Page 1

OPERATOR’S MANUAL

MANUEL D’UTILISATION

MANUAL DEL OPERADOR

TRI-STACK

™

5 GALLON AIR COMPRESSOR

COMPRESSEUR D’AIRE DE 18,93 l (5 GAL.)

COMPRESOR AIRE DE 18,93 I (5 GAL.)

OF50150TS

To register your RIDGID

product, please visit:

http://register.RIDGID.com

Pour enregistrer votre

produit de RIDGID,

s’il vous plaît la visite:

http://register.RIDGID.com

Para registrar su producto

de RIDGID, por favor visita:

http://register.RIDGID.com

TABLE OF CONTENTS

****************

General Safety Rules .......................2-3

Air Compressor Safety Warnings ....3-4

Symbols ...........................................5-6

Electrical ............................................. 7

Glossary of Terms ...............................8

Features .............................................. 9

Assembly .......................................9-10

Operation .....................................11-15

Maintenance ..................................... 15

Troubleshooting ................................ 16

Illustrations ..................................19-21

Parts Ordering/Service ....... Back Page

WARNING:

To reduce the risk of injury, the

user must read and understand the

operator’s manual before using this

product.

SAVE THIS MANUAL FOR

FUTURE REFERENCE

TABLE DES MATIÈRES

****************

Règles de sécurité générales

........................................................2-3

Avertissements de sécurité relatifs

compressuer d’aire .........................3-4

Symboles .........................................5-6

Caractéristiques électriques ............... 7

Glossary of Terms ...............................8

Caractéristiques .................................9

Assemblage ...................................9-10

Utilisation .....................................11-15

Entretien ...........................................16

Troubleshooting ...........................17-18

Illustrations ..................................19-21

Commande de pièces /

réparation ..........................Page arrière

AVERTISSEMENT :

Pour réduire les risques de

blessures, l’utilisateur doit lire

et veiller à bien comprendre

le manuel d’utilisation avant

d’employer ce produit.

CONSERVER CE MANUEL

POUR FUTURE RÉFÉRENCE

ÍNDICE DE CONTENIDO

****************

Reglas de seguridad

generales .........................................2-3

Advertencias de seguridad

compresor aire ................................3-4

Símbolos .........................................5-6

Aspectos eléctricos ............................ 7

Glossary of Terms ...............................8

Características ...................................9

Armado ..........................................9-10

Funcionamiento ...........................11-15

Mantenimiento ..................................16

Troubleshooting ...........................17-18

Ilustraciones ................................19-21

Pedidos de piezas /

servicio .......................... Pág. posterior

ADVERTENCIA:

Para reducir el riesgo de

lesiones, el usuario debe leer

y comprender el manual del

operador antes de usar este

producto.

CONSERVER CE MANUEL

POUR FUTURE RÉFÉRENCE

Page 2

GENERAL SAFETY RULES

WARNING:

Read and understand all instructions. Failure

to follow all instructions listed below may result

in electric shock, fire, and/or serious personal

injury.

SAVE THESE INSTRUCTIONS

WORK AREA

Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents. Floor must not

be slippery from wax or dust.

Do not operate air compressors in explosive atmo-

spheres, such as in the presence of flammable liquids,

gases, or dust. Power tools create sparks which may

ignite the dust or fumes.

Keep bystanders, children, and visitors away while

operating an air compressor. Distractions can cause you

to lose control.

Operate air compressor in an open area at least 18 in.

away from any wall or object that could restrict the

flow of fresh air to ventilation openings.

ELECTRICAL SAFETY

Avoid body contact with grounded surfaces such as

pipes, radiators, ranges, and refrigerators. There is an

increased risk of electric shock if your body is grounded.

Don’t expose air compressors to rain or wet condi-

tions. Water entering an air compressor will increase the

risk of electric shock.

Do not abuse the cord. Never use the cord to carry

the air compressor or pull the plug from an outlet.

Keep cord away from heat, oil, sharp edges, or moving

parts. Replace damaged cords immediately. Damaged

cords increase the risk of electric shock.

When operating an air compressor outside, use an out-

door extension cord marked “W-A” or “W”. These cords

are rated for outdoor use and reduce the risk of electric

shock.

PERSONAL SAFETY

Eye protection which conforms to ANSI specifications

and provides protection against flying particles both

from the FRONT and SIDE should ALWAYS be worn by

the operator and others in the work area when loading, operating, or servicing this product. Eye protection

is required to guard against flying fasteners and debris,

which could cause severe eye injury.

The employer and/or user must ensure that proper

eye protection is worn. We recommend a Wide Vision

Safety Mask for use over eyeglasses or standard safety

glasses that provide protection against flying particles

both from the front and side. Always use eye protection

which is marked to comply with ANSI Z87.1.

Additional safety protection will be required in some

environments. For example, the working area may

include exposure to a noise level which can lead to hearing damage. The employer and user must ensure that any

necessary hearing protection is provided and used by the

operator and others in the work area. Some environments

will require the use of head protection equipment. When

required, the employer and user must ensure that head

protection marked to comply with ANSI Z89.1 is used.

Stay alert, watch what you are doing, and use com-

mon sense when operating the air compressor. Do

not use product while tired or under the influence of

drugs, alcohol, or medication. A moment of inattention

while operating an air compressor may result in serious

personal injury.

Dress properly. Do not wear loose clothing or jewelry.

Contain long hair. Keep your hair, clothing, and gloves

away from moving parts. Loose clothes, jewelry, or long

hair can be caught in moving parts.

Do not overreach. Keep proper footing and balance

at all times. Proper footing and balance enables better

control of the product in unexpected situations.

Use safety equipment. Always wear eye protection.

Dust mask, nonskid safety shoes, hard hat, or hearing

protection must be used for appropriate conditions.

Do not use on a ladder or unstable support. Stable

footing on a solid surface enables better control of the

air compressor in unexpected situations.

AIR COMPRESSOR USE AND CARE

Do not exceed the pressure rating of any component

in the system.

Protect material lines and air lines from damage or

puncture. Keep hose and power cord away from sharp

objects, chemical spills, oil, solvents, and wet floors.

Check hoses for weak or worn condition before each

use, making certain all connections are secure. Do not

use if defect is found. Purchase a new hose or notify an

authorized service center for examination or repair.

Release all pressures within the system slowly. Dust

and debris may be harmful.

Store idle air compressors out of the reach of children

and other untrained persons. Air compressors are dan-

gerous in the hands of untrained users.

Maintain air compressors with care. Follow mainte-

nance instructions. Properly maintained products are

easier to control.

Check for misalignment or binding of moving parts,

breakage of parts, and any other condition that may

affect the product’s operation. If damaged, have the

air compressor serviced before using. Many accidents

are caused by poorly maintained products.

2 – English

Page 3

GENERAL SAFETY RULES

Keep the exterior of the air compressor dry, clean, and

free from oil and grease. Always use a clean cloth when

cleaning. Never use brake fluids, gasoline, petroleumbased products, or any strong solvents to clean the unit.

Following this rule will reduce the risk of deterioration of

the enclosure plastic.

SERVICE

When servicing a product, use only identical

replacement parts. Follow instructions in the

Maintenance section

parts or failure to follow Maintenance instructions may

create a risk of injury.

of this manual. Use of unauthorized

SPECIFIC SAFETY RULES

Know your air compressor. Read operator’s manual

carefully. Learn its applications and limitations, as well

as the specific potential hazards related to this product.

Following this rule will reduce the risk of electric shock,

fire, or serious injury.

Drain tanks of moisture after each day’s use.

If unit will not be used for a while, it is best to leave drain

valve open until such time as it is to be used. This will

allow moisture to completely drain out and help prevent

corrosion on the inside of tanks.

Risk of Fire or Explosion. Do not spray flammable liquid

in a confined area. Spray area must be well ventilated. Do

not smoke while spraying or spray where spark or flame

is present. Keep compressors as far from the spraying

area as possible, at least 15 feet from the spraying area

and all explosive vapors.

Risk of Bursting. Do not adjust regulator to result in

output pressure greater than marked maximum pressure

of attachment. Do not use at pressure greater than 150 psi.

If connected to a circuit protected by fuses, use time-

delay fuses with this product.

To reduce the risk of electric shock, do not expose to

rain. Store indoors.

Inspect tanks yearly for rust, pin holes, or other

imperfections that could cause it to become unsafe.

Never weld or drill holes in the air tanks.

Make sure the hose is free of obstructions or snags.

Entangled or snarled hoses can cause loss of balance or

footing and may become damaged.

Use the air compressor only for its intended use. Do

not alter or modify the unit from the original design

or function.

Always be aware that misuse and improper handling of

this product can cause injury to yourself and others.

Service must be performed only by qualified repair

personnel. Service or maintenance performed by

unqualified personnel may result in a risk of injury.

Disconnect power supply, open drain valve to decom-

press tanks and allow water to drain, and allow air

compressor to become cool to the touch before

servicing. Turn pressure regulator knob fully counter-

clockwise after shutting off air compressor.

Never leave a tool unattended with the air hose

attached.

Never point any air tool toward yourself or others.

Do not operate this air compressor if it does not

contain a legible warning label.

Do not continue to use a tool or hose that leaks air or

does not function properly.

Always disconnect the air supply and power supply

before making adjustments, servicing a product, or when

a product is not in use.

Do not attempt to pull or carry the air compressor by

the hose.

Your tool may require more air consumption than this

air compressor is capable of providing.

Always follow all safety rules recommended by the

manufacturer of your air tool, in addition to all safety

rules for the air compressor. Following this rule will

reduce the risk of serious personal injury.

Never direct a jet of compressed air toward people or

animals. Take care not to blow dust and dirt towards

yourself or others. Following this rule will reduce the risk

of serious injury.

Do not use this air compressor to spray chemicals.

Your lungs can be damaged by inhaling toxic fumes. A

respirator may be necessary in dusty environments or

when spraying paint. Do not carry while painting.

Inspect product cords and hoses periodically and, if

damaged, have repaired at your nearest Authorized

Service Center. Constantly stay aware of cord location.

Following this rule will reduce the risk of electric shock or

fire.

Never use an electrical adaptor with this grounded

plug.

3 – English

Page 4

SPECIFIC SAFETY RULES

Check damaged parts. Before further use of the air

compressor or air tool, a guard or other part that is

damaged should be carefully checked to determine

that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding

of moving parts, breakage of parts, mounting, and

any other conditions that may affect its operation. A

guard or other part that is damaged should be properly

repaired or replaced by an authorized service center.

Following this rule will reduce the risk of shock, fire, or

serious injury.

Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one

heavy enough to carry the current your product will

draw. A wire gauge size (A.W.G.) of at least 14 is

recommended for an extension cord 25 feet or less in

length. A cord exceeding 50 feet is not recommended.

If in doubt, use the next heavier gauge. The smaller

the gauge number, the heavier the cord. An undersized

cord will cause a drop in line voltage resulting in loss of

power and overheating.

This tool has an air source that is not regulated. An

unregulated air source must not be connected directly

to a pneumatic tool or accessory. Without pressure

regulation the air pressure may exceed the maximum

pressure of the driven tool or accessory.

The main tank that can be removed from this machine

is suitable for use only with this machine.

Use caution when lifting the air compressor with

the main tank installed to ensure that it is properly

connected to the machine.

This equipment incorporates parts, such as snap

switches, receptacles, and the like that tend to produce arcs or sparks and, therefore, when located in a

garage, it should be in a room or enclosure provided for

the purpose, or should be 18 in. (457 mm) or more above

the floor.

Never store a tool with air connected. Storing the tool

with air connected can result in unexpected firing and

possible serious personal injury.

Protect your lungs. Wear a face or dust mask if the

operation is dusty. Following this rule will reduce the risk

of serious personal injury.

If the power supply cord is damaged, it must be replaced

only by the manufacturer or by an authorized service

center to avoid risk.

Save these instructions. Refer to them frequently and use

them to instruct others who may use this product. If you

loan someone this product, loan them these instructions

also.

4 – English

Page 5

SYMBOLS

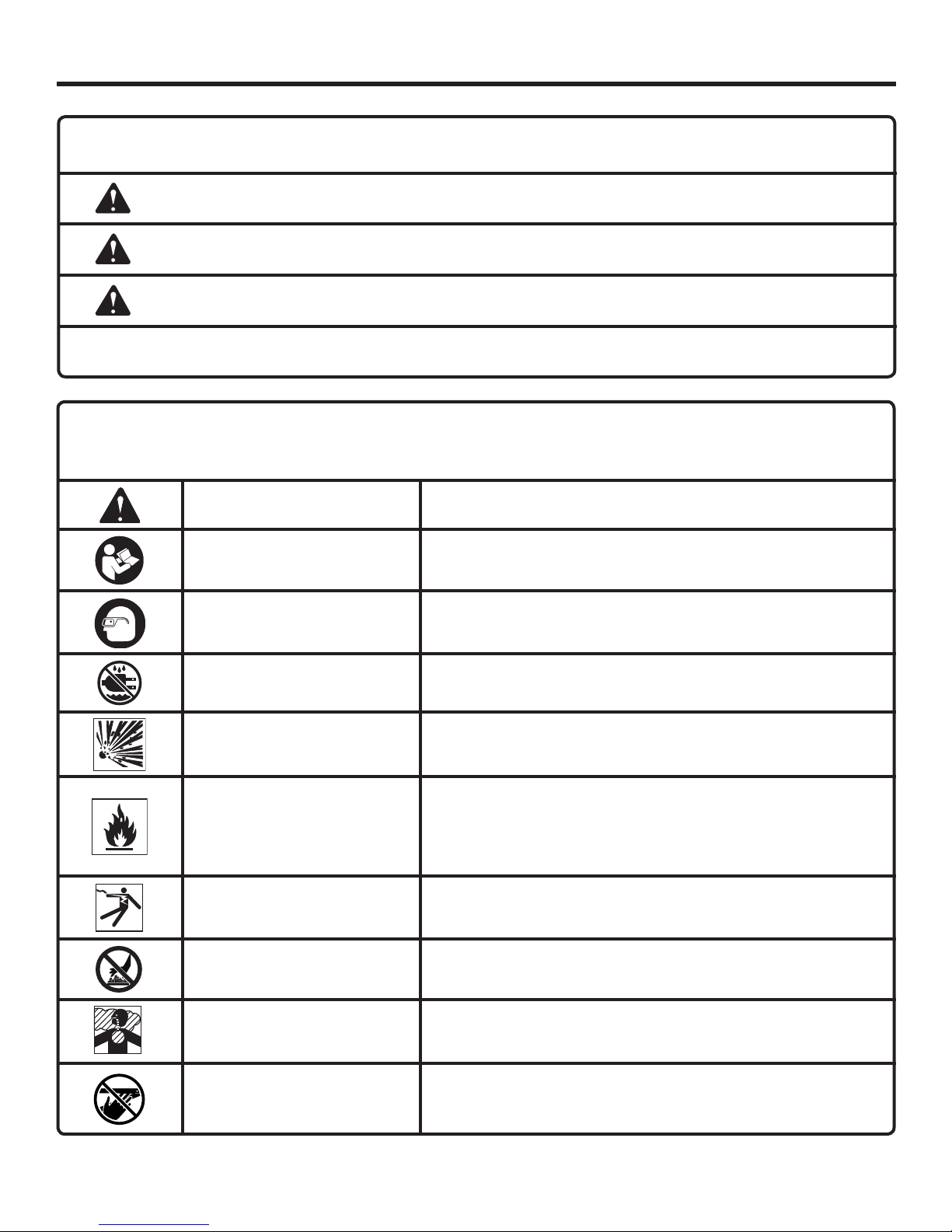

The following signal words and meanings are intended to explain the levels of risk associated with this product.

SYMBOL SIGNAL MEANING

DANGER:

WARNING:

CAUTION:

NOTICE:

Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper

interpretation of these symbols will allow you to operate the product better and safer.

SYMBOL NAME

Safety Alert Indicates a potential personal injury hazard.

Read Operator’s Manual

Eye Protection

Indicates an imminently hazardous situation, which, if not avoided, will result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, could result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, may result in

minor or moderate injury.

(Without Safety Alert Symbol) Indicates important information not related to an

injury hazard, such as a situation that may result in property damage.

DESIGNATION/EXPLANATION

To reduce the risk of injury, user must read and understand

operator’s manual before using this product.

Always wear eye protection with side shields marked to comply

with ANSI Z87.1.

Wet Conditions Alert Do not expose to rain or use in damp locations.

Do not adjust regulator to result in output pressure greater than

Risk of Bursting

Risk of Fire or Explosion

Risk of Electrical Shock

Hot Surface

Risk to Breathing

Pinch Point

marked maximum pressure of attachment. Do not use at pressure

greater than 150 PSI.

Do not spray flammable liquid in a confined area. Spray area must

be well ventilated. Do not smoke while spraying or spray where

spark or flame is present. Keep compressors as far from the spraying area as possible, at least 15 feet from the spraying area and

all explosive vapors.

Hazardous Voltage: Disconnect from power source before servicing. Compressor must be grounded.

To reduce the risk of injury or damage, avoid contact with any hot

surface.

Air obtained directly from the air compressor should never be used

to supply air for human consumption.

To reduce the risk of injury or damage, avoid contact with any

pinch point.

5 – English

Page 6

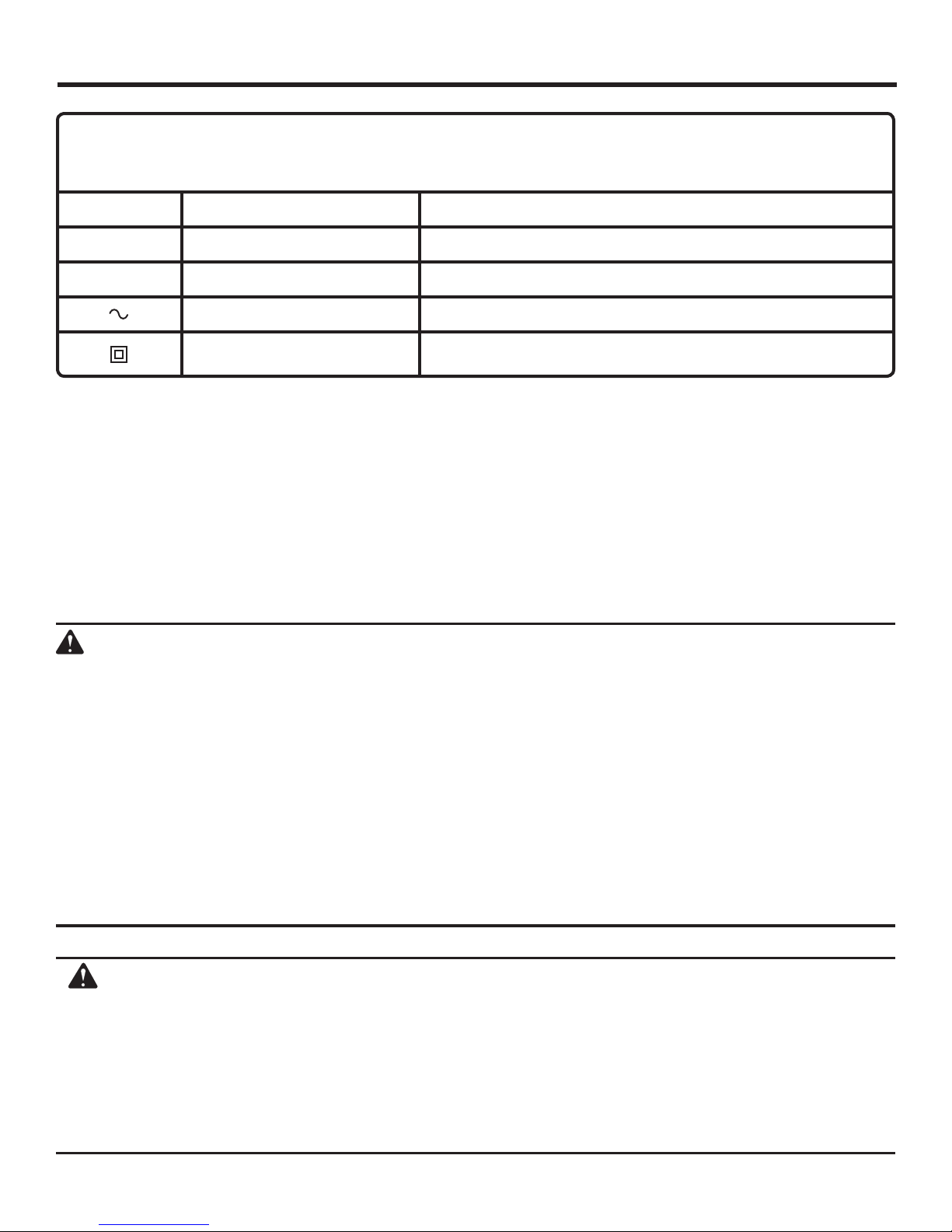

SYMBOLS

Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper

interpretation of these symbols will allow you to operate the product better and safer.

SYMBOL NAME

V Volts Voltage

A Amperes Current

Hz Hertz Frequency (cycles per second)

Alternating Current Type of current

Class II Construction Double-insulated construction

DESIGNATION/EXPLANATION

DANGER:

This compressor/pump is not equipped and should not be used to supply breathing quality air. Additional equipment would be necessary to properly filter and purify the air to meet minimal specifications for Grade D breathing

as described in Compressed Gas Association Commodity Specification G 7.1 - 1966, OSHA 29 CFR 1910.134.

Compressed Gas Association, 4221 Walney Road, Fifth Floor, Chantilly, VA 20151-2923, (703) 788-2700,

www.cganet.com. Any such additional equipment has not been examined and no implication of proper use for

breathing air is intended or implied.

If this compressor is altered in any way, existing warranties shall be voided. RIDGID® and One World Technologies,

Inc. disclaim any liabilities whatsoever for any loss, personal injury, or damage.

DISCLAIMER OF WARRANTIES

In the event the compressor is used for the purpose of breathing air application and proper in-line safety and alarm

equipment is not simultaneously used, existing warranties shall be voided, and RIDGID® disclaims any liabilities

whatsoever for any loss, personal injury, or damage.

WARNING:

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure

to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those

dust masks that are specially designed to filter out microscopic particles.

6 – English

Page 7

ELECTRICAL

EXTENSION CORDS

Use only 3-wire extension cords that have 3-prong grounding plugs and 3-pole receptacles that accept the product’s

plug. When using a power tool at a considerable distance

from the power source, use an extension cord heavy enough

to carry the current that the tool will draw. An undersized

extension cord will cause a drop in line voltage, resulting in

a loss of power and causing the motor to overheat. Use the

chart provided below to determine the minimum wire size

required in an extension cord. Only round jacketed cords

listed by Underwriter’s Laboratories (UL) should be used.

**Ampere rating (on product data plate)

0-2.0 2.1-3.4 3.5-5.0 5.1-7.0 7.1-12.0 12.1-16.0

Cord Length Wire Size (A.W.G.)

25' 16 16 16 16 14 14

50' 16 16 16 14 14 12

100' 16 16 14 12 10 —

**Used on 12 gauge - 20 amp circuit.

NOTE: AWG = American Wire Gauge

When working with the product outdoors, use an extension

cord that is designed for outside use. This is indicated by the

letters “W-A” or “W” on the cord’s jacket.

Before using an extension cord, inspect it for loose or

exposed wires and cut or worn insulation.

WARNING:

Keep the extension cord clear of the working area.

Position the cord so that it will not get caught on

lumber, tools, or other obstructions while you are

working with a power tool. Failure to do so can

result in serious personal injury.

WARNING:

Check extension cords before each use. If

damaged replace immediately. Never use the

product with a damaged cord since touching

the damaged area could cause electrical shock

resulting in serious injury.

SPEED AND WIRING

The no-load speed of this product is approximately 3,450

rpm. This speed is not constant and decreases under a load

or with lower voltage. For voltage, the wiring in a shop is as

important as the motor’s horsepower rating. A line intended

only for lights cannot properly carry an air compressor motor.

Wire that is heavy enough for a short distance will be too

light for a greater distance. A line that can support one power

tool may not be able to support two or three tools.

GROUNDING INSTRUCTIONS

This product must be grounded. In the event of a malfunction

or breakdown, grounding provides a path of least resistance

for electric current to reduce the risk of electric shock.

This product is equipped with an electric cord having an

equipment-grounding conductor and a grounding plug. The

plug must be plugged into a matching outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

Do not modify the plug provided. If it will not fit the outlet,

have the proper outlet installed by a qualified electrician.

WARNING:

Improper installation of the grounding plug is liable

to result in a risk of electric shock. When repair or

replacement of the cord is required, do not connect

the grounding wire to either flat blade terminal.

The wire with insulation having an outer surface

that is green with or without yellow stripes is the

grounding wire.

Check with a qualified electrician or service personnel if

the grounding instructions are not completely understood,

or if in doubt as to whether the product is properly

grounded.

Repair or replace a damaged or worn cord immediately.

This product is for use on a nominal 120 V circuit and has

a grounding plug similar to the plug illustrated in figure 1,

page 19. Only connect the product to an outlet having the

same configuration as the plug. Do not use an adaptor with

this product.

ELECTRICAL CONNECTION

This product is powered by a precision-built electric motor.

It should be connected to a power supply that is 120 V, AC

only (normal household current), 60 Hz. Do not operate

this product on direct current (DC). A substantial voltage

drop will cause a loss of power and the motor will overheat.

If the product does not operate when plugged into an outlet,

double check the power supply.

7 – English

Page 8

GLOSSARY OF TERMS

Air Filter

Porous element contained within a metal or plastic housing

attached to the compressor cylinder head which removes

impurities from the intake air of the compressor.

Air Tank

Cylindrical component which contains the compressed air.

Amperage Overload Switch (Manual)

Automatically shuts off the compressor if the temperature of

the electric motor exceeds a predetermined limit.

Check Valve

Device that prevents compressed air from flowing back from

the air tank to the compressor pump.

Cut-In Pressure

The low pressure at which the motor will automatically

restart.

Cut-Off Pressure

The high pressure at which the motor will automatically

shut off.

Electric Motor

Device which provides the rotational force necessary to

operate the compressor pump.

On/Off Switch

Control which turns the air compressor on or off. The

pressure switch will not automatically start and control the

compressor unless the manual On/Off Switch is in the ON( l )

position.

NPT (National Pipe Thread)

A seal thread tape must be used to provide a leak-free seal

on pipe threaded connections.

Pressure Regulator Knob

Regulates the outgoing pressure from the air outlet to the

tool. It is possible to increase or decrease the pressure at

the outlet by adjusting this control knob.

Pressure Switch

Automatically controls the on/off cycling of the compressor.

It stops the compressor when the cut-off pressure in the tank

is reached and starts the compressor when the air pressure

drops below the cut-in pressure.

PSI (Pounds Per Square Inch)

Measurement of the pressure exerted by the force of the

air. The actual psi is measured by a pressure gauge on the

compressor.

Pump

Produces the compressed air with a reciprocating piston

contained within the cylinder.

Regulator Pressure Gauge

Displays the current line pressure. Line pressure is adjusted

by rotating the pressure regulator knob.

Safety valve

Prevents air pressure in the air tank from rising over a

predetermined limit.

SCFM (Standard Cubic Feet Per Minute) or CFM (Cubic

Feet Per Minute)

A unit of measure of air delivery.

Tank Pressure Gauge

Indicates the pressure in the air tank.

SPECIAL TERMS

Quarter turn drain valves:

Quarter turn drain valves are located on tanks for easy

draining of condensation to help prevent tank corrosion.

Compressor tank:

The air compressor and 0.5 gallon tank.

Main tank:

The 4.5 gallon tank.

Unregulated air hose:

This hose transmits the compressed air from the compressor

tank to the main tank.

Unregulated air quarter turn ball valve lever:

This valve opens to allow compressed air to flow from the

compressor tank to the main tank and closes to stop air flow

form the compressor tank to the main tank.

Unregulated air intake coupler:

This coupler is an air inlet only for the unregulated air hose

and is located on the main tank.

Unregulated air fitting:

This 1/4 in. NPT quick-connect fitting connects the

unregulated air hose and is located on the main tank.

Lock/release knob:

Detaches and reattaches compressor tank and main tank.

Docking plate:

This plate supports the compressor tank when it is seated

on top of the main tank.

8 – English

Page 9

FEATURES

PRODUCT SPECIFICATIONS

Air Tank Capacity ....................................................5.0 gal.

Air Pressure .................................................... 150 psi max.

Air Delivery (High Flow Filter) ...............4.9 SCFM @ 90 psi

Air Delivery (Easy Start Filter) ............... 3.6 SCFM @ 90 psi

Gauges ..........................................................2 in. diameter

Input ..............................120 V, AC only, 14.5 Amps, 60 Hz

KNOW YOUR AIR COMPRESSOR

See Figure 2, page 19.

The safe use of this product requires an understanding of

the information on the product and in this operator’s manual

as well as a knowledge of the project you are attempting.

Before use of this product, familiarize yourself with all

operating features and safety rules.

5 IN 1 TRI-STACK AIR COMPRESSOR

Detachable compressor tank allows for convenient

transportation and flexibility at job site.

AIR FILTERS

Easy Start Air Filter - Designed to improve starting char-

acteristics.

High Flow Air Filter - Can be used to increase your

compressor’s air delivery (SCFM) when adequate electric

power is available.

HANDLES

The air compressor is equipped with handles for carrying

compressor tank in one hand and main tank in the other.

QUARTER TURN DRAIN VALVES

Quarter turn drain valves are located on tanks for easy

draining of condensation to help prevent tank corrosion.

REGULATOR PRESSURE GAUGES

The current line pressure is displayed on the regulator

pressure gauges. This pressure can be adjusted by rotating

the pressure regulator knobs.

SAFETY VALVE

The safety valve is designed to automatically release air if

the air tank pressure exceeds the preset maximum.

TANK PRESSURE GAUGES

The air compressor has two tank pressure gauges to indicate

the pressure of the air in the tanks. One is located on the

compressor tank and one on the main tank.

TWO INDEPENDENT LOCKING REGULATORS

Air pressure can be controlled separately on compressor

tank which has a regulator knob and on the main tank,

which has a separate regulator knob, for maximum utility

at the job site.

ASSEMBLY

UNPACKING

This product requires assembly.

Carefully remove the product and any accessories from

the box. Make sure that all items listed in the packing list

are included.

WARNING:

Do not use this product if any parts on the Packing

List are already assembled to your product when

you unpack it. Parts on this list are not assembled

to the product by the manufacturer and require

customer installation. Use of a product that may

have been improperly assembled could result in

serious personal injury.

Inspect the product carefully to make sure no breakage

or damage occurred during shipping.

Do not discard the packing material until you have

carefully inspected and satisfactorily operated the

product.

If any parts are damaged or missing, please call

1-866-539-1710 for assistance.

PACKING LIST

Air Compressor

Wrench

High Flow Filter

Manuel d’utilisation

9 – English

Page 10

ASSEMBLY

WARNING:

If any parts are damaged or missing do not operate

this product until the parts are replaced. Use of

this product with damaged or missing parts could

result in serious personal injury.

WARNING:

Do not attempt to modify this product or create

accessories not recommended for use with this

product. Any such alteration or modification is

misuse and could result in a hazardous condition

leading to possible serious personal injury.

WARNING:

Do not connect to power supply until assembly

is complete. Failure to comply could result in

accidental starting and possible serious personal

injury.

ADJUSTING COMPRESSOR TANK HANDLE

INTO CARRY POSITION

See Figure 3, page 20.

Using the wrench (included) remove screws from handle

brackets.

Pivot handle into upright position for carrying.

Reinstall screws securely through handle holes and

through handle bracket holes located on top of motor

housing on compressor tank.

ATTACHING COMPRESSOR TANK TO MAIN

TANK

See Figures 5 - 6, pages 20 - 21.

Make sure the air compressor is off and unplugged.

Rotate pressure regulator knobs fully in the counterclock-

wise direction so that the outlet pressure is at zero (0) psi.

Pull lock/release knob and turn counterclockwise to the

release position. Hooks will lower beneath docking plate

on main tank.

NOTE: Lock/release knob is spring loaded in the unlock

direction.

Lift compressor tank and center over main tank so that

the gauge panels face the same direction.

Set compressor tank gently onto main tank.

Turn lock/release knob clockwise to lock position. Hooks

on main tank will lock onto pins located on the underside

of compressor tank.

Lift air compressor slightly to be sure compressor tank

and main tank are securely locked together.

Attach 1/4 in. NPT quick-connect air fitting on unregulated

air hose to unregulated air intake coupler, located on top

of main tank. Make sure to push the hose fitting fully into

the coupler until the coupler sleeve locks it into place.

Turn unregulated air quarter-turn ball valve lever on

unregulated air hose, ON (90º). This is the open position,

allowing air flow from the compressor tank into the main

tank.

RELEASING COMPRESSOR TANK FROM MAIN

TANK

See Figure 4, page 20.

Make sure the air compressor is off and unplugged.

Rotate pressure regulator knobs fully in the counterclock-

wise direction so that the outlet pressure is at zero (0) psi.

Turn ball valve lever, on unregulated air hose, OFF

(90º). Be sure unregulated air hose is turned off before

connecting or disconnecting from unregulated air intake

coupler.

Disconnect unregulated air hose.

Push hose into unregulated air hose storage clip.

Pull lock/release knob and turn counterclockwise to the

unlock position. Hooks will detach from pins and lower

beneath docking plate.

Carefully lift and remove compressor tank from main tank.

10 – English

Page 11

OPERATION

DANGER:

Do not disassemble check valve, tank drain valves

or safety relief valve with air in tank — bleed

tanks.

WARNING:

Do not allow familiarity with products to make you

careless. Remember that a careless fraction of a

second is sufficient to inflict severe injury.

WARNING:

Always wear eye protection with side shields

marked to comply with ANSI Z87.1. Failure to do

so could result in objects being thrown into your

eyes resulting in possible serious injury.

WARNING:

This equipment incorporates parts, such as snap

switches, receptacles, and the like that tend to

produce arcs or sparks and, therefore, when

located in a garage, it should be in a room or

enclosure provided for the purpose, or should be

18 in. or more above the floor.

WARNING:

Do not attach any tools to the open end of the hose

until start-up has been completed.

NOTICE:

Do not use in an environment that is dusty or

otherwise contaminated. Using the air compressor

in this type of environment may cause damage to

the unit.

APPLICATIONS

Air compressors are utilized in a variety of air system

applications. Match hoses, connectors, air tools, and

accessories to the capabilities of the air compressor.

You may use this product for the purposes listed below:

Operating some air-powered tools

Operating air accessories such as air nozzles and tire

inflators

TRANSPORTING

See Figure 7, page 21.

The air compressor can be separated for easy transport to

the job site.

Follow instructions for Releasing Compressor tank from

Main tank in Assembly section of manual.

Using handles, located on top of compressor tank and

main tank, lift with your knees, not your back.

ATTACHING/DISCONNECTING A HOSE

See Figure 8, page 21.

WARNING:

Never exceed the air tool’s pressure rating as

recommended by the manufacturer. When using

this air compressor as an inflation device, always

follow the maximum inflation guidelines stated by

the manufacturer of the item being inflated.

Make sure the air compressor is off and unplugged.

Rotate pressure regulator knobs fully in the

counterclockwise direction so that the outlet pressure is

at zero (0) psi.

Attach a air hose with 1/4 in. NPT quick-connect air fitting

to a quick coupler (1/4 in.) on air compressor. Make sure

to push the air fitting fully into the coupler until the sleeve

springs forward to lock in place.

To disconnect an air hose or an air tool:

Confirm that the outlet pressure is at zero (0) psi.

When disconnecting a hose from quick coupler (1/4 in.),

always firmly hold fitting end of hose.

Pull back on the release sleeve on the 1/4 in. quick-

connect coupler.

With a firm grip, pull out the quick-connect air fitting that

is attached to the quick coupler.

BREAK IN PERIOD

Before first use, run the air compressor at zero (0) tank pressure with the drain valves fully open for 30 minutes.

TURNING THE AIR COMPRESSOR ON/OFF

See Figure 9, page 21.

With the air compressor plugged in, turn the power switch

to the AUTO position to power the compressor on.

To turn the air compressor off, turn the power switch to

the OFF position.

NOTE: When the compressor is in the AUTO position, the

air compressor will automatically turn back on when the

designated tank air pressure drops below the preset pressure

limit. It will also shut off again when the desired pressure

is reached.

WARNING:

Never exceed the air tool’s pressure rating as

recommended by the manufacturer. When using

this air compressor as an inflation device, always

follow the maximum inflation guidelines stated by

the manufacturer of the item being inflated.

11 – English

Page 12

OPERATION

WARNING:

Always ensure the switch is in the OFF (O) position

and the regulator pressure gauge reads zero before

changing air tools or disconnecting the hose

from the air outlet. Failure to do so could result in

possible serious personal injury.

CAUTION:

Only use main tank with air compressor Model

No. OF50150TS to avoid damage to the tool or

risk of personal injury.

WARNING:

The compressor tank will become hot during use.

Failure to avoid contact with the hot surface may

result in serious personal injury.

Check that the ball valve lever, on the unregulated air

hose, is in the ON (0º) position, allowing air flow from the

compressor tank to main tank.

Pull out and rotate pressure regulator knobs to desired

line pressure. Turning the knobs clockwise increases air

pressure at the outlets; turning counterclockwise reduces

air pressure at the outlets.

When the desired pressure has been set, the regulator

knobs can be locked in place by pushing them in.

Following all safety precautions in this manual and the

manufacturer’s instructions in the air tool manual, you

may now proceed to use your air-powered tool.

CAUTION:

Air powered tools may require more air consumption

than this air compressor is capable of providing.

Check the tool manual to avoid damage to the tool

or risk of personal injury.

INDEPENDENT LOCKING REGULATORS

Air pressure can be controlled separately with the regulator

knob on the compressor tank and the regulator knob on

the main tank.

To unlock the regulator knobs, pull outward and rotate

clockwise or counterclockwise to adjust the working

pressure up or down.

When the desired pressure has been set, the regulator knobs

can be locked into place by pushing them in.

COMPRESSOR TANK AND MAIN TANK

TOGETHER - DUAL PRESSURE REGULATION

AND MAXIMUM TANK CAPACITY

See Figure 10, page 22.

Keep the compressor tank and main tank together for maximum tank capacity and dual pressure regulation. One tool

may be installed on the compressor tank and regulated,

while up to two tools can be installed on the main tank and

regulated at a different psi.

Follow instructions for Attaching Compressor tank to Main

tank in Assembly Section of manual.

Attach hose(s) to one of the quick-connect couplers (1/4

in.) on compressor tank or main tank.

NOTE: If two tools are installed on the main tank, they

must use the same psi.

Attach a 1/4 in. NPT quick-connect air fitting to accessory

or tool(s) you intend to use.

Insert the other end of the quick-connect air fitting to the

quick coupler on the open end of hose.

Connect the power cord to the power supply.

Turn the power switch to AUTO ( l ).

Control the amount of air flow with the pressure regulator

knob. Turning the knob fully counterclockwise will

completely stop the flow of air.

NOTE: Always use the minimum amount of pressure

necessary for your application. Using a higher pressure

than needed will drain air from the tank more rapidly and

cause the unit to cycle on more frequently.

When finished, always drain the tanks and unplug the

unit. Never leave the unit plugged in and/or running

unattended.

COMPRESSOR TANK ALONE - FINISH

APPLICATIONS

See Figure 11, page 22.

The compressor tank can be used separately and alone for

finish work. Only one tool can be used with the compressor tank.

Ensure power switch is in the OFF (O) position and air

compressor is unplugged.

Follow instructions for Releasing Compressor tank from

Main tank in Assembly section of manual.

Move compressor tank to job site.

Attach hose to compressor tank as previously instructed.

Attach a 1/4 in. NPT quick-connect air fitting to tool or

accessory you intend to use.

Insert the other end of the quick-connect air fitting to the

quick coupler on the open end of hose.

Connect the power cord to the power supply.

Turn the power switch to AUTO ( l ).

Pull out and rotate pressure regulator knob to desired

line pressure. Turning the knob clockwise increases air

pressure at the outlet; turning counterclockwise reduces

air pressure at the outlet.

12 – English

Page 13

OPERATION

Following all safety precautions in this manual and the

manufacturer’s instructions in the air tool manual, you

may now proceed to use your air-powered tool.

Control the amount of air flow with the pressure regulator

knob. Turning the knob fully counterclockwise will

completely stop the flow of air.

NOTE: Always use the minimum amount of pressure

necessary for your application. Using a higher pressure

than needed will drain air from the tank more rapidly and

cause the unit to cycle on more frequently.

When finished, always drain the tank and unplug the

unit. Never leave the unit plugged in and/or running

unattended.

MAIN TANK ALONE - REGULATED CARRY

TANK FOR SMALL JOBS

See Figure 12, page 22.

The main tank can be separated from compressor tank and

power supply to be carried to remote location for small jobs.

One tool should be used in this instance.

Ensure power switch is in the OFF (O) position and air

compressor is unplugged.

Follow instructions for Releasing Pump Tank from Main

tank in Assembly section of manual.

Move main tank to job site.

Attach hose to one of the two quick-connect couplers

located on front gauge panel of the main tank as

previously instructed.

Attach 1/4 in. NPT quick-connect air fitting to accessory

or tool you intend to use.

Insert the other end of the quick-connect air fitting to the

quick-connect coupler on the open end of hose.

Pull out and rotate pressure regulator knob to desired

line pressure. Turning the knob clockwise increases

air pressure at the outlet; turning counterclockwise

reduces air pressure at the outlet.

Following all safety precautions in this manual and the

manufacturer’s instructions in the air tool manual, you

may now proceed to use your air-powered tool.

Control the amount of air flow with the pressure regulator

knob. Turning the knob fully counterclockwise will

completely stop the flow of air.

NOTE: Always use the minimum amount of pressure

necessary for your application. Using a higher pressure

than needed will drain air from the tank more rapidly and

cause the unit to cycle on more frequently.

When finished, always drain the tank. There are two

quarter turn drain valves on the main tank. Never leave

the unit plugged in and/or running unattended.

COMPRESSOR TANK AND MAIN TANK

SEPARATED AND CONNECTED WITH A HOSE

See Figure 13, page 22.

The compressor tank and main tank can be separated and

connected with a hose (up to 50 ft.) for maximum flexibility

at job site, remote regulation, to prevent pressure drop and

to keep noise outside.

Ensure power switch is in the OFF (O) position and air

compressor is unplugged.

Follow instructions for Releasing Compressor tank from

Main tank in Assembly section of manual.

Attach unregulated air hose, on compressor tank, to air

hose (up to 50 ft.).

Attach a 1/4 in. NPT quick-connect air fitting to air hose

and connect to 1/4 in. quick-connect intake coupler on

main tank.

Move main tank to job area.

WARNING:

Only connect unregulated air hose between

compressor tank and unregulated air intake

coupler.

Attach hose to one of the two quick-connect couplers

located on front gauge panel of the main tank as

previously instructed.

NOTE: If two tools are installed on the main tank, they

must use the same psi.

A tool or accessory may be attached to compressor tank

if needed.

Attach 1/4 in. NPT quick-connect air fitting to accessory

or tool you intend to use.

Insert the other end of the quick-connect air fitting to the

quick-connect coupler on the open end of hose.

Connect the power cord to the power supply.

Turn the power switch to AUTO ( l ).

Turn quarter turn ball valve lever, on unregulated air hose,

ON (0º) allowing air flow from compressor tank to main

tank.

Pull out and rotate pressure regulator knob to desired

line pressure. Turning the knob clockwise increases air

pressure at the outlet; turning counterclockwise reduces

air pressure at the outlet.

Following all safety precautions in this manual and the

manufacturer’s instructions in the air tool manual, you

may now proceed to use your air-powered tool.

13 – English

Page 14

OPERATION

Control the amount of air flow with the pressure regula-

tor knob. Turning the knob fully counterclockwise will

completely stop the flow of air.

NOTE: Always use the minimum amount of pressure

necessary for your application. Using a higher pressure

than needed will drain air from the tank more rapidly and

cause the unit to cycle on more frequently.

When finished, always drain the tank and unplug the

unit. Never leave the unit plugged in and/or running

unattended.

DRAINING THE TANKS

See Figure 14, page 23.

To help prevent tank corrosion and keep moisture out of the

air used, the air tanks of the compressor should be drained

daily.

NOTE: The air compressor has three tanks and three drain

valves. Be sure to open drain valves for all three tanks and

perform this operation for all tanks.

To drain:

Turn the air compressor off.

Pull the rings on the pressure relief valves to release until

tank pressure gauges read less than 20 psi.

Release the rings.

Rotate drain valves counterclockwise to open.

Tilt tank to drain moisture from tank into a suitable

container.

NOTE: Condensate is a polluting material and should be

disposed of in compliance with local regulations.

If drain valves are clogged, release all air pressure, remove

and clean valves, then reinstall.

WARNING:

Unplug the air compressor and release all air from

the tanks before servicing. Failure to depressurize

tanks before attempting to remove valve can cause

serious personal injury.

Safety valves will automatically release air if the air tank

pressure exceeds the preset maximum. The valves should be

checked before each day of use by pulling the ring by hand.

NOTE: The air compressor has two pressure relief valves.

Be sure to open both pressure relief valves.

Turn the air compressor on and allow the tanks to fill. The

compressor will shut off when the pressure reaches the

preset maximum.

Turn the air compressor off.

Pull the rings on both safety valves to release air for three

to five seconds.

WARNING:

If air leaks after the ring has been released, or if

the valve is stuck and cannot be actuated by the

ring, do not use the air compressor until the safety

valve has been replaced. Use of the air compressor

in this condition could result in serious personal

injury.

RESET BUTTON

See Figure 16, page 23.

When amperage into the air compressor exceeds the

specified amperage, the air compressor will automatically

shut off.

To reset the air compressor:

Turn the air compressor off.

Unplug the air compressor.

Press the reset button.

Plug the air compressor into an approved outlet.

Turn the air compressor on.

NOTICE:

Do not operate the air compressor without an air

filter in place. Doing so can damage the unit.

Rotate drain valves clockwise until tightly closed.

CHECKING THE SAFETY VALVES

See Figure 15, page 23.

DANGER:

Do not attempt to tamper with the safety valves.

Anything loosened from this device could fly up

and hit you. Failure to heed this warning could

result in death or serious personal injury.

INSTALLING THE HIGH FLOW AIR FILTER

See Figure 17, page 23.

An easy start air filter is factory installed on the air

compressor. If an increase in performance is needed for

your application, you may achieve better results with the

high flow air filter.

The high flow filter is packed separately with the unit.

Turn the air compressor off.

Unplug the air compressor.

Turn the easy start air filter and adaptor counterclockwise

to remove.

14 – English

Page 15

OPERATION

NOTE: Use a 1 in. box wrench if needed.

Insert the high flow filter into the air inlet opening, turning

the filter clockwise to tighten.

NOTE: Do not use thread seal tape.

INSTALLING THE EASY START FILTER

See Figure 18, page 23.

The easy start filter may be reinstalled if you have difficulty

starting the unit.

Turn the air compressor off.

MAINTENANCE

WARNING:

Before inspecting, cleaning, or performing any

maintenance, make sure the switch is in the off

( O ) position, wait for all moving parts to stop, and

disconnect from the power supply. Failure to follow

these instructions can result in death, serious

personal injury, or property damage.

WARNING:

Always wear eye protection with side shields

marked to comply with ANSI Z87.1. Failure to do

so could result in objects being thrown into your

eyes resulting in possible serious injury.

Unplug the air compressor.

Turn the air filter counterclockwise to remove.

NOTE: Use a 23 mm box wrench if needed.

If the adaptor is not installed on the easy start filter, attach

and tighten the adaptor.

Insert the easy start filter with the adaptor attached into

the air inlet opening, turning the filter clockwise to tighten.

NOTE: Do not use thread seal tape.

and grindings are highly abrasive to bearings, brushes, commutators, etc. Consequently, we do not recommend using

this product for extended work on these types of materials.

However, if you do work with any of these materials, it is

extremely important to clean the product using compressed

air.

LUBRICATION

All of the bearings in this product are lubricated with a sufficient amount of high grade lubricant for the life of the unit

under normal operating conditions. Therefore, no further

lubrication is required.

POWER SUPPLY CORD REPLACEMENT

If replacement of the power supply cord is necessary, this

must be done by an authorized service center in order to

avoid a safety hazard.

WARNING:

When servicing, use only identical replacement

parts. Use of any other parts could create a hazard

or cause product damage.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use. Use

clean cloths to remove dirt, dust, oil, grease, etc.

WARNING:

Do not at any time let brake fluids, gasoline,

petroleum-based products, penetrating oils, etc.,

come in contact with plastic parts. Chemicals can

damage, weaken or destroy plastic which could

result in serious personal injury.

Electric tools used on fiberglass material, wallboard, spackling compounds, or plaster are subject to accelerated wear

and possible premature failure because the fiberglass chips

REPLACING THE HIGH FLOW AIR FILTER

See Figure 19, page 23.

Turn the air filter cover counterclockwise to remove.

Remove the cover.

Remove the air filter.

Install new air filter.

Replace the air filter cover and secure it by turning it

clockwise.

REPLACING THE EASY START AIR FILTER

See Figure 20, page 23.

Turn the air filter assembly counterclockwise to remove.

NOTE: Use a 1 in. box wrench if needed.

Remove the o-ring using a flat head screwdriver.

Remove the plastic shroud.

Remove the existing filter.

NOTE: If you do not see the filter, it may be inside the

shroud.

Install the new filter onto the body of the filter assembly.

Reinstall the plastic shroud and replace the o-ring.

Make sure the o-ring is completely installed in the groove.

15 – English

Page 16

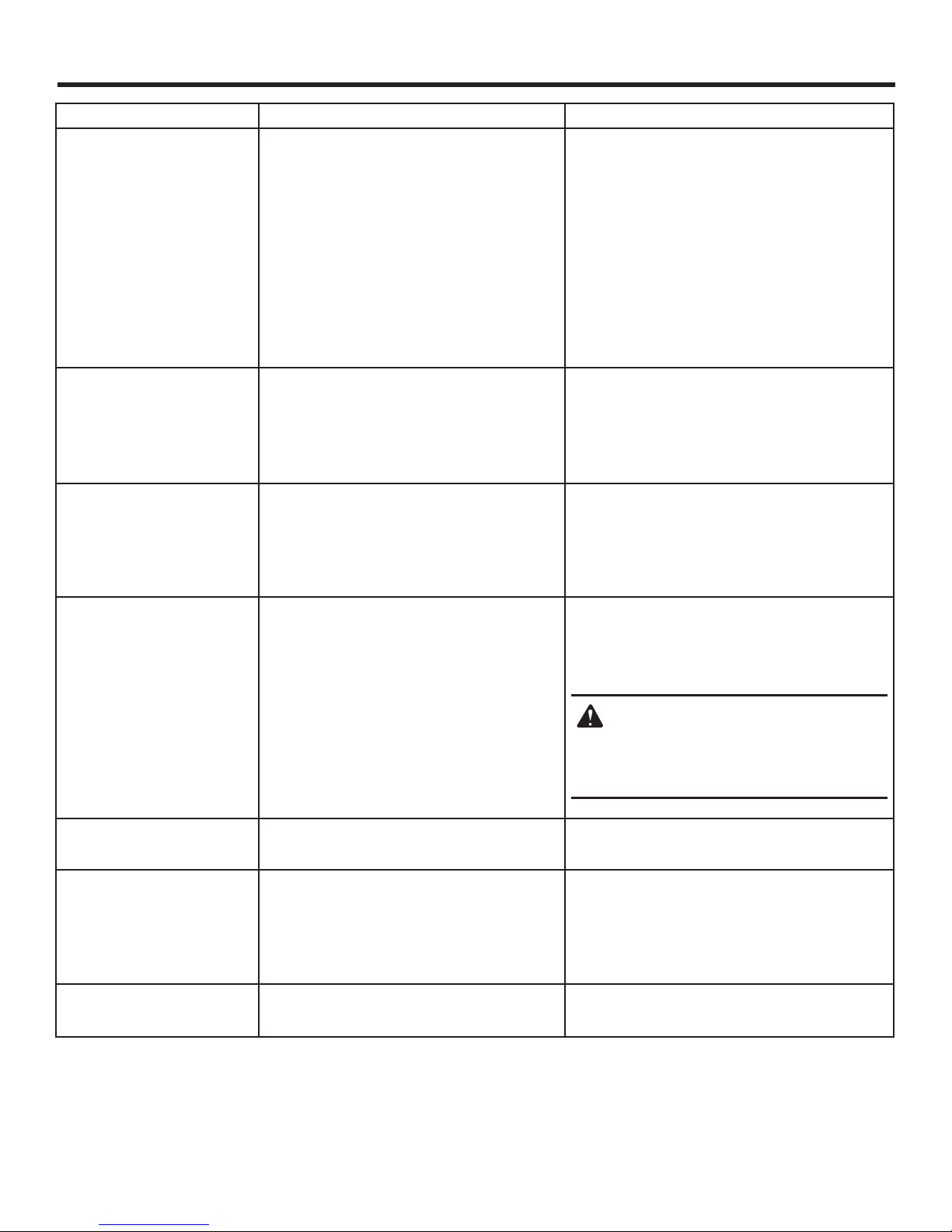

TROUBLESHOOTING

PROBLEM CAUSE SOLUTION

Compressor will not run Insufficient power to motor

Loss of power or overheating

No electrical power

Blown shop/house fuse

Shop/house breaker open

Current limiting protector open

Pressure switch bad

Tank is full of air

Motor hums but cannot run

or runs slowly

Current limiting protector

cuts out repeatedly

Air tank pressure drops when

compressor shuts off

Insufficient power to motor

Low voltage

Wrong gauge wire or length of extension cord

Shorted or open motor winding

Defective check valve or unloader

Insufficient power to motor

Low voltage

Lack of proper ventilation/room temperature

too high

Wrong gauge wire or length of extension cord

Loose connections (fittings, tubing, etc.)

Loose drain valve

Check valve leaking

Ensure that the easy start filter is installed

Check for proper use of extension cord

Check to be sure unit is plugged in

Check fuse/breaker

Replace shop/house blown fuse

Reset shop/house breaker, determining why

problem happened

Press restart button. Motor will restart when cool

Replace pressure switch

Compressor will turn on when tank pressure

drops to cut-in pressure

Ensure that the easy start filter is installed

Check with voltmeter

Check for proper gauge wire and cord length

Take compressor to service center

Take compressor to service center

Ensure that the easy start filter is installed

Check with voltmeter

Move compressor to well-ventilated area

Check for proper gauge wire and cord length

Check all connections with soap and water solu-

tion and tighten

Tighten drain valve

Take compressor to service center

Excessive moisture in discharge air

Compressor runs continuously

Air output lower than normal Broken inlet valves

Excessive water in air tanks

High humidity

Defective pressure switch

Excessive air usage

Piston rings are worn

Connections leaking

NOTE: Illustrations start on page 19 after French

and Spanish language sections.

This product has a 90-Day Satisfaction Guarantee Policy,

as well as a Three-year Limited Warranty. For Warranty and Policy details,

please go to www.RIDGID.com or call (toll free) 1-866-539-1710.

DANGER:

Do not disassemble check valve, tank drain

valves or safety relief valve with air in tank

— bleed tanks.

Drain tanks

Move to area of less humidity; use air line filter

Take compressor to service center

Decrease air usage; compressor not large

enough for tool’s requirement

Replace piston rings; Call customer service for

assistance

Take compressor to service center

Tighten connections

16 – English

Page 17

RÈGLES DE SÉCURITÉ GÉNÉRALES

protection est requise, car les clous / agrafes et débris

AVERTISSEMENT :

Lire et veiller à bien comprendre toutes les

instructions. Le non-respect de toutes les

instructions ci-dessous peut entraîner un choc

électrique, un incendie et/ou des blessures

graves.

CONSERVER CES INSTRUCTIONS

LIEU DE TRAVAIL

Garder le lieu de travail propre et bien éclairé. Les

établis encombrés et les endroits sombres sont propices

aux accidents. Le sol ne doit pas être rendu glissant par

de la cire ou de la sciure.

Ne pas utiliser d’outils électriques dans des

atmosphères explosives, par exemple en présence

de liquides, gaz ou poussières inflammables. Les

outils électriques produisent des étincelles risquant

d’enflammer les poussières ou vapeurs.

Garder les badauds, enfants et visiteurs à l’écart

pendant l’utilisation d’outils. Les distractions peuvent

causer une perte de contrôle.

Utiliser le compresseur d’air dans un endroit dégagé,

à au moins 460 mm (18 po) de toute paroi ou objet

risquant de gêner l’entrée de l’air dans les ouvertures

de ventilation.

SÉCURITÉ ÉLECTRIQUE

Éviter tout contact du corps avec des surfaces mises

à la terre, telles que tuyaux, radiateurs, cuisinières

et réfrigérateurs. Le risque d’électrocution est accru

lorsque le corps est mis à la terre.

Ne pas exposer les outils électriques à la pluie ou

l’humidité. La pénétration d’eau dans ces outils accroît

le risque de choc électrique.

Ne pas maltraiter le cordon d’alimentation. Ne jamais

utiliser le cordon d’alimentation pour transporter

l’outil et ne jamais débrancher ce dernier en tirant sur

le cordon. Garder le cordon à l’écart de la chaleur,

de l’huile, des objets tranchants et des pièces en

mouvement. Remplacer immédiatement tout cordon

endommagé. Un cordon endommagé accroît le risque

d’électrocution.

Pour les travaux à l’extérieur, utiliser un cordon

spécialement conçu à cet effet, marqué « W-A » ou

« W ». Ces cordons sont spécifiques à l’emploi en plein-

air et réduisent les risques d’électrocution.

SÉCURITÉ PERSONNELLE

Lors du chargement, de l’utilisation ou de l’entretien

de cet outil, l’opérateur et les personnes se trouvant

sur le lieu de travail doivent TOUJOURS porter

un dispositif oculaire à protection FRONTALE et

LATÉRALE, conforme aux normes ANSI. Une telle

projetés peuvent causer des lésions oculaires graves.

Il incombe à l’employeur et/ou l’utilisateur de veiller

à ce qu’une protection oculaire adéquate soit

utilisée. Nous recommandons d’utiliser un masque

facial à champ de vision se portant par-dessus des

lunettes de vue ou de sécurité et potégeant des débris

projetés sur le devant et les côtés. Toujours porter

une protection oculaire certifiée conforme à la norme

ANSI Z87.1.

Des équipements de protection supplémentaires sont

requis dans certains environnements. Par exemple,

le lieu de travail peut présenter un niveau de bruit

susceptible d’entraîner des lésions auditives. Il incombe à

l’opérateur et à l’utilisateur qu’une protection audidive soit

fournie et utilisée par l’opérateur et les autres personnes

se trouvant sur le lieu de travail. Certains environnements

requièrent le port d’un casque. Il incombe à l’employeur

et/ou l’utilisateur de veiller à ce qu’un casque conforme

à la norme ANSI Z89.1 soit utilisé.

Rester attentif, prêter attention au travail et faire

preuve de bon sens lors de l’utilisation de tout

outil électrique. Ne pas utiliser cet outil en état de

fatigue ou sous l’influence d’alcool, de drogues ou

de médicaments. Un moment d’inattention pendant

l’utilisation d’un outil électrique peut entraîner des

blessures graves.

Porter une tenue appropriée. Ne porter ni vêtements

amples, ni bijoux. Attacher ou couvrir les cheveux

longs. Garder les cheveux, les vêtements et les gants

à l’écart des pièces en mouvement. Les vêtements

amples, bijoux et cheveux longs peuvent se prendre dans

les pièces en mouvement.

Ne pas travailler hors de portée. Toujours se tenir

bien campé et en équilibre. Une bonne tenue et un bon

équilibre permettent de mieux contrôler l’outil en cas de

situation imprévue.

Utiliser l’équipement de sécurité. Toujours porter une

protection oculaire. Suivant les conditions, le port d’un

masque antipoussière, de chaussures de sécurité, d’un

casque ou d’une protection auditive est recommandé.

Ne pas utiliser l’outil sur une échelle ou un support

instable. Une bonne tenue et un bon équilibre permettent

de mieux contrôler l’outil en cas de situation imprévue.

UTILISATION ET ENTRETIEN DE L’OUTIL

Ne pas dépasser les pressions nominales des

composants du système.

Protéger les flexibles d’alimentation et d’outil contre

les dommages et risques de perforation. Garder le

flexible et le cordon d’alimentation électrique à l’écart

de la chaleur, de l’huile, des solvants et sols humides ou

mouillés.

2 – Français

Page 18

RÈGLES DE SÉCURITÉ GÉNÉRALES

Avant chaque utilisation, s’assurer que les fexibles

ne sont pas affaiblis ou endommagés et vérifier tous

les branchements. Ne pas utiliser le compresseur si les

flexibles ne sont pas en bon état. Acheter de nouveaux

flexibles ou contacter un centre de réparations agréé,

pour les faire inspecter ou réparer.

Relâcher toutes les pressions du système lentement.

La projection de poussières et de débris peut être

dangereuse.

Ranger les outils non utilisés hors de portée des

enfants et des personnes n’ayant pas reçu des

instructions adéquates. Dans les mains de personnes

n’ayant pas reçu des instructions adéquates, les outils

sont dangereux.

Entretenir soigneusement les outils. Respecter toutes

les instructions d’entretien. Les outils correctement

entretenus sont plus faciles à contrôler.

Vérifier qu’aucune pièce mobile n’est mal alignée,

grippée ou brisée et s’assurer qu’aucun autre

problème risque d’affecter le bon fonctionnement

de l’outil. En cas de dommages, faire réparer l’outil

avant de l’utiliser de nouveau. Beaucoup d’accidents

sont causés par des outils mal entretenus.

Ne pas pointer un outil quel qu’il soit vers soi ou

d’autres personnes.

Garder l’extérieur du compresseur sec, propre et

exempt d’huile ou de graisse. Toujours utiliser un chiffon

propre pour le nettoyage. Ne jamais utiliser de liquide

de freins, d’essence, de produits à base de pétrole ou

de solvants puissants pour nettoyer l’outil. Le respect

de cette règle réduira les risques de perte du contrôle et

d’endommagement du boîtier en plastique.

DÉPANNAGE

Utiliser exclusivement des pièces identiques à celles

d’origine pour les réparations. Se conformer aux

instructions de la section Entretien de ce manuel.

L’usage de pièces non autorisées ou le non respect des

instructions d’entretien peut présenter des risques de

blessures.

Le dépannage des outils doit être confié exclusivement

à un personnel qualifié. Les réparations ou entretiens

effectués par des personnes non qualifiées présentent

des risques de blessures.

Débrancher le compresseur, ouvrir le robinet de purge

pour relâcher la pression, laisser l’eau s’écouler et

laisser la machine refroidir avant de procéder à tout

entretien. Après avoir arrêté le compresseur, tourner

le bouton du détendeur à fond vers la gauche.

RÈGLES DE SÉCURITÉ PARTICULIÈRES

Apprendre à connaître l’outil. Lire attentivement le

manuel d’utilisation. Apprendre les applications et les

limites de l’outil, ainsi que les risques spécifiques relatifs

à son utilisation. Le respect de cette règle réduira les

risques d’incendie, de choc électrique et de blessures.

Purger le réservoir après chaque journée de travail.

Si le compresseur ne doit pas être utilisé pendant un

certain temps, il est préférable de laisser le robinet de

purge ouvert. Cela permettra d’évacuer complètement

l’humidité et aidera à empêcher la corrosion de l’intérieur

du réservoir.

Risque d’incendie ou d’explosion. Ne pas vaporiser de

liquides inflammables dans un endroit confiné. La zone de

pulvérisation doit être bien ventilée. Ne pas fumer pendant

la pulvérisation ou pulvériser en présence de flammes.

Garder les compresseurs le plus loin possible des zones

de pulvérisation, au moins à 4,6 m (15 pi) de la zone de

pulvérisation et de toutes vapeurs explosives.

Risque d’éclatement. Ne pas régler le détendeur pour

obtenir une pression de sortie supérieure à la pression

nominale de l’accessoire utilisé. Ne pas utiliser une

pression de plus de 1 034 kPa (150 psi).

Si connecter à un circuit protéger par des fusibles,

utiliser des fusibles coussinets avec ce produit.

Pour réduire le risque de choc électrique, ne pas

exposer à la pluie. Remiser à l’intérieur.

Une fois l’an, s’assurer que le réservoir n’est pas

rouillé ou piqué et ne présente aucun défaut risquant

de le rendre dangereux. Ne jamais percer ou souder le

réservoir.

S’assurer que le flexible n’est ni bloqué, ni accroché.

Un flexible emmêlé ou entortillé peut causer une perte

d’équilibre et être endommagé.

Le compresseur ne doit être utilisé que pour les

applications pour lesquelles il est conçu. Ne pas

altérer ou modifier le compresseur ou l’utiliser pour

des applications pour lesquelles il n’est pas conçu.

Ne jamais oublier qu’un usage incorrect ou abusif

de cet outil peut mettre l’opérateur et les autres

personnes présentes en danger.

Ne jamais laisser l’outil sans surveillance avec le

flexible d’air branché.

3 – Français

Page 19

RÈGLES DE SÉCURITÉ PARTICULIÈRES

Ne pas utiliser cet outil s’il ne comporte pas

d’autocollant d’avertissement.

Ne pas utiliser un outil qui présente des fuites d’air

ou ne fonctionne pas correctement.

Toujours débrancher l’outil des alimentations

pneumatique et électrique avant d’effectuer des

réglages ou entretiens et lorsque l’outil n’est pas utilisé.

Ne pas essayer de tirer ou de transporter le

compresseur par son flexible.

La consommation d’air de l’outil peut être supérieure

à la capacité de ce compresseur.

Toujours respecter les consignes de sécurité du

fabricant de l’outil pneumatique, ainsi que toutes les

règles de sécurité d’utilisation du compresseur. Le

respect de cette consigne réduira les risques de blessures

graves.

Ne jamais diriger le jet d’air comprimé vers des

personnes ou animaux. Veiller à ne pas projeter de la

poussière ou de la saleté vers soi-même ou d’autres

personnes. Le respect de cette règle réduira les risques

de blessures graves.

Ne pas utiliser ce compresseur pour la pulvérisation

de produits chimiques. L’inhalation de vapeurs toxiques

peut causer des lésions pulmonaires. Le port d’un

respirateur peut être nécessaire dans les environnements

poussiéreux ou lors de la pulvérisation de peinture. Ne

pas porter lorsque vous êtes en train de peindre.

Inspecter régulièrement le cordon d’alimentation de

l’outil et les flexibles. S’ils sont endommagés, les

confier au centre de réparations agréé le plus proche.

Toujours être conscient de l’emplacement du cordon.

Le respect de cette consigne réduira les risques de choc

électrique et d’incendie.

Ne jamais utiliser un adaptateur électrique avec cette

prise de terre.

Vérifier l’état des pièces. Avant d’utiliser le

compresseur de nouveau, examiner soigneusement

les pièces et dispositifs de protection qui semblent

endommagés afin de déterminer s’ils fonctionnent

correctement et remplissent les fonctions prévues.

Vérifier l’alignement des pièces mobiles, s’assurer

qu’aucune pièce n’est bloquée ou cassée, vérifier la

fixation de chaque pièce et s’assurer qu’aucun autre

problème ne risque d’affecter le bon fonctionnement

de l’outil. Toute protection ou pièce endommagée

doit être correctement réparée ou remplacée

dans un centre de réparations agréé. Le respect de

cette consigne réduira les risques de choc électrique,

d’incendie et de blessures graves.

S’assurer que le cordon prolongateur est en bon

état. Si un cordon prolongateur est utilisé, s’assurer

que sa capacité est suffisante pour supporter le

courant de fonctionnement de l’outil. Un calibre

de fil (A.W.G) d’au minimum 14 est recommandé

pour un cordon prolongateur de 8 mètres (25

pi) maximum. L’usage d’un cordon de plus de

15 mètres (50 pi) est déconseillé. En cas de doute,

utiliser un cordon du calibre immédiatement

supérieur. Moins le numéro de calibre est élevé, plus

la capacité du fil est grande. Un cordon de capacité

insuffisante causerait une baisse de la tension de ligne,

entraînant une perte de puissance et une surchauffe.

La source d’air de cet outil n’est pas régulée.

Une source d’air non régulée ne doit pas être

reliée directement à un outil ou à un accessoire

pneumatique. Si elle n’est pas régulée, la pression

d’air peut excéder la pression maximale tolérée par

l’outil ou l’accessoire employé.

Le réservoir principal amovible de cet appareil n’est

compatible qu’avec lui.

Avant de soulever le compresseur d’air avec le

réservoir principal installé, s’assurer que ce dernier

est bien arrimé au compresseur.

Un cet équipement incorpore des parties,

commutateurs telles que de claquement, les prises,

et l’aimé qu’avoir tendance à produire des arcs ou des

étincelles et, donc, quand localisé dans un garage, ce doit

être dans une pièce ou la clôture a pourvu au but, ou doit

être 18 dans. (457 mm) ou plus au-dessus du plancher.

Ne jamais emmagasiner l’outil avec l’air connecté.

Emmagasiner l’outil avec l’air connecté peut avoir pour

résultat vider imprévu et la blessure personnelle, sérieuse

et possible.

Protection respiratoire. Porter un masque facial ou

respiratoire si le travail produit de la poussière. Le respect

de cette règle réduira les risques de blessures graves.

Si le cordon d’alimentation est endommagé, il doit être

remplacé uniquement pas le fabricant ou par un centre

de réparation agréé pour éviter tout risque.

Conserver ces instructions. Les consulter fréquemment

et les utiliser pour instruire les autres utilisateurs éventuels.

Si cet outil est prêté, il doit être accompagné de ces

instructions.

4 – Français

Page 20

SYMBOLES

Les termes de mise en garde suivants et leur signification ont pour but d’expliquer le degré de risques associé à l’utilisation

de ce produit.

SYMBOLE SIGNAL SIGNIFICATION

DANGER:

AVERTISSEMENT :

ATTENTION :

AVIS :

Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper

interpretation of these symbols will allow you to operate the product better and safer.

SYMBOL NAME

Symbole d’alerte de sécurité Indique un risque de blessure potentiel.

Lire manuel d’utilisation

Protection oculaire

Indique une situation extrêmement dangereuse qui, si elle n’est pas évitée, aura

pour conséquences des blessures graves ou mortelles.

Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée,

pourrait entraîner des blessures graves ou mortelles.

Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée,

pourraît entraîner des blessures légères ou de gravité modérée.

(Sans symbole d’alerte de sécurité)Indique une information importante ne

concernant pas un risque de blessure comme une situation pouvant occasionner

des dommages matériels.

DESIGNATION/EXPLANATION

Pour réduire les risques de blessures, l’utilisateur doit lire et

veiller à bien comprendre le manuel d’utilisation avant d’utiliser

ce produit.

Toujours porter une protection oculaire avec écrans latéraux

certifiée conforme à la norme ANSI Z87.1.

Avertissement concernant

l’humidité

Risque d’éclatement

Risque d’incendie ou

d’explosion

Risque de choc électrique

Surface brûlante

Risques d’inhalation

Ne pas exposer à la pluie ou l’humidité.

Ne pas régler le détendeur pour obtenir une pression de sortie

supérieure à la pression nominale de l’accessoire utilisé. Ne pas

utiliser une pression de plus de 1 034 kPa (150 PSI).

Ne pas vaporiser de liquides inflammables dans un endroit confiné.

La zone de pulvérisation doit être bien ventilée. Ne pas fumer pendant la pulvérisation ou pulvériser en présence de flammes.Garder

les compresseurs le plus loin possible des zones de pulvérisation,

au moins à 4,6 m (15 pi) de la zone de pulvérisation et de toutes

vapeurs explosives.

Tension dangereuse : Débrancher de la prise secteur avant de

faire des réparations. Le compresseur doit être mis à la terre.

Pour éviter les risques de blessures ou de dommages, éviter

tout contact avec les surfaces brûlantes.

L’air sortant directement du compresseur ne doit jamais être

utilisé pour la respiration.

5 – Français

Page 21

SYMBOLES

Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper

interpretation of these symbols will allow you to operate the product better and safer.

SYMBOL NAME

Point de pincement

V Volts Tension

A Ampères Intensité

Hz Hertz Fréquence (cycles par seconde)

Courant alternatif Type de courant

Construction de classe II Construction à double isolation

Pour éviter les risques de blessures ou de dommages, éviter

tout contact avec les points de pincement.

DESIGNATION/EXPLANATION

DANGER