RIDGID 603, 604, 606, 605, 608 Instruction Sheet

...

600 Hand Tube Bender Instruction Sheet

WARNING

Read these instructions and the warnings and

instructions for all equipment being used before

using to reduce the risk of serious personal injury.

• Always use safety glasses to reduce the risk of

eye injury.

• Do not use handle extensions (such as a piece

of pipe). Han dle extensions can slip or come off and increase

the risk of serious injury.

Test

Equipment Depot - 800.517.8431

99 Washington Street, Melrose, MA 02176

TestEquipmentDepot.com

®

The RIDGID

materials such as copper, steel, stainless steel and other hard metal

tube to a maximum of 180°. Built-in rollers and a heavy-duty handle

design combine to produce high quality bends with greatly reduced

effort when compared to conventional benders.

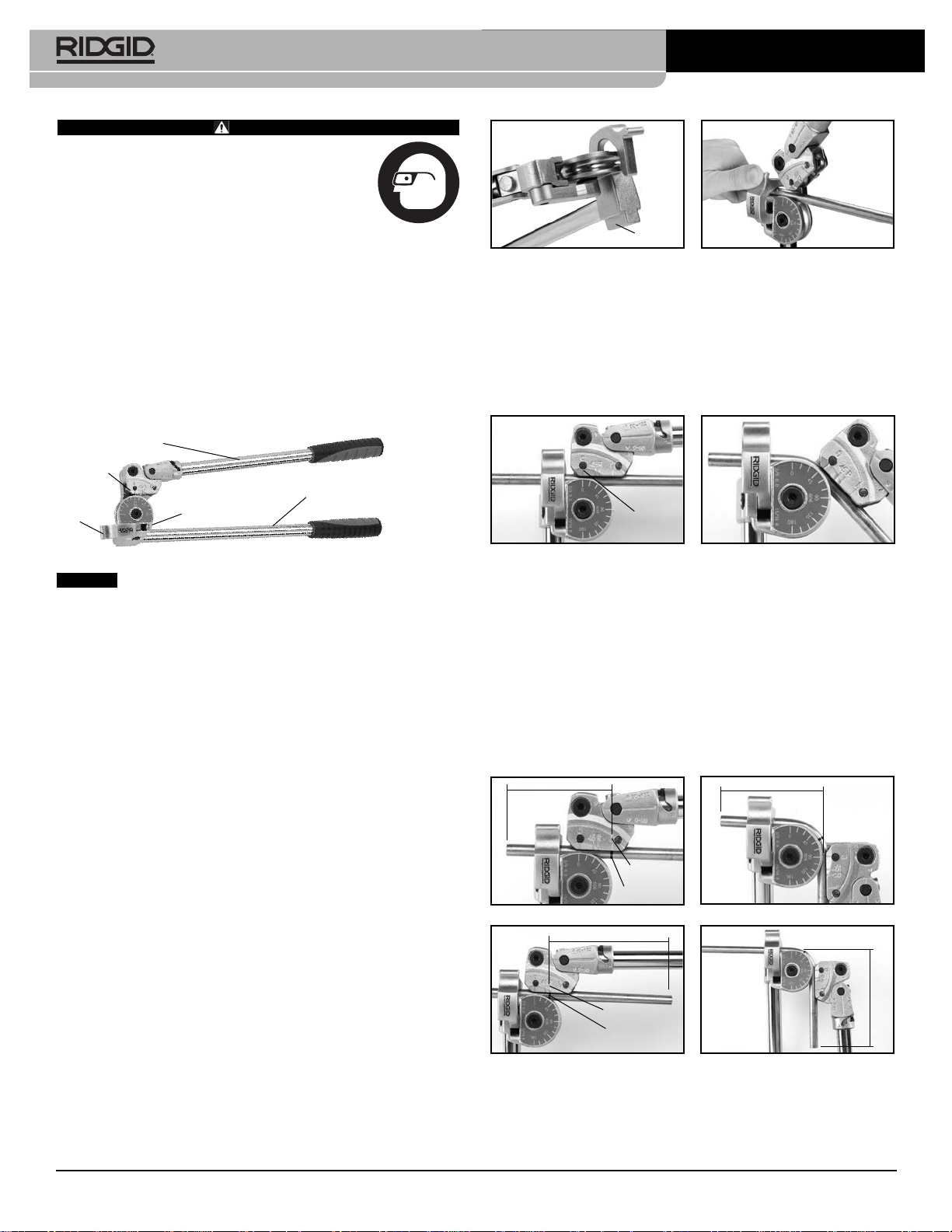

Carriage Handle

Carriage

Tube

Latch

600 series lever benders are designed to easily bend

Form Handle

Form

Grip In

Vise

Figure 2 – Vise Mounting Point Figure 3

2. Move Carriage Handle and Tube Latch away from Form.

3. Position tubing in Form groove and secure tubing in Form with

Latch (Figure 3).

4. Lower Carriage Handle until the “0” Line on the Carriage aligns with

the 0° designation on the Form (Figure 4).

5. Rotate the Carriage Handle around the Form until the “0” Line on the

Carriage aligns with the desired degree of bend on the Form (Figure

5).

0 Line

Figure 1 – 600 Series Bender

NOTICE

Selection of appropriate materials and installation, joining

and forming methods is the responsibility of the system designer and/or

installer. Selection of improper materials and methods could cause system failure.

Stainless steel and other corrosion resistant materials can be contaminated during installation, joining and forming. This contamination could

cause corrosion and premature failure. Careful evaluation of materials

and methods for the specific service conditions, including chemical and

temperature, should be completed before any installation is attempted.

Inspection/Maintenance

The bender should be inspected before each use for wear or damage

that could affect safe use. Clean as needed to aid inspection and to prevent handles and controls from slipping from your grip during use.

Make sure the bender is complete and properly assembled. If any problems are found, do not use until the problems are corrected. Lubricate

all moving parts/joints as needed with a light lubricating oil, and wipe

any excess oil from the bender.

Operation

The 600 Series Lever Benders can be used either hand held or with the

bender mounted in a vise. Vise mounting is especially useful when

bending hard or thick walled materials.

Spring Back

All tubing will exhibit spring back after a bend is completed. Softer tubing, such as copper, will have less spring back than harder tubing, such

as stainless steel. Experience will help you predict the amount of spring

back. Depending on tubing material and hardness, expect to overbend

approximately 1° to 3° to compensate for spring back.

General Operating Instruction

1. Grasp bender by the Form Handle or mount the bender in vise.

(Figure 2).

Figure 4 Figure 5

Measured Bends Relative to Other

Features (Tube ends, Bends, etc.)

For 90° Bends:

• Mark the tube at the desired distance (X) from the feature (end of

tube, bend, etc.). The center of the leg of the bend will be this distance from the feature.

• Place the tube in the bender as described in Steps 1-5 above.

• If the feature is to the LEFT of the mark (see Figure 6 – Before),

align the mark on the tube with the “L” line on the Carriage.

• If the feature is to the RIGHT of the mark (see Figure 8 – Before),

align the mark on the tube with the “R” line on the Carriage.

X

L Line

Mark On

Tube

Figure 6 – Before Figure 7 – After

X

R Line

Mark On

Tube

Figure 8 – Before Figure 9 – After

• With the mark on the tube appropriately aligned, move the Carriage

so that the “0” Line aligns with the 90 degree line on the Form. (See

Figures 7 and 9 – After).

X

X

Printed 12/15

EC38632

The Emerson logo and RIDGID logo are registered trademarks of Emerson Electric Co. or RIDGID, Inc. in the U.S. and other countries.

©2011, 2015, RIDGID, Inc.

All other trademarks belong to their respective holders.

999-999-403.10

REV. C

600 Hand Tube Bender Instruction Sheet

1.50

45°

2.00

3.00

1 .00

REFERENCE MARK

For 45° Bends:

• Mark the tube at the desired distance (X) from the feature (end of

tube, bend, etc.). The center of the arc segment will be this distance

from the feature.

• Place the tube in the bender as described in Steps 1-5 above.

• Align the mark on the tube with the 45° line on the Carriage (see

Figure 10).

X

45 Line

Mark On

Tube

X

Figure 10 – Before Figure 11 – After

• With the mark on the tube appropriately aligned, move the Carriage

Handle so that the “0” Line aligns with the 45 degree line on the Form.

Making Bends 90° to 180°

Follow the steps 1-5 for making 90° bends.

1. When the “0” Line on the Carriage reaches the 90° mark on the

Form, turn the carriage handle so that the pin moves the “unlock”

Position (Figure 12).

Figure 12 – UNLOCK Figure 13 – Rotate Handle

2. Rotate the handle around the Carriage until the 90~180° triangle

mark on the Handle aligns with the triangle mark on the Carriage

(Figure 13).

3. Turn the Carriage Handle so that the pin moves toward the “lock”

position. Make sure the Handle is secure to the Carriage. (Figure

14).

Figure 14 – LOCK Figure 15

4. Swing the Carriage Handle around the Form until the “0” Line on

the Carriage aligns with the desired bend angle (Figure 15). The

Handles will not cross.

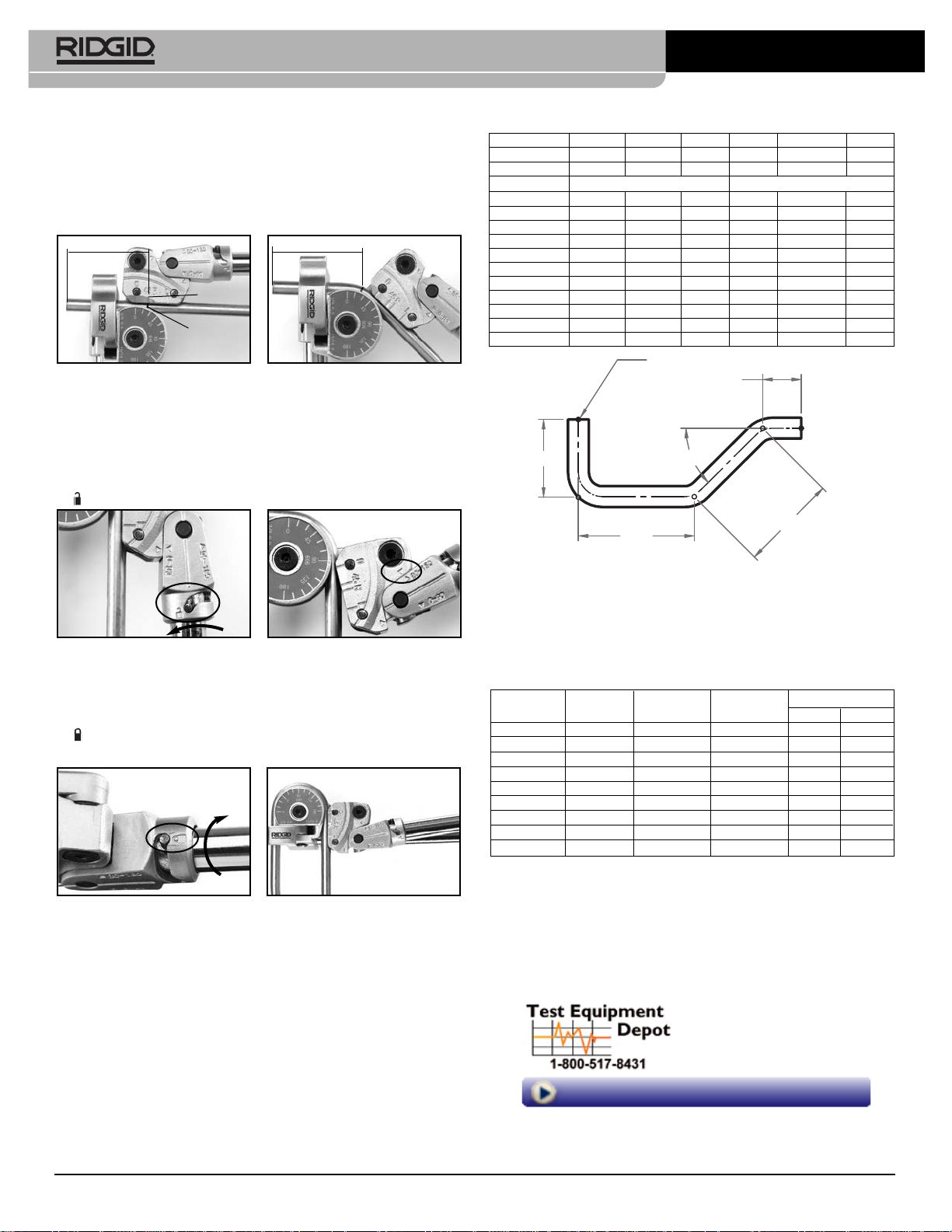

Bend Adjustment Chart

Model No. 603/604 605/606 608 606M 608M/610M 612M

Tube OD

Bend Radius

Degree Bend Adjustment (Inches) Bend Adjustment (mm)

90 0.27 0.40 0.65 6.88 10.32 16.34

85 0.22 0.33 0.52 5.59 8.38 13.27

80 0.18 0.26 0.42 4.52 6.78 10.73

75 0.14 0.21 0.34 3.61 5.42 8.58

70 0.11 0.17 0.27 2.86 4.29 6.80

65 0.09 0.13 0.21 2.24 3.36 5.32

60 0.07 0.10 0.16 1.72 2.58 4.08

55 0.05 0.08 0.12 1.32 1.98 3.14

50 0.04 0.06 0.09 0.96 1.44 2.27

45 0.03 0.04 0.06 0.69 1.03 1.63

40 0.02 0.03 0.05 0.48 0.72 1.15

EXAMPLE:

TUBE SIZE = 3/8" Adjustment for 90° bend = 0.40 (x 1)

BEND RADIUS = 15/16" Adjustment for 45° bend = 0.04 (x 2)

ACTUAL TUBE = Sum of Centerline Dimensions - Adjustments for Bends

LENGTH REQUIRED = 2.00 + 3.00 + 1.50 + 1.00 - 0.40 - 0.04 - 0.04 =

3

/16", 1/4"5/16, 3/

5

8

/

8

15

16

/

(Values Found In Adjustment Chart)

= 7.02"

1

2

/

6mm 8mm, 10mm 12mm

11/216mm 24mm 38mm

Bender Specification

Catalog Model Capacity Bend Weight

No. No. (O.D.) Radius lbs. kgs.

38028 603

38033 604

38038 605

38043 606

38048 608

3

/16"

1

/4"

5

/16"

3

/8"

1

/2"1

5

/8" 1.68 0.76

5

/8" 1.68 0.76

15

/16" 4.1 1.84

15

/16" 4.1 1.84

1

/2" 6.1 2.76

38053 606M 6mm 16mm 1.68 0.76

38038 608M 8mm 24mm 4.1 1.84

38058 610M 10mm 24mm 4.1 1.84

38063 612M 12mm 38mm 6.1 2.76

Supporting Products Recommendation

Cat. No. 31803 65S Quick-Acting Tubing Cutter

Cat. No. 29963 35S Stainless Steel Tubing Cutter

Cat. No. 29993 227S Stainless Steel Inner-Outer Reamer

Cat. No. 29983 223S Stainless Steel Inner-Outer Reamer

Adjustment (Gain) Calculations

When determining tube bend locations, adjustment factors must be

considered to achieve proper layout. Adjustment (Gain) is the difference

in the length of tubing used in a radiused bend compared to the length

of tubing required in a sharp bend, when measured from one end to

another.

The distance around a radiused bend is always less than a sharp bend.

The adjustment factor is determined by the radius of the tube bender

and the number of degrees of the bend. See the following chart for ad justment factors. Adjustment factors are subtracted from the center line

distances (see the example).

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

Loading...

Loading...