Page 1

Page 2

Table of Contents

Section Page

Table of Contents ...........................................2

Safety Instructions For Miter Saw ................3

Safety Signal Words ....................................3

Before Using The Saw ..... .... ... .....................3

When Installing Or Moving The Miter Saw ....4

Before Each Use ............................................4

To Reduce the Risk of Injury From Jams, Slips

Or Thrown Pieces ........................................5

Plan Ahead To Protect Your Eyes, Hands, Face

and Ears ......................................................5

Dress For Safety ............................................6

Preparing to Make Cut ...................................6

Plan The Way You Will Hold The Workpiece

From Start To Finish. ...................................7

Whenever Saw Is Running ............................7

Before Leaving The Saw ...............................8

Glossary of Terms for Woodworking ...........8

Motor Specifications and Electrical Require-

ments .......................................................... 9

Power Supply and Motor Specifications ......9

General Electrical Connections ...................9

110-120 Volt, 60 Hz. Tool Information .........9

Motor Safety Prote c tio n .............................10

Wire Sizes ..................................................10

Unpacking and Checking Contents ............11

Tools Needed ............................................11

Unpacki ng ..... ........... ............ ........... ...........11

List of Loose Parts .....................................11

Getting to Know Your Miter Saw .................12

Assembly .......................................................13

Installing or Removing the Blade ...............13

Assembling Dust Bag ..................................15

Workpiece Clamp Installation ....................15

Four Basic Saw Controls .............................15

Alignment (Adjustments) .............................17

Miter Lock Lev er Ad justm e nt .......... .... .... ...20

Bevel Lock Lever Adjustment ....................20

Bevel Pivot Movement/Adjustment ............21

Mounting The Miter Saw ..............................22

Safety Instructions for Basic Saw

Operations ........ ............ .... ... .... .... ...........23

Before Each Use ..........................................23

To Reduce the Risk of Injury From Jams, Slips

Or Thrown Pieces ......................................23

Plan Ahead To Protect Your Eyes, Hands,

Face and Ears ............... ..........................24

Dress For Safety ..........................................24

Preparing to Make the Cut ...........................25

Section Page

Whenever Saw Is Running .. ........................26

Before Leaving The Saw: ............................26

Basic Saw Operations ..................................27

Making Common Slide Compound Cuts ... 27

Slide Cutting ............................................. 27

Chop Cutting ............................................. 28

Body and Hand Posit ion ........... ................ 28

Miter Cut ................................................... 29

Miter Scale Usage ..................................... 29

Bevel Cut .................................................. 29

Sliding Fence ............................................ 29

Vernier Bevel Scale Operation: ................ 29

Compound Cut ... .... ...................... .... .... .... . 30

Cutting Compound Miters on Picture Frames

and Boxes ............................................... 30

Cutting Bowed Material ............................. 30

Workpiece Clamp Usage .......................... 31

Workpiece Support ................................... 32

Auxiliary Fenc e ..................... .... ... .... .... ..... 32

Rough Cutting A Dado .............................. 33

Helpful Hints When Cutting Compound

Miters ....... ............ ........... ........... ........ ..... 33

Cutting Base Moldings .............................. 33

Cutting Crown Moldings ............................ 34

Two Methods of Cutting Crown Molding ... 34

Laser System ..................................... 38

Mounting the Laser System ...................... 38

Operation ... ............... ................... ............. 4 0

Changing Batteries ................................... 41

Maintenance and Lubrication .....................42

Maintenance ............................................. 42

Lubrication ................................................ 43

Motor Belt Tension .................................... 43

Accessories ..................................................44

Recommende d Ac cess o rie s ............ .... .... . 4 4

Basic Blade Requirements ....................... 44

Prohibited Accessories ................................44

Using Carbide Tipped Blades .....................44

Troubleshooti ng Guide ................................45

General .. ................... ................... ............. 4 5

Motor ...... ....................... .... .... .... ... ............. 46

Wiring Diagram .............................................46

Trouble S ho o tin g of Brake by Qual ifi ed Ser-

vice Person Only .................................... 46

Notes ..............................................................47

Repair Parts ...................................................48

Notes ..............................................................59

2

Page 3

Safety Instructions For Miter Saw

Safety is a combination of common sense, staying alert and knowing how

your miter saw works. Read this manual to understand this miter saw.

Safety Signal Words

DANGER: means if the safety infor-

mation is not followed someone will

be seriously injured or killed.

Before Using The Saw

WARNING: Some dust created by

power sa ndin g, sa win g, g rin ding ,

drilling, and other construction

activities contains chemicals

known (to the State of California)

to cause cancer, birth defects or

other repr od uc ti v e harm. Some

examples of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks

and cement and other masonry

products, and

• Arsenic and chromium from

chemically-treated lumber.

Yo ur risk from these exposures

varies, depending on how often

you do this type of work. To

reduce your exposure to these

chemicals: work in a well ventilated area, and work with

approved safety equipment,

such as those dust masks that

are specially designed to filter

out microscopic particles.

WARNING: To reduce the risk of

mistakes that could cause serious, permanent inju ry, do not

plug the miter saw in until the following steps have been satisfactorily completed.

• Completely assemble and align

saw. (See “Assembly” and “Alignment” sections within.)

• Learn the use and function of the

ON-OFF switch, upper and lower

blade guards, miter lock lever , bevel

lock lever , co ver plate stop scre w,

depth adjustment clamp and head

WARNING: means if the safety information is not followed someone

could be seriously injured or killed.

CAUTION: means if the safe ty infor-

mation is not followed someone ma y

be injured.

hold down, fence slide lock knobs

and workpiece clamp. (See “Getting to Know Your Miter Saw” section within.)

• Review and understand all safety

instructions and operating procedures in this manual.

• Review the maintenance methods

for this miter saw. (See “Maintenance” section within).

Find and read the following labels on

the miter saw.

3

Page 4

Safety Instructions for Miter Saws (continued)

When Installing Or Moving The Miter Saw

Before moving the saw, lock the

miter, bevel, slide and power head

posi ti on s. Unp lu g th e po wer cor d .

To reduce the risk of back injury, get

help when you need to lift the saw.

Never carry the tool by the cord or

power head trigger handle. Damage

to insulation could cause an electric

shock. Damage to wire connections

could cause a fire.

Reduce the Risk of Dangerous

Environment. Use the miter saw in a

dry, lo ca tion, protected from rain.

Keep work area well lighted.

Place the saw so neither the user nor

bystanders are forced to stand in line

with the blade. Thrown debris could

injure people in its path.

To reduce the risk of injury from

unexpected saw movement:

• Place the miter saw on a firm level

surface where there is plenty of

room for handling and properly sup-

porting the workpiece.

• Support the miter saw so the tabl e is

level and the saw does not rock.

• Bolt, screw or clamp the saw to its

support.

• Never Stand On Tool. Serious

injury could occur if the tool tips or

you accidentally hit the cutting tool.

Do not store anything above or near

the tool where anyone might stand

on the tool to reach them.

To reduce the risk of injury or

death from electrical shock:

• Make sure your fingers do not touch

the plug’s metal prongs when plugging or unplugging the miter saw.

• This TOOL IS DOUBLE INSULATED to give you added protection. Double insulation does not take

the place of normal safety precautions when operating this tool. When

servicing this double insulated tool,

use only identical parts.

Before Each Use

Inspect your miter saw.

Disconnect The Miter Saw. To

reduce the risk of injury from accidental starting, unplug the saw, before

changing the setup, changing the

blade or adjusting anything.

Compare the direction of rotation

arrow on the guard to the direction

arrow on the blade. The blade teeth

should always point downward at the

front of the saw.

Tighten the arbor screw.

Tighten the cover plate stop screw.

Check For Damaged Parts. Check

for:

• Proper Alignment of moving parts,

• Damaged electric cords,

• Binding of moving parts,

• Broken parts,

• Stable mounting,

• Function of arm return spring and

lower guard: Push the arm all the

way down, then let it rise up until it

stops by itself. Check the lower

guard to see if it closed fully. If it did

not, follow the instructions in the

“Troubleshooting” section.

• Smooth, solid movement of sliding

assembly.

• Other conditions that may affect the

way the miter saw works.

4

Page 5

If any part of t his miter saw is missing,

bent, or broken in any way, or any

electrical parts don't work, turn the

saw off and unplug it. Replace damaged, missing, or failed parts before

using the saw again.

Keep Guards In Place, in working

order, and in proper adjustment.

Maintain Tools With Care. Keep the

miter saw clean for best and safest

performance. Follow instructions for

lubricating. DON’T put lubricants on

the blade while it’s spinning.

Remove Adjusting Keys And

Wrenches from tool before turning it

on.

T o Reduce the Risk of Injury From Jams, Slips Or Thrown Pieces

• Use Only Recommended Accessories. (See “Accessory” section

within.) Consult this owner’s manual

for recommended accessories. Follow the instructions that come with

the accessories. The use of

improper accessories may cause

risk of injury to persons.

• Choose the right 12-inch diameter

blade for the saw and the material

you plan to cut.

• Make sure the blade is sharp,

undamaged and properly aligned.

With the saw unplugged, push the

power head all the way down. Hand

spin the blade and check for clearance. Tilt the power head to 45

degrees left and right bevel and

repeat the check. If the blade hits

anything, make the adjustments

shown in “Alignment (Adjustments)”

section.

• Make sure the blade, arbor collars

and laser system are clean.

• Make sure the arbor collars' and

laser discs’ recessed side s are facing the blade.

• Using the 1/4” hex end of combination wrench (supplied) or a 1/2-inch

box end wrench, make sure the left

hand thread arbor screw is firmly

tightened counterclockwise.

• Make sure all clamps and locks are

tight and there is no excessive play

in any parts.

• Keep Work Area Clean. Cluttered

areas and benches invite accidents.

Floor must not be slippery.

To reduce the risk of burns or other

fire damage, never use the saw near

flammable liquids, vapors or gases.

Plan Ahead To Protect Your Eyes, Hands, Face and Ears

Know Your Miter Saw. Read and

understand the owner’s manual and

labels affixed to the tool. Learn its

applications and limitations as well as

the specific potential hazards peculiar

to this tool.

To reduce the risk of injury from accidental contact with moving parts,

don’t do layout, assembly, or setup

work on the miter saw while any parts

are moving.

To Red uce the Risk of Accidental

Starting. Make sure switch is “OFF”

before plugging miter saw into a

power outlet.

Plan your work.

Use The Right Tool. Don’t force tool

or attachment to do a job it was not

designed to do. Use a different tool

for any workpiece that can’t be held in

a solidly braced, fixed position.

5

Page 6

Safety Instructions for Miter Saws (continued)

CAUTION: Because of the slidin g

action of this saw, this machine

is not designed for cutting metals. Use this miter saw to cut

only wood and wood like products. Other materials may shatter, bind on the blade, start fires

or create other dangers.

Dress Fo r Safety

Any power tool can throw foreign

objects into the eyes. This can result

in permanent eye damage. Wear

safety goggles (not glasses) that

comply with ANSI Z87.1 (or in Canada CSA Z94.3-99) shown on package. Everyday eyeglasses have only

impact resistant lenses. They are not

safety glasses. Safety goggles are

available at many local retail stores.

Glasses or goggles not in compliance

with ANSI or CSA could seriously hurt

you when they break.

Do not wear loose clothing, gloves,

neckties or jewelry (rings, wrist

watches) They can get caught and

draw you into moving parts.

• Wear nonslip footwear.

• Tie back long hair.

• Roll long sleeves above the elbow.

• Noise levels vary widely. To reduce

the risk of possible hearing damage,

wear ear plugs or muffs when using

miter saw for hours at a time.

• For dusty operations, wear a dust

mask along with safety goggles.

Preparing to Make Cut

Inspect Your Workpiece. Make sur e

there are no nails or foreign objects in

the part of the workpiece to be cut.

Plan your work to reduce the risk

of thrown pieces caused when the

workpiece binds on the blade and

is torn from your hands.

Plan how you will make the cut.

Always:

• Make sure the blade is not spinning.

• Raise the blade.

• Slide the saw out above the front

edge of the workpiece before starting saw, and

• Push the sawblade down on top of

the wood and back toward the rear

of the saw to make the cut.

DANGER: NEVER pull the saw

toward you during a cut. The

blade can suddenly cli mb up on

top of the workpiece and force

itself toward you .

6

Page 7

Plan The Way You Will Hold The Work piece From Start To Finish.

• Avoid awkward operations and hand

positions where a sudden slip could

cause fingers or hand to move into

the blade.

• Don’t Overreach. Keep good footing and balance.

• Keep your face and body to one

side of sawblade, out of line with a

possible thrown piece.

• Cut only one workpiece at a time.

• Never cut Freehand:

- Brace your workpiece solidly

against the fence and table top so

it will not rock or twist during the

cut.

-Make sure there’s no debris

between the workpiece and its

supports.

- Make sure no gaps between the

workpiece, fence and table will let

the workpiece shift after it is cut in

two.

• Keep the cut off piece free to move

sideways after it's cut off. Otherwise,

it could get wedged against the

blade and thrown violently.

• Clear everything except the workpiece and related support devices

off the table before turning the miter

saw on.

• Secure W o rk. Use clamps or a

vise to help hold the wor k wh en it’s

practical.

Use extra caution with large, very

small or awkward workpieces:

• Use extra supports (tables, saw

horses, blocks, etc.) for any workpieces large enough to tip when not

held down to the table top.

• Never use another person as a substitute for a table extension, or as

additional support for a workpiece

that is longer or wider than the basic

miter saw table or to help feed, support or pull the workpiece.

• Do not u se thi s s a w to cut p i eces

too small to let you easily hold the

work while you keep the thumb side

of your index (pointer) finger against

the outside edge of the fence.

• When cutting irregularly shaped

workpieces, plan your work so it will

not slip and pinch the blade and be

torn from your hands. A piece of

molding, for example, must lie flat

against the table or fence, or be held

by a fixture or jig that will not let it

twist, rock or slip while being cut.

• Properly support round material

such as dowel rods, or tubing. They

have a tendency to roll while being

cut, causing the blade to "bite." To

avoid this, always use a fixture

designed to properly hold your

workpiece.

Whenever Saw Is Running

WARNING: Do n't al low famil iarity

(gained f rom f requent use of

your miter saw) cause a careless

mistake. A careless fraction of a

second is enough to cause a

severe injury.

Before starting your cut, observe the

miter saw while it runs. If it makes an

unfamiliar noise or vibrates excessively , stop immediately. T urn the saw

off. Unplug the saw. Do not restart

until finding and correcting the problem.

Keep Children Away. Ke ep all visitors a safe distance from the miter

saw. Make sure bystanders are clear

of the miter saw and workpiece.

7

Page 8

Safety Instructions for Miter Saws (continued)

Never confine the piece being cut

off. Never hold it, clamp it, touch it, or

use length stops against it while the

blade is spinning. It must be free to

move sideways on its own. If confined, it could get wedged against the

blade and be thrown violently.

Let the blade reach full speed

before cutting. This will help avoid

thrown workpieces.

Don’t Force Tool. It will do the job

better and safer at its designed rate.

Feed the saw into the workpiece only

fast enough to let the blade cut without bogging down or binding.

Before Leaving The Saw

Never Leave Tool Running Unattended. Turn power off. Wait for all

moving parts to stop.

Make Workshop Child Proof. Install

a padlock through the hole provided

Before freeing jammed material:

• Turn miter saw “OFF” by releasing

trigger switch.

• Wait for all moving parts to stop.

• Unplug the miter saw.

After finishing a cut:

• Keep holding the power head down.

• Release the switch, and wait for all

moving parts to stop before moving

your hands or raising power head.

• If blade doesn’t stop within 6 seconds, unplug the saw and follow the

instructions in the Trouble Shooting

section for fixing the blade brake

before using the saw again.

in the trigger to prevent unauthorized

usage. Lock the shop. Disconnect

master switches. Store tool away

from children and others not qualified

to use the tool.

Glossary of Terms for Woodworking

Arbor

The shaft on which a cutti ng tool is

mounted.

Bevel Cut

An angle cutting operation made through

the face of the workpiece.

Compound Cut

A simultaneous bevel and miter cutting

operation.

Crosscut

A cutting operation made acr oss the width

of the workpiece.

Dado

A non-through cut which produces a

square sided notch or

piece

Freehand

Doing a cut without holding the workpiece

against both the table and fence. Most

workpieces can be held down with your

trough in the work-

hand. Large or wide pieces should be

clamped to the fenc e or table.

Gum

A sticky, sap based residue from wood

products.

Heel

Misalignment of the blade.

Kerf

The amount of material removed by the

blade in a throug h cut or the slot produced

by the blade in a nonthrough or parti al cut.

Miter Cut

An angle cutting operation made across

the width of the work piece.

Offal

Unsecured peice of material after making

cut.

Resin

A sticky, sap based substance that has

hardened.

8

Page 9

Revolutions Per Minute (RPM)

The number of turns complet ed by a spinning object in one minute.

Sawblade Path

The area of the workpiece or t able top

directly in line wit h either the travel of the

blade or the part of the workpiece which

will be, or has been, cut by the blade.

Set

The distance that the tip of the sawblade

tooth is bent (or set ) outward from the

face of the blade.

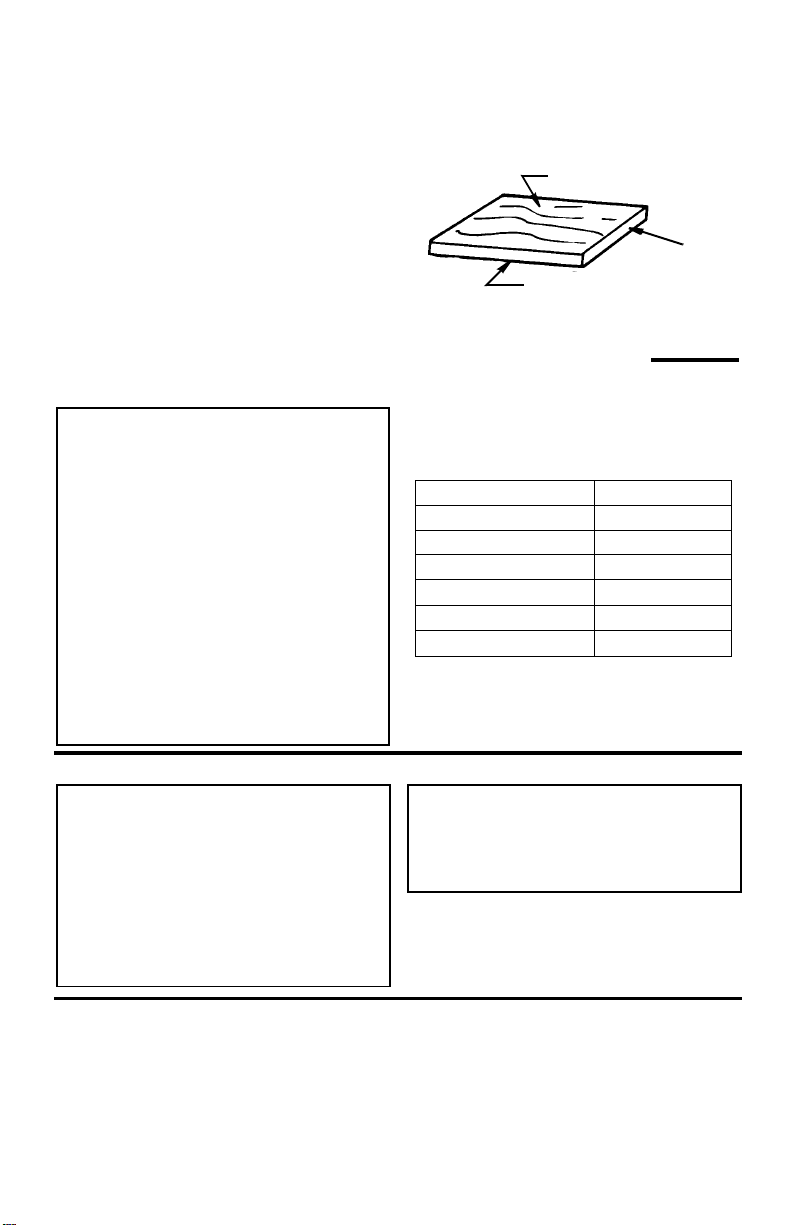

Workpiece

The item on which the cutting operation is

being performed. The surfaces of a workpiece are commonly referred to as faces,

ends, and edges.

Face

Edge

Motor Specificat ions and Electrical Requirements

Power Supply and Motor Specifications

WARNING: To reduce the risk of

electrical hazards, fire hazards

or damage to the tool, use

proper circuit protection. Your

tool is wired at the factory for

operation using the voltage

shown. Connect tool to a power

line with the appropriate voltage

and a 15-amp branch circuit.

Use a 15-amp time delay type

fuse or circuit breaker. To

reduce the risk of shock o r fire,

if powe r cord is wor n or cut, or

damaged in any way, have it

replaced immediately.

The A-C motor used on this tool is a nonreversibl e universal type, hav ing the following speci fi cations:

Voltage 120

Amperes 15

Hertz (Cycles) 60

Phase Single

RPM 4000

Shaft Rotation Clockwise

Brake Automatic

End

General Electrical Connections

DANGER: To reduce the risk of

electrocution:

1. Use only identical replacement

parts when servicing. Servicing should be performed by a

qualified service technician.

2.Do not use in rain or where

floor is wet.

110-120 Volt, 60 Hz. Tool Information

Double Insulated

The miter saw is double insul ated to provide a double layer of ins ulation between

you and the tool’s electrical system. All

exposed meta l parts are isolated from the

WARNI NG Do not permit fingers

to touch the terminals of plug

when installing or removing the

plug to or from the outlet.

If power cord is cut, or damaged in any

way, have it replaced immediately.

internal metal motor components with

protecti ng insulation.

9

Page 10

Motor Specifica tio ns a nd Ele ctrical Requirements (continued)

Polarized Plug

Y our unit has a plug that looks like the one

shown on next page.

To reduce the risk of electrical shock, this

appliance has a po lari zed plug (one blade

is wider than the other) . This plug wi ll fit in

a polarized outlet only one way, if the plug

does not fit fully in the out let, reve rse plug.

If it still does not fit, contact a qualified

electrician to install the proper outlet. Do

not change the plug in any way.

Motor Safety Protection

1. Connect this tool to a 120v, 15-amp

branch circuit wi th a 15-amp time delay

fuse or circuit br eaker. Using the wrong

size fuse can damage the motor.

2. If the motor won't start, release the trigger switch immediately . Unplug The

Tool. Check the saw blade to make

sure it turns free ly. If the blade is free,

try to start the motor again. If the motor

still does not st art, refer to the "Motor

Troubleshooting Chart."

3. If the motor suddenly stalls while cutting wood, release the trigger switch,

unplug the too l, and f ree the blade f rom

the wood. The motor may now be

restart ed and the cut finished.

4. Fuses may "blow" or circui t br eakers

may trip frequen tl y if:

WARNI NG: Double insulation

does not take the place of normal

safety precautions when operating th is tool .

a.Motor Is Overloaded-Overloading

can occur if you cut too rapidly or

make too many start/stops in a short

time.

b. Line voltages are more than 10%

above or below the nameplate voltage. For heavy loads, however, the

voltage at m ot o r term i na ls m ust equal

the voltag e specified on nameplate.

c. Improper or du ll saw blades are used.

5. Most motor troubles may be traced to

loose or incorrect connections, overload, low voltage (such as small size

wire in the supply circui t) or to overly

long supply circuit wire. Always check

the connections, the load and the supply circu it whe never motor doesn' t wor k

well. Check wire sizes and length with

the Wire Size Chart below.

Wire Sizes

NOTE: Make sure the proper extension

cord is used and is in good condit ion. The

use of any extension cor d wil l cause

some loss of power. T o keep this to a minimum and to prevent overheating and

motor burn-out, use the t able below to

determine the min imum wire size (A. W. G . )

extension cord.

For circuits that are farther than 100 feet

away from electrical service box, the wire

size must be incr eased proportionatel y in

order to deliver ample voltage to the saw

motor.

Extension Cord

Length

0-25 F t .

26-50 Ft.

10

Wire Sizes

Required for 120V

(A.W.G.)

14

12

Page 11

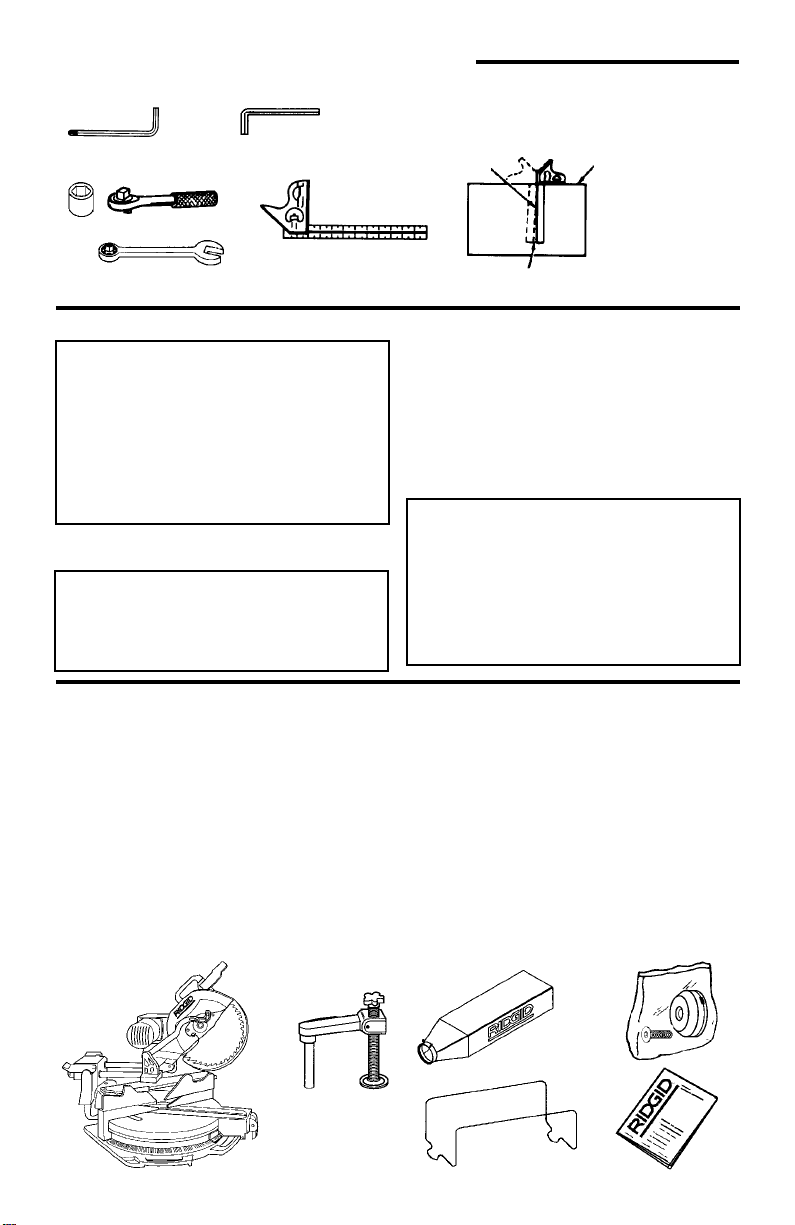

Unpacking and Checking Contents

Tools Needed

Combination Square Must be True

Draw Light

Hex “L” Wrench

1/4" (su pplied)

19 mm Socket

Combination

Wrench (2) 12 mm

Hex “L” Wrench

4mm, 5mm, 6mm

Combination Square

Line on Board

Along this Edge

Should be no Gap or Overlap when Square

is Flipped Over in Dotted Position

Straight Edge of

Board 3/4" Thick

This Edge Must

be Perfectly

Straight

Unpacking

WARNING: To reduce the risk of

injury from unexpected starting

or electrical shock, do not plug

the power cord into a power

source outlet during unpacking

and assembly. This cord must

remai n unpl ug ge d whe n ever yo u

are working on the saw.

This Miter Saw is shipped complete in

one box.

WARNING: Although comp act ,

this saw is heavy. To reduce the

risk of back injury, get help whenever you have to li ft the saw.

List of Loose P arts

NOTE: Before beginning ass embly , che ck

that all parts are included. If you are missing any part, do not assem ble the saw. Email us at info@ridgidwoodworking.com if

any parts are damaged or mi ssing.

Sometimes small parts can get lost in

packaging material. Do not throw away

any packaging until saw is put together.

Check packaging for missing parts before

contacting RIDGID. A complete parts list

(Repair Parts) is at the end of the manual .

1. Before removi ng the miter saw from t he

carton tighten the slide lock knob to

guard against sudden movement.

2. Remove the miter saw from the carton by

lifting the saw with the carrying handle.

3. Place the saw on a secure, stat ionary

work surface and look the saw over

carefully.

WARNING: If any part is missing

or damaged, do not plug the saw

in until the missing or dama ge d

part is correctly replaced. To

avoid electric shock, use only

identical replacement parts when

servicing double insulated tools.

Use the list to identify the number of the

missing par t .

The following parts are included:

Part or Assembly Qty.

A Basic Saw Assembly .......................... 1

B Work p ie ce C la m p ..... ... ....................... 1

C Dust Bag............................................. 1

D Dust Bag Frame.................................. 1

E Laser System Bag Asm ...................... 1

F Operators Manual................ .......... .....1

11

C

D

E

F

A

B

Page 12

Getting to Know Your Miter Saw

1

10

2

3

5

4

6

11

12

24

20

25

21

19

18

9

7

17

8

16

1.Warning Label

2.Upper Blade Guard - Supports the

motor, handle, switch , blade an d lower

guard.

3. Lower Blade Guard - The blade g uard

helps protect your hands from the

blade in the raised position. To reduce

the risk of binding on the workpiece, it

retracts as the blade is lowered.

4.Cover Plate - Ho lds the lo wer guard

and is attached to upper guard. Prevents the arbor sc rew from backing

out when proper ly attached with the

cover plate stop screw.

5.Cover Plate Stop Screw - When this

screw is loosened, the cover plate is

rotated to the rear, allowing for blade

removal/replacement.

6.Sliding Fence(s) - Fence(s) sli de left/

right to provide maximum support for

the workpiece.

7. Table - Sits in base, supports pivot

and allows for approximat ely 62° miter

left and right.

8.Base - Supports table, hol ds accessories and allows for work bench or l eg

set mounting.

9. Miter Indicator - Indicates the angle

(miter) the blade is set at .

10.Bevel Lock Lever - Locks the miter

23

13

14

26

15

saw at a desired bevel angle.

11.Top Carrying Handle - Convenient

way to transport saw.

12. Slide Tube(s) - Allow the blade to slide

for cutting various workpiece widths.

13.Slide Lock Kn ob - Prevent s the saw’s

sliding motion by locking the carriage

in place.

14.Slide Fence Lock Knob - Locks

fence at correc t cutting position.

15.Combination Wrench - 1/4" Hex “ L”

wrench.

16. Miter Lock Lever/Miter Index

Thumbwheel - The miter lock lever

securely locks the saw at a desired

miter angle. Index points have been

provided at 0°, 15°, 22.5°, 31.6° (Crown

molding), 45°, 60° Left and Right.

17.The Repea t-A-Cut™ - Surfac e allows

pencil marks to be made and easily

erased for duplicate cuts.

18.Depth Adjustment Clamp and Head

Hold Down - Limits the saw’s down-

ward travel for use when cutting

dadoes and locks the saw in the lowered positi on for com pact storage.

19.Arbor Lock Pin - Allows the user to

keep blade from ro tating while tight ening or loosening arbor during blade

replacement or removal.

12

22

Page 13

20. Switc h In te rlock Bu tton - Prevents

trigger switch from being accidentally

engaged.

21.On/Off Trigger Switch - To prevent

the trigger from being accidentally

engaged, a loc k-of f butto n is provid ed.

To start the tool, press in the swit ch

interlock button and squeeze the trigger. Release the trigger to stop the

miter saw. Install a padlock through

the hole in the tri gger to prevent unauthorized use.

22.Bevel Index Pin - This pin provides

Assembly

indexes at 0° and 22.5°, CM, and 45°

left and right.

23.Front Carry Handles - Convenient

way to transport the saw.

24.Workpiece Clamp - Helps to hold

workpiece in position for precise cutting. Quick release allows easy movement for workpiece width adjustment.

Pin of clamp fits in either hole in rear

at fence.

25.Bevel Indicator - Indicates the angle

(bevel) the blade is set.

26.Cord Wra p Brackets

WARNING: For yo ur own safety,

never connect plug to power

source outlet until all assembly

steps are complete, and you

have read and understood the

safety and operational instructions.

Installing or Removing the Blade

WARNING: To reduce the risk of

injury from a thrown workpiece

or thrown pieces of blade, do not

use a blade larger or smaller than

12" diameter.

WARNING: To reduce the risk of

injury from u nexp ected starting,

unplug the saw whenever you are

removing or installing the blade .

NOTE: See “Mounting the Laser System”

section of the owners man ual for directions on installing the laser system.

1.Unplug t he saw from the outlet. Cutting head is up.

2.Rotat e the l ower blade g uard by hand.

Loosen, but do not remove, the cover

plate stop sc rew usi ng the Phi llip s en d

of combination wrench.

3.Lift the lower guard up and tilt t he

lower guard assembly back so the

arbor screw is expose d.

4.Fit 1/ 4” hex end of combination t ool in

arbor screw or use 1/ 2” box end

wrench.

Coverplate

Stop

Screw

Arbor

Screw

Blade

n

e

s

o

o

L

5.Press the arbor lock and hold it in

firmly while tu rni ng the wrench clockwise. The arbor lock will engage after

some turning of the wrench.

Arbor Lock

NOTE: The arbor screw has a left hand

thread. This helps prevent unwanted

loosening of the arbor screw during normal operation .

13

Page 14

Assembly (continued)

6. Remove the arbor screw, arbor

washer, outer blade collar, and the

blade.

NOTE: Pay attention to pieces removed,

noting their posit ion and direction they

face (see illustration). Wipe the blade collars clean of any sawd ust before i nst alli ng

the new blades.

CAUTION: To reduce the risk of

cuts from extremely sharp teeth:

Wear gloves when installing or

removing sawblade.

See cautions in “Using Carbide Tipped

Blades” section concerning inspection,

use, and selection o f car bide tipped and

other sawblades.

7.Install the new 12" blade (see recommended accessory list). Make sure

the rotation arrow on the blade

matches the clockwise rotation arrow

on the upper guard. The blade teet h

should always point downward at the

front of the saw.

8.Install the outer blade collar, blade

washer and arbor screw. Press the

arbor lock and turn the combination

wrench or the 1/2" wrench count er

clockwise to secure th e blade. T i ghten

arbor screw using mo derate f orce, but

do not overtighten.

9.Lower the l ower bl ade guard until the

slot in cover plate rests all the way

down on the cover plate stop screw.

Tighten the screw wi th th e Phil lip s end

of the combination wrench.

DANGER: Never use saw without

guard cover plate securely in

place. It keeps the arbor screw

from falling out if it accidentally

loosens, and prevents the spinning blade from coming off the

machine.

10.Be sur e the ar bor lock is released so

the blade turns freely.

Blade

Blade

Washer

(Hollowed Side

Toward Blade)

Arbor screw

(Left Hand Thread)

Sawblade

NOTE: The arbor lock can be damaged

by improper use. If the arbor l ock will not

hold, lower the blade down on to a scrap

piece of wood positioned against the

fence. This will serve as an alter nate locking means.

Collars

WARNING: Make sure the collars

are clean and properly arranged .

After installing a new blade,

make sure the blade clears the

table slot at the 0° and 45° bevel

positions. Lower the blade into

the table slot and check for any

contact with the base or turn

table structure. If blade contacts

table, seek authorized service.

If blade contacts insert, refer to “Alignment“section for adjustment.

14

Page 15

Assembling Dust Bag

1. Locate the dust bag frame and cloth

dust bag.

2. Clip the dust bag frame in place on the

slide tubes as shown.

3. Slide the cloth dust bag over the dust

bag frame.

4. Connect the dust elbow to the dus t port

on the upper blade guar d.

5. Clamp dust bag onto elbow.

NOTE: If connecting a 2- 1/2" wet/dry vac

hose to the saw, do not attach the dust

bag frame, dust bag and elbow to t he

saw. Connect the wet/dry vac hose

directly to the dust port on the upper blade

guard.

Workpiece Clamp Installation

The workpiece cl am p is used to help hold

the workpiece in the cor rect cutting position. It may be used on either the left side

of the miter saw or the right si de. Before

turning the saw on make sure the workpiece clamp does not interfere with the

cutting action of t he saw.

1. Align pin in clamp shaft with keyway in

fence. Inser t clamp shaft and rotate.

Clamp

Support

Shaft

Quick Relea se

Button

Four Basic Saw Controls

In order to properly adjust and align the

Sliding Compound Miter Saw there are

four basic controls that must be understood.

1. Miter lock lever and miter index wheel

To change the miter setting of the

blade:

a. Raise the miter lock lever.

b. Rotate the miter index wheel part ially

downward to di sengage the current

index and engage the next index.

c. Rotate the miter index wheel com-

pletely downward to bypass all miter

indexes.

d. Turn the table to the desi red miter

setting and lock the miter lock lever.

15

Page 16

Four Basic Saw Controls (continued)

2. B e vel lo c k le v e r/i n de x pin

To change the bevel setting of the

blade:

a. Pull the bevel lock lever forward .

Then rotate the bevel index pi n

downward. This will all ow the blade

to be tilted and at the sa me time “bypass” the preset bevel indexes.

b. T o engage the preset bevel indexes,

rotate the bevel lock index pin up.

c. Engage bevel index pin and/or bevel

lock lever before cutting.

3. Depth Adjustment Cam and Head Hold

Down

To release the blade a. While applying light downward pres-

sure on the handle, pull the depth

adjustment cam to th e right, then

raise the blade.

NOTE: It is not necessary to loosen

depth adjust ment knob.

b. Rotate the depth adjustment cam so

the flat on the cam is facing upward.

NOTE: Head Hold Down is for transport and storage purposes only. No

cutting operations should take place

while hold down is engaged.

To lock the blade in the lower position.

a. Pull the depth adjustment c am to the

right and lower the bl ade into the

table.

b. Rotate the depth adjustment cam

until slot engages pin on upper

guard.

4. Slide lock knob

Turn the slide lock knob counterclock-

wise to l oosen and cl ockw ise t o ti ghten.

Loosening the knob wi ll all ow the powerhead to slide back and forth. Tightening the knob will lock the powerhead in

place.

Bevel Lock

Lever

Bevel Index

Pin

Depth

Adjustment

Cam

Depth

Adjustment

Knob

16

Page 17

Alignment (Adju stm en ts)

WARNING: To reduce the risk of

injury from unexpected starting

or electrical shock, do not plug

the saw in. The power cord must

remai n unpl ug ge d whe n ev er y ou

are working on the saw.

NOTE: For best results, the saw must be

properaly aligned before mounting and

using the laser sys tem.

Step One: Repositioning Zero Clearance Blade Insert

The zero clearance bl ade insert needs to

be repositioned so it is temporarily out of

the way when al igning the blade. It may

be replaced after the blade is aligned.

1. Loosen the three screws that secure

the zero cleara nce blade insert on one

side of the blade.

2. Slide the zero clearance insert away

from th e blade as f a r as pos s i b le.

3. Retighten the three screws.

4. Repeat steps 1-3 for the opposite side

of the blade.

Step Two: Slide Tube Adj ustment

1. Place the powerhead in the 0° miter/0°

bevel index and lock head in lower position.

2. Check to see that the blade is appr oximately centered between the two zer o

clearance blade inserts. Also check for

play between the right slid e rail and th e

pivot assemb ly.

3. If adjustment is required loosen the jam

nuts on all four gi b screws as shown.

4. Loosen the top two gib screws.

5. Tighten or loosen the lower two gib

screws as required to center the blade

between the zero clearance inserts.

6. Tighten the lower two jam nuts.

7. To minimize play i n the sl ide tubes

gradually tighten the top two gib

screws while at the same ti m e sliding

the powerhead back and for th. Tighten

the top jam nuts.

Slide Rail

Pivot

Assembly

Gib Screw

17

Page 18

Alignment (Adju stm en ts) (cont inu ed)

Step Three: Blade Square to Fence

(Miter Alignment)

1. Place the blade in the 0° miter index

and lock the miter lock.

2. To check blade squareness to fence,

lock powerhead in lower position. Use

a combination square. Place the

square against the fence and next to

the blade as illustrated. Locate th e

square properl y so it does not contact

the set in the teeth of sawblade, giving

an inaccurate reading. The sawblade

body should contact the full length of

the square.

3. If blade contacts full length of square,

no alignment is necessary, skip a-c

below . If blade is not square to t he

fence, follow the alignment procedur e.

a. Remove sliding fences by loosening

fence lock knobs approximately two

turns. Sl ide fences toward blade an d

lif t u p to remove.

b. Loosen the three ( 3) fence lock bolts.

c. Place a combination square against

the sawblade and adju st the fence

until it is 90° to the blade.

d. Tighten the three (3) f ence lock bolts.

e. Replace sliding fences and tighten

fence lock knobs.

Adjust Miter Scale Indicator

1. Loosen the Phillips screw that holds the

indicator in place.

2. Reposition the indica tor to al ign it with

0° mark, and retight en screw.

18

Page 19

Step Four: Blade Square to Table

(Bevel Adjustment)

1. Place the saw in the 0° bevel index

position and make sure bevel lock is

disengaged.

2. Lower the blade and engage the head

hold down.

3. Use a combin ation squar e t o che ck th at

the blade i s 90° to t he t abl e. If t he b lade

does not contact the full length of th e

square:

a. Lift the bevel lock lever.

b. Loosen the two socket head screws

that secure the bevel scale.

c. Grasp the upper metal guard and

move the powerhead lef t or right unt il

the blade makes full contact with the

length of the squa re.

d. Securely tighten two socket head

screws.

Adjust Bevel Scale Indicat or

1. Loosen the Phillips screw that holes the

indicator in place.

2. Reposition the indica tor to al ign it with

0° mark and retighte n screw.

Step Five: Positioning Zero Clearance Blade Insert (When Minimal

Tear Out or Con trol of S mall Offal is

Desired)

1. Loosen the three screws that secure

the zero cleara nce blade insert on one

side of the blade.

2. Slide the zero clearance blade insert in

towards the blade until it is as close to

the blade as possib le wi thout actually

touching the blade.

3. Retighten the three screws.

4. Repeat steps 1-3 for the opposite side

of the blade.

19

Page 20

Alignment (Adju stm en ts) (cont inu ed)

Miter Lock Lever Adjustment

With the blade s et at a n “unin dexed ” mite r

position (other t han 0° , 15°, 22.5°, 31.6°,

45° and 60°) and the miter lock lever set

in the “locked” position the locking action

should feet tight and secure.

Considerable effort should be requi red t o

move the table (blade). While it is always

possi bl e to fo rc e th e tabl e to m o ve, it

should resist moving when a reasonable

amount of for ce is applied.

To check, foll ow these steps:

1. Release miter lock lever and position

blade at an “uninde xed” position. Lock

the miter lo c k le v e r.

2. Try and rotate the table/blade. If the

table easi ly moves:

a. Release the miter lock lever. Locate

the set sc rew underneath the miter

lock lever.

b. Use a 4mm hex wrench to adjust the

set screw.

c. Lock the miter lock lever and try mov-

ing the table. Readjust if necessary.

Miter

Lock Lever

20

Page 21

Bevel Lock Lever Adjustment

With the blade set at an “unindexed” bevel

posit ion ( oth er th an 0° , 22 . 5°, 3 3- 7 /8° , 45° )

and the bevel lock lever set in the “locked”

position the locking action should feel tight

and se cure.

Considerable effort should be requi red t o

move the blade. While it is always possible to force the blade to move, it should

resist moving when a reasonable amount

of force is applied.

To check, foll ow these steps:

1. Release the bevel lock lever and position the blade at an “unindexed” position. Lock the bevel lock lever.

2. Try and bevel the blade. If the blade

moves easily:

a. Release the bevel lock lever.

b. Locate the two 12mm locking jam

nuts behind the bevel lock lever.

c. Loosen the top locking jam nut.

d. To tighten the bevel lock lever mecha -

nism turn t he bott om ja m nut cl ockwi s e.

T o loosen the lock lever mechanism turn

the bottom jam nut counterclockwise.

e. Lock the beve l loc k l ever an d tr y mo v-

ing the blade. Readjust if necessary.

NOTE: When unlocked the bevel

mechanism should freely pivot. A

grating sound indicates the bevel

mechanism needs to be loosened

slightly.

Bevel Lock

Lever

Bevel Index

Pin

Bevel Pivot Movem ent / A dj ustment

Check that the mi ter saw bevels ea sily by

unlocking the bevel lock lever and tilting

the blade. NOTE: At least one thread of

the pivot bolt shou ld stick o ut past th e hex

lock nut.

If the movement is tight or there is looseness in the pivot, do the following adjustment procedure:

a. Unlock the bevel lock lever.

b. Turn the hex lock nut with 3/4" or

19mm socket.

Recheck the bevel movement and readjust if necessary.

Locking

Jam Nuts

Hex

Nut Lock

21

Page 22

Mounting The Miter Saw

WARNING: To reduce the risk of

injury from unexpected saw

movement:

a. Before moving the saw, unplug

electri c cord . L ock the miter

and bevel knobs and lock the

power head in the lower position.

b. To reduce the risk of back

injur y, hold the tool clos e to

your body when lifting. Bend

your knees so you can lift with

your legs, not your back. Lift

by using the hand-hold areas

at each side of the bottom of

the base, by the carrying handle, or the handles on the front

of base.

c. Never carry the miter saw by

the power cord or the trigger

Place the saw in the desired location

either on a work bench or other recommended leg set. The base of the saw has

eight holes to mount the mit er saw. Four

smaller holes for screws are labeled A.

Four holes for bolts are labeled B (see

illustration) . If t he saw is to be used in o ne

location, permanent ly fas ten it to the work

bench or leg set.

NOTE: When mounted on a large flat surface, the miter saw table is 4-1/2” high.

Three stacked 2 x 4’ s can be used as a

work support extension.

Portable Applications

To mount the saw to a 3/4” piece of plywood, use 4, 1/4" bolt holes or

holes. The mounting board can then be

clamped down to prevent it from tipping.

Plywood mount also helps protect saw from

damage during the rough handling associated with portable miter saw usage.

the 4 screw

grip of the plastic handle. Carrying the tool by the power

cord could cause damage to

the insulation or the wire connections resulting in electric

shock or fire.

d. Place the saw so other people

cannot stand behind it. Thrown

debris coul d i nj ure people in

its path.

e. Plac e the saw on a firm, level

surface where there is plenty

of room for handling and properly supporting the workpiece.

f. Support the saw so the table is

level and the saw does not

rock.

g.Bolt or clamp the saw to its

support.

Work Bench Applications

Mount as specifi ed in portable appli cations. Check f or workpiece clearances to

left and right of saw.

B

A

B

A

B

A

A

B

22

Page 23

Safety Instructions for Basic Saw Operations

Before Each Use

Inspect your saw.

Disconnect The Miter Saw. To

reduce the risk of injury from accidental starting, unplug the saw, before

changing the setup, changing the

blade or adjusting anything.

Compare the direction of rotation

arrow on the guard to the direction

arrow on the blade. The blade teeth

should always point downward at the

front of the saw.

Tighten the arbor screw.

Tighten the cover plate stop screw.

Check Damaged Parts. Check for:

• Proper alignment of moving parts,

• Damaged electric cords,

• Binding of moving parts,

• Broken parts,

• Stable mounting

• Function of arm return spring and

lower guard: Push the arm all the

way down, then let it rise up until it

stops by itself. Check the lower

guard to see if it closed fully. If it did

not, follow the instructions in the

“Troubleshooting” section.

• Smooth, solid movement of sliding

assembly.

• Other conditions that may affect the

way the miter saw works.

If any part of this miter saw if missing,

bent, or broken in any way, or any

electrical parts don’t work, turn the

saw off and unplug it. Replace damaged, missing, or failed parts before

using the saw again.

Keep Guards In Place, in work in g

order, and in proper adjustment.

Maintain Tools With Care. Keep the

miter saw clean for best and safest

performance. Follow instructions for

lubricating. DON’T put lubricants on

the blade while it’s spinning.

Remove Adjusting Keys And

Wrenches from tool before turning it

on.

T o Reduce the Risk of Injury From Jams, Slips Or Thrown Pieces

• Use Only Recommended Accessories. (See “Accessory” section

within.) Consult this Owner’s manual for recommended accessories.

Follow the instructions that come

with the accessories. The use of

improper accessories may cause

risk of injury to persons.

• Choose the right 12-inch diameter

blade for the saw and material you

plan to cut.

• Make sure the blade is sharp,

undamaged and properly aligned.

With the saw unplugged, push the

power head all the way down. Hand

spin the blade and check for clearance. Tilt the power-head to 45

degree bevel and repeat the check.

If the blade hits anything, make the

adjustments shown in the Maintaining “Alignment (Adjustments)” section.

• Make sure the blade, arbor collars

and laser system are clean.

• Make sure the arbor collars' and

laser discs’ recessed side s are facing the blade.

• Using 1/4” hex end of combination

wrench (supplied) or 1/2-inch box

end wrench, make sure the left hand

thread arbor screw is firmly tightened counterclockwise.

• Make sure all clamps and locks are

tight and there is no excessive play

in any parts.

23

Page 24

Safety Instructions for Basic Saw Operations (con’t.)

• Keep work area clean. Cluttered

areas and benches invite accidents.

Floor must not be slippery.

Plan Ahead To Protect Your Eyes, Hands, Face and Ears

Know your miter saw. Read and

understand the owner’s manual and

labels affixed to the tool. Learn its

application and limitations as well as

the specific potential hazards peculiar

to this tool.

To reduce the risk of injury from accidental contact with moving parts,

don’t do layout, assembly, or setup

work on the miter saw while any parts

are moving.

Reduce the Risk of Accidental

Starting. Make sure switch is “OFF”

before plugging miter saw into a

power outlet.

Dress Fo r Safety

The operation of any power miter saw

can throw foreign objects into the

eyes. This can result in permanent

eye damage. Wear safety goggles

(not glasses) that comply with ANSI

Z87.1 (or in Canada CSA Z94.3-99)

shown on package. Everyday eyeglasses have only impact resistant

lenses. They are not safety glasses.

Safety goggles are available at many

local retail stores. Glasses or goggles

not in compliance with ANSI or CSA

could seriously hurt you when they

break.

To reduce the risk of burns or other

fire damage, never use the miter saw

near flammable liquids, vapors or

gases.

Plan your work.

Use The Right Tool. Don’t force tool

or attachment to do a job it was not

designed to do. Use a different tool

for any workpiece that can’t be held in

a solidly braced, fixed position.

CAUTION: Because of the sliding action of this saw, this

machine is not designed for cutting metals. Use this miter saw

to cut only w ood , and wood like

products. Other materials may

shatter, bind on the blade, start

fires or create other dangers.

• Do not wear loose clothing, gloves,

necktie s or je w elr y ( rin gs , w ris t

watches) They can get caught and

draw you into moving parts.

• Wear nonslip footwear.

• Tie back long hair.

• Roll long sleeves above the elbow.

• Noise levels vary widely. To reduce

the risk of possible hearing damage,

wear ear plugs or muffs when using

miter saw for hours at a time.

• For dusty operations, wear a dust

mask along with safety goggles.

24

Page 25

Preparing to Make the Cut

Inspect Your Workpiece. Make sur e

there are no nails or foreign objects in

the part of the workpiece to be cut.

Plan your work to avoid thrown

pieces caused when the workpiece

binds on the blade and is torn from

your hands.

Plan how you will make the cut.

Always:

• Make sure the blade is not spinning.

• Raise the blade.

• Slide the saw out above the front

edge of the workpiece before starting saw, and

• Push the sawblade down on top of

the wood and back toward the rear

of the saw to make th e cut.

DANGER: NEVER pull the saw

toward yo u during a cut. The

blade can suddenly climb up on

top of t he workpiece and forc e

itself toward you.

Plan the way you will hold the workpiece from start to finish.

• Avoid awkward operations and hand

positions where a sudden slip could

cause fingers or hand to move into

the blade.

• Don’t Overreach. Keep good footing

and balance.

• Keep your face and body to one

side of sawblade, out of line with a

poss ible th r o wba c k.

• Cut only one workpiece at a time.

Never cut Freehand:

• Brace your workpiece solidly

against the fence and table top so it

will not rock or twist during the cut.

• Make sure there’s no debris

between the workpiece and its supports.

• Make sure no gaps between the

workpiece, fence and table will let

the workpiece shift after it is cut in

two.

• Cut only one workpiece at a time.

• Keep the cut off piece free to move

sideways after it's cut off. Otherwise,

it could get wedged against the

blade and could be thrown violently.

• Clear everything except the workpiece and related support devises

off the table before turning the miter

saw on.

• Secure Work. Use clamps or a vise

to help hold the work when it’s practical.

Use extra caution with large, very

small or awkward workpieces:

• Use extra supports (tables, saw

horses, blocks, etc.) for any workpieces large enough to tip when not

held down to the table top.

• Never use another person as a substitute for a table extension, or as

additional support for a workpiece

that is longer or wider than the basic

miter saw table or to help feed, support or pull the workpiece.

• Do not u se thi s s a w to cut p i eces

too small to let you easily hold the

work while you keep the thumb side

of your index (pointer) finger against

the outside edge of the fence.

• When cutting irregularly shaped

workpieces, plan your work so it will

not slip and pinch the blade and be

torn from your hands. A piece of

molding, for example, must lie flat or

be held by a fixture or jig that will not

let it twist, roc k or s lip w h il e be in g

cut.

25

Page 26

Safety Instructions for Basic Saw Operations (con’t.)

• Properly support round material

such as dowel rods. They have a

tendency to roll while being cut,

Whenever Saw Is Running

causing the blade to "bite." To avoid

this, always use a fixture designed

to properly hold your workpiece.

WARNING: Do n't al low famil iarity

(gained f rom f requent use of

your miter saw) cause a careless

mistake. A careless fraction of a

second is enough to cause a

severe injury.

Before starting your cut, observe the

miter saw while it runs. If it makes an

unfamiliar noise or vibrates excessively , stop immediately. Tu rn the saw

off. Unplug the saw. Do not restart

until finding and correcting the problem.

Keep Children Away. Keep all visitors a safe distance from the miter

saw. Make sure bystanders are clear

of the miter saw and workpiece.

Never confine the piece being cut

off. Never hold it, clamp it, touch it, or

use length stops against it while the

blade is spinning. It must be free to

move sideways on its own. If confined, it could get wedged against the

blade and thrown violently.

Let the blade reach full speed

before cutting. This will hel p reduce

the risk of a thrown workpiece.

Don’t Forc e Tool. It will do the job

better and safer at its designed rate.

Feed the saw into the workpiece only

fast enough to let the blade cut without bogging down or binding.

Before freeing jammed material:

• Turn miter saw “OFF” by releasing

trigger switch.

• Wait for all moving parts to stop.

• Unplug the miter saw.

After finishing a cut:

• Keep holding the power head down.

• Release the switch, and wait for all

moving parts to stop before moving

your hands or raising power head.

• If blade doesn’t stop within 6 seconds, unplug the saw and follow the

instructions in the Trouble Shooting

section for fixing the blade brake

before using the saw again.

Before Leaving The Saw:

Never Leave Tool Running Unattended.Turn power off. Wait for all

moving parts to stop.

Make workshop child-p roof. Install

a padlock through the hole provided

in the trigger to prevent unauthorized

usage. Lock the shop. Disconnect

master switches. Store tool away

from children and others not qualified

to use the tool.

26

Page 27

Basic Saw Operations

Making Common Slide Compound

Cuts

There are two types of cuts that can be

made with the slide compound miter saw;

1.Slide Cutting

a. The slide lock knob is left loose, the

cutting head is pulled towards the

operator, the sawblade is lowered into

the workpiece and then pushed to the

rear of the saw to complete the cut.

b. Used for cutting wide pieces.

2.Chop Cutting

a. The slide lock knob is tightened and

the saw handle is pushed down to

cut through the workpiece.

b. This type of cut is used mainly for

narrow pieces.

Slide Cutting

Plan your work to avoid the spinning

blade and keep the workpiece from

binding on the blade and flying out of

your hands.

DANGER: Never pull the saw

toward yo u during a cut. The

blade can suddenly climb up on

top of t he workpiece and forc e

itself toward you.

DANGER: Never lower the saw

completely in front of the workpiece and then cut only on the

forward push. The upward moving re ar porti on of the blade

could twist the workpiece from

your grasp.

Workpieces up to 13-1/2” wide and 3-1/2”

thick can be cut following the directions

below:

1. Put wood against fence and secure

with clamp as appropriate.

2.Lo osen the slide lock knob.

3.Gr asp the saw handle and pull the car-

riage until the arbor (center of sawblade) is over the fr ont edge of the

workpiece.

4.Swit ch on the saw and allow t o come to

full speed.

WARNING: For your co nv enient

use, your saw has a blade brake.

The brake is not a safety device.

Never rely on it to replace proper

use of the guard on your saw. If

the blade does not stop within 6

seconds, unplug the saw and follow the instructions in the T r ou ble Shooting section for fixing

the brake before using saw

again.

WARNING: Do not try to cut

short pieces. You cannot properly support the workpiece and

keep your hold down hand the

required distance from the blade.

5.Push the saw handle all the way down

and cut through the leading edge of the

workpiece.

6.Gently push the saw handle towards

the fence completing the cut.

7.Push power head to full rear position

after each cut.

8.Turn motor off and allow blade to come

to a complete stop before moving hands.

Push Down

Slide Back

27

Page 28

Basic Saw Operations (continued)

Chop Cutting

1. Slide the cutti ng head to the rear as far

as it will go.

2.Lock slide lock knob.

3.Position workpiece on table and against

fence and secure with clamp as appropriate.

4.Turn on saw and lower blade into workpiece.

5.After cut is complete turn off saw, allow

blade to stop rotating before allowing

cutting head to rise up.

Body and Hand Position

• Never place hands near cutting area.

Place hand at least 4" from path of

blade.

• Hold workpiece fir mly t o the fence to

prevent movement toward the blade.

• When holding the workpiece to the left

side of the blade, always use your left

hand. Use your right hand to hold the

workpiece to the right side of the blade.

• Before making a cut, make a “dry run”

with the power off so you can see the

path of the blade.

• Keep hands in position unt il trigger has

been released and the blade has completely stopped.

WARNING: Do not try to cut short

pieces, you cannot properly support the workp iece and

your hold down hand the

required distance from the blade.

keep

28

Page 29

Miter Cut

When a miter cut is required, mo ve the

saw to the desired angle. Move wi th t he

handle to the miter angle to make the cut.

There are settings on the miter scale for

angles (degrees) and crown molding.

NOTE: Remember to unlock the miter

5°

Miter Scale

lock lever before changing the miter

angle.

Miter Scale Usage

Vernier Miter Scale Operation:

The Vernier mite r scale can quickly and

accurately help the user to adjust the saw

to any 1/4° increment as illustrated below.

5-1/4°

Indicator over

5° scale mark

Vernier

Miter Indicator

1/2° Indicator l ine

over 7° scale mark

5-1/2°

Bevel Cut

When a bevel cut is required tilt the blade

to desired bevel angle. Stand to the left

side of the handle to make the cut .

Sliding Fe nce

When beveling the blade to the l eft or

right fence may have to be repositioned.

Loosen the fence locking knob and slide

the fence to the left or right as needed.

Adjust the f ence as close t o the g uard and

link as possible to pr ovide maximum support for the workpiece . Securely tighten

1/4° Indicator line

over 6° scale mark

5-3/4°

3/4° Indicator line

over 8° scale mark

knob and make a dry run with the saw of f

to check for clearance between the fence

and guard. On c ert ain extreme c ompound

cuts it may be necessary to remove a sliding fence to avoid interference. After completing bevel cut(s) remember to repl ace

and/or sli de the f ence back.

Vernier Bevel Scale Operation:

The Vernier bevel scal e can quickly and

accurately help the user to adjust the saw

to any 1/2° increment as illustrated.

29

Page 30

Basic Saw Operations (continued)

Compound Cut

When a compound cut is required, select

the desired bevel and miter positions.

Cutting C om pound Miters on

Picture Frames and Boxes

A compound miter is a cut requiring both

a miter setting and bevel setting. A compound miter i s used for making frames or

boxes that have sloping sides and are

wide at one end and narrow at the opposite end. Compound miter s are “tricky” to

make because the miter s etti ng and bevel

setting are direct ly related to each other.

Every time the miter sett ing is changed

the bevel setting mu st al so be adjusted;

likewise every adjustment to bevel

requires a corresponding adjustment to

miter . Beca use it may t ak e several trie s to

obtain the desired angle, it is advisable to

make test cuts on a scrap piece of m aterial.

Cutting Bowed Material

Before cutting a workpi ece, check to

make sure it is not bowed. If it is bowed

the workpiece must be pos itioned and cut

as illustrated. Do not position workpiece

incorrectly or try to cut the workpi ece with-

out the support of the fence. This will

cause pinchi ng of the workpiece on the

blade. The workpiece could suddenly

jump or mov e and your hand could hit the

blade.

Compound Cut Box

Hold wo rkpiece tight

against fence so

there is no gap

Correct

Incorrect

30

Page 31

Workpiece Clamp Usage

WARNING: Avoid thrown

workpieces. A void binding the

work agai n st the blade:

- Always hold or clamp your

work do wn to the saw.

- Do not hold or c la m p t he wo rk piece on both sides of the

blade. The blade can throw a

cut off piece if you confine the

workpiece on both sides of the

blade.

- Read and follow the instructions in the remainder of your

saw’s owners man ual.

- This accessory was designed

to make your miter saw operations more convenient. Read

and understand these instructions completely before use.

NOTE: The clamp can be used only in a

vertical position.

1. Place material to be cut on table of

miter saw. Secure workpiece to the

fence and table by turning knob to

tighten clamp. Do not overtighten the

clamp. It should just lightly hold the

wood against the fence and table.

2.Perform a dry run with the saw

unplugged. Af ter you believe that the

saw is complet ely s et up, pull the power

head down as if you were making an

actual cut. Check for interference s and

for potentiall y dangerous situations.

Adjust the set up so that a safe operation can be complete d.

3. Complete the cut as instructed in the

remainder of you miter saw owners

manual.

- Always perform dry runs. Make

sure the saw is unplugged.

Completely set up your saw.

Pull the blade and power head

through the full range of motion

to check for interference. The

clamp c an be used in a left or

right configuration. Make sure

that your blade, saw guard or

motor does not interfere with

the clamp. Correct any interference be fore use.

- Always tighten the clamp so

that the workpiece is secured

between the clamp and fence,

support or base. No visible gap

should be present between saw

and wood .

Workpiece

to be cut off

IMPORTANT: To help perform the safest

and most precise miter saw cut, make th e

cut and then release the power switch.

Hold the power head down and keep your

hands in place until the blade stops rotating. Then raise the power head and

remove workpiece from work table.

31

Page 32

Basic Saw Operations (continued)

Workpiece Support

Long pieces need extra supports. The

supports shoul d be placed along the

workpiece so the wor kpiece does not sag

and your hand holding the workpi ece is

positioned 4” or mor e fro m the blade p at h.

The support should let the workpiece lay

flat on the base and work table during the

cutting operation.

NOTE: When mount ed on a large flat surface, the miter saw t able is 4-1/2” high.

Three stacked 2 x 4’s can be used as a

work support ext ension.

Auxiliary Fence

Certain unusual cuts may benefit from a

fence face extensi on due to the size and

position of the workpiece. Holes are provided in the fence to attach an auxiliary

fence. Get a straight piece of wood typically 1/2 inch t hick by 4 -1/4 i nches hig h by

23 inches long. To attach auxil iary fence,

place the piece of wood on the mite r saw

fence. Mark the hole locations from the

backside of the miter saw fe nce. Drill

.200”-.250” holes, then countersi nk the

holes on front of wood to receive #10 flat

head screws. Attach the auxiliary fence

securely and make a full depth cut. This

will create the blade sl ot. Check for interference between the auxiliary fence and

lower blade guard. Correct any interfer-

ence before proceeding. The auxiliary

fence is used with t he saw in the 0° bevel

position. If a bevel cut is desired, the auxiliary fen c e will hav e to be re m o v ed.

32

Page 33

Rough C utt i ng A D ado

By using the depth adjustment cam it is

possible to rough cut a dado as shown.

On the outsi de of the depth adjustment

cam are a series of marks. Use these

marks as a refer ence to help s et the bl ade

to the correct cutting depth.

After the two outside cuts have been completed the inside material (represented

by slanted lines) is removed with a chisel.

To set the depth stop:

1. Position depth adjustment cam so it

engages locking col lar.

2. Loosen lock knob.

3. Position depth stop cam so the power-

head stops at the desired depth.

4.Cut the two outside grooves.

5.Use a wood chisel to remove the mate-

rial between the outside grooves.

6.To override depth setting pull depth

stop cam outward and rot ate so flat is

up.

NOTE: It is not neces sar y to l oosen dept h

adjustment knob.

NOTE: Because of the sawblades cutting

arc material at the beg inning or end of the

cut(s) may have to be removed with a

chisel.

Cut These Grooves

Use a Chisel to

Cutout the Middle

With Saw

Workpiece

Depth

Adjustment

Cam

Depth

Adjustment

Knob

Cutting Base Moldings

Base moldings and many other moldings

can be cut on a miter saw. The set up of

the saw depends on your molding and

your application as shown. Always make

sure moldings rest firmly against fence

and table.

F

e

n

c

e

Miter Saw Table

(Miter at 45° (Miter at 0°,

Cutting Base Molding

Bevel at 0°) Bevel at 45°)

F

e

n

c

e

33

Miter Saw Table

Page 34

Basic Saw Operations (continued)

Cutting Crown Moldings

Your compound miter saw does an excellent job of cutting crown molding. However, in order to fit properly, crown

molding must be cut with extreme accuracy.

Two Methods of Cutting Crown Molding

Crown molding may either be cut (1) flat

on the miter saw table or (2) ang led to the

table and fenc e. (See sq uare below) Most

standard (U.S.) crown m olding has a top

rear angle (angle that fits next to the ceiling) of 52° and a bottom rear an gle (angle

that fits against wall) of 38°. Your miter

saw has special mi ter s etti ngs at 31.6° lef t

and right and a bevel setti ng at 33.9° to

use when cutting crown molding flat on

the miter saw table. These settings are

identified with a “CM” mark.

Remember: Even though all of these

angles are standard, rooms are very

rarely constructed so the corners are

exactly 90°. You will need to “fine tune”

these settings and make necessary

adjustments to the cutting angle s.

F

e

n

c

e

Miter Saw Table

1.Wor kpiece Lyin g

See Chart for Bevel

and Miter Settings

Cutting Crown Molding Flat on the

Miter Saw Table

The advantage of cutting crown molding

flat on the table is that it is easier to

secure the molding at the correct cutti ng

position. Also larger pieces of crown

molding may be cut lay ing flat on the mite r

saw table.

1. Set the bevel and miter angles using

the chart belo w. Tighten the miter lo ck

knob and the bevel loc k knob.

2. Once again using the chart below cor-

rectly positions the molding.

3. Lower the head assembly, activate the

switch and make the cut. W ait until the

blade comes to a complete stop before

allowing the he ad as sembly t o ret urn to

the “UP” position and/or removing t he

workpiece.

4. ALWAYS PRETEST COMPOUND

SETTINGS ON SCRAP MATERIAL TO

CONFIRM CORRECT ANGLES.

Flat

F

e

n

c

38°

e

52°