Page 1

User’s Guide RIGOL

Publication number UGA07107-1110

July 2008

DS1000E, DS1000D Series

Digital Oscilloscopes

© 2008 RIGOL Technologies, Inc.

All Rights Reserved

DS1102E, DS1052E, DS1102D, DS1052D

Page 2

Page 3

RIGOL

I

© 2008 RIGOL Technologies, Inc. All Rights Reserved

RIGOL products are protected by patent law in and outside of P.R. China.

Information in this publication replaces all previously corresponding material.

RIGOL Technologies, Inc. reserves the right to modify or change part of or all

the specifications and pricing policies at company’s sole decision.

NOTE: RIGOL is registered trademark of RIGOL Technologies, Inc.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 4

RIGOL

II

Safety Notices

Review the following safety precautions carefully before operating the instrument to

avoid any personal injuries or damages to the instrument and any products

connected to it. To avoid potential hazards use the instrument as specified by this

user’s guide only.

The instrument should be serviced by qualified personnel only.

To Avoid Fire or Personal Injury

Use Proper Power Cord. Use the power cord designed for the instrument and

authorized in your country only.

Connect and Disconnect Accessories. Do not connect or disconnect probes or

test leads while they are connected to a voltage source

Ground The Instrument. The oscilloscope is grounded through the grounding

conductor of the power cord. To avoid electric shock the instrument grounding

conductor(s) must be grounded properly. Before making connections to the input or

output terminals of the instrument.

Connect The Probe. The probes’ ground terminals are at the same voltage level of

the instrument ground. Do not connect the ground terminals to a high voltage.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and marks on the instrument. Follow the user’s guide for further ratings information

before making connections to the instrument.

Do Not Operate Without Covers. Do not operate the instrument with covers or

panels removed.

Use Proper Fuse. Use the fuse of the type, voltage and current ratings as specified

for the instrument.

Avoid Circuit or Wire Exposure. Do not touch exposed connections and

components when power is on.

Do Not Operate With Suspected Failures. If suspected damage occurs with the

instrument, have it inspected by qualified service personnel before further

operations.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 5

RIGOL

III

Provide Proper Ventilation. Refer to the installation instructions for proper

ventilation of the instrument.

Do not operate in wet/damp conditions

Do not operate in an explosive atmosphere

Keep product surfaces clean and dry

The disturbance test of all the models meet the limit values of A in the

standard of EN 61326: 1997+A1+A2+A3, but can’t meet the limit values

of B.

Measurement Category

The DS1000E, DS1000D series Digital Oscilloscope is intended to be used for

measurements in Measurement Category I.

Measurement Category Definitions

Measurement Category I is for measurements performed on circuits not directly

connected to MAINS. Examples are measurements on circuits not derived from

MAINS, and specially protected (internal) MAINS derived circuits. In the latter case,

transient stresses are variable; for that reason, the transient withstand capability of

the equipment is made known to the user.

WARNING

IEC Measurement Category I. The input terminals may be connected to circuit

terminal in IEC Category I installations for voltages up to 300 VAC. To avoid the

danger of electric shock, do not connect the inputs to circuit’s voltages above 300

VAC. Transient overvoltage is also present on circuits that are isolated from mains.

The DS1000E, DS1000D series Digital Oscilloscopes is designed to safely withstand

occasional transient overvoltage up to 1000Vpk. Do not use this equipment to

measure circuits where transient overvoltage could exceed this level.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 6

RIGOL

IV

!

Hazardous

Voltage

Refer to

Instructions

Protective

Earth Terminal

Test

Grounding

Terminal

Grounding

Terminal of

Chassis

!

!

Safety Terms and Symbols

Terms in This Guide. These terms may appear in this guide:

WARNING: Warning statements identify conditions or practices that could

result in injury or loss of life.

CAUTION: Caution statements identify conditions or practices that could

result in damage to this product or other property.

Terms on the Product: These terms may appear on the product:

DANGER indicates an injury hazard may be immediately accessible.

WARNING indicates an injury hazard may be not immediately accessible.

CAUTION indicates that a potential damage to the instrument or other property

might occur.

Symbols on the Product: These symbols may appear on the Instrument:

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 7

V

RIGOL

General-Purpose Oscilloscopes

This book covers the following four types of DS1000E, DS1000D Series Digital

Oscilloscopes:

DS1102E, DS1052E,

DS1102D, DS1052D. (With Logic Analyzer)

RIGOL DS1000E, DS1000D Series Digital Oscilloscopes provide exceptional

waveform viewing and measurements in a compact, lightweight package. The

DS1000E, DS1000D series is ideal for production test, field service, research, design,

education and training applications involving analog/digital circuits test and

troubleshooting, as well as education and training.

Features of DS1000E, DS1000D Series:

Dual Channel, Bandwidth:

100MHz (DS1102E, DS1102D)

50MHz (DS1052E, DS1052D)

Optional 16 digital channels (DS1000D series), each channel can be turned on

or off independently, or in a 8 bit group

Mono/Color TFT LCD Displays at 320× 234 resolution

USB storage and printing supports, software upgradeable via USB connectivity

Adjustable waveform intensity, more effective waveform viewing

One-touch automatic setup for ease of use (AUTO)

Saves 10 Waveforms, 10 setups, supports CSV and bitmap format

Newly designed Delayed Scan Function, easy to give attention to both details

and overview of a waveform

20 Automatic measurements

Automatic cursor tracking measurements

Waveform recorder, record and replay dynamic waveforms

User selectable fast offset calibration

Built-in FFT function, Frequency Counter

Digital filters, includes LPF, HPF, BPF, BRF

Pass/Fail Function, optically isolated Pass/Fail output

Add, Subtract and Multiply Mathematic Functions

Advanced trigger types include: Edge, Video, Pulse width, Slope, Alternative,

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 8

RIGOL

VI

Pattern and Duration (DS1000D series)

Adjustable trigger sensitivity

Multiple Language User Interface

Pop-up menu makes it easy to read and easy to use

Built-in Chinese and English help system

Easy-to-use file system supports Chinese & English characters input

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 9

RIGOL

VII

Content

Safety Notices .......................................................................................... II

General-Purpose Oscilloscopes ................................................................... V

Chapter 1 : Getting Started ............................................................... 1-1

The Front Panel and User Interface .......................................................... 1-2

To Inspect the Instrument ....................................................................... 1-5

To Perform a Functional Check ................................................................. 1-6

To Compensate Probes ............................................................................ 1-8

Digital Leads (DS1000D Series) ................................................................ 1-9

To Display a Signal Automatically ........................................................... 1-11

To Understand the Vertical System ......................................................... 1-12

To Understand the Horizontal System ..................................................... 1-14

To Trigger the Oscilloscope .................................................................... 1-16

Chapter 2 : Operating Your Oscilloscope ........................................... 2-1

To Set up the Vertical System .................................................................. 2-2

Settings of the Channels ..................................................................... 2-2

Math Functions ................................................................................ 2-13

Using REF ....................................................................................... 2-16

Set up LA Channel (DS1000D Series) ................................................. 2-23

Turn on/off Channels ........................................................................ 2-28

Set up Vertical Position and Scale ...................................................... 2-29

To Set up the Horizontal System............................................................. 2-30

To Set up the Trigger System ................................................................. 2-36

Settings for Edge Trigger .................................................................. 2-38

Settings for Pulse Width Trigger ......................................................... 2-39

Settings for Video Trigger .................................................................. 2-41

Slope Trigger ................................................................................... 2-45

Alternative Trigger ............................................................................ 2-47

Pattern Trigger (DS1000D Series) ...................................................... 2-51

Duration Trigger (DS1000D Series) .................................................... 2-53

Trigger Setup ................................................................................... 2-55

To Set up the Sampling System .............................................................. 2-61

To Set up the Display System ................................................................. 2-65

To Store and Recall ............................................................................... 2-67

To Set up the Utility .............................................................................. 2-75

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 10

RIGOL

VIII

The I/O setup ................................................................................. 2-77

Preference ...................................................................................... 2-78

Self-Calibration ................................................................................ 2-79

Pass/Fail ......................................................................................... 2-80

Mask Setting ................................................................................... 2-81

Print Setting .................................................................................... 2-85

Waveform Recorder ......................................................................... 2-86

Language ....................................................................................... 2-91

To Measure Automatically ..................................................................... 2-92

The automatic measurement of voltage parameters ............................ 2-96

The automatic measurement of time parameters ................................ 2-97

To Measure with Cursors ....................................................................... 2-98

Manual Mode .................................................................................. 2-99

Track Mode .................................................................................... 2-102

Auto mode ..................................................................................... 2-104

To Use Run Control Buttons ................................................................. 2-105

Chapter 3 : Application & Examples ................................................... 3-1

Example 1: Taking Simple Measurements ................................................. 3-1

Example 2: View a Signal Delay Caused by a Circuit ................................... 3-2

Example 3: Capture a Single-Shot Signal .................................................. 3-3

Example 4: To Reduce the Random Noise on a Signal ................................ 3-4

Example 5: Making Cursor Measurements ................................................. 3-6

Example 6: The application of the X-Y operation ....................................... 3-8

Example 7: Triggering on a Video Signal ................................................. 3-10

Example 8: FFT Cursor measurement ..................................................... 3-12

Example 9: Pass/Fail Test...................................................................... 3-14

Example 10: Triggering on a Digital Signal .............................................. 3-15

Chapter 4 : Prompt Messages & Troubleshooting .............................. 4-1

Prompting Message ................................................................................ 4-1

Troubleshooting ..................................................................................... 4-3

Chapter 5 : Specifications .................................................................. 5-1

Specifications ......................................................................................... 5-2

General Specifications ............................................................................. 5-6

Chapter 6 : Appendix ......................................................................... 6-1

Appendix A: Accessories .......................................................................... 6-1

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 11

RIGOL

IX

Appendix B: Warranty ............................................................................. 6-2

Appendix C: Care and Cleaning ................................................................ 6-3

Appendix D: Contact RIGOL .................................................................... 6-4

Index ................................................................................................... 6-1

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 12

Page 13

1-1

Chapter 1 : Getting Started

This chapter covers the following topics:

The front panel and user interface

To inspect the instrument

To perform a functional check

To compensate probes

To use digital leads

To display a signal automatically

To understand the vertical system

To understand the horizontal system

To trigger the oscilloscope

RIGOL

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 14

RIGOL

1-2

The Front Panel and User Interface

The first thing to do with a new oscilloscope is to know its front panel. This chapter

helps to be familiar with the layout of the knobs and keys and how to use them. Read

the chapter carefully before further operations.

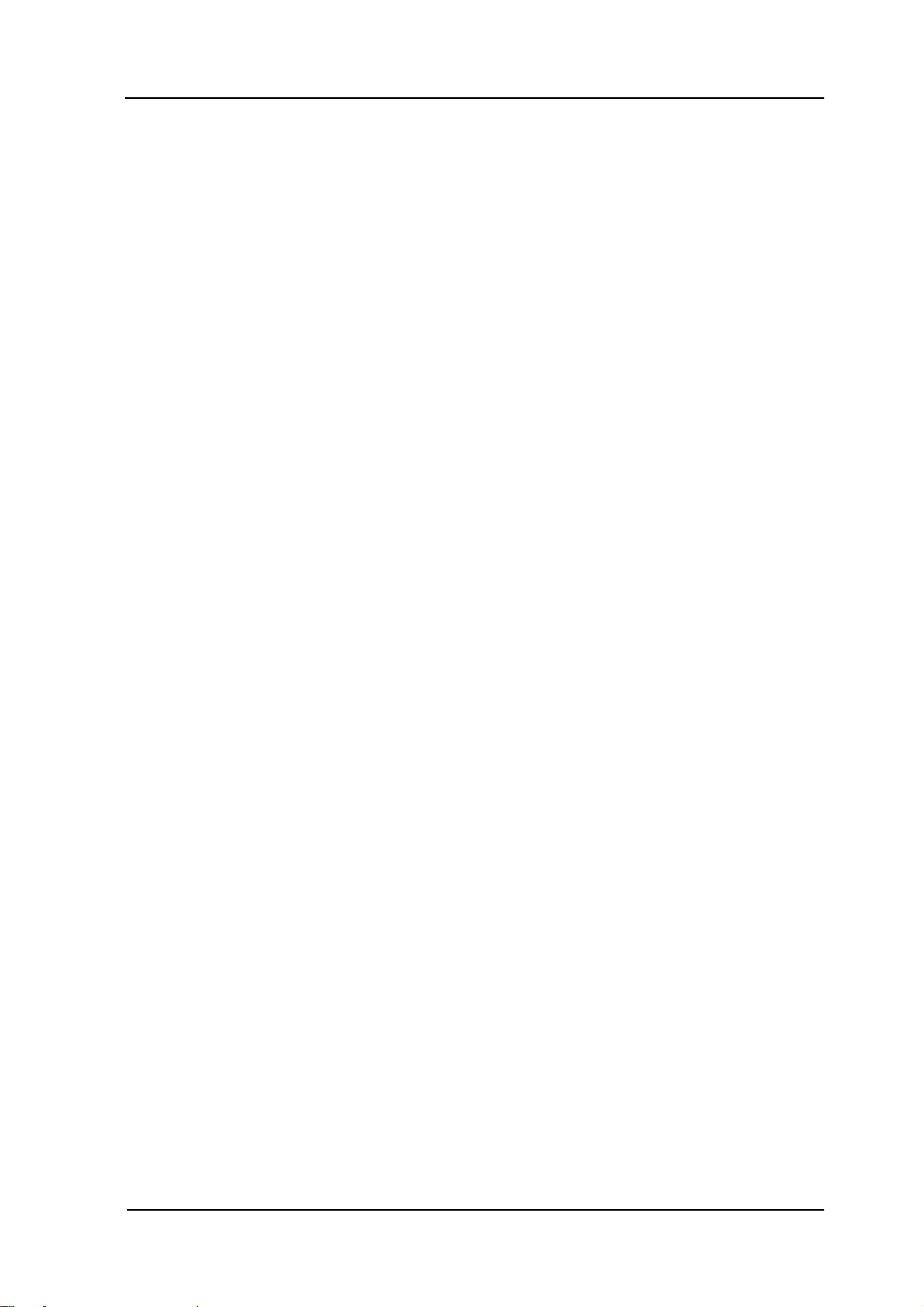

Figure 1- 1, Front Panel; the knobs are used most often and are similar to the knobs

on other oscilloscopes. The buttons allow you to use some of the functions directly

but also bring up soft button menus on the screen, which enable the access to many

measurement features associated with advanced functions, mathematics, and

reference or to run control features.

The front panel of DS1000E:

The front panel of DS1000D:

Figure 1- 1

Front Panel Figure of DS1000E, DS1000D Series Oscilloscope

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 15

RIGOL

1-3

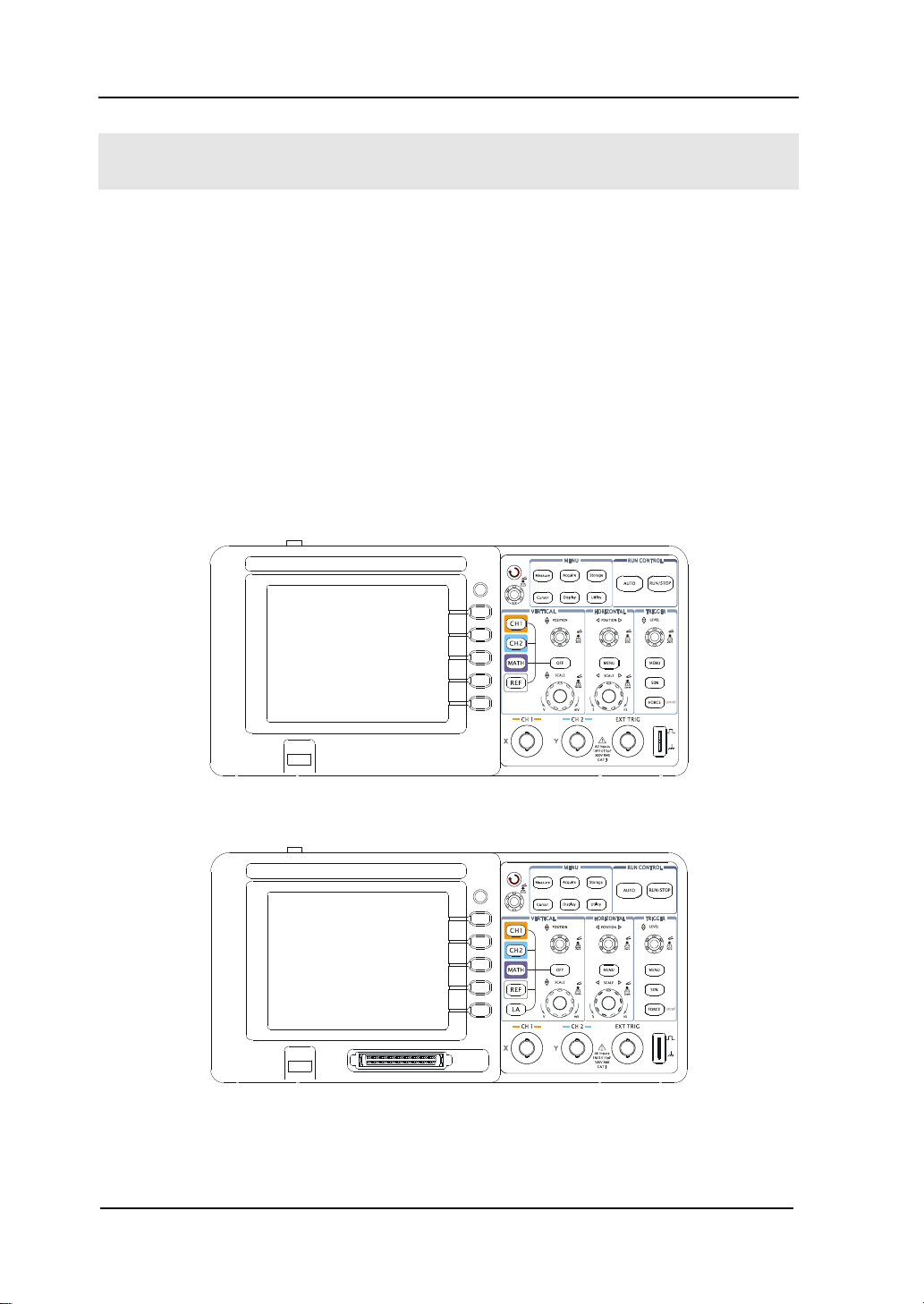

Multi-function Common Menu Run Control

Knob Buttons Buttons

Trigger Control

Horizontal

Control

Vertical Control

USB Host Logic Analyzer Port Signal Input EXT Trigger Probe

Channel Input Compensation

Figure 1- 2

Front Panel Instruction

Notation definitions in this User’s Guide:

Throughout this manual, notation symbols of buttons and knobs are the same to

those on front-panel.

A box around the name of the key denotes MENU function buttons on

front-panel, such as Measure.

( ) denotes the multi-function knob .

denotes the two POSITION knobs.

denotes the two SCALE knobs.

denotes the LEVEL knob.

The name with a drop shadow denotes the menu operating key, such as

WAVEFORM soft key in STORAGE menu.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 16

RIGOL

1-4

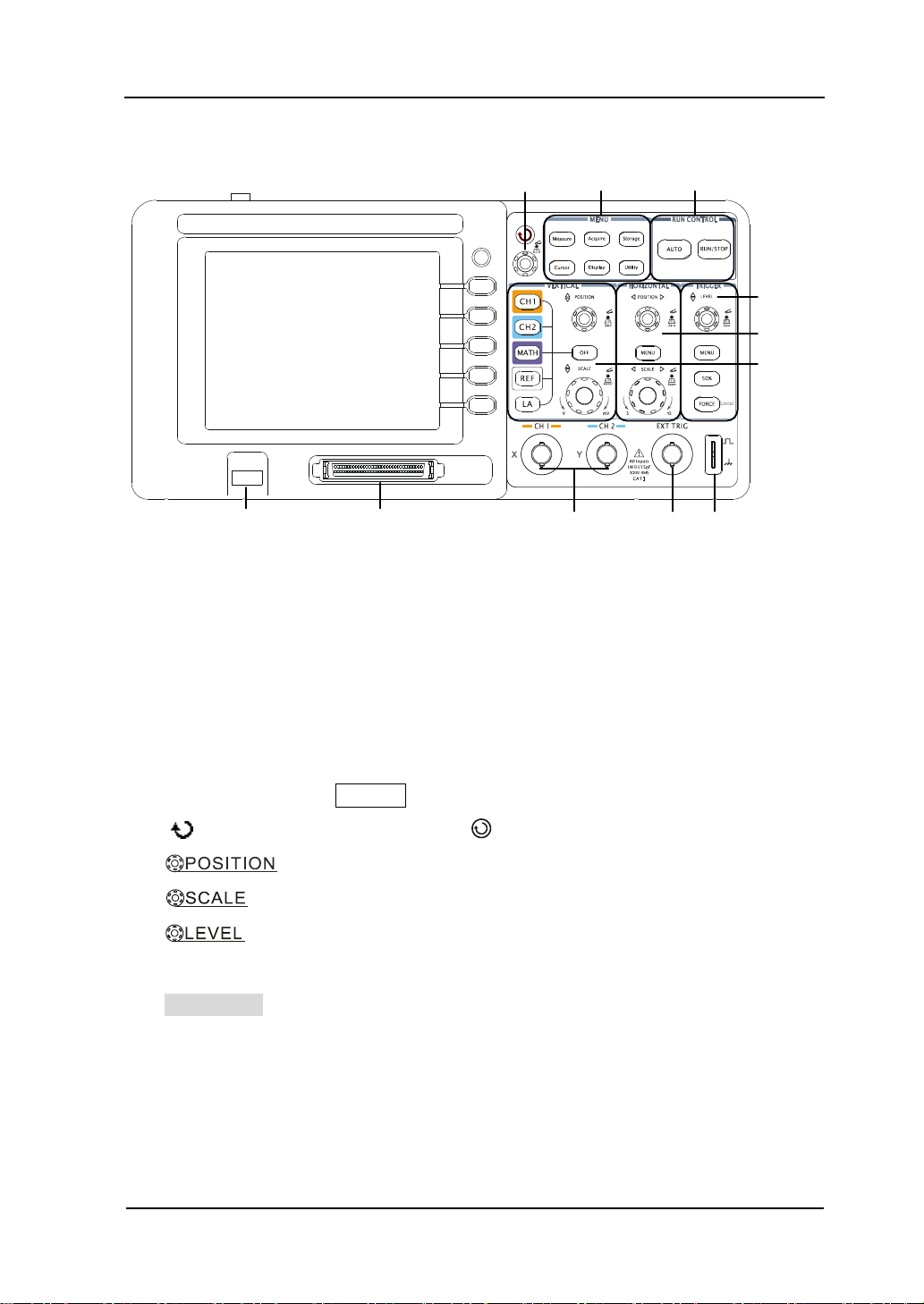

Waveform

display window

Menu

Channel 1

Channel 2

Running status

Location of

waveform window

in memory

Trigger point in

waveform window

Digital channels

Digital channels

turned off

Running status

Channel 1

Digital

channels

Channel coupling

and vertical div.

Horizontal

time base div.

Trigger

offset

Trigger point in

memory

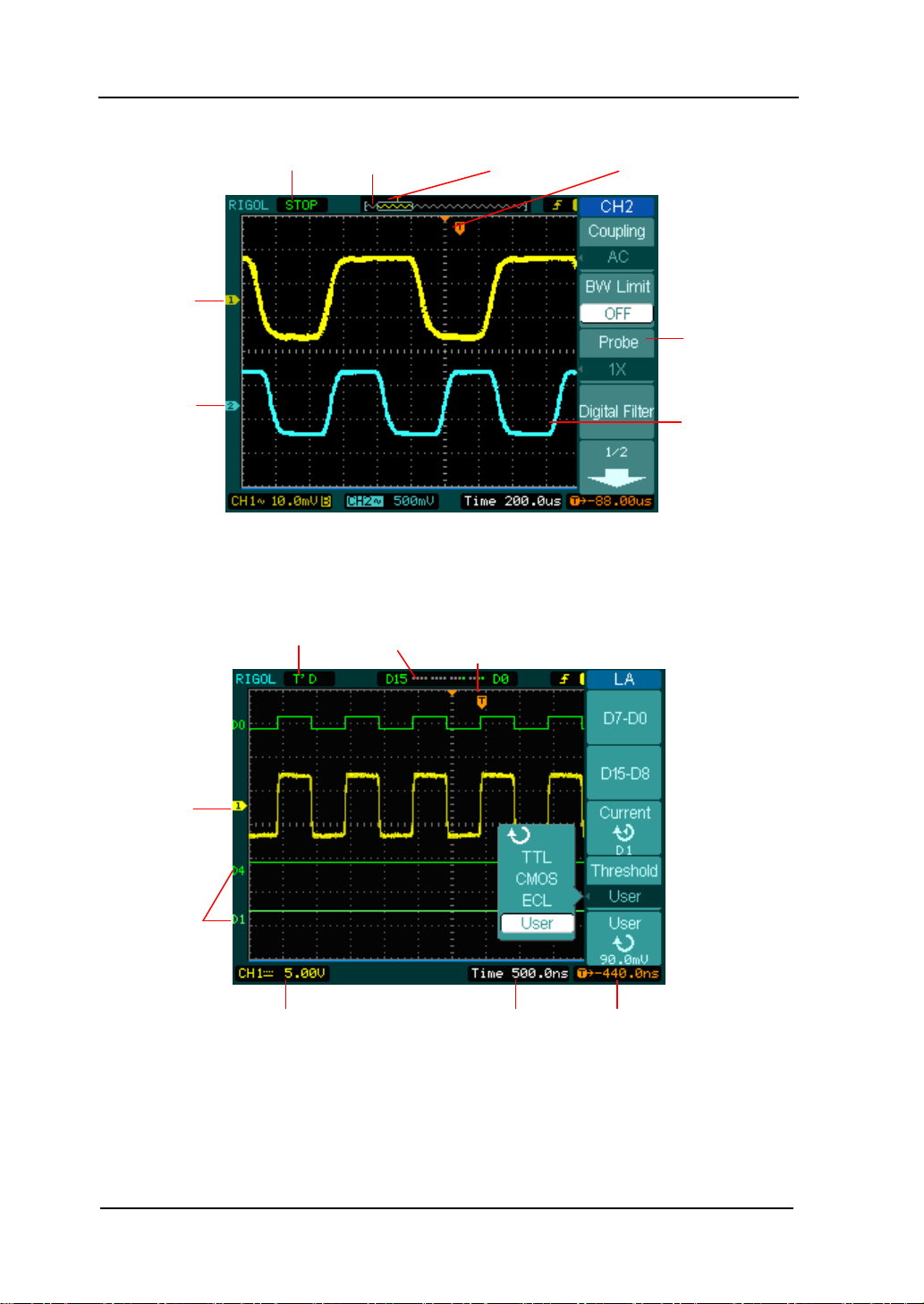

Figure 1- 3

Display screen (Analog channels only)

© 2008 RIGOL Technologies, Inc.

Figure 1- 4

User Interface (Analog and Digital channels)

User’s Guide for DS1000E, DS1000D Series

Page 17

1-5

RIGOL

To Inspect the Instrument

When you get a new DS1000E, DS1000D series oscilloscope, please inspect the

instrument according to the following steps:

1. Inspect the shipping container for damage.

Keep a damaged shipping container or cushioning material until the contents of

the shipment have been checked for completeness and the instrument has been

checked mechanically and electrically.

2. Check the accessories.

Accessories supplied with the instrument are listed in "

in this guide.

If the contents are incomplete or damaged, please notify your RIGOL Sales

Representative.

3. Inspect the instrument.

In case there is any mechanical damage or defect, or the instrument does not

operate properly or fails performance tests, please notify the RIGOL Sales

Representative.

If the shipping container is damaged, or the cushioning materials show signs of

stress, please notify the carrier as well as the RIGOL sales office. Keep the

shipping materials for the carrier’s inspection.

RIGOL offices will arrange for repair or replacement at RIGOL’s option without

waiting for claim settlement.

Appendix A: Accessories

"

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 18

RIGOL

1-6

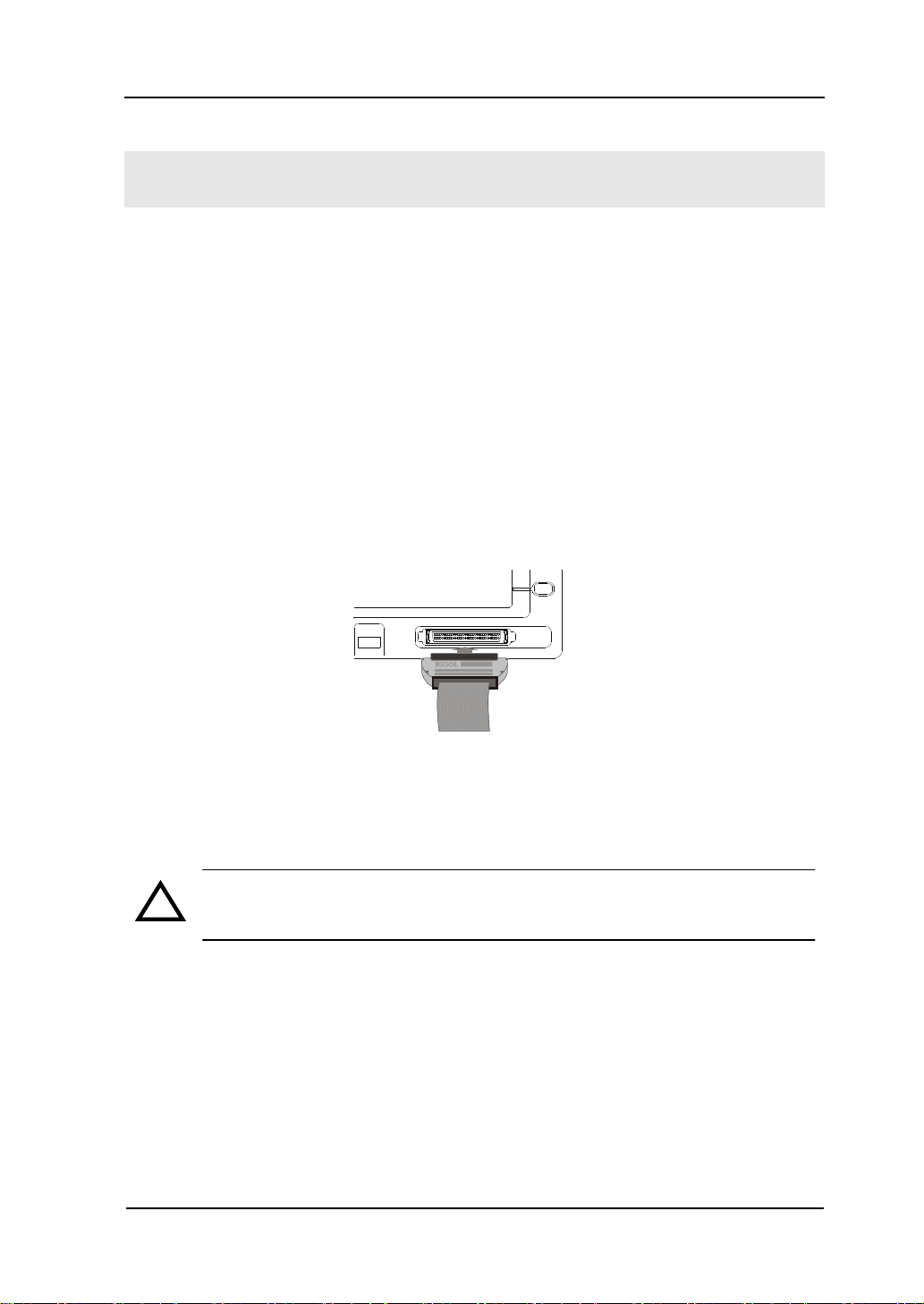

Power button

Storage button

!

To Perform a Functional Check

Perform this quick functional check to verify that the instrument is operating

correctly.

1. Turn on the instrument.

Use the power cord designed for the oscilloscope only.

Use a power source that delivers 100 to 240 VAC

, 45Hz to 440Hz.

RMS

Turn on the instruments, and wait until the display shows the waveform window.

Push the Storage button, select Storage in the top menu box and push the

Factory menu box.

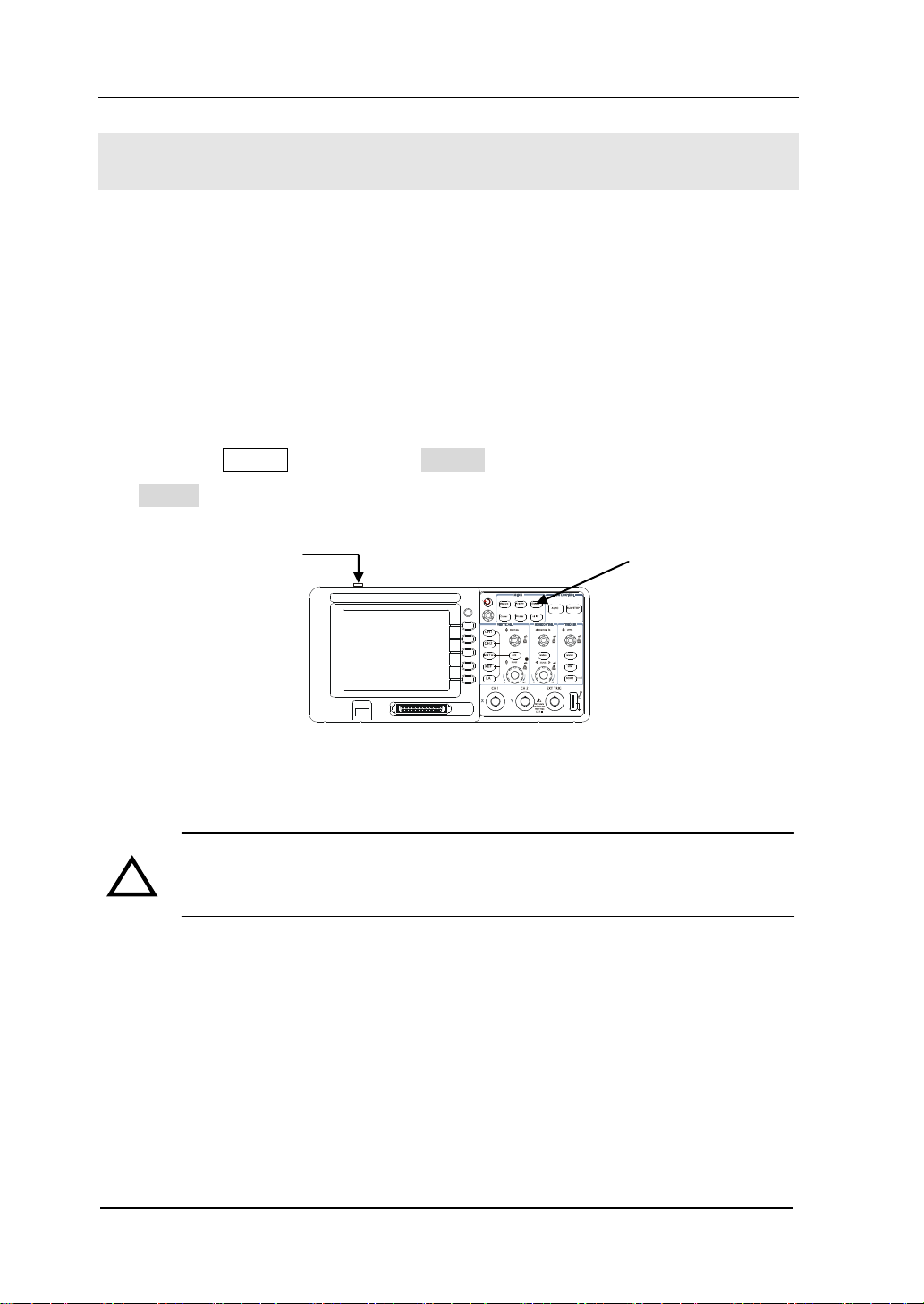

Figure 1- 5

Turn on and Check the instrument

WARNNING:

To avoid electric shock, be sure the oscilloscope is properly grounded.

2.Input a signal to a channel of the oscilloscope

DS1000E series: 2 channels input + 1 external trigger channel input

DS1000D series: 2 channels input + 1 external trigger channel input +16 channels

digital input

Do the following steps:

① Set the switch on the probe to 10X and connect the probe to Channel 1 on the

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 19

1-7

oscilloscope:

Probe compensator

Probe scale

Align the slot in the probe connector with the key on the CH 1 BNC.

Push to connect, and twist to the right to lock the probe in place.

Attach the probe tip and ground lead to the PROBE COMP connector.

Figure 1- 6

Attach the probe

② Set the probe attenuation to 10X. To do this, push CH1→Probe→10X.

RIGOL

Figure 1- 7 Figure 1- 8

Set attenuation on the probe Set attenuation in the menu

③ Push the AUTO button. Within a few seconds, a square wave will display.

④ Push the OFF button or push the CH1 button again to turn off Channel 1.

Push the CH2 button to turn on channel 2, repeat steps 2 and 3.

NOTE: The signal output from Probe compensator should only be used for probe

compensation, not for calibration.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 20

RIGOL

1-8

!

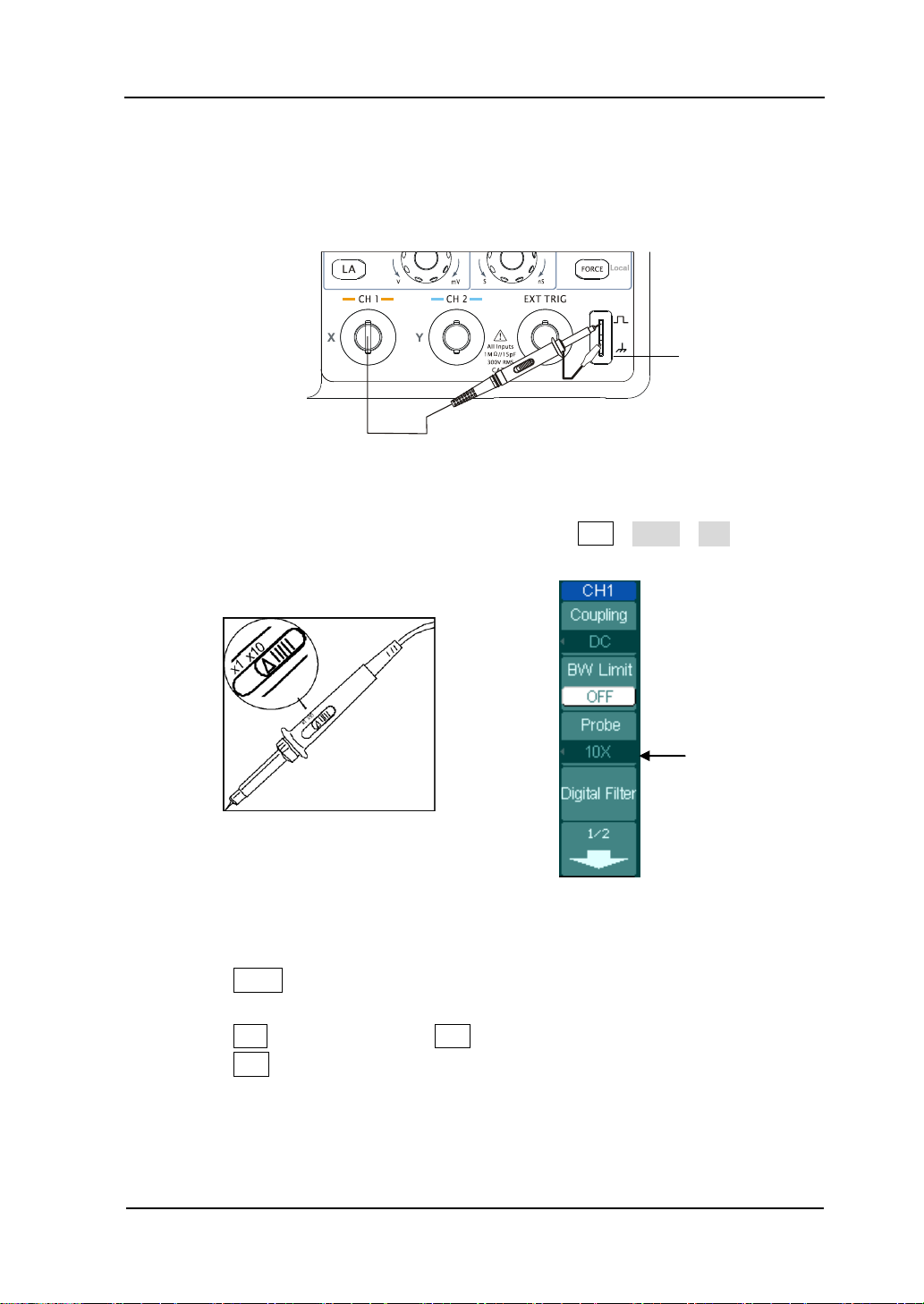

To Compensate Probes

Perform this adjustment to match the characteristics of the probe and the channel

input. This should be performed whenever attaching a probe to any input channel for

the first time.

1. From CH1 menu, set the Probe attenuation to 10X (press CH1→Probe→10X).

Set the switch to 10X on the probe and connect it to CH1 of the oscilloscope.

When using the probe hook-tip, inserting the tip onto the probe firmly to ensure

a proper connection.

Attach the probe tip to the Probe compensator connector and the reference lead

to the ground pin, Select CH1, and then press AUTO.

2. Check the shape of the displayed waveform.

Over compensated Correctly Compensated Under Compensated

Figure 1-9

Figure 1- 9

Probe Compensation

3. If necessary, use a non-metallic tool to adjust the trimmer capacitor on the probe

for the flattest square wave possible as displayed on the oscilloscope.

4. Repeat as necessary.

WARNNING: To avoid electric shock while using the probe, be sure the

perfection of the insulated cable, and do not touch the metallic portions of

the probe head while it is connected with a voltage source.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 21

1-9

!

RIGOL

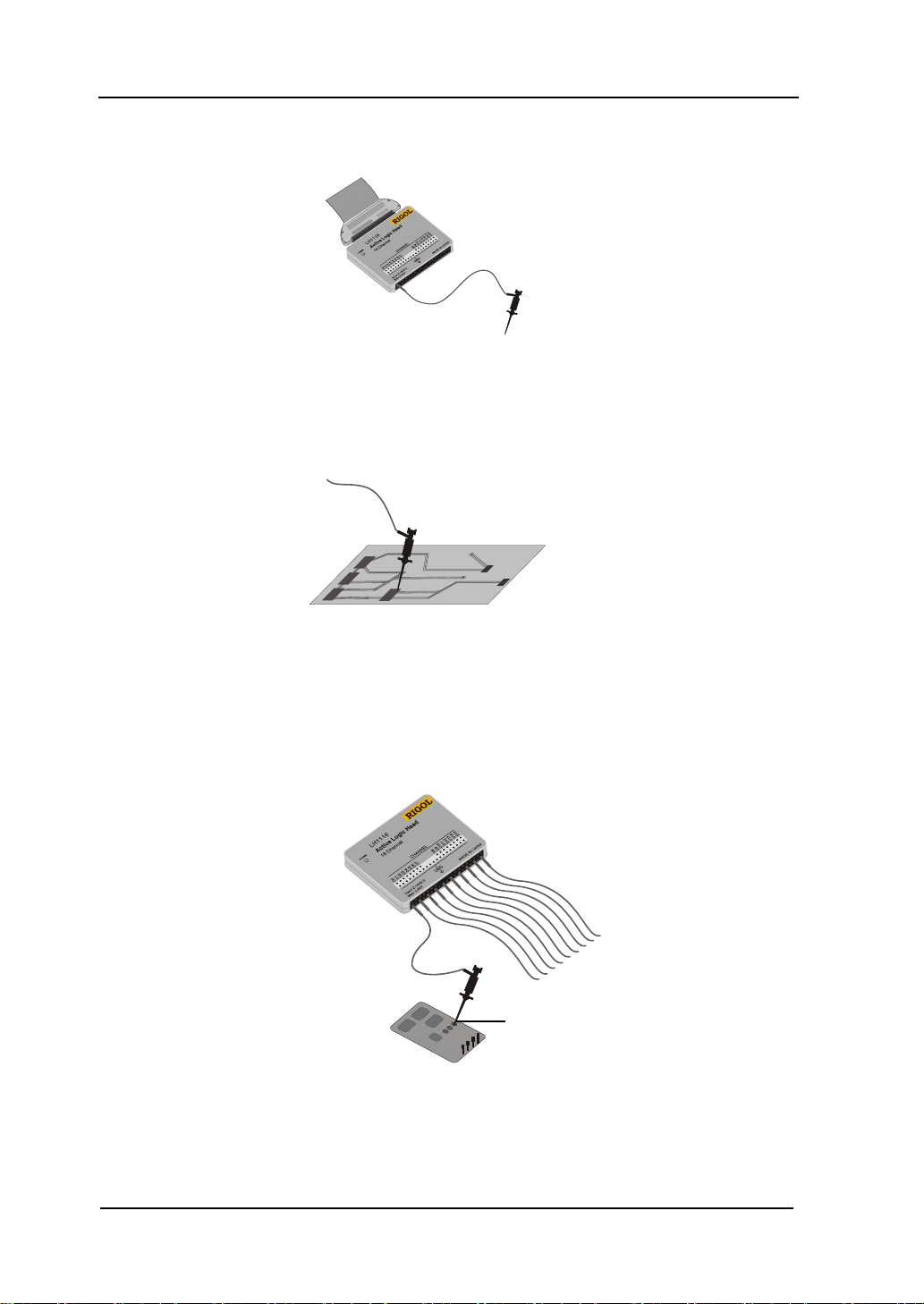

Digital Leads (DS1000D Series)

Digital leads are provided only for DS1000D series which have Logic Analyzer.

1. Switch off power supply of the device under test if necessary to avoid short

circuit. Since no voltage is applied to the leads at this step, you may keep the

oscilloscope on.

2. Connect one end of the flat cable FC1868 to the Logic Analyzer Input; connect

the other end to Logic Head LH1116. An identifier is located on each end of the

flat cable; it can only be connected in one way. It is unnecessary to switch off

power supply of your oscilloscope when connecting the cable.

Figure 1- 10

Connect the digital leads

CAUTION: Use only FC1868, LH1116, TC1100 and LC1150 made by

RIGOL for specified DS1000D series.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 22

RIGOL

1-10

Test clip

GND

3. Connect a test clip to one lead wire; make sure it’s connection good.

Figure 1- 11

4. Test your device with the clip.

Figure 1- 12

5. Remember to connect Ground Channel to the DUT’s ground terminal.

Figure 1- 13

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 23

1-11

RIGOL

To Display a Signal Automatically

The oscilloscope has an automated feature to display the input signal best-fit. The

input signal should be 50Hz or higher and a duty cycle is greater than 1%.

Press the AUTO button, the oscilloscope automatically sets up VERTICAL,

HORIZONTAL and TRIGGER controls to display the input signal. Adjust the controls

manually to get the best results if necessary.

Connect a signal to the Channel 1 (CH1).

1. Connect a signal to the oscilloscope as described above.

2. Press AUTO.

The oscilloscope may change the current settings to display the signal; and adjusts

the vertical and horizontal scaling, the trigger coupling, type, position, slope, level,

and mode.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 24

RIGOL

1-12

Measurement hints

If the channel is DC coupled, measuring the DC component of the signal by

simply noting its distance from the ground symbol.

If the channel is AC coupled, the DC component of the signal is blocked, allow

you to use greater sensitivity to display the AC component of the signal.

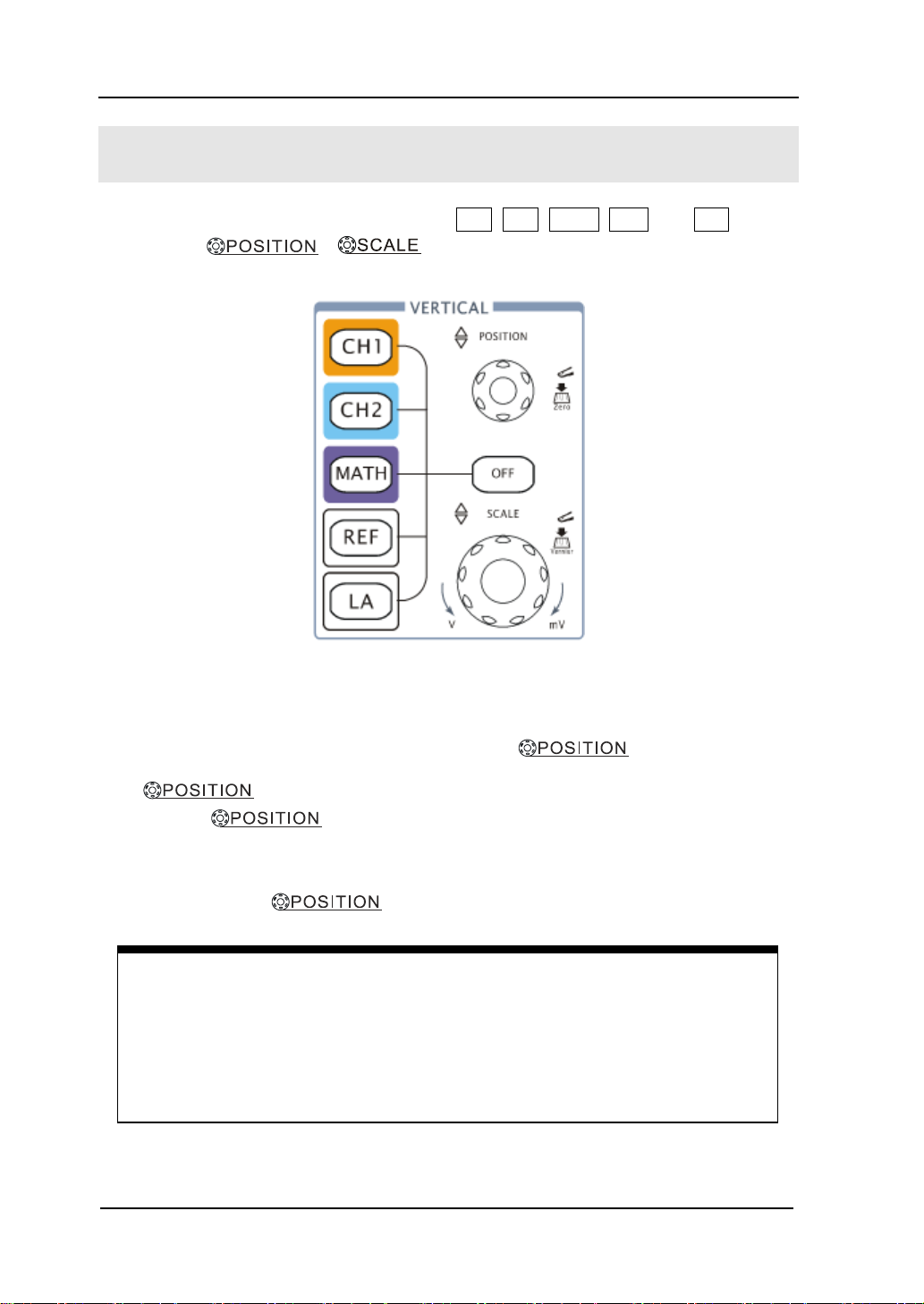

To Understand the Vertical System

Figure 1- 14 shows the VERTICAL controls, CH1, CH2, MATH, REF , and OFF buttons

and vertical , knobs. Following the exercise of the buttons,

knobs, and the status bar to be familiar with the vertical parameters settings.

1. Center the signal on the display with the knob.

The knob moves the signal vertically, and it is calibrated. Note that

turning the knob, a voltage value is displayed for a short time

indicating its value with respect to the ground reference located at the center of the

screen. Also notice that the ground symbol on the left side of the display moves in

conjunction with the knob.

Figure 1- 14

The vertical window

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 25

RIGOL

1-13

Vertical offset back to 0 shortcut key

Turn the knob to change the vertical display position of

channel and press the knob to set the vertical display position

back to 0 as a shortcut key, this is especially helpful when the trace position is

far out of the screen and want it to get back to the screen center immediately.

Coarse/Fine Shortcut key

The Coarse/Fine vertical control can be set by simply pressing the vertical

knob.

2. Change the vertical setup and notice that each change affects the

status bar differently.

View the status bar which is on the bottom of the screen to understand the

vertical scale.

Change the vertical scale by turning the knob and notice the change

in the status bar.

Press OFF button to turn off the channel.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 26

RIGOL

1-14

Delayed Scan Shortcut key

To press the knob in the horizontal control area on the front-panel

is another way to enter or exit Delayed Scan mode and it is equal to the

following menu operations, MENU→Delayed→ON.

To Understand the Horizontal System

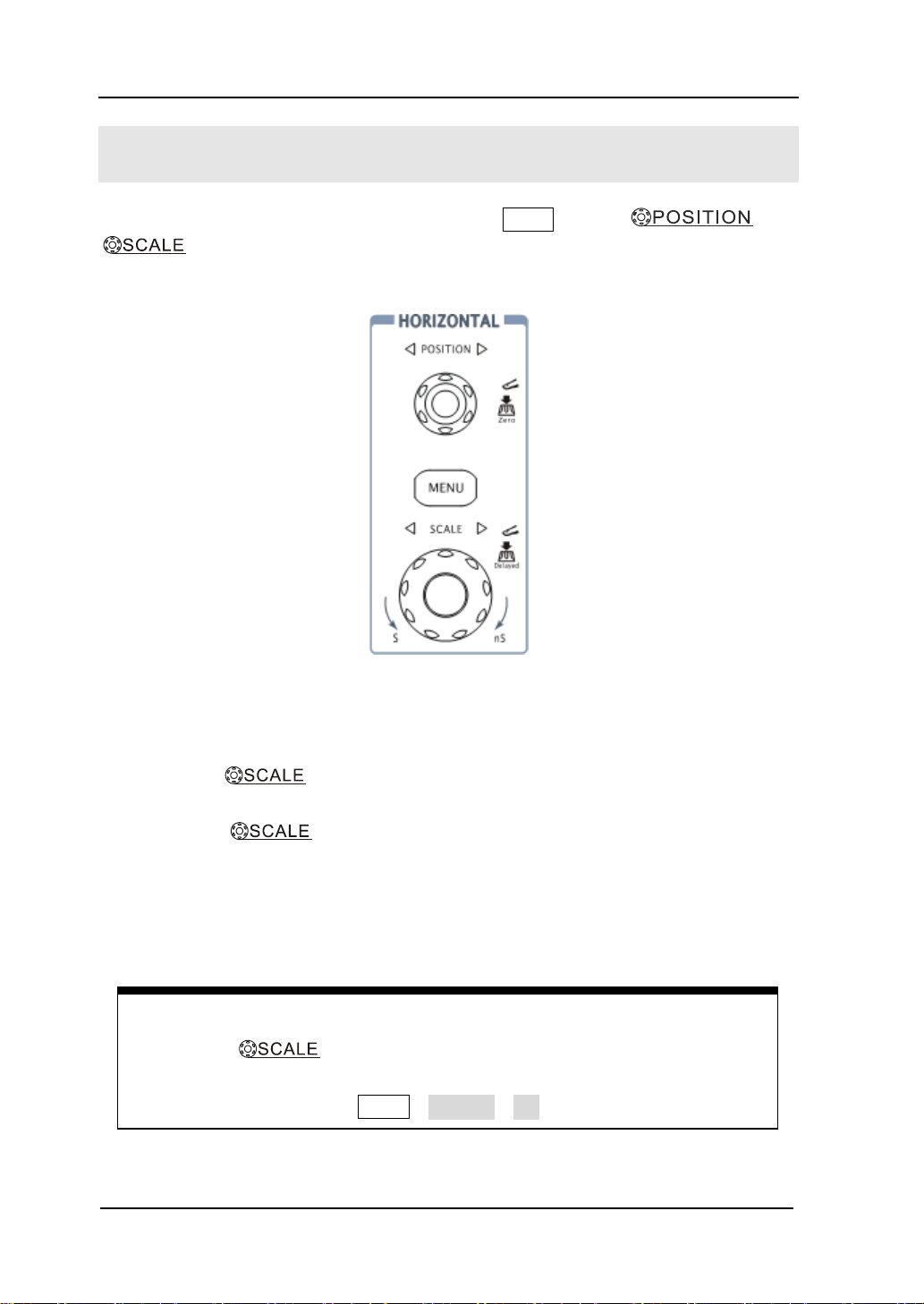

Figure 1- 15 shows the HORIZONTAL controls: MENU button, and

knobs of horizontal system. Following the exercise to familiarize with the

buttons, knobs, and status bar.

Figure 1- 15

The horizontal system

1. Turn the knob and notice the change in the status bar.

The horizontal knob changes the sweep speed in a 1-2-5 step sequence,

and displays the value in the status bar. The time base ranges of the oscilloscope is

from 2ns/div* to 50s/div.

* NOTE: The speed of horizontal scan varies by different models.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 27

RIGOL

1-15

Horizontal offset back to 0 shortcut key

Press the knob to set the horizontal offset to 0 as a shortcut

key, this is especially helpful when the trigger point is far out of the screen and

want it to get back to the screen center immediately.

Horizontal position control

Trig-Offset: In this setting, the trigger position will be changed horizontally

when you turn the knob.

2. The horizontal knob moves displayed signal horizontally

on waveform window

3. Press the MENU key to display the TIME menu.

To enter or exit the Delayed Scan mode, set the display to Y-T, X-Y or ROLL mode,

and turn the horizontal knob to adjust trigger offset.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 28

RIGOL

1-16

Turn the knob to change trigger level value and press the

knob to set trigger level back to 0 as a shortcut key.

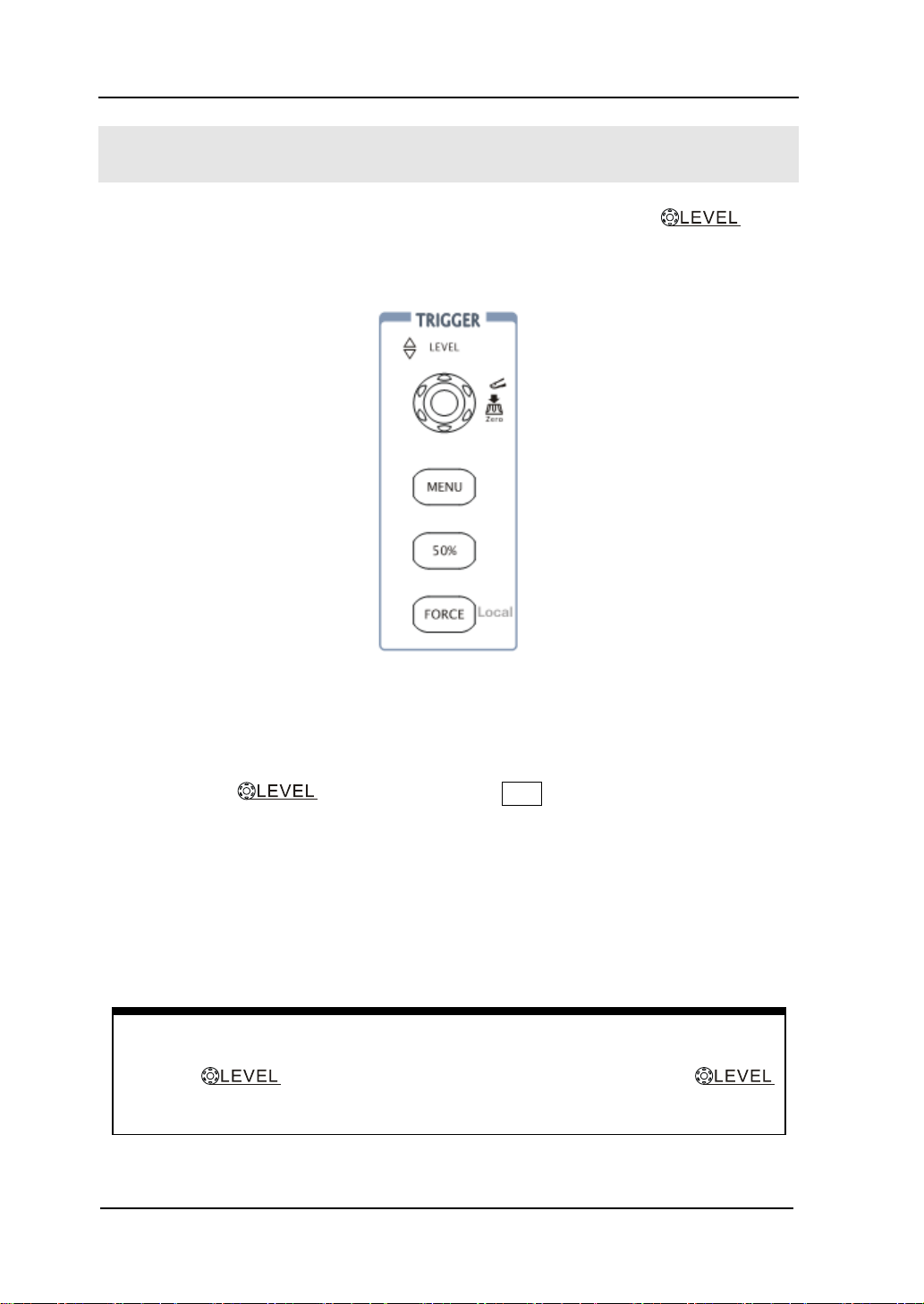

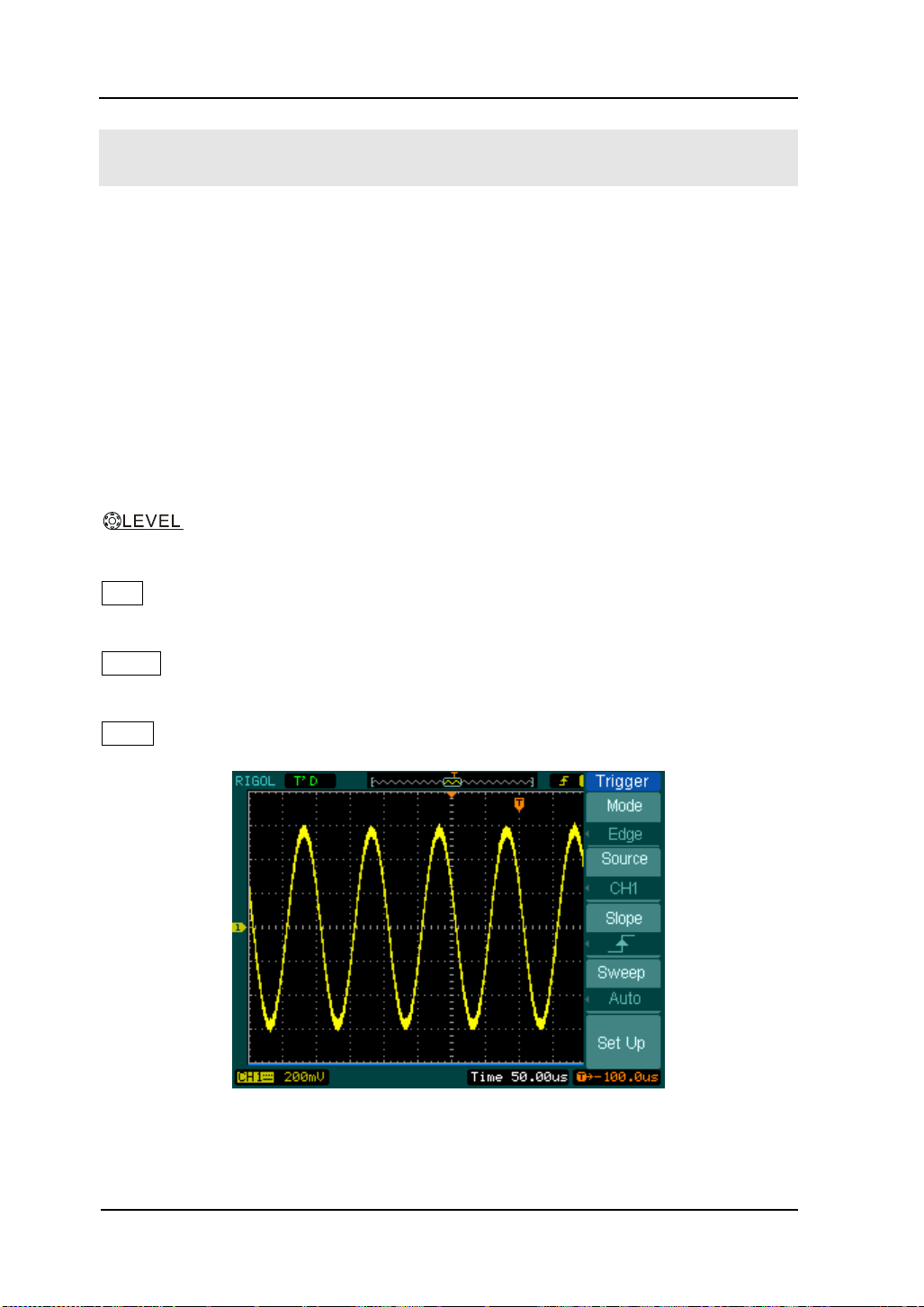

To Trigger the Oscilloscope

Figure 1- 16 shows the trigger control: MENU, 50%, FORCE and a trigger

level knob. Following the exercise to familiarize with the buttons, trigger level knob

and status bar.

Figure 1- 16

The trigger control window

1. Turn the trigger Level knob and notice the changes on the display.

As you turn the knob or pressing the 50% button, two things will happen

on the display for a short time.

First, the trigger level value is displayed at the bottom-left of the screen. If the

trigger is DC coupled, it is displayed as a voltage value. If the trigger is AC

coupled or LF reject, it is displayed as a percentage of the trigger range.

Second, a line is displayed showing the location of the trigger level (as long as

AC coupling or low frequency reject are not selected).

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 29

RIGOL

1-17

Key point:

Holdoff: A time interval before the oscilloscope response to next trigger

signal. During this holdoff period, the trigger system becomes “blind” to

trigger signals. This function helps to view complex signals such as an AM

waveform. Press Holdoff button to activate ( ) knob, then turn it to adjust

Holdoff time.

2. Change the trigger setup and notice these changes in the status bar.

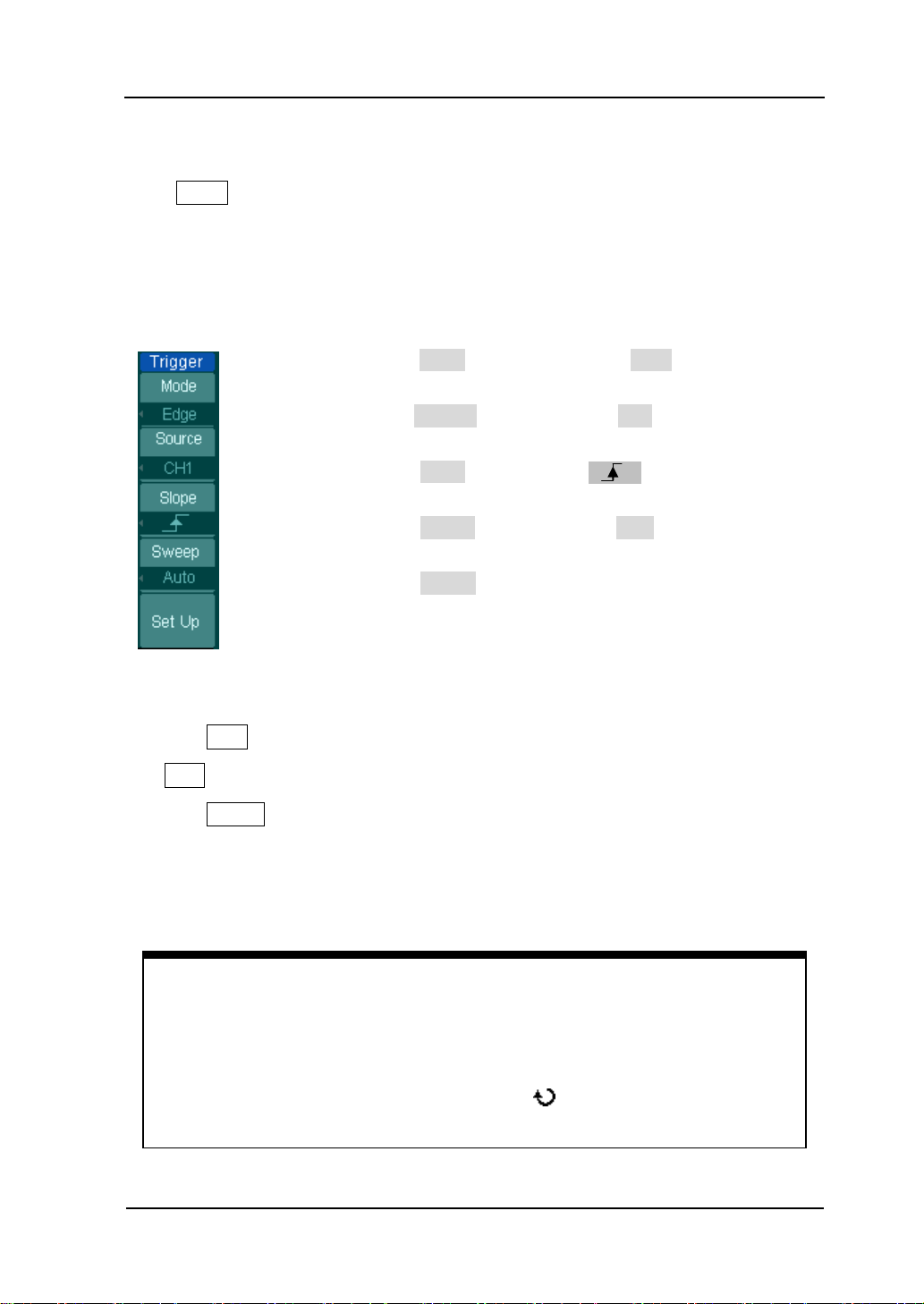

Press MENU button in the Trigger control.

A soft button menu appears on the display showing the trigger setting choices as

shown in

Figure 1- 17 .

Figure 1- 17

· Press the trigger Mode button and choose Edge.

· Press the trigger Source button to select CH1.

· Press the trigger Slope button to choose .

· Press the trigger Sweep button to select Auto.

· Press the trigger Set Up button to enter secondary menu.

NOTE: The trigger type, slope and source change in conjunction with the status bar

on the top-right of the screen.

3. Press 50%

The 50% button sets the trigger level to the center of the signal.

4. Press FORCE

Starting an acquisition regardless of an adequate trigger signal, usually used in

“Normal” or “Single” trigger mode. This button has no effect if the acquisition is

already stopped.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 30

RIGOL

1-18

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 31

RIGOL

2-1

Chapter 2 : Operating Your Oscilloscope

By now, a user should understand the VERTICAL, HORIZONTAL and TRIGGER

control systems and knows how to determine the system setup by status bar of a

DS1000E, DS1000D series digital oscilloscope.

This chapter will go through all groups of front-panel buttons, knobs and menus;

and further the knowledge of the operation by hints in this guide.

It is recommended to perform all of the following exercises to get the most of the

powerful measurement capabilities of the oscilloscope.

This chapter covers the following topics:

To set up the vertical system ( CH1, CH2, MATH, REF, LA, OFF,

Vertical , Vertical )

To set up the horizontal system ( MENU, Horizontal ,

Horizontal )

To set up the trigger system ( , MENU, 50%, FORCE)

To set up the sampling system ( Acquire)

To set up the display system ( Display)

To save and recall waveforms, CSV format, bmp format and other setups

( Storage)

To set up utility ( Utility)

To measure automatically ( Measure)

To measure with cursors ( Cursor)

To use run control buttons ( AUTO, RUN/STOP)

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 32

RIGOL

2-2

Menu

Settings

Comments

Coupling

AC

DC

GND

Blocks the DC component of the

input Signal

Passes both AC and DC

components of the input signal

Disconnects the input signal

BW Limit

ON

OFF

Limits the channel bandwidth to

20MHz to reduce display noise.

Get full bandwidth.

Probe

1X

5X

10X

50X

100X

500X

1000X

Set this to match your probe

attenuation factor to make the

vertical scale readout correct

Digital filter

Setup digital filter (See table 2-4)

1/2

Go to the next menu page (The

followings are the same, no

more explanation)

To Set up the Vertical System

Settings of the Channels

Each channel has an operation menu and it will pop up after pressing CH1 or CH2

button. The settings of all items in the menu are shown in the table below.

Figure 2- 1 Table 2- 1 The Channel menu (Page 1/2)

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 33

2-3

Menu

Settings

Comments

2/2

Back to the previous menu page

(The followings are the same, no

more explanation)

Volts/Div

Coarse

Fine

Selects the resolution of the

knob

Defines a 1-2-5 sequence.

To change the resolution to small

steps between the coarse settings.

Invert

ON

OFF

Turn on the invert function.

Restore original display of the

waveform.

Figure 2- 2 Table 2- 2 The Channel menu (Page 2/2)

RIGOL

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 34

RIGOL

2-4

AC coupling

setup

AC coupling

status symbol

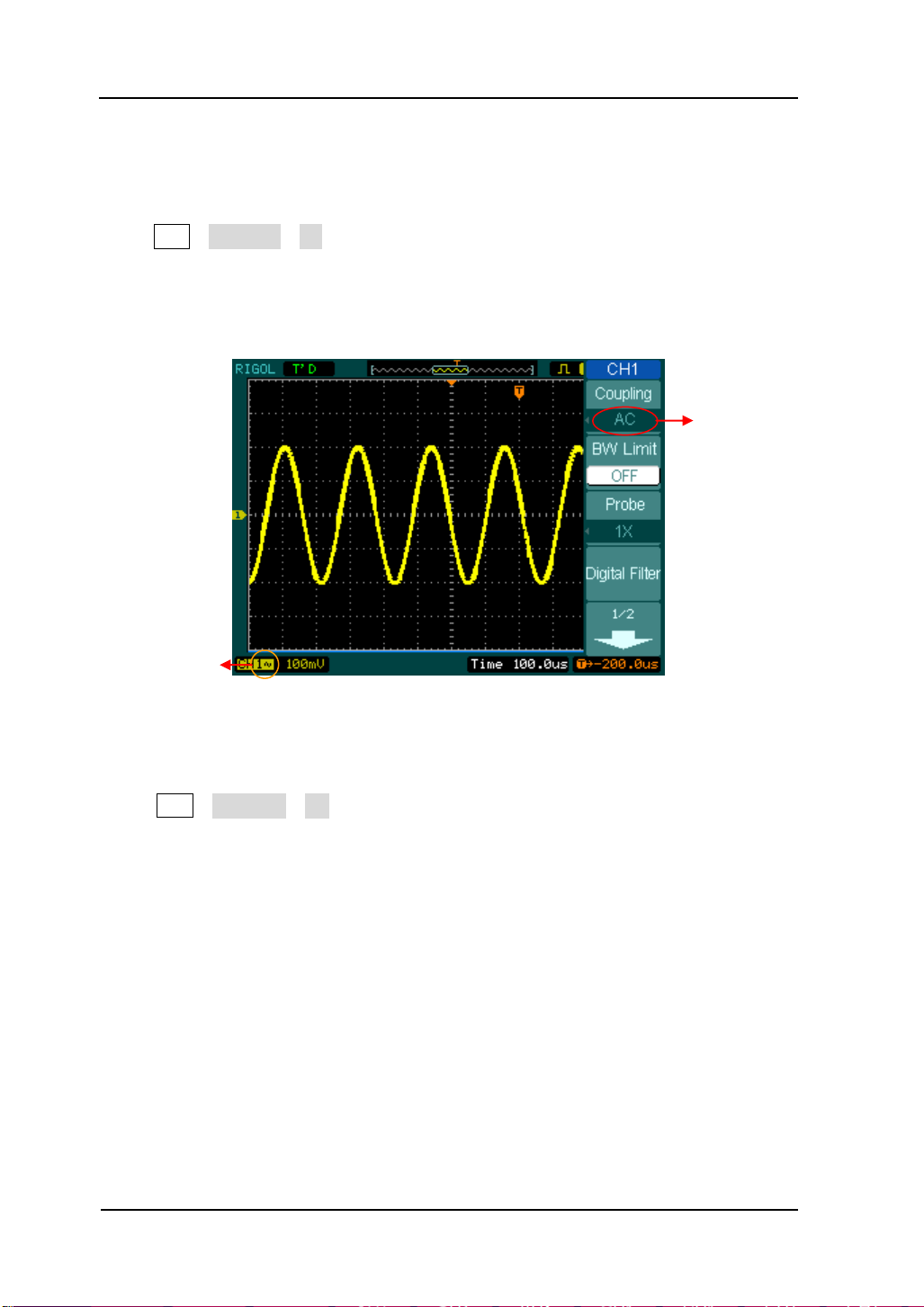

1. Channel coupling

To use Channel 1 as an example, input a sine wave signal with DC shift.

Press CH1→Coupling→AC to set “AC” coupling. It will pass AC component blocks

the DC component of the input signal.

The waveform is displayed as Figure 2- 3:

Figure 2- 3

AC coupling setting

Press CH1→Coupling→DC, to set “DC” coupling. It will pass both AC and DC

components of the input signal.

The waveform is displayed as Figure 2- 4:

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 35

RIGOL

2-5

GND coupling

setup

GND coupling

status symbol

DC coupling

setup

DC coupling

status symbol

Figure 2- 4

DC coupling setting

Press CH1→Coupling→GND, to set “GND” coupling, it disconnects the input signal.

The screen displays as Figure 2-5:

Figure 2- 5

GND coupling setting

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 36

RIGOL

2-6

Turn off the BW

limit

2. Set up the channel bandwidth limit

To use Channel 1 as an example, input a signal containing high frequency

component.

Press CH1 →BW Limit→OFF, to set up bandwidth limit to “OFF” status. The

oscilloscope is set to full bandwidth and passing the high frequency component in

the signal.

The waveform is displayed as Figure 2- 6:

Figure 2- 6

Turn off the BW limit

Press CH1→BW Limit→ON, to set up bandwidth limit to “ON” status. It will reject

the frequency component higher than 20MHz.

The waveform is displayed as Figure 2- 7:

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 37

2-7

20M BW limit

Mark of

BW limit

Figure 2- 7

Turn on the BW limit

RIGOL

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 38

RIGOL

2-8

Probe attenuation factors

Corresponding settings

1:1

1X

5:1

5X

10:1

10X

50:1

50X

100:1

100X

500:1

500X

1000:1

1000X

Probe

attenuation

Vertical volt/div.

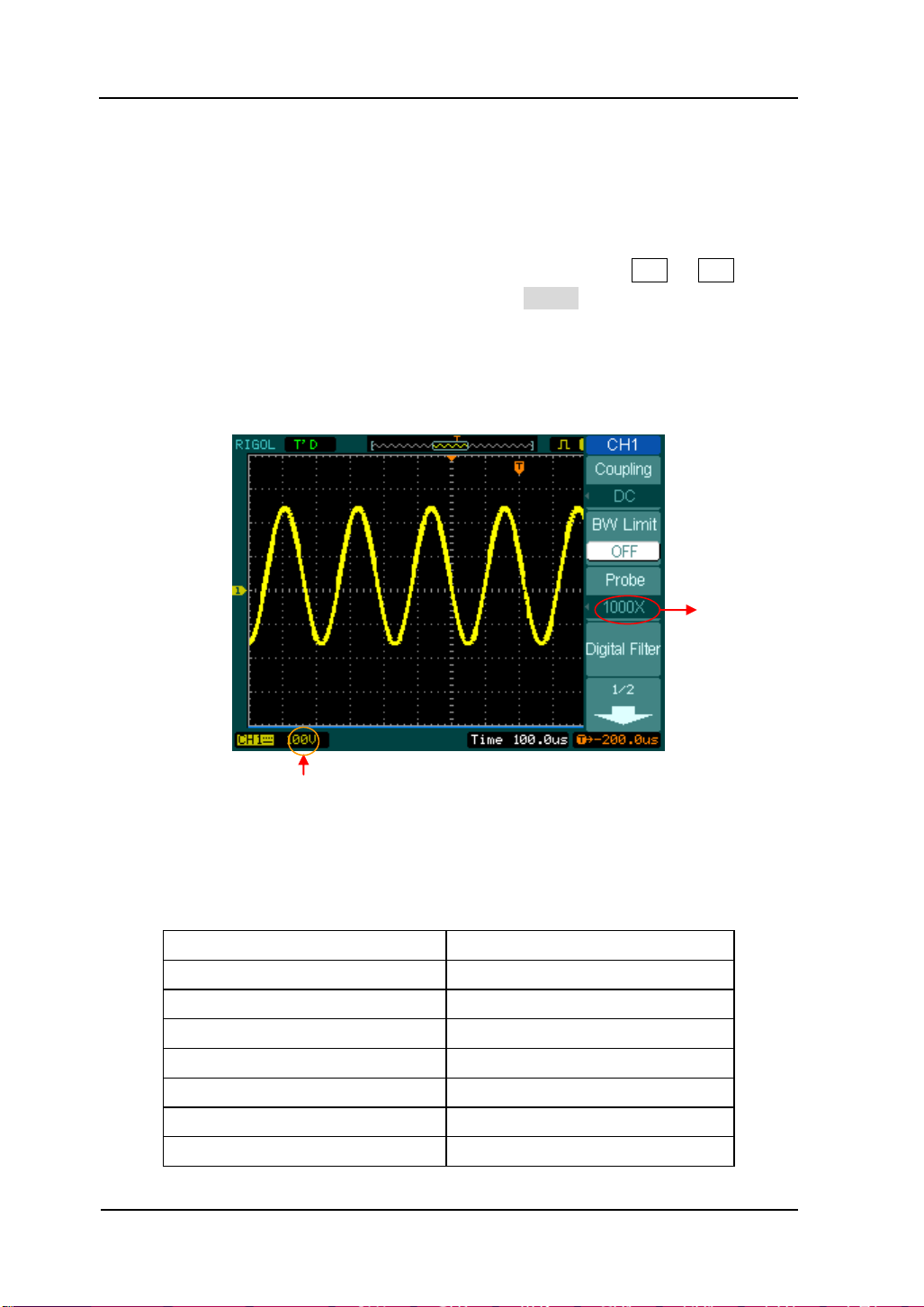

3. Probe Attenuation Setting

The oscilloscope allows selecting the attenuation factor for the probe. The

attenuation factor changes the vertical scaling of the oscilloscope so that the

measurement results reflect the actual voltage levels at the probe tip.

To change (or check) the probe attenuation setting, press the CH1 or CH2 button

(according to which channel in using). Toggle the Probe soft button to match the

attenuation factor of the probe.

This setting remains in effect until changed again.

Figure 2-8 shows an example for using a 1000:1 probe and its attenuation factor.

Figure 2- 8

Use the 1000:1 attenuation

Table 2- 3 Probe setting

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 39

RIGOL

2-9

Coarse/Fine Shortcut key:

To change Coarse/Fine setting, not only by menu but also by pressing vertical

knob

Fine adjustment

Fine adjustment data

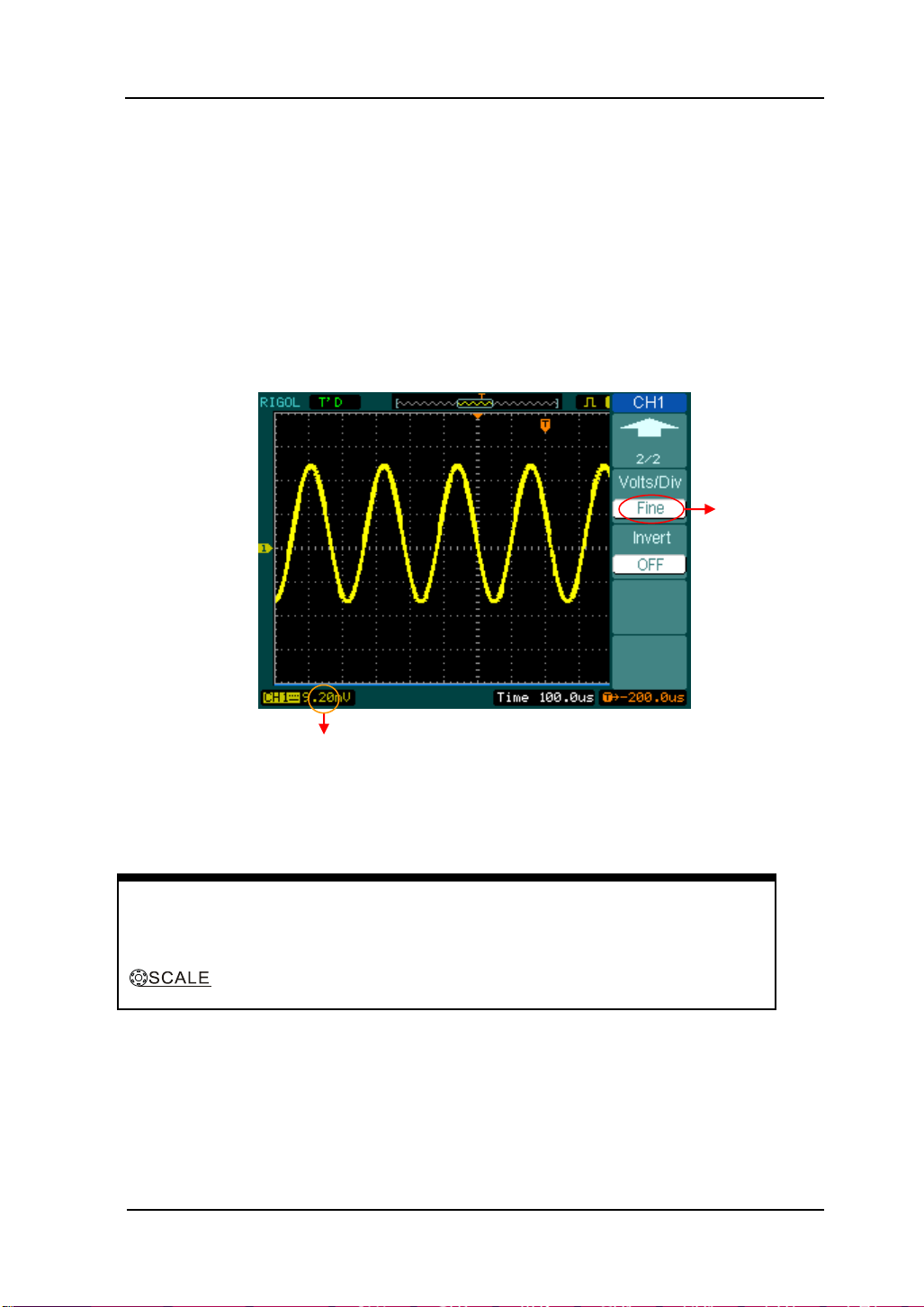

4. Volts/Div settings

The Volts/Div control has Coarse or Fine configuration. The Vertical Sensitivity is

2mV/div - 10V/div.

Coarse: It is the default setting of Volts/Div in a 1-2-5-step sequence from

2mV/div、5mV/div、10mV/div、20mV/div……10V/div.

Fine: This setting changes the vertical scale to small steps between the coarse

settings. It will be helpful to adjust the waveform in smooth steps.

© 2008 RIGOL Technologies, Inc.

Figure 2- 9

Fine configurations

User’s Guide for DS1000E, DS1000D Series

Page 40

RIGOL

2-10

Invert ON

Invert OFF

5. To invert a waveform

Invert turns the displayed waveform 180 degrees, as respect to the ground level.

When the oscilloscope is triggered on the inverted signal, the trigger is also inverted.

Figure 2- 10 and Figure 2- 11 show the changes after inversion.

Figure 2- 10

The waveform before inversion

Figure 2- 11

The waveform after inversion

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 41

RIGOL

2-11

Turn off digital filter

Turn on digital filter

Mark of digital filter

Digital Filter:

Press CH1→Digital filter, display the digital filter menu. Turn ( ) knob to set high

and low limit of frequency.

Figure 2- 12

The waveform when turning off digital filter

Figure 2- 13

The waveform when turning on digital filter

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 42

RIGOL

2-12

Menu

Settings

Comments

Digital Filter

ON

OFF

Turn on the digital filter

Turn off the digital filter

Filter Type

Setup as LPF (Low Pass Filter)

Setup as HPF (High Pass Filter)

Setup as BPF (Band Pass Filter)

Setup as BRF (Band Reject Filter)

Upper limit

<frequency>

Turn ( ) knob to set high limit

Lower limit

<frequency>

Turn ( ) knob to set low limit

Back to higher level menu (The

followings are the same, no more

explanation)

Figure 2- 14 Table 2- 4 The Filter menu

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 43

RIGOL

2-13

Menu

Settings

Comments

Operation

A+B

A-B

A× B

FFT

Add source A and source B

Subtract source B from source A

Multiply source B by source A

Fast Fourier Transform

Source A

CH1

CH2

Define CH1 or CH2 as source A

Source B

CH1

CH2

Define CH1 or CH2 as source B

Invert

ON

OFF

Invert the MATH waveform.

Restore to original waveform display.

MATH scale

Math Functions

The mathematic functions include “add”, “subtract”, “multiply” and “FFT” for

Channel 1 and Channel 2. The mathematic result can be measured by grid and

cursor.

Figure 2- 15

The Math function

Figure 2- 16 Table 2- 5 The Math menu

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 44

RIGOL

2-14

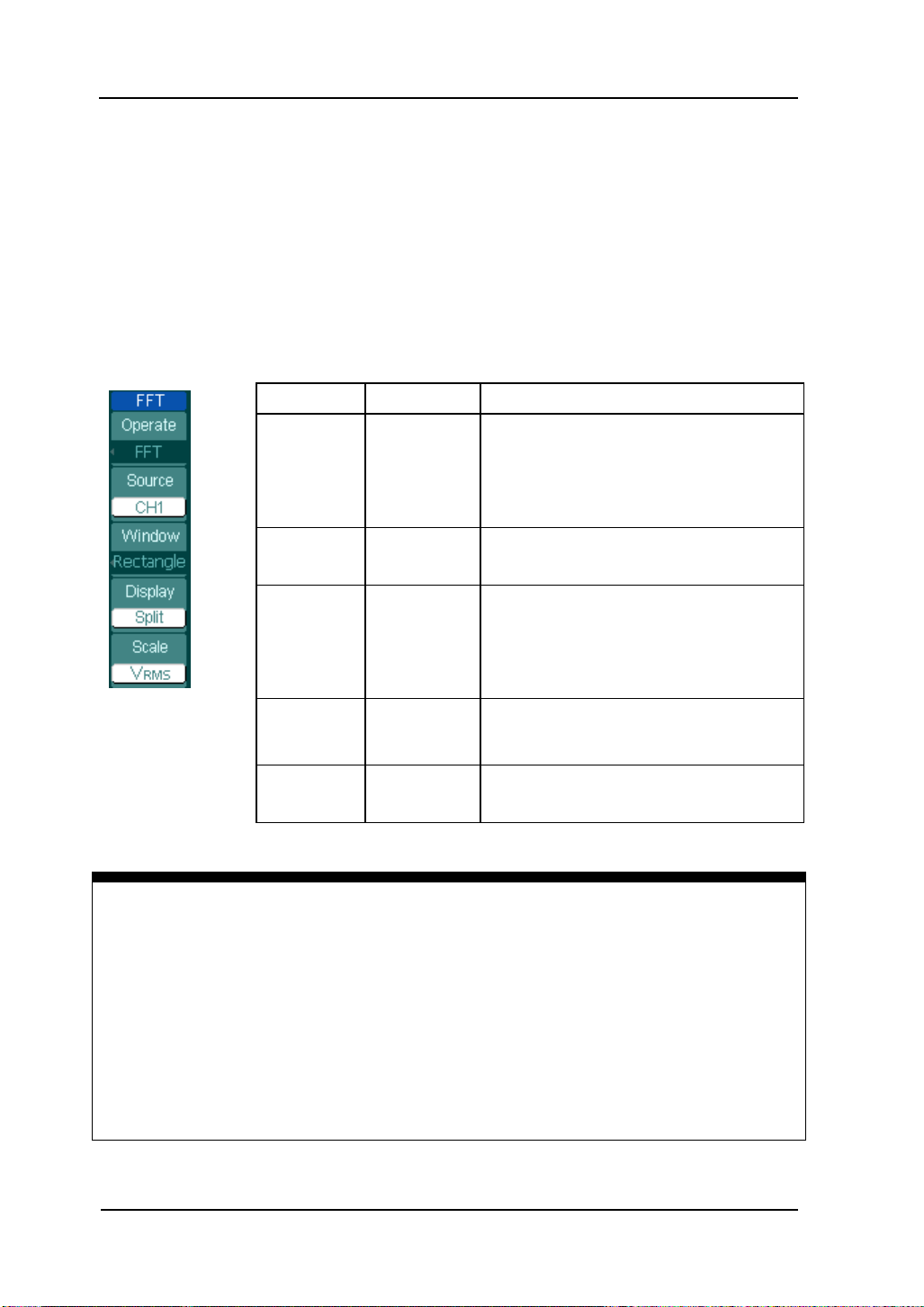

Menu

Settings

Comments

Operate

A+B

A-B

A x B

FFT

Add source A to source B

Subtract source B from source A

Multiply source B by source A

Fast Fourier Transform

Source

CH1

CH2

Define CH1 or CH2 as FFT source

Window

Rectangle

Hanning

Hamming

Blackman

Select window for FFT

Display

Split

Full screen

Display FFT waveform on half screen

Display FFT waveform on full screen

Scale

Vrms

dBVrms

Set “Vrms ” as vertical unit

Set “dBVrms ” as vertical unit

Key points for FFT

1. Signals that have a DC component or offset can cause incorrect FFT waveform

component magnitude values. To minimize the DC component, choose AC

Coupling on the source signal.

2. To reduce random noise and aliases components in repetitive or single-shot

events, set the oscilloscope acquisition mode to average.

3. To display FFT waveforms with a large dynamic range, use the dBVrms scale.

The dBVrms scale displays component magnitudes using a log scale.

Using the FFT

The FFT (Fast Fourier Transform) process converts a time-domain signal into its

frequency components mathematically. FFT waveforms are useful in the following

applications:

Measuring harmonic content and distortion in systems

Characterizing noise in DC power supplies

Analyzing vibration

Figure 2- 17 Table 2- 6 The FFT menu

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 45

RIGOL

2-15

Window

Features

Best for measuring

Rectangle

Best frequency

Resolution and worst

magnitude resolution.

This is essentially the

same as no window.

Transients or bursts, the signal

levels before and after the event

are nearly equal.

Equal-amplitude sine waves with

fixed frequencies.

Broadband random noise with a

relatively slow varying spectrum.

Hanning

Hamming

Better frequency,

poorer magnitude

accuracy than

Rectangular.

Hamming has slightly

better frequency

resolution than

Hanning.

Sine, periodic, and narrow-band

random noise.

Transients or bursts where the

signal levels before and after the

events are significantly different.

Blackman

Best magnitude, worst

frequency resolution.

Single frequency waveforms, to

Find higher order harmonics.

Key points:

FFT Resolution: the quotient between sampling rate and number of FFT

points. With a fixed FFT points, the lower sampling rate results in better

resolution.

Nyquist Frequency

The highest frequency that any real-time digitizing oscilloscope can acquire

without aliasing. It’s normally half of the sample rate. This frequency is called

the Nyquist frequency. Frequency above the Nyquist frequency will be under

sampled, causing a situation known as aliasing.

Selecting an FFT Window

The oscilloscopes provide four FFT windows. Each window is a trade-off between

frequency resolution and amplitude accuracy. What you want to measure and your

source signals characteristics help determine which window to use. Use the

following guidelines to select the best window.

Table 2- 7 FFT Windows

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 46

RIGOL

2-16

Menu

Settings

Comments

Source

CH1

CH2

MATH/FFT

LA

Select channel1 as REF channel

Select channel2 as REF channel

Select Math/FFT as REF channel

Select LA as REF channel (DS1000D series)

Location

Internal

External

Select memory location in scope

Select memory location out scope

Save

Save REF waveform

Imp./Exp.

Go to import/export menu(see table 2-10)

Reset

Reset REF waveform

Menu

Settings

Comments

Source

CH1

CH2

MATH/FFT

LA

Select channel1 as REF channel

Select channel2 as REF channel

Select Math/FFT as REF channel

Select LA as REF channel (DS1000D series)

Location

Internal

External

Select memory location in scope

Select memory location out scope

Save

Save REF waveform to outer memory

location

Import

Go to import menu(see table 2-14)

Reset

Reset REF waveform

Using REF

Reference Waveforms are saved waveforms to be selected for display. The reference

function will be available after saving the selected waveform to non-volatile memory.

Press REF button to display reference waveform menu.

Figure 2- 18 Table 2- 8 REF menu when using internal memory

Figure 2- 19 Table 2- 9 REF menu when using external memory

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 47

2-17

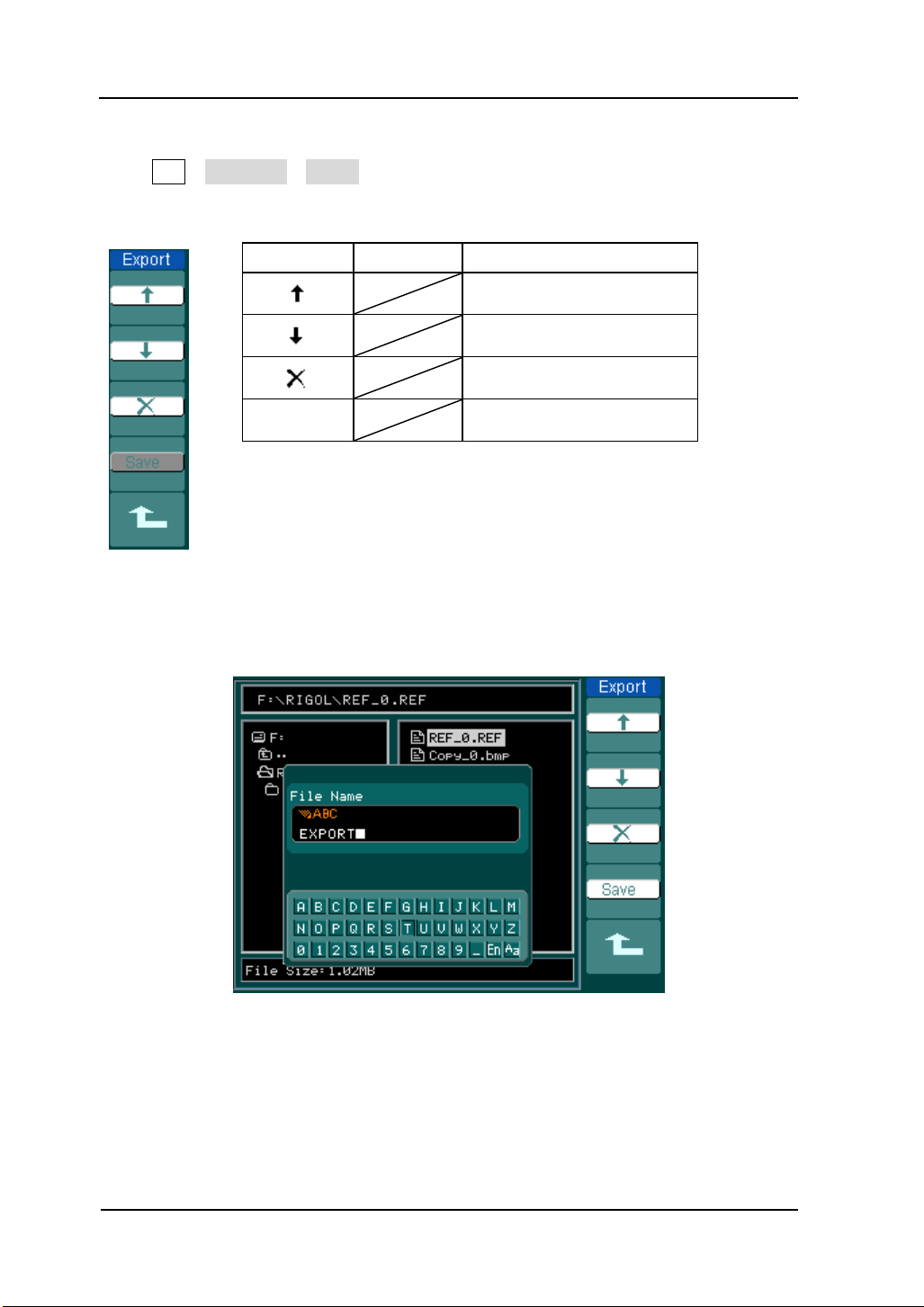

Import and Export

Menu

Settings

Comments

Explorer

Path

Directory

File

Switch to Path, directory or file

Export

Export the REF file from internal

memory to export memory (see

table 2-11)

Import

Import the REF file to internal

memory

Delete

File

Delete file

Press REF →Imp./Exp. and go to the following menu.

Figure 2- 20 Table 2- 10 The Imp./Exp. menu

The figure of import and export as following

RIGOL

© 2008 RIGOL Technologies, Inc.

Figure 2- 21

Import of export the figure

User’s Guide for DS1000E, DS1000D Series

Page 48

RIGOL

2-18

Menu

Settings

Comments

Move the cursor up

Move the cursor down

To delete chosen letter

Save

Execute the operation

Export

Press REF→Imp./Exp.→Export and go to the following menu.

Figure 2- 22 Table 2- 11 The Export menu

The figure of export as following.

© 2008 RIGOL Technologies, Inc.

Figure 2- 23

Figure export

User’s Guide for DS1000E, DS1000D Series

Page 49

2-19

Save to External Memory

Menu

Settings

Comments

Explorer

Path

Directory

File

Switch among Path, Directory

and File

New File

(Folder)

Set up new file in Path and File.

Set up new folder in directory.

Delete

File(Folder)

Delete file(Folder)

Press REF→Save and go to the following menu.

Figure 2- 24 Table 2- 12 The Save menu

The figure of Save as following:

RIGOL

© 2008 RIGOL Technologies, Inc.

Figure 2- 25

Save the figure

User’s Guide for DS1000E, DS1000D Series

Page 50

RIGOL

2-20

Menu

Settings

Comments

Move the cursor up

Move the cursor down

To delete chosen letter

Save

Execute the operation

Character

window

Switch Capital on/off

Switch Chinese/English

Spell key in

File name

key in

New File (or New Folder)

Press REF→Save→New File (or New Folder) and go to the following menu.

Figure 2- 26 Table 2- 13 The New File menu

The figure of key in as following

Figure 2- 27

Chinese Input

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 51

2-21

Import

Menu

Settings

Comments

Explorer

Path

Directory

File

Switch among Path, Directory and

File

Import

Import the REF file into internal

memory

Press REF→Import and go to the following menu.

Figure 2- 28 Table 2- 14 The Import menu

The figure of import as following.

RIGOL

© 2008 RIGOL Technologies, Inc.

Figure 2- 29

Figure import

User’s Guide for DS1000E, DS1000D Series

Page 52

RIGOL

2-22

Displaying a Reference Waveform

Figure 2- 30

Reference waveform display

1. Push REF button to show the reference waveform menu.

2. Press soft button No.1 to select the reference channel: CH1, CH2, MATH, FFT or

LA (DS1000D series).

3. Turn vertical and vertical to adjust the REF waveform

to a suitable position.

4. Press soft button No.2 to select the save location of REF waveform.

5. Press soft button No.3 to save the waveform as REF.

NOTE: The reference function is not available in X-Y mode.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 53

RIGOL

2-23

Menu

Settings

Comments

D7-D0

Set up channel group D7-D0 (see table

2-16)

D15-D8

set up channel group D15-D8 (see 2-17)

Current

<D15-D0>

Select channel by turning ( ) knob

Threshold

TTL

CMOS

ECL

User

Select mode of whole digital channels.

The threshold voltage can set by user

when in user-defined style.

User

<Threshold

Voltage>

Set threshold voltage by turning ( )

knob.

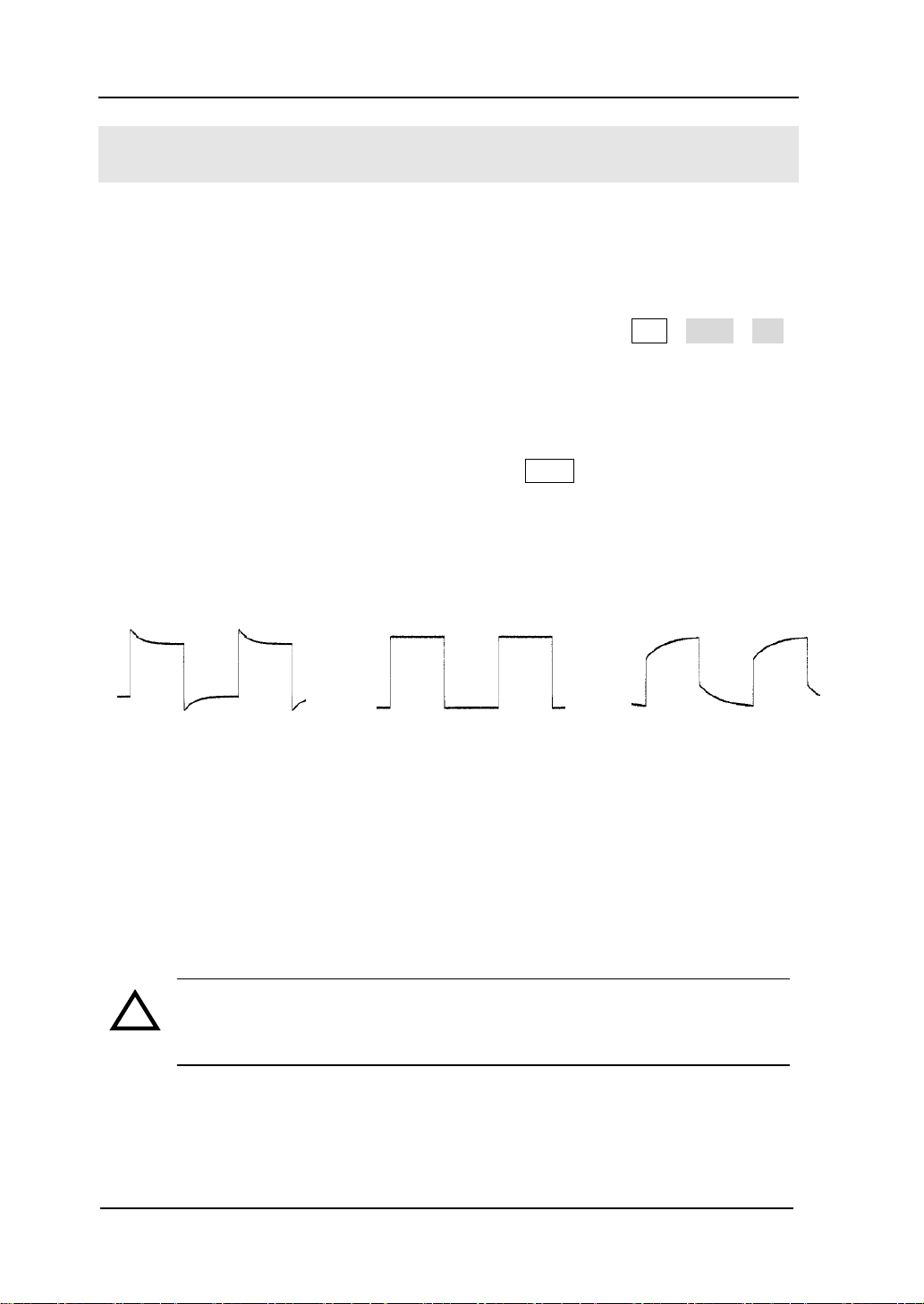

Set up LA Channel (DS1000D Series)

Single channel or group channels can be chosen ON or OFF, and also can set the size

of waveform. Change display location of digital channel on screen and select

threshold style.

Press LA function button and go to the following menu.

Figure 2- 31 Table 2- 15 The LA menu

1. Display and re-line up the digital channels

(1) Press LA→D7-D0 or D15-D8 and go to the group channel setting menu. Turn on

or turn off the display of the digital channels.

(2) Press LA→current and choose digital channel by turning ( ) knob. The chosen

channel will display in red color.

(3) Turn vertical knob to re-position the channel in screen.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 54

RIGOL

2-24

Select

running

channel

Running

channel

Setup threshold

Setup data of

threshold by user

The figure of menu shows as follow.

Turn on the digital channel

Figure 2- 32

2. Set threshold mode of digital channels

Press LA→Threshold, select logic standard or User to define your own threshold

voltage.

The figure of menu shows as follow.

Figure 2- 33

Set the threshold

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 55

RIGOL

2-25

Threshold explanation

LOGIC STANDARD THRESHOULD VLOTAGE

TTL 1.4V

CMOS 2.5V

ECL -1.3V

User -8V to +8V

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 56

RIGOL

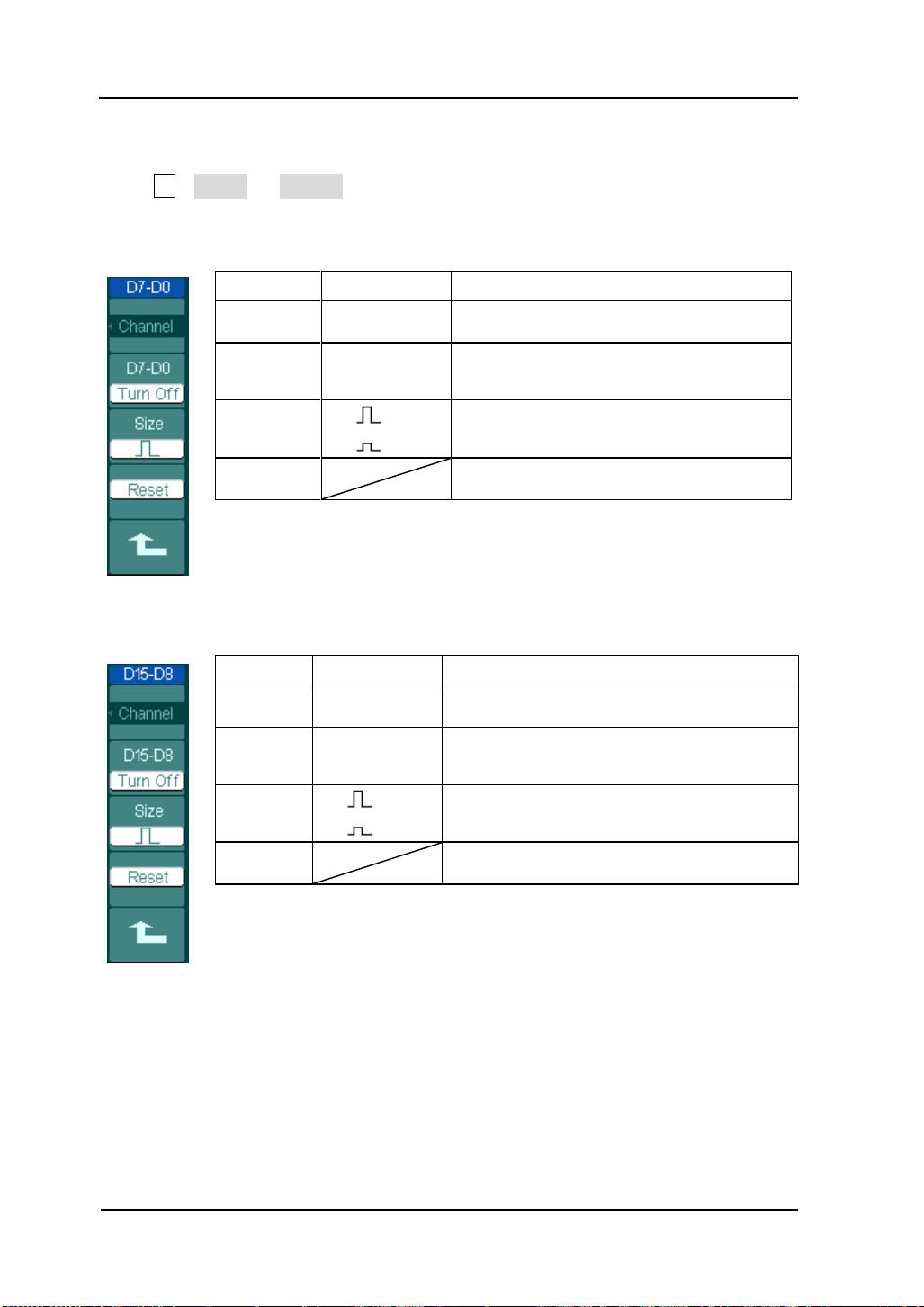

2-26

Menu

Settings

Comments

channel

D7-D0

Turn on or off single channel of D7-D0

D7-D0

Turn on

Turn off

Turn on or off all 8 channels together

Size

Display 8 channels in a single screen

Display 16 channels in a single screen

Reset

Reset waveform of channel D7-D0

Menu

Settings

Comments

channel

D15-D8

Turn on or off single channel of D15-D8

D15-D8

Turn on

Turn off

Turn on or off 8 channels together

Size

Display 8 channels in a single screen

Display 16 channels in a single screen

Reset

Reset waveform of channel D15-D8

Set up Channel Group

Press LA→D7-D0 or D15-D8; turn on/off the channel single, or in a group. Also

you can change the size of waveforms in 8 bits as a group. See table 2-16 and 2-17

Figure 2- 34 Table 2- 16 The Digital Channel menu (Page 1)

Figure 2- 35 Table 2- 17 The Digital Channel menu (Page 2)

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 57

RIGOL

2-27

On-off

channels

Channel list

and status of

on-off

1. Turn on or off a single logic channel

Press LA →D7-D0→Channel, and choose the wanted channel by turning ( ) knob.

Press No. 1 soft button or push down ( ) knob to turn on /off the channel. When

the channel is on, we can see the mark ( ). When the channel is turned off; the

mark will display as ( ).

As figure 2-36 shows.

Figure 2- 36

Turn on or off the digital channel

2. Force turn on or off all logic channels

Press LA →D7-D0→Turn On / Turn Off (or D15-D8 →Turn On / Turn Off) will force

to turn all the channels on/off. If you want to turn on/off any single channel instead,

select the Channel by turning ( ) knob, then press No. 1 soft button or ( ) knob.

3.Set up the viewing size of logic channels:

Press LA→D7-D0→Size, or D15-D8→Size, to select wave size of logic channels.

Select to view 8 channels on the screen;Select to view all of the 16

channels on the screen.

4.Reset the logic channels display:

Press LA→D7-D0→Reset, or D15-D8→Reset to reset the display of logic channels.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 58

RIGOL

2-28

Channel Mode

Settings

Status Indicator

Channel 1 (CH1)

ON

Selected

OFF

CH1 (black letter)

CH1 (yellow letter)

No indicator

Channel 2 (CH2)

ON

Selected

OFF

CH2 (black letter)

CH2 ( blue letter)

No indicator

MATH

ON

Selected

OFF

Math (black letter)

Math (purple letter)

No indicator

Turn on/off Channels

The CH1, CH2, Ext. Trigger and LA (DS1000D series) channels are input channels.

All functionalities applied will be based on operating the instrument with channels.

So MATH and REF can be regarded as relatively isolated channels.

To turn on/off any one of the channels, press the corresponding button on the front

panel. The key backlight indicates the channel is currently active. Press the button

again to turn the channel off. Or when channel is currently selected, press OFF will

turn the channel off as well, and the key backlight also goes off.

Table 2- 18 Status of the channels

NOTE:

The channel status symbol is displayed at the lower-left of the screen. Pressing LA

will turn all the digital channels on/off.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 59

RIGOL

2-29

Set up Vertical Position and Scale

You can use the vertical controls to display waveforms, adjust vertical

and , and set input parameters.

1. Using vertical knob.

The vertical control changes the position of signal waveforms in

all channels (including MATH and REF). The resolution changes according to the

vertical level set. Pressing this knob will clear the channel offset to zero. (The

function is available for DS1000D series, but not includes digital channel.)

2. Using vertical knob.

The vertical can change the vertical sensitivity of waveforms in all

channels (including MATH and REF, excluding LA). If the Volts/Div is set to

“Coarse”, the waveform scales in a 1-2-5 step sequence from 2 mV to 5 V. If the

Volts/Div is set to “Fine”, it scales to small steps between the coarse settings.

3. Channels can be adjusted by the vertical and only when

they are selected.

4. During the vertical position, a position message is displayed on the left bottom

of the screen, in the same color as the corresponding channel. The unit is V

(Volts).

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 60

RIGOL

2-30

To Set up the Horizontal System

The oscilloscope shows the time per division in the scale readout. Since all active

waveforms use the same time base, the oscilloscope only displays one value for all

the active channels, except when using Delayed Scan, or Alternative Trigger.

The horizontal controls can change the horizontal scale and position of waveforms.

The horizontal center of the screen is the time reference for waveforms. Changing

the horizontal scale causes the waveform to expand or contract about the screen

center.

Horizontal position changes the displayed waveform position, relative to the trigger

point.

The Horizontal Knobs

: The horizontal knob adjusts the horizontal position of

all channel (include Math) waveforms. The resolution of this control

varies with the time base. Pressing this button clears trigger offset

and moves the trigger point to the horizontal center of the screen.

: Use to select the horizontal time/div (scale factor) for the

main or the Delayed Scan time base. When Delayed Scan is enabled, it

changes the width of the window zone by changing the Delayed Scan

time base.

Horizontal Menu.

Press the horizontal MENU button to display the horizontal menu. The settings of

this menu are listed in the following table.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 61

2-31

Menu

Settings

Comments

Delayed

ON

OFF

Turn on Delayed Scan mode

Turn off the Delayed Scan mode

Time Base

Y-T

X-Y

Roll

Show the relative relation between

vertical voltage and horizontal

time.

Show CH1 value at X axis; CH2

value at Y axis.

In Roll Mode, the waveform display

updates from right to left.

Sa Rate

Show system sample rate

Trig-offset Reset

Adjust to the center

Figure 2- 37 Table 2- 19 The Horizontal menu

RIGOL

④ ⑤

© 2008 RIGOL Technologies, Inc.

① ② ③

Figure 2- 38

Status bar and mark for Horizontal control

User’s Guide for DS1000E, DS1000D Series

Page 62

RIGOL

2-32

Key Points

Y-T: The conventional oscilloscope display format. It shows the voltage of a

waveform record (on the vertical axis) as it varies over time (on the

horizontal axis).

X-Y: XY format displays channel 1 in the horizontal axis and channel 2 in the

vertical axis.

Roll Mode: In this mode, the waveform display rolls from right to left. No trigger

or horizontal offset control of waveforms is available during Roll Mode, and

it’s only available when set to 500 ms/div or slower.

Slow Scan Mode: This mode is available when the horizontal time base is set to

50ms/div or slower. In this mode, the oscilloscope acquires sufficient data

for the left part to the trigger point, then wait for trigger, when trigger

occurs, it continues to draw the rest part from the trigger point to the end of

the right side. When choosing this mode to view low frequency signals, it is

recommended that the channel coupling be set as DC.

Time/Div: Horizontal scale. If the waveform acquisition is stopped (using the

RUN/STOP button), the Time/Div control expands or compresses the

waveform.

Marks Indicator

① The current waveform window’s position in the memory.

② The trigger position in the memory.

③ The trigger position in the current waveform windows.

④ The horizontal time base (main time base).

⑤ The trigger’s horizontal offset according to the center of the window.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 63

RIGOL

2-33

Waveform to be horizontally expanded

Expanded waveform in horizontal

Main timebase

Time base of

Delayed Scan

Delayed Scan:

The Delayed Scan is a magnified portion of the main waveform window. Use

Delayed Scan to locate and horizontally expand part of the main waveform window

for a more detailed (higher horizontal resolution) analysis of signal. The Delayed

Scan time base setting cannot be set slower than the Main time base setting.

Figure 2- 39

Delayed Scan window

The following steps show you how to use Delayed Scan.

1. Connect a signal to the oscilloscope and obtain a stable display.

2. Press horizontal MENU→Delayed→ON or press horizontal knob to

enter Delayed Scan mode.

The screen splits into two parts. The upper half displays the main waveform window

and the lower half displays an expanded portion of the main waveform window. This

expanded portion of the main window is called the Delayed Scan window. Two

blocks shaded at the upper half; the un-shaded portion is expanded in the lower half.

The horizontal and knobs control the size and position of

the Delayed Scan. The value at bottom of the screen is the main time base and the

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 64

RIGOL

2-34

Delayed Scan Shortcut Key:

Delayed Scan function can be activated not only by menu but also by pressing

horizontal knob.

value on the center bottom means the Delayed Scan time.

Use the horizontal knob to change the position of the expanded

portion.

Use the horizontal knob to adjust the Delayed Scan resolution.

To change the main time base, turn off the Delayed Scan mode.

Since both the main and Delayed Scan are displayed; there are half as many

vertical divisions so the vertical scaling is doubled. Notice the changes in the

status bar.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 65

RIGOL

2-35

X-Y Format

This format is useful for studying phase relationships between two signals.

Channel 1 in the horizontal axis(X) and channel 2 in the vertical axis(Y), the

oscilloscope uses a none-trigger acquisition mode, data is displayed as dots.

Figure 2- 40

X-Y display format

NOTE:In Y-T format, all sample rates are available. But in X-Y format, 100 MSa/s

is not available. In common, deceasing the sample rate can display the wavefrom

better.

The following modes or functions will not work in X-Y format.

LA Function (DS1000D series)

Automatic Measurements

Cursor Measurements

REF and MATH Operations

Delayed Scan Mode

Vector Display Mode

Horizontal knob

Trigger Controls

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 66

RIGOL

2-36

To Set up the Trigger System

The trigger determines when the oscilloscope starts to acquire data and display a

waveform. When a trigger is set up properly, it can convert unstable displays or

blank screens into meaningful waveforms.

When the oscilloscope starts to acquire a waveform, it collects enough data so that it

can draw the waveform to the left of the trigger point. The oscilloscope continues to

acquire data while waiting for the trigger condition to occur. After it detects a trigger,

the oscilloscope continues to acquire enough data so that it can draw the waveform

to the right of the trigger point.

The trigger control area on the front panel includes a knob and three buttons:

: The knob that set the trigger level; press the knob and the level will

reset to zero.

50%: The instant execute button setting the trigger level to the vertical

midpoint between the peaks of the trigger signal

FORCE: Force to create a trigger signal and the function is mainly used in

Normal and Single mode

MENU: The button that activates the trigger controls menu.

Figure 2- 41

Trigger controls

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 67

RIGOL

2-37

Trigger Modes

The oscilloscope provides seven trigger modes: Edge, Pulse, Slope, Video,

Alternative, Pattern (only for DS1000D series) and Duration trigger (only for

DS1000D series).

Edge: An edge trigger occurs when the trigger input passes through a specified

voltage level in the specified slope direction.

Pulse: Use this trigger type to catch pulses with certain pulse width.

Video: Use video trigger on fields or lines for standard video signals.

Slope: The oscilloscope begins to trigger according to the signal rising or falling

speed.

Alternative: Trigger on non-synchronized signals

Pattern: To Trigger through detecting a specified code.

Duration: To trigger within a specified time on the conditions of a specified code

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 68

RIGOL

2-38

Menu

Settings

Comments

Source

CH1

CH2

EXT

AC Line

D15-D0

Select CH1 as trigger signal

Select CH2 as trigger signal

Select EXT TRIG as trigger signal

Select power line as trigger signal

Select a digital channel in D15-D0 as

trigger source (for DS1000D series)

Slope

Rising

Falling

Rising &

Falling

Trigger on rising edge

Trigger on falling edge

Trigger on both ring & falling edge

Sweep

Auto

Normal

Single

Acquire waveform even no trigger

occurred

Acquire waveform when trigger occurred.

When trigger occurs, acquire one

waveform then stop

Set up

To go to Set Up menu, see table 2-38

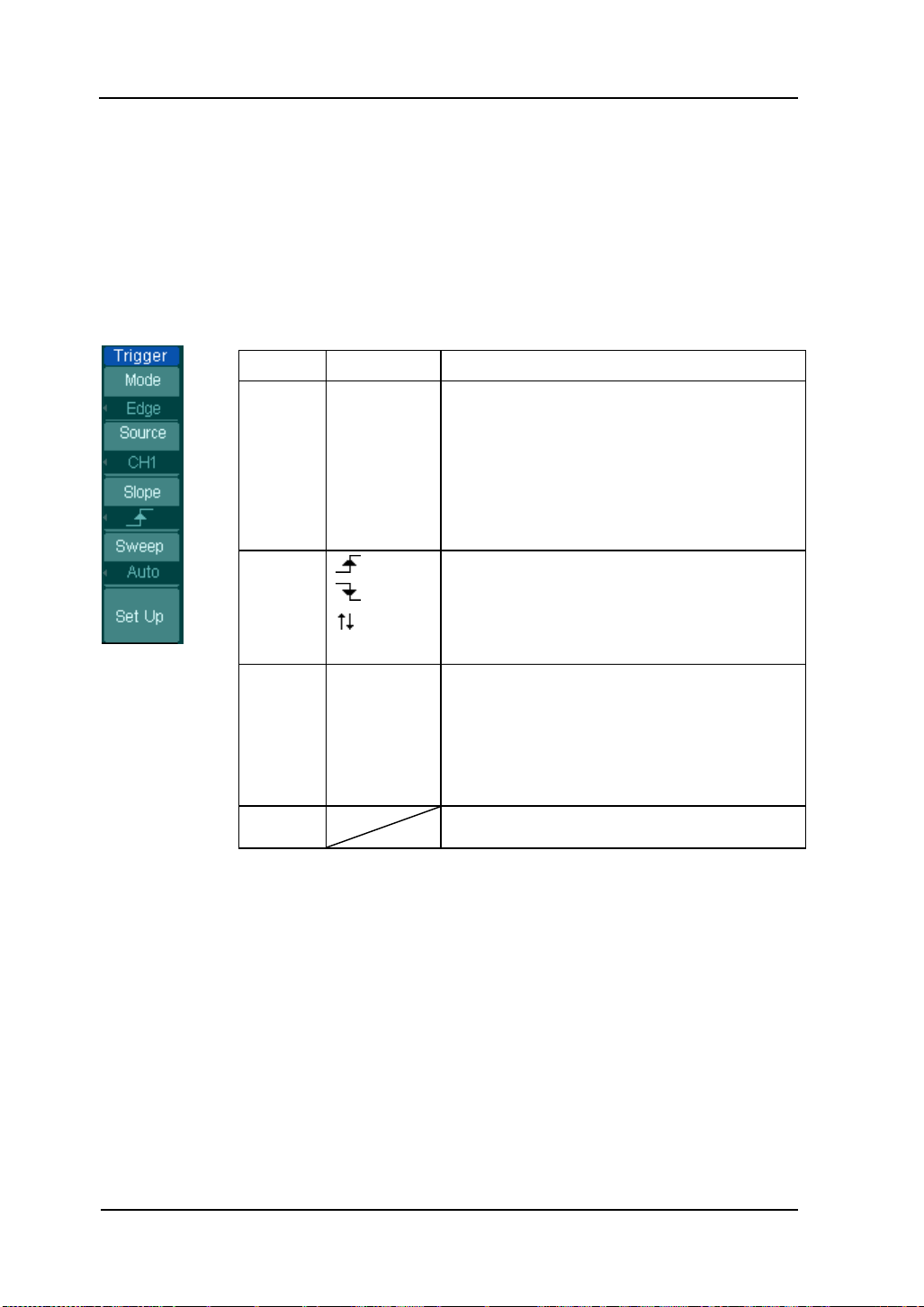

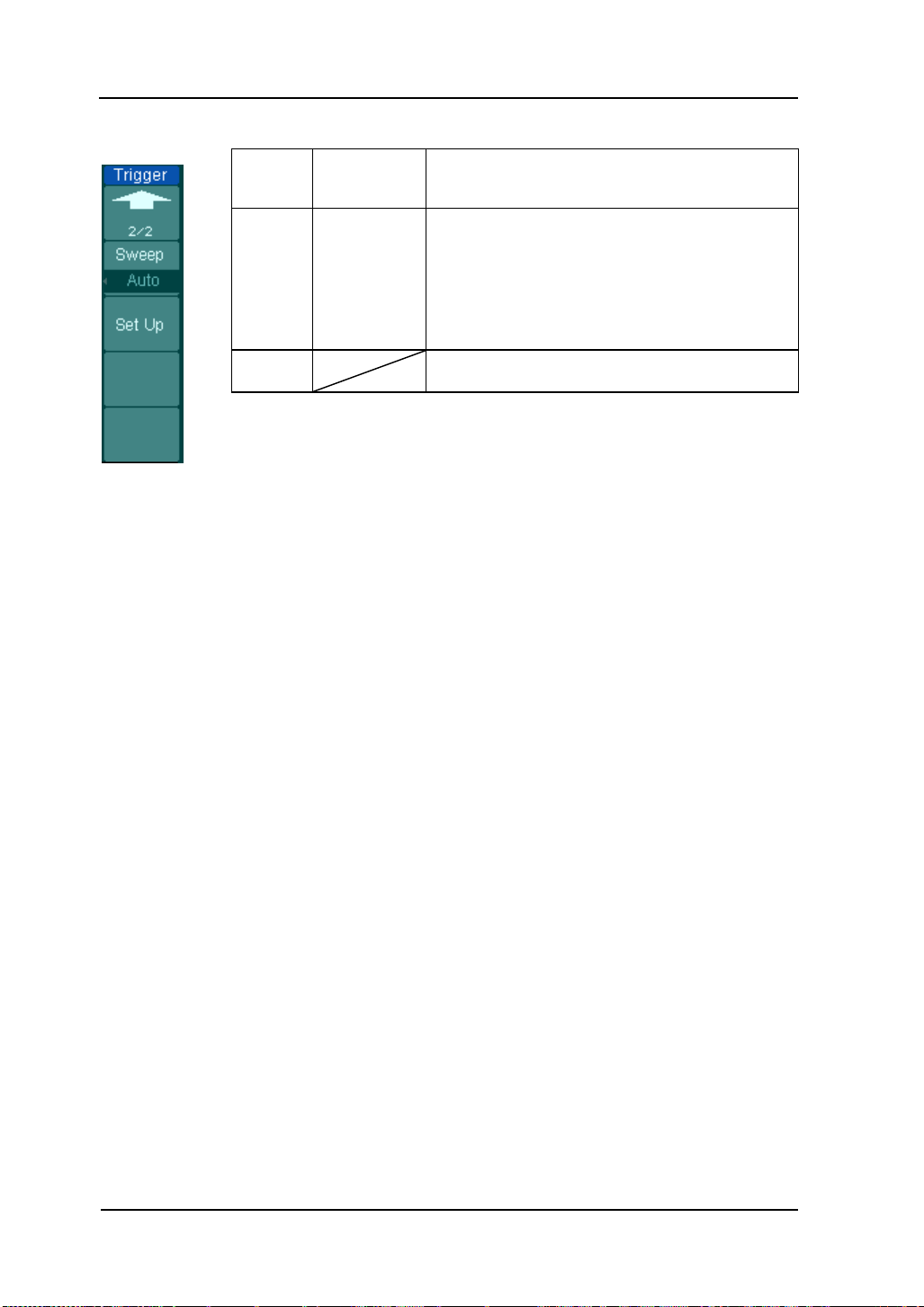

Settings for Edge Trigger

An edge trigger determines whether the oscilloscope finds the trigger point on the

rising or the falling edge of a signal. Select Edge trigger Mode to trigger on Rising

edge, falling edge or rising & falling edge.

Figure 2- 42 Table 2- 20 The Edge Trigger menu

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 69

RIGOL

2-39

Menu

Settings

Comments

Source

CH1

CH2

EXT

D15-D0

Selects CH1 as trigger signal

Select CH2 as trigger signal

Select EXT TRIG as trigger signal

Select a digital channel in

D15-D0 as trigger source( Only

for DS1000D series)

When

(+Pulse width

less than)

(+Pulse width

more than)

(+Pulse width

equal to)

(-Pulse width

less than)

(-Pulse width

more than)

(-Pulse width

equal to)

To select pulse condition

Settings

<Width>

Set required pulse width

Settings for Pulse Width Trigger

Pulse trigger occurs according to the width of pulse. The abnormal signals can be

detected through setting up the pulse width condition.

Figure 2- 43 Table 2- 21 The Pulse Trigger menu (page 1/2)

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 70

RIGOL

2-40

Menu

Settings

Comments

Sweep

Auto

Normal

Single

Acquire waveform even no trigger

occurred

Acquire waveform when trigger occurred.

When trigger occurs, acquire one

waveform and then stop

Set Up

To go to Set Up menu, see table 2-38

Figure 2- 44 Table 2- 22 The Pulse Trigger menu (page 2/2)

NOTE: The Pulse width adjust range is 20ns ~ 10s. When the condition is met, it will

trigger and acquire the waveform.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 71

RIGOL

2-41

Menu

Settings

Comments

Source

CH1

CH2

EXT

Selects CH1 as trigger source

Select CH2 as trigger source

Select EXT TRIG as trigger

source

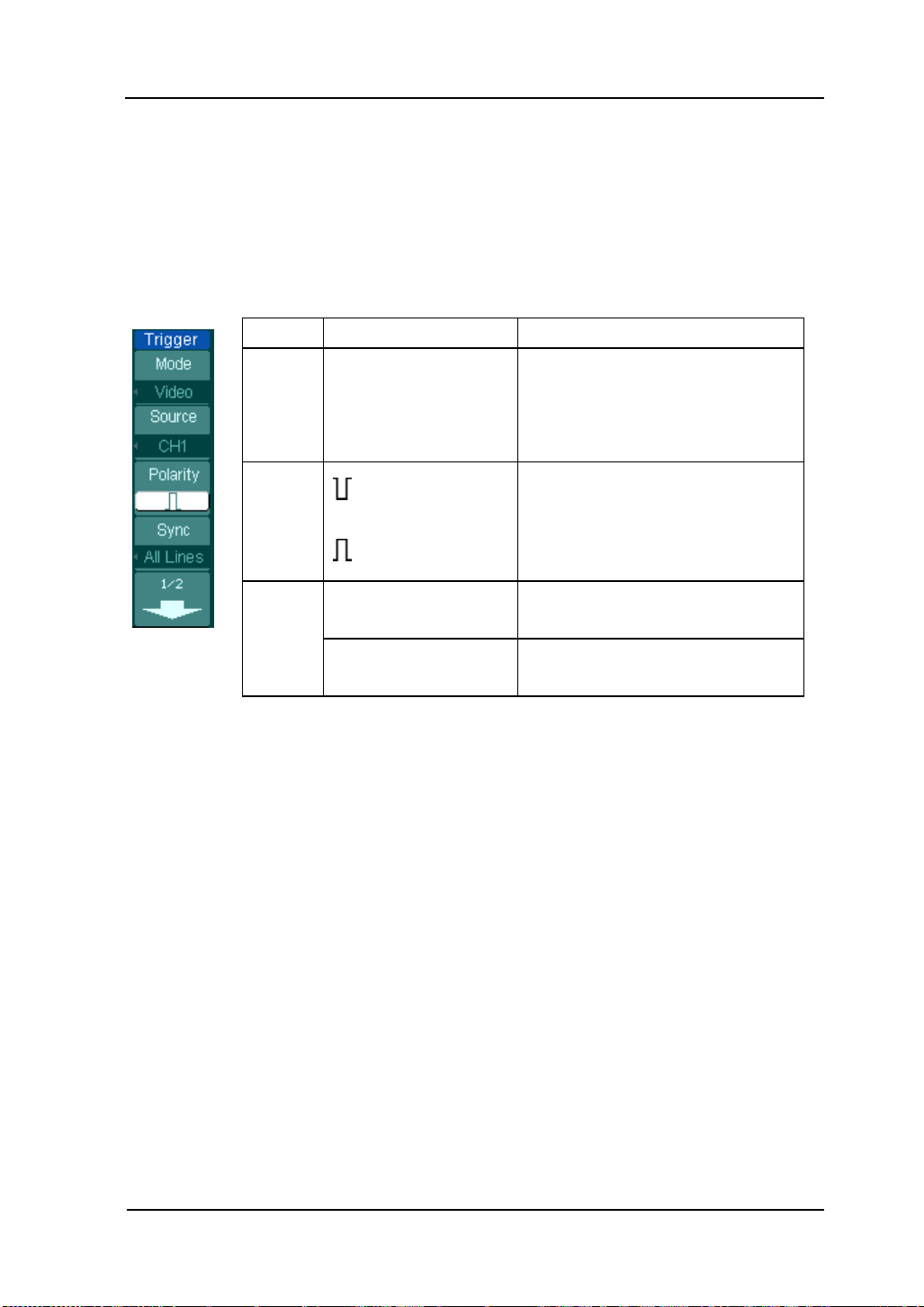

Polarity

Normal polarity

Inverted polarity

Triggers on negative going sync

pulses

Triggers on positive going sync

pulses

Sync

All Lines

Line Num

Trigger on all lines

Trigger on an specified line

Odd field

Even field

Select to trigger on odd field

Select to trigger on even field

Settings for Video Trigger

Choose video trigger to trigger on fields or lines of NTSC, PAL, or SECAM standard

video signals. Trigger coupling preset to DC.

Figure 2- 45 Table 2- 23 The Video Trigger menu (Page 1/2)

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 72

RIGOL

2-42

Menu

Settings

Comments

Line Num

< Line sync >

Select the specified line number for

sync

Standard

PAL/SECM

NTSC

Select Video standard

Sweep

Auto

Normal

Single

Acquire waveform even no trigger

occurred

Acquire waveform when trigger

occurred.

When trigger occurs, acquire one

waveform and then stop

Set Up

To go to set up menu, see table

2-39

Figure 2- 46 Table 2- 24 The Video Trigger menu (Page 2/2, when Sync is set as

the specified line)

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 73

RIGOL

2-43

Menu

Settings

Comments

Standard

PAL/SECAM

NTSC

Select Video standard

Sweep

Auto

Normal

Single

Acquire waveform even no trigger

occurred

Acquire waveform when trigger

occurred.

When trigger occurs, acquire one

waveform and then stop

Set Up

To go to set up menu, see table 2-39

Figure 2- 47 Table 2- 25 The Video menu (When the Sync is set as All lines, Odd

field and Even field)

Key points

Sync Pulses: When Normal Polarity is selected, the trigger always occurs on

negative-going sync pulses. If the video signal has positive-going

sync pulses, use the inverted Polarity selection.

Figure 2- 48

Video Trigger: Line Synchronization

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 74

RIGOL

2-44

Figure 2- 49

Video Trigger: Field Synchronization

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 75

RIGOL

2-45

Menu

Settings

Comments

Source

CH1

CH2

EXT

Set channel 1 as trigger source

Set channel 2 as trigger source

Set EXT. channel as trigger source

When

To select the pulse condition

Time

<Time Set >

To set slope time

Menu

Settings

Comments

Vertical

Select the level that can be adjusted

by

Sweep

Auto

Normal

Single

Acquire waveform even when no

trigger condition is met.

Acquire waveform when trigger

condition is met.

When trigger condition is met, acquire

one waveform and then stop

Set Up

To go to set up menu. See table 2-38

Slope Trigger

Slope trigger sets the oscilloscope as the positive/negative slope trigger within the

specified time.

Figure 2- 50 Table 2- 26 The Slope Trigger menu (Page 1/2)

Figure 2- 51 Table 2- 27 The Slope Trigger menu (Page2/2)

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 76

RIGOL

2-46

NOTE: Slope time can be set from 20ns to 10s. When a signal meets the trigger

condition, scope will execute the acquisition. You can adjust LEVEL A/ LEVEL B or

both simultaneous by turning the knob.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 77

RIGOL

2-47

Menu

Settings

Comments

Select

CH1

CH2

Set trigger mode for Channel 1

Set trigger mode for Channel 2

Type

Edge

Set Edge Trigger as the trigger

type

Slope

(Rising)

(Falling)

Trigger on rising edge

Trigger on falling edge

Set Up

To go to set up menu. See table

2-38

Alternative Trigger

When alternative trigger is on, the trigger sources come from two vertical channels.

This mode can be used to observe two non-related signals. You can choose two

different trigger modes for the two vertical channels. The options are as follows:

Edge, Pulse, Slope and video. The info of the trigger level of the two channels will be

displayed on the upper-right of the screen.

Figure 2- 52 Table 2- 28 The Alternative menu (Trigger Type: Edge)

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 78

RIGOL

2-48

Menu

Settings

Comments

Select

CH1

CH2

Set trigger mode for Channel 1

Set trigger mode for Channel 2

Type

Pulse

Set Pulse Trigger for the

channel

When

(+Pulse width less than)

(+Pulse width more than)

(+Pulse width equal to)

(-Pulse width less than)

(-Pulse width more than)

(-Pulse width equal to)

To select pulse condition

Menu

Settings

Comments

Setting

<pulse width>

Set the width of the pulse

Set Up

To go to set up menu. See table 2-38

Figure 2- 53 Table 2- 29 (Trigger Type: Pulse, Page 1/2)

Figure 2- 54 Table 2- 30 The Alternative menu (Trigger Type: Pulse, Page 2/2)

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 79

RIGOL

2-49

Menu

Settings

Comments

Select

CH1

CH2

Set trigger mode for Channel 1

Set trigger mode for Channel 2

Type

Slope

Set Slope Trigger for the vertical

channel

When

Set trigger condition

Menu

Settings

Comments

Time

<Time Set >

Set slope time

Vertical

Select the level to be adjusted by

Set Up

To go to set up menu. See table

2-38

Figure 2- 55 Table 2- 31 The Alternative menu (Trigger Type: Slope, Page 1/2)

Figure 2- 56 Table 2- 32 The Alternative menu (Trigger Type: Slope Page 2/2)

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 80

RIGOL

2-50

Menu

Settings

Comments

Select

CH1

CH2

Set trigger mode for Channel 1

Set trigger mode for Channel 2

Type

Video

Video Trigger for the channel

Polarity

Normal polarity

Inverted polarity

Triggers on negative going sync pulses

Triggers on positive going sync pulses

Menu

Settings

Comments

Sync

ALL lines

Line Num

Trigger on all lines

Trigger on an specified line

Odd field

Even field

Select to trigger on odd field or even

field

Line Num

<Lines Set >

Select the specified line number for sync

Standard

PAL/SECM

NTSC

Select Video standard

Set Up

To go to set up menu, see table 2-39

Figure 2- 57 Table 2- 33 The Alternative menu (Trigger Type: Video, Page 1/2)

Figure 2- 58 Table 2- 34 The Alternative menu (Trigger Mode: Video, Page 2/2)

© 2008 RIGOL Technologies, Inc.

User’s Guide for DS1000E, DS1000D Series

Page 81

RIGOL

2-51

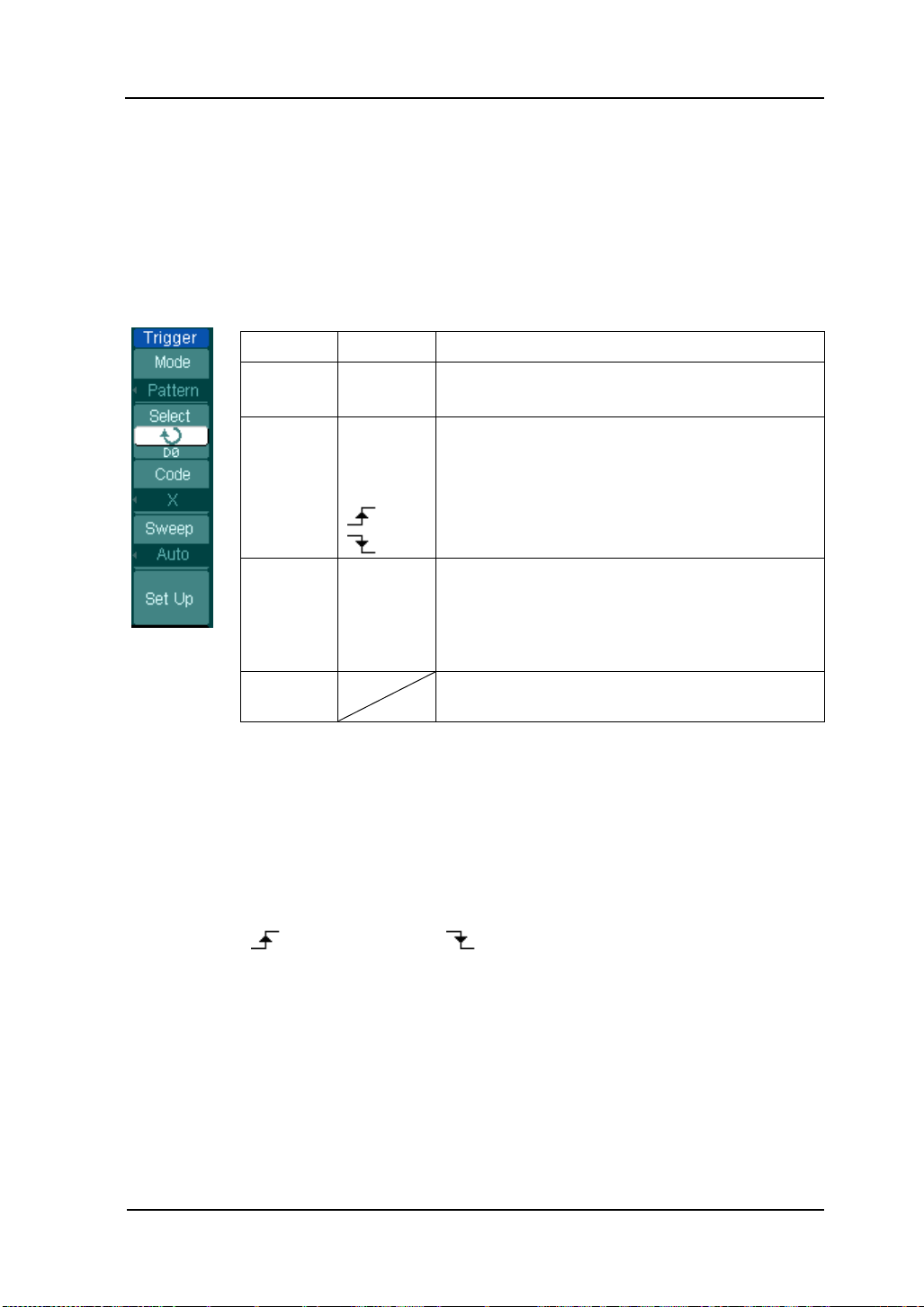

Menu

Settings

Comments

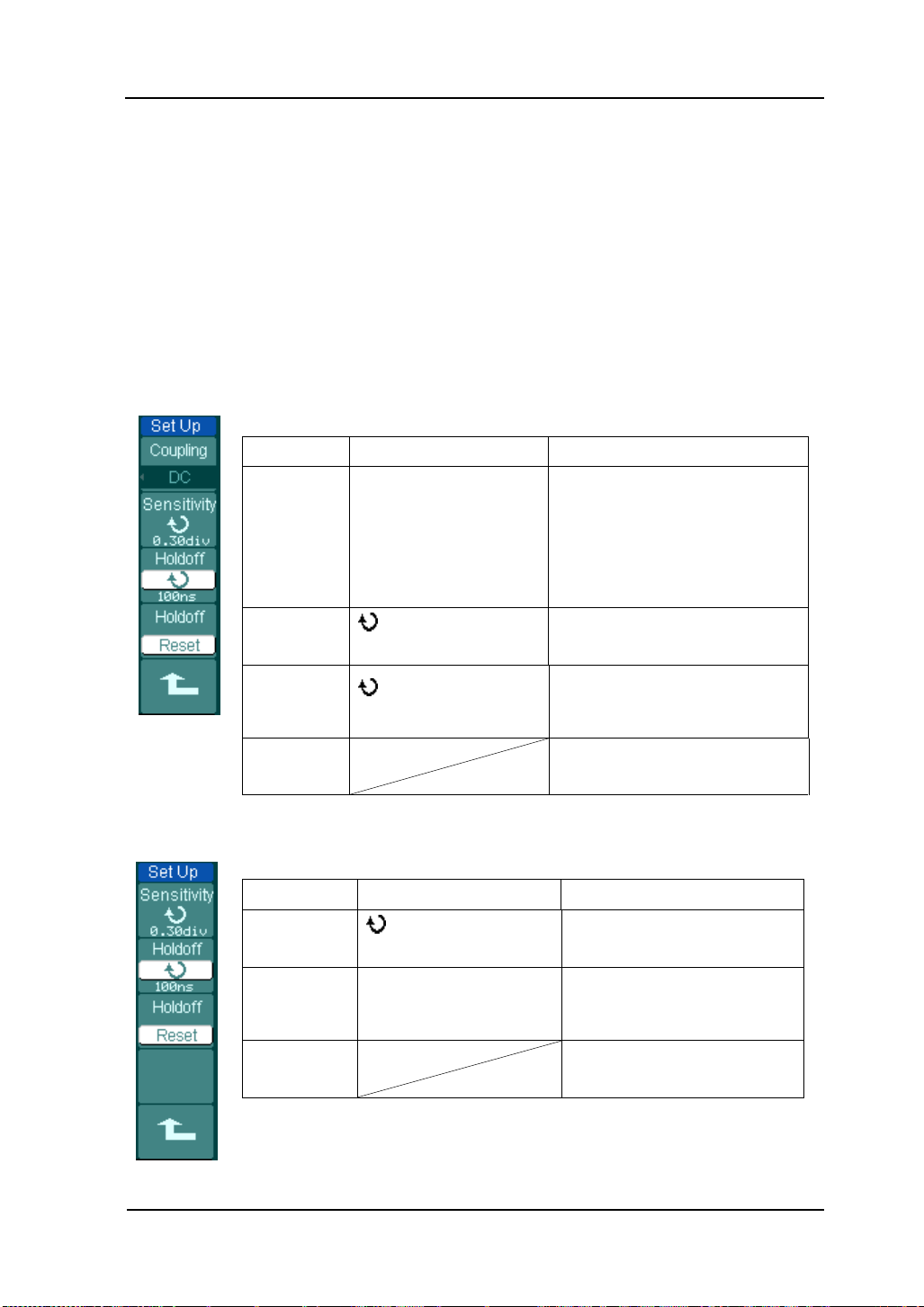

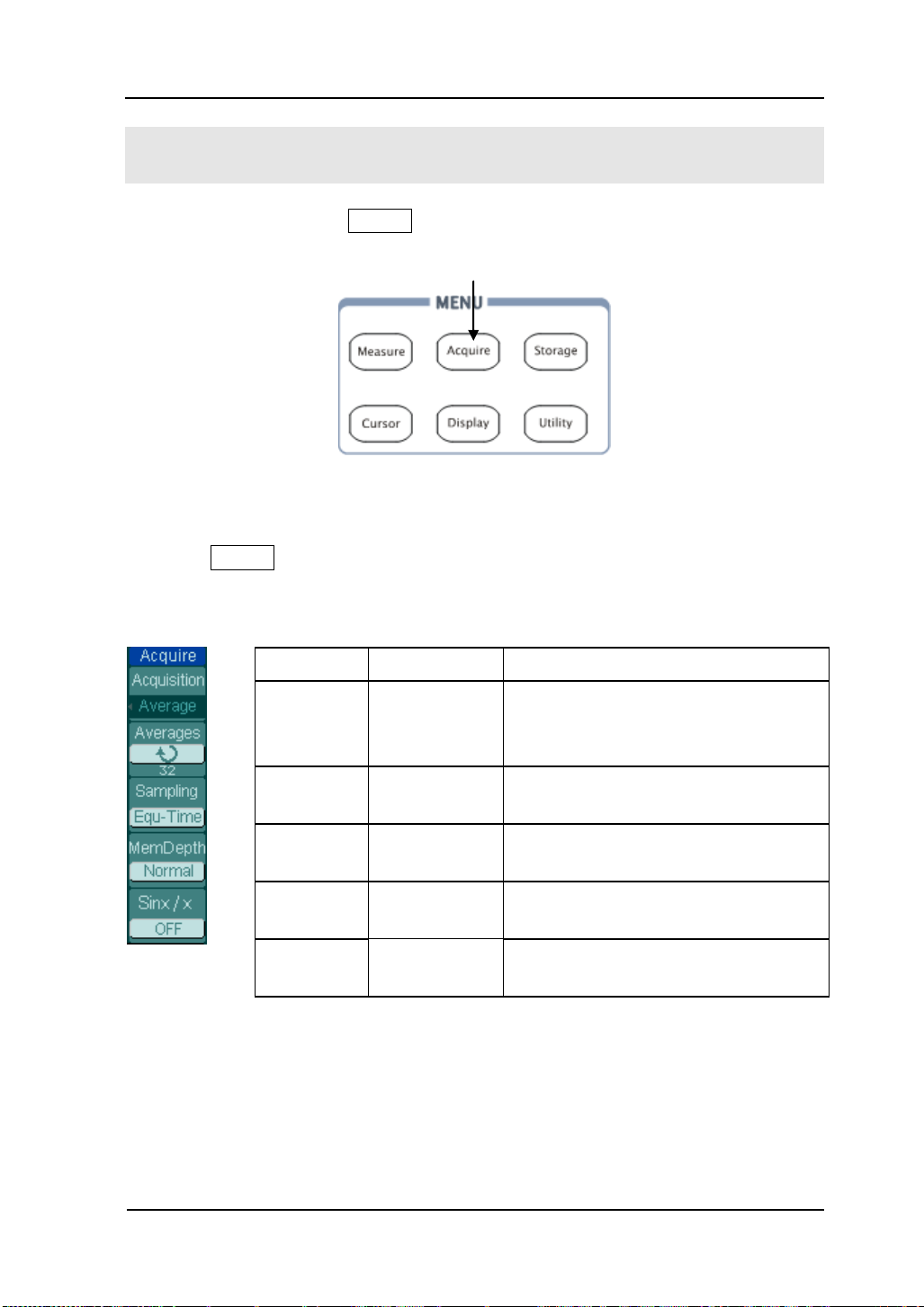

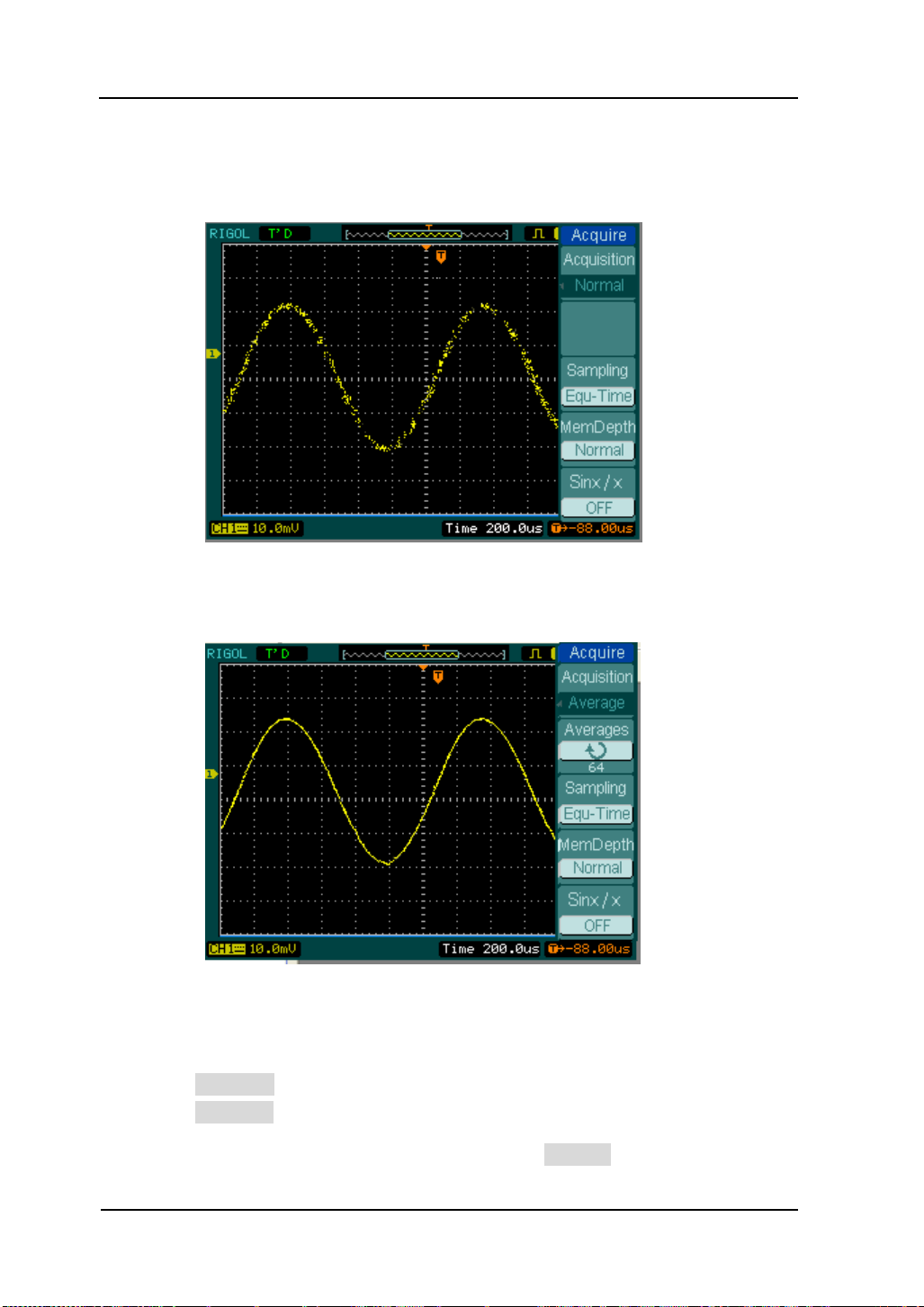

Select