Page 1

OPERATOR’S MANUAL

MANUEL D’UTILISATION

MANUAL DEL OPERADOR

4-1/2 in. ANGLE GRINDER

115 mm (4-1/2 po) MEULEUSE D’ANGLE

115 mm (4-1/2 pulg.) AMOLADOR ANGULAR

R1005

To register your RIDGID

product, please visit:

http://register.RIDGID.com

Pour enregistrer votre

produit de RIDGID,

s’il vous plaît la visite:

http://register.RIDGID.com

Para registrar su producto

de RIDGID, por favor visita:

http://register.RIDGID.com

Your angle grinder has been engineered and manufactured to our high standards for dependability, ease of operation, and

operator safety. When properly cared for, it will give you years of rugged, trouble-free performance.

WARNING:

To reduce the risk of injury, the user must read and understand the operator’s manual before using this product.

Thank you for buying a RIDGID® product.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Cette meuleuse d’angle a été conçue et fabriquée conformément

à nos strictes normes de fiabilité, simplicité d’emploi et sécurité

d’utilisation. Correctement entretenue, elle vous donnera des

années de fonctionnement robuste et sans problèmes.

AVERTISSEMENT :

Pour réduire les risques de blessures, l’utilisateur doit

lire et veiller à bien comprendre le manuel d’utilisation

avant d’employer ce produit.

Merci d’avoir acheté un produit RIDGID®.

CONSERVER CE MANUEL POUR

FUTURE RÉFÉRENCE

Su amoladora angular ha sido diseñada y fabricada de conformidad

con nuestras estrictas normas para brindar fiabilidad, facilidad de

uso y seguridad para el operador. Con el debido cuidado, le brindará

muchos años de sólido funcionamiento y sin problemas.

ADVERTENCIA:

Para reducir el riesgo de lesiones, el usuario debe leer

y comprender el manual del operador antes de usar

este producto.

Le agradecemos la compra de un producto RIDGID®.

GUARDE ESTE MANUAL PARA

FUTURAS CONSULTAS

Page 2

TABLE OF CONTENTS

TABLE DES MATIÈRES / ÍNDICE DE CONTENIDO

Introduction ......................................................................................................................................................................2

Introduction / Introducción

General Safety Rules .....................................................................................................................................................3-4

Règles de sécurité générales / Reglas de seguridad generales

Specific Safety Rules .....................................................................................................................................................4-5

Règles de sécurité particulières / Reglas de seguridad específicas

Symbols ............................................................................................................................................................................ 6

Symboles / Símbolos

Electrical ........................................................................................................................................................................... 7

Caractéristiques électriques / Aspectos eléctricos

Features ............................................................................................................................................................................8

Caractéristiques / Características

Assembly .....................................................................................................................................................................8-10

Assemblage / Armado

Operation ...................................................................................................................................................................10-11

Utilisation / Funcionamiento

Maintenance ................................................................................................................................................................... 12

Entretien / Mantenimiento

Warranty .........................................................................................................................................................................13

Garantie / Garantía

Figure numbers (illustrations) ....................................................................................................................................14-16

Figure numéros (illustrations) / Figura numeras (ilustraciones)

Parts Ordering and Service ...............................................................................................................................Back Page

Commande de pièces et réparation / Pedidos de piezas y servicio ......................................................... Page arrière / Pág. posterior

INTRODUCTION

INTRODUCTION / INTRODUCCIóN

This product has many features for making its use more pleasant and enjoyable. Safety, performance, and dependability

have been given top priority in the design of this product making it easy to maintain and operate.

* * *

Ce produit offre de nombreuses fonctions destinées à rendre son utilisation plus plaisante et satisfaisante. Lors de la

conception de ce produit, l’accent a été mis sur la sécurité, les performances et la fiabilité, afin d’en faire un outil facile à

utiliser et à entretenir.

* * *

Este producto ofrece numerosas características para hacer más agradable y placentero su uso. En el diseño de este producto

se ha conferido prioridad a la seguridad, el desempeño y la fiabilidad, por lo cual se facilita su manejo y mantenimiento.

2

Page 3

GENERAL SAFETY RULES

WARNING:

Read all instructions. Failure to follow all

instructions listed below may result in electric

shock, fire and/or serious injury.

SAVE THESE INSTRUCTIONS

WORK AREA

Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases,

or dust. Power tools create sparks which may ignite the

dust or fumes.

Keep bystanders, children, and visitors away while

operating a power tool. Distractions can cause you to

lose control.

ELECTRICAL SAFETY

Double insulated tools are equipped with a polarized

plug (one blade is wider than the other). This plug will

fit in a polarized outlet only one way. If the plug does

not fit fully in the outlet, reverse the plug. If it still

does not fit, contact a qualified electrician to install a

polarized outlet. Do not change the plug in any way.

Double insulation

wire grounded power cord and grounded power supply

system.

Avoid body contact with grounded surfaces such as

pipes, radiators, ranges, and refrigerators. There is an

increased risk of electric shock if your body is grounded.

Don’t expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric shock.

Do not abuse the cord. Never use the cord to carry the

tools or pull the plug from an outlet. Keep cord away

from heat, oil, sharp edges, or moving parts. Replace

damaged cords immediately. Damaged cords increase

the risk of electric shock.

When operating a power tool outside, use an outdoor

extension cord marked “W-A” or “W”. These cords

are rated for outdoor use and reduce the risk of electric

shock.

PERSONAL SAFETY

Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use tool

while tired or under the influence of drugs, alcohol,

or medication. A moment of inattention while operating

power tools may result in serious personal injury.

Dress properly. Do not wear loose clothing or jewelry.

Contain long hair. Keep your hair, clothing, and gloves

away from moving parts. Loose clothes, jewelry, or long

hair can be caught in moving parts.

eliminates the need for the three-

Avoid accidental starting. Be sure switch is off

before plugging in. Carrying tools with your finger on the

switch or plugging in tools that have the switch on invites

accidents.

Remove adjusting keys or wrenches before turning

the tool on. A wrench or a key that is left attached to a

rotating part of the tool may result in personal injury.

Do not overreach. Keep proper footing and balance

at all times. Proper footing and balance enables better

control of the tool in unexpected situations.

Use safety equipment. Always wear eye protection.

Dust mask, nonskid safety shoes, hard hat, or hearing

protection must be used for appropriate conditions.

Do not wear loose clothing or jewelry. Contain long

hair. Loose clothes, jewelry, or long hair can be drawn

into air vents.

Do not use on a ladder or unstable support. Stable

footing on a solid surface enables better control of the

tool in unexpected situations.

TOOL USE AND CARE

Use clamps or other practical way to secure and

support the workpiece to a stable platform. Holding

the work by hand or against your body is unstable and

may lead to loss of control.

Do not force tool. Use the correct tool for your

application. The correct tool will do the job better and

safer at the rate for which it is designed.

Do not use tool if switch does not turn it on or off. Any

tool that cannot be controlled with the switch is dangerous and must be repaired.

Disconnect the plug from power source before making

any adjustments, changing accessories, or storing the

tool. Such preventive safety measures reduce the risk of

starting the tool accidentally.

Store idle tools out of the reach of children and other

untrained persons. Tools are dangerous in the hands of

untrained users.

Maintain tools with care. Keep cutting tools sharp

and clean. Properly maintained tools with sharp cutting

edges are less likely to bind and are easier to control.

Check for misalignment or binding of moving parts,

breakage of parts, and any other condition that may

affect the tool’s operation. If damaged, have the tool

serviced before using. Many accidents are caused by

poorly maintained tools.

Use only accessories that are recommended by the

manufacturer for your model. Accessories that may be

suitable for one tool, may become hazardous when used

on another tool.

Keep the tool and its handle dry, clean and free from

oil and grease. Always use a clean cloth when clean-

ing. Never use brake fluids, gasoline, petroleum-based

products, or any strong solvents to clean your tool. Following this rule will reduce the risk of loss of control and

deterioration of the enclosure plastic.

3 - English

Page 4

GENERAL SAFETY RULES

SERVICE

Tool service must be performed only by qualified

repair personnel. Service or maintenance performed by

unqualified personnel may result in a risk of injury.

SPECIFIC SAFETY RULES

This power tool is intended to function as a grinder,

sander, wire brush, or polisher. Read all safety warnings,

instructions, illustrations and specifications provided

with this power tool. Failure to follow all instructions listed

below may result in electric shock, fire and/or serious injury.

Operations such as cutting-off are not recommended to

be performed with this power tool. Operations for which

the power tool was not designed may create a hazard and

cause personal injury.

Do not use accessories which are not specifically de-

signed and recommended by the tool manufacturer. Just

because the accessory can be attached to your power tool,

does not assure safe operation.

The rated speed of the accessory must be at least equal

to the maximum speed marked on the power tool. Ac-

cessories running faster than their RATED SPEED can break

and fly apart.

The outside diameter and the thickness of your acces-

sory must be within the capacity rating of your power

tool. Incorrectly sized accessories cannot be adequately

guarded or controlled.

The arbour size of wheels, flanges, backing pads or

any other accessory must properly fit the spindle of the

power tool. Accessories with arbour holes that do not match

the mounting hardware of the power tool will run out of balance, vibrate excessively and may cause loss of control.

Do not use a damaged accessory. Before each use in-

spect the accessory such as abrasive wheels for chips

and cracks, backing pad for cracks, tear or excess wear,

wire brush for loose or cracked wires. If power tool or

accessory is dropped, inspect for damage or install an

undamaged accessory. After inspecting and installing an

accessory, position yourself and bystanders away from

the plane of the rotating accessory and run the power

tool at maximum no-load speed for one minute. Damaged

accessories will normally break apart during this test time.

Wear personal protective equipment. Depending on

application, use face shield, safety goggles or safety

glasses. As appropriate, wear dust mask, hearing

protectors, gloves and workshop apron capable of

stopping small abrasive or workpiece fragments. he eye

protection must be capable of stopping flying debris

generated by various operations. The eye protection must

be capable of stopping flying debris generated by various

operations. The dust mask or respirator must be capable of

filtrating particles generated by your operation. Prolonged

exposure to high intensity noise may cause hearing loss.

Keep bystanders a safe distance away from work area.

When servicing a tool, use only identical replacement

parts. Follow instructions in the Maintenance section

of this manual. Use of unauthorized parts or failure to

follow Maintenance Instructions may create a risk of

shock or injury.

Anyone entering the work area must wear personal

protective equipment. Fragments of workpiece or of a

broken accessory may fly away and cause injury beyond

immediate area of operation.

Hold power tool by insulated gripping surfaces only,

when performing an operation where the cutting accessory may contact hidden wiring or its own cord. Cutting

accessory contacting a ²live² wire may make exposed metal

parts of the power tool ²live² and shock the operator.

Position the cord clear of the spinning accessory. If you

lose control, the cord may be cut or snagged and your hand

or arm may be pulled into the spinning accessory.

Never lay the power tool down until the accessory has

come to a complete stop. The spinning accessory may grab

the surface and pull the power tool out of your control.

Do not run the power tool while carrying it at your side.

Accidental contact with the spinning accessory could snag

your clothing, pulling the accessory into your body.

Regularly clean the power tool’s air vents. The motor’s

fan will draw the dust inside the housing and excessive

accumulation of powdered metal may cause electrical

hazards.

Do not operate the power tool near flammable materials.

Sparks could ignite these materials.

Do not use accessories that require liquid coolants. Using

water or other liquid coolants may result in electrocution or

shock.

Maintain a firm grip on the power tool and position your

body and arm to allow you to resist kickback forces.

Always use auxiliary handle, if provided, for maximum

control over kickback or torque reaction during start-up.

The operator can control torque reactions or kickback

forces, if proper precautions are taken.

Never place your hand near the rotating accessory.

Accessory may kickback over your hand.

Do not position your body in the area where power tool

will move if kickback occurs. Kickback will propel the tool

in direction opposite to the wheel’s movement at the point

of snagging.

Use special care when working corners, sharp edges etc.

Avoid bouncing and snagging the accessory. Corners,

sharp edges or bouncing have a tendency to snag the

rotating accessory and cause loss of control or kickback.

Do not attach a saw chain woodcarving blade or toothed

saw blade. Such blades create frequent kickback and loss

of control.

Use only wheel types that are recommended for your

power tool and the specific guard designed for the

4 - English

Page 5

SPECIFIC SAFETY RULES

selected wheel. Wheels for which the power tool was not

designed cannot be adequately guarded and are unsafe.

The guard must be securely attached to the power tool

and positioned for maximum safety, so the least amount

of wheel is exposed towards the operator. The guard

helps to protect operator from broken wheel fragments and

accidental contact with wheel.

Wheels must be used only for recommended applications.

For example: do not grind with the side of cut-off wheel.

Abrasive cut-off wheels are intended for peripheral grinding,

side forces applied to these wheels may cause them to

shatter.

Always use undamaged wheel flanges that are of correct

size and shape for your selected wheel. Proper wheel

flanges support the wheel thus reducing the possibility of

wheel breakage. Flanges for cut-off wheels may be different

from grinding wheel flanges.

Do not use worn down wheels from larger power tools.

Wheel intended for larger power tool is not suitable for the

higher speed of a smaller tool and may burst.

Do not use excessively oversized sanding disc paper.

Follow manufacturers recommendations, when selecting

sanding paper. Larger sanding paper extending beyond the

sanding pad presents a laceration hazard and may cause

snagging, tearing of the disc or kickback.

Do not allow any loose portion of the polishing bonnet

or its attachment strings to spin freely. Tuck away or

trim any loose attachment strings. Loose and spinning

attachment strings can entangle your fingers or snag on the

workpiece.

Be aware that wire bristles are thrown by the brush even

during ordinary operation. Do not overstress the wires by

applying excessive load to the brush. The wire bristles

can easily penetrate light clothing and/or skin.

If the use of a guard is recommended for wire brushing,

do not allow any interference of the wire wheel or brush

with the guard. Wire wheel or brush may expand in diameter

due to work load and centrifugal forces.

Always use proper guard with grinding wheel. A guard

protects operator from broken wheel fragments.

Know your power tool. Read operator’s manual carefully.

Learn its applications and limitations, as well as the

specific potential hazards related to this tool. Following

this rule will reduce the risk of electric shock, fire, or serious

injury.

Always wear eye protection with side shields marked

to comply with ANSI Z87.1. Failure to do so could result

in objects being thrown into your eyes, resulting in possible

serious injury.

Protect your lungs. Wear a face or dust mask if the

operation is dusty. Following this rule will reduce the risk

of serious personal injury.

Protect your hearing. Wear hearing protectors during

extended periods of operation. Following this rule will

reduce the risk of serious personal injury.

Inspect tool cords periodically and, if damaged, have

repaired at your nearest authorized service center.

Constantly stay aware of cord location. Following this

rule will reduce the risk of electric shock or fire.

Check damaged parts. Before further use of the tool, a

guard or other part that is damaged should be carefully

checked to determine that it will operate properly and

perform its intended function. Check for alignment of

moving parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that may affect its

operation. A guard or other part that is damaged should

be properly repaired or replaced by an authorized service

center. Following this rule will reduce the risk of shock, fire,

or serious injury.

Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one heavy

enough to carry the current your product will draw. A

wire gauge size (A.W.G.) of at least 14 is recommended

for an extension cord 50 feet or less in length. A cord

exceeding 100 feet is not recommended. If in doubt, use

the next heavier gauge. The smaller the gauge number,

the heavier the cord. An undersized cord will cause a drop

in line voltage resulting in loss of power and overheating.

Inspect for and remove all nails from lumber before using

this tool. Following this rule will reduce the risk of serious

personal injury.

If the power supply cord is damaged, it must be replaced

only by the manufacturer or by an authorized service center

to avoid risk.

Save these instructions. Refer to them frequently and use

them to instruct others who may use this tool. If you loan

someone this tool, loan them these instructions also.

WARNING:

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals

known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

•leadfromlead-basedpaints,

•crystallinesilicafrombricksandcementandothermasonryproducts,and

•arsenicandchromiumfromchemically-treatedlumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure

to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust

masks that are specially designed to filter out microscopic particles.

5 - English

Page 6

SYMBOLS

The following signal words and meanings are intended to explain the levels of risk associated with this product.

SYMBOL SIGNAL MEANING

DANGER:

WARNING:

CAUTION:

CAUTION:

Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper

interpretation of these symbols will allow you to operate the product better and safer.

SYMBOL NAME

Safety Alert Indicates a potential personal injury hazard.

Read Operator’s Manual

Indicates an imminently hazardous situation, which, if not avoided, will result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, could result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, may result in

minor or moderate injury.

(Without Safety Alert Symbol) Indicates a situation that may result in property

damage.

DESIGNATION/EXPLANATION

To reduce the risk of injury, user must read and understand

operator’s manual before using this product.

Eye and Hearing Protection

Wear gloves Always wear gloves when operating.

Wet Conditions Alert Do not expose to rain or use in damp locations.

V Volts Voltage

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

min Minutes Time

Alternating Current Type of current

n

o

.../min Per Minute Revolutions, strokes, surface speed, orbits etc., per minute

No Load Speed Rotational speed, at no load

Class II Tool Double-insulated construction

Always wear eye protection with side shields marked to comply

with ANSI Z87.1 along with hearing protection.

6 - English

Page 7

ELECTRICAL

DOUBLE INSULATION

Double insulation is a concept in safety in electric power

tools, which eliminates the need for the usual three-wire

grounded power cord. All exposed metal parts are isolated

from the internal metal motor components with protecting

insulation. Double insulated products do not need to be

grounded.

WARNING:

The double insulated system is intended to protect

the user from shock resulting from a break in the

product’s internal wiring. Observe all normal safety

precautions to avoid electrical shock.

NOTE: Servicing of a product with double insulation requires

extreme care and knowledge of the system and should be

performed only by a qualified service technician. For service,

we suggest you return the product to your nearest authorized

service center for repair. Always use original factory replacement parts when servicing.

ELECTRICAL CONNECTION

This product has a precision-built electric motor. It should

be connected to a power supply that is 120 volts, AC only

(normal household current), 60 Hz. Do not operate this

product on direct current (DC). A substantial voltage drop

will cause a loss of power and the motor will overheat. If

the product does not operate when plugged into an outlet,

double-check the power supply.

EXTENSION CORDS

When using a power tool at a considerable distance from

a power source, be sure to use an extension cord that has

the capacity to handle the current the product will draw. An

undersized cord will cause a drop in line voltage, resulting in

overheating and loss of power. Use the chart to determine

the minimum wire size required in an extension cord. Only

round jacketed cords listed by Underwriter’s Laboratories

(UL) should be used.

When working outdoors with a product, use an extension

cord that is designed for outside use. This type of cord is

designated with “WA” or “W” on the cord’s jacket.

Before using any extension cord, inspect it for loose or

exposed wires and cut or worn insulation.

**Ampere rating (on product data plate)

0-2.0 2.1-3.4 3.5-5.0 5.1-7.0 7.1-12.0 12.1-16.0

Cord Length Wire Size (A.W.G.)

25' 16 16 16 16 14 14

50' 16 16 16 14 14 12

100' 16 16 14 12 10 —

**Used on 12 gauge - 20 amp circuit.

NOTE: AWG = American Wire Gauge

WARNING:

Keep the extension cord clear of the working area.

Position the cord so that it will not get caught on

lumber, tools, or other obstructions while you are

working with a power tool. Failure to do so can

result in serious personal injury.

WARNING:

Check extension cords before each use. If

damaged replace immediately. Never use tool with

a damaged cord since touching the damaged area

could cause electrical shock resulting in serious

injury.

7 - English

Page 8

FEATURES

PRODUCT SPECIFICATIONS

Grinding Wheel Capacity .......................................4-1/2 in.

Spindle Thread ........................................ 5/8 in. x 11 UNC

No Load Speed .................................. 10,000 r/min. (RPM)

Input ..................................120 V, AC only, 60 Hz, 7 Amps

Net Weight .............................................................. 4.7 lbs.

KNOW YOUR ANGLE GRINDER

See Figure 1, page 14.

The safe use of this product requires an understanding of

the information on the product and in this operator’s manual

as well as a knowledge of the project you are attempting.

Before use of this product, familiarize yourself with all

operating features and safety rules.

EXTERNALLY ACCESSIBLE BRUSHES

Externally accessible brushes extend the life of the grinder.

ILLUMINATED PLUG

This grinder is equipped with a plug that illuminates when

power is supplied to the tool. This allows the operator to

easily identify live tools.

ASSEMBLY

LOCK-OFF / LOCK-ON BUTTON

The combination lock-off / lock-on button reduces the possibility of accidental starting and is convenient for continuous

grinding for extended periods of time.

SPINDLE LOCK BUTTON

The spindle lock button secures the spindle so that only one

wrench is needed to change the grinding wheel.

THREE POSITION SIDE HANDLE

The side handle provided stabilizes your grinder and must

be used during all operations. In addition to maintaining safe

control during use, the side handle also provides convenient

ease of operation for the operator.

WHEEL GUARD

The wheel guard adjusts into 6 positions to provide protection against sparks and metal chips during use.

UNPACKING

This product requires assembly.

Carefully remove the product and any accessories from

the box. Make sure that all items listed in the packing list

are included.

WARNING:

Do not use this product if any parts on the Packing

List are already assembled to your product when

you unpack it. Parts on this list are not assembled

to the product by the manufacturer and require

customer installation. Use of a product that may

have been improperly assembled could result in

serious personal injury.

Inspect the product carefully to make sure no breakage

or damage occurred during shipping.

Do not discard the packing material until you have care-

fully inspected and satisfactorily operated the product.

If any parts are damaged or missing, please call

1-866-539-1710 for assistance.

PACKING LIST

Angle Grinder

Wheel guard

Flange nut

Disc Flange

Grinding Wheel

Side Handle

Wrench

Tool Bag

Operator’s Manual

8 - English

Page 9

ASSEMBLY

WARNING:

If any parts are damaged or missing do not operate

this product until the parts are replaced. Use of

this product with damaged or missing parts could

result in serious personal injury.

WARNING:

Do not attempt to modify this product or create

accessories not recommended for use with this

product. Any such alteration or modification is

misuse and could result in a hazardous condition

leading to possible serious personal injury.

WARNING:

Do not connect to power supply until assembly

is complete. Failure to comply could result in

accidental starting and possible serious personal

injury.

If replacing the grinding wheel, unplug the grinder.

Depress the spindle lock button and rotate the flange

nut until the spindle locks.

NOTE: To prevent damage to the spindle or spindle lock,

always allow motor to come to a complete stop before

engaging spindle lock.

If replacing the grinding wheel, loosen and remove the

flange nut from the spindle. Do not remove the disc

flange.

Make sure the flats on the bottom of the disc flange are

engaged with the flats on the spindle.

Place the grinding wheel over the spindle.

WARNING:

Always install a grinding wheel with the depressed

center against the disc flange. Failure to do so

will cause the grinding wheel to crack when

tightening the flange nut. This could result in

serious personal injury because of loose particles

breaking off and being thrown from the grinder. Do

not overtighten.

INSTALLING THE WHEEL GUARD

See Figure 2, page 14.

Place the wheel guard on the shoulder of the bearing cap

by aligning index arrows on wheel guard and bearing cap.

Press down on wheel guard until it is fully seated.

Depress the lever and rotate wheel guard until it locs into

one of the six possible positions. Refer to Positioning

the Wheel Guard.

NOTE: Be sure the three tabs on the wheel guard are

seated in the three grooves on the bearing cap.

Install disc flange, grinding wheel, and flange nut. Refer

to Installing/Replacing Grinding Wheel.

Tighten flange nut securely with the wrench provided.

INSTALLING/REPLACING GRINDING WHEEL

See Figure 2, page 14.

WARNING:

Thoroughly inspect a new grinding wheel before

you install it on the grinder.

• Tap lightlyaround thegrindingwheelusinga

wooden hammer.

• Listencarefullytotheresultingsounds.Places

with fissures or cracks will result in a different

sound.

Do not use a grinding wheel containing fissures

or cracks.

When you install a new grinding wheel, carry out a

no load revolution test of approximately one minute

with the grinding wheel facing a safe direction, i.e.,

away from people or objects.

Thread the flange nut on the spindle with the flat side

of the nut facing up.

Fit the raised, small diameter portion of the flange nut

into the hole in the wheel and finger tighten.

Depress the spindle lock button and rotate the

grinding wheel clockwise until the spindle locks in

position.

Tighten the flange nut securely with the wrench

provided. Do not overtighten.

DANGER:

Never attach a TYPE 1 straight or cut-off wheel to

this angle grinder. It is only designed for grinding.

Use for any other purpose is not recommended

and creates a hazard, which will result in serious

injury.

ATTACHING THE SIDE HANDLE

See Figure 3, page 15.

Unplug the grinder.

Screw the side handle into the gear housing.

NOTE: You can install the side handle on either the left

or right side or top of the grinder, depending on operator

preference. It must always be used to prevent loss of

control and possible serious injury.

Tighten the side handle securely.

9 - English

Page 10

ASSEMBLY

POSITIONING THE WHEEL GUARD

See Figures 4 - 6, page 15.

The wheel guard on the grinder should be correctly installed

depending on which location the side handle is mounted.

Never use the grinder without the wheel guard correctly

locked into place.

WARNING:

Never place the wheel guard so that it is in front

of the grinder. This could result in serious injury

because sparks and loose particles thrown from

the grinding wheel would be directed toward the

operator. Always place the wheel guard in the

correct location as shown.

OPERATION

WARNING:

Do not allow familiarity with this product to make

you careless. Remember that a careless fraction of

a second is sufficient to inflict severe injury.

WARNING:

Always wear eye protection with side shields

marked to comply with ANSI Z87.1 along with

hearing protection and where necessary a full

face shield. Failure to do so could result in objects

being thrown into your eyes and other possible

serious injuries.

To adjust the wheel guard:

Unplug the grinder.

Depress the lever and rotate wheel guard until it locks

into one of the six possible positions.

NOTE: Be sure the three tabs on the wheel guard are

seated in the three grooves on the bearing cap. Always

make sure wheel guard is locked into place in one of the

six lock positions. Never use the grinder without the wheel

guard in place and properly adjusted.

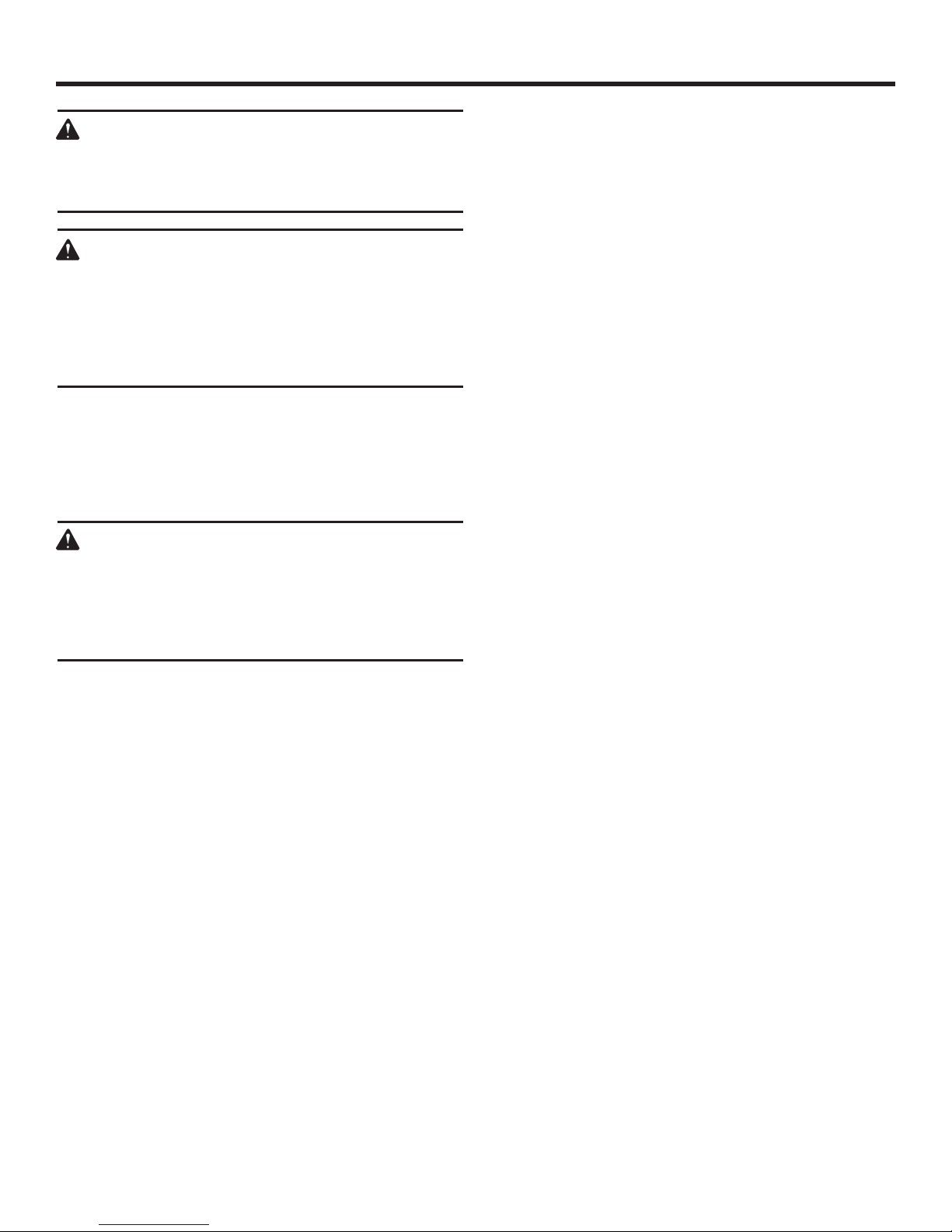

DANGER:

Use ONLY Type 27 depressed center grinding

wheels (such as the one provided with this

product). NEVER attach a Type 1 straight or cut-off

wheel to this angle grinder. Use of any other wheel

is not recommended and creates a hazard, which

will result in serious injury.

Type 27 − OK TO use Type 1 − dO nOT use

WARNING:

Do not use any attachments or accessories

not recommended by the manufacturer of this

product. The use of attachments or accessories

not recommended can result in serious personal

injury.

APPLICATIONS

You may use this product for the purposes listed below:

Grinding metals

Sanding wood or metal surfaces with an abrasive mop

disc. (sold separately)

DANGER:

Never attach a wood cutting or carving blade of

any type to this angle grinder. It is only designed for

grinding and sanding. Use for any other purpose

is not recommended and creates a hazard, which

will result in serious injury.

TURNING THE GRINDER ON/OFF

See Figure 7, page 16.

To turn the grinder ON:

Partially depress the lock-off / lock-on button and depress

the switch trigger.

To turn the grinder OFF:

Release the switch trigger.

LOCK-OFF / LOCK-ON BUTTON

See Figure 7, page 16.

This grinder is equipped with a lock-off / lock-on feature,

which is convenient for continuous grinding for extended

periods of time.

To lock-on:

Hold the grinder in front and away from you, keeping the

grinding wheel clear of the workpiece.

Partially depress the lock-off / lock-on button and depress

the switch trigger.

10 - English

Page 11

OPERATION

Depress and hold lock-off / lock-on button and release

the switch trigger.

Release the lock-off / lock-on button and the grinder will

continue running.

To release the lock, depress and release the switch

trigger.

NOTE: Ifthelock-off/lock-onfeatureisengagedandthe

grinder becomes disconnected from the power supply, disengage the lock-off / lock-on feature immediately.

WARNING:

To prevent loss of control and possible serious

injury, always operate the grinder with the side

handle installed.

OPERATING THE GRINDER

See Figure 8, page 16.

Always carefully select and use grinding wheels that are

recommended for the material to be ground. Make sure

that the operating speed of any accessory wheel selected is

rated at 10,000 r/min. or more. The grinding wheel provided

with the grinder is suitable for grinding welds, preparing

surfaces to be welded, grinding structural steel, and grinding stainless steel.

To operate the grinder:

Secure all work in a vise or clamp to a workbench.

DANGER:

Never use the grinder with the wheel guard

removed and always be sure the wheel guard is

locked into place. It has been designed for use

only with the wheel guard installed. Attempting to

use grinder with wheel guard removed will result in

loose particles being thrown against the operator

resulting in serious personal injury.

Hold the grinder in front and away from you with

both hands, keeping the grinding wheel clear of the

workpiece.

Turn on the grinder and let the motor and grinding wheel

build up to full speed.

Lower the grinder gradually until the grinding wheel con-

tacts the workpiece.

Keep the grinder tilted at an angle from 5 to 15 de-

grees.

WARNING:

To prevent loss of control and possible serious

personal injury, always operate the grinder

with both hands, keeping one hand on the side

handle.

Move the grinder continuously at a steady, consistent

pace.

CAUTION:

If the grinder is held in one spot too long, it will

gouge and cut grooves in the workpiece. If the

grinder is held at too sharp an angle, it will also

gouge the workpiece because of concentration of

pressure on a small area.

Use just enough pressure to keep the grinder from chat-

tering or bouncing.

NOTE: Heavy pressure will decrease the grinder’s speed and

put a strain on the motor. Normally the weight of the tool

alone is adequate for most grinding jobs. Use light pressure

when grinding jagged edges or loose bolts where there is the

potential for the grinder to snag on the metal edge.

Lift the grinder away from the workpiece before turning

off the grinder.

11 - English

Page 12

MAINTENANCE

WARNING:

When servicing use only identical RIDGID®

replacement parts. Use of any other parts may

create a hazard or cause product damage.

WARNING:

Always wear eye protection with side shields

marked to comply with ANSI Z87.1 along with

hearing protection and where necessary a full

face shield. Failure to do so could result in serious

personal injury. If operation is dusty, also wear a

dust mask.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use. Use

clean cloths to remove dirt, dust, oil, grease, etc.

WARNING:

Do not at any time let brake fluids, gasoline,

petroleum-based products, penetrating oils, etc.,

come in contact with plastic parts. Chemicals can

damage, weaken or destroy plastic which may

result in serious personal injury.

Electric tools used on fiberglass material, wallboard, spackling compounds, or plaster are subject to accelerated wear

and possible premature failure because the fiberglass chips

and grindings are highly abrasive to bearings, brushes,

commutators, etc. Consequently, we do not recommend

using this product for extended work on these types

of materials. However, if you do work with any of these

materials, it is extremely important to clean the product using compressed air.

LUBRICATION

All of the bearings in this product are lubricated with a sufficient amount of high grade lubricant for the life of the unit

under normal operating conditions. Therefore, no further

lubrication is required.

REPLACING THE WHEEL GUARD

After extended use, the wheel guard may wear and need

replacing. If you drop the grinder and damage the wheel

guard it may also be necessary for you to replace it. Refer

to Installing the Wheel Guard earlier in this manual.

BRUSH REPLACEMENT

See Figure 9, page 16.

This product has externally accessible brush assemblies

that should be periodically checked for wear.

Unplug the angle grinder.

With a flat head screwdriver, remove the brush caps. The

brush assembly is spring loaded and will pop out when

you remove the brush cap.

Remove the brush assembly (brush and spring). Check

for wear. Replace both brushes when either has less than

1/4 in. length of carbon remaining. Do not replace one

side without replacing the other.

Reassemble using new brush assemblies. Make sure

curvature of brush matches curvature of motor and that

brush moves freely in brush tube.

Replace brush cap and tighten securely. Do not over-

tighten.

NOTE: FIGURES (ILLUSTRATIONS) START ON PAGE 14

AFTER FRENCH AND SPANISH LANGUAGE SECTIONS

12 - English

Page 13

WARRANTY

RIDGID® HAND HELD AND STATIONARY POWER TOOL

3 YEAR LIMITED SERVICE WARRANTY

Proof of purchase must be presented when requesting

warranty service.

Limited to RIDGID® hand held and stationary power tools

purchased 2/1/04 and after. This product is manufactured

by One World Technologies, Inc. The trademark is licensed

from RIDGID, Inc. All warranty communications should be

directed to One World Technologies, Inc., attn: RIDGID Hand

Held and Stationary Power Tool Technical Service at (toll

free) 1-866-539-1710.

90-DAY SATISFACTION GUARANTEE POLICY

During the first 90 days after the date of purchase, if you are

dissatisfied with the performance of this RIDGID® Hand Held

and Stationary Power Tool for any reason you may return

the tool to the dealer from which it was purchased for a full

refund or exchange. To receive a replacement tool you must

present proof of purchase and return all original equipment

packaged with the original product. The replacement tool

will be covered by the limited warranty for the balance of

the 3 YEAR service warranty period.

WHAT IS COVERED UNDER THE 3 YEAR

LIMITED SERVICE WARRANTY

This warranty on RIDGID® Hand Held and Stationary Power

Tools covers all defects in workmanship or materials and

normal wear items such as brushes, chucks, motors, switches, cords, gears and even cordless batteries in this RIDGID®

tool for three years following the purchase date of the tool.

Warranties for other RIDGID® products may vary.

HOW TO OBTAIN SERVICE

To obtain service for this RIDGID® tool you must return it;

freight prepaid, or take it in to an authorized service center

for RIDGID® branded hand held and stationary power tools.

You may obtain the location of the authorized service center nearest you by calling (toll free) 1-866-539-1710 or by

logging on to the RIDGID® website at www.ridgid.com.

When requesting warranty service, you must present the

original dated sales receipt. The authorized service center will

repair any faulty workmanship, and either repair or replace

any part covered under the warranty, at our option, at no

charge to you.

WHAT IS NOT COVERED

This warranty applies only to the original purchaser at

retail and may not be transferred. This warranty only covers

defects arising under normal usage and does not cover any

malfunction, failure or defect resulting from misuse, abuse,

neglect, alteration, modification or repair by other than

an authorized service center for RIDGID® branded hand

held and stationary power tools. Consumable accessories

provided with the tool such as, but not limited to, blades,

bits and sand paper are not covered.

RIDGID, INC. AND ONE WORLD TECHNOLOGIES, INC.

MAKE NO WARRANTIES, REPRESENTATIONS OR

PROMISES AS TO THE QUALITY OR PERFORMANCE

OF ITS POWER TOOLS OTHER THAN THOSE SPECIFICALLY STATED IN THIS WARRANTY.

ADDITIONAL LIMITATIONS

To the extent permitted by applicable law, all implied

warranties, including warranties of MERCHANTABILITY or

FITNESS FOR A PARTICULAR PURPOSE, are disclaimed.

Any implied warranties, including warranties of merchantability or fitness for a particular purpose, that cannot be

disclaimed under state law are limited to three years from the

date of purchase. One World Technologies, Inc. and RIDGID,

Inc. are not responsible for direct, indirect, incidental or

consequential damages. Some states do not allow

limitations on how long an implied warranty lasts and/or

do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitations may not

apply to you. This warranty gives you specific legal rights,

and you may also have other rights which vary from state

to state.

One World Technologies, Inc.

P.O. Box 35, Hwy. 8

Pickens, SC 29671

13 - English

Page 14

RÈGLES DE SÉCURITÉ GÉNÉRALES

AVERTISSEMENT :

Lire toutes les instructions. Le non-respect de

toutes les instructions ci-dessous peut entraîner un

choc électrique, un incendie et / ou des blessures

graves.

CONSERVER CES INSTRUCTIONS

LIEU DE TRAVAIL

Garder le lieu de travail propre et bien éclairé. Les établis

encombrés et les endroits sombres sont propices aux

accidents.

Ne pas utiliser d’outils électriques dans des atmosphères

explosives, par exemple en présence de liquides, gaz ou

poussières inflammables. Les outils électriques produisent

des étincelles risquant d’enflammer les poussières ou

vapeurs.

Garder les badauds, enfants et visiteurs à l’écart pendant

l’utilisation d’un outil électrique. Les distractions peuvent

causer une perte de contrôle.

SÉCURITÉ ÉLECTRIQUE

Les outils à double isolation sont équipés d’une fiche

polarisée (une broche est plus large que l’autre). Cette

fiche ne peut être branchée sur une prise polarisée

que dans un sens. Si la fiche ne peut pas être insérée

dans la prise, l’inverser. Si elle ne peut toujours pas

être insérée, faire installer une prise polarisée par un

électricien qualifié. Ne pas modifier la fiche, de quelque

façon que ce soit. La double isolation

de cordon d’alimentation à trois fils et d’un circuit secteur

mis à la terre.

Éviter tout contact du corps avec des surfaces mises

à la terre,

réfrigérateurs. Le risque de choc électrique est accru lorsque

le corps est mis à la terre.

Ne pas exposer les outils électriques à la pluie ou

l’humidité. La pénétration d’eau dans ces outils accroît le

risque de choc électrique.

Ne pas maltraiter le cordon d’alimentation. Ne jamais

utiliser le cordon d’alimentation pour transporter l’outil et

ne jamais débrancher ce dernier en tirant sur le cordon.

Garder le cordon à l’écart de la chaleur, de l’huile,

des objets tranchants et des pièces en mouvement.

Remplacer immédiatement tout cordon endommagé. Un

cordon endommagé accroît le risque de choc électrique.

Pour les travaux à l’extérieur, utiliser un cordon spécialement

conçu à cet effet, marqué « W-A » ou « W ». Ces cordons

réduisent les risques de choc électrique.

SÉCURITÉ PERSONNELLE

Rester attentif, prêter attention au travail et faire preuve

de bon sens lors de l’utilisation de tout outil électrique.

Ne pas utiliser cet outil en état de fatigue ou sous

l’influence d’alcool, de drogues ou de médicaments.

Un moment d’inattention pendant l’utilisation d’un outil

électrique peut entraîner des blessures graves.

Porter une tenue appropriée. Ne porter ni vêtements

amples, ni bijoux. Attacher ou couvrir les cheveux longs.

telles que tuyaux, radiateurs, cuisinières et

élimine le besoin

Retirer les outils et clés de réglage avant de mettre l’outil

Ne pas travailler hors de portée. Toujours se tenir bien

Utiliser l’équipement de sécurité. Toujours porter une

Ne porter ni vêtements amples, ni bijoux. Attacher

Ne pas utiliser l’outil sur une échelle ou un support

UTILISATION ET ENTRETIEN DE L’OUTIL

Utiliser des serre-joints ou un autre système approprié

Ne pas forcer l’outil. Utiliser un outil approprié pour

Ne pas utiliser l’outil si le commutateur ne permet pas

Débrancher l’outil davant d’effectuer des réglages, de

Ranger les outils non utilisés hors de portée des enfants

Entretenir soigneusement les outils. Garder les outils

Vérifier qu’aucune pièce mobile n’est mal alignée,

3 - Français

Garder les cheveux, les vêtements et les gants à l’écart

des pièces en mouvement. Les vêtements amples, bijoux

et cheveux longs peuvent se prendre dans les pièces en

mouvement.

Éviter les démarrages accidentels. S’assurer que le

commutateur est en position d’arrêt avant de brancher

l’outil. Porter un outil avec le doigt sur son commutateur ou

brancher un outil dont le commutateur est en position de

marche de marche peut causer un accident.

en marche. Un outil ou une clé laissée sur une pièce rotative

de l’outil peut causer des blessures.

campé et en équilibre. Une bonne tenue et un bon équilibre

permettent de mieux contrôler l’outil en cas de situation

imprévue.

protection oculaire. Suivant les conditions, le port d’un

masque antipoussière, de chaussures de sécurité, d’un

casque ou d’une protection auditive est recommandé.

ou couvrir les cheveux longs. Les vêtements amples,

bijoux et cheveux longs peuvent se prendre dans les ouïes

d’aération.

instable. Une bonne tenue et un bon équilibre permettent

de mieux contrôler l’outil en cas de situation imprévue.

pour maintenir fermement la pièce sur une surface

stable. Une pièce tenue à la main ou contre son corps est

instable et peut causer une perte de contrôle.

le travail. Un outil approprié exécutera le travail mieux et

de façon moins dangereuse s’il est utilisé dans les limites

prévues.

de le mettre en marche et de l’arrêter. Tout outil qui ne

peut pas être contrôlé par son commutateur est dangereux

et doit être réparé.

changer d’accessoire ou de ranger l’outil. Ces mesures

de sécurité réduisent les risques de démarrage accidentel

de l’outil.

et des personnes n’ayant pas reçu des instructions

adéquates. Dans les mains de personnes n’ayant pas reçu

des instructions adéquates, les outils sont dangereux.

bien affûtés et propres. Des outils correctement entretenus

et dont les tranchants sont bien affûtés risquent moins de

se bloquer et sont plus faciles à contrôler.

grippée ou brisée et s’assurer qu’aucun autre problème

risque d’affecter le bon fonctionnement de l’outil. En cas

de dommages, faire réparer l’outil avant de l’utiliser de

nouveau. Beaucoup d’accidents sont causés par des outils

mal entretenus.

Page 15

RÈGLES DE SÉCURITÉ GÉNÉRALES

Utiliser exclusivement les accessoires recommandés par le

fabricant pour le modèle d’outil. Des accessoires appropriés pour

un outil peuvent être dangereux s’ils sont utilisés avec un autre.

Garder l’outil et sa poignée secs, propres et exempts d’huile ou

de graisse. Toujours utiliser un chiffon propre pour le nettoyage.

Ne jamais utiliser de liquide de freins, d’essence, de produits

à base de pétrole ou de solvants forts pour nettoyer l’outil. Le

respect de cette consigne réduira les risques de perte de contrôle

et d’endommagement du boîtier en plastique.

RÈGLES DE SÉCURITÉ PARTICULIÈRES

Cet outil électrique est conçu pour servir de meuleuse, de

ponceuse, de brosse métallique ou de polisseuse. Consulter

tous les avertissements et toutes les instructions, les

illustrations et les précisions fournis avec cet outil électrique.

Ne pas suivre l’ensemble des instructions décrites ci-dessous peut

entraîner une électrocution, un incendie ou des blessures graves.

Il n’est pas recommandé d’utiliser cet outil électrique pour

couper des pièces. Le fait d’utiliser l’outil pour effectuer des

tâches pour lesquelles il n’est pas conçu peut présenter du danger

et entraîner des blessures.

Ne pas utiliser des accessoires qui ne sont pas spécialement

conçus pour le modèle d’outil ou qui ne sont pas recommandés

par le fabricant. Le simple fait qu’un accessoire peut s’ajuster

sur l’outil électrique ne signifie pas qu’il peut être utilisé en toute

sécurité.

La vitesse nominale de l’accessoire doit au moins être égale à la

vitesse maximale indiquée sur l’outil électrique. Les accessoires

qui sont utilisés à une vitesse supérieure à leur VITESSE NOMINALE

peuvent se briser et se détacher.

Le diamètre extérieur et l’épaisseur de l’accessoire doivent être

conformes à la capacité de l’outil électrique. Il est impossible

d’envelopper ou de contrôler adéquatement un accessoire de

dimension inappropriée.

La taille de l’arbre des meules, des brides, des plateaux porte-

disque ou de tout autre accessoire doit convenir parfaitement à

la broche de l’outil électrique. Si les accessoires utilisés sont dotés

d’alésages centraux qui ne conviennent pas à la pièce de montage

de l’outil, ils se déstabiliseront, vibreront de façon excessive et

pourront causer une perte de contrôle.

Ne pas utiliser un accessoire endommagé. Inspecter

l’accessoire avant chaque utilisation afin de s’assurer que

les meules, par exemple, sont exemptes d’ébréchures et de

fissures, que le plateau porte-disque est exempt de fissures

et qu’il n’est pas usé de façon excessive, et que la brosse

métallique ne comprend pas de fils détachés ou craquelés.

Si l’outil électrique ou l’accessoire est échappé, s’assurer

qu’il n’est pas endommagé ou installer un autre accessoire.

Après avoir effectué cette opération, se tenir à distance de

l’accessoire en rotation et faire fonctionner l’outil à sa vitesse

à vide maximale pendant une minute. S’assurer que personne

ne se tient à proximité de l’outil. Les accessoires endommagés se

brisent généralement lors de cette vérification.

Porter de l’équipement de protection de qualité professionnelle.

Selon le type d’opération, porter un masque de protection

ou des lunettes de sécurité. Au besoin, porter également un

masque antipoussières, un protecteur d’oreille, des gants et

un tablier d’atelier résistant aux petits fragments abrasifs ou

aux fragments provenant des pièces à travailler. La protection

oculaire utilisée doit résister aux débris projetés lors des

différentes opérations. La protection oculaire utilisée doit résister

aux débris projetés lors des différentes opérations. Le masque

anti-poussières et le masque filtrant doivent filtrer les particules

DÉPANNAGE

Le dépannage des outils doit être confié exclusivement à un

personnel qualifié. Les réparations ou entretiens effectués par des

personnes non qualifiées présentent des risques de blessures.

Utiliser exclusivement des pièces identiques à celles d’origine

pour les réparations. Se conformer aux instructions de la

section Entretien de ce manuel. L’usage de pièces non autorisées

ou le non-respect des instructions peut présenter des risques de

choc électrique ou de blessures.

produites lors de l’opération. Une exposition prolongée à un bruit

fort peut entraîner une perte auditive.

S’assurer que personne ne se tient à proximité du lieu de

travail. Toute personne qui entre sur le lieu de travail doit porter

l’équipement de protection requis. Des fragments provenant de

la pièce à travailler ou d’un accessoire brisé peuvent être projetés

et causer des blessures, même à des personnes se tenant à une

certaine distance du lieu de travail immédiat.

Tenir l’outil par ses surfaces de préhension isolées lors des

opérations pendant lesquelles l’accessoire de coupe peut

entrer en contact avec du câblage caché ou avec son propre

cordon d’alimentation. Le contact d’un accessoire de coupe avec

un fil sous tension « électrifie » les pièces métalliques exposées de

l’outil et peut électrocuter l’utilisateur.

Tenir le cordon loin de l’accessoire en rotation. En cas de perte

de contrôle, le cordon peut être coupé ou accroché, et la main ou

le bras de l’utilisateur risquent d’entrer en contact avec l’accessoire

en rotation.

Ne jamais déposer l’outil électrique avant l’arrêt complet de

l’accessoire. L’accessoire en rotation peut attraper la surface et

occasionner une perte de contrôle.

Ne jamais laisser l’outil électrique fonctionner en le transportant

à ses côtés. L’acc essoire en rotation peut s’acc rocher

accidentellement aux vêtements et entrer en contact avec

l’utilisateur.

Nettoyer régulièrement les évents d’aération de l’outil

électrique. Le ventilateur du moteur aspire la poussière dans le

logement et crée une accumulation excessive de métal fritté, ce

qui peut causer un danger électrique.

Ne pas faire fonctionner l’outil électrique à proximité de

matériaux inflammables. Les étincelles peuvent enflammer ces

matériaux.

Ne pas utiliser d’accessoires qui nécessitent des liquide

de refroidissement. L’utilisation d’eau ou d’un autre liquide

de refroidissement peut entraîner une électrocution ou un choc

électrique.

Tenir fermement l’outil électrique et placer le corps et les mains

de manière à pouvoir résister aux rebonds. Toujours utiliser

la poignée auxiliaire, s’il y en a une, pour assurer un contrôle

optimal en cas de rebond ou de réaction de couple lors du

démarrage de l’outil. L’utilisateur peut contrôler les rebonds et

les réactions de couple s’il respecte les directives prescrites.

Ne jamais placer les mains à proximité de l’accessoire en

rotation. En cas de rebond, l’accessoire peut dévier sur celles-ci.

Ne pas positionner le corps à l’endroit où sera entraîné l’outil

électrique si un rebond se produit. Un rebond entraînera l’outil

dans le sens opposé au mouvement de la meule, à l’endroit de

l’accrochage.

Faire preuve d’une extrême prudence au moment d’utiliser

l’outil sur des coins ou des rebords tranchants. Les coins, les

rebords tranchants et les surfaces qui tressautent ont tendance à

4 - Français

Page 16

RÈGLES DE SÉCURITÉ PARTICULIÈRES

s’accrocher à la pièce en rotation et à causer une perte de contrôle

ou des rebonds.

Ne pas fixer une lame de sculpteur pour scie à chaîne ou une

lame de scie dentée. Ces deux types de lame occasionnent de

nombreux rebonds et des pertes de contrôle fréquentes.

Utiliser seulement les types de meule recommandés pour cet

outil électrique et le garde-meule spécialement conçu pour la

meule utilisée. Il est impossible d’envelopper de façon adéquate

et sécuritaire les meules qui ne sont pas spécialement conçues

pour l’outil électrique.

Le garde-meule doit être fixé solidement à l’outil électrique

et positionné de manière à garantir une sécurité optimale;

il importe donc de diriger le moins possible la meule vers

l’utilisateur. Le garde meule aide à protéger l’utilisateur des

fragments qui peuvent se détacher de la meule et du contact

accidentel avec la meule.

Utiliser seulement les meules pour effectuer des opérations

pour lesquelles elles sont conçues. Par exemple, ne pas meuler

avec le côté d’une meule à tronçonner. Seule la périphérie des

meules à tronçonner abrasives doit être utilisée pour le meulage.

Le fait d’appliquer une force latérale sur ces meules peut provoquer

leur éclatement.

Toujours utiliser des brides de meule non endommagées de

formes et de dimensions convenables pour la meule choisie. Les

brides de meule adéquates soutiennent la meule, ce qui minimise

les risques de bris de celle-ci. Les brides de meules à tronçonner

peuvent différer des brides de meules standards.

Ne pas utiliser de meules usées qui proviennent d’outils

électriques de plus grandes dimensions. Les meules conçues

pour des outils électriques de plus grandes dimensions ne

conviennent pas à la vitesse plus élevée des outils de plus petites

dimension et peuvent éclater.

Ne pas utiliser un papier pour disque abrasif surdimensionné.

Suivre les recommandations du fabricant au moment de choisir

le papier abrasif. Un papier abrasif qui excède la surface du disque

de ponçage présente un danger de lacération et peut s’accrocher,

se déchirer, ou entraîner un rebond.

Ne permettre à aucune partie lâche de la coiffe à polir ou à

ses filaments de tourner librement. Enlever ou couper tous

les filaments libres. Les filaments libres et en rotation peuvent

s’empêtrer dans les doigts ou s’accrocher à la pièce à travailler.

Porter une attention particulière à la brosse métallique, dont

les poils peuvent être projetés même pendant une opération

régulière. Éviter de surcharger les poils en appuyant sur la

brosse de manière excessive. Les poils de la brosse métallique

peuvent pénétrer facilement dans les vêtements légers ou la

peau.

S’il est recommandé d’installer un dispositif protecteur pour

utiliser une brosse métallique, s’assurer qu’il n’entre pas en

contact avec la brosse. Le diamètre de la brosse métallique peut

augmenter en raison de la charge et de la force centrifuge.

Toujours utiliser le garant correct avec la meule. Un garant

protège l’opérateur des fragments de roue cassés.

Apprendre à connaître l’outil. Lire attentivement le manuel

d’utilisation. Apprendre les applications et les limites de l’outil,

ainsi que les risques spécifiques relatifs à son utilisation. Le

respect de cette consigne réduira les risques d’incendie, de choc

électrique et de blessures graves.

Toujours porter une protection oculaire avec écrans latéraux

certifiée conforme à la norme ANSI Z87.1. Le non respect de

cette règle peut faire en sorte que des liquides soient projetés dans

vos yeux, ce qui peut entraîner des blessures graves.

Protection respiratoire. Porter un masque facial ou un masque

anti-poussière si le travail produit de la poussière. Le respect

de cette consigne réduira les risques de blessures graves.

Protection auditive. Porter une protección auditiva lors de

l’utilisation prolongée. Le respect de cette règle réduira les risques

de blessures graves.

Inspecter régulièrement les cordons d’alimentation des outils

et s’ils sont endommagés, les confier au centre de réparations

agréé le plus proche. Toujours être conscient de l’emplacement

du cordon. Le respect de cette règle réduira les risques de choc

électrique et d’incendie.

Vérifier l’état des pièces. Avant d’utiliser l’outil de nouveau

examiner soigneusement les pièces et dispositifs de protection

qui semblent endommagés afin de déterminer s’ils fonctionnent

correctement et s’ils remplissent les fonctions prévues. Vérifier

l’alignement des pièces mobiles, s’assurer qu’aucune pièce

n’est bloquée ou cassée, vérifier la fixation de chaque pièce

et s’assurer qu’aucun autre problème ne risque d’affecter

le bon fonctionnement de l’outil. Toute protection ou pièce

endommagée doit être correctement réparée ou remplacée

dans un centre de réparations agréé. Le respect de cette

consigne réduira les risques de choc électrique, d’incendie et de

blessures graves.

S’assurer que le cordon prolongateur est en bon état. Si un

cordon prolongateur est utilisé, s’assurer que sa capacité

est suffisante pour supporter le courant de fonctionnement

de l’outil. Un calibre de fil (A.W.G) d’au minimum 14 est

recommandé pour un cordon prolongateur de 8 m (25 pi)

ou moins. L’usage d’un cordon de plus de 15 m (50 pi) est

déconseillé. En cas de doute, utiliser un cordon du calibre

immédiatement supérieur. Moins le numéro de calibre est

élevé, plus la capacité du fil est grande. Un cordon de capacité

insuffisante causerait une baisse de la tension de ligne, entraînant

une perte de puissance et une surchauffe.

Inspecter la pièce et retirer les clous éventuels avant d’utiliser

cet outil. Le respect de cette consigne réduira les risques de

blessures graves.

Si le cordon d’alimentation est endommagé, il doit être remplacé

uniquement pas le fabricant ou par un centre de réparation agréé

pour éviter tout risque.

Conserver ces instructions. Les consulter fréquemment et les

utiliser pour instruire les autres utilisateurs éventuels. Si cet outil

est prêté, il doit être accompagné de ces instructions.

AVERTISSEMENT :

La poussière dégagée par certains matériaux lors du ponçage, sciage, meulage perçage et autres opérations de construction

contient des produits chimiques reconnus causer le cancer, des malformations congénitales ou des lésions de l’appareil

reproducteur. Voici certains exemples de ces produits chimiques :

•plombcontenudanslapeintureauplomb,

•silicecristallinecontenuedanslesbriques,lecimentetd’autresproduitsdemaçonnerie,ainsique

•arsenicetchromecontenusdansleboisdeconstructiontraitéparproduitschimiques.

Le risque présenté par l’exposition à ces produits varie en fonction de la fréquence de ce type de travail. Pour réduire l’exposition

à ces produits chimiques : travailler dans un endroit bien aéré et utiliser des équipements de sécurité approuvés tels que

masques antipoussière spécialement conçus pour filtrer les particules microscopiques.

5 - Français

Page 17

SYMBOLES

Les termes de mise en garde suivants et leur signification ont pour but d’expliquer le degré de risques associé à

l’utilisation de ce produit.

SYMBOLE SIGNAL SIGNIFICATION

DANGER :

AVERTISSEMENT :

ATTENTION :

ATTENTION :

Certains des symboles ci-dessous peuvent être utilisés sur produit. Veiller à les étudier et à apprendre leur signification.

Une interprétation correcte de ces symboles permettra d’utiliser produit plus efficacement et de réduire les risques.

Indique une situation extrêmement dangereuse qui, si elle n’est pas

évitée, aura pour conséquences des blessures graves ou mortelles.

Indique une situation potentiellement dangereuse qui, si elle n’est pas

évitée, pourrait entraîner des blessures graves ou mortelles.

Indique une situation potentiellement dangereuse qui, si elle n’est

pas évitée, pourraît entraîner des blessures légères ou de gravité

modérée.

(Sans symbole d’alerte de sécurité) Indique une situation pouvant

entraîner des dommages matériels.

SYMBOLE NOM DÉSIGNATION / EXPLICATION

Symbole d’alerte de sécurité Indique un risque de blessure potentiel.

Pour réduire les risques de blessures, l’utilisateur doit lire et

Lire le manuel d’utilisation

veiller à bien comprendre le manuel d’utilisation avant d’utiliser

ce produit.

Protection oculaire et auditive

Porter des gants Toujours porter des gants au moment d’utiliser le produit.

Avertissement concernant

l’humidité

V Volts Tension

A Ampères Intensité

Hz Hertz Fréquence (cycles par seconde)

W Watts Puissance

min Minutes Temps

Courant alternatif Type de courant

n

o

Vitesse à vide Vitesse de rotation à vide

Construction de classe II Construction à double isolation

Toujours porter une protection oculaire certifiée conforme à la norme

ANSI Z87.1 ainsi qu’un protection auditive.

Ne pas exposer à la pluie ou l’humidité.

.../min Par minute Tours, coups, vitesse périphérique, orbites, etc., par minute

6 - Français

Page 18

CARACTÉRISTIQUES ÉLECTRIQUES

DOUBLE ISOLATION

La double isolation est un dispositif de sécurité utilisé sur les

outils à moteur électriques, éliminant le besoin de cordon

d’alimentation habituel à trois fils avec terre. Toutes les

pièces métalliques exposées sont isolées des composants

internes du moteur par l’isolation protectrice. Les outils à

double isolation ne nécessitent pas de mise à la terre.

AVERTISSEMENT :

Le système à double isolation est conçu pour

protéger l’utilisateur contre les chocs électriques

causés par une rupture du câblage interne de

l’outil. Prendre toutes les précautions de sécurité

normales pour éviter les chocs électriques.

NOTE : La réparation d’un outil à double isolation exige

des précautions extrêmes ainsi que la connaissance du

système, elle ne doit être confiée qu’à un réparateur qualifié.

En ce qui concerne les réparations, nous recommandons de

confier l’outil au centre de réparations le plus proche. Utiliser

exclusivement des pièces d’origine pour les réparations.

CONNEXIONS ÉLECTRIQUES

Ce produit est équipé d’un moteur électrique de précision.

Il doit être branché uniquement sur une alimentation 120 V,

c.a. (courant résidentiel standard), 60 Hz. Ne pas utiliser

cet outil sur une source de courant continu (c.c.). Une chute

de tension importante causerait une perte de puissance et

une surchauffe du moteur. Si l’outil ne fonctionne pas une

fois branché, vérifier l’alimentation électrique.

CORDONS PROLONGATEURS

Lors de l’utilisation d’un outil électrique à grande distance

d’une prise secteur, veiller à utiliser un cordon prolongateur

d’une capacité suffisante pour supporter l’appel de courant

de l’outil. Un cordon de capacité insuffisante causerait

une baisse de la tension de ligne, entraînant une perte

de puissance et une surchauffe. Se reporter au tableau

ci-dessous pour déterminer le calibre minimum de fil requis

pour un cordon donné. Utiliser exclusivement des cordons à

gaine cylindrique homologués par Underwriter’s Laboratories

(UL).

Pour le travail à l’extérieur, utiliser un cordon prolongateur

spécialement conçu à cet effet. Ce type de cordon porte

l’inscription « WA » ou « W » sur sa gaine.

Avant d’utiliser un cordon prolongateur, vérifier que ses fils

ne sont ni détachés ni exposés et que son isolation n’est ni

coupée, ni usée.

**Intensité nominale (sur la plaquette signalétique de l’outil)

0-2,0 2,1-3,4 3,5-5,0 5,1-7,0 7,1-12,0 12,1-16,0

Longueur du cordon Calibre de fil (A.W.G.)

25´ 16 16 16 16 14 14

50´ 16 16 16 14 14 12

100´ 16 16 14 12 10 —

**Utilisé sur circuit de calibre 12 – 20 A

NOTE : AWG = American Wire Gauge

AVERTISSEMENT :

Maintenir le cordon prolongateur à l’écart de la

zone de travail. Lors du travail avec un cordon

électrique, placer le cordon de manière à ce qu’il ne

risque pas de se prendre dans les pièces de bois,

outils et autres obstacles. Ne pas prendre cette

précaution peut entraîner des blessures graves.

AVERTISSEMENT :

Vérifier l’état des cordons prolongateurs avant

chaque utilisation. Remplacer immédiatement tout

cordon endommagé. Ne jamais utiliser un outil

dont le cordon d’alimentation est endommagé,

car tout contact avec la partie endommagée

pourrait causer un choc électrique et des blessures

graves.

7 - Français

Page 19

CARACTÉRISTIQUES

FICHE TECHNIQUE

Taille de meule .........................................115 mm (4,5 po)

Diamètre de broche ....................... 5/8 po x 11 UNC (M14)

Vitesse à vide ......................................10 000 r/min. (RPM)

Entrée ....................120 volts, c.a. uniquement, 60 Hz, 7 A

Poids net ...................................................... 2,1 kg (4.7 lb)

VEILLER À BIEN CONNAÎTRE LA MEULEUSE

D’ANGLE

Voir la figure 1, page 14.

L’utilisation sûre de ce produit exige une comprehension

des renseignements figurant sur l’outil et contenus dans le

manuel d’utilisation, ainsi qu’une bonne connaissance du

projet entrepris. Avant d’utiliser ce produit, se familiariser

avec toutes ses caractéristiques et règles de sécurité.

BALAIS ACCESSIBLES DE L’EXTÉRIEUR

Balais accessibles de l’extérieur pour une longévité accrue

de la meuleuse.

FICHE LUMINEUSE

Cette meuleuse est équipée d’une fiche qui s’illumine lorsque

l’outil est sous tension. La fiche lumineuse permet d’identifier

rapidement les outils sous tension.

BOU T ON D E VER R OUI L LAG E ET D E

DÉVERROUILLAGE

Le bouton de verrouillage et de déverrouillage permet de

réduire le risque d’un démarrage accidentel et est pratique

pour un meulage continu pendant une période prolongée.

BOUTON DE VERROUILLAGE DE L’AXE

Ce bouton bloque l’axe, ce qui permet de remplacer la meule

avec une seule clé.

POIGNÉE LATÉRALE À TROIS POSITIONS

La poignée latérale est conçue pour stabiliser la meuleuse

et elle doit être utilisée en toutes circonstances. Outre le

maintien du contrôle pendant l’utilisation, la poignée facilite

le travail.

GARDE-MEULE

Le garde-meule est réglable en 6 positions afin d’assurer

une protection contre les étincelles et les éclats de métal

pendant l’utilisation.

ASSEMBLAGE

DÉBALLAGE

Ce produit nécessite l’assemblage.

Avec précaution, sortir le produit et les accessoires de la

boîte. S’assurer que toutes les pièces figurant sur la liste

de contrôle sont incluses.

AVERTISSEMENT :

Ne pas utiliser le produit si, en le déballant, vous

constatez que des éléments figurant dans la liste

de contrôle d’expédition sont déjà assemblés.

Certaines pièces figurant sur cette liste n’ont pas

été assemblées par le fabricant et exigent une

installation. Le fait d’utiliser un produit qui a été

assemblé de façon inadéquate peut entraîner des

blessures.

Examiner soigneusement le produit pour s’assurer

que rien n’a été brisé ou endommagé en cours de

transport.

Ne pas jeter les matériaux d’emballage avant d’avoir

soigneusement examiné le produit et avoir vérifié qu’il

fonctionne correctement.

Si des pièces sont manquantes ou endommagées,

appeler le 1-866-539-1710.

LISTE DE CONTRÔLE D’EXPÉDTION

Meuleuse d’angle

Garde-meule

Écrou à épaulement

Bride circulaire

Meule

Poignée latérale

Clé

Sacoche à outils

Manuel d’utilisation

8 - Français

Page 20

ASSEMBLAGE

AVERTISSEMENT :