Page 1

Portable Band Saw

Band Saw Vise

OPERATOR’S

MANUAL

• Pour français voire page 11

• Para el castellano vea la

página 23

932VS

32V

W ARNING!

Read this Operator’s Manual

carefully before using this

tool. Failure to understand

and follow the contents of

this manual may result in

electrical shock, fire and/or

serious personal injury.

Page 2

Table of Contents

Recording Form for Machine Model and Serial Number............................................................................................1

General Safety Information

Work Area Safety........................................................................................................................................................2

Electrical Safety...........................................................................................................................................................2

Personal Safety...........................................................................................................................................................2

Tool Use and Care......................................................................................................................................................3

Service ........................................................................................................................................................................3

Specific Safety Information

Tool Safety..................................................................................................................................................................3

Description, Specifications and Equipment

Description ..................................................................................................................................................................4

Specifications..............................................................................................................................................................4

Standard Equipment....................................................................................................................................................4

Accessories.................................................................................................................................................................4

Machine Operation Instructions

932VS Band Saw........................................................................................................................................................4

To Start and Stop Saw.............................................................................................................................................5

Selecting the Blade .....................................................................................................................................................5

Band Saw Blades.....................................................................................................................................................5

Which Blade to Use..................................................................................................................................................5

Blade Care ..................................................................................................................................................................5

Cutting Procedures......................................................................................................................................................5

932VS Band Saw with 32V Vise .................................................................................................................................6

To Assemble 32V Vise.............................................................................................................................................6

To Use 32V Vise .........................................................................................................................................................6

Cutting Procedures Using 32V Vise............................................................................................................................7

Special Procedures

Changing Saw Blades.................................................................................................................................................7

To Adjust Blade Tracking............................................................................................................................................8

Maintenance Instructions

Motor Brush Inspection and Lubrication......................................................................................................................9

Saw Ventilation............................................................................................................................................................9

Machine Storage............................................................................................................................................................9

Service and Repair ........................................................................................................................................................9

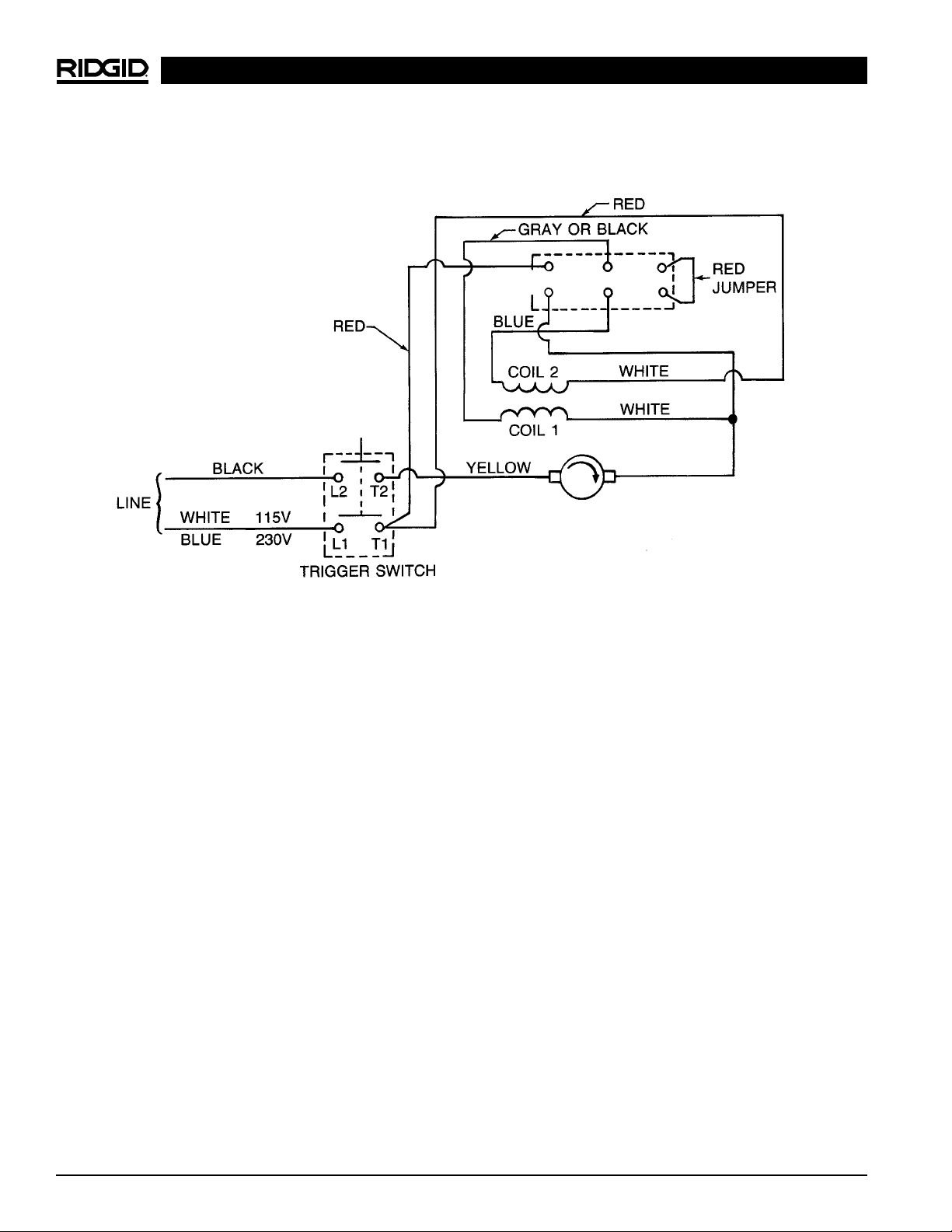

Wiring Diagram............................................................................................................................................................10

Lifetime Warranty..........................................................................................................................................Back Cover

Ridge Tool Companyii

932VS Portable Band Saw

Page 3

932VS Portable Band Saw

Record Serial Number below and retain product serial number which is located on nameplate.

Serial

No.

932VS Portable Band Saw

32V Band Saw V ise

Page 4

932VS Portable Band Saw

Ridge Tool Company2

General Safety Information

WARNING! Read and understand all instructions. Failure

to follow all instructions listed below may result in electric shock, fire, and/or serious

personal injury.

SAVE THESE INSTRUCTIONS!

Work Area Safety

• Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

• Do not operate power tools in explosive atmo-

spheres, such as in the presence of flammable

liquids, gases or dust. Tools create sparks which

may ignite the dust or fumes.

• Keep bystanders, children, and visitors away while

operating a power tool. Distractions can cause you to

lose control.

• Do not let visitors contact the tool or extension

cord. Such preventative measures reduce the risk of

injury.

Electrical Safety

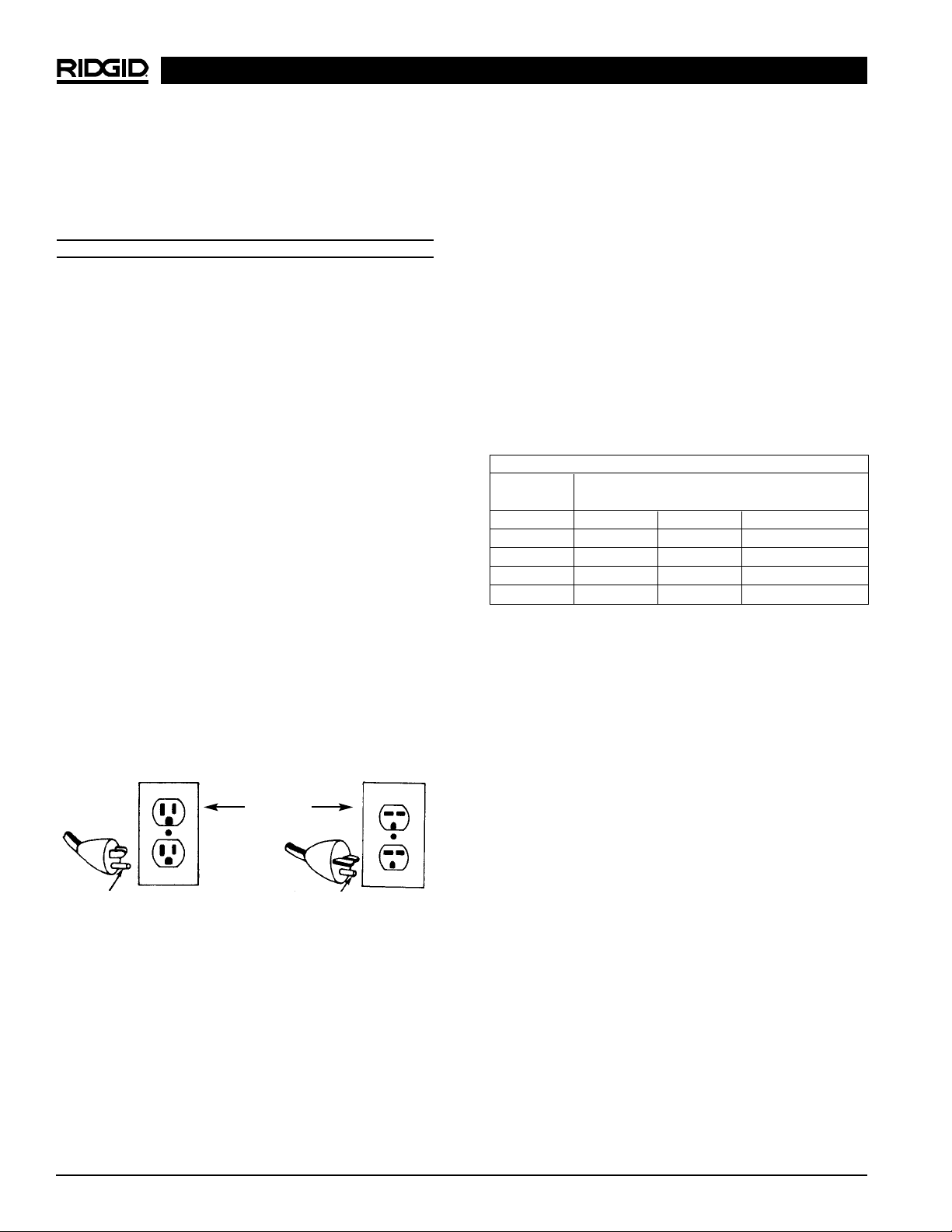

• Grounded tools must be plugged into an outlet,

properly installed and grounded in accordance

with all codes and ordinances. Never remove the

grounding prong or modify the plug in any way. Do

not use any adapter plugs. Check with a qualified

electrician if you are in doubt as to whether the outlet is properly grounded. If the tools should electrically

malfunction or break down, grounding provides a low

resistance path to carry electricity away from the user.

• Avoid body contact with grounded surfaces such

as pipes, radiators, ranges and refrigerators. There

is an increased risk of electrical shock if your body is

grounded.

• Don’t expose power tools to rain or wet condi-

tions. Water entering a power tool will increase the risk

of electrical shock.

• Do not abuse cord. Never use the cord to carry the

tools or pull the plug from an outlet. Keep cord

away from heat, oil, sharp edges or moving parts.

Replace damaged cords immediately. Damaged

cords increase the risk of electrical shock.

• When operating a power tool outside, use an out-

door extension cord marked “W-A” or “W”. These

cords are rated for outdoor use and reduce the risk of

electrical shock.

• Connect the tool to an AC power supply that

matches the name plate specifications. Incorrect

voltage supply can cause electrical shock or burns.

• Use only three-wire extension cords which have

three-prong grounding plugs and three-pole receptacles which accept the machines plug. Use

of other extension cords will not ground the tool and increase the risk of electrical shock.

• Use proper extension cords. (See chart.) Insufficient

conductor size will cause excessive voltage drop and

loss of power.

Personal Safety

• Stay alert, watch what you are doing and use common sense when operating a power tool. Do not

use tool while tired or under the influence of drugs,

alcohol, or medications. A moment of inattention

while operating power tools may result in serious personal injury.

• Dress properly. Do not wear loose clothing or jew-

elry. Contain long hair. Keep your hair, clothing,

and gloves away from moving parts. Loose clothes,

jewelry, or long hair can be caught in moving parts.

• Avoid accidental starting. Be sure switch is OFF

before plugging in. Carrying tools with your finger on

the switch or plugging tools in that have the switch ON

invites accidents.

• Remove adjusting keys or switches before turning

the tool ON. A wrench or a key that is left attached to

a rotating part of the tool may result in personal injury.

• Do not over-reach. Keep proper footing and bal-

ance at all times. Proper footing and balance enables

better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protec-

tion. Dust mask, non-skid safety shoes, hard hat,

or hearing protection must be used for appropriate

conditions.

Grounding pin

Cover of

grounded

outlet box

Grounding pin

Minimum Wire Gauge for Cord Set

Nameplate

Amps

Total Length (in feet)

0 – 25 26 – 50 51 – 100

0 – 6 18 AWG 16 AWG 16 AWG

6 – 10 18 AWG 16 AWG 14 AWG

10 – 12 16 AWG 16 AWG 14 AWG

12 – 16 14 AWG 12 AWG

NOT RECOMMENDED

Page 5

932VS Portable Band Saw

Ridge Tool Company 3

Some dust created by power sanding,

sawing, grinding, drilling, and other construction activities

contains chemicals known to the State of California to

cause cancer, birth defects, or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks and cement and other

masonry products

• Arsenic and chromium from chemically-treated lumber

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such as

those dust masks that are specially designed to filter out

microscopic particles.

Tool Use and Care

• Use clamp or other practical way to secure and

support the workpiece to a stable platform. Holding

the work by hand or against your body is unstable

and may lead to loss of control.

• Do not force tool. Use the correct tool for your

application. The correct tool will do the job better

and safer at the rate for which it is designed.

• Do not use tool if switch does not turn it ON or

OFF. Any tool that cannot be controlled with the switch

is dangerous and must be repaired.

• Disconnect plug from the power source before

making any adjustments, changing accessories, or

storing the tool. Such preventive safety measures re-

duce risk of starting tool accidentally.

• Store idle tools out of the reach of children and

other untrained persons. Tools are dangerous in

the hands of untrained users.

• Maintain tools with care. Keep cutting tools sharp

and clean. Properly maintained tools with sharp cutting

edges are less likely to bind and are easier to control.

• Check for misalignment or binding of moving parts,

breakage of parts, and any other condition that

may affect the tools operation. If damaged, have the

tool serviced before using. Many accidents are

caused by poorly maintained tools.

• Use only accessories that are recommended by the

manufacturer for your model. Accessories that may

be suitable for one tool may become hazardous when

used on another tool.

• Inspect tool and extension cords periodically and

replace if damaged. Damaged cords increase the

risk of electrical shock.

• Keep handles dry and clean; free from oil and

grease. This allows for better control of the tool.

Service

• Tool service must be performed only by qualified repair personnel. Service or maintenance performed

by unqualified repair personnel could result in injury.

• When servicing a tool, use only identical replacement parts. Follow instructions in the Maintenance

Section of this manual. Use of unauthorized parts or

failure to follow maintenance instructions may create a

risk of electrical shock or injury.

• Follow instructions for lubricating and changing

accessories. Accidents are caused by poorly main-

tained tools.

Specific Safety Information

WARNING

Read this operator’s manual carefully before using

the machine. Failure to understand and follow the

contents of this manual may result in electrical

shock, fire and/or serious personal injury.

Call the Ridge Tool Company, Technical Service

Department at (800) 519-3456 if you have any questions.

Tool Safety

• Do not alter or misuse tool. Other uses may in-

crease the risk of injury.

• Always use the blade recommended for the material

being cut. Recommended blades that are sharp are

less likely to bind and tool is easier to control.

• Secure workpiece before attaching vise. Clamp

work vise securely to the work piece before attaching band saw to vise. To maintain control,

workpiece must support weight of work vise and band

saw without movement.

• Stay clear of workpieces that may fall after cut. May

result in injury.

• Maintain a firm grip on band saw handle while

making a cut. Support saw weight as cut is completed. Will prevent losing control of the saw.

• Turn band saw OFF and disconnect from power

source while mounting and dismounting the saw

from work vise. Prevents accidental starting.

• Keep hands away from cutting area when operating saw. Fingers or hands can be cut.

• Do not use if guards are damaged or removed.

WARNING

Page 6

932VS Portable Band Saw

Ridge Tool Company4

Accessories

No. 32V Work Vise

When using 32V Vise, the maximum size that may

be cut is as follows:

Rounds – 41/2″ diameter

Squares – 3″ x 3″

Angles – 3″ x 3″

CAUTION

Cutting of other shapes is not recommended.

Operating Instructions

Operator should be thoroughly familiar

with preceding Safety Precautions before attempting to

operate this equipment.

Do not operate Saw at voltages that are

not within correct limits. Check specification plate on

saw for type of power circuit on which it will operate.

932VS Band Saw

To Start and Stop Saw

1. Make sure power circuit voltage is the same as that

shown on the specification plate on the saw. Connect

machine to power circuit.

2. Squeeze trigger switch Figure 1 to START motor.

Release trigger to STOP motor.

3. A LOCK button Figure 1 is provided to keep the saw

running without holding the switch trigger ON. To

LOCK the switch trigger ON, squeeze the trigger as far

Exposed blades and moving parts increases the risk

of injury.

• Do not attach the work vise to the end of the workpiece that is being cut off. Prevents saw from falling

after cut.

• Do not operate band saw and work vise without

safety clip installed. Prevents separation of band

saw from work vise.

• Use extreme caution when cutting magnesium.

Never use water or fire extinguisher to fight a magnesium fire - use only G-1 Power (Graphite). Chips

can ignite resulting in a fire hazard.

• Exercise extreme caution when cutting blind into

conduit and pipe. Be certain the object being cut

does not contain electrical wires, gases or water.

Could create a hazardous condition resulting in serious injury.

SAVE THESE INSTRUCTIONS!

Description, Specifications and

Accessories

Description

The RIDGID No. 932VS Portable Band Saw will cut

most ferrous and non ferrous bar, tubing and irregular

shaped materials. Its 43/4″ capacity will allow cutting

nominal size 4″ soil pipe or 4″ conduit. It features ball and

needle bearing construction throughout which assures

long and continued service.

Specifications

Cutting Capacity..........43/4″ Round Stock,

41/2″ x 43/4″ Rectangular Stock,

Motor

No..............................932VS

Type ..........................Universal

Volts ..........................115 VAC, 50-60 Hz

Amps.........................6

No Load

Speed SFM ...............Variable 100-245

Drive .............................Spur Gear and Chain

Blade Size ....................

1

/2″ x .020 x 447/

8

″

Weight ..........................14 Lbs.

Standard Equipment

Steel Carrying Case

Bi-Metal Blade

Blade Wax

The control knob is numbered “1” through “6” with “1” being the

slowest speed (approximately 90 SFM) and “6” being the fastest

speed (approximately 240 SFM). The speed control may be adjusted with or without the motor running.

SFM-Surface Feet per Minute

Figure 1 – Variable Speed Control

WARNING

WARNING

Page 7

932VS Portable Band Saw

Ridge Tool Company 5

as it will go and push in the lock button and release

trigger.

To UNLOCK the lock, squeeze trigger allowing lock

button free to spring out and release trigger.

4. The 932VS is equipped with an adjustable variable

speed control. The speed is adjusted by turning the

control knob. (Figure 1)

Selecting the Blade

Band Saw Blades

Model 932VS Band Saw requires blades that are .020

thick;

1

/2″ wide; and 447/8″ long.

NOTE! DO NOT USE blades for stationary band saws.

Blades for stationary band saws are of different thickness

than above and WILL NOT fit the precision blade guides

on portable band saws.

REFER TO THE BLADE SELECTION CHART (Figure

11) for types of blades available and their recommended

usages. This chart is provided as a guide only. Due to

the many materials that can be cut, operator’s experience will determine which blade will have the longest life

for any specific operation.

Which Blade to Use

In general, select a blade which will allow at least two

teeth to be engaged in the material thickness. The thinner or the harder the material, the finer the blade teeth

should be. For thicker or softer material, a blade with

coarser blade teeth is recommended. The hi-speed

steel blades stay sharp longer than alloy steel blades.

Blade Care

Blade life will be extended by using a wax-type cutting lubricant as supplied with saw. Keep sharp blade in saw.

Under no condition should a liquid coolant

be used with this saw. The bearings and rubber tires on

pulleys may be damaged as a result.

NOTE! Stick wax is especially helpful when cutting large

sections of aluminum and soft brass because it

will help keep gullets clean. On hard materials,

stick wax will help keep blade cool so hardness

will not be drawn from teeth. The use of this lubricant promotes a cleaner, smoother surface

on sides of cut.

Cutting Procedures

1. Be sure work to be cut is held securely and is properly

positioned so that greatest number of teeth will contact work when cutting. (Figure 2)

2. Plug saw power cord into properly grounded electrical outlet.

3. Set variable speed switch in desired position. Speed

CAN be changed while machine is running.

4. Hold saw in a natural position away from work.

5. Start saw by depressing switch trigger in rear handle.

6. Keeping blade rear guide stop firmly against work and

lower saw to cut material.

NOTE! Let weight of saw furnish cutting pressure. Do not

bear down during cutting operations. This will

slow down speed of blade and reduce cutting efficiency.

7. Upon completion of cut, hold Saw firmly so it does not

fall against work.

8. Release switch trigger and unplug power cord.

NOTE! After prolonged cutting, wax will cling to pulleys of

Saw. This does not affect operation of Saw. All

that is necessary is to unplug Saw from power

source and wipe wax from pulleys.

Figure 2 – Work Properly Positioned For Saving

CAUTION

Right

Right

Wrong

Wrong

Page 8

932VS Portable Band Saw

Ridge Tool Company6

932VS Band Saw with 32V Vise

To Assemble 32V Vise

WARNING

Saw must be disconnected from power source

before assembling the 32V Vise.

1. Remove two screws (A) and remove knob (C) and

screw (B) (Figure 3).

2. Position vise mounting bracket to band saw (Figure 4)

and secure with two hex head bolts furnished with

32V Vise. (Torque: 40 to 50 in. lbs.)

3. Reassemble knob (C), (Figure 3), using two longer

mounting screws furnished with 32V Vise.

4. Position power cord to slot as shown in Figure 4.

To Use 32V Vise

Make sure band saw is disconnected from

power source before securing to the workpiece.

1. Secure the workpiece to prevent movement during

the cutting operation.

The workpiece must be secured to sup-

port the weight of the work vise and the band saw.

2. Position the work vise on the workpiece and secure

by tightening the clamp screw firmly (see Figure 5).

The clamp must support the band saw.

NOTE! The vise should be positioned so that the clamp

screw is vertical and above the workpiece.

Figure 6

3. Attach band saw to work vise.

Keep hands away from saw blade when

attaching and removing band saw.

Figure 3

A

B

C

Figure 4

Bolts

Cord

Slot

Figure 5

Clamp Screw

RIGHT

WRONG

WARNING

WARNING

WARNING

Page 9

A. Insert mounting bracket pin through hole in work vise

(Figure 7A).

B. Install safety clip and gently lower saw until it rests on

workpiece (Figure 7B).

Safety clip must be installed to prevent

separation of band saw from work vise during operation.

Cutting Procedures Using 32V Vise

Make sure band saw trigger switch is in

OFF position. Connect saw to power source. Only use

the vise at heights where a firm grip can be maintained

on the saw handle throughout the cut.

1. Grasp band saw handle and lift so blade is clear of

workpiece.

2. Depress trigger switch to start saw. Make any necessary speed adjustment.

3. Slowly lower saw until blade engages work. Maintain

a firm grip on saw handle while saw completes the

cut under its own weight. DO NOT FORCE the saw

through the workpiece. Support saw weight as cut is

completed.

Ridge Tool Company 7

NOTE! During the first cut; the index pin (Figure 8) will

also be cut OFF. On subsequent cuts, the index

pin is used to accurately position the vise to the

workpiece so that the cut will follow a predetermined line.

4. As soon as the cut is completed, release trigger

switch and disconnect saw from power source.

5. Remove safety clip and lift saw from work vise.

6. Release clamp and remove work vise from workpiece.

NOTE! It may be necessary to add shims (see Figure 9)

between the bracket and the saw to produce a

90° cut. See the following instructions: Shim

washers are supplied in the hardware package.

Figure 9

Special Procedures

Changing Saw Blades

Make certain that power cord is un-

plugged before changing blade.

1. Turn blade tension handle at front of saw 180 degrees

clockwise so it points FORWARD to release tension

on saw blade.

2. Remove blade, first from pulleys and then from guides.

3. Insert replacement blade between rollers and faces

of guides.

932VS Portable Band Saw

Figure 7A Figure 7B

Figure 8

WARNING

WARNING

Figure 10 – Correct Positioning of Saw Blade.

Direction of blade travel on left

side of saw.

Position of teeth on left side

of saw.

WARNING

Page 10

932VS Portable Band Saw

Ridge Tool Company8

NOTE! Make sure blade teeth on left side of saw point to-

ward rear of saw. If they should point toward

front of saw, remove blade and turn inside out.

(Figure 10)

4. Hold blade in place between rollers and guides with

one hand while positioning it around pulleys with the

other hand.

5. Turn blade tension handle at front of saw counterclockwise toward rear of saw. Blade will be securely

held by the pulleys.

6. Work switch trigger a few times to make sure blade

operates freely and spring returns to OFF position.

To Adjust Blade Tracking

This band saw is equipped with an adjustable blade

tracking mechanism. When properly adjusted: the back

edge of the blade will run lightly against at least one of the

back-up rollers, but will not press heavily against the

roller. If the blade fails to track correctly, adjust as follows:

WARNING

DISCONNECT SAW FROM POWER SOURCE.

1. Use a 9/16″ wrench to loosen the adjustment locking nut

(See Figure 12), by turning it counter-clockwise, one

or two turns.

2. Use a flat screwdriver to turn the tracking screw 1/

4

turn. Turning the screw CLOCKWISE will move the

blade further up, toward the blade guide rollers.

Turning the screw COUNTERCLOCKWISE will move

the blade down, away from the blade guide rollers.

3. Tighten the adjustment locking nut.

4. Following the directions in TO START AND STOP

SAW, operate the saw and observe blade tracking.

5. Repeat steps 1 through 5 as necessary to achieve

proper tracking.

Figure 12

Material Teeth

Thickness Per

To Be Cut Inch Type

5

/32″ to 1/2″ 14

1

/8″ to 1/4″ 18 Carbon Steel

3

/32″ to 3/8″ 24

5

/32″ to 3/4″ 14

1

/8″ to 1/2″ 18 Bi-Metal

3

/32″ to 1/8″ 24

Figure 11 – Blade Selection Chart

Blade Recommendation Chart

Aluminum, Angle Iron, Cast Iron, Bronze, Brass, Copper, Galvanized Pipe,

Mild Steel. Also Electric Cable to 3

1

/4″ Diameter

Angle Iron, Bronze, Brass, Copper, Galvanized Pipe, Thin Wall Tubing,

Mild Steel

Angle Iron, Bronze, Brass, Copper, Cast Iron, Galvanized Pipe, Chrome,

Tungsten & Stainless Steel at Slow Speed

Aluminum, Angle Iron, Cast Iron, Bronze, Brass, Copper, Galvanized Pipe,

Mild Steel. Tougher Steels, Chrome Steel and Tungsten Steel at Slow

Speed. Also Electric Cable

Angle Iron, Bronze, Brass, Copper, Galvanized Pipe, Thin Wall Tubing,

Mild Steel. Chrome Steel and Tungsten Steel at Slow Speed

Angle Iron, Bronze, Brass, Copper, Cast Iron, Galvanized Pipe Mild Steel.

Chrome, Tungsten & Stainless Steel at Slow Speed

Page 11

932VS Portable Band Saw

Ridge Tool Company 9

Maintenance Instructions

Always unplug power cord before per-

forming any service on this tool.

Motor Brush Inspection and Lubrication

At approximately 100 hours of use, take or send your tool to

your nearest RIDGID Authorized Service Center to be thoroughly cleaned and inspected; worn parts replaced, when

necessary; relubricate with fresh lubricant, if required; reassemble with new brushes; and performance tested.

Any loss of power before the above maintenance check

may indicate the need for immediate servicing of your tool.

DO NOT CONTINUE TO OPERATE TOOL UNDER THIS

CONDITION if proper operating voltage is present. Return

your tool to the Service Station for immediate service.

Saw Ventilation

Keep inlet and outlet air passages clean to insure a cool

running motor. Blow out motor cooling air passages occasionally to help keep motor clean and free of dirt.

Machine Storage

Motor-driven equipment must be kept indoors or well covered in rainy weather. Store the saw in

a locked area that is out of reach of children and people

unfamiliar with band saws. This band saw can cause serious injury in the hands of untrained users.

Service and Repair

WARNING

The “Maintenance Instructions” will take care of most of

the service needs of this saw. Any problems not addressed by this section should only be handled by an

authorized RIDGID service technician.

Tool should be taken to a RIDGID Independent Authorized Service Center or returned to the factory. All

repairs made by Ridge service facilities are warranted

against defects in material and workmanship.

When servicing this saw, only identical replacement parts should be used. Failure to follow these

instructions may create a risk of electrical shock or other

serious injury.

If you have any questions regarding the service or repair

of this saw, call or write to:

Ridge Tool Company

Technical Service Department

400 Clark Street

Elyria, Ohio 44035-6001

Tel: (800) 519-3456

E-mail: TechServices@ridgid.com

For name and address of your nearest Independent

Authorized Service Center, contact the Ridge Tool

Company at (800) 519-3456 or http://www.ridgid.com

WARNING

WARNING

WARNING

Page 12

932VS Portable Band Saw

Ridge Tool Company10

Wiring Diagram Model 932 (115/230V, 60/50 Hz)

Page 13

Scie à ruban portative 932VS

Etau de scie à ruban 32V

Scie à ruban portative 932VS

Inscrivez ci-dessous le numéro de série de la plaque signalétique l’appareil pour future référence.

N° de

série :

Page 14

Table des matières

Formulaire d’enregistrement des numéros de modèle et de série de l’appareil...................................................11

Consignes générales de sécurité

Sécurité du chantier ..................................................................................................................................................13

Sécurité électrique.....................................................................................................................................................13

Sécurité personnelle..................................................................................................................................................13

Utilisation et entretien des outils................................................................................................................................14

Réparations...............................................................................................................................................................14

Consignes de sécurité spécifiques

Sécurité de l’appareil.................................................................................................................................................15

Description, spécifications et accessoires

Description ................................................................................................................................................................15

Spécifications............................................................................................................................................................15

Equipements de base................................................................................................................................................16

Accessoires...............................................................................................................................................................16

Utilisation de l’appareil

Scie à ruban 932VS ..................................................................................................................................................16

Mise en marche et arrêt de la scie.........................................................................................................................16

Sélection de la lame appropriée................................................................................................................................16

Lames de scie à ruban...........................................................................................................................................16

Sélection des lames...............................................................................................................................................16

Entretien des lames...................................................................................................................................................16

Méthode de coupe.....................................................................................................................................................17

Scie à ruban 932VS avec étau 32V ..........................................................................................................................17

Assemblage de l’étau 32V......................................................................................................................................17

Utilisation de l’étau 32V.............................................................................................................................................17

Coupe à l’aide de l’étau 32V .....................................................................................................................................18

Opérations particulières

Remplacement des lames.........................................................................................................................................19

Réglage de l’alignement des lames ..........................................................................................................................19

Entretien

Inspection des balais du moteur et lubrification ........................................................................................................20

Ventilation de la scie .................................................................................................................................................20

Stockage de l’appareil.................................................................................................................................................20

Entretien et réparations ..............................................................................................................................................21

Schéma électrique.......................................................................................................................................................22

Garantie à vie............................................................................................................................................Page de garde

Ridge Tool Company12

Scie à Ruban Portative 932VS

Page 15

Scie à Ruban Portative 932VS

Ridge Tool Company 13

Consignes de sécurité générales

MISE EN GARDE ! Familiarisez-vous avec l’ensemble des

instructions ci-devant. Le respect des

consignes suivantes vous permettra

d’éviter les risques de choc électrique,

d’incendie et de blessure corporelle grave.

CONSERVEZ CES INSTRUCTIONS !

Sécurité du chantier

• Gardez le chantier propre et bien éclairé. Les établis encombrés et les locaux mal éclairés sont une

invitation aux accidents.

• N’utilisez pas d’appareils électriques dans un milieu explosif tel qu’en présence de liquides, de

gaz ou de poussières inflammables. L’appareil pro-

duit des étincelles qui pourraient provoquer la

combustion des poussières et vapeurs.

• Gardez les tiers, les enfants et les visiteurs à l’écart

lorsque vous utilisez un appareil électrique. Les dis-

tractions peuvent vous faire perdre le contrôle de

l’appareil.

• Ne laissez pas les visiteurs toucher l’appareil ou sa

rallonge électrique. De telles mesures préventives ré-

duisent les risques d’accident.

Sécurité électrique

• Les appareils électriques avec terre doivent être

branchés sur une prise avec terre appropriée et

conforme aux normes en vigueur. Ne jamais enlever

la barrette de terre ou tenter de modifier la fiche

d’aucune manière. Ne jamais utiliser d’adaptateurs

de prise. Consultez un électricien qualifié en cas de

doute sur la bonne mise à la terre de la prise. Dans

le cas d’une panne ou d’une défaillance électrique de

l’appareil, la terre assure un passage de faible résistance qui éloigne le courant électrique de l’opérateur.

• Evitez d’entrer en contact avec les objets reliés à la

terre tels que les canalisations, les radiateurs, les

cuisinières et les réfrigérateurs. Tout contact avec

des masses augmente les risques de choc électrique.

• N’exposez pas les appareils électriques aux in-

tempéries ou à l’eau. Toute pénétration d’eau à

l’intérieur de l’appareil augmente les risques de choc

électrique.

• Ne maltraitez pas le cordon électrique de l’ap-

pareil. Ne jamais porter l’appareil par son cordon

électrique, ni tirer sur celui-ci pour débrancher

l’appareil. Gardez le cordon à l’abri des sources de

chaleur, de l’huile, des angles tranchants et des

pièces mobiles. Remplacez immédiatement tout

cordon endommagé. Les cordons endommagés aug-

mentent les risques de choc électrique.

• A l’extérieur, utilisez une rallonge électrique portant

l’indication “W-A” ou “W”. Ce type de cordon est

prévu pour être utilisé à l’extérieur et réduit les risques

de choc électrique.

• Branchez l’appareil sur une source d’alimentation

à courant alternatif qui correspond aux indications de la plaque signalétique de l’appareil. Une

tension électrique incorrecte peut entraîner des chocs

et des brûlures électriques.

• Utilisez uniquement des rallonges à trois fils

équipées de fiches et de prises avec terre capables de recevoir la fiche de l’appareil. L’utilisation

d’autres types de rallonge n’assurerait pas la mise à

la terre de l’appareil et augmenterait les risques de

choc électrique.

• Utilisez la section de rallonge appropriée (voir le

tableau). Une section de conducteurs insuffisante en-

traînera des pertes de charge excessive et un manque

de puissance.

Sécurité personnelle

• Restez attentif, faites attention à ce que vous faites

et faites preuve de bon sens lorsque vous utilisez

un appareil électrique. N’utilisez pas ce type d’appareil lorsque vous êtes fatigués ou lorsque vous

prenez des médicaments, de l’alcool ou des produits pharmaceutiques. Un instant d’inattention peut

entraîner de graves blessures lorsque l’on utilise un ap-

pareil électrique.

• Habillez-vous de manière appropriée. Ne portez

pas de vêtements amples ni de bijoux. Attachez les

cheveux longs. Gardez vos cheveux, vos vête-

Barrette de terre

cache-prise

avec

terre

Barrette de terre

Sections minimales des fils conducteurs des rallonges

Ampères indiqués

sur la plaque Longueur totale (en pieds)

signalétique

0 à 25 26 à 50 51 à 100

0 à 6 18 AWG 16 AWG 16 AWG

6 à 10 18 AWG 16 AWG 14 AWG

10 à 12 16 AWG 16 AWG 14 AWG

12 à 16 14 AWG 12 AWG

Déconseillé

Page 16

Scie à Ruban Portative 932VS

Ridge Tool Company14

• N’utilisez pas l’appareil si son interrupteur ne permet pas de le mettre en marche ou de l’arrêter. Tout

appareil qui ne peut pas être contrôlé par son interrupteur est dangereux et doit être réparé.

• Débranchez le cordon d’alimentation de l’appareil

avant son réglage, le remplacement d’accessoires

ou son rangement. De telles mesures préventives

réduisent les risques de démarrage accidentel de

l’appareil.

• Rangez les appareils non utilisés hors de la portée

des enfants et des personnes non-initiées. Ces

appareils sont dangereux entre les mains de personnes

non initiées.

• Entretenez les outils avec soin. Gardez les outils de

coupe propres et bien affûtés. Des outils bien en-

tretenus et bien affûtés minimisent les risques de

grippage et sont plus faciles à contrôler.

• Examinez l’appareil pour signes de mauvais alignement ou de grippage, de pièces endommagées

ou de toute autre condition qui pourrait nuire à

son bon fonctionnement. Le cas échéant, faites-le

réparer avant de l’utiliser. De nombreux accidents

sont le résultat d’appareils mal entretenus.

• Utilisez exclusivement les accessoires spéciale-

ment prévus pour votre type d’appareil. Les

accessoires prévus pour un type d’appareil peuvent

être dangereux lorsqu’ils sont utilisés sur un autre.

• Examinez le cordon de l’appareil et les rallonges

électriques régulièrement et remplacez tout élément endommagé. Les cordons électriques endom-

magés augmentent les risques de choc électrique.

• Gardez les poignées de l’appareil propres, sèches

et dépourvues d’huile ou de graisse. Cela assurera

un meilleur contrôle de l’appareil.

Réparations

• Toutes réparations de l’appareil doivent être confiées à un réparateur qualifié. La réparation ou

l’entretien de l’appareil par du personnel non qualifié

peut entraîner des blessures.

• Lors de la réparation de l’appareil, utilisez exclusivement des pièces de rechange identiques à

celles d’origine. Suivez les instructions de la section “Service et réparations” du mode d’emploi.

L’utilisation de pièces de rechange non homologuées

ou le non respect des consignes d’entretien peut créer

un risque de choc électrique ou de blessure corporelle

et annuler la garantie.

ments et vos gants à l’écart des pièces mobiles.

Les vêtements amples, les bijoux et les cheveux longs

peuvent s’entraver dans les pièces mobiles.

• Evitez les risques de démarrage accidentel.

Assurez-vous que l’interrupteur marche/arrêt est en

position OFF (arrêt) avant de brancher l’appareil.

Porter l’appareil avec un doigt sur la gâchette ou le

brancher lorsque son interrupteur est en position de

marche est une invitation aux accidents.

• Enlevez les clés de réglage avant de mettre l’appareil en marche. Une clé restée sur un des

mécanismes rotatifs de l’appareil peut être dangereuse.

• Ne vous mettez pas en porte-à-faux. Maintenez

une bonne assise et un bon équilibre à tout moment. Une bonne assise et un bon équilibre vous

permettent de mieux contrôler l’appareil en cas d’im-

prévu.

• Utilisez les équipements de sécurité appropriés.

Portez systématique une protection oculaire. Un

masque à poussière, des chaussures de sécurité, le

casque et/ou une protection auditive doivent être portés

selon les conditions d’utilisation.

Certaines poussières émises durant le ponçage, le sciage, le meulage ou le perçage

électrique et par autres activités de construction contiennent des produits chimiques que l’état de la Californie

a reconnus comme étant cancérigène ou responsable de

malformations congénitales et autres maladies du système reproductif. Parmi ces produits chimiques se

trouvent :

• Le plomb contenu dans les peintures à base de plomb;

• La silice cristalline contenue dans les briques, le

ciment et autres produits de maçonnerie ;

• L’arsenic et le chrome provenant des bois traités.

Les risques encourus dépendent de la fréquence d’exposition à ce type de travail. Afin de réduire les risques

d’exposition à ces produits chimiques : travaillez dans un

local bien ventilé et portez des équipements de sécurité

homologués, tels que les masques spécialement conçus

pour filtrer les particules microscopiques.

Utilisation et entretien de l’appareil

• Servez-vous d’un serre-joint ou autre moyen pra-

tique pour arrimer l’ouvrage à une plate-forme

stable. Tenir l’ouvrage à la main ou contre le corps est

instable et risque de vous en faire perdre le contrôle.

• Ne forcez pas l’appareil. Servez-vous de l’outil

prévu pour le travail en question. L’outil approprié

fera le travail avec plus d’efficacité et plus de sécurité

lorsqu’il fonctionne au régime prévu.

MISE EN GARDE

Page 17

Scie à Ruban Portative 932VS

Ridge Tool Company 15

• Suivez les instructions visant la lubrification de

l’appareil et le changement des accessoires. Les

outils mal entretenus sont souvent à l’origine des

accidents.

Consignes de

sécurité particulières

MISE EN GARDE !

Familiarisez-vous complètement avec le mode

d’emploi avant d’utiliser l’appareil. La non compréhension ou le non respect des consignes qu’il

contient augmenterait les risques de choc électrique, d’incendie et de grave blessure corporelle.

Veuillez adresser toutes questions éventuelles aux

Services techniques de la Ridge Tool Company en

composant le (800) 519-3456.

Sécurité de l’appareil

• Ne pas tenter de modifier ou utiliser l’appareil

pour des applications non prévues. Les applications

non prévues peuvent accroître les risques d’accident.

• Utilisez exclusivement la lame recommandée pour

le type de matériau à couper. Les lames recommandées et bien affûtées minimisent les risques de

grippage et facilite le contrôle de l’appareil.

• Arrimez l’ouvrage avant d’installer l’étau. Montez

l’étau sur l’ouvrage et serrez-le avant d’installer la

scie à ruban sur l’étau. Pour pouvoir stabiliser l’en-

semble, l’ouvrage doit pouvoir soutenir le poids de

l’étau et celui de la scie à ruban sans bouger.

• Restez à l’écart des ouvrages qui risquent de

tomber en fin de coupe. Ceux-ci risqueraient de

vous blesser.

• Tenez la scie à ruban fermement des deux mains

durant l’opération de coupe. Préparez-vous à

soutenir le poids de la scie en fin de coupe. Cela

vous évitera de perdre le contrôle de la scie.

• Arrêtez la scie à ruban et débranchez-la avant de

l’installer ou de l’enlever de l’étau. Cela évitera les

risques de démarrage accidentel.

• Ecartez vos mains de la zone de coupe lorsque

vous utilisez la scie. Vos doigts et vos mains risquent

d’être coupés.

• N’utilisez pas l’appareil si ses carters de protection

ont été endommagés ou enlevés. Les lames et mé-

canismes exposés augmentent les risques d’accident.

• Ne montez pas l’étau sur la partie d’ouvrage qui

doit être coupé. Cela évitera que la scie tombe en fin

de coupe.

• N’utilisez pas la scie à ruban et l’étau sans la

bride de sécurité. Celle-ci empêche la scie à ruban de

se séparer de l’étau.

• Faites très attention lors de la coupe du magné-

sium. Ne jamais utiliser d’eau ou un extincteur

traditionnel pour éteindre du magnésium en feu.

Utilisez exclusivement de la poudre de graphite

type G-1. Les copeaux de magnésium peuvent s’en-

flammer et créer un risque d’incendie.

• Faites très attention lors des coupes aveugles

dans des conduites ou des tuyaux. Vérifiez que

l’objet devant être coupé ne contient pas de fils

électriques, de gaz ou d’eau. Cela pourrait créer

une situation dangereuse accompagnée d’un risque de

grave blessure corporelle.

CONSERVEZ CES INSTRUCTIONS !

Description, spécifications et

accessoires

Description

La scie à ruban portative RIDGID 932VS est prévue pour

la coupe des matériaux ferreux et non ferreux, qu’il

s’agisse de barres, de tubes ou de formes irrégulières.

Sa capacité de 43/4po lui permet de couper les canalisations d’évacuation d’une section nominale de 4 po.

L’ensemble est monté sur roulements à bille et à aiguille,

ce qui lui assure une grande longévité et fiabilité.

Spécifications

Capacité de coupe.......Profilés ronds jusqu’à 43/4po,

profilés rectangulaires jusqu’à

41/2x 43/4po

Moteur

N°..............................932VS

Type ..........................Universal

Tension .....................115V (ca), 50/60Hz

Ampères....................6

Régime à

vide SFPM.................variable, de 100 à 245

Système

d’entraînement.............pignon et chaîne

Dimensions de lame....

1

/2po x 0,020 po x 447/8po

Poids.............................14 livres.

Page 18

Scie à Ruban Portative 932VS

Ridge Tool Company16

Equipements de base

Mallette de transport en acier

Lame bimétal

Cire à lame

Accessoires

Etau N° 32V

Lors de l’utilisation de l’étau 32V, les sections maximales de coupe sont les suivantes :

Rond – Ø 4

1

/2po

Carré – 3 po x 3 po

Cornière – 3 po x 3 po

AVERTISSEMENT

La coupe d’autres types de profilés n’est pas

recommandée.

Utilisation de l’appareil

L’utilisateur doit s’être complètement

familiarisé avec les consignes de sécurité précédentes

avant toute tentative d’utilisation de ce matériel.

N’utilisez pas la scie à une tension

électrique qui ne soit pas dans la plage prévue. Vérifiez

la plaque signalétique pour le type de circuit d’alimentation applicable.

Scie à ruban 932VS

Mise en marche et arrêt de la scie

1. Vérifiez que la tension d’alimentation correspond à

celle indiquée sur la plaque signalétique de la scie.

Branchez l’appareil sur le circuit d’alimentation.

2. Appuyez sur la gâchette (Figure 1) pour mettre le

moteur en marche. Lâchez la gâchette pour arrêter

le moteur.

3. Un bouton de verrouillage (LOCK) Figure 1 est prévu

pour permettre à la scie de fonctionner sans avoir à

appuyer sur la gâchette. Pour verrouiller la gâchette

en position de marche, appuyez à fond sur celle-ci,

enfoncez le bouton de verrouillage, puis lâchez la

gâchette.

Pour libérer le bouton de verrouillage, appuyez momentanément sur la gâchette.

4. La 932VS est équipée d’un variateur de vitesse. La

vitesse de l’appareil se règle en tournant la manette

de réglage (Figure 1).

Sélection de la lame appropriée

Lames de scie à ruban

La scie à ruban modèle 932VS utilise des lames de 0,020

po d’épaisseur, de 1/2po de large et de 447/8po de long.

NOTA ! NE PAS UTILISER ces lames sur une scie à

ruban stationnaire. Les lames prévues pour

les scies à ruban stationnaires ont une épaisseur différente et ne PEUVENT PAS passer

entre les guide-lame haute précision des scies

à ruban portatives.

Reportez-vous au tableau de sélection des lames (Figure

11) pour les lames disponibles et leurs applications

prévues. Ce tableau n’est sensé servir que de guide. En

raison de la variété des matériaux pouvant être coupés,

l’expérience de l’utilisateur devra déterminer laquelle offrira le plus haut niveau d’efficacité et de longévité de

lame en fonction de l’application envisagée.

Sélection des lames

Sélectionnez, de préférence, une lame dont au moins

deux dents s’engagent sur l’épaisseur du matériau simultanément. Plus le matériau est mince ou dur, plus

fines doivent être les dents de lame. Pour les matériaux

plus épais ou moins durs, une lame avec des dents plus

grosses est recommandée. Les lames en acier rapide

restent affûtées plus longtemps que les lames en alliage.

Entretien des lames

L’utilisation d’une cire de lubrification, telle que celle fournie

avec la scie, prolongera la vie utile des lames. Assurezvous que la scie est équipée d’une lame bien affûtée.

En aucun cas doit-on utiliser un

lubrifiant liquide avec cette scie. Les roulements et les

galets en caoutchouc des poulies risqueraient d’être

endommagés.

La mollette est numéroté de “1” à “6”, “1” étant la vitesse la plus

lente (90 SFM environ) et “6” étant la vitesse la plus élevée (240

SFM environ). La commande de vitesse peut être réglée que le

moteur soit en marche ou non.

Figure 1 – Commande à vitesse variable

MISE EN GARDE

MISE EN GARDE

AVERTISSEMENT

Page 19

NOTA ! L’utilisation de cire en bâtons est particulière-

ment recommandée lors de la coupe de

grandes sections d’aluminium et de laiton doux,

car celle-ci aide à nettoyer les creux de lame.

Sur les matériaux durs, la cire en bâtons aide à

refroidir la lame et à éviter qu’elle ne perde sa

dureté. L’utilisation de ce type de lubrifiant assure aussi une coupe plus nette et plus propre.

Méthode de coupe

1. S’assurer que l’ouvrage est bien arrimé et orienté

de manière à ce que le plus grand nombre de dents le

contacteront durant la coupe (Figure 2).

2. Branchez le cordon d’alimentation de la scie dans

une prise avec terre appropriée.

3. Réglez le sélecteur de vitesse à la vitesse voulue. La

vitesse peut être modifiée avec l’appareil en marche.

4. Tenez la scie dans une position neutre, éloignée de

l’ouvrage.

5. Mettez la scie en marche en appuyant sur la gâchette

de la poignée arrière.

6. Appuyez la butée de lame arrière fermement contre

l’ouvrage et rabaissez la scie pour couper le matériau.

NOTA ! Laissez le poids de la scie fournir la pression de

coupe nécessaire. N’appuyez pas sur la scie durant la coupe. Cela ralentirait la lame et nuirait à

l’efficacité de coupe.

7. Une fois la coupe terminée, retenez la scie fermement

pour l’empêcher de tomber contre l’ouvrage.

8. Lâchez la gâchette et débranchez le cordon d’alimentation.

NOTA ! Suite à une coupe prolongée, la cire collera

aux poulies de la scie. Cela n’a aucun effet sur

son fonctionnement. Il suffit simplement de

débrancher la scie et d’essuyer la cire accumulée sur les poulies.

Ridge Tool Company 17

Scie à ruban 932VS avec étau 32V

Assemblage de l’étau 32V

MISE EN GARDE !

La scie doit être débranchée avant d’installer

l’étau 32V.

1. Enlevez les deux vis (A), puis retirez la poignée (C) et

l’écrou (B) (Figure 3).

2. Positionnez le support de fixation de l’étau sur la scie

à ruban (Figure 4) et retenez-le à l’aide des deux

écrous fournis avec l’étau 32V. (Serrez-les à un cou-

ple de 40 à 50 in/lb.)

3. Remontez la poignée (C), (Figure 3), à l’aide des

deux longues vis fournies avec l’étau 32V.

4. Engagez le cordon d’alimentation dans le logement

comme indiqué à la Figure 4.

Utilisation de l’étau 32V

Assurez-vous que la scie est

débranchée avant de l’installer sur l’ouvrage.

1. Arrimez l’ouvrage afin d’éviter son déplacement en

cours de coupe.

Scie à Ruban Portative 932VS

Figure 3

A

B

C

Figure 4

Ecrous

Logement

de cordon

Figure 2 – Ouvrage correctement positionné pour coupe

Correct

Correct

Incorrect

Incorrect

MISE EN GARDE

Page 20

Scie à Ruban Portative 932VS

Ridge Tool Company18

L’ouvrage doit être suffisamment

bien arrimé pour pouvoir supporter le poids de l’étau et de

la scie à ruban.

2. Positionnez l’étau sur l’ouvrage et fixez-le en serrant

la vis de blocage (Figure 5). La vis devra supporter

tout le poids de la scie à ruban.

NOTA ! L’étau doit être positionné de manière à ce que

la vis de blocage se trouve à la verticale et audessus de l’ouvrage.

Figure 6

3. Montez la scie à ruban sur l’étau.

Ecartez vos mains de la lame de

scie lors du montage et de la dépose de la scie à ruban.

A. Introduisez la broche du support de fixation dans le

trou de l’étau (Figure 7A).

B. Installez l’attache de sécurité, puis rabaissez la scie

doucement jusqu’à ce qu’elle repose sur l’ouvrage

(Figure 7B).

L’attache de sécurité doit être instal-

lée afin d’empêcher la scie à ruban de se séparer de

l’étau en cours de coupe.

Coupe à l’aide de l’étau 32V

Assurez-vous que la gâchette de la

scie à ruban se trouve en position OFF (arrêt). Branchez

la scie. Utilisez l’étau uniquement à une hauteur permettant une bonne prise en main de la poignée de scie

durant toute l’opération de coupe.

1. Prenez la scie à ruban par sa poignée et relevez-la

pour l’écarter de l’ouvrage.

2. Appuyez sur la gâchette pour mettre la scie en

marche. Si nécessaire, réglez la vitesse de la scie.

3. Rabaissez la scie lentement jusqu’à ce que la lame

entame l’ouvrage. Tenez la scie fermement avec les

deux mains tandis qu’elle se charge d’effectuer la

coupe sous son propre poids. NE FORCEZ PAS la

scie contre l’ouvrage. Soutenez le poids de la scie en

fin de coupe.

Figure 7A

Figure 7B

Figure 8

Figure 5

Vis de blocage

MISE EN GARDE

CORRECT

INCORRECT

MISE EN GARDE

MISE EN GARDE

MISE EN GARDE

Page 21

Scie à Ruban Portative 932VS

Ridge Tool Company 19

NOTA ! La baguette de repérage sera coupée lors de la

première coupe (Figure 8). Celle-ci servira à

assurer le positionnement précis de l’étau par

rapport à l’ouvrage lors des coupes suivantes et

permettra de suivre une ligne prédéterminée.

4. Dès la coupe achevée, lâchez la gâchette et

débranchez la scie.

5. Enlevez l’attache de sécurité et retirez la scie de l’étau.

6. Desserrez la vis de blocage et retirez l’étau de l’ou-

vrage.

NOTA ! Il peut être nécessaire d’ajouter des cales

(Figure 9) entre le support et la scie afin

d’obtenir une coupe à l’équerre. Voir les in-

structions suivantes : des rondelles de calage

sont prévus dans la pochette d’accessoires.

Figure 9

Opérations particulières

Remplacement des lames de scie

Assurez-vous que l’appareil est

débranché avant de changer de lame.

1. Tournez la poignée du tendeur de lame qui se trouve

à l’avant de la scie 180°à droite, jusqu’à l’indication

FORWARD (avant) afin de détendre la lame.

2. Enlevez la lame, d’abord au niveau des poulies, puis

au niveau des guides.

3. Introduisez la lame de rechange entre les galets et les

guides.

NOTA ! Assurez-vous que, vu du côté gauche, les dents

de la lame de scie sont orientées vers l’arrière de

la scie. Si elles sont orientées vers l’avant de la

scie, enlevez la lame et retournez-la (Figure 10).

4. Tenez la lame en position entre les galets et les

guides d’une main, puis faites-les passer autour des

poulies avec l’autre.

5. Tournez le tendeur de lame qui se trouve en tête de

scie à gauche, vers l’arrière de la scie.

6. Activez la gâchette à plusieurs reprises afin de vous

assurer que la lame se déplace librement et que le

ressort revient à la position OFF (arrêt).

Réglage de l’alignement de la lame

Cette scie à ruban est équipée d’un mécanisme d’aligne-

ment de lame réglable. Lorsque celui-ci est correctement

réglé, le bord arrière de la lame devrait frôler au moins un

des galets de secours, sans pour autant s’appuyer lourdement contre le galet. Si la lame n’est pas correctement

alignée, réglez-la de la manière suivante :

MISE EN GARDE !

DÉBRANCHEZ LA SCIE.

1. Utilisez une clé de 9/16po pour desserrer l’écrou de

blocage du mécanisme (Figure 12) en le tournant

un tour ou deux à gauche.

2. Servez-vous d’un tournevis plat pour tourner la vis

d’alignement un quart de tour. Tourner la vis à

DROITE déplacera la lame vers le haut, voire vers les

galets de guidage. Tourner la vise à GAUCHE dé-

placera la lame vers le bas, c’est à dire, à l’opposé des

galets de guidage.

3. Resserrez l’écrou de blocage du mécanisme.

4. En suivant les instructions de la section Mise en

marche et arrêt de la scie, faites fonctionner la scie

afin de vérifier l’alignement de la lame.

5. Répétez les étapes 1 à 5 autant de fois que nécessaire pour obtenir l’alignement voulu.

Figure 10 – Orientation appropriée des lames de scie.

Direction de rotation de la lame

du côté gauche de la scie.

Orientation des dents de lame

du côté gauche de la scie.

MISE EN GARDE

Support

Cale

Ajouter cales à

‘A’ et ‘B’

Ajouter cales

à ‘A’

Ajouter cales

à ‘C’

Ajouter cales à

‘B’ et ‘C’

Page 22

Scie à Ruban Portative 932VS

Ridge Tool Company20

Figure 12

Entretien

Débranchez l’appareil systématique-

ment avant toute intervention.

Inspection des balais du moteur

et lubrification

Après environ 100 heures d’utilisation, apportez ou expédiez l’appareil chez le réparateur RIDGID le plus proche

pour nettoyage et inspection, remplacement éventuel des

composants usés, lubrification éventuelle, installation de

nouveaux balais et vérification des performances.

Toute perte de puissance constatée entre les révisions

périodiques indiquées peut signaler un besoin de réparation immédiate de l’appareil. Le cas échéant, et s’il

ne s’agit pas d’un problème au niveau du secteur d’alimentation électrique, cessez d’utiliser l’appareil. Confiez

l’appareil à votre réparateur pour intervention immédiate.

Ventilation de la scie

Nettoyez régulièrement les grilles de ventilation de l’ap-

pareil afin d’assurer le refroidissement adéquat du

moteur. Passez les grilles de ventilation à l’air com-

primé occasionnellement afin d’assurer la propreté et la

ventilation du moteur.

Stockage de l’appareil

Tout matériel électrique doit être

stocké à l ’intérieur ou bien protégé contre les intempéries.

Rangez la scie dans un lieu sou clé, hors de la portée des

enfants et des individus non familiers avec ce type de

matériel. Cette scie à ruban peut être dangereuse entre les

mains d’utilisateurs non initiés.

Epaisseur Dents

des par

matériaux pouce Type

5

/32à 1/2po 14

1

/8à 1/4po 18 Acier au

3

/32à 3/8po 24

carbone

5

/32à 3/4po 14

1

/8à 1/2po 18 Bimétal

3

/32à 1/8po 24

Figure 11 – Tableau de sélection des lames

Tableau de sélection des lames

Aluminium, cornières d’acier, fonte, bronze, laiton, cuivre, tuyaux galvanisés, acier doux et câbles électriques jusqu’à 3

1

/4po de diamètre

Cornière d’acier, bronze, laiton, cuivre, tuyaux galvanisés, tuyaux à parois

minces, acier doux

Cornière d’acier, bronze, laiton, cuivre, fonte, tuyaux galvanisés, chrome,

acier au tungstène et acier inoxydable à petite vitesse

Aluminium, cornière d’acier, fonte, bronze, laiton, cuivre, tuyaux galvanisés, acier doux, aciers plus durs, acier chromé et acier au tungstène

à petite vitesse, ainsi que câbles électriques

Cornière d’acier, bronze, laiton, cuivre, tuyaux galvanisés, tuyaux à parois

minces, acier doux, acier chromé et acier au tungstène à petite vitesse

Cornière d’acier, bronze, laiton, cuivre, fonte, tuyaux galvanisés, acier

doux, chrome, acier au tungstène et acier inoxydable à petite vitesse

MISE EN GARDE

MISE EN GARDE

Page 23

Scie à Ruban Portative 932VS

Ridge Tool Company 21

Entretien et réparations

MISE EN GARDE !

La section “Entretien” devrait couvrir la majorité des besoins d’entretien de la scie. Tous problèmes qui n’ont pas

été adressés dans cette section doivent être confiés à un

technicien RIDGID agréé.

L’appareil devrait être alors confié à un réparateur agréé

par RIDGID ou renvoyé à l’usine. Toutes réparations ef-

fectuées par les services Ridge sont garanties contre

les vices de matériaux et de main d’œuvre.

N’utilisez que des pièces de rechange identiques à celles d’origine lors de la réparation

de cette scie. Le non respect de cette consigne pourrait

accroître les risques de choc électrique ou autre blessure

corporelle grave.

En cas de questions éventuelles concernant l’entretien ou

la réparation de cette scie, veuillez nous consulter par télé-

phone ou par écrit aux coordonnées suivantes :

Ridge Tool Company

Technical Service Department

400 Clark Street

Elyria, Ohio 44035-6001

Tel: (800) 519-3456

E-mail: TechServices@ridgid.com

Pour obtenir les coordonnées du réparateur agréé le

plus proche, veuillez contacter la Ridge Tool Company au

(800) 519-3456 ou http://www.ridgid.com

MISE EN GARDE

Page 24

Scie à Ruban Portative 932VS

Ridge Tool Company22

Schéma électrique du modèle 932VS (115/230V, 60/50Hz)

Rouge

Cavalier

rouge

Gris ou noir

Rouge

Bleu

Blanc

Blanc

Bobine 2

Bobine 1

Noir

Blanc

Ligne

Bleu

Jaune

Interrupteur de gâchette

Page 25

Sierra de banda portátil

932VS y su

Prensa de tornillo No. 32V

Sierra de banda portátil 932VS

Apunte aquí y conserve el número de serie del producto, el que se encuentra en la placa

de características.

No. de

Serie

Page 26

Indice

Formulario para apuntar el Modelo y Número de Serie de la máquina..................................................................23

Información general de seguridad

Seguridad en la zona de trabajo ...............................................................................................................................25

Seguridad eléctrica....................................................................................................................................................25

Seguridad personal...................................................................................................................................................25

Uso y cuidado de la herramienta...............................................................................................................................26

Servicio......................................................................................................................................................................26

Información específica de seguridad

Seguridad de la herramienta.....................................................................................................................................27

Descripción, especificaciones y equipo estándar

Descripción................................................................................................................................................................27

Especificaciones........................................................................................................................................................27

Equipo estándar........................................................................................................................................................28

Accesorios.................................................................................................................................................................28

Instrucciones para el funcionamiento

Sierra de banda 932VS.............................................................................................................................................28

Cómo echar a andar y parar la sierra.....................................................................................................................28

Elección de cuchillas.................................................................................................................................................28

Cuchillas para la sierra de banda...........................................................................................................................28

Cuál cuchilla usar...................................................................................................................................................29

Cuidado de las cuchillas............................................................................................................................................29

Cómo cortar...............................................................................................................................................................29

Sierra de Banda 932VS con una Prensa de Tornillo 32V.........................................................................................29

Montaje de la Prensa de Tornillo 32V....................................................................................................................29

Cómo usar la Prensa de Tornillo 32V .......................................................................................................................30

Cómo cortar empleando la Prensa de Tornillo 32V ..................................................................................................30

Procedimientos especiales

Recambio de cuchilla................................................................................................................................................31

Regulación de la trayectoria de la cuchilla................................................................................................................31

Instrucciones de mantenimiento

Inspección de las escobillas del motor y lubricación.................................................................................................32

Ventilación de la sierra..............................................................................................................................................32

Almacenamiento de la herramienta...........................................................................................................................33

Servicio y reparaciones ..............................................................................................................................................33

Diagrama de cableado.................................................................................................................................................33

Garantía vitalicia..................................................................................................................................carátula posterior

Ridge Tool Company24

Sierra de banda portátil 932VS

Page 27

Sierra de banda portátil 932VS

Ridge Tool Company 25

Información general de seguridad

¡

ADVERTENCIA! Lea y comprenda todas las instruc-

ciones. Pueden ocurrir golpes eléctricos,

incendios y/u otras lesiones personales

graves si no se siguen todas las instrucciones detalladas a continuación.

¡

GUARDE ESTAS INSTRUCCIONES!

Seguridad en la zona de trabajo

• Mantenga su área de trabajo limpia y bien alumbrada. Los bancos de trabajo desordenados y las

zonas oscuras son una invitación a los accidentes.

• No haga funcionar herramientas a motor en at-

mósferas explosivas como, por ejemplo, en la

presencia de líquidos, gases o polvos inflamables.

Las herramientas autopropulsadas generan chispas

que pueden inflamar el polvo o los gases.

• Al hacer funcionar una herramienta, mantenga

apartados a los espectadores, niños y visitantes.

Las distracciones pueden hacerle perder el control.

• No deje que los visitantes entren en contacto con

la herramienta o el cordón de extensión. Estas me-

didas preventivas reducen el riesgo de que se

produzcan lesiones.

Seguridad eléctrica

• Las herramientas provistas de una conexión a

tierra deben enchufarse a un tomacorriente debidamente instalado y conectado a tierra según

todos los códigos y ordenanzas vigentes. Jamás

extraiga la clavija de conducción a tierra ni lo

modifique de manera alguna. No use ningún tipo de

enchufe adaptador. Si tiene dudas respecto a la

conexión a tierra del tomacorriente, consulte a un

electricista calificado. Si una herramienta sufre una

avería eléctrica o de otro tipo, la conexión tierra proporciona una vía de baja resistencia para conducir la

electricidad lejos del usuario.

• Evite el contacto de su cuerpo con superficies

conectadas a tierra, tales como tubería, radiadores,

cocinas, estufas y refrigeradores. Si su cuerpo

ofrece conducción a tierra, aumenta el riesgo de que

sufra un choque eléctrico.

• No exponga las herramientas eléctricas a la lluvia

o a condiciones mojadas. Cuando entra agua en una

herramienta a motor, aumenta el riesgo de que se

produzca un choque eléctrico.

• No abuse del cordón. Nunca use el cordón para

transportar las herramientas o para arrancar el

enchufe del tomacorriente. Mantenga el cordón

lejos del calor, aceite, bordes cortantes o piezas

movibles. Recambie los cordones dañados inmediatamente. Los cordones en mal estado aumentan

los riesgos de que se produzca un choque eléctrico.

• Al hacer funcionar una herramienta autopropul-

sada a la intemperie, emplee un cordón de

extensión fabricado para uso exterior y rotulado

“W-A” o “W”. Estos cordones han sido diseñados

para su empleo al aire libre y reducen el riesgo de que

se produzca un choque eléctrico.

• Enchufe la herramienta a una fuente de corriente

alterna que corresponda a las especificaciones

en la placa de caracaterísticas. El suministro de un

voltaje incorrecto puede causar choques eléctricos o

quemaduras.

• Sólo emplee cordones de extensión de tres alambres que tengan enchufes de tres clavijas para

conexión a tierra, y tomacorrientes de tres polos

que acojan al enchufe de la herramienta. La herra-

mienta no quedará a tierra si utiliza otros cordones de

extensión y aumentará el riesgo de choques eléctricos.

• Use cordones de extensión apropiados (vea la

tabla). Una dimensión insuficiente del conductor

causará una caída excesiva del voltaje y pérdida de

potencia.

Seguridad personal

• Manténgase alerta, preste atención a lo que está

haciendo y use sentido común cuando trabaje

con una herramienta autopropulsada. No la use si

está cansado o se encuentra bajo la influencia de

drogas, alcohol o medicamentos. Sólo un breve

descuido mientras hace funcionar una herramienta a

motor puede resultar en lesiones personales graves.

Clavija para la

conexión a tierra

Tapa del

enchufe conectado

a tierra

Clavija para la

conexión a tierra

Dimensión mínima de alambre para cordones de extensión

Amperios en

la placa de Longitud total (en pies)

características

0-25 26-50 51-100

0-6 18 AWG 16 AWG 16 AWG

6-10 18 AWG 16 AWG 14 AWG

10-12 16 AWG 16 AWG 14 AWG

12-16 14 AWG 12 AWG

NO SE RECOMIENDA

Page 28

Sierra de banda portátil 932VS

Ridge Tool Company26

• Vístase adecuadamente. No lleve ropa suelta ni

joyas. Contenga el cabello largo. Mantenga su cabello, ropa y guantes apartados de las piezas en

movimiento. La ropa suelta, las joyas o el pelo largo

pueden engancharse en la piezas móviles.

• Evite la puesta en marcha no intencional. Antes de

enchufar la herramienta, asegure que el interruptor

se encuentre en la posición OFF (apagado). Cargar

las herramientas con el dedo sobre el interruptor o

enchufarlas cuando su interruptor está en la posición

de encendido (ON) constituyen una invitación a que se

produzcan accidentes.

• Antes de poner en marcha la herramienta, extraiga

las llaves de ajuste o regulación. Una llave mecánica