Guaranty and Declaration

Copyright

© 2022 RIGOL TECHNOLOGIES CO., LTD. All Rights Reserved.

Trademark Information

RIGOL®is the trademark of RIGOL TECHNOLOGIES CO., LTD.

Software Version

Software upgrade might change or add product features. Please acquire the latest software version

from RIGOL website or contact RIGOL to upgrade the software.

Notices

• RIGOL products are covered by P.R.C. and foreign patents, issued and pending.

• RIGOL reserves the right to modify or change parts of or all the specifications and pricing

policies at the company's sole decision.

• Information in this publication replaces all previously released materials.

• Information in this publication is subject to change without notice.

• RIGOL shall not be liable for either incidental or consequential losses in connection with the

furnishing, use, or performance of this manual, as well as any information contained.

• Any part of this document is forbidden to be copied, photocopied, or rearranged without prior

written approval of RIGOL.

Product Certification

RIGOL guarantees that this product conforms to the national and industrial standards in China as

well as the ISO9001:2015 standard and the ISO14001:2015 standard. Other international standard

conformance certifications are in progress.

Contact Us

If you have any problem or requirement when using our products or this manual, please contact

RIGOL.

E-mail: service@rigol.com

Website:

http://www.rigol.com

Safety Requirement

1

Safety Requirement

1.1 General Safety Summary

Please review the following safety precautions carefully before putting the instrument

into operation so as to avoid any personal injury or damage to the instrument and

any product connected to it. To prevent potential hazards, please follow the

instructions specified in this manual to use the instrument properly.

1 Only the exclusive power cord

designed for the instrument and

authorized for use within the

destination country could be

used.

2 Ensure that the instrument is

safely grounded.

3 Observe all terminal ratings. 11 Do not operate in wet conditions.

4 Use proper overvoltage

protection.

5 Do not operate without covers. 13 Keep instrument surfaces clean

6 Do not insert objects into the air

outlet.

7 Use the proper fuse. 15 Handle with caution.

8 Avoid circuit or wire exposure.

9 Do not operate the instrument

with suspected failures.

10 Provide adequate ventilation.

12 Do not operate in an explosive

atmosphere.

and dry.

14 Prevent electrostatic impact.

WARNING

Equipment meeting Class A requirements may not offer adequate protection to broadcast

services within residential environment.

1.2 Safety Notices and Symbols

Safety Notices in this Manual:

WARNING

Indicates a potentially hazardous situation or practice which, if not avoided, will result in

serious injury or death.

CAUTION

Indicates a potentially hazardous situation or practice which, if not avoided, could result

in damage to the product or loss of important data.

Copyright ©RIGOL TECHNOLOGIES CO., LTD. All rights reserved.

1

Safety Requirement

Safety Notices on the Product:

• DANGER

• WARNING

• CAUTION

Safety Symbols on the Product:

It calls attention to an operation, if not correctly performed, could result in injury

or hazard immediately.

It calls attention to an operation, if not correctly performed, could result in

potential injury or hazard.

It calls attention to an operation, if not correctly performed, could result in

damage to the product or other devices connected to the product.

Hazardous

Voltage

Safety Warning Protective Earth

1.3 Measurement Category

Measurement Category

This instrument can make measurements in Measurement Category I.

WARNING

This instrument can only be used for measurements within its specified measurement

categories.

Measurement Category Definitions

• Measurement category I is for measurements performed on circuits not directly

connected to MAINS. Examples are measurements on circuits not derived from

MAINS, and specially protected (internal) MAINS derived circuits. In the latter

case, transient stresses are variable. Thus, you must know the transient withstand

capability of the equipment.

Chassis Ground Test Ground

Terminal

• Measurement category II is for measurements performed on circuits directly

connected to low voltage installation. Examples are measurements on household

appliances, portable tools and similar equipment.

• Measurement category III is for measurements performed in the building

installation. Examples are measurements on distribution boards, circuit-breakers,

wiring (including cables, bus-bars, junction boxes, switches and socket-outlets) in

the fixed installation, and equipment for industrial use and some other

2

Copyright ©RIGOL TECHNOLOGIES CO., LTD. All rights reserved.

equipment. For example, stationary motors with permanent connection to a

fixed installation.

• Measurement category IV is for measurements performed at the source of a

low-voltage installation. Examples are electricity meters and measurements on

primary overcurrent protection devices and ripple control units.

1.4 Ventilation Requirement

This instrument uses a fan to force cooling. Please make sure that the air inlet and

outlet areas are free from obstructions and have free air. When using the instrument

in a bench-top or rack setting, provide at least 10 cm clearance beside, above and

behind the instrument for adequate ventilation.

CAUTION

Inadequate ventilation may cause an increase of temperature in the instrument, which

would cause damage to the instrument. So please keep the instrument well ventilated and

inspect the air outlet and the fan regularly.

Safety Requirement

1.5 Working Environment

Temperature

Operating: 0℃ to +50℃

Non-operating: -30℃ to +60℃

Humidity

• Operating:

Below +30℃: ≤90% RH (without condensation)

+30℃ to +40℃: ≤75% RH (without condensation)

+40℃ to +50℃: ≤45% RH (without condensation)

• Non-operating:

Below +60℃: ≤90% RH (without condensation)

WARNING

To avoid short circuit inside the instrument or electric shock, never operate the

instrument in a humid environment.

Altitude

• Operating: below 3 km

• Non-operating: below 15 km

Copyright ©RIGOL TECHNOLOGIES CO., LTD. All rights reserved.

3

Safety Requirement

Protection Level Against Electric Shock

ESD ±8kV

Installation (Overvoltage) Category

This product is powered by mains conforming to installation (overvoltage) category II.

WARNING

Ensure that no overvoltage (such as that caused by a bolt of lightning) can reach the

product. Otherwise, the operator might be exposed to the danger of an electric shock.

Installation (Overvoltage) Category Definitions

Installation (overvoltage) category I refers to signal level which is applicable to

equipment measurement terminals connected to the source circuit. Among these

terminals, precautions are done to limit the transient voltage to a low level.

Installation (overvoltage) category II refers to the local power distribution level which

is applicable to equipment connected to the AC line (AC power).

Pollution Degree

Pollution Degree 2

Pollution Degree Definition

• Pollution Degree 1: No pollution or only dry, nonconductive pollution occurs.

The pollution has no effect. For example, a clean room or air-conditioned office

environment.

• Pollution Degree 2: Normally only nonconductive pollution occurs. Temporary

conductivity caused by condensation is to be expected. For example, indoor

environment.

• Pollution Degree 3: Conductive pollution or dry nonconductive pollution that

becomes conductive due to condensation occurs. For example, sheltered

outdoor environment.

• Pollution Degree 4: The pollution generates persistent conductivity caused by

conductive dust, rain, or snow. For example, outdoor areas.

Safety Class

Class 1 – Grounded Product

1.6 Care and Cleaning

Care

Do not store or leave the instrument where it may be exposed to direct sunlight for

long periods of time.

4

Copyright ©RIGOL TECHNOLOGIES CO., LTD. All rights reserved.

Safety Requirement

Cleaning

Clean the instrument regularly according to its operating conditions.

1. Disconnect the instrument from all power sources.

2. Clean the external surfaces of the instrument with a soft cloth dampened with mild

detergent or water. Avoid having any water or other objects into the chassis via the

heat dissipation hole. When cleaning the LCD, take care to avoid scarifying it.

CAUTION

To avoid damage to the instrument, do not expose it to caustic liquids.

WARNING

To avoid short-circuit resulting from moisture or personal injuries, ensure that the

instrument is completely dry before connecting it to the power supply.

1.7 Environmental Considerations

The following symbol indicates that this product complies with the WEEE Directive

2002/96/EC.

The equipment may contain substances that could be harmful to the environment or

human health. To avoid the release of such substances into the environment and

avoid harm to human health, we recommend you to recycle this product

appropriately to ensure that most materials are reused or recycled properly. Please

contact your local authorities for disposal or recycling information.

You can click on the following link

to download the latest version of the RoHS&WEEE certification file.

https://int.rigol.com/services/services/declaration

Copyright ©RIGOL TECHNOLOGIES CO., LTD. All rights reserved.

5

Document Overview

2

Document Overview

This manual gives you a quick overview of the front and rear panel, user interface as

well as basic operation methods of DHO4000 series.

TIP

For the newest version of this manual, download it from RIGOL official website (

www.rigol.com

Publication Number

QGA33103-1110

Software Version

Software upgrade might change or add product features. Please acquire the latest

version of the manual from RIGOL website or contact RIGOL to upgrade the software.

Format Conventions in this Manual

1. Key

).

http://

The front panel key is denoted by the menu key icon. For example,

indicates the "DEFAULT" key.

2. Menu

The menu item is denoted by the format of "Menu Name (Bold) + Character

Shading" in the manual. For example,

the "Utility" function menu. You can click or tap

3. Operation Procedures

The next step of the operation is denoted by ">" in the manual. For example,

> Storage indicates first clicking or tapping and then clicking or tapping

Storage.

4. The front/rear panel connector is denoted by "Brackets + Connector Name (Bold)",

for example, [AUX OUT].

Content Conventions in this Manual

DHO4000 series digital oscilloscope includes the following models. Unless otherwise

specified, this manual takes DHO4804 as an example to illustrate the basic operation

methods of DHO4000 series.

Setup indicates the "Setup" sub-menu under

Setup to access the "Setup" menu.

Model

DHO4204 200 MHz 4

6

Max. Analog Bandwidth Analog Channels

Copyright ©RIGOL TECHNOLOGIES CO., LTD. All rights reserved.

Document Overview

Model Max. Analog Bandwidth Analog Channels

DHO4404 400 MHz 4

DHO4804 800 MHz 4

Copyright ©RIGOL TECHNOLOGIES CO., LTD. All rights reserved.

7

General Inspection

3

General Inspection

1. Inspect the packaging

If the packaging has been damaged, do not dispose the damaged packaging or

cushioning materials until the shipment has been checked for completeness and

has passed both electrical and mechanical tests.

The consigner or carrier shall be liable for the damage to the instrument resulting

from shipment. RIGOL would not be responsible for free maintenance/rework or

replacement of the instrument.

2. Inspect the instrument

In case of any mechanical damage, missing parts, or failure in passing the electrical

and mechanical tests, contact your RIGOL sales representative.

3. Check the accessories

Please check the accessories according to the packing lists. If the accessories are

damaged or incomplete, please contact your RIGOL sales representative.

Recommended Calibration Interval

RIGOL suggests that the instrument should be calibrated every 18 months.

8

Copyright ©RIGOL TECHNOLOGIES CO., LTD. All rights reserved.

Product Overview

4

Product Overview

DHO4000 series digital oscilloscope is designed to meet the requirements for the

design, debug, and test of the mainstream oscilloscope market. Adopting the brandnew chipset "Centaurus" developed by RIGOL, this series achieves a fast waveform

capture rate of 1,500,000 wfms/s with the UltraAcquire mode, 500 Mpts memory

depth, 12-bit resolution, all combined with excellent noise floor performance and

vertical accuracy to meet your requirements for more accurate measurements.

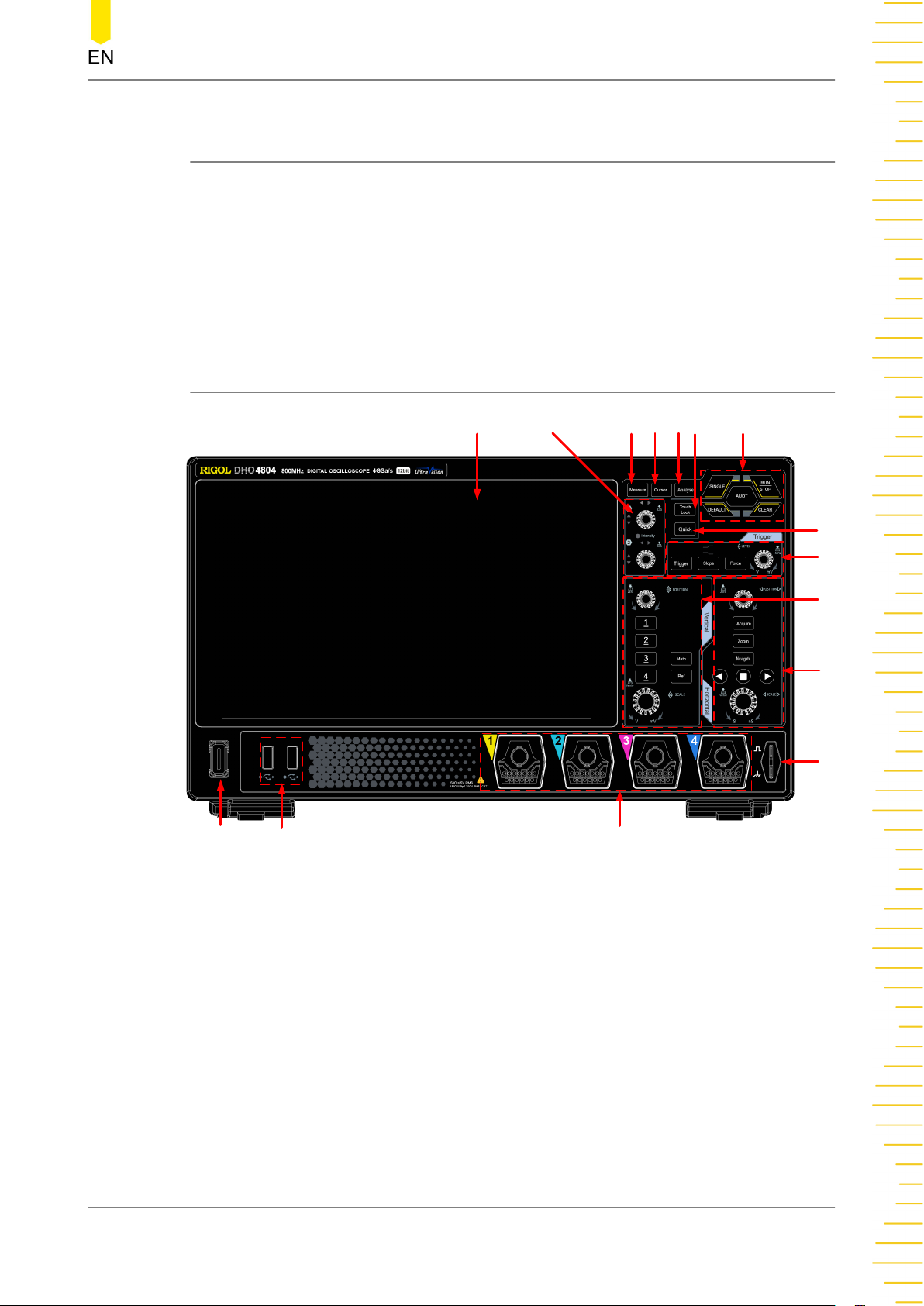

4.1 Front Panel Overview

1

2

3

6

5

4

7

8

9

15

1

2 Multipurpose Knobs 10 Vertical Controls

3 Measure Key 11 Horizontal Controls

4

5 Analyse Key 13 Analog Channel Input Terminals

6 Touch Lock Key 14 USB HOST Port

7 Common Tools Keys 15 Power Switch

8

14

Figure 4.1 Front Panel

10.1'' Capacitive Touch Screen 9 Trigger Controls

Cursor Key 12 Probe Compensation Signal

Quick Action Key (Self-defined

function)

13

Output Terminal/Ground Terminal

10

11

12

Copyright ©RIGOL TECHNOLOGIES CO., LTD. All rights reserved.

9

Product Overview

4.2 Rear Panel Overview

5

4

6

7

3

8

2

1

9

10

13

12

Figure 4.2 Rear Panel

1

2 External Trigger Input Connector

3 10 MHz Reference Clock Input Connector

4 10 MHz Reference Clock Output Connector

5

6 HDMI Connector

7 USB DEVICE Port

8 LAN Port

9 AC Power Cord Connector

10 Fuse

11 Battery Pack Connector

12 Security Lock Hole

13 Snap-in Slots for Battery Pack

11

Trigger Output Connector

Snap-fit Grooves for Battery Pack

10

Copyright ©RIGOL TECHNOLOGIES CO., LTD. All rights reserved.

4.3 User Interface Overview

Product Overview

Figure 4.3 User Interface

1

2 Run State Label 9 Notification Area

3 Horizontal Timebase Label 10 Split-screen Display

4 Sample Rate & Memory Depth

5 Horizontal Delay Label 12 Channel Labels

6 Trigger Label 13 Function Navigation Icon

7 Function Toolbar

Waveform View

Label

8

11 Math Labels

Result Sidebar

Copyright ©RIGOL TECHNOLOGIES CO., LTD. All rights reserved.

11

To Prepare for Use

5

To Prepare for Use

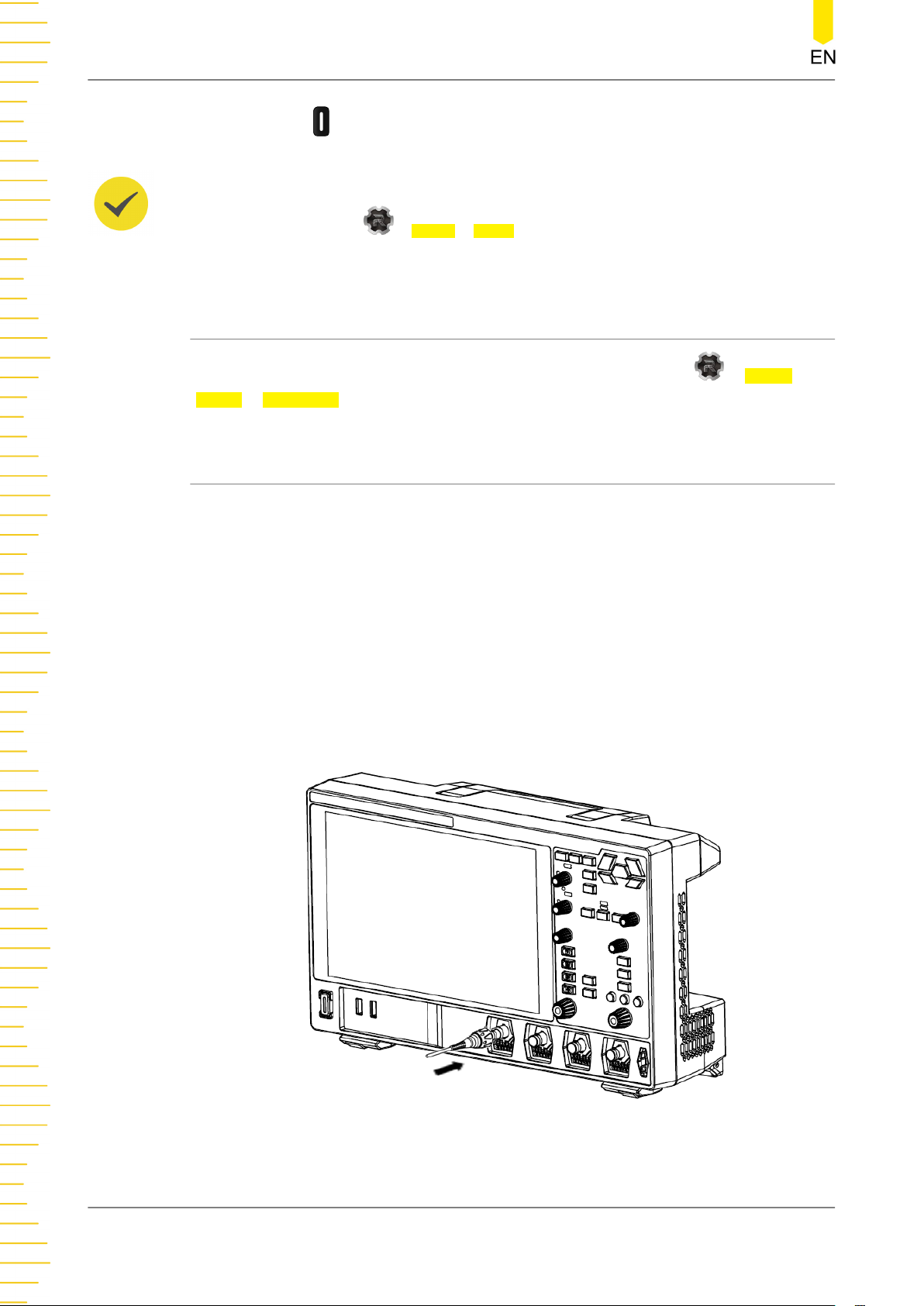

5.1 Tilting the Oscilloscope for Easier Viewing

Flip out the tabs under the oscilloscope's rear feet to tilt the oscilloscope to stabilize it

for easier operation and viewing. Flip in the tabs for storage or transporting when not

using the instrument. Please see the figure below.

Figure 5.1 Flipping in/out Tabs

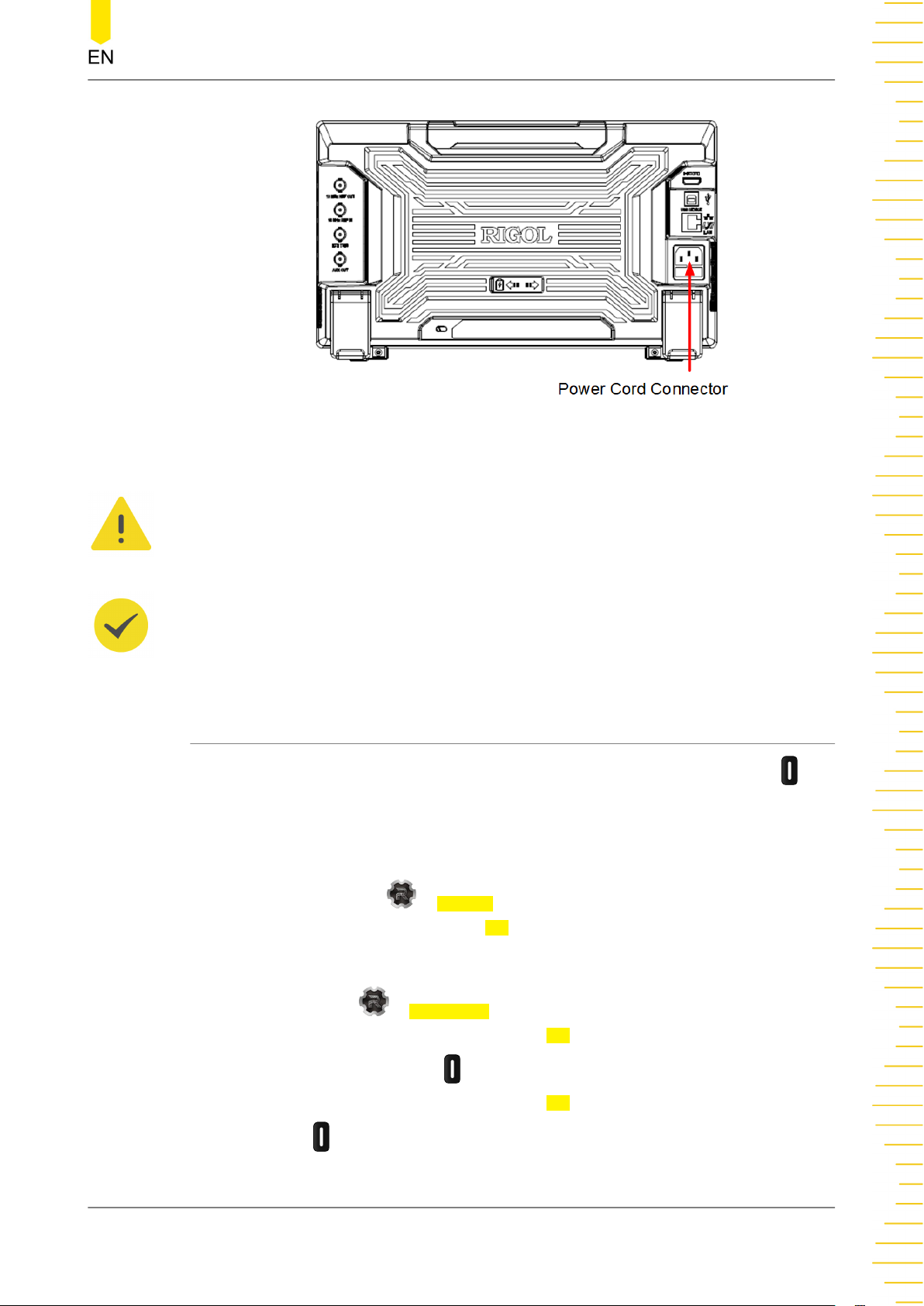

5.2 Connecting to Power

The power requirements of the oscilloscope are 100-240 V, 50-60 Hz. Please use the

power cord provided in the accessories to connect the oscilloscope to the AC power

source, as shown in the figure below.

12

Copyright ©RIGOL TECHNOLOGIES CO., LTD. All rights reserved.

Figure 5.2 Connecting to Power

To Prepare for Use

WARNING

To avoid electric shock, ensure that the instrument is correctly grounded.

TIP

If the oscilloscope is equipped with battery pack, the battery will also be powered.

5.3 Turn-on Checkout

After the instrument is connected to the power source, press the power switch at

the lower-left corner of the front panel to power on the instrument. During the startup process, the instrument performs a series of self-tests. After the self-test, the

splash screen is displayed.

• Restart: Click or tap > Restart. Then a prompt message "Are you sure to

reboot?" is displayed. Click or tap

OK to restart the instrument.

• Shutdown:

- Click or tap > Shutdown. Then a prompt message "Are you sure to

shutdown?" is displayed. Click or tap OK to shut down the instrument.

- Press the power switch and a prompt message "Are you sure to

shutdown?" is displayed. Click or tap

- Press twice to directly shut down the instrument.

Copyright ©RIGOL TECHNOLOGIES CO., LTD. All rights reserved.

OK to shut down the instrument.

13

To Prepare for Use

- Press for three seconds to directly shut down the instrument.

TIP

You can also click or tap > Utility > Setup and select "Switch On" in "Power Status" item.

In this way, the instrument powers on once connected to power.

5.4 Setting the System Language

This oscilloscope supports multiple languages. You can click or tap > Utility >

Setup > Language to select the system language.

5.5 Connecting Probes

RIGOL provides passive and active probes for DHO4000 series. For specific probe

models, please refer to

of the probes, please refer to the corresponding Probe User Guide.

Connect the Passive Probe

1. Connect the BNC terminal of the probe to an analog channel input terminal of the

oscilloscope on the front panel as shown in the figure below.

2. Connect the ground alligator clip or spring of the probe to the circuit ground

terminal, and then connect the probe tip to the circuit point to be tested.

DHO4000 series Data Sheet

. For detailed technical information

14

Figure 5.3 Connecting the Passive Probe

Copyright ©RIGOL TECHNOLOGIES CO., LTD. All rights reserved.

To Prepare for Use

After you connect the passive probe, check the probe function and probe

compensation adjustment before making measurements. For details, please refer to

Function Inspection

and

Probe Compensation

.

Connect the Active Probe

Take PVA7250 (active differential probe) as an example.

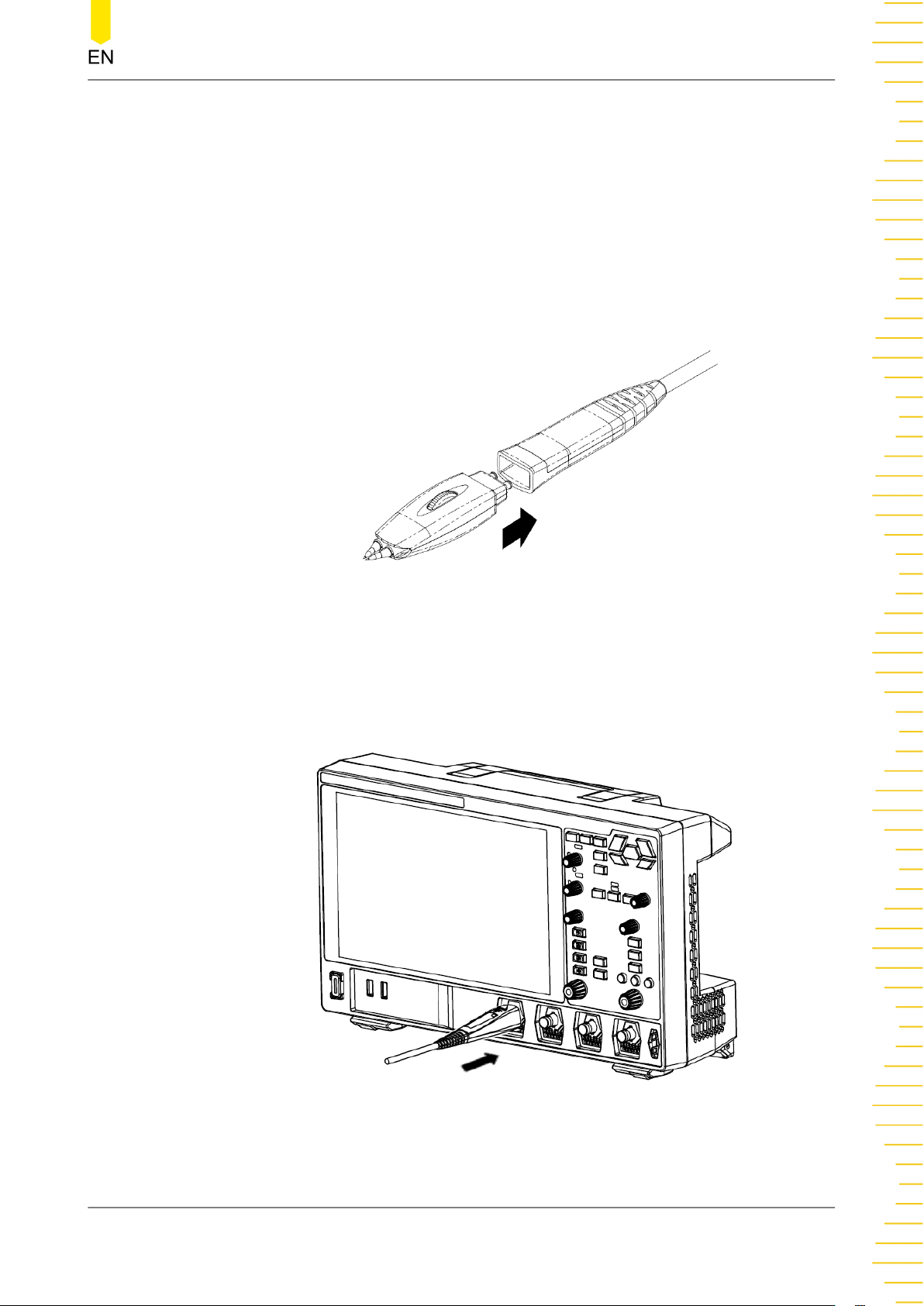

1. Connect the probe head to the preamp of the active probe, as shown in the figure

below.

Figure 5.4 Connecting the Probe Head to the PA of the Active Probe

2. Connect the other end of the preamp to an analog channel input terminal of the

oscilloscope on the front panel, as shown in the figure below. Note that you need

to push the probe to the due position to lock it firmly.

Figure 5.5 Connecting the Active Probe

Copyright ©RIGOL TECHNOLOGIES CO., LTD. All rights reserved.

15

To Prepare for Use

3. Use the probe's auxiliary device to connect the probe head to the circuit under

test. For detailed information of the probes, please refer to

PVA7000 Series Active Probe

After connecting the active probe, you can perform probe calibration and offset

voltage adjustment if necessary. For details, refer to descriptions about the active

probe in this series User Guide.

5.6 Function Inspection

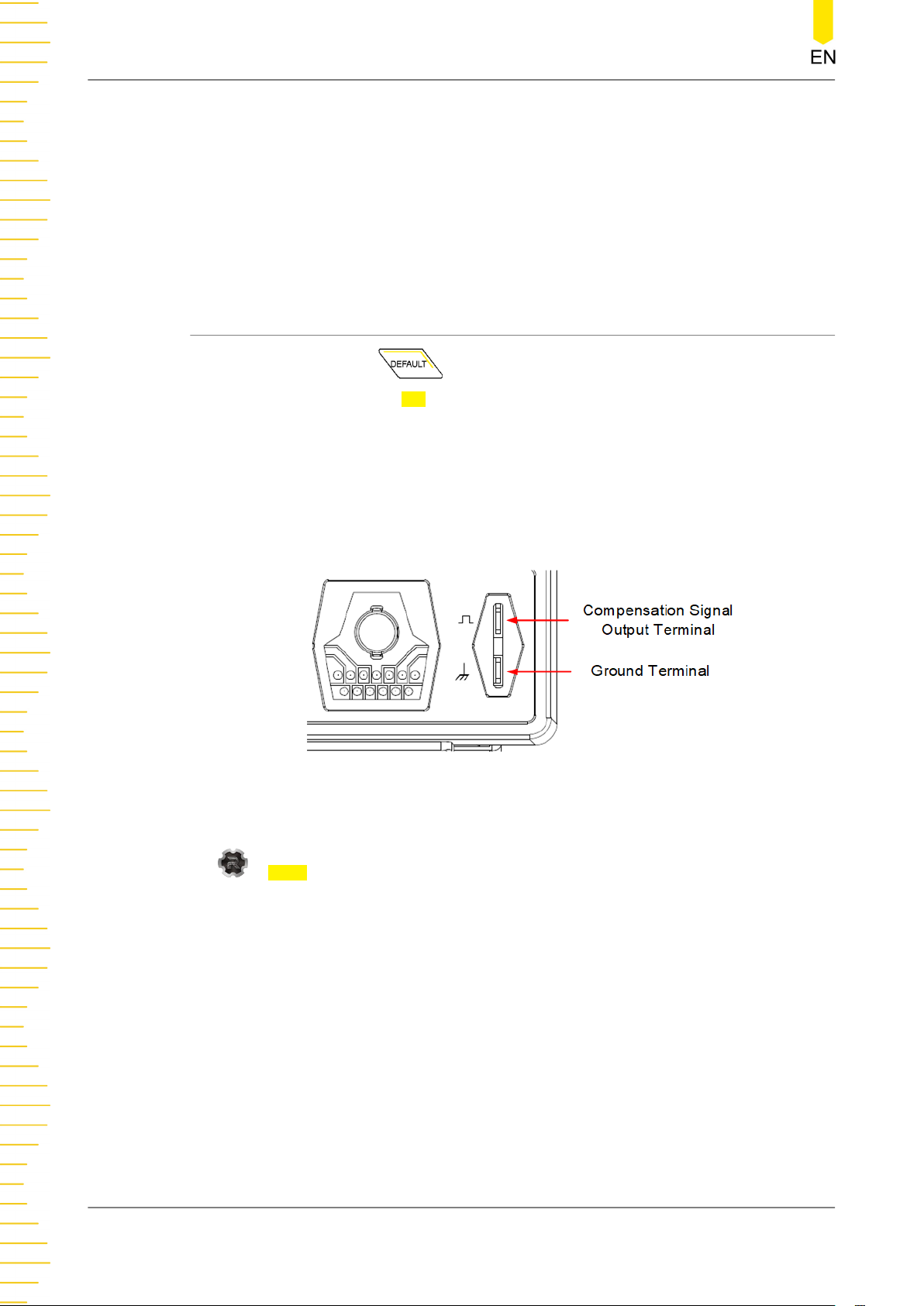

1. Press the front-panel and a prompt message "Restore default settings?"

is displayed. Click or tap OK to restore the instrument to its factory default

settings.

2. Connect the ground alligator clip of the probe to the "Ground Terminal" as shown

Figure 5.6

in

.

User Guide for

.

3. Use the probe to connect the input terminal of CH1 and the "Compensation Signal

Output Terminal" of the probe, as shown in

Figure 5.6 Using the Compensation Signal

4. Set the probe ratio based on the attenuation of the probe, and then click or tap

> Auto.

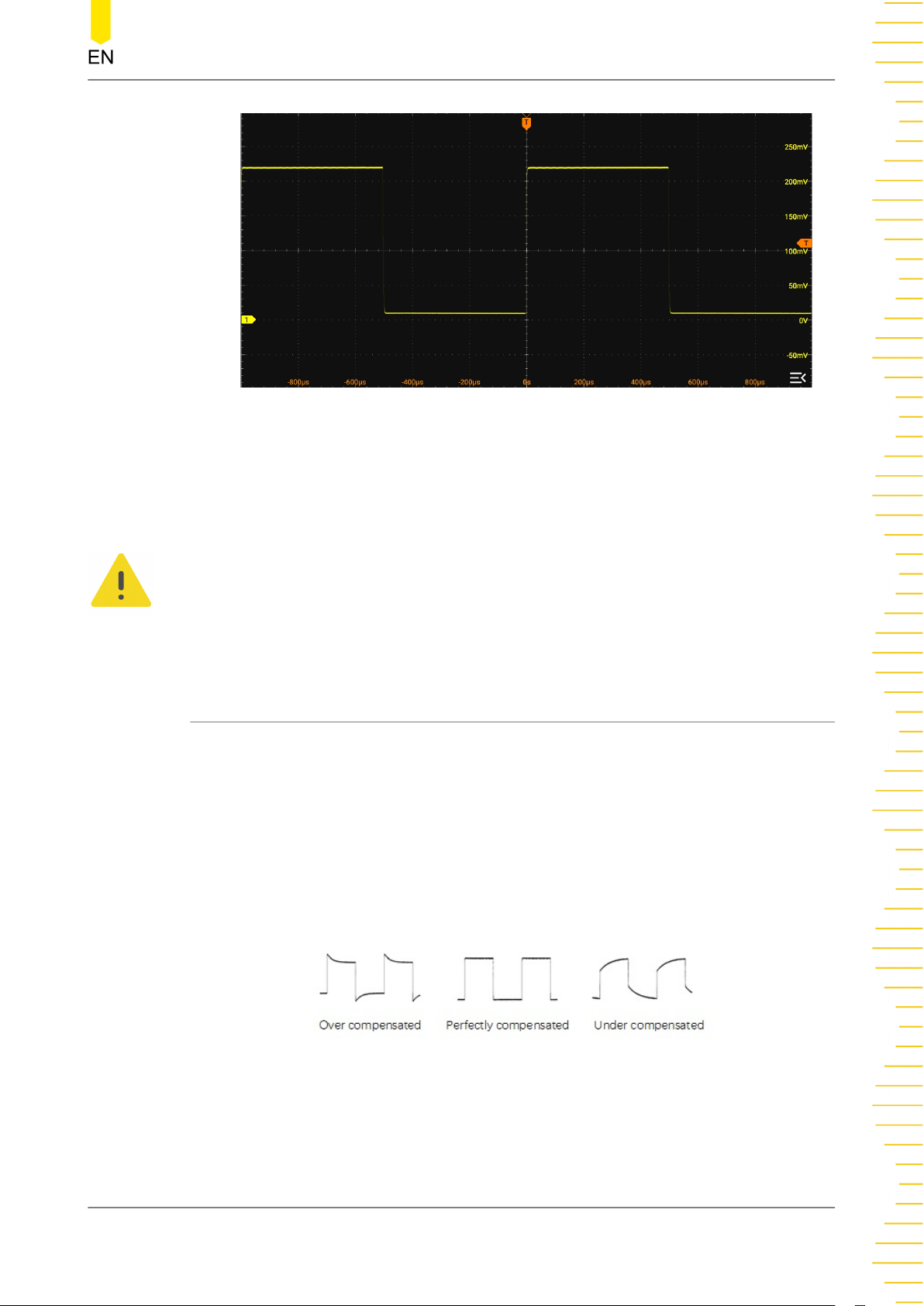

5. Observe the waveform on the display. In normal condition, you should see a

square waveform similar to the waveform shown in the figure below.

Figure 5.6

.

16

Copyright ©RIGOL TECHNOLOGIES CO., LTD. All rights reserved.

To Prepare for Use

Figure 5.7 Square Waveform Signal

6. Test the other channels in the same way. If you see the waveform, but the square

wave is not shaped correctly as shown above, perform the procedure described in

Probe Compensation

. If you do not see the waveform, perform these steps again.

WARNING

To avoid electric shock when using the probe, please make sure that the insulated wire of

the probe is in good condition. Do not touch the metallic part of the probe when the

probe is connected to high voltage source.

5.7 Probe Compensation

When used for the first time, the oscilloscope probe must be compensated to match

the input characteristics of the oscilloscope channel to which it is connected. A noncompensated or poorly compensated probes can introduce measurement inaccuracy

or errors. The compensation procedure is as follows:

1. Perform step 1, 2, 3, and 4 in

2. Check the displayed waveforms and compare them with waveforms shown in the

figure below.

Function Inspection

.

Figure 5.8 Probe Compensation

3. Use the probe compensation adjustment tool provided in the accessories to adjust

the low-frequency compensation adjustment hole on the probe until the displayed

Copyright ©RIGOL TECHNOLOGIES CO., LTD. All rights reserved.

17

To Prepare for Use

waveform is consistent with the "Perfectly compensated" waveform shown in the

figure above.

18

Copyright ©RIGOL TECHNOLOGIES CO., LTD. All rights reserved.

Touch Screen Gestures

6

Touch Screen Gestures

The instrument's large capacitive touch screen makes operation and configuration

easy and flexible. The highly sensitive user interface designed for touch has a strong

waveform display capability, bringing an extraordinary user experience. The actions

supported by the touch screen controls include tapping, pinching&stretching, as well

as dragging.

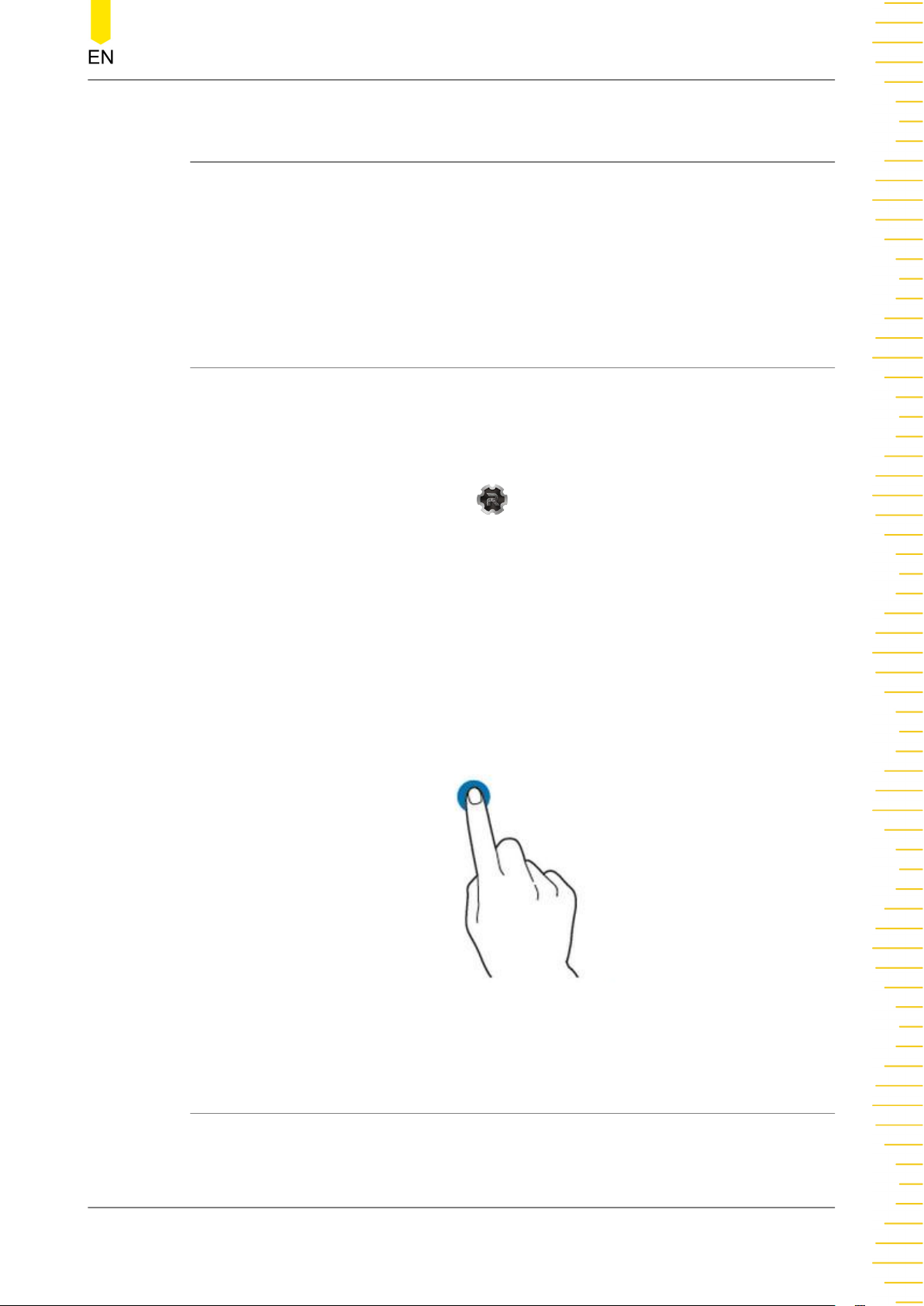

6.1 Tap

Use one finger to tap the symbol or characters on the screen slightly, as shown in

Figure 6.1

• Tap the menu displayed on the screen to operate on the menu.

• Tap the function navigation icon at the lower-left corner of the touch screen

• Tap the displayed numeric keypad to set the parameters.

. With the Tap gesture, you can perform the following operation:

to enable the function navigation.

• Tap the virtual keypad to set the label name and the filename.

• Tap the close button at the upper-right corner of the message box to close the

prompt window.

• Tap other windows on the touch screen and operate on the windows.

Figure 6.1 Tap Gestures

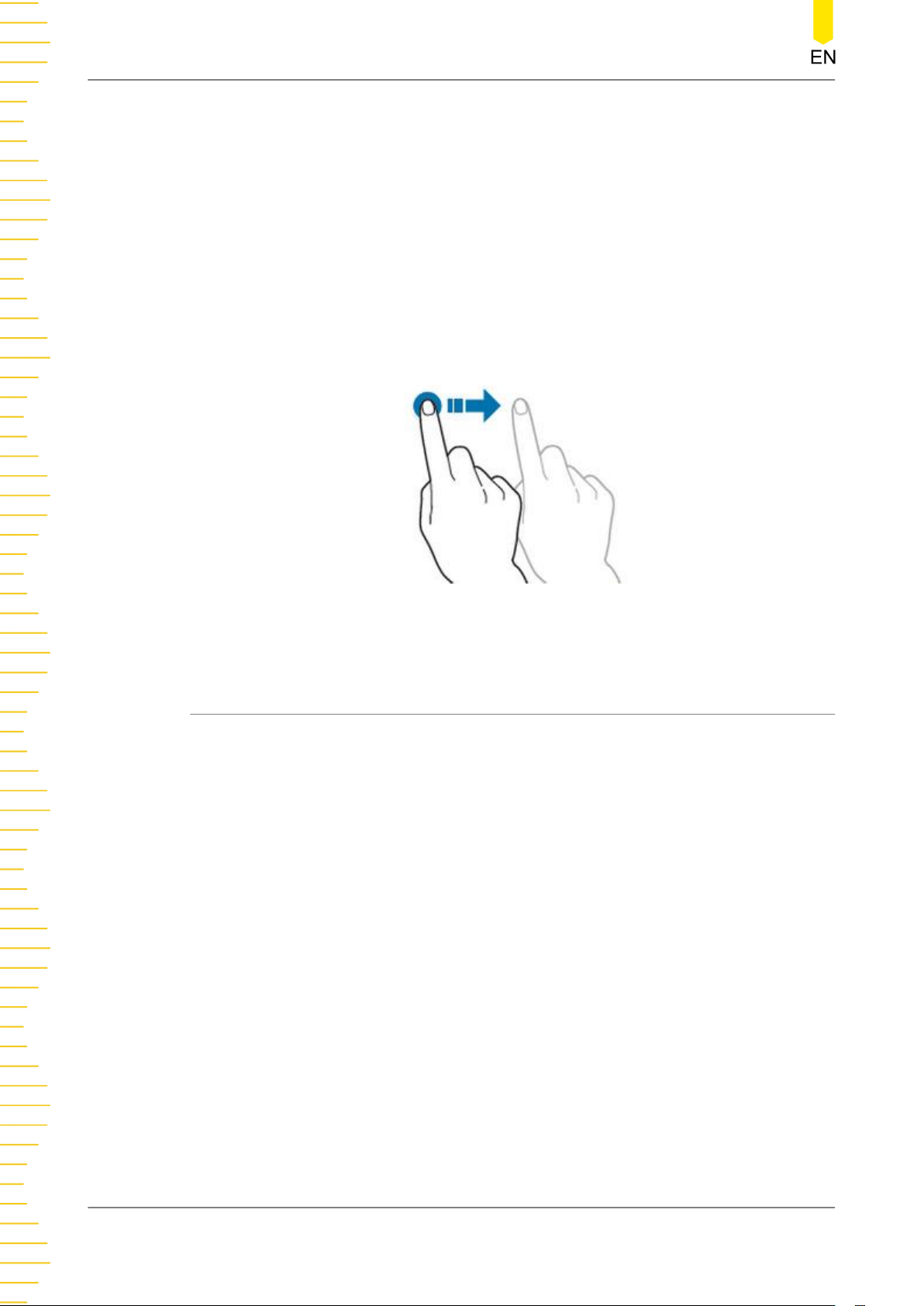

6.2 Drag

Use one finger to select the object, and then drag the object to a destination place, as

shown in the figure below. With the drag gesture, you can perform the following

operation:

Copyright ©RIGOL TECHNOLOGIES CO., LTD. All rights reserved.

19

Touch Screen Gestures

• Drag the waveform to change its position or scale.

• Drag the window controls to change the position of the window (e.g. numeric

keypad).

• Drag the cursor to move the cursor.

• Drag the trigger cursor to change the trigger level.

• In multi-window display, drag one of the displayed windows to change its

position on the display.

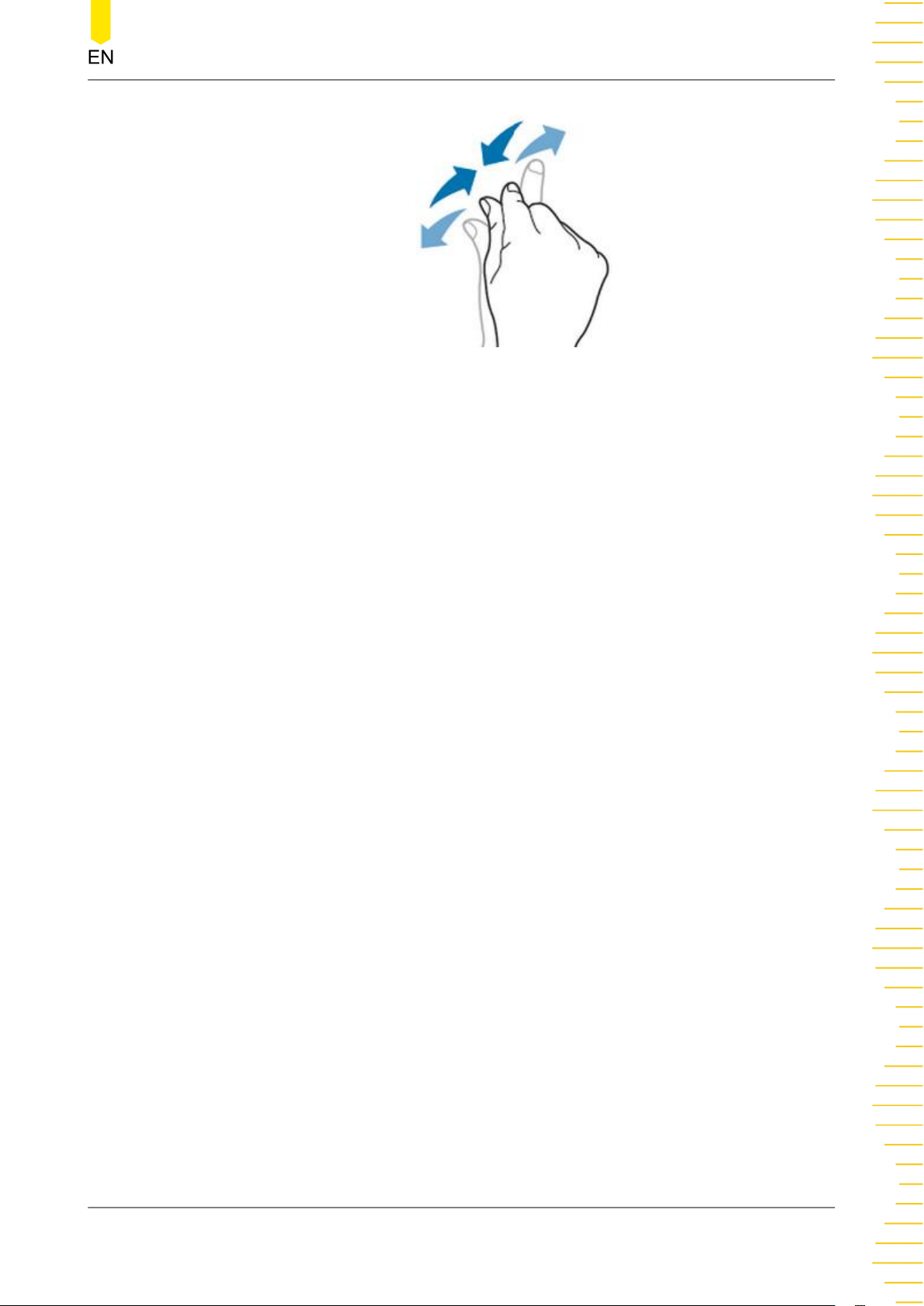

6.3 Pinch&Stretch

Pinch or stretch two points on the screen with two fingers to zoom in or out the

waveform. To zoom in the waveform, first pinch the two fingers and then stretch the

fingers; to zoom out the waveform, first stretch the two fingers, and then pinch the

fingers together, as shown in the figure below. With the pinch&stretch gesture, you

can perform the following operation:

• Pinching&stretching in the horizontal direction can adjust the horizontal time

base of the waveform.

• Pinching&stretching in the vertical direction can adjust the vertical scale of the

waveform.

Figure 6.2 Drag Gesture

20

Copyright ©RIGOL TECHNOLOGIES CO., LTD. All rights reserved.

Figure 6.3 Pinch&Stretch Gesture

Touch Screen Gestures

Copyright ©RIGOL TECHNOLOGIES CO., LTD. All rights reserved.

21

Accessing the Built-in Help System

7

Accessing the Built-in Help System

The built-in help system provides instructions for all the front-panel keys and their

corresponding menu keys. Click or tap > Help to access the "Help" menu.

After that, you can get its help information by clicking on or tapping the link for the

desired item.

22

Copyright ©RIGOL TECHNOLOGIES CO., LTD. All rights reserved.

Parameter Setting Method

8

Parameter Setting Method

For this instrument, you can use the knobs and touch screen to set parameters. The

common parameter setting methods are as follows:

• Method 1: Some parameters can be adjusted by rotating the front-panel knobs.

• Method 2: Click or tap the input field of a specified parameter, then a virtual

keypad is displayed. Complete the parameter setting with the keypad.

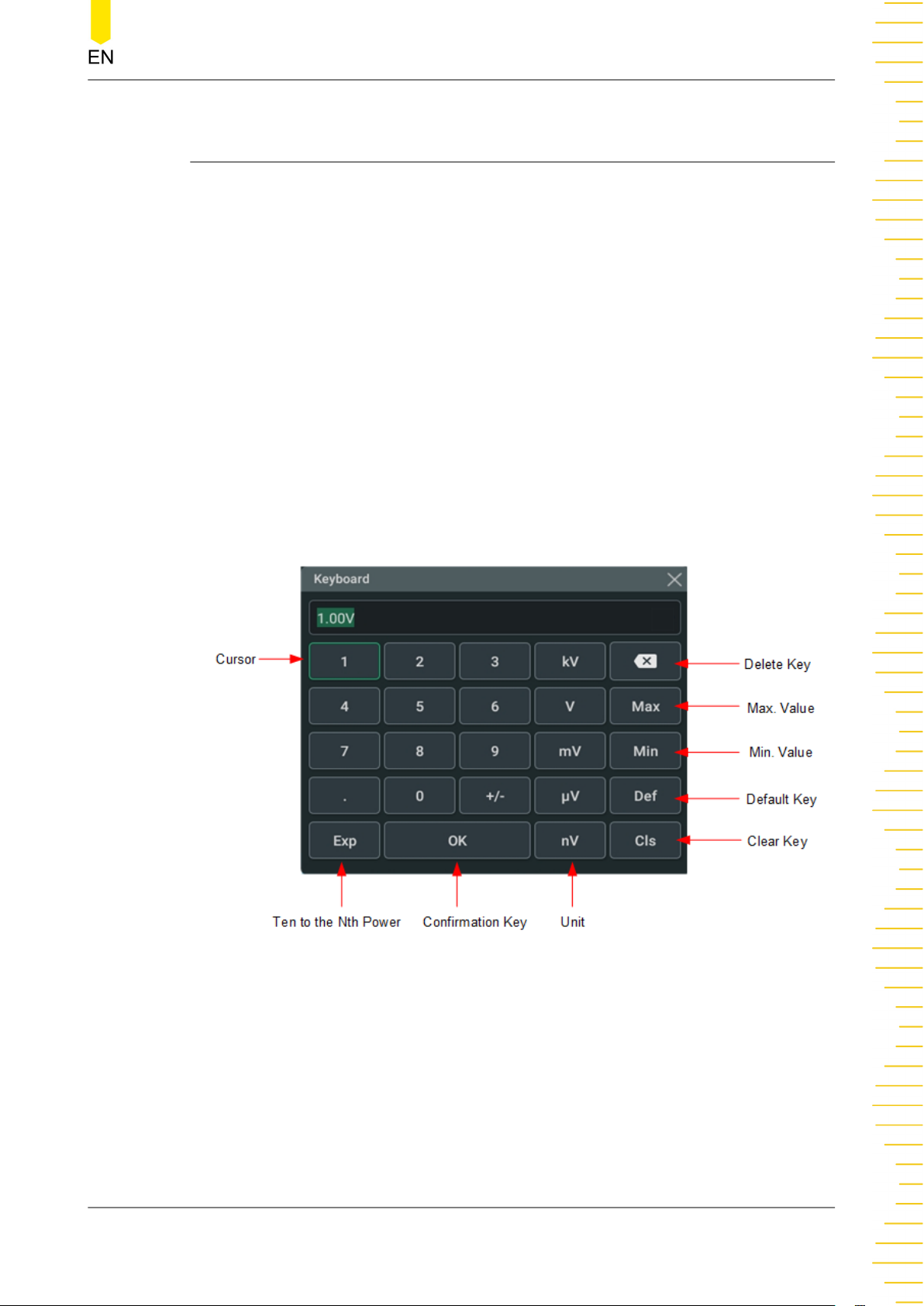

Input a Value

When setting or modifying a parameter, you can input an appropriate value with the

numeric keypad.

• Input a value or unit in the keypad using the touch screen.

• You can also rotate the multipurpose knob (1 or 2) to move the cursor and select

the desired value and unit. Then press the knob to input the selected value or

unit.

Figure 8.1 Numeric Keypad

After you input all the values and select the desired units, the numeric keypad is

turned off automatically. This indicates that you have completed parameter setting.

Besides, after you have input the values, you can also press "OK" directly to close the

numeric keypad. At this time, the unit of the parameter is the default unit. In the

numeric keypad, you can perform the following operations:

• Delete the parameter value that has been input;

Copyright ©RIGOL TECHNOLOGIES CO., LTD. All rights reserved.

23

Parameter Setting Method

• Set the parameter value to a maximum or minimum value;

• Set the parameter to a default value.

• Clear the parameter input field.

24

Copyright ©RIGOL TECHNOLOGIES CO., LTD. All rights reserved.

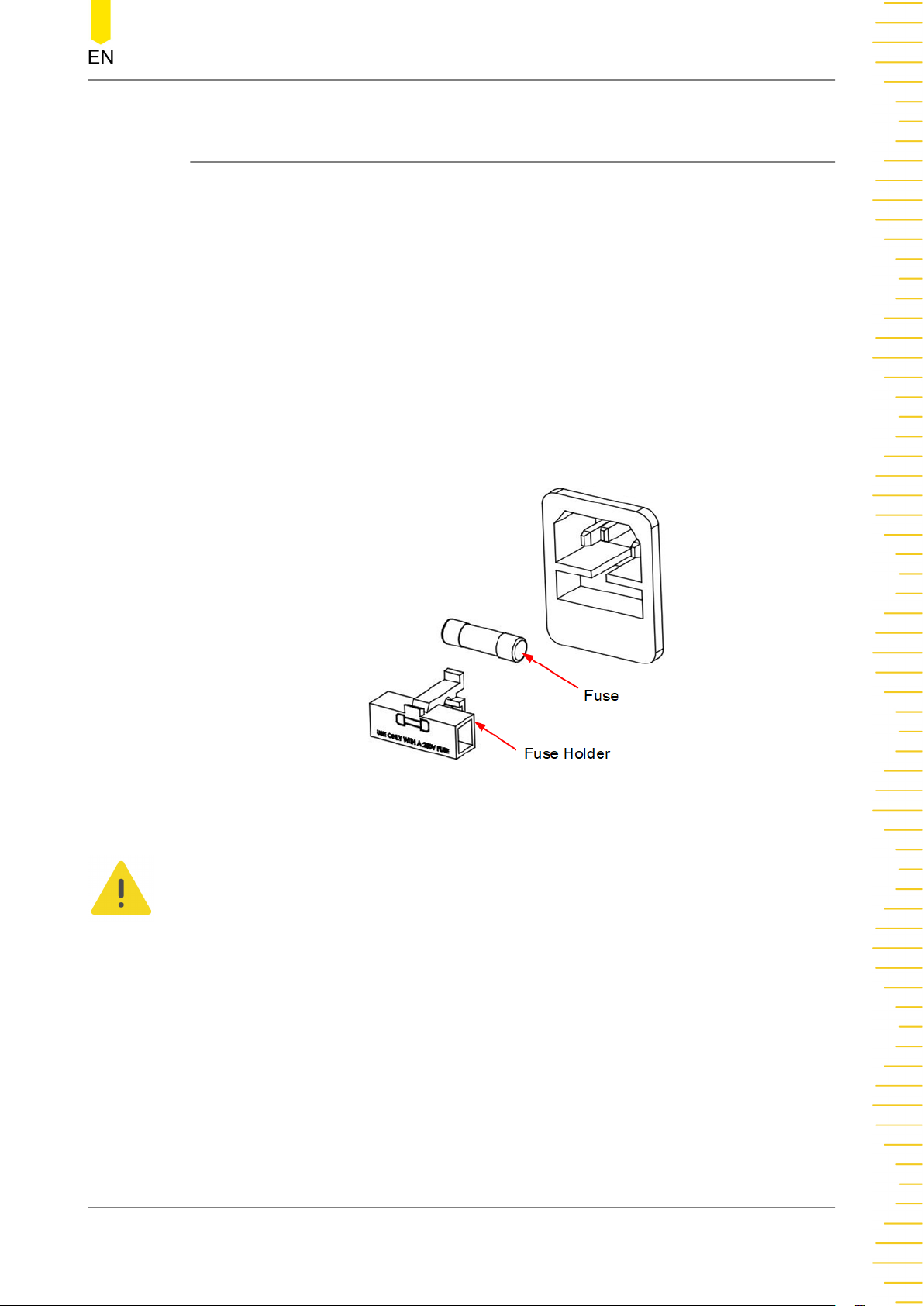

Replacing the Fuse

9

Replacing the Fuse

If you need to replace the fuse, please use the correct fuse (AC 250 V, T3.15 A; 5.2

mm×20 mm) and follow the steps shown below (see

1. Power off the instrument and remove the power cord.

2. Insert a small straight screwdriver into the slot at the power socket and pry out the

fuse holder gently.

3. Remove the fuse.

4. Insert the proper fuse into the fuse holder.

5. Re-insert the fuse holder into the power socket.

Figure 9.1

).

Figure 9.1 Replacing the Fuse

WARNING

To avoid electric shock, please make sure that the instrument is powered off and

disconnected from the power before replacing the fuse. Also, please make sure the fuse is

consistent with the required fuse rating.

Copyright ©RIGOL TECHNOLOGIES CO., LTD. All rights reserved.

25

Remote Control

10

Remote Control

The instrument can be remotely controlled by the following three methods:

• User-defined Programming

Users can program and control the instrument by using the SCPI (Standard

Commands for Programmable Instruments) commands. For details about the

SCPI commands and programming, refer to

• PC Software

Users can use the PC software to send commands to control the instrument

remotely. RIGOL Ultra Sigma is recommended. You can download the software

from RIGOL official website (

Operation Procedures:

- Set up communication between the instrument and PC.

- Run Ultra Sigma and search for the instrument resource.

- Open the remote command control panel to send commands.

http://www.rigol.com

Programming Guide

).

.

• Web Control

This instrument supports Web Control. Connect the instrument to the network,

then input the IP address of the instrument into the address bar of the browser

of your computer. The web control interface is displayed. Click Web Control to

enter the web control page. Then you can view the display of the real-time

interface of the instrument. Through the Web Control method, you can migrant

the device control to the control terminals (e.g. PC, Mobile, iPad, and other smart

terminals) to realize remote control of the instrument. When you first log in to

the Web Control, the user name is "admin" and password is "rigol".

This instrument can be connected to the PC via the USB, LAN, or GPIB interface to set

up communication and realize remote control through the PC. The remote control can

be realized by using SCPI (Standard Commands for Programmable Instruments)

commands.

CAUTION

Before connecting the communication cable, please turn off the instrument to avoid

causing damage to the communication interfaces.

26

Copyright ©RIGOL TECHNOLOGIES CO., LTD. All rights reserved.

More Product Information

11

More Product Information

1. Obtain the Device Information

Click or tap > Utility > About to obtain the information of the instrument,

such as the model, serial number, and firmware version number.

2. View the Option Information and Install the Option

The instrument is installed with the trial versions of the options before leaving

factory. The trial time starts from the time when you power on the instrument for

the first time, and the trial time is about 2,160 minutes. Open the "Utility" menu,

and then click or tap

oscilloscope and their information. For details, refer to descriptions in this series

User Guide.

For more information about the instrument, refer to the relevant manuals by logging

in to the official website of RIGOL (

DHO4000 User Guide:

•

operation methods, remote control methods, possible failures and solutions in

using the instrument, specifications, and order information.

Option to view the options currently installed on the

http://www.rigol.com

introduces the functions of the instrument and the

) to download them.

DHO4000 Programming Guide:

•

commands and programming examples of the instrument.

DHO4000 Data Sheet:

•

the instrument.

provides the key features and technical specifications of

provides detailed descriptions of SCPI

Copyright ©RIGOL TECHNOLOGIES CO., LTD. All rights reserved.

27

Loading...

Loading...