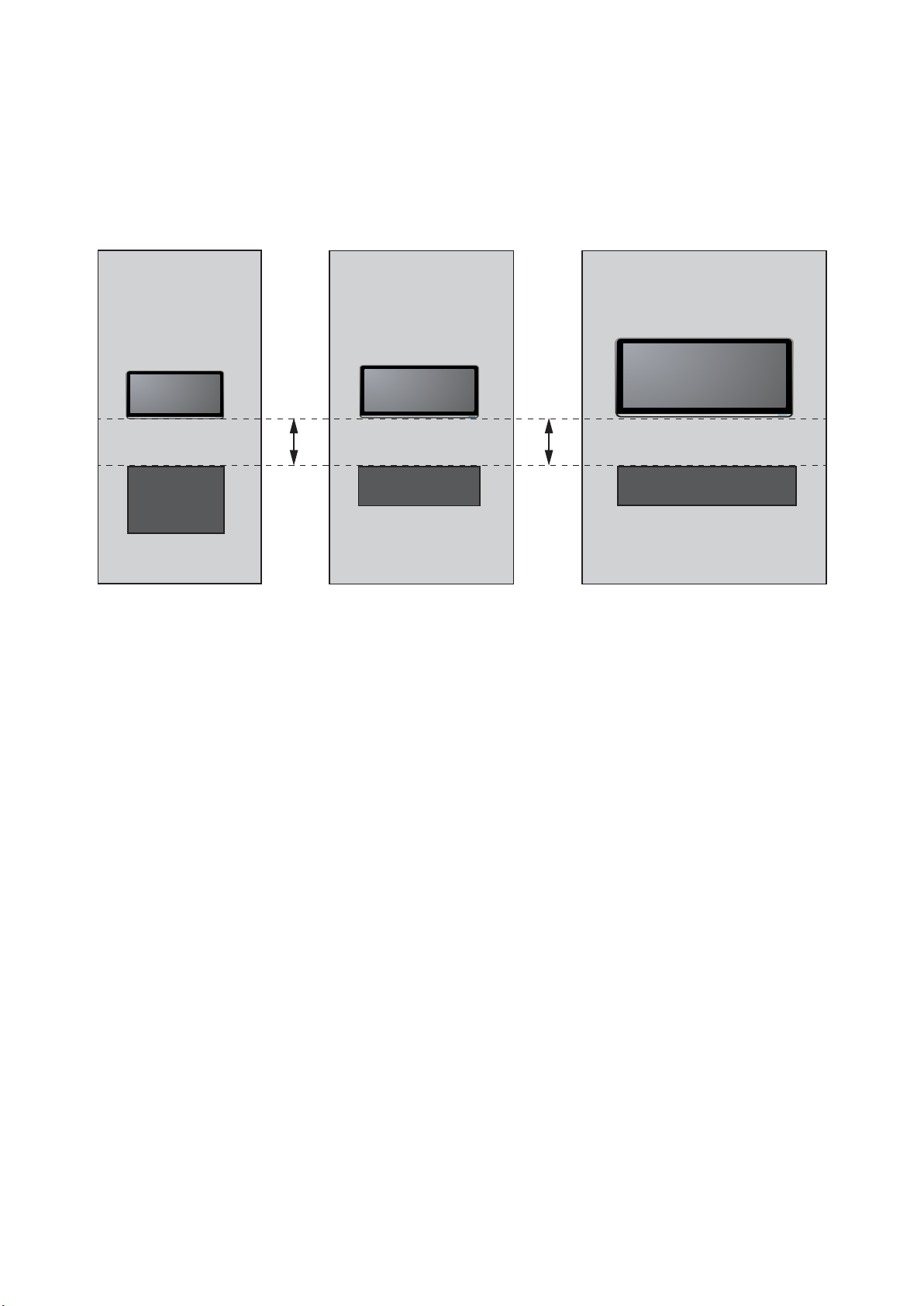

Installation of the Linear higher up the wall, in

some room congurations, can create draughts

due the convection air being pushed out from

the top of the appliance.

For more accurate room temperature control

and to prevent heat build-up inside the cavity,

it is strongly recommended to ventilate the

replace enclosure. Refer p.12 for more

information.

Convection fan

2-speed fan. Heat is distributed from the top of

the appliance.

800/1000

Base of the combustion chamber, LHS, on the

convection fan access panel.

Gas connection

½ “ BSP, the gas supply terminates inside the

unit—lower left hand side of the appliance.

Ignition: Continuous spark electronic ignition.

Noise level: 37-45 dB(A)

Power ue

Inner 50 mm, outer 70~80 mm. Appliance must

be installed with a Rinnai ue system.

Power consumption/electrical supply

High = 50 W

Standby = <8 W

The Linear has a 1.5 m power cord with a three

pin plug supplied. The power cord passes

through a slot in the right hand side of the

appliance.

Safety devices

Flame failure sensing system, pressure relief,

overheat safety switch, air temperature sensor,

thermal fuse, overcurrent fuse, and spark

detection.

Temperature control

The Linear can be operated using the basic

infra-red remote, or for more features, such as

timers and thermostatic control, using Rinnai’s

Wi-Fi replace controller app.

Weights

Unit Packaged

800 100 kg 120 kg

Data plate

1500

Base of the combustion chamber towards the

LHS, between the gas control and convection

fan access panel.

1000 100 kg 125 kg

1500 110 kg 140 kg

Linear installation guide 13563-H 08-19 | 5

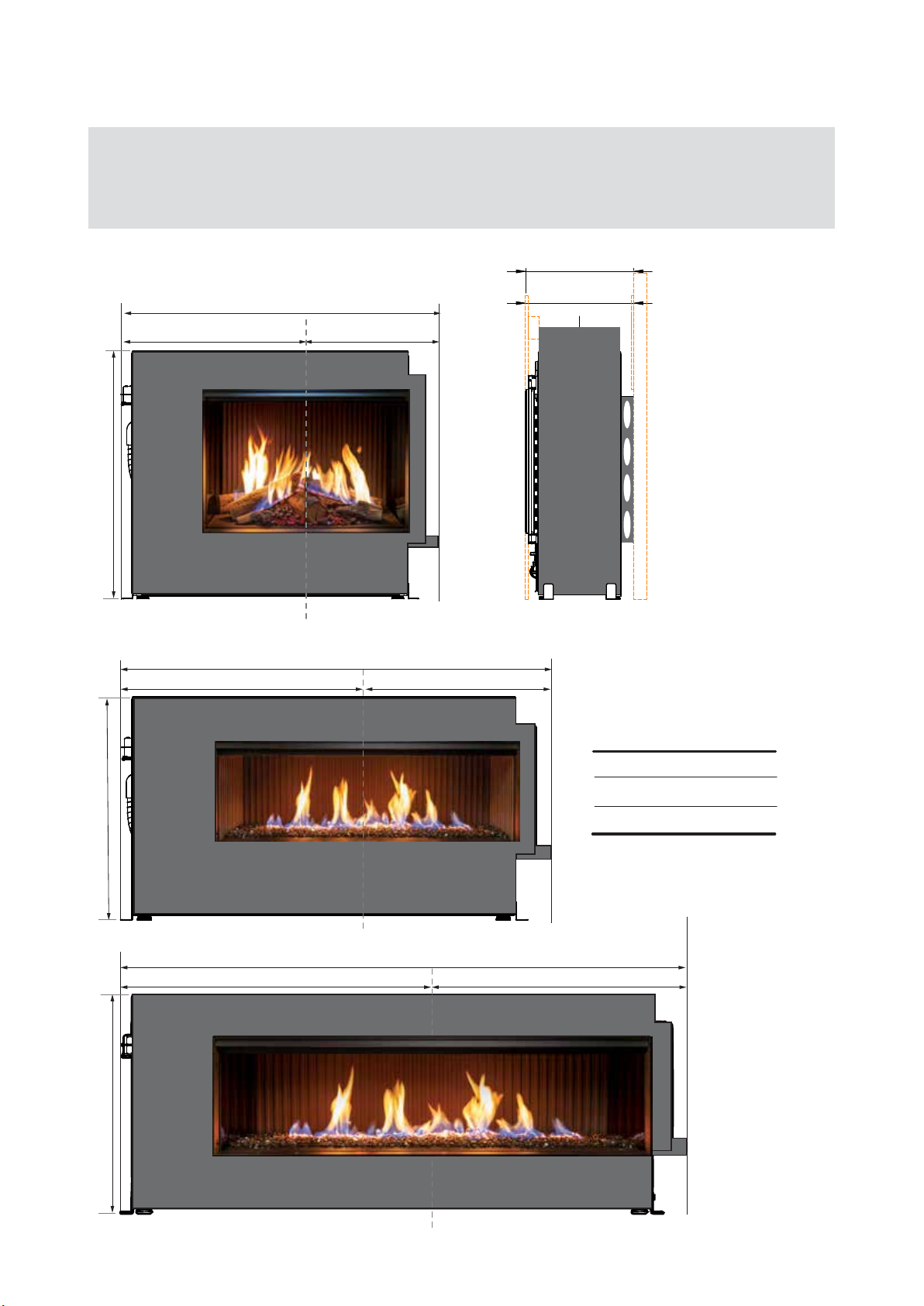

Unit dimensions (mm)

IMPORTANT

• These are the unit dimensions only, not the framing/cavity dimensions, refer p.14-16

• The centre of the glass is NOT the centre of the appliance

• Depth dimension is the same for all models

425 min.

singled sided

425 face-to-face

1245 mm

726 mm 519 mm

966 ± 5 mm

double sided

Adjustable feet on all models

Glass centreline

741 ± 5 mm

Glass centreline

1435 mm

816 mm 619 mm

Glass centreline

1935 mm

1066 mm

Glass dimensions

800 800 x 505 mm

1000 1000 x 280 mm

1500 1500 x 280 mm

869 mm

741 ± 5 mm

6 | Linear installation guide 13563-H 08-19

Glass centreline

Clearances from combustibles

B - mantel depth

The clearances listed below, measured from the edge of the glass, are minimum

clearances unless otherwise stated.

While the heater is operating

The appliance must not be installed where

curtains or other combustible materials could

come into contact with the re. The 400 mm side

clearance includes side walls. The 1000 mm

clearance is in front of the re.

Floor protection

Heat emanating from this re may over time

aect the appearance of some materials used

for ooring, such as, carpet, vinyl, cork or timber.

This may be amplied if the air contains cooking

vapours or cigarette smoke. To avoid this

occurring, it is recommended that a mat be placed

in front of the appliance.

Mantels and surrounds

Combustible mantels and surrounds require

clearance from the unit to minimise the risk of

re.

1000 mm

400 mm

400 mm400 mm

A

Mantels and surrounds, made of combustible

material such as wood are allowed providing

C

they are outside the minimum clearances shown

below.

A Mantel needs to be a minimum of 400 mm away from the edge of the glass

B Maximum mantel depth at 400 mm (A) is 250 mm maximum

C Surround needs to be a minimum of 400 mm away from the edge of the glass

For every 50 mm of added mantel depth there must be an additional 100 mm of clearance from the

edge of the glass. For example:

Mantel depth A: clearance required

300 mm 500 mm

350 mm 600 mm

400 mm 700 mm

Linear installation guide 13563-H 08-19 | 7

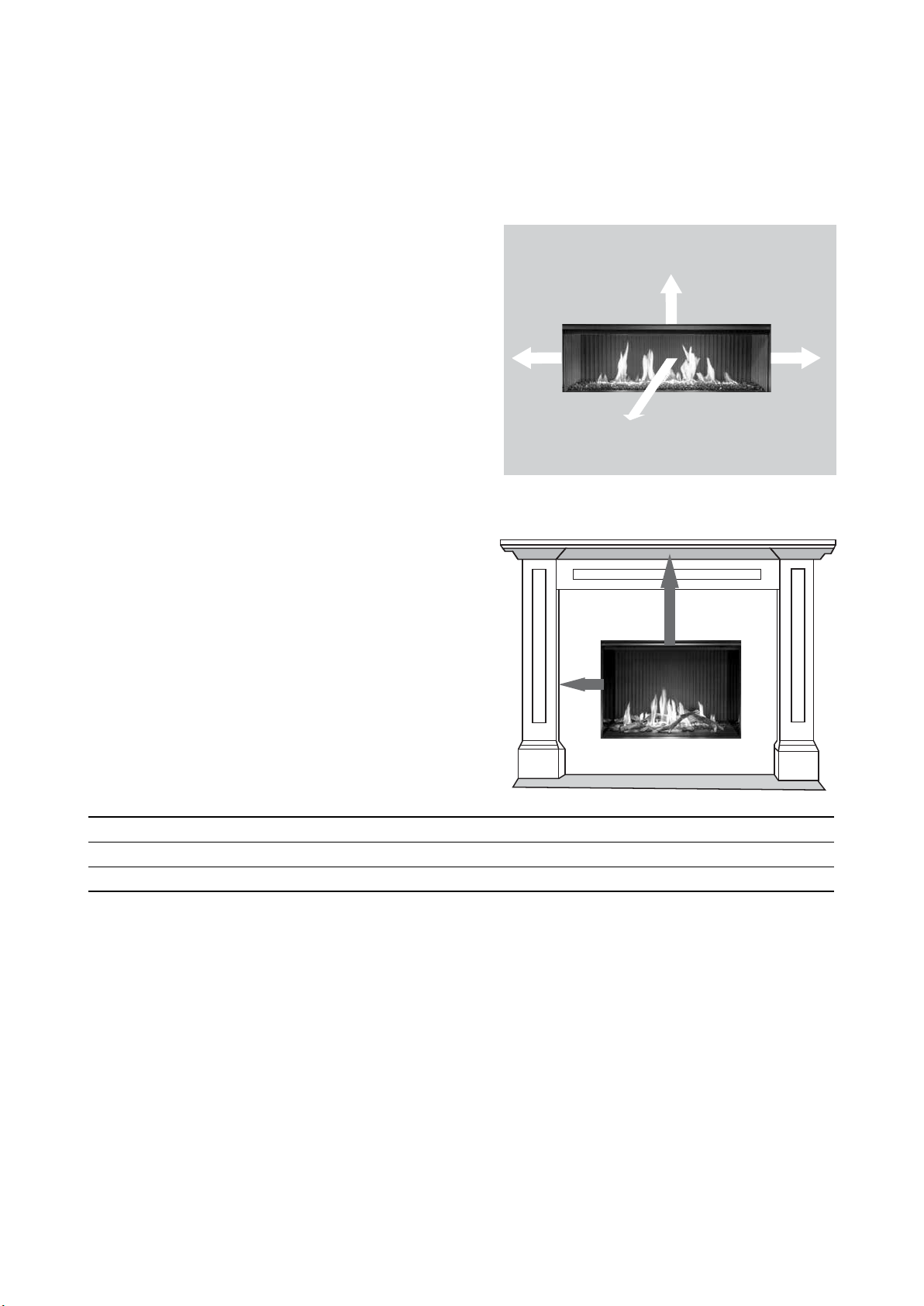

The below diagrams are to assist in determining the full clearance area around the

Linear.

1600

400

Clearance

1157-1167

505

Glass height

Linear 800Linear 1000Linear 1500

257 ± 5*

400

Clearance

800

Glass width

400

Clearance

* Adjustable

firebox feet

932-942

Clearance

932-942

400

1800

1000

Glass width

2300

400

Clearance

400

Clearance

280

Glass

height

257 ± 5*

* Adjustable

firebox feet

400

280

Clearance

Glass

height

400

Clearance

8 | Linear installation guide 13563-H 08-19

1500

Glass width

400

Clearance

257 ± 5*

* Adjustable

firebox feet

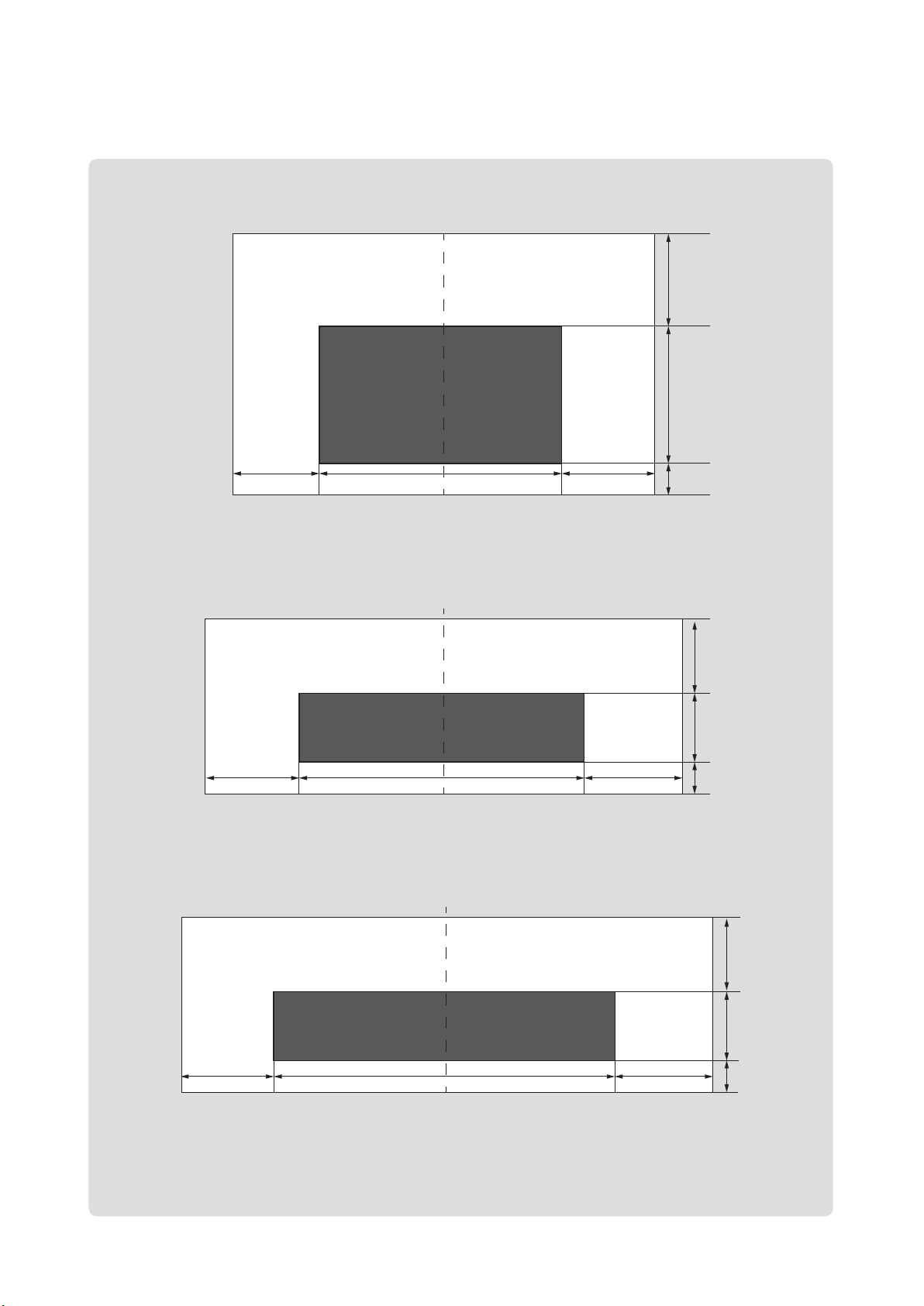

Hearths

Any hearth that is installed in the shaded area (shown below) must

be capable of withstanding temperatures up to 100 °C. Some

laminated materials may buckle or delaminate when exposed to

high levels of heat.

1

3

2

1. A 3 mm air gap between the hearth and lower re lip is critical. This allows for air ow to critical

components and for correct operation of the IR receiver.

2. The lower support rail is only required if the side rails are used, side rails are required for

combustible wall linings.

3. The nishing trims latches are not needed if a hearth is installed, they can be snapped o if

they are in the way.

Please note:

Shaded area

300

must be capable

of withstanding

temperatures up to

100 °C.

200

45°

100

Linear installation guide 13563-H 08-19 | 9

TV installation

The Linear has a fan that distributes warm air from the top of the appliance out into

the room. As warm air is dispersed outwards and not directly upwards, installation

of a TV may be an option.

400 mm 400 mm

The diagram shows recommended clearances when installing a TV directly above the Linear, or

into a recess. All dimensions are in millimetres.

Always check with the TV manufacturer

It is up to the owner to check the TV installation with the TV manufacturer—some have warranty

conditions that state a TV is not to be installed above a replace.

Rinnai does not accept any responsibility for damage to a TV resulting from the use of this

information.

10 | Linear installation guide 13563-H 08-19

Installation overview

Complete framing and base panel, p.12-16.

Prepare gas and electrical connections, and cavity ventilation.

Fit the Linear

Move the Linear into the cavity. Tip forward slightly to get the two back feet in rst. To reduce the

weight you can remove the glass rst (p.20). The Linear as adjustable feet on all corners. Use these

feet to level the re. This is critical so the wall lining can be installed ush to the lips of the re. Once

level, secure the Linear to the base of the enclosure using the four brackets, which also act as

seismic restraints (p.19).

Complete the gas connection

To access the gas connection and gas control, remove the screws holding the Wi-Fi panel in place

(refer image on p.28 for Wi-Fi assembly position). At this stage also check the ue conguration to

see if a dip switch change is required. Check for gas leaks.

Fit the ue, refer p.36-47 for more information.

Commission with the glass o

Follow the commissioning instructions, p. 21-24.

Install the burn media

Placement of the burn media is critical to the performance and safe operation of the appliance. Refer

p.26 for more information.

New build

Install the glass front

Reinstall the glass front, check operation of the re, check the remote and Wi-Fi module is working

(p.28).

Complete nal framing and install the wall lining

Complete the nal framing once you are satised the re is working correctly—there will be limited

access to the unit once nal framing is completed.

Install the wall lining as one piece (so it doesn’t crack), with a cutout for the glass, up to the lips of

the unit. DO NOT go over the lips. There is an air gap of at least 3 mm around the lips of the re,

which is CRITICAL to safe operation, to ensure air ow in and around the unit.

Fix the wall lining in place. We recommend gluing as screws will transfer heat, and during installation

there is the potential to damage some controls of the re if screws are used, refer p. 29-35 for more

information.

N.B: For new builds the nal stage could be completed prior to commissioning.

Helpful tips

To level the unit and not aect where the feet go, the seismic brackets need to be elevated

once the unit is o the pallet.

We STRONGLY recommend the gas is on to check the inlet pressure as access to controls

after the wall lining is on is more dicult.

Linear installation guide 13563-H 08-19 | 11

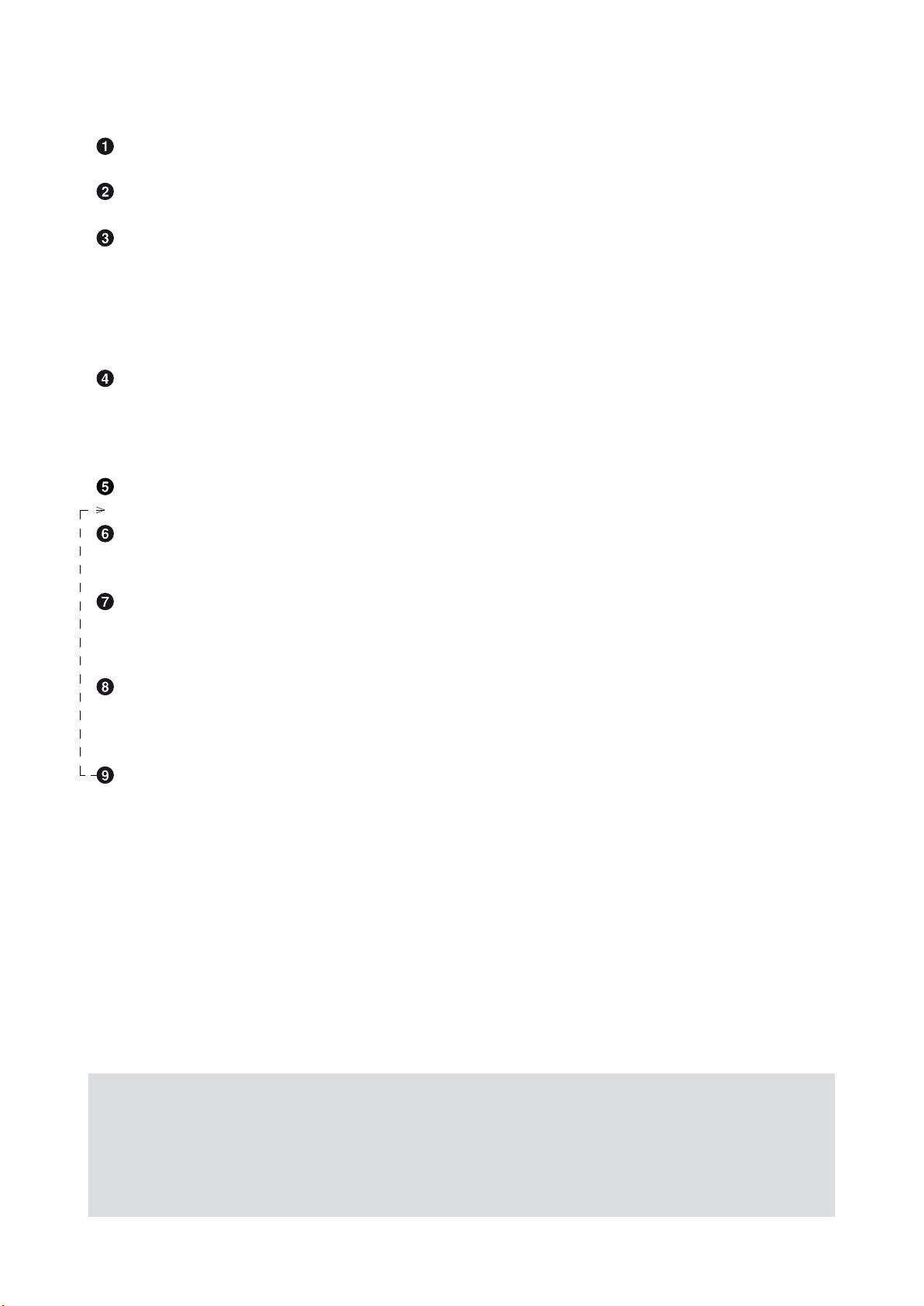

front view front view

Cavity ventilation

Ventilation of at least 2000 mm2 is recommended in the cavity, ideally below the base of the re.

This

is to provide room air at ambient room temperature to the re thermistor located in the base of the

1

. Ventilation can be via a vent or an open toe kick at the base of the cavity—it must be in the

re

same room as the re.

Additionally the top of the cavity needs to be ventilated into the room or another space. This

2.

ventilation opening must also be at least 2000 mm

This opening prevents heat build up inside the

cavity, which if left unvented could cause damage to wall surfaces or coverings and/or cause the

re to cut out.

Cavity ventilation design ideas

front view peninsular top view

peninsular side view

1

Alternatively provide a way of moving the room temperature thermistor into the room, for example under the hearth—ensure it can be

accessed/removed for service.

12 | Linear installation guide 13563-H 08-19

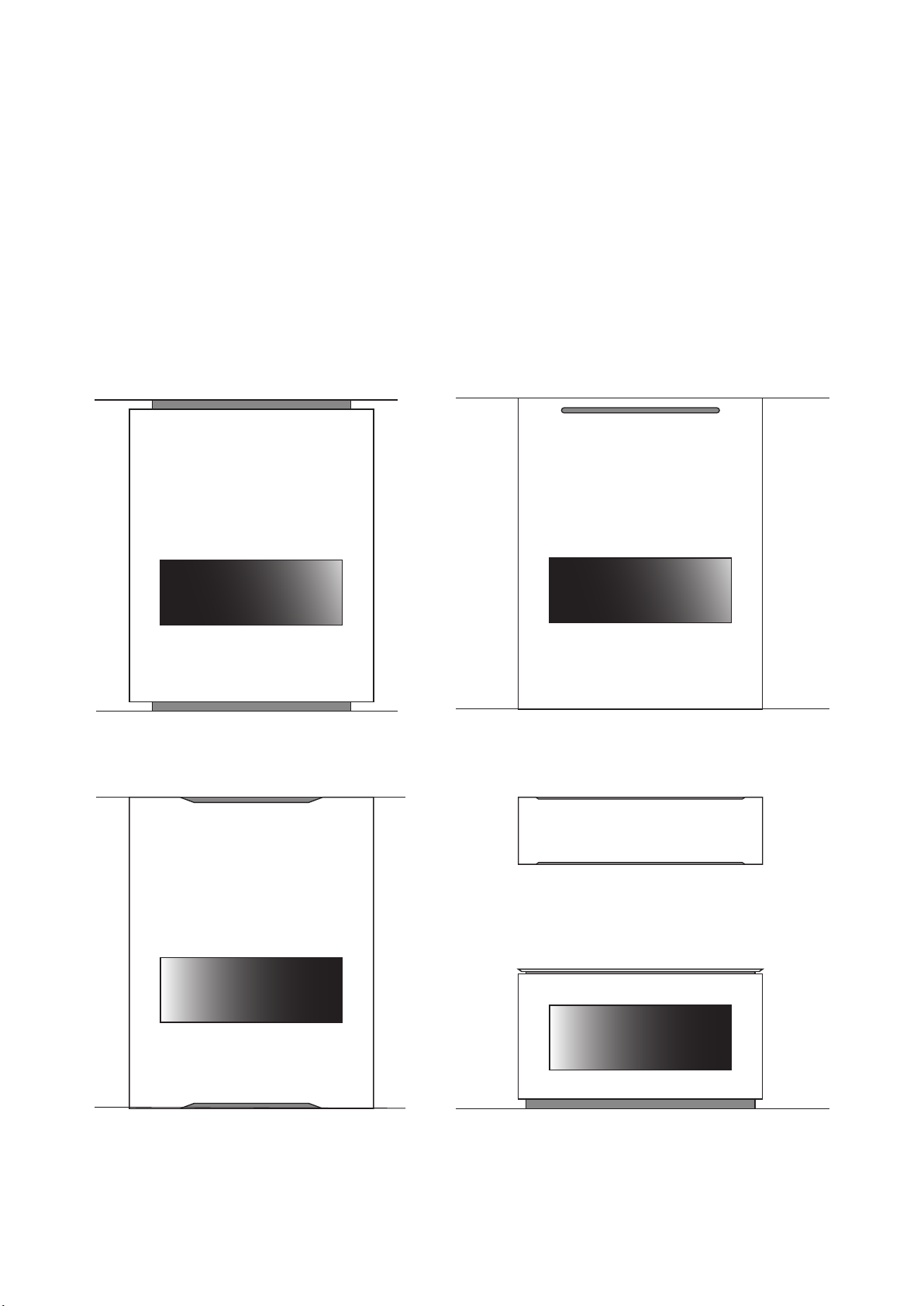

Framing dimensions

The framing dimensions have the studs oset. This is because the cavity needs to be

IMPORTANT

Base board and connection cutouts

To ensure everything lines up and ts properly it’s recommended

that on the base the following dimensions are pencilled; glass

centreline, unit depth centreline, feet position, gas and room

thermistor cutouts.

framed based on the centreline of the Linear glass, NOT the opening size.

Where there is a requirement for a symmetrical installation, the cavity size will need to

increase. To calculate a rough opening width, double the ue to centreline gure on the

following pages.

Glass centreline

C D

A

B

Gas supply access

Thermistor / room supply air Ø 40 mm

Linear 800 Linear 1000 Linear 1500

A (room supply air) 50 mm 50 mm 255 mm

B (gas supply) 220 mm 220 mm 220 mm

C (support feet centres) 640 mm 740 mm 990 mm

D (support feet centres) 360 mm 460 mm 710 mm

E* (from front of cavity) 77 mm 77 mm 77 mm

* E asssumes 10 mm wall board

E

Additional framing notes

• Wallboard is set 1 mm back from the front edge of the lips to allow for a slim edge plaster nish.

• To ensure the appliance performs correctly, without rattling, the Linear MUST BE installed on

a at level support base. The joists must be capable of supporting a minimum of 1.5 times the

weight of the appliance—base panel is also designed to take the weight of the wallboard.

Issues caused by rattling res not installed on a at level base, as detailed in this guide,

IMPORTANT

will not be covered by warranty.

Linear installation guide 13563-H 08-19 | 13

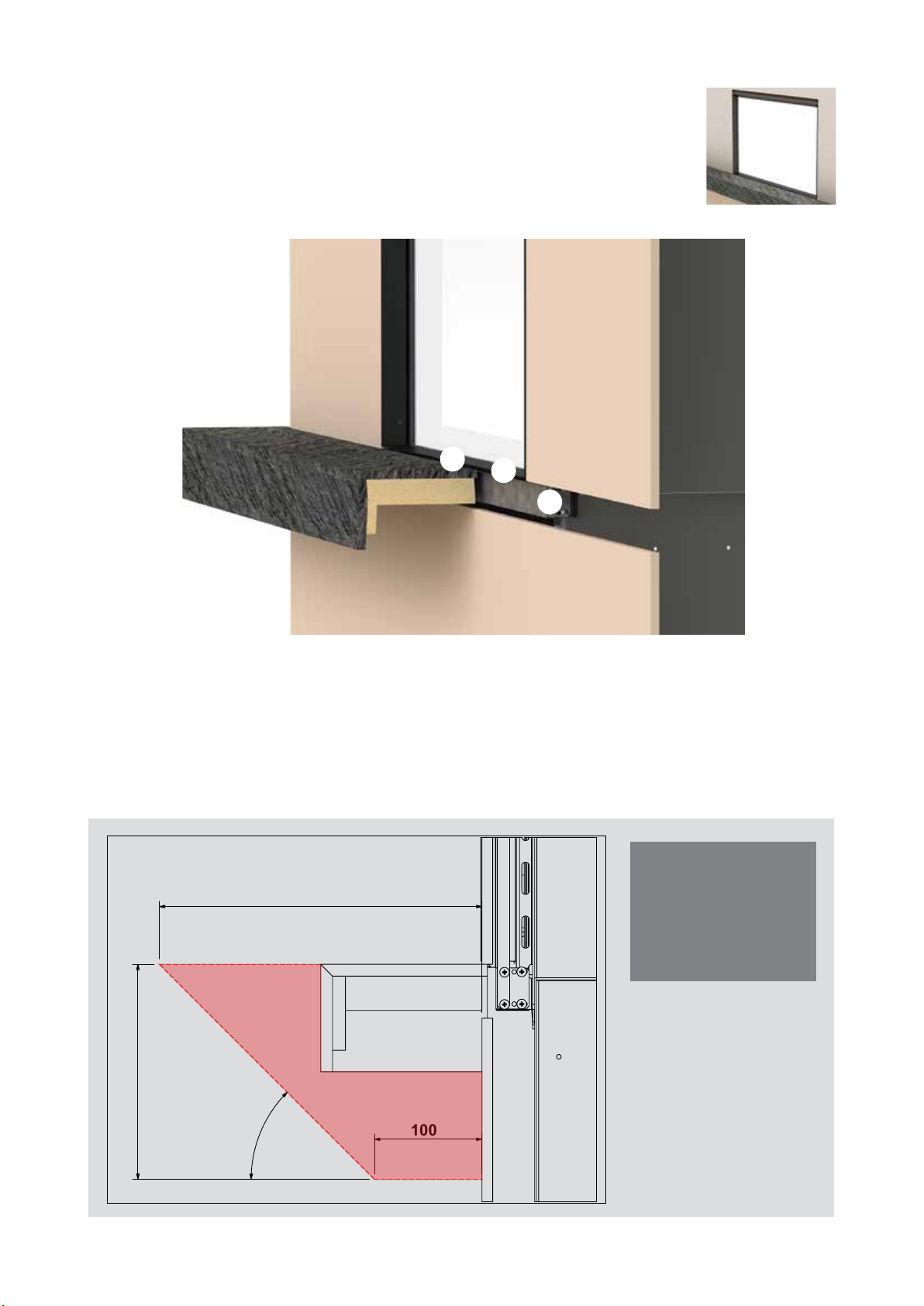

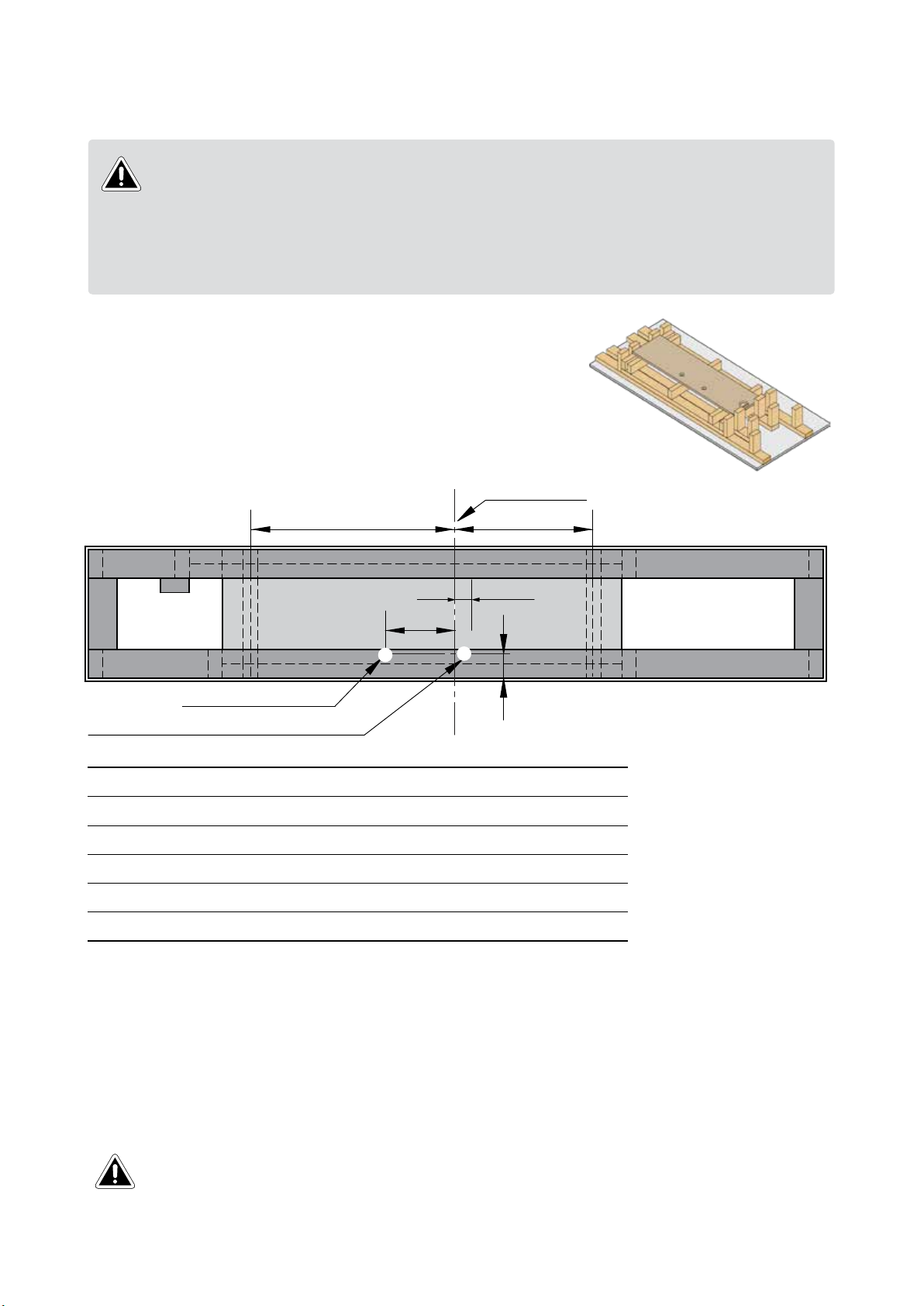

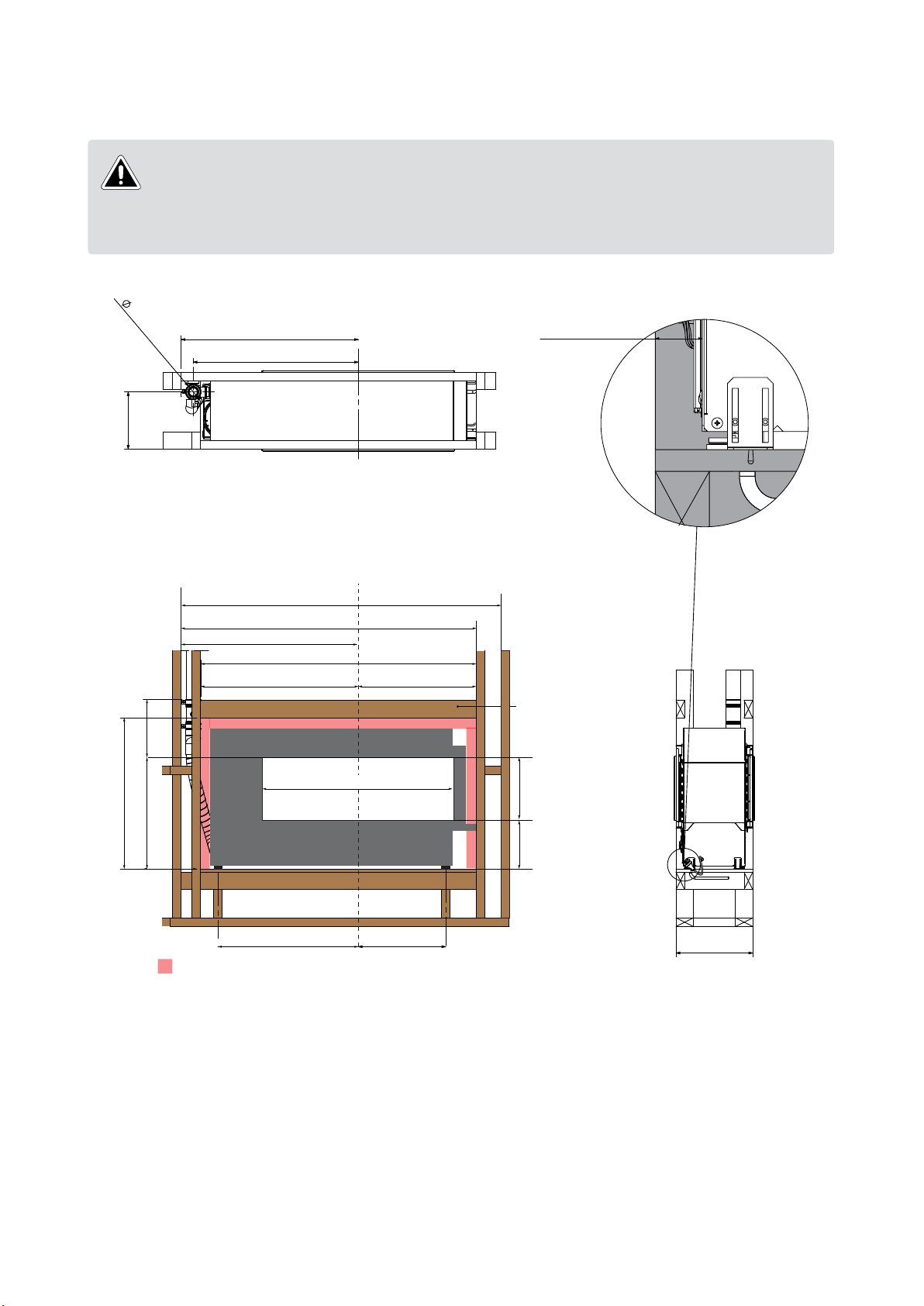

Linear 800 minimum framing dimensions (mm)

The framing dimensions have the studs oset. This is because the cavity needs to be

framed based on the centreline of the Linear glass, NOT the opening size.

IMPORTANT

Where there is a requirement for a symmetrical installation, the cavity size will need to

increase, refer diagram below.

80**

Front face to

center of flue

300

500 **

845

770

Glass centreline

1690 (for symmetrical cavity)

1365

845

1250

Clearance (approx. 50 mm)

39 assumes

10 mm wallboard

520 730

Recommend that the lintel is left

until the fire is installed so min.

clearances can be maintained

816*

1020 min.

~800

257±5* 566*

640 360

Shaded area denotes a clearance around the fire of approx. 50 mm.

On the RHS this is automatically achieved with the carry bar.

403 mm assumes a 10 mm wallboard

on both sides of a double-sided unit.

415 mm is the min. for a single-sided

unit to maintain 50 mm clearance to

the back of the fire.

* Minimum wallboard cutout, refer table on p.29

** Maintain 25 mm clearance to combustibles for the rst 500 mm of ue

• All dimensions are assuming a 10 mm wallboard

• Studs and joist are required directly below the support feet of the re

• Framing shown is 90 x 45 mm

• Fire platform shown is 18 mm plywood

• Allow room underneath the appliance for the gas supply to enter the re cavity (min. 100 mm)

403

14 | Linear installation guide 13563-H 08-19

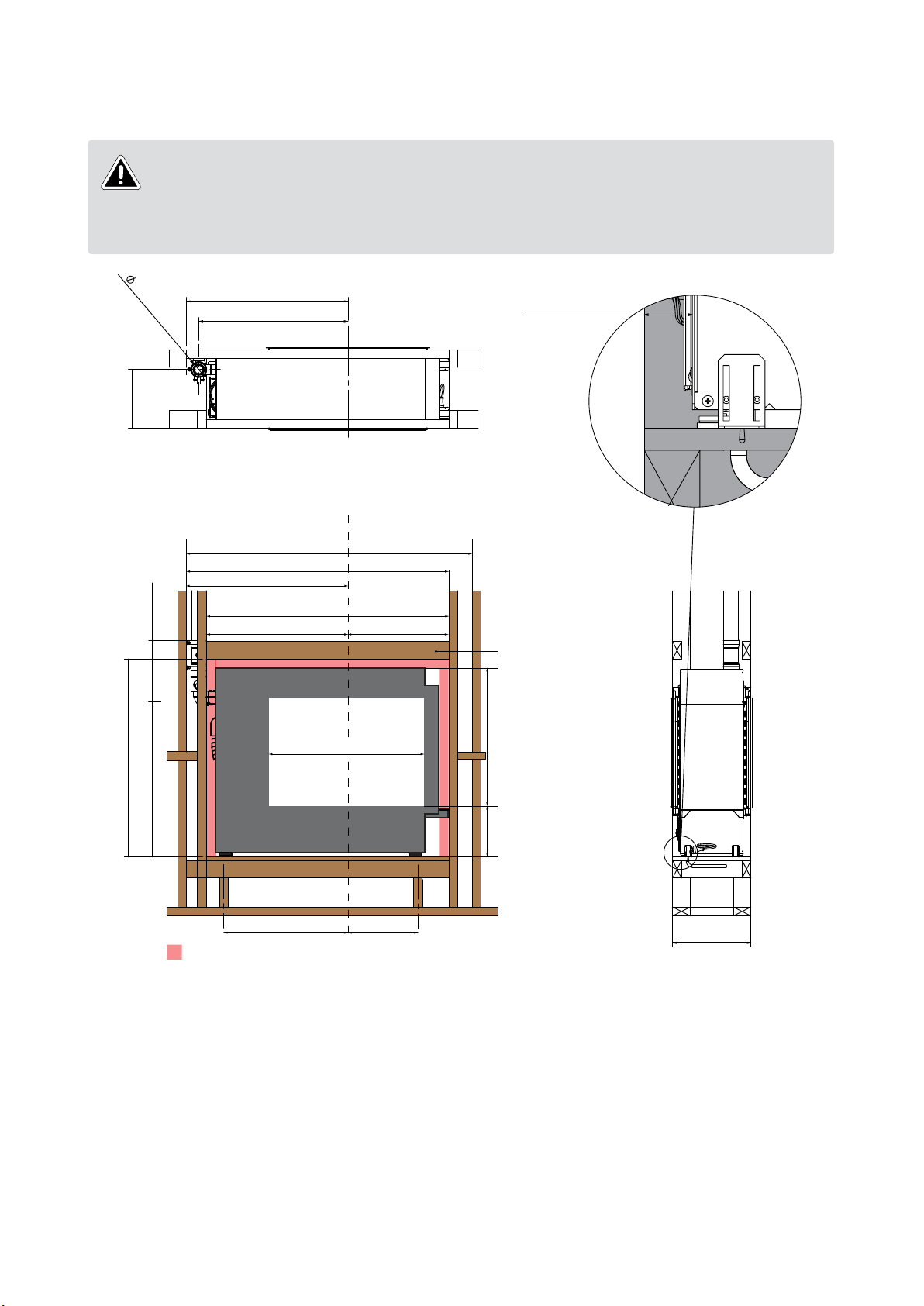

Linear 1000 minimum framing dimensions (mm)

The framing dimensions have the studs oset. This is because the cavity needs to be

framed based on the centreline of the Linear glass, NOT the opening size.

IMPORTANT

Where there is a requirement for a symmetrical installation, the cavity size will need to

increase, refer diagram below.

80**

Front face to

center of flue

300

945

870

39 assumes

10 mm wallboard

500 **

796 min

~ 575

Glass centreline

1890 (for symmetrical cavity)

1565

945

1450

620 830

Clearance (approx. 50 mm)

1016*

740 460

Shaded area denotes a clearance around the fire of approx. 50 mm.

On the RHS this is automatically achieved with the carry bar.

Recommend that the lintel is left

until the fire is installed so min.

clearances can be maintained

257±5* 341*

403 mm assumes a 10 mm wallboard

on both sides of a double-sided unit.

415 mm is the min. for a single-sided

unit to maintain 50 mm clearance to

the back of the fire.

403

* Minimum wallboard cutout, refer table on p.29

** Maintain 25 mm clearance to combustibles for the rst 500 mm of ue

• All dimensions are assuming a 10 mm wallboard

• Studs and joist are required directly below the support feet of the re

• Framing shown is 90 x 45 mm

• Fire platform shown is 18 mm plywood

• Allow room underneath the appliance for the gas supply to enter the re cavity (min. 100 mm)

Linear installation guide 13563-H 08-19 | 15

Loading...

Loading...