RIDGID Micro CM-100 Operator's Manual

Micro CM-100 Digital Clamp Meter

micro CM-100

Digital Clamp Meter

micro CM-100

TECH DATA SHEET 6806709/03/18

micro CM-100 Digital Clamp Meter

Record Serial Number below and retain product serial number which is located on nameplate.

Serial

No.

1

micro CM-100 Digital Clamp Meter

Safety Symbols

In this operator’s manual and on the product, safety symbols and signal words are used

to communicate important safety information. This section is provided to improve understanding of these signal words and symbols.

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible injury

or death.

DANGER

WARNING

CAUTION

NOTICE

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

NOTICE indicates information that relates to the protection of property.

This symbol means read the operator’s manual carefully before using the equipment. The operator’s manual contains important information on the safe and

proper operation of the equipment.

This symbol indicates the risk of electrical shock.

This symbol indicates the presence of a high voltage hazard.

General Safety Rules

Read all safety warnings and in struc tions. Failure to follow the warn ings and instructions may result in electric shock, fire and/or serious injury.

SAVE THESE INSTRUCTIONS!

Work Area Safety

• Keep your work area clean and well lit. Cluttered or dark areas invite accidents.

• Do not operate equipment in explosive atmospheres, such as in the presence

of flammable liquids, gases or dust. E quip ment can create sparks which may ignite

the dust or fumes.

• Keep children and by-standers a way while operating equipment. Distrac tions can

cause you to lose control.

Electrical Safety

• Avoid body contact with earthed or grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an in creased risk of electrical shock if your body is

earthed or grounded.

• Do not expose equipment to rain or wet conditions.Water en tering equipment will

increase the risk of electrical shock.

Personal Safety

• Stay alert, watch what you are doing and use common sense when operating

equipment. Do not use equipment while you are tired or under the influence of

drugs, alcohol or medication. A moment of inattention while operating equipment

may result in serious personal injury.

WARNING

2

micro CM-100 Digital Clamp Meter

• Use personal protective equipment. Always wear eye protection. Protective equip-

ment such as as protective gloves and clothing, dust mask, non-skid safety shoes, hard

hat, or hearing protection used for appropriate conditions will reduce personal injuries.

• Do not overreach. Keep proper footing and balance at all times. This enables bet-

ter control of the equipment in unexpected situations.

Equipment Use and Care

• Do not force equipment. Use the correct equipment for your application. The

correct equipment will do the job better and safer at the rate for which it is designed.

• Do not use equipment if the switch does not turn it ON and OFF. Any tool that can-

not be controlled with the switch is dangerous and must be repaired.

• Store idle equipment out of the reach of children and do not allow persons un-

familiar with the equipment or these instructions to operate the equipment.

Equipment can be dangerous in the hands of untrained users.

• Maintain equipment. Check for missing parts, breakage of parts and any other con-

dition that may affect the equipment’s operation. If damaged, have the equipment repaired before use. Many accidents are caused by poorly maintained equipment.

• Use the equipment and accessories in accordance with these instructions, tak-

ing into account the working conditions and the work to be performed. Use of

the equipment for operations different from those intended could result in a hazardous

situation.

• Use only accessories that are recommended by the manufacturer for your

equipment. Accessories that may be suitable for one piece of equipment may become hazardous when used with other equipment.

• Keep handles dry and clean; free from oil and grease. Allows for better control of

the equipment.

Service

• Have your equipment serviced by a qualified repair person using on ly identical

replacement parts. This will ensure that the safety of the tool is maintained.

Specific Safety Information

This section contains important safety information that is specific to this tool.

Read these precautions carefully before using the RIDGID

Clamp Meter to reduce the risk of electrical shock or other serious injury.

SAVE THESE INSTRUCTIONS!

Keep this manual with the tool for use by the operator.

Digital Clamp Meter Safety

• Use caution when working with voltages above 30 V AC RMS, 42 V AC peak or 60

V DC. These voltages pose serious shock hazard. High-voltage circuits, both DC and

AC, are very dangerous and should be measured with great care. Avoid working alone.

• Do not connect to voltages that exceed 600 VAC or VDC relative to earth ground.

This may damage the meter and expose the operator to a shock hazard.

• When using the probes, keep your fingers behind the finger guards on the

probes. This reduces the risk of electric shock.

• Never ground yourself when taking electrical measurements. Do not touch ex-

WARNING

®

micro CM-100 Digital

3

micro CM-100 Digital Clamp Meter

posed metal pipes, outlets, fixtures, etc., which might be at ground potential. Keep your

body isolated from ground using appropriate methods.

• Disconnect the test leads from the meter before making current clamp meas-

urements. This reduces the risk of electric shock.

• When measuring resistance, disconnect all power (remove batteries, unplug

cord, discharge all capacitors, etc.) to the circuit being measured. This reduces

the risk of electric shock.

• After resistance test, the capacitive circuits must be discharged. This will help

protect against electric shock.

• Use extreme caution when working near bare conductors and bus bars. Acci-

dental contact with conductors could result in electrical shock.

• Turn OFF power to the circuit under test before cutting, unsoldering, or break-

ing the circuit. Small amount of current can expose the operator to a shock hazard.

The EC Declaration of Conformity (890-011-320.10) will accompany this manual as a

separate booklet when required.

If you have any question concerning this RIDGID

• Contact your local RIDGID distributor.

• Visit www.RIDGID.com or www.RIDGID.eu to find your local RIDGID contact point.

• Contact Ridge ToolTechnical Service Department at rtctechservices@emerson.com,

or in the U.S. and Canada call (800) 519-3456.

®

product:

Description, Specifications And Standard Equipment

Description

The RIDGID® micro CM-100 Digital Clamp Meter is a handheld digital instrument with

clamp-on current measuring capability. The unit can measure DC and AC Voltage and

Current, Resistance, Capacitance, Frequency, Temperature, Continuity (audible signal)

and Test Diodes.

The unit has data hold, peak hold and DC Amps zero adjustment functions. Overload

protection and low battery indication are provided in the unit. The unit has a four Digit

backlight LCD.

The Clamp Meter is powered by a 9V battery and has auto power-off function after 20

minutes of inactivity.

Specifications

Display..........................................4-Digit backlight LCD

Clamp Size ...................................1.2" (30 mm) Opening

Overvoltage Category...................CAT III 600 V, CAT II 1000 V

Safety Compliance........................IEC 61010-1, EN 61010-1

Measurement Rate .......................2 per Second, Nominal

Power Supply .................................9V Battery, NEDA 1604, IEC 6F22 or 6LR61

Operating Temperature ..................0°C to 50°C (32°F to 122°F)

Weight...........................................0.67 lbs (304 g)

Dimension.....................................9.0" x 3.1" x 1.9" (229 x 79 x 48 mm)

4

micro CM-100 Digital Clamp Meter

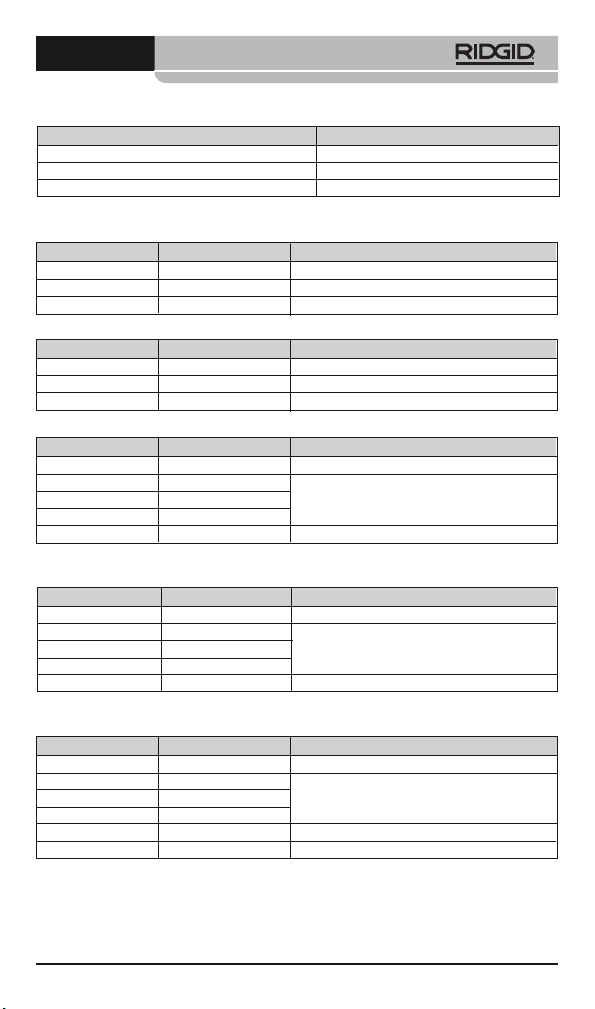

Input Limits

Function Maximum Input

Voltage V DC/AC 600 V DC/AC

Current A DC/AC 1000 A DC/AC

Frequency, Duty Cycle 600 V DC/AC

Accuracy is given at 18°C to 28°C (65°F to 83°F), less than 70% RH

DC Current

Range Resolution Accuracy

40 A 0.01 A ±2.8% of Reading ± 10 Digits

400 A 0.1 A ±2.8% of Reading ± 8 Digits

1000 A 1 A ±3.0% of Reading ± 8 Digits

AC Current

Range Resolution Accuracy

40 A 0.01 A ±2.8% of Reading ± 10 Digits

400 A 0.1 A ±2.8% of Reading ± 8 Digits

1000 A 1 A ±3.0% of Reading ± 8 Digits

DC Voltage (Autoranging)

Range Resolution Accuracy

400 mV 0.1 mV ±0.8% of Reading ± 2 Digits

4 V 0.001 V

40 V 0.01 V ±1.5% of Reading ± 2 Digits

400 V 0.1 V

600 V 1 V ±2.0% of Reading ± 2 Digits

Input Impedance...........................10.0 MΩ

AC Voltage (Autoranging)

Range Resolution Accuracy

400 mV 0.1 mV ±1.0% of Reading ± 10 Digits

4 V 0.001 V

40 V 0.01 V ±1.5% of Reading ± 8 Digits

400 V 0.1 V

600 V 1 V ±2.0% of Reading ± 8 Digits

Input Impedance...........................10.0 MΩ

Resistance (Autoranging)

Range Resolution Accuracy

400 Ω 0.1 Ω ±1.0% of Reading ± 4 Digits

4 kΩ 1 Ω

40 kΩ 10 Ω ±1.5% of Reading ± 2 Digits

400 kΩ 100 Ω

4 MΩ 1 kΩ ±2.5% of Reading ± 5 Digits

40 MΩ 10 kΩ ±3.5% of Reading ± 10 Digits

5

Loading...

Loading...