RIDGID Press Booster, Z3 Instructions Manual

Press Booster/Z3 Actuator Instructions

Press Booster/Z3 Actuator Instructions

WARNING

Read these instructions and the warnings and instructions for all equipment

and material being used before operating this tool to reduce the risk of serious personal injury.

SAVE THESE INSTRUCTIONS!

• Keep your fingers and hands away from pressing attachments

during press cycle. Your fingers or hands can be crushed, frac-

tured or amputated if they become caught between the attachment

r between these components and any other object.

o

• Large forces are generated during product use that can break

or throw parts and cause injury. Stand clear during use and wear

ppropriate protective equipment, including eye protection.

a

• Use proper tool, attachment and fitting combinations. Improper

combinations can result in an incomplete or improper joint, damage

the equipment, void warranties or cause severe personal injury or

death.

• Use the RIDGID Press Booster only with RIDGID 32kN Stan-

dard Series press tools. Use of other power sources can damage

the tool and/or cause serious personal injury.

• Do not modify the tool. Modifying the tool in any manner may re-

sult in personal injury.

• Do not overreach. Keep proper footing and balance at all

times. This enables better control of the power tool in unexpected

situations.

• Before operating the RIDGID Press Booster Unit, read and un-

derstand:

– These instructions,

– The Press Tool operator’s manual,

– The attachment instructions,

– The fitting manufacturer’s installation instructions,

– The instructions for any other equipment used with this tool,

Failure to follow all instructions and warnings may result in property damage and/or serious injury.

RIDGID Contact Information

If you have any questions concerning this RIDGID®product:

• Contact your local RIDGID distributor,

• Visit RIDGID.com to find your local RIDGID contact point.

• Contact Ridge Tool Technical Service Department at rtctechser vic es@em er son.com, or in the U.S. and Canada call (800) 519-3456.

Description

The RIDGID Press Booster converts multiple cycles of a press tool into

a single cycle of the Press Booster to actuate attachments requiring a

Z3 actuator, such as MegaPress

the Press Booster cycle is complete.

®

XL Press Rings. It will not retract until

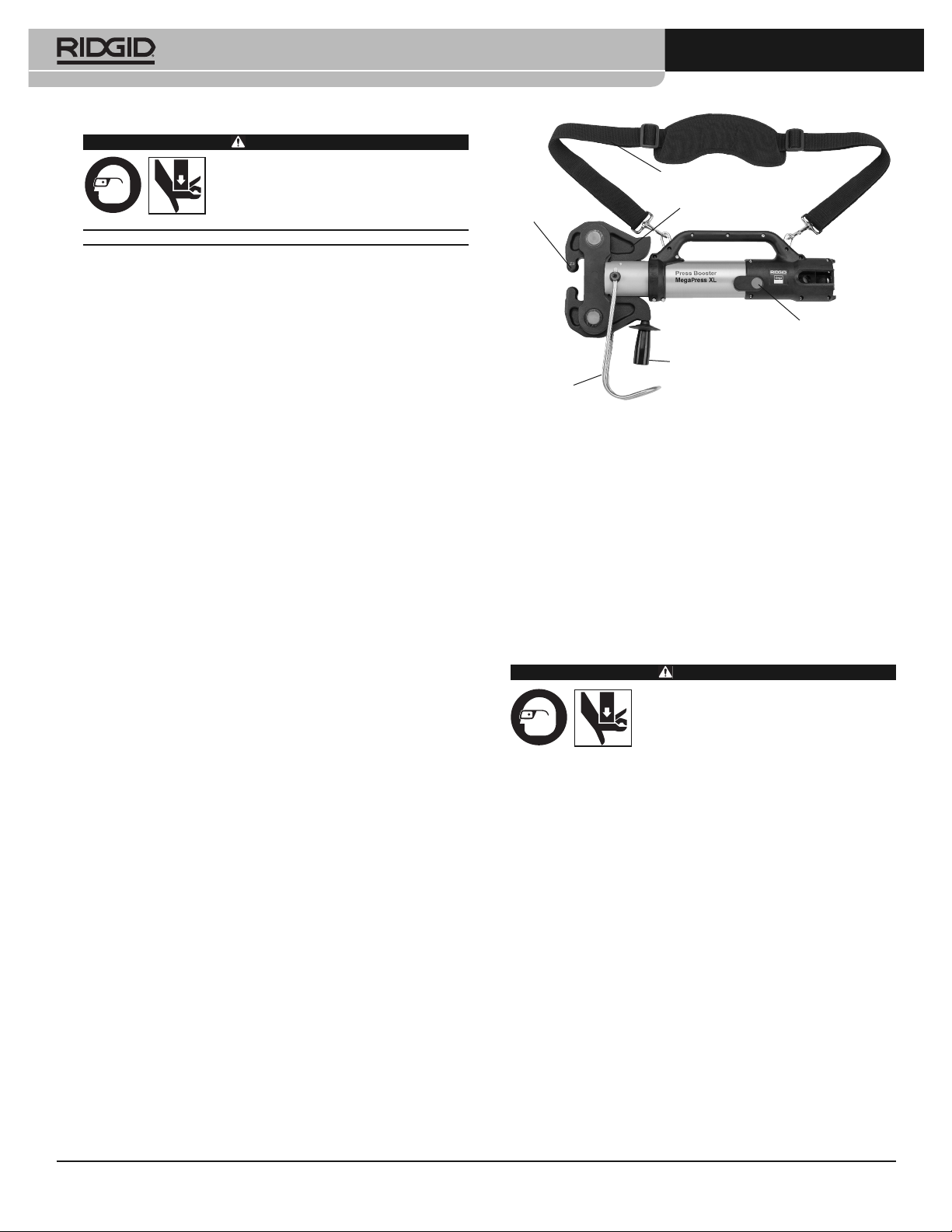

Shoulder Strap

ctuator

A

pherical Tip

S

upport

S

racket

B

Figure 1 – Press Booster/Z3 Actuator

Actuator

Arm

Handle

ressure Release

P

utton

B

Specifications

Actuator/Ring Designation...Z3

For use with........................RIDGID Standard Series 32 kN Press

Tools (such as the RP330 and RP340).

Not for use with the CT-400 and 320E.

Max. Operating Pressure .....580 bar

Hydraulics Volume................2.57 oz. (76 cm

3

)

Storage Temperature............32°F to 113°F (0°C to 45°C)

Operating Temperature........23°F to 113°F (-5°C to 45°C)

Humidity Range....................0% to 80%

Dimensions...........................19.7" × 12.2" × 3.5" (500 × 310 × 90 mm)

Weight ...................................21 lbs. (9.5 kg)

Pre-Operation Inspection

WARNING

Daily before use, inspect your tool and

correct any problems to reduce the risk

of serious injury from crushing injures,

jaw failure, and other causes, and prevent tool damage.

1. Make sure that the press tool is removed from the press booster.

2. Clean any oil, grease or dirt from the press booster. This aids inspection and improves control.

3. Inspect press booster for:

• Proper assembly, maintenance and completeness.

• Broken, worn, missing, misaligned or binding parts. Confirm

shoulder strap is in good condition.

• Oil leaks. If leaking have serviced – do not attempt to add oil.

• Presence and readability of warning label and markings.

• Any other condition which may prevent safe and normal opera-

tion.

Do not use tool until any problems have been repaired.

4. Inspect and maintain the press tool and any other equipment

being used per its instructions to make sure it is functioning properly.

MegaPress®is a registered trademark of Viega GmbH & Co.

Printed 1/18 999-995-129

EC43245 REV. A

The Emerson logo and RIDGID logo are registered trademarks of Emerson Electric Co. or RIDGID, Inc. in the U.S. and other countries.

All other trademarks belong to their respective holders.

©2018 RIDGID, Inc.

.10

ress Booster/Z3 Actuator Instructions

P

et Up/Operation

S

WARNING

Keep your fingers and hands away from

pressing attachments during press cy cle. Your fingers or hands can be

crushed, fractured or amputated if they

become caught between the attach-

ment or between these components and any other object.

Follow set up and operating instructions to reduce the risk

of injury from crushing, electrical shock and other causes

and to prevent tool damage.

Follow the press tool instructions to set up the tool and work area.

pen

O

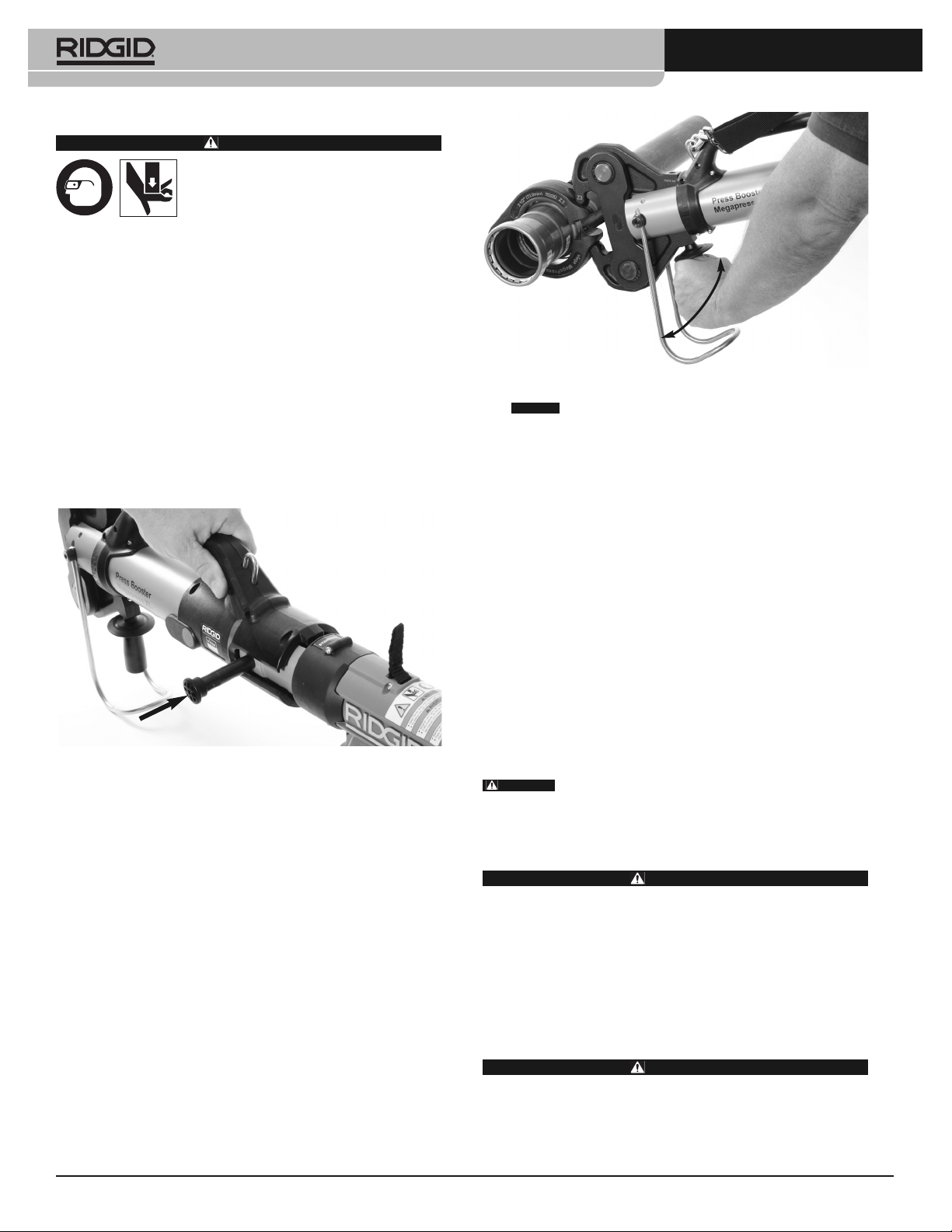

Installing the Press Booster on Press Tool

. Make sure that the press tool is unplugged or the battery is re-

1

moved and fully open the press tool attachment mounting pin. See

Figure 2. If there is an attachment in the tool, slide it out of the tool.

2. Attach the press booster to the press tool as shown in Figure 2 and

fully close the press tool attachment mounting pin. If the press

booster does not fit on the press tool do not force it. Be aware that

the combined weight can approach 37 lbs. (17 kg).

3. Securely attach shoulder strap as shown in Figure 1. Adjust strap

length as desired.

4. Power the press tool per it’s operating instructions.

Figure 2 – Installing Press Booster on Press Tool

Pressing a Fitting with Press Ring

1. Prepare the connection per fitting manufacturer’s installation instructions. Properly install correct press ring for fitting. Confirm

press ring uses Z3 actuator.

2. Place the shoulder strap to support the press booster. Be aware

that the combined weight can approach 37 lbs. (17 kg). Place one

hand on the handle of the Press Booster and the other on the handle of the press tool.

3. Pull back on the press booster handle to open the actuator arms.

Engage actuator spherical tips into the actuator pockets in the

press ring (Figure 3). Move the press booster handle forward, mak-

ing sure tips are fully engaged in pockets. Do not attempt to hang

tool from press ring. Tool could unexpectedly drop causing serious

injury or death.

Engaged

igure 3 – Placing Actuator Tips Into Ring Pockets

F

N

OTICE

4. Operating without a press ring can cause the Press

Booster to jam. With hands on handles and away from pinch

points, operate the press tool per its instructions. Allow the press

tool to complete the cycle.

Repeat the procedure and cycle the press tool a second time. If

the Press Booster has not retracted (you are unable to disengage

the Z3 actuator tips with the pockets) cycle the press tool for a third

time.

The Press Booster should complete its cycle after 2 or 3 press cycles.

If more than three tool cycles are required for the Press Booster to

retract, the Press Booster or the Press Tool need to be serviced.

If tool must be removed before the Press Booster retracts, depress

the pressure release button (Figure 1). Any time release button is

depressed, press is NOT complete and the connection must be

pressed again to ensure completion. If the tool malfunctions during operation, use this procedure.

5. Pull back on the press booster handle to open the actuator arms

and remove the Press Booster from the actuator pockets.

6. Turn press tool OFF.

7. Inspect and test the system in accordance with fitting manufacturer

instructions, normal practice and applicable codes.

Storage

WARNING

booster in the carrying case and place in a dry, secured area that is out

of reach of children and people unfamiliar with the tool. The tool is dangerous in the hands of untrained users.

Remove press booster from press tool. Store the press

Maintenance Instructions

WARNING

Make sure press booster is removed from press tool before

performing maintenance or making any adjustment.

1. After each use, wipe any oil or dirt off the press booster with a

clean, dry, soft cloth.

2. Monthly, or more often if needed, apply a light machine oil to the

pivot points. Wipe off any excess lubricant.

Do not attempt to add hydraulic oil to the Press Booster. Have tool serviced if leaking.

Service and Repair

WARNING

Improper service or repair can make the machine unsafe to

operate.

2

Service and repair on the press booster must be performed by a

RIDGID Independent Service Center. Use only RIDGID service parts.

For information on your nearest RIDGID Independent Service Center

r any service or repair questions, see Contact Information.

o

Fiche d’utilisation de l’amplificateur

de sertissage Press Booster avec

Actionneur Z3

AVERTISSEMENT

Afin de limiter les risques d’accident

grave, familiarisez-vous avec les consignes ci-présentes, ainsi qu’avec celles

visant l’en semble du matériel et des

outil.

CONSERVEZ CES INSTRUCTIONS !

• Eloignez vos doigts et vos mains des pinces de sertissage en

cours d’opération. Les doigts et les mains risquent d’être écrasés,

fracturés ou amputés par les pinces ou entre celles-ci et tout autre

objet.

• Ce produit génère suffisamment de couple en cours d’utilisation

pour briser et projeter des pièces de manière dangereuse. Tenezvous à l’écart durant le processus de sertissage et prévoyez les

équipements de protection appropriés, notamment une protection oculaire.

• Utilisez la combinaison d’outil, de pince et de raccord de ser-

tissage appropriée. Une mauvaise combinaison de ces éléments

risque de produire des raccords incomplets ou non-étanches, d’endommager le matériel, d’annuler sa garantie ou de provoquer des

accidents graves et potentiellement mortels.

• N’utilisez le RIDGID Press Booster qu’avec les sertisseuses

série Standard RIDGID de 32kN. L’emploi de tout autre type d’appareil pourrait endommager l’outil et/ou provoquer de graves

blessures corporelles.

• Ne tentez pas de modifier cet outil. La modification de cet outil de

manière quelconque risquerait de provoquer des accidents.

• Ne vous mettez pas en porte-à-faux. Maintenez votre équilibre

et stabilité à tout moment. Cela vous permettra de mieux contrôler

l’appareil en cas d’imprévu.

• Avant d’utiliser le RIDGID Press Booster, familiarisez-vous avec :

– Les consignes ci-présentes

– Le manuel de la sertisseuse

– Les consignes visant les accessoires utilisés

– Les consignes du fabricant des raccords de sertissage

– Les consignes visant tout autre matériel utilisé avec cet outil,

Le non-respect de l’ensemble de ces consignes et avertissements

pourraient occasionner des dégâts matériels et/ou de graves

blessures corporelles.

Coordonnées RIDGID

En cas de questions visant ce produit RIDGID®, veuillez :

• Consulter le distributeur RIDGID le plus proche

• Visiter le site RIDGID.com pour localiser le représentant RIDGID le

plus proche

• Consulter les services techniques de Ridge Tool à rtctechservic es@emerson.com, ou bien en composant le (800) 519-3456 à partir

des Etats-Unis ou du Canada.

Description

Le RIDGID Press Booster converti de multiples cycles de sertisseuse

en un seul cycle amplifié capable de mouvoir les pinces de sertissage

utili sant un actionneur type Z3, tels que celui prévu pour les bagues de

sertissage MegaPress

Press Booster est complet.

matériaux utilisés avant d’utiliser cet

®

XL. Il ne se rétracte que lorsque le cycle du

ress Booster/Z3 Actuator Instructions

P

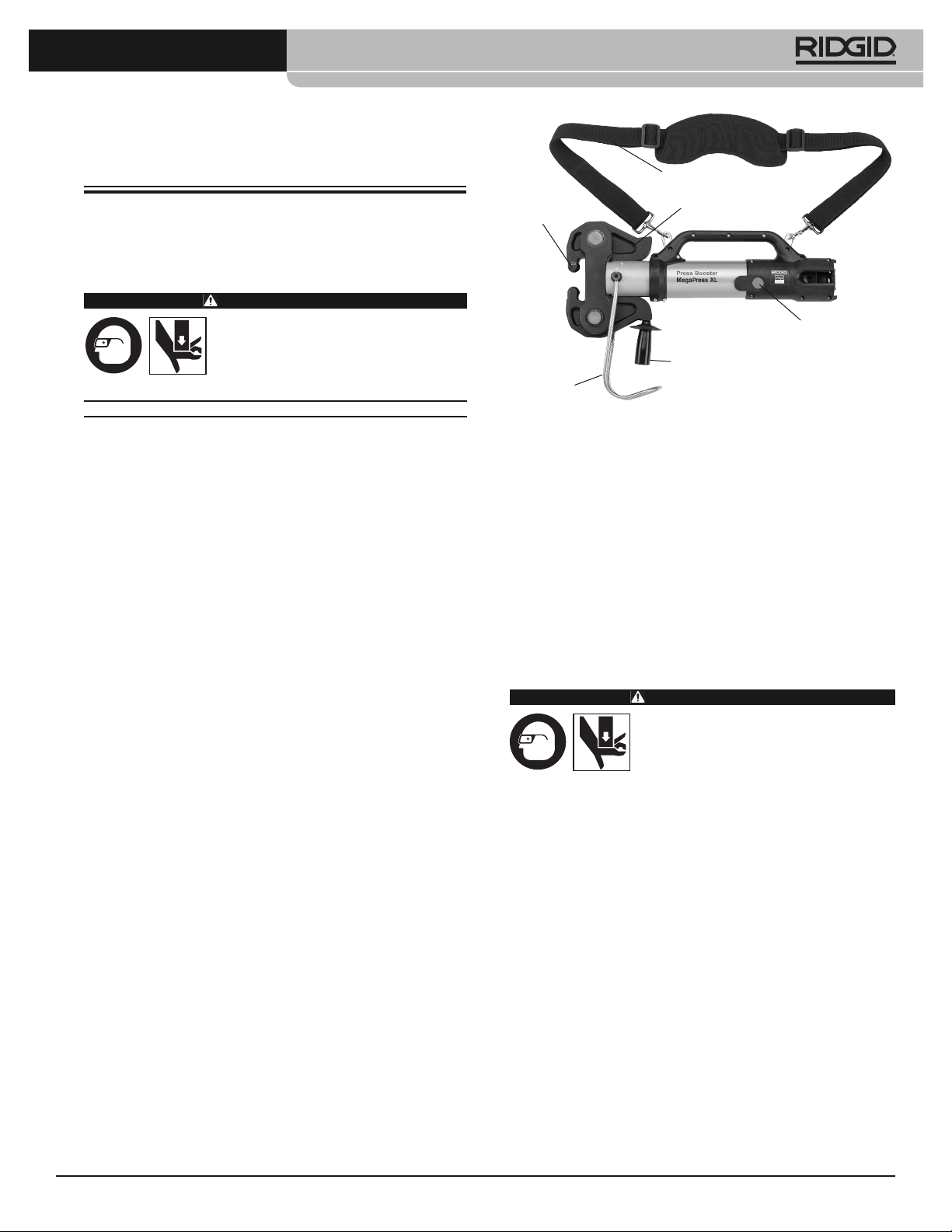

Bretelle

mbout

E

phérique de

s

’actionneur

l

Support

Figure 1 – Press Booster avec actionneur Z3

Bras de

l’actionneur

Poignée

D

Caractéristiques techniques

Désignation d’actionneur

et bague ..............................Z3

Compatibilité........................Sertisseuses RIDGID série Standard de

Pression hydraulique maxi.....580 bar

Capacité hydraulique.............2,57 oz. (76 cm

Température de stockage......32 à 113 °F (0 à 45 °C)

Température de

fonctionnement.......................23 à 113 °F (-5 à 45 °C)

Plage d’humidité.....................0% à 80%

Dimensions.............................19,7" × 12,2" × 3,5" (500 × 310 × 90 mm)

Poids .......................................21 livres (9,5 kg)

32kN telles que les RP330 et RP340.

Incompatible avec la CT-400 et la 320E.

3

)

Inspection préalable

AVERTISSEMENT

Inspectez l’outil avant chaque intervention afin de corriger toute anomalie

éven tuelle qui serait susceptible de

provoquer un accident grave ou la défaillance du matériel.

1. Retirez le Press Booster de la sertisseuse.

2. Nettoyez le Press Booster afin d’éliminer toutes traces de crasse.

Cela facilitera l’inspection et améliorera le contrôle de l’appareil.

3. Concentrez votre inspection du Press Booster sur les points sui vants:

• L’assemblage approprié, l’entretien et l’intégralité de l’outil.

• Signes d’éléments endommagés, usés, manquants, désalignés ou

grippés. Vérifiez le bon état de la bretelle.

• Fuites d’huile hydraulique. Le cas échéant, faites réviser l’outil. Ne

tentez pas de faire l’appoint.

• La présence et lisibilité des avertissements et marquages.

• Toute autre anomalie qui risquerait de compromettre la sécurité et

le bon fonctionnement de l’outil.

Corrigez toute anomalie éventuelle avant de réutiliser l’outil.

4. Inspectez et maintenez la sertisseuse et tout autre matériel utilisé

selon les consignes correspondantes afin d’assurer le bon fonctionnement de l’ensemble.

MegaPress®est une marque déposée de la société Viega GmbH & Co

étente

3

Loading...

Loading...