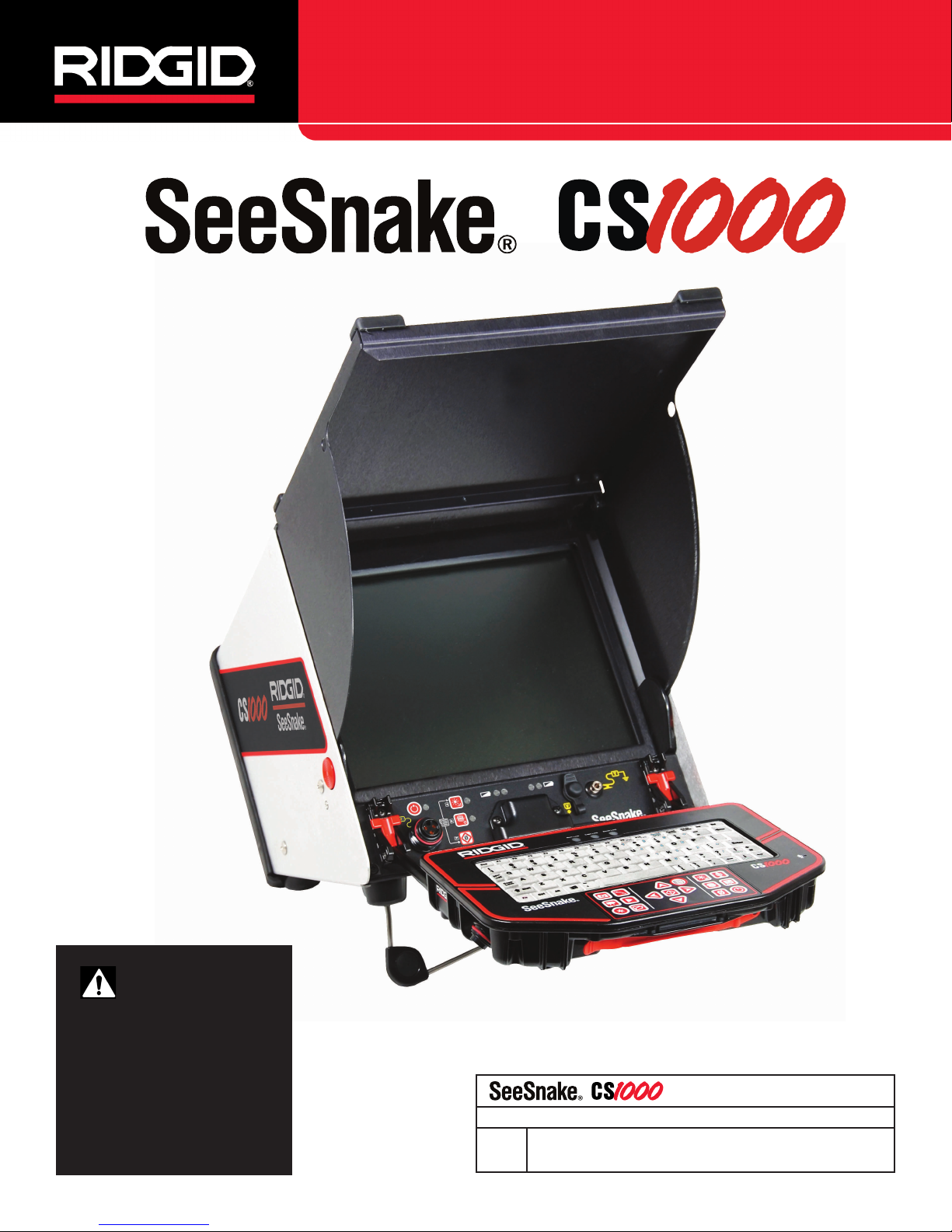

RIDGID SeeSnake CS1000 Operator's Manual

Operator’s Manual

WARNING!

Read this Operator’s Manual carefully before using

this tool. Failure to understand and follow the contents of this manual may

result in electrical shock,

fire and/or serious personal injury.

Record product serial number below as it appears on the nameplate.

Serial

No.

TM

Original Instructions – English – 1

TM

Table of Contents

Recording Form for Machine Serial Number ����������������������������������������������������������������������������������������������������������������������������� 1

Safety Symbols ����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������3

General Safety Rules

Work Area Safety ������������������������������������������������������������������������������������������������������������������������������������������������������������������������������3

Electrical Safety ��������������������������������������������������������������������������������������������������������������������������������������������������������������������������������3

Personal Safety ��������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 3

Equipment Use and Care ������������������������������������������������������������������������������������������������������������������������������������������������������������������3

Battery Use and Care ������������������������������������������������������������������������������������������������������������������������������������������������������������������������ 4

Service ���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 4

Specific Safety Information

CS1000 Safety ��������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 4

Description, Specifications, and Standard Equipment

Description ���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 5

Specifications ������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������5

Standard Equipment �������������������������������������������������������������������������������������������������������������������������������������������������������������������������6

Components ���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������6

Pre-Operation Inspection ���������������������������������������������������������������������������������������������������������������������������������������������������������������� 7

Work Area and Equipment Setup

Placement ����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������8

Connecting the CS1000 ��������������������������������������������������������������������������������������������������������������������������������������������������������������������9

Powering the CS1000 �����������������������������������������������������������������������������������������������������������������������������������������������������������������������9

Interface Overview

Software Overview �������������������������������������������������������������������������������������������������������������������������������������������������������������������������10

Keypad Overview ���������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 12

Operating Instructions

Starting a Job ���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 15

Capturing and Creating Media �������������������������������������������������������������������������������������������������������������������������������������������������������� 15

Adding Job Information �������������������������������������������������������������������������������������������������������������������������������������������������������������������18

Reviewing a Job ������������������������������������������������������������������������������������������������������������������������������������������������������������������������������ 18

Adding a New Session ��������������������������������������������������������������������������������������������������������������������������������������������������������������������19

Closing a Job ���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 21

Powering OFF the CS1000 �������������������������������������������������������������������������������������������������������������������������������������������������������������22

Configuring the CS1000

Customizing Settings ����������������������������������������������������������������������������������������������������������������������������������������������������������������������23

Delivering Reports ��������������������������������������������������������������������������������������������������������������������������������������������������������������������������25

SeeSnake HQ Software ������������������������������������������������������������������������������������������������������������������������������������������������������������������ 27

Maintenance Instructions

Software Updates ����������������������������������������������������������������������������������������������������������������������������������������������������������������������������28

Cleaning ������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������28

Accessories ��������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������28

Transport and Storage �������������������������������������������������������������������������������������������������������������������������������������������������������������������28

Service and Repair �������������������������������������������������������������������������������������������������������������������������������������������������������������������������28

Disposal ���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������29

Battery Disposal ������������������������������������������������������������������������������������������������������������������������������������������������������������������������������29

Troubleshooting �������������������������������������������������������������������������������������������������������������������������������������������������������������������������������29

Issue Tag Icons and Descriptions �����������������������������������������������������������������������������������������������������������������������������������������������30

Lifetime Warranty ��������������������������������������������������������������������������������������������������������������������������������������������������������������Back Cover

2 – English

TM

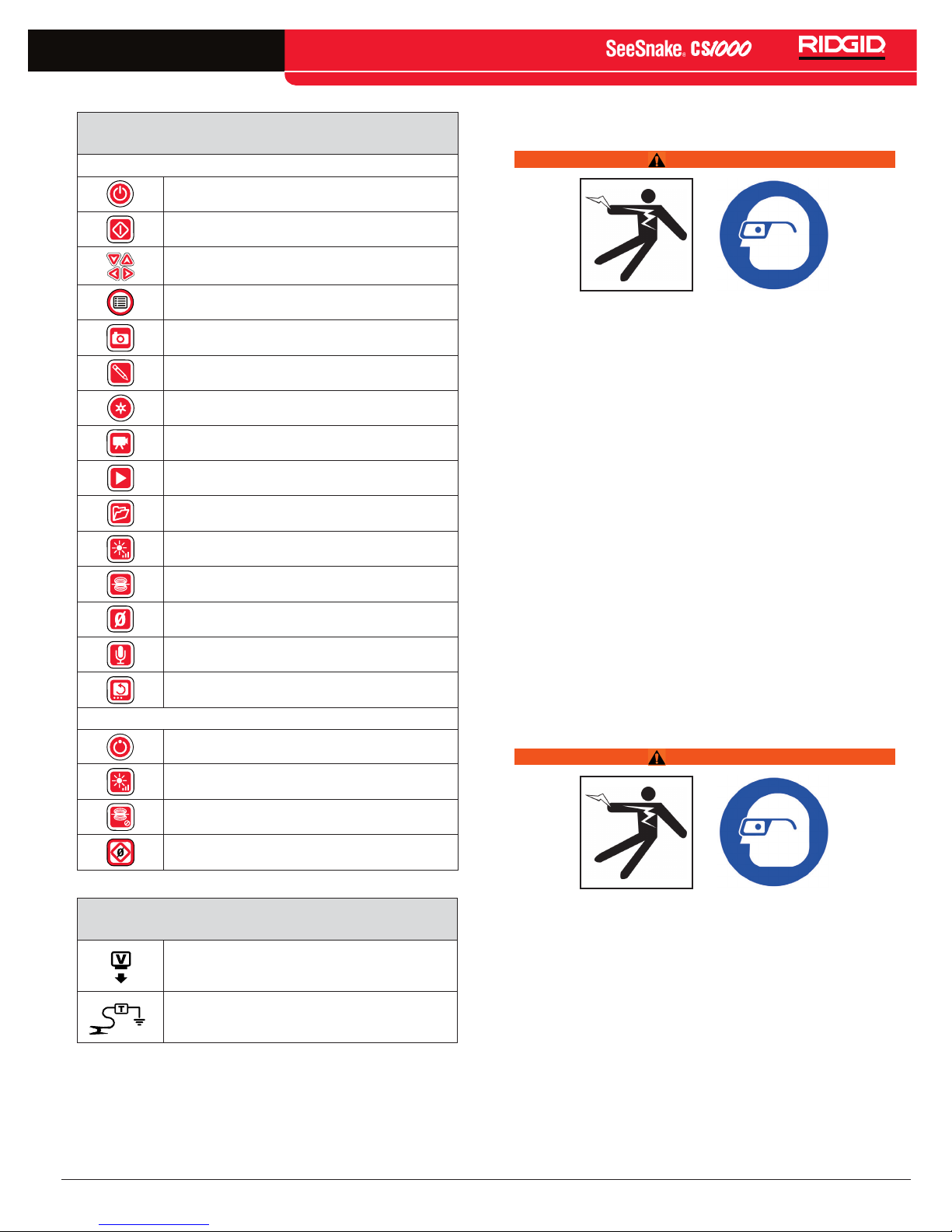

Safety Symbols

In this operator’s manual and on the product, safety symbols and signal words are used to communicate important safety

information� This section is provided to improve understanding of these signal words and symbols�

This is the safety alert symbol� It is used to alert you to potential personal injury hazards� Obey all safety messages that follow

this symbol to avoid possible injury or death�

DANGER

WARNING

CAUTION

NOTICE

This symbol means read the operator’s manual carefully before using the equipment� The operator’s manual contains important

information on the safe and proper operation of the equipment�

This symbol means always wear safety glasses with side shields or goggles when handling or using this equipment to reduce

the risk of eye injury�

This symbol indicates the risk of electrical shock�

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury�

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury�

CAUTION indicates a hazardous situation which, if not avoided, could result in minor or moderate injury�

NOTICE indicates information that relates to the protection of property�

General Safety Rules

WARNING

Read all safety warnings and instructions. Failure to follow the warnings and instructions may result in electric

shock, re, and/or serious injury.

SAVE THESE INSTRUCTIONS!

Work Area Safety

• Keep your work area clean and well lit. Cluttered or

dark areas invite accidents�

• Do not operate equipment in explosive atmospheres,

such as in the presence of flammable liquids, gases,

or dust. Equipment can create sparks which may ignite

the dust or fumes�

• Keep children and bystanders away while operating

equipment. Distractions can cause you to lose control�

Electrical Safety

• Avoid body contact with earthed or grounded sur-

faces such as pipes, radiators, ranges, and refrigerators. There is an increased risk of electrical shock if your

body is earthed or grounded�

• Do not expose equipment to rain or wet conditions.

Water entering equipment will increase the risk of electrical shock�

• Do not abuse the cord. Never use the cord for carrying,

pulling, or unplugging the power tool� Keep cord away

from heat, oil, sharp edges, and moving parts� Damaged

or entangled cords increase the risk of electric shock�

• If operating equipment in a damp location is un-

avoidable, use a ground fault circuit interrupter

(GFCI) protected supply. Use of a GFCI reduces the

risk of electric shock�

• Keep all electrical connections dry and off the

ground. Do not touch equipment or plugs with wet

hands to reduce the risk of electrical shock�

Personal Safety

• Stay alert, watch what you are doing, and use com-

mon sense when operating equipment. Do not use

equipment while you are tired or under the influence of

drugs, alcohol, or medication� A moment of inattention

while operating equipment may result in serious personal injury�

• Use personal protective equipment. Always wear eye

protection� The appropriate use of protective equipment

such as a dust mask, non-skid safety shoes, a hard hat,

and hearing protection will reduce personal injuries�

• Do not overreach. Keep proper footing and balance at

all times� This enables better control of the equipment in

unexpected situations�

• Dress properly. Do not wear loose clothing or jewel-

ry� Keep your hair, clothing, and gloves away from moving parts� Loose clothes, jewelry, and long hair can be

caught in moving parts�

Equipment Use and Care

• Do not force equipment. Use the correct equipment

for your application� The correct equipment will do the

job better and safer at the rate for which it is designed�

• Do not use equipment if the power switch does not

turn it ON and OFF. Any equipment that cannot be controlled with the power switch is dangerous and must be

repaired�

English – 3

TM

• Disconnect the plug from the power source and/or

the battery pack from the equipment before making

adjustments, changing accessories, or storing. Pre-

ventive safety measures reduce the risk of injury�

• Store idle equipment out of the reach of children

and do not allow persons unfamiliar with the equipment or these instructions to operate the equipment.

Equipment can be dangerous in the hands of untrained

users�

• Maintain equipment. Check for misalignment or bind-

ing of moving parts, missing parts, breakage of parts,

and any other condition that may affect the equipment’s

operation� If damaged, have the equipment repaired before use� Many accidents are caused by poorly maintained equipment�

• Use the equipment and accessories in accordance

with these instructions; taking into account the

working conditions and the work to be performed.

Use of the equipment for operations different from those

intended could result in a hazardous situation�

• Use only accessories that are recommended by the

manufacturer for your equipment. Accessories that

may be suitable for one piece of equipment may become

hazardous when used with other equipment�

• Keep handles dry, clean, and free from oil and grease.

This allows for better control of the equipment�

moisture can damage batteries and result in leakage,

electrical shock, fire or burns� See charger manual for

more information�

• Do not cover charger while in use. Proper ventilation

is required for correct operation� Covering charger in use

could result in fire�

• Properly dispose of batteries. Exposure to high tem-

peratures can cause the batteries to explode; do not dispose of in a fire� Some countries have regulations concerning battery disposal� Follow all applicable regulations�

Service

Ensure a qualified repair person services your equipment

using only identical replacement parts to maintain the safety

of the tool� Remove the batteries and refer servicing to quali-

fied service personnel under any of the following conditions:

• If liquid has been spilled or objects have fallen into product�

• If the product does not operate normally when following

the operating instructions�

• If the product has been dropped or damaged�

• When the product exhibits a distinct change in perfor-

mance�

Specic Safety Information

Battery Use and Care

WARNING

Read the battery charger manual before using the charger

or batteries. Failure to read, understand and follow the

contents of the charger manual may result in extensive

property damage, severe personal injury, or death.

• Recharge only with the charger specified by the

manufacturer. A charger suitable for one type of battery

pack may create a risk of fire when used with another

battery pack�

• Use equipment only with specifically designated

battery packs. Use of any other battery packs may create a risk of injury and fire�

• Do not probe battery with conductive objects. Short-

ing of battery terminals may cause sparks, burns, or

electrical shock� When the battery pack is not in use,

keep it away from other metal objects, like paper clips,

coins, keys, nails, screws or other small metal objects

that can make a connection from one terminal to another� Shorting the battery terminals together may cause

burns or a fire�

• Under abusive conditions, liquid may eject from bat-

tery; avoid contact. If contact occurs, flush with water� If

liquid contacts eyes, seek medical help� Liquid ejected

from the battery may cause irritation or burns�

• Use and store batteries and chargers in dry, appro-

priate temperature areas. Extreme temperatures and

WARNING

This section contains important safety information that is

specic to the CS1000. Read these precautions carefully

before using the CS1000 to reduce the risk of electrical

shock, re, or other serious personal injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE!

Keep this manual with the equipment for use by the operator�

CS1000 Safety

• The equipment is intended for indoor use when used

with the AC power supply. When powered by battery

protect it from exposure to weather� This product is not

water resistant� Do not expose the equipment to moisture or rain� Water entering the unit housing can increase

the risk of safety hazards and electrical shock� Only the

camera and cable in a SeeSnake Pipe Inspection Reel

are water-resistant�

• An improperly grounded electrical outlet can cause

electrical shock and/or severely damage equipment.

Always check work area for a properly grounded elec-

trical outlet� Presence of a three-prong or GFCI outlet

does not ensure that the outlet is properly grounded� If in

doubt, have the outlet inspected by a licensed electrician�

• Power the CS1000 only with a specifically designat-

ed battery or a double insulated power supply. This

minimizes the risk of electrical hazards from moisture or

faulty electrical outlets�

4 – English

TM

• Do not operate this equipment if operator or CS1000

is standing in water. Operating CS1000 while in water

increases the risk of electrical shock�

• The CS1000 is not waterproof. It is dust resistant and

splash-resistant� Only the camera and push cable are

waterproof� Do not expose the equipment to water or

rain� This increases the risk of electrical shock�

• Do not use where a danger of high voltage contact is

present. The equipment is not designed to provide high

voltage protection and isolation�

• Read and understand this operator’s manual, the

reel operator’s manual, the instructions for any

other equipment in use and all warnings before operating the CS1000. Failure to follow all instructions and

warnings may result in property damage and/or serious

personal injury�

• Always use appropriate personal protective equip-

ment when handling and using equipment in drains.

Drains may contain chemicals, bacteria, and other substances that may be toxic, infectious, cause burns or

other issues� Appropriate personal protective equipment

always includes safety glasses and may include drain

cleaning gloves or mitts, latex or rubber gloves, face

shields, goggles, protective clothing, respirators, and

steel toed footwear�

• If using drain cleaning equipment at the same time

as drain inspection equipment, only wear RIDGID

drain cleaning gloves. Never grasp the rotating drain

cleaning cable with anything else, including other gloves

or a rag� They can become wrapped around the cable

and cause hand injuries� Only wear latex or rubber

gloves under RIDGID drain cleaner gloves� Do not use

damaged drain cleaning gloves�

• Practice good hygiene. Use hot, soapy water to wash

hands and other body parts exposed to drain contents

after handling or using drain inspection equipment� Do

not eat or smoke while operating or handling drain inspection equipment� This will help prevent contamination

from toxic or infectious material�

The information supplied with this product cannot

cover all possible conditions and situations that may

occur, and should be used in conjunction with appropriate training, sound judgment, and good work practices. These factors cannot be built into the product, but

must be supplied by the operator.

The EC Declaration of Conformity (890-011-320�10) will

accompany this manual as a separate booklet when

required�

Description, Specications, and

Standard Equipment

Description

The CS1000 is designed to provide a convenient accessi-

ble portal for all your pipe inspection, recording, monitoring,

and report generation needs� Use the CS1000 with RIDGID

SeeSnake reels and cameras to make a complete inspec-

tion system�

The CS1000 will help you organize your inspections by

grouping all the associated still photos, videos, Autolog

videos, text notes, job location information, and customer

information into “Jobs�” Jobs give you a convenient way to

transfer inspection data from the CS1000, and they form

the basis for creating “Reports” in the CS1000� As you work

with your CS1000, Jobs are automatically assembled from

the information you collect during the inspection process;

making organization easy to understand�

Your CS1000 is fully compatible with SeeSnake HQ�

SeeSnake HQ is a new report generating software that you

can use to quickly generate customized reports for your cus-

tomer that can then be emailed, printed, burned onto DVD,

or exported for viewing online� You can download the latest

version of SeeSnake HQ for free at www�hq�seesnake�com�

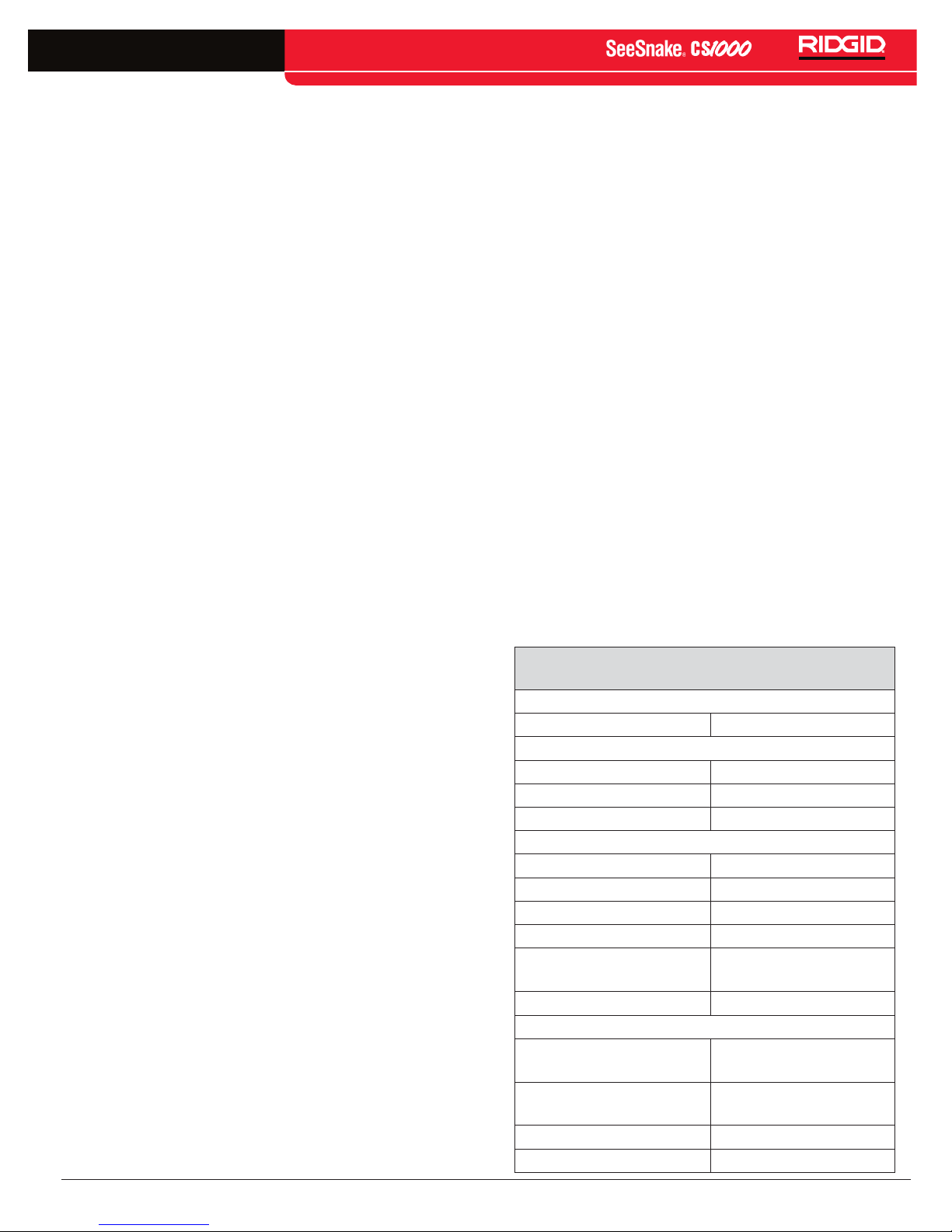

Specications

Table 1

SeeSnake CS1000 Specifications

Weight:

without batteries 14�65 lb [6�64 kg]

Closed dimensions:

Length 14�3 in [36�3 cm]

Width 11�9 in [30�2 cm]

Height 12�4 in [31�5 cm]

LCD display:

Working resolution VGA 640 x 480 pixels

Display size (HxV) 12�1 in [30�7 cm]

Contrast ratio 700:1

Brightness 500 cd/m

Power source

Battery type 18 V Li-Ion Rechargeable

Operating environment:

Temperature

Storage temperature

Humidity 5% to 95% RH

Altitude 13,120 ft [4,000 m]

100-240VAC/50-60Hz

1�5A or 18 VDC

32°F to 104°F

[0°C to 40°C]

14°F to 158°F

[−10°C to 70°C]

2

English – 5

TM

Standard Equipment

• CS1000

• Operator’s Manual

• Quick Start Guide

• Instructional DVD

Components

Front Cover

Keyboard LED Indicators

LCD Screen

Microphone

Figure 3 – CS1000 Keyboard

USB Ports Video Out Port

Mini Keypad

Tilt Stand

SeeSnake System Connector

Figure 1 – CS1000 Front View

Serial Number Label

External Power Cord

Keyboard

Factory Interface PortConnector Cover

Figure 4 – Keyboard Connections

Main Keypad

Battery Indicator LEDs

Video OutKeyboard Latch

Optional Batteries

Figure 2 – CS1000 Rear View

6 – English

SeeSnake System Connector

Cover (Connector Not Used)

Transmitter Clip-on

Terminal

Figure 5 – Mini Keypad and ConnectionsIcon

Legend

TM

Table 2

CS1000 Keypads and Icons

Main Keypad

Power Key

Select Key

Arrow Keys

Menu Key

Photo Key

Photo Tag Key

Autolog Key

Video Key

Job Review Key

Job Manager Key

LED Brightness Key

Sonde Key

Zero Key

Microphone Mute Key

Pre-Operation Inspection

WARNING

Before each use, inspect your CS1000 and correct any

problems to reduce the risk of serious injury from electrical shock or other causes and prevent machine damage.

1� Confirm that the power is OFF, that any external power

and cords are disconnected, and that the battery is removed� Inspect the cords, cables, and connectors for

damage or modification�

2� Clean any dirt, oil, or other contamination from the

CS1000 to aid in inspection and to prevent the unit

from slipping from your grip during transport or use�

3� Inspect the CS1000 for any broken, worn, missing, mis-

aligned or binding parts, or any other condition which

might prevent safe, normal operation�

4� Inspect any other equipment being used per its instruc-

tions to make sure it is in good, usable condition�

5� If any problems are found, do not use the unit until the

problems are corrected�

Image Flip Key

Mini Keypad

Power Key

LED Brightness Key

Sonde Key

Zero Key

Table 3

Connection Icons

Video Out

Transmitter Clip-on Terminal

Work Area and Equipment Setup

WARNING

Set up the CS1000 and work area in accordance with

these procedures to reduce the risk of injury from electrical shock, re, and other causes and to prevent damage

to the CS1000.

1� Check work area for the following:

• Adequate lighting�

• Flammable liquids, vapors, or dust that may ignite�

If present, do not work in area until sources have

been identified and corrected� The CS1000 is not

explosion proof� Electrical connections can cause

sparks�

• Clear, level, stable dry place for operator� Do not use

the machine while standing in water�

English – 7

TM

• Clear path to electrical outlet that does not contain

any potential sources of damage for the power cord

when using external power�

2� Inspect the work to be performed� If possible, deter-

mine the drain access points, sizes and lengths� Determine the presence of drain cleaning chemicals or other

chemicals� If chemicals are present, it is important to

understand the specific safety measures required to

work around the chemicals� Contact the chemical manufacturer for required information�

3� Determine the correct equipment for the application�

The CS1000 is made to view and record inspections

with a SeeSnake inspection camera�

4� Make sure all equipment has been properly inspected�

5� Evaluate the work area and determine if any barriers

are needed to keep bystanders away� Bystanders can

distract the operator during use� If working near traffic,

erect cones or other barriers to alert drivers�

6� If needed, remove fixture (water closet, sink, etc�) to

allow access�

Placement

Place the CS1000 to allow easy access and viewing while

manipulating the camera and push cable for inspection�

Setup the CS1000 so its screen is easy to see� Adjust the

controls so they are easy to reach during use� In brightly lit

areas, point the screen away from bright light sources and/

or use the monitor’s front cover as a sun shade to reduce

glare� Make sure that the location is not wet and will not let

the CS1000 and other equipment get wet during use� The

CS1000 is not waterproof and exposure to wet conditions

can cause electrical shock or equipment damage�

Place camera and reel as instructed in their operator’s

manual� Ensure the CS1000 and cable reel are stable�

Tilt Stand

You can use the tilt stand to customize the viewing angle of

the screen and the positioning of keyboard depending on

the inspection environment and personal preference�

1

2

Figure 6 – Placing the CS1000 and Setting Up the

Tilt Stand

Front Cover

The CS1000 front cover serves two purposes: it protects the

unit during transportation and storage, and it acts as a sun

hood to reduce glare during inspections�

Opening the Front Cover

1� Depress the orange Front Cover Release Buttons (See

Item 1, Figure 7) on each side of the unit�

2� Raise the front cover (See Item 2, Figure 7) to its up-

permost position where it will lock securely into place�

3� Lower the keyboard (See Item 3, Figure 7) into its op-

erating position�

4� (Optional) Use the keyboard latches (See Item 4, Fig-

ure 7) to adjust and secure the position of your keyboard� Pull the red T-shaped latches toward you to lock

the keyboard into an upwardly angled position�

2

1� Use the handle (See Item 1, Figure 6) on the top of the

CS1000 to place the unit in the desired location�

2� Tilt the unit back slightly and pull forward on the tilt

stand (See Item 2, Figure 6) until it locks in place�

3� To store the tilt stand, tilt the unit back slightly, and push

the tilt stand toward the back of the unit until it lays flat

against the base of the unit�

8 – English

1

4

Figure 7 – Opening the Front Cover

3

TM

Closing the Front Cover

1� Disconnect all connections, including USB�

2� Fold up the keyboard�

3� Keeping fingers clear of the front cover, depress the or-

ange Front Cover Release Buttons on both sides of the

unit to drop the cover to the lower position� Press front

cover into place until it locks�

Connecting the CS1000

System Connector

NOTICE

System Cable, twist only the locking sleeve! To prevent

damage to pins, never bend or twist the connector or

cable!

1� Unwrap the SeeSnake System Cable from its holder

and insert the System Cable plug into the SeeSnake

System Connector (See Item 1, Figure8) on the front

edge of the keyboard�

2� To join the connectors, align the guide pin to the guide

socket, push the connector straight in� A guide ridge

(See Item 2, Figure 8) molded into the top of the cable

connector will point up when the plug is correctly

aligned�

3� Tighten the outer locking sleeve (See Item 3, Figure8)�

When connecting or disconnecting the

Additional CS1000 Ports

There are four ports located behind the red rubber connec-

tor cover on the front edge of the keyboard�

NOTICE

containing the USB ports, Video Out Port, and Factory

Interface Port are not internally sealed. Keep the connector cover in place in wet or moist conditions to pre-

vent damage to the ports.

The areas behind the connector cover,

Figure 9 – CS1000 Ports

USB Ports

The two USB ports are suitable for thumb drives or other

storage devices� Use any one USB port at a time�

Video Out Port

The Video Out Port enables you to connect the CS1000 to an

external monitor for video display� The Video Out Port only

outputs audio on video playback and not during recording�

1

3

2

Figure 8 – Connecting SeeSnake System Cable to

CS1000 System Connection

Factory Interface Port

To perform diagnostics the manufacturer will use the Fac-

tory Interface Port� Do not use the Factory Interface Port for

other devices�

Powering the CS1000

The CS1000 can be powered with one or two RIDGID Li-Ion

rechargeable battery or plugged into an outlet using a AC

power converter� Battery power is the preferred powering

method to reduce the risk of electrical shock� The power

converter is not rated for outdoor use� Only use the CS1000

indoors when powered with the AC converter�

When fully charged, one 18 V Li-Ion battery rated at 2�2Ah

will power the CS1000 for approximately 1�75hours; and

two batteries will power the CS1000 for approximately 4�5

hours� Actual battery operation time will vary with battery

rating and use�

Battery Power

• With dry hands, insert one or two 18 V Li-Ion batteries

into the battery docks in the back of the unit� The unit

can be tilted forward and rested on the closed face for

convenience�

• Only recharge the batteries with the approved charger�

Attempting to charge batteries with the wrong charger

can damage the batteries�

English – 9

TM

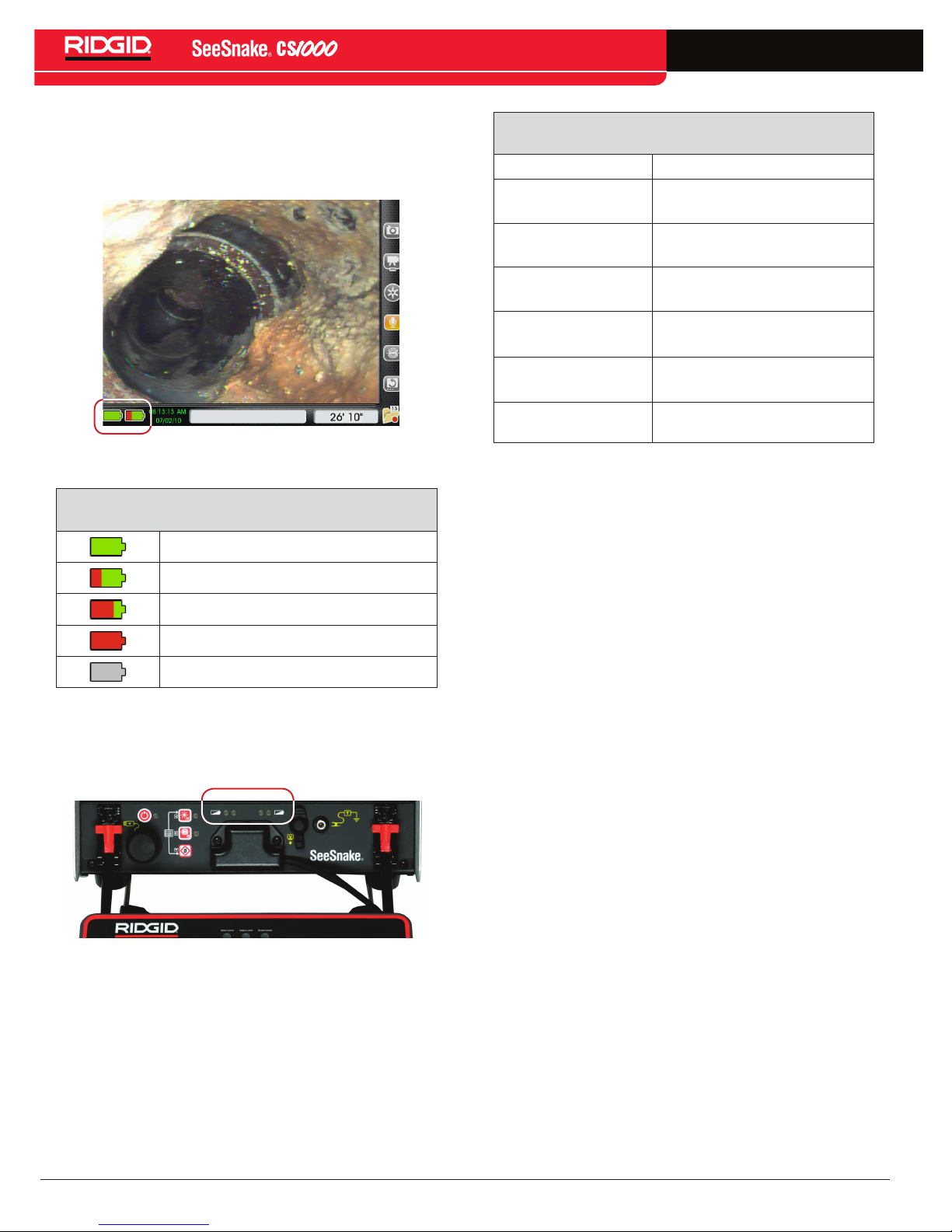

Checking Battery Status: Icons

You can monitor your battery levels using the two battery

icons in the bottom left corner of the screen� Table 4 shows

the on-screen battery indicator icons�

Figure 10 – On-Screen Battery Icons

Table 4

On-Screen Battery Icons

Full charge

Partial charge

Battery low

No charge

AC power

Table 5

Battery Status LED Indicators

LED Behavior Meaning

Left LED is Green

Right LED is OFF

Left LED is Green

Right LED is Red

Left LED is OFF

Right LED is Red

Blinking red and beeps

Solid red and continu-

ous tone

Slow blink

Battery full charge

Battery partial charge

Battery low

Replace batteries immediately�

Shutdown in 1 min

Dead batteries�

Shutdown in 5 sec

External power in use�

Beeps when disconnected

Outlet Power

NOTE: The provided external power supply is intended for

indoor use only.

For plug-in operation, a double insulated AC power cord is

supplied to reduce wall outlet voltage to the correct voltage

for the CS1000�

1� To power the system using AC power with the power

cord, locate the power cord on the back of the unit� Unhook the Velcro® strap and remove the plug from its

holder�

Checking Battery Status: LEDs

The CS1000 has four battery indicator LEDs, two for each

battery, located just below the screen�

Figure 11 – Battery Indicator LEDs

When the unit is turned ON and there are batteries in the

battery docks, the LEDs on the CS1000 will reflect the state

of each battery as shown in Table 5�

2� With dry hands, plug the power cord into an approved

outlet� If using an extension cord ensure the use of adequate wire gauge� For cords no greater than 25 ft [7�6

m] long, use a wire gage of at least 18 AWG is required�

For cords longer than 25 ft [7�6 m], use a wire gauge of

at least 16 AWG�

3� Never power the unit from AC using the power cord in

a wet environment�

Sometimes you may need to move locations during a job� If

you are running your CS1000 using AC power and have at

least one battery in the rear battery docks, you can unplug

the CS1000 to move it without powering it OFF�

Interface Overview

Software Overview

The on-screen interface has three regions: Live View, Dash-

board, and Status Bar�

Live View

The largest area of the screen, where the live video feed

appears, is called “Live View” (See Item 1, Figure 12)�

10 – English

Loading...

Loading...