Rimoldi 227-00-20, 227-00-32 Manual

|

Rimoldi® |

|

SPARE PARTS CATALOGUE |

|

CATALOGO PEZZI Dl RICAMBIO |

(J |

CATALOGUE RECHANGES |

|

|

|

ERSATZTEILELISTE |

class 227-00-20 and subclasses 227-00-32

C!

n.24

l\

.)~~

].

l

_..-l~

·, ]!!-'

)

l

)''

~·

n

\

a

.u

n

SPARE PARTS CATALOGUE

class 227-00-20

and subclasses

227-00-32

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

n.24

.-

r··.,

"'' '

INTRODUCTION

:·.

I

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

n

••

0

,r--,

.~.

c·.

~,

'' .

•'\

t

0 ~--

~~-.

CONTENS

.-

INTRODUCTION

• MACHINE HEAD IDENTIFICATION

II. TECHNICAL DATA BY MACHINE HEAD CLASS

Ill TECHNICAL DATA BY SUB-CLASS

INTRODUCTIONS

· INSTALLATION AND TIMING

a. Positioning of head

b. Assembly of trasmission

c. Filling lube oil sump

d. Assembly and adjustment of sewing parts

e• Positioning and adjustment of presserfoot arm

f. Adjustment of front cover plate

g. Adjustment of needle thread tak.,.up

h• Electric lubrication control device

Timing table

|

|

II |

• USE |

a |

. Threading |

||

b . Needle change |

|||

c |

. Positioning and adjustment of presserfoot |

||

d . Tensioning discs adjustment |

|||

e |

· |

Stitch length adjustment |

|

f |

. |

Seam width adjustment |

|

g . |

Trouble due to incorrect handling of machine |

||

|

|

Ill · MAINTENANCE |

|

a |

• |

Daily |

|

b · |

Weekly |

||

c |

. |

Quarterly |

|

d |

. |

Sharpening knives |

|

e |

. |

Instructions for changing Cam Shaft (if required) |

|

|

|

|

SPARE PARTS CATALOGUE |

|

|

|

INSTRUCTIONS FOR USE |

a |

. |

Introduction |

|

|

|

II |

· ORDER PLACING PROCEDURE |

a |

. All spare parts |

||

b . Needles |

|||

|

|

Ill |

· ILLUSTRATIONS |

Page 5 5

6

Page 9

"9

9

9

14

14

14

14

15

16

Page 17

17

19

"19

19

19

19

20

Page 21

21

21

21

21

21

Page 25

"25

..

.. 2525 25

Page 27

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

INSTRUCTIONS FOR USE

.-

a)Introduction

1.The Spare Parts Catalogue Consists of a set of illustrations of the different mechanisms or assemblies making up the basic machine head and its subclasses.

2.For easy look-up, the illustration index shows the position of each assembly on the machine.

·3. The conver.sion groups of the basic head and its subclasses are illustrated in individual drawings.

4.The illustrations show the number identifying subclasses printed in bold type at top right.

5.On each illustration the single parts of the assembly shown are identified by a number. Assemblies of which parts cannot be supplied separately, are identified by capital letters. Parts and devices which are not standard equipment with the machine but which can be supplied on request are listed at the bottom of each illustration page and illustrated complete with all components at the end of the catalogue.

6.The catalogue carries a general list of parts in numerical order by drawing number, covering all the parts in our machines, with the number of the illustration where the part can be found.

IIORDER PLACING PROCEDURE

a) All spare parts

The following instructions should be carefully followed to make sure that required spare parts are shipped thout delay:

1.State machine head serial number

2.State drawing number of spare parts ordered.

3.Write name of spare part required in full.

4.State quantity required.

I M P 0 R T A N T

RIMOLDI are desirous of throughly studying all cases of breakage, wear or unsatisfactory performance en- countered with parts they have manufactured. For this reason, such parts should be dispatched together with the spare part order.

b)Needles

1.Only straight RIM 27 needles should be used on the machine heads illustrated in this catalogue.

2.The needle system and size are mar1<ed on the needle shank.

3.The gauge indicates the average diameter in hundredths of a millimetre taken on the blade of the needle.

4.The system and size are also stamped on the RIMOLDI needle envelope.

5.When ordering, always state clearly the required needle system and size. (Example: 100 needles, size 90, system RIM 27).

6.In case of doubt, attach a sample needle or art empty envelope of the needle required.

,_\ |

7. For sewing elastic or elasticised materials special ball-point needles classed as SKU are available. |

|

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

-----

.-

SPARE PARTS CATALOGUE

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

-· |

r]j |

|

|

|

1 |

:t

'IHI |

|

|

|

~ |

Ull |

UiVd." |

|

•• |

|

|

N0tldl!l:tS1CJ |

g |

:H |

N |

N01ldi!IJS"3C |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

~~....-(Ji.:_ |

.•\ |

Hjlllllill.'tl''il•l |

:.achlrol:ji!!C"I:lil"·.A |

|

|

|

|

-::·:.!.:?, |

-~li:Cl!•l'l.Aun:m~ |

|

|

|

|

||

t'-'.ilf·l.' |

:.("0· |

'aciAIil~il\l:h'LII |

ilji'IC!;)1111'11 |

|

|

|

|

···;-.·

i

I From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

,---------------------

, ...'',,... ------

1

.....................

I

I

I

I

I

I

~.

~- ,\

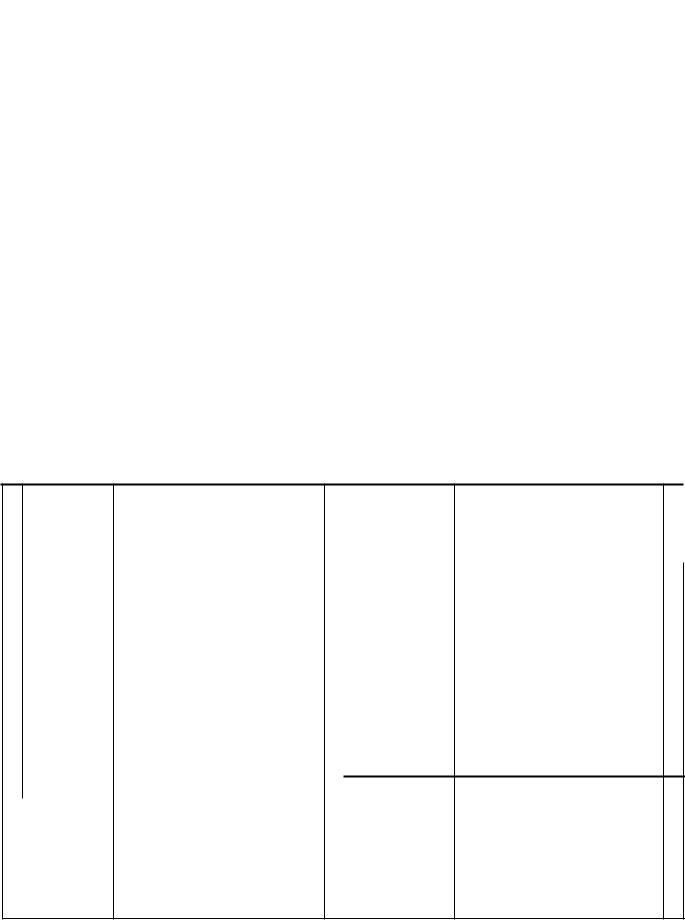

ltEF, |

PART. |

•• |

N• |

1 |

270-016 |

2 |

270-09711 |

3 |

270-05812 |

4 |

270-05711 |

5 |

270-268 |

6 |

202004·0·11 |

7 |

202005-3·11 |

|

|

|

|

a .. |

N' |

|

|

|

|

|

|

|

|

|

|

|

=~ |

||||

OESCRIPT10N |

s |

IEF. |

PART. |

|

OESCRIPTION |

s |

||||

|

|

|

|

|

|

|

||||

bushing, needle hilr shaft |

1 |

B |

270-912 |

latch pin, work plate |

1 |

|||||

bushing, upper knife holder |

1 |

9 |

202045·0·11 |

bushing, differential shaft |

1 |

|||||

rear bushing,looper shaft |

2 |

10 |

270-042/3 |

bushing {left), differential shaft |

1 |

|||||

front bushing. looper shaft |

2 |

11 |

270-642 |

pin, coverplate centeriny |

2 |

|||||

guide tube. looper thread |

2 |

12 |

270-082/1 |

hushing, presserfuut lifter lever |

1 |

|||||

base, rnachine |

1 |

13 |

270-264 |

thread guide, needle |

1 |

|||||

base with bushings and thread guides |

1 |

|

|

|

|

|

|

|||

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

.-

2

20

IS

15

36---- |

1 |

'

'

,/'

'

33 '

'

'

'

'

'

''

|

|

22 |

' |

/ |

-~' |

|

' |

|

.. |

|

N' |

|

~ |

|

.. |

|

|

N• |

|

|

•I |

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

IEF. |

|

PART, |

DESCRIPTION |

z"' |

|

llf. |

|

PART. |

|

DESCRIPTION |

|

|

|

|

|

|

|

|

~ |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

PM.27·n·009/3 |

main shaft, with connecting rods |

1 |

|

20 |

|

270·510 |

|

pivot, handwheel |

1 |

|

|

|

|

2 |

|

280-012/3 |

control rod, needle bar |

1 |

|

21 |

|

270·617/2 |

· |

rockers |

2 |

|

|

|

|

3 |

|

270-116/2 |

control rod, knife |

1 |

|

22 |

270-999 |

|

screws. rocker |

4 |

|

|

||

|

4 |

|

270-061/2 |

control rod, secondary looper |

2 |

|

73 |

|

010-H-13,7 |

|

screw for control rods 2~0.01213 |

|

|

|

|

|

5 |

|

270-060/1 |

sleeve, secondary looper control rod |

1 |

|

|

|

270-975 |

|

and 270-116/2 |

4 |

|

|

|

|

6 |

|

270-059/1 |

steeve, primary looper control rod |

1 |

|

24 |

|

|

screw, sleeve |

4 |

|

|

||

|

7 |

|

270-009/4 |

main shaft |

1 |

|

25 |

|

290·944 |

|

lock-screw, connecting rod guide |

2 |

|

|

|

··:. |

a |

|

270·707 |

ball bearing, right |

2 |

|

26 |

|

092-D-14 |

|

oil wick, main. shaft |

1 |

|

|

|

|

|

|

|

|

|

||||||||||

|

9 |

|

270·613 |

spacer, bearing |

1 |

|

27 |

|

092·C·2 |

|

wick |

2 |

|

|

|

|

10 |

|

270-709 |

ball bearing, left |

1 |

|

28 |

|

270-01012 |

|

bush, intermediate |

1 |

|

|

|

|

11 |

|

270-062 |

guide, connecting rod |

2 |

|

29 |

|

074-A·12 |

|

washer, differential |

1 |

|

|

|

|

|

|

|

|

|

|

|||||||||

|

12 |

|

270-704 |

snao-ring, right ball bearing |

1 |

|

30 |

|

270-722 |

|

ring, adjustment |

1 |

|

|

|

|

13 |

|

270-705 |

sr.•ring, cup |

1 |

|

31 |

270-750 |

|

cap, main shaft |

1 |

|

|

||

|

14 |

|

260-620 |

flange, right |

1 |

|

37 |

|

016-D-5 |

|

screw, adjustment ring |

2 |

|

|

|

|

15 |

|

270-614 |

spacer, main shaft right |

1 |

|

33 |

270-938 |

|

lock-screw, intermediate bush |

1 |

|

|

||

|

16 |

|

270-00a/1 |

handwheel |

1 |

|

34 |

023-N-5.5 |

|

grub-screw, pin |

2 |

|

|

||

|

17 |

|

270-612/1 |

washer with guide |

1 |

|

35 |

001-E-10 |

|

screw, right flange |

3 |

|

|

||

|

1a |

|

270-9a1 |

set~rew, hanwheel |

1 |

|

36 |

01 0-0·11,5 |

|

screw, looper control rod |

a |

||||

|

19 |

|

270-608/5 |

cover with handwheel |

1 |

|

37 |

|

PM.271J.059/1 |

|

sleeve assembly · |

1 |

|

|

|

|

|

|

|

|

|

|

38 |

PM.270-060/o |

|

sleeve assembly |

1 |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

N. B. Beatings reference number B can be |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

supplied as separate spares, however |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

it is indisQensable to specify on the |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

order sheet the Aoman numeral ap· |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

pearing on the outer race of there· |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

moved bearing. |

|

|

|

|

|

|

|

for 227-00-32 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

PM 276 B-009/6 |

main shaft. with connecting. rods |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

270:060/1 |

slnve, primary looper control rod |

1 |

|

|

|

|

|

|

|

|

|

|

|

7 |

|

270-009/3 |

main shaft |

1 |

|

|

|

|

|

|

|

|

|

|

|

37 |

PM 270-060/1 |

sleeve assembly |

1 |

|

Machine & Supply LLC - www.supsew.com |

|

|

|

||||||

|

|

|

From the |

library of Superior Sewing |

|

|

|

|

|||||||

|

|

|

|

--- |

|

|

|

-- · |

|

|

|

|

|

|

|

|

85 6 21 |

3 |

|

|

.- |

;" |

|

|

|

23 L L/ 16 |

IS '\'"" 82 |

|

57 |

|

2 |

2• s ~,[I |

,b. <:J '1r11 , 0 |

9 |

1 3 / |

-~~.~·~"~-'t' |

|

'J!.ti' |

||

|

........ ~~~·-~~ |

2 |

||

|

|

|

I |

69 |

61 |

r; |

·:.

55

|

|

|

PART, |

|

|

|

,_, |

|

IEF. |

|

PART. |

|

~ |

|

|

|

|

Rlf. |

|

|

DESCRIPTION |

z |

|

|

DESCRIPTION |

|

|

||||

|

|

•• |

N• |

|

|

;:: |

|

H' |

|

N' |

|

|

|||

|

|

|

|

|

~ |

|

|

|

|

;;: |

|

|

|||

|

|

1 |

PM.270-049/1 |

assembly, differential slide |

1 |

47 |

270-037/3 |

rod, differential control |

1 |

|

|

||||

|

2 |

27-27-051 |

feed dog, rear |

1 |

48 |

270-984 |

screw, feed lever |

1 |

|

|

|||||

|

3 |

270-977 |

screw, attach rear feed dog |

1 |

49 |

070-B-3 |

washer, feed lever |

1 |

|

|

|||||

|

4 |

270-640/3 |

guide block, right differential |

1 |

50 |

023-N-5,5 |

securing screw, pin |

1 |

|

|

|||||

|

5 |

092-B-1 |

oil wick |

4 |

51 |

270-735 |

eccentric regulation |

1 |

|

|

|||||

|

6 |

270-937/1 . |

securing screw, differential eccentric shaft |

1 |

52 |

PM.270-045/2 |

attachment, differential segment |

1 |

|

|

|||||

|

7 |

27·27·052 |

feed dog, chaining |

1 |

53 |

270-033/1 |

link, differential slide |

1 |

|

|

|||||

|

8 |

27U-b11/1 |

eccentric, feed dog lifter |

1 |

54 |

270-980 |

securing screw, differential link |

1 |

|

|

|||||

|

9 |

270-979 |

securing screw,link |

1 |

55 |

270-943 |

grub-screw, securing pushbutton |

1 |

|

|

|||||

|

|

||||||||||||||

|

10 |

070-M-4,5 |

washer, differential links |

2 |

56 |

270-034 |

bush for differential slide |

1 |

|

|

|||||

|

|

||||||||||||||

|

11 |

270-035 |

bush. differential feed slide |

1 |

57 |

005-L-11 |

securing screw for guide |

2 |

I |

||||||

|

12 |

!1030-06 |

collar |

1 |

58 |

270-997 |

screw, difierential control lever |

2 I |

|||||||

|

13 |

270-048 |

link, differential feed slide |

1 |

59 |

270-566/1 |

control lever. differential segment |

1 |

i |

||||||

|

14 |

073-C-8 |

washer, pin |

1 |

60 |

092-D-4 |

oil wick, differential link |

1 |

|||||||

|

15 |

270-054 |

pin, differential segment |

1 |

61 |

270-978 |

securing screw, front feed dog |

1 |

' |

|

|||||

|

16 |

071-M-5,5 |

washer, diff. ratio increase segment |

1 |

62 |

27-27·050 |

front feed dog |

1 |

|

|

|||||

|

17 |

279-047/2 |

guide segment, diff. ratio increase |

1 |

63 |

290-700 |

snap-ring for pushbutton |

1 |

|

|

|||||

|

18 |

070-F-4 |

washer, diff. ratio pin |

1 |

64 |

270-736/3 |

shank, pushbutton |

1 |

|

|

|||||

|

19 |

057-F-4 |

nut for pin 270-054 |

1 |

65 |

270-738 |

soring, pushbutton |

1 |

|

|

|||||

|

20 |

270-975 |

screw, segment |

1 |

66 |

001A·2,5 |

screw |

1 |

|

|

|||||

|

|

21 |

270-039 |

shaft, differential eccentric |

1 |

67 |

270-729 |

set-screw |

1 |

|

|

||||

|

22 |

270-7391 |

securing pin |

1 |

68 |

279-249/1 |

shield |

1 |

|

|

|||||

|

23 |

071·H·5 |

washer. differential eccentric shaft |

1 |

69 |

270-250/2 |

rubber guard for feed dogs |

1 |

|

|

|||||

|

24 |

270-036/1 |

sliding block, for differential |

1 |

70 |

270-253 |

gasket, slide guide |

1 |

|

|

|||||

|

25 |

270-935 |

counter-washer |

1 |

71 |

004-L-7 |

securing screw, guard |

2 |

|

|

|||||

|

26 |

026·C·7 |

screw, counter-washer |

1 |

72 |

PM.270-732/3 |

housing and cam stitch length eccentric |

1 |

|

|

|||||

|

|

-27 |

PM.270-038/3 |

complete adjustable differential assembly |

1 |

73 |

270-734 |

flat spring |

1 |

|

|

||||

|

|

28 |

270-040 |

yoke, connecting rod |

1 |

74 |

270·032/3 |

plate, differential mechanism cursor |

1 |

|

|

||||

|

29 |

270-031/1 |

pin. fork yoke |

1 |

75 |

004-P-6 |

securing screw, cursor plate |

2 |

|

|

|||||

|

|

30 |

092-D-6 |

oil wick, dowel |

1 |

76 |

270-928 |

grub-screw, for eccentric slide |

2 |

|

|

||||

|

31 |

092-D-12 |

oil wick, rear pivot |

1 |

77 |

270-929 |

lock-screw, for grub-screw |

2 |

|

|

|||||

|

32 |

270-041/1 |

rear pivot, differential |

1 |

78 |

270-747 |

gib, eccentric slide |

1 |

|

|

|||||

|

33 |

250-471 |

screw, yoke |

1 |

79 |

007-C-11 |

screw, collar |

2 |

|

|

|||||

|

34 |

017-E-11 ,5 |

securing screw, adjustable eccentric |

1 |

80 |

023-E-12 |

set-screw. eccentric |

1 |

|

|

|||||

|

|

3S. |

039-H-9 |

screw, differential segment |

1 |

81 |

270-595 |

gasket, differential control lever |

1 |

|

|

||||

|

|

j6 |

064-F·5 |

washer, segment |

2 |

82 |

270-717 |

collar, differential collar |

1 |

|

|

||||

|

|

37 |

270-992 |

screw, differential segment |

2 |

83 |

270·927 |

screw, collar |

1 |

|

|

||||

|

|

J8 |

270-287/1 |

upper sector |

1 |

84 |

270-915 |

plu·g, differential pinion bore |

1 |

|

|

||||

|

|

39 |

073-A-8 |

washer, differential drive shaft |

2 |

85 |

Olj2-D·11 |

oil wick |

1 |

|

|

||||

|

40 |

PM.270-562/2 |

lever, complete differential control |

1 |

86 |

092-D-23 |

oil wick |

1 |

|

|

|||||

|

|

41 |

270-28811 |

stop |

1 |

87 |

270-594 |

gasket |

1 |

|

|||||

|

42 |

270-567 |

sector with setting marks |

1 |

|

A |

270-046/3 |

slide for differential adjustment |

1 |

|

|||||

From |

43 |

065·0-6 |

washer, knurled knob |

1 |

|

B |

270-038/3 |

segment for differential adjustment |

1 |

|

|||||

the library of Superior Sewing Machine |

1 |

& |

Supply LLC |

- www.supsew.com |

1 |

|

|||||||||

|

44 |

270-568 |

knurled knob, lever lock |

1 |

|

c |

|

|

|

, |

|

||||

|

|

45 |

270-702 |

snap ring |

|

D |

270-732.'3 |

stitch len~;~th eccentnc cam |

|

|

|

||||

|

46 |

270-703 |

needle roller bearing cage |

'' |

|

|

|

|

for 227-00-32 |

|

|

|

|||

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

.-

r

4

?-

~

14

3'A""".-.}<IS l

'·

|

|

|

|

|

|

|

|

|

|

|

|

Rlf. |

PART. |

|

s |

|

,.Ef. |

|

PART. |

|

~ |

|

•• |

N' |

DESCRIPTION |

a |

|

K' |

|

N• |

DESCRIPTION |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

1 |

092·0·16 |

oil wick, for pinions |

2 |

|

13 |

|

16·8·2.5 |

grub-screw, for pin |

I |

|

|

|

||||||||

|

2 |

073-N-10 |

washers, looper control leVer |

2 |

14 |

|

7-77·067 |

control lever, secondary looper |

1 |

|

|

3 |

270·070 |

pin, secondary looper control lever |

1 |

15 |

|

92·8·1 |

oil-wick, for·pin |

2 |

|

|

4 |

270-064 |

shaft,' secondary looper control |

I |

16 |

|

2·0·7 |

oil-wick |

1 |

|

|

5 |

27.277-074/2 |

secondary looper with large eye |

1 |

17 |

|

70-053 |

shim, adjustment |

I |

|

|

6 |

270-Q75/2 ·~- |

primary looper with large eye |

1 |

18 |

|

15·8·3 |

set-screw |

2 |

|

|

7 |

270-Q69 |

shaft, primary looper control |

1 |

19 |

|

17-F-11 |

set-screw |

1 |

|

·.··· |

8 |

250·471 |

screw, looper lever |

2 |

20 |

|

092-C-2 |

felt tube |

4 |

|

|

9 |

270-068/3 |

looper-holder; primary |

I |

|

A |

27-77-0SIJ/1 |

adjustable bush |

I |

|

|

10 |

G.27-77·065/l |

oscillating guide, with screw-type bush |

1 |

8 |

|

27·77·065/3 |

oscillating guide |

1 |

|

|

11 |

270-97411 |

set-screw, looper |

2 |

|

c |

270-063/2 |

looper-holder, secondary |

I |

|

|

12 |

016·8·4 |

·set-screw, primary looper travel |

I |

21 |

|

002F·14 |

screw looper l•ver |

I |

|

|

|

|

|

|

|

|

|

|

On reQuest: |

|

|

|

|

|

|

|

|

|

|

27-277-0745/2 |

|

|

|

|

|

|

|

|

|

|

270-075 |

|

|

for 227-QQ.32 |

5127.277-0745 |

seCondary looper |

6 270.057 |

t:H"imary looper |

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

227-00-32

.- a::.·-6

REf. PA.kT.

H' N"

1 PM.27Q-138/1

2 PM.270-137/1

3 270-132/1

4 270-728/1

5 290-027/1

6 270-933

7 270-713

8 270-006/1

9 073-F-9

10 270-719

11 007-C-11

12 270-007/1

13 270-975/1

14 270-031/1

15 092-D-6

16 071-E-5

17 001-G-10

18 270-708

-.

I

!

!

|

|

|

|

|

|

|

-' |

|

~ |

lEF. |

PART. |

|

|||

DESCRIPTION |

DESCRIPTION |

;!; |

|||||

|

=a |

II' |

|

N' |

|

=0 |

|

|

|

|

|

|

|

|

|

pin, needle lever rocker |

1 |

19 |

250-708/1 |

|

.needle bearing cage, needle control lever |

1 |

|

lever, fork |

'1 |

20 |

016-B-2.5 |

screw, pin securing |

1 |

||

bush. fork lever |

1 |

21 |

G.27·27-025/4 |

needle bar assembly with clamp, complete |

1 |

||

securing screw. bush |

1 |

22 |

RIM.27 |

needle |

1 |

||

washer, needle rocker pin |

1 |

23 |

290-944 |

|

screw, needle clamp |

2 |

|

lock·nut, guide pin |

1 |

24 |

270-130 |

|

pin, needle clamp |

1 |

|

flexible washer |

1 |

25 |

092-B-1 |

oil-wick for needle clamp pin |

2 |

||

drive shaft, needle bar |

1 |

26 |

016-A-2,5 |

grub-screw, needle bar clamp pin |

I |

||

washer, upper shah |

2 |

27 |

270-135 |

|

lever, needle holder slide control |

1 |

|

collar, upper shaft |

2 |

28 |

092-D-5 |

oil-wick for pin |

1 |

||

screw. for collar |

2 |

29 |

270-133/1 |

|

pin, fork lever |

1 |

|

attachment, drive shaft |

1 |

30 |

023-N-5,5 |

set-screw, needle bar control lever |

1 |

||

screw. attachment drive shaft |

1 |

31 |

001-E-7 |

screw. upper shaft |

1 |

||

pin, attachment drive shaft |

, |

32 |

270-131 |

|

shim, adjustment |

, |

|

oil-wick, for pin |

1 |

33 |

092-D-11 |

oil-wick, for pm |

1 |

||

washer, upper shaft |

1 |

34 |

092·A-10 |

oil-wick, for needle bar |

1 |

||

screw, washer |

1 |

A |

27·27-020/3 |

needle clamp |

1 |

||

bearing, upper shaft |

1 |

B |

290-025/1 |

|

needle bar |

1 |

|

|

|

|

|

|

|

|

|

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

Loading...

Loading...