RIDGID seesnake compact2 Operator's Manual

WARNING!

Operator’s Manual

Read this manual carefully before using this tool.

Failure to understand and

follow the contents of this

manual may result in electrical shock, fire, and/or serious injury.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Table of Contents

Introduction

Regulatory Statements ...............................................................................................................................................3

Safety Symbols ...........................................................................................................................................................3

General Safety Rules

Work Area Safety ........................................................................................................................................................ 4

Electrical Safety .......................................................................................................................................................... 4

Personal Safety ..........................................................................................................................................................4

Equipment Use and Care ...........................................................................................................................................5

Pre-Operation Inspection

Specific Safety Information

SeeSnake Compact2 Safety ......................................................................................................................................6

Product Overview

Description

Specifications

Standard Equipment ................................................................................................................................................... 8

System Components .................................................................................................................................................. 8

Operating Instructions

Placement ................................................................................................................................................................ 10

Routing the Camera .................................................................................................................................................10

Connecting to a SeeSnake Monitor .......................................................................................................................... 11

Inspection Overview ................................................................................................................................................. 12

Best Practices ........................................................................................................................................................... 13

Pipe Guides .............................................................................................................................................................. 14

Locating the Sonde .................................................................................................................................................. 15

Line Tracing the Push Cable ..................................................................................................................................... 16

Retrieving the Camera .............................................................................................................................................. 16

Individual Components

Self-Leveling Camera ............................................................................................................................................... 17

System Cable Assembly ........................................................................................................................................... 17

Docking System ........................................................................................................................................................ 18

Maintenance and Support

Maintaining Components .......................................................................................................................................... 20

Cleaning ...................................................................................................................................................................21

Accessories .............................................................................................................................................................. 22

Transport and Storage .............................................................................................................................................. 22

Service and Repair ................................................................................................................................................... 22

Disposal ....................................................................................................................................................................22

Troubleshooting ........................................................................................................................................................23

Appendices

Appendix A: Docking Fin Removal ............................................................................................................................24

Appendix B: Camera Fault Isolation .........................................................................................................................24

Appendix C: Camera Removal .................................................................................................................................25

Appendix D: Camera Installation ..............................................................................................................................26

.................................................................................................................................................................7

.............................................................................................................................................................8

2 – English

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Introduction

The warnings, cautions, and instructions discussed in this manual cannot cover all possi-

ble conditions and situations that may occur. It

must be understood by the operator that common sense and caution are factors which cannot

be built into this product, but must be supplied

by the operator.

Regulatory Statements

The EC Declaration of Conformity (890-011-

320.10) will accompany this manual as a separate booklet when required.

This device complies with Part 15 of FCC rules.

Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that

may cause undesired operation.

Safety Symbols

In this manual and on the product, safety symbols and

signal words are used to communicate important safety

information. This section is provided to improve understanding of these signal words and symbols.

This is the safety alert symbol. It is used to alert

you to potential injury hazards. Obey all safety

messages that follow this symbol to avoid possible injury or death.

DANGER

DANGER indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

CAUTION indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

NOTICE

NOTICE indicates information that relates

to the protection of property.

This symbol means read the operator’s manual

carefully before using the equipment. The manual contains important information on the safe

and proper operation of the equipment.

This symbol means always wear safety glasses

with side shields or goggles when handling or

using this equipment to reduce the risk of eye injury.

This symbol indicates the risk of electrical shock.

English – 3

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

General Safety Rules

WARNING

Read all safety warnings and instructions. Failure to

follow the warnings and instructions may result in

electrical shock, fire, and/or serious injury.

SAVE THESE INSTRUCTIONS!

Work Area Safety

• Keep your work area clean and well lit. Cluttered or

dark areas invite accidents.

• Do not operate equipment in explosive atmo-

spheres, such as in the presence of flammable liquids, gases, or dust. Equipment can create sparks

which may ignite the dust or fumes.

• Keep children and bystanders away while operat-

ing equipment. Distractions can cause you to lose

control.

• Avoid traffic. Pay attention to moving vehicles when

using on or near roadways. Wear high-visibility clothing or reflector vests.

Electrical Safety

• Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges, and refrigerators. There is an increased risk of electrical shock

if your body is earthed or grounded.

Personal Safety

• Stay alert, watch what you are doing, and use common sense when operating equipment. Do not use

equipment while you are tired or under the influence of

drugs, alcohol, or medication. A moment of inattention

while operating equipment may result in serious injury.

• Dress properly. Do not wear loose clothing or jewelry.

Loose clothes, jewelry, and long hair can be caught in

moving parts.

• Practice good hygiene. Use hot, soapy water to wash

hands and other body parts exposed to drain contents

after handling or using drain inspection equipment. To

prevent contamination from toxic or infectious material, do not eat or smoke while operating or handling

drain inspection equipment.

• Always use appropriate personal protective equip-

ment when handling and using equipment in

drains. Drains may contain chemicals, bacteria, and

other substances that may be toxic, infectious, and

cause burns or other issues. Appropriate personal protective equipment always includes safety glasses and

may include a dust mask, hard hat, hearing protection,

drain cleaning gloves or mitts, latex or rubber gloves,

face shields, goggles, protective clothing, respirators,

and steel toed, non-skid footwear.

• If using drain cleaning equipment and drain in-

spection equipment at the same time, wear RIDGID

drain cleaning gloves. Never grasp the rotating drain

cleaning cable with anything else, including other

gloves or a rag which can become wrapped around

the cable and cause hand injuries. Only wear latex

or rubber gloves underneath RIDGID drain cleaner

gloves. Do not use damaged drain cleaning gloves.

• Do not expose equipment to rain or wet condi-

tions. Water entering equipment will increase the risk

of electrical shock.

• Keep all electrical connections dry and off the

ground. Touching equipment or plugs with wet hands

can increase the risk of electrical shock.

• Do not abuse the cord. Never use the cord for car-

rying, pulling, or unplugging the power tool. Keep cord

away from heat, oil, sharp edges, and moving parts.

Damaged or entangled cords increase the risk of electrical shock.

• If operating equipment that is powered by an AC

adapter in a damp location is unavoidable, use a

ground fault circuit interrupter (GFCI) protected

supply. Use of a GFCI with an AC adapter reduces

the risk of electrical shock.

4 – English

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Equipment Use and Care

• Do not force equipment. Use the correct equipment

for your application. The correct equipment does the

job better and more safely.

• Do not use equipment if the power switch does not

turn it on and off. Any equipment that cannot be controlled with the power switch is dangerous and must

be repaired.

• Disconnect the plug from the power source and/or

the battery pack from the equipment before making adjustments, changing accessories, or storing.

Preventive safety measures reduce the risk of injury.

Pre-Operation Inspection

WARNING

To reduce the risk of serious injury from electrical

shock or other causes, and to prevent damage to

your equipment, inspect all equipment and correct

any problems before each use.

• Store idle equipment out of the reach of children

and do not allow persons unfamiliar with the equipment or these instructions to operate the equipment. Equipment can be dangerous in the hands of

untrained users.

• Maintain equipment. Check for misalignment or bind-

ing of moving parts, missing parts, breakage of parts,

and any other condition that may affect the equipment’s operation. If damaged, have the equipment

repaired before use. Many accidents are caused by

poorly maintained equipment.

• Do not overreach. Keep proper footing and balance

at all times. This enables better control of the equipment in unexpected situations.

• Use the equipment and accessories in accordance

with these instructions; taking into account the

working conditions and the work to be performed.

Use of the equipment for operations different from

those intended can result in hazardous situations.

• Use only accessories that are recommended by

the manufacturer for your equipment. Accessories

that may be suitable for one piece of equipment may

become hazardous when used with other equipment.

• Keep handles dry, clean, and free from oil and

grease. Clean handles give better control of the equipment.

To inspect all equipment, follow these steps:

1. Power off your equipment.

2. Disconnect and inspect all cords, cables, and connectors for damage or modification.

3. Clean any dirt, oil, or other contamination from your

equipment to ease inspection and to prevent it from

slipping from your grip during transport or use.

4. Inspect your equipment for any broken, worn, missing, misaligned, or binding parts, or any other condition which might prevent safe, normal operation.

5. Refer to the instructions for all other equipment to inspect and make sure it is in good, usable condition.

6. Check your work area for the following:

• Adequate lighting.

• The presence of flammable liquids, vapors, or

dust that may ignite. If present, do not work in

area until sources have been identified and corrected. The equipment is not explosion proof.

Electrical connections can cause sparks.

• A clear, level, stable, and dry place for the operator. Do not use the equipment while standing

in water.

7. Examine the job to be done and determine the correct equipment for the task.

8. Observe the work area and erect barriers as necessary to keep bystanders away.

English – 5

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Specic Safety Information

WARNING

This section contains important safety information

that is specific to the SeeSnake Compact2. Read

these precautions carefully before using the equipment to reduce the risk of electrical shock, fire, and/

or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE!

SeeSnake Compact2 Safety

• Read and understand this manual, the digital reporting monitor’s manual, and the instructions for

any other equipment you are using before operating the equipment. Failure to follow all instruction

may result in property damage and/or serious injury.

Keep this manual with the equipment for future use.

• Do not carry the Compact2 by the monitor’s dock-

ing handle or its front handle when transporting

the system long distances or under conditions

where disengagement of the docking system

would be hazardous. An unexpected disengagement

of the docking system may result in property damage

and/or injury.

• Placing the Compact2 where the drum cannot spin

freely may result in the push cable over-winding

inside the drum. Over-winding the push cable may re-

sult in property damage and/or serious injury. During

operation, place the Compact2 on a stable surface

and make sure the drum can spin freely.

• Operating the equipment while in water increas-

es the risk of electrical shock. Do not operate the

Compact2 if operator or equipment are standing in

water.

• The digital reporting monitor’s battery and other

electrical equipment and connections are not waterproof. Do not expose the equipment to wet loca-

tions.

• The equipment is not designed to provide high

voltage protection and isolation. Do not use where

a danger of high voltage contact is present.

• To prevent damage to the Compact2 and to de-

crease the risk of injury, do not expose the

Compact2 to mechanical shocks. Exposure to me-

chanical shocks can damage equipment and increase

the risk of serious injury.

6 – English

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Product Overview

Description

The SeeSnake Compact2 camera reel offers fast, easy

setup and can take on the most diverse and demanding

inspection conditions. The Compact2 features a self-leveling camera at the end of a push cable stiff enough to

give you the power to push through small or restricted

pipes, yet flexible enough to make multiple tight turns.

The Compact2’s unique docking system gives you ultra-fast setup. Tilt the CS6Pak to the desired viewing

angle while docked or easily remove it from the dock for

convenient placement in your work area.

The CS6Pak is a compact, portable digital reporting monitor that you can use to capture audio, video, and photos

of your pipe inspections. When you use the CS6Pak with

the Compact2, you can deliver a USB drive containing

an automatically generated professional report of the inspection to your customer before leaving the premises.

The Compact2 has a 30m [100ft] long, friction-reducing

push cable and a 25mm [1in] self-leveling camera designed to inspect pipes ranging from 38mm to 152mm

[1.5in to 6in] in diameter, depending on pipe conditions.

Once a point of interest has been found in the pipe, use

the integrated 512Hz sonde and a receiver to locate its

position.

All SeeSnake monitors can connect to the Compact2 with

the SeeSnake system cable. The SeeSnake CS6Pak is

specifically designed to mount on the Compact2’s docking system for viewing ease, quick setup, and effortless transport. You can retrofit the SeeSnake MiniPak to

mount on the docking system with the Docking Handle

Kit, sold separately.

English – 7

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Specifications

Weight 8kg [17lb]

Overall Dimensions

Length 625mm [25in]

Height 432mm [17in]

Width 360mm [14in]

Drum Diameter 432mm [17in]

Camera

Type Self-leveling

Length 38mm [1.5in]

Diameter 25mm [1in]

Light source 6 LEDs

Sonde 512Hz

Resolution

NTSC

656 × 492 pixels

PA L 768 × 576 pixels

Spring Assembly

Type Single

Length including camera 325mm [12.8in]

Push Cable

Length 30m [100ft]

Diameter 6mm [0.26in]

Fiberglass core diameter 3mm [0.14in]

Minimum bend radius 63mm [2.5in]

Pipe Capacity

§

38mm to 152mm

[1.5in to 6in]

System Cable Length 3m [10ft]

Operating Environment

Temperature ‡

Storage temperature

Ingress protection

without monitor

-10°C to 50°C

[14°F to 122°F]

-10°C to 70°C

[14°F to 158°F]

IP×5

Relative humidity 5 to 95 percent

Altitude 4,000m [13,120ft]

§ Actual pipe capacity depends on pipe conditions.

‡ While the camera can function in extreme temperatures,

some image quality changes may occur.

Standard Equipment

• SeeSnake Compact2

• Docking System

• Operator’s Manual

• Product Video

• Pipe Guide Kit

• Spanner Wrench

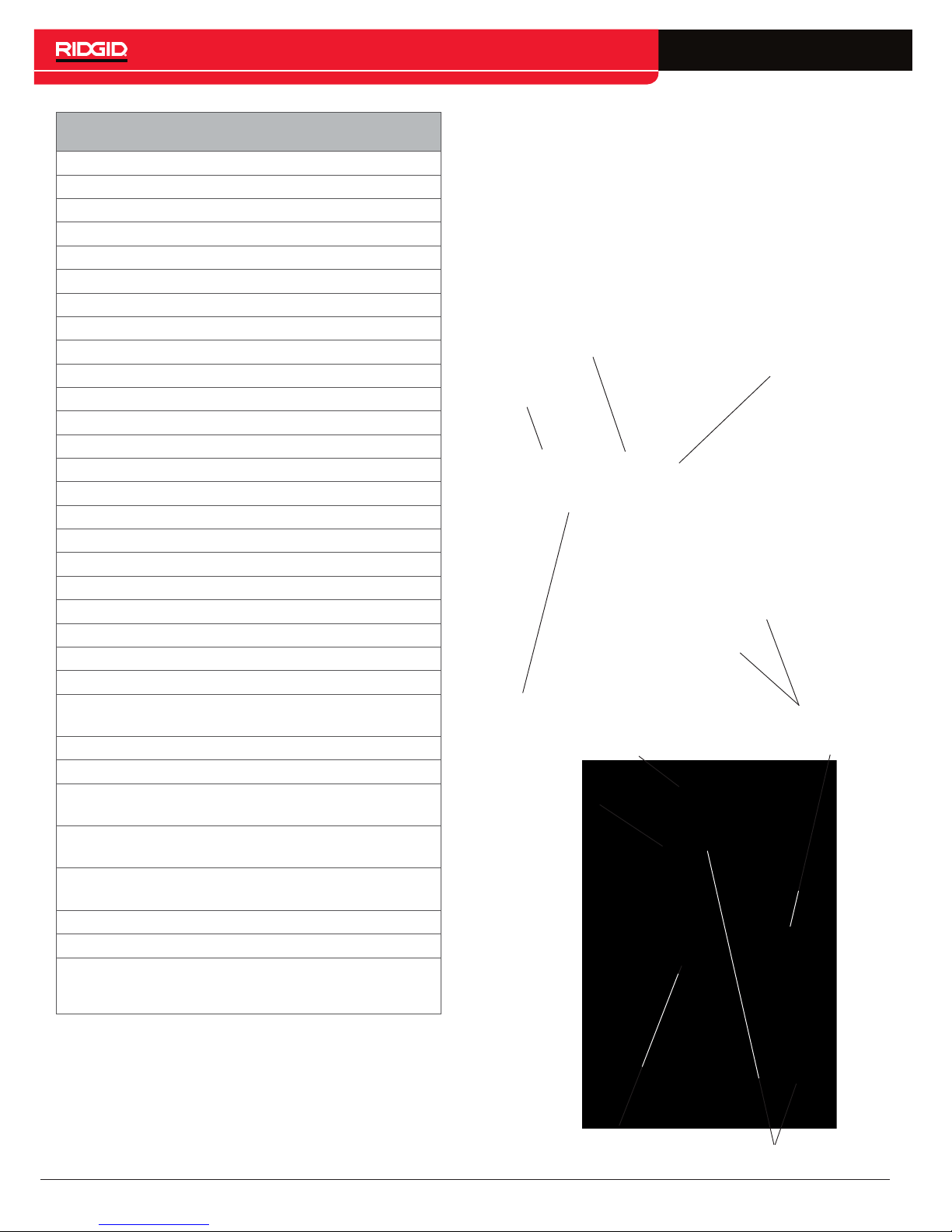

System Components

SeeSnake System Connector

Frame

SeeSnake System Cable

Frame Handle

Frame

Docking System

Cable Wraps

Drum

Serial Number Label

Rubber Feet

8 – English

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Loading...

Loading...