RIDGID SeeSnake microReel Operator's Manual

Inspection System

SeeSnak e®microReel

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Ridge Tool Company

ii

Table of Contents

Recording Form for Machine Serial Number..............................................................................................................1

Safety Symbols..............................................................................................................................................................2

General Safety Information

Work Area Safety........................................................................................................................................................2

Electrical Safety ..........................................................................................................................................................2

Personal Safety ..........................................................................................................................................................2

Equipment Use and Care............................................................................................................................................2

Service........................................................................................................................................................................3

Specific Safety Information..........................................................................................................................................3

SeeSnake microReel Inspection System Product Safety ..........................................................................................3

Description, Specifications And Standard Equipment

Description..................................................................................................................................................................4

Specifications..............................................................................................................................................................4

Standard Equipment ..................................................................................................................................................4

Icon Legend ...................................................................................................................................................................4

microReel System Components ..................................................................................................................................5

Assembly

Camera Head Routing ................................................................................................................................................5

Opening The Case......................................................................................................................................................6

Installing System Cable ..............................................................................................................................................7

Reversing/Installing The Display Cradle (microEXPLORER Camera Monitor) ..........................................................7

Connecting microEXPLORER Camera Monitor to microReel System ......................................................................8

microReel System Ball Guides ..................................................................................................................................8

Installing Ball Guides ..................................................................................................................................................8

Pre-Operation Inspection ............................................................................................................................................8

Work Area And Equipment Set Up ..............................................................................................................................9

Setting Up The microReel System..............................................................................................................................9

CountPlus Settings ..................................................................................................................................................10

Operating Instructions................................................................................................................................................11

Performing An Inspection..........................................................................................................................................11

Using The CountPlus Counter Option ......................................................................................................................12

Locating The microReel System Sonde....................................................................................................................14

Retrieving The Camera ............................................................................................................................................14

Cleaning Instructions..................................................................................................................................................15

Accessories ................................................................................................................................................................15

Transport And Storage ..............................................................................................................................................16

Service and Repair......................................................................................................................................................16

Disposal ......................................................................................................................................................................16

Troubleshooting..........................................................................................................................................................16

Lifetime Warranty ........................................................................................................................................Back Cover

SeeSnake®microReel Inspection System

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Ridge Tool Company

2

SeeSnake®microReel Inspection System

General Safety Rules

WARNING

Read all safety warnings and instructions. Failure to follow

the warnings and instructions may result in electric shock,

fire and/or serious injury.

SAVE THESE INSTRUCTIONS!

Work Area

• Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

• Do not operate equipment in explosive atmo-

spheres, such as in the presence of flammable

liquids, gases, or dust. Equipment can create sparks

which may ignite the dust or fumes.

• Keep children and by-standers away while oper-

ating equipment. Distractions can cause you to lose

control.

Electrical Safety

• Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electrical shock

if your body is earthed or grounded.

• Do not expose equipment to rain or wet condi-

tions. Water entering equipment will increase the risk

of electrical shock.

• Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the equipment.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase

the risk of electric shock.

• If operating equipment in a damp location is un-

avoidable, use a ground fault circuit interrupter

(GFCI) protected supply. Use of a GFCI reduces

the risk of electric shock.

• Keep all electrical connections dry and off the

ground. Do not touch equipment or plugs with

wet hands. This reduces the risk of electrical shock.

Personal Safety

• Stay alert, watch what you are doing and use common sense when operating equipment. Do not

use equipment while you are tired or under the influence of drugs, alcohol or medication. A moment

of inattention while operating equipment may result in

serious personal injury.

• Use personal protective equipment. Always wear

eye protection. Protective equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce

personal injuries.

• Do not overreach. Keep proper footing and balance

at all times. This enables better control of the equipment in unexpected situations.

Equipment Use And Care

• Do not force equipment. Use the correct equipment for your application. The correct equipment will

Safety Symbols

In this operator’s manual and on the product, safety symbols and signal words are used to communicate important safety

information. This section is provided to improve understanding of these signal words and symbols.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

NOTICE indicates information that relates to the protection of property.

This symbol means read the operator’s manual carefully before using the equipment. The operator’s manual contains important

information on the safe and proper operation of the equipment.

This symbol means always wear safety glasses with side shields or goggles when handling or using this equipment to reduce

the risk of eye injury.

This symbol indicates the risk of electrical shock.

NOTICE

DANGER

WARNING

CAUTION

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Ridge Tool Company

3

SeeSnake®microReel Inspection System

do the job better and safer at the rate for which it is designed.

• Do not use equipment if the switch does not turn it

ON and OFF. Any equipment that cannot be controlled with the switch is dangerous and must be repaired.

• Disconnect the plug from the power source and/or

the battery pack from the equipment before making

any adjustments, changing accessories, or storing.

Such preventive safety measures reduce the risk of injury.

• Store idle equipment out of the reach of children

and do not allow persons unfamiliar with the equipment or these instructions to operate the equipment. Equipment can be dangerous in the hands of

untrained users.

• Maintain equipment. Check for misalignment or bind-

ing of moving parts, missing parts, breakage of parts

and any other condition that may affect the equipment’s operation. If damaged, have the equipment

repaired before use. Many accidents are caused by

poorly maintained equipment.

• Use the equipment and accessories in accordance

with these instructions, taking into account the

working conditions and the work to be performed.

Use of the equipment for operations different from

those intended could result in a hazardous situation.

• Use only accessories that are recommended by

the manufacturer for your equipment. Accessories

that may be suitable for one piece of equipment may

become hazardous when used with other equipment.

• Keep handles dry and clean; free from oil and

grease. Allows for better control of the equipment.

Service

• Have your equipment serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the equipment is maintained.

Specific Safety Information

WARNING

This section contains important safety information

that is specific to this equipment.

Read these precautions carefully before using the

SeeSnake

®

microReel Inspection System to reduce the risk of electrical shock, fire or other serious personal injury.

SAVE THESE INSTRUCTIONS!

Keep this manual with the equipment for use by the operator.

SeeSnake microReel Inspection System

Product Safety

• An improperly grounded electrical outlet can cause

electrical shock and or severely damage equipment. Always check work area for a properly grounded

electrical outlet. Presence of a three prong or GFCI outlet does not insure that the outlet is properly grounded.

If in doubt, have the outlet inspected by a licensed electrician.

• Do not operate this equipment if operator or ma-

chine is standing in water. Operating machine while

in water increases the risk of electrical shock.

• The microReel System camera and pushrod are

waterproof. The monitor and other electrical equipment and connections are not. Do not expose the

equipment to water or rain. This increases the risk of

electrical shock.

• Do not use where a danger of high voltage contact

is present. The equipment is not designed to provide high voltage protection and isolation.

• Read and understand this operator’s manual, the

monitor operators’ manual, and the instructions for

any other equipment in use before operating the

microReel System. Failure to follow all instruction

may result in property damage and/or serious personal injury.

• Always use appropriate personal protective equip-

ment while handling and using equipment in drains.

Drains may contain chemicals, bacteria and other substances that may be toxic, infectious, cause burns or

other issues. Appropriate personal protective equipment always includes safety glasses, and may include

equipment such as drain cleaning gloves or mitts, latex

or rubber gloves, face shields, goggles, protective

clothing, respirators and steel-toed footwear.

• If using drain cleaning equipment at the same time

as using drain inspection equipment, only wear

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Ridge Tool Company

4

SeeSnake®microReel Inspection System

RIDGID Drain Cleaning Gloves. Never grasp the rotating drain cleaning cable with anything else, including

other gloves or a rag. They can become wrapped

around the cable, causing hand injuries. Only wear

latex or rubber gloves under RIDGID Drain Cleaner

Gloves. Do not use damaged drain cleaning gloves.

• Practice good hygiene. Use hot, soapy water to

wash hands and other exposed body parts exposed to

drain contents after handling or using drain inspection

equipment. Do not eat or smoke while operating or

handling drain inspection equipment. This will help

prevent contamination with toxic or infectious material.

Description, Specifications

And Standard Equipment

Description

The SeeSnake®microReel Inspection System is a portable

pipe inspection diagnostic reel and camera. It comes with

a sonde (transmitter) within the camera head and there is

also an optional CountPlus counter to measure the pushrod

distance traveled. The microReel has a unique removable

cable drum, for convenience in cleaning or replacing

pushrods. It also has a removable system cable, enabling

the microReel to be configured for use with any SeeSnake

®

camera control units (CCU) or for use with the lightweight

hand-held microEXPLORER™ Digital Inspection Camera

monitor.

The microReel uses a 100 foot (30 meters) pushrod of

more rigid design than the microDrain pushrod. Where the

microDrain pushrod is built for maneuverability and short

runs through toilets and P Traps, the microReel has a

stiffer pushrod design that makes it suited for longer runs in

pipes 11/2" to 4" (3.8 to 10.2 cm) in diameter.

DO NOT ATTEMPT to negotiate toilet traps with the

microReel pushrod. It is less flexible than its cousin

the SeeSnake microDrain™ pushrod and will not handle

the close tight turns of a standard P-trap, closet bend or Strap which the microDrain may pass through.

With an appropriate SeeSnake control unit, the operator

can connect an external Line Transmitter and use a standard locator to line-trace the path of the microReel push

cable in a pipe.

Specifications

Weight ...........................12.2 lbs (5.5 kg) (with

microEXPLORER Camera

Monitor),

10.3 lbs. (4.7 Kg) (without

microEXPLORER Camera

Monitor)

Dimensions:

Length .........................13.25" (33.6 cm)

Depth...........................6.6 " (16.7 cm)

Height..........................14.2" (36 cm) (without

microEXPLORER Camera

Monitor Cradle)

Line Capacity.................1

1

⁄2" to 4" (3.8 to 10.2 cm)

Maximum Run ...............100' (30 m)

Sonde Transmitter.........512Hz

Reel & Frame

Diameter........................12.75" (32 cm)

Camera Diameter..........0.98" (25 mm)

Camera Length..............1.48" (37.6 mm)

Push Cable Diameter ....0.265" (6.7 mm)

Operating Environment:

Temperature................32° to 115° F (5°C to 46°C)

Humidity ......................5% to 95%

Storage Temperature....-4°F to 158°F (-20°C to 70°C)

Waterproof Depth ........266' (81 m)

The microReel System is protected under pending U.S.

and International patent applications.

Standard Equipment

• Operator’s Manual

• Instructional DVD

• Ball Guides

• Sonde (Transmitter)

Slip-Ring Unlock Position

Slip-Ring Lock Position

Icon Legend

.............................656 x 492 NTSC

Video

Number Of Pixels ..........323K NTSC

Lighting..........................6 High Flux LEDs

768 x 576 PAL

442K PAL

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Ridge Tool Company

5

SeeSnake®microReel Inspection System

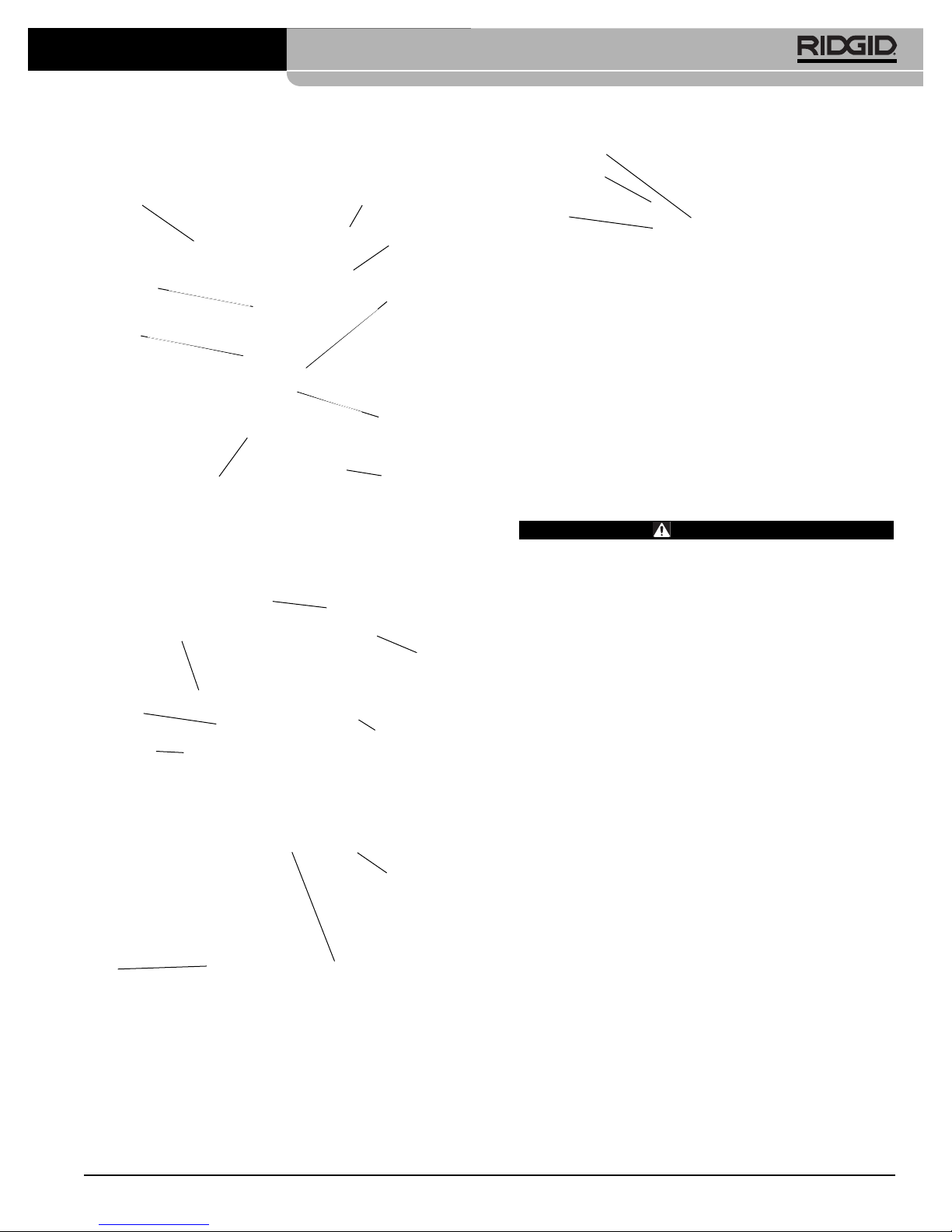

Figure 1 – Front View (SeeSnake Configuration)

microReel System Components

System Cable for

SeeSnake CCU

Camera Head

Shoulder Strap

Camera Clip

Case Latch

Pushrod

Guide

Feet

Front Case

Figure 2 – Rear View (microEXPLORER Camera Monitor

Configuration)

Assembly

WARNING

To reduce the risk of serious injury during use, follow

these procedures for proper assembly.

Camera Head Routing

1. Set the unit on a level surface laying it on its side.

2. Unfasten the case latches on either side of the

microReel

(Figure 4)

.

Figure 4 – Unlatching the microReel Case

3. Open the case carefully and only far enough to slip

the camera out through the cable guide. When routing the camera head out through the cable guide be

careful to avoid letting the pushcable spring out of

the drum or uncoil freely. Close the case and secure

the camera head in the provided clip.

microEXPLORER

Camera Monitor

Slip Ring Module

System Cable for

MicroEXPLORER

Camera Monitor

Case Latch

Feet

Rear Case

microEXPLORER

Camera Monitor

Connector Plug

microEXPLORER

Camera Monitor

Cradle

Cord Wrap

Figure 3 – Opening The Case

Camera

Head

Removable

Pushrod Drum

Pushrod

CountPlus

Keypad

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Loading...

Loading...