RIDGID 918-i, 64977, 65902 Operator's Manual

Heavy Duty

Roll Grooving

Machine

OPERATOR’S

MANUAL

918-I

WARNING!

Read this Operator’s Manual

carefully before using this

tool. Failure to understand

and follow the contents of

this manual may result in

electrical shock, fire and/or

serious personal injury.

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

918-I Heavy Duty Roll Grooving Machine

Ridge Tool Company2

General Safety Information

WARNING! Read and understand all instructions.

Failure to follow all instructions listed

below may result in electric shock, fire,

and/or serious personal injury.

SAVE THESE INSTRUCTIONS!

Work Area Safety

• Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

• Do not operate electric tools in explosive atmo-

spheres, such as in the presence of flammable

li quids, gases, or dust. Electric motors create sparks

which may ignite the dust or fumes.

• Keep bystanders, children, and visitors away while

operating a tool. Distractions can cause you to lose

control.

• Keep floors dry and free of slippery materials such

as oil. Slippery floors invite accidents.

Electrical Safety

• Grounded tools must be plugged into an outlet,

properly installed and grounded in accordance

with all codes and ordinances. Never remove the

grounding prong or modify the plug in any way. Do

not use any adapter plugs. Check with a qualified

electrician if you are in doubt as to whether the outlet is properly grounded. If the tools should electrically

malfunction or break down, grounding provides a low

resistance path to carry electricity away from the user.

• Avoid body contact with grounded surfaces. There

is an increased risk of electrical shock if your body is

grounded.

• Don’t expose electrical tools to rain or wet condi-

tions. Water entering an electrical tool will increase the

risk of electrical shock.

• Do not abuse cord. Never use the cord to pull the

plug from an outlet. Keep cord away from heat, oil,

sharp edges or moving parts. Replace damaged

cords immediately. Damaged cords increase the risk

of electrical shock.

• When operating a tool outside, use an outdoor

extension cord marked “W-A” or “W”. These cords

are rated for outdoor use and reduce the risk of electrical shock.

• Keep all extension cord connections dry and off the

ground. Do not touch plugs with wet hands. This

practice reduces the risk of electrical shock.

• Use only three-wire extension cords which have

three-prong grounding plugs and three-pole receptacles which accept the machine plug. Use of

other extension cords will not ground the tool and increase the risk of electrical shock.

• Use proper extension cords.

(See chart.)

Insufficient

conductor size will cause excessive voltage drop, loss

of power.

Personal Safety

• Stay alert, watch what you are doing and use com-

mon sense when operating a tool. Do not use tools

while tired or under the influence of drugs, alcohol,

or medications. A moment of inattention while oper-

ating tools may result in serious personal injury.

• Dress properly. Do not wear loose clothing or jew-

elry. Contain long hair. Keep your hair and clothing

away from moving parts. Loose clothes, jewelry, or

long hair can be caught in moving parts.

• Avoid accidental starting. Be sure switch is OFF be-

fore plugging in. Plugging tools in that have the

switch ON invites accidents.

• Remove wrenches or adjusting keys before turning

the tool ON. A wrench or a key that is left attached to

a rotating part of the tool may result in personal injury.

• Do not over-reach. Keep proper footing and bal-

ance at all times. Proper footing and balance enables

better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protec-

tion. Dust mask, non-skid safety shoes, hard hat,

or hearing protection must be used for appropriate

conditions.

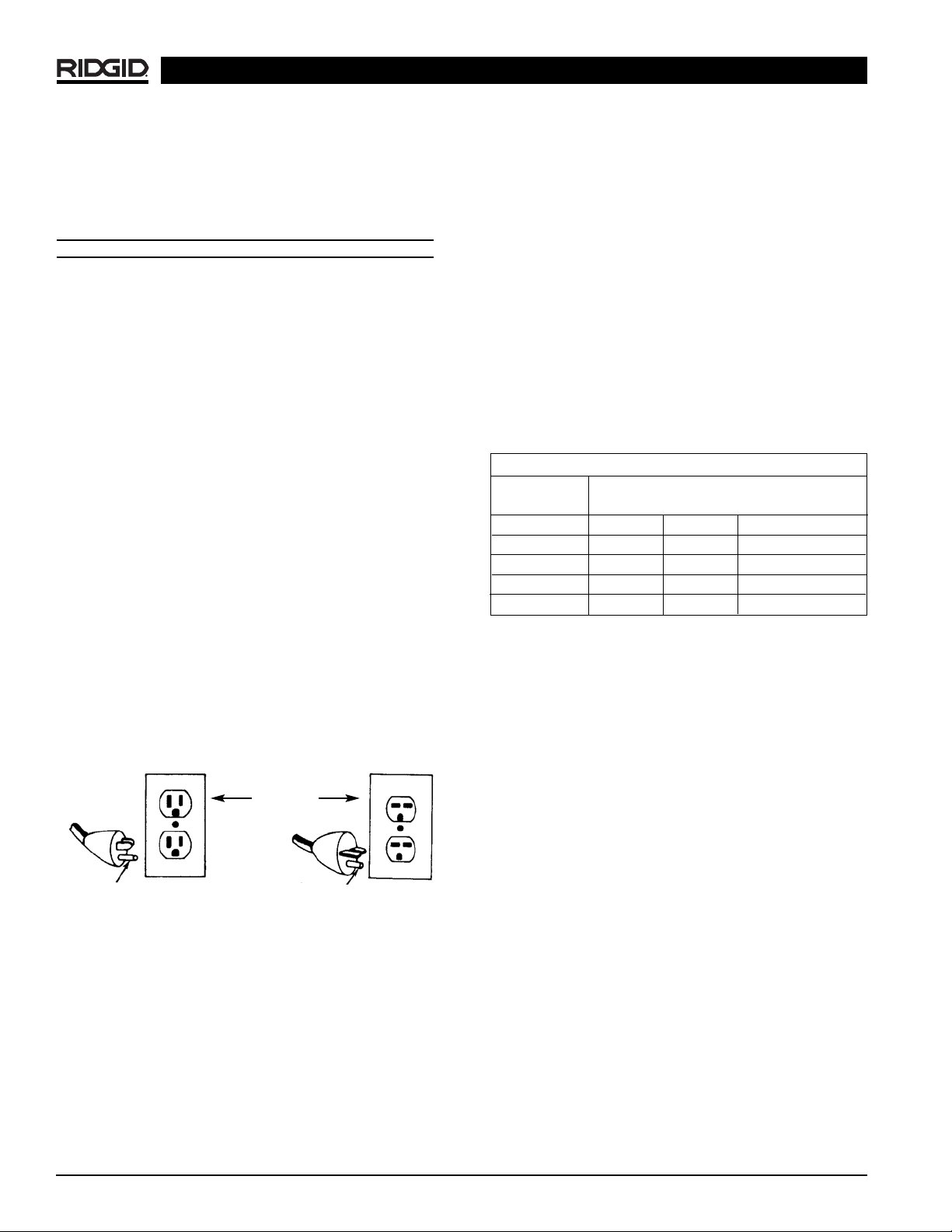

Grounding prong

Cover of

grounded

outlet box

Grounding prong

Minimum Wire Gauge for Extension Cord

Nameplate

Amps Total Length (in feet)

0-25 26-50 51-100

0-6 18 AWG 16 AWG 16 AWG

6-10 18 AWG 16 AWG 14 AWG

10-12 16 AWG 16 AWG 14 AWG

12-16 14 AWG 12 AWG

NOT RECOMMENDED

918-I Heavy Duty Roll Grooving Machine

Ridge Tool Company

3

Tool Use and Care

• Do not use tool if switch does not turn it ON or

OFF. Any tool that cannot be controlled with the switch

is dangerous and must be repaired.

• Disconnect plug from the power source before

making any adjustments, changing accessories, or

storing the tool. Such preventive safety measures re-

duce risk of starting the tool accidentally.

• Store idle tools out of the reach of children and

other untrained persons. Tools are dangerous in

the hands of untrained users.

• Check for misalignment or binding of moving parts,

breakage of parts, and any other condition that

may affect the tool’s operation. If damaged, have

the tool serviced before using. Many accidents are

caused by poorly maintained tools.

• Use only accessories that are recommended by the

manufacturer for your model. Accessories that may

be suitable for one tool may become hazardous when

used on another tool.

• Keep handles dry and clean; free from oil and

grease. This allows for better control of the tool.

Service

• Tool service must be performed only by qualified

repair personnel. Service or maintenance performed

by unqualified repair personnel could result in injury.

• When servicing a tool, use only identical replace-

ment parts. Follow instructions in the Maintenance

Section of this manual. Use of unauthorized parts or

failure to follow maintenance instructions may create a

risk of electrical shock or injury.

Specific Safety Information

WARNING

Foot Switch Safety

Using this machine without a foot switch increases the

risk of serious injury. A foot switch provides better control

by letting you shut off the motor by removing your foot. If

clothing should become caught in the machine, it will continue to wind up, pulling you into the machine. Because the

machine has high torque, the clothing itself can bind around

your arm or other body parts with enough force to crush or

break bones.

Roll Groover Safety

• Roll Groover is made to groove pipe and tubing.

Follow instructions in Operator’s Manual on machine uses. Other uses may increase the risk of injury.

• Keep hands away from grooving rolls. Do not wear

loose fitting gloves when operating unit. Fingers

could get caught between grooving and drive rolls.

• Keep guards in place. Do not operate the groover

with guard removed. Exposure to grooving rolls may

result in entanglement and serious injury.

• Set-up groover on a flat, level surface. Be sure

the groover and stands are stable. Will prevent tipping of the unit.

• Do not wear loose clothing. Keep sleeves and

jackets buttoned. Do not reach across the machine or pipe. Clothing can be caught by the pipe

resulting in entanglement and serious injury.

• Do not use this Roll Groover without a foot switch.

Foot switch is a safety device to prevent serious injury.

• Properly support pipe with pipe stands. Use two

pipe stands to groove pipe over recommended

minimum lengths. Prevents tipping of the unit.

• When grooving pipe, keep hands away from the

end of the pipe. Do not reach inside pipe end. Will

prevent being cut on sharp edges and burrs.

• Lock foot switch when not in use.

(See Figure 1.)

Avoids accidental starting.

Figure 1 – Locked Foot Switch

SAVE THESE INSTRUCTIONS!

Description, Specifications,

Standard Equipment and

Accessories

Description

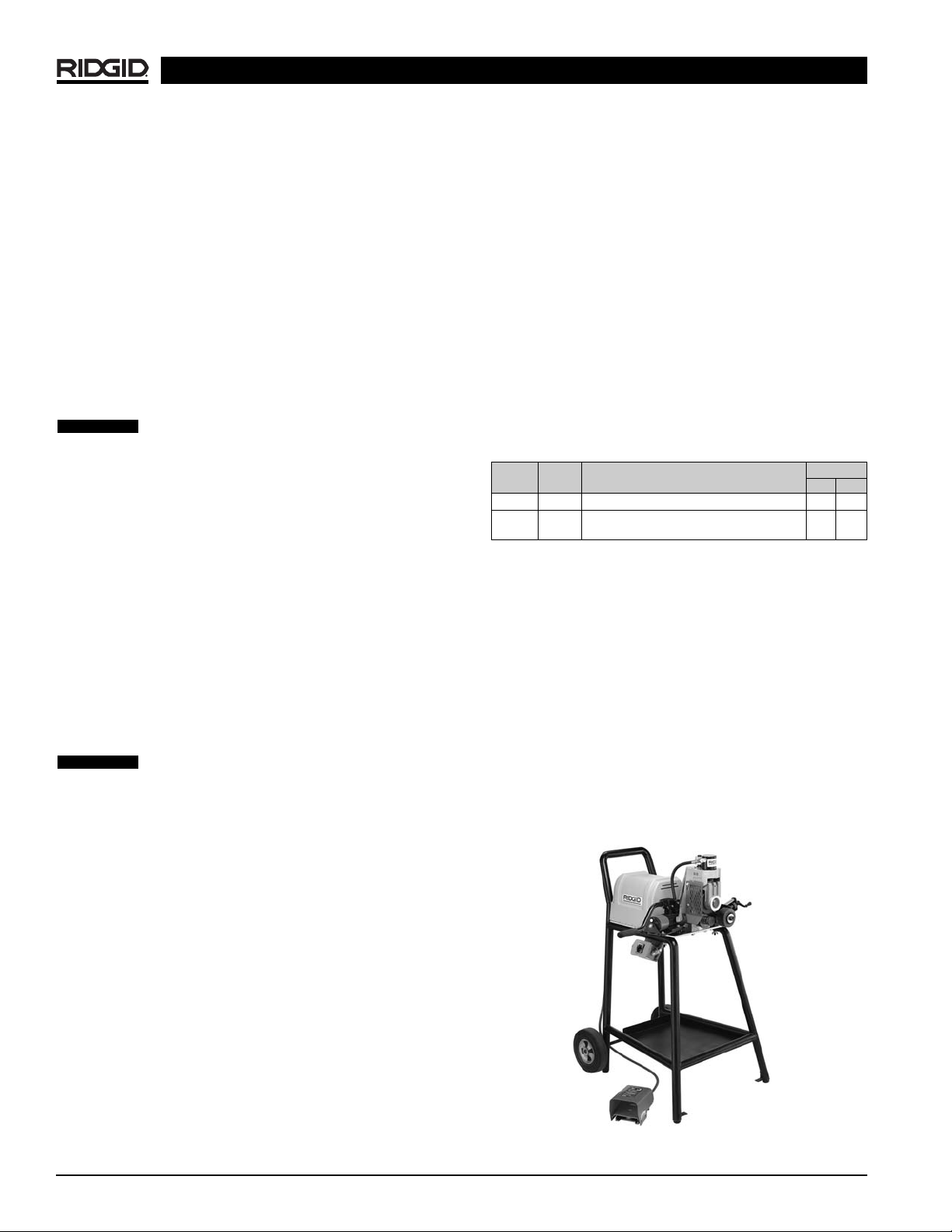

The RIDGID 918-I Roll Groover forms rolled grooves in

steel, stainless steel, aluminum, PVC pipe and copper

WARNING

Read this operator’s manual carefully before using

the Roll Groover. Failure to understand and follow

the contents of this manual may result in electrical

shock, fire and/or serious personal injury.

918-I Heavy Duty Roll Grooving Machine

Ridge Tool Company4

Standard Equipment

918-I Roll Groover Only

• 918-I Groover with 2″ – 6″ Drive Shaft and Groove

Set

•8″ – 12″ Drive Shaft and Groove Set

• Carrying Case for Drive Shaft and Groove Set

•1/8″ T-Handle Hex Wrench (groove roll changeout)

•

3

/16″ Hex Wrench (transmission coupling)

•5/32″ Hex Wrench (transmission cover)

• Spanner Wrench (Drive shaft changeout)

• Nipple Bracket/Pipe Stabilizer

A pipe stabilizer is available as an accessory to aid in the

grooving of short lengths of pipe.

918-I Roll Groover Models

Accessories

• Groove and drive roll set for 11/4″ – 11/2″ Schedule 10

and Schedule 40. (set includes drive shaft, groove roll

and carrying case.)

• Groove and drive roll set for 1″ Schedule 10 and

Schedule 40, groove and drive roll for 11/4″ – 11/

2

″

Schedule 10, 40. (Set includes groove rolls, drive

shaft, and carrying case.)

NOTE! Drive shaft change-out is necessary for roll groov-

ing below 2″.

• Groove Roll and Drive Roll Set for Copper 2″ – 6″

(Types K, L, M and DWV)

• VJ-99 Pipe Stand

Figure 2 – 918-I Roll Groover

tubing. The grooves are formed by the hydraulic feeding

of a grooving roll into the pipe which is supported by a

drive roll.

The 918-I Roll Groover includes two (2) groove and

drive shaft sets that can groove the following pipe:

•2″ – 6″ Schedule 10 and 40

•8″ – 12″ Schedule 10 and 8″ Schedule 40

With additional roll sets, the groover can also be adapted

to groove the following:

•2″ – 6″ copper tubing (Types K, L, M, DWV)

•1″ Schedule 10 and 40

•11/4″ – 11/2″ Schedule 10 and 40

When properly used, the Model 918-I makes

grooves that are dimensionally within the specifications of

AWWA C606-87. Selection of appropriate materials and

joining methods is the responsibility of the system designer and/or installer. Before any installation is attempted,

careful evaluation of the specific service environment, including chemical environment and service temperature,

should be completed.

Specifications

Roll Grooving Capacity

(See Table II for wall thickness)

•1″ to 12″ Schedule 10

•1″ to 8″ Schedule 40

•2″ – 6″ Copper Types K, L, M, DWV

•2″ – 8″ Schedule 40 PVC

Do not use to groove 8″ Schedule 40 steel

pipe harder than 150 BHN. Doing so may result in improperly formed grooves that do not meet required

specifications.

Depth Adjustment .......Indexed Adjustment Knob

Actuation......................Hydraulic Hand Pump

Motor

Type ...........................Universal

Horsepower................1.2

Volts ...........................120V Single Phase AC, 60Hz

Amps..........................12 Amps

Controls........................Rotary Type ON/OFF Switch

and ON/OFF Foot switch

Weight ..........................185 lbs. (84.1 kg)

Operating Speed..........45 RPM (no load)

CAUTION

CAUTION

Catalog Model Weight

No. No. Description

lb. kg.

64977 918-I Roll Grooving Machine Complete, 115V 185 84,1

65902 918-I Roll Grooving Machine Complete, 230V 185 84,1

(Export Only)

918-I Heavy Duty Roll Grooving Machine

Ridge Tool Company

5

Roll Groover Assembly

Instructions

WARNING

To prevent serious injury, proper assembly of the

Roll Groover is required. The following procedures

should be followed:

Assembling Roll Groover

1. To identify the parts for the 918-I Roll Groover, refer

to the parts diagram and parts list.

2. Attach right and left legs to the rear support/handle assembly using 3/8″ – 16 x 21/2″ hex screws and lock

washers. Do not tighten screws.

3. Attach the tool tray assembly to the rear and front legs

using the four (4) 3/8″ – 16 x 23/4″ hex screws and lock

washers. Do not tighten screws.

4. Insert axle into tabs extending from the rear support/handle assembly and secure using four (4)

retaining rings.

5. Mount the roll groover/base assembly to the stand

using four (4) 3/8″ – 16 x 21/2″ hex screws, washers and

wing nuts. Be careful not to “hook” the switch assembly on the stand rail. Movement of the stand legs may

be required to align the base assembly.

Bolt heads go to top, wing nuts and lock washers to the

bottom (stand) side. Installation of the last bolt requires opening of the motor cover.

6. Tighten the six (6) screws and four (4) wing nuts

holding the leg and tray assemblies together. Slide the

wheels onto the axle and install retaining rings to

hold the wheels on the axle.

7. Cut the tie wrap that holds the hydraulic pump in

place for shipping. Remove the bolts/wing screws

from the bottom of the pump’s mounting plate.

8. Place the pump mounting plate over the hole and slot

on the left side of the 918-I (left side as you look at the

front of the 918-I). From the bottom of the base plate,

insert the 3/8- 16 x 1″ bolt with washer into the hole and

screw into pump mounting plate. Secure the bolt with

the 3/8″ nut.

9. From the bottom of the base plate, insert the wing

screw with lock washer into the pump mounting plate

(through the slot) and tighten as required.

NOTE! During 918-I operation, the hydraulic pump should

be in the outermost position. During transportation,

the hydraulic pump should be in the inner most position.

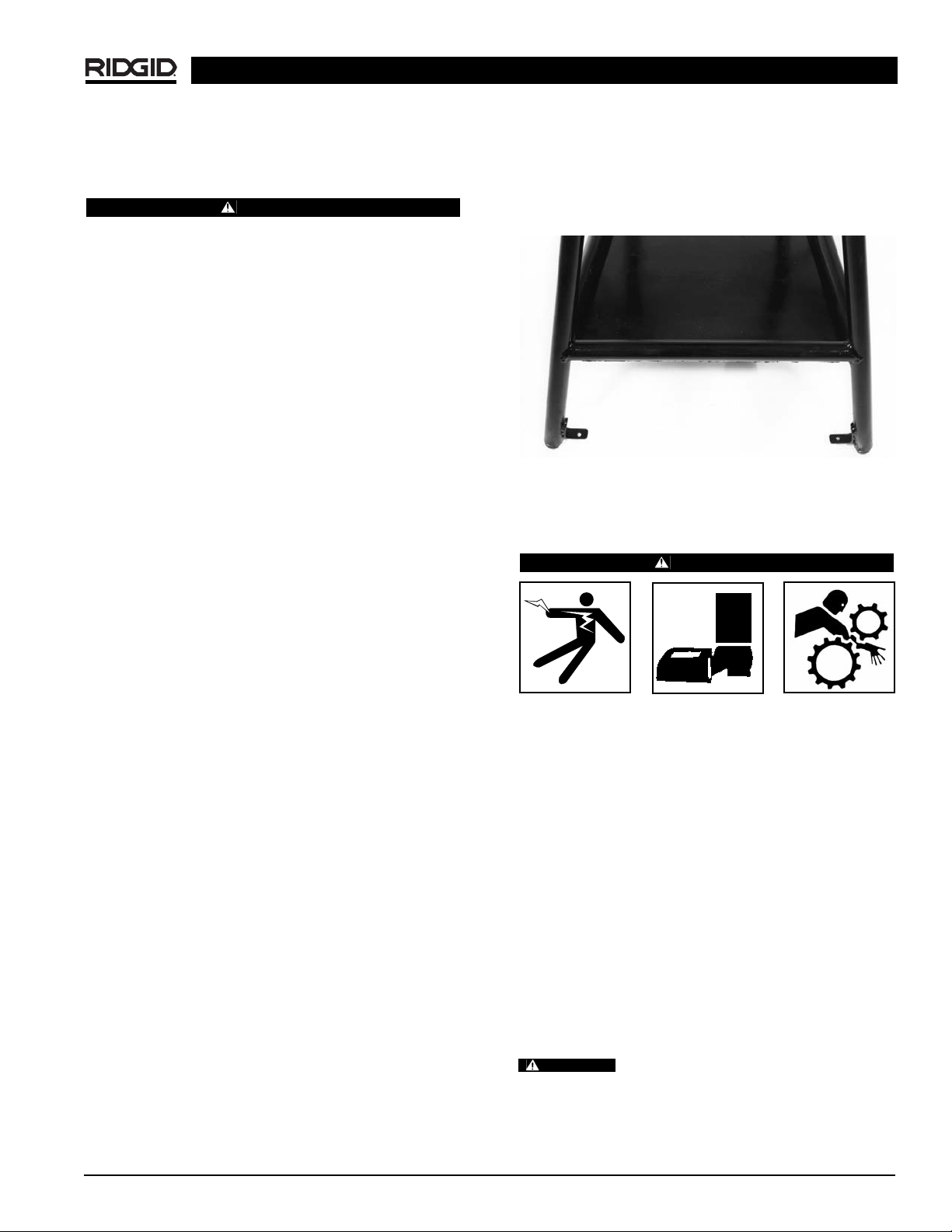

Bolting the 918-I Stand to the Shop Floor

1. Mark the spot where the 918-I is to be bolted.

2. Align spot with the 918-I stand bolt-down attachment

holes

(Figure 3)

.

Figure 3 – Bolt-Down Attachment Holes

Machine Inspection

WARNING

Do not use this Roll Groover without a foot switch.

To prevent serious injury, inspect your Roll Groover.

The following inspection procedures should be performed on a daily basis.

1. Make sure machine is unplugged and the switch is set

to the OFF position.

2. Make sure the foot switch is present and attached to

the machine.

3. Inspect the power cord and plug for damage. If the

plug has been modified, is missing the grounding

pin or if the cord is damaged, do not use the machine

until the cord has been replaced.

4. Make sure all bolts holding the Roll Groover and hydraulic pump to the base are tight.

5. Check that guard mounted to the roll groover is in

place

(Figure 3)

.

Do not operate Roll Groover with guard

removed. Exposure to moving grooving rolls may result

in fingers being crushed.

WARNING

918-I Heavy Duty Roll Grooving Machine

Ridge Tool Company6

6. Inspect the Roll Groover for any broken, missing,

misaligned or binding parts as well as any other conditions which may affect the safe and normal oper ation of this equipment. If any of these conditions are

present, do not use the Roll Groover until any problem

has been repaired.

7. Lubricate the Roll Groover if necessary according

to the Maintenance Instructions.

8. Use groover rolls and accessories that are designed

for your Roll Groover and meet the needs of your application. The correct groover tools and accessories

allow you to do the job successfully and safely. Ac cessories suitable for use with other equipment may

be hazardous when used with this Roll Groover.

9. Clean any oil, grease or dirt from all equipment handles and controls. This reduces the risk of injury due

to a tool or control slipping from your grip.

10. Inspect the groove rolls to insure they are not damaged or worn. Worn groover rolls can lead to pipe

slippage and poor quality grooves.

Machine and Work Area Set-Up

WARNING

To prevent serious injury, proper set-up of the machine and work area is required. The following

procedures should be followed to set-up the machine:

1. Locate a work area that has the following:

• Adequate lighting

• No flammable liquids, vapors or dust that may ignite.

• Grounded electrical outlet

• Clear path to the electrical outlet that does not

contain any sources of heat or oil, sharp edges or

moving parts that may damage electrical cord.

• Dry place for machine and operator. Do not use

the machine while standing in water.

• Level ground

2. Clean up the work area prior to setting up any equipment. Always wipe up any oil that may be present.

3. Place machine on a flat, level surface. Be sure the

groover and stands are stable. See Assembly In structions for bolting 918-I stand to shop floor.

4. Properly support the pipe with pipe stands. See Chart

“A” for maximum lengths with one (1) stand.

Failure to properly support the pipe can

result in the unit tipping or the pipe falling.

5. Make sure switch is in the OFF position.

6. Position the foot switch so that the operator can

safely control the roll groover and workpiece. It should

allow the operator to do the following:

• Stand with left hand on pump handle.

• Use the foot switch with his left foot.

• Have convenient access to the groover without

reaching across the machine.

Machine is designed for one person operation.

7. Plug the machine into the electrical outlet making

sure to position the power cord along the clear path

selected earlier. If the power cord does not reach

the outlet, use an extension cord in good condition.

To avoid electrical shock and electrical

fires, never use an extension cord that is damaged or

does not meet the following requirements.

• The cord has a three-prong plug similar to shown in

Electrical Safety section.

• The cord is rated as “W” or “W-A” if being used outdoors.

• The cord has sufficient wire thickness (14 AWG

below 25′/12AWG 25′ - 50′). If the wire thickness is

too small, the cord may overheat, melting the cord’s

insulation or causing nearby objects to ignite.

To reduce risk of electrical shock, keep

all electrical connections dry and off the ground. Do

not touch plug with wet hands.

8. Check the unit to insure it is operating properly.

• Flip the switch to ON. Press and release the foot

switch. Check that the groove roll rotates in a clockwise direction as you are facing the groover. Have

the machine serviced if it rotates in the wrong direction or if the foot switch does not control its

stopping or starting.

• Depress and hold the foot switch. Inspect the moving parts for misalignment, binding, odd noises or

any other unusual conditions that may affect the

safe and normal operation of the machine. If such

conditions are present, have the roll groover drive

serviced.

• Release the foot switch and flip the switch to OFF.

9. Check the groove and drive rolls to insure they are the

correct size.

WARNING

WARNING

WARNING

Loading...

Loading...