Page 1

Performance Verification Guide

DG2000 Series

Function/Arbitrary Waveform Generator

Aug. 2019

RIGOL (SUZHOU) TECHNOLOGIES INC.

Page 2

Page 3

RIGOL

I

Guaranty and Declaration

Copyright

© 2019 RIGOL (SUZHOU) TECHNOLOGIES INC. All Rights Reserved.

Trademark Information

RIGOL is a registered trademark of RIGOL (SUZHOU) TECHNOLOGIES INC.

Publication Number

PVB12100-1110

Notices

RIGOL produ cts are cov ered by P.R.C. and f oreign pa tents, issue d and pendin g.

RIGOL reserves the right to modify or change parts of or all the specifications

and pricing policies at the company’s sole decision.

Information in this publication replaces all previously released materials.

Information in this publication is subject to change without notice.

RIGOL shall not be liable for either incidental or consequential losses in

connection with the furnishing, use, or performance of this manual, as well as

any information contained.

Any part of th is d ocu ment is f orbi dden to be c opie d, ph oto copie d, o r rea r ran ged

without prior written approval of RIGOL.

Product Certification

RIGOL guarantees that this product conforms to the national and industrial

standards in China as well as the ISO9001:2015 standard and the ISO14001:2015

standard. Other international standard conformance certifications are in progress.

Contact Us

If you have any problem or requirement when using our products or this manual,

please contact RIGOL.

E-mail: service@rigol.com

Website: www.rigol.com

DG2000 Performance Verification Guide

Page 4

RIGOL

II

General Safety Summary

Please review the following safety precautions carefully before putting the

instrument into operation so as to avoid any personal injury or damage to the

instrument and any product connected to it. To prevent potential hazards, please

follow the instructions specified in this manual to use the instrument properly.

Use the BNC Output Connector Properly.

The BNC output connector on the f ront panel only allows to output the signal b ut not

to input the signal.

Use Proper Power Cord.

Only the exclusive power cord designed for the instrument and authorized for use

within the local country could be used.

Ground the Instrument.

The instrument is grounded th rou gh t he Protective Earth lead of the power cord. To

avoid e lectric shock, connect the earth terminal of the power cord to the Protective

Earth terminal before connecting any input or output terminals.

Connect the Probe Correctly.

If a probe is used, the probe ground lead must be connected to earth ground. Do not

connect the ground lead to hi gh volta ge. Imprope r way of connection could r esult in

dangerous voltages being present on the connectors, controls or other surfaces of

the oscilloscope and probes, which will cause potential hazards for operators.

Observe All Terminal Ratings.

To a void fire or shock hazard, obse rve all r atings an d markers on t he instru ment and

check your manual for more information about ratings before connecting the

instrument.

Use Proper Overvoltage Protection.

Ensure that no over voltage (su ch as that cause d by a bolt of lightni ng) can reach the

product. Otherwise, the operator might be exposed to the danger of an electric

shock.

Do Not Operate Without Covers.

Do not operate the instrument with covers or panels removed.

Do Not Insert Objects Into the Air Outlet.

Do not insert objects into the air outlet, as doing so may cause damage to the

instrument.

Use Proper Fuse.

Please use the specified fuses.

DG2000 Performance Verification Guide

Page 5

RIGOL

III

Avoid Circuit or Wire Exposure.

Do not touch exposed junctions and components when the unit is powered on.

Do Not Operate With Suspected Failures.

If you suspect that any damage may occur to the instrument, have it inspected by

RIGOL authorized personnel before further operations. Any maint enance,

adjustment or replacement especially to circuits or accessories must be performed

by RIGOL authorized personnel.

Provide Adequate Ventilation.

Inadequate ventilation may cause an increase of temperature in the instrument,

which would cause damage to the instrument. So please keep the instrument well

ventilated and inspect the air outlet and the fan regularly.

Do Not Operate in Wet Conditions.

To avoid short circuit inside the instrument or electric shock, never operate the

instrument in a humid environment.

Do Not Operate in an Explosive Atmosphere.

To avoid personal injuries or damage to the instrument, never operate the

instrument in an explosive atmosphere.

Keep Product Surfaces Clean and Dry.

T o a void dust or moisture from af fecting the pe rformance of the inst rument, keep th e

surfaces of the instrument clean and dry.

Prevent Electrostatic Impact.

Operate the instrume nt i n an el ectr ostatic dischar ge protectiv e e nvi ron ment to a void

damage induced by static discharges. Always ground both the internal and external

conductors of cables to relea s e sta t i c be fore makin g connections.

Use the Battery Properly.

Do not expose the battery (if available) to high temperature or fire. Keep it out of the

reach of children. Improper change of a battery (lithium battery) may cause an

explosion. Use the RIGOL specified battery only.

Handle with Caution.

Please handle with care during transportation to avoid damage to keys, knobs,

interfaces, and other parts on the panels.

DG2000 Performance Verification Guide

Page 6

RIGOL

IV

Document Overview

This manual is used to gui de users to corre ctly test the perfo rmance specifications of

DG2000 series function/arbitrary waveform generator. The performance verification

test mainly verifies whether DG2000 series can work normally and is within

specifications.

Main topics in th is Manual:

Chapter 1 Test Overview

This chapter introduces the preparations before the performance verification test,

the recommended test devic e s, the test result r ecord, the test notices a n d the

related information of the technical parameters.

Chapter 2 Performance Verification Test

This chapter introduces t he test method, p r oce du res and limits of e ac h performance

specif ication in details.

Appendix

The appendix provides the test results record forms and performance specifications

of DG2000 series function/arbitrary waveform generator.

Format Conventions in this Manual:

1. Keys:

2. Menu Labels:

3. Connectors:

4. Operation Procedures:

The keys on the front panel are usually denoted by the format of "Key Name

(Bold) + Text Box". For example, Pulse/Utility denotes the Utility key.

The menu labels are usually denoted by the format of "Menu Word (Bold) +

Character Shading". For example, System Setting.

The connectors on the front or rear panel are usually denoted by the format of

"Connector Name (Bold) + Square Bracket s (Bold)". For example, [Counter].

"" repre sents the next step of operation. For example, when the backlight of

the Shift key is illuminated, pressing Pulse/Utility System Sett in g

denotes that first press Pulse/Utility on the front panel, and then tap the

System Setting menu label.

DG2000 Performance Verification Guide

Page 7

RIGOL

V

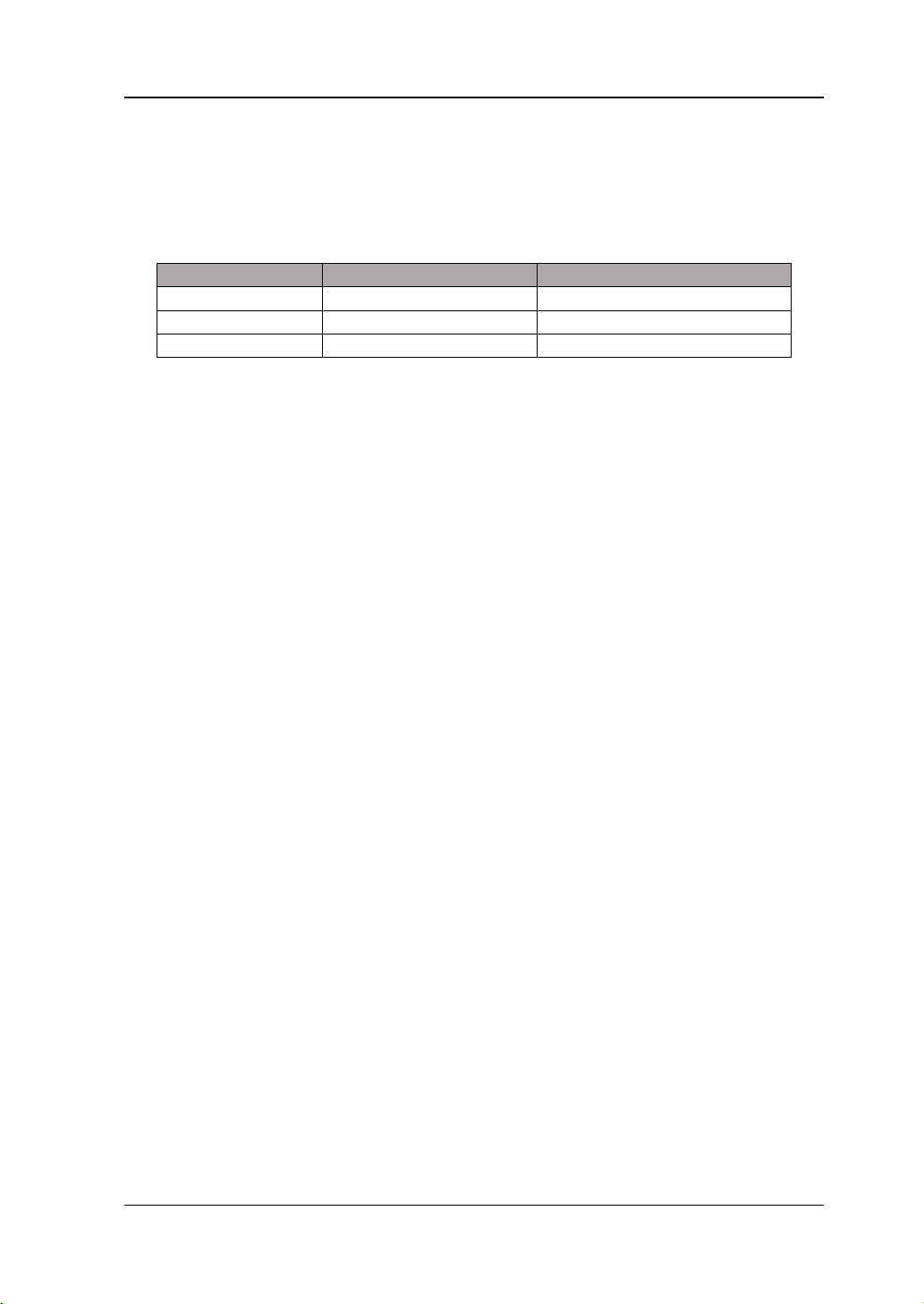

Model

No. of Channels

Max. Output Frequency

DG2052

2

50 MHz

DG2072

2

70 MHz

DG2102

2

100 MHz

Content Conventions in this Manual:

DG2000 series fun ction /arbitra ry w a vef orm gener ator in cludes the f ollowi ng m odels .

Unless otherwise noted in this manual, DG2102 is taken as an example to illustrate

the performance verification test methods of DG2000 series.

DG2000 Performance Verification Guide

Page 8

Contents RIGOL

VI

Contents

Guaranty and Declaration ......................................................................... I

General Safe ty Sum mary ......................................................................... II

Document Overview ............................................................................... IV

Chapter 1 Test Overview .................................................................... 1-1

Test P reparations ................................................................................... 1-1

Recommended Test Devices .................................................................... 1-1

Tes t Result Record ................................................................................. 1-2

Test Notices ........................................................................................... 1-2

Technical Parameters .............................................................................. 1-2

Chapter 2 Performance Verification Test ........................................... 2-1

Frequency Accuracy Test ......................................................................... 2-2

Specification ................................................................................... 2-2

Test Procedures ............................................................................... 2-2

Test Record Form ............................................................................ 2-3

AC Ampli t ude Accuracy Test .................................................................... 2-4

Specification ................................................................................... 2-4

Test Procedures ............................................................................... 2-4

Test Record Form ............................................................................ 2-5

DC Offset Accuracy Test .......................................................................... 2-6

Specification ................................................................................... 2-6

Test Procedures ............................................................................... 2-6

Test Record Form ............................................................................ 2-7

AC Flatness Test ..................................................................................... 2-8

Specification ................................................................................... 2-8

Test Procedures ............................................................................... 2-8

Test Record Form .......................................................................... 2-11

Harmonic Distortion Test ....................................................................... 2-12

Specification ................................................................................. 2-12

Test Procedures ............................................................................. 2-12

Test Record Form .......................................................................... 2-14

Spurious Signal Test ............................................................................. 2-15

Specification ................................................................................. 2-15

Test Procedures ............................................................................. 2-15

Test Record Form .......................................................................... 2-17

Rise/Fall Time Test ............................................................................... 2-18

Specification ................................................................................. 2-18

Test Procedures ............................................................................. 2-18

Test Record Form .......................................................................... 2-19

Overshoot Test .................................................................................... 2-20

Specification ................................................................................. 2-20

Test Procedures ............................................................................. 2-20

Test Record Form .......................................................................... 2-21

DG2000 Performance Verification Guide

Page 9

Contents RIGOL

VII

Appendix .................................................................................................. 1

Appendix A: Test Result Record Form ......................................................... 1

Appendix B: Performance Specifications ..................................................... 8

DG2000 Performance Verification Guide

Page 10

Page 11

Chapter 1 Test Overview RIGOL

1-1

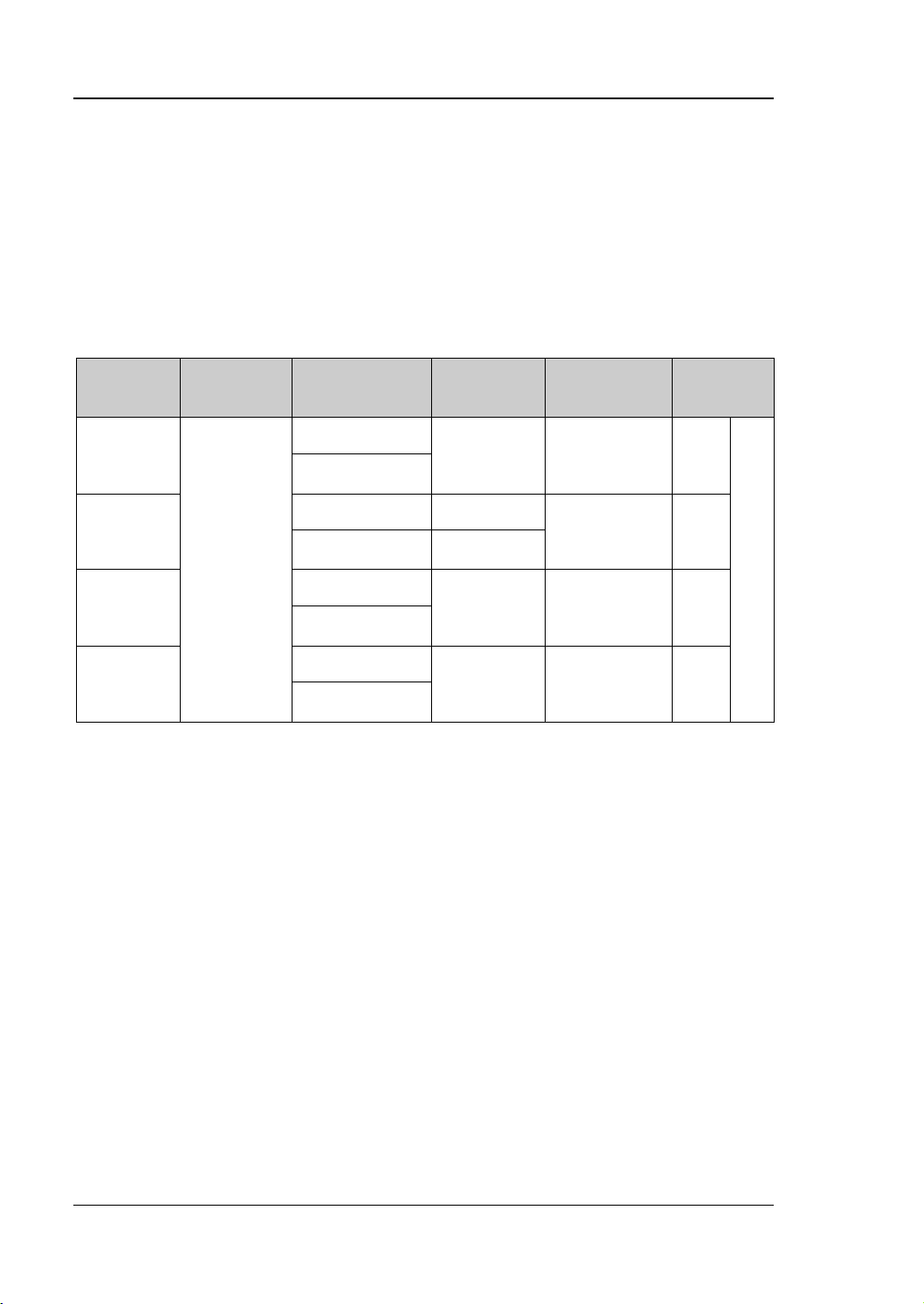

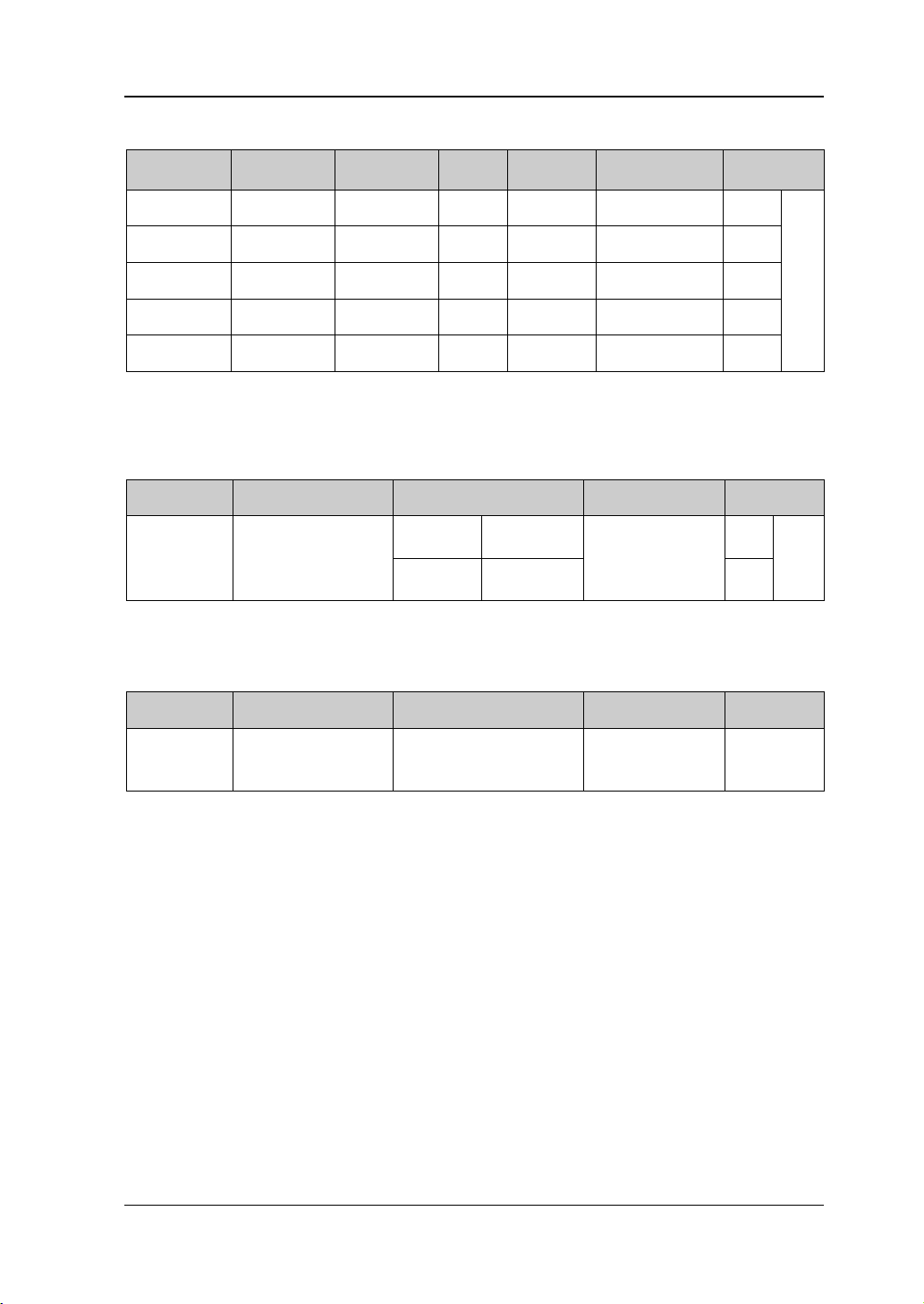

Recommended

Instrument

>10MHz

Accuracy: 0.1ppm

Digital Multimeter

61/2 digits

RIGOL DM3068

-30dBm to +20dBm

Resolution: 0.01dB

Power Sensor

-30dBm to +20dBm

Keysight N8482A

Minimum resolution bandwidth i s

100Hz

Bandwidth: 500MHz

function

Power Sensor

Connecting Cable

Used to connect the power meter

and power sensor

Connecting Cable

BNC (m)-BNC (m)

--

Connecting Cable

BNC (m)-Dual banana plug (m)

--

50Ω Load

50Ω/1W

--

Adaptor

N (f)-BNC (m)

--

Adaptor

BNC (f)-N (m)

--

Chapter 1 Test Overview

Test Preparations

Before performing the test, make sure that the instrument is within the calibration

period (the recommended calibration period is 1 year) and has been warmed up for

at least 30 minutes under the specified operation temperature (18℃ to 28℃).

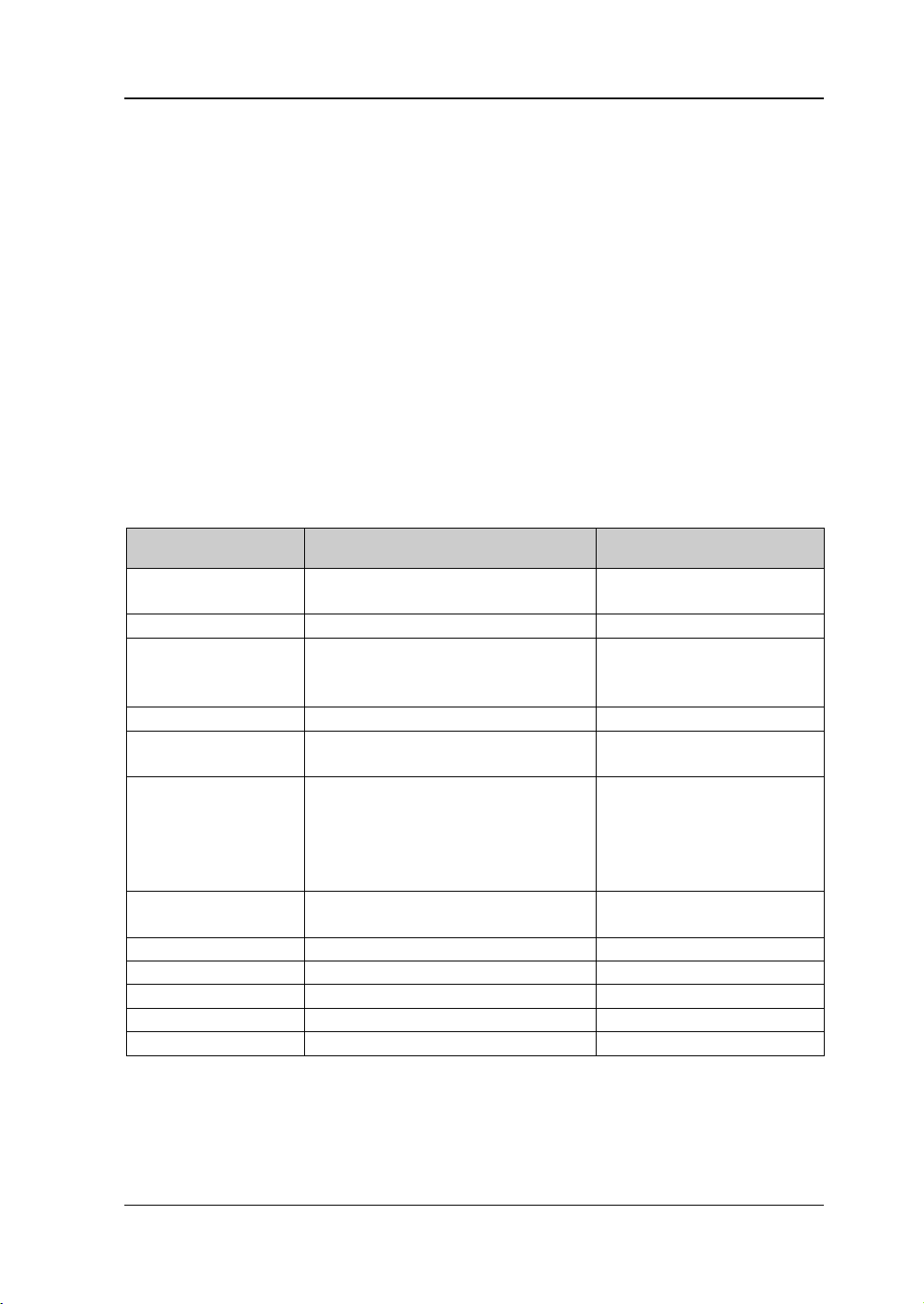

Recommended Test Devices

It is recommended that you use the test devices listed in the table below or other test

devices whose performance specifications satisfy the "Per formance Requirement"

listed in the table below to test the performance specifications of the DG2000 series.

Table 1-1 Recommended test devices

Device Performance Requirement

Frequency Counter

Power Meter

Spectrum Analyzer

Oscilloscope

Accuracy: ±0.02dB

Rise/Fall time measurement

function

Overshoot measurement

Keysight 53131A

Keysight N1913A

RIGOL DSA815

RIGOL DS4052/DS4054

--

DG2000 Performance Verification Guide

Page 12

RIGOL Chapter 1 Test Overview

1-2

be used repeatedly.

Test Result Record

Record and keep the test results of each test item. The test result record forms,

which provide all the test items and the corresponding performance specification

limits as well as spaces for users to record the test results, are provid ed in

“Appendix A: Test Result Record Form” of this manual.

Tip:

It is recommended that you p hotocopy the test result record form bef ore each test.

During the test process, record the test results on the copies so that the forms can

Test Notices

To achieve optimum test effect, all the test procedures should follow the following

recommendations.

1) Make sure that the environment temperature is between 18℃ and 28℃ and

every test is performed under the specified operation temperature (18℃ to

28℃).

2) Before performing each test, make sure that the instrum ent has been warmed

up for at least 30 minutes.

3) Before performing each test, restore the instrument to factory setting.

Technical Parameters

Chapter 2 of this manual provides the corresponding specification of each test item.

Besides, "Appendix B: Performance Specifications" provides the detailed

performance specifications of DG2000 series.

DG2000 Performance Verification Guide

Page 13

Chapter 2 Performance Verification Test RIGOL

2-1

Chapter 2 Performance Verification Test

This chapter introduces the performance verification test methods of DG2000 series

function/arbitrary wa vefo rm gene rator by taking CH1 of DG2102 as an example. The

test methods are also applica b l e to CH2.

The test items include:

Frequency Accuracy Test

AC Amplitude Accuracy Test

DC Offset Accuracy Test

AC Flatness Test

Harmonic Distortion Test

Spurious Signal Test

Rise/Fall Time Test

Overshoot Test

DG2000 Performance Verification Guide

Page 14

RIGOL Chapter 2 Performance Verification Test

2-2

Frequency characteristic

Accuracy

±(1 ppm

[1]

of the setting value + 10 pHz), 18℃ to 28℃

Frequency Accuracy Test

Specification

[1]

Note

: ppm denotes one part per million. For example, if the setting frequency is 1MHz and the actual output

frequency is between 0.999 998 999 999 999 99MHz and 1.000 001 000 0 00 000 01MHz, the instru ment is u p

to the specification requirement and the test passes.

Test Procedures

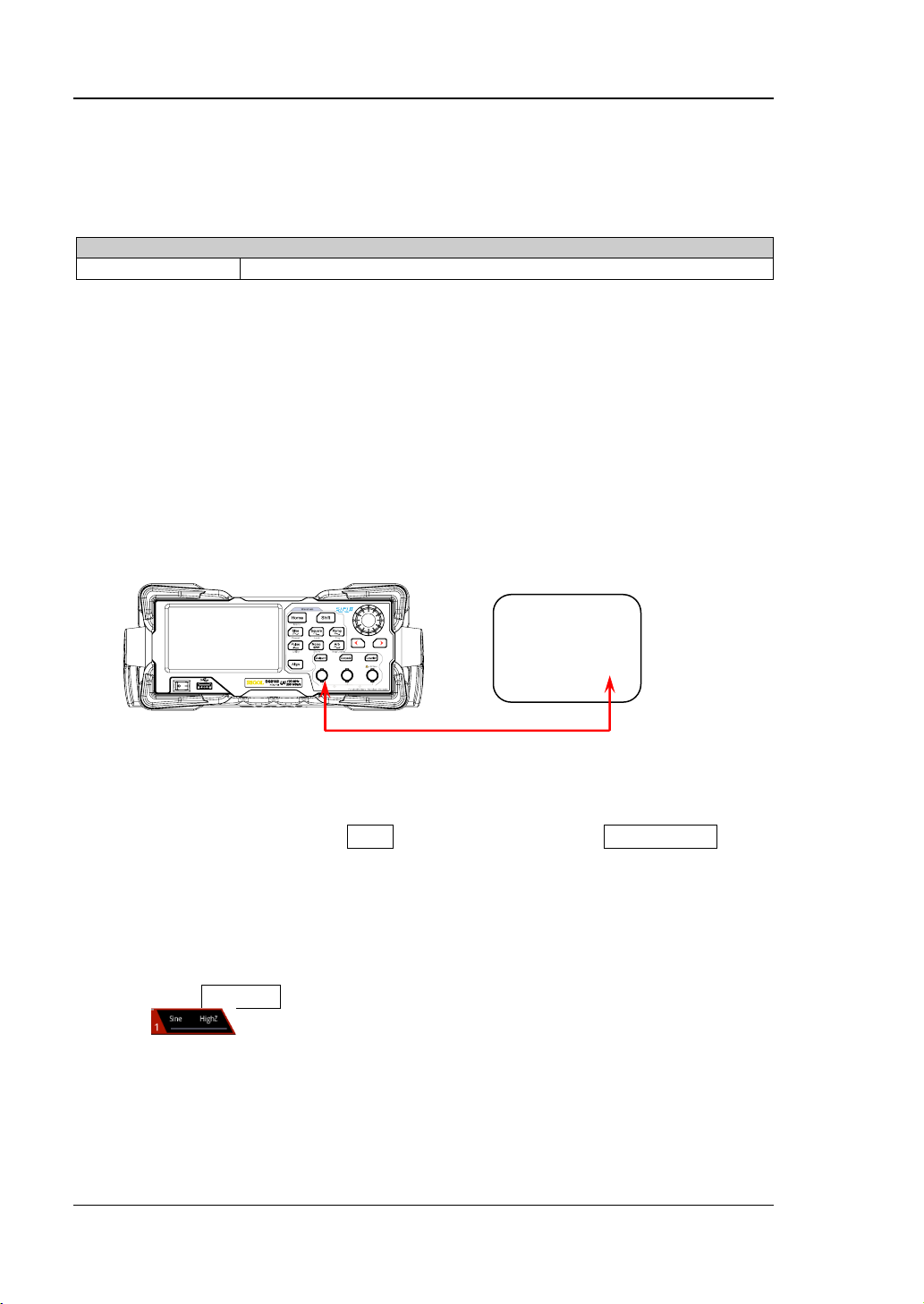

1. Make sure that the environment temperature is between 18℃ and 28℃ and

DG2000 has been warmed up for at least 30 minutes. Connect the channel

output terminal (take CH1 as an example; the test method is also ap plicable to

CH2) of DG2000 with the signal input terminal of the frequency counter using a

dual-BNC cable as shown in Figure 2-1.

DG2000 Series Frequency Counter

◎

Figure 2-1 Connect DG2000 and the Frequency Counter

2. Turn on the frequency counter and set its output impedance to 1MΩ.

3. Turn on DG2000. When the Shift key is illuminated, press Sine/Preset and

tap the Def icon, then a dialog box is displayed, tap "Apply" to restore DG2000

to the factory settin g.

4. Set DG2000:

a) Set the output waveform of CH1 to a sine waveform with 1MHz frequency

and 1Vpp amplitude.

b) Press Output1 or tap the channel output configuration status bar

to turn on the output of CH1 in the channel setting interface.

5. Record the reading of the frequency counter and judge whether the reading is

between 0.999 998 999 999 999 99MHz and 1.000 001 000 000 000 01MHz.

6. Set CH1 of DG2000 to output square, ramp and pulse waveforms (the

frequencies are 1MHz and the amplitudes are 1Vpp) respectively. Record the

DG2000 Performance Verification Guide

Page 15

Chapter 2 Performance Verification Test RIGOL

2-3

Setting

Value

Measurement

Value

readings of the frequenc y counter respectively and judge whether the readings

are between 0.999 998 999 999 999 99MHz and 1.000 001 000 000 000 01MHz.

7. Repeat steps 1 to 6 to test the frequency accuracy of CH2 and record the test

results.

Test Record Form

Waveform

Sine

Square

Ramp

Pulse

Frequency:

1MHz

Amplitude:

1Vpp

Specification Pass/Fail

0.999 998 999 999 999

99MHz to 1.000 001 000 000

000 01MHz

DG2000 Performance Verification Guide

Page 16

RIGOL Chapter 2 Performance Verification Test

2-4

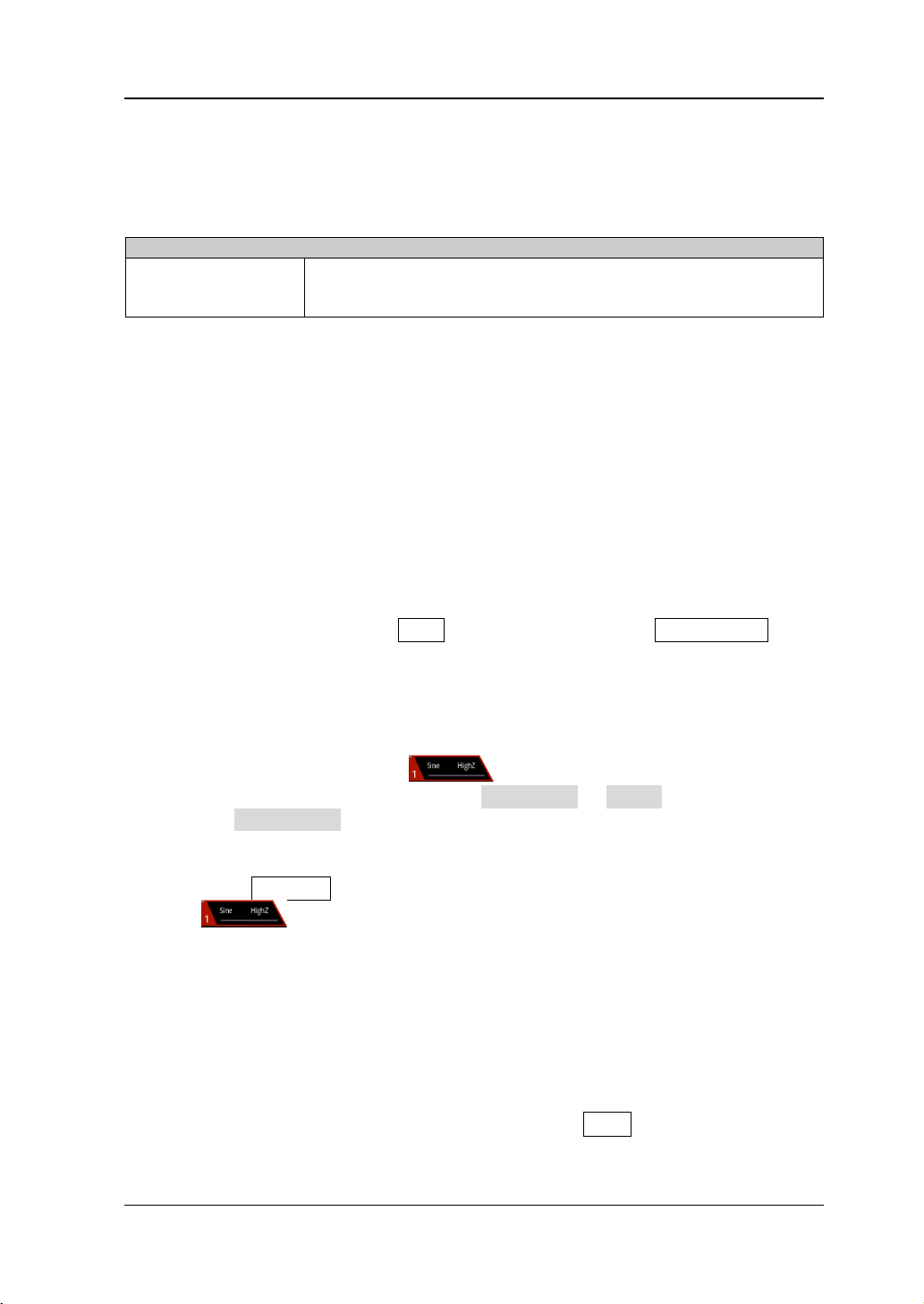

Output Characteristic

Amplitude (into 50Ω)

Typical (1kHz Sine, 0V Offset, >10mVpp, Auto)

±(1% of setting value) ±5mV

AC Amplitude Accuracy Test

Specification

Accuracy

Test Procedures

1. Make sure that the environment temperatu re is between 18℃ and 28℃ and

DG2000 has been warmed up for at least 30 minutes. Connect the 50Ω load to

the channel output terminal (take CH1 as an example; the test method is also

applicable to CH2) of DG2000; connect the 50Ω lo ad and the voltage input

terminals of the digital multimeter using a BNC-Dual banana plug conne cting

cable as shown in Figure 2-2.

DG2000 Series Digital Multimeter

◎ ◎

◎ ◎

◎

50Ω Load

Figure 2-2 Connect DG2000 and the Digital Multimeter via a 50Ω Load

2. Turn on the multimeter, select the ACV measurement f unction and set the rang e

to “Auto”.

3. Turn on DG2000. When the Shift key is illuminated, press Sine/Preset and

tap the Def icon, then a dialog box is displayed, tap "Apply" to restore DG2000

to the factory setting.

4. Set DG2000:

a) Set the output impedance of CH1 to 50Ω. (Tap the channel output

conf iguration status bar

under the user interface to enter the

channel setting interface. Tap the OutputSet HighZ to select "Off". Tap

the Impedance menu label, and set the impedanc e to 5 0Ω.)

b) Set the output waveform of CH1 to a sine waveform with 1kHz frequency,

20mVpp amplitude and 0V

offset.

dc

DG2000 Performance Verification Guide

Page 17

Chapter 2 Performance Verification Test RIGOL

2-5

Amplitude

(Vpp)

rms22pp VV =

Amplitude

Value

c) Press Output1 or tap the channel output configuration status bar

to turn on the output of CH1 in the channel setting interface.

5. Record the reading of the multimeter and judge whether it is within the

specif ication ("Amplitude Output Value (Vrms)" in Table 2-1) range.

6. Keep the out put i mpe da n ce of CH1 o f DG2000 at 50Ω and the output wave form

of CH1 as a sine waveform with 1kHz frequency and 0V

offset. Set the output

dc

amplitude of CH1 to 100mVpp, 500mVpp, 1Vpp, 5Vpp and 10Vpp respectively.

Record the readings of the multimeter respectively and judge whether the

readings are within the specification (“Amplitude Output Value (Vrms)” in Table

2-1) range.

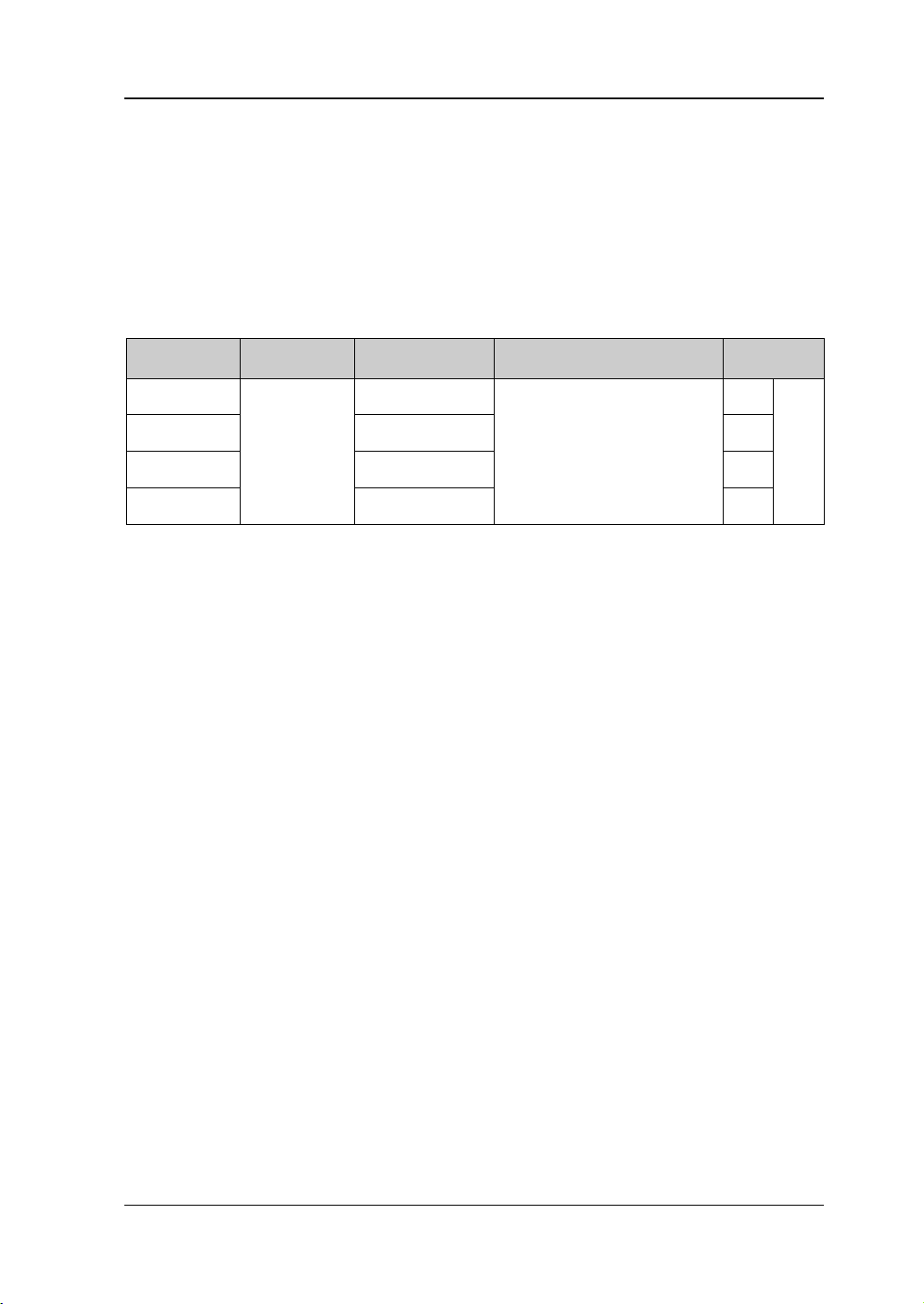

Table 2-1 Amp litude output values (Vrms) of AC amplitude accuracy t es t

Setting

Value

20mVpp ±5.2mVpp 14.8mVpp to 25.2mVpp 5.2mVrms to 8.9mVrms

100mVpp ±6mVpp 94mVpp to 106mVpp 33.2mVrms to 37.5mVrms

500mVpp ±10mVpp 490mVpp to 510mVpp 173.3mVrms to 180.3mVrms

1Vpp ±15mVpp 0.985Vpp to 1.015Vpp 348.3mVrms to 358.9mVrms

5Vpp ±55mVpp 4.945Vpp to 5.055Vpp 1.75Vrms to 1.7875Vrms

10Vpp ±105mVpp 9.895Vpp to 10.105Vpp 3.5Vrms to 3.5732Vrms

[1]

Note

: "Allowed Error" is calculated from the specification "±(1% of setting value) ±5mVpp".

[2]

Note

: "Amplitude Output Value (Vrms)" is calculated from "Amplitude Output Value (Vpp)".

The conversion relation between Vrms and Vpp is

Allowed

Error (Vpp)

Amplitude Output

[1]

Value (Vpp)

Amplitude Output Value

(Vrms)

[2]

.

7. Repeat Step 1-6 to test the AC amplitude accuracy of CH2 and record the test

results.

Test Record Form

Setting

20mVpp

Setting

Measurement

Value

5.2mVrms to 8.9mVrms

Specification Pass/Fail

100mVpp 33.2mVrms to 37.5mVrms

500mVpp 173.3mVrms to 180.3mVrms

1Vpp 348.3mVrms to 358.9mVrms

5Vpp 1.75Vrms to 1.7875Vrms

10Vpp 3.5Vrms to 3.5732Vrms

DG2000 Performance Verification Guide

Frequency:

1kHz

Offset: 0V

Impedance:

50Ω

dc

Page 18

RIGOL Chapter 2 Performance Verification Test

2-6

Output Characteristic

Offset (into 50Ω)

Accuracy

±(1% of setting value + 5mV + 1% of amplitude)

DC Offset Accuracy Test

Specification

Test Procedures

1. Make sure that the environment temperatu re is between 18℃ and 28℃ and

DG2000 has been warmed up for at least 30 minutes. Connect the 50Ω load to

the channel output terminal ( take CH1 as an example; the test method is also

applicable to CH2) of DG2000; connect the 50Ω lo ad and the voltage input

terminals of the digital multimeter using a BNC-Dual banana plug connecting

cable as shown in Figure 2-2.

2. T urn on the multimeter, select the DCV measurement function and set the range

to "20V".

3. Turn on DG2000. When the Shift key is illuminated, press Sine/Preset and

tap the Def icon, then a dialog box is displayed, tap "Apply" to restore DG2000

to the factory setting.

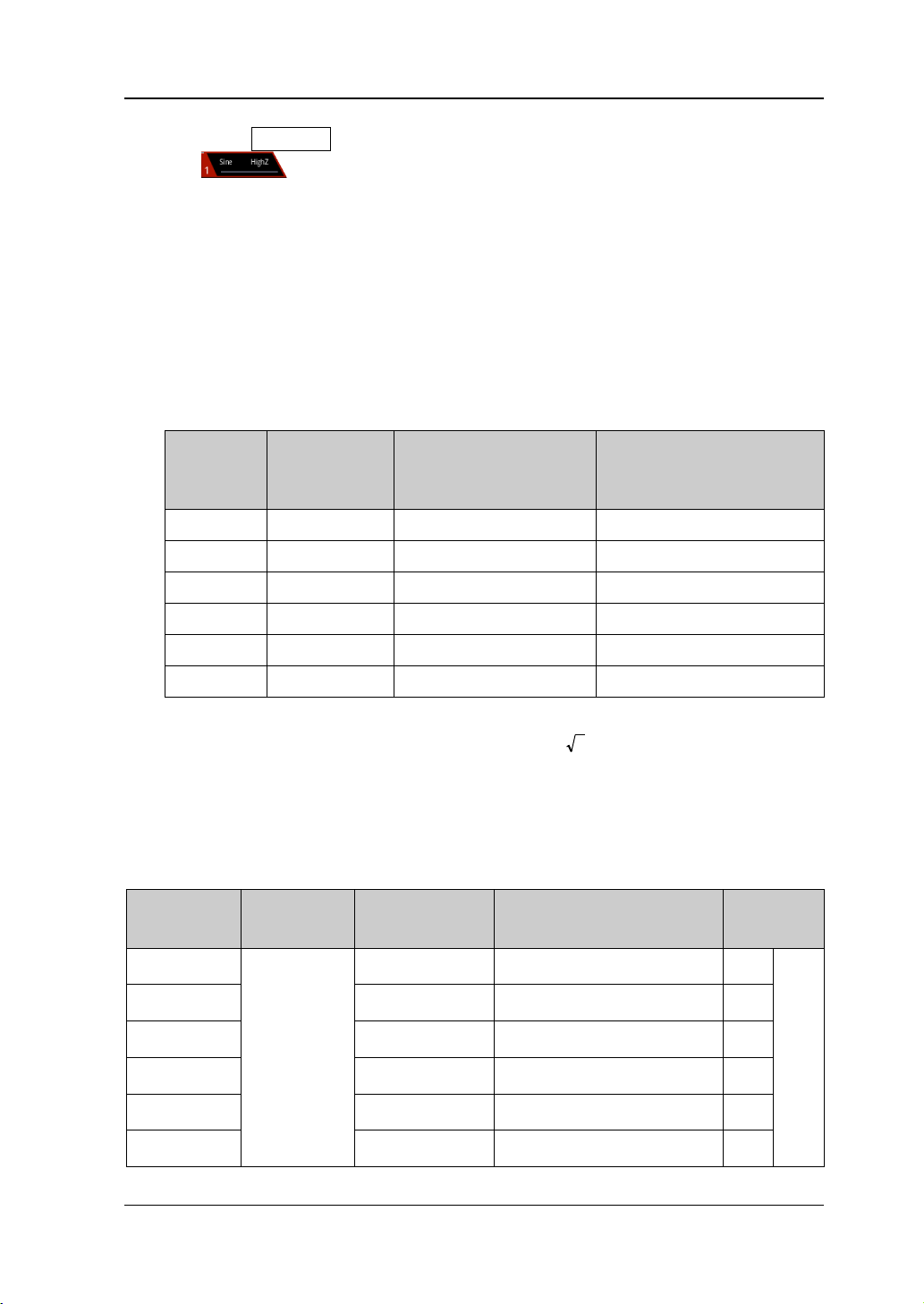

4. Set DG2000:

a) Set the output impedance of CH1 to 50Ω. (Tap the channel output

conf iguration status bar

channel setting interface. Tap the OutputSet HighZ to select "Off". Tap

the Impedance menu label, and set the impedanc e to 5 0Ω.)

b) Set the output waveform of CH1 to a sine waveform with 1kHz frequency,

5Vpp amplitude and 0V

offset.

dc

c) Press Output1 or tap the channel output configuration status bar

under the user interface to enter the

to turn on the output of CH1 in the channel setting interface.

5. Record the reading of the multimeter and judge whether it is within the

specif ication ("Offset" in Table 2-2) range.

6. Keep the out put i mpe da n ce of CH1 o f DG2000 at 50Ω and the output wave form

of CH1 as a sine waveform with 1kHz frequency and 5Vpp amplitude. Set the

offset of th e out put wa vef orm of C H1 t o -2.5V

and 2.5V

respectively. Record the readings of the multimeter respectively and

dc

judge whether the readings are within the specification ("Offset" in Table 2-2)

range.

, -1Vdc, -500mVdc, 500mVdc, 1Vdc

dc

DG2000 Performance Verification Guide

Page 19

Chapter 2 Performance Verification Test RIGOL

2-7

Offset Setting

Value

Amplitude

Setting Value

Offset

Value

Table 2-2 Offset limits of DC offset accuracy test

Allowed Error

[1]

Offset

[2]

-2.5Vdc

±0.080Vdc -2.580Vdc to -2.420Vdc

-1Vdc ±0.065Vdc -1.065Vdc to -0.935Vdc

-500mVdc ±0.060Vdc -0.560Vdc to -0.440Vdc

0Vdc ±0.055Vdc -0.055Vdc to 0.055Vdc

5Vpp

500mVdc ±0.060Vdc 0.440Vdc to 0.560Vdc

1Vdc ±0.065Vdc 0.935Vdc to 1.065Vdc

2.5Vdc ±0.080Vdc 2.420Vdc to 2.580Vdc

[1]

Note

: “Allowed Err or ” is calculated from the specification “± (1% of setting value + 5 mV + 1% of

amplitude)”.

[2]

Note

: Offset = offset setting value ± allowed error.

7. Repeat Step1-6 to test the DC offset accuracy of CH2 and record the test results.

Test Record Form

Setting

-2.5Vdc

Setting

Measurement

Value

Specification Pass/Fail

-2.580Vdc to -2.420Vdc

-1Vdc -1.065Vdc to -0.935Vdc

Frequency:

-500mVdc -0.560Vdc to -0.440Vdc

0Vdc -0.055Vdc to 0.055Vdc

500mVdc 0.440Vdc to 0.560Vdc

1kHz

Amplitude:

5Vpp

Impedance:

50Ω

1Vdc 0.935Vdc to 1.065Vdc

2.5Vdc 2.420Vdc to 2.580Vdc

DG2000 Performance Verification Guide

Page 20

RIGOL Chapter 2 Performance Verification Test

2-8

Typical (Sine, 1 Vpp)

>40 MHz: ±1 dB

]1

/)/[(10

ref

2

reading10

mWRVLogdBm ×=

AC Flatness Test

Specification

Output Characteristic

≤5 MHz: ±0.1 dB

Flatness

Test Procedures

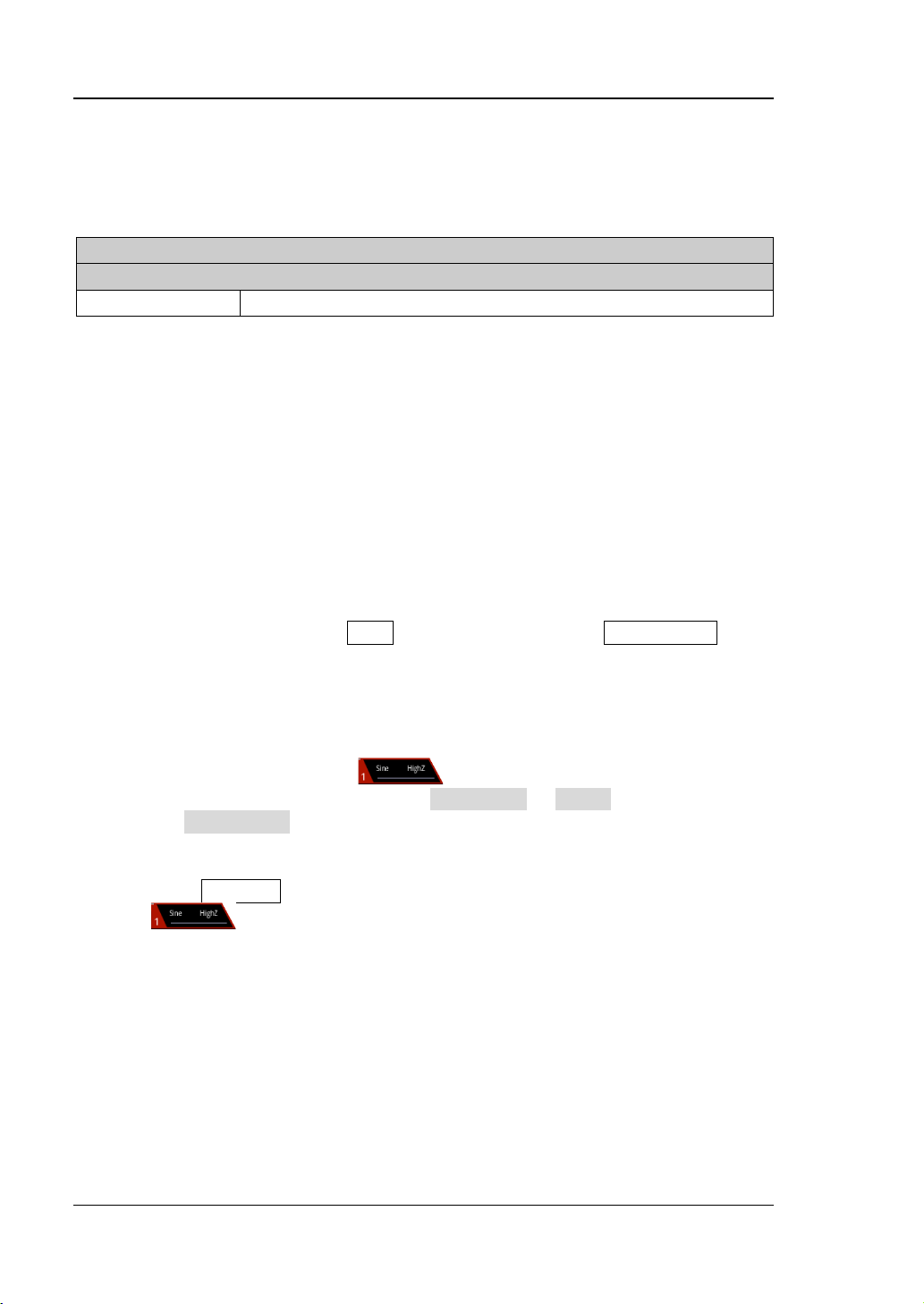

1. Make sure that the environment temperatu re is between 18℃ and 28℃ and

DG2000 has been warmed up for at least 30 minutes. Connect the 50Ω load to

the channel output terminal ( take CH1 as an example; the test method is also

applicable to CH2) of DG2000; connect the 50Ω lo ad and the voltage input

terminals of the digital multimeter using a BNC-Dual banana plug connecting

cable as shown in Figure 2-2.

2. Turn on DG2000. When the Shift key is illuminated, press Sine/Preset and

tap the Def icon, then a dialog box is displayed, tap "Apply" to restore DG2000

to the factory setting.

3. Set DG2000:

a) Set the output impedance of CH1 to 50Ω. (Tap the channel output

conf iguration status bar

channel setting interface. Tap the OutputSet HighZ to select "Off". Tap

the Impedance menu label, and set the impedanc e to 5 0Ω.)

b) Set the output waveform of CH1 to a sine waveform with 1kHz frequency

and 1Vpp amplitude.

c) Press Output1 or tap the channel output configuration status bar

≤15 MHz: ±0.2 dB

≤25 MHz: ±0.3 dB

≤40MHz: ±0.5 dB

under the user interface to enter the

4. Turn on the multimeter and select the ACV measurement function. Turn on the

dBm operation function and set the reference resistance to 50Ω. Rea d th e

measurement value and take it as the reference power (P

Tip:

In this step, if the dBm operation function is not turned on, you can also

calculate the reference power using the formula

to turn on the output of CH1 in the channel setting interface.

).

ref

according to the measurement value of

DG2000 Performance Verification Guide

Page 21

Chapter 2 Performance Verification Test RIGOL

2-9

reading

V

the multimeter.

Wherein,

is the measurement value of the multimeter.

5. Calibrate the power meter:

a) Connect the power sensor to the input ter minal and [POWER REF]

terminal of the power meter respectively.

b) Press Zero/Cal Zero Cal. Turn on power reference after t he

calibration finishes and observe whether the measurement value of the

power meter is a 0dBm, 50MHz signal.

c) Turn off power reference.

6. Disconnect DG2000 and the multimeter. Connect the power sensor and the

channel output terminal (take CH1 as an example; the test method is also

applicable t o CH 2) of DG2000 using a BNC (f)-N (m) adaptor, as shown in Figure

2-3.

DG2000 Series Power Meter

◎

Figure 2-3 Connect DG2000 a nd the Power Meter

7. Keep the output impe dance of CH1 of DG2000 at 50Ω. Set the output waveform

of CH1 as a sine waveform with 5MHz frequency and 1Vpp amplitu d e. S et the

frequency fa cto r of the po wer me ter to 5MHz, re cord the measurement value o f

the power meter and judge whether “measurement value-P

” is between

ref

-0.1dB and +0.1dB.

8. Keep the output impe dance of CH1 of DG2000 at 50Ω. Set the output waveform

of CH1 as a si ne waveform with 10MHz frequency and 1Vpp amplitude. Set the

frequency factor of the power meter to 10MHz, record the measurement value

of the power meter and judge whether “measur ement value-P

” is between

ref

-0.2dB and +0.2dB.

9. Keep the output impe dance of CH1 of DG2000 at 50Ω. Set the output waveform

of CH1 as a sine waveform with 15MHz frequency and 1Vpp amplitude. Set the

frequency factor of the power meter to 15MHz, record the me asurement va lue

of the power meter and judge whether “measurement value-P

” is between

ref

-0.2dB and +0.2dB.

DG2000 Performance Verification Guide

Page 22

RIGOL Chapter 2 Performance Verification Test

2-10

10. K ee p the output impe dance of CH 1 of DG2000 at 50Ω. Set the output waveform

of CH1 as a sine waveform with 20MHz frequency and 1Vpp amplitude. Set the

frequency factor of the power meter to 20MHz, recor d the measurement value

of the power meter and judge whether "measurement value-P

" is between

ref

-0.3dB and +0.3dB.

11. K ee p the output impe dance of CH 1 of DG2000 at 50Ω. Set the output waveform

of CH1 as a si ne waveform with 25MHz frequency and 1Vpp amplitude. Set the

frequency factor of the power meter to 25MHz, record the measurement value

of the power meter and judge whether "measurement value-P

" is between

ref

-0.3dB and +0.3dB.

12. K ee p the output impe dance of CH 1 of DG2000 at 50Ω. Set the output waveform

of CH1 as a si ne waveform with 30MHz frequency and 1Vpp amplitude. Set the

frequency factor of the power meter to 30MHz, record the measurement value

of the power meter and judge whether "measurement value-P

" is between

ref

-0.5dB and +0.5dB.

13. K ee p the output impe dance of CH 1 of DG2000 at 50Ω. Set the output waveform

of CH1 as a si ne waveform with 40MHz frequency and 1Vpp amplitude. Set the

frequency factor of the power meter to 40MHz, record the measurement value

of the power meter and judge whether "measurem ent value-P

" is between

ref

-0.5dB and +0.5dB.

14. K ee p the output impe dance of CH 1 of DG2000 at 50Ω. Set the output waveform

of CH1 as a si ne waveform with 50MHz frequency and 1Vpp amplitude. Set the

frequency factor of the power meter to 50MHz, record the measurement va lue

of the power meter and judge whether "measurement value-P

" is between

ref

-1dB and +1dB.

15. Repeat Step 1-14 to test the AC flatness of CH2 and record the test results.

DG2000 Performance Verification Guide

Page 23

Chapter 2 Performance Verification Test RIGOL

2-11

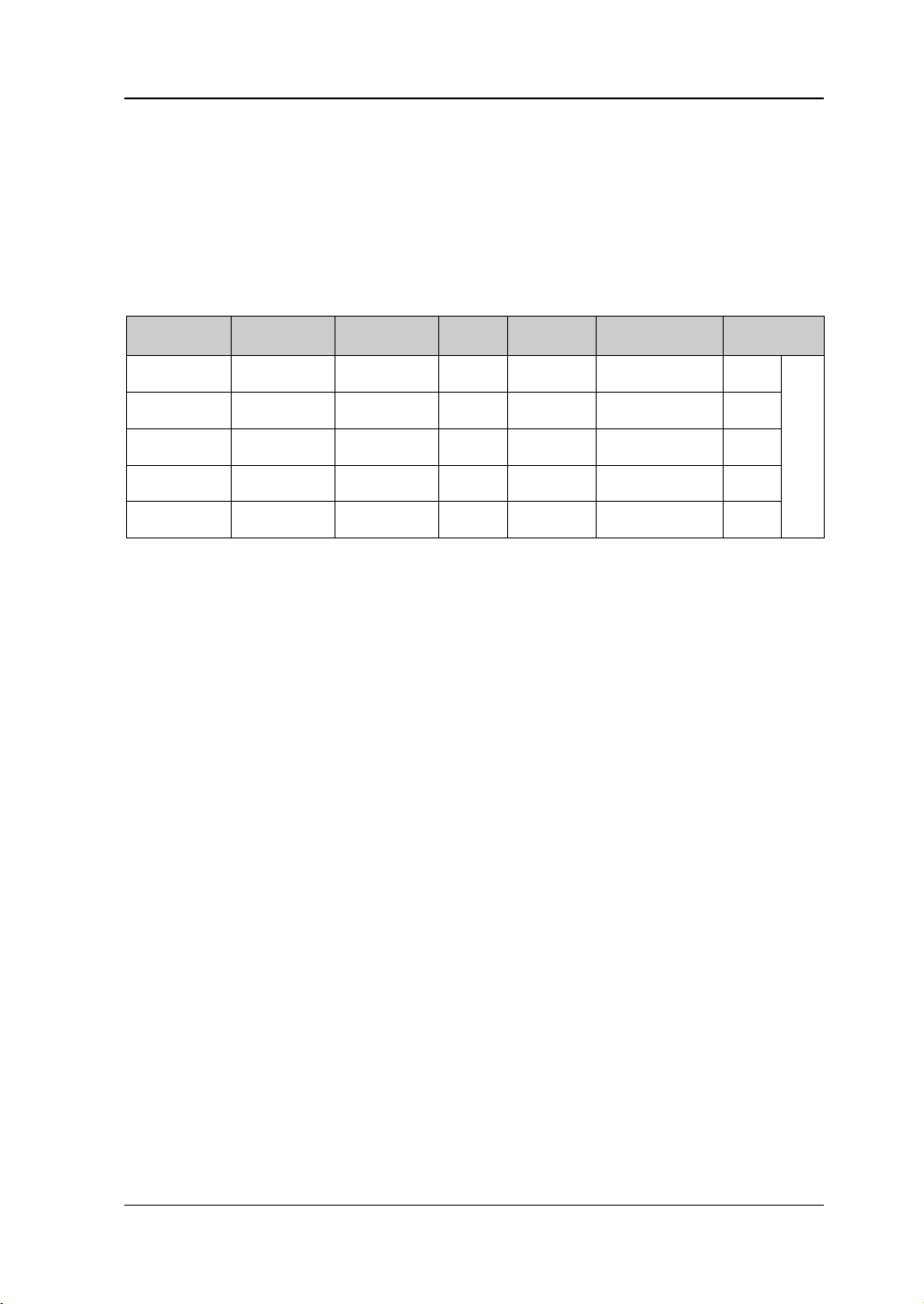

Frequency

Value

Test Record Form

Setting

5MHz

Setting

Measurement

Value

±0.1dB

Calculation

[1]

Result

Specification Pass/Fail

10MHz ±0.2dB

15MHz ±0.2dB

Amplitude:

20MHz ±0.3dB

25MHz ±0.3dB

1Vpp

Impedance:

50Ω

30MHz ±0.5dB

40MHz ±0.5dB

50MHz

[1]

Note

: Calculation result = Measurem en t value - P

±1dB

ref.

DG2000 Performance Verification Guide

Page 24

RIGOL Chapter 2 Performance Verification Test

2-12

Sine Wave Spectrum Purity

Typical

[1]

>40 MHz: <-35 dBc

Harmonic Distortion Test

Specification

DC to 10 MHz (included): <-55 dBc

Harmonic Distortion

[1]

Note

: 0 dBm output, DC offset 0, impedance 50 Ω.

Test Procedures

1. Make sure that the environment temperature is between 18℃ and 28℃ and

DG2000 has been warmed up for at least 30 minutes. Connect the channel

output terminal (take CH1 as an example; the test method is also applic ab le to

CH2) of DG2000 with the signal input terminal of the spectrum analyzer us ing a

dual-BNC connecting cable and N-BNC adaptor as shown in Figure 2-4.

DG2000 Series Spectrum Analyzer

10 MHz to 20 MHz (included): < -50 dBc

20 MHz to 40 MHz (included) : <-40 dBc

◎

Figure 2-4 Connect DG2000 and the Spectrum Analyzer

2. Turn on DG2000. When the Shift key is illuminated, press Sine/Preset and

tap the Def icon, then a dialog box is displayed, tap "Apply" to restore DG2000

to the factory setting.

3. Set DG2000:

a) Set the outp ut impedance of CH1 to 50Ω. (Tap the channel output

conf iguration status bar

under the user interface to enter the

channel setting interface. Tap the OutputSet HighZ to select "Off". Tap

the Impedance menu label, and set the impedanc e to 5 0Ω.)

b) Set the outpu t wav eform of CH 1 to a sine wa vefor m with 10 MHz frequen cy,

0dBm amplitude and 0V

offset.

dc

c) Press Output1 or tap the channel output configuration status bar

to turn on the output of CH1 in the channel setting interface.

DG2000 Performance Verification Guide

Page 25

Chapter 2 Performance Verification Test RIGOL

2-13

4. Turn on and set the sp e ctrum analyzer:

a) Set the reference level to 10dBm and input attenuation to 20dB.

b) Set the start frequency to 5MHz and stop frequency to 30MHz.

c) Set the resolution bandwidth to 3kHz.

5. Use the marker function to make measurements a n d record the measureme nt

values of the base waveform and 2

nd

order harmonic. Calculate

[2]

the harmonic

distortion and judge whether it is less than -55dBc.

6. Keep the output impe dance of CH1 of DG2000 at 50Ω. Set the output waveform

of CH1 as a sine waveform with 20MHz frequency, 0dBm amplitude and 0V

dc

offset.

7. Keep the reference level, input attenuation and resolution bandwidth of the

spectrum analyzer as 10dBm, 20dB and 3kHz respectively. Set its start

frequency to 10MHz and stop frequency to 60MHz.

8. Use the marker function to make measurements and rec o r d the measurement

values of the base waveform a nd 2

nd

order harmonic. Calculate

[2]

the harmonic

distortion and judge whether it is less than -50dBc.

9. Keep the output impe dance of CH1 of DG2000 at 50Ω. Set the output waveform

of CH1 as a sine waveform with 40MHz frequency, 0dBm amplitude and 0V

dc

offset.

10. Keep the input attenuation, reference level and resolution bandwidth of the

spectrum analyzer as 20dB, 10dBm and 3kHz respectively. Set its start

frequency to 30MH z and stop frequency to 130MHz.

11. Use the marker function to make measurements and reco r d the measurement

values of the base waveform a nd 2

nd

order harmonic. Calculate

[2]

the harmonic

distortion and judge whether it is less than -40dBc.

12. Keep the output impe dance of CH 1 of DG2000 at 50Ω. Set the output waveform

of CH1 as a sine waveform with 60MHz frequency, 0dBm amplitude and 0V

dc

offset.

13. Keep the input attenuation, reference level and resolution bandwidth of the

spectrum analyzer as 20dB, 10dBm and 3kHz respectively. Set its start

frequency to 50MH z and stop frequency to 150MHz.

14. Use the marker function to make measurements and recor d the measurement

values of the base waveform a nd 2

nd

order harmonic. Calculate

[2]

the harmonic

distortion and judge whether it is less than -35dBc.

15. Repeat Step 1-14 to test the harmonic distortion of CH2 and record the tes t

DG2000 Performance Verification Guide

Page 26

RIGOL Chapter 2 Performance Verification Test

2-14

Frequency

Value

2nd order

harmonic:

2nd order

harmonic:

2nd order

harmonic:

2nd order

harmonic:

results.

[2]

Note

: 2nd order harmonic distortion = 2nd order harmonic measurement value – base waveform

measurement value

For example, when the output waveform frequency of the channel is 10MHz, if the base

waveform measurement value is 0.8dBm and the 2

is -56.2dBm, the 2

nd

order harmonic distortion = (-56.2) -0.8=-57dBc<-55dBc and the

nd

order harmonic measurement value

test result fulfills the specification requirement.

Test Record Form

Setting

Setting

Measurement

Value

Calculation

[3]

Result

Specification Pass/Fail

Base waveform:

10MHz

<-55dBc

Base waveform:

20MHz

Waveform:

Sine

<-50dBc

Amplitude:

40MHz

0dBm

Offset: 0V

Base waveform:

dc

<-40dBc

Base waveform:

60MHz

[3]

Note

: Calculation result = 2th order harmonic measurement value - base waveform measurement value.

<-35dBc

DG2000 Performance Verification Guide

Page 27

Chapter 2 Performance Verification Test RIGOL

2-15

Sine Wave Spectrum Purity

Typical

[1]

>10 MHz: <-60 dBc + 6 dB/octave

Spurious Signal Test

Specification

Spurious signal

(non-harmonic)

[1]

Note

: 0 dBm output, DC offset 0, impedance 50 Ω.

[1]

Note

: 6 dBc/octave means that when the frequency doubles, the specification increases by 6 dBc. For example,

when the output frequency of DG2000 is 10MHz, the specification is <-60dBc and when the output frequency

is 30MHz, the specif ic a t io n is <-60dBc+2×6dBc, namely <-48dBc.

≤10 MHz: <-60 dBc

[2]

Test Procedures

1. Make sure that the environment temperatu re is between 18℃ and 28℃ and

DG2000 has been warmed up for a t least 30 minutes. Connect the channel

output terminal (take CH1 as an example; the test method is also applic ab le to

CH2) of DG2000 with the RF input terminal of the spectrum analy zer using a

dual-BNC cable and N-BNC adaptor as shown in Figure 2-4.

2. Turn on DG2000. When the Shift key is illuminated, press Sine/Preset and

tap the Def icon, then a dialog box is displayed, tap "Apply" to restore DG2000

to the factory setting.

3. Set DG2000:

a) Set the output impedance of CH1 to 50Ω. (Tap the channel output

conf iguration status bar

channel setting interface. Tap the OutputSet HighZ to select "Off". Tap

the Impedance menu label, and set the impedanc e to 5 0Ω.)

b) Set the output waveform of CH1 to a sine waveform with 5MHz frequency,

0dBm amplitude and 0V

offset.

dc

d) Press Output1 or tap the channel output configuration status bar

under the user interface to enter the

4. Turn on and set the spectrum analyzer :

a) Set the reference level to 10dBm and input attenuation to 20dB.

b) Set the start frequency to 0Hz and stop frequency to 30MHz.

c) Set the resolution bandwidth to 1kHz.

d) Set the peak offset to 3dB.

e) Set the sweep mode to single.

5. After the spectrum analyzer finishes a sweep, use Peak and the marker

function to measure the maximum spurious signal (except harmonics) and

DG2000 Performance Verification Guide

to turn on the output of CH1 in the channel setting interface.

Page 28

RIGOL Chapter 2 Performance Verification Test

2-16

record the measurement result as A. Calcul ate the non-harmonic sp urious signal

(A-0dBm) and judge whether it is within the specification range.

6. Keep the output impedance of CH1 of DG2000 at 50Ω. Set the output waveform

of CH1 as a si ne waveform with 10MHz frequency, 0dBm amplitude and 0V

dc

offset.

7. Keep the reference level, input attenuation, resolution bandwidth, peak offset

and sweep mode of the spectrum analyzer as 10dBm, 20dB, 1kHz, 3dB and

single respectively. Set its start frequency to 0Hz and stop frequency to 50MHz.

8. Press Sweep/Trig Single to perform a sweep.

9. After the spectrum analyzer finishes a sweep, use Peak and the marker

function to measure the maximum spurious signal (except harmonics) and

record the measurement result as A. Calcul ate the non-harmonic sp urious signal

(A-0dBm) and judge whether it is within the specification range.

10. K ee p the output impe dance of CH 1 of DG2000 at 50Ω. Set the output waveform

of CH1 as a si ne waveform with 20MHz frequency, 0dBm amplitude and 0V

dc

offset.

11. Keep the reference level, input attenuation, resolution bandwidth, peak offset

and sweep mode of the spectrum analyzer as 10dBm, 20dB, 1kHz, 3dB and

single respectively. Set its start fre quency to 0Hz and stop frequency to 100MHz.

12. Repeat Step 8 and 9.

13. K ee p the output impe dance of CH 1 of DG2000 at 50Ω. Set the output waveform

of CH1 as a si ne waveform with 30MHz frequency, 0dBm amplitude and 0V

dc

offset.

14. Keep the reference level, input attenuation, resolution bandwidth, peak offset

and sweep mode of the spectrum analyzer as 10dBm, 20dB, 1kHz, 3dB and

single respectively. Set its start fre quency to 0Hz and stop frequency to 150MHz.

15. Repeat Step 8 and 9.

16. K ee p the output impe dance of CH 1 of DG2000 at 50Ω. Set the output waveform

of CH1 as a sine waveform with 60MHz frequency, 0dBm amplitude and 0V

dc

offset.

17. Keep the reference level, input attenuation, resolution bandwidth, peak offset

and sweep mode of the spectrum analyzer as 10dBm, 20dB, 1kHz, 3dB and

single respectively. Set its start fre quency to 0Hz and stop frequency to 300MHz.

DG2000 Performance Verification Guide

Page 29

Chapter 2 Performance Verification Test RIGOL

2-17

Output

Frequency

Start

Frequency

Stop

Frequency

18. Repeat Step 8 and 9.

19. Repeat Step 1-18 to test the spurious signal (non-harmonic) of CH2 and record

the test results.

Test Record Form

A A-0dBm Specification Pass/Fail

5MHz 0Hz 30MHz <-60dBc

10MHz 0Hz 50MHz <-60dBc

20MHz 0Hz 100MHz <-54dBc

30MHz 0Hz 150MHz <-48dBc

60MHz

0Hz 300MHz <-30dBc

DG2000 Performance Verification Guide

Page 30

RIGOL Chapter 2 Performance Verification Test

2-18

Typical (1 Vpp, 1 kHz)

≤9 ns

Rise/Fall Time Test

Specification

Signal Characteristic

Square

Rise/Fall Time

Test Procedures

1. Make sure that the environment temperatu re is between 18℃ and 28℃ and

DG2000 has been warmed up for at least 30 minutes. Connect the channel

output terminal (take CH1 as an example; the test method is also ap p licable to

CH2) of DG2000 with the signal input terminal o f the oscilloscope using a

dual-BNC connecting cable as shown in Figure 2-5.

DG2000 Series Oscilloscope

◎

Figure 2-5 Connect DG2000 and the Oscilloscope

2. Turn on DG2000. When the Shift key is illuminated, press Sine/Preset and

tap the Def icon, then a dialog box is displayed, tap "Apply" to restore DG2000

to the factory setting.

3. Set DG2000:

a) Set the output impedance of CH1 to 50Ω. (Tap the channel output

conf iguration status bar

under the user interface to enter the

channel setting interface. Tap the OutputSet HighZ to select "Off". Tap

the Impedance menu label, and set the impedanc e to 50Ω.)

b) Set the output w av eform o f CH1 to a square waveform with 1kHz frequency,

1Vpp amplitude and 0V

offset.

dc

c) Press Output1 or tap the channel output configuration status bar

to turn on the output of CH1 in t he channel setting interface.

4. Turn on and set the oscilloscope:

a) Set the ver tica l scale to 200mV/div.

DG2000 Performance Verification Guide

Page 31

Chapter 2 Performance Verification Test RIGOL

2-19

Measurement

Value

b) Set the horizontal time base to 1us.

c) Adjust the trigger level to a proper value.

d) Set the input impedance to 50Ω.

e) Turn on the rise time and fall time measurement functions.

5. Set the edge type of the oscilloscope to rising edge, record the measur ement

result of the rise time and judge whether it is within the specification range.

6. Set the edge type of the oscilloscope to falling edge, record the measurement

result of the fall time and judge whether it is within the specification range.

7. Repeat Step 1-6 to test the rise/fall time of CH2 and record the measurement

results.

Test Record Form

Waveform Setting

Frequency: 1kHz

Square

Amplitude: 1Vpp

Offset: 0Vdc

Rise Time

Fall Time

Specification Pass/Fail

Typical (1 Vpp, 1

kHz)

≤9 ns

DG2000 Performance Verification Guide

Page 32

RIGOL Chapter 2 Performance Verification Test

2-20

Typical (100kHz, 1Vpp)

≤5%

Overshoot Test

Specification

Signal Characteristic

Square

Overshoot

Test Procedures

1. Make sure that the environment temperature is between 18℃ and 28℃ and

DG2000 has been warmed up for at least 30 minutes. Connect the channel

output terminal (take CH1 as an example; the test method is also app licable to

CH2) of DG2000 with the signal input terminal o f the oscilloscope using a

dual-BNC conne cting cable as s hown in Figure 2-5.

2. Turn on DG2000. When the Shift key is illuminated, press Sine/Preset and

tap the Def icon, then a dialog box is displayed, tap "Apply" to restore DG2000

to the factory setting.

3. Set DG2000:

a) Set the output impedance of CH1 to 50Ω. (Tap the channel output

conf iguration status bar

channel setting interface. Tap the OutputSet HighZ to select "Off". Tap

the Impedance menu label, and set the impedanc e to 5 0Ω.)

b) Set the output waveform of CH1 to a square waveform with 100kHz

frequency, 1Vpp amplitude and 0V

c) Press Output1 or tap the channel output configuration status bar

under the user interface to enter the

offset.

dc

4. Turn on and set the oscilloscope:

a) Set the inpu t impe dance to 50Ω.

b) Set the vertical scale to 200mV/div.

c) Set the horizontal time base to 50ns.

d) Adjust the trigger level to a proper value.

e) Turn on the overshoot measurement function.

5. Record the overshoot measurement value and judge whether it is within the

specification range.

6. Repeat Step 1-5 to test the overshoot of CH2 and rec o rd the meas urement

result.

to turn on the output of CH1 in the channel setting interface.

DG2000 Performance Verification Guide

Page 33

Chapter 2 Performance Verification Test RIGOL

2-21

dc

Test Record Form

Waveform Setting Measurement Value Specification Pass/Fail

Square

Frequency: 100kHz

Amplitude: 1Vpp

Offset: 0V

Typical (100kHz,

1Vpp)

≤5%

DG2000 Performance Verification Guide

Page 34

Page 35

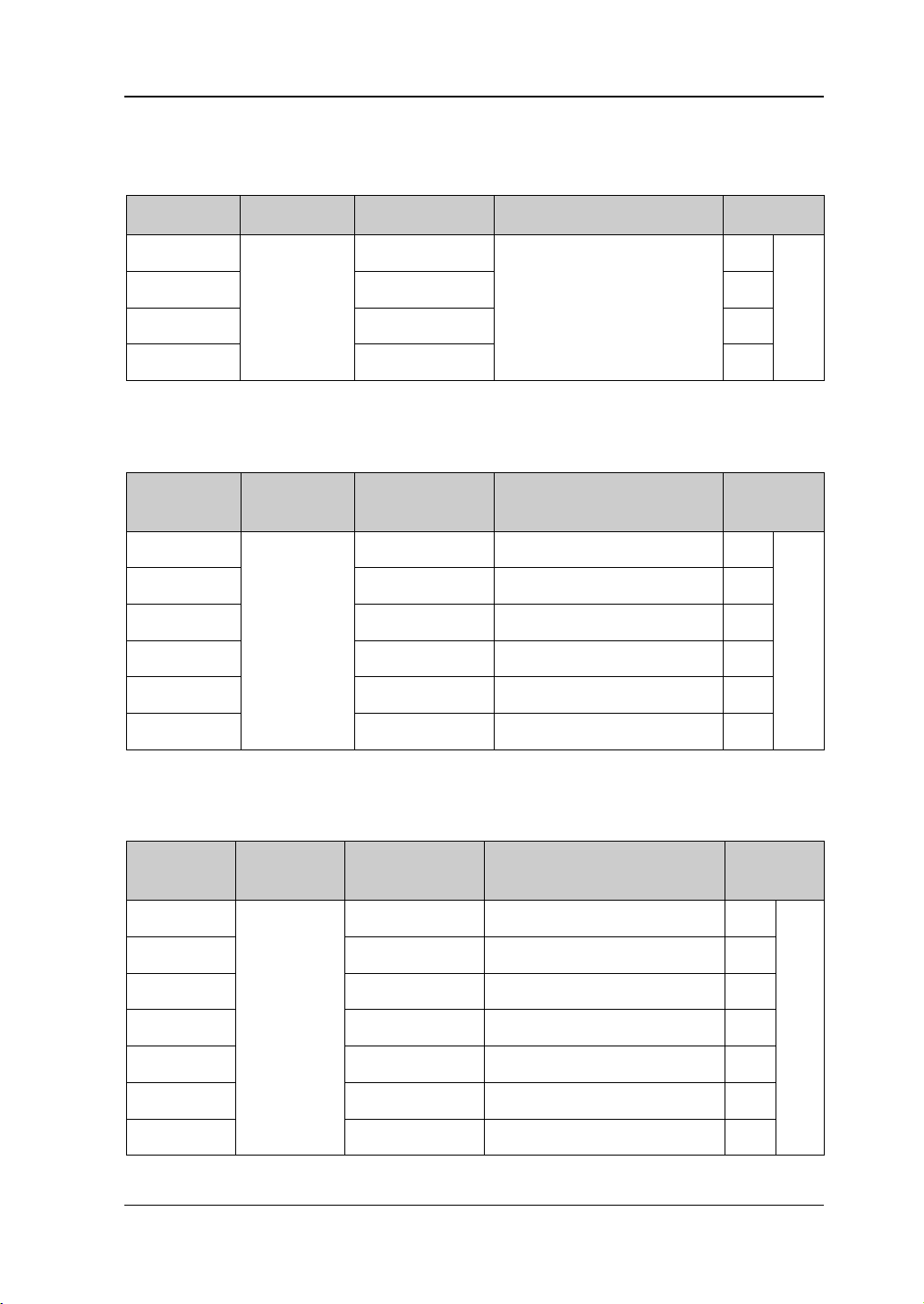

Appendix RIGOL

1

Model:

Tested by:

Test Date:

Setting

Value

Measurement

Value

Amplitude

Value

Appendix

Appendix A: Test Result Record Form

RIGOL DG2000 Series Function/Arbitrary Waveform Generator

Performance Verification Test Record Form

Channel: CH1

Frequency Accuracy Test

Waveform

Sine

Square

Ramp

Pulse

Frequency:

1MHz

Amplitude:

1Vpp

Specification Pass/Fail

0.999 998 999 999 999

99MHz to 1.000 001 000 000

000 01MHz

AC Amplitude Accuracy Test

Setting

20mVpp

100mVpp 33.2mVrms to 37.5mVrms

500mVpp 173.3mVrms to 180.3mVrms

1Vpp 348.3mVrms to 358.9mVrms

5Vpp 1.75Vrms to 1.7875Vrms

10Vpp 3.5Vrms to 3.5732Vrms

Setting

Frequency:

1kHz

Offset: 0V

Impedance:

50Ω

Measurement

Value

5.2mVrms to 8.9mVrms

dc

Specification Pass/Fail

DG2000 Performance Verification Guide

Page 36

RIGOL Appendix

2

Offset

Value

Frequency

Value

DC Offset Accuracy Test

Setting

-2.5Vdc

-1Vdc -1.065Vdc to -0.935Vdc

-500mVdc -0.560Vdc to -0.440Vdc

0Vdc -0.055Vdc to 0.055Vdc

500mVdc 0.440Vdc to 0.560Vdc

1Vdc 0.935Vdc to 1.065Vdc

2.5Vdc 2.420Vdc to 2.580Vdc

Setting

Frequency:

1kHz

Amplitude:

5Vpp

Impedance:

50Ω

Measurement

Value

-2.580Vdc to -2.420Vdc

Specification Pass/Fail

AC Flatness Test

Setting

5MHz

10MHz ±0.2dB

Setting

Measurement

Value

±0.1dB

Calculation

[1]

Result

Specification Pass/Fail

15MHz ±0.2dB

20MHz ±0.3dB

25MHz ±0.3dB

30MHz ±0.5dB

40MHz ±0.5dB

50MHz

[1]

Note

: Calculation result = Measurement value - P

Amplitude:

1Vpp

Impedance:

50Ω

±1dB

.

ref

DG2000 Performance Verification Guide

Page 37

Appendix RIGOL

3

Frequency

Value

2nd order

harmonic:

2nd order

harmonic:

2nd order

harmonic:

2nd order

harmonic:

Output

Frequency

Start

Frequency

Stop

Frequency

Harmonic Distortion Test

Setting

Setting

Measurement

Value

Calculation

[1]

Result

Specification Pass/Fail

Base waveform:

10MHz

<-55dBc

Base waveform:

20MHz

Waveform:

Sine

<-50dBc

Amplitude:

0dBm

40MHz

[2]

60MHz

[1]

Note

: Calculation result = 2th order harmonic measurement value - base waveform measurement value.

[2]

Note

: Only applicable to DG2102 and DG2072.

Offset: 0Vdc

Base waveform:

<-40dBc

Base waveform:

<-35dBc

Spurious Signal Test

A A-0dBm Specification Pass/Fail

5MHz 0Hz 30MHz <-60dBc

10MHz 0Hz 50MHz <-60dBc

20MHz 0Hz 100MHz <-54dBc

30MHz 0Hz 150MHz <-48dBc

[1]

60MHz

[1]

Note

: Only applicable to DG2102 and DG2072.

0Hz 300MHz <-30dBc

Rise/Fall Time Test

Waveform Setting Measurement Value Specification Pass/Fail

Square

Frequency: 1kHz

Amplitude: 1Vpp

Offset: 0Vdc

Rise Time

Fall Time

Typical (1 Vpp, 1

kHz)

≤9 ns

DG2000 Performance Verification Guide

Page 38

RIGOL Appendix

4

dc

Overshoot Test

Waveform Setting Measurement Value Specification Pass/Fail

Square

Frequency: 100kHz

Amplitude: 1Vpp

Offset: 0V

Typical (100kHz,

1Vpp)

≤5%

DG2000 Performance Verification Guide

Page 39

Appendix RIGOL

5

Setting

Value

Measurement

Value

Amplitude

Value

Offset

Value

Channel: CH2

Frequency Accuracy Test

Waveform

Sine

Square

Ramp

Pulse

Frequency:

1MHz

Amplitude:

1Vpp

Specification Pass/Fail

0.999 998 999 999 999

99MHz to 1.000 001 000 000

000 01MHz

AC Amplitude Accuracy Test

Setting

20mVpp

100mVpp 33.2mVrms to 37.5mVrms

500mVpp 173.3mVrms to 180.3mVrms

1Vpp 348.3mVrms to 358.9mVrms

5Vpp 1.75Vrms to 1.7875Vrms

10Vpp 3.5Vrms to 3.5732Vrms

Setting

Frequency:

1kHz

Offset: 0V

Impedance:

50Ω

Measurement

Value

5.2mVrms to 8.9mVrms

dc

Specification Pass/Fail

DC Offset Accuracy Test

Setting

-2.5Vdc

-1Vdc -1.065Vdc to -0.935Vdc

-500mVdc -0.560Vdc to -0.440Vdc

0Vdc -0.055Vdc to 0.055Vdc

500mVdc 0.440Vdc to 0.560Vdc

1Vdc 0.935Vdc to 1.065Vdc

2.5Vdc 2.420Vdc to 2.580Vdc

DG2000 Performance Verification Guide

Setting

Frequency:

1kHz

Amplitude:

5Vpp

Impedance:

50Ω

Measurement

Value

-2.580Vdc to -2.420Vdc

Specification Pass/Fail

Page 40

RIGOL Appendix

6

Frequency

Value

Frequency

Value

2nd order

harmonic:

2nd order

harmonic:

2nd order

harmonic:

2nd order

harmonic:

AC Flatness Test

Setting

5MHz

Setting

Measurement

Value

±0.1dB

Calculation

[1]

Result

Specification Pass/Fail

10MHz ±0.2dB

15MHz ±0.2dB

Amplitude:

20MHz ±0.3dB

25MHz ±0.3dB

1Vpp

Impedance:

50Ω

30MHz ±0.5dB

40MHz ±0.5dB

50MHz

[1]

Note

: Calculation result = Measurement value - P

±1dB

.

ref

Harmonic Distortion Test

Setting

10MHz

Setting

Measurement

Value

Base waveform:

Calculation

[1]

Result

Specification Pass/Fail

<-55dBc

20MHz

Waveform:

Sine

<-50dBc

Amplitude:

Base waveform:

0dBm

40MHz

[2]

60MHz

[1]

Note

: Calculation result = 2th order harmonic measurement value - base waveform measurement value.

[2]

Note

: Only applicable to DG2102 and DG2072.

Offset: 0V

Base waveform:

dc

Base waveform:

<-40dBc

<-35dBc

DG2000 Performance Verification Guide

Page 41

Appendix RIGOL

7

Output

Frequency

Start

Frequency

Stop

Frequency

dc

Spurious Signal Test

A A-0dBm Specification Pass/Fail

5MHz 0Hz 30MHz <-60dBc

10MHz 0Hz 50MHz <-60dBc

20MHz 0Hz 100MHz <-54dBc

30MHz 0Hz 150MHz <-48dBc

[1]

60MHz

[1]

Note

: Only applicable to DG2102 and DG2072.

0Hz 300MHz <-30dBc

Rise/Fall Time Test

Waveform Setting Measurement Value Specification Pass/Fail

Square

Frequency: 1kHz

Amplitude: 1Vpp

Offset: 0V

dc

Rise Time

Fall Time

Typical (1 Vpp, 1

kHz)

≤9 ns

Overshoot Test

Waveform Setting Measurement Value Specification Pass/Fail

Square

Frequency: 100kHz

Amplitude: 1Vpp

Offset: 0V

Typical (100kHz,

1Vpp)

≤5%

DG2000 Performance Verification Guide

Page 42

RIGOL Appendix

8

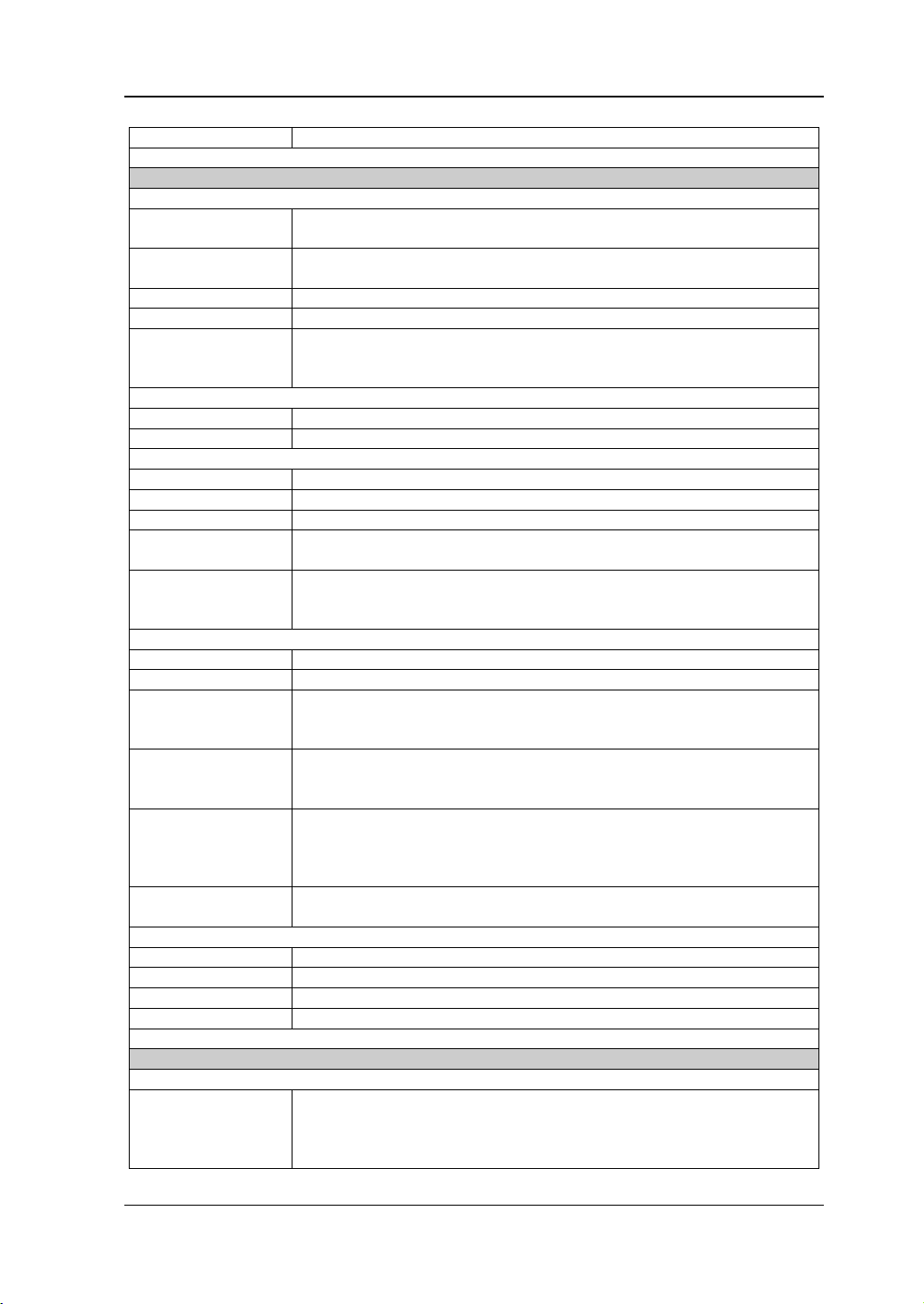

Model

DG2052

DG2072

DG2102

Channel

2 2 2

Max. Frequency

50 MHz

70 MHz

100 MHz

Sample Rate

250 MSa/s

Waveform

Basic Waveforms

Sine, Square, Ramp, Pulse, Noise, DC, Dual-tone

Advanced

Waveforms

Built-in Arbitrary

Waveforms

160 types of waveforms, including Sinc, Exponential Rise, Exponential

Fall, ECG, Gauss, HaverSine, Lorentz, etc.

Frequency Characteristics

Sine

1 μHz to 50 MHz

1 μHz to 70 MHz

1 μHz to 100 MHz

Square

1 μHz to 15 MHz

1 μHz to 20 MHz

1 μHz to 25 MHz

Pulse

1 μHz to 15 MHz

1 μHz to 20 MHz

1 μHz to 25 MHz

Harmonic

1 μHz to 20 MHz

1 μHz to 20 MHz

1 μHz to 25 MHz

PRBS

2 kbps to 40 Mbps

2 kbps to 50 Mbps

2 kbps to 60 Mbps

Dual-tone

1 μHz to 20 MHz

1 μHz to 20 MHz

1 μHz to 20 MHz

baud rate range: 9600, 14400, 19200, 38400, 57600, 115200, 128000,

230400

Sequence

2 k to 60 MSa/s

Noise (-3 dB)

100 MHz bandwidth

Arbitrary Wavef orm

1 μHz to 15 MHz

1 μHz to 20 MHz

1 μHz to 20 MHz

Resolution

1 μHz

Sine Wave Spectrum Purity

Typical

[1]

>40 MHz: <-35 dBc

Total Harmonic

Distortion

Typical

[1]

>10 MHz: <-60 dBc + 6 dB/octave

Phase Noise

Typical (0 dBm, 10 kHz offset)

Appendix B: Performance Specifications

Unless otherwise specified, all the specifications can be guaranteed when the

following two conditions are met.

The signal generator is within the calibration period.

The signal generator has been running ceaselessly for over 30 minutes under

the sp ecif ied operati ng temperature (23℃±5℃).

All the specifications are guaranteed except the parameters marked with "Typical".

PRBS, RS232, Sequence

Ramp 1 μHz to 1.5 MHz 1 μHz to 1.5 MHz 1 μHz to 2 MHz

RS232

Accuracy

Harmonic Distortion

[1]

Spurious

(non-harmonic)

±(1 ppm of the setting value + 10 pHz), 18℃ to 28℃

DC to 10 MHz (included): <-55 dBc

10 MHz to 20 MHz (included): <-50 dBc

20 MHz to 40 MHz (included): <-40 dBc

<0.075% (10 Hz to 20 kHz)

≤10 MHz: <-60 dBc

DG2000 Performance Verification Guide

Page 43

Appendix RIGOL

9

10 MHz: <-105 dBc/Hz

Signal Characteristics

Square

Typical (1 Vpp, 1 kHz)

≤9 ns

Typical (100 kHz, 1 Vpp)

≤5%

Duty

0.01% to 99.99% (limited by the current frequency setting)

Non-symmetry

1% of the period + 4 ns

Typical (1 Vpp)

>5 MHz: 200 ps

Ramp

Linearity

≤1% of peak output (typical, 1 kHz, 1 VPP, 100% symmetry)

Symmetry

0% to 100%

Pulse

Pulse

16 ns to 1000 ks (limited by the current frequency setting)

Duty

0.001% to 99.999% (limited by the current frequency setting)

Rising/Falling Edge

≥8 ns (limited by the current frequency setting and pulse width setting)

Typical (1 Vpp, 1 kHz)

≤5%

Typical (1 Vpp)

>5 MHz: 200 ps

Arbitrary Waveform Sequence

Waveform Length

16 Mpts

Vertical Resolution

16 bits

Interpolation filter: 10 Sa/s to 60 MSa/s

Smooth filter: 2k Sa/s to 50 MSa/s

Interpolation f ilter: ≥8 ns

Smooth filter: 1.0/sample rate

Typical (1 Vpp)

Smooth filter: <5 ps

Typical (1 Vpp)

≤5%

Harmonic Output

Harmonic Order

≤8

Harmonic Type

Even Harmonic, Odd Harmonic, Order Harmonic, User

Harmonic Amplitude

The amplitude of each order of the harmonic can be set.

Harmonic Phase

The phase of each order of harmonic can be set.

Output Characteristics

Amplitude (into 50 Ω)

≤10 MHz: 1.0 mVpp to 10 Vpp

>60 MHz: 1.0 mVpp to 1 Vpp

Rise/Fall Time

Overshoot

Jitter (rms)

Overshoot

Jitter (rms)

Sample Rate

Min Rise/Fall Time

Jitter (rms)

≤5 MHz: 2 ppm of the period + 200 ps

≤5 MHz: 2 ppm of the per iod + 200 ps

Step filter: 2k Sa/s to 50 MSa/s

Step filter: 3.0/sample rate

Interpolation filter: 200 ps

Step filter: <5 ps

Overshoot

Range

DG2000 Performance Verification Guide

≤30 MHz: 1.0 mVpp to 5.0 Vpp

≤60 MHz: 1.0 mVpp to 2.5 Vpp

Page 44

RIGOL Appendix

10

Typical (1 kHz sine, 0 V offset, >10 mVpp, auto)

±(1% of the setting value) ± 5 mV

Typical (Sine, 1 Vpp)

>40 MHz: ±1 dB

Unit

Vpp, Vrms, dBm

Resolution

0.1 mVpp or 4 digits

Offset (into 50 Ω)

Range (Peak ac+dc)

±5 Vpk ac+dc

Accuracy

±(1% of the setting value + 5 mV + 1% of the amplitude)

Waveform Output

Output Impedance

50 Ω (typical)

Short-circuit protection, automatically disable the waveform output

when overload occurs

Modulation Characteristics

Modulation Type

AM, FM, PM, ASK, FSK, PSK, PWM

AM

Carrier Waveform

Sine, Square, Ramp, Arb

Source

Internal/External

Modulating

Waveform

Modulation Depth

0% to 120%

Modulation

Frequency

FM

Carrier Waveform

Sine, Square, Ramp, Arb

Source

Internal/External

Modulating

Waveform

Modulation

Frequency

PM

Carrier Waveform

Sine, Square, Ramp, Arb

Source

Internal/External

Modulating

Waveform

Phase Deviation

0° to 360°

Modulation

Frequency

ASK

Carrier Waveform

Sine, Square, Ramp, Arb

Source

Internal/External

Modulating

Waveform

Key Frequency

2 mHz to 1 MHz

FSK

Carrier Waveform

Sine, Square, Ramp, Arb

Source

Internal/External

Accuracy

≤5 MHz: ±0.1 dB

Flatness

Protection

≤15 MHz: ±0.2 dB

≤25 MHz: ±0.3 dB

≤40MHz: ±0.5 dB

Sine, Square, Ramp, Noise, Arb

2 mHz to 1 MHz

Sine, Square, Ramp, Noise, Arb

2 mHz to 1 MHz

Sine, Square, Ramp, Noise, Arb

2 mHz to 1 MHz

Square with 50% duty cycle

DG2000 Performance Verification Guide

Page 45

Appendix RIGOL

11

Modulating

Waveform

Key Frequency

2 mHz to 1 MHz

PSK

Carrier Waveform

Sine, Square, Ramp, Arb

Source

Internal/External

Modulating

Waveform

Key Frequency

2 mHz to 1 MHz

PWM

Carrier Waveform

Pulse

Source

Internal/External

Modulating

Waveform

Width Deviation

0% to 100% of the pulse width

Modulation

Frequency

External Modulation Input

AM, PM, FM: 75 mVRMS to ±5 (Vac+dc)

ASK, PSK, FSK: standard 5 V TTL

Input Bandwidth

50 kHz

Input Impedance

10 kΩ

Burst Characteristics

Sine, Square, Ramp, Pulse, Noise, Arb, PRBS, RS232, Sequence (except

DC, dual-tone, and Harmonic)

Carrier Frequency

2 mHz to 50 MHz

2 mHz to 70 MHz

2 mHz to 100 MHz

Burst Count

1 to 1,000,000 or Infinite

Internal Period

1 μs to 500 s

Gated Source

External Trigger

Source

Internal, External, Manual

Trigger Delay

0 ns to 100 s

Sweep Characteristics

Carrier Waveform

Sine, Square, Ramp, Arb

Type

Linear, Log, and Step

Orientation

Up/Down

Start/Stop

Frequency

Sweep Time

1 ms to 500 s

Hold/Return Time

0 ms to 500 s

Source

Internal, External, Manual

Marker

Falling edge of the sync signal (programmable)

Measurement

Function

Frequency

Resolution

Square with 50% duty cycle

Square with 50% duty cycle

Sine, Square, Ramp, Noise, Arb

2 mHz to 1 MHz

Input Range

Carrier Waveform

Same as the upper/lower limit of the corresponding carrier frequency

Frequency Counter

Frequency, Period, Positive/Negative Pulse Width, Duty Cycle

7 digits/s (Gate Time = 1 s)

Frequency Range 1 μHz to 240 MHz

DG2000 Performance Verification Guide

Page 46

RIGOL Appendix

12

Period

Measurement

Frequency and

Amplitude Ranges

50 mVRMS to ±2.5

(Vac+dc)

Pulse Width

Resolution

Measurement Range

(display)

Input

MΩ

High Frequency

Rejection

On: Input Bandwidth = 150 kHz;

Off: Input Bandwidth = 240 MHz

Trigger Sensitivity

Range

Trigger Characteristics

Trig Input

Level

TTL-compatible

Slope

Rising or falling (selectable)

Pulse Width

>100 ns

Sweep: <100 ns (typical)

Burst: <350 ns (typical)

Trigger Output

Measurement Range 4 ns to 1,000 ks

Voltage Range and Sensitivity (non-modulating signal)

DC Offset Range ±1.5 Vdc

DC Coupling

AC Coupling

Pulse Width and Duty Cycle Measurement

Duty

Input Characteristics

Input Signal Range Breakdown Voltage ±7 (Vac+dc)

Input Adjustment

Input Trigger

1 μHz to 100 MHz 50 mVRMS to ±2.5 (Vac+dc)

100 MHz to 240 MHz 100 mVRMS to ±2.5 (Vac+dc)

1 μHz to 100 MHz 50 mVRMS to ±2.5 Vpp

100 MHz to 240 MHz 100 mVRMS to ±2.5 Vpp

1 μHz to 25 MHz

Min. Pulse Width ≥20 ns

5 ns

0% to 100%

Coupling Mode AC DC

Trigger Level Range -2.5 V to +2.5 V

High, Low

DC Coupling Pulse Width

Impedance = 1

GateTime

Latency

1 ms 1.048 ms

10 ms 8.389 ms

100 ms 134.218 ms

1 s 1.074 s

10 s 8.590 s

>10 s >8.590 s

DG2000 Performance Verification Guide

Page 47

Appendix RIGOL

13

Level

TTL-compatible

Pulse Width

>60 ns (typical)

Max. Frequency

1 MHz

Waveform Phase

Resolution

Reference Clock

External Reference Input

Lock Range

10 MHz ± 50 Hz

Level

250 mVpp to 5 Vpp

Lock Time

<2 s

Input Impedance

(Typical)

Internal Reference Output

Frequency

10 MHz ± 50 Hz

Level

3.3 Vpp

Output Impedance

(Typical)

Synchronous Output

Level

TTL-compatible

Impedance

50 Ω, nominal value

Overvoltage Protection

Occurred when:

kHz). Disruptive discharge voltage: ±5(Vac + dc).

Overcurrent Protection

Occurred when: the current is greater than ±240 mA.

Programming Time

Configuration

Changes

USB

Function Change

10 ms

Amplitude Change

5 ms

Frequency Change

5 ms

General Specifications

Power Supply

100 V to 127 V (45 Hz to 440 Hz)

100 V to 240 V (45 Hz to 65Hz)

Power Consumption

Lower than 30 W

Display

Two-channel Characteristics - Phase Offset

Range 0° to 360°

0.03°

1 kΩ, AC coupling

50 Ω, AC coupling

The instrument amplitude setting is greater than 3.2 Vpp or the output AC+DC is greater

than |1.6 V

| and the input voltage is greater than ±12 × (1 ± 5%)V (<10 kHz).

DC

Disruptive discharge voltage: ±18(Vac + dc).

The instrument amplitude setting is smaller than or equal to 3.2 Vpp or the output AC+DC

is smaller than |1.6 VDC| and the input voltage is greater than ±2.6 × (1 ± 5%)V (<10

Power Voltage

DG2000 Performance Verification Guide

Page 48

RIGOL Appendix

14

Type

4.3-inch TFT LCD touch screen

Resolution

480 horizontal × RGB × 272 vertical resolution

Color

16 M

Environment

Cooling Method

Natural air cooling

Operating: below 3,000 meters

Non-operating: below 15,0 0 0 m eters

Mechanical Characteristics

Dimensions

(W×H×D)

Packag e excluded: 3.2 kg

Package included: 4.5 kg

Interface

USB Host, USB Device, and USB-GPIB

IP Protection

IP2X

Calibration

Interval

Certification Information

EMC

Compliant with EN

IEC 61000

±4.0 kV (Contact Discharge)

±4.0 kV (Air Discharge)

IEC 61000

3 V/m (80 MHz to 1 GHz); 3 V/m (1.4 GHz

IEC 61000

IEC 61000

IEC 61000

IEC 61000

Electrical Safety

complies with

USA: UL 61010

Canada:

No. 61010

EN 61010-1:2010,

Temperature Range

Humidity Range

Altitude

Weight

Operating: 0℃ to 45℃

Non-operating: -40℃ to 60℃

Below 30℃: ≤95%RH

30℃ to 40℃: ≤75%RH

40℃ to 50℃: ≤45%RH

261.5 mm × 112 mm × 318.4 mm

1 year (recommended)

61326-1:2006

-3-2:2000

-4-3:2002

to 2 GHz); 1 V/m (2.0 GHz to 2.7 GHz)

CAN/CSA-C22.2

[1]

Note

: 0 dBm output, DC offset 0, impedance 50 Ω.

-4-4:2004 1kV power line

0.5 kV (phase-to-neu t ral voltage);

-4-5:2001

0.5 kV (phase-to-earth voltage);

1 kV (neutral-to-earth voltage)

-4-6:2003 3 V, 0.15 MHz to 80 MHz

Voltage dip:

0% UT during half cycle

-4-11:2004

0% UT during 1 cycle

70% UT during 25 cycles

Short interruption:

0% UT during 1 cycle

-1:2012,

-1-2012

DG2000 Performance Verification Guide

Loading...

Loading...