Page 1

User’s Guide RIGOL

Publication Number UGB06111-1210

Jan. 2009

Dual-Channel Function/Arbitrary

Waveform Generator

DG1022, DG1012

© 2008 RIGOL Technologies, Inc.

All Rights Reserved

Page 2

Page 3

RIGOL

I

© 2008 RIGOL Technologies, Inc. All Rights Reserved.

RIGOL products are protected by patent laws in and outside of the P.R. China.

Information in this publication replaces all previous corresponding material.

RIGOL reserves the right to modify or change part of or all the specifications and

pricing policies at company’s sole decision.

NOTE: RIGOL is registered trademark of RIGOL Technologies, Inc.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 4

RIGOL

II

Safety Notices

Review the following safety precautions carefully before operating the instrument to

avoid any personal injury or damage to the instrument or products connected to it. To

avoid potential hazards, use the instrument in the manner specified in this user’s

guide.

The instrument should be serviced only by qualified personnel.

Avoid Fire or Personal Injury.

Use Proper Power Line. Only the special power line of the products approved by

the State should be used.

Insert or Draw Properly. Do not insert draw when the probe and the testing lead

are connected with the power.

Ground the Instrument. This generator is grounded through the protective terra

conductor of the power cord. To avoid electric shock, the grounding conductor must

be connected to the earth ground. Make sure that the instrument is properly grounded

before connecting the input or output terminals.

Observe All the Ratings of the Terminal. To avoid fire or shock, observe all the

ratings and symbols that marked on the instrument. Read the user’s guide carefully

before making connections to the instrument.

Do not Operate without Covers. Do not operate your generator without covers or

panels.

Use Proper Fuse. Only use the fuse type and rating specified for this product.

Avoid Circuit or Wire exposed. Do not touch the exposed connections or

components when the power is turn-on.

Do not operate with suspected failures. If you suspect there is damage with this

product, have it inspected by qualified service personnel authorized by RIGOL before

further operations.

Provide Proper Ventilation.

Do not Operate in Wet/Damp Conditions.

Do not Operate in an Explosive Atmosphere.

Keep the Product’s Surfaces Clean and Dry.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 5

RIGOL

III

!

Hazardous

Voltage

Refer to the

Instructions

Protective

earth terminal

Test

Grounding

Terminal

Grounding

Terminal

of Chassis

!

!

Safety Terms and Symbols

Terms in This Guide. These terms may appear in this manual:

WARNING: Warning statements indicate the conditions or practices that

could result in injury or loss of life.

CAUTION: Caution statements indicate the conditions or practices that

could result in damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury or hazard that may be immediately happen.

WARNING indicates an injury or hazard that may be not immediately happen.

CAUTION indicates that a potential damage to the instrument or other property

might occur.

Symbols on the Product. These symbols may appear on the Instrument:

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 6

RIGOL

IV

Instrument at a Glance

This guide covers the following two types of DG10× 2 Series Dual-Channel

Function/Arbitrary Waveform Generators:

DG1022、DG1012

RIGOL DG10× 2 Series Dual-Channel Function/ Arbitrary Waveform Generator adopt

the DDS technology, which can provide stable, high-precision, pure and low distortion

sine signal. It can also provide 5MHz square waveform with fast rising and falling

edges. Its combination of excellent system features, easiness in usage and versatile

functions makes this generator a perfect solution for your job now and in the future.

DG10× 2 Series Dual-Channel Function/ Arbitrary Waveform Generator have clear and

simple Front-Panel. The user-friendly panel layout and instructions, versatile terminals,

direct graph interface, built-in instructions and help system have greatly simplified the

operation process, thus, users do not have to spend a great deal of time learning and

familiarizing the operation of the generator before they can use it proficiently. The

built-in AM, FM, PM and FSK modulating functions generate modulated waveform at

ease, without the help of a separate modulating source. The USB I/O is the standard

accessory.

Characteristics and Specifications:

DDS technology provides precise, stable and low distortion output signal.

2-Channel Output.

Support channel coupling, channel copy.

5 basic waveforms and 48 built-In arbitrary waveforms output.

Counter supports frequency measurement: 100mHz ~ 200MHz (single channel).

100MSa/s sampling rate, enable to edit arbitrary waveform with 14-bit, 4K points.

Frequency characteristics (DG1022):

Sine: 1µHz to 20 MHz

Square: 1µHz to 5 MHz

Ramp: 1µHz to 150 kHz

Pulse: 500µHz to 3MHz

White Noise:5MHz bandwidth (-3dB)

Arbitrary waveform:1μHz to 5MHz

Amplitude range (CH1):

2mVPP to 10VPP (50)

4mVPP to 20VPP (High Z)

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 7

RIGOL

V

Abundant modulation function, various modulated waveform: AM, FM, PM and

FSK.

Linear, logarithm Sweep and Burst mode.

Abundant I/O: External Modulation Source, External 10 MHz Reference Input,

External trigger source, waveform output, synchronous signal output.

Support USB flash drive. Could store and read waveform configure parameters or

the edited arbitrary waveform with USB flash drive, System Updating could also

be performed by using USB flash drive.

Standard interface: USB Host & Device.

Graph interface which shows the signal setting directly.

Multilanguage user interface.

Embedded Chinese/English Help System.

Support Chinese/English Input.

NOTE:

All the descriptions in this guide are according to DG1022, if you need to know the

particular specifications about DG1012, please look over “

Chapter 5 Specifications

”.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 8

RIGOL

VI

Content

Safety Notices ............................................................................................. II

Instrument at a Glance ............................................................................... IV

Chapter 1 Quick Start ............................................................................ 1-1

General Inspection .................................................................................... 1-2

Handle Adjustment .................................................................................... 1-3

The Front/Rear Panel ................................................................................ 1-4

User Interface ........................................................................................... 1-6

To Set a Waveform ................................................................................... 1-7

To Set the Output ................................................................................... 1-11

To Set Modulate/Sweep/Burst .................................................................. 1-12

To Use Digital Input ................................................................................ 1-14

To Use Store/Utility/Help Function ............................................................ 1-15

Chapter 2 Operating Your Generator .................................................... 2-1

To Set Basic Waveforms ............................................................................ 2-2

To Set Sine Waveform ......................................................................... 2-2

To Set Square Waveform ..................................................................... 2-7

To Set Ramp Waveform ..................................................................... 2-10

To Set Pulse Waveform ..................................................................... 2-12

To Set Noise Waveform ..................................................................... 2-15

To Set Arbitrary Waveforms ..................................................................... 2-16

To Select Arbitrary Waveform ............................................................ 2-17

To Edit Arbitrary Waveform ................................................................ 2-21

To Set Modulated Waveforms .................................................................. 2-27

To Set AM Waveform ......................................................................... 2-28

To Set FM Waveform ......................................................................... 2-30

To Set FSK Waveform ........................................................................ 2-32

To Set PM Waveform ......................................................................... 2-34

To Generate Sweep Signal ....................................................................... 2-36

To Generate Burst Signal ......................................................................... 2-38

To Store and Recall ................................................................................. 2-42

To Set the Utility Function ........................................................................ 2-49

To Set the Sync Output ..................................................................... 2-52

Basic Setting of the Two Channels ...................................................... 2-54

Channel Coupling Settings ................................................................. 2-57

To Set the Counter ............................................................................ 2-59

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 9

RIGOL

VII

System Settings ............................................................................... 2-64

I/O Settings ..................................................................................... 2-71

Test/Cal Settings .............................................................................. 2-72

To Use the Help System .......................................................................... 2-74

Chapter 3 Examples .............................................................................. 3-1

Output from Single Channel ....................................................................... 3-2

Example 1: Output a Sine Waveform ................................................... 3-2

Example 2: Output a Square Waveform ............................................... 3-3

Example 3: Output a Ramp Waveform ................................................. 3-4

Example 4: Output a Pulse Waveform .................................................. 3-5

Example 5: Output a Noise Waveform .................................................. 3-6

Example 6: Output a Stored Arbitrary Waveform ................................... 3-7

Example 7: Create an Arbitrary Waveform ............................................ 3-8

Example 8: To Generate a AM Waveform............................................ 3-10

Example 9: To Generate a FSK Waveform ........................................... 3-12

Example 10: To Generate a Linear Sweep Waveform ........................... 3-13

Example 11: To Generate a Burst Waveform ....................................... 3-15

Output from Double Channels .................................................................. 3-17

Example for Channel Coupling ................................................................. 3-20

Example for Channel Copy ....................................................................... 3-22

To Measure with the Counter ................................................................... 3-23

Chapter 4 Prompt Messages & Troubleshooting ................................... 4-1

Prompting Messages ................................................................................. 4-2

Common Messages ............................................................................. 4-2

Error Messages .................................................................................. 4-4

Data Overflow .................................................................................... 4-5

Troubleshooting ...................................................................................... 4-14

Chapter 5 Specifications ....................................................................... 5-1

Characteristics .......................................................................................... 5-2

General Specifications ............................................................................... 5-8

Chapter 6 Appendix ............................................................................... 6-1

Appendix A: Accessories ............................................................................ 6-1

Appendix B: Warranty ............................................................................... 6-2

Appendix C: General Care and Cleaning ...................................................... 6-3

Appendix D: Contact RIGOL ..................................................................... 6-4

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 10

Page 11

1-1

Chapter 1 Quick Start

This chapter covers the following topics:

General Inspection 1-2

Handle Adjustment 1-3

The Front/Rear Panel 1-4

User Interface 1-6

To Set a Waveform 1-7

To Set the Output 1-11

To Set Modulation/Sweep/Burst 1-12

To Use Digital Input 1-14

RIGOL

To Use Store/Utility/Help Function 1-15

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 12

RIGOL

1-2

General Inspection

When you get a new DG10× 2 Series Dual-Channel Function/Arbitrary Waveform

Generator, you are suggested to take the following steps to inspect the instrument.

1. Inspect the shipping container for damage.

If there are damages in the packing or foam, keep them until he whole machine

and the accessories passing the electric and mechanical testing.

2. Check the accessories.

Accessories supplied with the instrument are listed in “

If the contents are incomplete or damaged, please contract the local selling

representative of RIGOL.

3. Inspect the instrument.

In case any mechanical damage or defect, or if the instrument does not operate

properly or pass performance tests, notify your RIGOL Sales Representative.

If the shipping container is damaged, or the cushioning materials show signs of

stress, notify the carrier of your RIGOL sales office. Keep the shipping materials

for the carrier’s inspection. RIGOL offices will arrange for repair or replacement

at RIGOL’s option without waiting for claim settlement.

Appendix A: Accessories

".

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 13

1-3

RIGOL

Handle Adjustment

To adjust the handle position of the Generator, please grip the handle by the sides and

pull it outward. Then, make the handle rotate to the desired position. The operating

methods are shown below in Figure 1-1 and Figure 1-2.

Figure 1-1 Handle Adjusting

Figure 1-2 Adjustable Positions

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 14

RIGOL

1-4

Power Menu Keys CH1 Output CH1 Output

Button Connector

Display Mode Waveform Channel Keypad CH2 Output CH2 Output/

Switch Keys Switch Button Counter Input

Mode/ Direction

USB Host LCD Screen Functions Key Knob

The Front/Rear Panel

When you get a new DG10× 2 Series Dual-Channel Function/Arbitrary Waveform

Generator, first you need to know how to operate the front/ Rear panel correctly. This

chapter will make a brief introduction and description for the operation and functions

of the Front/ Rear Panel.

The Front Panel at a Glance

DG10× 2 Generator has clear and simple front panel. The Front Panel has a knob,

functional keys and menu buttons. The 6 grey buttons below the screen are menu

buttons, by using which you can choose different options on the current menu. The

rests are the functional keys, with which you can enter different function menus or

obtain specific functional applications directly.

Figure 1-3

Front Panel for DG10× 2 Series

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 15

1-5

The Rear Panel at a Glance

10MHz Synchronous

Reference Input Output Power Socket

Modulation External USB Device Main Power

Input Trig/FSK/Burst Switch

Figure 1-4

Rear Panel for DG10× 2 Series

RIGOL

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 16

RIGOL

1-6

State

Parameters

Display Menu

Button

Waveform

Display

Current Channel Parameter Display

Waveform

State

Menu

Parameter Display

Current Channel Sign

Output Impedance

Current Channel Output Impedance

Output Sate

Waveform in

Selected Channel

Menu

User Interface

The Generator provides three display modes: Menu Mode (Single or Double Channel)

and Graph Mode (Single Channel). To switch the display mode, press the View button.

To select Channels, press the button.

Figure 1-5

User Interface in Menu Mode (Single Channel)

Figure 1-6

User Interface in Graph Mode (Single Channel)

Figure 1-7

User Interface in Menu Mode (Double Channel)

NOTE:

The buttons on the front panel of the instrument are represented by words in a pane,

such as Sine which represents the functional key with “Sine” on it on the front panel,

while the menu buttons are represented by shadow words such as Freq, which means

the “Frequency” option in the Sine menu.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 17

RIGOL

1-7

To Set a Waveform

At the left of the operation panel, there are several buttons with waveform icon and

two buttons which are used commonly. The following exercises will help you to be

familiar with the waveform selection settings. The instructions of the waveform

settings are all carried out in the Menu Display Mode.

Waveform Selection

Channel Switch Display Mode Switch

Figure 1-8

Function Buttons Selection

1. Press the Sine button, a “Sine” typeface will display in the state area. The

instrument can generate Sine signal with frequency from 1μHz to 20MHz. By

setting

signal with different parameters can be generated.

Frequency/Period, Amplitude/High Level, Offset/Low level and Phase,

Sine

Figure 1-9

Sine Signal in the Menu Display Mode

As shown in Figure 1-9, the default signal parameters are: 1kHz Frequency,

5.0VPP Amplitude, 0 VDC Offset and 0° initial phase.

2. Press the Square button, a “Square” typeface will display in the state area. The

instrument can generate Square signal with frequency from 1μHz to 5MHz and

variable duty cycle. By setting

Low level, Duty Cycle and Phase

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Frequency/Period, Amplitude/ High Level, Offset/

, Square signal with different parameters can be

Page 18

RIGOL

1-8

generated.

Figure 1-10

Square Signal in the Menu Display Mode

As shown in Figure 1-10, the default signal parameters are: 1kHz Frequency,

5.0VPP Amplitude, 0 VDC Offset, 50% Duty Cycle and 0° initial phase.

3. Press the Ramp button, a “Ramp” typeface will display in the state area. The

instrument can generate Ramp signal with frequency from 1μHz to 150 kHz and

variable Symmetry. By setting

Low level, Symmetry and Phase

Frequency/Period, Amplitude/ High Level, Offset/

, Ramp signal with different parameters can be

generated.

Figure 1-11

Ramp Signal in the Menu Display Mode

As shown in Figure 1-11, the default signal parameters are: 1kHz Frequency, 5.0

VPP Amplitude, 0 VDC Offset, 50% Symmetry and 0° initial phase.

4. Press the Pulse button, a “Pulse” typeface will display in the state area. The

instrument can generate Pulse signal with frequency from 500μHz to 3MHz and

variable Pulse Width. By setting

Low level, Pulse Width/Duty Cycle and Delay

Frequency/Period, Amplitude/ High Level, Offset/

, Pulse signal with different

parameters can be generated.

Figure 1-12

Pulse Signal in the Menu Display Mode

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 19

RIGOL

1-9

As shown in Figure 1-12, the default signal parameters are: 1kHz Frequency,

5.0VPP Amplitude, 0 VDC Offset, 50% Duty Cycle, 500μs Pulse Width and 0s Delay.

5. Press the Noise button, a “Noise” typeface will display in the state area. The

instrument can generate Noise signal with Band Width up to 5MHz. By setting

Amplitude/High Level, Offset/Low level

, Noise signal with different parameters can

be generated.

Figure 1-13

Noise Signal in the Menu Display Mode

As shown in Figure 1-13, the default signal parameters are: 5.0 VPP Amplitude

and 0 VDC Offset.

6. Press the Arb button, an “Arb” typeface will display in the state area. The

instrument can generate repeatable arbitrary waveform signals with at most 4K

points and 5MHz frequency. By setting

Offset/ Low level and Phase

, arbitrary waveform signals with different parameters

Frequency/Period, Amplitude/ High Level,

can be generated.

Figure 1-14

Arbitrary waveform Signal in the Menu Display Mode

As shown in Figure 1-14, the default Exponential Rise Signal parameters are:

1kHz Frequency, 5.0 VPP Amplitude, 0 VDC Offset and 0° initial phase.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 20

RIGOL

1-10

7. Press the button, the channel will switch between CH1 and CH2. Users can

edit parameters of the current selected channel.

8. Press the View button, the display modes will switch between Menu Mode in single

channel, Graph Mode in single channel and Menu Mode in double channel. If the

instrument is in remote mode, press this button it will return to local mode.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 21

RIGOL

1-11

CH1: Output Enable CH2: Output Disable

To Set the Output

As shown in Figure 1-15, there are two Output buttons on the right side of the front

panel, which are used to set the Output Control. The instruction below will help you to

be familiar with these functions.

Figure 1-15

Channel Output/Counter Input

Figure 1-16

Channel Output Control

1. Channel Output Control

Press the Output button to enable/disable the signal output of CH1 or CH2.

2. Counter Input

In the Counter mode, the output connector of CH2 is used as the signal input

terminal. At the same time, the output of CH2 will be disabled automatically.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 22

RIGOL

1-12

To Set Modulate/Sweep/Burst

As shown in the following figure, there are three buttons on the front panel, which are

used for Modulation, Sweep and Burst settings. The instructions below will help you to

be familiar with the settings of these functions.

Figure 1-17

Modulate/ Sweep/ Burst button

NOTE: Mod, Sweep and Burst functions are only used for CH1.

1. Press the Mod button, and a Modulated waveforms will be generated.

Parameters are set by using the menu buttons. The modulated waveform can be

changed by changing the parameters such as Type, Internal/external Modulation,

Depth, Frequency, Waveform, etc.

DG10× 2 Series can modulate waveform using AM, FM, PM and FSK. Sine, Square,

Ramp or Arbitrary waveforms can be modulated (Pulse, Noise and DC cannot be

modulated).

Figure 1-18

Modulated Waveform Signal in the Menu Display Mode

2. Press the Sweep button, Sine, Square, Ramp or Arbitrary waveform can be swept

(Pulse, Noise and DC can not be swept).

In the Sweep Mode, DG10× 2 Series generate signal with variable frequencies.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 23

RIGOL

1-13

Term Explanation

Burst:Output Waveforms with the set cycle times

Burst can last for certain times of waveform cycle (N-Cycle Burst) or be controlled by

external gated signals (Gated Burst). Burst applies to all kinds of waveforms, but

noise can only be used in gated burst.

Figure 1-19

Sweep Waveform Signal in the Menu Display Mode

3. Press the Burst button, Burst for Sine, Square, Ramp, Pulse or Arbitrary waveform

can be generated (Noise can only be used in the gated Burst).

Figure 1-20

Burst Waveform Signal in the Menu Display Mode

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 24

RIGOL

1-14

To Use Digital Input

As shown in Figure 1-21, there are two groups of buttons on the operation panel,

which are direction button, the knob and the keypad. The instruction below will help

you to be familiar with the Digital Input Function.

(1) Direction Key and the Knob (2) Keyboard

Figure 1-21

Front Panel Digital Input

1. Use the Direction keys to move the cursor left or right. Rotate the knob to change

a digit (clockwise to increase).

2. Use the Keypad to set the parameters values of the waveforms, which can change

its value directly.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 25

RIGOL

1-15

Operation Instructions

To get help:

Press the key and last 2~3 second, then the help message will appear.

To Use Store/Utility/Help Function

As shown in Figure 1-22, there are three buttons on the operation panel, which are

used to call the store/recall, utility and help function. The instruction below will help

you to be familiar with these Functions.

Figure 1-22

Store/Recall, Utility and Help Button

1. The Store/Recall Button is used to store waveform data and configure

information.

2. The Utility Button is used to set the auxiliary system function, change the output

configure parameters, interface setting, system setting information or perform the

instrument self-test and read the calibration information, etc.

3. The Help Button is used to read the help information.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 26

Page 27

RIGOL

Chapter 2 Operating Your Generator

By now you have got a brief understanding of DG10× 2 series with the front/rear panel,

every function control area and keys.

This chapter covers the following topics:

To Set Basic Waveforms 2-2

To Set Sine Waveform 2-2

To Set Square Waveform 2-7

To Set Ramp Waveform 2-10

To Set Pulse Waveform 2-12

To Set Noise Waveform 2-15

To Set Arbitrary Waveforms 2-16

To Select Arbitrary Waveform 2-17

To Edit Arbitrary Waveform 2-21

To Set Modulated Waveforms 2-27

To Set AM Waveform 2-28

To Set FM Waveform 2-30

To Set FSK Waveform 2-32

To Set PM Waveform 2-34

To Generate Sweep Signal 2-36

To Generate Burst Signal 2-38

To Store and Recall 2-42

To Set the Utility Function 2-49

To Set the Sync Output 2-52

Basic Setting of the Two Channels 2-54

Channel Coupling Settings 2-57

To Set the Counter 2-59

System Settings 2-64

I/O Settings 2-71

Test/Cal Settings 2-72

To Use the Help System 2-74

© 2008 RIGOL Technologies, Inc. 2-1

User’s Guide for DG10× 2 Series

Page 28

RIGOL

2-2

Menu

Settings

Explanation

Frequency/

Period

Setting the signal’s frequency or period; the

current parameter will switch at a second press.

Amplitude/

High Level

Setting the signal’s Amplitude or High Level; the

current parameter will switch at a second press.

Offset/

Low Level

Setting the signal’s Offset or Low Level; the

current parameter will switch at a second press

Phase

Setting the initial phase of the signal

To Set Basic Waveforms

To Set Sine Waveform

In the Menu Mode, press the Sine button to call the Sine operation. The top left corner

of the screen will show the name of the current waveform. The output Sine waveform

parameters are set using the Sine operation menu.

The parameters for Sine waveforms are:

Offset/ Low Level and Phase

parameters. As shown in Figure 2-1, select Freq in the operation menu and the

frequency parameter will be shown in the parameter area. Users then can change the

frequency by using the direction button and the knob or the keypad.

. Different Sine Signals are generated by using these

Frequency/ Period, Amplitude/ High Level,

Figure 2-1

Sine Signal Parameter Setting Interface

Table 2-1 Operation Menu for Sine Signal

NOTE:

Waveforms in single channel needn’t to set the Aligpha parameter. It is always used to

align the phases of the two channels’ output signals.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 29

Instructions

When using the keypad to enter the digit, you can use the Left direction button to

move the cursor backward and delete or change the value of the previous digit.

When using the knob to input, use the direction buttons to select the digit

you want to edit and rotate the knob to change its value.

Current Parameter:

Frequency

To Set the Output Frequency/Period

1. Press Sine Freq/Period Freq, to set the frequency parameter.

The frequency shown on the screen is the default value when the instrument is

powered or the set value beforehand. When setting the function, if the current

value is valid for the new waveform, it will be used sequentially. If you want to set

the period for the waveform, press Freq/Period button again, switch to the Period

parameter (The current operation is displayed in inverse color).

2. Input the desired frequency.

Use the keypad to input the parameter value directly, and press the

corresponding button to select the parameter unit. Or you can use the direction

button to select the digit you want to edit, and then use the knob to change its

value.

RIGOL

Figure 2-2

Setting the Frequency

© 2008 RIGOL Technologies, Inc. 2-3

User’s Guide for DG10× 2 Series

Page 30

RIGOL

2-4

Current Parameter:

Amplitude

To Set the Output Amplitude

1. Press Sine Ampl/HiLev Ampl, to set the amplitude.

The amplitude shown on the screen is the default value when the instrument is

powered or the set value beforehand. When changing the function, if the current

value is valid for the new waveform, it will be used sequentially. If you want to set

the waveform by high Level or Low Level, press Ampl/HiLev or Offset/Lolev again,

switch to HiLev or LoLev parameter (The current operation is displayed in inverse

color).

2. Input the desired Amplitude

Use the keypad or the knob to input the desired value, choose the unit, and press

the corresponding button.

Figure 2-3

Setting the Amplitude

NOTE:

The “dBm” option will appear only when the output impedance is set to “50”.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 31

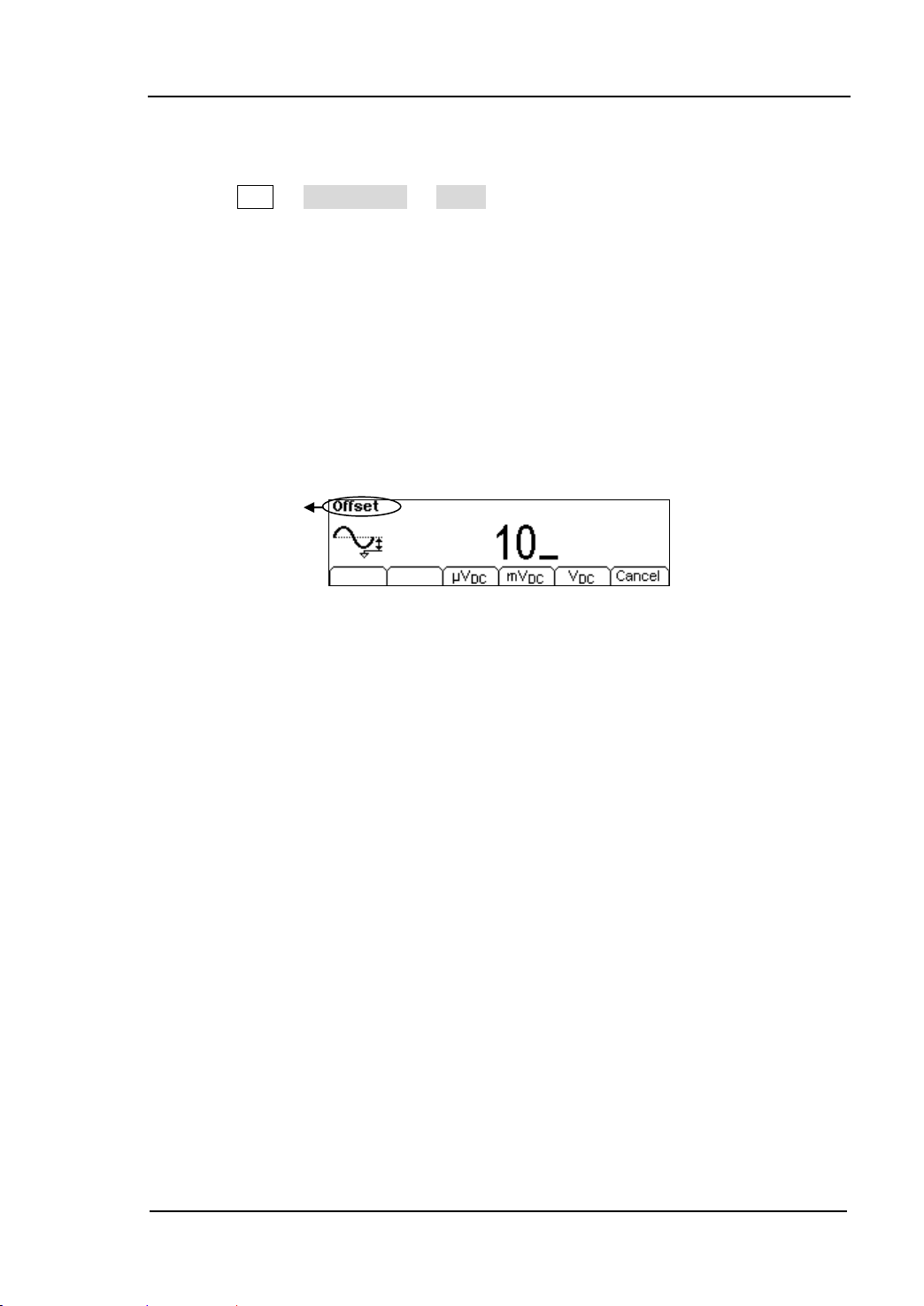

To Set the Offset

Current Parameter:

Offset

1. Press Sine Offset/LoLev Offset, to set the offset.

The offset shown on the screen is the default value when the instrument is

powered or the set value beforehand. When changing the function, if the current

value is valid for the new waveform, it will be used sequentially.

2. Input the desired Offset

Use the keypad or the knob to input the desired value, choose the unit, and press

the corresponding button.

RIGOL

Figure 2-4

Setting the Offset

NOTE: The setting of any waveform for Offset is the same as sine wave, so we will

not cover this topic again.

© 2008 RIGOL Technologies, Inc. 2-5

User’s Guide for DG10× 2 Series

Page 32

RIGOL

2-6

Current Parameter:

Phase

To Set the Initial Phase

1. Press Sine Phase, to set the initial phase.

The phase shown on the screen is the default value when the instrument is

powered or the set value beforehand. When changing the function, if the current

value is valid for the new waveform, it will be used sequentially.

2. Input the desired Offset

Use the keypad or the knob to input the desired value, choose the unit, and press

the corresponding button.

Figure 2-5

Setting the initial phase

After finishing the above operations, press View , in the Graph Mode, the waveform is

shown in the following figure.

Figure 2-6

Waveform Parameter in the Graph Mode

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 33

RIGOL

Menu

Settings

Explanation

Frequency/

Period

Setting the signal’s frequency or period; the

current parameter will switch at a second press.

Amplitude/

High Level

Setting the signal’s Amplitude or High Level; the

current parameter will switch at a second press.

Offset/Low

Level

Setting the signal’s Offset or Low Level; the

current parameter will switch at a second press

Duty Cycle

Setting the Duty Cycle for Square Waveform

Phase

Setting the initial phase of the signal

To Set Square Waveform

Press the Square button, in the Normal Mode, the operation menu will appear at the

bottom of the screen. Set the Square parameters by using the operation menu.

The parameters for Square waveforms are:

Offset/ Low Level, Duty Cycle and Phase

Frequency/ Period, Amplitude/ High Level,

. See Figure 2-7. In the operation menu,

select DtyCyc, and the corresponding parameter will be displayed in inverse color for

which users can make a change.

Figure 2-7

Square Signal Parameter Setting Interface

Table 2-2 Square Signal Operation Menu

© 2008 RIGOL Technologies, Inc. 2-7

User’s Guide for DG10× 2 Series

Page 34

RIGOL

2-8

Term Explanation:

Duty Cycle: The percentage that the High Level takes up in the whole Period.

Please Note : for the Frequency Duty Cycle Value

Below 3MHz(included): 20% to 80%

From 3MHz to 4MHz (included): 40% to 60%

From 4MHz to 5MHz (included): 50%

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 35

To Set the Duty Cycle

Current Parameter:

Duty Cycle

1. Press Square DtyCyc, to set the Duty Cycle.

The Duty Cycle shown on the screen is the default value when the instrument is

powered or the set value beforehand. When changing the function, if the current

value is valid for the new waveform, it will be used sequentially.

2. Input the desired Duty Cycle

Use the keypad or the knob to input the desired value, choose the unit, and press

the corresponding button. The Generator will change the waveform immediately.

RIGOL

Figure 2-8

Setting the Duty Cycle

Press View, in the Graph Mode, the waveform is shown in the following figure.

Figure 2-9

Waveform Parameters in the Graph Mode

© 2008 RIGOL Technologies, Inc. 2-9

User’s Guide for DG10× 2 Series

Page 36

RIGOL

2-10

Menu

Settings

Explanation

Frequency/

Period

Setting the signal’s frequency or period; the

current parameter will switch at a second press.

Amplitude/

High Level

Setting the signal’s Amplitude or High Level; the

current parameter will switch at a second press.

Offset/Low

Level

Setting the signal’s Offset or Low Level; the

current parameter will switch at a second press

Symmetry

Setting the Symmetry for Ramp Waveform

Phase

Setting the initial phase of the signal

Term Explanation:

Symmetry: The percentage that the Rising Period takes up in the whole Period.

Input Range: 0~100%

To Set Ramp Waveform

Press the Ramp button, in the Normal Mode, the operation menu will appear at the

bottom of the screen. Set the Ramp parameters by using the operation menu.

The parameters for Ramp waveforms are:

Offset/ Low Level, Symmetry and Phase

Frequency/ Period, Amplitude/ High Level,

. See Figure 2-10. In the operation menu,

select Symm, and the corresponding parameter will be displayed in inverse color for

which users can make a change.

Figure 2-10

Ramp Signal Parameter Setting Interface

Table 2-3 Ramp Signal Operation Menu

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 37

To Set the Symmetry

Current Parameter:

Symmetry

1. Press Ramp Symm, to set the Symmetry.

The Symmetry shown on the screen is the default value when the instrument is

powered or the set value beforehand. When changing the function, if the current

value is valid for the new waveform, it will be used sequentially.

2. Input the desired Symmetry.

Use the keypad or the knob to input the desired value, choose the unit, and press

the corresponding button. The Generator will change the waveform immediately.

RIGOL

Figure 2-11

Setting the Symmetry

Press View, in the Graph Mode, the waveform is shown in the following figure.

Figure 2-12

Waveform Parameter in the Graph Mode

© 2008 RIGOL Technologies, Inc. 2-11

User’s Guide for DG10× 2 Series

Page 38

RIGOL

2-12

Term Explanation:

Pulse Width: The time span between thresholds of 50% of the rising edge

amplitude to the next 50% of the falling edge amplitude.

Menu

Settings

Explanation

Frequency/

Period

Setting the signal’s frequency or period; the

current parameter will switch at a second press.

Amplitude/

High Level

Setting the signal’s Amplitude or High Level; the

current parameter will switch at a second press.

Offset/Low

Level

Setting the signal’s Offset or Low Level; the

current parameter will switch at a second press.

Width/

DtyCyc

Setting the Pulse Width or Duty Cycle for Pulse

Waveform.

Delay

Setting the Delay time.

To Set Pulse Waveform

Press the Pulse button, in the Normal Mode, the operation menu will appear at the

bottom of the screen. Set the Pulse parameters by using the operation menu.

The parameters for Pulse waveforms are:

Offset/ Low Level, Pulse Width/ Duty Cycle and Delay

operation menu, select Width, and the corresponding parameter will be displayed in

inverse color for which users can make a change.

Frequency/ Period, Amplitude/ High Level,

. See Figure 2-13, in the

Figure 2-13

Pulse Signal Parameter Setting Interface

Table 2-4 Pulse Signal Operation Menu

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 39

To Set the Pulse Width

Current Parameter:

Pulse Width

1. Press Pulse Width, to set the Pulse Width.

The Pulse Width shown on the screen is the default value when the instrument is

powered or the set value beforehand. When changing the function, if the current

value is valid for the new waveform, it will be used sequentially.

2. Input the desired Pulse Width

Use the keypad or the knob to input the desired value, choose the unit, and press

the corresponding button. The Generator will change the waveform immediately.

Figure 2-14

Setting the Pulse Width

RIGOL

Key Points:

Pulse width is limited by the minimum pulse width and the Pulse

period.

Minimum Pulse width= 20ns

Pulse width ≥ Minimum Pulse width

Pulse width ≤ Pulse period-Minimum Pulse width

Pulse duty cycle is limited by the minimum pulse width and the Pulse

period.

Pulse duty cycle ≥ 100 × Minimum Pulse width ÷ Pulse period

Pulse duty cycle ≤ 100 × (1-Minimum Pulse width ÷ Pulse period)

Settings of “Pulse Width” and “Duty Cycle” are equivalent.

Once a parameter is changed, the other one will change accordingly. For instance,

the current period is 1ms, the pulse width is 500µs and the duty cycle is 50%,

when setting the pulse width to be 200µs, the duty cycle will become 20%.

© 2008 RIGOL Technologies, Inc. 2-13

User’s Guide for DG10× 2 Series

Page 40

RIGOL

2-14

Current Parameter:

Delay time

To Set the Pulse Delay

1. Press Pulse Dela, to set the Pulse Delay time.

The Delay time shown on the screen is the default value when the instrument is

powered or the set value beforehand.

2. Input the desired Delay time.

Use the keypad or the knob to input the desired value, choose the unit, and press

the corresponding button. The Generator will change the waveform immediately.

Figure 2-15

Setting the Delay time

Press View, in the Graph Mode, the waveform is shown as in the following figure.

Figure 2-16

Waveform parameters in the Graph mode

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 41

RIGOL

Menu

Settings

Explanation

Amplitude/

High Level

Setting the signal’s Amplitude or High Level; the

current parameter will switch at a second press.

Offset/Low

Level

Setting the signal’s Offset or Low Level; the

current parameter will switch at a second press

To Set Noise Waveform

Press the Noise button, in the Normal Mode, the operation menu will appear at the

bottom of the screen. Set the Noise parameters by using the operation menu.

The parameters for Noise waveforms are: Amplitude/ High Level and Offset/ Low

Level. See Figure 2-17, in the operation menu, select Ampl, and the corresponding

amplitude will be displayed in inverse color for which users can make a change for the

amplitude of Noise, which has no frequency or period.

Figure 2-17

Noise Signal Parameter Setting Interface

Table 2-5 Noise Signal Operation Menu

Press View, in the Graph Mode, the waveform is shown in the following figure.

Waveform Parameter in the Graph Mode

© 2008 RIGOL Technologies, Inc. 2-15

User’s Guide for DG10× 2 Series

Figure 2-18

Page 42

RIGOL

2-16

Menu

Settings

Explanation

Frequency/

Period

Setting the signal’s frequency or period; the

current parameter will switch at a second press.

Amplitude/

High Level

Setting the signal’s Amplitude or High Level; the

current parameter will switch at a second press.

Offset/Low

Level

Setting the signal’s Offset or Low Level; the

current parameter will switch at a second press.

Load

Select the built-in Arbitrary Signal as Output.

Edit

Create and Edit Arbitrary Waveform.

Phase

Setting the initial phase of the signal

To Set Arbitrary Waveforms

Press the Arb button, in the Normal Mode, the operation menu will appear at the

bottom of the screen. Set the Arbitrary Waveform parameters by using the operation

menu.

Arbitrary Signals are divided into two categories: the built-in optional system

waveforms and the user-definable arbitrary waveforms. The parameters for Arbitrary

Waveforms are:

Phase

. See Figure 2-19, in the operation menu, select Freq, and the corresponding

frequency will be displayed in inverse color for which users can make a change.

Frequency/ Period, Amplitude/ High Level, Offset/ Low Level and

Figure 2-19

Arbitrary Signal Parameter Setting Interface

Table 2-6 Arbitrary Signal Operation Menu

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 43

RIGOL

Instructions

When there is no waveform stored in the Non-Volatile Memory, the

Stored Menu and the Delete Menu will hide.

When there is no waveform in the Volatile Memory, the Volatile menu will

hide.

Menu

Settings

Explanation

Builtin

Select one of the five built-in Arbitrary Waveforms

(See Table 2-8)

Stored

Select one of Arbitrary Waveforms stored in the

Non-volatile memory.

Volatile

Select one of Arbitrary Waveforms stored in the

Volatile memory. When a new waveform is

created, the old one will be erased.

Delete

Delete one of the Arbitrary Waveforms stored in

the Non-volatile memory. The five Built-in

Waveforms can not be deleted.

Cancel the current operation, and return to the

upper menu. (The rest are the same and will not

be covered)

To Select Arbitrary Waveform

There are 48 built-in Arbitrary Waveforms and 10 Non-Volatile memories for storing

the user-defined Arbitrary Waveforms in the Generator.

Press Arb Load, enter the interface shown below.

Figure 2-20 Operation Menu

Table 2-7 Selection Menu for Built-in Arbitrary Waveform

© 2008 RIGOL Technologies, Inc. 2-17

User’s Guide for DG10× 2 Series

Page 44

RIGOL

2-18

Menu

Settings

Explanation

Common

NegRamp/AttALT/AmpALT/StairDown/StairUp/Stai

rUD/CPulse/PPulse/NPulse/Trapezia/RoundHalf/Ab

sSine/AbsSineHalf/SineTra/SineVer

Choose common

Waveforms

Maths

ExpRise/ExpFall/Tan/Cot/Sqrt/X∧2/Sinc/Gauss/Hav

erSine/Lorentz/Dirichlet/GaussPulse/Airy

Choose Math

Waveforms

Engine

Cardic/Quake/Gamma/Voice/TV/Combin/BandLimi

ted/StepResp/Butterworth/Chebyshev1/

Chebyshev2

Choose Engine

Waveforms

Window

Boxcar/Barlett/triang/Blackman/Hamming/Hannin

g/Kaiser

Choose Window

Waveforms

Others

RounsPM/DC

Choose other

Waveforms

Select

Press to select the

waveform

To Select the Built-in Waveform

Press Arb Load BuiltIn, enter the following interface.

Figure 2-21 Operation Menu

Table 2-8 Built-in Arbitrary Waveforms Menu

As shown in the following figure, Press Math, use the knob to choose “ExpRise” and

press Select. Press View to view the waveform of “ExpRise” function.

Figure 2-22

Choose “ExpRise” function

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 45

Figure 2-23

Waveform Parameter in the Graph Mode

RIGOL

© 2008 RIGOL Technologies, Inc. 2-19

User’s Guide for DG10× 2 Series

Page 46

RIGOL

2-20

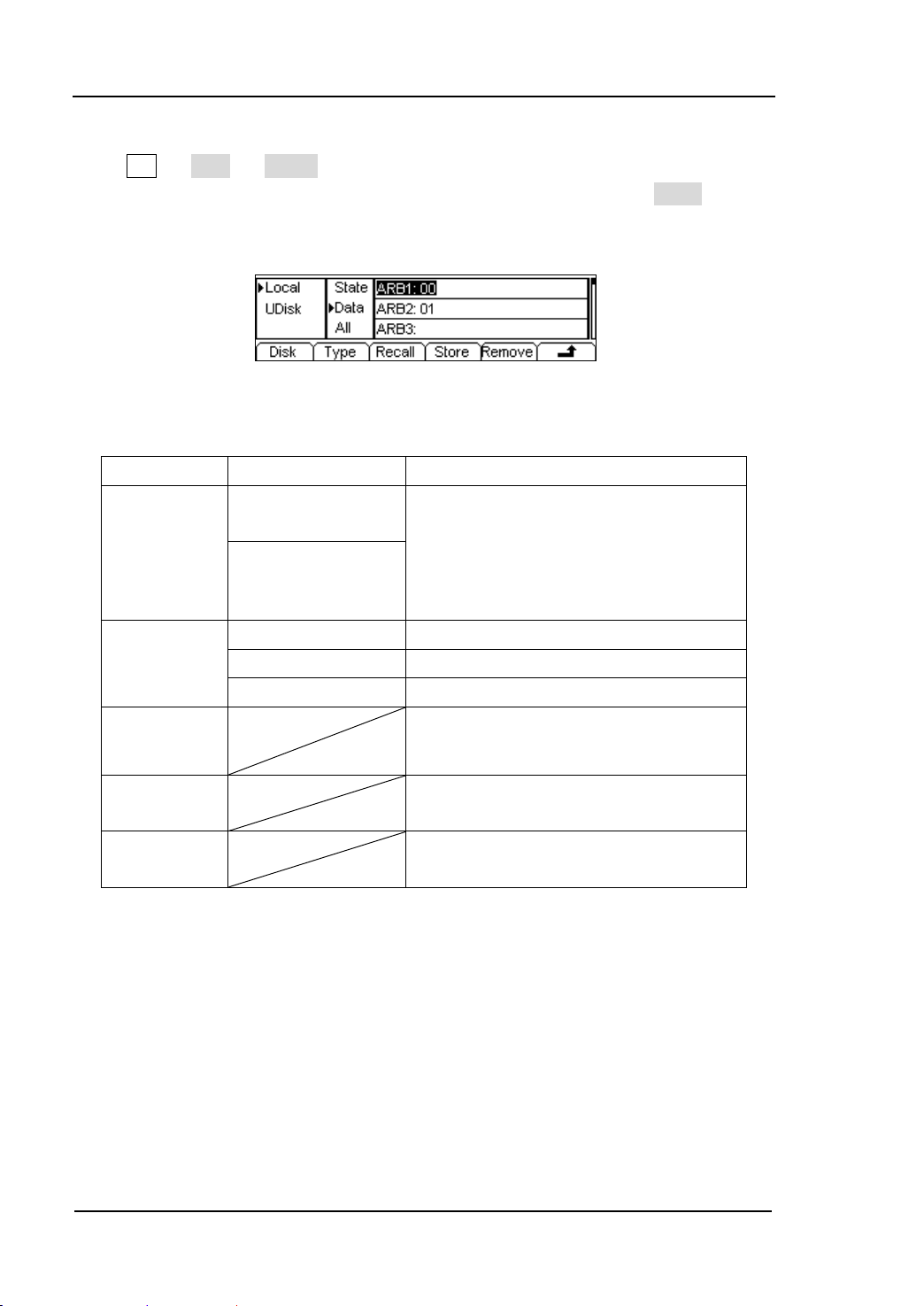

Menu

Settings

Explanation

Disk

Local

Choose display route for the system

information

U Disk

(When U Disk is

connected )

Type

State

Setting of the Generator

Data

Arbitrary waveform file

All

All types of documentation

Recall

Recall the waveform or Setting

information in the specific position in

the memory.

Store

Save the waveform to the appointed

place

Remove

Remove any waveform that has been

stored in the memory

To Select the Stored Waveform

Press Arb Load Stored, and enter the following interface. Select the desired

waveform document which will be displayed in inverse color and press Recall to recall

it from the memory.

Figure 2-24 Operation Menu

Table 2-9 The Stored Arbitrary Waveform Menu

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 47

RIGOL

Instructions

When there is no waveform stored in the Non-Volatile Memory, the Stored

Menu and the Delete Menu will hide.

When there is no waveform in the Volatile Memory, the Volatile menu will

hide.

Menu

Settings

Explanation

Create

Create a new waveform, and erase the waveform

in the Volatile memory.

Stored

Edit the waveform stored in the non-Volatile

memory

Volatile

Edit the waveform stored in the Volatile memory

Delete

Delete one of the Arbitrary Waveforms stored in

the Non-volatile memory. But The five Built-in

Waveforms can not be deleted.

To Edit Arbitrary Waveform

The Generator allows users to edit Arbitrary Waveforms, which can create any new

waveform by initializing points. The operation steps are as follows:

Press Arb Edit, enter the interface shown below.

Figure 2-25 Operation Menu

Table 2-10 Waveform Edition Operation Menu

© 2008 RIGOL Technologies, Inc. 2-21

User’s Guide for DG10× 2 Series

Page 48

RIGOL

2-22

Menu

Settings

Explanation

Period

Setting the Period for the Waveform

LevelHi

Setting the Level High for the Waveform

LevelLo

Setting the Level Low for the Waveform

Interp On/

Off

Activate the linear Interpolation between the

defined points

Deactivate the linear Interpolation between

the defined points

Points

Set the number of points when Initializing

the waveform

EditPt

Start the Waveform Editor

To Create a New Waveform

Press Arb Edit Create, to set the overall parameters for the waveform. The

setting interface is shown in the following Figure.

Figure 2-26

Interface for setting the new waveform parameters

Table 2-11 Setting the parameters for the new waveform

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 49

RIGOL

1. To Set the Point Number

Press Points, set the number of the initializing points.

Figure 2-27

Set the points of the editing waveform

When a new waveform is created, the waveform editor will firstly create a

waveform with two points. The Waveform Editor connects the last point to the

Voltage Level of point #1 to create a continuous waveform automatically. A

waveform with at most 4K points can be created.

In the default setting, point #1 is Level High, fixed on 0 second, while point #2 is

Level Low and on the half of the set Cycle period.

2. To Set the Interpolation

Press Interp., if you choose Interpolation On, and the points will be connected

with beelines; otherwise, the voltages between the two consecutive points will

not change and the waveform looks like a step-up one.

3. To Edit the Waveform Points

Press Arb Edit Create EditPt, The waveform can be defined by setting the

time and voltage for each point using this function. The interface is as follows:

Figure 2-28

Operation Menu

© 2008 RIGOL Technologies, Inc. 2-23

User’s Guide for DG10× 2 Series

Page 50

RIGOL

2-24

Menu

Settings

Explanation

Point#

Select the point to be edited

Time

Set time for the Selected point

Voltage

Set Voltage for the Selected point

Insert

Insert a new point between the defined

points. Use the “Time” and “Voltage” to

define the new point.

Remove

Remove the current point

Save

Save the created waveform to the

non-Volatile Memory.

Instructions

The time for the last definable point should be less than the cycle period in the

waveform.

Figure 2-29

To Set the voltage

Figure 2-30

To Edit the Second Point

Table 2-12 Waveform Parameter Edition Menu

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 51

4. Save the Waveform to the Non-Volatile Memory

Instructions

To save the Arbitrary Waveform:

In the Non-volatile Memory, each waveform storage place can only save one

waveform. If a new one is stored, the old one will be erased.

Default Arbitrary

Waveform

Press Arb Edit Create EditPt Save, enter the following interface. Select

the desired location (ARB1~ARB10) used to save, which will be displayed in

inverse color and press Store to save it to the specific place.

Figure 2-31

Operation Menu

RIGOL

After the storage, press Recall to read the waveform to volatile memory. Press View,

the edited waveform is shown in the following figure.

Figure 2-32

Waveform under the Graph Mode

© 2008 RIGOL Technologies, Inc. 2-25

User’s Guide for DG10× 2 Series

Page 52

RIGOL

2-26

To Edit the Stored Waveform

Press Arb Edit Stored, enter the following interface.

Figure 2-33

Select the waveform to edit

Select the desired waveform document to edit, which will be displayed in inverse

color and press Recall to recall and edit it in the Volatile memory. As shown in the

following figures, users can edit the parameters as in need and store it after the

modification.

Figure 2-34

Edit the waveform parameters

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 53

RIGOL

To Set Modulated Waveforms

Use the Mod button to generate modulated waveform. DG10× 2 Series can generate

AM, FM, FSK, PM modulated waveforms. The modulation parameters should be set in

different types of modulation.

In AM, users can set the Source (Internal/ External), depth, Modulating

Frequency, Modulating Waveform and Carrier Waveform;

In FM, users can set the Source (Internal/ External), Frequency Deviation,

Modulating Waveform and Carrier Waveform;

In FSK, users can set the Source (Internal/ External), Frequency Range, Internal

Rate, Modulating Waveform and Carrier Waveform;

In PM, users can set the Source (Internal/ External), Phase Deviation, Modulating

Frequency, Modulating Waveform and Carrier Waveform, etc.

We will introduce how to set these parameters in details according to different types of

modulation.

© 2008 RIGOL Technologies, Inc. 2-27

User’s Guide for DG10× 2 Series

Page 54

RIGOL

2-28

Menu

Settings

Explanation

Type

AM

Choose Amplitude Modulation

SrcInt

Depth

Set the amplitude range(0%~120%)

AMFreq

Set the modulating waveform frequency

(2mHz~20kHz)

Shape

Choose internal modulating Waveform:

Sine

Square

Triangle

UpRamp

DnRamp

Noise

Arb

SrcExt

Choose External modulation, the modulating

waveform is inputted form the [Modulation In]

port on the rear panel.

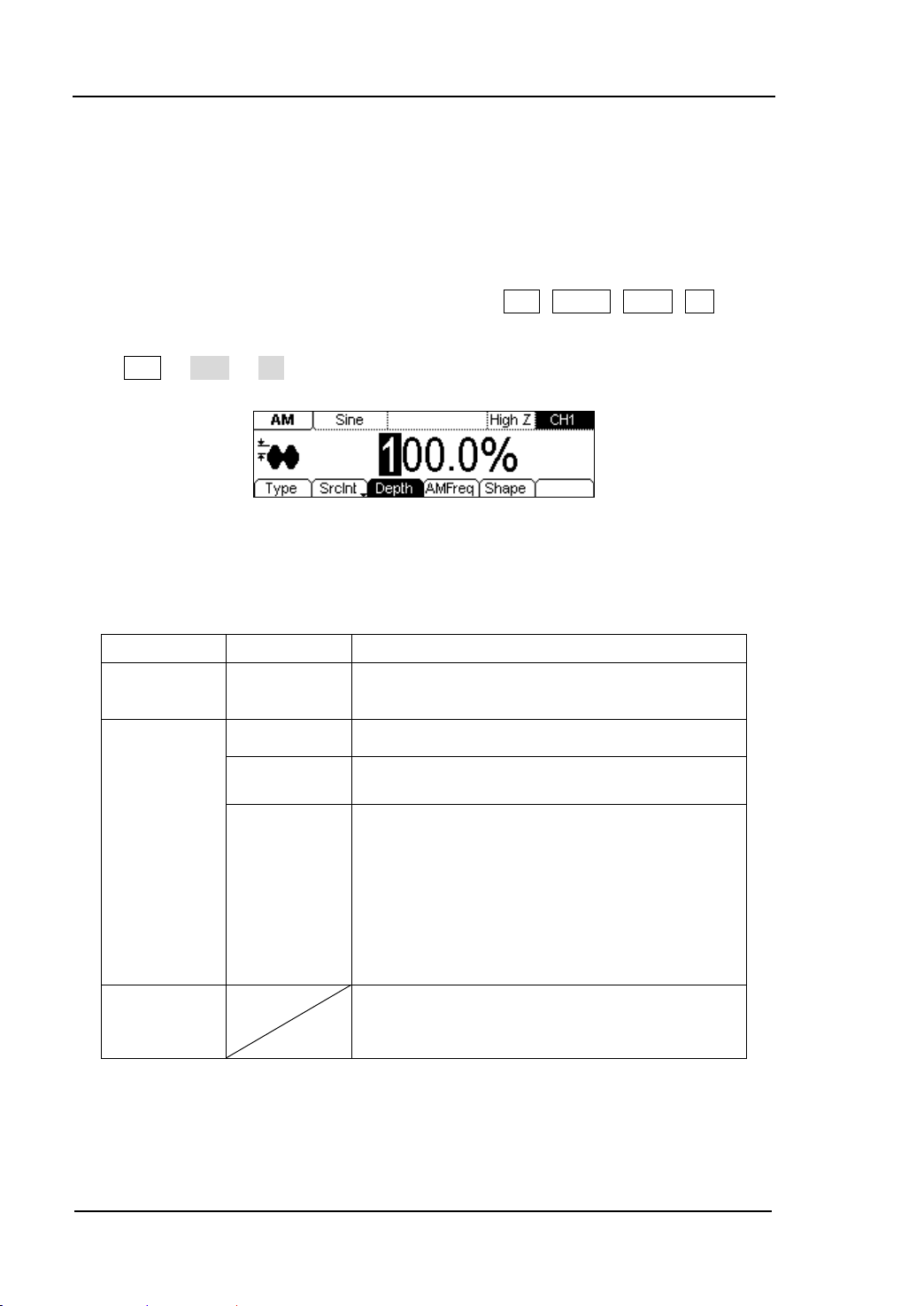

To Set AM Waveform

The modulated waveform consists of two parts: the Carrier Waveform and the

Modulating Waveform. In AM, the Amplitude of the Carrier Waveform varies with the

instantaneous voltage of the modulating waveform.

Carrier Waveform used in AM can be set through the Sine、Square、Ramp、Arb button

on the front panel.

Press Mod Type AM, enter the following interface.

Figure 2-35

Modulated Waveform Parameters Interface for AM

Table 2-13 Setting the AM parameters

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 55

Term Explanation

Modulation Depth

The Amplitude Range (also called “percentage Modulation”). Modulation Depth

varies from 0% to 120%.

In the 0% Modulation, the output amplitude is the half of the set one.

In the 100% Modulation, the output amplitude is the same with the set one.

When the modulation is greater than 100%, the instrument output no greater

than 10 VPP.

For an external source, the depth of AM is controlled by the voltage level of the

connector connected to the [Modulation In]. +5V external source corresponds

to the 100% internal Modulation.

Waveform

Depth

Carrier

Modulated

Source

Type

Frequency

In the Graph Mode, the waveform is shown in the following figure.

Figure 2-36

Waveform Parameter in the Graph Mode

RIGOL

© 2008 RIGOL Technologies, Inc. 2-29

User’s Guide for DG10× 2 Series

Page 56

RIGOL

2-30

Menu

Settings

Explanation

Type

FM

Choose Frequency Modulation

SrcInt

Deviat.

Set the Frequency Deviation between the

Modulating Waveform and the Carrier

Waveform.

FMFreq

Set the modulating waveform frequency

(2mHz~20kHz)

Shape

Choose internal modulating Waveform:

Sine

Square

Triangle

UpRamp

DnRamp

Noise

Arb

SrcExt

Deviat.

Choose External modulation, the modulating

waveform is inputted form the [Modulation In]

port on the rear panel. Only “Deviat.” needs to

be set.

To Set FM Waveform

The modulated waveform consists of two parts: the Carrier Waveform and the

Modulating Waveform. In FM, the Frequency of the Carrier Waveform varies with the

instantaneous voltage of the modulating waveform.

Carrier Waveform used in FM can be set through the Sine、Square、Ramp、Arb

button on the front panel.

Press Mod Type FM, enter the following interface.

Figure 2-37

FM Waveform Parameter Setting Interface

Table 2-14 Setting the FM parameters

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 57

In the Graph Mode, the waveform is shown as in the following figure.

Term Explanation

Frequency Deviation

The Deviation should be equal to or less than the Carrier Waveform Frequency.

The Sum of the Deviation and the Carrier Frequency should be equal to or less

than maximum frequency of the selected function plus 1kHz.

For an External Source, the Deviation is controlled by the ± 5V voltage Level of

the Connector connected to the [Modulation In]. +5V corresponds to the

selected Deviation. Lower external voltage generates less deviation, while

negative voltage reduces the modulated signal frequency to below the

corresponding carrier’s.

Modulating

Frequency

Frequency

Deviation

Figure 2-38

Waveform Parameter in the Graph Mode

RIGOL

© 2008 RIGOL Technologies, Inc. 2-31

User’s Guide for DG10× 2 Series

Page 58

RIGOL

2-32

To Set FSK Waveform

The FSK Modulation is a modulation method, the output frequency of which switches

between the two pre-set frequencies (Carrier Waveform Frequency and the Hop

Frequency). The Output Frequency which shifts from the carrier frequency to the Hop

frequency is called the FSK rate. The frequency by which the output frequency switch

from each other is determined by the Internal Frequency generator or the Signal

Voltage Level offered by the [Ext Trig/FSK/Burst] connector on the rear panel.

If you choose the Internal Modulation, the frequency at which the output

frequency shift between the carrier frequency and the Hop frequency is

determined by the set FSK rate.

If you choose External Modulation and overlook the FSK rate, the output frequency

is determined by the Voltage Level of the [Ext Trig/FSK/Burst] connector on the

rear panel. If the Voltage Level is Low, then generate the carrier frequency; when

the voltage level is high, generate the Hop frequency.

Carrier Waveform used in FSK can be set through the Sine、Square、Ramp、Arb button

on the front panel.

Press Mod Type FSK, enter the following interface.

Figure 2-39

FSK Waveform Parameter Setting Interface

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 59

Menu

Settings

Explanation

Type

FSK

Choose Frequency Shift Keying Modulation

SrcInt

HopFreq

Set the Hop Frequency Range

(Internal Source: Square with 50% duty

cycle)

FSK Rate

Set the frequency at which the output

frequency shifts between the carrier

frequency and the jumping frequency:

2mHz~50kHz.

SrcExt

HopFreq

Choose External modulation, the

modulating waveform is inputted form the

[Ext Trig/FSK/Burst] port on the rear

panel. Only “HopFreq” needs to be set.

FSK Frequency

Hop Frequency

Table 2-15 Setting the FM parameters

Press View, in the Graph Mode, the waveform is shown in the following figure.

RIGOL

Figure 2-40

Waveform Parameter in the Graph Mode

© 2008 RIGOL Technologies, Inc. 2-33

User’s Guide for DG10× 2 Series

Page 60

RIGOL

2-34

Menu

Settings

Explanation

Type

PM

Choose Phase Modulation

SrcInt

Deviat.

Set the Phase Deviation between the

Modulating Waveform and the Carrier

Waveform ( 0o~360o)

PMFreq

Set the modulating waveform frequency

(2mHz~20kHz)

Shape

Choose internal modulating Waveform:

Sine

Square

Triangle

UpRamp

DnRamp

Noise

Arb

SrcExt

Deviat.

Choose External modulation, the

modulating waveform is inputted form the

[Modulation In] port on the rear panel.

Only “Deviat.” needs to be set.

To Set PM Waveform

The modulated waveform consists of two parts: the Carrier Waveform and the

Modulating Waveform. In PM, the Phase of the Carrier Waveform varies with the

instantaneous voltage Level of the modulating waveform.

Carrier Waveform used in PM can be set through the Sine、Square、Ramp、Arb button

on the front panel.

Press Mod Type PM, enter the following interface.

Figure 2-41

PM Waveform Parameter Setting Interface

Table 2-16 Setting the PM parameters

Press View, in the Graph Mode, the waveform is shown in the following figure.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 61

Modulating

Frequency

Phase

Deviation

Figure 2-42

Waveform Parameter in the Graph Mode

RIGOL

© 2008 RIGOL Technologies, Inc. 2-35

User’s Guide for DG10× 2 Series

Page 62

RIGOL

2-36

Menu

Settings

Explanation

Linear

log

Set the Sweep with linear spacing

Set the Sweep with logarithmic spacing

Start

Center

Set the Start Frequency of the Sweep

Set the Center Frequency of the Sweep

Stop

Span

Set the Stop Frequency of the Sweep

Set the Frequency Span of the Sweep

Time

Set the Time Span of the Sweep for which the Frequency

changes from the Start Frequency to Stop Frequency.

Trigger

Source

Int: Choose Internal Source

Ext: Choose External Source, use the [Ext

Trig/FSK/Burst] connector on the rear panel

Manual: Choose manual trigger. Press Manual will

trigger a Sweep.

TrigOut

: Signal Triggered at Rise Edge

: Signal Triggered at Fall Edge

Off: Turn off Trigger Setting

Finish Setting

To Generate Sweep Signal

In the frequency sweep mode, the function generator “sweep” from the start

frequency to the stop frequency at the sweep rate you specify. Sweeping can be

generated by Sine, Square, Ramp or Arbitrary Waveforms (Pulse, Noise and DC are

not allowed).

Press the Sweep button, in the Normal Mode, the operation menu will appear on the

bottom of the screen. See Figure 2-43, set the Waveform parameters by using the

operation menu.

Figure 2-43

Sweep Waveform Parameter Setting Interface

Table 2-17 Waveform Sweep Setting Menu

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 63

RIGOL

Instructions

Possible changes or varies to the amplitude characteristic of output signal may

happen while sweep frequency on a large scale.

Sweep Frequency Setting

Use Start and Stop or Center and Span to set the range of the frequency. Press the

button again to switch to each other.

To Sweep upward, set the Start Frequency lower than the Stop Frequency, or set a

positive frequency interval.

To Sweep downward, set the Start Frequency higher than the Stop Frequency, or

set a negative frequency interval.

© 2008 RIGOL Technologies, Inc. 2-37

User’s Guide for DG10× 2 Series

Page 64

RIGOL

2-38

To Generate Burst Signal

Burst Function can generate versatile waveforms in burst, which can last specific

times of waveform cycle(N-Cycle Burst), or when the external gated signals (Gated

Burst) is applied, any waveform could be used, but noise can only be used in Gated

Burst.

Press the Burst button, in the Normal Mode, the operation menu will appear on the

screen, see Figure 2-59. Set the Waveform parameters by using the operation menu.

Figure 2-44

Burst Waveform Parameter Setting Interface

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 65

Set the N-Cycle Burst

Menu

Settings

Explanation

N-Cycle

Gated

Use the N-Cycle Mode

Use the Gated Mode

Cycles

Infinite

Set the Number of the bursts in a N-Cycle

Set the Number of the bursts in a N-Cycle

to be infinite

Phase

Set the Start Phase of the Burst

Period

Set the Period of the Burst

Delay

Set the Delay for the burst

Trigger

Source

Int: Choose Internal Source

Ext: Choose External Source, use the [Ext

Trig/FSK/Burst] connector in the rear

panel

Manual: Choose manual trigger. Press

Manual will output a burst signal

TrigOut

: Signal Triggered at Rise Edge

: Signal Triggered at Fall Edge

Off: Turn off Trigger Setting

Finish Setting

Press Burst NCycle, enter the following interface.

Figure 2-45

Operation Menu

Table 2-18 Setting the N-Cycle parameters

RIGOL

© 2008 RIGOL Technologies, Inc. 2-39

User’s Guide for DG10× 2 Series

Page 66

RIGOL

2-40

Start Phase

Burst Period

Cycle Times

Delay

N-Cycle

1. N-Cycle/ Gated

N-Cycle has specific number of waveform cycles, and every burst is activated by a

trigger event. Gated burst use external source to control burst when to be

activated.

2. Cycle Number

Set the number of Waveform Cycle in an N-Cycle (1 to 50,000 or Infinite).

If you choose Infinite, then a continuous waveform will be generated.

If needed, Burst Period will increase to cater to the specific number of cycles.

For an infinite-cycle Burst, External or Manual Trigger is needed to activate

burst. To stop the infinite burst, press Manual again.

3. Phase

Define the Start and the Stop Point in a waveform. The phase varies from -180°

to +180°, and the default setting is 0°. For an Arbitrary Waveform, 0° is the

phase of the first waveform point.

4. Period

Set the time span between an N-Cycle Burst to the next. If necessary the period

will increase to allow the specific number of cycles in a burst.

Burst Period> Period X Burst Number

5. Delay

Set the Time Delay between the Trigger Input and the Start of the N-Cycle Burst.

The minimum delay is a function of the specific burst period, and should always

be greater than (or equal to) 0.

Press View, in the Graph Mode, the waveform is shown in the following figure.

Figure 2-46

Waveform Parameter in the Graph Mode

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 67

Menu

Settings

Explanation

NCycle

Gated

Set the Gated Mode

Polarity

Pos

Neg

Set the Polarity for the Gated Signal

Phase

Set the Start Phase for the Gated Signal

Positive Gated Signal

Gated

Start Phase

Set the Gated Burst

Press Burst Gated, enter the following interface.

Figure 2-47

Operation Menu

Table 2-19 Setting the Gated parameters

RIGOL

Press View, in the Graph Mode, the waveform is shown in Figure 2-63.

Figure 2-48

Waveform Parameter in the Graph Mode

© 2008 RIGOL Technologies, Inc. 2-41

User’s Guide for DG10× 2 Series

Page 68

RIGOL

2-42

Menu

Settings

Explanation

Disk

Local

Choose display route for the

system information

U Disk

(When U Disk is

connected )

Type

State

Can store 10 States

Data

Can store 10 Waveforms

All

All types of documentation

Recall

Recall the waveform or Setting

information in the specific

position in the memory.

Store

Save the waveform to the

appointed place.

Remove

Remove any waveform that

has been stored in the memory

To Store and Recall

Press the Store/Recall Button, and the operation menu will appear at the bottom of

the screen. You can save or read the State or Data Documentation inside the

Generator or build and delete documentation in the U Disk. File names can either be

Chinese or English.

Figure 2-49

Save and Read Interface

Table 2-20 Save and Read Menu

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 69

RIGOL

To Save the Instrument State

Users are allowed to store the instrument state on any of the 10 Non-Volatile

Memories. When the power is restored, the instrument will return to the state when it

is powered off automatically. The state storage will “memorize” the selected function

(including the Arbitrary Waveform), Frequency, Amplitude, DC Offset, Phase, Duty

Cycle, Symmetry, and other modulation parameter used.

To Save the Instrument State, following the steps:

(1) Choose the file Type to store

Press Store/Recall State, and choose the storage type to be “State”.

(2) Choose the location of the file.

There are ten positions in the Local STATE1, STATE2……STATE10, choose one of

them by rotating the knob.

(3) Name the file and Save it

Press Store button, enter the desired name. Press Store to finish.

© 2008 RIGOL Technologies, Inc. 2-43

User’s Guide for DG10× 2 Series

Page 70

RIGOL

2-44

To Save Data

Users are allowed to store data document in any of the 10 Non-Volatile Memories. If

the place is already occupied, the new document will cover the old one. To save the

data, following the steps:

(1) Choose the file Type to store

Press Store/Recall State data, and choose “data” as the storage type.

(2) Choose the location of the file.

There are ten positions in the Local ARB1, ARB2……ARB10, choose one of them

by rotating the knob.

(3) Name the file and Save

Press Store button, enter the desired name. Press Store to finish.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 71

RIGOL

To Use USB storage

As shown in Figure 2-50, the storage location is divided into: the inherent Local

storage and the USB storage. At the left side of the front panel, there is a USB

interface. When USB flash drive is connected, the storage menu will show “U Disk”.

Otherwise, the default location is the internal location Local.

Figure 2-50

To use the USB Storage

(1) Install the USB flash drive

Insert the mobile memory to the USB interface on the front panel, and the screen

will show “ ”.

(2) Choose the USB Disk

Press Disk, move the cursor upward or downward to select “U Disk”. Choose

“Data” type and press Store. Enter the file name and then press Store to save the

file.

(3) Uninstall the USB flash drive

Remove the USB flash drive from the Interface and the system will inform you

that the USB flash drive has been removed, and the “ ” Sign will disappear.

© 2008 RIGOL Technologies, Inc. 2-45

User’s Guide for DG10× 2 Series

Page 72

RIGOL

2-46

Menu

Settings

Explanation

Lang

EN

English Input

CN

Chinese Input

Select

Select the current character

Remove

Delete the current character

Store

Store the file with the current name

Cancel the current operation

To Save a File

Press Store/Recall Store, enter the following interface. Enter the desired file name

in the “File Name” frame. Under the frame is the input keypad. Use the direction

button to select the desired character. When the character is in inverse color, press

Select to input it.

Figure 2-51

File Storage Interface

Table 2-21 File Storage Menu

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 73

RIGOL

File Name

Input

Keypad

1. English Input

The English Input Interface is shown in the following figure, to save a file named

as “NewFile”, following the steps below.

Figure 2-52

English Input Interface

(1) Press Lang EN, enter the English Interface.

(2) Input the file name “NewFile”.

Use the Knob to adjust the cursor to the right character, and press Select. Repeat

this until you have selected all the characters needed. Press +/- to choose the

majuscule or lowercase.

(3) Edit the File Name

When you have entered a wrong character, move the cursor to the wrong

character and press Remove to delete it. And then enter the file name again.

(4) Press Store to finish and save the file.

© 2008 RIGOL Technologies, Inc. 2-47

User’s Guide for DG10× 2 Series

Page 74

RIGOL

2-48

Key Pad

Input menu

File Name Input

Page Controller

2. Chinese Input

The Chinese Input Interface is shown in the following figure. To save a new file,

follow the instructions below:

Figure 2-53

Chinese Input Interface

(1) Press Lang CN, enter the Chinese Input Interface.

(2) Press “+/-”to choose the lowercase, and input the spell of the Chinese.

(3) Input the file name: “新文件”

Use the Knob to adjust the cursor to the right character, and press Select. Input

“Xin”. In the Input Menu, choose the Chinese character you need with the help

of the page controller and the 1~9 button on the keypad.

(4) Edit the wrong input

When a file name is wrong, move the cursor to the character and press Remove

to delete it and enter the file name again.

(5) Press Store to finish and save the file.

© 2008 RIGOL Technologies, Inc.

User’s Guide for DG10× 2 Series

Page 75

RIGOL

To Set the Utility Function

With the Utility Function, you can set the Sync On/Off, Channel Output Parameters,

Channel Coupling, Channel Copy, Counter Measurement, Interface Parameter, System

Setting and Test/Cal Parameter.

Sync switch offers the option to choose the Sync Signal or not.

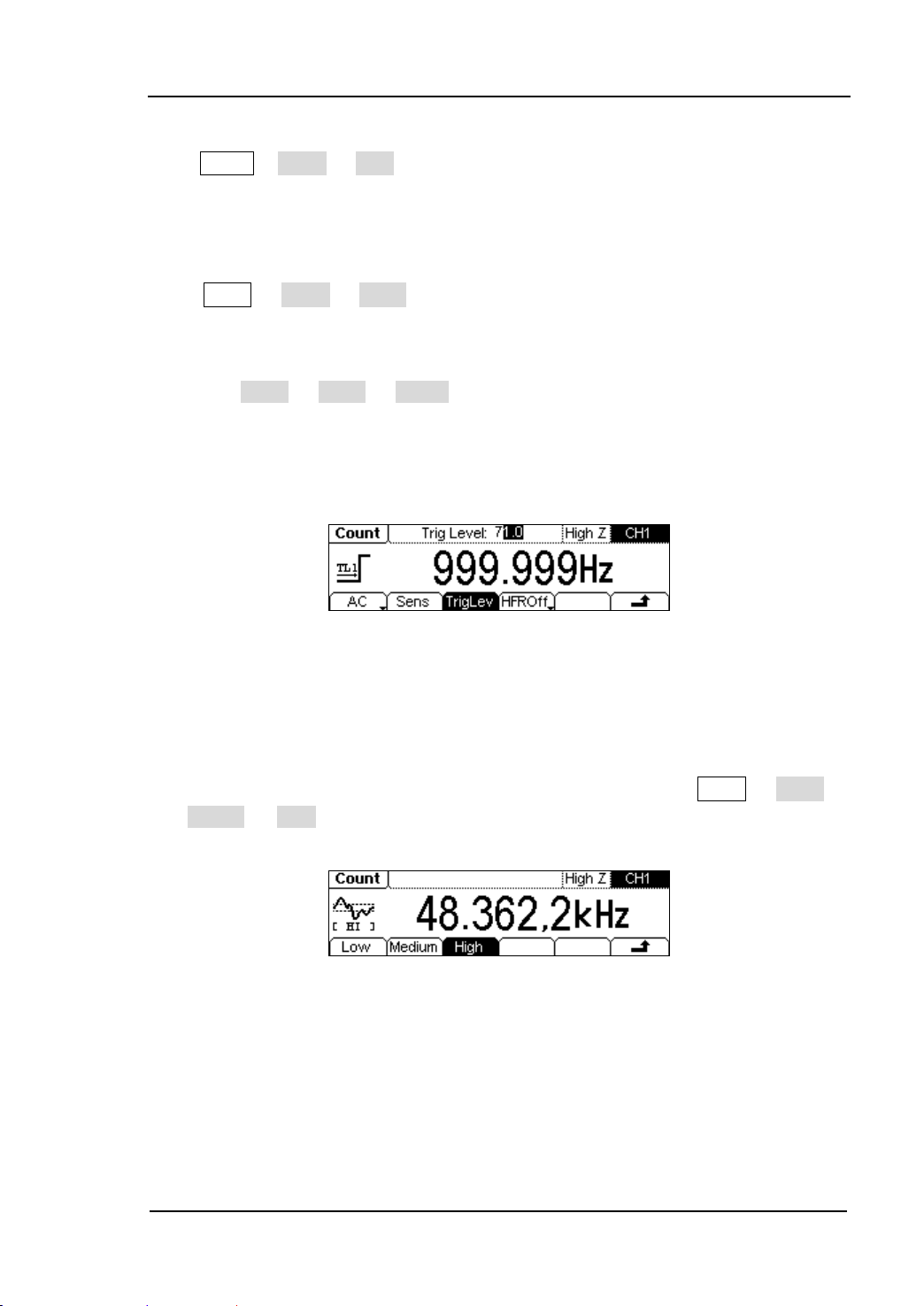

The Channel Output parameters provide the parameter setting for