Page 1

OF45150

OPERATOR’S MANUAL

TWIN STACK

PORTABLE AIR

COMPRESSOR

To reduce the risk of injury, the user

must read and understand the

Operator’s Manual before using this

product.

IN610301AV 6/04 Printed in U.S.A.

!

WARNING:

Page 2

Safety Instructions

This manual contains information that is

very important to know and understand.

This information is provided for SAFETY

and to PREVENT EQUIPMENT PROBLEMS. To help recognize this information, observe the following symbols.

Safety Signal Words

Danger indicates

an imminently hazardous situation which, if not avoided,

WILL result in death or serious injury.

Warning indicates

a potentially hazardous situation which, if not avoided,

COULD result in death or serious injury.

Caution indicates a

potentially hazardous situation which, if not avoided,

MAY result in minor or moderate injury.

Notice indicates

important information, that if not followed, may cause damage to equipment.

3

Air compressors are utilized in a variety

of air system applications. Because air

compressors and other components

(material pump, spray gun, filters, lubrications, hoses, etc.) used make up a

high pressure pumping system, the following safety precautions should be

observed at all times. Only persons well

acquainted with these rules of safe operation should be allowed to use the air

compressor.

1. Read instruction manuals for each

component carefully, before attempting to assemble, disassemble or

operate your particular system.

2. Wear safety glasses (meeting ANSI

Z87.1 or in Canada CSA Z94.3-99)

and use hearing protection when

operating the pump or unit. Everyday

glasses are not safety glasses.

3. Do not exceed pressure rating of any

component in system.

4. Protect material lines and air lines

from damage or puncture. Keep hose

and power cable away from sharp

objects, chemical spills, oil, solvents,

and wet floors.

5. Never point a spray gun at oneself or

any other person. Accidental discharge may result in serious injury.

6. Check hoses for weak or worn condition, before each use, making certain

all connections are secure; do not

use if deficiency is found. Notify an

authorized service facility for examination or repair.

7. Release all pressures within system

slowly; dust and debris may be harmful.

Before Using the Air Compressor

All electrical work should be

done by a qualified (licensed or

certified) electrician. On a properly wired circuit, the black

wires supply a voltage potential

even when the unit is off.

Disconnect power and depressurize system before servicing

air compressor! (Turn pressure

regulator knob fully clockwise

after shutting off compressor.)

Table of Contents

Section Page

Table of Contents . . . . . . . . . . . . . . . .2

Safety Instructions . . . . . . . . . . . . . . .3

Safety Signal Words . . . . . . . . . . . . .3

Before Using the Air

Compressor . . . . . . . . . . . . . . . . . . . .3

Spraying Precautions . . . . . . . . . . . .5

Breathable Air Warning . . . . . . . . . . .5

Warning Labels . . . . . . . . . . . . . . . . .6

Motor Specifications and

Electrical Requirements . . . . . . . . . .7

Power Supply and Motor

Specifications . . . . . . . . . . . . . . . . . .7

General Electrical Connections . . . . .7

110-120 Volt, 60 Hz Tool

Information . . . . . . . . . . . . . . . . . . . .8

Extension Cords . . . . . . . . . . . . . . . .8

Thermal Overload Protector . . . . . . .9

Glossary of Terms . . . . . . . . . . . . . . .9

Unpacking and Checking

Content . . . . . . . . . . . . . . . . . . . . . . .10

Installation . . . . . . . . . . . . . . . . . . . .10

Section Page

Getting to Know Your Air

Compressor . . . . . . . . . . . . . . . . . . .11

Operating Your Air Compressor . . .13

Moisture in Compressed Air . . . . . .13

Operating Your Air Compressor . . .13

For Trouble-Free Operation . . . . . .13

Maintenance . . . . . . . . . . . . . . . . . . .14

Tank . . . . . . . . . . . . . . . . . . . . . . . . .15

Filter Removal, Inspection, and

Replacement . . . . . . . . . . . . . . . . . .15

Lubrication . . . . . . . . . . . . . . . . . . . .15

Storage . . . . . . . . . . . . . . . . . . . . . .15

Maintenance Schedule . . . . . . . . . .15

Troubleshooting . . . . . . . . . . . . . . . .16

Repair Parts . . . . . . . . . . . . . . . . . . .18

Notes . . . . . . . . . . . . . . . . . . . . . . . . .22

Warranty . . . . . . . . . . . . . . . . . . . . . .24

2

!

DANGER:

!

WARNING:

!

WARNING:

!

CAUTION:

NOTICE:

!

WARNING:

Page 3

1. Do not smoke when spraying paint,

insecticides, or other flammable substances.

2. Use a face mask/respirator when spraying and

spray in a well ventilated

area to prevent health and

fire hazards.

3. Do not direct paint or other sprayed

material at the compressor. Locate

compressor as far away from the

spraying area as possible to minimize

overspray accumulation on the compressor.

4. When spraying or cleaning with solvents or toxic chemicals, follow the

instructions provided by the chemical

manufacturer.

5

Spraying Precautions

Do not spray flammable materials in vicinity of open flame or

near ignition sources including

the compressor unit.

Breathable Air Warning

This compressor/pump is not equipped and should not be used “as

is” to supply breathing quality air. For any application of air for

human consumption, the air compressor/pump will need to be fitted

with suitable in-line safety and alarm equipment. This additional

equipment is necessary to properly filter and purify the air to meet

minimal specifications for Grade D breathing as described in

Compressed Gas Association Commodity Specification G 7.1 - 1966,

OSHA 29 CFR 1910. 134, and/or Canadian Standards Associations

(CSA).

DISCLAIMER OF WARRANTIES

In the event the compressor is used for the purpose of breathing air

application and proper in-line safety and alarm equipment is not

simultaneously used, existing warranties shall be voided, and

Campbell Hausfeld disclaims any liability whatsoever for any loss,

personal injury or damage.

8. Follow all local electrical and safety

codes, as well as the National

Electrical Code (NEC) and the

Occupational Safety and Health Act

(OSHA).

9. Wiring and fuses should follow electrical codes, current capacity, and be

properly grounded.

10. Electric motors must be securely and

adequately grounded. See grounding

instructions and extension cord information in this manual.

11. Always disconnect power source

before working on or near a motor, or

its connected load. If power disconnect point is out-of-sight, lock it in the

open position and tag to prevent

unexpected application of power.

12. Guard all moving parts; keep visitors

away. Never allow children in work

area.

13. Use only a properly grounded outlet

that will accept a three pronged plug,

and wear shoes to prevent shock

hazards.

14. Be careful when touching exterior of

operating motor; it may be hot

enough to cause injury.

15. Protect power cable from coming in

contact with sharp objects.

16. Clean electrical or electronic equipment with an approved cleaning

agent, such as dry, nonflammable

cleaning solvent.

17. To avoid spontaneous combustion,

discard waste rags into approved

metal waste cans.

18. Never store flammable liquids or

gases in vicinity of compressor.

19. When spraying with solvent of toxic

chemicals, follow instructions provided by the chemical manufacturer.

20. Spray in a well ventilated area, to

keep fumes from collecting and causing health and fire hazards.

21. Do not spray in vicinity of open

flames or other places where a spark

can cause ignition. Do not smoke

when spraying paint, insecticides, or

other flammable substances.

22. Use a respirator when spraying.

23. NEVER reset safety valve or pressure switch. Keep safety valve free

from paint and other accumulations.

This provides safety against over

pressure.

24. Do regular maintenance; keep all

nuts, bolts, and screws tight, to be

sure equipment is in safe working

condition .

25. Keep cleaning rags and other flammable waste materials in a tightly

closed metal container and dispose of

later in the proper fashion.

26. Drain tanks of moisture after each

day’s use. If unit will not be used for a

while, it is best to leave drain cock

open until such time as it is to be

used. This will allow moisture to completely drain out and help prevent

corrosion of inside of tank.

27. Inspect tank yearly for rust, pin holes

or any other imperfections that could

cause it to become unsafe. NEVER

weld or drill holes in air tank.

Safety Instructions (continued)

4

!

WARNING:

!

DANGER:

Page 4

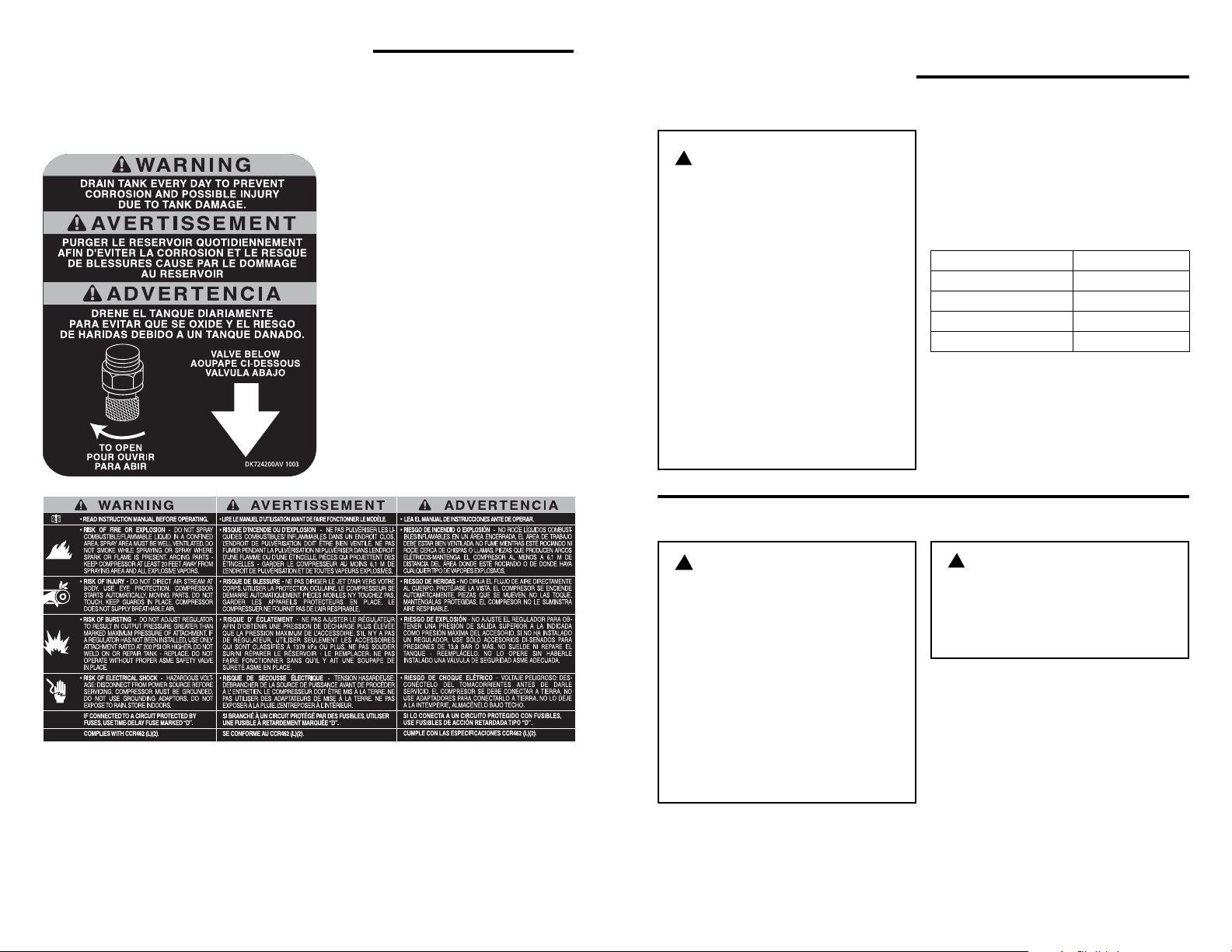

The A-C motor used on this compressor

is a capacitor start, capacitor run nonreversible induction type, having the following specifications. It is wired at the

factory for operation on 110V-120V AC,

60 Hz service.

Voltage 110-120

Amperes 14.5

Hertz (Cycles) 60

Phase Single

RPM 3450

Motor Specifications and

Electrical Requirements

7

Power Supply and Motor Specifications

To reduce the risk of electrical

hazards, fire hazards or damage

to the tool, use proper circuit

protection. Your tool is wired at

the factory for operation using

the voltage shown. Connect

tool to a power line with the

appropriate voltage and a 15amp branch circuit. Use a 15amp time delay type fuse or circuit breaker.To reduce the risk

of shock or fire, if power cord is

worn or cut, or damaged in any

way, have it replaced immediately.

General Electrical Connections

To reduce the risk of electrocution:

1. Use only identical replacement parts when servicing.

Servicing should be performed by a qualified technician.

2. Do not use in rain or where

floor is wet. This too is

intended for indoor residential use only.

Do not permit fingers to touch

the terminals of plug when

installing or removing the plug

to or from the outlet.

Safety Instructions (continued)

6

Find and read all warning labels found on

the air compressor shown below

Warning Labels

0

!

WARNING:

!

!

DANGER:

DK724100AV 100

WARNING:

Page 5

9

Thermal Overload Protector

If thermal overload protector shuts motor

OFF frequently look for the following

causes.

1. Low voltage.

2. Wrong gauge wire.

3. Clogged air filter.

4. Lack of proper ventilation.

5. Unit is being used with an extension

cord.

See Troubleshooting Chart for corrective

action.

This compressor is equipped

with an automatic reset thermal

overload protector which will

shut off motor if it becomes

overheated.

The motor must be allowed to

cool down before start-up is

possible. The motor will automatically restart without warning if left plugged into electrical

outlet, and the motor is turned

on.

ASME Safety Valve

A safety valve that automatically releases

the air if the air receiver (tank) pressure

exceeds the preset maximum.

PSI (Pounds per Square Inch)

Measurement of the pressure exerted by

the force of the air. The actual psi output

is measured by a pressure gauge on the

compressor

SCFM (Standard Cubic Feet per

Minute)

Sometimes called CFM (Cubic Feet per

Minute). Measurement of air volume

delivered by the compressor.

Air Delivery

A combination of psi and SCFM. The air

delivery required by a tool is stated as

(number) SCFM at (number) psi. The

combination of these figures determines

what size unit is needed.

Air Tank Capacity

The volume of air stored in the tank and

available for immediate use. A large tank

allows the intermittent use of an air tool

with an air requirement higher than the

compressor’s rated delivery.

Volts or Voltage

A measurement of the force of an electrical current.

Amps or Amperage

A measure of the electrical force minus

the resistance on an electrical line.

Ridgid air compressors require 15 amps

for operation. Be sure the compressor

will operate on an electrical line with the

proper amps. If other appliances operate

on the same line, they will reduce the

available amps. If the amperage is not

adequate, the result will be blown fuses

or tripped circuits.

Regulator

A control that adjusts the line pressure to

the proper amount needed to operate

spray guns and air tools.

Tanks Pressure Gauge

Indicates tank pressure in psi.

Glossary of Terms

8

The plug supplied on your tool may not

fit into the outlet you are planning to use.

Your local electrical code may require

slightly different power cord plug connections. If these differences exist refer to

and make the proper adjustments per

you local code before your tool is

plugged in and turned on.

In the event of a malfunction or breakdown, grounding provides a path of least

resistance for electrical current to reduce

the risk of electric shock. This tool is

equipped with an electric cord having an

equipment-grounding conductor and a

grounding plug, as shown. The plug must

be plugged into a matching outlet that is

properly installed and grounded in accordance with all local codes and ordinances.

Do not modify the plug provided. If it will

not fit the outlet, have the proper outlet

installed by a qualified electrician.

Improper connection of the equipmentgrounding conductor can result in a risk

of electric shock. The conductor with

insulation having an outer surface that is

green with or without yellow stripes is the

equipment-grounding conductor. If repair

or replacement of the electric cord or

plug is necessary, do not connect the

equipment-grounding conductor to a live

terminal.

If the grounding instructions are not completely understood, or if you are in doubt

as to whether the tool is properly grounded check with a qualified electrician or

service personnel.

Motor Specifications and

Electrical Requirements (continued)

110-120 volt, 60Hz Tool Information

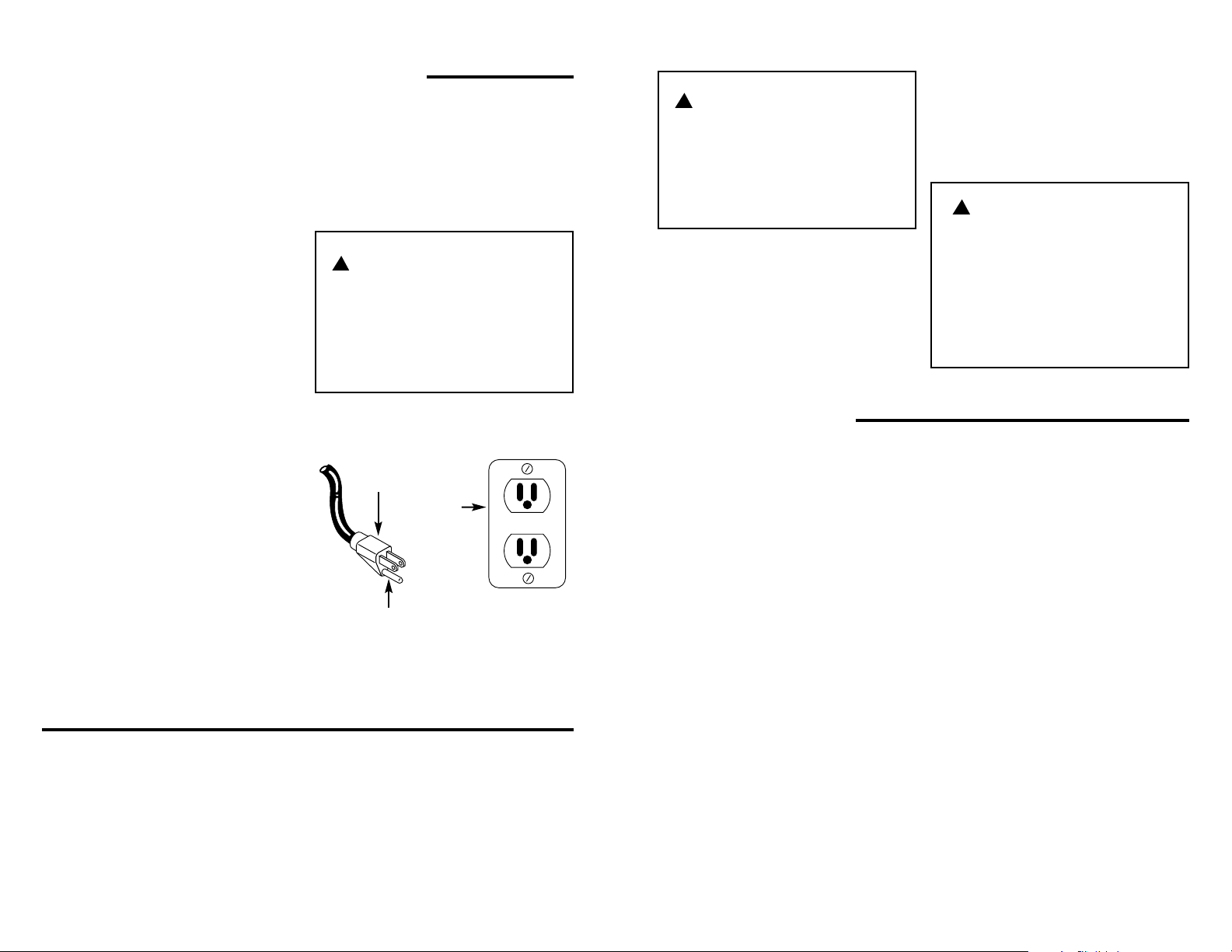

If not properly grounded, this

tool can cause an electrical

shock, particularly when used

in damp locations, in proximity

of plumbing, or out of doors.

Grounding Prong

3-Prong Plug

Properly

Grounded

3-Prong

Outlet

Extension Cords

1. The air compressor should be located

where it can be directly plugged into

an outlet. An extension cord should

not be used with this unit.

2. To avoid loss of power and overheating, additional air hose must be used

to reach work area instead of extension cords.

!

WARNING:

TEST

RESET

!

CAUTION:

!

CAUTION:

Page 6

11

Getting to Know Your Air Compressor

2 Regulated

Outlet Gauge

5 Tank Pressure

Gauge

4 Regulator

Knob

1 Air Storage

Tanks

3 Handle

7 Air Outlet

Fittings

8 Air Filter

9 On/Off Switch

10 Tank Drain Valve

6 Safety Valve

10

Line Pressure Gauge

Displays the current line pressures. It is

regulated by the regulator knob.

Cut-in/Cut-off Pressure

Specific psi at which a compressor starts

and stops while refilling the air tank.

Glossary of Terms (Continued)

1. Remove the air compressor from the

carton.

2. Place the compressor on a secure,

stationary work surface and look it

over carefully.

Unpacking and Checking Contents

Do not operate unit if damaged

during shipping, handling or

use. Damage may result in

bursting and cause injury or

property damage.

For your own safety, never

operate unit until all assembly

steps are complete and until

you have read and understood

the entire operator’s manual.

To reduce the risk of injury, if

any parts are missing, do not

attempt to operate the air compressor until the missing parts

are obtained and installed correctly.

1. Check and tighten all bolts, fittings,

etc., before operating compressor.

2. Operate compressor in a ventilated

area so that compressor may be

properly cooled.

3. Compressor should be located where

it can be directly plugged into an outlet. An extension cord should not be

used with this unit.

4. To avoid loss of power and overheating, additional air hose must be used

to reach work area instead of extension cords.

Installation

!

WARNING:

!

WARNING:

!

WARNING:

Page 7

1. Read instructions: Carefully read

through this operator’s manual

BEFORE OPERATING the new air

compressor. It contains information

about operation and maintenance of

the unit.

2. Drain tank daily: Depressurize system

prior to draining tank. Open tank

drain valve and drain moisture from

tank. This helps prevent tank corrosion and keeps oil and moisture out

of the compressed air system. Be

sure to close tank drain valve tightly

before operating compressor.

3. Change air filter: Never run compressor without an air filter nor with a

clogged air filter. Replace with a new

filter when the element is dirty.

Operating Your Air Compressor

13

Moisture in compressed air will form into

droplets as it comes from an air compressor pump. When humidity is high or

when a compressor is in continuous use

for an extended period of time, this moisture will collect in the tank. When using a

paint spray or sandblast gun, this water

will be carried from the tank through the

hose, and out of the gun as droplets

mixed with the spray material.

IMPORTANT: This condensation will

cause water spots in a paint job, especially when spraying other than water

based paints. If sandblasting, it will

cause the sand to cake and clog the gun,

rendering it ineffective.

A filter in the air line, located as near to

the gun as possible, will help eliminate

this moisture.

For Trouble-Free Operation

Moisture in Compressed Air

Make sure the tank drain valve is closed,

the regulator knob is turned fully counterclockwise, and the On/Off switch is in the

OFF position.

Plug compressor into a dedicated 15

Amp (minimum) circuit.

Turn On/Off switch to the ON position.

The compressor will now start building

pressure.

After compressor reaches cut-off pressure, install a hose (with the desired air

tool attached) into the outlet fitting.

Adjust the regulator knob to the desired

pressure.

The compressor is now ready to operate.

Operating Your Air Compressor

Do not over-pressurize any air

tool. Consult air tool instructions for proper air tool pressure.

Getting to Know Your Air

Compressor (Continued)

12

1. Air Storage Tanks. The tanks store

air for later use.

2. Regulated Outlet Gauge. This gauge

shows at-a-glance, air pressure at

outlet. Air pressure is measured in

pounds per square inch (PSI). Most

tools have maximum pressure ratings.

Never exceed the maximum pressure

rating of the tool you are using. Be

sure this gauge reads ZERO before

changing air tools or disconnecting

hose from outlet.

3. Handle. Used to move the compres-

sor.

4. Regulator Knob. This knob controls

air pressure to an air operated tool or

paint spray gun. Turning the knob

clockwise increases air pressure at

the outlet. Turning counterclockwise

will lower air pressure at the outlet.

Fully counterclockwise will shut off the

flow of air completely.

5. Tank Pressure Gauge. Gauge shows

pressure in air receiver indicating

compressor is building pressure properly.

6. ASME Safety Valve. This valve auto-

matically releases air if the tank pressure exceeds the preset maximum.

7. Air Outlet Fittings. These fittings are

1/4” universal-style quick connect fittings and allow rapid tool changes.

8. Air Filter. The air filter keeps dirt and

debris from entering the compressor

pump and reduces compressor noise.

9. On/Off Switch. This switch allows

manual control of the compressor.

Note that when the switch is turned

on, the compressor will automatically

start and stop depending on tank

pressure.

10. Tank Drain Valve. The tank drain

valve allows moisture to be removed

from the tank.

Close

Open

!

WARNING:

Page 8

1. Check compressor for any visible

problems, especially check air filter to

be sure it is clean.

2. Pull ring on safety valve and allow it to

snap back to normal position.

3. Drain moisture from tank daily. Shut

compressor off. Depressurize system

prior to draining tank. Drain moisture

from tank by opening the tank drain

valve underneath the tank.

4. Turn power OFF and clean dust and

dirt from motor, tank, air lines and

pump cooling fins.

NOTE: The air filter in the filter housing

on the side of the head must be checked

and cleaned periodically, more often if

used under very dusty conditions or

when a great deal of fog from spraying is

allowed to circulate near unit.

IMPORTANT: Unit should be located as

far from spraying area as hose will allow

to prevent over-spray from clogging filter.

Maintenance

14

Safety valve must be replaced if

it cannot be actuated or it leaks

air after ring is released.

Tank

Drain

Valve

Release all pressure and disconnect power before making

any repair.

1. When not in use, compressor should be

stored in a cool dry place.

2. Tank should be drained of moisture.

3. Hose should be disconnected and hung

open ends down to allow any moisture

to drain.

15

The tank should be carefully inspected at

a minimum of once a year. Look for

cracks forming near the welds. If a crack

is detected, remove pressure from tank

immediately and replace.

Tank

Never attempt to repair or modify a tank! Welding, drilling or

any other modification will

weaken the tank resulting in

damage from rupture or explosion. Always replace worn,

cracked or damaged tanks.

Drain liquid from tank daily.

To change a filter, pull off the filter housing

cover. If filter element is dirty, replace element or entire filter.

Filter Removal, Inspection and Replacement

This is an oilless type compressor requiring no lubrication.

Lubrication

Storage

Operation Daily Weekly

Drain Tank

Check Air Filter

Check Safety Valve

Blow Dirt From Inside Motor

Maintenance Schedule

!

WARNING:

!

DANGER:

NOTICE:

!

WARNING:

Page 9

Troubleshooting

16

For your own safety do not try

and run the air compressor

while troubleshooting.

TROUBLE PROBABLE CAUSE REMEDY

Compressor will not

run

Motor hums but cannot run or runs slowly

Fuses blow/circuit

breaker trips repeatedly

1. Unit is plugged into

extension cord

2. No electrical power

3. Blown fuse

4. Breaker open

5. Thermal overload open

6. Pressure switch bad

1. Low voltage

2. Unit is plugged into

extension cord

3. Shorted or open motor

winding

4. Defective check valve or

unloader

1. Incorrect size fuse, circuit

overloaded

2. Unit is plugged into

extension cord

3. Defective check valve or

unloader

1. Remove extension cord

2. Plugged in? Check

fuse/breaker or motor overload

3. Replace blown fuse

4. Reset, determining why

problem happened

5. Motor will restart when cool

6. Replace

1. Check with voltmeter

2. Remove extension cord

3. Replace motor

4. Replace or repair

1. Check for proper fuse, use

time-delay fuse.

Disconnect other electrical

appliances from circuit or

operate compressor on its

own branch circuit

2. Remove extension cord

3. Replace or repair

17

TROUBLE PROBABLE CAUSE REMEDY

Thermal overload

protector cuts out

repeatedly

Air tank pressure

drops when compressor shuts off

Excessive moisture

in discharge air

Compressor runs

continuously

Compressor vibrates

Air output lower than

normal

1. Low voltage

2. Clogged air filter

3. Lack of proper ventilation/room temperature

too high

4. Unit is plugged into

extension cord

1. Loose connections (fittings, tubing, etc.)

2. Loose drain lock

3. Check valve leaking

1. Excessive water in air

tank

2. High humidity

1. Defective pressure

switch

2. Excessive air usage

Loose mounting bolts

1. Broken inlet valves

2. Intake filter dirty

3. Connections leaking

1. Check with voltmeter

2. Clean filter (see

Maintenance section)

3. Move compressor to well

ventilated area

4. Remove extension cord

1. Check all connections with

soap and water solution

and tighten

2. Tighten

3. Disassemble check valve

assembly, clean or replace

Do not disassemble

check valve with air in

tank; bleed tank

1. Drain tank

2. Move to area of less

humidity; use air line filter

1. Replace switch

2. Decrease air usage; compressor not large enough

for a requirement

Tighten

1. Have authorized service

representative repair unit

2. Clean or replace intake filter

3. Tighten connections

!

WARNING:

!

DANGER:

Page 10

Repair Parts

18

1

21

22

23

24

26

28

17

29

30

31

33

34

35

36

37

38

39

40

2

3

4

5

6

7

8

9

10

11

13

14

27

15

16

19

20

4

4

6

To Pump Head

To Unloader

12

25

16

32

41

18

Repair Parts

19

For Repair Parts, Call 1-800-4-RIDGID

Please provide following information:

-Model number

-Serial number (if any)

-Part description and number as shown in parts list

Ref. Catalog Part

No. Number Number Descriptons Qty

1 17698 WL373000AJ Pump/motor assembly 1

2 17703 WL012000AV Filter 1

3 17708 WL012300AV Filter element 1

4 17713 ST158000AV Shoulder bolt 4

5 17718 WL003202AV Rubber bushing (Rear) 2

6 17723 WL003203AV Rubber bushing (Front) 2

7 17728 CV222203AJ Check valve 1

8 17733 WL016200AP Exhaust tube 1

9 17738 ST039700AV Nut 1

10 17743 ST039800AV Ferrule 1

11 17748 ST117802AV 1/4" Flexible tube 1

12 17753 ST209800AV Strain relief screw 1

13 17758 CW209600AV Strain relief 1

14 17763 EC012600AV Cord 1

15 17878 GA016901AV Tank gauge 1

16 17783 ST071626AV 1/4”-20 x 1/2” Screw 4

17 17793 WL024501AV Regulator assy. (includes 15, 27 & 28) 1

18 17798 V-215106AV 165 psi Safety valve 1

19 17808 ST185600AV Grip 1

20 17813 WL025900AV Roll bar 1

21 17838 WL025800AV Control panel bracket 1

22 17848 ST073276AV Foot screw 4

23 17853 ST158300AV Molded rubber bumper 4

24 17858 WL021400AV 3/8” Nylon tube 1

25 17863 ST074415AV 1/4”-20 x 1/2” Thread cutting screw 4

26 17868 ST119704AV 3/8” 90o Push to connect 1

27 17873 HF203300AV Coupler 2

28 17773 GA016900AV Outlet gauge 1

29 17883 CW210000AV Unloader 1

30 17888 ST022500AV Plug 1

31 17893 ST119305AV 3/8” Push to connect 1

32 17898 HF002401AV Nipple 1

33 17903 CW211700AV Pressure switch cover 1

34 17908 CW211300AJ Pressure switch 1

35 17913 D-1403 Tank drain valve 1

36 17918 ST073612AV Plug 1

37 17923 AR052700CG 4.5 gal. twin tank 1

38 17928 ST129301AV Shroud screw 1

39 17933 ST129302AV Shroud screw 2

40 17938 WL012406AV Shroud 1

41 17943 ST072224AV Exhaust fitting 1

REPAIR PARTS KITS

18713 WL209308AJ Exhaust tube kit (without check valve) 1

Page 11

Repair Parts

20

13

1

3

4

12

5

11

7

6

10

9

8

2

14

Repair Parts

21

For Repair Parts, Call 1-800-4-RIDGID

Please provide following information:

-Model number

-Serial number (if any)

-Part description and number as shown in parts list

Ref. Catolog Part

No. Number Number Descriptons Qty

1 17948 WL010500AV Head 1

2— Head bolts 4

3— Exhaust valve 1

4— Valve plate 1

5 17958 XA012100AV Cylinder gasket 1

6 17963 MC302300AJ Motor assembly (includes

eccentric/bearing assembly) 1

7 — (Included M5 x .8 x 20 HH cap screw 1

with piston

assembly,

Ref. No. 11)

8— M5 x .8 x 12 HHCS (L.H.) 1

9— Washer 1

10 — Fan 1

11 17968 WL210300AJ Piston assembly (includes. #7) 1

12 — Intake valve 1

13 17973 XA010800AV Head gasket 1

14 17978 XA012001AV Discharge valve gasket 1

REPAIR PARTS KITS

17953 WL602801AJ Head bolt kit (set of 4) 1

17983 WL201405AJ Valve plate kit (Includes #2-5, 12-14) 1

17988 WL209802AJ Fan kit (includes #8-10) 1

Page 12

Notes

23

Notes

22

Page 13

© 2004 RIDGID, INC.

Part No. IN610301AV 6/04 Form No. IN610301AV Printed in U.S.A. 6/04

RIDGID“ AIR COMPRESSOR LIMITED THREE YEAR WARRANTY

This product is manufactured by Campbell Hausfeld. The trademark is licensed from

Ridgid, Inc. All warranty communications should be directed to RIDGID air compressor technical service at (toll free) 1-800-4-RIDGID.

WHAT IS COVERED UNDER THE LIMITED THREE YEAR WARRANTY

This warranty covers all defects in workmanship or materials in this RIDGID air compressor for the three-year period from the date of purchase. This warranty is specific to this air compressor. Warranties for other RIDGID products may vary.

HOW TO OBTAIN SERVICE

To obtain service for this RIDGID air compressor you must return it, freight prepaid,

to a service center authorized to repair RIDGID air compressors. You may obtain the

location of the service center nearest you by calling (toll free) 1-800-4-RIDGID or by

logging on to the RIDGID website at www.ridgid.com. When requesting warranty

service, you must present the proof of purchase documentation, which includes a

date of purchase. The authorized service center will repair any faulty workmanship,

and either repair or replace any defective part, at Campbell Hausfeld’s option at no

charge to you.

WHAT IS NOT COVERED

This warranty applies only to the original purchaser at retail and may not be transferred. This warranty does not cover normal wear and tear or any malfunction, failure or defect resulting from misuse, abuse, neglect, alteration, modification or repair

by other than a service center authorized to repair RIDGID branded air compressors.

Expendable materials, such as oil, filters, etc. are not covered by this warranty.

Gasoline engines and components are expressly excluded from coverage and you

must comply with the warranty given by the engine manufacturer, which is supplied

with the product. CAMPBELL HAUSFELD MAKES NO WARRANTIES,

REPRESENTATIONS OR PROMISES AS TO THE QUALITY OR PERFORMANCE OF ITS AIR COMPRESSORS OTHER THAN THOSE

SPECIFICALLY STATED IN THIS WARRANTY. RIDGID, INC. MAKES NO

WARRANTIES OR REPRESENTATIONS, EXPRESS OR IMPLIED,

INCLUDING AS NOTED BELOW.

ADDITIONAL LIMITATIONS

To the extent permitted by applicable law, all implied warranties, including warranties

of MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE, are disclaimed.

Any implied warranties, including warranties of merchantability or fitness for a particular purpose, that cannot be disclaimed under state law are limited to three years

from the date of purchase. Campbell Hausfeld is not responsible for direct, indirect,

incidental, special or consequential damages. Some states do not allow limitations

on how long an implied warranty lasts and/or do not allow the exclusion or limitation

of incidental or consequential damages, so the above limitations may not apply to

you. This warranty gives you specific legal rights, and you may also have other

rights, which vary from state to state.

QUESTIONS OR COMMENTS

CALL 1-800-4-RIDGID

www.ridgid.com

Please have your Model Number and Serial Number on hand when calling.

Catalog No. OF45150

Model No. OF45150 Serial No. ___________

The model and serial numbers may be found on your

unit. You should record both model and serial number

in a safe place for future use.

Loading...

Loading...