Page 1

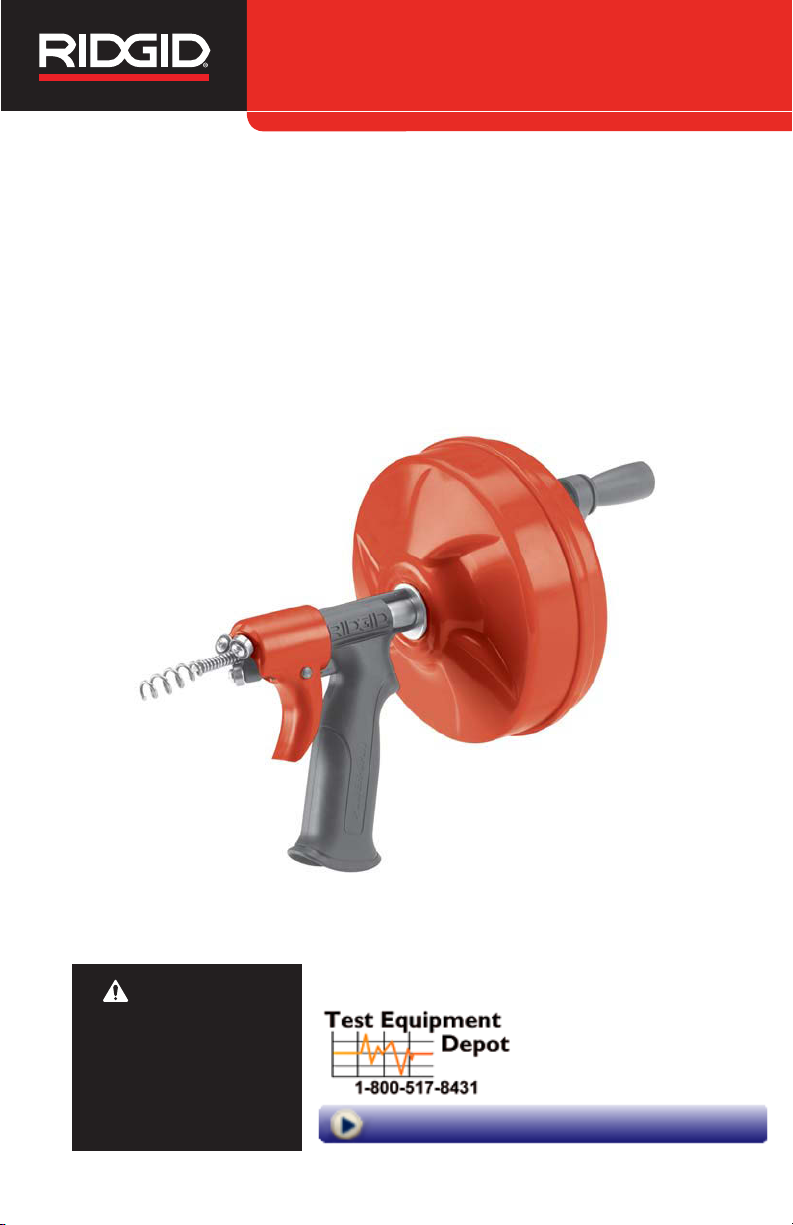

Power-Spin

®

WARNING!

Read this Operator’s Man ual

carefully before using this

tool. Failure to understand

and follow the contents of this

manual may result in electrical shock, fire and/or serious

person al injury.

Drain Cleaner Operator’s Manual

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

Page 2

4

POWER-SPIN®Drain Cleaner

Table of Contents

Safety Symbols ....................................................................................................4

Specific Safety Information

Drain Cleaner Safety .........................................................................................5

Description and Specifications

Description.........................................................................................................5

Specifications.....................................................................................................6

Machine Inspection..............................................................................................6

Machine and Work Area Set-Up..........................................................................6

Operating Instructions ........................................................................................8

Maintenance Instructions....................................................................................9

Cleaning.............................................................................................................9

Installing Replacement Cable............................................................................9

To Remove Cable From Drum .........................................................................9

To Install Replacement Cable ..........................................................................9

Troubleshooting.................................................................................................10

Lifetime Warranty.................................................................................Back Cover

*Original Instructions - English

Safety Symbols

In this operator’s manual and on the product, safety symbols and signal words are used to

communicate important safety information. This section is provided to improve understanding of these signal words and symbols.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey

all safety messages that follow this symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could result in minor

or moderate injury.

NOTICE indicates information that relates to the protection of property.

This symbol means read the operator’s manual carefully before using the equipment. The operator’s manual contains important information on the safe and proper operation of the equipment.

This symbol means always wear safety glasses with side shields or goggles when handling

or using this equipment to reduce the risk of eye injury.

This symbol indicates th risk of hands, fingers or other body parts being caught, wrapped or

crushed in the drain cleaning cable.

NOTICE

DANGER

WARNING

CAUTION

Page 3

5

POWER-SPIN®Drain Cleaner

• Do not operate this machine if operator

or machine is standing in water. Oper -

ating machine while in water increases the

risk of electrical shock.

• Only use drain cleaner to clean drains

of recommended sizes according to

these instructions. Other uses or modify-

ing the drain cleaning machine for other

applications may increase the risk of injury.

• Read and understand these instruc-

tions, the battery drill instructions and

the instructions for any other equipment used with this tool before operating. Failure to follow all instructions may re-

sult in property damage and/or serious injury.

The EC Declaration of conformity (890-011-

320.10) will accompany this manual as a separate booklet when required.

Description and

Specifications

Description

The RIDGID®Power-Spin®Drain Cleaner will

clean drain lines up to 1

1

/2" (40 mm) in diameter and up to 25' (7,6 m) in length such as

bathroom and kitchen sinks, bathtub and

shower drains. It features 25' (7,6 m) of durable

1

/4" (6 mm) MAXCORE®cable that is positive ly retained in the drum to prevent cable pullout.

It is equipped with an AUTO FEED

®

that advances and retrieves the cable with just the pull

of a trigger. The Power-Spin can be operated

either manually or driven with a battery powered drill with a maximum speed of 500 rpm.

The Power-Spin is not recommended for use

with toilets.

Specific Safety

Information

WARNING

This section contains important safety

information that is specific to this tool.

Read these precautions carefully before

using the Power-Spin

®

Drain Cleaner to

reduce the risk of electrical shock or

other serious personal injury.

SAVE THESE INSTRUCTIONS!

Drain Cleaner Safety

• Wear leather work gloves. Never grasp

the rotating cable with anything else, including cloth gloves or a rag. They can

become wrapped around the cable, causing hand injuries. Only wear latex or rubber

gloves

under

leather work gloves. Do not

use damaged gloves.

• Do not allow the end of cable to stop

turn ing while the machine is running.

This can overstress the cable and may cause

twisting, kinking or breaking of the cable.

• Position machine within 4" of the drain

inlet or properly support exposed cable

when the distance exceeds 4". Greater

dis tances can cause control problems leading to twisting, kinking or breaking of the

cable.

• Do not wear loose clothing or jewelry.

Keep your hair and clothing away from

moving parts. Loose clothing, jewelry or

hair can be caught in moving parts.

• Always use appropriate personal protec-

tive equipment while handling and using

drain cleaning equipment. Drains may

contain chemicals, bacteria and other substances that may be toxic, infectious, cause

burns or other issues. Appropriate per-

sonal protective equipment always includes safety glasses and leather work

gloves in good condition, and may in-

clude equipment such as latex or rubber

gloves, face shields, goggles, protective

clothing, respirators and steel toed footwear.

• Practice good hygiene. Use hot, soapy

water to wash hands and other body parts

exposed to drain contents after handling or

using drain cleaning equipment. Do not

eat or smoke while operating or handling

drain cleaning equipment. This will help

prevent contamination with toxic or infectious material.

Recommended Line

Cable Size Size & Reach

Line Size Reach

1

/4" (6 mm) Cable Up to 11/2" (40mm) 25' (7,6 m)

Page 4

6

POWER-SPIN®Drain Cleaner

• Proper assembly and completeness

• Broken, worn, missing, misaligned or

binding parts

• Smooth and free movement of the trigger and drum

• Presence and readability of the warning label

(see Figure 2.)

If any problems are found, do not use

the drain cleaner until the problems have

been repaired.

3. Inspect cable for wear and damage –

Look for:

• Obvious flats worn into the outside of

the cable (cable is made from round

wire and profile should be round).

• Multiple or excessively large kinks (slight

kinks up to 15 degrees can be straightened).

• Space between the cables indicating

the cable has been deformed by

stretch ing, kinking or run in REVERSE.

• Excessive corrosion from storing wet or

exposure to drain chemicals.

All of these forms of wear and damage

weaken the cable and make cable twisting, kinking or breaking more likely during

use. Replace worn and damaged cable

before using drain cleaner.

4. If using the Power-Spin Drain Cleaner

with a Battery Power Drill, inspect the

drill per it’s instructions. Make sure that

the drill is in good operating condition

and the switch controls the drill operation.

Confirm that the drill turns at less than

500 rpm.

Machine and Work Area

Set-Up

WARNING

Set up the drain cleaning machine and

work area according to these procedures to reduce the risk of injury from

electric shock, twisted or broken cables, chemical burns, infections and

other causes, and prevent drain cleaner

damage.

Always wear safety glasses, leather

gloves, and other appropriate protective

e quip ment when setting up your drain

cleaner. For extra protection from chemicals and bacteria on the machine and in

the work area, wear latex, rubber or

Specifications

Drum Capacity...........25' (7,6 m) of 1/4"

(6 mm) Diameter

MAXCORE Cable

Drum Speed ...............Maximum 500 RPM

Weight.........................4.7 lbs. (2,1 kg)

This machine is made to clean

drains. If properly used it will not damage a

drain that is in good condition and properly designed, constructed and maintained. If the drain

is in poor condition, or has not been properly

designed, constructed and maintained, the

drain cleaning process may not be effective or

could cause damage to the drain. The best

way to determine the condition of a drain before

cleaning is through visual inspection with a

camera. Improper use of this drain cleaner can

damage the drain cleaner and the drain. This

machine may not clear all blockages.

Figure 1 – Power-Spin

Machine Inspection

WARNING

Before each use, inspect your drain

clean ing machine and correct any problems to reduce the risk of serious injury

from electric shock, twisted or broken

cables, chemical burns, infections and

other causes and prevent drain cleaner

damage.

1. Clean any oil, grease or dirt from all

equipment, including handles and controls. This aids inspection and helps prevent the machine or control from slipping

from your grip. Clean any debris from

the cable and drum.

2. Inspect the drain cleaner for the following

items:

NOTICE

Cable End

Crank

Drum

Handle

Tri gg er

Page 5

7

POWER-SPIN®Drain Cleaner

Figure 2 – Removing Crank Handle From Power-

Spin

8. If needed, take appropriate steps to access the drain to be cleaned.

• For many drains, the cable can be

threaded through the cross hairs in

the drain

(See Figure 3).

• For a sink with a pop up drain plug:

Remove lift rod and drain plug

(See

Figure 4)

. Be sure to place a container

under the clean out or trap to catch

any water that may come out.

• For other sinks a clean out plug or

trap may need to be removed

(See

Figure 5.)

Be sure to place a container under the clean out or trap to

catch any water that may come out.

• For bathtubs, never try to go through

the drain, this will damage the cable.

Remove the overflow plate and any

mechanism to access the drain

(See

Fi gure 6)

.

9. Determine if the Power-Spin can be

placed within 4" (100 mm) of the drain

other liquid barrier gloves under the

leather gloves.

1. Check work area for:

• Adequate lighting

• Clear, level, stable, dry place for machine and operator. Do not use the machine while standing in water. If needed,

remove the water from the work area.

2. Inspect the drain to be cleaned. If possible, determine the access point(s) to the

drain, the size(s) and length(s) of the

drain, distance to mainlines, the nature of

the blockage, presence of drain cleaning

chemicals or other chemicals, etc. If

chemicals are present in the drain, it is

important to understand the specific

safety measures required to work around

those chemicals. Contact the chemical

manufacturer for required information.

3. Determine the correct drain cleaning

equipment for the application. The PowerSpin is made for:

• Up to 1

1

/2"(40 mm) lines up to 25' (7,6 m)

long with

1

/4"(6 mm) cable.

• Drain cleaners for other applications can

be found by consulting the Ridge Tool

Catalog, on line at www.RIDGID.com or

by calling RIDGID Tech nical Services at

800-519-3456.

4. Make sure machine has been properly inspected.

5. If needed, place protective covers in the

work area. The drain cleaning process

can be messy.

6. If using the Power-Spin by hand, make

sure that the crank is present and firmly

attached.

7. If using the Power-Spin with a battery

powered drill, remove the crank from the

back of the drum by pressing the tabs on

the either side

(See Figure 2)

. Securely

attach the chuck of the drill to the drum

shaft.

Drain

Plug

Cap

Nut

Lift Rod

Set

Screw

Figure 3

Figure 5

Figure 4

Cross

Hairs

Clean-out

Plug

Figure 6

Warning

Label

Drum Shaft

Page 6

opening. If not, the drain opening will

need to be extended using similar size

pipe and fittings so that the Power-Spin

can be placed within 4" (100 mm) of

the drain opening

(See Fi gure 7)

.

Improper cable support can allow the

cable to kink or twist and damage the

cable/fixture or injure the operator.

Figure 7 – Example of Extending Drain to Within

4" (100 mm) of Drain Opening

Operating Instructions

WARNING

Always wear eye protection to protect

your eyes against dirt and other foreign

objects.

When cleaning drains that might contain hazardous chemicals or bacteria,

wear appropriate protective equipment,

such as goggles, face shields or respirators, to prevent burns and infections.

For extra protection from chemicals and

bacteria on the machine and in the work

area, wear latex, rubber or other liquid

barrier gloves under the leather gloves.

Follow operating instructions to reduce

the risk of injury from twisted or broken cables, cable ends whipping around,

machine tipping, chemical burns, infections and other causes.

1. Make sure that the work area is free of

bystanders and other distractions.

2. Assume a proper operating position that

will allow

• Good balance and not require any

over reaching.

• Control of the drain cleaner (and drill if

used).

• Ability to maintain the unit 4" (100 mm)

or less from the drain opening.

This will help maintain control of the cable

and machine.

3. Pull cable out of the drum and push into

drain as far as it will go. At least one foot

of cable must be in the drain so that the

cable will not come out and whip around

when the cable starts turning.

4. If using a battery powered drill, confirm

set to low speed (less than 500 rpm)

and with dry hands insert the battery,

but do not place you finger on the drill

switch yet.

5. Make sure that the drain cleaner is within

4" (100 mm) of the drain opening, and

maintain that distance throughout the

cleaning process. This helps to prevent

twisting and kinking of the cable.

6. Place one hand on the drain cleaner handle with one or two fingers on the trigger

and the other hand on the drill grip or

the crank.

7. Turn the drum clockwise (as marked with

an arrow on the back of the drum,

see

Figure 2

) If using the Power-Spin manu-

ally, use the crank

(see Figure 8)

. If using

a drill, operate it in the forward direction.

To feed the cable into the drain, squeeze

the trigger firmly.

Figure 8 – Power-Spin Used By Hand

8

POWER-SPIN®Drain Cleaner

Page 7

Figure 8A – Power-Spin Powered By Battery

Drill

8. Continue to advance the cable until the resistance is encountered. Carefully work

the cable through the blockage. Do not

force the cable – if the cable stops turning,

it is not cleaning the drain. It may be necessary to spin the cable without advancing

it, or advancing the cable very slowly. This

will help to break up the blockage.

9. If the cable becomes stuck in the blockage, do not continue turning the drum.

Continuing to turn the drum may cause

the cable to twist and kink. It may be

necessary to back the cable out of the

blockage by turning the drum in reverse.

In some cases, it may be possible to pull

the cable and the blockage out of the

drain by hand. If this is done, be careful to

not damage the cable. Remove the blockage from the cable, feed cable back into

the drum, and continue cleaning the drain

as detailed above.

10. Once the blockage is broken up and drain

is flowing, if possible, turn the water on to

flush any debris down the drain.

11. Continue to clean the rest of the drain.

Pay attention to how far the cable has

gone. Do not overrun the cable into a

larger drain. This can cause the cable to

knot up or cause other damage.

12. Once the drain has been cleaned, turn

the drum counterclockwise while squeezing the drain cleaner trigger to retract

the cable. Pay close attention, as the

cable may lodge in a blockage while

being retracted.

13. Release the drain cleaner trigger and

stop turning the drum when the end of

the cable nears the drain opening. Do

not pull the cable end from drain while it is

9

POWER-SPIN®Drain Cleaner

rotating. The cable can whip around and

could cause serious injury.

14. Several passes through a line are recommended for complete cleaning. If

needed, repeat the above procedure.

15. Pull any remaining cable from the line

by hand and push the cable into the

drum.

Maintenance

Instructions

WARNING

Always wear safety glasses and leather

gloves when performing any maintenance.

Drill should be removed from drain

cleaner before any maintenance is performed.

Cleaning

Cable, drum and AUTOFEED should be thoroughly flushed with water after every use to

prevent the damaging effects of chemicals

and sediment. Clean exterior as needed with

hot soapy water and/or disinfectants. Drain

drum by tipping forward after every use and

cleaning.

Installing Replacement Cable

To Remove Cable From Drum

1. Pull out excess cable from drum.

2. Remove 4 screws on back of drum.

3. Loosen clamp screw and pull end of old

cable from drum and discard.

To Install Replacement Cable

1. Replacement

1

/4" (6 mm) x 25' (7,6 m)

MAXCORE

®

cables are available under

catalog number 42163.

2. To make cable installation easier, completely uncoil new cable before proceeding. Use caution when removing the

cable from the package. The cable is

under tension and could strike the user.

3. Insert about 12" (0,3 m) of cable through

the front rollers and guide tube into the

drum.

4. Push end of cable into holder and under

clamp screw and washer. Tighten clamp

screw

(see Figure 9)

.

Page 8

Figure 9 – Installing Cable End Into Holder

5. Replace drum back and retighten the 4

screws.

6. Feed cable into drum.

10

POWER-SPIN®Drain Cleaner

PROBLEM POSSIBLE REASONS SOLUTION

Cable kinking or breaking.

Cable won’t feed.

Troubleshooting

Cable is being forced.

Cable used in incorrect pipe diameter.

Motor switched to reverse.

Cable exposed to acid.

Cable worn out or damaged.

Cable not properly supported.

Cable bearings are dirty or greasy.

AUTOFEED not fully engaged.

Do Not Force Cable! Let the auger do

the work.

Do not use in lines over 11/ " (40 mm).

Use reverse only if cable gets caught in

pipe or to retract cable.

Clean cables routinely.

If cable is worn or damaged, replace it.

Support cable properly, see instructions.

Clean cable and bearings with hot,

soapy water.

Be aware and squeeze trigger harder.

2

Clamp

Screw

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 9

What is covered

®

RIDGID

tools are warranted to be free of defects in workmanship and material.

How long coverage lasts

This warranty lasts for the lifetime of the RIDGID

product becomes unusable for reasons other than defects in workmanship or material.

What we will do to correct problems

Warranted products will be repaired or replaced, at RIDGE TOOL

charge; or, if after three attempts to repair or replace during the warranty period the product

is still defective, you can elect to receive a full refund of your purchase price.

What is not covered

Failures due to misuse, abuse or normal wear and tear are not covered by this warranty. RIDGE

TOOL shall not be responsible for any incidental or consequential damages.

How local law relates to the warranty

Some states do not allow the exclusion or limitation of incidental or consequential damages,

so the above limitation or exclusion may not apply to you. This warranty gives you specific

rights, and you may also have other rights, which vary, from state to state, province to

province, or country to country.

No other express warranty applies

This FULL LIFETIME WARRANTY is the sole and exclusive warranty for RIDGID

ucts. No employee, agent, dealer, or other person is authorized to alter this warranty or make

any other warranty on behalf of the RIDGE TOOL COMPANY.

FULL LIFETIME

WARRANTY

®

tool. Warranty coverage ends when the

Against Material Defects

& Workmanship

’S option, and returned at no

®

prod-

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Printed in U.S.A. 5/12 999-999-436.10

EC39039 REV. A

Loading...

Loading...