Page 1

OL50135AL

OPERATOR’S MANUAL

ALUMINUM

TWIN STACK

PORTABLE AIR

COMPRESSOR

To reduce the risk of injury, the user

must read and understand the

Operator’s Manual before using this

product.

IN619302AV 10/07

!

WARNING:

Page 2

Table of Contents

Section Page

Table of Contents . . . . . . . . . . . . . . . .2

Safety Instructions . . . . . . . . . . . . . . .3

Safety Signal Words . . . . . . . . . . . . .3

Before Using the Air

Compressor . . . . . . . . . . . . . . . . . . . .3

Spraying Precautions . . . . . . . . . . . .5

Breathable Air Warning . . . . . . . . . . .5

Warning Labels . . . . . . . . . . . . . . . . .6

Motor Specifications and

Electrical Requirements . . . . . . . . . .7

Power Supply and Motor

Specifications . . . . . . . . . . . . . . . . . .7

General Electrical Connections . . . . .7

110-120 Volt, 60 Hz Tool

Information . . . . . . . . . . . . . . . . . . . .8

Extension Cords . . . . . . . . . . . . . . . .8

Thermal Overload Protector . . . . . . .9

Glossary of Terms . . . . . . . . . . . . . . .9

Unpacking and Checking

Content . . . . . . . . . . . . . . . . . . . . . . .10

Installation . . . . . . . . . . . . . . . . . . . .10

Section Page

Getting to Know Your Air

Compressor . . . . . . . . . . . . . . . . . . .11

Operating Your Air Compressor . . .13

Moisture in Compressed Air . . . . . .13

Operating Your Air Compressor . . .13

For Trouble-Free Operation . . . . . .13

Maintenance . . . . . . . . . . . . . . . . . . .14

Tank . . . . . . . . . . . . . . . . . . . . . . . . .15

Filter Removal, Inspection, and

Replacement . . . . . . . . . . . . . . . . . .15

Lubrication . . . . . . . . . . . . . . . . . . . .15

Storage . . . . . . . . . . . . . . . . . . . . . .15

Maintenance Schedule . . . . . . . . . .15

Troubleshooting . . . . . . . . . . . . . . . .16

Repair Parts . . . . . . . . . . . . . . . . . . .18

Notes . . . . . . . . . . . . . . . . . . . . . . . . .23

Warranty . . . . . . . . . . . . . . . . . . . . . .24

2

Page 3

Safety Instructions

This manual contains information that is

very important to know and understand.

This information is provided for SAFETY

and to PREVENT EQUIPMENT PROBLEMS. To help recognize this information, observe the following symbols.

Safety Signal Words

Danger indicates

an imminently hazardous situation which, if not avoided,

WILL result in death or serious injury.

Warning indicates

a potentially hazardous situation which, if not avoided,

COULD result in death or serious injury.

Caution indicates a

potentially hazardous situation which, if not avoided,

MAY result in minor or moderate injury.

Notice indicates

important information, that if not followed, may cause damage to equipment.

3

Air compressors are utilized in a variety

of air system applications. Because air

compressors and other components

(material pump, spray gun, filters, lubrications, hoses, etc.) used make up a

high pressure pumping system, the following safety precautions should be

observed at all times. Only persons well

acquainted with these rules of safe operation should be allowed to use the air

compressor.

1. Read instruction manuals for each

component carefully, before attempting to assemble, disassemble or

operate your particular system.

2. Wear safety glasses (meeting ANSI

Z87.1 or in Canada CSA Z94.3-99)

and use hearing protection when

operating the pump or unit. Everyday

glasses are not safety glasses.

3. Do not exceed pressure rating of any

component in system.

4. Protect material lines and air lines

from damage or puncture. Keep hose

and power cable away from sharp

objects, chemical spills, oil, solvents,

and wet floors.

5. Never point a spray gun at oneself or

any other person. Accidental discharge may result in serious injury.

6. Check hoses for weak or worn condition, before each use, making certain

all connections are secure; do not

use if deficiency is found. Notify an

authorized service facility for examination or repair.

7. Release all pressures within system

slowly; dust and debris may be harmful.

Before Using the Air Compressor

All electrical work should be

done by a qualified (licensed or

certified) electrician. On a properly wired circuit, the black

wires supply a voltage potential

even when the unit is off.

Disconnect power and depressurize system before servicing

air compressor! (Turn pressure

regulator knob fully clockwise

after shutting off compressor.)

!

WARNING:

!

CAUTION:

!

DANGER:

!

WARNING:

NOTICE:

!

WARNING:

Page 4

8. Follow all local electrical and safety

codes, as well as the National

Electrical Code (NEC) and the

Occupational Safety and Health Act

(OSHA).

9. Wiring and fuses should follow electrical codes, current capacity, and be

properly grounded.

10. Electric motors must be securely and

adequately grounded. See grounding

instructions and extension cord information in this manual.

11. Always disconnect power source

before working on or near a motor, or

its connected load. If power disconnect point is out-of-sight, lock it in the

open position and tag to prevent

unexpected application of power.

12. Guard all moving parts; keep visitors

away. Never allow children in work

area.

13. Use only a properly grounded outlet

that will accept a three pronged plug,

and wear shoes to prevent shock

hazards.

14. Be careful when touching exterior of

operating motor; it may be hot

enough to cause injury.

15. Protect power cable from coming in

contact with sharp objects.

16. Clean electrical or electronic equipment with an approved cleaning

agent, such as dry, nonflammable

cleaning solvent.

17. To avoid spontaneous combustion,

discard waste rags into approved

metal waste cans.

18. Never store flammable liquids or

gases in vicinity of compressor.

19. When spraying with solvent of toxic

chemicals, follow instructions provided by the chemical manufacturer.

20. Spray in a well ventilated area, to

keep fumes from collecting and causing health and fire hazards.

21. Do not spray in vicinity of open

flames or other places where a spark

can cause ignition. Do not smoke

when spraying paint, insecticides, or

other flammable substances.

22. Use a respirator when spraying.

23. NEVER reset safety valve or pressure switch. Keep safety valve free

from paint and other accumulations.

This provides safety against over

pressure.

24. Do regular maintenance; keep all

nuts, bolts, and screws tight, to be

sure equipment is in safe working

condition.

25. Keep cleaning rags and other flammable waste materials in a tightly

closed metal container and dispose of

later in the proper fashion.

26. Drain tanks of moisture after each

day’s use. If unit will not be used for a

while, it is best to leave drain cock

open until such time as it is to be

used. This will allow moisture to completely drain out and help prevent

corrosion of inside of tank.

27. Inspect tank yearly for pin holes or

any other imperfections that could

cause it to become unsafe. NEVER

weld or drill holes in air tank.

Safety Instructions (continued)

4

Page 5

1. Do not smoke when spraying paint,

insecticides, or other flammable substances.

2. Use a face mask/respirator when spraying and

spray in a well ventilated

area to prevent health and

fire hazards.

3. Do not direct paint or other

sprayed material at the compressor.

Locate compressor as far away from

the spraying area as possible to minimize overspray accumulation on the

compressor.

4. When spraying or cleaning with solvents or toxic chemicals, follow the

instructions provided by the chemical

manufacturer.

5

Spraying Precautions

Do not spray flammable materials in vicinity of open flame or

near ignition sources including

the compressor unit.

!

Breathable Air Warning

This compressor/pump is not equipped and should not be used “as

is” to supply breathing quality air. For any application of air for

human consumption, the air compressor/pump will need to be fitted

with suitable in-line safety and alarm equipment.This additional

equipment is necessary to properly filter and purify the air to meet

minimal specifications for Grade D breathing as described in

Compressed Gas Association Commodity Specification G 7.1 - 1966,

OSHA 29 CFR 1910. 134, and/or Canadian Standards Associations

(CSA).

DISCLAIMER OF WARRANTIES

In the event the compressor is used for the purpose of breathing air

application and proper in-line safety and alarm equipment is not

simultaneously used, existing warranties shall be voided, and

Campbell Hausfeld disclaims any liability whatsoever for any loss,

personal injury or damage.

WARNING:

!

DANGER:

Page 6

Safety Instructions (continued)

6

Find and read all warning labels found on

the air compressor shown below

Warning Labels

DRAIN TANK EVERYDAY FOR PROPER

COMPRESSOR OPERATION

RÉSERVOIR DE VIDANGE JOURNALIER

POUR L'EXÉCUTION APPROPRIÉE

DE COMPRESSEUR

DEPÓSITO DE DESAGÜE DIARIO PARA

LA OPERACIÓN APROPIADA

DEL COMPRESSOR

DK812200AV 906

WARNING

AVERTISSEMENT

ADVERTENCIA

0

DK724100AV 100

Page 7

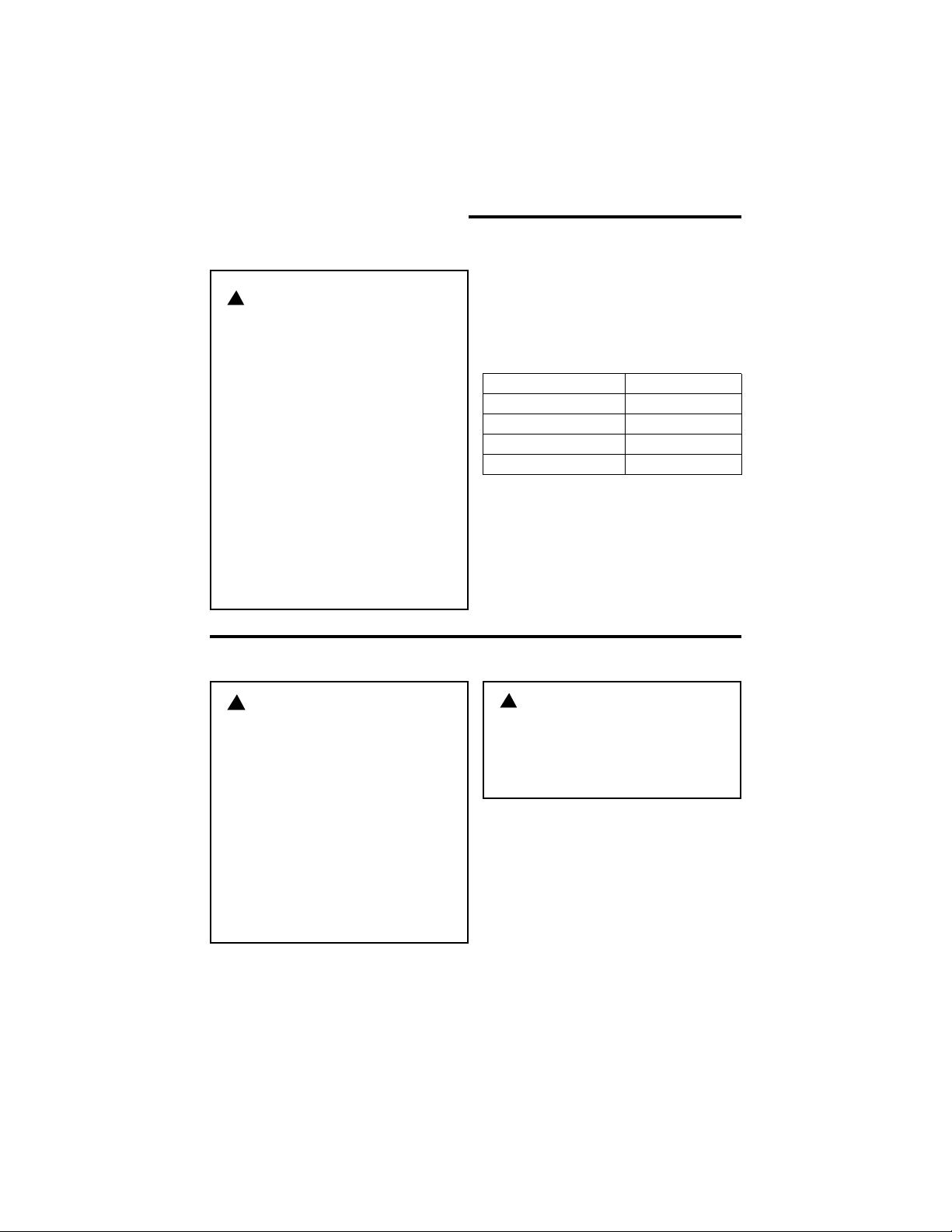

The A-C motor used on this compressor

is a PSC, permanent split capacitor type,

having the following specification. It is

wired at the factory for operation on

110V-120V AC, 60 Hz service.

Voltage 110-120

Amperes 15

Hertz (Cycles) 60

Phase Single

RPM 3450

Motor Specifications and

Electrical Requirements

7

Power Supply and Motor Specifications

To reduce the risk of electrical

hazards, fire hazards or damage

to the tool, use proper circuit

protection.Your tool is wired at

the factory for operation using

the voltage shown. Connect

tool to a power line with the

appropriate voltage and a 15amp branch circuit. Use a 15amp time delay type fuse or circuit breaker.To reduce the risk

of shock or fire, if power cord is

worn or cut, or damaged in any

way, have it replaced immediately.

!

General Electrical Connections

To reduce the risk of electrocution:

1. Use only identical replacement parts when servicing.

Servicing should be performed by a qualified technician.

2. Do not use in rain or where

floor is wet. This too is

intended for indoor residential use only.

Do not permit fingers to touch

the terminals of plug when

installing or removing the plug

to or from the outlet.

WARNING:

!

DANGER:

!

WARNING:

Page 8

8

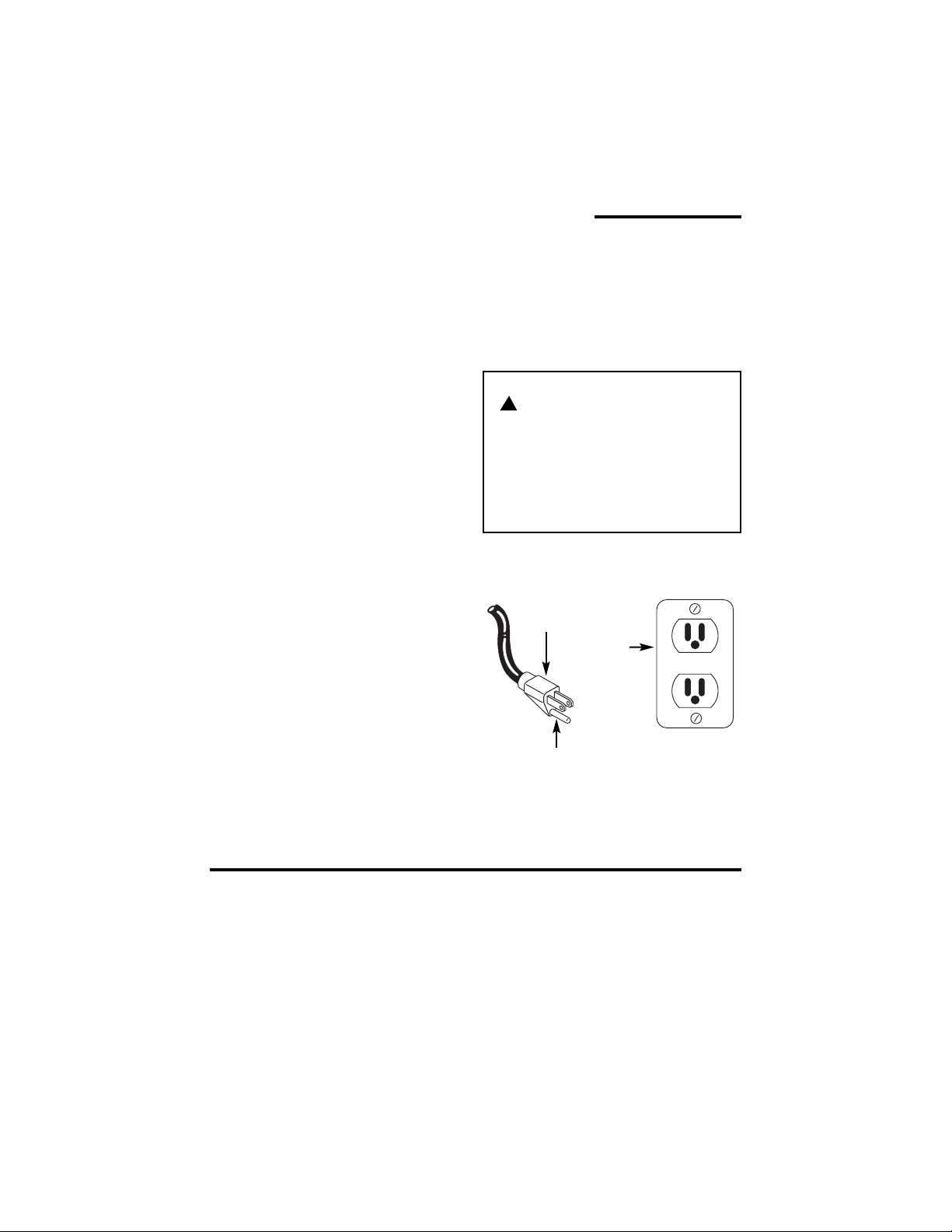

The plug supplied on your tool may not

fit into the outlet you are planning to use.

Your local electrical code may require

slightly different power cord plug connections. If these differences exist refer to

and make the proper adjustments per

you local code before your tool is

plugged in and turned on.

In the event of a malfunction or breakdown, grounding provides a path of least

resistance for electrical current to reduce

the risk of electric shock. This tool is

equipped with an electric cord having an

equipment-grounding conductor and a

grounding plug, as shown. The plug must

be plugged into a matching outlet that is

properly installed and grounded in accordance with all local codes and ordinances.

Do not modify the plug provided. If it will

not fit the outlet, have the proper outlet

installed by a qualified electrician.

Improper connection of the equipmentgrounding conductor can result in a risk

of electric shock. The conductor with

insulation having an outer surface that is

green with or without yellow stripes is the

equipment-grounding conductor. If repair

or replacement of the electric cord or

plug is necessary, do not connect the

equipment-grounding conductor to a live

terminal.

If the grounding instructions are not completely understood, or if you are in doubt

as to whether the tool is properly grounded check with a qualified electrician or

service personnel.

Motor Specifications and

Electrical Requirements (continued)

110-120 volt, 60Hz Tool Information

If not properly grounded, this

tool can cause an electrical

shock, particularly when used

in damp locations, in proximity

of plumbing, or out of doors.

Grounding Prong

3-Prong Plug

Properly

Grounded

3-Prong

Outlet

Extension Cords

1. The air compressor should be located

where it can be directly plugged into

an outlet. An extension cord should

not be used with this unit.

2. To avoid loss of power and overheating, additional air hose must be used

to reach work area instead of extension cords.

!

WARNING:

Page 9

9

Thermal Overload Protector

If thermal overload protector shuts motor

OFF frequently look for the following

causes.

1. Low voltage.

2. Wrong gauge wire.

3. Dirty air filter.

4. Lack of proper ventilation.

5. Unit is being used with an extension

cord.

6. Low oil level

See Troubleshooting Chart for corrective

action.

This compressor is equipped

with an automatic reset thermal

overload protector which will

shut off motor if it becomes

overheated.

!

The motor must be allowed to

cool down before start-up is

possible. The motor will automatically restart without warning if left plugged into electrical

outlet, and the motor is turned

on.

ASME Safety Valve

A safety valve that automatically releases

the air if the air receiver (tank) pressure

exceeds the preset maximum.

PSI (Pounds per Square Inch)

Measurement of the pressure exerted by

the force of the air. The actual psi output is

measured by a pressure gauge on the compressor

SCFM (Standard Cubic Feet per Minute)

Sometimes called CFM (Cubic Feet per

Minute). Measurement of air volume delivered by the compressor.

Air Delivery

A combination of psi and SCFM. The air

delivery required by a tool is stated as

(number) SCFM at (number) psi. The combination of these figures determines what

size unit is needed.

Air Tank Capacity

The volume of air stored in the tank and

available for immediate use. A large tank

allows the intermittent use of an air tool

with an air requirement higher than the

compressor’s rated delivery.

Volts or Voltage

A measurement of the force of an electrical

current.

Amps or Amperage

A measure of the electrical force minus the

resistance on an electrical line. Ridgid air

compressors require 15 amps for operation.

Be sure the compressor will operate on an

electrical line with the proper amps. If other

appliances operate on the same line, they

will reduce the available amps. If the

amperage is not adequate, the result will be

blown fuses or tripped circuits.

Regulator

A control that adjusts the line pressure to

the proper amount needed to operate spray

guns and air tools.

Tanks Pressure Gauge

Indicates tank pressure in psi.

Regulated Outlet Gauge

Displays the current line pressures. It is

regulated by the regulator knob.

Cut-in/Cut-off Pressure

Specific psi at which a compressor starts

and stops while refilling the air tank.

Glossary of Terms

CAUTION:

!

CAUTION:

Page 10

10

1. Remove the air compressor from the

carton.

2. Place the compressor on a secure,

level, and stationary work surface and

look it over carefully.

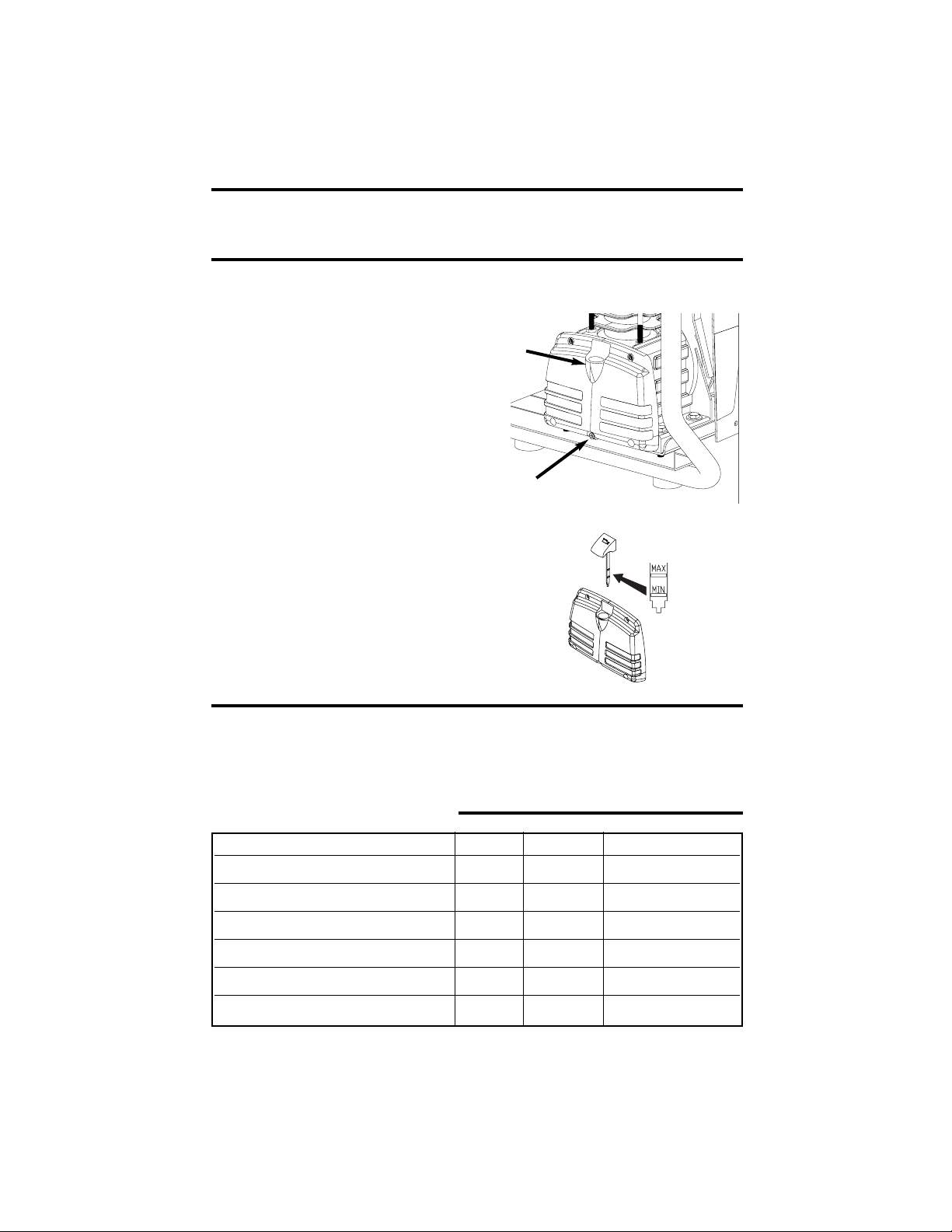

3. Make sure the dipstick is in a plastic

bag secured to the pump.

4. The pump has been filled with the

appropriate amount of oil (250 mL /

8.4 oz) by the factory.

5. Replace the plug with the dipstick

located inside the bag. Check the oil

level using the dipstick.

6. If the oil level is below the “MIN” line,

fill the pump until the oil level reads

between “MIN” and “MAX” lines. (For

oil type and fill directions, see

“Lubrication” section in the manual)

Unpacking and Checking Contents

Do not operate unit if damaged

during shipping, handling or

use. Damage may result in

bursting and cause injury or

property damage.

For your own safety, never

operate unit until all assembly

steps are complete and until

you have read and understood

the entire operator’s manual.

To reduce the risk of injury, if

any parts are missing, do not

attempt to operate the air compressor until the missing parts

are obtained and installed correctly.

1. Check and tighten all bolts, fittings,

etc., before operating compressor.

2. Make sure compressor is filled to

proper oil level before use.

3. Operate compressor in a ventilated

area so that compressor may be

properly cooled.

4. Compressor should be located where

it can be directly plugged into an outlet. An extension cord should not be

used with this unit.

5. To avoid loss of power and overheating, additional air hose must be used

to reach work area instead of extension cords.

Installation

!

WARNING:

!

WARNING:

!

WARNING:

Page 11

11

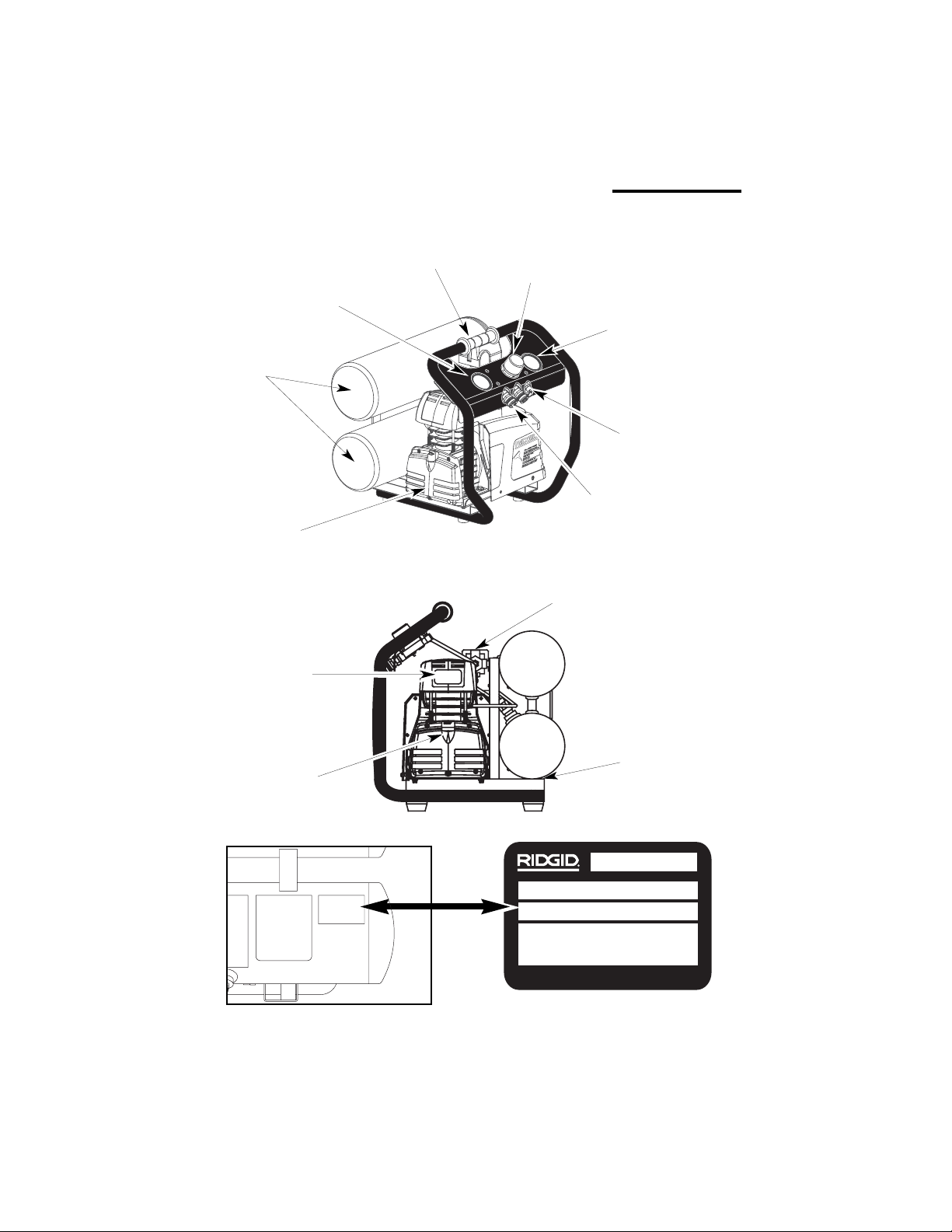

Getting to Know Your Air Compressor

2 Regulated

Outlet Gauge

5 Tank Pressure

Gauge

4 Regulator

Knob

1 Air Storage

Tanks

3 Handle

7 Air Outlet

Fittings

9 Air Filter

(Underneath

shroud)

10 On/Off Switch

11 Tank Drain

Valve

6 Safety Valve

12 Dipstick

Model/Serial Number Decal

8 Pump

ridgid.com 1-800-474-3443

Page 12

Getting to Know Your Air

Compressor (Continued)

12

1. Air Storage Tanks. The tanks store

air for later use.

2. Regulated Outlet Gauge. This

gauge shows at-a-glance, air

pressure at outlet. Air pressure is

measured in pounds per square

inch (PSI). Most tools have

maximum pressure ratings. Never

exceed the maximum pressure

rating of the tool you are using. Be

sure this gauge reads ZERO before

changing air tools or disconnecting

hose from outlet.

3. Handle. Used to move the com

pressor.

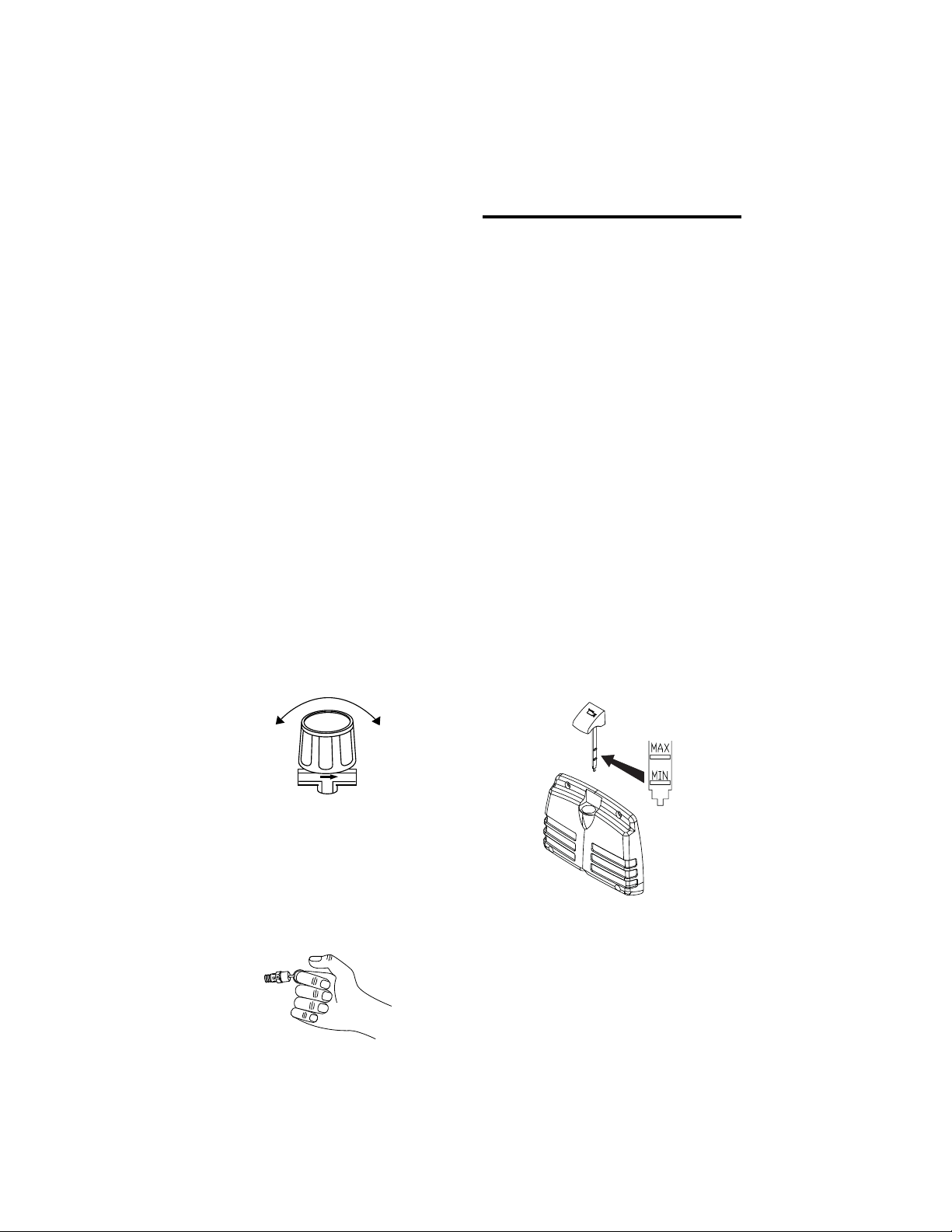

4. Regulator Knob. This knob

controls air pressure to an air

operated tool or paint spray gun.

Turning the knob clockwise

increases air pressure at the outlet.

Turning counterclockwise will lower

air pressure at the outlet. Fully

counterclockwise will shut off the

flow of air completely.

5. Tank Pressure Gauge. Gauge

shows pressure in air receiver indi

cating compressor is building

pressure properly.

6. ASME Safety Valve. This valve

automatically releases air if the tank

pressure exceeds the preset maxi

mum.

7. Air Outlet Fittings. These fittings

are 1/4” universal-style quick

connect fittings and allow rapid tool

changes.

8. Pump. The pump takes in air and

generates the pressurized air in the

air storage tanks.

9. Air Filter. The air filter keeps dirt

and debris from entering the com

pressor pump and reduces com

pressor noise.

10. On/Off Switch. This switch allows

manual control of the compressor.

Note that when the switch is turned

on, the compressor will

automatically start and stop

depending on tank pressure.

11. Tank Drain Valve. The tank drain

valve allows moisture to be

removed from the tank.

12. Dipstick. The dipstick measures

the oil level in the compressor

pump.

Close

Open

Page 13

1. Read instructions: Carefully read

through this operator’s manual

BEFORE OPERATING the new air

compressor. It contains information

about operation and maintenance of

the unit.

2. Drain tank daily: Depressurize system

prior to draining tank. Open tank

drain valve and drain moisture from

tank. This helps keep oil and moisture out of the compressed air system. Be sure to close tank drain valve

tightly before operating compressor.

3. Change air filter: Never run compressor without an air filter nor with a dirty

air filter. Replace with a new filter

when it is dirty.

4. Follow maintenance schedule for

checking and changing the oil.

Operating Your Air Compressor

13

Moisture in compressed air will form into

droplets as it comes from an air compressor pump. When humidity is high or

when a compressor is in continuous use

for an extended period of time, this moisture will collect in the tank. When using a

paint spray or sandblast gun, this water

will be carried from the tank through the

hose, and out of the gun as droplets

mixed with the spray material.

IMPORTANT: This condensation will

cause water spots in a paint job, especially when spraying other than water

based paints. If sandblasting, it will

cause the sand to cake and clog the gun,

rendering it ineffective.

A filter in the air line, located as near to

the gun as possible, will help eliminate

this moisture.

For Trouble-Free Operation

Moisture in Compressed Air

Make sure the crank case has the proper

oil level. Make sure the tank drain valve

is closed, the regulator knob is turned

fully counterclockwise, and the On/Off

switch is in the OFF position.

Plug compressor into a dedicated 15

Amp (minimum) circuit.

Turn On/Off switch to the ON position.

The compressor will now start building

pressure.

After compressor reaches cut-off pressure, install a hose (with the desired air

tool attached) into the outlet fitting.

Adjust the regulator knob to the desired

pressure.

The compressor is now ready to operate.

Do not over-pressurize any air

tool. Consult air tool instructions for proper air tool pressure.

Operating Your Air Compressor

!

WARNING:

Page 14

1. Check compressor for any visible

problems, especially check air filter to

be sure it is clean.

2. Pull ring on safety valve and allow it to

snap back to normal position.

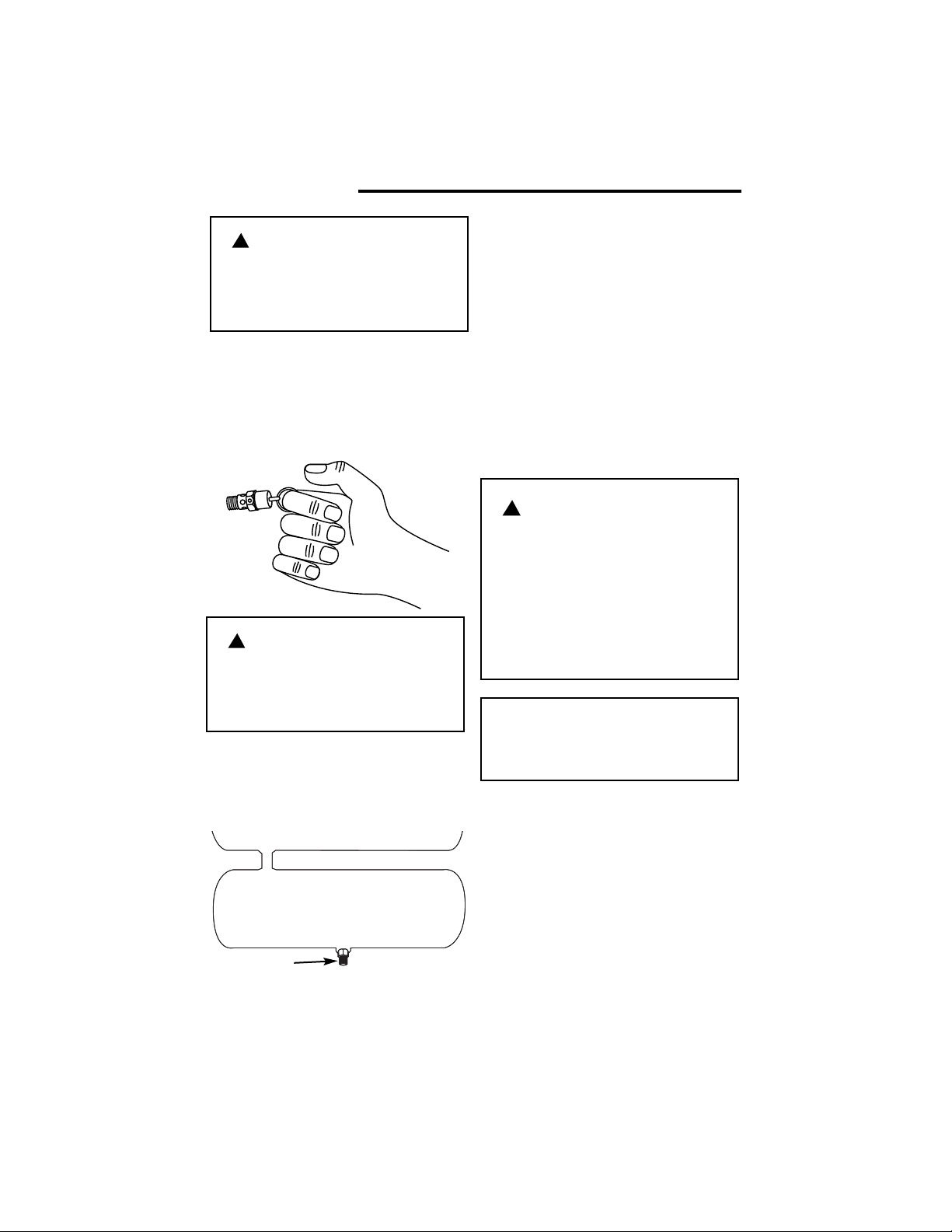

3. Drain moisture from tank daily. Shut

compressor off. Depressurize system

prior to draining tank. Drain moisture

from tank by opening the tank drain

valve underneath the tank.

4. Turn power OFF and clean dust and

dirt from motor, tank, air lines and

pump cooling fins.

NOTE: The air filter located in the filter

slot in the pump head must be checked

and cleaned periodically, more often if

used under very dusty conditions or

when a great deal of fog from spraying is

allowed to circulate near unit.

IMPORTANT: Unit should be located as

far from spraying area as hose will allow

to prevent over-spray from clogging filter.

Maintenance

14

Tank

Drain

Valve

Release all pressure and disconnect power before making

any repair.

!

Safety valve must be replaced if

it cannot be actuated or it leaks

air after ring is released.

Never attempt to repair or modify a tank! Welding, drilling or

any other modification will

weaken the tank resulting in

damage from rupture or explosion. Always replace worn,

cracked or damaged tanks.

Tank

Drain liquid from tank daily.

The tank should be carefully inspected at

a minimum of once a year. Look for

cracks forming near the welds. If a crack

is detected, remove pressure from tank

immediately and replace.

WARNING:

!

WARNING:

!

DANGER:

NOTICE:

Page 15

1. When not in use, compressor should be

stored in a cool dry place.

2. Tank should be drained of moisture.

3. Hose should be disconnected and hung

open ends down to allow any moisture

to drain.

15

To change a filter, remove the pump/ motor shroud to expose pump. If filter is dirty,

replace.

Filter Removal, Inspection and Replacement

Lubrication

Storage

Operation Daily Weekly Every 3 Months

Check Oil Level

Drain Tank

Check Air Filter

Check Safety Valve

Blow Dirt From Inside Motor

Change Oil

Maintenance Schedule

Oil fill

hole

Drain

Plug

Before plugging in compressor, make sure

the crankcase is filled with 250ml/ 8.4 oz. of

ISO 100 (SAE 30), non-detergent

compressor oil, or Mobil 1 5W30 synthetic.

Use dipstick to check oil-level.

To Drain and replace the oil:

- Place a suitable container underneath

the drain to collect used oil.

- Remove oil drain plug with a 4mm hex

wrench.

- When the used oil has drained, reinstall

the drain plug and tighten using the 4mm

hex wrench.

- Remove the dipstick

- Add 250ml/ 8.4 oz. of ISO 100 (SAE 30),

non-detergent compressor oil, or Mobil 1

5W30 synthetic.

NOTE: Avoid overfilling with oil. Make sure

to check that the oil level is not above MAX

line on the dipstick.

- Re-insert the dipstick.

Page 16

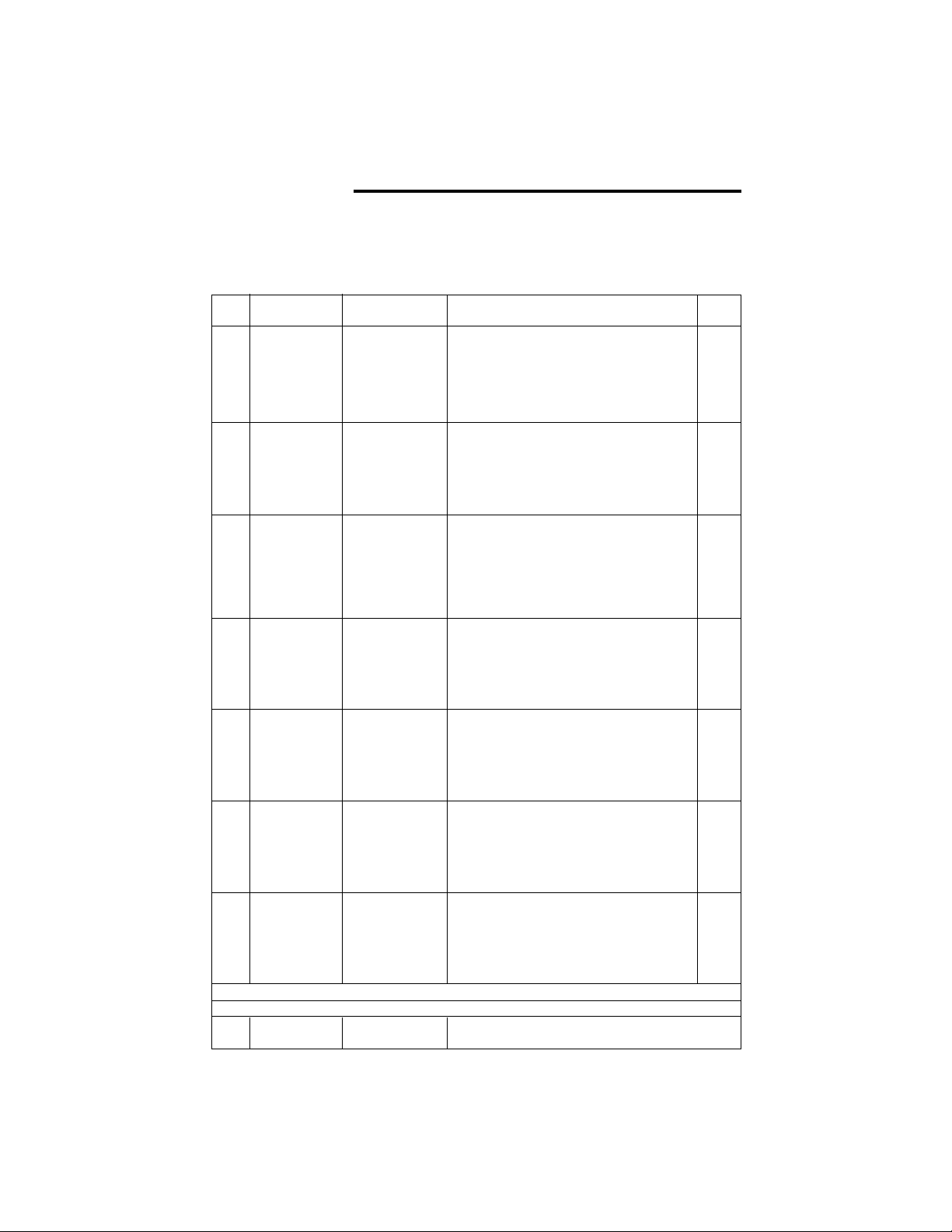

Troubleshooting

16

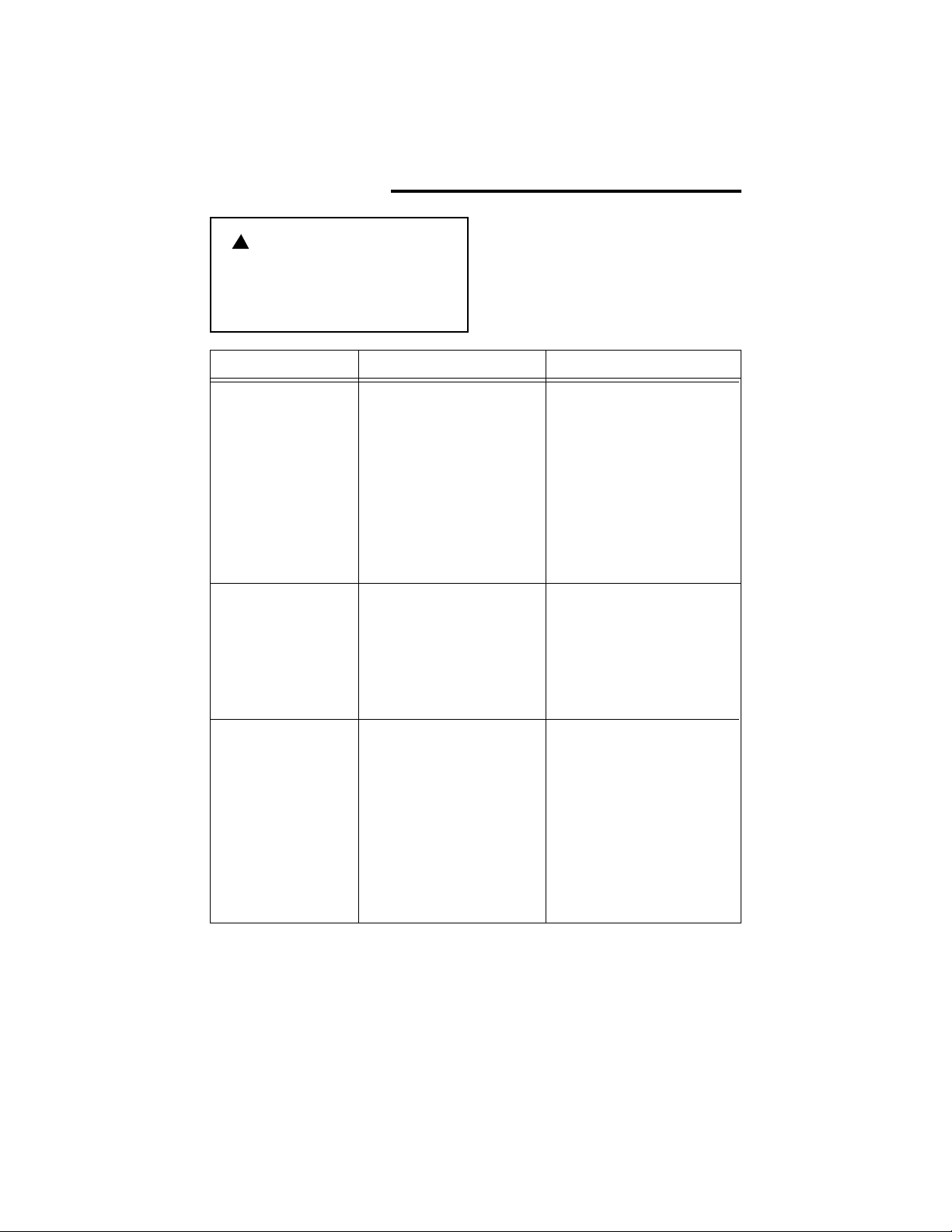

For your own safety do not try

and run the air compressor

while troubleshooting.

!

TROUBLE PROBABLE CAUSE REMEDY

Compressor will not

run

Motor hums but cannot run or runs slowly

Fuses blow/circuit

breaker trips repeatedly

1. Unit is plugged into

extension cord

2. No electrical power

3. Blown fuse

4. Breaker open

5. Thermal overload open

6. Pressure switch bad

1. Low voltage

2. Unit is plugged into

extension cord

3. Shorted or open motor

winding

4. Defective check valve or

unloader

1. Incorrect size fuse, circuit

overloaded

2. Unit is plugged into

extension cord

3. Defective check valve or

unloader

1. Remove extension cord

2. Plugged in? Check

fuse/breaker or motor overload

3. Replace blown fuse

4. Reset, determining why

problem happened

5. Motor will restart when cool

6. Replace

1. Check with voltmeter

2. Remove extension cord

3. Replace motor

4. Replace or repair

1. Check for proper fuse, use

time-delay fuse.

Disconnect other electrical

appliances from circuit or

operate compressor on its

own branch circuit

2. Remove extension cord

3. Replace or repair

WARNING:

Page 17

17

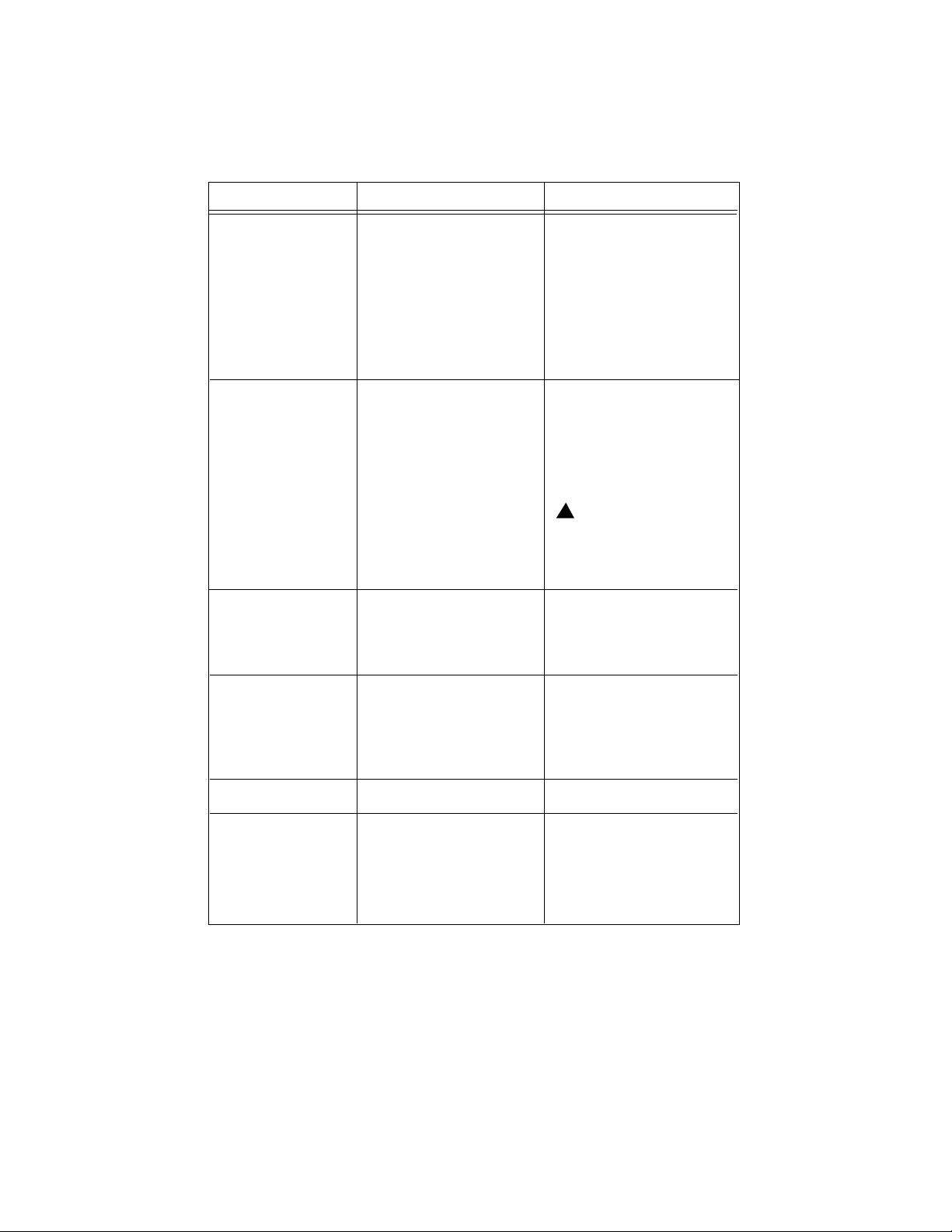

TROUBLE PROBABLE CAUSE REMEDY

Thermal overload

protector cuts out

repeatedly

Air tank pressure

drops when compressor shuts off

Excessive moisture

in discharge air

Compressor runs

continuously

Compressor vibrates

Air output lower than

normal

1. Low voltage

2. Clogged air filter

3. Lack of proper ventilation/room temperature

too high

4. Unit is plugged into

extension cord

5. Low oil level

1. Loose connections (fittings, tubing, etc.)

2. Loose drain valve

3. Check valve leaking

1. Excessive water in air

tank

2. High humidity

1. Defective pressure

switch

2. Excessive air usage

Loose mounting bolts

1. Broken inlet valves

2. Intake filter dirty

3. Connections leaking

1. Check with voltmeter

2. Clean filter (see

Maintenance section)

3. Move compressor to well

ventilated area

4. Remove extension cord

5. Add oil to proper level

1. Check all connections with

soap and water solution

and tighten

2. Tighten

3. Disassemble check valve

assembly, clean or replace

Do not disassemble

check valve with air in

tank; bleed tank

1. Drain tank

2. Move to area of less

humidity; use air line filter

1. Replace switch

2. Decrease air usage; compressor not large enough

for a requirement

Tighten

1. Have authorized service

representative repair unit

2. Clean or replace intake filter

3. Tighten connections

!

DANGER:

Page 18

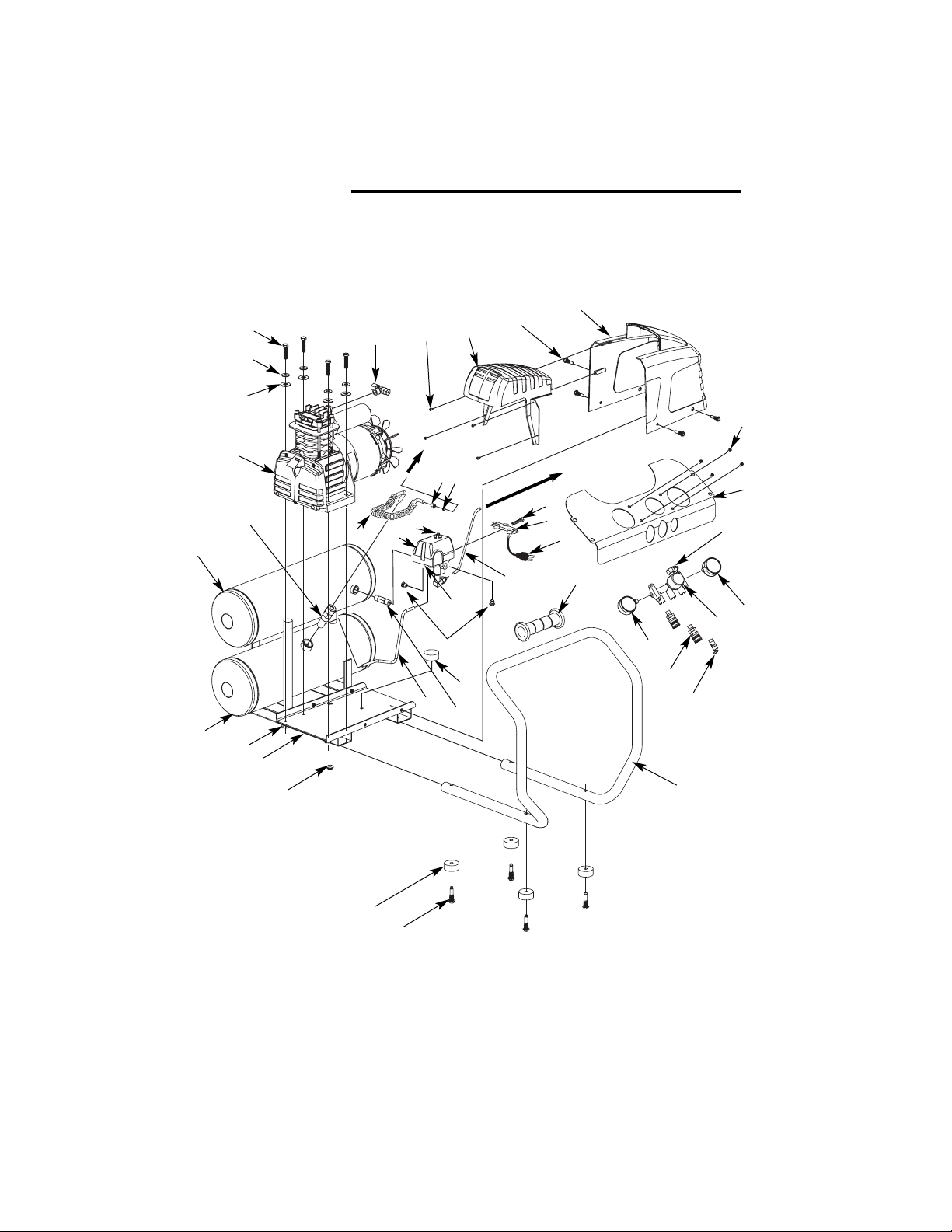

Repair Parts

18

To pump

head

To manifold

1

2

19

20

21

22

23

25

26

27

28

29

30

31

32

33

34

3

4

5

6

7

8

9

38, 10, 12

11

12

13

14

15

16

17

35

36

37

24

39

40

18

41

42

(back)

Page 19

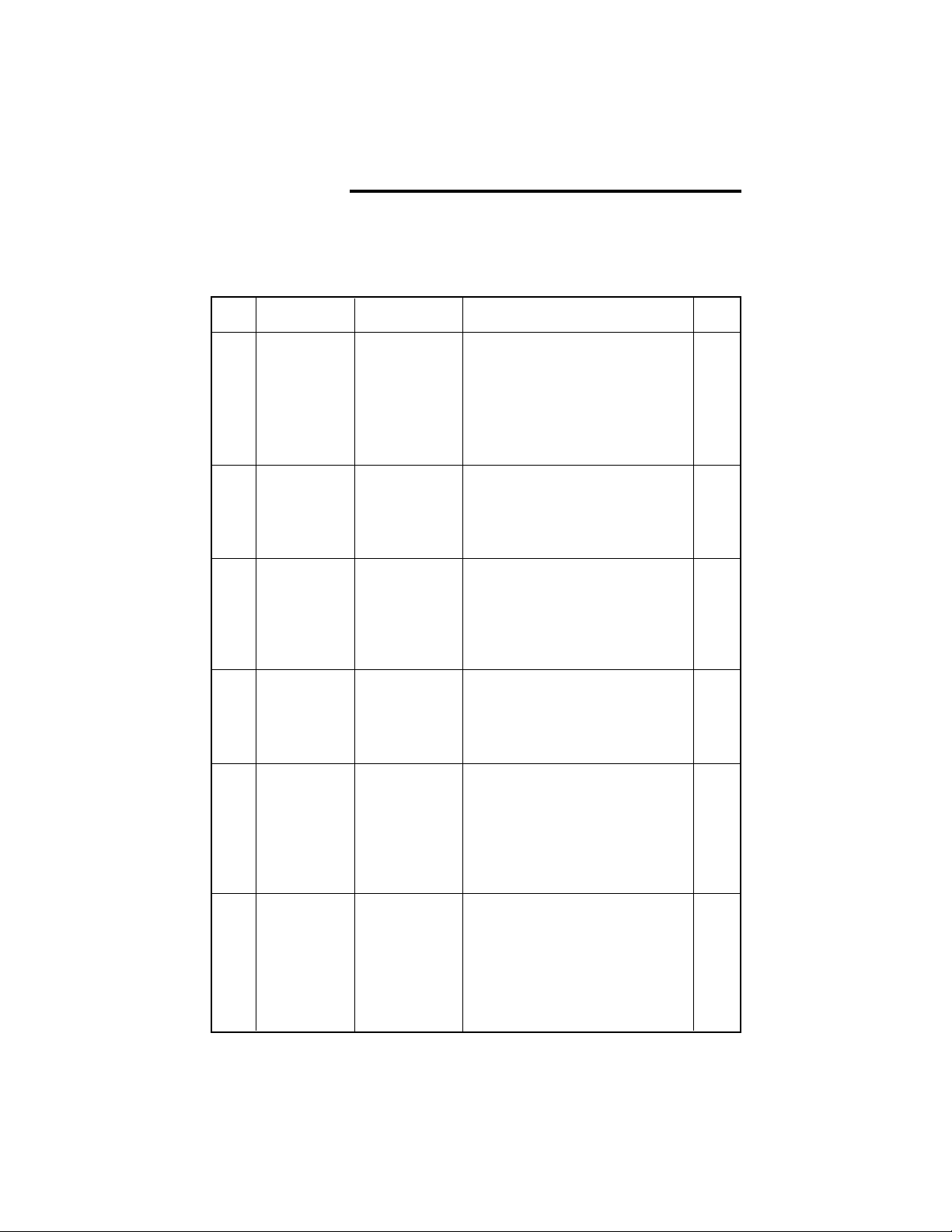

Repair Parts

19

For Repair Parts, Call 1-800-4-RIDGID

Please provide following information:

-Model number

-Serial number (if any)

-Part description and number as shown in parts list

Ref. Catalogue Part

No. Number Number Description Qty

1 24933 HL015300AV Self-tapping HHCS

(M10 x 40) 4

2 N/A Lock washer (metric 8.2) 4

*3 24938 HL167700AV Tee Fitting Assembly 1

4 N/A Phillips head screw (M 4.2 x 10mm) 4

5 24943 HL011100AV Pump head shroud 1

6 N/A Phillips HHCS (M6 x 19mm) 4

7 24948 HL011200AV Motor shroud 1

8 24953 HL300001AV Oil lube pump 1

9 24958 AR057800AV Twinstack tank 1

*10 24963 CV223800AV Check valve 1

11 24968 HL009700AV Hex nut 1

12 24973 HL009800AV Ferrule 2

13 17808 ST185600AV Handle Grip 1

14 — Exhaust tube 1

15 24978 HL015900AV Pipe nipple 1/4” NPT 1

16 24983 HL016000AV Unloader tube (includes nuts & ferrules) 1

*17 24988 CW213300AV Pressure switch (includes pressure 1

switch cover and unloader valve)

18 25118 CW217700AV Unloader Valve 1

*19 17903 CW211700AV Pressure switch cover 1

20 17753 ST209800AV Strain relief screw 1

21 17758 CW209600AV Strain relief 1

22 20388 EC012602AV Cord 1

23 24993 V-215105AV 150 PSI safety valve 1

24 17888 ST022500AV 1/4” - 18 NPT pipe plug 2

25 24998 — Control panel tube (includes tube inserts) 1

26 25003 — Elbow compression fitting (includes nut & ferrule) 2

27 25008 HL015400AV Grommet 1

28 25013 ST192200AV Rubber foot 4

29 17848 ST073276AV Self-tapping HHCS 4

30 N/A Flat washer 4

31 25018 ST192100AV Motor support pad 1

32 N/A Hex nut (8mm) 3

33 17783 ST071626AV Button head torx screw 4

*34 25023 WL024501AV Manifold 1

*35 17873 HF203300AV 1/4” Universal coupler 2

*36 17878 GA016705AV Outlet pressure gauge 1

*37 17773 GA016709AV Tank pressure gauge 1

38 N/A Hex Nut 1

39 17838 WL025800AV Control Panel Bracket 1

40 17813 WL025900AV Roll Bar 1

41 25688 HL029200AV Motorcord clamp 1

42 17913 D-1403 Drain valve 1

* Considered wear items N/A = Standard Hardware Item

REPAIR PARTS KITS

25033 HL029100AV Exhaust tube kit (without check valve)

17858 ST170400AV Control panel tube kit (includes inserts, nuts, ferrules)

Page 20

Repair Parts

20

1

2

3

4

5

6

7

8

9

14

10

14

12

10

12

13

15

11

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31 32

33

34

35

36

37

38

39

40

41

43

42

44

45

46

47

48

Page 21

Repair Parts

21

For Repair Parts, Call 1-800-4-RIDGID

Please provide following information:

-Model number

-Serial number (if any)

-Part description and number as shown in parts list

Ref. Catalogue Part

No. Number Number Description Qty

1 Socket head cap screw M6-

1.25 x 110 mm - cylinder head 4

2 Lock washer M6 4

3 Flat washer M6 4

4 Self-tapping Phillips head screw

3.5 mm OD x 12 mm 1

5 Air filter retainer clip 1

6 Air filter 1

7 Air filter screen 1

8 25038 HL007600AV Cylinder head 1

*9 Head gasket 1

10 Valve plate 2

*11 Center valve gasket 1

*12 Valve 2

*13 Cylinder gasket 1

14 Roll pin XC5.4 mm x 7 mm -

valve plate 2

15 25043 HL007500AV Cylinder 1

16 Compression ring 2

17 Oil control ring 1

18 Piston 1

19 Wrist pin 1

20 Wrist pin retainer 2

21 Connecting rod 1

22 25048 HL012000AV Dipstick assembly with o-ring 1

23 † Socket head cap screw

M4-1.25 x 14 mm - front cover 4

24 † Crankcase front cover 1

25 25123 HL012100AV Oil drain with o-ring -

M5-1.25 x 10 mm 1

26 25053 HL009100AV Crankcase cover gasket 1

27 †† SHCS M8-1.25 x 25 mm

L.X. thread - eccentric 1

28 †† Eccentric counter weight 1

29 †† Bearing - pump crankcase 1

30 †† Oil seal 20 mm x 35 mm x

7 mm - crankcase 1

Page 22

Repair Parts (

continued)

22

Ref. Catalogue Part

No. Number Number Description Qty

31 Cylinder o-ring

65 mm x 2.65 mm 1

32 †† Crankcase 1

33 25058 †† HL008500AV Motor run capacitor 1

*34 †† Motor 1

*35 †† Motor bearing 1

*36 †† Motor bearing retainer 1

37 †† Motor rear end bell frame 1

38 †† ‡‡ Motor fan 1

39 †† Hex head cap screw M5 - 1.25 x

11.5 mm - motor bolts 4

40 †† Flat washer M5 4

41 †† Lock washer M5 4

42 †† ‡‡ Lock washer serrated

14.5 x 24 mm 1

43 †† ‡‡ Flat washer - M8 1

44 †† ‡‡ Hex head cap screw

M8 - 1.25 x 30 mm - fan bolt 1

45 25063 HL012800AV Self tapping Phillips head screw

4.2 x 10 mm (screw kit) 4

46 24943 HL011100AV Pump head shroud 1

47 24948 HL011200AV Motor shroud 1

48 25068 HL012900AV Self-tapping Phillips head screw

M6 - 19 mm (screw kit) 4

REPLACEMENT PARTS KITS

25073 HL011500AV Pump cylinder bolt kit

25078 HL011600AV Filter/screen kit

25083 HL011700AV Valve plate/gasket kit

25088 HL011800AV Ring kit

25093 HL011900AV Piston assembly

† 25098 HL012200AV Crankcase cover kit

†† 25108 HL012400AV Motor kit

‡‡ 25113 HL012500AV Motor fan kit

* Considered wear items

Page 23

Notes

23

Page 24

© 2007 RIDGID, INC.

Part No. IN619302AV 10/07 Form No. IN619302AV

RIDGID“ AIR COMPRESSOR LIMITED THREE YEAR WARRANTY

This product is manufactured by Campbell Hausfeld. The trademark is licensed from

Ridgid, Inc. All warranty communications should be directed to RIDGID air compressor technical service at (toll free) 1-800-4-RIDGID.

WHAT IS COVERED UNDER THE LIMITED THREE YEAR WARRANTY

This warranty covers all defects in workmanship or materials in this RIDGID air compressor for the three-year period from the date of purchase. This warranty is specific to this air compressor. Warranties for other RIDGID products may vary.

HOW TO OBTAIN SERVICE

To obtain service for this RIDGID air compressor you must return it, freight prepaid,

to a service center authorized to repair RIDGID air compressors. You may obtain the

location of the service center nearest you by calling (toll free) 1-800-4-RIDGID or by

logging on to the RIDGID website at www.ridgid.com. When requesting warranty

service, you must present the proof of purchase documentation, which includes a

date of purchase. The authorized service center will repair any faulty workmanship,

and either repair or replace any defective part, at Campbell Hausfeld’s option at no

charge to you.

WHAT IS NOT COVERED

This warranty applies only to the original purchaser at retail and may not be transferred. This warranty does not cover normal wear and tear components (see repair

parts) or any malfunction, failure or defect resulting from misuse, abuse, neglect,

alteration, modification or repair by other than a service center authorized to repair

RIDGID branded air compressors. Expendable materials, such as oil, filters, etc. are

not covered by this warranty. Gasoline engines and components are expressly

excluded from coverage and you must comply with the warranty given by the engine

manufacturer, which is supplied with the product. CAMPBELL HAUSFELD

MAKES NO WARRANTIES, REPRESENTATIONS OR PROMISES AS TO

THE QUALITY OR PERFORMANCE OF ITS AIR COMPRESSORS

OTHER THAN THOSE SPECIFICALLY STATED IN THIS WARRANTY.

RIDGID, INC. MAKES NO WARRANTIES OR REPRESENTATIONS,

EXPRESS OR IMPLIED, INCLUDING AS NOTED BELOW.

ADDITIONAL LIMITATIONS

To the extent permitted by applicable law, all implied warranties, including warranties

of MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE, are disclaimed.

Any implied warranties, including warranties of merchantability or fitness for a particular purpose, that cannot be disclaimed under state law are limited to three years

from the date of purchase. Campbell Hausfeld is not responsible for direct, indirect,

incidental, special or consequential damages. Some states do not allow limitations

on how long an implied warranty lasts and/or do not allow the exclusion or limitation

of incidental or consequential damages, so the above limitations may not apply to

you. This warranty gives you specific legal rights, and you may also have other

rights, which vary from state to state.

QUESTIONS OR COMMENTS

CALL 1-800-4-RIDGID

www.ridgid.com

Please have your Model Number and Serial Number on hand when calling.

Catalog No. OL50135AL

Model No. OL50135AL Serial No. ___________

The model and serial numbers may be found on your

unit. You should record both model and serial number

in a safe place for future use.

Page 25

OL50135AL

MANUAL DEL OPERADOR

COMPRESOR DE

AIRE PORTÁTIL

CON TANQUES

GEMELOS DE

ALUMINIO

Para reducir el riesgo de lesiones,

el usuario debe leer y comprender

el Manual del Operador antes de

usar este producto.

IN619302AV 10/07

!

ADVERTENCIA:

Page 26

Índice

Sp 2

Sección Página

Índice . . . . . . . . . . . . . . . . . . . . . . .Sp 2

Instrucciones de seguridad . . . . .Sp 3

Palabras de señal de seguridad .Sp 3

Antes de usar el

compresor de aire . . . . . . . . . . . .Sp 3

Precauciones Para Rociar . . . . . .Sp 5

Advertencia Sobre el Aire

Respirable . . . . . . . . . . . . . . . . . .Sp 5

Etiquetas de advertencia . . . . . . .Sp 6

Especificaciones del motor y requisi-

tos eléctricos . . . . . . . . . . . . . . . .Sp 7

Especificaciones del suministro

de energía y del motor . . . . . . . . .Sp 7

Conexiones eléctricas generales .Sp 7

Información de la herramienta

de 110-120 V, 60 Hz . . . . . . . . . .Sp 8

Cordones de extensión . . . . . . . .Sp 9

Protector Térmico . . . . . . . . . . . .Sp 9

Glosario . . . . . . . . . . . . . . . . . . . .Sp 10

Desempaque y verificación

del contenido . . . . . . . . . . . . . . . .Sp 11

Instalación . . . . . . . . . . . . . . . . . .Sp 11

Conozca su compresor

de aire . . . . . . . . . . . . . . . . . . . . .Sp 12

Sección Página

Funcionamiento del compresor

de aire . . . . . . . . . . . . . . . . . . . . .Sp 14

Humedad en el Aire

Comprimido . . . . . . . . . . . . . . . .Sp 14

Funcionamiento del compresor

de aire . . . . . . . . . . . . . . . . . . . .Sp 14

Para Evitar Problemas . . . . . . . .Sp 14

Mantenimiento . . . . . . . . . . . . . . .Sp 15

Tanque . . . . . . . . . . . . . . . . . . . .Sp 16

Para Desmontar, Chequear y

Reemplazar el Filtro . . . . . . . . . .Sp 16

Lubricación . . . . . . . . . . . . . . . . .Sp 16

Almacenamiento . . . . . . . . . . . .Sp 16

Planificación del

mantenimiento . . . . . . . . . . . . . .Sp 16

Diagnóstico de problemas . . . . .Sp 17

Piezas de repuesto . . . . . . . . . . .Sp 19

Garantía . . . . . . . . . . . . . . . . . . . .Sp 24

Page 27

Este manual contiene información que es

muy importante que sepa y comprenda.

Esta información se la suministramos

como medida de SEGURIDAD y para

EVITAR PROBLEMAS CON EL

EQUIPO. Debe reconocer los siguientes

símbolos.

Palabras de señal de seguridad

Ésto le indica que hay una situación

inmediata que, si no se evita,

LE OCASIONARIA la muerte o heridas

de gravedad.

Ésto le indica que hay una situación que,

si no se evita, PODRIA ocasionarle la

muerte o heridas de gravedad.

Ésto le indica que hay una situación que,

si no se evita, PODRIA ocasionarle

heridas no muy graves.

Ésto le indica una información

importante, que de no seguirla,

le podría ocasionar daños al equipo.

Instrucciones de seguridad

Sp 3

Antes de usar el compresor de aire

Los compresores de aire se utilizan en

una variedad de aplicaciones.Como el

compresor de aire y otros componentes

usados (bomba de material, pistolas

pulverizadoras, filtros, lubricadores,

mangueras, etc.) intengran un sistema

de alta presión, en todo momento deberá

seguir las siguientes medidas de

seguridad. Sólo las personas que conocen

muy bien las reglas de seguridad para el

funcionamiento deben estar autorizadas

a usar el compresor de aire.

1. Lea con cuidado todos los manuales

incluídos con este producto antes de

tratar de ensamblar, desman-telar

o utilizar el sistema.

2. Use gafas de seguridad (aprobadas

por ANSI Z87.1 o en Canadá CSA

Z94.3-99) y protecciones para los

oídos cuando opera la bomba o la

unidad. Las gafas diarias no son

gafas de seguridad.

3. No exceda la presión máxima de

ninguno de los componentes del

sistema.

4. Proteja las líneas de material y de aire

contra daños y roturas. Mantenga las

mangueras y cordones alejados de

objetos afilados, derrames químicos,

solventes de aceite y pisos húmedos.

5. Nunca apunte la pistola pulveriza-dora

hacia nadie. Una descarga accidental

puede ocasionarle heridas de gravedad.

6. Antes de cada uso, revise las

mangueras para ver si están

deterioradas o hay fugas. Antes de

usarlo cerciórese de que las

conecciones estén bien apretadas

y no lo use si encuentra

irregularidades. Notifíquele a un

centro de servicio autorizado para

que lo chequeen o reparen.

7. Libere el aire lentamente; de lo

contrario éste podría levantar polvo

y despredicios que podrían

ocasionarle daños.

Todos los trabajos de electricidad

los debe hacer un electricista

calificado (con licencia o

certificación). En los circuitos

conectados adecuadamente los

cables negros podrían sumunistrar

tensión inclusive cuando la unidad

esté desconectada.

!

PELIGRO:

!

ADVERTENCIA:

!

PRECAUCION:

AVISO:

!

ADVERTENCIA:

Page 28

8. Siga todos los códigos de electricidad

y seguridad locales y nacionales al

igual que las medidas de seguridad

laboral.

9. Las conecciones eléctricas y fusibles

deben estar conectadas a tierra

adecuadamente, seguir los códigos

locales de electricidad y no

sobrepasar las capacidades.

10. Los motores eléctricos deben

asegurarse bien y estar conectados

a tierra adecuadamente. Vea las

instrucciones para conectar a tierra

y la información sobre cordones de

extensión en este manual.

11. Siempre desconecte la unidad antes

de hacer trabajos en el motor o áreas

cercanas. Si el interruptor se

encuentra fuera de su alcance,

bloquéelo y póngale una etiqueta

para que no se encienda

accidentalmente.

12. Proteja todas las piezas en

movimiento y mantenga a los

visitantes alejados. Nunca permita la

presencia de niños en el área de

trabajo.

13. Sólo use tomacorrientes adecuados

que estén conectados a tierra y use

zapatos aislantes para evitar

electrocutamiento.

14. Tenga cuidado al tocar la parte

externa del motor encendido; éste

podría estar lmuy caliente

y ocasionarle heridas.

15. Evite que el cordón eléctrico tenga

contacto con objetos afilados.

16. Limpie los equipos eléctricos o

electrónicos con agentes aprobados

tales como solventes secos no

inflamables.

17. Para evitar la combustión espontánea

tire los trapos que usó para limpiar en

envases de metal aprobados para

este tipo de desperdicios.

18. Nunca alamcene líquidos inflamables

o gases cerca del compresor.

19. Al rociar solventes de químicos

tóxicos siga las instrucciones del

fabricante de dichos químicos.

20. Rocie en áreas bien ventiladas

para evitar la acumulación de humos

nocivos a la salud y evitar peligro

de incendio.

21. No rocíe cerca de llamas al

descubierto o en otros sitios donde

chispas puedan ocasionar incendios.

No fume al rociar pinturas,

insecticidas u otras substancias

inflamables.

22. Use un respirador para rociar.

23. NUNCA modifique la válvula de

seguridad o el presostato. Evite la

acumulación de pintura u otras

substancias en la válvula de

seguridad. Ésto evita el peligro de

exceso de presión.

24. Siempre debe darle el mantenimiento

necesario; mantenga todas las

tuercas, pernos y tornillos bien

apretados para cerciorarse de que

el equipo esté en buenas condiciones

de funcionamiento.

25. Mantenga los trapos para limpiar

y otros desperdicios inflamables en

envases de metal cerrados

hermeticamente y posteriormente tire

la basura adecuadamente.

26. Drene el tanque diariamente. Si no

piensa usar el compresor por un

Instrucciones de seguridad (continuación)

Sp 4

¡Desconecte la unidad y libere la

presión del sistema antes de darle

servicio al compresor! (Gire la

perilla del regulador

completamente en el mismo

sentido de las agujas del reloj

después de apagar el compresor).

!

ADVERTENCIA:

Page 29

tiempo, es preferible que deje la llave

de salida abierta hasta que lo vaya a

usar una vez más. Ésto permitirá que

el tanque se drene completamente

y ayudará a evitar que se oxide por

dentro.

27. Anualmente inspeccione el tanque

para ver si tiene agujeros u otros

defectos que podrían hacerlo

inseguro. NUNCA solde o le abra

agujeros al tanque.

1. No fume mientras esté rociando

pintura, insecticidas u otras

substancias inflamables.

2. Use una

máscara/respirador

cuando vaya a rociar y

siempre rocíe en un área

bien ventilada, para evitar peligros de

salud e incendios.

3. Nunca rocíe la pintura y otros

materiales, directamente hacia el

compresor. Coloque el compresor lo

más lejos posible del área de trabajo,

para minimizar la acumulación de

residuos en el compresor.

4. Al rociar o limpiar con solventes o

químicos tóxicos, siga las

instrucciones del fabricante de dichos

químicos.

Precauciones Para Rociar

Nunca rocíe

materiales

inflamables cerca de

llamas al descubierto

o fuentes de ignición,

incluyendo el compresor.

Advertencia Sobre el Aire Respirable

Este compresor/cabezal no viene listo de fábrica para suministrarle

aire respirable. Antes de utilizarlos con este fin deberá instalarle un

sistema de seguridad y alarma incorporado a la línea. Este sistema

adicional es necesario para filtrar y purificar el aire adecuadamente

para cumplir con las especificaciones mínimas sobre aire respirable

de Grado D descritas en la Especificación de Productos G 7.1 - 1966

de la Asociación de Aire Comprimido.Igualmente, deberá cumplir

los requisitos establecidos por el Articulo 29 CFR 1910. 134 de la

Organización norteamericana OSHA y/o la Canadian Standards

Associations (CSA).

RENUNCIA A LAS GARANTIAS

Si el compresor se utiliza para producir aire respirable SIN haberle

instalado el sistema de seguridad y alarma, todas la garantías se

anularán y la compañía Campbell Hausfeld no asumirá NINGUNA

responsabilidad por pérdidas, heridas personales o daños.

Sp 5

!

ADVERTENCIA:

!

PELIGRO:

Page 30

Instrucciones de seguridad (continuación)

Sp 6

Busque y lea todas las etiquetas de

advertencia que se muestran a

continuación y que se encuentran en el

compresor de aire.

Etiquetas de advertencia

DRAIN TANK EVERYDAY FOR PROPER

COMPRESSOR OPERATION

RÉSERVOIR DE VIDANGE JOURNALIER

POUR L'EXÉCUTION APPROPRIÉE

DE COMPRESSEUR

DEPÓSITO DE DESAGÜE DIARIO PARA

LA OPERACIÓN APROPIADA

DEL COMPRESSOR

DK812200AV 906

WARNING

AVERTISSEMENT

ADVERTENCIA

0

DK724100AV 100

Page 31

Especificaciones del motor

y requisitos eléctricos

Especificaciones del suministro de energía y del motor

El motor de CA usado en este compresor

es un PSC, de tipo de condensador

siempre intercalado, que tiene las

siguientes especificaciones. El cableado

se realizó en fábrica para funcionar con

un servicio de 110-120 V CA, 60 Hz.

Voltaje 110-120

Amperios 15

Hertzios (ciclos) 60

Fase Monofásico

RPM 3450

Para reducir los riesgos

eléctricos, de incendio o daño

a las herramientas, use la

protección del circuito

adecuada. El cableado de su

herramienta se realiza en fábrica

para que funcione con el voltaje

que se muestra. Conecte la

herramienta a una línea de

energía con el voltaje apropiado

y un circuito derivado de

15 amperios. Utilice un

disyuntor o fusible de tiempo

de retardo de 15 amperios.

Para reducir el riesgo de choque

eléctrico o incendio, si el cable

de corriente está gastado

o cortado, o dañado

de cualquier modo, haga que

lo reemplacen inmediatamente.

!

Conexiones eléctricas generales

Para reducir el riesgo de

eletrocución:

1. Utilice solamente piezas de

repuesto idénticas cuando se

realiza el servicio. El servicio

lo debe realizar un técnico

calificado.

2. No utilice bajo la lluvia

o donde el piso esté húmedo.

Esta herramienta está

diseñada para usarse en

interiores residenciales

solamente.

No permite que los dedos

toquen los bornes del enchufe

cuando enchufa o retira el

enchufe en el tomacorrientes.

Sp 7

ADVERTENCIA:

!

ADVERTENCIA:

!

ADVERTENCIA:

Page 32

Especificaciones del motor

y requisitos eléctricos (continuación)

Sp 8

El enchufe que se proporciona con la

herramienta puede no calzar en el

tomacorrientes que planea usar. El

código eléctrico local puede requerir

pequeños cambios en la conexión del

cable de corriente. Si existen estas

diferencias, refiérase a su código local

y realice los cambios adecuados de

acuerdo al mismo antes de enchufar

y encender la herramienta.

En caso de que haya un funcionamiento

defectuoso o una avería, la conexión a

tierra proporciona la ruta de menor

resistencia a la corriente eléctrica para

reducir el riesgo de choques eléctricos.

Esta herramienta está equipada con un

cable de corriente que tiene un conductor

de puesta a tierra del equipo y un

enchufe con conexión a tierra, como se

muestra. El enchufe debe estar

enchufado a un tomacorrientes que

coincida, que esté correctamente

instalado y con conexión a tierra de

acuerdo a todos los códigos y

ordenanzas locales.

No modifique el enchufe que se

proporciona. Si no calza en el

tomacorrientes, haga que un electricista

calificado instale el tomacorrientes

adecuado.

La conexión incorrecta del conductor de

descarga a tierra del equipo puede dar

como resultado un riesgo de choque

eléctrico. El conductor con aislante que

tiene una superficie exterior de color

verde con o sin bandas amarillas es el

conductor de conexión a tierra del

equipo. Si es necesario reparar o

reemplazar el cable de corriente, no

conecte el conductor de conexión a tierra

del equipo a una terminal con corriente.

Verifique con una persona de servicio

o electricista calificado si no comprende

totalmente las instrucciones de conexión

de descarga a tierra o si tiene alguna

duda sobre si el equipo está conectado

a tierra de forma adecuada.

Información de la herramienta de 110-120 V, 60 Hz

Si no tiene una conexión de

descarga a tierra adecuada esta

herramienta puede provocar un

choque eléctrico,

particularmente cuando se usa

en lugares húmedos, próximo a

tuberías de agua o en espacios

exteriores.

Clavija de conexión

a tierra

Enchufe de

tres clavijas

Tomacorriente

de tres clavijas

conectado a

tierra

correctamente

!

ADVERTENCIA:

Page 33

Sp 9

Cordones de extensión

1. El compresor de aire debe ubicarse

donde pueda enchufarse

directamente a un tomacorrientes.

No se deberá usar un cordón de

extensión con esta unidad.

2. Para evitar la pérdida de energía o el

sobrecalentamiento, se deberá usar

una manguera de aire adicional que

llegue al área de trabajo, en lugar de

utilizar cordones de extensión.

Protector Termico

Si el protector térmico apaga al

compresor con mucha frecuencia puede

ser por lo siguiente:

1. Voltaje bajo.

2. Cordón de extensión de calibre

inadecuado.

3. Filtro de aire sucio.

4. La ventilación es inadecuada.

5. La unidad se está usando con un

cordón de extensión.

6. Bajo nivel de aceite.

Consulte la tabla de diagnóstico de

problemas para ver las acciones de

corrección.

Esta compresora está equipada

con un protector de sobrecarga

térmica de reposición

automática que apaga el motor

si se recalienta.

Para poder arrancar de nuevo

el motor, se debe dejar enfriar.

El motor se pondrá en marcha

de nuevo, sin ninguna señal de

aviso, si se deja conectado a un

tomacorriente y si el motor ya

está encendido.

!

PRECAUCION:

!

PRECAUCION:

Page 34

Sp 10

Válvula de seguridad ASME

Esta válvula libera automáticamente

el exceso de aire cuando la presión ha

alcanzado la presión máxima fijada.

PSI (libras por pulgada cuadrada)

Unidad de medida de la presión ejercida

por la fuerza del aire. La salida real en

psi se mide con un manómetro en el

compresor

SCFM (pies cúbicos estándar por

minuto)

A veces llamado CFM (pies cúbicos por

minuto). Unidad de medida del volumen

de aire entregado por el compresor.

Entrega de aire

Una combinación de psi y SCFM.

La entrega de aire que necesita una

herramienta está dada por (número)

SCFM a (número) psi. La combinación

de estas cifras determina el tamaño de

unidad que se necesita.

Capacidad del tanque de aire

El volumen de aire almacenado en el

tanque y disponible para su uso

inmediato. Un tanque grande permite el

uso intermitente de una herramienta

neumática con un requisito de aire mayor

que la entrega promedio del compresor.

Voltios o Voltaje

La medida de la fuerza de una corriente

eléctrica.

Amperios o amperaje

Una medida de la fuerza eléctrica menos

la resistencia en una línea eléctrica.

Los compresores de aire rígidos

necesitan 15 amperios para funcionar.

Asegúrese que el compresor funcionará

en una línea eléctrica con el amperaje

correcto. Si tiene otros artefactos

domésticos funcionando en la misma

línea, éstos reducirán el amperaje

disponible. Si el amperaje no es

adecuado, el resultado serán fusibles

quemados o que se corten los circuitos.

Regulador

Un control que ajusta la presión de la

línea a la cantidad adecuada necesaria

para hacer funcionar pistolas de rociado

y herramientas neumáticas.

Manómetro del depósito

Indica la presión del tanque en psi.

Manómetro de salida regulado

Muestra la presión actual de la línea.

Se regula con la perilla reguladora.

Presión de conexión/desconexión

PSI específico al que un compresor se

enciende o se detiene mientras se

rellena el tanque de aire.

Glosario

Page 35

Sp 11

1. Retire el compresor de aire de la caja.

2. Coloque el compresor en una

superficie de trabajo segura, nivelada

y fija, y examínelo cuidadosamente.

3. Asegúrese de que la varilla de

medición esté en una bolsa de

plástico sujetada a la bomba.

4. La bomba ha sido llenada con la

cantidad de aceite adecuada

(250 mL/8.4 oz.) en la fábrica.

5. Reemplace el tapón con la varilla de

medición ubicada dentro de la bolsa.

Controle el nivel de aceite con la

varilla de medición.

6. Si el nivel de aceite está por debajo

de la línea de “MIN”, llene la bomba

hasta que el nivel de aceite esté entre

las líneas de “MIN” y “MAX”.

(Para saber el tipo de aceite y las

instrucciones de llenado, consulte la

sección “Lubricación” del manual)

Desempaque y verificación del contenido

No haga funcionar la unidad

si se dañó durante el envío,

el manejo o el uso. Los daños

pueden provocar una explosión

y causar lesiones o daño a la

propiedad.

Para su propia seguridad,

nunca haga funcionar la unidad

hasta que todos los pasos de

ensamblaje estén completos

y hasta que haya leído y

entendido todo el manual del

operador.

Para reducir el riesgo de

lesiones, si falta alguna pieza,

no intente hacer funcionar el

compresor de aire hasta obtener

e instalar correctamente las

piezas faltantes.

1. Chequée y apriete todos los pernos,

conecciones, etc., antes de utilizar el

compresor.

2. Asegúrese de que el aceite del

compresor esté lleno al nivel

adecuado antes del uso.

3. Utilice el compresor en un área bien

ventilada para que éste se pueda

enfriar adecuadamente.

4. El compresor debe ubicarse donde

pueda enchufarse directamente a un

tomacorrientes. No se deberá usar un

cordón de extensión con esta unidad.

5. Para evitar la pérdida de energía o el

sobrecalentamiento, se deberá usar

una manguera de aire adicional que

llegue al área de trabajo, en lugar de

utilizar cordones de extensión.

Instalación

!

ADVERTENCIA:

!

ADVERTENCIA:

!

ADVERTENCIA:

Page 36

Sp 12

Conozca su compresor de aire

5 Manometro

del Tanque

4 Perilla del

Regulador

1 Tanques de

almacenamiento

de aire

3 Mango

7 Conectores de

la salida de

aire

9 Filtro de aire

(debajo de

la cubierta)

6 Valvula de

Seguridad

ASME

10 Interruptor de

encendido/apagado

11 Válvula de drenaje

del tanque

2 Manometro

Regulador de

la Salida

12 Varilla del

nivel de aceite

Etiqueta adhesiva con

modelo/número de serie

8 Pompe

ridgid.com 1-800-474-3443

Page 37

Sp 13

1. Tanques de almacenamiento de

aire. Los tanques almacenan aire

para usarlo más tarde.

2. Manometro Regulador de la Salida.

Este manómetro le permite verificar la

presión de salida muy facilmente.

Dicha presión se mide en libras por

pulgadas al cuadrado (PSI). La

mayoría de las herramientas tienen

una clasificación máxima de presión.

Nunca exceda la clasificación máxima

de presión de la herramienta que está

usando. Cerciórese de que el

manómetro esté en ZERO antes de

cambiar de herramientas neumáticas

o desconectar la manguera.

3. Mango. Se usan para mover el

compresor.

4. Perilla del Regulador. Esta perilla

controla la presión de aire hacia una

herramienta neumática o una pistola

pulverizadora de pintura. Al girar la

perilla hacia la derecha aumenta la

presión de aire en la salida. Al girar la

perilla hacia la izquierda disminuye la

presión de aire en la salida. Al poner la

perilla totalmente hacia la izquierda se

cerrará el flujo de aire por completo.

5. Manometro del Tanque. Mide la

presión del tanque para verificar que

está funcionando adecuadamente.

6. Valvula de Seguridad ASME.

Esta válvula libera el aire

automáticamente si la presión del

tanque supera el máximo

preestablecido.

7. Conectores de la salida de aire.

Estos conectores son de conexión

rápida y estilo universal de 1/4" y

permiten cambios de herramienta

rápidos.

8. Bomba. La bomba aspira aire y

genera aire comprimido en los

tanques de almacenamiento de aire.

9. Filtro de aire. El filtro de aire evita

que la suciedad y los residuos entren

a la bomba del compresor y reduce el

ruido del compresor.

10. Interruptor de encendido/

apagado. Este interruptor permite el

control manual del compresor. Tenga

en cuenta que cuando el interruptor

esté en encendido, el compresor se

encenderá o apagará

automáticamente según la presión

del tanque.

11. Válvula de drenaje del tanque.

La válvula de drenaje del tanque

permite que la humedad salga del

tanque.

12.Varilla de nivel de aceite. La varilla

de nivel de aceite mide el nivel de

aceite que hay en la bomba del

compresor.

Cerrar

Abrir

Page 38

Sp 14

1. Lea las instrucciones: Lea atentamente

este manual del operador ANTES DE

HACER FUNCIONAR este nuevo

compresor de aire.En el manual

encontrará información sobre el

funcionamiento y mantenimiento de la

unidad.

2. Drene el tanque diariamente:

Despresurice el sistema antes de

drenar el tanque. Abra la válvula de

drenaje del tanque y drene la humedad

del tanque. Esto ayuda a mantener el

aceite y la humedad fuera del sistema

de aire comprimido. Asegúrese de

cerrar la válvula de drenaje del tanque

firmemente antes de hacer funcionar el

compresor.

3. Cambie el filtro de aire: nunca ponga

el compresor en funcionamiento sin un

filtro de aire ni con un filtro de aire

sucio. Cambie el filtro por uno nuevo

cuando esté sucio.

4. Siga el programa de mantenimiento

para controlar y cambiar el aceite.

Funcionamiento del compresor de aire

La humedad que se acumula en el aire

comprimido se convierte en gotas a

medida que sale del cabezal del

compresor de aire. Cuando el nivel de

humedad es muy alto o cuando el

compresor ha estado en uso continuo

por mucho tiempo, ésta se acumulará en

el tanque. Al usar una pistola

pulverizadora de pintura o una rociadora

de arena, la misma saldrá a través de la

manguera mezclada con el material que

esté rociando.

IMPORTANTE: Esta condensacion

ocasionara manchas en la superficie

pintada, especialmente cuando este

pulverizando pinturas que no sean

a base de agua. Al rociar arena ésta

ocasionará que la arena se aglutine

y obstruya la pistola, reduciendo su

eficacia.

Para eliminar este problema, coloque un

filtro en la línea de aire, lo más cerca

posible de la pistola.

Para Evitar Problemas

Humedad en el Aire Comprimido

Asegúrese de que la caja del cigüeñal

tenga el nivel de aceite adecuado.

Asegúrese que la válvula de drenaje del

tanque esté cerrada, que la perilla

reguladora esté totalmente hacia la

izquierda, y que el interruptor de

encendido/apagado esté apagado (Off).

Conecte el compresor a un circuito

dedicado de 15 amperios (mínimo).

Ponga el interruptor de

encendido/apagado en la posición de

encendido (On). El compresor empezará

a acumular presión.

Después que el compresor alcance la

presión de desconexión, instale una

manguera (con la herramienta neumática

deseada conectada a la misma) en la

salida del conector. Ajuste la perilla

reguladora en la presión deseada.

Ahora el compresor está listo para

funcionar.

Funcionamiento del compresor de aire

No presurice excesivamente

ninguna herramienta neumática.

Consulte las instrucciones de la

herramienta neumática para ver

la presión correcta.

!

ADVERTENCIA:

Page 39

1. Chequee el compresor a ver si tiene

algún problema visible, especialmente

chequee el filtro de aire para

cerciorarse de que esté limpio.

2. Hale el anillo de la válvula de

seguridad y deje que calce en

su posición normal.

3. Drene la humedad del tanque a diario.

Apague el compresor. Despresurice el

sistema antes de drenar el tanque.

Drene la humedad del tanque abriendo

la válvula de drenaje debajo del

tanque.

Mantenimiento

Libere toda la presión

y desconecte la unidad

antes de hacer cualquier

tipo de reparación.

!

Debe reemplazar la válvula de

seguridad si no la puede activar

o si hay fugas de aire una vez

que haya soltado el anillo.

Válvula de

drenaje del

tanque

Sp 15

4. Apague el compresor (póngalo en

OFF) y limpie completamente el motor,

tanque, líneas de aire y las aletas de

enfriamiento del cabezal.

NOTA: el filtro de aire ubicado en la

ranura para el filtro en el cabezal de

la bomba debe controlarse y limpiarse

periódicamente, más seguido aún si se

usa bajo condiciones de mucho polvo

o cuando hay una gran circulación de

niebla a causa del rocío junto a la unidad.

IMPORTANTE: Debe ubicar la unidad lo

más lejos posible del área de trabajo

para evitar que el filtro se atasque.

El tanque se debe inspeccionar por lo

menos una vez al año. Chequée a ver si

hay grietas en las soldaduras. De

haberlas, libere la presión del tanque

inmediatamente y reemplácelo.

Tanque

¡Nunca trate de reparar

o modificar el tanque! Si lo

suelda, taladra o modifica de

cualquier otra manera, el tanque

se debilitará y podría romperse

o explotar. Siempre reemplace

los tanques desgastados

o dañados.

Drene el líquido del tanque

diariamente.

ADVERTENCIA:

!

ADVERTENCIA:

!

PELIGRO:

AVISO:

Page 40

Antes de enchufar el compresor,

asegúrese de que la caja del cigüeñal

tenga una cantidad de 250ml/8.4 oz. de

aceite para compresor no detergente

ISO 100 (SAE 30), o aceite sintético

Mobil 1 5W30. Use la varilla de medición

para controlar el nivel de aceite.

Para drenar y cambiar el aceite:

- Coloque un recipiente adecuado debajo

del drenaje para recoger el aceite usado.

- Retire el tapón de drenaje del aceite

con una llave hexagonal de 4 mm.

- Cuando se haya drenado el aceite

usado, vuelva a colocar el tapón del

drenaje y ajústelo usando la llave

hexagonal de 4 mm.

- Retire la varilla de medición

- Agregue 250 ml/8.4 oz. de aceite para

compresor no detergente ISO (SAE 30)

o aceite sintético Mobil 1 5W30.

NOTA: evite llenar en exceso. Asegúrese

de controlar que el nivel de aceite no esté

por encima de la línea de MAX en la

varilla de medición.

- Vuelva a introducir la varilla de medición.

Mantenimiento (continuación)

Sp 16

1. Mientras no lo esté usando debe

almacenar el compresor en un sitio seco

y frío.

2. Debe drenar el tanque.

3. Debe desconectar las mangueras

y colgarlas con los extremos hacia

abajo para que se drenen.

Para cambiar un filtro, retire la cubierta del motor de la bomba para dejar la bomba

a descubierto. Si el filtro está sucio, cámbielo.

Para Desmontar, Chequear y Reemplazar el Filtro

Lubricacion

Almacenamiento

Cada 3

Servicio Necesario Diariamente Semanalmente meses

Verifique el nivel de aceite

Drene el tanque

Chequée el filtro de aire

Chequée la válvula de seguridad

Limpie el interior del motor con aire

Cambie el aceite

Planificación del mantenimiento

Orificio

de

llenado

del

aceite

Tapón de

drenaje

Page 41

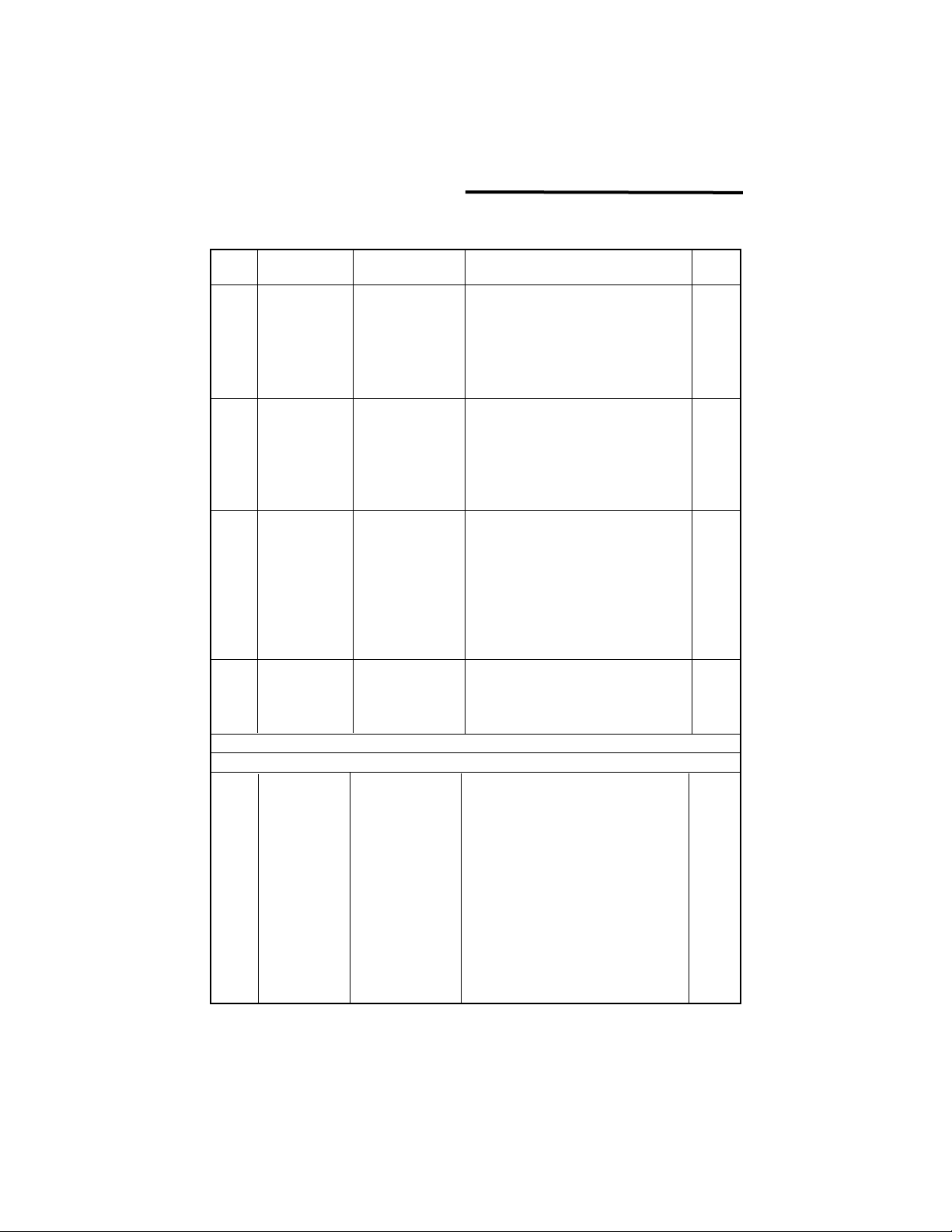

Diagnóstico de problemas

Para su propia seguridad, no pruebe

ni haga funcionar el compresor de

aire mientras realiza el diagnóstico

de problemas.

!

PROBLEMA CAUSA PROBABLE SOLUCIÓN

Compresor

no funciona

Motor hace ruido

pero no funciona o

funciona lentamente

Fusibles/cortacircuito

se dispara con

frecuencia

1. Unidad conectada a un

cordón de extensión

2. No hay energía eléctrica

3. Fusible quemado

4. Cortacircuito

desconectado

5. Protector térmico abierto

6. Presostato dañado

1. Voltaje bajo

2. Unidad conectada a un

cordón de extensión

3. Defecto de la bobina del

motor

4. Válvula de chequeo o

desfogue defectuosa

1. Fusible inadecuado,

circuito sobrecargado

2. Unidad conectada a un

cordón de extensión

3. Válvula de retención o

descargador defectuosos

1. Chequée el cordón de

extensión adecuado (vea

la sección CORDONES DE

EXTENSION, página 15)

2. ¿Está conectado?

Chequée el

fusible/cortacircuito

o protector de sobrecarga

del motor

3. Reemplace el fusible

quemado

4. Reconéctelo y determine

cual es el problema

5. El motor se enciende

después de enfriarse

6. Reemplácelo

1. Chequee con un voltimetro

2. Retire el cordón

3. Reemplace el motor

4. Reemplace o repare

1. Cerciórese de que está

usando el fusible

adecuado, use un fusible

diferido. Desconecte los

otros artefactos del circuito

o conecte el compresor

a su propio circuito

2. Chequee la tabla en la

sección de funcionamiento

3. Reemplace o repare

Sp 17

ADVERTENCIA:

Page 42

Sp 18

PROBLEMA CAUSA PROBABLE SOLUCIÓN

El protector de

sobrecarga térmica

se dispara

constantemente

La presión del

tanque disminuye

cuando el compresor

se apaga

Exceso de humedad

en el aire de salida

Compresor funciona

constantemente

Compresor vibra

El suministro de aire

es menos de lo

normal

1. Voltaje bajo

2. Filtro de aire está atascado

3. Poca ventilación/

temperatura ambiental

muy alta

4. Unidad conectada a un

cordón de extensión

5. Bajo nivel de aceite

1. Conecciones flojas

(coneciones, tuberías,

etc.)

2. Válvula de drenaje floja

3. Hay fugas en la válvula

de chequeo

1. Exceso de agua

en el tanque

2. Humedad alta

1. Presostato está dañado

2. Uso excesivo de aire

Pernos están flojos

1. Válvulas de entrada están

rotas

2. Filtro de entrada está

sucio

3. Fugas en las conecciones

1. Chequée con un voltimetro

2. Limpie el filtro (vea la

sección de Mantenimiento)

3. Mueva el compresor a un

área bien ventilada

4. Retire el cordón de

extensión

5. Agregue aceite hasta

el nivel adecuado

1. Chequée todas las

conecciones con agua

enjabonada y apriete las

conecciones flojas

2. Apriete la llave

3. Desmantele la válvula

de chequeo, límpiela

o reemplácela

Antes de desmantelar la

válvula de chequeo purgue

el aire del tanque

1. Drene el tanque

2. Mueva el compresor a un

área menos humeda;

use un filtro de línea

1. Reemplácelo

2. Disminuya el uso de aire;

el compresor no tiene la

capacidad de suministro

necesaria

Apriete los pernos

1. Un técnico autorizado de

servicio debe repararlo

2. Limpie o reemplace el filtro

de entrada

3. Apriete las conecciones

Diagnóstico de problemas (continuación)

PELIGRO:

!

Page 43

Sp 19

Piezas de repuesto

Al cabezal de la

bomba

Al

distribuidor

1

2

19

20

21

22

23

25

26

27

28

29

30

31

32

33

34

3

4

5

6

7

8

9

38, 10, 12

11

12

13

14

15

16

17

35

36

37

24

39

40

18

41

42

(atrás)

Page 44

Piezas de repuesto

Por piezas de repuesto, llame al 1-800-4-RIDGID

Sírvase darnos la siguiente información:

-Número del modelo

-Número de Serie (de haberlo)

-Descripción y número del repuesto según la lista de repuestos

No. de No de Número

Ref. catálogo de pieza Descripción Ctd

1 24933 HL015300AV HHCS autorroscantes

(M10 x 40) 4

2 N/A Arandela de presión (métrica 8.2) 4

*3 24938 HL167700AV Ensamble de la conexión en T 1

4 N/A Tornillo de cabeza Phillips (M 4.2 x 10 mm) 4

5 24943 HL011100AV Cubierta del cabezal de la bomba 1

6 N/A HHCS Phillips (M6 x 19 mm) 4

7 24948 HL011200AV Cubierta del motor 1

8 24953 HL300001AV Bomba de lubricación por aceite 1

9 24958 AR057800AV Tanques gemelos 1

*10 24963 CV223800AV Válvula de retención 1

11 24968 HL009700AV Tuerca hexagonal 1

12 24973 HL009800AV Casquillo 2

13 17808 ST185600AV Mango 1

14 — Tubo de salida 1

15 24978 HL015900AV Niple de la tubería de 1/4" NPT 1

16 24983 HL016000AV Tubo de descarga (incluye tuercas y casquillos) 1

*17 24988 CW213300AV Interruptor de presión (incluye tapa del 1

interruptor de presión y válvula de descarga)

18 25118 CW217700AV Válvula de descarga 1

*19 17903 CW211700AV Tapa del interruptor de presión 1

20 17753 ST209800AV Tornillo de liberación de tensión 1