RIDGID SeeSnake Compact, SeeSnake Color Compact Operator's Manual

Table of Contents

Recording Form for Machine Model and Serial Number ...........................................................................................1

General Safety Information

Work Area Safety ........................................................................................................................................................2

Electrical Safety...........................................................................................................................................................2

Battery Precautions ..................................................................................................................................................2

Personal Safety ...........................................................................................................................................................2

Tool Use and Care ......................................................................................................................................................3

Service ........................................................................................................................................................................3

Specific Safety Information

Equipment Safety ........................................................................................................................................................4

Description, Specifications and Standard Equipment

Description ..................................................................................................................................................................4

System Components ...................................................................................................................................................4

Camera Head ..............................................................................................................................................................4

Reel/Frame..................................................................................................................................................................5

Monitor Pack Camera Control Unit (CCU) ..................................................................................................................5

Locating System (Optional) .........................................................................................................................................7

Specifications ..............................................................................................................................................................7

Standard Equipment....................................................................................................................................................7

Set Up and Operation

Equipment Set Up .......................................................................................................................................................7

Connections .............................................................................................................................................................8

Operation..................................................................................................................................................................9

Video Recording.......................................................................................................................................................9

At the Job Site .............................................................................................................................................................9

Transportation & Storage ...........................................................................................................................................11

Centering Guides

Installing the SeeSnake®Star-Type Centering Guides..............................................................................................11

Installing Star-Type Centering Guides ...................................................................................................................12

Removing Star-Type Centering Guides .................................................................................................................12

Installing the SeeSnake®Compact, and FlatPack Ball-Type Centering Guides........................................................12

Maintenance and Cleaning

Preventative Maintenance.........................................................................................................................................13

Camera Head .........................................................................................................................................................13

Spring Assembly ....................................................................................................................................................13

Push Cable, Reel/Frame ........................................................................................................................................13

Monitor Pack ..........................................................................................................................................................14

Locating Faulty Components.....................................................................................................................................14

Service and Repair ......................................................................................................................................................14

Troubleshooting ..........................................................................................................................................................15

Icon Legend .................................................................................................................................................................15

Lifetime Warranty..........................................................................................................................................Back Cover

Ridge Tool Companyii

SeeSnake®Compact and Color Compact

Ridge Tool Company2

SeeSnake®Compact and Color Compact

General Safety Information

CAUTION! Read and understand all instructions. Failure

to follow all instructions listed below may

result in electric shock, fire, and/or serious

personal injury.

SAVE THESE INSTRUCTIONS!

Work Area Safety

• Keep your work area clean and well lit. Cluttered

benches and dark areas may cause accidents.

• Do not operate electrical devices or power tools in

explosive atmospheres, such as in the presence of

flammable liquids, gases, or heavy dust. Electrical

devices or power tools create sparks which may ignite

the dust or fumes.

• Keep bystanders, children, and visitors away

while operating tool. Distractions can cause you

to lose control.

• Do not let visitors contact the tool or extension

cord. Such preventative measures reduce the risk

of injury.

Electrical Safety

• Avoid body contact with grounded surfaces such

as pipes, radiators, ranges and refrigerators. There

is an increased risk of electrical shock if your body is

grounded.

• Tool is only splash resistant when the Monitor

Shield is in place. Water entering a power tool will increase the risk of electrical shock. Keep battery out of

direct contact with water. Protect AC adapter from

damp or wet conditions.

• Do not abuse cord. Never use the cord to carry the

tool or pull the plug from an outlet. Keep cord

away from heat, oil, sharp edges, or moving parts.

Replace damaged cords immediately. Damaged

cords increase the risk of electrical shock.

• When operating a power tool outside, use an out-

door extension cord marked “W-A” or “W”. These

cords are rated for outdoor use and reduce the risk of

electrical shock.

• Connect the tool to an AC power supply that

matches the name plate specification (120 or 240

Volts). Incorrect voltage supply can cause electrical

shock or burns.

• Use proper extension cords.

(See chart.)

Insufficient

conductor size will cause excessive voltage drop and

loss of power.

• Reduce the risk of electrical shock! Keep all elec-

trical connections dry and off the ground. Do not

touch plug with wet hands.

Battery Precautions

• Use only the size and type of battery specified.

• Be sure to install the battery with the correct po-

larity as indicated in the battery compartment.

• Recharge batteries with charging units specified by

the battery manufacturer. Using an improper charger

can overheat and rupture the battery.

• Properly dispose of the battery. Exposure to high

temperatures can cause the battery to explode,

so do not dispose of in a fire. Some countries have

regulations concerning battery disposal. Please follow all applicable regulations.

Personal Safety

• Stay alert, watch what you are doing and use common sense when operating a power tool. Do not

use tool while tired or under the influence of drugs,

alcohol, or medications. A moment of inattention

while operating power tools may result in serious personal injury.

• Dress properly. Do not wear loose clothing or jew-

elry. Contain long hair. Keep your hair, clothing, and

gloves away from moving parts. Loose clothes, jew-

elry, or long hair can be caught in moving parts.

• Gloves should always be worn for health and safety

reasons. Sewer lines are unsanitary and may contain

harmful bacteria and viruses.

• Do not overreach. Keep proper footing and bal-

ance at all times. Proper footing and balance enables

better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protection.

Dust mask, non-skid safety shoes, hard hat, or hearing

protection must be used for appropriate conditions.

• Use proper accessories. Do not place this product

on any unstable cart or surface. The product may fall

causing serious injury to a child or adult or serious

damage to the product.

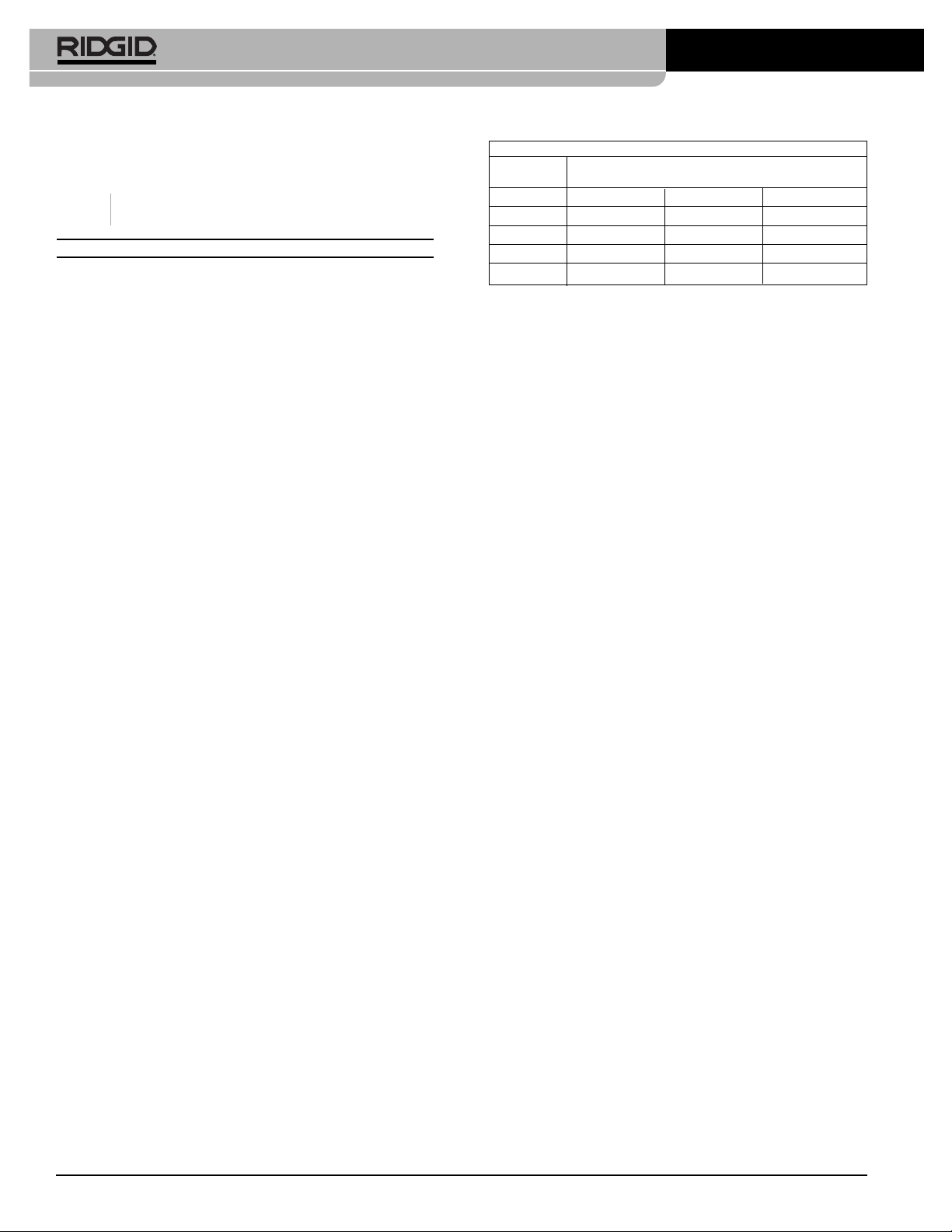

Minimum Wire Gauge for Extension Cord

Nameplate Total Length (in feet/meters),

Amps Gauge (in AWG/mm2)

0 - 25/0 - 8 26 - 50/8 - 15 51 - 100/15 - 30

0 – 6

18 AWG/.75mm216 AWG/1.00mm216 AWG/1.00mm

2

6 – 10

18 AWG/1.00mm216 AWG/1.00mm214 AWG/1.00mm

2

10 – 12

16 AWG/1.50mm216 AWG/1.50mm214 AWG/1.50mm

2

12 – 16

14 AWG/1.50mm212 AWG/1.50mm

2

NOT RECOMMENDED

Ridge Tool Company 3

• Prevent object and liquid entry. Never spill liquid

of any kind on the product. To prevent electrical

shock never push objects of any kind into this product

through openings as they may touch dangerous voltage points or short to parts that could result in a fire or

electrical shock.

• Make sure the pipe you are going to inspect is not

electrically charged, or

hot

! In some cases ground

circuits may be returned to cast iron pipes causing them to be electrically charged. If you have

any reason to suspect the pipe is

hot

have it

checked by a qualified electrician before putting

the camera in the line. As sections of pipe joined

with shielded hubless connections or compression

gaskets may be electrically isolated, care should be

taken to check the entire length of any pipe you are

going to inspect.

Tool Use and Care

• Always transport the SeeSnake Compact with the

Monitor Shield closed. This prevents product damage.

• Do not use tool if switch does not turn it ON or

OFF. Any tool that cannot be controlled with the switch

is dangerous and must be repaired.

• Store idle tools out of the reach of children and

other untrained persons. Tools are dangerous in

the hands of untrained users.

• Maintain tools with care. Properly maintained tools

are less likely to cause injury.

• Check for breakage of parts, and any other condi-

tions that may affect the tool’s operation. If damaged,

have the tool serviced before using. Many accidents are

caused by poorly maintained tools.

• Use only accessories that are recommended by the

manufacturer for your tool. Accessories that may be

suitable for one tool may become hazardous when

used on another tool.

• Inspect tool and extension cords periodically and

replace if damaged. Damaged cords increase the risk

of electrical shock.

• Keep handles dry and clean; free from oil and

grease. Allows for better control of the tool.

• Store tools in dry, shaded place. Such measures re-

duce the risk of electrical shock.

• Protect against lightning. For added protection for

this product during a lightning storm, or when it is

left unattended and unused for long periods of time,

unplug it from the wall outlet. This will prevent damage

to the product due to lightning and power surges.

SeeSnake®Compact and Color Compact

• Protect against excessive heat. The product should

be situated away from heat sources such as radiators,

heat registers, stoves or other products (including amplifiers) that produce heat.

Service

• Tool service must be performed only by qualified

repair personnel. Service or maintenance performed

by unqualified repair personnel could result in injury.

• When servicing a tool, use only identical replace-

ment parts. Follow instructions in the Maintenance

Section of this manual. Use of unauthorized parts or

failure to follow maintenance instructions may create a

risk of electrical shock or injury.

• Follow instructions for changing accessories.

Accidents are caused by poorly maintained tools.

• Provide proper cleaning. Unplug this product from the

wall outlet and remove battery before cleaning. Do

not use liquid cleaners or aerosol cleaners. Use a

damp cloth for cleaning.

• Conduct a safety check. Upon completion of any

service or repair of this product, ask the service technician to perform safety checks to determine that the

product is in proper operating condition.

• Damage to the product that requires service.

Unplug this product from the wall outlet, remove the

battery and refer servicing to qualified service personnel under any of the following conditions:

• When the power cord or plug is damaged;

• If liquid has been spilled, or objects have fallen into

product;

• If product does not operate normally by following the

operating instructions;

• If the product has been dropped or damaged in

any way;

• When the product exhibits a distinct change in per-

formance.

If you have any questions regarding the service or repair

of this machine, call or write to:

Ridge Tool Company

Technical Service Department

400 Clark Street

Elyria, Ohio 44035-6001

Tel: (800) 519-3456

E-mail: TechServices@ridgid.com

On the Web: www.ridgid.com

or www.seesnake.com

In any correspondence, please give all the information

shown on the nameplate of your tool including model

number, voltage and serial number.

Ridge Tool Company4

SeeSnake®Compact and Color Compact

controllers: Monitor Pack, Color Video Tool Case, Color

Monitor+VCR, Monitor+, Monitor+VCR, Power+A, Power+.

System Components

The SeeSnake Compact pipe inspection system contains

the following three sub assemblies: Camera Head,

Reel/Frame, and Monitor Pack (CCU). Please take a moment to learn the functions of each of these components.

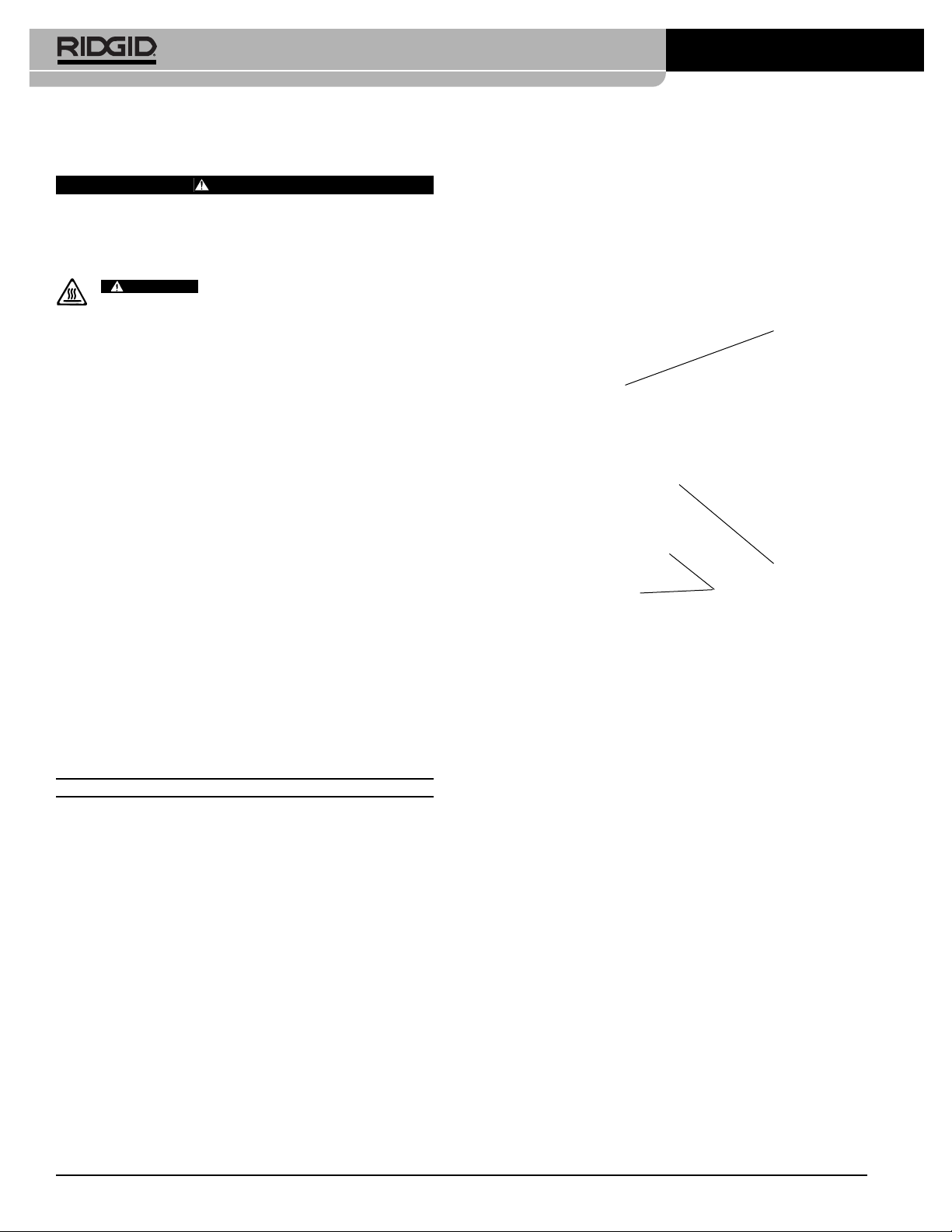

(Figure 1)

Figure 1 – System Components

1) Camera Head

The camera head

(Figure 2)

has adjustable lighting elements and a highly scratch-resistant sapphire window

(Lens Port). The Camera is rated to a water depth of 330′

(100m).

Figure 2 – Camera Head

LED – Light Emitting Diode. The SeeSnake B&W Compact

uses infrared LEDs that are invisible to the human eye

but provide the camera’s imaging sensor with enough

light for a clear picture. The color version uses white LEDs

which can be seen.

LED Window – The donut shaped window that covers

and protects the LEDs from abrasion.

Specific Safety Information

CAUTION

Read this operator’s manual carefully before using

the product. Failure to understand and follow the

contents of this manual may result in electrical

shock, fire and/or serious personal injury.

Camera head can get HOT! Turn

OFF camera while not in use.

Equipment Safety

• Extension cords are not recommended unless they

are plugged into a Ground Fault Circuit Interrupter

(GFCI) found in circuit boxes or receptacles.

• Do not operate the system with electrical components removed. Exposure to internal parts increases

the risk of injury.

• Do not place the unit in water. Water entering the

housings will increase the risk of electrical shock.

• Do not use the unit as a chair or table. Dropping or

shocking the unit can result in damage to the unit,

which increases the risk of electrical shock.

• If used on a cart, product and cart should be

moved with care. Quick stops, excessive force and uneven surfaces may cause the product and cart

combination to overturn.

• Only the camera head and cable are waterproof.

The monitor is splash-resistant only when the Monitor

Shield is covering the monitor screen and the unit is

operating under battery power. Do not expose AC

adapter to damp conditions.

SAVE THESE INSTRUCTIONS!

Description, Specifications and

Standard Equipment

Description

The SeeSnake Compact pipe inspection system includes

a camera reel and splash-resistant Monitor Pack mounted

on a sturdy metal frame. The Monitor Pack camera control

unit (CCU) has a built-in high-resolution monitor and can

be powered from its included AC adapter or from a

rechargeable battery. The Compact is available in both

B&W and color versions.

The SeeSnake Compact pipe inspection system is designed for inspecting 11/2" to 4" (38mm to 102mm) drain

lines. Its flexible camera head can negotiate multiple

hard 90° bends and be pushed up to 100' (30m).

The SeeSnake Compact reel is a UL Listed accessory, intended for use only with the following UL Listed SeeSnake

CAUTION

Monitor Pack

Reel & Frame

Camera Head

Guide Hoops

LED Window

Spring Assembly

Ridge Tool Company 5

SeeSnake®Compact and Color Compact

Spring Assembly – Flexible stainless steel spring and associated components that hold the camera to the push

cable. It provides a flexible transition from camera to push

cable, and protects the terminations within the spring.

In Line Transmitter – Is contained within the spring assembly and transmits at 512Hz.

Safety Cable – Stainless steel cable within the spring

assembly that keep the spring from over-extending.

This ensures the camera’s internal connectors are not

stressed when pulling the camera out of a pipe.

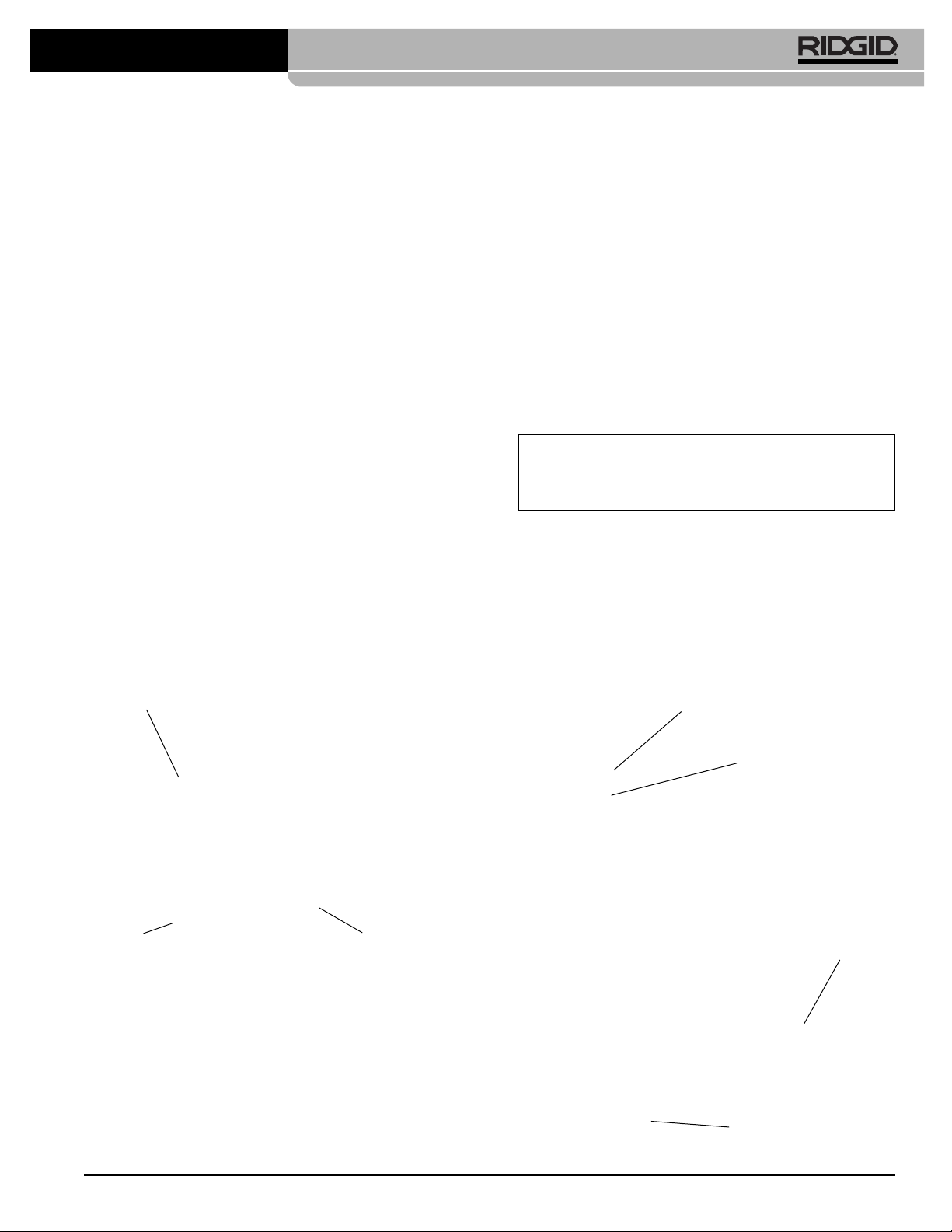

2) Reel/Frame

Push Cable –

(Figure 3)

Terminates right behind the

spring. It has a high-strength fiberglass core stiff enough

to allow long distance pushing while flexible enough to

negotiate tight turns.

Drum – The push cable is stored in the molded gray

drum mounted underneath the frame. Mercury-free slip

rings inside the drum’s hub provide a rotating electrical

connection between the drum and frame.

Frame – The sturdy, powder coated metal structure that

holds the reel and Monitor Pack. The guide hoops on the

frame guide the push cable in and out of the drum.

Interconnect Cord – Stores on the frame and provides

the connection between the camera reel and the Monitor

Pack (CCU).

(Figure 3)

Figure 3 – Reel and Frame

Distance Counter – Measures the distance the cable

has traveled inside the pipe. Displays in feet and inches.

Can be zeroed by turning the monitor OFF/ON.

Kickstand – The kickstand attaches to the front of the

frame for positioning the system at different viewing

angles.

Locking Sleeve – Found at the end of the Interconnect

Cord, it provides a solid connection between the CCU

and the reel.

NOTE! When attaching or removing the Interconnect Cord

from the CCU, ONLY turn the connector’s outer

locking sleeve! Bending or twisting the connector

body inside the locking sleeve will damage the

connector!

3) Monitor Pack Camera Control Unit

(CCU)

The Monitor Pack is a camera control unit (CCU) that provides power to the camera reel, control of the camera’s light

intensity and a built-in monitor for viewing the image. The

Monitor Pack

(Figure 4)

may be powered by either a 120

volt or 230 volt AC source. A 14.4V Makita®rechargeable

battery can also power the system.

(See Table below.)

The following Makita®batteries are approved for use with

this system: 1422 (RIDGID P/N 83407), 1433 and 1434.

Monitor Shield – Protects the monitor and internal electronics

(Figure 4)

.

Figure 4 – Monitor Pack

Tilt Stand – The front handle attached to the monitor

shield also acts as a tilt stand for positioning the monitor

at different viewing angles

(Figure 5)

.

Figure 5 – Tilt Stand

Interconnect Cord

Frame

Drum (Push

Cable Storage)

RIDGID Catalog Numbers Description

83407 14.4V Battery

83417 115V Charger

84112 230V Charger

Monitor Shield

and

Release Lever

Monitor Shield

Tilt Stand/Handle

Loading...

Loading...