Rinnai RH180 User Manual

Hybrid Tank-Tankless Water Heater

RH180 (REU-VA1320WF-US)

Technical Data Sheet

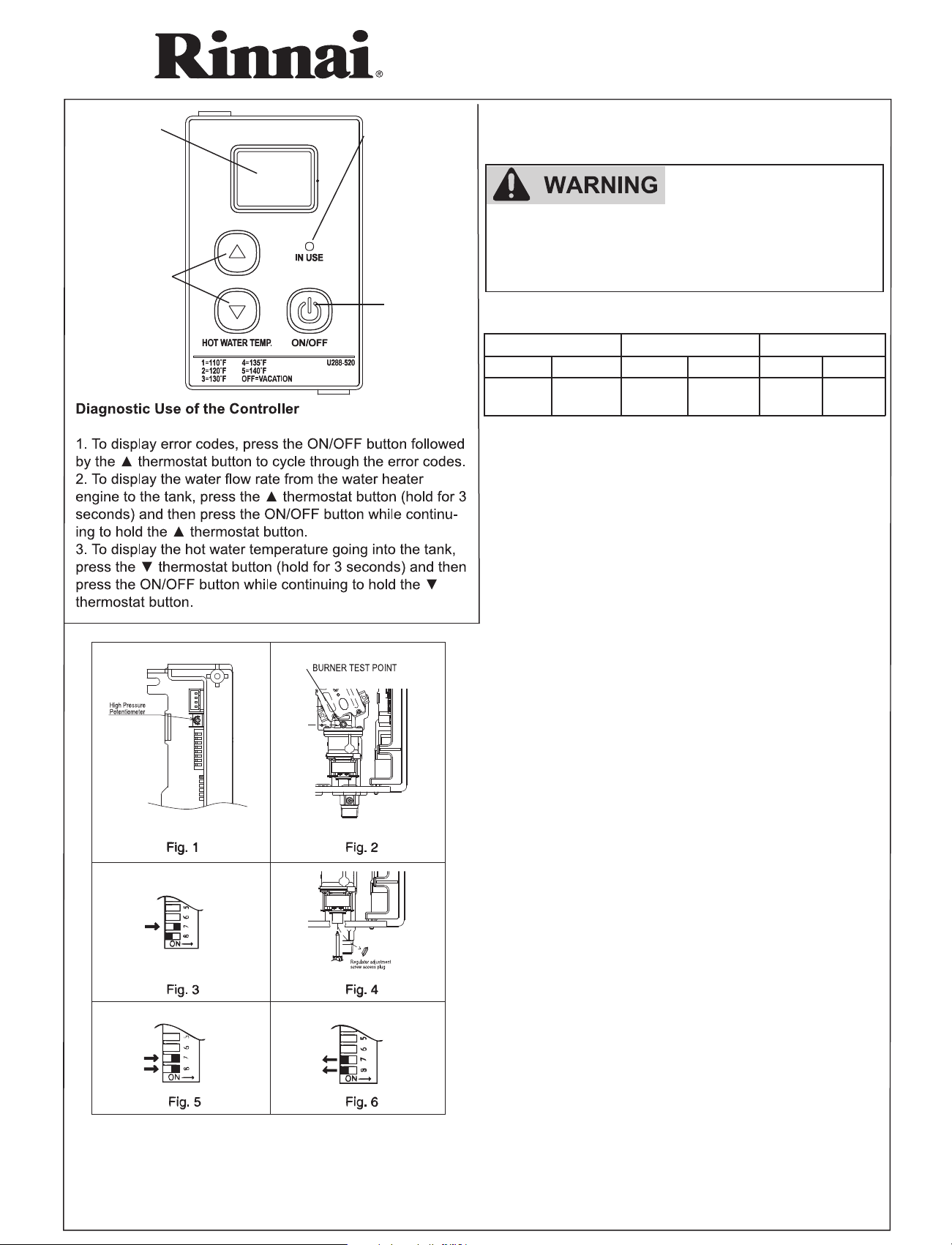

Temperature

Display

Indicates

temperature

setting or flashes

error code.

Temperature

Selector

In Use Indicator

Indicates the

water heater is in

a recovery mode.

ON / OFF

Button

Gas Pressure Setting

NOTE: For additional installation and commissioning information

refer to the Operation and Installation Manual.

This appliance must be installed, serviced and removed by a

trained and qualified person. During pressure testing of the

consumer piping, ensure gas valve is turned off before unit is shut

off. Failure to do so may result in serious injury to yourself or

damage to the unit.

APPLIANCE OPERATING PRESSURES

Water Inlet Max is 150 PSI

Gas Inlet Min/Max

Nat. G. LPG Nat. G. LPG Nat. G. LPG

4" W.C. /

10.5" W.C.

Ensure gas pressure check under Commissioning has been

completed first! The regulator is electronically controlled and

factory pre-set. Under normal circumstances it does not require

adjustment during installation. Make adjustments only if the unit is

not operating correctly and all other possible causes for incorrect

operation have been eliminated.

1. Turn OFF the gas supply.

2. Turn OFF the 120 V power supply.

3. Remove the front panel from the appliance.

4. Check the gas type using the data plate on the side of the unit.

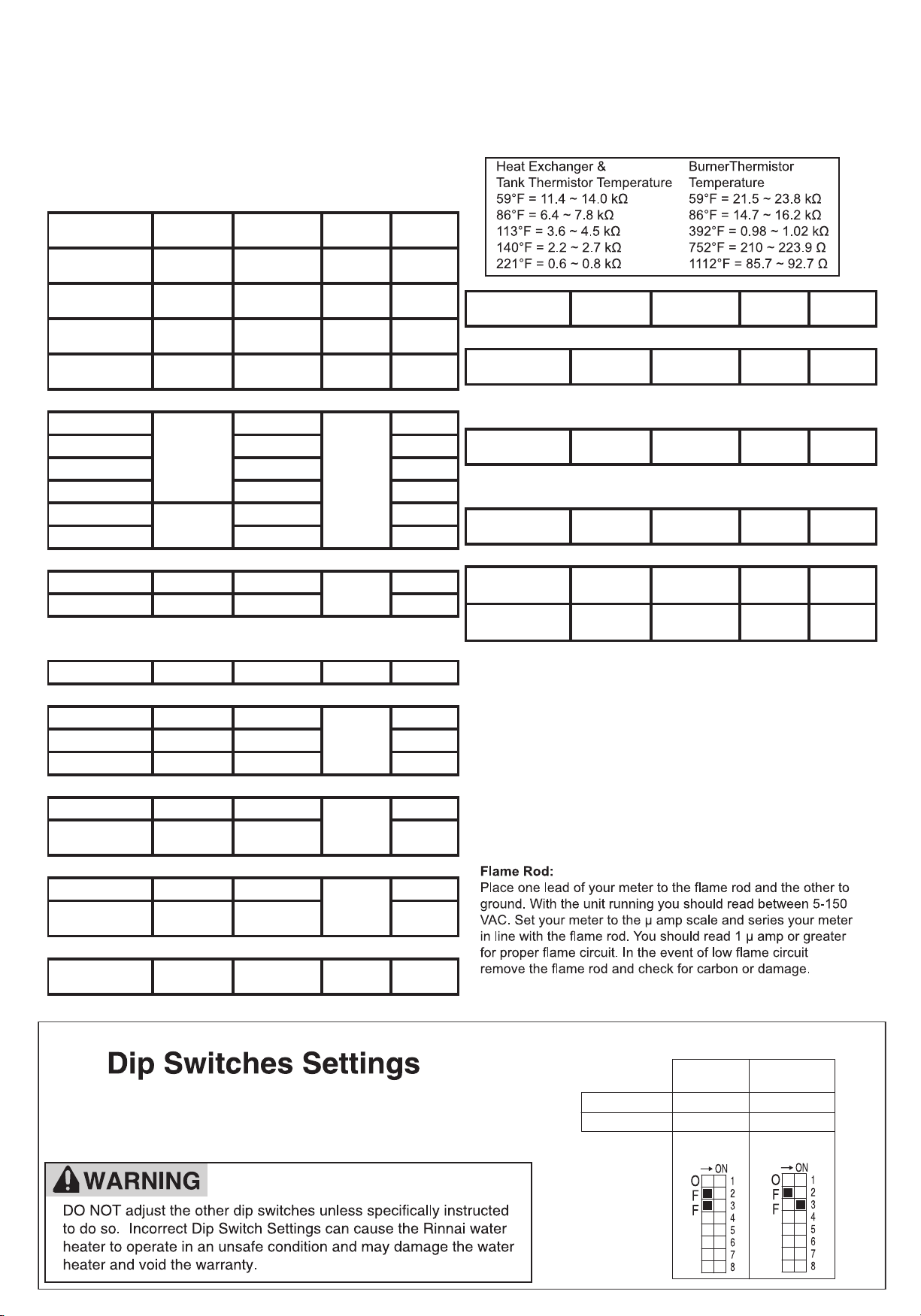

If using a spare PC board, check that the gas type switches are

in the correct position (dip switch 1: ON for natural gas, NG, and

OFF for propane, LPG). See dip switch settings section below. (ON

is towards the right and OFF is towards the left.)

5. Attach the pressure gauge to the burner test point, located on

the gas control (Fig. 2).

6. Turn ON the gas supply.

7. Turn ON the 120 V power supply.

8. Turn the unit ON with the controller. Select the maximum delivery

temperature and open an available hot water fixture. Leave the

fixture on until all gas pressure setting is complete

9. When the red “In Use” light turns on, set the unit to “Forced Low”

combustion by setting No. 7 dip switch to ON (Fig. 3).

10. Check the burner test point pressure.

11. Remove the rubber access plug and adjust the regulator screw

on the modulating valve (Fig. 4) as required in Table 1. Replace the

rubber access plug.

12. Set the unit to “Forced High” combustion by setting both No. 7

and No. 8 dip switches to ON (Fig. 5). Ensure maximum water flow.

13. Check the burner test point pressure.

14. Adjust the high pressure potentiometer (POT) on the PC board

as required to the pressure shown in Table 1.

15. Return the unit to normal operation by setting dip switches 7

and 8 back to OFF (Fig. 6). Close all water taps.

16. Turn OFF the gas supply and 120 V power supply.

17. Remove the pressure gauge and install sealing screw.

18. Turn ON the gas supply and 120 V power supply.

19. Operate the unit and check for gas leaks at the test point.

20. Install the front panel.

NOTE: For additional installation and commissioning information

refer to the Operation and Installation Manual.

8" W.C. /

13.5" W.C.

Forced Low

1.10" W.C. 1.23" W.C. 2.8" W.C. 3.0"

Forced High

Table 1

W .C

Commissioning

With all gas appliances in operation at maximum gas rate, the

flowing inlet pressure at the incoming test point on the Rinnai

water heater should read 4" W.C. - 10.5" W.C. on natural gas

and 8" W.C. - 13.5" W.C. on propane gas. If the pressure is

lower, the gas supply is inadequate and the unit will not operate

to specification. Check the gas meter regulator and pipework for

correct operation/sizing and correct as required.

TROUBLESHOOTING

tor

#

Above

4

Above

8

Above

(A)11

tor

#

Black

VDC

Black

VDC

Black

VDC

Orange

mVDC

mVDC

VDC

(A) 6

Important Safety Notes

There are a number of (live) tests that are required when fault

finding this product. Extreme care should be used at all times

to avoid contact with energized components inside the water

heater. Only trained and qualified service technicians should

attempt to repair this product. Before checking for resistance

readings, disconnect the power source to the unit and isolate

the item from the circuit (unplug it).

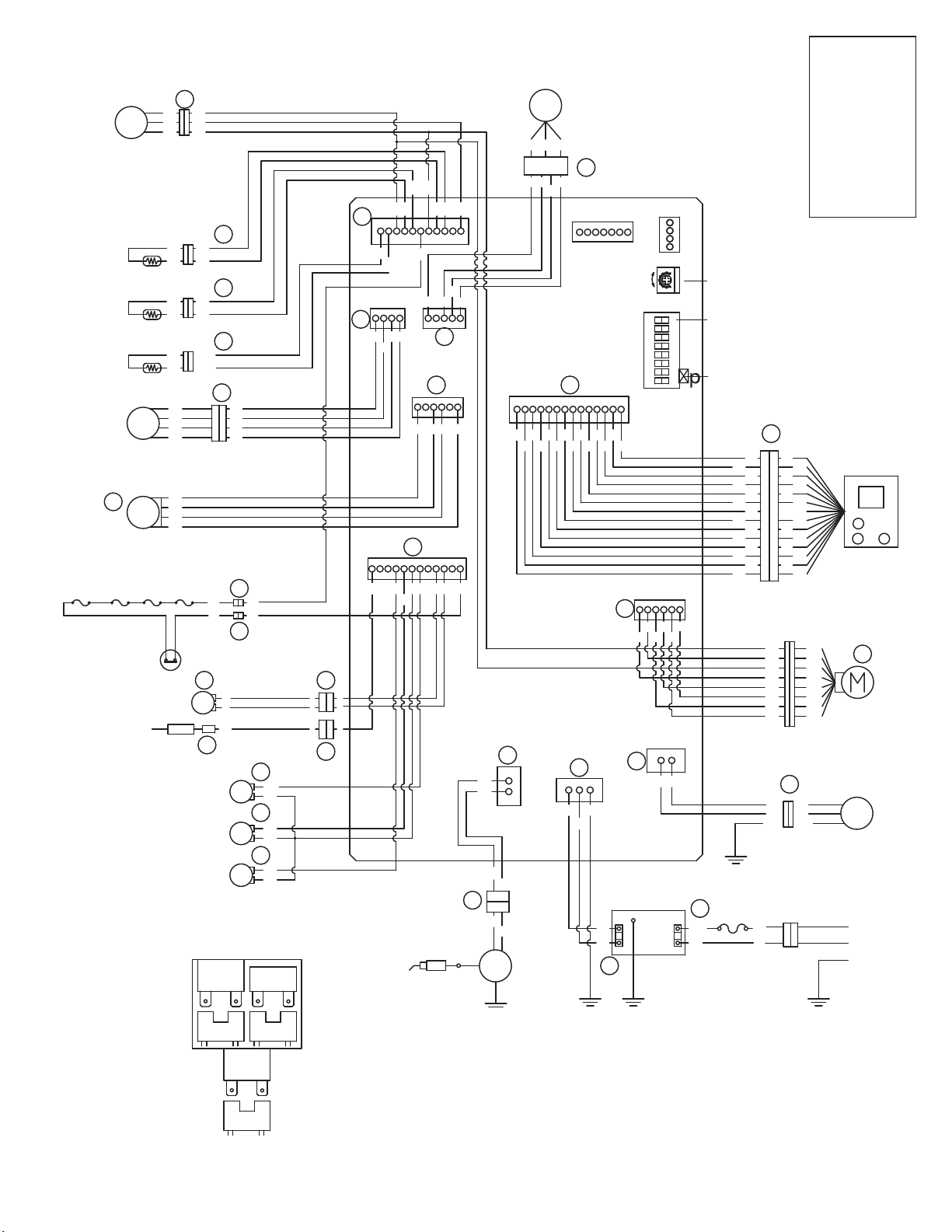

(SV1, SV2 and POV) Gas valve and Modulating solenoids

(Set meter above 2K)

Wire Color Voltage Resistance

Connec

Pin #’s

Thermistors:

Check all thermistors by inserting meter leads into each end

of the thermistor plug. Set your meter to the 20 K scale and

read resistance. Applying heat to the thermistor bulb should

decrease the resistance. Applying ice to the thermistor bulb

should increase the resistance. See below for examples of

typical temperatures and resistance readings.

(Main) Pink -

(SV1) Blue -

(SV2) Yellow -

(POV) Orange -

(M) Water Flow Control Servo or Geared Motor

Red - Orange N/A (G) 5 - O

Blue - Orange N/A (G) 3 - O

Grey - Yellow N/A GY - (G)1

(QS) Water Flow Sensor:

Red - Black

Yellow - Black 4 ~ 7 VDC N/A (A) 1 - 5

Note: Red turns to Orange and Black turns Grey on the PCB.

(IG) Ignition System

Grey - Grey

(FM) Combustion Fan Motor:

Red - Black 7 ~ 45 VDC N/A (B) 1 - 2

Yellow - Black

White - Black 7 ~ 45 VDC N/A (B) 4 - 2

(FV) Flammable Vapor Sensor:

Red - Black

White - Yellow

11 ~ 13

11 ~ 13

11 ~ 13

2 ~ 15 VDC

5 ~ 7 VDC

4 ~ 6 VDC

11 ~ 13

90 ~ 110

11 ~ 13

1.9 ~ 2.1

25.5 ~ 39.5

39 ~ 44

35 ~ 41

39 ~ 44

65 ~ 85

ohms

ohms

ohms

ohms

N/A (A) 9 - 5

N/A H1 (H) 1 - 2

N/A (B) 3 - 2

N/A (D) 1 - 6

N/A (D) 4 - 3

F6 (F) 6 - 7

F7 (F) 5 - 6

F8 (F) 4 - 6

F2 & F3 (F) 9 - 10

G1

A1

B1

D1

6 - 5 )G(A/NkniP - deR

4 - 3 )G(A/NetihW - eulB

Wire Color Voltage Resistance

Tank Temperature Thermistor (White & Yellow at the PCB)

White - W hite

Heat Exchanger Temperature Thermistor

(Brown & Yellow at the PCB)

White - W hite

Burner Sensor Temperature Thermistor

(Pink & Grey at the PCB)

Black - Black

2)G( - YGA/NnworB - yerG

Surge Protector:

Blue - Brown

Black White

With the power off you can check the continuity through the

surge protector. Place a meter lead on the top pin #1 of the

surge protector and pin #3 on the bottom of the surge protector. Check across the top pin #3 and bottom pin #1. If you read

continuity across these two points then the surge protector is

good. If you do not get continuity then replace the surge

protector.

Amp Fuses:

This unit has one inline (5) amp glass fuse. Remove the fuse

and check continuity through it. If you have continuity through

the fuseB then it is good. Otherwise the fuse is blown and

N/A

N/A

N/A

108 ~ 132

VAC

108 ~ 132

VAC

See Chart

See Chart

See Chart

N/A

N/A

Connec

A2

A3

A4

I1

I2

Pin #’s

(A) 3 - (A)

(A) 7 - (A)

(A)10 -

(I)1 - (I)3

N/A

(COS) Carbon Monoxide Sensor:

Red - Black

Blue - Yellow

Thermal Fuse / Overheat Switch

White - White

Note: White turns to red on the PCB

Set dip switches 2 and 3 to the values shown in table below for your altitude.

The default setting for the appliance is 0 - 2000 ft (0 - 610 m) with switches

No. 2 and No. 3 in the OFF position.

1.9 ~ 2.1

29 ~ 31

11 ~ 13

N/A (C) 1 - 5

C1

N/A (C) 4 - 3

Below 1 ohm A6 F1

(F) 12 -

Switch No. 2

Switch No. 3

0-2000 ft

(0-610 m)

OFF

OFF

SWITCH

2001-5400 ft

(610-1646 m)

OFF

ON

SWITCH

WATER FLOW

SENSOR

Y

QS

BK

TANK THERMISTOR

OUTGOING THERMISTOR

BURNER THERMISTOR

BK

BK

BK

FM

COMBUSTION FAN

D

1

FV

FLAM ABLE SENSOR

THERMAL FUSES

OVERHEAT

SWITCH

MODUL ATING

SOLENOID VALVE

FLAME ROD

MAIN SOLENOID VALVE

SOLENOID VALVE 1

(SMALL)

SOLENOID VALVE 2

(LARGE)

A

1

OR

Y

GY

A

W

Y

BR

Y

P

GY

F

3

POV

F

2

A

3

A

4

B

1

R

BK

Y

W

A

6

R

W

W

R

F

1

O

O

Y

5

F

6

SV0

Bk

F

7

BL

SV1

Bk

F

8

SV2

Bk

W

W

W

W

R

Y

W

BK

R

Y

W

GAS CONTROL UNIT

SV2

SV1

WIRE DIAGRAM

COLOR CODING

W :White

BK:Black

BR

PU

PU

Y

P

P

W

J

1

BL

R

BL

GY

Y

GY

BK

WW

BK

G/Y

GY

BR

O

Y

W

P

BL

R

BR:Brown

R :Red

BL:Blue

Y :Yellow

P :Pink

O :Orange

GY:Gray

PU:Purple

OPERATION

UNIT

G

1

PUMP

P

AC120VAC120V

HOT

HOT

NEUTRAL

GROUND

GNDGND

COS

CO SENSOR

R Y BK

C

1

BK

Y

GY

GY

IG

14

GY

GY

R

BL

7

ED

BK

W

H

2

1

I

1 3

G/Y

BL

BR

1

MAX

MIN

Dip SW1

O

F

F

1

RBRBLPUGYPYPUGY

YBLP

1

G

W

BR

BL

Y

1

MODUL ATING VALVE

CURRENT ADJUSTING

1

Gas t ype

2

3

4

5

6

7

Gas p ressu re Setting

8

BL

R

BL

GY

Y

GY

BK

6

P

R

2

E

1

Y

P

BR

PU

P

PU

W

WATER FLOW

CONTROL D EVICE

GY

BR

O

Y

W

P

BL

R

J

BK

W

BK

G/Y

GND

G/Y

SURGE

PROTECTOR

1

BL

3

BR

I

1

3

1

G/Y

I

BK

W

2

FUSE

(5A)

BK

W

GY

BR

A

11

O Y

P

GY

1 4

YWY

R

1

BL

Y

R

BK

B

WYBKR

1 5

C

1 6

WY BKR

F

1

Y

Y

BK

BL

F

2

O

O

O

O

Y

Y

F

4

P

Y

12

R

O

P

O

GY

GY

H

1

IGNITER

SPARK

ELECTRODE

GND

GND

SOLENOID VALVE

CONNECTING

WIRING COLOR

BK

BK

Y

SV0

BK

P

BL

Loading...

Loading...