Page 1

User’s Guide RIGOL

Publication number DM3-070920

September 2007

DM3000 Series Digital Multimeter

DM3061/2/3/4

DM3051/2/3/4

© Copyright RIGOL Technologies, Inc. 2007

All Rights Reserved

Page 2

Page 3

RIGOL

z Copyright © RIGOL TECHNOLOGIES, INC. 2007 All Rights Reserved.

z RIGOL products are protected by patent law in and outside of P.R. China.

z Information in this publication replaces that in all previously corresponding

material.

z RIGOL Technologies, Inc. reserves the right to modify or change pat of or

all the specifications and pricing policies at company’s sole decision.

NOTE: RIGOL is the registered trademark of RIGOL TECHNOLOGIES, INC.

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

I

Page 4

RIGOL

Safety Notices

Review the following safety precautions carefully before operate the instrument

to avoid any personal injury or to damage the instrument and any products

connected to it.

To avoid potential hazards use the instrument in a manner only as specified by

this user’s guide.

The instrument should be serviced only by qualified personnel.

To Avoid Fire or Personal Injury.

Use proper power cord. Use only the power cord designed for your

oscilloscope and authorized in your country.

Connect and Disconnect accessories properly. Do not connect or

disconnect probes or test leads while they are connected to a voltage source.

Ground the instrument. This product is grounded through the protective terra

conductor of the power cord. To avoid electric shock the grounding conductor

must be connected to earth ground. Before making connections to the input or

output terminals of the oscilloscope ensure that the instrument is properly

grounded.

Connect the probe properly. The probes’ ground terminals are at the same

voltage level with earth terminal of the instrument. Do not connect the ground

terminals to a high voltage.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all

ratings and marks on the instrument. Follow the User’s Guide for further ratings

information before making connections to the instrument.

Do not operate without Covers. Do not operate your oscilloscope with covers

or panels removed.

II

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

Page 5

RIGOL

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Circuit or Wire Exposure. Do not touch exposed connections and

components when power is on.

Do not operate with suspected failures. If you suspect damage with this

product, have it inspected by qualified service personnel who were authorized by

RIGOL before further operations.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details as to the oscilloscope has proper ventilation.

Do not operate in wet/damp conditions.

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry.

The disturbance test of all the models can meet the limit values of A in

the standard of EN 61326: 1997+A1+A2+A3, but can't meet the limit

values of B.

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

III

Page 6

RIGOL

Safety Terms and Symbols

Terms in This Guide. These terms may appear in this guide:

!

!

!

Terms on the Product: These terms may appear on the product:

DANGER indicates an injury hazard may happen immediately.

WARNING indicates an injury hazard may not happen immediately.

CAUTION indicates that a potential damage to the instrument or other property

might occur.

Symbols on the Product: These symbols may appear on the Instrument:

Hazardous

Voltage

WARNING: Warning statements identify conditions or practices that

could result in injury or loss of life.

CAUTION: Caution statements identify conditions or practices that

could result in damage to this product or other property.

CAT II (300V): IEC Measurement Category II. Inputs may be

connected to mains (up to 300 VAC) under Category II overvoltage

conditions.

!

Refer to

Instructions

Protective

Earth Terminal

Grounding

Terminal

of Chassis

Test

Grounding

Terminal

IV

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

Page 7

RIGOL

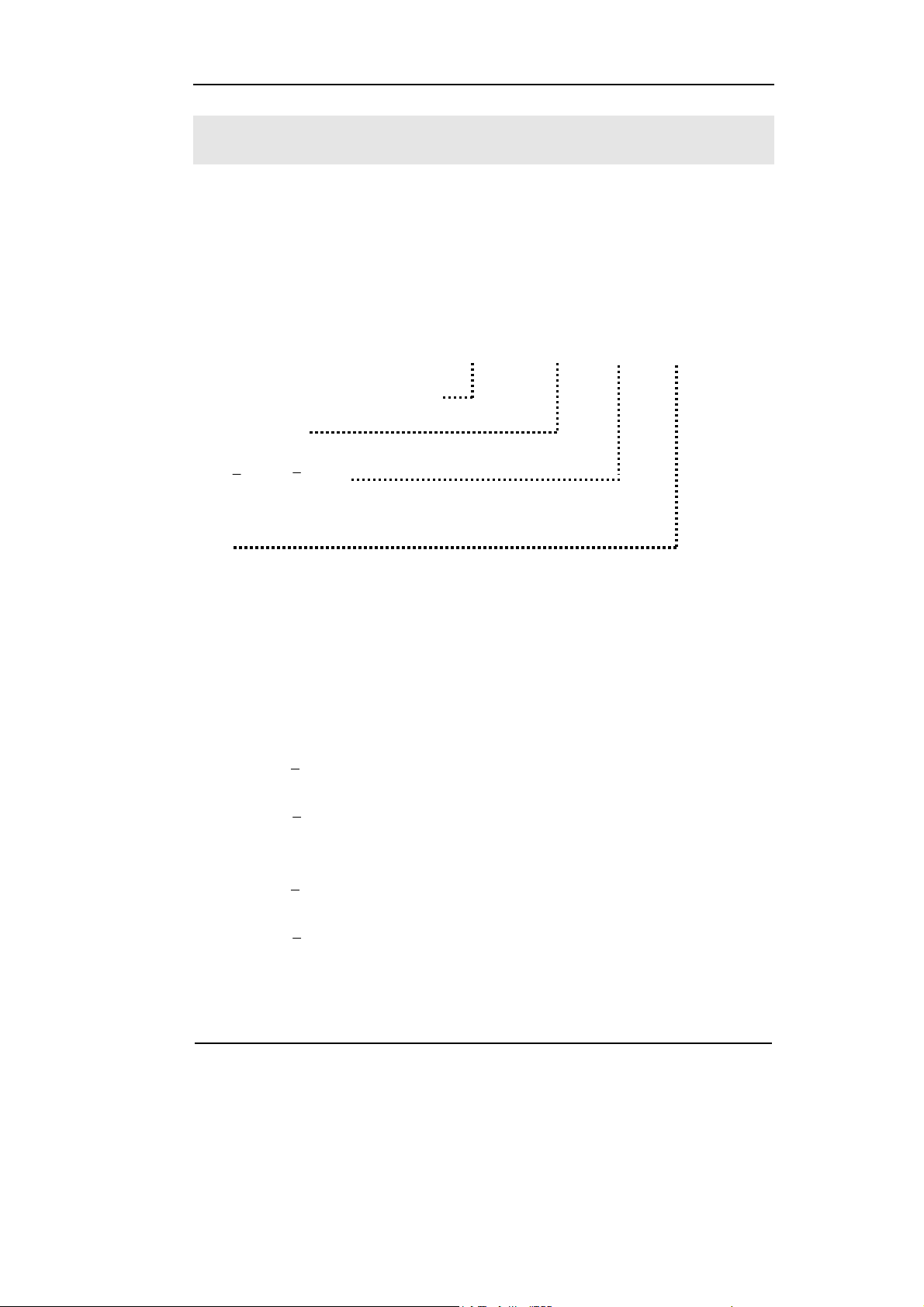

General-Purpose Multimeter

The book covers the following description and eight models DM3000 Series

Digital Multimeter:

DM3061, DM3062, DM3063, DM3064;

DM3051, DM3052, DM3053, DM3054.

DM3000 Series Digital Multimeter desktop naming rules:

DM

30

6 1

Prefix desktop Digital Multimeter

Serial Number

3

4

digit

6-6

1

2

, 5-5

No.

1-Basic; 2-Interface models with expansion board;

3-Inspection plate with the model;

4-Inspection plate with the model and interface extended board.

Application examples:

1

DM3061- 6

2

DM3000 series, Basic type.

1

DM3062- 6

2

DM3000 series, Basic type. Append the interface board with

LAN/GPIB module.

1

DM3063- 6

DM3064- 6

2

DM3000 Series, Basic type. Append the inspection board.

1

2

DM3000 series, Basic type. Append the interface board with

LAN/GPIB and inspection board.

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

V

Page 8

RIGOL

RIGOL DM3000-Series Digital Multimeter is a high-precision, multifunction,

1

multi-automatic measurement for user’s designment of products, including 6

2

digits multimeter, high-speed data acquisition, automatic measurement and

inspection, many mathematical transform, in one of sensor measurements and

other functions. In support RS-232, USB, LAN and GPIB interface. It supports U

disk storage and print.

In performance, the DM3000 has high-resolution monochrome LCD display

system, supports a simple waveform display and data recording waveform

display; clear and easy to operate the button backlight keyboard layout and

operation make it more flexible, user-friendly operating features; 50k/s high data

sampling rate, can be used, such as the rapidly changing high-precision audio

waveform data; depth 2Mbyte of internal storage, external storage can be

arbitrary depth; adopt true RMS AC voltage and current measurement; virtual

terminal display and control, and remote network access.

From the performance and characteristics are given below, you will Understand

how can DM3000 satisfy your measurement requirements.

z 50k/s data sampling rate can be used, such as the rapidly changing

high-precision audio waveform data. Meanwhile waveform can be displayed

on LCD Screen

z Measurement accuracy: more than 6 1/2 and 2,400,000 Count

z 26 measurement functions

DC voltage and current, AC voltage and current, two-wire and four-wire

resistance, capacitance, continuity test, diode test, frequency, cycle

ratio measurements, arbitrary sensor measurement,

And so on.

Upper limit and lower limit on the threshold measurement

Arithmetic include: maximum, minimum, average, dBm, dB

Data acquisition functions include : data records, inspection, automatic

measurement

z True RMS AC voltage and current measurement

z 16- Road inspection functional measurement and control software (optional)

z DC voltage >10GΩ input impedance to achieve the scope of 48V (±24V)

z With data acquisition function,

the maximum sampling rate support to

50kSP/s

z 10 groups measuring set-up storage and embedded PC measuring set up

VI

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

Page 9

RIGOL

unlimited storage

z Saturating responses of 256 x 64 pixel monochrome LCD

z I/O: RS-232, USB, LAN and GPIB

z Built-in USB Host to support USB disk and USB printer

z Simple, convenient, flexible control software: Ultralogger, Supports for

Microsoft® Windows 98/2000/Me/XP

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

VII

Page 10

RIGOL

Content

Safety Notices ......................................................................................................................II

General-Purpose Multimeter ..............................................................................................V

CHAPTER 1 BASIC MULTIMETER OPERATIONS ........................................ 1-1

General Inspection ...........................................................................................................1-2

Handle Adjustment...........................................................................................................1-3

The Front/Rear Panel and User Interface..................................................................... 1-4

To Measure DC Voltage...................................................................................................1-7

To Measure AC Voltage ...................................................................................................1-9

To Measure DC Current.................................................................................................1-11

To Measure AC Current .................................................................................................1-13

To Measure Resistance.................................................................................................. 1-15

To Measure Capacitance ...............................................................................................1-19

To Test Continuity..........................................................................................................1-21

To Check Diodes.............................................................................................................1-23

To Measure Frequency and Period ..............................................................................1-25

To Measure Arbitrary Sensor........................................................................................1-29

To Choice Digits resolving index ..................................................................................1-34

To Choose Data Digit Display.......................................................................................1-35

To Choose Range Options.............................................................................................1-36

To Control Trigger Options ...........................................................................................1-38

CHAPTER 2 OPERATING YOUR MULTIMETER ........................................... 2-1

To Set up Measurement Parameters.............................................................................2-2

Math Functions ...............................................................................................................2-12

To Set Up Triggering Parameter Function..................................................................2-19

Store and Recall..............................................................................................................2-27

To Set Up the Utility.......................................................................................................2-32

High-speed Data Logger ...............................................................................................2-46

Multi-route Scanning......................................................................................................2-53

How to Use the Built-in Help System ..........................................................................2-61

CHAPTER 3 APPLICATION & EXAMPLES .................................................... 3-1

Example 1: Reading Statistic Functions........................................................................3-1

Example 2: Elimination Test Leads Resistance Error...................................................3-3

Example 3: dB Measurement..........................................................................................3-4

Example 4: dBm Measurement ......................................................................................3-5

VIII

User’s Guide for DM3000 Series

©Copyright RIGOL Technologies, Inc. 2007.

Page 11

RIGOL

Example 5: Limit Test.......................................................................................................3-6

Example 6: Temperature Sensor ....................................................................................3-7

Example 7: Reading Hold............................................................................................. 3-11

CHAPTER 4 PROMPT MESSAGES& TROUBLESHOOTING .........................4-1

Prompting Message..........................................................................................................4-1

Troubleshooting ................................................................................................................4-3

CHAPTER 5 SUPPORT & SERVICE ................................................................5-4

CHAPTER 6 APPENDIX...................................................................................6-1

Appendix A: Specifications ..............................................................................................6-1

Appendix B: DM3000 Series Accessories ......................................................................6-7

Appendix C: General Care and Cleaning .......................................................................6-8

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

IX

Page 12

Page 13

RIGOL

Chapter 1 Basic Multimeter Operations

This chapter covers the following topics:

General Inspection

Handle Adjustment

The Front Panel and User Interface

To Measure DC Voltage

To Measure AC Voltage

To Measure DC Current

To Measure AC Current

To Measure Resistance

To M ea su re Ca pa c i t an ce

To Test Continuity

To Check Diodes

To Measure Frequency and Period

To Make an Arbitrary Sensor measurement

To Choice Digits resolving index

To Choose Data Digit Display

To Choose Range Options

To Control Trigger Options

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

1-1

Page 14

RIGOL

General Inspection

After you get a new DM3000 Digital Multimeter, you are suggested the following

steps to inspect the instrument.

1. Inspect the shipping container for damage.

Keep a damaged shipping container or cushioning material until the contents of

the shipment have been checked for completeness and the instrument has been

checked mechanically and electrically.

2. Check the accessories.

Accessories supplied with the instrument are listed in "Appendix B" in Chapter 6.

If the contents are incomplete or damaged, please notify your RIGOL Sales

Representative.

3. Inspect the instrument.

In case any mechanical damage or defect, or if the instrument does not operate

properly or pass performance tests, notify your RIGOL Sales Representative.

If the shipping container is damaged, or the cushioning materials show signs of

stress, notify the carrier as well as your RIGOL sales office. Keep the shipping

materials for the carrier’s inspection.

RIGOL offices will arrange for reparation or replacement at RIGOL’s option without

waiting for claim settlement.

1-2

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

Page 15

RIGOL

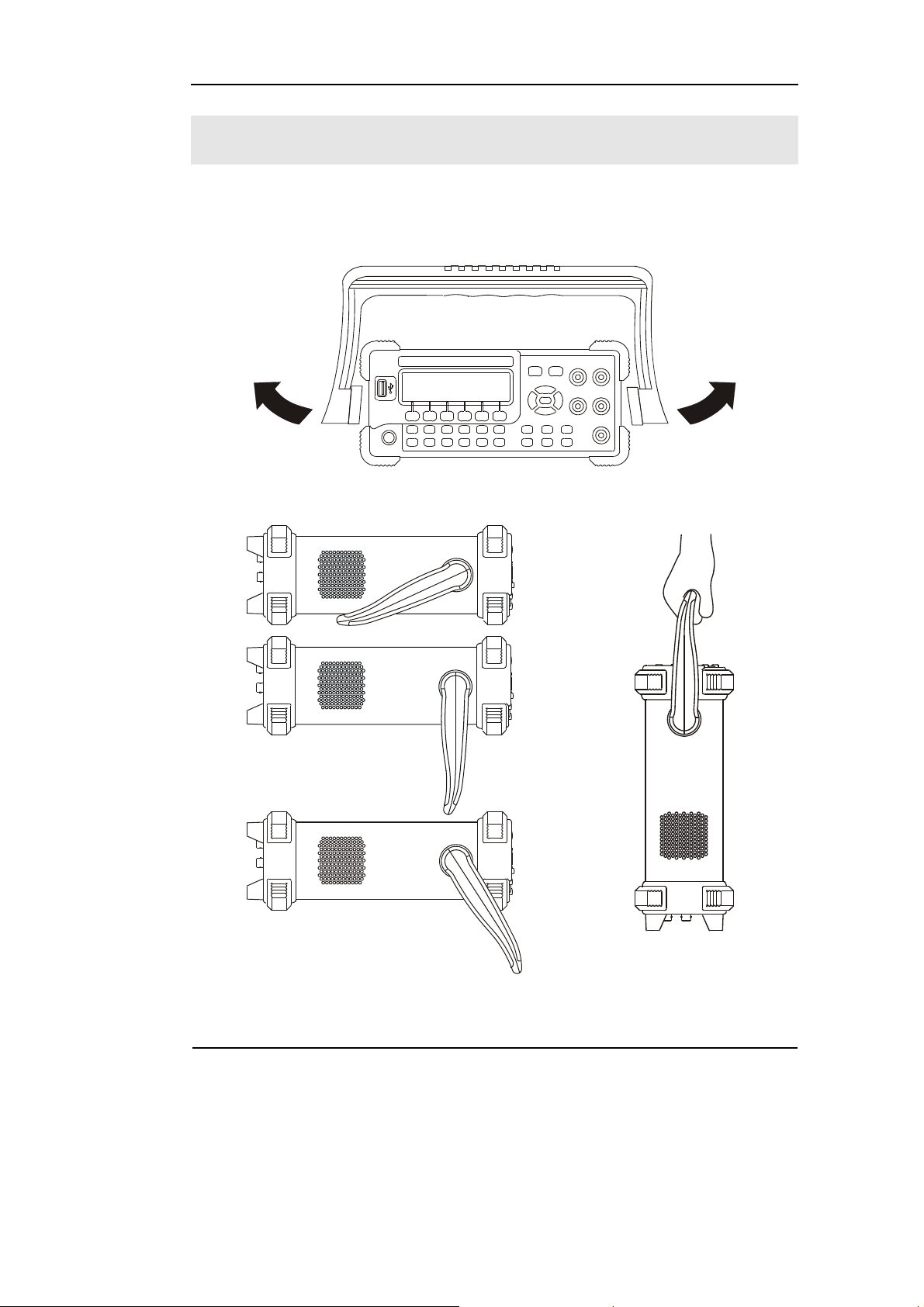

Handle Adjustment

To adjust the handle position of DM3000 Digital Multimeter, please grip the handle by

the sides and pull it outward. Then, make the handle rotate to the desired position.

The operation methods are shown in the graphs 1-1, 1-2, 1-3.

Figure 1-1

Figure 1-2 Figure 1-3

Viewing Positions Carrying Position

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

1-3

Page 16

RIGOL

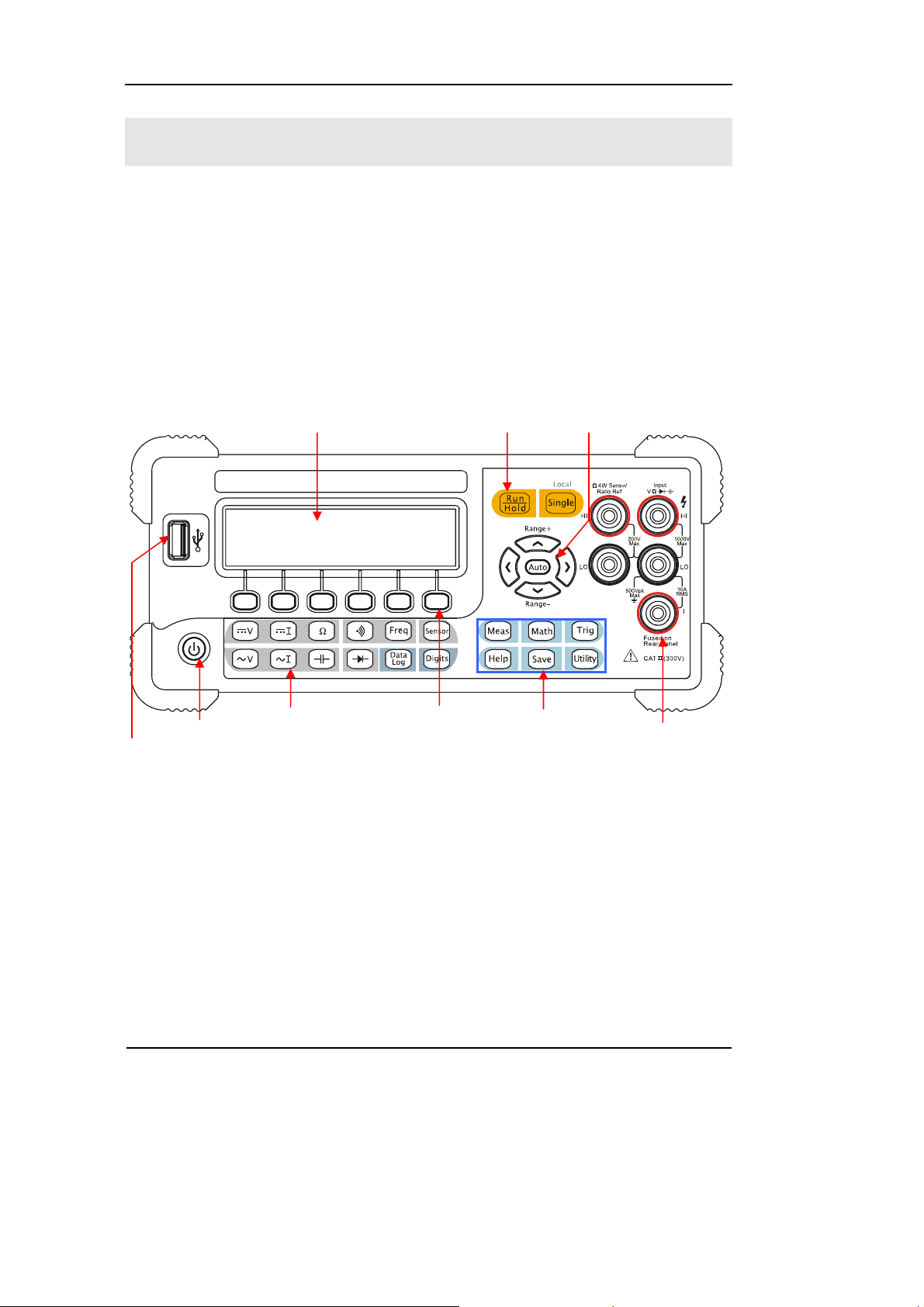

eys

y

The Front/Rear Panel and User Interface

After you get a new DM3000 Digital Multimeter, first, you need to clear how to

operate the front panel of the DM3000 correctly. This chapter will make a brief

introduction and description for the operation and functions of the Front Panel.

The front panel of the DM3000 is very simple and clear for users operation. The front

panel include direction buttons and functions buttons.

LCD Display

District Yellow:

Trigger Control Keys

Direction Keys

USB Host

1-4

On/Off

District Purple:

Measurement

Function K

Menu Operation

Keys

Blue Direction:

Function Selective

Ke

Figure 1-4

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

Current Input Terminal

s

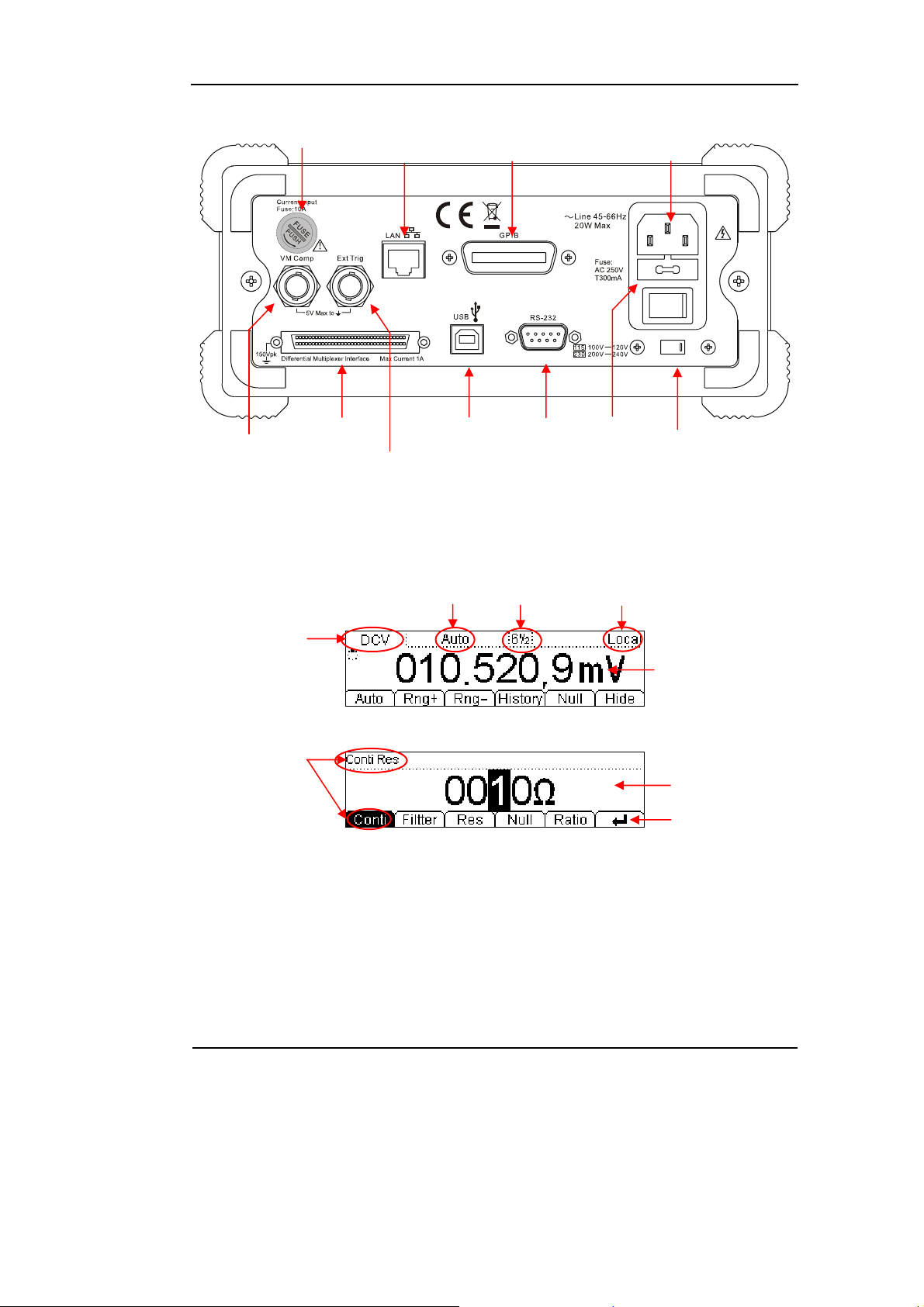

Page 17

RIGOL

play

Current Input Fuse

10/100

Ethernet

GPIB

(IEEE--488)

Power Socket

VMC

Current

Measurement

Parameters

Differential

Multiplexer Interface

Name

USB Device RS--232

Ext Trigger

Figure 1-5

Range

Figure 1-6

The interface explanation

Digits

resolving

index

Power Fuse

Local/Remote

Operation

AC Voltage

Selector

Measurement

Data Display

Parameters

Dis

Operation

Menu

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

1-5

Page 18

RIGOL

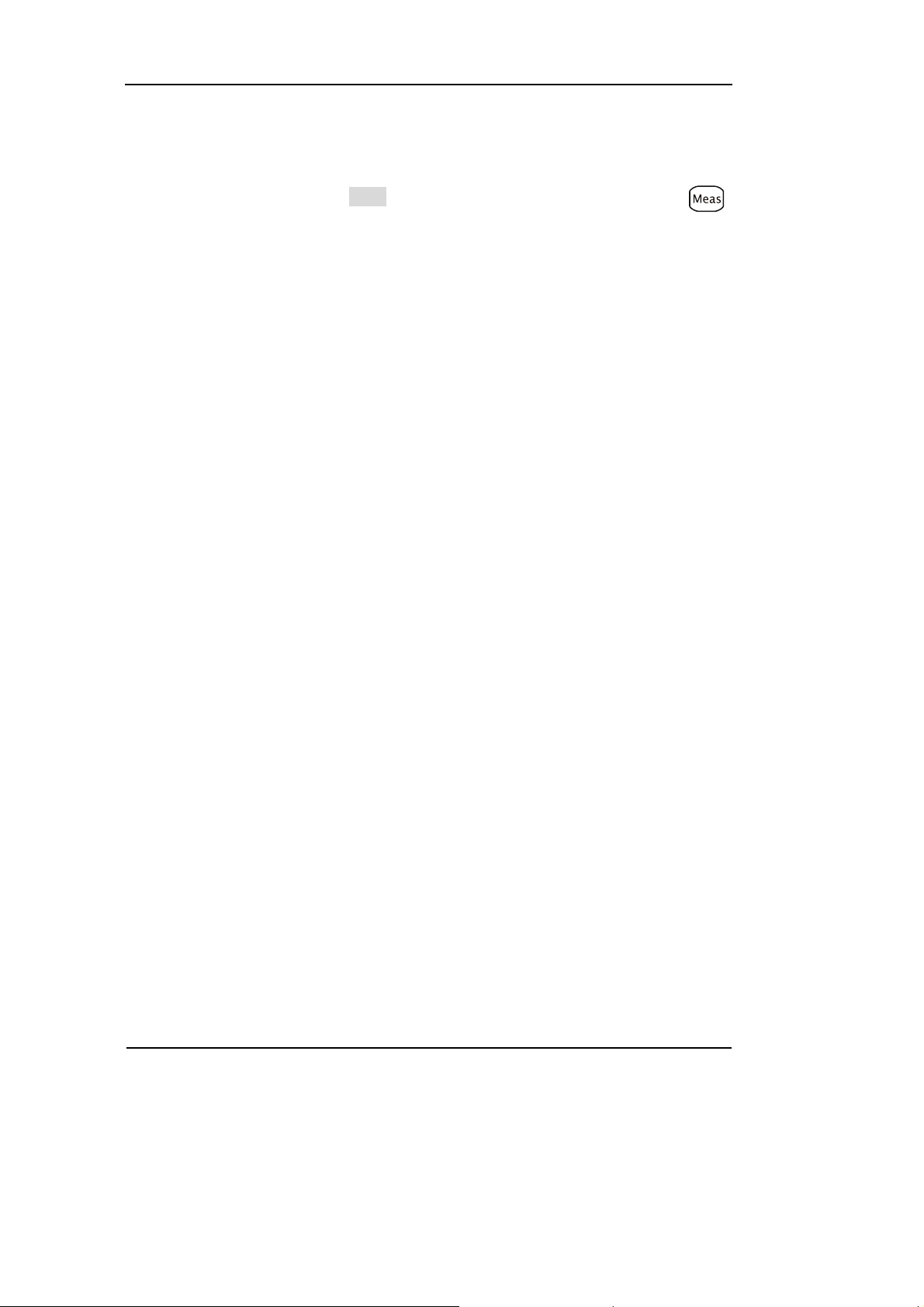

How the definitions express in this book:

In this book, the regarding keys writing expression has the same log with the

keys on the front panel. It is noteworthy that the menu operates keys, marking with

the belt shadow. For example, Conti indicates the short circuit option in menu .

1-6

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

Page 19

RIGOL

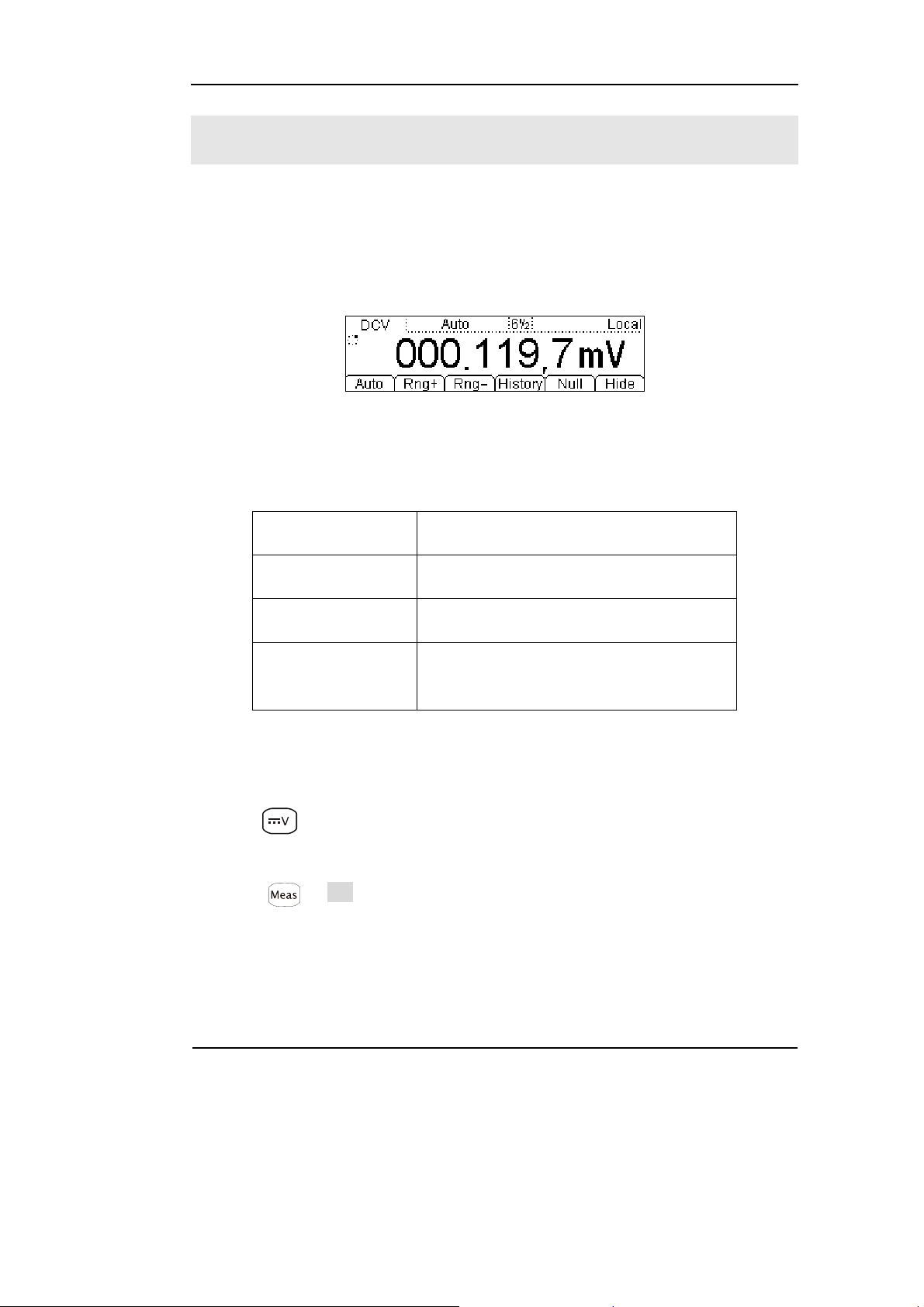

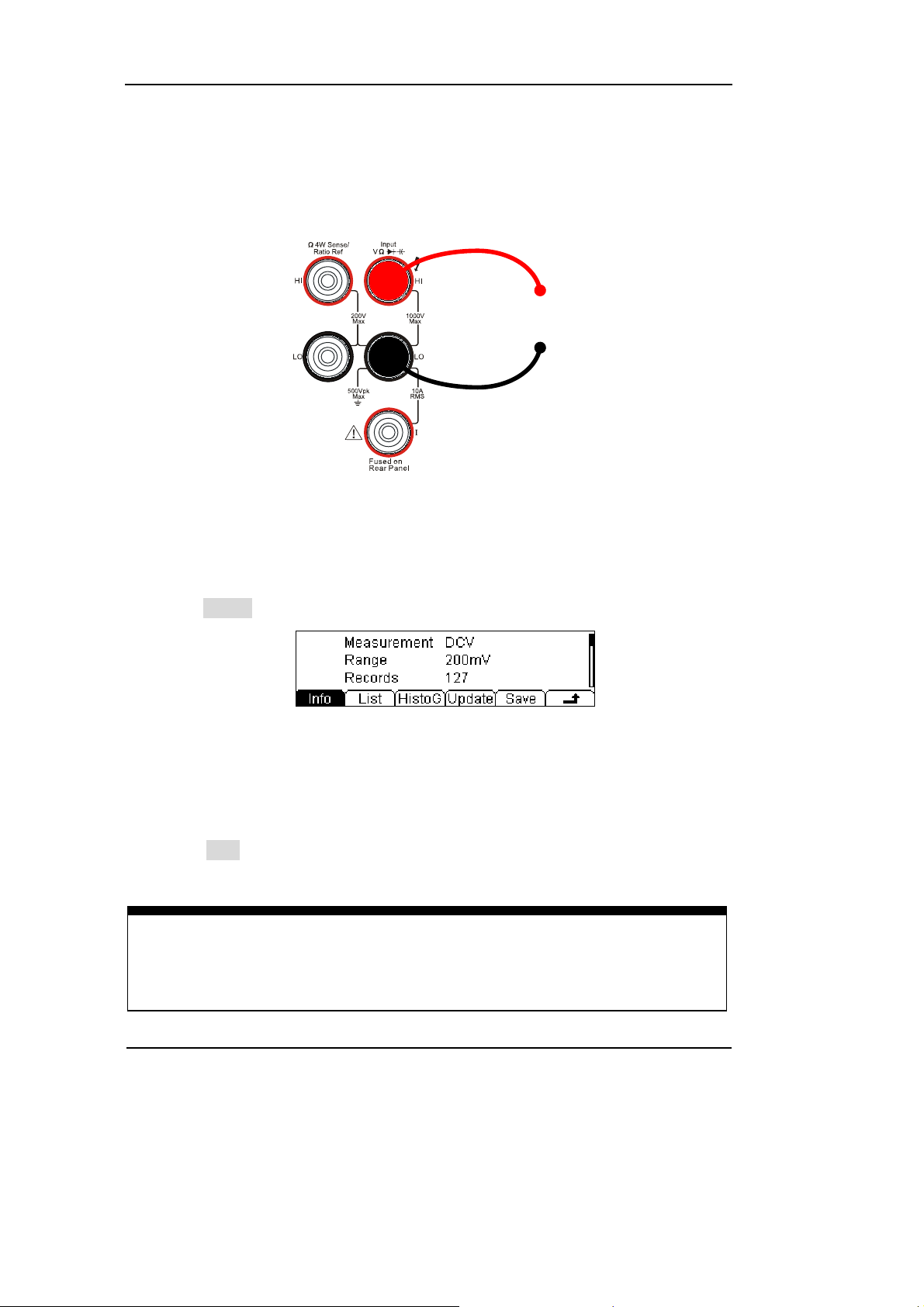

To Measure DC Voltage

In view of DC voltage measurement function, the following part demonstrated how

to link the measurement connection and how to choose measurement functions. The

following practice will gradually guide you to be familiar with the DC Voltage

measurement technique.

Figure 1-7

DC Voltage measurement data interface

Table 1-1 DC Voltage measurement characteristics

Five Range 200mV, 2V, 20V, 200V, 1000V

Max Resolution 100nV

Import Protection 1000V on all ranges (HI Ter mi na l)

Configurable

Parameters

Range, DC impedance, Null value

Basic measurement:

1. Connect test leads as Figure 1-8 shown. Red test lead connects the HI Terminal,

Black test lead connects the LO Terminal.

2. Press to select the DC Voltage measurement function.

3. According to the voltage measuring scope, choose the correct range.

4. Setup the DC impedance.

Press Æ Res, to setup the DC input impedance. Default value of the DC

input impedance will be 10MΩ, this parameter had been setup, and users may carry

on the DC Voltage measurement directly without modification.

5. Set the Null value.

Null computing will be an option operation; it could be setup in accordance with

user demand. If user does not implement Null computing, this parameter is not

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

1-7

Page 20

RIGOL

required, direct implementation of the next step.

(To know the specific setting methods of the Null value setting, please refer to

Chapter 2 “To Set Up Measurement Parameters”, Null computing)

6. Lead test leads into circuit, start to measure.

DC Voltage

Figure 1-8

DC Voltage measurement instruction chart

7. Measurement history data processing.

Press History, enter the menu shown below:

Figure 1-9

To check or save the data that has measured by current measurement function, you

can use the history function. In this function you can get the “Info” (information),

“List” and “Graph” of this measurement. Also, you can save this information data

with press Save softkey.

Note

If the users cannot predict the scope of the measurement, please choose Auto

range to obtain more accurate measurement data.

1-8

User’s Guide for DM3000 Series

©Copyright RIGOL Technologies, Inc. 2007.

Page 21

RIGOL

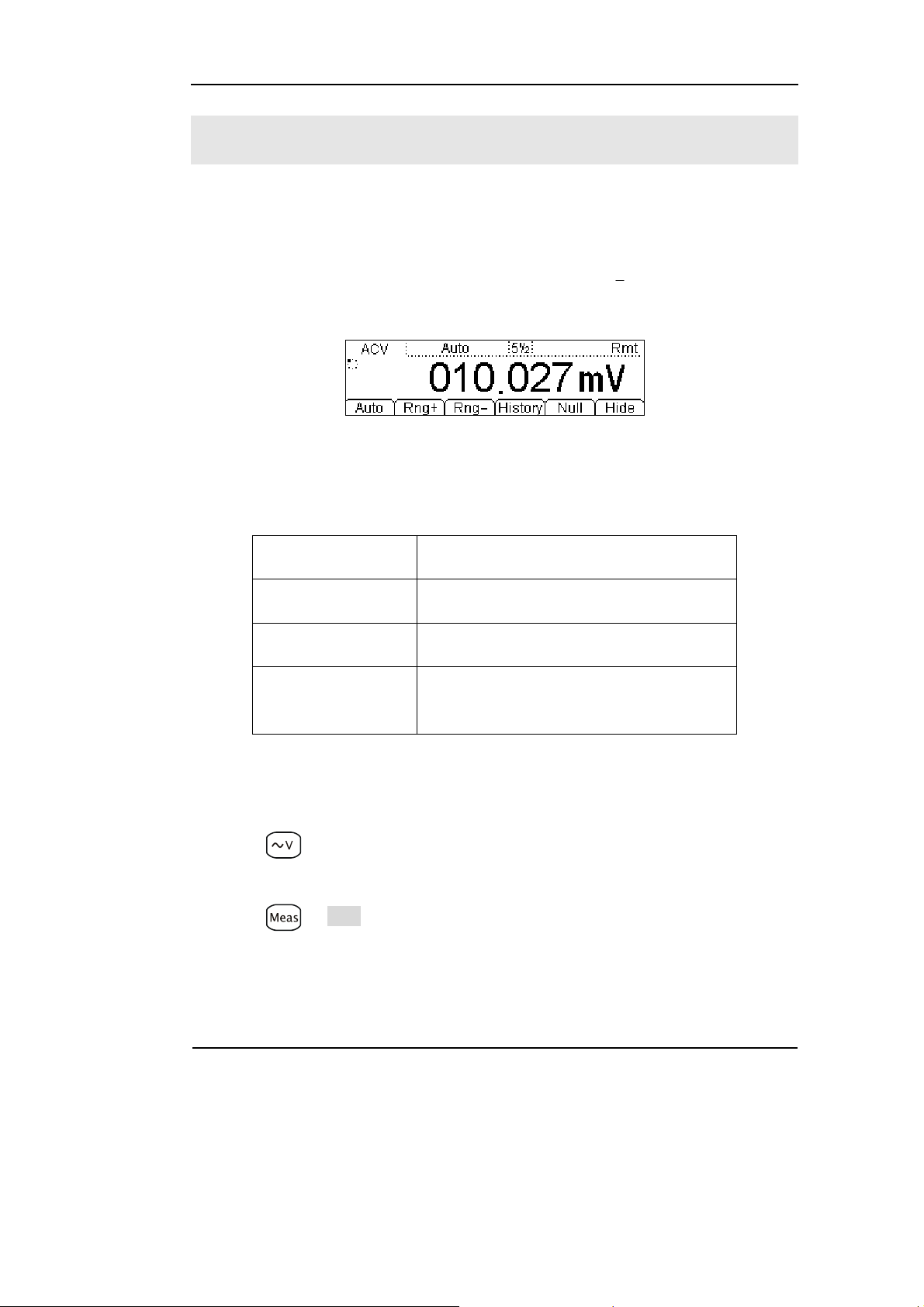

To Measure AC Voltage

In view of AC voltage measurement function, the following part demonstrated how

to link the measurement connection and how to choose measurement functions. The

following practice will gradually guide you to be familiar with the AC Voltage

1

measurement technique. (The AC functions only support 5

Figure 1-10

AC Voltage measurement data interface

Table 1-2 DC Voltage measurement characteristics

2

digits measurement.)

Five Range 200mV, 2V, 20V, 200V, 750V

Max Resolution 100nV

Import Protection 750VRMS on all ranges (HI Ter mi na l)

Configurable

Parameters

Range, DC impedance, Null value

Basic measurement:

1. Connect test leads as Figure 1-11 shown. Red test lead connects the HI Terminal,

Black test lead connects the LO Terminal.

2. Press to select the AC Voltage measurement function.

3. According to the voltage measuring scope, choose the correct range.

4. Setup the DC impedance.

Press Æ Filter, to setup the AC Filter Bandwidth. Default value of the AC

Filter Bandwidth will be 10MΩ, this parameter had been setup, and users may carry

on the AC Voltage measurement directly without modification.

5. Set the Null value.

Null computing will be an option operation, could be setup in accordance with

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

1-9

Page 22

RIGOL

users’ demand. If user does not implement Null computing, this parameter is not

required, direct implementation of the next step.

(To know the specific setting methods of the Null value setting, please refer to

Chapter 2 “To Set Up Measurement Parameters”, Null computing)

6. Lead test leads into circuit, start to measure.

AC Voltage

Figure 1-11

AC Voltage measurement instruction chart

7. Measurement history data processing.

Press History, enter the menu shown below:

Figure 1-12

To check or save the data that has measured by current measurement function, you

can use the history function. In this function you can get the “Info” (information),

“List” and “Graph” of this measurement. Also, you can save this information data

with press Save softkey.

1-10

User’s Guide for DM3000 Series

©Copyright RIGOL Technologies, Inc. 2007.

Page 23

RIGOL

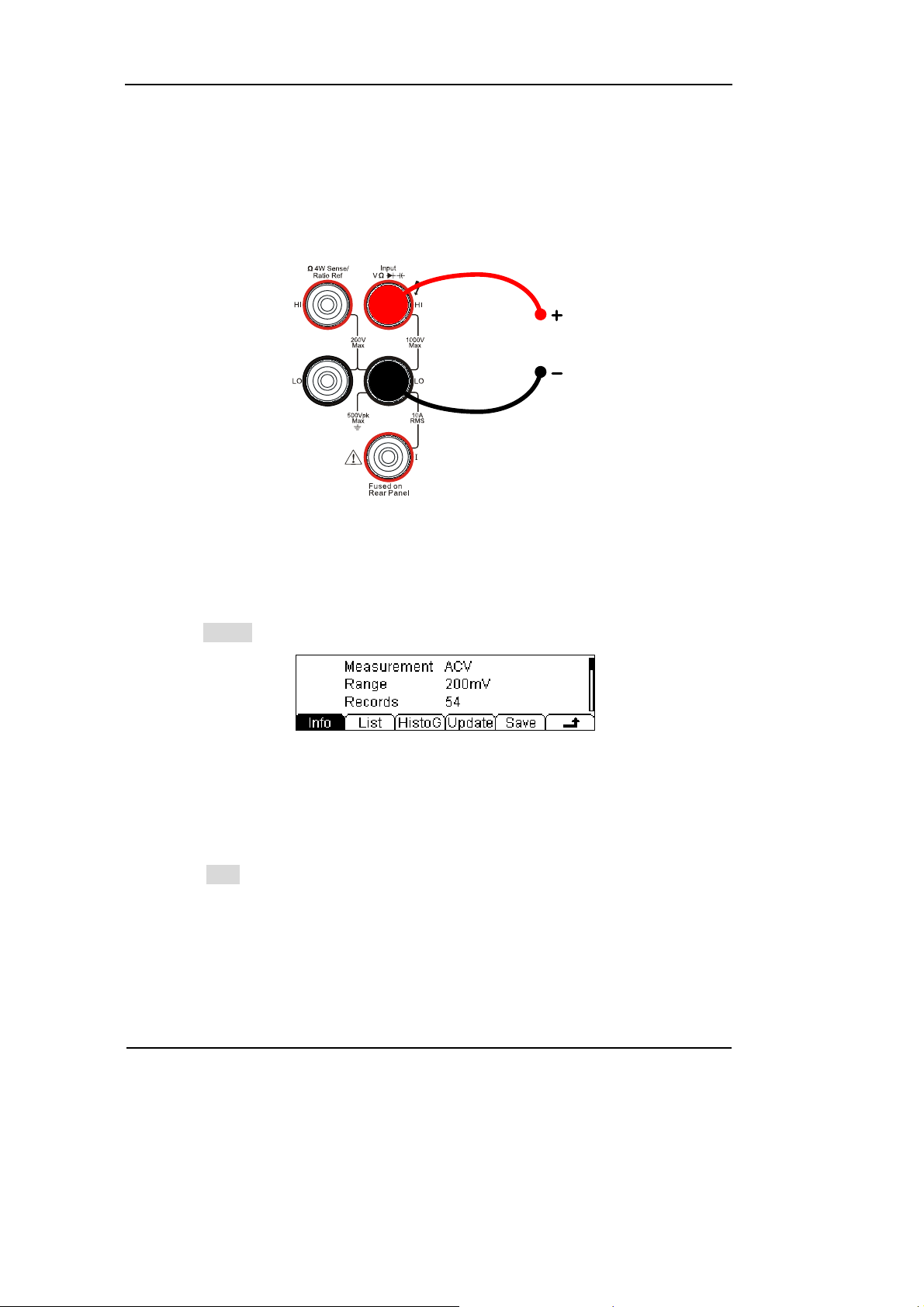

To Measure DC Current

In view of DC current measurement function, the following part demonstrated how

to link the measurement connection and how to choose measurement functions. The

following practice will gradually guide you to be familiar with the DC Current

measurement technique.

Figure 1-13

DC Current measurement data interface

Table 1-3 DC Current measurement characteristics

Five Range 2mA, 20mA, 200mA, 1A, 10A

Max Resolution 10nA

Import Protection

Configurable

Parameters

10A, 250V Current Input Fuse on rear

panel

Range, Null value

Basic measurement:

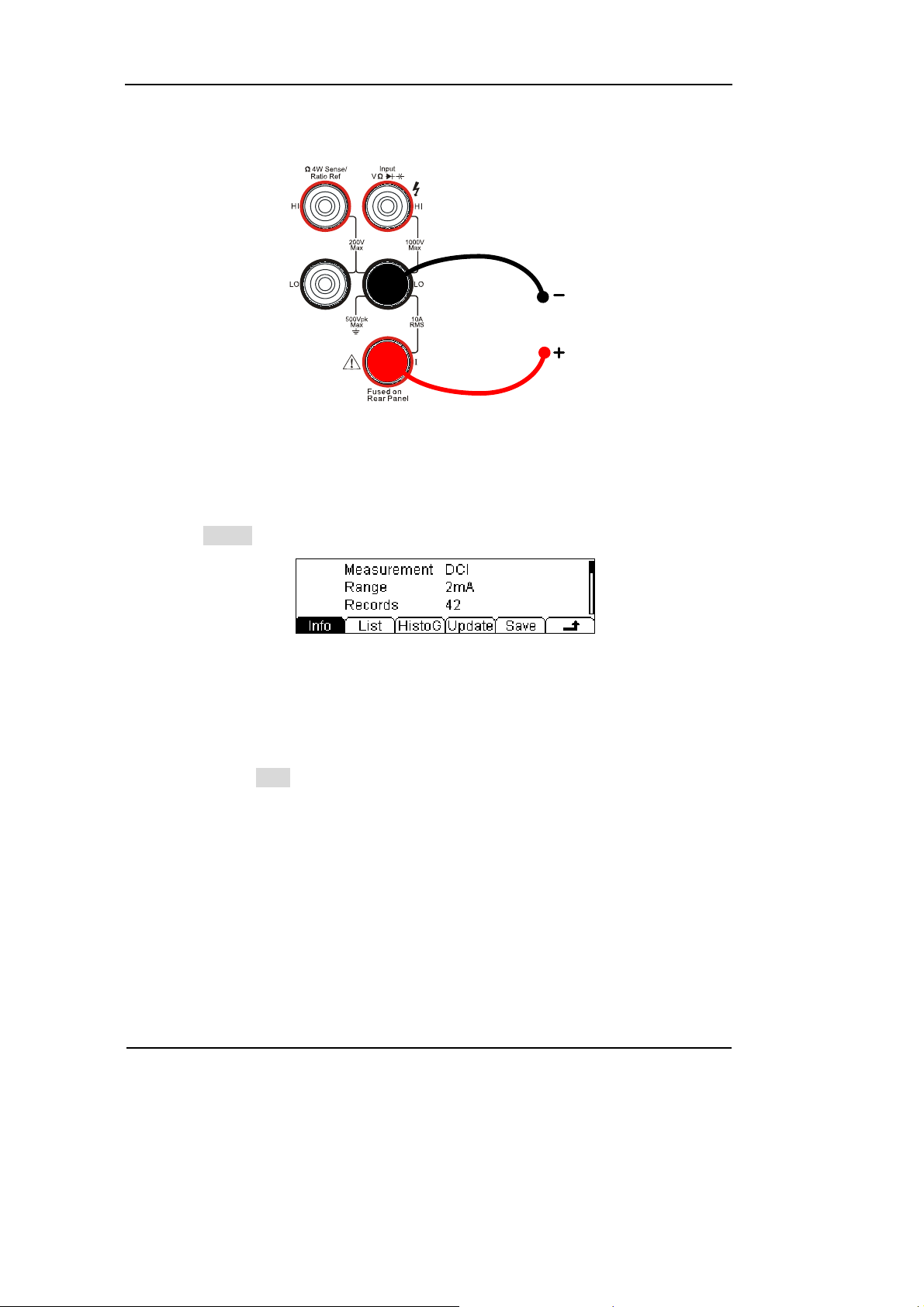

1. Connect test leads as Figure 1-14 shown. Red test lead connects the HI Terminal,

Black test lead connects the LO terminal.

2. Press to select the DC Current measurement function.

3. According to the current measuring scope, choose the correct range.

4. Set the Null value.

Null computing will be an option operation, could be setup in accordance with

user demand. If user does not implement Null computing, this parameter is not

required, direct implementation of the next step.

(To know the specific setting methods of the Null value setting, please refer to

Chapter 2 “To Set Up Measurement Parameters”, Null computing)

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

1-11

Page 24

RIGOL

5. Lead test leads into circuit, start to measure.

Figure 1-14

DC Current measurement instruction chart

6. Measurement history data processing.

Press History, enter the menu shown below:

DC Current

Figure 1-15

The history data

To check or save the data that has measured by current measurement function, you

can use the history function. In this function you can get the “Info” (information),

“List” and “Graph” of this measurement. Also, you can save this information data

with pressing the Save softkey.

1-12

User’s Guide for DM3000 Series

©Copyright RIGOL Technologies, Inc. 2007.

Page 25

RIGOL

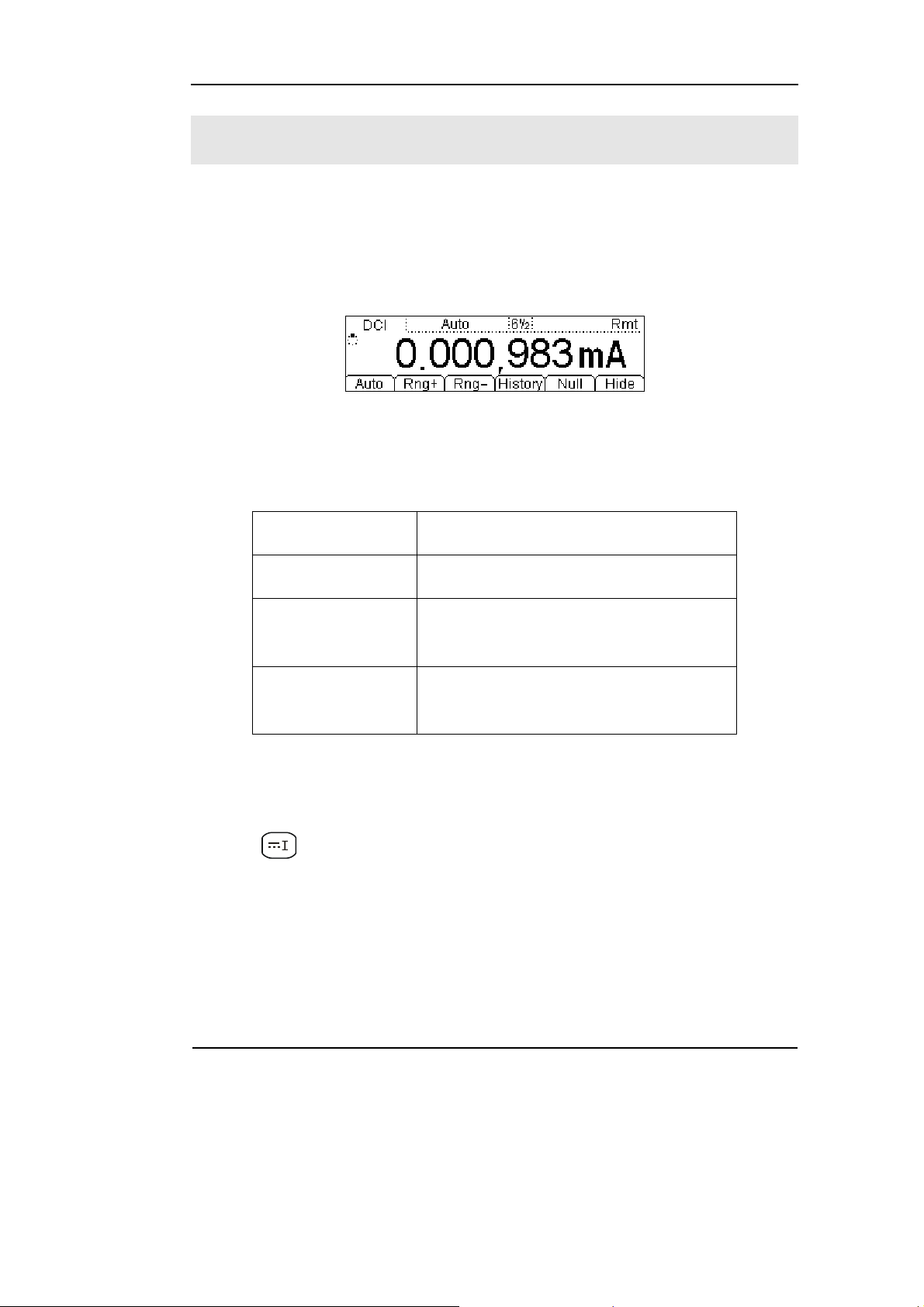

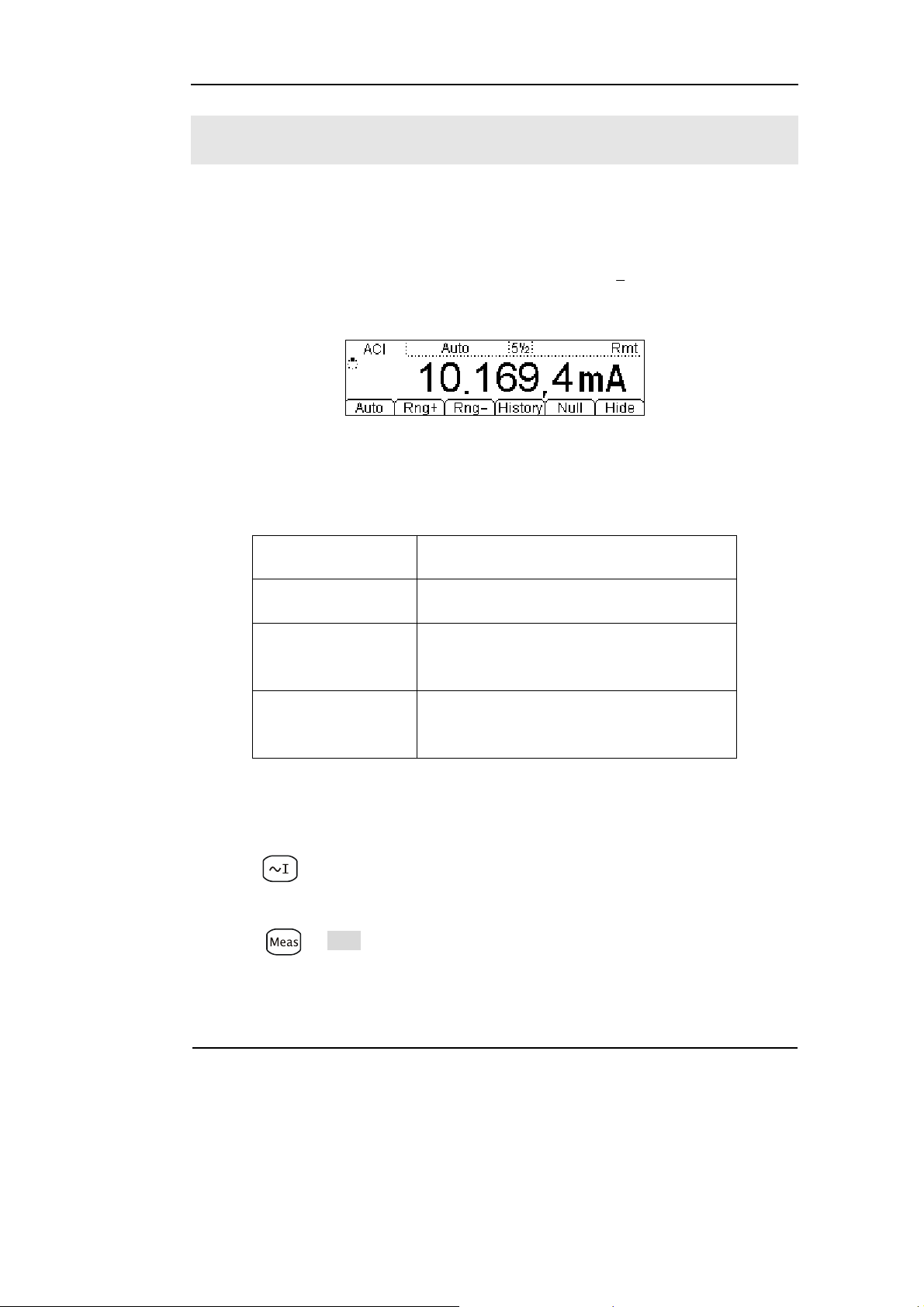

To Measure AC Current

In view of AC current measurement function, the following part demonstrated how to

link the measurement connection and how to choose measurement functions. The

following practice will gradually guide you to be familiar with the AC Current

1

measurement technique. (The AC functions only support 5

Figure 1-16

AC Current measurement data interface

Table 1-4 AC Current measurement characteristics

2

digits measurement.)

Five Range 20mA, 200mA, 1A, 10A

Max Resolution 100nA

Import Protection

Configurable

Parameters

10A, 250V Current Input Fuse on rear

panel

Range, Null value

Basic measurement:

1. Connect test leads as Figure 1-17 shown. Red test lead connects the HI Terminal,

Black test lead connects the LO terminal.

2. Press to select the DC Current measurement function.

3. According to the current measuring scope, choose the correct range.

4. Setup the DC impedance.

Press Æ Filter, to setup the AC Filter Bandwidth. Default value of the AC

Filter Bandwidth will be “Mid”(Middle), this parameter had been setup, and the users

may carry on the AC Voltage measurement directly without modification.

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

1-13

Page 26

RIGOL

5. Set the Null setting value.

Null computing will be an option operation, could be setup in accordance with

user demand. If user does not implement Null computing, this parameter is not

required, direct implementation of the next step.

(To know the specific setting methods of the Null value setting, please refer to

Chapter 2 “To Set Up Measurement Parameters”, Null computing)

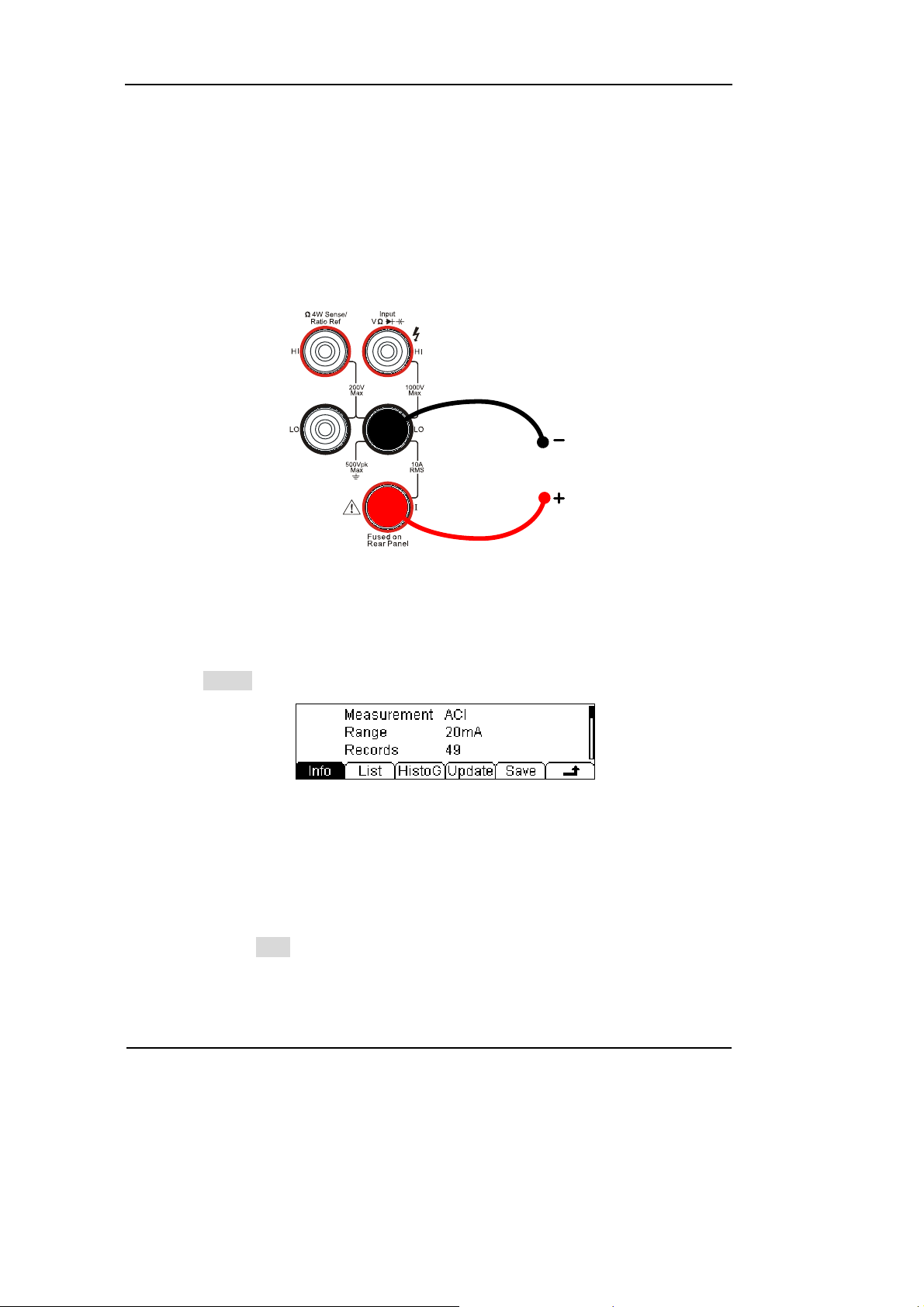

6. Lead test leads into circuit, start to measure.

AC Current

Figure 1-17

AC Current measurement instruction chart

7. Measurement history data processing.

Press History, enter the menu shown below:

Figure 1-18

The history data

To check or save the data that has measured by current measurement function, you

can use the history function. In this function you can get the “Info” (information),

“List” and “Graph” of this measurement. Also, you can save this information data

with pressing the Save softkey.

1-14

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

Page 27

RIGOL

To Measure Resistance

In view of Resistance measurement function, the following part demonstrated how

to link the measurement connection and how to choose measurement functions. The

following practice will gradually guide you to be familiar with the Resistance

measurement technique. Resistance measurement methods include 2-Wire

Resistances Measurement and 4-Wire Resistances Measurement; we will

perform to explain separately.

2-Wire Resistance Measurement

Figure 1-19

Table 1-5 Resistance measurement characteristics

Seven Range 200Ω, 2kΩ, 20kΩ, 200kΩ, 1MΩ, 10MΩ, 100MΩ

Max Resolution 100uΩ

Open-circuit

Voltage

<5V

Import Protection 1000V on all ranges (HI Ter mi na l)

Configurable

Parameters

Range, Null value

Basic measurement:

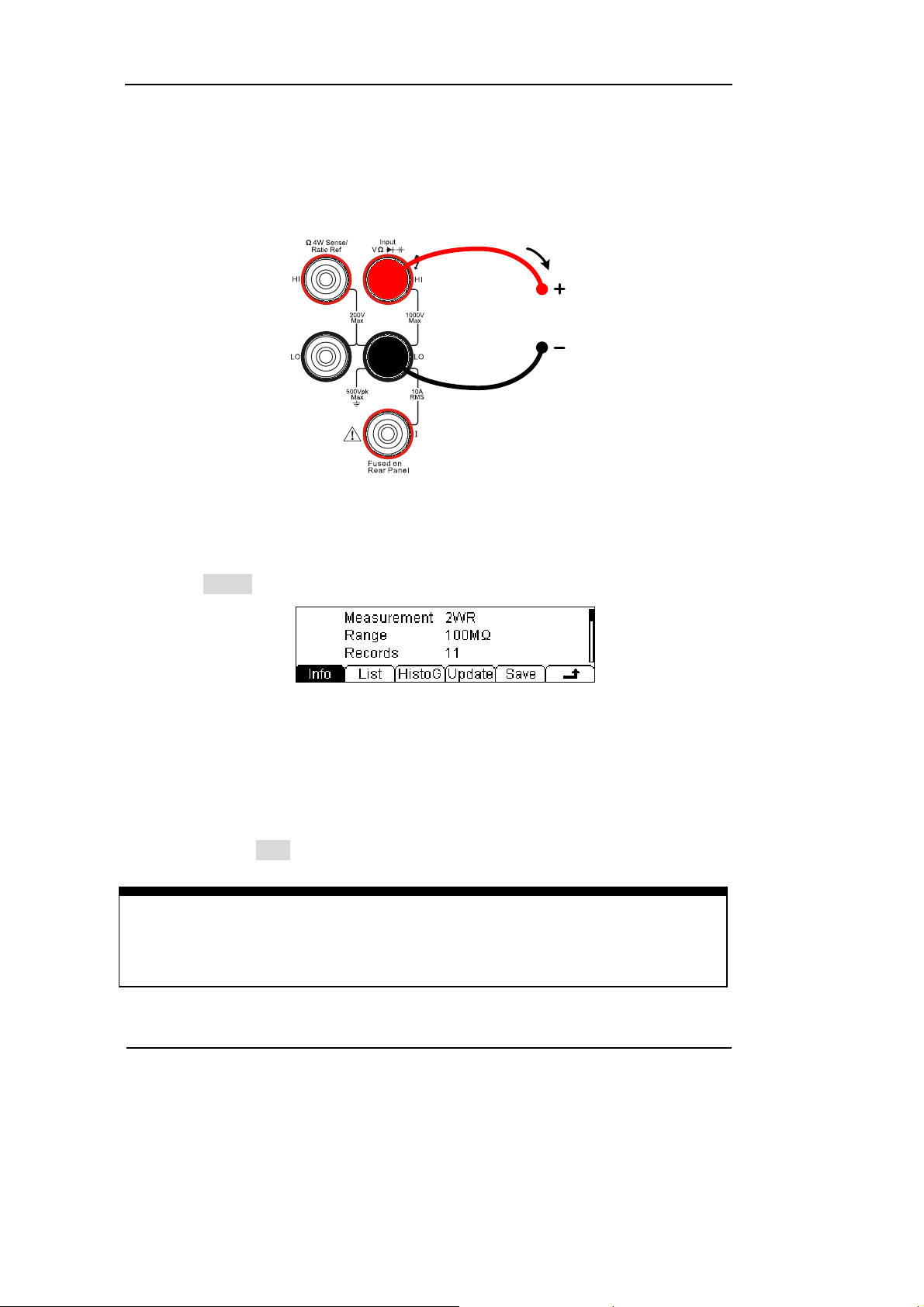

1. Connect test leads as Figure 1-20 shown. Red test lead connects the HI Terminal,

Black test lead connects the LO Terminal.

2. Press to select the 2-Wire Resistance Measurement.

3. According to the resistance measuring scope, choose the correct range.

4. Set the Null value

Null computing will be an option operation, could be setup in accordance with

user demand. If user does not implement Null computing, this parameter is not

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

1-15

Page 28

RIGOL

required, direct implementation of the next step.

(To know the specific setting methods of the Null value setting, please refer to

Chapter 2 “To Set Up Measurement Parameters”, Null computing)

5. Lead test leads into circuit, start to measure.

Resistance

Figure 1-20

2-Wire Resistance Measurement instruction chart

6. Measurement history data processing.

Press History, enter the menu shown below:

Figure 1-21

The history data

To check or save the data that has measured by current measurement function, you

can use the history function. In this function you can get the “Info” (information),

“List” and “Graph” of this measurement. Also, you can save this information data

with pressing the Save softkey.

NOTE

When measuring small value resistance, Null operation will be recommended, the

test wire impedance error could be eliminated.

1-16

User’s Guide for DM3000 Series

©Copyright RIGOL Technologies, Inc. 2007.

Page 29

RIGOL

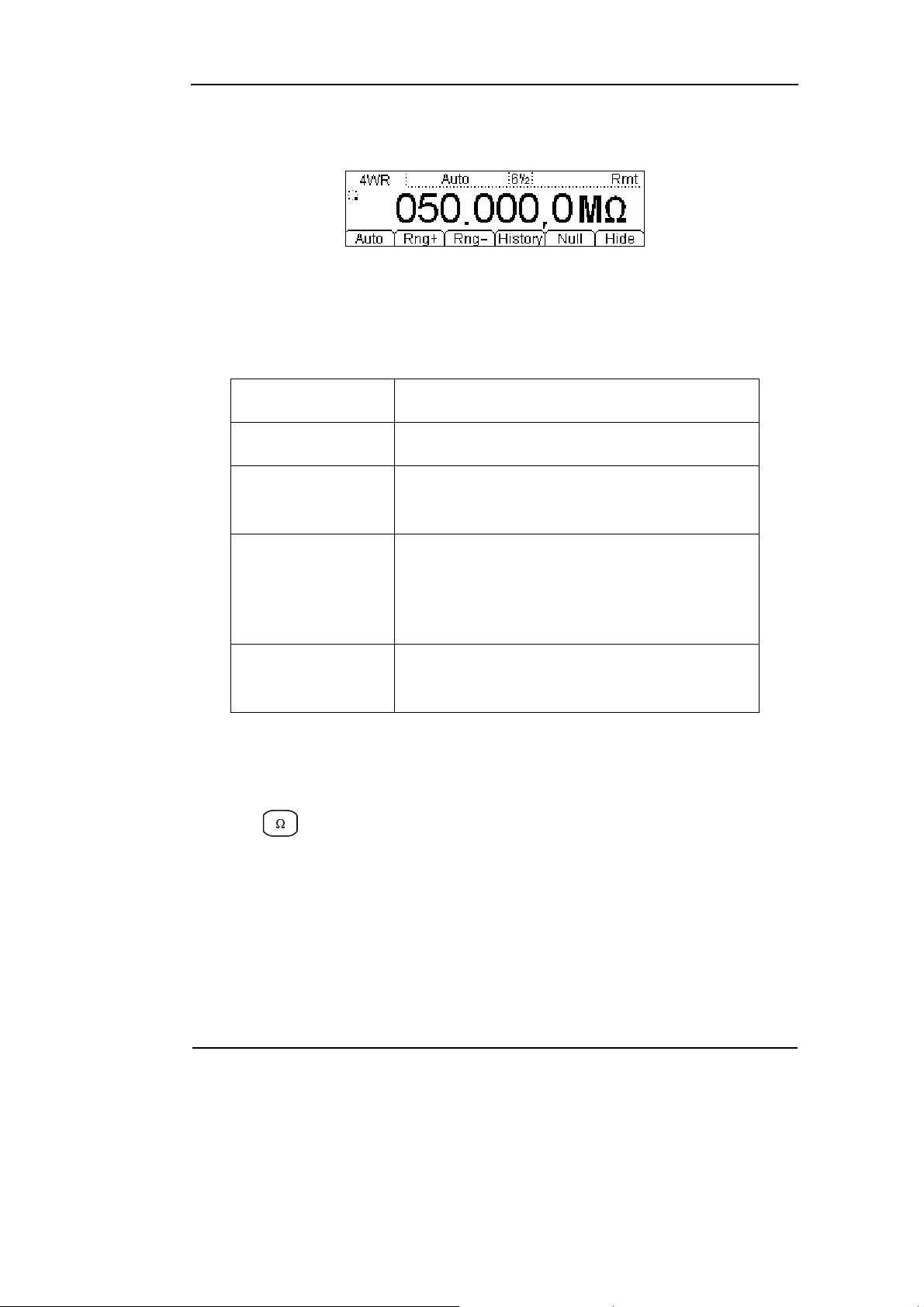

4-Wire Resistance Measurement

Figure 1-22

Table 1-6 Resistance measurement characteristics

Seven Range 200Ω, 2kΩ, 20kΩ, 200kΩ, 1MΩ, 10MΩ, 100MΩ

Max Resolution 100uΩ

Open-circuit

Voltage

Import Protection

<5V

(1). 200V

PK

(2). 1000V on all ranges (HI

Ter mi na l)

(3). 200V on all ranges (HI Sense, LO Sense)

Configurable

Parameters

Range, Null value

Basic measurement:

1. Connect test leads as Figure 1-23 shown. Red test leads connect the HI Terminal,

Black test leads connect the LO Terminal.

2. Press twice to select the 4-Wire Resistance Measurement.

3. According to the resistance measuring scope, choose the correct range.

4. Set the Null setting value.

Null computing will be an optional operation, it could be setup in accordance

with users’ demand. If user does not implement Null computing, this parameter is

not required, direct implementation of the next step.

(To know the specific setting methods of the Null value setting, please refer to

Chapter 2 “To Set Up Measurement Parameters”, Null computing)

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

1-17

Page 30

RIGOL

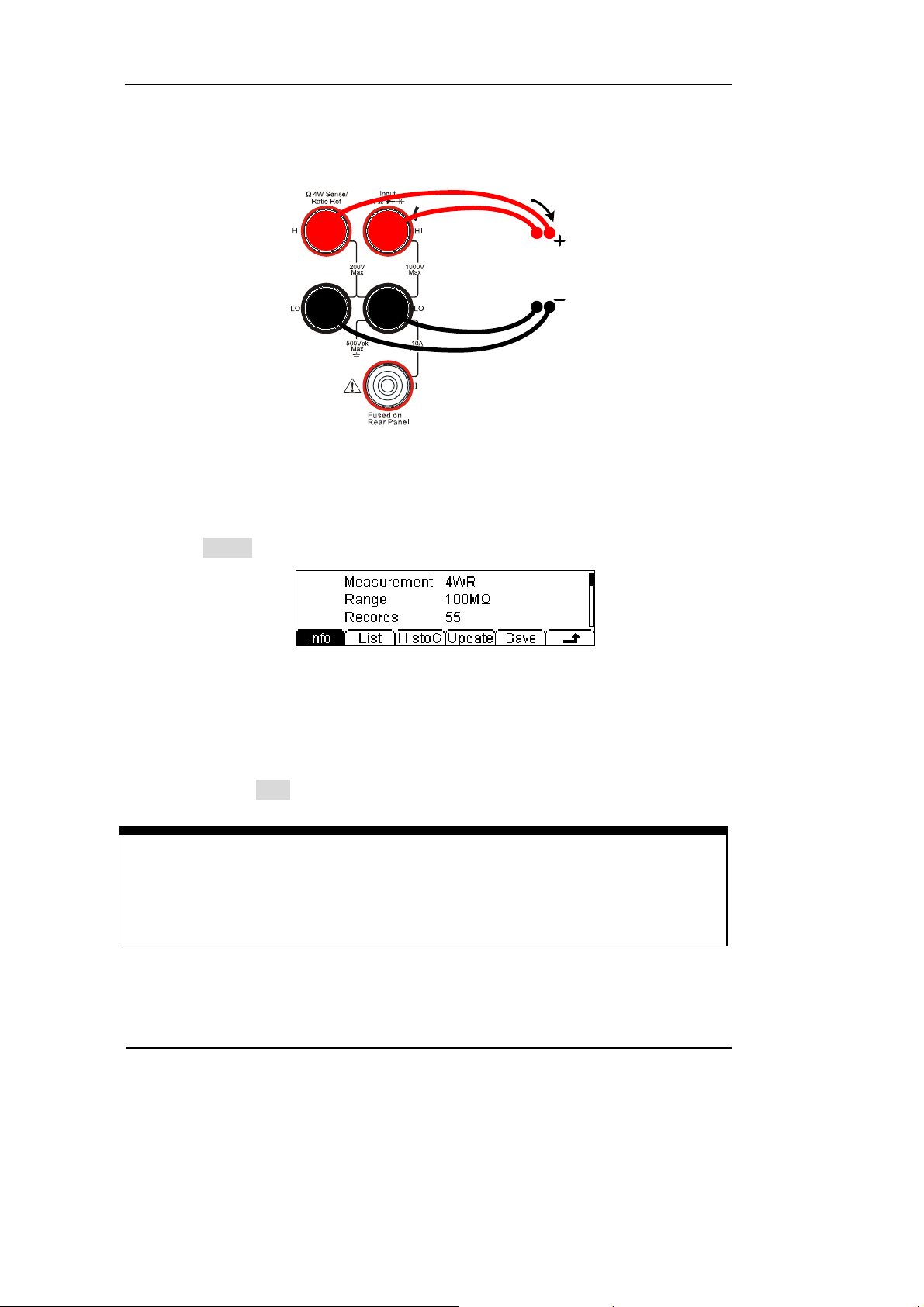

5. Lead test leads into circuit, start to measure.

4-Wire Sense HI

4-Wire Sense LO

Figure 1-23

4-Wire Resistance Measurement instruction chart

6. Measurement history data processing.

Press History, enter the menu shown below:

Resistance

Figure 1-24

To check or save the data that has measured by current measurement function,

you can use the history function. In this function you can get the “Info” (information),

“List” and “Graph” of this measurement. Also, you can save this information data

with pressing the Save softkey.

NOTE

When measuring resistances, you could not touch both ends of the resistance. It

will cause the measurement inaccurate.

1-18

User’s Guide for DM3000 Series

©Copyright RIGOL Technologies, Inc. 2007.

Page 31

RIGOL

To Measure Capacitance

In view of DC voltage measurement function, the following part demonstrated how

to link the measurement connection and how to choose measurement functions. The

following practice will gradually guide you to be familiar with the DC Voltage

measurement technique.

Figure 1-25

Capacitance measurement data interface

Table 1-7 Capacitance measurement characteristics

Six Range 2nF, 20nF, 200nF, 2uF, 20uF, 200uF

Max Resolution 0.1pF

Import Protection 1000V on all ranges (HI Ter mi na l)

Configurable

Parameters

Range, Null value

Basic measurement:

1. Connect test leads as Figure 1-26 shown. Red test lead connects the HI Terminal,

Black test lead connects the LO Terminal.

2. Press to select the Capacitance measurement function.

3. According to the capacitance measuring scope, choose the correct range.

4. Set the Null value.

Null computing will be an optional operation, could be setup in accordance with

user demand. If user does not implement Null computing, this parameter is not

required, direct implementation of the next step.

(To know the specific setting methods of the Null value setting, please refer to

Chapter 2 “To Set Up Measurement Parameters”, Null computing)

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

1-19

Page 32

RIGOL

5. Lead test leads into circuit, start to measure.

Figure 1-26

Capacitance measurement instruction chart

6. Measurement history data processing.

Press History, enter the menu shown below:

Capacitance

Figure 1-27

To check or save the data that has measured by current measurement function, you

can use the history function. In this function you can get the “Info” (information),

“List” and “Graph” of this measurement. Also, you can save this information data

with pressing the Save softkey.

NOTE

Before measuring the electrolytic capacitance, you should make the two legs of the

electrolytic capacitance short circuit and let it be discharged, and then you can

measure it.

1-20

User’s Guide for DM3000 Series

©Copyright RIGOL Technologies, Inc. 2007.

Page 33

RIGOL

To Test Continuity

In view of Continuity measurement function, the following part demonstrated how to

link the measurement connection and how to choose measurement functions. The

following practice will gradually guide you to be familiar with the Continuity

measurement technique.

Figure 1-28

Table 1-8 Continuity measurement characteristics

Tests Current 1mA

Max Resolution Range fixed at 2KΩ

Open-circuit Voltage <5V

Import Protection 1000V (HI Terminal)

0≤R

≤Short-circuit impedance

testing

Configurable Parameters

(0Ω≤Short-circuit impedance≤2kΩ)

Basic measurement:

1. Connect test leads as Figure 1-29 shown. Red test lead connects the HI Terminal,

Black test lead connects the LO Terminal.

2. Press to select the Continuity Measurement.

3. Setup the Short-circuit resistance.

Press Æ Res, to set up the Short-circuit Impedance. Default value of the

Short-circuit Impedance will be 10MΩ, this parameter had been setup, and the user

may carry on the Continuity measurement directly without modification.

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

1-21

Page 34

RIGOL

4. Lead test leads into circuit, start to measure.

Open or Closed Circuit

Figure 1-29

Continuity Measurement instruction chart

I

1-22

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

Page 35

RIGOL

To Check Diodes

In view of Check Diodes function, the following part demonstrated how to link the

measurement connection and how to choose measurement functions. The following

practice will gradually guide you to be familiar with the Check Diodes technique.

Figure 1-30

Table 1-9 Check Diodes characteristics

Tests Current 1mA

Max Resolution Range fixed at 2VDC

Open-circuit Voltage <5V

Import Protection 1000V (HI Terminal)

Configurable Parameters 0.3V≤V

measured

≤2V

Basic measurement:

1. Connect test leads as Figure 1-31 shown. Red test lead connects the HI Terminal,

Black test lead connects the LO Terminal.

2. Press to select the Check Diodes.

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

1-23

Page 36

RIGOL

3. Lead test leads into circuit, start to check.

Figure 1-31

Check Diodes instruction chart

I

Forward Bias

1-24

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

Page 37

RIGOL

To Measure Frequency and Period

In view of Frequency and Period Measurement function, the following part

demonstrated how to link the measurement connection and how to choose

measurement functions. The following practice will gradually guide you to be familiar

with the Frequency and Period Measurement technique.

Frequency Test

Figure 1-32

Table 1-10 Frequency Test characteristics

Range 200mV, 2V, 20V, 200V, 750V

Measurement Range 3Hz~300kHz

Input Signal Range 100mVAC ~ 750VAC

Import Protection 750VRMS on all ranges (HI Te rm in al )

Configurable Parameters Null value

Basic measurement:

1. Connect test leads as Figure 1-33 shown. Red test lead connects the HI Terminal,

Black test lead connects the LO Terminal.

2. Press to select the Frequency Test.

3. Set the Null value.

Null computing will be an option operation, could be setup in accordance with

user demand. If user does not implement Null computing, this parameter is not

required, direct implementation of the next step.

(To know the specific setting methods of the Null value setting, please refer to

Chapter 2 “To Set Up Measurement Parameters”, Null computing)

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

1-25

Page 38

RIGOL

4. Lead test leads into circuit, start to check.

Figure 1-33

Frequency Test instruction chart

5. Measurement history data processing.

Press History, enter the menu shown below:

AC Signal

Figure 1-34

To check or save the data that has measured by current measurement function, you

can use the history function. In this function you can get the “Info” (information),

“List” and “Graph” of this measurement. Also, you can save this information data

with pressing the Save softkey.

1-26

User’s Guide for DM3000 Series

©Copyright RIGOL Technologies, Inc. 2007.

Page 39

RIGOL

Period Test

Figure 1-35

Table 1-10 Period Test characteristics

Range 200mV, 2V, 20V, 200V, 750V

Measurement Range 0.33s ~ 3.3us

Input Signal Range 100mVAC~750VAC

Import Protection 750VRMS on all ranges (HI Te rm in al )

Configurable Parameters Null value

Basic measurement:

1. Connect test leads as Figure 1-36 shown. Red test lead connects the HI Terminal,

Black test lead connects the LO Terminal.

2. Press twice to select the Period Test.

3. Set the Null value.

Null computing will be an optional operation, could be setup in accordance with

users’ demand. If user does not implement Null computing, this parameter is not

required, direct implementation of the next step.

(To know the specific setting methods of the Null value setting, please refer to

Chapter 2 “To Set Up Measurement Parameters”, Null computing)

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

1-27

Page 40

RIGOL

4. Lead test leads into circuit, start to check.

Figure 1-36

Period Test instruction chart

5. Measurement history data processing.

Press History, enter the menu shown below:

AC Signal

Figure 1-37

To check or save the data that has measured by current measurement function, you

can use the history function. In this function you can get the “Info” (information),

“List” and “Graph” of this measurement. Also, you can save this information data

with pressing the Save softkey.

1-28

User’s Guide for DM3000 Series

©Copyright RIGOL Technologies, Inc. 2007.

Page 41

RIGOL

To Measure Arbitrary Sensor

To set an arbitrary sensor, you will need to set the sensor name, sensor type, sensor

physical unit, sensor reference data, and arithmetic.

Figure 1-38

Table 1-11 Period Test characteristics

New Newly built sensor reference data file

Edit Edit a sensor reference data file

Load Load a sensor reference data file

Display Set display mode

Basic measurement:

1. Connect test leads as Figure 1-54, 1-55 shown. Red test leads connect the HI

Terminal, Black test leads connect the LO Terminal.

2. Press to select the Sensor function.

3. Press New, enter the newly- built sensor reference data file interface.

Figure 1-39

(1). In New function interface, you are allowed to edit the sensor Name, sensor Type

and physical value Unit of the sensor.

Figure 1-40

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

1-29

Page 42

RIGOL

Press Name button, you are allowed to create a name for the sensor reference value

document.

Figure 1-41

Press Type button, you are allowed to select the sensor type, include: DCV, DCI,

2-Wire resistance, and frequency.

Figure 1-42

Press Unit button, you are allowed to select the physical unit, include: , ℃ Pa, % , °,

and F.

Figure 1-43

In New interface, press Define button to build the reference value table. The

reference value documents for each kind of sensor are different, so you need input

reference value in abundance.

Figure 1-43

Press Add button, you are allowed to input the Measured and Corresponding value to

reference value data. In order be suitable for the different type sensor, the reference

value is able to separate into several SEGment in accordance with the different

algorithms.

1-30

Figure 1-44

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

Page 43

RIGOL

Figure 1-45

Figure 1-46

Press SEG button, you are allowed to segment the reference value with different

arithmetic.

Press Arith button select the algorithms to Line or Curve.

Figure 1-47

Figure 1-48

Press return to New interface then press Done button, you have finished the

input work, then you can use this sensor reference immediately, or you can save it

into the built-in storage space or your U-disk for the future work.

Figure 1-49

Press Apply button, to use this reference value file.

Press Save to save the file.

Figure 1-50

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

1-31

Page 44

RIGOL

Press Save button, to finish the save operation.

Figure 1-51

Press Apply button, to start the sensor measurement.

Figure 1-52

(2). Press Edit button, enter the edit function. With this function you can edit the

sensor reference value file that you had saved.

(3). Press Load button, enter the store function interface, you can load the sensor

reference file you had saved.

(4). Press Disp button, you can choose which value will be shown on the display

interface.

(5). Press History, enter the menu shown below:

Figure 1-53

To check or save the data that has measured by current measurement function, you

can use the history function. In this function you can get the “Info” (information),

“List” of this measurement. Also, you can save this information data with pressing

the Save button.

1-32

User’s Guide for DM3000 Series

©Copyright RIGOL Technologies, Inc. 2007.

Page 45

RIGOL

4. Lead test leads into circuit, start to check.

Sensor

Figure 1-54

Voltage, Resistance, and Frequency mode sensor instruction chart

Sensor

Figure 1-55

Current mode sensor instruction chart

Figure 1-56

Choosing interfaces of measure and correspond value

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

1-33

Page 46

RIGOL

To Choose Digits resolving index

The digits resolving index (the accurate of reading) differentiates 4 1/2, 5 1/2, 6 1/2

three kinds. Three kinds of digits resolving index are suitable for all measurement

function.

Reduce the index

Increases the index

Figure 1-57

The digits resolving index Choice Keys

Methods:

In the main interface, use left and right direction key to adjust the digits resolving

index. Press left button to lower accuracy, press right button to upper accuracy.

The digits resolving index Selection

(1). Each precision of the measure function can be set separately without influence.

(2). Choose the reading precision of 6 1/2 bit when measuring AC for the best.

(3). Store the digits resolving index in volatile memory.

1-34

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

Page 47

RIGOL

To Choose Data Digit Display

Function is used to set up data display digit. It has 5, 6, 7 three kinds of data

digit display choice. The default display digit is 5.

Figure 1-58

The data digits is 7

Figure 1-59

The data digits is 6

Figure 1-60

The data digits is 5

NOTE

In high-accuracy measurement, if users need to show less data digit, it can show

fewer digits for user-friendly reading.

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

1-35

Page 48

RIGOL

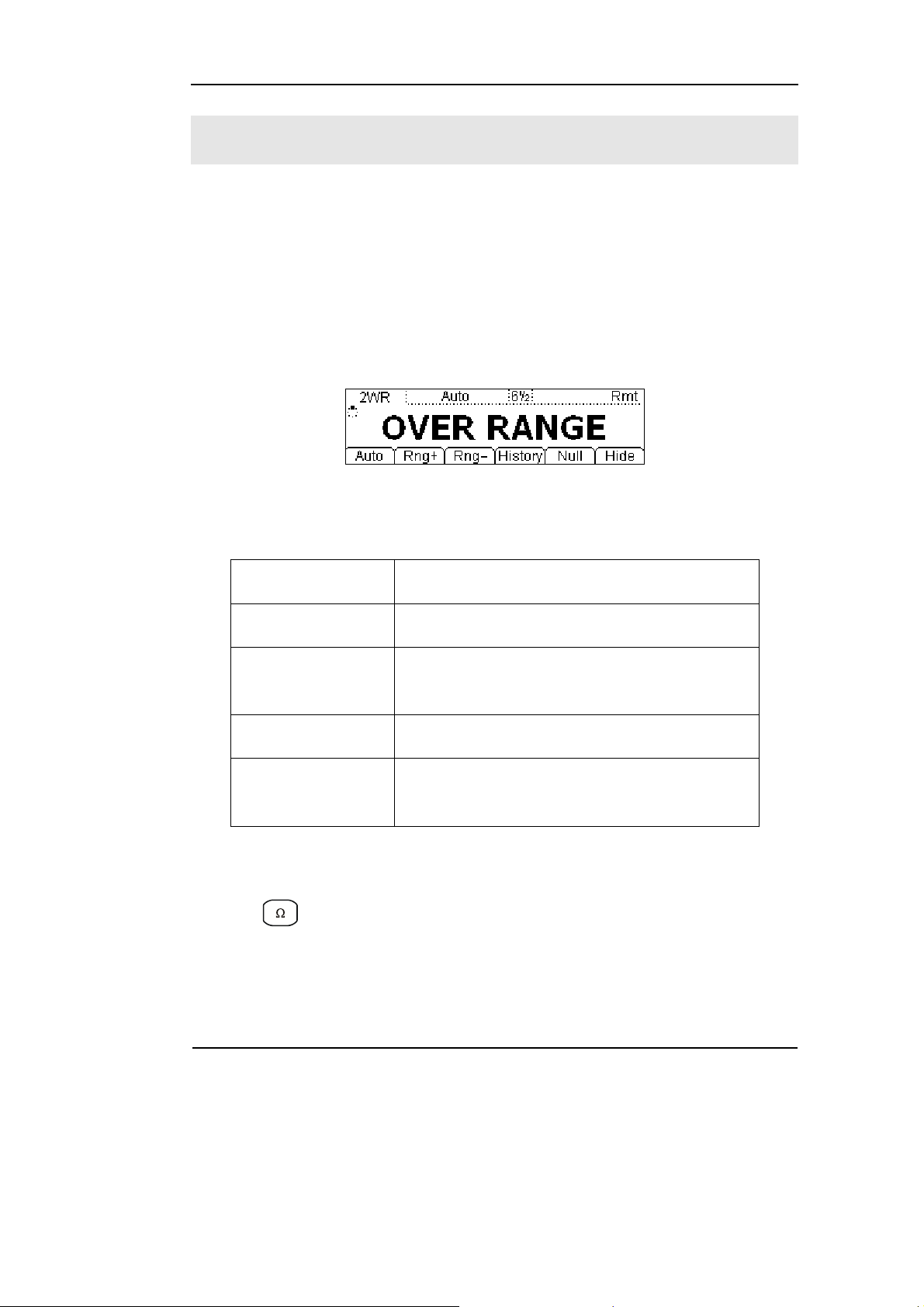

Choose Range Options

To choose measurement range may complete through the manual choice and the

automatic determination two methods. The automatic determination is user-friendly,

but if you want to obtain a better performance you should choose the range in

manual choice.

Increased range

Automatic

selection range

Reduced range

Figure 1-61

Choice Range Options Keys

Methods 1:

In the main interface, use up and down direction key to adjust the Range. Press Up

to increase the range, press Down to reduce the range.

Press key, start the automatic determination.

Methods 2:

In the main interface, use the menu option keys to adjust the range.

Figure 1-62

Choice Range Options Menu

1-36

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

Page 49

RIGOL

Table 1-12 Choice Range Option Menu

Option Menu Explain

Auto

Manually+

Manually-

Started automatically adjustment range, and

banned manually adjustment range.

Started manually increased range, and banned

automatically adjustment range.

Started manually reduced range, and banned

automatically adjustment range.

Save all changes, end the current operation,

Quit

hidden the menu. When the menu was hidden,

press this key to show the menu.

Operation Explanation:

• When the input signal is beyond the current scope of the measurement range, the

multimeter will show “OVER RANGE”.

• After restarting and remote- replacement, range options will turn back default

option “Automatic choice range”.

• When testing the Continuity and Checking the diodes, the range option are fixed.

The range of Continuity is 2KΩ while the diodes are 2V

DC.

NOTE

Other functions of the direction keys:

In measurement parameters setting menu, press the up and down keys to choose

setting areas.

In data input interface, press up and down keys to change the number.

In data input interface, press left and right keys to change the different digits.

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

1-37

Page 50

RIGOL

To Control Trigger Options

Press or to trigger the multimeter. When you start the multimeter, the

Key will turn light, it means this function is running.

Figure 1-63

Trigger Control Keys

Multimeter triggering options include Automatically, Single and Hold.

Auto Triggering

Press key once, it will takes continuous readings at the fastest rate possible for

the specified measurement configuration.

Single Triggering

Press key, The multimeter takes one reading, or a number of readings specified

by a sample count you enter.

Holding Triggering

Press key. The reading- hold mode allows you to capture and hold a stable

reading on the front panel display.

NOTE

Press key, in Remote Mode, by switching back to the local mode.

1-38

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

Page 51

RIGOL

Chapter 2 Operating Your Multimeter

By now you have got a brief understanding of DM3000 series with the front/rear

panel, every function control area and keys. You should also know how to determine

the setup of the multimeters by viewing the status bar.

This chapter takes you through all groups of front-panel buttons and menus. You will

also further your knowledge of the operation instruction by reading this guide.

We recommend you perform all of the following exercises, so that you could get the

most of the powerful measurement capabilities of your multimeters.

This chapter covers the following topics:

To Set up Measurement Parameters ( )

To Make Mathematics Operation ( )

To Set up Trigger System ( )

To Save and Recall ( )

To Set up Utility ( )

To Set up High-speed data acquisition ( )

Use the built-in help system ( )

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

2-1

Page 52

RIGOL

To Set up Measurement Parameters

Press key to operate the Measurement Parameters Menu. Use the measurement

parameters menu to set up the measurement parameters. The default parameters

had been set up by RIGOL, users may carry on any measurement operation directly,

and users also can set up any measurement parameters as their wish.

The measurement parameters menu include: Conti, Filter, Res, Null, and Ratio. To

change these parameters, satisfy the dissimilar condition of the measurement

request.

Figure 2-1

Table 2-1 Menu Explanation

Function

Menu

Explanation

Conti Set up the resistance value in short test.

Filter Choose the AC filter bandwidth.

Res Choose the DC voltage input resistance.

Null Set up null value.

Ratio Measured the ratio of two DC voltage signal.

Freq Measured the frequency of AC signal.

Save all changes, and end the current operation.

2-2

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

Page 53

RIGOL

Continue Resistance

To set up the continue resistance value in the short test, when the test resistance

below the continue resistance value, the DM3000 will judge whether the circuit is

connected or not. The continue resistance is only using at Continue Test.

Press Æ Conti, enter the menu shown below:

Figure 2-2

Use direction keys to change the parameter values:

Press left and right key to choose different digits. Press up and down key to change

the current digital value.

Continue Resistance

The range of continue resistance is 1Ω~1000Ω. The default value is 10Ω.

The continue resistance stored in the easy-lost memorizer, the resistance still keep

when the power is off.

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

2-3

Page 54

RIGOL

AC Filter

There are three kinds of AC Filter. Choose correct filter may make the measurement

more accuracy. This function could only be used in AC Voltage and AC Current

measurement.

Press Æ Filter, enter the menu shown below:

Figure 2-3

Table 2-2 AC Filter Menu Explanation

Table 2-3 AC Filter Parameters Characteristics

AC Filter

Function

Menu

Explanation

Slow Set up the filter with low speed.

Mid Set up the filter with to middle speed.

Fast

Set up the filter with high speed.

Save all changes, back to a higher level menu.

AC Filter Options Input Frequency Setting Timer

Slow

Mid

Fast

3Hz~300kHz

20Hz~300kHz

200Hz~300kHz

1.2 reading/s

0.5 reading/s

0.3 reading/s

The AC Filter Parameters are saved in the volatile memory, the data will lose when

the power is off.

The default value of AC Filter Parameters is “Mid” (middle).

2-4

User’s Guide for DM3000 Series

©Copyright RIGOL Technologies, Inc. 2007.

Page 55

RIGOL

DC Input Resistance

To choose DC voltage current measuring input resistance value. The parameters

include 10MΩ and >10GΩ. The default resistance is 10MΩ, but for 200mV, 2V, 20V

measuring ranges may choose >10MΩ for getting a greater measurement value.

Press Æ Res, enter the menu shown below:

Figure 2-4

Table 2-4 DC Input Resistance Menu Explanation

Function

Menu

10MΩ Set up the DC Input Resistance to 10MΩ.

>10GΩ Set up the DC Input Resistance to >10GΩ.

Save all changes, back to a higher level menu.

DC input resistance selection:

(1). While the DC input resistance is selected to 10MΩ, the input resistance of all

measurement range is 10MΩ;

(2). While the DC input resistance is selected to >10GΩ, the input resistance of

200mV, 2V and 20V measurement range is >10GΩ; 200V and 1000V

measurement range will be still keep 10MΩ input resistance.

Explanation

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

2-5

Page 56

RIGOL

Null Measurement

The DM3000 allows separate null settings to be saved for each of the following

measurement functions: dc voltage, ac voltage, dc current, ac current, resistance,

frequency/period, and capacitance.

When making null measurements, each reading is different between a stored

(selected or measured) null value and the input signal. One possible application is to

increase the accuracy of two–wire resistance measurements by nulling the test lead

resistance. Null the leads are particularly important prior to making capacitance

measurements. The formula used for calculating null measurements is:

Result = reading - null value

The null value is adjustable, and you can set it to any value between 0 and

the highest range, for the present function.

Press Æ Null, enter the menu shown below:

±120% of

2-6

Figure 2-5

Table 2-5 Null Measurement Menu Explanation

Function

Menu

Explanation

Current The current measured value will be the setting value.

Clear Set the value to be zero.

On/Off Turn the Null function on or off.

Save all changes, back to a higher level menu.

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

Page 57

RIGOL

Null measurement parameters setting methods:

(1). In operation interface press Null button, use the current value to Null value;

(2). To select Zero function. Start null function, the multimeter will use the current

value to Null value.

(3). In Null setting display interface, it uses the Direction Keys to input the setting

null value.

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

2-7

Page 58

RIGOL

Ratio Measurement

Ratio measurement is used to measure the ratio of 2 directions DC voltage signal.

Ratio measurement is only for measuring DC voltage.

Press Æ Ratio, enter the menu shown below:

Figure 2-6

Table 2-6 Ratio Measurement Menu Explanation

Function

Menu

ON Open the Ratio Measurement Function.

OFF Close the Ratio Measurement Function.

Save all changes, back to a higher level menu.

The method of the radio measurement:

DC Voltage

VoltageDC

Ratio=

DC Reference Voltage

(1). Measuring Sense Terminal, for measuring reference DC voltage. Default range

option is auto.

(2). Measuring Input Terminal, for measuring DC voltage. The measuring voltage

scope is 0V~1000V.

(3). Input LO Terminal and Sense LO Terminal must have a common reference

value, and the voltage difference cannot surpass ±2V.

Re

⋅

tagefrenceVaolDC

Explanation

2-8

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

Page 59

RIGOL

V

Basic measurement:

1. Connect test leads as Figure 2-7 shown. Red test leads connect the HI Terminal,

Black test leads connect the LO Terminal.

2. Press to select the DC Voltage measurement function.

3. According to the voltage measuring scope, choose the correct range.

4. Set up the DC Ratio Measurement.

Press Æ Ratio Æ On, to start the DC Ratio Measurement.

Press

to save all changes, back to a higher level menu.

5. Lead test leads into circuit, start to measure.

Signal

oltage

Reference

Voltage

Figure 2-7

Ratio Measurement instruction chart

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

2-9

Page 60

RIGOL

Frequency Measurement

Frequency measurement function is only used for measuring the frequency of an AC

signal (AC voltage and AC current).

Press Æ Freq, enter the menu shown below:

Figure 2-8

Table 2-7 Ratio Measurement Menu Explanation

Function

Menu

Explanation

ON Open the Frequency Measurement Function

OFF Close the Frequency Measurement Function

Save all changes, back to a higher level menu.

Basic measurement:

1. Connect test leads as Figure 2-9 shown. Red test lead connects the HI Terminal,

Black test lead connects the LO Terminal.

2. Press or to select the AC voltage or current measurement function.

3. According to the voltage measuring scope, choose the correct range.

4. Set up the DC Ratio Measurement.

Press Æ Freq Æ On, to start the AC Frequency Measurement.

Press

to save all changes, back to a higher level menu.

2-10

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

Page 61

RIGOL

5. Lead test leads into circuit, start to measure.

AC Voltage

Figure 2-9

AC Current

Figure 2-10

Figure 2-11

Frequency measurement display interface

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

2-11

Page 62

RIGOL

Math Functions

Press key, enter the menu shown below:

Figure 2-12

The DM3000 provides five math functions: Null, statistic, dB, dBm and Limit testing.

Only one of these math functions can be enabled at a time and remains in effect until

you turn it off or change it.

In Math function interface, you could choose the math function that you want to use.

Then press On to start the Math function that you have chosen.

Math functions are used by union basic measurement function. However, not all

combinations are effective. If the math function you selected does not support the

measurement function you have just choose, the math function will automatic turn

off.

Table 2-8 Math Function Menu Explanation

Function

Menu

Statistic

dB

Settings Explanation

Reading statistic functions, including: Max, Min,

Average, and Reading Count.

The dB measurement is the difference between

the input signal and a stored relative value.

The dBm function is logarithmic, and is based on

dBm

a calculation of power delivered to a reference

resistance.

The limit test function enables you to perform

Limit

pass/fail testing to upper and lower limits that

you specify.

2-12

ON/OFF

ON

OFF

Turn on Math function.

Turn off Math function.

Save all changes, back to a higher level menu.

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

Page 63

RIGOL

The Math function does not used for all basic measurement function. The table

2-9 showed the effective functions combination.

Table 2-9 Math Functions is used for basic measuring function applicable scope

Measurement

DC Voltage Support Support Support Support

AC Voltage Support Support Support Support

DC Current Support Support

AC Current Support Support

Resistance

Resistance

Frequency Support Support

Continuity

Capacitance Support Support

Supported the Math function

Function

2-Wire

4-Wire

Total dB dBm Limit

Support Support

Support Support

Period Support Support

Diodes

Ratio Support Support

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

2-13

Page 64

RIGOL

Math Functions Selective

The DM3000 provides five math functions: Null measurements, Total

measurements, dB measurements, dBm measurements, and Limit testing. Only one

of these math functions can be enabled at the same time, and remains in effect until

you turn it off or change it.

Press key, enter the menu shown below:

Figure 2-13

Table 2-10 Math Functions Menu Function Explanation

Function

Menu

Statistic

dB

dBm

Limit

ON/OFF

Settings Explanation

Reading statistic functions, including: Max, Min,

Average, and Reading Count.

The dB measurement is the difference between

the input signal and a stored relative value.

The dBm function is logarithmic, and is based on

a calculation of power delivered to a reference

resistance.

The limit test function enables you to perform

pass/fail testing to upper and lower limits that

you specify.

ON

OFF

Turn on Math function.

Turn off Math function.

Save all changes, back to a higher level menu.

2-14

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

Page 65

RIGOL

1. Statistic Measurement

The Statistic function allows to measure the following measurement functions: dc

voltage, ac voltage, dc current, ac current, resistance, frequency/period, and

capacitance.

From the front panel, you can view the following statistical data for any set of

readings: average (Ave), maximum (Max), minimum (Min), and you can read all of

these with All functions

Press Æ Stats, enter the menu shown below:

and the number of samples taken (Count).

Figure 2-14

Table 2-11 Statistic Measurement Menu Function Explanation

Function Menu Explanation

Max (Maximum) Statistical measurement all reading Max value.

Min (Minimum) Statistical measurement all reading Min value.

Ave (Average) Statistical measurement all reading Average value.

All Statistical measurement all the number of readings.

Save all changes, back to a higher level menu.

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

2-15

Page 66

RIGOL

2. Limit Measurement

The Limit test function enables you to perform pass/fail testing to upper and lower

limits that you specify. You can set the upper and lower limits to any value between

0 and ±120% of the highest range, for the present function. The upper limit you

select must be a more positive number than the lower limit.

Press Æ Limit, enter the menu shown below:

Figure 2-15

Table 2-12 Limit Measurement Menu Function Explanation

Function

Menu

Settings Explanation

High Set the desired Upper limit.

Low Set the desired Lower limit.

Save all changes, back to a higher level menu.

The parameters value scope of Limit function:

(1). The limit value scope is 0%~±120% of the current measurement range.

(2). The upper limit value should be always bigger than the lower limit value.

2-16

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

Page 67

RIGOL

3. dB Measurement

The dB function applies to AC voltage and DC voltage measurements only.

Each dB measurement is different between the input signal and a stored relative

value, with both values converted to dBm.

Press Æ dB, enter the menu shown below:

Figure 2-16

Table 2-13 dB Measurement Function Menu Function Explanation

Function

Menu

Explanation

Default Use the default value.

Save all changes, back to a higher level menu.

dB =10xLog

[ (Reading2 / R

10

) / 0.001W ] – (dB setting value)

REF

The relative value can take any value between 0 dBm and ±200.0 dBm.

The default relative value is 10 dBm. You can either let the instrument automatically

measure this value, or you can enter a specified value.

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

2-17

Page 68

RIGOL

4. dBm Measurement

This function applies to AC voltage and DC voltage measurements only.

The dBm function is logarithmic, and is based on a calculation of power delivered to

a reference resistance, relative to 1 milliwatt.

Press Æ dBm, enter the menu shown below:

Figure 2-17

Table 2-14 dB Measurement Function Menu Function Explanation

Function

Menu

Explanation

Default Use the default value.

Save all changes, back to a higher level menu.

The computation method of the dBm:

dBm = 10 x Log

R

expressed measuring the resistance value in the actual electric circuit.

REF

[ (Reading2 / R

10

) / 0.001W ]

REF

2-18

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

Page 69

RIGOL

To Set Up Triggering Parameter Function

The DM3000 triggering system allows you to generate triggers either manually or

automatically, take multiple readings per trigger. The DM3000 also allows you to set

a level for internal triggering, and to set up pre-triggering.

Selecting a Trigger Source

Specify the source from which the multimeter will accept a trigger. The power–on

default is auto triggering from the front panel. Several types of triggering are

described in the sections that follow.

The power–on trigger default mode was auto trigger (RUN) mode. Press to go

to the hold trigger mode. Press to go to the single trigger mode. A single

reading is taken, and another reading is taken each time you press , or when a

hardware trigger is received on the Ext Trig connector.

Figure 2-18

Table 2-15 Trigger Parameters Setting Menu Function Explanation

Function

Menu

Auto

Setting system fixed time Auto trigger and reading

Hold scope parameters.

Explanation

Single Setting Single manual trigger parameter.

Ext Setting the reading Hold scope.

VMC Setting the pulse width of sampling ending signal.

Save all changes, back to a higher level menu.

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

2-19

Page 70

RIGOL

Auto Triggering

Auto triggering takes continuous readings at the fastest rate possible for the

specified measurement configuration (function, range, resolution, and so forth).

Auto trigger is a default trigger mode when the multimeter power-on.

Press Æ Auto, enter the menu shown below:

Figure 2-19

Table 2-16 Auto Trigger Function Menu Explanation

Function

Menu

Interval

Setting Explanation

Set interval time in 400~2000ms.

Hold

Save all changes, back to a higher level menu.

Interval time:

You can manually specify a delay between the trigger signal and the first sample

that follows. This may be useful in applications where you want to allow the input

signal to settle before taking a reading, or for pacing a burst of readings.

• The trigger delay may be set from 400 to 2000 ms.

• The continuity and diode test functions ignore the trigger delay segment.

• If a trigger delay is not manually set, the default trigger delay is automatically set.

• If you manually specify a trigger delay, that delay is used for all measurement

functions (except continuity and diode test).

2-20

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

Page 71

RIGOL

Reading Hold

The reading hold mode allows you to capture and hold a stable reading on the front

panel display. This is useful in situations when you want to take a reading, remove

the test probes, and have the reading remain on the display. When a stable reading

is detected the reading will hold on the display. Hold scope include 0.01%, 0.1%, 1%,

and 10%.

Press Æ Auto Æ Hold, enter the menu shown below:

Figure 2-20

Table 2-17 Reading Hold Function Menu Explanation

Function

Menu

On/Off

Turn on/off the reading hold function.

Explanation

0.01% Set the hold scope is 0.01%.

0.1% Set the hold scope is 0.1%.

1%

10%

Set the hold scope is 1%.

Set the hold scope is 10%.

Save all changes, back to a higher level menu.

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

2-21

Page 72

RIGOL

Reading Hold Function

Start the Reading Hold Function, the hold measurement use the following rules

judge the reading count:

When Max() - Min() ≤ hold scope x ReadingN, the multimeter hold ReadingN on the

display.

The display update a new reading was based on the current value of reading and the

following three readings before the reading was hold:

Max (ReadingN, ReadingN-1, ReadingN-2, ReadingN-3)

Min (ReadingN, ReadingN-1, ReadingN-2, ReadingN-3)

NOTE

When reading hold started, the input resistance was automatism set to 10MΩ for all

DC voltage range. This set-up is conducive to reducing noise arising from the

open-loop testing.

2-22

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

Page 73

RIGOL

Single Triggering

The multimeter takes one reading, or a number of readings specified by a sample

count you enter, each time you press.

Press Æ Single, enter the menu shown below:

Figure 2-21

Table 2-18 Single Trigger Function Menu Explanation

Function

Menu

Single Set a sample count, the default sample count is 1.

Save all changes, back to a higher level menu.

Sample Count

While the multimeter receives a single trigger single, the multimeter takes one

reading or a number of readings.

The number of sample count scope from 1 to 50,000. The factory default is 1.

Explanation

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

2-23

Page 74

RIGOL

External Triggering

is used to set the parameter which accomplish the triggering function, the

external triggering function needs to set the following parameter: the Rise edge, the

Fall edge, HiLev (high level) and LoLev (low level). After ensuring the setting is

correct, press Done to startup the external triggering, the key and on the

front panel will wink out, it means that the instrument has been working in the

external triggering mode.

Press Æ Ext, enter the following menu.

Figure 2-22

The interface of the external triggering

Users could set the triggering mod as the following: the rise edge, the fall edge, high

level and low level.

2-24

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

Page 75

RIGOL

To start up the triggering function

Auto, hold and Single trigger can switch by using and , press on the

triggering interface to startup the external triggering.

Figure 2-23

The interface of the external triggering

After the external triggering start, the key and on the front panel both will

wink out.

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

2-25

Page 76

RIGOL

To Set up the VMC

Once in the external triggering mode, when the data sampling is over, the instrument

outputs a pulse signal pass the signal over-put port (VM Comp) on the rear panel. By

setting the output, the pulse width can be intercalated.

Press Æ VMC, enter the following menu. Output the export Terminal.

Figure 2-24

Table 2-19 The interface of the external triggering(polarity: positive)

Function

Menu

Polar

Setting Explanation

Pos

Neg

Setting the pulse signal’s polarity.

PWidth Setting the pulse width.

Store the changing and return.

Export the VMC function setting range

(1). Once in the external triggering mode, when the data sampling is over, the

instrument will export a pulse signal and hint over.

(2). Once in the external triggering mode, when operate the math limited value,

the instrument will export a pulse signal and hint it has over pass.

2-26

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

Page 77

RIGOL

Store and Recall

To use the Storage and Recall function, you can save, load, and delete the

measurement data, parameters and sensor documents in the local storage. And also

you can do the same operation in USB storage.

Press key, and enter the menu shown below:

Figure 2-25

Table 2-20 Storage and Recall Function Menu Explanation

Function

Menu

Setting Explanation

C:\ (Local)

Disk

A:\ (U-Disk)

Choose Local or U-Disk storage.

Data/

Parameters/

Typ e

Sensor

Choose the type of the files shown.

…

Read

Save

Load the documents you have selected.

Save the document to the location which you

have selected.

Erase Delete the document which you have selected.

Save all changes, back to a higher level menu.

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

2-27

Page 78

RIGOL

Local/U-Disk Storage

Local storage block is built-in the multimeter. The U-Disk storage will be a USB flash

disk.

Press key, enter the menu shown below:

Figure 2-26

Table 2-21 Storage and Recall Function Menu Explanation

Function

Menu

Explore

Setting Explanation

Choose Local storage or U-Disk rout.

Sys Setting/

Meas Data/

Data log/

Typ e

Sensor/

Choose the type of the files shown.

Sensor Data/

Scan Task

Read

Save

Load the document you have selected.

Save the document to the location which you

have selected.

Erase Delete the document which you have selected.

Save all changes, back to a higher level menu.

2-28

©Copyright RIGOL Technologies, Inc. 2007.

User’s Guide for DM3000 Series

Page 79

RIGOL

Document Storage

In local/U-disk storage area, you allowed to save, load and delete parameter, data

and sensor documents.