Page 1

A-Frame Operator’s Manual

A-Frame Fault Locator

Model FT-103 Transmitter and

Model FR-30 Receiver

• Français – 15

• Castellano – pág. 33

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

A-Frame Fault Locator

Table of Contents

Recording Form for Machine Serial Number .....................................................................1

Safety Symbols.....................................................................................................................2

General Safety Rules

Work Area Safety...............................................................................................................2

Electrical Safety.................................................................................................................2

Personal Safety .................................................................................................................2

Equipment Use and Care ..................................................................................................2

Service ..............................................................................................................................3

Specific Safety Information

A-Frame Fault Locator Safety............................................................................................3

RIDGID Contact Information................................................................................................4

Description............................................................................................................................4

Transmitter.........................................................................................................................4

Receiver ............................................................................................................................5

Specifications.......................................................................................................................5

Standard Equipment..........................................................................................................6

Changing/Installing Batteries..............................................................................................6

Transmitter.........................................................................................................................7

Receiver (A-Frame) ...........................................................................................................7

Pre-Operation Inspection ....................................................................................................7

Set-Up And Operation Instructions ....................................................................................7

Fault Locating

Connecting Transmitter......................................................................................................8

Locating.............................................................................................................................9

Locating Below Paved Surfaces ......................................................................................10

Multiple Faults..................................................................................................................11

Path Locating

Direct Connect Path Locating Method .............................................................................11

Inductive Clamp Path Locating ........................................................................................12

Broadcast Inductive Path Locating ..................................................................................12

Storage ................................................................................................................................13

Maintenance

Cleaning ..........................................................................................................................13

Calibration .......................................................................................................................13

Service And Repair..........................................................................................................13

Optional Equipment ...........................................................................................................14

Disposal ..............................................................................................................................14

Battery Disposal ..............................................................................................................14

EC Declaration of Conformity............................................................................................14

FCC Statement....................................................................................................................14

Electromagnetic Compatibility (EMC) ..............................................................................14

Lifetime Warranty .................................................................................................Back Cover

*Original Instructions - English

ii

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

999-995-095.10_REV. A

Page 3

A-Frame Fault Locator

A-Frame Fault Locator

Model FT-103 Transmitter and

Model FR-30 Receiver

WARNING!

Read this Operator’s Man ual

carefully before using this

tool. Failure to understand

and follow the contents of this

manual may result in electrical shock, fire and/or serious

person al injury.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

A-Frame Fault Locator

Record Serial Number below and retain product serial number which is located on nameplate.

Serial

No.

Page 4

A-Frame Fault Locator

Safety Symbols

In this operator’s manual and on the product, safety symbols and signal words are used to

communicate important safety information. This section is provided to improve understanding of these signal words and symbols

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

DANGER

WARNING

CAUTION

NOTICE

This symbol means read the operator’s manual carefully before using the equipment. The operator’s manual contains important information on the safe and proper operation of the equipment.

This symbol means always wear safety glasses with side shields or goggles when handling

or using this equipment to reduce the risk of eye injury.

This symbol indicates the risk of electrical shock.

DANGER indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could result in minor

or moderate injury.

NOTICE indicates information that relates to the protection of property.

.

General Safety Rules

WARNING

Read all safety warnings and instructions. Failure to follow the warnings and

instructions may result in electric shock,

fire and/or serious injury.

SAVE ALL WARNINGS

AND INSTRUCTIONS FOR

FUTURE REFERENCE!

Work Area Safety

• Keep your work area clean and well lit.

Cluttered or dark areas invite accidents.

• Do not operate equipment in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. E quip -

ment can create sparks which may ignite

the dust or fumes.

• Keep children and by-standers a way

while operating equipment. Distrac tions

can cause you to lose control.

Electrical Safety

• Avoid body contact with earthed or

ground ed surfaces such as pipes, radiators, ranges and refrigerators. There

is an increased risk of electrical shock if

your body is earthed or grounded.

• Do not expose equipment to rain or wet

conditions. Water en tering equipment will

increase the risk of electrical shock.

Personal Safety

• Stay alert, watch what you are doing

and use common sense when operating equipment. Do not use equipment

while you are tired or under the influence of drugs, alcohol or medication. A

moment of inattention while operating

equipment may result in serious personal

injury.

• Use personal protective equipment. Al -

ways wear eye protection. Protective equipment such as dust mask, non-skid safety

shoes, hard hat or hearing protection used

for appropriate conditions will reduce personal injuries.

• Do not overreach. Keep proper footing

and balance at all times. This enables

better control of the power tool in unexpected situations.

• Do not let familiarity gained from fre-

quent use of tools allow you to become

complacent and ignore tool safety principles. A careless action can cause severe

injury within a fraction of a second.

Equipment Use and Care

• Do not force equipment. Use the correct

equipment for your application. The cor-

2

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

999-995-095.10_REV. A

Page 5

A-Frame Fault Locator

rect equipment will do the job better and

safer at the rate for which it is designed.

• Do not use equipment if the switch does

not turn it ON and OFF. Any tool that cannot be controlled with the switch is dangerous and must be repaired.

• Remove the battery pack from the equip-

ment before making any adjustments,

changing accessories, or storing. Such

preventive safety measures reduce the risk

of injury.

• Store idle equipment out of the reach of

children and do not allow persons unfamiliar with the equipment or these instructions to operate the equipment.

Equipment can be dangerous in the hands

of untrained users.

• Maintain equipment. Check for missing

parts, breakage of parts and any other

condition that may affect the equipment’s

operation. If damaged, have the equipment repaired before use. Many accidents

are caused by poorly maintained equipment.

• Use the equipment and accessories in

accordance with these instructions,

taking into account the working conditions and the work to be performed.

Use of the equipment for operations different from those intended could result in a

hazardous situation.

• Keep handles and grasping surfaces

dry, clean and free from oil and grease.

Slippery handles and grasping surfaces

do not allow for safe handling and control of

the tool in unexpected situations.

Service

• Have your equipment serviced by a qual i fied repair person using on ly identical

replacement parts. This will ensure that the

safety of the tool is maintained.

Specific Safety

Information

WARNING

This section contains important safety information that is specific to this tool.

Read these precautions carefully before

using the RIDGID

to reduce the risk of electrical shock or

serious personal injury.

®

A-Frame Fault Locator

SAVE ALL WARNINGS

AND INSTRUCTIONS FOR

FUTURE REFERENCE!

Keep this manual with the tool for use by

the operator.

A-Frame Fault Locator Safety

• Do not expose the equipment to water

or rain. This increases the risk of electrical

shock.

• Do not operate the transmitter if opera-

tor or transmitter is standing in water.

Operating transmitter while in water increases the risk of electrical shock.

• Do not connect to live voltage or ac-

tive utility lines. Disconnect the conductor

to be tested from any other service, components, or anything that might be affected

by high voltage. De-energize any circuits in

or around the work area.

• Always attach transmitter test leads be-

fore turning unit ON and turn unit OFF

before disconnecting leads. This will re-

duce the risk of electrical shock.

• Never turn transmitter ON when anyone

is touching the conductor, ground stake,

or any part of the transmitter. Tur n O F F

transmitter before touching test lead or any

un-insulated conductor.

• Do not use where a danger of high volt-

age contact is present. Do not attach

leads to high voltage conductors. The

equipment is not designed to provide high

voltage protection and isolation.

• Locating equipment uses electromag-

netic fields that can be distorted and interfered with. More than one utility may

be present in a given area. Follow local

guidelines and one call/call before you dig

service procedures. Exposing a utility is

the only way to verify its existence, location

and depth.

• Avoid traffic. Pay close attention to mov-

ing vehicles when using on or near

roadways. Wear visible clothing or reflec-

tor vests.

• Before operating the RIDGID A-Frame

Fault Locator, read and understand this

operator’s manual and the instructions

for any other equipment used. Failure to

follow all instructions and warnings may result in property damage and/or serious injury.

999-995-095.10_REV. A

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

3

Page 6

A-Frame Fault Locator

• Use this manual in conjunction with all

company, utility or facility procedures

and policies. Familiarize yourself with all

required procedures and policies, including

safety practices, prior to entering an area

and using the equipment.

NOTICE

Ridge Tool Company, its affiliates

and suppliers, will not be liable for any injury or

any direct, indirect, incidental or consequential

damages sustained or incurred by reason of

the use of the A-Frame Fault Locator.

RIDGID Contact

Information

If you have any question concerning this

RIDGID

– Contact your local RIDGID distributor.

(800)

®

product:

Receiver

Black Test Lead

(To Ground Stake)

Red Test Lead

(To Conductor)

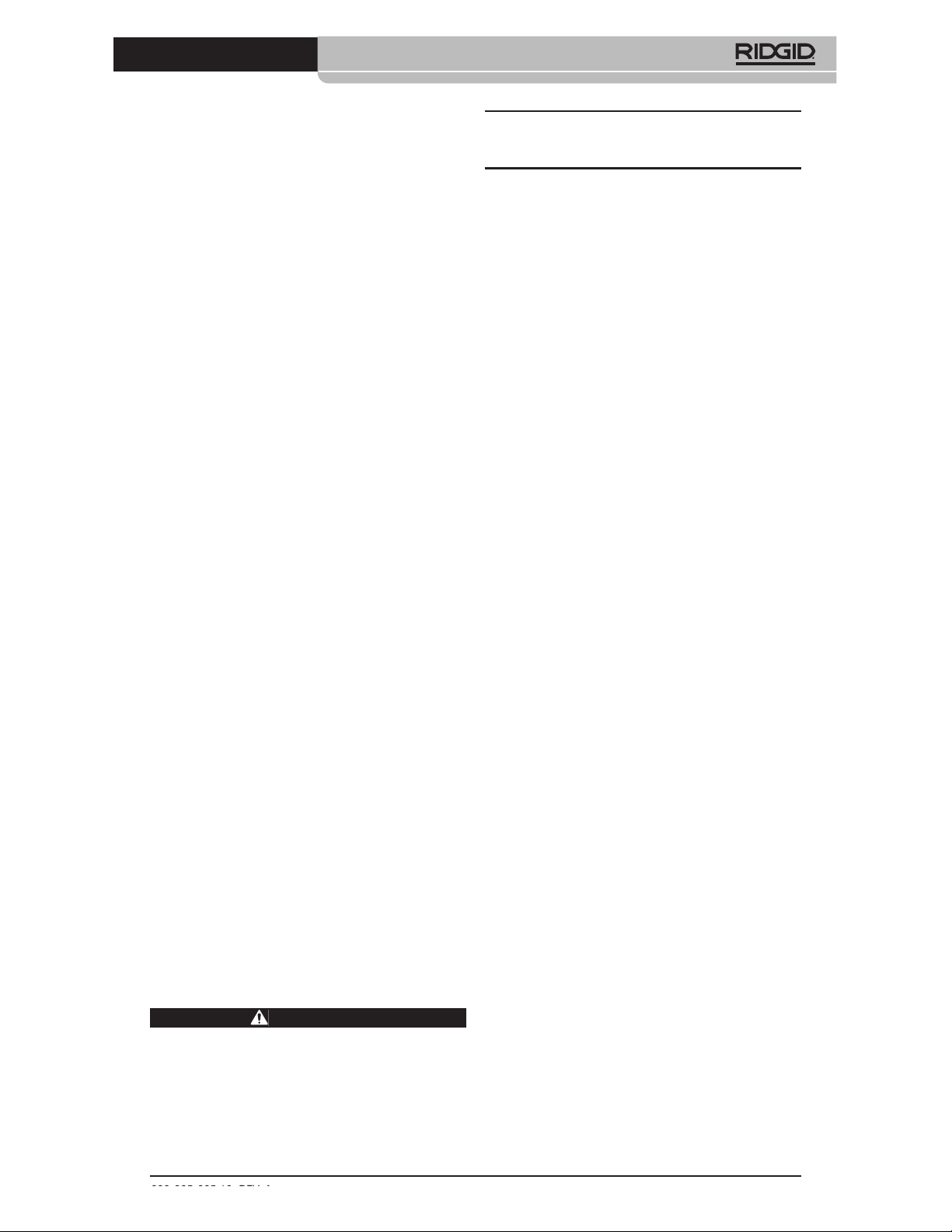

Figure 1 – A-Frame Fault Locator

Transmitter

Transmitter

Transmitter Controls:

9

Ground Stake

4

Description

The RIDGID®A-Frame Fault Locator is a highly

sensitive transmitter and receiver specifically

designed to detect the location of a path to

ground fault (Direct Fault Finding (DFF)) in

the insulation of a buried conductor (such as a

wire or cable). Damaged insulation, severed

conductor, and other faults with ground leakage are easily and precisely located.

Model FT-103 Transmitter connects to the insulated conductor and establishes a current flow,

the current leaks to ground through the insulation fault and back to the ground stake. Model

FR-30 Receiver detects the current flow to

ground through the insulation fault. The receiver provides audio and visual indications of

both signal strength and direction to assist in

detecting and locating the fault. For the AFrame fault detector to work, the conductor

must be in contact with the earth – it will not

work with conductors in conduit.

Additionally, the transmitter can be used to

apply a signal to the conductor for path locating with other receivers, such as RIDGID

SeekTech

done by direct connect and inductive methods.

Multiple frequencies and power levels are provided.

®

or NaviTrack®Locators. This can be

1

2

3

9

# Icon Description

1. — LCD Screen

2. ON/OFF and Inductive Mode Switch

3. Frequency Selection

4. — Serial and Warning Label (back of unit)

5. Inductive Clamp Jack

6. — Positive Terminal (to Conductor)

7. Negative Terminal (to Ground Stake)

8. Signal Power Setting

9. — Broadcast Inductive Decal (top and bottom)

Figure 2 – Transmitter Controls

Main Power Switch – Short press turns unit ON/OFF

Long press (5 seconds) enables Broadcast Inductive mode.

Selects the frequency of transmitter from preloaded frequencies. See Specifications for frequencies

Depressing the Signal Power Button cycles the Signal

Power between Low, Medium and High

5

6

7

8

4

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

999-995-095.10_REV. A

Page 7

A-Frame Fault Locator

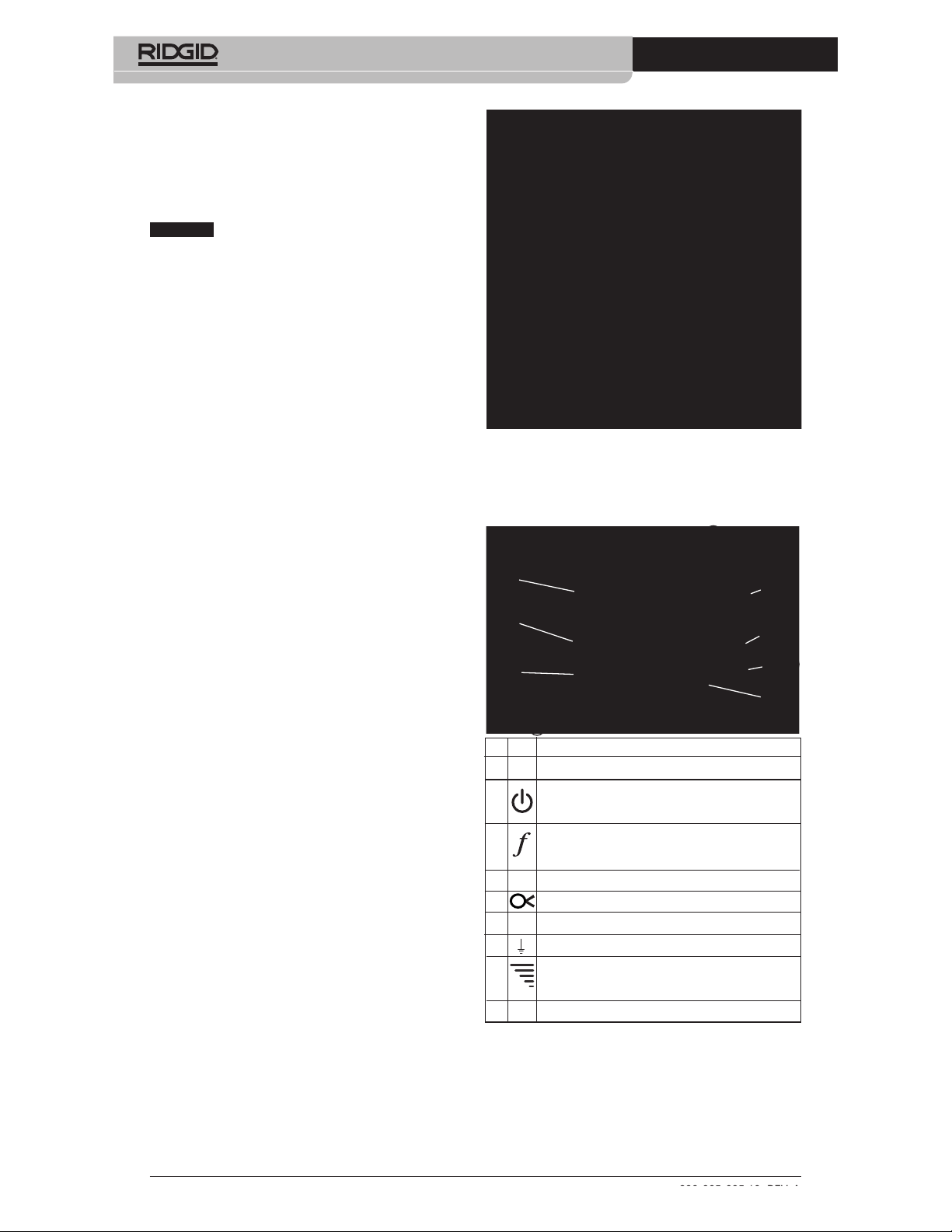

Transmitter Display:

2

3

4

Number Icons Description

1 – – – kHz Frequency. “dFF” shown for fault finding.

2 Signal Power - # Of Bars On Increases with Increasing Power. Three Levels – Low, Medium

3

4 Voltage Warning – Transmitter connected to energized conductor – risk of electrical shock.

5 Transmitter Set for Fault Finding (dFF displayed in Frequency area (1)).

6 Transmitter Set for Inductive Clamp Use for Path Locating (Insert Inductive clamp into Jack)

7 Transmitter Set for Direct Connect Use for Fault Finding or Path Locating.

8 Transmitter Set for Broadcast Inductive Mode for Path Locating.

9 Transmitter Battery Status.

–––

and High.

Circuit Information, mA, V or Resistance in Ohms. Transmitter cycles through each at 2

second intervals.

Do not touch transmitter, leads or connections. Use high voltage precautions to disconnect.

1

5

6

7

8

9

Figure 3 – Transmitter Display

Receiver

Battery

Compartment

Serial Label

Warning

Label

Rear

Spike

Figure 4 – A Frame Receiver

Screen and

Front

Spike

Display

Controls

Receiver Controls/Display:

1

# Icon Description

1 Reference Button

Ref

2 ON/OFF Button

3 Directional Arrow

4

––

5 Low Battery Indicator

2

Stores and displays starting signal strength when pressed.

Main Power Switch – Press to turn unit ON/OFF

Indicates direction of fault

Signal Strength

Displays absolute signal Strength from 0 to 99.

Figure 5 – Receiver Controls

3

4

5

Specifications

FT-103 Transmitter:

Operating

Frequencies .......Direct Fault Finding:

797 Hz - “dFF” displayed

999-995-095.10_REV. A

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

5

Page 8

A-Frame Fault Locator

Path locating:

128 Hz, 1 kHz, 8 kHz, 33

kHz, 93 kHz

Direct Connect:

128 Hz, 1 kHz, 8 kHz, 33

kHz, 93 kHz

Inductive Clamp:

8 kHz, 33 kHz, 93 kHz

Broadcast Inductive:

33 kHz, 93 kHz

Load Range .......5 Ω to 2M Ω

Output Power.....Up to 3 Watts (Low,

medium and high settings)

Output Voltage ...5 Volts - 600 Volts

Power Supply .....8 × C (R14) Cell

Batteries, 12 Volt

Battery Life.........Continuous: up to 15 hours,

Intermittent: up to 60 hours

(on low at 1000 Ohm load)

Operating

Temperature .......-4°F to 133°F

(-20°C to 55°C)

Storage

Temperature.......-13°F to 140°F

(-25°C to 60°C)

IP Rating ............IP54

Size....................8.5" x 5.8" x 2.5"

(21 cm x 15 cm x 6 cm)

Weight................2.2 lbs. (1 kg)

Test Lead

Jacks..................0.16" (4mm) as per

IEC61010

FR-30 A-Frame Receiver:

Operating

Frequencies .......Fault Finding:

797 Hz - “dFF” displayed

Direct Connect:

Power Supply.....6 × AA (LR6) Batteries,

9 Volt

Battery Life..........Continuous: up to 40 hours,

Intermittent: up to 82 hours

Operating

Temperature .......-4°F to 133°F

(-20°C to 55°C)

Storage

Temperature.......-13°F to 140°F

(-25°C to 60°C)

IP Rating ............IP54

Size....................30.3" x 30.4" x 1.5"

(77 cm x 77 cm x 4 cm)

Weight................3 lbs. (1.3 kg)

Standard Equipment

The A-Frame Fault Locator package includes

the following items:

• FR-30 A-Frame Receiver

• FT-103 Transmitter

• Ground Stake

• Red and Black Test Leads (7.5' (2.3 m) long)

• Carry Cases

• Batteries

• Operator’s Manual Pack

NOTICE

This equipment is used for conductor fault and path locating. Incorrect use or

improper application may result in incorrect or

inaccurate locating. Selection of appropriate locating methods for the conditions and proper

operation is the responsibility of the user.

Changing/Installing

Batteries

WARNING

Switch unit OFF and remove any connections from the Transmitter/Receiver

before changing batteries.

Fault Finding

Depth .................Up to 20' (6m) (depend-

ing on conditions)

Fault Finding

Length................Up to 3 miles (4800 m)

(depending on conditions)

Display ...............Black and White LCD

Audio

Indication ...........Piezo Response

6

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

The A-Frame Fault Locator is supplied without

the batteries installed. Remove the batteries

prior to storage to avoid battery leakage. When

the low battery indicator appears on the transmitter ( ) or receiver ( ) display, the batteries need to be replaced.

NOTICE

Use the batteries that are of same

type. Do not mix battery types. Do not mix

new and used batteries. Mixing batteries can

cause overheating and battery damage.

999-995-095.10_REV. A

Page 9

A-Frame Fault Locator

Transmitter:

1. With device OFF, remove the battery compartment cover. If needed, remove batteries (Figure 6).

Battery Compartment

+

-

+

-

+

-

Batteries

Figure 6 – Changing the Batteries (Transmitter)

+

-

Cover

2. Install eight new C Cell alkaline batteries

(R14), observing correct polarity as indicated in the battery compartment.

3. Securely reinstall the battery compartment cover.

Receiver (A-Frame):

1. With device OFF, unscrew the battery

com partment cover on the top tube (Fi -

gure 7). If needed, remove batteries.

Battery

Compartment Cover

Fault Locator and correct any problems

to reduce the risk of serious injury from

electric shock and other causes, and

prevent equipment damage.

1. Make sure the transmitter and receiver

units are OFF.

2. Remove the batteries and inspect for

signs of damage. Replace if necessary.

Do not use if the batteries are damaged.

3. Clean the equipment. This aids inspection

and helps prevent the tool from slipping

from your grip.

4. Inspect the locator for the following:

• Proper assembly, maintenance and com -

pleteness.

• Any broken, worn or missing parts.

• Inspect the transmitter test leads for

damaged insulation or exposed wire.

• Presence and readability of the transmit-

ter and receiver warning labels (Figure

2 and 4).

• Any other condition which may prevent

safe and normal operation.

If any problems are found, do not use

the A-Frame Fault Locator until the problems have been repaired.

5. Inspect and maintain any other equipment being used per its instructions to

make sure it is functioning properly.

Set-Up And Operation

Instructions

Batteries

Figure 7 – Changing the Batteries (Receiver)

2. Install six new AA alkaline batteries (LR6),

observing correct polarity as indicated

in the battery compartment.

3. Securely reinstall the battery compartment cover.

Pre-Operation Inspection

WARNING

Daily before use, inspect your A-Frame

999-995-095.10_REV. A

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Do not connect to live voltage or active

utility lines. Disconnect the conductor

to be tested from any other service, components, or anything that might be affected by high voltage. De-energize any

circuits in or around the work area.

Always attach transmitter test leads before turning unit ON and turn unit OFF before disconnecting leads. This will reduce the risk of electrical shock.

Never turn transmitter ON the unit when

anyone is touching the conductor, ground

stake, or any part of the transmitter. Turn

WARNING

7

Page 10

A-Frame Fault Locator

OFF transmitter before touching test lead

or any un-insulated conductor.

Do not use where a danger of high voltage contact is present. Do not attach

leads to high voltage conductors. The

equipment is not designed to provide

high voltage protection and isolation.

Locating equipment uses electromagnetic fields that can be distorted and interfered with. More than one utility may

be present in a given area. Follow local

guidelines and one call/call before you dig

service procedures. Exposing a utility is

the only way to verify its existence, location and depth.

Follow set up and operating instructions

to reduce the risk of injury from electrical

shock and other causes and to prevent

tool damage

Model FT-103 Transmitter and Model FR-30

Receiver are used for fault locating of conductors through direct connect method.

The Model FT-103 Transmitter only can be

used for path locating with RIDGID SeekTech

and NaviTrack®Locators. This can be done by

direct connect and inductive methods.

1. Confirm have appropriate work area (See

General Safety Rules). Operate in clear,

level, stable, dry location.Do not use transmitter while standing in water.

2. Determine the correct equipment for the

application, see Description and Specifi -

cations sections.

3. Make sure all equipment has been inspected and set up as directed in their instructions.

Fault Locating

It is good practice to locate the conductor path

before attempting to fault locate. This can be

done using a variety of RIDGID locating equipment. If during the location of the conductor

path an unusual amount of signal loss occurs,

this may give some indication of the conductor

insulation fault location. Additionally, use visual

cues and past history to aid in identifying the

conductor path and potential fault locations.

Once the conductor path is determined, the

RIDGID FT-103 Transmitter and FR-30 A-Frame

Receiver can be used to locate ground faults in

the insulated conductor. The Model FT-103

Transmitter connects to the insulated conductor

and establishes a current flow, the current

leaks to ground through the insulation fault

and back to the ground stake. The Model FR-30

Receiver detects the current flow to ground

through the insulation fault. For the A-Frame

fault detector to work, the conductor must be in

contact with the earth – it will not work with conductors in conduit. Generally, the A-Frame Fault

Locator works best in earth. Use with gravel,

asphalt, concrete or other ground covers may

not work as well.

The signal strength at the fault depends on

the amount of current leaking there. The greater

the leakage, the greater the signal strength.

Connecting Transmitter

1. Disconnect all loads and grounds from

the conductor to be tested and all neighboring conductors to prevent damage from

high voltage and false reading. Both ends

should be known and disconnected. Dis connecting both ends of the conductor

forces all of the transmitter signal through

the fault, improving the fault locate.

2. Insert supplied ground stake into the earth.

®

Ideally, the ground stake should be in line

with the conductor, 3' to 6' (1m to 2m)

from the end. If conditions require, the

ground stake can be placed to the side of

the conductor. Do not to place the ground

stake over the conductor. It is not recommended to use other existing grounds,

existing grounds may result in signal being

inadvertently applied to non-target cables.

A good ground results in a stronger tracing

signal. To get a good ground, insert the

ground stake as far as possible into the

earth. Moist earth will give a better ground

than dry earth. Wetting the earth around

the ground stake can improve grounding.

This lowers the resistance of the circuit.

While moist earth around the ground stake

improves the circuit, do not use the transmitter in areas that are wet, this can increase the risk of electrical shock.

3. Make sure that the transmitter is OFF.

4. Connect BLACK test lead to the ground

stake. Always connect to the ground stake

first.

5. Connect the BLACK and RED test leads

to the Transmitter.

6. Connect the RED test lead to the conductor to be tested (see Figure 9).

8

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

999-995-095.10_REV. A

Page 11

Transmitter

A-Frame Fault Locator

Red

Black

Ground Rod

3" – 6"

(1 – 2 m)

Figure 8 – Transmitter Connections for Fault Locating

Buried Conductor

Locating

1. Make sure that no one is near or touching

the conductor, transmitter, leads or ground

stake. Press the ON/OFF button on the

transmitter to turn the transmitter ON.

Receiver

Return Path

Through Soil

THE TRANSMITTER, LEADS OR CONNECTIONS. The target conductor is energized and

there is the risk of electrical shock. Use high

voltage precautions to disconnect.

2. When fault locating, generally the receiver

When the transmitter is turned on, it is set

to the last used frequency. If needed,

press the frequency button on the transmitter until “dFF” is shown on screen

(Figure 9).

Earth

Fault

should be used over the conductor, with

the front receiver spike towards the expected fault and the rear receiver spike towards the ground stake. The receiver

spikes should evenly penetrate the earth

to make good electrical contact. The current flowing in and out of the ground

spikes supplies the signal to locate the insulation fault (see Figure 10).

Figure 9 – Transmitter Screen

Adjust the signal power by pressing the signal

Conductor (End View)

Figure 10 – Receiver Positioning

Conductor (Side View)

power button to cycle through the settings (low,

medium and high). Using high power may result in signal going to ground at non-target

points, low power may mean a circuit is not created. The transmitter will display circuit resistance (OHMS) at the bottom of the LCD. The

lower the resistance the better the locate signal.

To improve the circuit, improve the ground,

check the lead connections or increase the

power.

The transmitter will continuously beep when

there is a circuit. The lower the circuit resistance, the quicker the beep. The transmitter

will beep three times and a pause (repeating) if there is no circuit.

If the transmitter display shows voltage warning (Figure 3), the transmitter is connected to

3. To start the locate, place the A-Frame

receiver between the ground stake and

the transmitter connection to the conductor. Press the A-Frame Receiver ON/OFF

button to turn receiver ON.

The signal strength will appear on the

receiver display. Signal strength will be the

highest near the ground stake and at

faults. Press the “Ref” button to store a reference signal strength near the ground

stake.

The receiver display arrows will indicate

the direction of the fault. Fault direction is

also indicated audibly - a long slow beep

indicates forward direction and a quick

beep indicates backward direction.

live voltage. If this happens, DO NOT TOUCH

999-995-095.10_REV. A

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

9

Page 12

A-Frame Fault Locator

4. Remove the receiver from the earth and

move several steps as indicated by the

directional arrow and beeping along the

conductor path. Reinsert the receiver

spikes into the earth (Figure 11).

Continue moving away from the ground

stake along the conductor path. Signal

strength should drop (in some cases going

to zero) and then rise as you move towards a fault.

5. Signal strength will peak over the fault. If

you pass the fault, the directional arrow will

change direction and the beep will change

from long slow to quick beep and the signal strength will decrease. Continue to

move the receiver back and forth until

slight movement causes the directional

arrows and beeping to toggle back and

forth. At this point, the fault is centered between the spikes of the receiver.

Compare the signal strength to the refer-

ence signal strength taken near the

ground stake. They should be similar. If the

fault signal strength is much lower than the

reference value, you may not have located a fault. For instance, a grounded

splice point would behave as a fault during

the locate, but would give a much lower

signal strength. For a low fault signal

strength, you may want to mark the location and continue down the conductor

path looking for a fault signal strength

closer to the reference signal.

Once a fault is located with a signal similar

to the reference signal, turn the A-Frame

Locator perpendicular to the path of the

conductor. Move the receiver back and

forth until slight movement causes the directional arrows and beeping to toggle

back and forth. At this point, the fault is

centered between the spikes of the receiver. See Figure 12. Mark the location of

the fault.

6. Once the locating is completed, press the

ON/OFF button to turn the transmitter OFF.

Always turn the unit OFF before disconnecting the cable leads to reduce the risk

of electrical shock. Remove the cable lead

from the target conductor first. Always disconnect the cable lead from the target

conductor first before removing the cable

lead from the ground spike to reduce the

risk of electrical shock. Disconnect the

cable lead from the ground spike.

Locating Below Paved

Surfaces

Locating can be difficult if the fault is below a

paved surface, because the receiver spikes

cannot make good electrical contact with

the earth. In this case, there are several

methods that can be used.

Signal Strength

Ground Rod

Figure 11 – Signal Strength

Conductor (End View)

Fault

Figure 12 – Final Locate

10

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Fault

Signal

Strength

Conductor (Side View)

Fault

999-995-095.10_REV. A

Page 13

A-Frame Fault Locator

• If the paved area is relatively small, the

receiver can be used around the periphery

of the area. The receiver can be rotated

side to side, and where the receiver directional arrows and beeping toggle back

and forth, extend a straight line perpendicular to the center of the A-Frame Receiver.

Do this in several locations around the

suspected fault area. The straight lines

should all intersect at the same point. This

is the location of the fault. This method of

locating is less exact than placing the receiver directly over the conductor. See

Figure 13.

• An alternate way to locate below paved

surfaces is to improve the conductivity between the pavement and the receiver with

water. One method is to attach sponges to

the spikes of the receiver. Wet the sponges

with water and keep wet. Conduct the fault

locate normally.

• Another method is to wet the surface of the

pavement with water and conduct the fault

locate normally. Do not do this in the area

of the transmitter – this increases the risk of

electrical shock.

Paved Area

Conductor

can be used to apply an active tracing signal to

a conductor in three ways:

• Direct Connect – The transmitter’s leads

are connected directly to the target conductor and a suitable ground. This method is

most commonly used when the target utility is accessible. Direct connect should not

be used for energized (live) conductors.

• Inductive Clamp (optional equipment) –

the jaws of the inductive clamp encircle

the target conductor; if the conductor is insulated, there is no metal to metal contact.

This method is commonly used when the

target utility is accessible but direct connect is not possible on an insulated cable.

• Broadcast Inductive Mode – The transmitter generates a field, which in turn induces

a current in the target conductor. There is no

direct connection between the transmitter

and the target conductor. The transmitter is

placed over and inline with the target conductor. The transmitter’s internal antenna induces a signal onto the target conductor.

This method is most commonly used when

the target utility is not accessible.

Disconnect all loads from the conductor to

be tested and all neighboring conductors to

prevent damage from high voltage and false

reading.

Fault

Figure 13 – Locating below paved surfaces

Multiple Faults

If there are multiple faults in the conductor,

the faults will have signals proportional to

the amount of current leaking. The locate is

done the same as for a single fault, but the

signal strength will not be as strong. Typically,

the largest fault (least resistance fault) is

easiest to find. Best practice is to find and repair the first fault and continue the locate

for other faults.

Path Locating

The FT-103 Transmitter can be used with other

commercially available receivers (such as the

RIDGID SeekTech or NaviTrack receivers) to

path locate conductors. The FT-103 transmitter

Direct Connect Path Locating

Method

1. Insert supplied ground stake into the

earth. Or, if other good grounds are available in the area, they can be used.

A good ground results in a stronger tracing

signal. To get a good ground, insert the

ground stake as far as possible into the

earth. Moist earth will give a better ground

than dry earth. Wetting the earth around

the ground stake can improve grounding.

This lowers the resistance of the circuit.

While moist earth around the ground

stake improves the circuit, do not use the

transmitter in areas that are wet, this can

increase the risk of electrical shock.

The far end of the conductor should be

grounded.

2. Make sure that the transmitter is OFF.

3. Connect BLACK test lead to the ground

stake. Always connect to the ground stake

first.

4. Connect the BLACK and RED test leads

to the Transmitter.

999-995-095.10_REV. A

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

11

Page 14

A-Frame Fault Locator

5. Connect the RED test lead to the conductor to be tested.

6. Press the ON/OFF button to turn the transmitter ON. When the transmitter is turned

on, it is set to the last used frequency.

Press the frequency selection button to

cycle through frequency settings to the

desired locating frequency.

Adjust the signal power by pressing the

signal power button to cycle through the

settings (low, medium and high). Using

high power can couple into non-target

conductors, low power may mean a circuit

is not created. The transmitter will display

circuit resistance (OHMS) at the bottom of

the LCD. The lower the resistance the better the locate signal. To improve the circuit,

improve the ground, check the lead connections, increase power or change the

frequency.

If the transmitter display shows voltage

warning (Figure 3), the transmitter is con-

nected to live voltage. If this happens,

DO NOT TOUCH THE TRANSMITTER,

LEADS OR CONNECTIONS. The tar-

get conductor is energized and there is

the risk of electrical shock. Use high voltage precautions to disconnect.

7. Check the circuit and adjust signal power,

grounding or connections to ensure locatable field.

8. Turn ON the receiver/locator and follow

the instructions for the receiver. Make sure

the receiver’s frequency is set to match that

on the transmitter. Confirm the receiver is

picking up the transmitted frequency by

holding it near the transmitter and observing the increase in receiver signal.

9. Once the locating is completed, press the

ON/OFF button to turn the transmitter

OFF. Always turn the unit OFF before disconnecting the cable leads to reduce the

risk of electrical shock. Remove the cable

lead from the target conductor first. Always

disconnect the cable lead from the target

conductor first before removing the cable

lead from the ground spike to reduce the

risk of electrical shock. Disconnect the

cable lead from the ground spike.

all instruction for the use of the inductive

clamp.

2. Insert the plug of the inductive clamp

into transmitter (see Figure 2).

3. Clamp the jaws of the inductive clamp

around the target conductor. Make sure

that the jaws of the clamp are fully closed.

(See Figure 14). Both ends of the conductor should be grounded for best results.

Figure 14 – Inductive Clamp Attached to a

Conductor

4. Press the ON/OFF button to turn the trans mitter ON. When the clamp is plugged in

the clamp symbol ( ) shows on the

screen and only clamp frequencies are

available. Press the frequency selection

button to cycle through frequency settings

to the desired locating frequency. Adjust

the signal power by pressing the signal

power button to cycle through the settings

(low, medium and high). The inductive

clamp typically works best with frequencies around 8kHz, 33 kHz, 93kHz.

5. Check the circuit and adjust signal strength

(see Figure 3, Circuit Information).

6. Turn ON the receiver/locator and follow

the instructions for the receiver. Make

sure the receiver’s frequency is set to

match that on the transmitter. Confirm

the receiver is picking up the transmitted

frequency by holding it near the transmitter and observing the increase in receiver signal.

7. Once the locating is completed, press

the ON/OFF button to turn the transmitter

OFF.

Inductive Clamp Path

Locating

1. This method requires an inductive clamp

(Optional equipment). Read and follow

Broadcast Inductive Path

Locating

1. Properly place the transmitter relative to

the target conductor (see Figure 15). On

the top of the transmitter is an arrow. Set

12

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

999-995-095.10_REV. A

Page 15

A-Frame Fault Locator

transmitter on ground,

align arrow with the

target conductor.

Conductor

2. Press the ON/OFF

button to turn the

trans mitter ON. Press

and hold the power

button for 5 seconds

selection button to

shift transmitter into

broadcast inductive

mode. Broadcast inductive icon ( ) appears on screen and

the transmitter will

start beeping to indicate that it is operating.

Figure 15 –

Orientation to the

Line – Inductive

Mode

Adjust the signal power by pressing the

signal power button to cycle through the

settings (low, medium and high) and

choose high. Press the frequency selection button to cycle through 33khz and

93kHz frequency settings to the desired

locating frequency. When using Broadcast

Inductive Mode, higher frequencies tend

to get a better signal at the receiver.

3. Turn ON the locator and follow its instructions. Make sure to set the receiver to

the same frequency as the transmitter.

ductor. This is called “Air Coup ling”. Operate

the receiver at least 30 feet from the transmitter to prevent this. (See Figure 16).

One way to confirm that you are tracing the

target conductor and not the transmitter

field is to look for a strong, stable prox imity

signal and a valid depth measurement on

the receiver. While directly over the energized line you can also raise the receiver a

set distance off of the ground, and verify

that the depth reading on the display e quals the distance that you raised the receiver.

4. Once the locating is completed, press the

Power ON/OFF button for 5 seconds to

exit broadcast inductive mode, then press

the ON/OFF button to turn the transmitter

OFF.

Storage

Remove batteries from tool. Store the A-Frame

Fault Locator in case. Avoid storing in extreme heat or cold.

WARNING

area that is out of reach of children and

people unfamiliar with the RIDGID A-Frame

Fault Locator. The locator is dangerous in

the hands of untrained users.

Store tool in a dry, secured

Transmitter Field

Induced

Field on

Target

Conductor

Conductor

30 feet

Minimum

Figure 16 – Orientation to the Line – Inductive

Mode

When the transmitter is in broadcast induc-

tive mode, it generates a field around the

transmitter. This field is in both the ground

(towards the target conductor) and into

the air around the transmitter. When the receiver is within approximately 30 feet (10

meters) of the transmitter, it will measure

the field directly from the transmitter and

not the signal induced on the target con-

Maintenance

WARNING

Remove batteries from tool before performing maintenance or making any

adjustment.

Cleaning

Do not immerse the A-Frame Fault Locator in

water. Wipe off dirt with a damp soft cloth.

Avoid rubbing too hard. Do not use aggressive

cleaning agents or solutions.

Calibration

The A-Frame Fault Locator is factory calibrated and only requires recalibration if repaired.

Service And Repair

WARNING

Improper service or repair can make

the machine unsafe to operate.

Service and repair on this A-Frame Fault Lo -

999-995-095.10_REV. A

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

13

Page 16

A-Frame Fault Locator

cator must be performed by a RIDGID Inde pendent Service Center. Use only RIDGID

service parts.

For information on your nearest RIDGID Inde pen dent Service Center or any service or repair

questions, see Contact Information Section in

this manual.

Optional Equipment

WARNING

To reduce the risk of injury, only use accessories specifically designed and recommended for use with the RIDGID AFrame Fault Locator, such as listed below.

Catalog

No. Description

20973 RIDGID SeekTech 4" (100 mm)

Inductive Signal Clamp

57763 Ground Stake, FT-103

57768 Red and Black Test Leads, FT-103

96967 RIDGID NaviTrack II Locator

19238 RIDGID NaviTrack Scout Locator

22163 RIDGID SeekTech SR-60 Line Locator

21893 RIDGID SeekTech SR-20 Line Locator

44473 RIDGID SR-24 Line Locator with

Bluetooth

®

and GPS

Disposal

Parts of this tool contain valuable materials

and can be recycled. There are companies

that specialize in recycling that may be found

locally. Dispose of the components in compliance with all applicable regulations. Contact

your local waste management authority for

more information.

For EC Countries: Do not dispose

of elec trical equipment with household waste!

According to the European Guide line 2012/ 19/EU for Waste Elec trical

and Electronic Equipment and its

imple men tation into national legislation, electrical equipment that is no longer usable must

be collected separately and disposed of in

an environmentally correct manner.

Battery Disposal

For EC countries: Batteries must be recycled

according to the guideline 2006/66/EEC.

EC Declaration of

Conformity

The EC Declaration of Conformity (890-011-

320.10) will accompany this manual as a separate booklet when required.

FCC Statement

This equipment has been found to comply

with the limits for a Class B digital device,

pursuant to part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful interference in a residential installation.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference

to radio communications.

However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can

be determined by turning the equipment OFF

and ON, the user is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Consult the dealer or an experienced radio/ TV technician for help.

Electromagnetic

Compatibility (EMC)

The term electromagnetic compatibility is taken

to mean the capability of the product to function

smoothly in an environment where electromagnetic radiation and electrostatic discharges

are present and without causing electromagnet

interference to other equipment.

NOTICE

conform to all applicable EMC standards.

However, the possibility of it causing interference in other devices cannot be precluded. All

EMC related standards that have been tested

are called out in the tool’s technical document.

The RIDGID A-Frame Fault Locator

14

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

999-995-095.10_REV. A

Page 17

What is covered

RIDGID®tools are warranted to be free of defects in workmanship and material.

How long coverage lasts

This warranty lasts for the lifetime of the RIDGID

®

tool. Warranty coverage ends when the

product becomes unusable for reasons other than defects in workmanship or material.

How you can get service

To obtain the benefit of this warranty, deliver via prepaid transportation the complete product to RIDGE TOOL COMPANY, Elyria, Ohio, or any authorized RIDGID

®

INDEPENDENT

SERVICE CENTER. Pipe wrenches and other hand tools should be returned to the place of purchase.

What we will do to correct problems

Warranted products will be repaired or replaced, at RIDGE TOOL’S option, and returned at no

charge; or, if after three attempts to repair or replace during the warranty period the product

is still defective, you can elect to receive a full refund of your purchase price.

What is not covered

Failures due to misuse, abuse or normal wear and tear are not covered by this warranty. RIDGE

TOOL shall not be responsible for any incidental or consequential damages.

How local law relates to the warranty

Some states do not allow the exclusion or limitation of incidental or consequential damages,

so the above limitation or exclusion may not apply to you. This warranty gives you specific

rights, and you may also have other rights, which vary, from state to state, province to

province, or country to country.

No other express warranty applies

This FULL LIFETIME WARRANTY is the sole and exclusive warranty for RIDGID

®

products. No employee, agent, dealer, or other person is authorized to alter this warranty or make

any other warranty on behalf of the RIDGE TOOL COMPANY.

Ce qui est couvert

Les outils RIDGID

Durée de couverture

Cette garantie est applicable durant la vie entière de l’outil RIDGID

que le produit devient inutilisable pour raisons autres que des vices de matériaux ou de main

d’oeuvre.

Pour invoquer la garantie

Pour toutes réparations au titre de la garantie, il convient d’expédier le produit complet en port

payé à la RIDGE TOOL COMPANY, Elyria, Ohio, ou bien le remettre à un réparateur RIDGID

agréé. Les clés à pipe et autres outils à main doivent être ramenés au lieu d’achat.

Ce que nous ferons pour résoudre le problème

Les produits sous garantie seront à la discrétion de RIDGE TOOL, soit réparés ou remplacés,

puis réexpédiés gratuitement ; ou si, après trois tentatives de réparation ou de remplacement

durant la période de validité de la garantie le produit s’avère toujours défectueux, vous aurez

l’option de demander le remboursement intégral de son prix d’achat.

Ce qui n’est pas couvert

Les défaillances dues au mauvais emploi, à l’abus ou à l’usure normale ne sont pas couvertes

par cette garantie. RIDGE TOOL ne sera tenue responsable d’aucuns dommages directs ou indirects.

L’influence de la législation locale sur la garantie

Puisque certaines législations locales interdisent l’exclusion des dommages directs ou indirects,

il se peut que la limitation ou exclusion ci-dessus ne vous soit pas applicable. Cette garantie vous

donne des droits spécifiques qui peuvent être éventuellement complétés par d’autres droits

prévus par votre législation locale.

Il n’existe aucune autre garantie expresse

Cette GARANTIE PERPETUELLE INTEGRALE est la seule et unique garantie couvrant les produits RIDGID®. Aucun employé, agent, distributeur ou tiers n’est autorisé à modifier cette

garantie ou à offrir une garantie supplémentaire au nom de la RIDGE TOOL COMPANY.

®

sont garantis contre tous vices de matériaux et de main d’oeuvre.

®

. La couverture cesse dès lors

®

FULL LIFETIME

WARRANTY

Against Material Defects

& Workmanship

Full lifetime warranty (garantie légale étendue à la durée de vie du produit,

voir conditions de garantie / legal warranty extended to the product lifecyle,

see warranty conditions)

Ridge Tool Company

Qué cubre

Las herramientas RIDGID

®

están garantizadas contra defectos de la mano de obra y de los

materiales empleados en su fabricación.

Duración de la cobertura

Esta garantía cubre a la herramienta RIDGID

®

durante toda su vida útil. La cobertura de la

garantía caduca cuando el producto se torna inservible por razones distintas a las de defectos en la mano de obra o en los materiales.

Cómo obtener servicio

Para obtener los beneficios de esta garantía, envíe mediante porte pagado, la totalidad del producto a RIDGE TOOL COMPANY, en Elyria, Ohio, o a cualquier Servicentro Independiente

RIDGID. Las llaves para tubos y demás herramientas de mano deben devolverse a la tienda

donde se adquirieron.

Lo que hacemos para corregir el problema

El producto bajo garantía será reparado o reemplazado por otro, a discreción de RIDGE TOOL,

y devuelto sin costo; o, si aún resulta defectuoso después de haber sido reparado o sustituido tres veces durante el período de su garantía, Ud. puede optar por recibir un reembolso

por el valor total de su compra.

Lo que no está cubierto

Esta garantía no cubre fallas debido al mal uso, abuso o desgaste normal. RIDGE TOOL no

se hace responsable de daño incidental o consiguiente alguno.

Relación entre la garantía y las leyes locales

Algunos estados de los EE.UU. no permiten la exclusión o restricción referente a daños incidentales o consiguientes. Por lo tanto, puede que la limitación o restricción mencionada

anteriormente no rija para Ud. Esta garantía le otorga derechos específicos, y puede que,

además, Ud tenga otros derechos, los cuales varían de estado a estado, provincia a provincia o país a país.

No rige ninguna otra garantía expresa

Esta GARANTIA VITALICIA es la única y exclusiva garantía para los productos RIDGID

®

.

Ningún empleado, agente, distribuidor u otra persona está autorizado para modificar esta

garantía u ofrecer cualquier otra garantía en nombre de RIDGE TOOL COMPANY.

Printed 3/17 999-995-095.10

EC42552 REV. A

Find Quality Products Online at: sales@GlobalTestSupply.com

The Emerson logo and RIDGID logo are registered trademarks of Emerson Electric Co. or RIDGID, Inc. in the U.S. and other countries.

All other trademarks belong to their respective holders.

www.GlobalTestSupply.com

©2017, RIDGID, Inc.

Loading...

Loading...