RIDGID 65R-C, 65R-TC User Manual

Ridge Tool Co., Elyria, Ohio, U.S.A.

9/05

Printed in U.S.A. 999-998-280.10

Rev. A

65R-C & 65R-TC Manual

Pipe Threader Instructions

RIDGID 65R-C and 65R-TC Threaders are designed to

thread 1″ to 2″ pipe and conduit using a manually operated internal ratchet.

Read these instructions carefully before

using this tool. Failure to follow all instructions may

result in property damage and/or serious injury.

Thread Size Adjustment

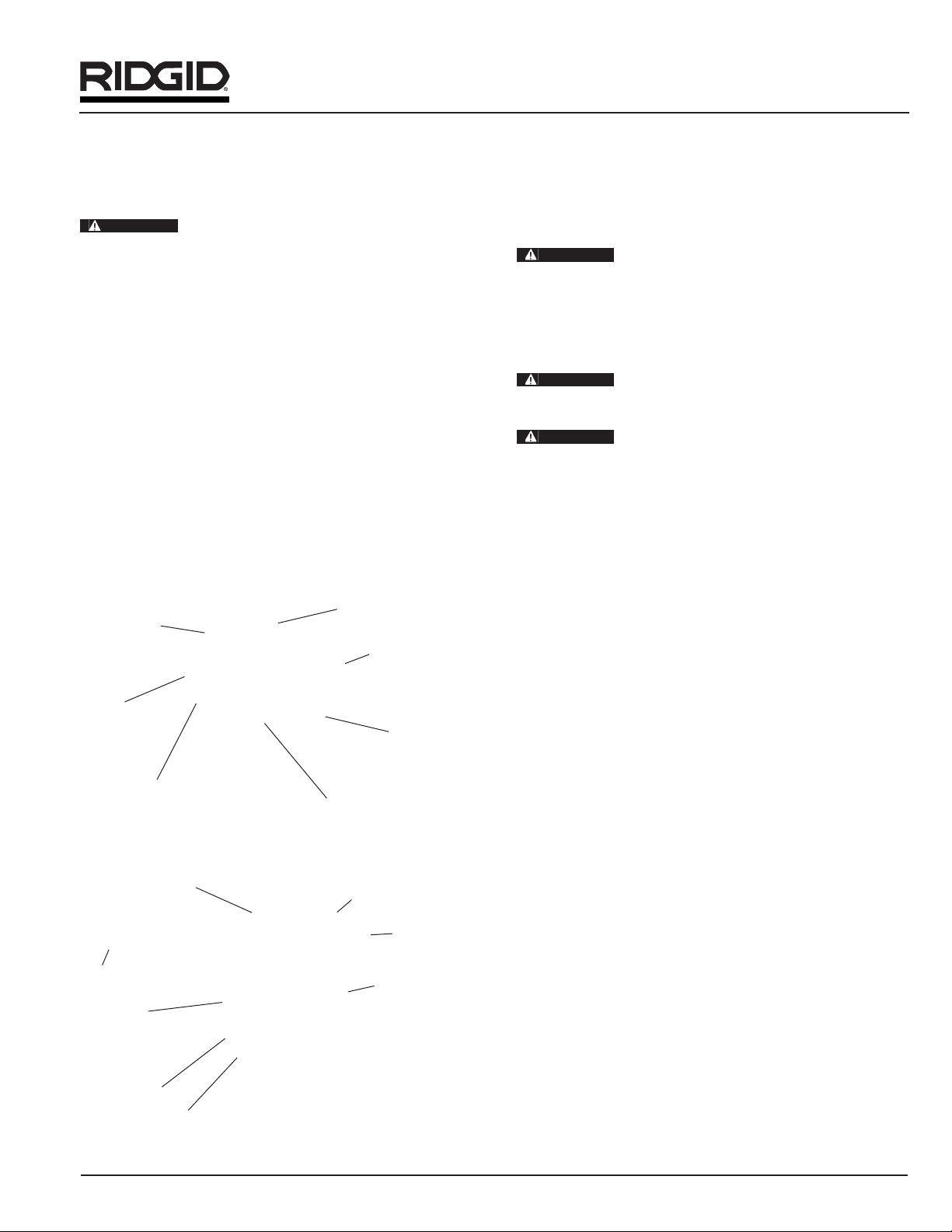

1. Place threader with workholder up (Figures 1 and 2)

and unscrew workholder by turning counter-clockwise

until change plate is clear of posts.

2. Move post to desired pipe size. Screw workholder

clockwise until change plate slides over post.

3. Adjust change plate to desired thread size.

Standard Size Thread: Set change plate between the

two “Standard” marks.

Oversize Thread: For oversize (shallow) thread, set

change plate slightly below the “Standard” marks.

Undersize Thread: For undersize (deep) thread, set

change plate slightly above the “Standard” marks.

Figure 1 – 65R-C Threader

Figure 2 – 65R-TC Threader

Threading:

1. Inspect the threader before use. Replace dies or any

other pat that shows damage or wear. To insure high

thread quality, only use RIDGID replacement dies.

Worn dies can result in poor thread quality

and high handle forces.

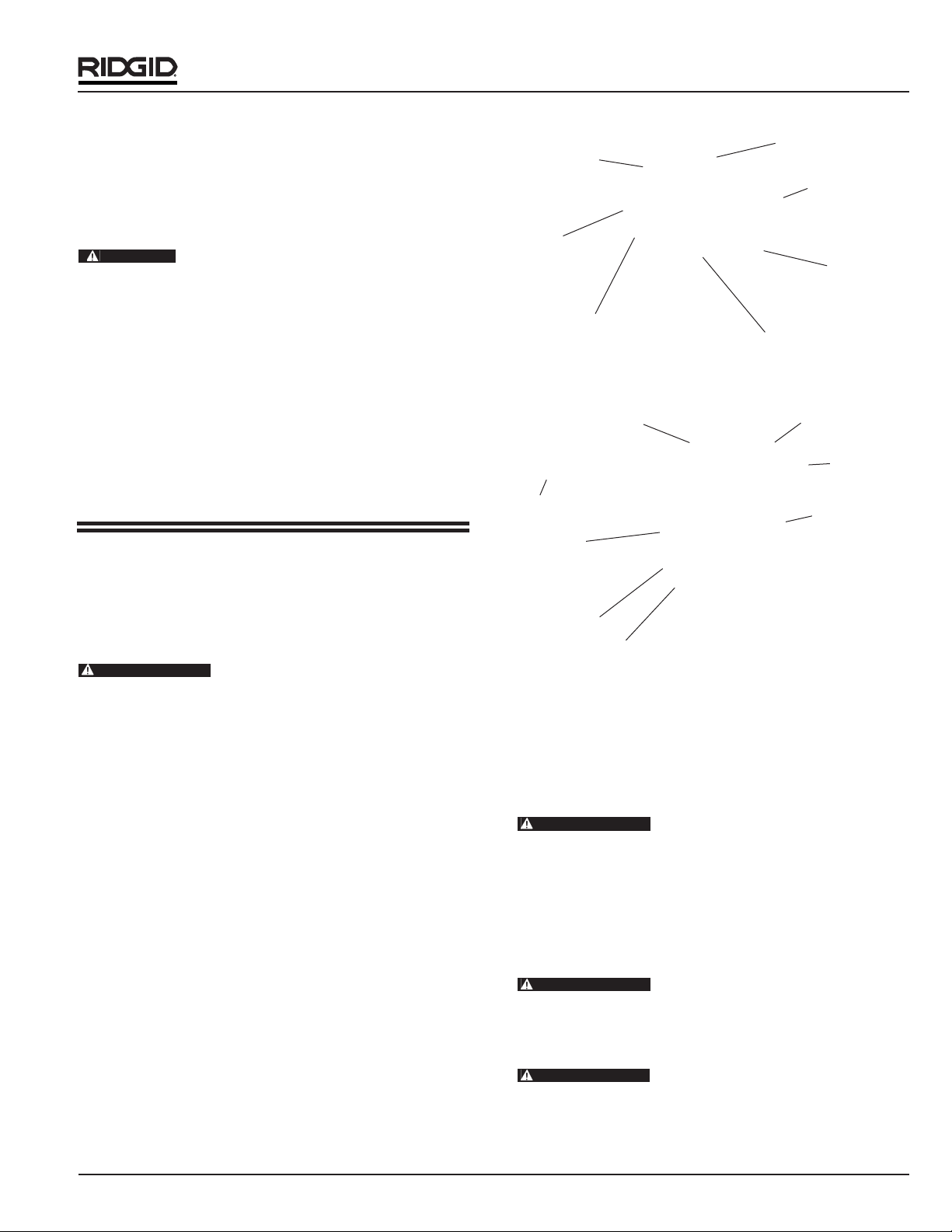

2. Mount the pipe firmly in a pipe vise. When threading

an existing pipe, make sure it is secure and will no

move. Cut the end of the pipe cleanly and squarely

using a pipe cutter (Figure 3).

To prevent tipping, long lengths of pipe

should also be supported with a pipe stand. Vise and

stands should be on level ground.

When working on a scaffold or lift, the operator should be properly secured to prevent injury in the

event of a fall.

Figure 3 – Cutting End Of Pipe

3. Ream the end of the pipe to remove any burrs that

may have been produced during the cutting of the

pipe (Figure 4).

Figure 4 – Reaming End Of Pipe

WARNING

WARNING

WARNING

WARNING

Gauge

Ring

Lugs

Clamp

Screw

Change

Plate

Post

Workholder

Jaw

Workholder

Pipe

Handle

Gauge Ring

Release Cam

Lever

Post

Change Plate

Clamp Screw

Workholder Jaw

Standard

Marks

4. Adjust thread size for the size pipe to be threaded

(refer to previous instructions for thread size adjustment).

5. Adjust workholder:

65R-C: Turn gage ring until desired pipe size corresponds with mark on top of workholder (Figure 1).

65R-TC: Turn gage ring until desired pipe size is aligned

with locking cam (Figure 2).

6. Turn release cam lever to the “closed” position. Slide

threader on the pipe with the workholder end first

(Figure 5). Center end of pipe in the throat of the dies.

7. Secure workholder on the pipe by tightening the

clamp screw (Figure 1) or the locking cam (Figure 2).

Figure 5 – Sliding Threader Onto Pipe

8. Move the handle in a pumping action to thread the

pipe.

Make sure the handle is clean and free from

oil and grease. This allows for better control of the tool.

9. When hand threading, your weight should be above

the handle ensuring maximum leverage. If possible,

do not do all the work with you arms; use your weight.

Do not overreach. Keep proper footing and balance to

maintain better control.

Do not slide a pipe or “cheater” over the

handle to gain extra leverage. This practice can result in

serious injury.

NOTE! When using the 65-R Threader with the 300

Power Drive, manually start the thread (approximately one turn) before starting power drive.

Figure 6 – Applying Thread Cutting Oil

10. Apply a generous quantity of RIDGID Thread Cutting

Oil when threading (Figure 6). Use of a lubricating oil

or a poor thread cutting oil can result in a poor quality

cut thread, leaky joints, short die life and high handle

forces.

11. 65R Threaders are jam-proof and will automatically

kick out and disengage the ratchet action when the

thread is complete.

12. Remove threader from pipe by turning release cam

lever to “OPEN” and spin threader back to the “STANDARD” position. Loosen clamp screw or locking cam

and slide threader off the pipe.

or

Remove by turning the release lever to “OPEN” position, loosening clamp screw or locking cam, and

pulling threader straight off pipe. Maintain close control of the threader so the threads are not damaged.

Spinning the threader back to the “STANDARD” position is not required.

NOTE! Clean any oil spill or splatter that is on the

ground. At the end of each job, always clean

your threader and store in a clean dry area to

protect against damage.

Changing Dies

1. Place threader in position as shown in Figure 1 and

unscrew workholder upwards until change plate is

clear of post. Turn release cam lever to OPEN position.

2. Push post to the left past the 2″ mark. Turn the threader over and remove dies. If the dies stick, tap the

ratchet ring lightly behind the die.

3. Insert new dies making sure die numbers correspond

to the slot numbers. Replace complete die set. Move

post to engage dies.

Failure to replace complete die set may result

in poor thread quality and leaky joints.

Ridge Tool Co., Elyria, Ohio, U.S.A.

65R-C & 65R-TC Manual Pipe Threader Instructions

WARNING

WARNING

CAUTION

2

Ridge Tool Co., Elyria, Ohio, U.S.A.

65R-C & 65R-TC Manual Pipe Threader Instructions

4. Turn threader over and set post to desired pipe size.

Screw workholder down so change plate is between

the “Standard” size marks and you are ready to

resume threading.

Service and Repair

When servicing this tool, only identical

replacement parts should be used. Failure to follow these

steps may create a risk of serious injury.

If you have any questions regarding the service or repair

of this machine, call or write to:

Ridge Tool Company

Technical Service Department

400 Clark Street

Elyria, Ohio 44035-6001

Tel: (800) 519-3456

E-mail: TechServices@ridgid.com

For name and address of your nearest Independent

Authorized Service Center, contact the Ridge Tool Company at (800) 519-3456 or http://www.ridgid.com

WARNING

3

Fileteuse manuelle 65R-C et 65R-TC :

Mode d’emploi

Les fileteuses RIDGID 65RC et 65R-TC sont prévues

pour le filetage des tuyaux et gaines de 1 à 2 po de

diamètre à l’aide d’une clé à cliquets manuelle.

Lisez ces instructions soigneusement avant d’utiliser l’appareil. Le non-respect de l’ensemble des consignes ci-devant pourrait entraîner

d’importants dégâts matériels et/ou de graves lésions

corporelles.

Réglage du pas de filetage

1. Positionnez la fileteuse avec son anneau de serrage

vers le haut (Figures 1 et 2), puis dévissez l’anneau de

serrage en le tournant à gauche jusqu’à ce que la platine de réglage se désengage du poteau.

2. Amenez le poteau jusqu’à la section de tuyau voulue.

Vissez l’anneau de serrage jusqu’à ce que la platine

de réglage s’engage sur le poteau.

3. Amenez la platine de réglage à la dimension de pas

voulu.

Pas standard : Centrez la platine de réglage entre les

deux repères «Standard».

Pas surdimensionné : Pour obtenir un pas surdimensionné (moins profond), descendez la platine de réglage

légèrement en dessous des repères «Standard».

Pas sousdimensionné : Pour obtenir un pas sousdimensionné (plus profond), montez la platine de réglage

légèrement au-dessus des repères «Standard».

Figure 1 – Fileteuse 65R-C

Figure 2 – Fileteuse 65R-TC

Le filetage :

1. Examinez la fileteuse avant toute utilisation. Remplacer les filières ou tout autre composant endommagé ou usé. N’utilisez que les filières de remplacement RIDGID afin d’assurer un filetage de qualité.

Les filières émoussées risquent de

produire de filetages de mauvaise qualité et de créer

une résistance excessive.

2. Arrimez le tuyau dans un étau à tubes. Lors du filetage d’un tuyau déjà installé, assurez-vous qu’il est

bien arrimé et ne risque pas de glisser. Coupez l’ex-

trémité du tuyau proprement et bien d’équerre à

l’aide d’un coupe-tubes (Figure 3).

Afin d’éviter les risques de renversement de l’ensemble, soutenez les tuyaux de

grande longueur à l’aide d’un porte-tubes. L’étau et les

porte-tubes éventuels doivent être installés sur un sol de

niveau.

Tout utilisateur travaillant sur échafaudage ou élévateur doit être correctement sanglé en

cas de chute.

Bague de

calibrage

Goujons

Vis de blocage

Platine de

réglage

Poteau

Mâchoire d’anneau

de serrage

Anneau de

serrage

Manche

tubulaire

Bague de

calibrage

Levier

d’ouverture

de came

Poteau

Platine de

réglage

Vis de blocage

Mâchoire d’anneau

de serrage

Repère

«Standard»

MISE EN GARDE

MISE EN GARDE

MISE EN GARDE

MISE EN GARDE

Loading...

Loading...